Page 1

OPERATION AND SERVICE MANUAL

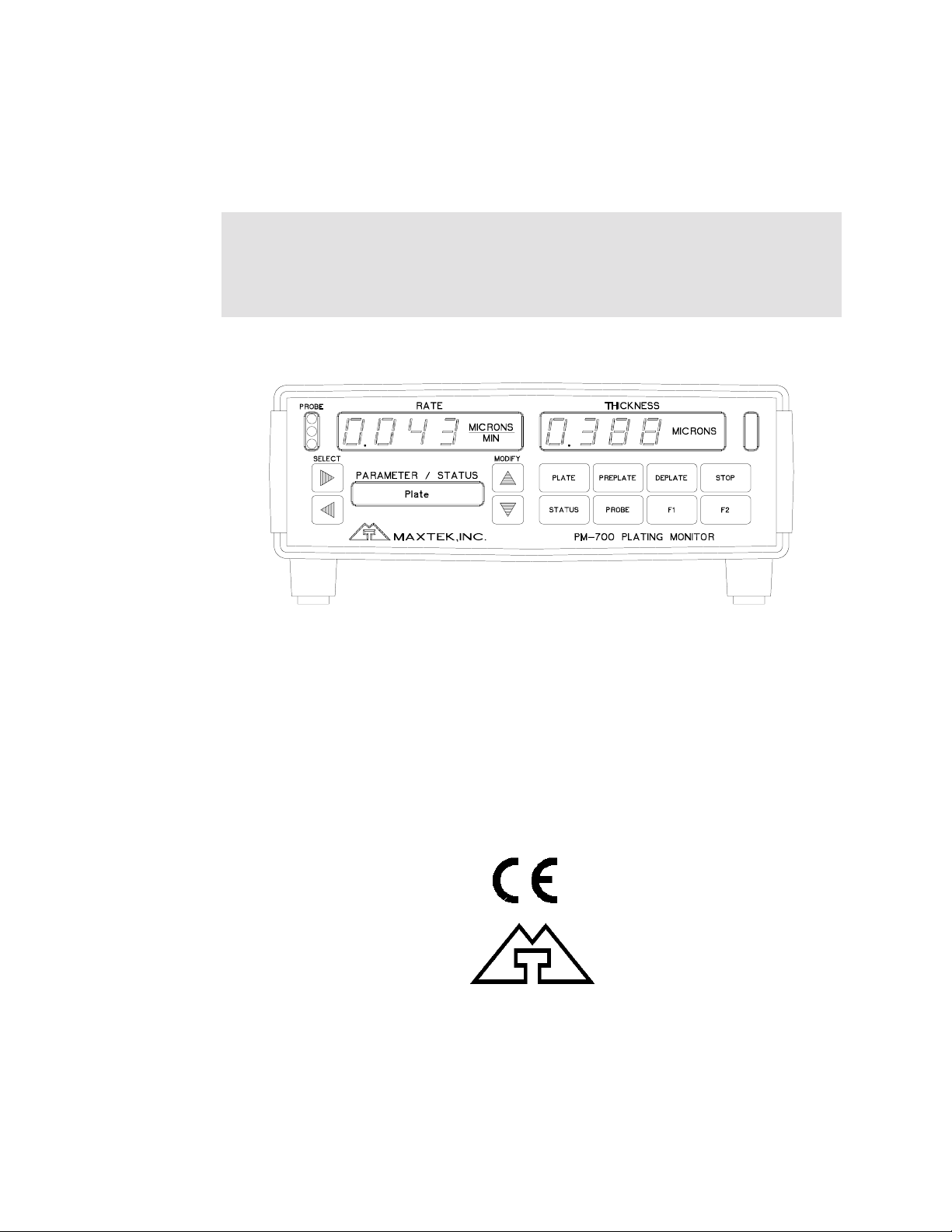

PM-700 SERIES

PLATING MONITOR

P/N 170800

S/N _____________

MAXTEK, INC.

11980 Tel egr aph Road, Suite 104

Sant a Fe Sprin gs, CA 90670-6084

Tel: (562) 906-1515 • Fax: (562) 906-1622

http://www.maxtekinc.com

Email: sales@maxtekinc.com • support@maxtekinc.com

Page 2

© 1992-2000 MAXTEK, INC. All rights reserved.

First Edition, August 1992

Second Edition, Revision A, March 1993

Third Edition, Revision B, October 1998

Third Edition, Revision C, March 2000

Page 3

WARRANTY

Maxtek, Inc. warrants the product to be free of functional defects in material and

workmanship and that it will perform in accordance with its published

specification for a period of (twenty-four) 24 months.

The foregoing warranty is subject to the condition that the product be properly

operated in accordance with instructions provided by Maxtek, Inc. or has not been

subjected to improper installation or abuse, misuse, negligence, accident,

corrosion, or damage during shipment.

Purchaser's sole and exclusive remedy under the above warranty is limited to, at

Maxtek's option, repair or replacement of defective equipment or return to

purchaser of the original purchase price. Transportation charges must be prepaid

and upon examination by Maxtek the equipment must be found not to comply

with the above warranty. In the event that Maxtek elects to refund the purchase

price, the equipment shall be the property of Maxtek.

This warranty is in lieu of all other warranties, expressed or implied and

constitutes fulfillment of all of Maxtek's liabilities to the purchaser. Maxtek does

not warrant that the product can be used for any particular purpose other than that

covered by the applicable specifications. Maxtek assumes no liability in any

event, for consequential damages, for anticipated or lost profits, incidental damage

of loss of time or other losses incurred by the purchaser or third party in

connection with products covered by this warranty or otherwise.

DISCLOSURE

The disclosure of this information is to assist owners of Maxtek equipment to

properly operate and maintain their equipment, and does not constitute the release

of rights thereof. Reproduction of this information and equipment described

herein is prohibited without prior written consent from Maxtek, Inc., 11980

Telegraph Road, Suite 104, Santa Fe Springs, California, 90670.

SAFETY

All standard safety procedures associated with the safe handling of electrical

equipment must be observed. Always disconnect power when working inside

the controller. Only properly trained personnel should attempt to service the

instrument.

v

Page 4

Table of Contents

1. GENERAL DESCRIPTION.................................................................................................1

1.1 SPECIFICATIONS ...................................................................................................................2

2. UNPACKING, INSPECTION AND BENCH CHECKOUT.............................................5

2.1 UNPACKING, INSPECTION.....................................................................................................5

2.2 BENCH CHECKOUT...............................................................................................................5

3. SIMPLIFIED OPERATION...............................................................................................13

3.1 SAMPLE PROCESS ..............................................................................................................15

4. DETAILED OPERATION..................................................................................................18

4.1 INTRODUCTION AND GENERAL CONCEPTS .........................................................................18

4.2 DISPLAYS...........................................................................................................................18

4.3 BUTTONS ...........................................................................................................................18

4.4 OPERATION........................................................................................................................20

4.4.1 Monitor Operating States.............................................................................................21

4.4.1.1 Electroless plating ............................................................................................................21

4.4.1.1.1 Ready State .................................................................................................................21

4.4.1.1.2 Preplate State..............................................................................................................21

4.4.1.1.3 Plate State ...................................................................................................................21

4.4.1.1.4 Deplate State...............................................................................................................21

4.4.1.1.5 Endpoint State.............................................................................................................21

4.4.1.2 Electrolytic plating...........................................................................................................22

4.4.1.2.1 Ready State .................................................................................................................22

4.4.1.2.2 Plate State ...................................................................................................................22

4.4.1.2.3 Deplate State...............................................................................................................22

4.4.1.2.4 Endpoint State.............................................................................................................22

4.4.2 Monitor Measurement Modes ......................................................................................22

4.4.2.1 Single Probe Measurement Modes...................................................................................22

4.4.2.1.1 Continuous.................................................................................................................. 22

4.4.2.1.2 Sample.........................................................................................................................23

4.4.2.1.3 Sample with Deplate ...................................................................................................23

4.4.2.2 Dual Probe Measurement Modes .....................................................................................23

4.4.2.2.1 Auto Probe Swap........................................................................................................ 23

4.4.2.2.2 Alternating Measurement mode..................................................................................23

4.4.2.2.3 Dual Probe Measurement mode..................................................................................23

4.4.3 Probe States and Modes...............................................................................................24

4.4.3.1 Probe States......................................................................................................................24

4.4.3.1.1 Failed state..................................................................................................................24

4.4.3.1.2 Standby state ...............................................................................................................24

4.4.3.1.3 Active state..................................................................................................................24

4.4.3.2 Probe modes.....................................................................................................................24

4.4.3.2.1 Ready mode.................................................................................................................24

4.4.3.2.2 Hold mode...................................................................................................................24

4.4.3.2.3 Deplate mode ..............................................................................................................25

4.4.3.2.4 Preplate mode..............................................................................................................25

4.4.3.2.5 Plate mode...................................................................................................................25

4.4.4 Main Display modes.....................................................................................................25

4.4.4.1 Rate and Thickness...........................................................................................................25

4.4.4.2 Rate and Efficiency..........................................................................................................25

4.4.4.3 Efficiency and Thickness..................................................................................................25

4.4.4.4 Frequency.........................................................................................................................26

4.4.5 Parameter/Status Display modes .................................................................................26

4.4.5.1 Status Display...................................................................................................................26

4.4.5.2 Frequency Display............................................................................................................26

4.4.5.3 Elapsed Time Display.......................................................................................................26

4.4.5.4 Time to Go Display..........................................................................................................26

4.4.5.5 Current Density Display...................................................................................................26

Page 5

4.4.5.6 A-B)% Display................................................................................................................ 27

4.4.6 Simulation Mode..........................................................................................................27

4.5 PARAMETERS.....................................................................................................................27

4.5.1 Viewing and modifying ................................................................................................27

4.5.2 Hidden parameters.......................................................................................................28

4.5.3 Descriptions.................................................................................................................28

4.5.3.1 Mode Menu..................................................................................................................... 30

4.5.3.2 Process Menu .................................................................................................................. 32

4.5.3.3 Bath Menu...................................................................................................................... .34

4.5.3.4 Display Menu .................................................................................................................. 36

4.5.3.5 Setup Menu..................................................................................................................... 37

4.5.4 Restoring to Default Values.........................................................................................39

4.6 STATUS ASSESSMENT ........................................................................................................39

4.6.1 Monitor Status..............................................................................................................39

4.6.2 Probe Status.................................................................................................................39

4.7 SWAPPING PROBES.............................................................................................................40

4.7.1 Manual probe swapping ..............................................................................................40

4.7.1.1 Assessing the probe status prior to initiating the swap.................................................... 40

4.7.1.2 Preplating prior to swapping............................................................................................ 40

4.7.1.3 Commanding the swap. ................................................................................................... 40

4.7.1.4 Deplating the Standby Probe........................................................................................... 40

4.7.1.5 Manual termination of Preplate or Deplate on the Standby probe. .................................. 40

4.7.2 Automatic probe swapping ..........................................................................................41

