Infinity Kappa 255-A Service manual

Kappa 255a

Automotive Amplifier

SERVICE MANUAL

Infinity Systems Incorporated

250 Crossways Park Dr.

Woodbury, New York 11797

Rev2 10/2004

Kappa 255a

- CONTENTS -

SPECIFICATIONS ……..…………………………………………………………..2

FEATURES ..……………………………….……………….……………….…...…3

APPLICATIONS (SET-UP GUIDE) ………………..……..……………………….4

PRECAUTION AND NOTES..…..………………….….…………………………..6

INSTALLATION ….………..…………..…………….……………………………..7

TROUBLESHOOTING ….………..………………….……………………………..9

SERVICE BULLETIN #INF9701 ….…………...…………………..……………..10

SERVICE BULLETIN #INF2001-02 ….…………………………………………..11

EXPLODED VIEW….………..…………………………………………………….13

PCB DRAWINGS ….………..……………………………………………………..14

BLOCK DIAGRAMS………...……………….……………….…………..….…….20

ELECTRICAL PARTS LIST ..……………….……………….…………..….…….22

SEMICONDUCTOR PINOUTS………………..……..…………………..……….30

SCHEMATICS …………..……………………..…….…….….………..………….31

REVISIONS ……………..……………………..…….…….….………..………….43

Occasional refinements may be made to existing products without notice but will always meet or exceed original specifications

unless otherwise stated

1

2

Kappa 255a

KAPPA 255A SPECIFICATIONS

POWER

4 OHM 4 x 50 and 1 x 200 watts

2 OHM 4 x 75 and 1 x 300 watts

BRIDGE 4 OHM 2 x 150 and 1 x 200 watts

1 OHM STABLE PROTECTION

FREQUENCY RESPONSE

EQUALIZATION

FIXED AT 40Hz Q=1 +11dB

CROSSOVER

FLAT/LOW/HIGH PASS SWITCH 2

DECADE SWITCH (40-320 & 250-2KHz)

VAR. CONTROL 2

SLOPE 12

INPUT SENSITIVITY

FULL DIFFERENTIAL INPUT

POWER FUSE

THD + NOISE

4 ohm 0.05%

2 ohm 0.10%

bridge 4 ohm 0.10%

SIGNAL TO NOISE

CHANNEL SEPARATION

DAMPING FACTOR

TURN ON TIME

DC OFFSET

OPERATING VOLTAGE

REMOTE ON CURRENT

QUIESCENT CURRENT

MAX CURRENT

PROTECTION auto reset

spkr short Yes

spkr to ground Yes

thermal Yes

over voltage 18vdc

under voltage 8vdc

DIMENSIONS 23 x 2 3 /16 x 8 1 /2 in. (W x H x L)

20-20KHz (+0 -3dB)

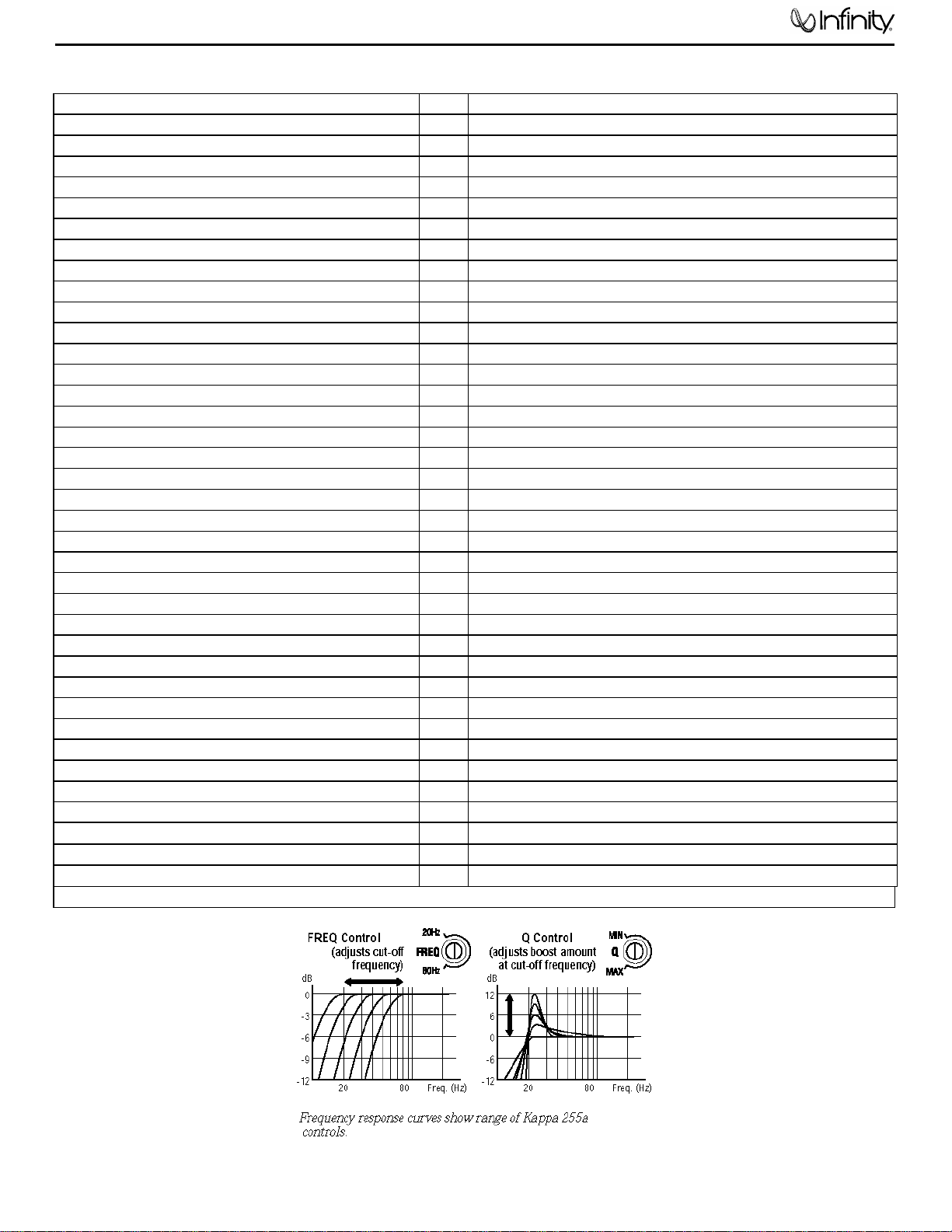

SEE CHART BELOW

250 mV ~ 9 V

>100K IMP

40A X 2 (ATC)

>95dB (A Weighted Referenced to Full Power)

>50dB (100 TO 20KHz)

>204

3 SEC

<50 mv

10 -16vdc

<2ma

<2.5 AMP

80

584.2 x 55.6 x 215.9 mm

All tests to be done from 20 to 20KHz at 14.4 VDC into 4 ohm loads, unless otherwise specified.

Infinity continually strives to update and improve existing products, as well as create new ones. The specifications and

construction details in this and related Infinity publications are therefore subject to change without notice.

3

Kappa 255a

FEATURES

The Kappa 255a is a 5-channel power amplifier that offers full-range stereo and bridged-mono

operation on four analog channels and band-limited mono operation on a class-D channel for

subwoofer applications. The front/rear amplifiers are rated at 50 watts (rms) per channel into a

4-ohm load, while the subwoofer channel is rated at 200 watts (rms) into a 4-ohm load. In

bridged-mono configurations, front and rear amplifiers can deliver up to 150 watts (rms) for the

same load.

