Page 1

e

a

E

c

e

Pir

PG

ni Gaug

500

e Enhan

ed

tinb21

1 (2016-06)

Op

Incl.

rating Manu

EU Declaration o

al

f Conformity

1

Page 2

Product Identification

In all communications with INFICON, please specify the information given on the product nameplate. For convenient reference copy that information into the space provided below.

2

tinb21e1 (2016-06)

Page 3

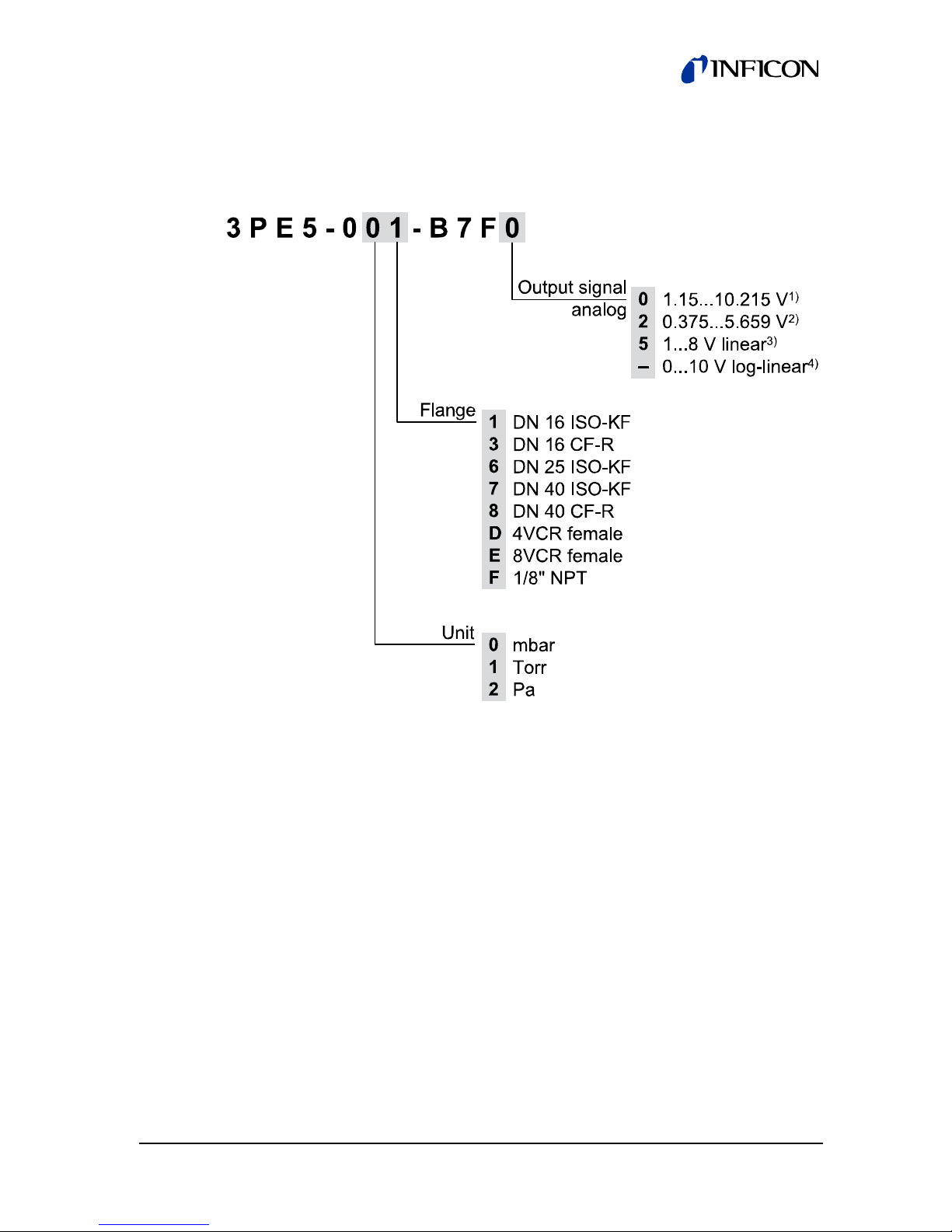

Validity

This document applies to products with part numbers:

1)

→ 67

2)

→ 48, 53

3)

→ 57, 61

4)

→ 68. Analog output 0 … 10 V is available on all devices by

default on pin 9.

The part number (PN) can be taken from the product nameplate.

If not indicated otherwise in the legends, the illustrations in this

document correspond to the product with vacuum connection

DN 25 ISO-KF. They apply to the other products by analogy.

We reserve the right to make technical changes without prior

notice.

tinb21e1 (2016-06) 3

Page 4

Important User Information

There are operational characteristic differences between solid

state equipment and electromechanical equipment. Because of

these differences, and because there are a variety of uses for

solid state equipment, all persons that apply this equipment must

take every precaution and satisfy themselves that the intended

application of this equipment is safe and used in an acceptable

manner.

In no event will INFICON be responsible or liable for indirect or

consequential damages that result from the use or application of

this equipment.

Any examples or diagrams included in this manual are provided

solely for illustrative purposes. Because of the many variables

and requirements imposed on any particular installation,

INFICON cannot assume responsibility or liability for any actual

use based on the examples and diagrams.

No patent liability is assumed by INFICON with respect to use of

information circuits, equipment, or software described in this

manual.

Throughout this manual we use notes, notices and apply internationally recognized symbols and safety messages to make

you aware of safety considerations.

4

tinb21e1 (2016-06)

Page 5

m

a

e

o

m

a

e

o

m

e

s

A

O

S

c

a

e

c

a

m

c

e

A

a

c

p

a

c

o

a

Identifies infor

cause electric

taken, could r

or economic l

C

Identifies infor

cause electric

taken, could r

or economic l

N

ation about pra

l or physical haz

sult in death or s

ss.

UTION

ation about pra

l or physical haz

sult in minor or

ss.

TICE

tices or circumst

rds which, if pre

rious injury, pro

tices or circumst

rds which, if pre

oderate injury, pr

nces that can

autions are not

erty damage,

nces that can

autions are not

perty damage,

Identifies infor

understanding

Labels may b

that dangerou

tinb21e1 (2016-06)

ation that is criti

of the product.

HOCK H

located on or ins

voltages may b

al for successful

ZARD

ide the device to

present.

application and

lert people

5

Page 6

General Safety Instructions

• Adhere to the applicable regulations and take the necessary

precautions for the process media used.

Consider possible reactions with the product materials.

Consider possible reactions (e.g. explosion) of the process

media due to the heat generated by the product.

• Adhere to the applicable regulations and take the necessary

precautions for all work you are going to do and consider the

safety instructions in this document.

• Before beginning to work, find out whether any vacuum components are contaminated. Adhere to the relevant regulations

and take the necessary precautions when handling contaminated parts.

Communicate the safety instructions to all other users.

Liability and Warranty

INFICON assumes no liability and the warranty becomes null

and void if the end-user or third parties

• disregard the information in this document

• use the product in a non-conforming manner

• make any kind of interventions (modifications, alterations etc.)

on the product

• use the product with accessories not listed in the product

documentation.

The end-user assumes the responsibility in conjunction with the

process media used.

Gauge failures due to contamination or wear and tear, as well as

expendable parts (e.g. Pirani filament), are not covered by the

warranty.

6

tinb21e1 (2016-06)

Page 7

Contents

Product Identification 2

Validity 3

Important User Information 4

General Safety Instructions 6

Liability and Warranty 6

1 Introduction / General Information 9

1.1 Description 9

1.2 Specifications 9

1.3 Dimensions 12

1.4 Options & Accessories 13

2 Important Safety Information 14

2.1 Safety Precautions - General 14

2.2 Safety Precautions - Service and Operation 15

2.3 Electrical Conditions 16

2.3.1 Proper Equipment Grounding 16

2.3.2 Electrical Interface and Control 17

2.4 Overpressure and use with hazardous gases 17

2.5 Gases other than Nitrogen / air 18

3 Installation 19

3.1 Mechanical Installation 19

3.2 Electrical Installation 21

3.2.1 Grounding 21

3.2.2 Electrical Connections 22

4 Setup and Operation 25

4.1 Initial Setup 25

4.2 User Interface Basics 26

4.3 Programming 27

4.4 Return to Factory Default Settings 33

5 Using the gauge with different gases 34

6 Display 37

6.1 Display - Torr / mTorr 37

6.2 Display - mbar 41

tinb21e1 (2016-06) 7

Page 8

7 Analog Output 46

7.1 Non-Linear Analog Output - 0.375 to 5.659 V,

Torr / mTorr 48

7.2 Non-Linear Analog Output - 0.375 to 5.659 V, mbar 53

7.3 Log-Linear Analog Output - 1-8 V, Torr 57

7.4 Log-Linear Analog Output - 1-8 V, mbar 61

7.5 Log-Linear Analog Output - 1.15-10.215 V,

mbar / Torr / Pa 67

7.6 Linear Analog Output 0-10 V, Torr 68

8 RS485 / RS232 serial communications 70

8.1 Device Specific Serial Communication Info 70

8.2 RS485 / RS232 Command Protocol Summary 71

9 Service 74

9.1 Calibration 74

9.2 Maintenance 74

9.3 Troubleshooting 75

9.4 Contamination 77

9.5 Module and sensor replacement 79

10 Factory Service and Support 80

11 Returning the Product 80

12 Disposal 81

EU Declaration of Conformity 82

For cross-references within this document, the symbol (→ XY)

is used.