4.7.2.1 Auto probe swap on active probe failure......................................................................... 41

4.7.2.2 Alternating Probe mode................................................................................................... 41

4.7.2.3 Failed Standby Probe inhibits automatic swap................................................................ 41

4.8 EXTERNAL INTERFACE.......................................................................................................41

4.8.1 Discrete Inputs.............................................................................................................41

4.8.2 Discrete Outputs ..........................................................................................................43

4.8.3 Digital to Analog Converters.......................................................................................45

4.8.3.1 Thickness DAC................................................................................................................ 45

4.8.3.2 Rate DAC ........................................................................................................................45

4.8.4 Computer Connection ..................................................................................................47

4.8.4.1 RS-232 Interface.............................................................................................................. 48

4.8.4.2 Protocol........................................................................................................................... 48

4.8.4.3 Remote Control ............................................................................................................... 49

4.8.4.3.1 Upload Parameter Store (Instruction 10h).................................................................. 49

4.8.4.3.2 Restore Parameter Store (Instruction 20h) ................................................................. 54

4.8.4.3.3 Remotely Activate (Instruction 30h).......................................................................... 54

4.8.4.4 Remote Monitoring ......................................................................................................... 55

4.8.4.4.1 Upload Machine Status (Instruction 40h) .................................................................. 55

4.8.4.5 Data Logging................................................................................................................... 59

4.8.4.5.1 Establish automatic data logging................................................................................ 59

4.8.4.5.2 Single data log............................................................................................................ 62

5. TROUBLESHOOTING......................................................................................................63

5.1 TROUBLE-SHOOTING AIDS.................................................................................................63

5.2 FAIL MESSAGES FOLLOWING POWER ON...........................................................................64

5.2.1 Power Failure..............................................................................................................64

5.2.2 Sensor Probe Failure...................................................................................................65

5.2.3 Invalid Parameters.......................................................................................................65

5.2.4 RAM Failure................................................................................................................65

5.2.5 ROM Failure................................................................................................................65

5.3 PROBE FAILED INDICATION................................................................................................65

6. APPENDIX ..........................................................................................................................67

6.1 THEORY OF THE QUARTZ CRYSTAL MICROBALANCE ........................................................67

6.1.1 Crystal Frequency........................................................................................................67

6.1.2 Crystal Health Calculation..........................................................................................67

vii

Page 6

6.1.3 Thickness Calculation ..................................................................................................67

6.1.4 Rate Calculation...........................................................................................................69

6.2 FINE TUNING WITH EMPIRICAL CALIBRATION ....................................................................69

6.2.1 Density..........................................................................................................................70

6.2.2 Tooling Factor.............................................................................................................70

6.2.3 Acoustic Impedance .....................................................................................................70

6.3 LIST OF MATERIAL CONSTANTS .........................................................................................72

Page 7

List of Figures

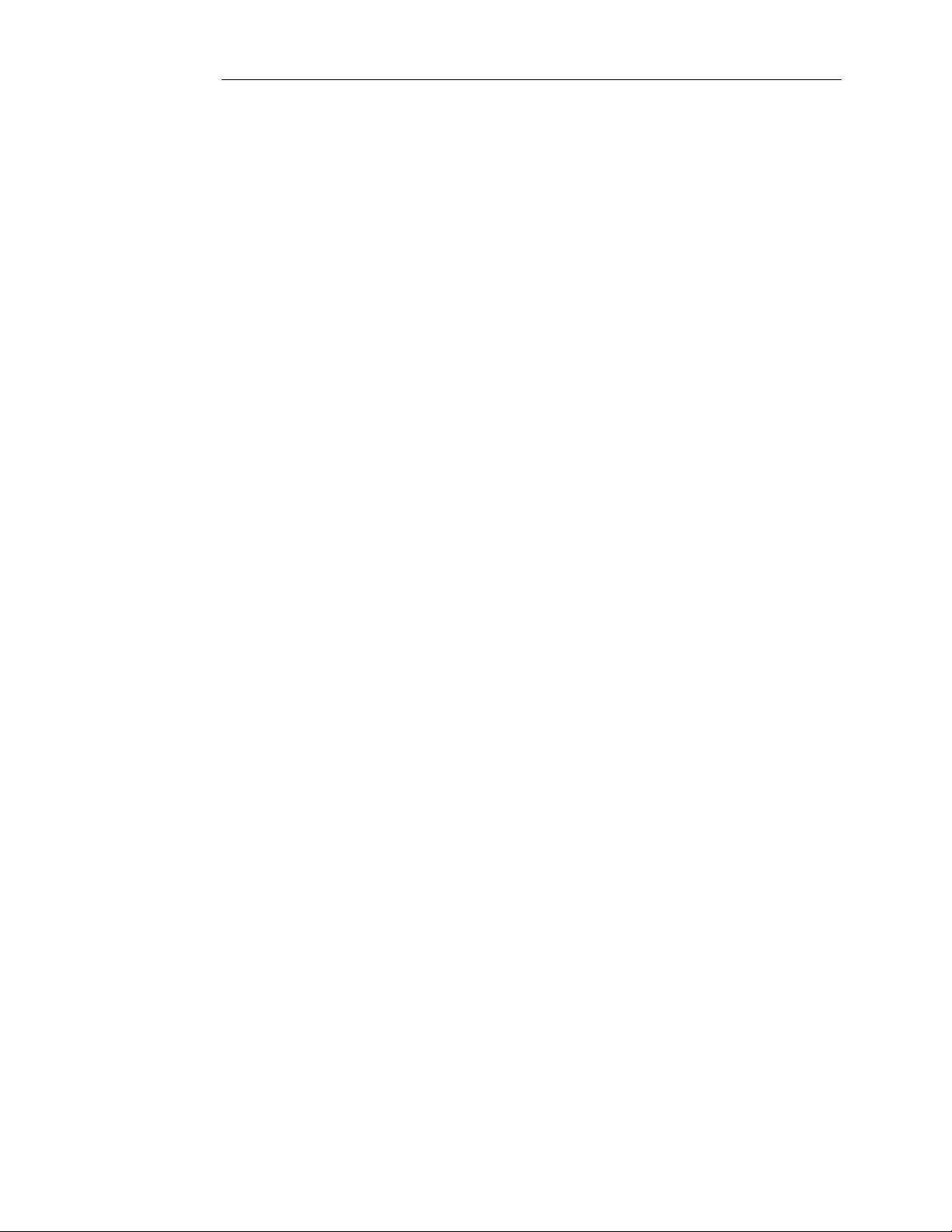

FIGURE 1 POWER SWITCH AND AC CONNECTOR .............................................................................6

FIGURE 2 FRONT PANEL INDICATION, FIRST POWER-ON .................................................................6

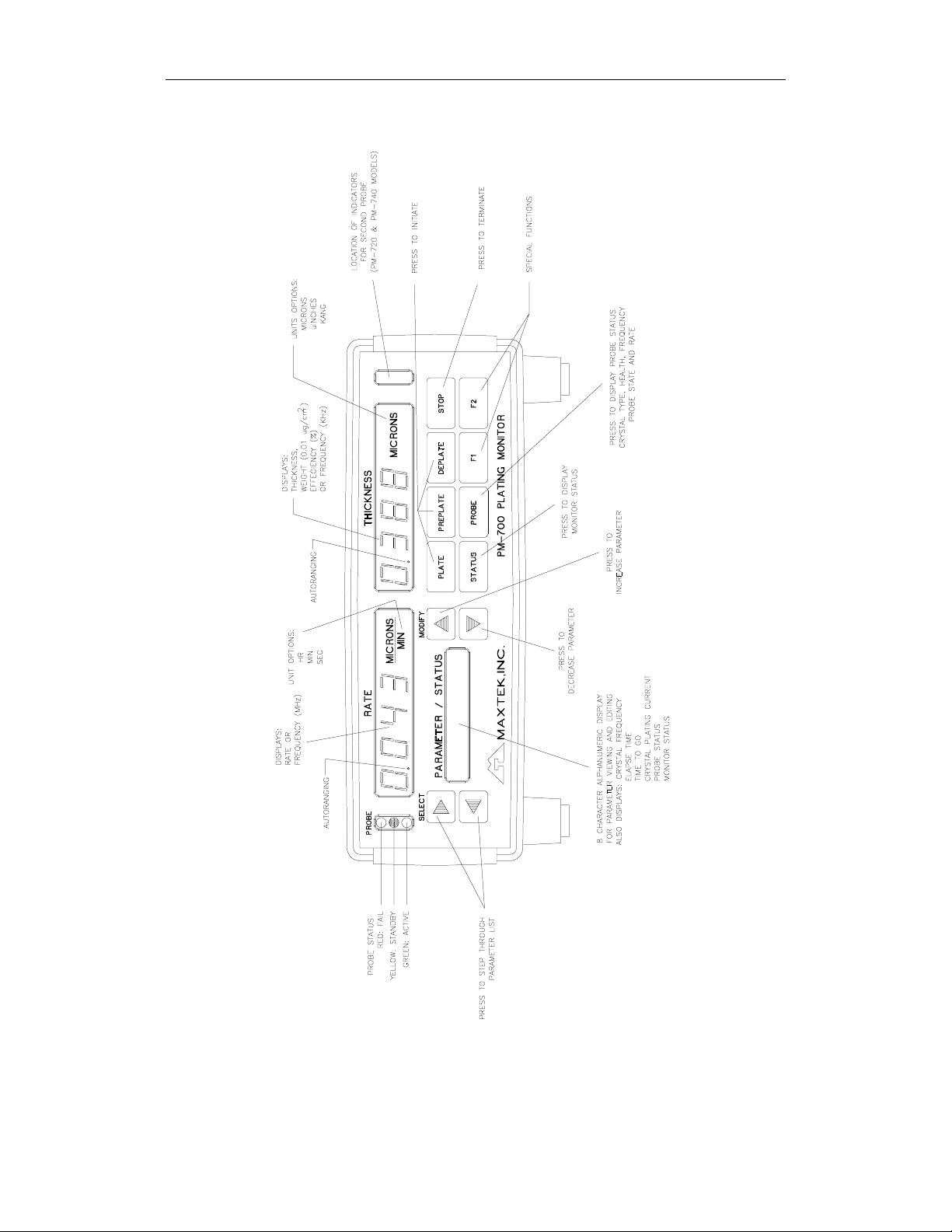

FIGURE 3 PM-700 FRONT PANEL OUTLINE......................................................................................8