· 2-ohm operation, rated at 75 watts (rms) per channel for front and rear channels and 300

watts (rms) for the subwoofer channel

· Bridge/stereo switches for fast system setup

· Built-in 12 dB-per-octave electronic crossovers, variable from 32 to 320 Hz, with an “x15”

front-channel switch (to increase the frequency range from 480 Hz to 4.8 kHz)

· Dynamic Bass Optimizer™ (DBO) 12 dB-per-octave subsonic filter with variable frequency

(20 to 80 Hz) and Q for enhancing subwoofer low frequencies while conserving amplifier

power

· Front and rear channels, individually selectable as highpass, low-pass, or through-pass

· External switch for subwoofer inputs allows direct connection to source units with subwoofer

outputs

· Amplifier input sensitivity controls to match a wide range of input signal levels from 250 mV

to 9 V

· Five protection levels guard against over-voltage, undervoltage, over-power, over-

temperature, and over-current situations

· 2-color LED array indicates green when power is on and orange when protection is

activated

· Industrial-grade, gold-plated, “pre-wire and plug-in” connectors for an easy-to-install high-

quality interface

· Transparent control cover to deter tampering yet provide a clear view of installation settings

· Built-in automotive type fuses to protect the amplifier

· Unibloc™ chassis provides improved heat-sink capacity and exceptional RFI shielding

characteristics

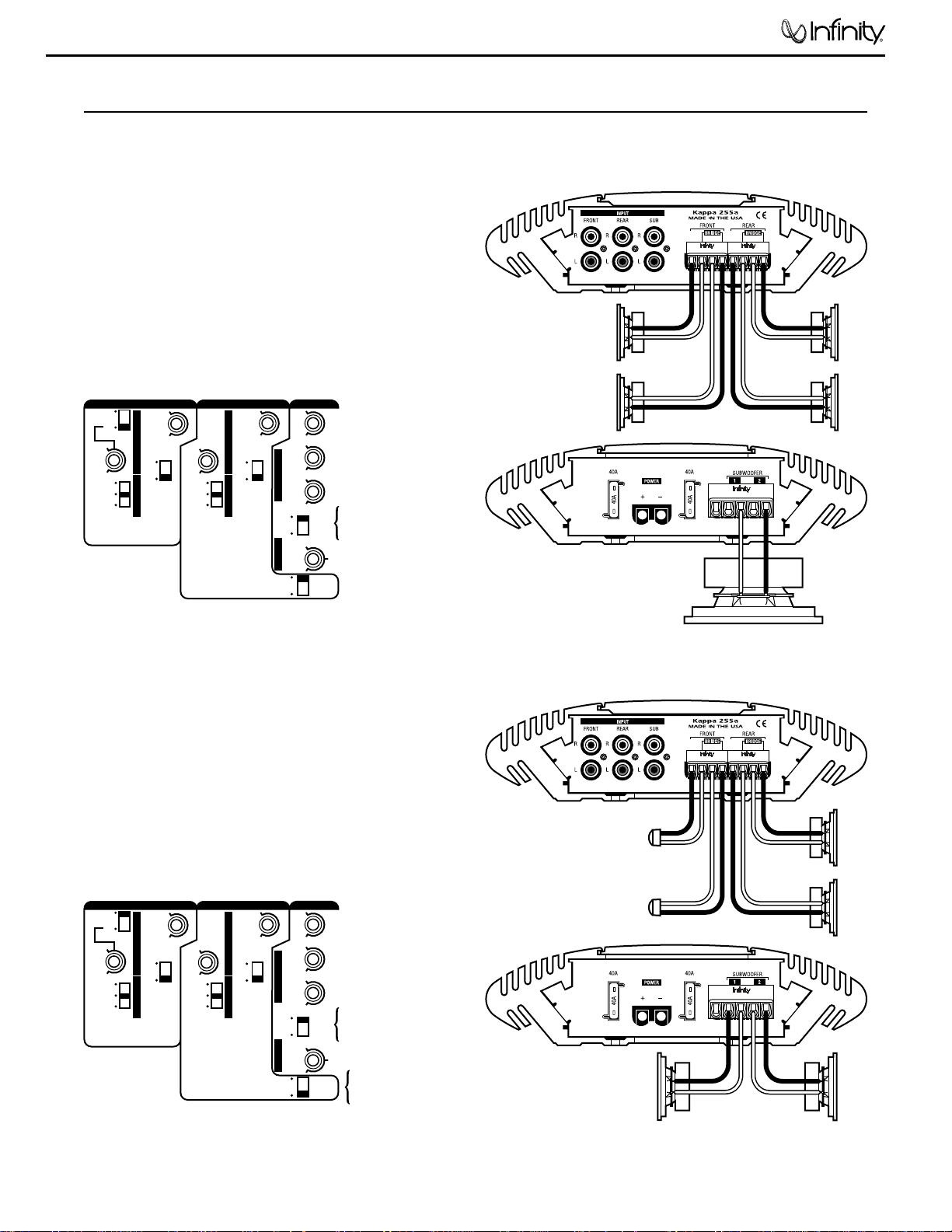

Enclosed are several diagrams to help you plan your own

system installation. Figures 1 through 3 (

on pages 4 and 5)

show how to configure the Kappa 255a to drive front and

rear speakers and a subwoofer, tweeters and midrange

speakers and a pair of subwoofers, and a tweeter/midrange

component set, midbass speakers, and a subwoofer.

For system expansion, see Figure 4 on the next page.

NOTE: For simplicity, Figures 1 through 4 do not show power,

remote, and input connections.

R

– ––

+ ++

L

R

– –

+ +

L

KAPPA 255a

(front panel)

KAPPA 255a

(rear panel)

REM

–

R

+–+

L

SUBWOOFER 1 and 2

are common outputs

and are supplied as

a convenience for

dual-subwoofer

applications

Subwoofer

LR

-

+

+

-

+

-

RRLF

+

-

RF

+

-

ST

BR

HP

FLAT

LP

.25V

9V

G

A

I

N

G

A

I

N

G

A

I

N

M

O

D

E

M

O

D

E

O

U

T

P

U

T

C

R

O

S

S

O

V

E

R

.25V

9V

.25V

9V

80Hz

20Hz

320Hz

32Hz

60

Hz

Q

FREQ

REAR

INPUT

SUB

INPUT

MIN

MAX

320Hz

32Hz

320Hz

32Hz

FRONT LP

EXT

INT

EXT

ST

BR

SUBWOOFER

FRONT REAR

O

U

T

P

U

T

C

R

O

S

S

O

V

E

R

D

B

O

X

O

V

E

R

HP

FLAT

LP

x1

x15

Set Switches As Shown

(set controls for your system plan)

Set to EXT for

source unit with

subwoofer outputs

KAPPA 255a

(top panel)

Figure 1. This wiring diagram shows

a Kappa 255a amplifier driving front

and rear pairs of full-range speakers

and a single subwoofer.

R

– ––

+ ++

L

R

– –

+ +

L

KAPPA 255a

(front panel)

KAPPA 255a

(rear panel)

REM

–

R

+–+

L

+

-

+

-

LF

Tweeter

+

-

RF

Tweeter

RR

Mid

LR

Mid

+

-

+

-

Subwoofer

(4 Ω min.)

Subwoofer

(4 Ω min.)

+

-

ST

BR

HP

FLAT

LP

.25V

9V

G

A

I

N

G

A

I

N

G

A

I

N

M

O

D

E

M

O

D

E

O

U

T

P

U

T

C

R

O

S

S

O

V

E

R

.25V

9V

.25V

9V

80Hz

20Hz

320Hz

32Hz

60

Hz

Q

FREQ

REAR

INPUT

SUB

INPUT

MIN

MAX

320Hz

32Hz

320Hz

32Hz

FRONT LP

EXT

INT

EXT

ST

BR

SUBWOOFER

FRONT REAR

O

U

T

P

U

T

C

R

O

S

S

O

V

E

R

D

B

O

X

O

V

E

R

HP

FLAT

LP

x1

x15

Set Switches As Shown

(set controls for your system plan)

Set to EXT for

source unit with

subwoofer outputs

FRONT LP creates

bandpass when rear

output is set to HP

KAPPA 255a

(top panel)

Figure 2. This wiring diagram shows a

Kappa 255a amplifier driving a pair of

tweeters, a pair of midrange speakers,

and a pair of subwoofers (4 Ω minimum).