8

tinb21e1 (2016-06)

Page 9

1 Introduction / General Information

1.1 Description

Thermal conductivity gauges measure pressure indirectly by

sensing the loss of heat from a sensor to the surrounding gases.

The higher the pressure of the surrounding gas, the more heat is

conducted away from the sensor. Pirani thermal conductivity

gauges maintain a sensor (usually a wire) at some constant temperature, and measure the current or power required to maintain

that temperature. A standard Pirani gauge has a useful measuring range of about 10

convection currents that are generated above 1 Torr, convectionenhanced Pirani gauges increase the measuring range to just

above atmosphere.

-4

Torr to 10 Torr. By taking advantage of

The INFICON PGE500 Pirani Gauge Enhanced module provides

the basic signal conditioning required to turn a convection

vacuum gauge into a complete measuring instrument. The module provides linear, non-linear or log-linear analog outputs, two

setpoint relays and RS232/485 serial communications. In addition, a built-in display provides a convenient user interface for

setup and operation of the vacuum gauge.

1.2 Specifications

Measurement range 1.3×10

Accuracy - N

1.3×10

1.3×10

530 … 1333 mbar

-4

1×10

-3

1×10

400 … 1000 Torr

(typical)

2

-4

… 1.3×10-3 mbar

-3

… 530 mbar

… 1×10-3 Torr

… 400 Torr

-4

… 1333 mbar

-4

1×10

1.3×10

… 1000 Torr

-2

Pa … 133 kPa

0.1 ×10

-3

mbar resolution

±10% of reading

±2.5% of reading

0.1 mTorr resolution

±10% of reading

±2.5% of reading

Repeatability - N

tinb21e1 (2016-06) 9

(typical) ±2% of reading

2

Page 10

Display bright OLED, 4 digits, user-

selectable mbar, Torr or Pa

1100 Torr … 1000 Torr 4 digits

999 Torr… 10.0 mTorr 3 digits

9.9 mTorr … 1.0 mTorr 2 digits

0.9 mTorr… 1.0 mTorr 2 digits

Materials exposed to vacuum gold-plated tungsten, 304 & 316

stainless steel, glass, nickel,

Teflon

®

Housing (electronics) aluminum extrusion

Internal volume 26 cm3 (1.589 in3)

Internal surface area 59.7 cm

2

(9.25 in2)

Weight 340 g (12 oz.)

Permissible temperature

Operating

0 … +40 °C

Storage –40 … +70 °C

Bakeout temperature ≤150 °C (gauge only - electro-

nics removed)

Relative humidity 0 … 95%, non-condensing

Use

Operating

altitude up to 2500 m (8200 ft.)

Storage altitude up to 12500 m

(41000 ft.)

Mounting orientation horizontal recommended

(orientation has no effect on

measurements below 1.3 mbar

(1 Torr))

10

tinb21e1 (2016-06)

Page 11

Output signal analog (measurement signal)

3PE5-0xx-B7F0 log-linear

1.15 … 10.215 V (dc),

1.286 V/decade

p = 10

0.778(U-c)

(→ 67)

-B7F2 non-linear S-curve

0.375 … 5.659 V (dc)

Granville-Phillips

vectron

®

compatible

®

Mini-Con-

(→ 48, 53)

-B7F5 log-linear

1 … 8 V (dc)

1 V/decade

P = 10

(V - 5)

, (→ 57, 61)

-B7F– linear

0 … 10 V (dc)

(→ 68)

RS232C / RS485 interface ASCII protocol

Supply voltage 12 … 28 V (dc), 2 W protected

against power reversal and

transient overvoltages

Setpoint relays two, single-pole double-throw

relays (SPDT), 1 A at 30 V (dc)

resistive, or V (ac) non-inductive

Electrical connection 9-pin D-sub male and

15-pin HD D-sub male (with

RS485)

tinb21e1 (2016-06) 11

Page 12

n

i

NDNDN

NDN

/

b

A

c

1

1

1

3

3

7

6

8

1.3

Dimensio

F

tting

s

Dimension

D

16 ISO-KF

25 ISO-KF

40 ISO-KF

D

16 CF-R

40 CF-R

4

VCR female

8

VCR female

1

8" NPT male

mm (in

25.9 (1.

25.9 (1.

25.9 (1.

34 (1.

34 (1.

43.7 (1.

40.9 (1.

21.8 (0.

h)

6)

6)

6)

4)

4)

2)

1)

6)

12

tin

21e1 (2016-06)

Page 13

f

2

d

o

t

W

p

e

p

s

w

e

w

d

1.4

Options &

Power supply

Input: 100 …

Output: 24 V (

Cable Length:

Accessories

or PGE300/500

40 V (ac)

c) @ 2.5 A (60

2 m (6 ft.)

Ordering No.

352-525

)

This variation

plug that is no

IEC60320 AC

supplied AC m

f the power sup

listed above is r

power entry rece

ains power cord

ly may be used

quired. The conv

tacle allows use

et available worl

hen an AC

ntional

ith any user

wide.

tinb21e

1 (2016-06)

13

Page 14

t

d

e

y

o

o

o

p

a

o

y

s

m

f

c

h

N

d

W

o

t

d

n

a

r

r

o

o

q

a

e

o

e

r

b

o

p

a

f

t

m

e

m

e

y

r

C

n

e

r

2

Importan

INFICON has

and reliable s

the strict safet

and follow all

To avoid seri

tion in this d

procedures c

death, and or

Failure to com

ards of installa

disclaims all li

these instructi

Safety Inf

esigned and tes

rvice, provided it

guidelines provi

warnings and i

ARNING

us injury or de

cument. Failure

uld result in se

property damag

ly with these wa

tion and intended

bility for the cust

ns.

rmation

ed this product t

is installed and o

ed in this manu

structions.

th, follow the sa

to comply with

ious bodily har

e.

nings violates th

use of this instru

mer’s failure to c

provide safe

erated within

l. Please read

ety informa-

hese safety

, including

safety stand-

ent. INFICON

mply with

2.1

Although ever

ble installation

that arises fro

of the module.

tion and use o

Safety Pre

The product s

moved.

WARNI

adjustments in

inside the pro

service trained

attempt has bee

, INFICON cann

various installat

If you have any

this product, ple

autions - G

ould never be op

G! There are n

side the product

uct enclosure is

personnel.

n made to consid

t anticipate ever

ions, operation, o

uestions about th

se contact INFI

neral

erated with the e

operator servic

nclosure. Howev

eplaceable. Refe

r most possi-

contingency

maintenance

e safe installa-

ON.

closure re-

able parts or

r, the sensor

servicing to

14

tin

21e1 (2016-06)

Page 15

q

c

h

u

N

o

a

d

r

e

d

d

s

o

o

c

g

n

c

e

n

p

o

a

b

m

u

d

e

s

u

s

a

m

o

e

t

s

a

d

e

n

o

t

p

c

g

h

o

e

c

e

y

C

e

a

e

e

e

N

e

o

o

e

o

s

u

p

0

d

r

m

s

o

Do not modify

thorization of

turn the produ

ter to ensure t

this product if

WARNI

product prior t

After servicing

made by a qu

required, ensu

stitutions of no

or other hazar

made to this p

To reduce the

product to rain

and careful att

onto these pro

been damage

of the product

this product or su

ualified INFICON

t to an INFICON

at all safety feat

nauthorized mo

G! Source pow

performing any

this product, ens

lified service per

re that the parts

n-qualified parts

s. Use of unauth

oduct will void th

risk of fire or elec

or moisture. The

ntion must be p

ucts. Do not us

. Immediately co

if it is damaged.

bstitute any parts

service trained p

qualified service

res are maintain

ifications have b

r must be remov

ervicing.

re that all safety

on. When replac

e specified by I

ay result in fire,

rized parts or m

warranty.

ric shock, do not

e products are n

id to not spill any

these products if

tact INFICON to

without au-

rsonnel. Re-

nd repair cen-

d. Do not use

en made.

d from the

checks are

ment parts are

FICON Sub-

lectric shock

difications

expose this

t waterproof

type of liquid

they have

arrange return

2.2

Due to the po

mental conditi

compromised

odically inspe

ment groundin

trical insulatio

Safety Pre

Ensure that th

gauge is mou

Use an appro

Turn off power

module.