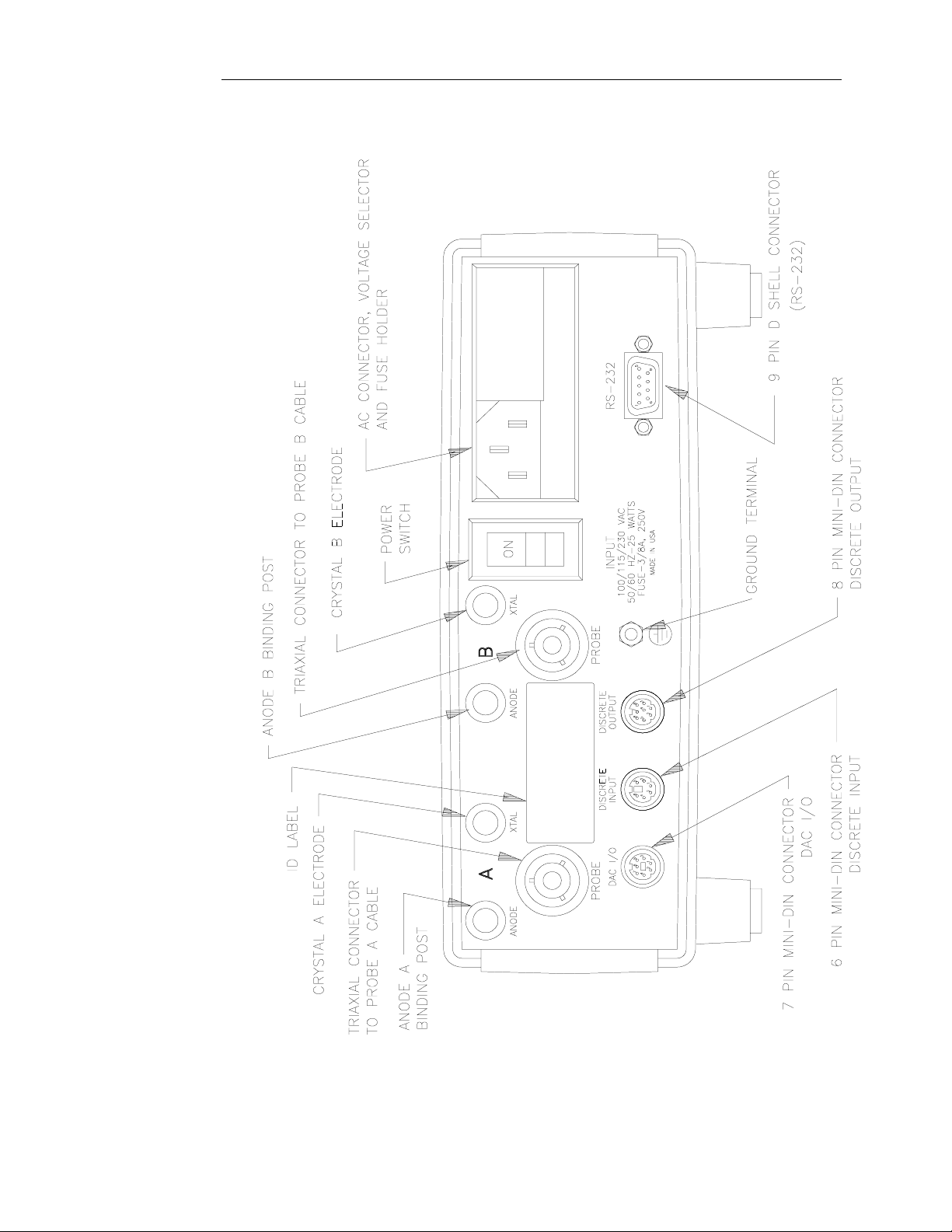

FIGURE 4 PM-720 & PM-740 REAR PANEL OUTLINE .....................................................................9

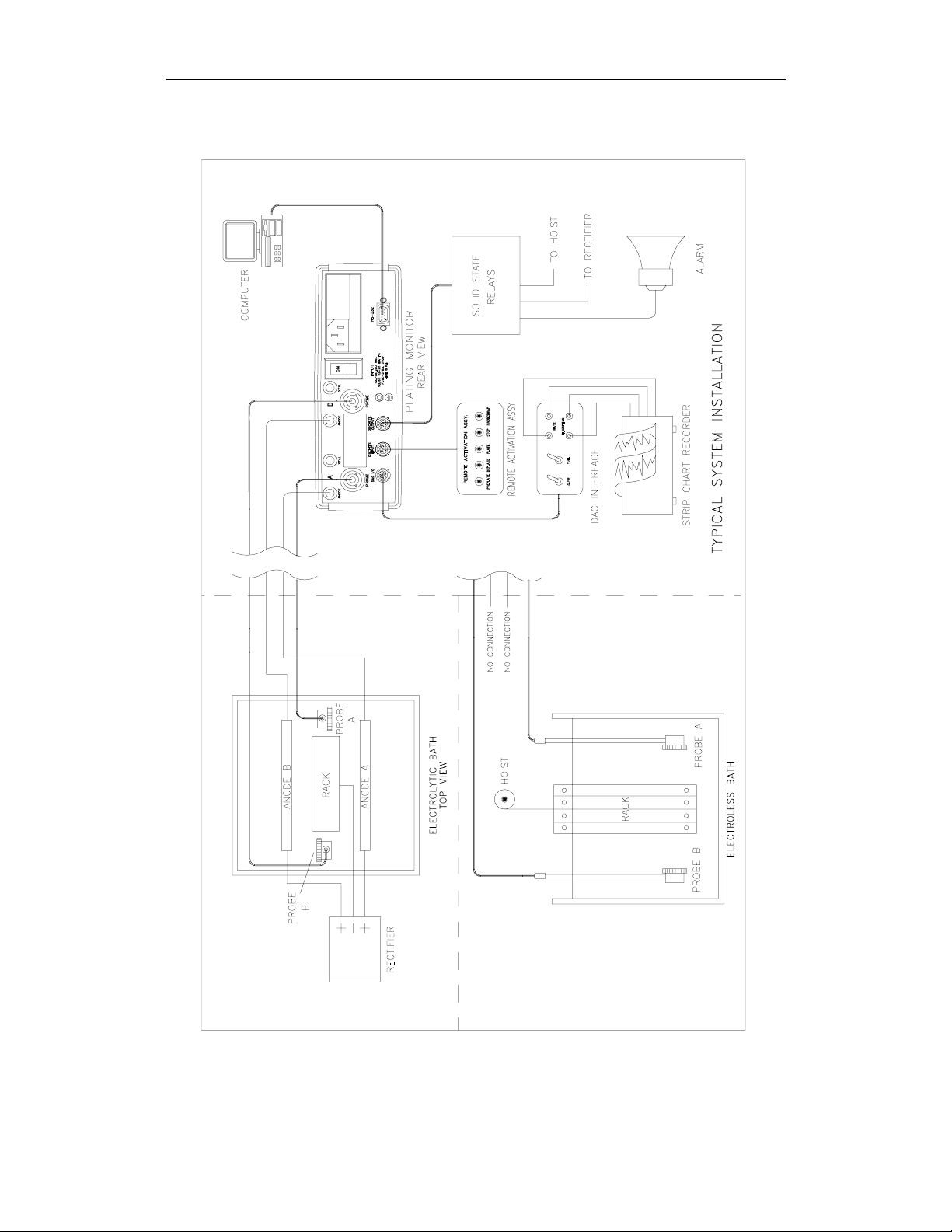

FIGURE 5 TYPICAL SYSTEM SETUP ................................................................................................10

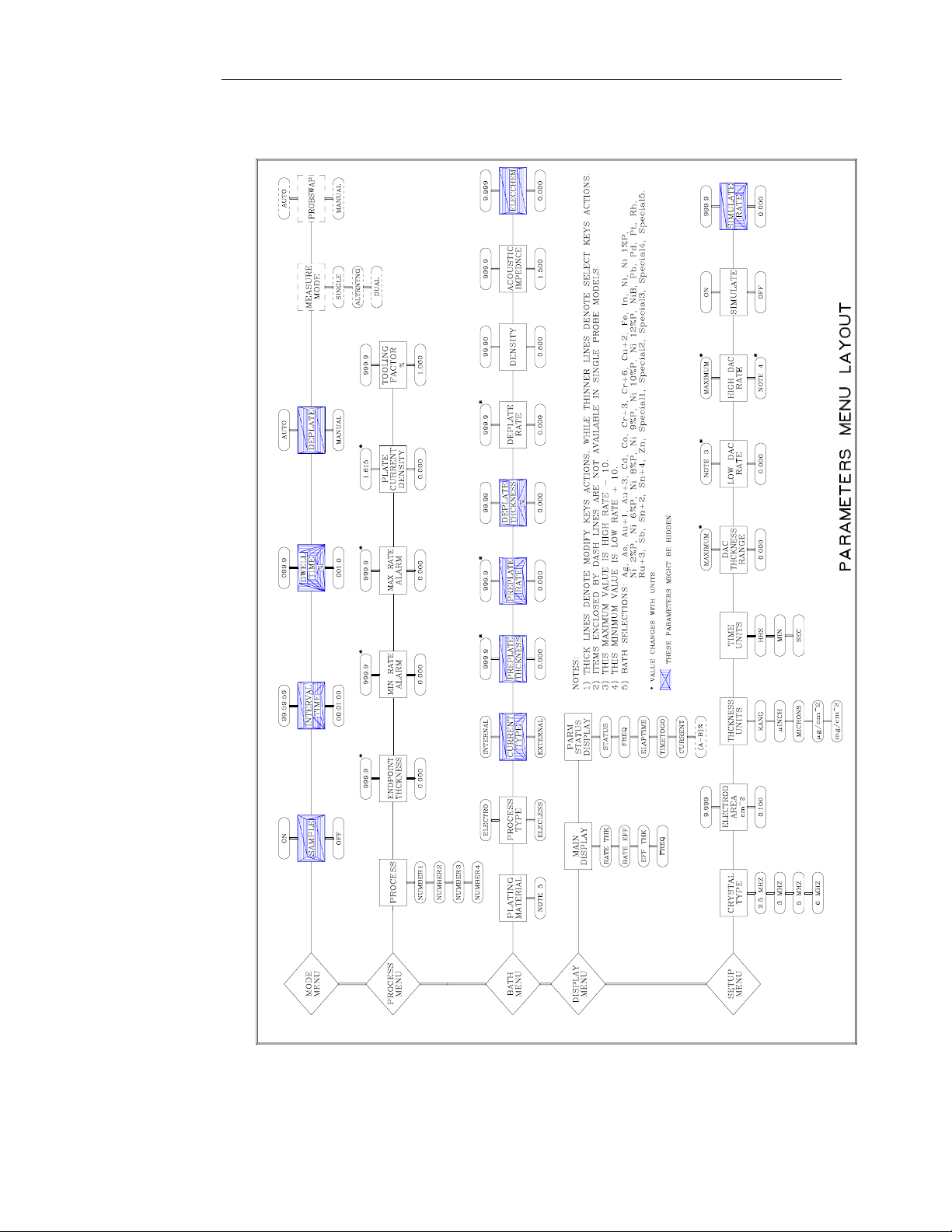

FIGURE 6 PARAMETER MENU LAYOUT ..........................................................................................11