APPLICATIONS

4

Kappa 255a

APPLICATIONS (continued)

R

– ––

+ ++

L

R

– –

+ +

L

KAPPA 255a

(front panel)

KAPPA 255a

(rear panel)

REM

–

R

+–+

L

SUBWOOFER 1 and 2

are common outputs

and are supplied as

a convenience for

dual-subwoofer

applications

Subwoofer

-

+

+

-

+

-

L

Plate

+

-

R

Plate

R

Midbass

L

Midbass

+

-

ST

BR

HP

FLAT

LP

.25V

9V

G

A

I

N

G

A

I

N

G

A

I

N

M

O

D

E

M

O

D

E

O

U

T

P

U

T

C

R

O

S

S

O

V

E

R

.25V

9V

.25V

9V

80Hz

20Hz

320Hz

32Hz

60

Hz

Q

FREQ

REAR

INPUT

SUB

INPUT

MIN

MAX

320Hz

32Hz

320Hz

32Hz

FRONT LP

EXT

INT

EXT

ST

BR

SUBWOOFER

FRONT REAR

O

U

T

P

U

T

C

R

O

S

S

O

V

E

R

D

B

O

X

O

V

E

R

HP

FLAT

LP

x1

x15

Set Switches As Shown

(set controls for your system plan)

Set to EXT for

source unit with

subwoofer outputs

FRONT LP creates

bandpass when rear

output is set to HP

KAPPA 255a

(top panel)

Figure 3. This wiring diagram shows a

Kappa 255a amplifier driving a front

set of tweeter/midrange components, a

rear pair of midbass speakers, and a

single subwoofer.

To Front L/R

Tweeters

To L/R

Midrange

Speakers

To L/R

Midbass

Speakers

To Rear L/R

Speakers

To Subwoofer(s)

Front L/R Inputs

(from Source Unit)

Subwoofer Inputs

(from Source Unit)

Rear L/R Inputs

(from Source Unit)

L/R Outputs

(Low-Pass)

Front L/R Inputs

KAPPA 52a

KAPPA 52a

KAPPA 255a

50w x 4 + 200W x 1

255a

ST

BR

HP

FLAT

LP

.25V

9V

G

A

I

N

G

A

I

N

G

A

I

N

M

O

D

E

M

O

D

E

O

U

T

P

U

T

C

R

O

S

S

O

V

E

R

.25V

9V

.25V

9V

80Hz

20Hz

320Hz

32Hz

60

Hz

Q

FREQ

REAR

INPUT

SUB

INPUT

MIN

MAX

320Hz

32Hz

320Hz

32Hz

HP

FLAT

LP

FRONT LP

EXT

INT

EXT

ST

BR

SUBWOOFER

FRONT REAR

50W X 4

+

200W CLASS D

DIGITAL SUBWOOFER

AMPLIFIER

O

U

T

P

U

T

C

R

O

S

S

O

V

E

R

D

B

O

X

O

V

E

R

x1

x15

SUBWOOFER

REAR

INPUT

FRONT LP

EXT

ST

BR

HP

FLAT

LP

O

U

T

P

U

T

C

R

O

S

S

O

V

E

R

FRONT

x1

x15

ST

BR

HP

FLAT

LP

O

U

T

P

U

T

REAR

SUB

INPUT

INT

EXT

Figure 4. In this expanded

system, a Kappa 52a

drives a front pair of

tweeters. The 52a’s lowpass outputs feed a Kappa

255a to drive stereo pairs

of midrange and midbass

speakers. An external

subwoofer signal feeds the

Kappa 255a to drive the

subwoofer(s). Another

Kappa 52a drives a rear

pair of speakers from the

source unit’s rear outputs.

SYSTEM EXPANSION

5

Kappa 255a

• The Kappa 255a has five levels of circuit protection that

monitor the amplifier and will shut it down if the

electrical system voltage drops below 10 Vdc or exceeds

15.5 Vdc, temperatures are above 194° F (90° C), short

circuits occur, or current draw exceeds product

specifications. For best performance, check the intended

mounting site to make sure the operating environment

does not create conditions that will trigger circuit

protection.

• Prior to installation, turn off all audio systems and other

electrical devices. Also disconnect the (–) negative lead

from the vehicle’s battery.

• At the installation site, locate and make a note of all fuel

lines, hydraulic brake lines, and electrical wiring. Use

extreme caution when cutting or drilling in and around

these areas.

• Use the amplifier as a mounting template to mark

locations for the mounting holes.

• Check clearances on both sides of a planned mounting

surface before drilling any holes or installing any screws.

Remember that mounting screws can extend up to an

inch behind the surface.

• Always wear protective eyewear when using tools.

• The Kappa 255a uses gold-plated, industrial-grade

Weco® plug-in connectors for power and speaker wiring.

Because of precision tolerances, do not insert the

connectors into the amplifier without pre-wiring them

first. Once the wires are fastened in each shell, they

provide additional gripping area for easy connector

removal.