Turn off power

product is not

manual. Cont

service or trou

this operating

sibility of corrosi

ns, it is possible

ver time. It is im

ted for sound ele

. Do not use if t

has been compr

autions - S

vacuum port on

ted is electrically

riate power sour

to the unit befor

to the unit if a ca

perating normall

ct qualified INFI

leshooting condi

anual.

n when used in c

hat the product’s

ortant that the pr

trical connection

e equipment gro

mised.

rvice and O

which the PGE5

grounded.

e of 12 … 28 V (

attempting to se

ble or plug is da

according to thi

ON service pers

tion that may not

rtain environsafety could be

duct be peri-

and equip-

nding or elec-

eration

0 vacuum

c), 2 W.

vice the

aged or the

operating

nnel for any

be covered by

tinb21e

1 (2016-06)

15

Page 16

t

a

p

h

d

r

C

N

h

e

a

a

i

d

e

T

c

s

N

j

d

o

e

U

a

e

d

o

d

O

v

c

u

a

o

a

r

p

s

t

d

v

w

y

b

m

e

n

.

b

p

n

a

c

o

f

n

u

o

r

t

d

p

0

e

f

o

o

a

2.3

It is important

sound electric

use if the equi

compromised.

Do not use if t

been damage

instructions fo

Electrical

WARNI

system, a life t

less all expos

ground potenti

tact with the g

discharge with

high voltage di

A person coul

with an expos

age potential.

come in conta

(vacuum / pre

hat the product b

l connections an

ment grounding

e unit has been

. Contact INFIC

returning the pro

onditions

G! When high

hreatening electri

d electrical cond

l. This applies t

s contained in v

in a gaseous envi

rectly to any ung

be seriously inju

d, ungrounded el

his condition ap

t with the gas in

sure containmen

periodically ins

equipment grou

r electrical insul

ropped or the en

N for return auth

duct to INFICON

oltage is present

al shock hazard

ctors are maintai

all products that

cuum chambers.

ronment may co

ounded conducto

red or killed by c

ectrical conducto

lies to all produc

ide the vacuum c

vessel).

ected for

ding. Do not

tion has been

losure has

rization and

or evaluation.

in any vacuum

may exist un-

ed at earth

ome in conAn electrical

ple dangerous

r of electricity.

ming in contact

at high volt-

s that may

amber

2.3.1

16

Proper Equi

WARNI

ure or cause

Verify that the

module is mou

Electrician if y

Proper ground

well as intend

dule vacuum g

earth ground.

connection / fl

pment Groun

G! Hazardous

eath are present

vacuum port on

nted is electricall

u are in doubt a

ing of your equip

d operation of th

auge must be co

se a ground lug

nge if necessary

ing

oltages that coul

in many vacuum

hich the PGE50

grounded. Cons

out your equipm

ent is essential

equipment. The

nected directly t

on the PGE500 g

tin

seriously in-

rocesses.

vacuum gauge

ult a qualified

nt grounding.

r safety as

PGE500 mo-

a good quality

uge vacuum

21e1 (2016-06)

Page 17

N

v

m

t

u

e

o

t

e

u

N

o

v

g

n

e

a

p

a

e

l

d

t

o

e

e

d

m

o

n

e

w

b

e

o

a

-

v

f

c

a

e

x

s

s

o

p

c

a

u

r

t

n

d

2.3.2

WARNI

shock and bod

potential high

vacuum syste

Electrical In

It is the user’s

from this prod

for example, r

Always double

to automate y

sis of your sys

safety measur

age.

G! In order to p

ily harm, shield a

oltage electrical

.

erface and C

responsibility to

ct and any conn

lays and solenoi

check the syste

ur process. Perf

em design and e

s are taken to pr

rotect personnel

l conductors whi

ischarges in or

ntrol

nsure that the el

ctions made to e

s, are used in a

set-up before u

rm a hazardous

sure safeguards

vent injury and

rom electric

h are subject to

round the

ctrical signals

ternal devices,

afe manner.

ing any signals

peration analyand personnel

roperty dam-

2.4

Overpress

WARNI

limit the level

than what the

of withstandin

sures exceedi

In cases wher

condition, alw

ample, use a

eration where

sures if the pr

chamber.

re and use

G! Install suita

f pressure inside

acuum chamber

. INFICON gaug

g 1000 Torr abs

an equipment f

ys implement fail

ressure relief de

malfunction cou

ssure relief devic

ith hazardo

le protective devi

your vacuum ch

system compone

s should not be

lute pressure.

ilure could cause

safe system ope

ice in an automa

ld result in high i

e was not installe

us gases

es that will

mber to less

nts are capable

sed at pres-

a hazardous

ation. For ex-

ic backfill op-

ternal pres-

on the

tinb21e

1 (2016-06)

17

Page 18

v

v

e

e

t

o

b

O

w

u

e

a

s

o

z

s

m

e

o

e

N

g

a

o

m

o

T

s

e

s

g

c

a

y

)

a

a

l

l

s

a

h

d

o

g

m

r

a

O

g

c

b

x

a

o

e

,

b

o

v

o

v

c

d

r

g

o

b

p

s

f

d

r

t

a

c

The PGE500

pressures abo

(<2½ bars) pr

higher pressur

sure relief devi

conditions. Wi

tions may be l

pression fitting

vacuum cham

rected barome

CAUTI

device is allo

metric press

tings may rel

may cause le

tube to relea

vironment. T

amples of ha

vacuum/pres

environment,

age to equip

volume to pr

using hazard

acuum gauge m

e 20 psia (1000

ssure inside the

s, you should in

ce to protect the

h some fittings, a

wer; for example

may forcibly rele

er fitting with onl

tric (atmospheric

N! If the intern

ed to increase

re (atmospheric

ase and possib

ks that would a

e into the atmo

xic, pyrophoric

ardous gases t

ure containmen

could cause bo

ent. Never exp

ssure above loc

us gases.

dule is not intend

orr); DO NOT e

ensor. If your ch

tall an isolation v

auge tube from

tual safe overpr

, a quick-connect

se the gauge tu

a few psi over l

pressure.

l pressure of a

bove local unc

pressure side),

e overpressure

low the gas insi

phere of the sur

nd flammable

at if allowed to l

t vessel into the

ily injury and p

se the gauge tu

al atmospheric

ed for use at

ceed 35 psig

mber goes to

lve or pres-

verpressure

ssure condi-

O-ring com-

e from the

cal uncor-

acuum gauge

rrected baro-

acuum fit-

onditions

e the gauge

ounding en-

ases are ex-

ak out of the

atmospheric

ssible dam-

e internal

ressure when

2.5

Gases oth

WARNI

nitrogen (N2) o

tables.

INFICON gau

of nitrogen or

argon (Ar) or c

data for N

"Using the gau

Output" for a

18

r than Nitro

G! Do not atte

r air without refer

es and modules

ir. Do not attemp

arbon dioxide (C

to

2

ther gas is prope

ge with different

ore complete dis

en / air

pt to use with ga

ing to correction

re calibrated for

t to use with othe

) unless accura

2

rly used. Refer to

ases", "Display"

ussion.

tin

es other than

actor data

irect readout

gases such as

e conversion

sections titled

nd "Analog

21e1 (2016-06)

Page 19

N

s

a

y

e

c

o

o

a

E

u

s

P

e

a

g

E

P

m

t

m

u

r

e

c

e

n

n

e

a

o

p

w

c

e

e

t

s

o

n

o

h

o

a

,

x

f

3

3.1

WARNI

phere or in the

Do not use thi

combustible g

gauge normall

occur, the wir

ture of certain

cause an expl

Installati

Mechanic

G! Do not use t

presence of flam

device to meas

ses or gas mixtu

operates at 125

temperature cou

ombustible gas

sion which could

n

l Installation

his device in an e

mable gases, va

re the pressure o

es. The sensor

°C, but if malfun

ld exceed the igni

s and gas mixtur

result in serious i

plosive atmos-

ors or fumes.

explosive or

ire in the

tion should

tion tempera-

. This could

njury or death.