FIGURE 7 FRONT PANEL BUTTONS.................................................................................................19

FIGURE 8 GRAPH OF INTERVAL TIME AND DWELL TIME %............................................................29

FIGURE 9 DISCRETE INPUT CONNECTOR, 6 PIN MINI-DIN ..............................................................42

FIGURE 10 DISCRETE OUTPUT CONNECTOR, 8 PIN MINI-DIN ........................................................44

FIGURE 11 DAC I/O CONNECTOR, 7 PIN MINI-DIN .......................................................................46

FIGURE 12 TYPICAL RS-232 INTERFACE CABLE............................................................................47

List of Tables

TABLE 1 PROCESS 2 PARAMETER DEFAULT VALUES.....................................................................14

TABLE 2 SAMPLE PROCESS PARAMETER VALUES..........................................................................15

TABLE 3 DISCRETE INPUT CONNECTOR PIN ASSIGNMENTS ...........................................................42

TABLE 4 DISCRETE OUTPUT CONNECTOR PIN ASSIGNMENTS........................................................44

TABLE 5 DAC I/O CONNECTOR PIN ASSIGNMENTS.......................................................................46

TABLE 6 RS-232 CONNECTOR PIN ASSIGNMENTS .........................................................................47

TABLE 7 UPLOAD PARAMETER STORE...........................................................................................49

TABLE 8 SELECT PARAMETER CODES ............................................................................................51

TABLE 9 REMOTE ACTIVATION COMMAND CODES........................................................................54

TABLE 10 UPLOAD MACHINE STATUS CODES................................................................................55

TABLE 11 MONITOR STATUS REGISTER ......................................................................................... 55

TABLE 12 FAILURE REGISTER........................................................................................................56

TABLE 13 FLAG REGISTER.............................................................................................................56

TABLE 14 MODE REGISTER............................................................................................................56

TABLE 15 RS-232 ERROR REGISTER .............................................................................................57

TABLE 16 OUTPUT #1 STATUS REGISTER ......................................................................................57

TABLE 17 OUTPUT #2 STATUS REGISTER ......................................................................................57

TABLE 18 DATA LOGGING BIT MAP...............................................................................................60

TABLE 19 PROBE FLAG REGISTER .................................................................................................61

TABLE 20 SUMMARY OF CALIBRAT ION ADJUSTMENT....................................................................71

TABLE 21 MATERIAL CONSTANTS .................................................................................................72

ix

Page 8

Page 9

PM-700 SERIES PLATING MONITOR

1. GENERAL DESCRIPTION

The PM-700 Series of Plating Monitors act like intelligent electronic coupon

systems. The monitor continuously displays the thickness of the film on the

coupon and the rate of change of that thickness. It does this rapidly, in fractions

of a second, and with very high resolution.

The heart of the intelligent coupon is the quartz crystal mounted in the end of the

probe. It is the film on this crystal whose thickness and rate of change of

thickness is displayed on the monitor.

Use of this technique allows instantaneous measurement and display of the plating

rate of any liquid plating or etching process.

The basic monitoring system consists of the monitor itself, a probe with the

crystal installed and a cable connecting the probe to the monitor.

Various configurations of monitor, probe and crystal are available to meet

different requirements and the monitors incorporate numerous user modifiable

parameters so that they can be tailored to specific processes.

1

Page 10

PM-700 SERIES PLATING MONITOR

1.1 SPECIFICATIONS

PM-700 Series Common Specifications

Monitor accuracy: 0.5 %

Basic measurement resolution:

Thickness: 0.01 µg/cm2

Frequency: 0.5 Hz @ 5 MHz

Display Resolution:

Weight: 0.01 µg/cm2

Efficiency: 0.1%

Frequency: 0.1 Hz

Discrete Outputs:

Preplate achieved.

Thickness achieved.

Low rate alarm.

High rate alarm.

Crystal failed.

Spare.

Spare.

Level: 0 to 5 Vdc CMOS logic level.

Source impedance: 100 ohm.

Discrete Inputs:

Start Preplate.

Start Plate.

Start Deplate

Stop or Reset.

Spare.

Logic level: Ground true.

Internal 4.7 kς pull-up to 5 Volt.

DAC Interface:

Outputs: Two independent analog outputs

Range: 0 to 5.0 Vdc

Accuracy: ± 3% of range + 1% of full scale.

Linearity: 0.5% of full scale

Output impedance: 10 kς ± 2%

Control inputs: Zero, Full Scale

Logic level: Ground true.

Internal 4.7 kς pull-up to 5 volt.

2

Page 11

PM-700 SERIES PLATING MONITOR

Plate/Deplate Current Supply:

Range: 0 to ± 22.12 ma.

0 to ± 1.615 ASD (amp per sq. decimeter)*

0 to ± 15 ASF (amp per sq. foot)*

* For standard crystal electrode area of 1.37 cm2

Resolution: 0.05%

Linearity: 0.1%

Accuracy: ± (0.5% of value + 0.1% full scale)

Compliance: ± 4 Vdc

RS-232 Interface:

Connector: 9 Pin, Male, D shell (IBM AT type)

Baud Rate: 9600, Full Duplex

Format: 8 bits, No parity, 1 Stop bit

Environmental:

Operating Temperature: 0 to 50o C.

Storage Temperature: -40o to +70o C.

Humidity: Up to 95% relative humidity at or below +40o C;

to 75% relative humidity from +41o to +50o C.

Power requirement: 90 VRMS to 140 VRMS or

200 VRMS to 260 VRMS

at 47 to 63 Hz, 25W.

Physical

Dimensions:

Height: 89 mm (3.5 in.)

Width: 216 mm (8.5 in.)

Depth: 235 mm (9.25 in.)

Net Weight: 8.3 kg (3.75 lbs.)

Shipping Weight: 11.3 kg (5.1 lbs.)

3

Page 12

Page 13

PM-700 SERIES PLATING MONITOR

2. UNPACKING, INSPECTION AND BENCH CHECKOUT

2.1 UNPACKING, INSPECTION

Carefully inspect your plating monitor and its shipping container for evidence of

possible shipping damage. If such evidence is present, notify the carrier and

Maxtek as soon as possible. Keep the shipping container as evidence if shipping

damage is present or for possible future return of the monitor. Check the material

received against the packing list to ensure that all materials are accounted for.

Items included with your plating monitor are:

1 Plating Monitor

1 Operation and Service Manual

1 Power cord

In addition, you may have ordered one or more of the accessories. If there is no

evidence of damage, the monitor can now be bench checked.

2.2 BENCH CHECKOUT

Before connecting ac power to your Plating Monitor, make sure input voltage

requirement is correct for your installation. The selected line voltage can be seen

through the plastic window on the monitor rear panel. If it does not correspond to

the power line voltage to be used, follow the steps below to select the correct line

voltage.

1. Slide plastic cover to the left, exposing fuse and voltage selector p.c. board.

2. Remove fuse by pulling "FUSE PULL" lever to the left.

3. Remove voltage selector p.c. board by pulling it with a suitable tool on the

small hole in the center of the board.

4. Select the voltage by positioning the p.c. board so the desired voltage is

indicated on upper left corner. Insert board into place in this position.

5. Install fuse and slide cover to the right. The selected voltage will be visible

through the plastic window.

Connect the ac power cord to the monitor rear panel line connector. Turn on the

monitor via the rear panel rocker switch. When power is applied to the monitor it

goes through an internal test routine during which all displays and indicators are

lit up. This condition lasts approximately six seconds. The Rate and Thickness

displays will begin to flash a P FAIL message indicating that power has been

interrupted. This is normal and it will happen every time the monitor is turned

off.

5

Page 14

PM-700 SERIES PLATING MONITOR

Figure 1 Power Switch and AC Connector

You may see an E FAIL or I FAIL message for a short time, this is normal.

However, if the display stops on either of those messages, an internal fault has

been detected and the monitor will remain inoperative until the fault has been

corrected. Further details of error messages can be found in the Troubleshooting

Section on page 63.

Figure 2 Front Panel Indication, First Power-On

Press the Stop button to clear the P FAIL message. Now, an O FAIL will be

flashing. The red light in the Probe Status window will be on indicating a probe

failure, because there is no probe with crystal has been connected to the monitor.

Note that during actual operation, a P FAIL message indicates the line power to

6

Page 15

PM-700 SERIES PLATING MONITOR

the monitor has been interrupted. The red light in the Probe Status window and

the O FAIL message indicates a problem with the probe or the sensor crystal.

The Parameter/Status display will show the last display mode selected prior to

removing power from the monitor. See Parameter/Status Display Modes Section

on page 26 for detail description of the Parameter/Status display.

Using the standard 3 meter triaxial cable and connect the Sensor Probe to the

Plating Monitor rear panel connector labeled PROBE A. Be careful not to touch

the surface of the sensor crystal installed in the crystal holder. After the Sensor

Probe has been connected, pressing the STOP button should step Probe Status

Indicator from red to green indicating a good Sensor Probe is connected and is in

active. The O FAIL message then should be clear.

Pressing PLATE or PREPLATE will reset thickness display to zero. Breathe

lightly onto the sensor crystal surface. The displayed thickness should increase

due to condensed water vapor on the crystal. The thickness then will decrease as

additional water vapor evaporates from the crystal surface.

If your monitor is a dual probe model, you may also want to connect a second

Sensor Probe to the monitor connector labeled PROBE B. You will need to make

Probe B the active probe by pressing PROBE B button follow by PLATE button

(Note that Probe A is now in standby). An O FAIL message should flash in the

main display indicating Probe B has been failing. Press STOP key, the O FAIL

message should be clear and the Probe B Status Indicator should change from red

to green. Probe B is now the active probe. Test Probe B the same way you have

tested Probe A.

If everything responds as described above, the total system is OK. The monitor

can now be programmed to suit your application.

7

Page 16

PM-700 SERIES PLATING MONITOR

Figure 3 PM-700 Front Panel Outline

8

Page 17

PM-700 SERIES PLATING MONITOR

Figure 4 PM-720 & PM-740 Rear Panel Outline

9

Page 18

PM-700 SERIES PLATING MONITOR

10

Figure 5 Typical System Setup

Page 19

PM-700 SERIES PLATING MONITOR

Figure 6 Parameter Menu Layout

11

Page 20

Page 21

PM-700 SERIES PLATING MONITOR

3. SIMPLIFIED OPERATION

This section is designed to help first time user of the PM-700 Series Plating

Monitor to become familiar with viewing, programming and editing of the

monitor parameters.

First, refer to Figure 7 Front Panel Buttons on page 19, locate the four arrow

buttons and study their functions. Next, refer to Figure 6, Parameter Menu

Layout, on page 6 and study the way the menus and parameters are laid out.

Notice that the SELECT buttons (left and right arrows) are used to move

horizontally through the parameters. The two MODIFY buttons (up and down

arrows) are used to vertically step through the menus or to change a parameter

value. Note that these arrow buttons have auto repeat functions. If one of them is

pressed and held down it will scroll to the ultimate limit (i.e. if you are at a

parameter with a numerical value, pressing and holding down the MODIFY UP

arrow will ultimately increase that parameter value to its maximum limit).