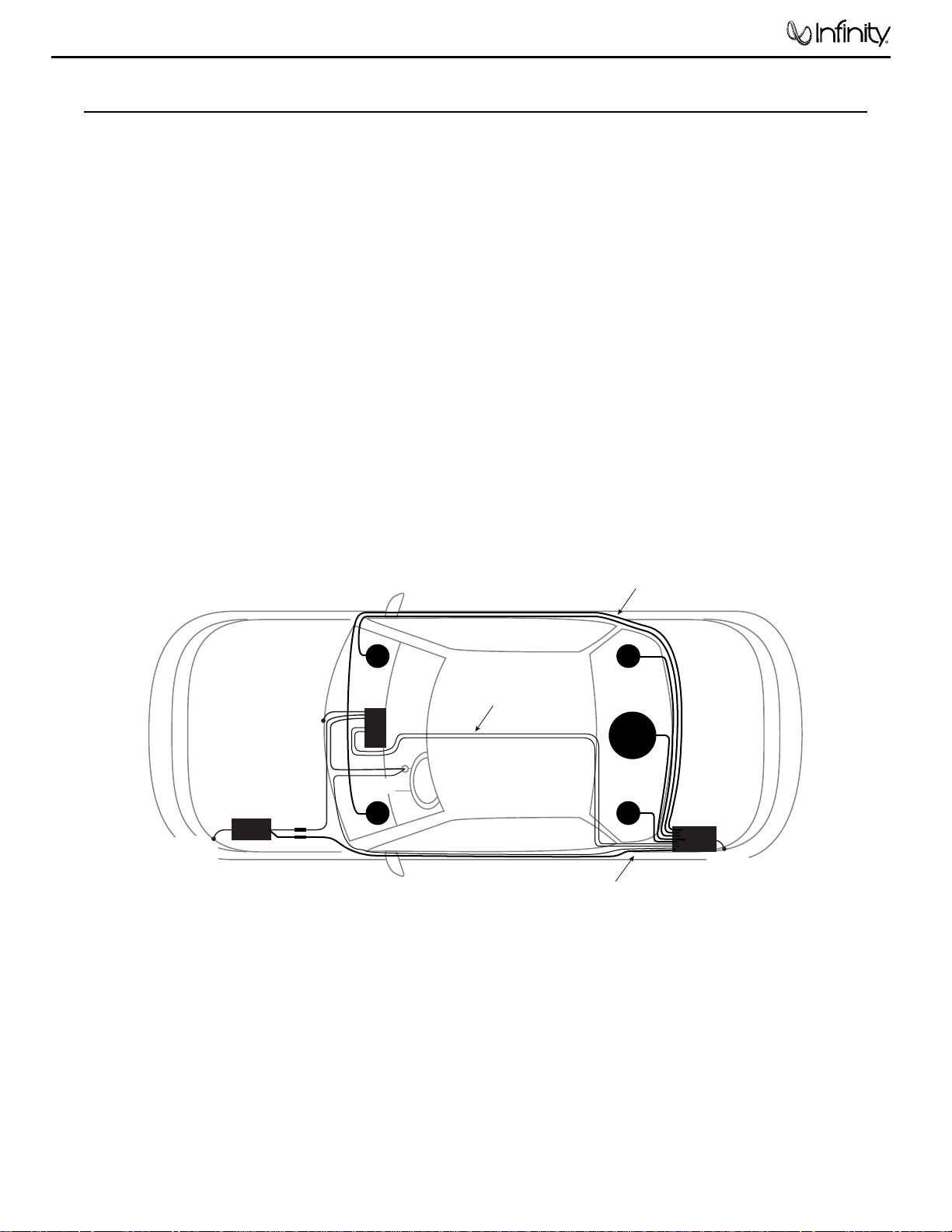

• When routing cables, keep input signal cables away from

power cables and output speaker wires, as shown in

Figure 5 (below).

• When making connections, make sure that each

connection is clean and properly secured. Observe the

polarity markings on the front and rear panels. Refer to

the application drawings (Figures 1 through 3 on pages 4

and 5 ) to set up the amplifier for operation of various

configurations.

• If the amplifier’s fuses need replacement, use only

the same rating and type as replacements. Do not

substitute another kind.

+–

Battery

Fuses

LF

RF

LR

RR

SUB

Kappa 255a

Amplifier

POWER and

REMOTE Cables

Chassis

Ground

Chassis

Ground

Chassis

Ground

Source

Unit

Ignition

SPEAKER Cables

AUDIO Cables

Figure 5. To minimize possible noise pickup, use this suggested cable

routing scheme to plan your amplifier installation.

PRECAUTIONS AND NOTES

6

Kappa 255a

The Kappa 255a is easy to install. For optimum

performance, we recommend using high-quality, twistedpair shielded RCA audio cables and 14-gauge or larger

speaker wire. Also, you’ll need a minimum of 10-gauge

stranded copper wire (e.g., red and black jackets) for the

power connections. Use 18-gauge (e.g., blue jacket) wire for

remote turn-on.

Depending on your total system plan, allow for adequate

time and the possibility of overnight storage of your vehicle,

since it may take more than one day to complete the

installation.

PARTS LIST...

Examine and verify that the package includes the following

items:

• (1) Kappa 255a Power Amplifier

• (2) Spare ATC fast-blow fuses (40 A)

• (1) Control cover with (2) machine screws

• (1) Weco 5-pin audio connector

• (2) Weco 4-pin audio connectors

• (1) Weco 2-pin power connector

• (4) #8 mounting screws

MOUNTING THE AMPLIFIER...

The Kappa 255a can be mounted in virtually any location

inside the vehicle. However, make sure to keep the

amplifier away from heater vents or ducts.

1. At the chosen site, use the amplifier as a mounting

template and mark locations of the four mounting holes.

2. Drill a small pilot hole at each marked location.

3. Mount the amplifier and securely tighten the mounting

screws.

WIRING THE AMPLIFIER...