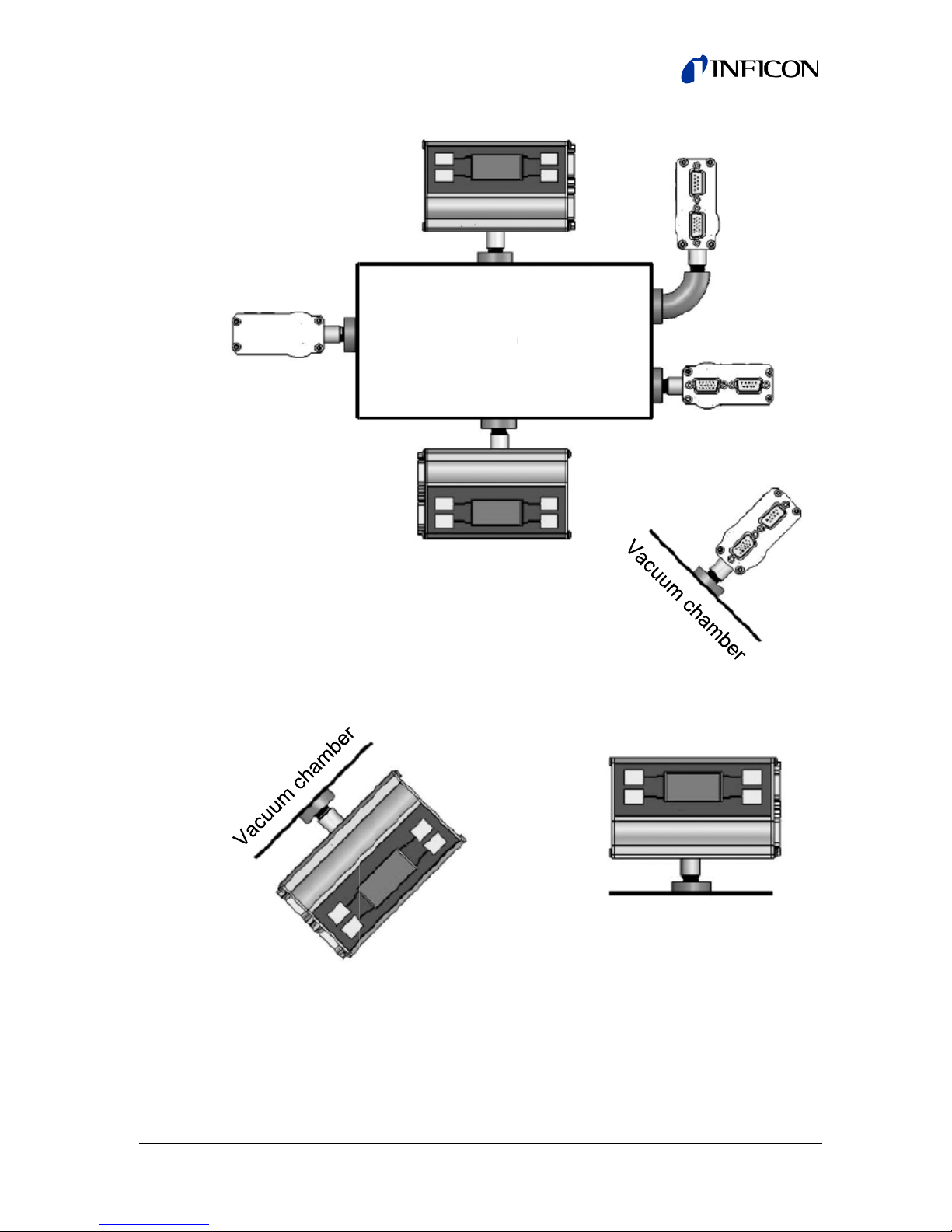

Mount the PG

want to measu

create a press

the gauge. Thi

changes.

Mounting the

cause measur

PGE500 near

air conditionin

Mount the PG

gram below).

the unit is not

position has lit

For accurate

horizontally as

500 as close as

re. Long or restri

re difference bet

may cause a d

GE500 too close

ment and contro

source of heati

vents.

500 with its mai

ressure reading

ounted horizont

le to no effect.

easurements ab

shown below:

possible to the pr

ted, small diame

ween your proce

lay in response t

to a gas source i

l instability. Do n

g or cooling, suc

(long) axis horiz

rrors may occur

lly. Below 1 Torr

ve 1 Torr, mount

ssure you

er tubing will

s chamber and

pressure

let may also

t mount the

as heaters or

ntal (see dia-

bove 1 Torr if

mounting

the gauge axis

tinb21e

1 (2016-06)

19

Page 20

n

E

n

w

a

b

o

r

m

r

Incorrect Orie

Vacuum ch

tation:

mbe

Mount the PG

the effect of a

gauge.

20

500 with port do

y particles or con

Vacuu

n, if possible, to

densation from c

tin

chambe

help minimize

llecting in the

21e1 (2016-06)

Page 21

t

V

a

g

o

a

o

o

o

e

a

e

e

r

a

g

h

s

n

h

g

o

e

e

e

r

t

d

c

m

o

e

u

i

a

e

n

a

a

y

3.2

3.2.1

Do not mount

sive vibration.

rement errors

the PGE500.

Flanges/ Fittin

and note the f

- NPT fittings:

apply a thread

with one-andas PTFE (Tefl

gauge port. D

age the gauge

Electrical I

Grounding

he PGE500 whe

ibrations may c

nd possible mec

s - follow the ma

llowing:

When connectin

sealant or wrap t

-half to two wrap

n®) tape and ha

not use a wrenc

.

nstallation

e it will be subjec

use unstable rea

hanical stress to

nufacturer's reco

the device using

e threaded porti

of pipe thread s

d tighten the ga

or other tool wh

ed to exces-

ings, measu-

omponents in

mendations

a NPT fitting,

n of the tubing

al tape such

ge into the

ch may dam-

Be sure

system are pr

operation of th

clamps must b

some vacuum

Teflon tape m

vacuum gaug

use a 12 gaug

gauge to a gro

low.

the vacuum gau

perly grounded f

equipment. Wh

e used to ensure

fittings such as N

y not allow for m

and the vacuum

or larger coppe

und lug on your v

e and the rest of

r safety as well

n using KF flang

proper grounding

PT connections i

tal-to-metal cont

chamber. If such

wire to connect t

acuum chamber

our vacuum

s intended

s, metal

. Be aware that

stalled using

ct between the

is the case,

he vacuum

s shown be-

tinb21e

1 (2016-06)

21

Page 22

V

Gauge tube

Metal clamp or

metal hose clamp

Use 12 gauge or

larger ground wire

Ground lug

acuum

chamber

Vacuum gauge fitting

3.2.2 Electrical Connections

A good recommended practice is to remove power from any

cable prior to connecting or disconnecting it.

Do not connect power to both the 9-pin and 15-pin D-Sub connectors. Apply power only to one or the other. The INFICON

PGE500 will directly replace Granville-Phillips® Mini-Convectron® modules that have a 9-pin D-sub connector (DE-9P) or

15-pin D-sub connector (DE-15P), and you can use your existing

cables and electronics. For new installations, fabricate a cable to

connect to the signals/functions you want to use. When using

RS232 or RS485 serial communications, you must fabricate your

own cable according to the 15-pin D-Sub pinout shown below. A

standard off-the-shelf serial communications cable will not work.

All signals and pin assignments are described below:

22

tinb21e1 (2016-06)

Page 23

9-pin D-sub Connector pinout

Pin no. Pin description

1 Relay 1 Normally Open

2 Relay 1 Normally Closed

3 Supply (12…28 V (dc))

4 Power Ground

5 Analog Output 1 (Log-Linear 1…8 V, Log-Linear

1.15…10.215 V, or Non-linear Granville-Phillips®

Mini-Convectron® compatible)

6 Relay 1 Common

7 Relay Disable (Disables both Relays when

connected to pin 4 - Ground)

8 Analog Ground

9 Analog Output 2 (Programmable Linear 0…10 V)

tinb21e1 (2016-06) 23

Page 24

15-pin D-sub Connector pinout

Pin no. Pin description

1 RS485 DATA B (+) Input/output

2 RS485 DATA A (-) Input/output

3 Supply (12…28 V (dc))

4 Power Ground (Also when using serial

communications, this pin is typically connected to

pin # 5 of your PC RS232 serial port 9-pin D-sub

connector, or ground pin of your RS485 converter)

5 Analog Output 1 (Log-Linear 1…8 V, Log-Linear

1.15…10.215 V, or Non-linear Granville-Phillips®

Mini-Convectron ®compatible)

6 Analog Ground

7 RS232 TX (This pin is typically connected to pin

# 2 of your PC serial port 9-pin D-sub connector)

8 RS232 RX (This pin is typically connected to pin

# 3 of your PC serial port 9-pin D-sub connector)

9 Relay Disable (Disables both Relays when

connected to pin 4 - Ground)

10 Relay 1 Normally Open

11 Relay 2 Normally Open

12 Relay 2 Common

13 Relay 2 Normally Closed

14 Relay 1 Normally Closed

15 Relay 1 Common

24

tinb21e1 (2016-06)

Page 25

4 Setup and Operation

4.1 Initial Setup

Two of the most important steps for the initial setup of the gauge

are to set zero (SET VAC) and set atmosphere (SET ATM) as

described in the Programming section 4.3 below. This will ensure proper operation of the gauge and accurate pressure measurements. The gauge is calibrated at the factory using nitrogen.