PM-700 Series Plating Monitor are shipped with Process Number 2 as the default

process. Process Number 1 may be programmed to your specific plating process

if you requested Maxtek to do so at the time you purchased your monitor. The

following table is a list of parameters default values for Process Number 2. Use

the four arrow buttons you have just learned above to step through the parameters

and check their default values against the list. Also, practice changing some of

the parameter values to get a feel on how to modify them. There are four material

parameters that could be reset to their factory set default values. If you wish to do

so, simply press the STATUS button while both of the Up and Down arrow

buttons are depressed.

13

Page 22

PM-700 SERIES PLATING MONITOR

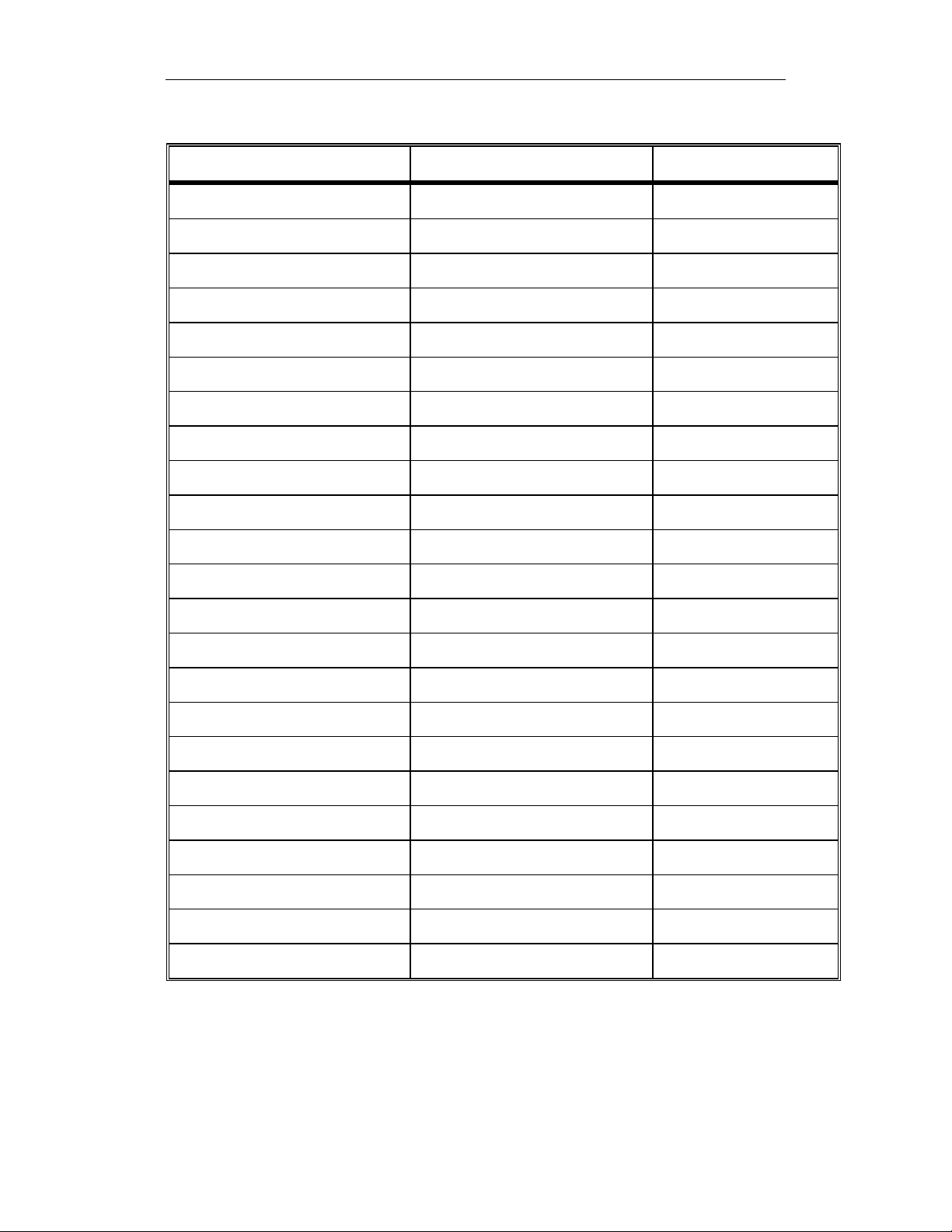

Table 1 Process 2 Parameter Default Values

Menu Parameter Default Value

Mode Menu Sample Off

Mode Menu Measure Mode * Single

Mode Menu ProbSwap * Manual

Process Menu Process Number 2

Process Menu Endpoint Setting 10.00

Process Menu Min Rate Alarm 0.000

Process Menu Max Rate Alarm 9.999

Process Menu Plate Current Density 0.001

Bath Menu Bath Special1

Bath Menu Type Elecless

Bath Menu Preplate Thckness 1.000

Bath Menu Preplate Rate 0.200

Bath Menu Deplate Rate 0.100

Bath Menu Density 1. 000

Bath Menu Acoustic Ratio 8.830

Display Menu Main Display Rate Thk

Display Menu Parm Status Display Status

Setup Menu Crystal Type 5 MHz

Setup Menu Crystal Area cm^2 1.370

Setup Menu DAC Thckness Range 5.000

Setup Menu DAC Low Rate 0.000

Setup Menu DAC High Rate 9.999

Setup Menu Simulate Mode Off

* These parameters are only available in dual probe models.

14

The following example is a typical plating process. It is provide for you to

practice parameter programming.

Page 23

PM-700 SERIES PLATING MONITOR

3.1 SAMPLE PROCESS

Suppose a PM-700 monitor is to be used to continuously measure the plating rate

and thickness in an electroless nickel bath, giving a deposit with 6%

phosphorus. Since this bath will not initiate plating on a pure gold surface, the

sensor crystal will have to be electrolytically preplated with, for example, .5

microns of nickel at a controlled rate in order to support subsequent autocatalytic

electroless plating. Assume that the desired plating thickness endpoint is 20

microns and it is desired that the plating monitor warns the operator if the plating

rate falls outside the normal limits of .100 ±0.02 micron/min. It is also desired

that the total elapsed time since introduction of the work into the plating bath be

displayed. These parameters will be established for process number 3.

Given the above example, the following list of parameters will need to be

programmed into the monitor.

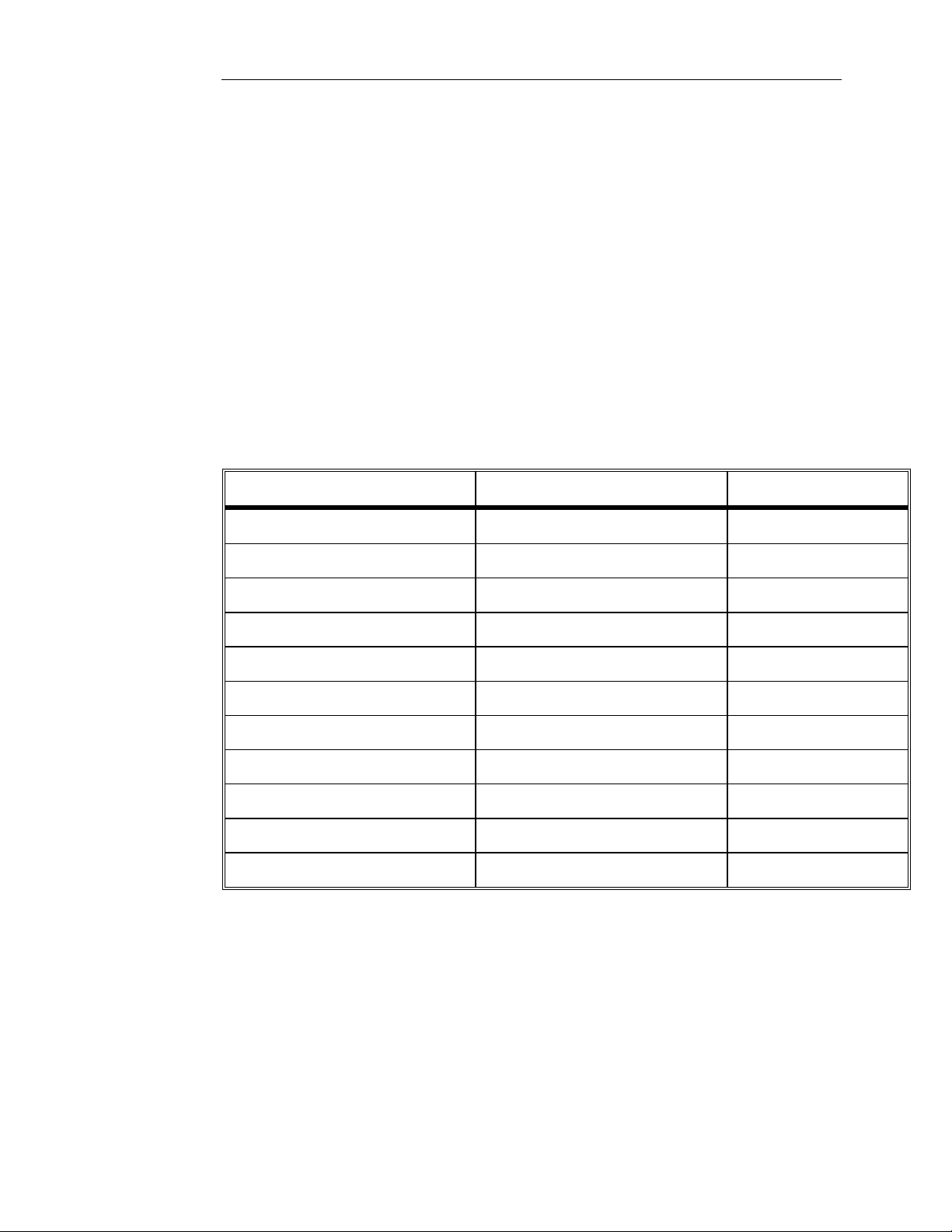

Table 2 Sample Process Parameter Values

Menu Parameter Value

Process Menu Process Number 3

Process Menu Endpoint Setting 20.00

Process Menu Min Rate Alarm 0.080

Process Menu Max Rate Alarm 0.120

Mode Menu Sample Off

Bath Menu Bath Ni 6%P

Bath Menu Type Elecless

Bath Menu Preplate Thckness 0.500

Bath Menu Preplate Rate 0.050

Display Menu Parm Status Display Elaptime

Setup Menu Simulate Off

Since the above parameters will be established for process number 3, the first

thing to do is select process number 3 as the current process. You can do this by

going to the Process parameter in the Process Menu and use the SELECT arrow

buttons to find Number 3. Then follow the above list to program the rest of the

parameters.