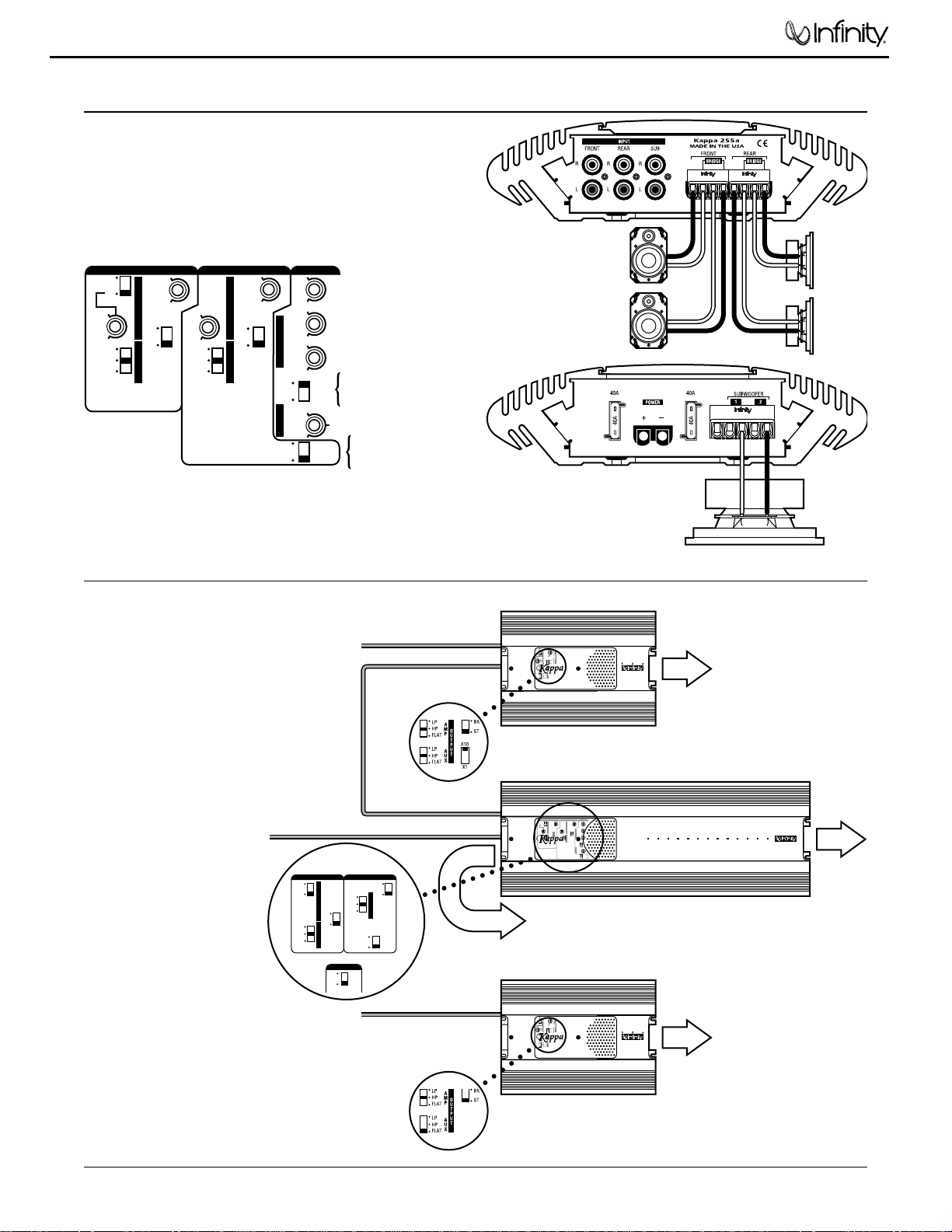

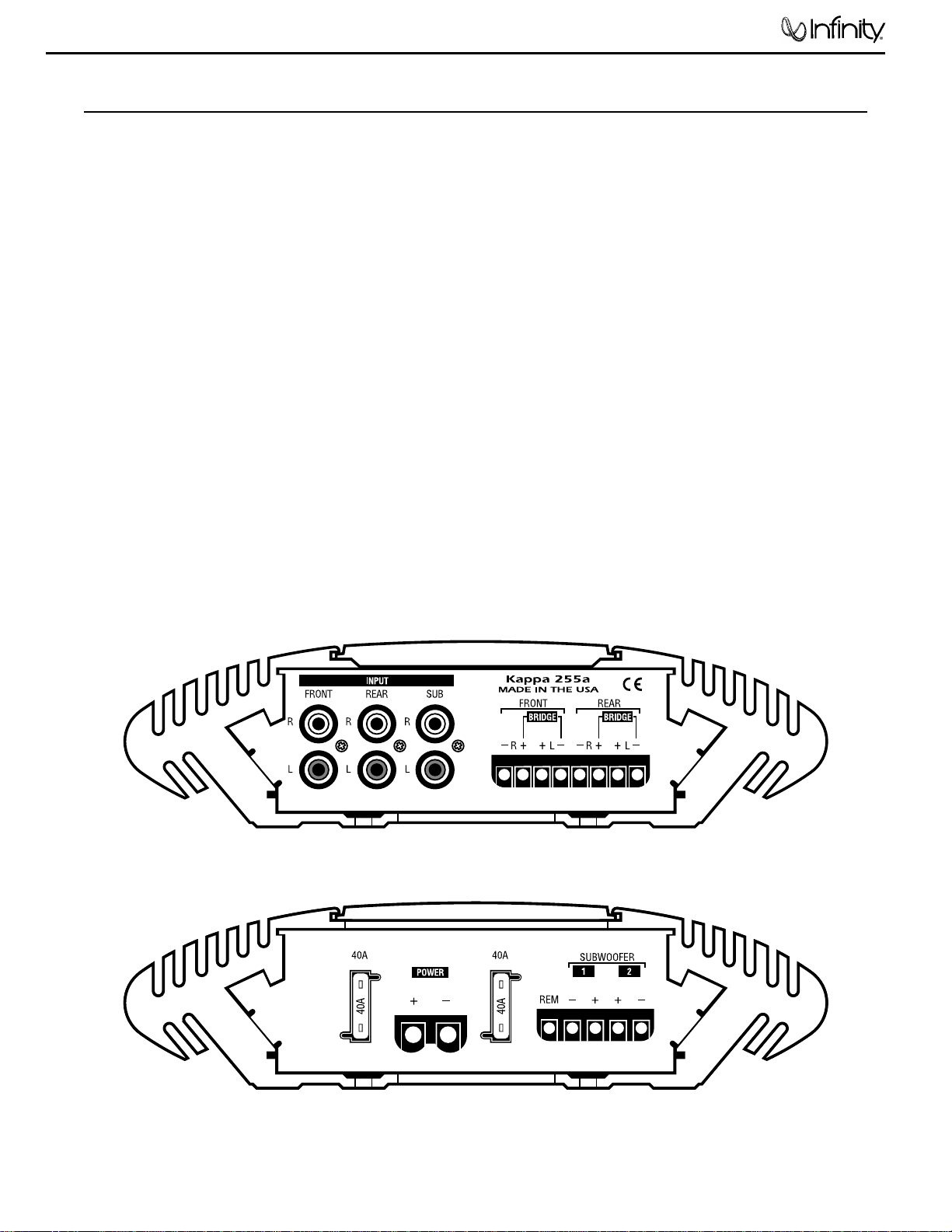

Refer to Figure 6 (below) for details of the Kappa 255a’s

front and rear panel connections.

1. For power, remote, and speaker wires, strip

1

⁄4" off one

end of each jacket to reveal bare wire for insertion into

the Weco connectors.

2. Using the Weco 2-pin power connector, connect a black

wire from the nearest bare-metal chassis component to

the (–) terminal. Then, connect a red wire from the

vehicle’s +12-volt battery terminal to the (+) terminal.

3. Make sure the wires are firmly seated in the Weco 2-pin

connector and that each screw is completely tightened.

Insert the wired connector into the POWER socket (on the

amplifier’s rear panel). Press it in until it stops.

KAPPA 255a WIRING CONNECTIONS

(front panel)

KAPPA 255a WIRING CONNECTIONS

(rear panel)

R L

Figure 6. W iring connections for the Kappa 255a amplifier.

INSTALLATION

7

Kappa 255a

4. Using the Weco 5-pin connector , connect a blue wire from

the source unit’s remote connection to the REM terminal.

Depending on polarity requirements (see Figures 1

through 3 on pages 4 and 5), connect speaker wires from

the subwoofer(s) to the L and R (+ and –) terminals, as

required by your system plan.

5. Make sure the wires are firmly seated in the Weco 5-pin

connector and that each screw is completely tightened.

Insert the wired Weco 5-pin connector into the

SUBWOOFER socket (on the amplifier’s rear panel).

Press it in until it stops.

6. Using Weco 4-pin connectors, connect speaker wires from

the front and rear speakers to the amplifier. Depending

on your system plan (see Figures 1 through 3 on pages 4

and 5 ), match the polarities on the L and R (+ and –)

terminals.

NOTE: In 3-way applications, the rear amplifier provides

bandpass channels to drive midrange or midbass speakers.

7. Make sure the wires are firmly seated in each Weco 4pin connector and that each screw is completely tightened.

Insert the wired Weco 4-pin connectors into the FRONT

and REAR sockets (on the amplifier’s front panel). Press

each one in until it stops.

8. Connect RCA cables from a source unit to the L /R,

FRONT/REAR INPUT jacks. If the source unit has

subwoofer outputs, also connect a pair of RCA cables from

those jacks to the SUB INPUT jacks and set the SUB

INPUT switch to EXT (see Figure 7).