Furthermore, the gauge is also installed in a certain orientation

when calibrated at the factory. Without setting zero and atmosphere after the gauge is installed in your system, the gauge may

not display the expected and correct pressures. This could be

caused by the fact that you may be using a different gas than

Nitrogen such as air to setup and calibrate the gauge (most commonly the case) and the gauge orientation is different than the

orientation used at the factory. As such, it is very important to

perform your own initial setup and calibration by setting zero and

atmosphere with the gauge installed in your actual system.

Please note the following:

Setting zero (SET VAC): Setting zero optimizes performance of

the gauge when operating at a low pressure range of

1.00×10

sure is higher than 1.00×10

-4

Torr to 1.00×10-3 Torr. If your minimum operating pres-

-3

Torr, it is not normally necessary to

set zero and thus setting atmosphere should be adequate. If you

are able to evacuate your system to below 1.00×10

-4

Torr, it is

always a good practice to check and set zero if necessary. See

"SET VAC" in section 4.3.

Setting Atmosphere (SET ATM): Setting atmosphere is the

most important step for a newly installed gauge. If you prefer to

use air to set atmosphere, vent your vacuum system chamber to

expose the gauge to the local atmospheric pressure (air) and set

atmosphere to match your known local uncorrected barometric

pressure (air). This is the reading of ambient air pressure you will

expect if you were to vent and open your vacuum chamber to the

atmosphere surrounding the outside of your chamber. At sea

level, this pressure is usually near 760 Torr.

tinb21e1 (2016-06) 25

Page 26

a

t

c

s

e

f

p

o

f

f

p

n

d

r

t

h

t

o

h

e

e

n

o

s

e

a

D

y

n

c

b

e

r

o

o

e

b

g

t

v

e

t

i

k

e

4.2

At elevations

your local avia

local weather

ed barometric

"SET ATM" in

Note - Setting

once during th

periodically. A

the initial setu

(warm-up) bef

User Inter

bove sea level, t

ion authority or a

onditions online

pressure if you d

ection 4.3.

zero and atmosp

initial setup and

ter power has be

, allow five minut

re setting zero a

ace Basics

e pressure decr

irport web sites o

o help find your l

not have this inf

ere is normally r

maybe checked

n applied to the

s for the gauge

d atmosphere.

ases. Check

your current

cal uncorrect-

rmation. See

quired only

y the user

auge during

o stabilize

The user inter

progression of

explanation of

There are four

side of the dis

the various fu

PGE500, the

sents.

To begin prog

play will indica

by the function

of the paramet

Programmi

ace is designed f

setup parameter

operation for add

soft-keys located

lay. These keys

ctions available.

isplay will identif

amming, press a

e a choice of fun

on the display to

er desired.

ng soft-keys

r easy operation

. This section gi

d clarity.

on the front pan

re used to selec

uring programm

what function ea

y one of the four

tions. Press the

continue with th

and a natural

es a brief

l, two on each

and program

ng of the

h key repre-

keys. The dis-

ey indicated

programming

26

tin

21e1 (2016-06)

Page 27

After setting the various parameters, press the SAVE key to

save the new setting and return to the main screen. To continue

setting additional parameters, scroll forward with the MORE key

until you reach the desired parameter.

4.3 Programming

SET VAC

NOTICE

When operating in units of either mbar or

pascals (Pa), you must perform SET ATM before setting the

vacuum reading (SET VAC). See SET ATM below. Failure to

do so will result in improper operation of the gauge. If you

change units of measure or reset to factory defaults, then this

same procedure must be followed again if the units of measure are being set to either mbar or Pa.

1) To properly set the vacuum reading ("zero" point), with the

PGE500 installed on your vacuum system, the gauge should

be evacuated to a pressure below 1.00×10

-4

Torr.

2) Go to the SET VAC screen. When the vacuum system pressure is below 1.00×10

-4

Torr, press the PRESS TO SET

VAC key. The zero point (displayed pressure reading with

gauge exposed to vacuum) is now set.

UNITS [Factory default = as ordered]

The unit comes factory preset as ordered. If you like to switch to

another unit, this should be the first parameter that is set. This

will be the units-of-measure (mBAR, TORR, PASCAl) that are

used for all other settings. If your PGE500 has been previously

configured and relay setpoints and linear analog output pressure

settings have been programmed, changing units-of-measure will

return the relays setpoints and the linear analog output pressure

settings to factory default setting values in TORR. In this case,

you must reprogram the relay setpoints and linear analog output

pressure settings in the newly programmed units-of-measure.

tinb21e1 (2016-06) 27

Page 28

SET ATM

1) To set the atmospheric pressure reading (also known as the

"span" adjustment), flow nitrogen gas or air into your closed

vacuum chamber to allow the pressure to rise to a known

value above 400 Torr. Alternatively, if your local uncorrected

barometric pressure (air) is known, simply vent your vacuum

system chamber to expose the gauge to the local atmospheric pressure.

2) Go to the SET ATM screen. When the desired pressure is

stable, adjust the displayed pressure reading on the

PGE500 to the known value using the INCR (increase) or

DECR (decrease) keys. Press the SAVE key to save the

new atmospheric (span) pressure value. For example, if your

known local uncorrected barometric pressure is 760 Torr,

enter 760 in the SET ATM screen. The main pressure measurement screen will now display 760 Torr while the gauge

is at atmosphere.

It is good practice to perform the sequence of checking and

adjusting span (ATM) then zero (VAC) and then, finally rechecking the span setting to ensure that the circuitry is

properly balanced for use in measuring pressure throughout

the intended measurement range.

SP1 ON and SP2 ON [Factory default = 100 mTORR]

These setpoints correspond to the pressures at which the relays

will turn on (energize). The relays will turn on when the pressure

is below the programmed pressure value. If you are unable to

increase the values of SP1 ON or SP2 ON , you must first go to

SP1 OFF or SP2 OFF and increase those values to a number

higher than the values of SP1 ON or SP2 ON you are trying to

set.

28

tinb21e1 (2016-06)

Page 29

SP1 OFF and SP2 OFF [Factory default = 200 mTORR]

These setpoints correspond to the pressures at which the relays

will turn off (de-energize). The relays will turn off when the pressure is above the programmed pressure value. If you are unable

to decrease the values of SP1 OFF or SP2 OFF, you must first

go to SP1 ON or SP2 ON and decrease those values to a number lower than the values of SP1 OFF or SP2 OFF you are trying

to set.

RS485 ADDR [Factory default = 1]

This is the lower nibble of the one byte RS485 device address.

Assuming the address offset (RS485 OFFSET) is equal to 0,

setting the ADDR to a 5 will make the address be 0x05 in hexadecimal. A 15 will set the ADDR to 0x0F in hexadecimal. Note

that the address (ADDR) must be used even when sending

RS232 commands.

RS485 OFFSET [Factory default = 0]

This is the upper nibble of the one byte RS485 address. Assuming the address (ADDR) is 0, setting the address offset (RS485

OFFSET) to a 5 will make the address be 0x50 hexadecimal.

Setting the address offset to 15 will make the device address be

0xF0 hexadecimal.

┌----------------BINARY ADDRESS-----------┐

ADDRESS

DECIMAL

ADDR OFFSET

1 0 0 0 0 0 0 0 1 01

5 0 0 0 0 0 1 0 1 05

15 0 0 0 0 1 1 1 1 0F

16 0 0 0 1 0 0 0 0 F0

┌-----------------------ONE BYTE-------------------┐ ADDRESS

HEXA-

DECIMAL

┌Upper nibble┐

(BINARY)

ADDR

┌Lower nibble┐

tinb21e1 (2016-06) 29

Page 30

BAUD [Factory default = 19,200]

This sets the baud rate for the RS485 and the RS232 serial communications. The baud rate can be set to various values through

the serial interface or via the front panel soft-keys. The parity can

only be changed through the serial interface command set.

When this occurs, the current setting will be shown in the list of

choices and can be re-selected if changed.