15

Page 24

Page 25

PM-700 SERIES PLATING MONITOR

17

Page 26

PM-700 SERIES PLATING MONITOR

4. DETAILED OPERATION

4.1 INTRODUCTION AND GENERAL CONCEPTS

Basic operation of the PM-700 monitors is straightforward but the many options

and operating modes available through the programmable parameters may appear

overwhelming on first glance. We believe, however, that once the basic operating

concepts are understood, operation of the system will be experienced as

straightforward and intuitive.

In order to facilitate a rapid understanding of the PM-700's basic operating

concepts, we have seen fit to describe the operation in terms of modes and states.

The monitor has a number of operating states and modes, which are described

below. In addition, the probes themselves have their own states and modes, which

may be different than those of the monitor.

For example, the monitor may be operating in the electroless plating mode; the

measurement mode might be single probe, with sampling. The monitor might

then be in the Plate State (as opposed to the Ready, Preplate, or EndPoint states).

Meanwhile the probe might also be in the Plate State or alternately in the Hold

State if the monitor is between samples. If the monitor supports dual probes, then

the second probe will likely be in the hold mode or it could be in the failed state if

the crystal is being replaced.

The monitor is shipped from the factory with default settings for all parameters so

that no more than a few parameters must be setup to begin operation.

4.2 DISPLAYS

There are five display windows in the plating monitor front panel. On the upper

left most and upper right most are the Probe Status windows. Each contains three

indicator LED's. Note that in the PM-700, only the left status window is utilized

since PM- 700 supports single probe. Located in- between the two Probe Status

windows is the Rate and Thickness displays. Each contains four large numerical

LED's for easy readout of monitor measurements. Below the Rate display is the

Parameter/Status display. This is an 8 character alphanumeric display used for

parameter programming, viewing and editing. It is also used for displaying the

monitor status or other functions. See Figure 3, page 6.

4.3 BUTTONS

There are twelve membrane push buttons on the plating monitor front panel. The

four left most buttons are used for parameter viewing and editing, and the eight

right most buttons are monitor operational buttons. Their uses are described

below.

18

Page 27

PM-700 SERIES PLATING MONITOR

Figure 7 Front Panel Buttons

19

Page 28

PM-700 SERIES PLATING MONITOR

Select Buttons

Select Buttons are used to step between parameter items.

Modify Buttons

Modify Buttons are used to step up and down between menus, and to modify

parameters values.

Plate Button

Plate Button is used to initiate the plating process.

Preplate Button

Preplate Button is used to initiate the preplate process.

Deplate Button

Deplate Button is used to initiate the deplate process.

Stop Button

Stop Button is used to terminate any active process. It is also used to clear failure

messages.

Status Button

When Status Button is pressed down, the Parameter/Status Display will

sequentially display important information involving the currently selected

process, such as thickness endpoint, type of bath, etc. This will save the user of

having to go to each menu to verify these parameters.

Probe Button

This button, when pressed, will display the Probe Sensor status in the Rate and

Thickness windows. The two left most digits of the Rate display shows the

crystal type. The next two digits show the crystal health and the Thickness

display will show the crystal frequency in megahertz. In PM-720 and PM-740

models, this button is labeled Probe A.

Probe B Button

This button is used in the same way as Probe A button. Probe B status

information will be displayed.

In PM-700 model, this button is labeled F1 and there is no function assigned to it.

Spare buttons

The lower right most button, either labeled F2 (PM-700) or F1 (PM-720 & PM-

740), is spare. Its function is not implemented.

20

4.4 OPERATION

The operation of the PM-700 is described in terms of Monitor States and

Measurement Modes and Probe Activity States and Operating States.

Page 29

PM-700 SERIES PLATING MONITOR

4.4.1 Monitor Operating States

The PM-700 can be in any one of a number of Operating States depending upon

the type of bath being monitored, electrolytic or electroless.

4.4.1.1 Electroless plating

Five different states are defined for operation with electroless plating baths.

4.4.1.1.1 Ready State

In the Ready State plating rate and thickness are being monitored, but the

Endpoint check is not being performed and the crystal electrode current is zero.

The Ready State is entered on power ON and also by pressing the Stop button.

Pressing the Preplate, Plate or Deplate buttons steps the monitor from the Ready

State into the selected state.

4.4.1.1.2 Preplate State

The Preplate State is activated by pressing the Preplate button while in the Ready

mode. If pressed in any state other than the Ready State, the Preplate button has

no effect. Upon entry to the Preplate state the crystal electrode current is adjusted

by the monitor to achieve the Preplate Rate parameter value and is maintained

until the Preplate Thickness is achieved at which time the monitor steps to the

Plate state.

4.4.1.1.3 Plate State

The Plate State can be entered from the Ready State, Preplate State or Deplate

State by pressing the Plate button or automatically upon completion of the

Preplate State. During the Plate State the indicated thickness is compared with

the Endpoint parameter. When the indicated thickness equals or exceeds the

Endpoint parameter, the monitor steps to the Endpoint State.

4.4.1.1.4 Deplate State

The Deplate State can be entered from the Ready State or the Endpoint State by

pressing the Deplate button. (Remember that monitor states are not the same as

probe states.) The Deplate State is exited to the Ready State by pressing the Stop

button or to the Plate State by pressing the Plate button. The Deplate State is

automatically terminated when the crystal health recovers to 95% at which time

the monitor returns to the Ready State.

4.4.1.1.5 Endpoint State

The Endpoint State is automatically entered from the Plate State when the

indicated thickness equals or exceeds the Endpoint parameter value. Pressing the

Stop or Deplate buttons steps the monitor from the Endpoint State to the Ready or

Deplate state. The Preplate and Plate buttons produce no action while in the

Endpoint State.

21

Page 30

PM-700 SERIES PLATING MONITOR

4.4.1.2 Electrolytic plating

Because the Preplate State is not necessary in the Electrolytic plating mode, the

Preplate button is ignored and only four different monitor states are defined for

this operating mode.

4.4.1.2.1 Ready State

In the Ready state plating rate and thickness are being monitored but the crystal

electrode current is zero so no plating will be occurring. The Ready State is

entered on power ON and also by pressing the Stop button. Pressing the Plate or

Deplate buttons steps the monitor from the Ready State into the selected state.

4.4.1.2.2 Plate State

The Plate State is entered from the Ready State by pressing the Plate button.

During the Plate state the crystal electrode current is set at the value required to

achieve a plating current density equal to that programmed in the Current Density

parameter. In addition, the indicated thickness is compared with the Endpoint

parameter. When the indicated thickness equals or exceeds the Endpoint

parameter, the monitor steps to the Endpoint State.

4.4.1.2.3 Deplate State

The Deplate State is entered from the Ready State or the Endpoint State by

pressing the Deplate button. In this state the crystal electrode current is adjusted

by the monitor as required to achieve the de-plating rate specified by the Deplate

Rate parameter. The Deplate State can be exited to the Ready State by pressing

the Stop button, or to the Plate State by pressing the Plate button. The Deplate

State is automatically terminated to the Ready State if the crystal health increases

to 95% or more.

4.4.1.2.4 Endpoint State

The Endpoint State is automatically entered from the Plate State when the

indicated thickness equals or exceeds the Endpoint parameter value. Pressing the

Stop or Deplate buttons steps the monitor from the Endpoint State to the Ready or

Deplate state. The Plate button is ignored while in the Endpoint State.

4.4.2 Monitor Measurement Modes

4.4.2.1 Single Probe Measurement Modes

The following three measurement modes require only one probe and can be

utilized on any of the PM-700 series of monitors.

22

4.4.2.1.1 Continuous

In this mode the bath is monitored continuously. Should the Probe fail during the

Preplate, Plate or Deplate state, the failure is enunciated, the Rate Display is held

at its most recent value, and the displayed Thickness is increased at the displayed

rate to indicate the best guess for the substrate thickness buildup.

Page 31

PM-700 SERIES PLATING MONITOR

4.4.2.1.2 Sample

This mode is used to increase the crystal's range. In the Sample mode the plating

rate is monitored on a sampled basis. Between samples the rate established during

the last sample is displayed and the displayed thickness value is increased at the

displayed rate to show the assumed substrate thickness buildup. Plating of the

probe crystal is halted by applying enough deplating current to the crystal to hold

the plating rate at zero. Should the Probe fail, the failure will be enunciated, but

the displayed thickness will continue to increase on the basis of the last valid rate

sample. Parameters are provided to allow the user to set the duration of the

sample period and the interval between sample periods.

4.4.2.1.3 Sample with Deplate

This mode is identical to the Sample mode except that the Probe crystal will be

electrolytically deplated between samples. The amount of deplating is established

by the user as a percentage of the amount plated during the sample. The rate of

deplating is set by the amount, which must be deplated, and the time between

samples.

4.4.2.2 Dual Probe Measurement Modes

The following measurement modes require two probes and, therefore, require the

use of a Dual Probe model.

4.4.2.2.1 Auto Probe Swap

The Auto Probe Swap mode can be applied to all three of the Single Probe

measurement modes. In the Auto Probe Swap mode a second probe is installed in

the bath. While the active probe monitors the bath, the second probe is held in

standby. In the event of a failure of the active probe, the monitor will automatically switch to the second, or standby, probe. If the standby probe requires

initializing, it will be initialized with a preplate cycle, prior to the swap. During

the time it takes the unit to switch over to the second probe, the rate display is

held at the last valid rate value and the displayed thickness continues to buildup at

the displayed rate.

4.4.2.2.2 Alternating Measurement mode

In this mode two probes are used to provide continuous monitoring. Usage of the

two probes is alternated. While one probe is monitoring the bath the second probe

is being deplated. The percentage of deplate between plating cycles is established

by the user. The rate at which the two probes are alternated is determined by the

Sample Interval parameter. The alternate probe is changed back to the plate mode

10 seconds before the probes are switched. This is done so when the probes are

switched, the plating rate is stabilized on the new probe. In the event that one of

the probes fails, the monitor reverts to the single probe Sample with Deplate

mode.

4.4.2.2.3 Dual Probe Measurement mode

23

Page 32

PM-700 SERIES PLATING MONITOR

In this mode both probes are actively monitoring the plating process. The monitor

compares the two probes and computes the average and the percentage difference

between the probes. A number of display modes are available.

4.4.3 Probe States and Modes

At any particular time a Probe can be in any one of three states and,

independently, in any one of three modes. For instance a Probe could be in the

Standby State and the Deplate mode or in the Standby State and the Hold mode.

The possible states and modes are described below:

4.4.3.1 Probe States

A probe can be in any one of the following three states: Failed, Standby, or

Active. The state of the probe is indicated by the three probe status LED's. (See

Figure 3.)

4.4.3.1.1 Failed state.

A failed probe means that for some reason, the monitor is not receiving a valid

frequency signal from the probe.

4.4.3.1.2 Standby state

The standby state indicates that the monitor is receiving a valid frequency from

the probe but the displayed information is not based on the output of this probe.