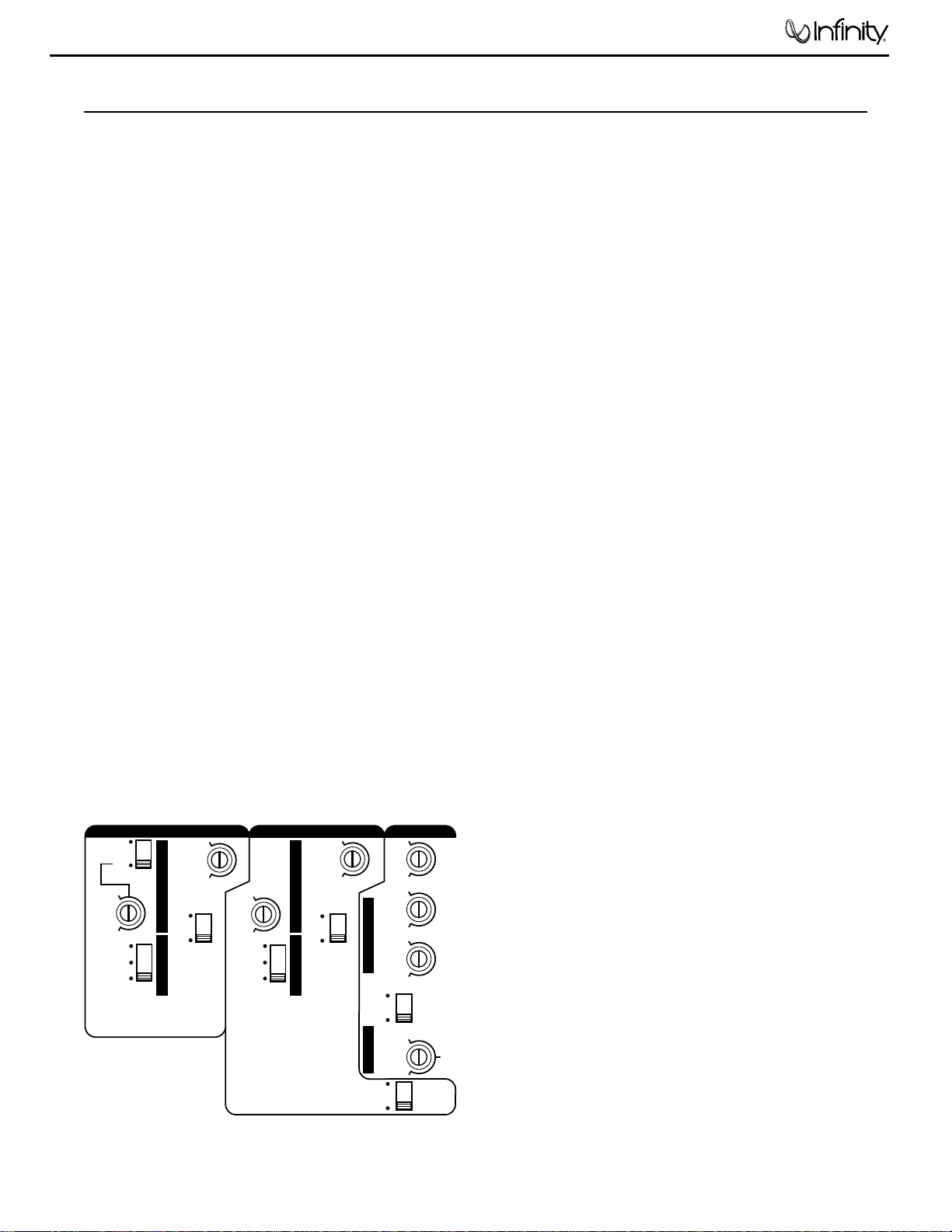

SETTING THE CROSSOVERS...

1. To use the Kappa 255a in a front/rear system, set the

CROSSOVER controls to frequencies recommended by

the speaker manufacturer (see Figure 7). If the value is

unknown, set the control midway.

2. For a 3-way system, set the OUTPUT and REAR INPUT

switches to create the appropriate bandpass filters (see

Figures 2 and 3 on pages 4 and 5).

SETTING INPUT SENSITIVITY...

Initially, turn the front and rear input sensitivity GAIN

controls to their minimum (counter-clockwise) positions

(refer to Figure 7).

1. Reconnect the (–) negative lead to your vehicle’s battery.

Apply power to the audio system and play a favorite

music track from CD or tape.

NOTE: After the source unit is on, green LEDs (on the top

panel) will illuminate, indicating the amplifier is on. If not,

check the wiring, especially the remote connection from the

source unit. Also refer to “Troubleshooting” on the next page.

2. On the source unit, increase the volume control to

maximum position. Slowly increase the Front and Rear

GAIN controls (clockwise) towards three o’ clock and, at

the same time, listen to the quality of the reproduced

sound. At some point, you’ll hear distortion on the music

peaks. Stop the adjustment and turn it back slightly.

SETTING DBO...

Dynamic Bass Optimizer (DBO) is a new approach to

enhancing low-frequency reproduction in a vehicle.

Conventional bass boost controls add bass at a fixed

frequency and cause the amplifier to consume considerable

power. DBO conserves valuable power at the lowest

frequencies and allows you to adjust the level and

“character” of the bass sound, instead of just the amount of

boom.

Since a subwoofer in a tuned box is given to overexcursion

below the tuned frequency, set the FREQ control below the

box’s resonant (tuned) frequency (see Figure 8 on

page 2).

Power typically wasted in this region will now be

conserved and instead be available for frequencies the

enclosure will reproduce. Use the Q control to boost the

bass at the set frequency by as much as 12 dB (at MAX

position –

see Figure 8 on Page 2).

For sealed enclosures, use DBO to enhance the output so it

sounds more like a tuned box. This is a result of 12 dB of

rolloff being added to the enclosure’s rolloff and a flattening

of frequency response (at the curve’s knee) when Q is

boosted.

For infinite baffles, set the FREQ control to the speaker ’s

F

s

value (to keep the subwoofer from trying to create bass

below the resonant frequency) and adjust the Q control

according to personal taste.

INSTALLING THE CONTROL COVER...

After wiring and testing the Kappa 255a amplifier, install

the control cover using the enclosed machine screws to

deter tampering and help seal out dust.

NOTE: Do not over-tighten the machine screws. Doing so may

crack the cover.

ST

BR

HP

FLAT

LP

.25V

9V

G

A

I

N

G

A

I

N

G

A

I

N

M

O

D

E

M

O

D

E

O

U

T

P

U

T

C

R

O

S

S

O

V

E

R

.25V

9V

.25V

9V

80Hz

20Hz

320Hz

32Hz

60

Hz

Q

FREQ

REAR

INPUT

SUB

INPUT

MIN

MAX

320Hz

32Hz

320Hz

32Hz

HP

FLAT

LP

FRONT LP

EXT

INT

EXT

ST

BR

SUBWOOFER

FRONT REAR

50W X 4

+

200W CLASS D

DIGITAL SUBWOOFER

AMPLIFIER

O

U

T

P

U

T

C

R

O

S

S

O

V

E

R

D

B

O

X

O

V

E

R

x1

x15

INSTALLATION (continued)

Figure 7. Kappa 255a controls for crossover, input, output, and

DBO (Dynamic Bass Optimizer).

8

Kappa 255a

Use the following guide to identify symptoms and solve

problems. Make sure the vehicle’s electrical system is

working properly and power is reaching the Kappa 255a

(i.e., green LEDs on the top panel are on).

SYMPTOM LIKELY CAUSE SOLUTION

No audio Low/No Remote Check connections;

Turn-On Voltage test turn-on voltage

Speakers are not Check wiring; use

connected or are VOM/DVM to

blown measure speaker

coil impedance

Distorted audio Input sensitivity See

Setting Input

is not set properly Sensitivity on

previous page

Audio lacks Speakers are wired Check polarity of

“punch” with wrong polarity connections; refer to

Applications

SYMPTOM LIKELY CAUSE SOLUTION

Audio cycles A protection circuit Verify the following–

off and on; is turning the electrical system is

Amber protec- amplifier off and on between

10 ~ 15.5

Vdc;

tion LEDs (on temperature is not

top panel) are on over 194°F (90°C);

no short circuits;

speaker loads are not

less than 1 ohm

(2 ohms in mono)

Audio cycles GAIN is set too high Set Input Sensitivity

off and on; correctly (see previous

Amber protection page)

LEDs (on top

panel) are on

Fuse blows Incorrect wiring or Check connections;

short circuit refer to Applications

TROUBLESHOOTING

9

Kappa 255a

10

Kappa 255a

Service Bulletin

Service bulletin INF9701 Rev1 - August 2001 This is considered a Major repair

To: All Infinity Service Centers

Models: Kappa 255a

Subject: Damaged Output Transistors

When the voltage from an automotive battery powering the Kappa 255a dips repeatedly dips below 8 volts, the

class D regulator can become unstable. As result, excessive current flow can damage output transistors

Q10,11,12,13 in the subwoofer section.

In the event you receive a Kappa 255a for any servicing reason, perform the modification as shown

below. Affected units will have an “HC” in the prefix in a white serial # label (bottom of the unit).

Note: Many components in this product, including two due for replacement, are Surface Mount Devices.

Procedure:

1) Remove the (24) 9/64” allen screws from both lower sides of the chassis.

2) Remove the (2) #10 Torx screws from the bottom chassis underneath the tamper-proof labels.

3) Turn amplifier vertically and strike on a hard surface, dislodging the main PCB; slide entire assembly out of

the chassis.