SET LINEAR

[Factory default = 0.01 VOLTS to 10 VOLTS corresponding to 1

mTORR to 1 TORR]

This will take the user to four different screens to setup the linear

analog output (see Analog Output section).

a) Set the minimum pressure

b) Set the minimum voltage corresponding to the minimum

pressure

c) Set the maximum pressure

d) Set the maximum voltage corresponding to the maximum

pressure

Note - The LINEAR analog output provides a linear 0…10 V (dc)

output signal. The linear output voltage can be any value between 10 mV and 10 V corresponding to displayed pressure

between 1 mTorr and 1000 Torr. However, the useful range of

the linear analog output is three decades. If your application

requires the analog output to cover a pressure range exceeding

three decades then consider using the non-linear or the loglinear analog output. See ANALOG TYPE menu below to select

log-linear or non-linear analog output.

INFO

This screen shows the unit software version.

30

tinb21e1 (2016-06)

Page 31

ANALOG TYPE [Factory default = as ordered]

Select "NONLIN" for non-linear (S-Curve) or "LOG" for log-linear

analog output (See Analog Output section).

AOUT CAL [Factory default = Factory Set]

This has been pre-set in the factory and is used to optimize the

analog output calibration. It is recommended that the user not

make this adjustment unless the displayed pressure on the

PGE500 and the resulting pressure calculation from the analog

output do not match closely. To perform this adjustment, connect

the PGE500 analog output to a high resolution voltmeter, your

system, PLC, etc. While in the AOUT CAL screen and with the

gauge exposed to atmosphere, use the INC or DECR soft-keys

to adjust the analog output to match the corresponding pressure

displayed on the screen. Example: The PGE500 ANALOG TYPE

menu above is set to LOG. In the AOUT CAL screen, the atmospheric pressure is displayed at 760 Torr. Based on the equation

and table given in section 7.3 the expected analog output at

760 Torr is 7.881 V. Use the INC or DECR soft-keys in the

AOUT CAL screen to set the analog output to 7.881 V as recorded by your voltmeter, PLC, etc. Alternatively, if the analog

output is used to display the pressure in your PLC or system

display console, adjust the AOUT CAL while the gauge is exposed to atmosphere so that the atmospheric pressure displayed

by your PLC matches the atmospheric pressure displayed by the

PGE500. The AOUT CAL can be performed at any pressure

between 400… 999 Torr (atmosphere recommended).

SCREEN SAVER [Factory default = ON]

The PGE500 uses an OLED type display which over an extended period of time can start to show divergence between

pixels that are on at all times verses pixels that are not. This

could result in pixels exhibiting a burned-in effect. To minimize

the burned-in effect, a screen saver function can be activated by

programming the SCREEN SAVER menu selection to ON. With

the screen saver function turned on, the display appearance

changes every 12 hours. The display will appear in the normal

mode with a dark background color for the first 12 hours and will

tinb21e1 (2016-06) 31

Page 32

then switch to a back-lit background color for the next 12 hours.

If you like to have the 12 hour period for the normal display

mode to start at a specific time of the day, simply access the

SCREEN SAVER menu and change setting to OFF and then ON

again. This initiates the screen saver function immediately.

Note - To increase longevity of the OLED display, INFICON

recommends that the screen saver function remains ON as

shipped from the factory.

AOUT OFFSET

It is recommended that the user not make this adjustment unless

it is critical for your application that when the display of PGE500

reads zero (0.00 mTorr), your data acquisition system (using the

analog output from the PGE500) also registers a pressure reading of exactly zero. Please note that adjusting the AOUT

OFFSET will affect the analog output calibration at atmosphere

(see AOUT CAL menu above). As such, avoid changing the

AOUT OFFSET unless it is critical for display and analog output

to exactly match when the displayed pressure is zero.

To perform this adjustment, pump your system down to below

0.1 mTorr and SET VAC (zero) so that the PGE500 displayed

pressure shows 0.0 mTorr. Connect the PGE500 analog output

to a high resolution voltmeter, your system, PLC, etc. While in

the AOUT OFFSET screen, use the INC or DECR soft-keys to

adjust the analog output to match the corresponding zero

pressure displayed on the screen.

Example 1: The PGE500 ANALOG TYPE menu above is set to

LOG. In the AOUT OFFSET screen, the pressure is displayed at

0.00 mTorr. The expected analog output at 0.00 mTorr is

0.954 V. Use the INC or DECR soft-keys in the AOUT CAL

screen to set the analog output to 0.954 V as recorded by your

voltmeter, PLC, etc. Alternatively, if the analog output is used to

display the pressure in your PLC or system display console,

adjust the AOUT OFFSET so that your PLC also reads

0.0 mTorr.

Example 2: The PGE500 ANALOG TYPE menu above is set to

NONLIN (Non-Linear). In the AOUT OFFSET screen, the pressure is displayed at 0.00 mTorr. Based on the equation and table

given in section 7.1 the expected analog output at 0.00 mTorr is

0.375 V. Use the INC or DECR soft-keys in the AOUT CAL

32

tinb21e1 (2016-06)

Page 33

screen to set the analog output to 0.375 V as recorded by your

voltmeter, PLC, etc. Alternatively, if the analog output is used to

display the pressure in your PLC or system display console,

adjust the AOUT OFFSET so that your PLC also reads

0.0 mTorr.

4.4 Return to Factory Default Settings

You can reset all values to the original factory default settings by

simultaneously pressing the upper left and upper right soft-keys.

The user will then be prompted "Set Factory Defaults?" Choose

Yes or No.

If you reset all values to original factory default settings, you

would need to repeat the initial setup procedure as described in

section 4.1 and reprogram other parameters as required.

tinb21e1 (2016-06) 33

Page 34

d

N

t

i

o

N

a

u

m

b

u

p

a

m

c

s

a

c

n

o

t

a

u

a

h

e

u

r

o

s

d

a

e

c

g

T

n

o

c

g

h

a

n

N

s

n

e

a

e

a

w

b

a

h

g

n

u

o

o

f

d

g

u

e

r

e

h

a

o

a

g

r

t

b

p

e

n

t

t

t

o

5

Using the

A thermal con

on the thermal

Since different

ductivities, the

be different. I

mal conductivi

When a gas ot

for the differen

and the gas in

indicate how d

an INFICON c

WARNI

gases other th

death or serio

manual when

gauge wit

uctivity gauge s

conductivity of th

gases, and mixt

indicated pressu

FICON convecti

y gauges) are ca

her than N

ce in thermal con

use. The charts

ifferent gases aff

nvection gauge.

G! Using a ther

n that for which i

s injury. Be sure

easuring pressu

/ air i

2

different g

nses heat loss w

e gas surroundin

res, have differe

e readings and o

n gauges (and m

librated using nitr

used, correction

uctivity between

nd tables on the

ct the display an

mal conductivity

t is calibrated co

to use gas correc

res of gases oth

ses

ich depends

the sensor.

t thermal con-

tputs will also

st other thergen (N2).

must be made

nitrogen (N

ollowing pages

output from

auge with

ld result in

ion data in this

r than N

/ air.

2

)

2

For N2 the cali

dicated and tr

1000 Torr. At

the different g

these low pres

between ther

At pressures a

diverge signifi

currents in the

loss from the

geometry and

Generally, air

thermal condu

ences in readi

ing a system t

change by 30

gradually displ

the effect is m

ous condition

ration shows ex

e pressure throu

ressures below 1

ses are similar.

sures is a consta

al conductivities

bove 1 Torr, indi

antly. At these hi

gauge become t

ensor and calibr

mounting positio

nd N2 are consid

tivity, but even

gs at higher pre

atmosphere usi

o 40 Torr after th

ces the N2 in th

ch more signific

s described belo

ellent agreement

hout the range f

Torr, the calibrat

he difference in r

t, a function of t

f the gases.

ated pressure re

her pressures c

e predominant c

tion depends on

as well as gas p

ered the same wi

and air will exhi

2

sures. For exam

g N2, you may s

chamber is ope

gauge. For mos

nt and may resul

.

between in-

m 10-4 to

ion curves for

adings at

e difference

dings may

nvection

use of heat

auge tube

operties.

h respect to

it slight differ-

le, when vent-

e readings

ed and air

other gases

in a hazard-

34

tin

21e1 (2016-06)

Page 35

e

r

N

e

c

u

e

g

d

u

a

t

s

h

a

c

g

s

,

a

s

s

o

r

t

o

f

s

u

m

o

y

r

e

h

d

n

a

e

o

t

o

o

k

h

s

s

s

r

t

r

Other consid

Flammable o

WARNI

trinsically safe

in the presenc

Under normal

convection ga

gases. Howev

ergy could be

ignite or explo

convection ga

or explosive g

Moisture / wa

In some proce

tion may not c

Water vapor c

gauge and cor

other gas.