4.4.3.1.3 Active state

The active state indicates that the probe is not failed and that it is the source of the

display information and is being used to control any active process.

4.4.3.2 Probe modes

In addition to the above, a probe may be in any one of the following four modes:

Hold, Deplate, Preplate, or Plate. The Hold and Preplate modes are applicable to

the electroless plating process. The Probe Deplate and Probe Plate mode is

applicable to both the electroless and the electrolytic plating processes.

4.4.3.2.1 Ready mode

In the Ready mode, the probe is not in preplate, deplate, plate or hold. The

monitor does not supply current to the probe.

4.4.3.2.2 Hold mode

In the Probe Hold mode, the plating rate on the probe is held at zero. For

electroplating processes, this is done by setting the electrode current to zero. For

electroless processes, this is done by maintaining the electrode current at the

negative value required to halt the electroless plating process. This current level

is automatically determined by the monitor.

24

Page 33

PM-700 SERIES PLATING MONITOR

4.4.3.2.3 Deplate mode

In the Probe Deplate mode, enough negative electrode current is supplied by the

monitor to create the desired deplating rate.

4.4.3.2.4 Preplate mode

In the Probe Preplate mode, enough positive electrode current is supplied by the

monitor to create the desired preplating rate.

4.4.3.2.5 Plate mode

In the Probe Plate mode, the electrode current is zero for electroless processes and

positive for electrolytic processes. In electrolytic processes the electrode current

is established by the monitor at the value necessary to achieve the programmed

current density.

The mode of the probe can be determined by pressing the Probe status button.

4.4.4 Main Display modes

The two four digit main displays are factory set to display plating rate and plating

thickness, however, three alternate display formats can be selected by means of

the Main Display parameter. All four possible Main Display modes are described

below.

4.4.4.1 Rate and Thickness

This is the normal or default display mode as set at the factory. The measurement

units will normally be displayed to the right of the digits unless the display units

have been changed from those that were preset at the factory. If the Thickness

Units parameter has been used to select and alternate set of units, then both units

display areas will be dark. If the Time Units parameter has been modified, but the

Thickness units are unchanged, then only the Rate display units will be dark.

4.4.4.2 Rate and Efficiency

In the Rate and Efficiency main display mode, the normal rate display is provided

in the left hand display area while the right hand display is used to display the

cathode efficiency in percent where 100% represents the theoretical maximum for

the bath selected. Since cathode efficiency is only meaningful for electrolytic

processes, a value of 00.00 is displayed if the monitor is in the Electroless plating

mode.

4.4.4.3 Efficiency and Thickness

In this display mode, the left-hand display area is used to display the cathode

efficiency in percent where 100% represents the theoretical maximum of the bath

selected. Since cathode efficiency is only meaningful for electrolytic plating

processes, a value of 00.0 is displayed if the monitor is in the Electroless plating

mode. The right hand display area provides the normal plating thickness display.

25

Page 34

PM-700 SERIES PLATING MONITOR

4.4.4.4 Frequency

In this Main Display mode the left-hand display is used to display the crystal

frequency in Megahertz while the right hand display is used to display the crystal

frequency in Hertz. This allows for display of the total crystal frequency to a

resolution of 0.1 hertz.

4.4.5 Parameter/Status Display modes

The Parameter/Status display serves a number of purposes. It is used to view and

modify parameter values, or to display monitor status or to display a user selected

variable. In the event of a warning condition or a failure condition, a descriptive

message will be flash alternately with the selected display.

When any of the arrow buttons are pressed, the display is used to show the value

of the previously selected parameter. Pressing one of the Probe buttons results in

the display of that probe's status alternating with the plating rate on that probe. If

the Status button is pressed, then the display cycles through a list of items, which

describe the status of the monitor. When the Probe or Status buttons are released,

or if the arrow buttons remain inactive for 30 seconds, then the display reverts to

one of the six displays described below. The 30-second hold of the parameter

display can be terminated early by pressing and releasing any of the Probe or

Status buttons.

4.4.5.1 Status Display

In the Status Display mode, the monitor state is displayed.

4.4.5.2 Frequency Display

In the Frequency Display mode the frequency is displayed as an eight-digit

number with a resolution of 0.1 hertz.

4.4.5.3 Elapsed Time Display

This display mode displays the time that has elapsed since the beginning of the

current state. I.e., if the current state is the Plate State then the time displayed is

the amount of time that has passed since the start of the Plate State. The time is

displayed in hh:mm:ss format.

4.4.5.4 Time to Go Display

This display mode displays the estimated time required to complete the current

state. In the case of the Plate State, the time to go is calculated by dividing the

difference between the Endpoint thickness and the current thickness by the

average rate.

4.4.5.5 Current Density Display

This display mode displays the current density at the probe electrode. The units

are Ampere per square decimeter for monitors with metric unit display and

Amperes per square foot for monitors with English unit display.

26

Page 35

PM-700 SERIES PLATING MONITOR

4.4.5.6 A-B)% Display

This display mode is only available on dual probe model monitors. In the Dual

Probe measurement mode, this display shows the percentage difference between

A and B probe measurements. The right four characters of the Parameter/Status

display indicate the percentage difference between the measurements made by the

A and B probes, the average of which is displayed in the right hand Main display.

The quantity displayed is 100*(A- B)/(A+B) or the percentage that the

measurement A is larger than the average of the two measurements. The format

of the display is +XX.X or -XX.X. A positive sign indicates that the A

measurement is larger than the B measurement. The left four characters of the

Parameter/Status display indicate the percentage difference between the

measurements made by the A and B probes, the average of which is displayed in

the left hand Main display. The same format is used.

4.4.6 Simulation Mode

The PM-700 series of monitors include a simulation function that is useful for

familiarization and demonstration of the monitor features and for trouble

shooting. In the simulation mode the frequency signal from the Probe is replaced

with a simulated frequency that reflects the change in frequency, which an ideal

crystal would produce when plated at the rate, specified by the Simulate Rate

parameter. The Simulation State is activated by the Simulation Mode parameter.

4.5 PARAMETERS

The PM-700 series of monitors incorporate a large number of parameters that

allow fine-tuning of the monitor for a particular application. All parameters are

provided with default factory set values so that the user need only be concerned

with those parameters that he desires to change. There are two different types of

parameters; they are the selection type and the value type. Selection type

parameters are parameters that are limited to a small number of possible

selections. Some have only two selections, On and Off. Value type parameters

may have any numeric value between a maximum and a maximum value.

4.5.1 Viewing and modifying

Pressing any one of the arrow keys results in the display of the last viewed

parameter. The parameters are arranged in five different menus according to their

usage. See Figure 6. Once a parameter is displayed, the left and right arrow keys

provide for horizontal movement as shown in Figure 7. The up and down keys

allow for vertical movement which corresponds to selection of selection type

parameters or for increasing or decreasing the value of value type parameters.

Note that movement between menus is only available when menus are being

displayed as indicated by the vertical lines between the menu selections. Holding

the left arrow key down will rapidly take you to the menu parameter. The up and

down keys can then be used to choose a particular menu. The rate at which value

type parameters change value increases for as long as a direction key is held

down. When the key is released, the rate of change returns to its minimum value.

27

Page 36

PM-700 SERIES PLATING MONITOR

This feature allows for very fine setting over a very broad range in a minimum

amount of time.

4.5.2 Hidden parameters

Parameters, which are not applicable to the selected mode of operation, are not

displayed. They are hidden. For example, Interval Time and Dwell Time are

applicable only when the monitor is in the Sample measurement mode. Thus

when the Sample mode is Off, these parameters are hidden. See Section 4.5

starting on page 27 to determine which parameters may be hidden and under what

conditions.

4.5.3 Descriptions

The following is a list of the available parameters, organized according to menu,

along with their type and their range.

28

Page 37

PM-700 SERIES PLATING MONITOR

Figure 8 Graph of Interval Time and Dwell Time %

29

Page 38

PM-700 SERIES PLATING MONITOR

4.5.3.1 Mode Menu

Numonic Name/Description Minimum Maximum Default

Sample Sample

Allows the user to turn the

monitor Sample Mode on or

off. For a detail description of

Sample Mode operation, refer

to Sample section. Note this

parameter will be hidden if the

Measure Mode parameter is

set to Altrntng.

Interval

Time

Interval Time

Defines the time of one

sampling cycle. Refer to

Figure 11 for an illustration of

Interval Time. Note that this

parameter will be hidden if the

Sample Mode is off.

Dwell

Time

%

Dwell Time Percentage

Defines the time, as a

percentage of the Interval

Time, during which the

monitor is actually taking

measurement from the Sensor

Probe. Figure 11 illustrates

Dwell Time % with respect to

Interval Time. Note this

parameter will be hidden from

the Mode Menu if the Sample

parameter is set to Off. I t a lso

is hidden if the Measure Mode

is set to Altrntng.

Off On Off

00:00:00

HH:MM:SS

99:59:59

HH:MM:SS

00:01:00

000.0 099.9 050.0

30

Deplate Deplate

Sets the plating monitor to

Automatic Deplate Mode or

Manual Deplate Mode. This

parameter will be hidden if the

Sample Mode is set to Off. It

is also hidden if the Measure

Mode parameter is set to

Altrntng.

Measure

Measure Mode Single Single

Manual Auto Manual

Page 39

PM-700 SERIES PLATING MONITOR

Mode Allows for selection of one of

the three measuring modes

listed in the Minimum

column. For detail description

of these modes, refer to

Monitor Measurement Modes

section. Note that this

parameter is only av aila ble in

the dual probe models.

ProbSwap Probe Swap

Sets the monitor to perform

probes swapping

automatically or manua lly.

Swapping Probes section

offers a detail description of

the Probe Swap feature. This

parameter is available only in

the dual probe models. Note

this parameter will be hidden

if the Measure Mode

parameter is set to Altrntng or

Dual.

Altrntng

Dual

Manual Auto Manual

31

Page 40

PM-700 SERIES PLATING MONITOR

p

4.5.3.2 Process Menu

Numonic Name/Description Minimum Maximum Default

Process Process

The plating monitor is

capable of holding up to

four different processes.

This parameter allows

selection of one of the four

processes.

EndPoint

Setting

Endpoint Setting

Allows setting of the plating

endpoint thickness. This is

the desired thickness to be

plated on the substrate.

When the monitor displaye d

thickness reaches this

thickness setting, the

monitor displayed thickness

will begin flashing rapidly,

informing the user that the

plating process is done.

Also, the Thickness

Achieved Output will goes

high (true). This output

could be used to turn on

other remote of alarming

device.

Number 1 Number 4 Number 1

0.000 999.9 10.00

32

Min Rate

Alarm

Max Rate

Alarm

Minimum Rate Alarm

Allows the user to set the

minimum allowable plating

rate. When the plating rate

drops below this set value,

the displayed rate will fla sh

rapidly. Also there is a Low

Rate Alarm Output that will

come on at this time. It

could be used to turn on

other remote alarming

device.