4) Remove and replace any defective

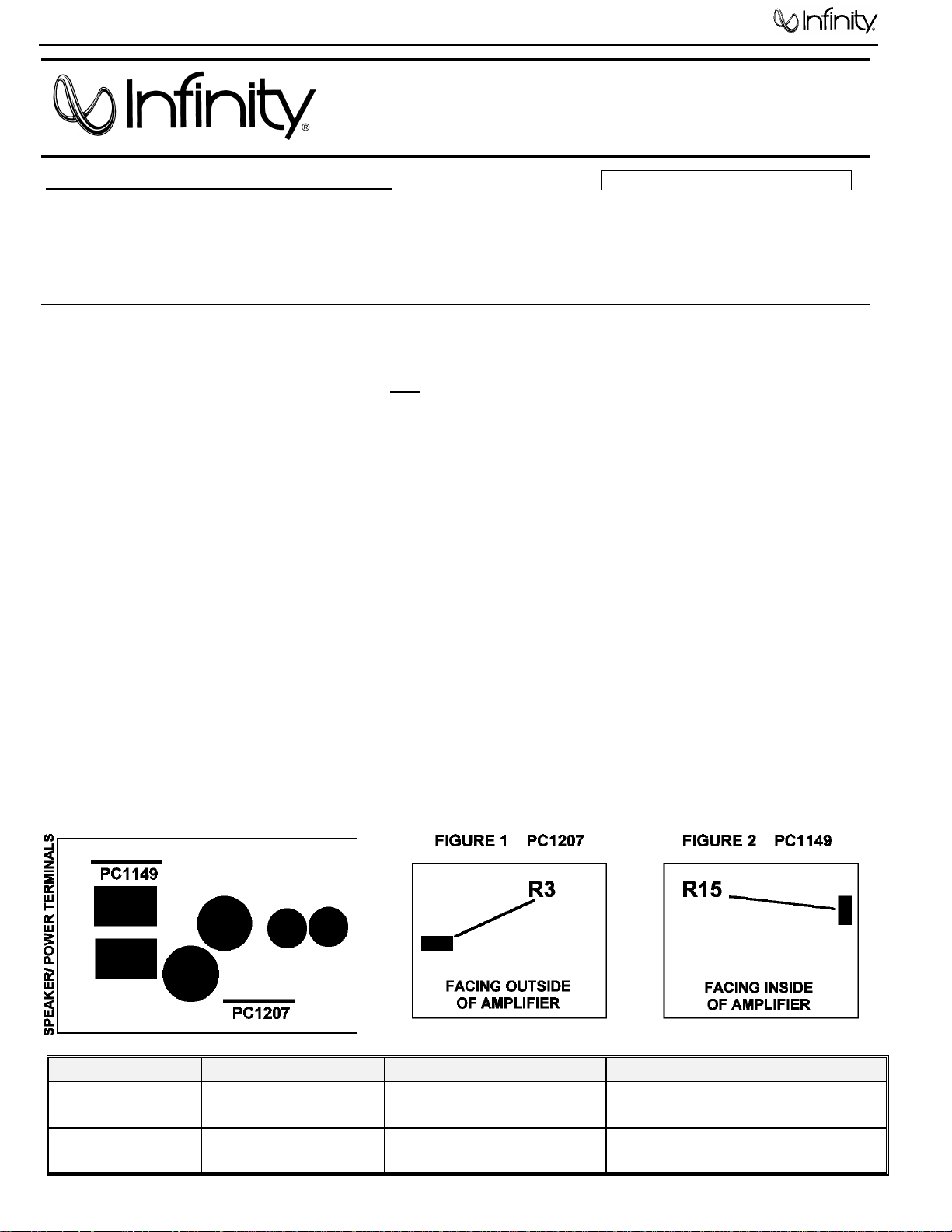

5) Change R3 on the Digital Predriver Module (PC1207) from 22kW to 2.2kW (Infinity part# RS1703). PC1207

is the small upright board located near the main PCB filter capacitors. R3 is on the component side of the

board facing the outside of the amplifier. See Figure 1.

6) Change R15 on PWM Module (PC1149) from 1kW to 2.2kW W (Infinity part# RS1703). PC1149 is the small

upright board located near the main power supply transformers. R15 is on the component side of the board

facing the inside of the amplifier. See Figure 2.

7) Reinsert main PCB into chassis; confirm that all (20) insulators are still in place, attached with heat sink

compound to each output device.

8) Insert and tighten all (24) chassis screws, including the (2) Torx screws on the bottom of the unit. Note: the

(4) shorter, 5/8” screws are inserted at the ends of the amp chassis.

9) Attach all power, speaker and signal cables to amplifier and test.

IRFS250 output transistors. (Q10-13 are Infinity part# TR1238)

Model Serial number Status Acti on

KAPPA 255a “HC” in the prefix

below -01701

KAPPA 255a “HC” in the prefix

-01701and above

Damaged Q10,11,12 or 13 Change R3 & R15

to 2.2kW

Modified by factory NONE REQUIRED

11

Kappa 255a

Service Bulletin

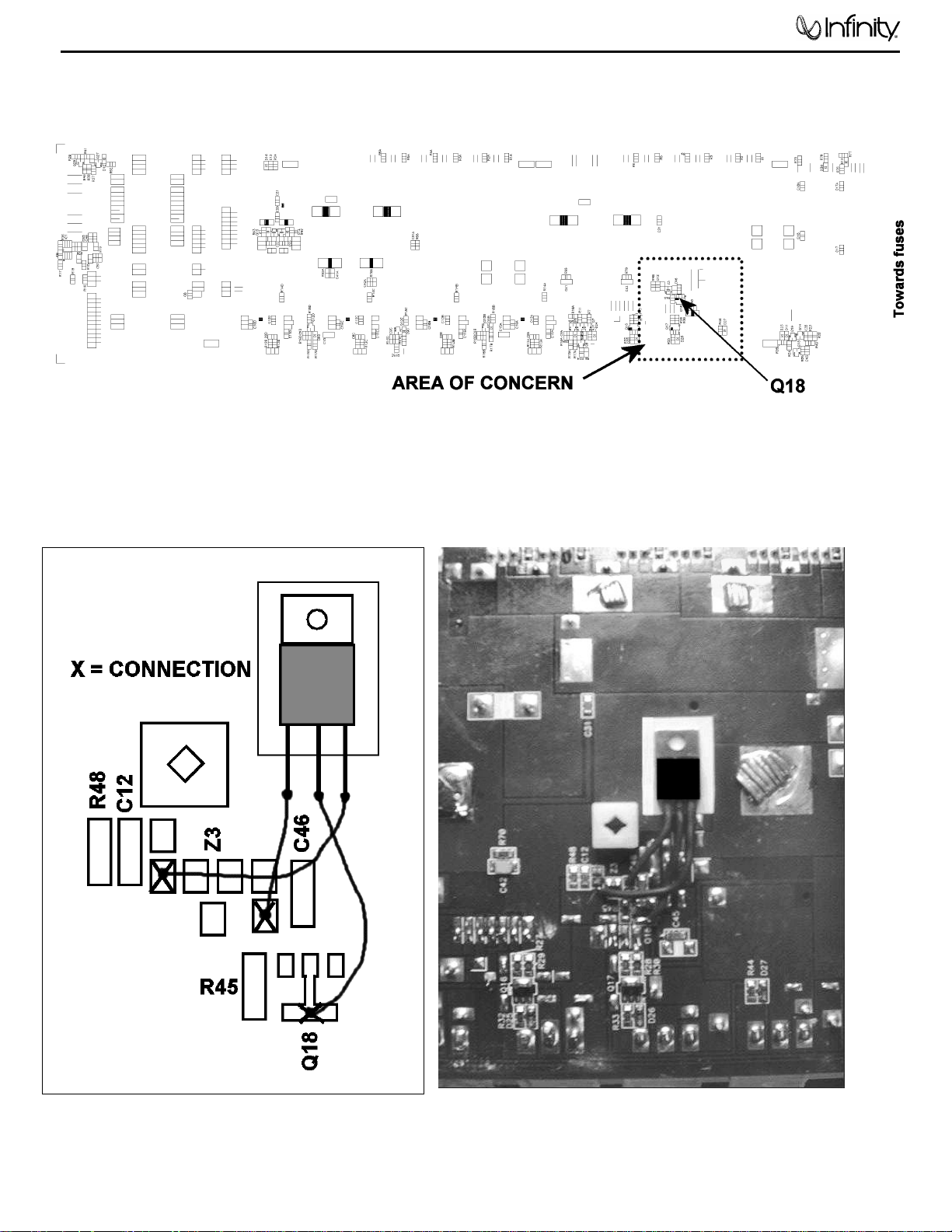

Service Bulletin INF2001-02 - September 2001 Warranty labor rate: MAJOR repair

To: All Infinity Service Centers

Model: Kappa 255a

Subject: No Sound from Subwoofer Output

In the event you receive a Kappa 255a with the complaint: “No sound from the subwoofer output”,