rations when u

explosive gase

G! INFICON co

nor explosion pr

of flammable o

onditions the vol

ges are too low t

r, under certain

enerated to cau

e. Thermal cond

ges are not reco

ses.

er vapor

ses (lyophilizati

ange significantl

n significantly ch

rection should be

ing gases other

nvection gauges

of and are not int

explosive gases

ages and curren

cause ignition

ailure conditions,

e flammable vap

ctivity gauges li

mended for use

n, for example) t

, except for mois

ange the respon

made, as you wo

than N2 / air

re neither in-

nded for use

r vapors.

s in INFICON

f flammable

sufficient en-

rs or gases to

e the INFICON

with flammable

e gas composi-

ure content.

e of a thermal

uld for any

Other contam

If your gases

calibration and

ally, if the gau

these change

zero and span

for evaluation

inants

ondense, coat, o

response to diff

e can be "calibra

are small enoug

the gauge shoul

nd possible clea

corrode the sen

rent gases will ch

ted" ("zero" and "

to be ignored. If

be replaced or

ing.

or, the gauge

ange. Gene

-

pan" settings),

you can’t set

eturn to factory

tinb21e1 (2016-06)

35

Page 36

t

o

s

e

t

a

h

e

o

d

t

r

t

g

k

e

s

d

f

t

n

n

r

A

m

6

o

b

2

a

e

o

o

®

o

t

r

e

,

s

f

o

Indicated vs.

rue total pressu

re (test gases N

, Ar, He)

Gas Correcti

The Y- axis of

by a capacitan

true total pres

is the pressur

test. This char

gauge (CVG)

illustrate that t

types of gaug

CAUTION! D

gauges which

section 6.1 an

Example A: If

sure is 500 To

Example B: If

100 Torr, the

If you are bac

system reach

will be reading

n Chart

the above chart i

ce manometer, a

ure independent

reading indicate

shows readings

nd Granville-Phil

e difference in th

s is virtually indis

not assume this

may or may not b

note the followi

he gas is nitroge

r, the gauge will

he gas is argon (

auge will read ab

filling your vacuu

s a pressure of 7

about 23 Torr. C

actual pressure

diaphragm gaug

of gas compositi

by the convecti

or an INFICON c

lips® Convectron

e response for b

inguishable.

data applies to o

e the same. Refe

g examples:

(N2), when the t

ead 500 Torr.

r), when the tru

out 9 Torr.

system with Ar

0 Torr true pres

ntinuing to back

s measured

that measures

n. The X-axis

n gauge under

nvection

gauge to

th of these

her convection

to the table in

ue total pres-

pressure is

when your

ure your gauge

ill your system,

36

tin

21e1 (2016-06)

Page 37

attempting to increase the reading up to 760 Torr, you will over

pressurize your chamber which may present a hazard.

Example C: If the gas is helium (He), the gauge will over pressure (OP) when pressure reaches about 10 Torr true pressure

and opening the chamber to atmosphere prematurely may present other hazards for both people and product.

CAUTION! What these examples illustrate is that using gases

other than nitrogen (N

) without using accurate gas conversion

2

data and other proper precautions could result in injury to personnel and/or damage to equipment.

Suggested precautions when using gases other than

nitrogen (N

):

2

Install a pressure relief valve or burst disk on your chamber, to

protect it from overpressure. Post a warning label on your gauge

readout that states "Do Not Exceed ____ Torr Indicated Pressure" (fill in the blank for maximum indicated pressure for the gas

you use) so that an operator using the gauge will not exceed a

safe pressure.

6 Display

6.1 Display - Torr / mTorr

Displayed pressure readings vs. true pressure for selected

gases - engineering units in Torr / mTorr (see following table):

Pressure shown in bold italic font in the shaded areas are in

mTorr.

Pressure shown in normal font in non shaded areas are in Torr.

tinb21e1 (2016-06) 37

Page 38

4

CH

0.0

0.1

0.2

0.5

1.7

3.3

7.7

15.3

30.4

77.2

159

Ne

2

D

22

Freon

12

Freon

KR

2

CO

2

O

0.0

0.0

0.0

0.0

0.0

0.0

0.1

0.1

0.1

0.1

0.1

0.1

0.2

0.2

0.2

0.2

0.2

0.2

0.5

0.5

0.5

0.5

0.5

0.5

0.7

1.3

1.5

1.5

0.4

1.1

1.5

2.4

3.1

3.1

1.0

2.3

3.5

6.0

7.0

7.6

2.3

4.4

7.1

12.1

13.5

14.7

4.8

11.0

14.1

24.3

27.2

29.9

9.5

22.2

34.8

60.0

69.0

72.5

23.5

54.9

70.0

121

136

143

46.8

107

(continued)

0.0

0.1

0.2

0.5

1.0

2.0

5.0

9.7

19.8

49.2

97.2

He

Ar

2

N

Pressure

True Total

0.0

0.0

0.0

0.1

0.1

0.1

[Torr / mTorr]

0 mTorr

0.1 mTorr

38

0.2

0.2

0.2

0.2 mTorr

0.5

0.5

0.5

0.5 mTorr

0.8

0.7

1.0

1 mTorr

1.6

1.4

2.0

2 mTorr

4.0

3.3

5.0

5 mTorr

8.1

6.6

10.0

10 mTorr

16.1

13.1

20.0

20 mTorr

tinb21e1 (2016-06)

40.5

32.4

50.0

50 mTorr

82.0

64.3

100

100 mTorr

Page 39

4

CH

315

781

1.60

3.33

7.53

27.9

355

842

OP

OP

Ne

2

D

22

Freon

12

Freon

KR

2

CO

2

O

141

250

262

275

91.1

210

194

359

687

594

611

217

489

486

745

1.55

1.04

1.05

400

950

970

1.59

4.13

1.66

1.62

700

1.71

1.94

5.24

246

2.62

2.45

1.28

3.34

4.98

21.5

OP

3.39

2.96

1.78

4.97

10.3

584

OP

3.72

3.32

2.29

6.59

22.3

OP

OP

4.14

3.79

2.57

8.22

77.6

OP

OP

4.91

4.68

2.74

9.25

209

OP

OP

6.42

5.99

3.32

12.3

(continued)

295

He

Ar

2

N

165

126

200

Table "Displayed pressure readings vs. true pressure - units in Torr / mTorr" (continued)

Pressure

True Total

[Torr / mTorr]

tinb21e1 (2016-06) 39

200 mTorr

435

312

500

500 mTorr

940

600

1.00

1 Torr

2.22

1.14

2.00

2 Torr

13.5

2.45

5.00

5 Torr

OP

4.0

10.0

10 Torr

OP

5.80

20.0

20 Torr

OP

7.85

50.0

50 Torr

OP

8.83

100

100 Torr

OP

9.79

200

200 Torr

Page 40

4

CH

OP

OP

OP

OP

OP

OP

OP

OP

OP

Ne

2

D

22

Freon

12

Freon

KR

2

CO

2

O

OP

OP

7.52

6.89

3.59

16.9

380

OP

OP

8.42

7.63

3.94

22.4

485

OP

OP

9.21

8.28

4.21

28.7

604

OP

OP

9.95

8.86

4.44

36.4

730

OP

OP

10.7

9.42

4.65

46.1

859

OP

OP

11.1

9.76

4.75

53.9

941

OP

OP

11.4

9.95

4.84

59.4

997

OP

OP

12.0

10.5

4.99

79.5

OP

OP

OP

12.7

11.1

5.08

111

OP

He

Ar

2

N

Table "Displayed pressure readings vs. true pressure - units in Torr / mTorr" (concluded)

Pressure

True Total

[Torr / mTorr]

40

OP

11.3

300

300 Torr

OP

13.5

400

400 Torr

OP

16.1

500

500 Torr

OP

18.8

600

600 Torr

OP

21.8

700

700 Torr

OP

23.7

760

760 Torr

OP

25.1

800

800 Torr

tinb21e1 (2016-06)

OP

28.5

900

900 Torr

OP

32.5

1000

1000 Torr

Page 41

Notes:

1) OP = overpressure indication: display will read over pressure

2) Display auto-ranges between Torr and mTorr at 1 Torr

Examples:

1) Gas used is nitrogen (N

surement of 10 Torr. True pressure of nitrogen is 10 Torr.

2) Gas used is argon (Ar). Display shows pressure measurement of 600 mTorr. True pressure of argon is 1 Torr.

3) Gas used is oxygen (O

ment of 486 mTorr. True pressure of oxygen is 500 mTorr.

6.2 Display - mbar

The table below shows the displayed readings at various pressures for selected gases when engineering units selected is in

mbar.