Maximum Rate Alarm

Similar to the Minimum

Rate Alarm

arameter, this

0.000 999.9 0.000

0.000 999.9 9.999

Page 41

PM-700 SERIES PLATING MONITOR

parameter allows the user to

set the maximum allowable

plating rate. The displayed

rate will flash rapidly , a nd

the High Rate Alarm Output

will come on.

Plate

Current

Density

Tooling

Factor

%

Plate Current Density

Establishes the current

density for the Sensor

Crystal electrode.

Tooling Factor Percentage

Use to calibrate for the

different in thicknesses, if

any, between the Sensor

Crystal and the pla ting

substrate.

0.000 1.615 0.001

1.000 999.9 100.0

33

Page 42

PM-700 SERIES PLATING MONITOR

4.5.3.3 Bath Menu

Numonic Name/Description Minimum Maximum Default

Bath Bath

This parameter contains a list

of readily programmed baths.

The user can simply select a

bath material that the plating

monitor will be used with.

See Figure___ for a list of

selectable bath.

Type Type

Defines the type of plating

bath that the monitor will be

used in, either electrode

plating or electroless plating .

PrePlate

Thckness

PrePlate Thickness

Defines the thickness to be

PrePlated on the cry sta l, as a n

adhesion layer, in electroless

plating bath. Note if the

monitor is set to work in

electrode plating bath, this

parameter will be turned off.

Special1

Elecless Electro Elecless

0.000 999.9 1.000

34

PrePlate

Rate

DePlate

Thckness

%

DePlate

Rate

PrePlate Rate

Defines the rate at which the

monitor will use in the Sensor

Crystal PrePlate proc ess. This

parameter will be off if Type

parameter is set for Electro.

DePlate Thickness Percentage

Defines a percentage of

thickness to be deplated off

the Sensor Crysta l.

DePlate Rate

Allows setting of the DePlate

rate at which the monitor will

use in DePlating the plated

material off the Sensor

Crystal.

0.000 999.9 0.200

0.000 999.9 50.00

0.000 999.9 0.100

Page 43

PM-700 SERIES PLATING MONITOR

Density Material Density

Allows setting of the density

of the material being plated so

that the monitor can calculate

and display the correct

physical film thickness. A list

of the commonly used

material density is pr ese nted

in Table 21.

Acoustic

Ratio

Acoustic Ratio

Allows setting of the acoustic

impedance of the plated

material. This value is

necessary for the monitor to

accurately establish the sensor

scale factor when the sensor

crystal is heavily plated. A

list of the commonly used

material acoustic impedance is

presen t e d i n Table 21.

0.800 99.90 1.000

1.500 999.9 8.830

ElecChem ElectroChemical Equivalent

Allows setting of the electro

chemical equivalent of the

plated material. A list of the

commonly used electro

chemical equivalent value is

presented in Table 21. Note

this value is only needed for

the electrolytic plating bath.

Therefore, this parameter is

hidden if the Type parameter

is set to Elecless (electroless).

0.000 9.999 1.000

35

Page 44

PM-700 SERIES PLATING MONITOR

4.5.3.4 Display Menu

Numonic Name/Description Minimum Maximum Default

Main

Display

Parm

Status

Display

Main Display Mode

This parameter allows a

selection of four different

Main Display Modes listed

in the Minimum column.

For a description of each of

these modes, refer to Main

Display Modes section.

Parameter/Status Display

Allows selection of one of

the six Display Modes

available to be display in the

Parameter/Status Display

window. These six Display

Modes are listed in the

Minimum and Maximum

columns. For further detail

of these modes, refer to

Parameter/Status Display

Modes section.

Rate Thk

Rate Eff

Eff Thk

Freq

Status

Freq

ElapTime

Rate Thk

TimeToGo

Status

Current

(a - b)%

36

Page 45

PM-700 SERIES PLATING MONITOR

4.5.3.5 Setup Menu

Numonic Name/Description Minimum Maximum Default

Crystal

Type

Electro

Area

Thckness

Units

Crystal Type

Allows the user to set the

monitor to work with different

types of cry stal frequency.

Selectable crystal frequency

are listed in the Minimum

column.

Crystal Electrode Area

Allows for Sensor Crysta ls

that have different electrode

area. Enter the electrode area

in cm2 if the crysta l in use is

not the monitor default area.

Thickness Units

Allows the user to change the

monitor default thickness

measurement unit to a

different measurement unit.

Warning if selected thickne ss

measurement is not the default

unit, the Thickness Unit

Display will be off.

2.5 MHz

5 MHz

3 MHz

5 MHz

6 MHz

9.999 0.100 1.370

kΧ

Micron

µInch

Micron

µg/cm2

mg/cm2

Time

Units

Selectable units are listed in

the Minimum column. For

other possible plating

measurement units, contact

manufacturer.

Time Units

Similar to the Thickness Units

parameter, this parameter

allows the user the change the

manufacturer default setting .

The Rate Units Display will

be off when the default is

changed. Minimum column

listed three selectable Rate

Measurement Units. Call

Maxtek for other possible rate

measurement units.

Hrs

Min

Sec

Min

37

Page 46

PM-700 SERIES PLATING MONITOR

DAC

Thckness

Range

Low DAC

Rate

High DAC

Rate

Digital to Analog Converter

Thickness Range

Establishes the full scale value

of the DAC. See Digital to

Analog Converters section for

a detail description.

Low DAC Rate

Establishes the lower limit of

the DAC rate scale factor.

See Digital to Analog

Converters section for further

details.

High DAC Rate

Establishes the higher limit of

the DAC rate scale factor.

See Digital to Analog

Converters section for further

details.

0.000 Maximum 5.000

0.000 High

0.000

rate

minus 10

Low rate

Maximum 9.999

plus 10

Simulate Simulate Mode

Allows user to turn the

monitor Simulate Mode on or

off. For detail description of

the Simulate Mode operation,

refer to Simulation Mode

section.

Simulate

Rate

Simulate Rate

Defines the rate at which the

monitor will use in Simulate

Mode. Refer to Simulation

Mode section for a detail

description. Note this

parameter is hidden if

Simulate parameter is set to

Off.

On Off Off

0.000 999.9 0.200

38

Page 47

PM-700 SERIES PLATING MONITOR

4.5.4 Restoring to Default Values

The four material parameters, Tooling Factor, Density, Acoustic Impedance and

ElecChem can be reset to their factory set default values by pressing the Status

button while both the Up and Down arrow buttons are depressed.

4.6 STATUS ASSESSMENT

4.6.1 Monitor Status

The monitor status can be assessed any time by pressing the Status button. When

the Status button is pressed, the following list of status parameters are displayed in

the Parameter/Status display:

Simulate mode

Monitor state

Process Number

Top Left display quantity

Top Right display quantity

PRM/STATUS display quantity

Sample mode (ON/OFF)

Deplate mode (Manual/Auto)

Probe Swap mode (Manual/Auto)

Bath Type (Electro/Elecless)

Material (Bath Material)

Time units (Hours/Minutes/Seconds)

Thickness units (KΧ/µinch/Micron/µg per cm2/mg per cm2)

Crystal type (6 Mhz/5 Mhz/3 Mhz/2.5 MHz)

4.6.2 Probe Status

Pressing the Probe status button results in the display of the following

information: crystal frequency type and health, crystal frequency in Megahertz, the

plating mode of the crystal, and the plating rate on the crystal.

The crystal frequency and type is displayed in the Rate display area.

The crystal frequency, in Megahertz, is displayed in the Thickness display area.

The Probe mode and the plating rate are displayed alternately in the

Parameter/Status display area.

39

Page 48

PM-700 SERIES PLATING MONITOR

4.7 SWAPPING PROBES

Swapping from the current active probe to the Standby probe can be manually

initiated at any time. If the Probe Swap parameter is set to Auto then automatic

probe swapping can occur.

4.7.1 Manual probe swapping

Manual probe swapping is accomplished by means of the Probe A and Probe B

buttons.

4.7.1.1 Assessing the probe status prior to initiating the swap.

Pressing the Probe button for the probe that you wish to switch over activates the

probe status display. The probe status display provides you with the information

you need to be sure that the alternate probe is working properly before you

command the swap.

4.7.1.2 Preplating prior to swapping.

Preplating of the standby probe can be initiated at any time prior to swapping

probes by pressing the Standby Probe's button and then pressing Preplate button

while holding the Standby Probes button down. This will initiate the Preplate

cycle on the Standby probe. How do we terminate? Care must be taken to insure

that the Standby Probe's button is pressed and held prior to pressing the Preplate

button or a Preplate cycle may be initiated on the Active probe.

4.7.1.3 Commanding the swap.

To command the swap, simply press the Plate button while continuing to hold the

Probe button down. The monitor will switch over to the alternate probe and the

Probe status display will indicate that the probes have been swapped. The

thickness accumulated on the previously active probe prior to the swap will be

added to that accumulated on the new probe after the swap so that the displayed

thickness will continue to increase at the displayed rate.

4.7.1.4 Deplating the Standby Probe.

Deplating of the Standby probe can be initiated at any time by pressing the

Standby Probe's button and then pressing the Deplate button while holding the

Standby probe's button down. This will initiate the Deplate cycle on the Standby

probe. Care must be taken to insure that the Standby probe's button is pressed and

held, prior to pressing the Preplate button. Otherwise, Deplate cycle may be

initiated on the Active probe.

4.7.1.5 Manual termination of Preplate or Deplate on the Standby probe.

Manual termination of a Preplate or Deplate cycle on the Standby probe can be

accomplished by pressing the Standby probe's button and then pressing the Stop

button while continuing to hold the Standby probe's button down. Again, care

must be taken to insure that the Standby probe's button is pressed and held prior to

40

Page 49

PM-700 SERIES PLATING MONITOR

pressing the Stop button or the ongoing active process may be inadvertently

terminated.

4.7.2 Automatic probe swapping

When the Probe Swap parameter is set to Auto, certain conditions will initiation

an automatic probe swap. Conditions that will initiate an automatic probe swap

are listed below:

4.7.2.1 Auto probe swap on active probe failure.

If the Probe Swap parameter is set to Auto, and the monitor is in the Plate State,

then an automatic swap to the standby probe will be initiated if the active probe

should fail.

4.7.2.2 Alternating Probe mode.

When the monitor is in the Alternating Probe mode the probe is automatically

swapped at the end of each sample period.

4.7.2.3 Failed Standby Probe inhibits automatic swap.

The Standby probe is checked for a valid frequency signal prior to initiation of an

automatic probe swap. If the Standby probe has failed, the swap is not initiated

and the monitor automatically goes into the Auto Complete mode.

4.8 EXTERNAL INTERFACE

In addition to front panel controls, PM-700 Series Plating Monitors are equipped

with I/O connectors allowing the monitor to interface with external devices. The

I/O connectors are located on the rear panel of the monitor. The following

sections provide descriptions of each connector.

4.8.1 Discrete Inputs