replace transistor Q18 SMD (Surface Mount Device) with a TO-220 package, TIP31C transistor. For

details, see instructions as described below. All KAPPA 255A amplifiers with serial numbers starting

with letters “CL” should be modified. The serial number is printed on a white label, located on the

bottom of the Kappa 255A enclosure.

Note: Many components in this product, including the one due for replacement, are Surface Mount Devices.

Procedure:

1) Remove the (24) 9/64” Allen screws from both lower sides of the chassis.

2) Remove the (2) #10 Torx screws from the bottom chassis underneath the tamper-proof labels.

3) Turn amplifier vertically and strike on a hard surface, dislodging the main PCB; slide entire assembly out

of the heatsink.

4) Locate, identify, and remove Q18 SMD transistor on the bottom of the main PCB. See illustrations on

page 2.

5) Prepare the nearby area on the PCB by applying a white .5" x .75" BONDPLY insulator, (Infinity part#

TO-220 BONDPLY-100) in the area where a new TIP31C transistor will be mounted.

6) Apply a transistor TIP31C (Infinity part# TR1183) on top of the insulator; press firmly to set. Transistor

should be flat on the PCB.

7) Extend the three leads of the transistor by soldering a length of 22 gauge buss wire to each lead, the

length determined by the connection points. Solder each wire piece to each lead (longer is better as it

can always be cut) and then trim to the correct length. You will NOT be re-connecting the three leads to

the tiny solder pads for the original SMD device; study the illustrations to locate the three final connection

points.

8) Cut three pieces of 1/16” vinyl or shrink tubing to insulate the three exposed leads, leaving enough wire

exposed at the end to make the final soldered connections.

9) Solder the three leads in the areas shown in the illustration. Transistor Q18 and new connecting wires

MUST NOT be higher than the square plastic standoff next to it.

10) Add a dab of RTV (silicon seal or similar non-conductive compound) to the area of the three leads.

11) Test the unit, still out of the heatsink, by applying power, with signal and subwoofer connections WITH

NO LOUDSPEAKER LOAD other than a DMM or an oscilloscope on the output terminals.

12) Reinsert main PCB into chassis; confirm that all (20) insulators on the output devices are still in place,

attached with heat sink compound on each one.

13) Insert and tighten all (24) chassis screws, including the (2) Torx screws on the bottom of the unit. Note:

the (4) shorter, 5/8” screws are inserted at the ends of the amp chassis.

14) Attach all power, speaker and signal cables to amplifier and test with loudspeaker load.

MODEL SERIAL NUMBER

KAPPA 255a

“CL” in the serial # prefix

All units affected

STATUS

Q18 Overheating

ACTION

Replace Q18 with

TIP31C transistor

12

Kappa 255a

13

Kappa 255a

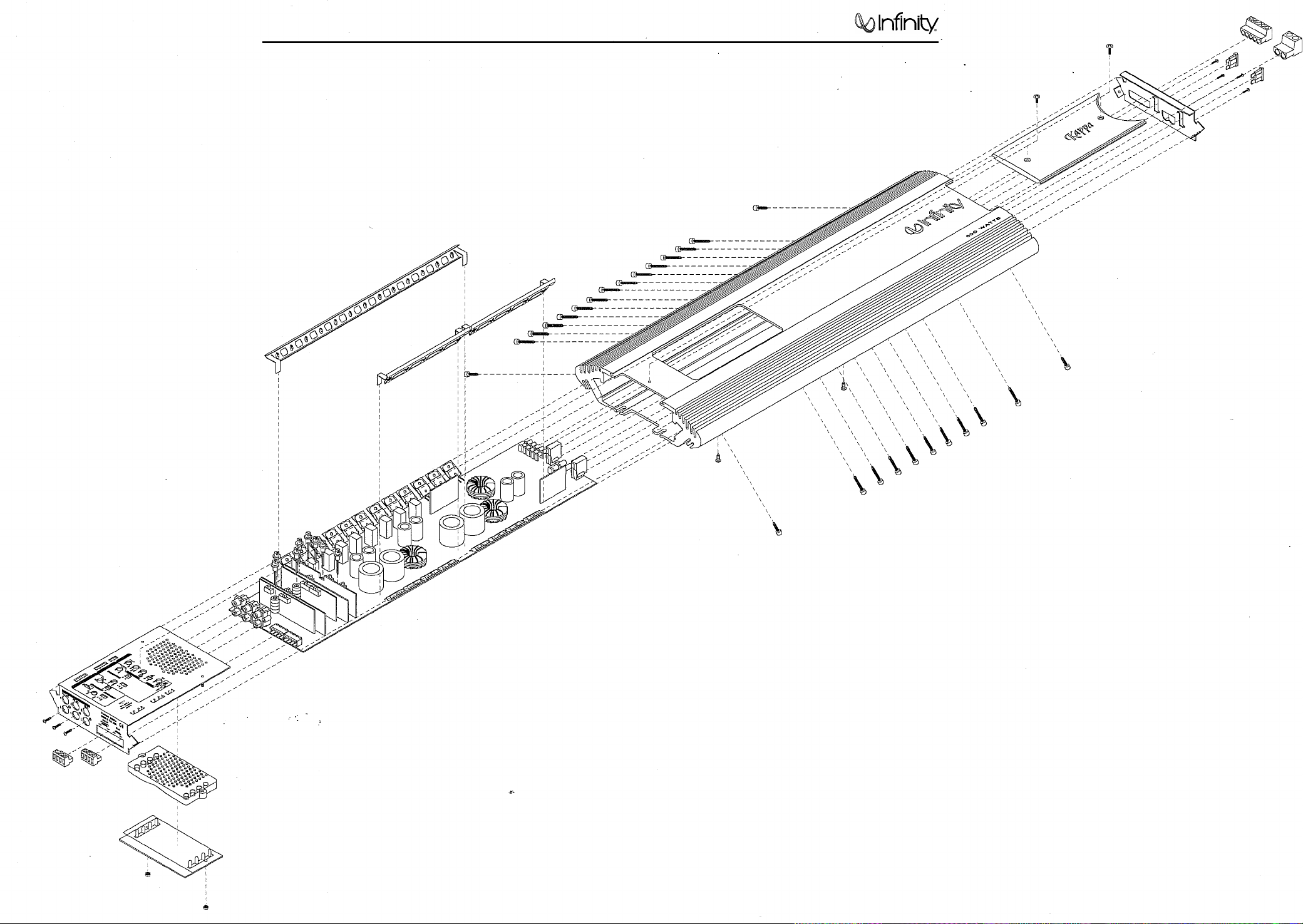

Kappa 255a Exploded View

Loading...

Loading...