Displayed pressure readings vs. true pressure for selected

gases - engineering units in mbar (see following table):

). Display shows pressure mea-

2

). Display shows pressure measure-

2

tinb21e1 (2016-06) 41

Page 42

4

CH

0.0

.0001

.0003

.0006

.0023

.0044

.0102

.0203

.0405

.0100

0.210

Ne

2

D

22

Freon

12

Freon

KR

2

CO

2

O

0.0

0.0

0.0

0.0

0.0

0.0

.0001

.0001

.0001

.0001

.0001

.0001

.0003

.0003

.0003

.0003

.0003

.0003

.0006

.0006

.0006

.0006

.0004

.0006

.0009

.0017

.0020

.0020

.0005

.0015

.0020

.0032

.0041

.0041

.0013

.0031

.0047

.0080

.0093

.0101

.0031

.0059

.0095

.0161

.0179

.0195

.0064

.0146

.0187

.0323

.0362

.0398

.0126

.0295

.0463

.0799

.0919

.0966

.0313

.0731

0.100

0.160

0.180

0.190

0.0623

0.140

(continued)

0.0

.0001

.0003

.0006

.0013

.0027

.0067

.0129

.0263

.0655

0.120

He

Ar

2

N

0.0

0.0

0.0

.0001

.0001

.0001

0

[mbar]

.0001

True Pressure

42

.0003

.0003

.0003

.0003

.0006

.0006

.0006

.0006

.0011

.0009

.0013

.0013

.0021

.0019

.0027

.0027

.0053

.0044

.0067

.0067

.0107

.0088

.0133

.0133

.0214

.0174

.0206

.0206

tinb21e1 (2016-06)

.0539

.0431

.0666

.0666

0.110

.0857

0.130

0.130

Page 43

4

CH

0.410

1.04

2.13

4.43

10.0

37.1

473

1012

OP

OP

Ne

2

D

22

Freon

12

Freon

KR

2

CO

2

O

0.180

0.330

0.340

0.360

0.120

0.270

0.470

0.910

0.790

0.810

0.280

0.650

0.990

2.06

1.38

1.39

0.530

1.26

2.11

5.50

2.21

2.15

0.930

2.27

6.98

327

3.49

3.26

1.70

4.45

28.6

OP

4.51

3.94

2.37

6.62

778

OP

4.95

4.42

3.05

8.78

OP

OP

5.51

5.05

3.42

10.9

OP

OP

6.54

6.23

3.65

12.3

OP

OP

8.55

7.98

4.42

16.3

(continued)

0.250

0.640

1.29

2.58

6.63

13.7

29.7

103

278

393

He

0.210

Ar

0.160

2

N

0.260

Table "Displayed pressure readings vs. true pressure - units in mbar" (continued)

[mbar]

0.260

True Pressure

tinb21e1 (2016-06) 43

0.570

0.410

0.666

0.666

1.25

0.790

1.33

1.33

2.95

1.51

2.66

2.66

17.9

3.26

6.66

6.66

OP

5.33

13.3

13.3

OP

7.73

26.6

26.6

OP

10.4

66.6

66.6

OP

11.7

133

133

OP

13.0

266

266

Page 44

4

CH

OP

OP

OP

OP

OP

OP

OP

OP

OP

Ne

2

D

22

Freon

12

Freon

KR

2

CO

2

O

OP

OP

10.0

9.18

4.78

22.5

506

OP

OP

11.2

10.1

5.25

29.8

646

OP

OP

12.2

11.0

5.61

38.2

805

OP

OP

13.2

11.8

5.91

48.5

973

OP

OP

14.2

12.5

6.19

61.4

1140

OP

OP

14.7

13.0

6.33

71.8

1250

OP

OP

15.1

13.2

6.45

79.1

1320

OP

OP

16.0

13.9

6.65

105

OP

OP

OP

16.9

14.7

6.77

147

OP

He

Ar

2

N

Table "Displayed pressure readings vs. true pressure - units in mbar" (concluded)

[mbar]

True Pressure

44

OP

15.0

400

400

OP

17.9

533

533

OP

21.4

666

666

OP

25.0

800

800

OP

29.0

933

933

OP

31.5

1011

1011

OP

33.4

1060

1060

tinb21e1 (2016-06)

OP

37.9

1190

1190

OP

Values listed under each gas type are in mbar.

43.3

1330

1330

Page 45

Notes:

1) OP = Overpressure indication; display will read

"overpressure".

Examples:

1) Gas used is nitrogen. Display shows pressure measurement

of 13.3 mbar. True pressure of nitrogen is 13.3 mbar.

2) Gas used is argon. Display shows pressure measurement of

11.7 mbar. True pressure of argon is 133 mbar.

3) Gas used is CO

. Display shows pressure measurement of

2

.0731 mbar. True pressure of CO

is .0666 mbar.

2

tinb21e1 (2016-06) 45

Page 46

7 Analog Output

The PGE500 provides either a non-linear or two different loglinear analog outputs. Additionally a linear 0-10 V (dc) analog

output is provided.

Non-Linear Output

The first Convectron® gauge controllers produced a non-linear

output signal of 0.375 to 5.659 V (dc) for 0 to 1000 Torr of N

roughly in the shape of an "S" curve, as shown as follows.

Non-Linear Analog Output

6

6

6

Non-Linear Analog Output

,

2

Output - Volts

Output - Volts

Output - Volts

5

5

5

4

4

4

3

3

3

2

2

2

1

1

1

-3

-3

-3

10

10

10

Granville-Phillips

their Mini-Convectron

10

10

10

-2

-2

-2

®

-1

-1

-1

10

10

10

adopted the same output curve for most of

®

modules and controllers with non-linear

output (although in recent years, some Granville-Phillips

Pressure - Torr

Pressure - Torr

Pressure - Torr

10010

10010

10010

+1

+1

+1

10

10

10

+2

+2

+2

10

10

10

+3

+3

+3

®

con-

trollers may output variations of the original S-curve).

The non-linear output from INFICON convection gauges, mod-

ules and controllers duplicates the original S-curve of 0.375 to

5.659 V (dc) for 0 to 1000 Torr.

The tables shown in section 7.1 and 7.2 contain the lookup data

for converting the non-linear output voltage into pressure values

for nitrogen and various other gases.

46

tinb21e1 (2016-06)

Page 47

Log-Linear Output

Many INFICON modules and controllers also provide a log-linear

output signal, as an alternative to the non-linear signal described

below. This output, shown above, is a 1 Volt per decade signal

that may be easier to use for data logging or control.

Log-Linear Analog Output

8

8

7

7

6

6

5

5

4

4

Log-Linear Analog Output

Output - Volts

Output - Volts

3

3

2

2

1

1

10

10

-3

-3

10

10

-2

-2

Pressure - Torr

Pressure - Torr

-1

-1

10

10

10010

10010

+1

+1

10

10

+2

+2

10

10

+3

+3

The table shown in section 7.3, 7.4 and 7.5 contain the lookup

data and provides the formulas for converting the log-linear

output voltage into pressure values for nitrogen and various

other gases.

Linear 0-10 V (dc) Analog Output

The PGE500 also provides a linear 0-10 V (dc) analog output.

The linear output voltage can be any value between 10 mV and

10 V corresponding to displayed pressure between 1 mTorr and

1000 Torr. However, the useful range of the linear analog output

is three decades. For example if the minimum pressure selected

is 1 mTorr (1.00×10

age output of 0.01 volts, then maximum pressure selected to

correspond to a maximum voltage output of 10 volts should not

exceed 1.0 Torr. If your application requires the analog output to

cover a pressure range exceeding three decades then consider

-3

Torr) with a corresponding minimum volt-

tinb21e1 (2016-06) 47

Page 48

using the non-linear or the log-linear analog output. An analog

output of less than 0.01 volts to near 0 volt indicates a damaged

or faulty sensor.

7.1 Non-Linear Analog Output

0.375 to 5.659 V, Torr / mTorr

You may calculate the N2/air pressure represented by the 0.375

to 5.659 V non-linear analog output voltage for the "S-curve"

using a multi-segment, n

The coefficients for the n

various pressure measurement ranges are given in the following

table:

For Non-Linear Analog Output voltage range of 0.375 to

2.842 volts, use this table.

th

order polynomial function calculation.

th

order polynomial equation defined for

Coefficients for y(x) = a + bx + cx2 + dx3 + ex4 +fx5

a -0.02585

b 0.03767

c 0.04563

d 0.1151

e -0.04158

f 0.008738

For Non-Linear Analog Output voltage range of 2.842 to

4.945 volts, use this table.

Coefficients for =

a 0.1031

b -0.3986

c -0.02322

48

d 0.07438

e 0.07229

f -0.006866

tinb21e1 (2016-06)

Page 49

For Non-Linear Analog Output voltage range of 4.94 to

5.659 volts, use this table.

Coefficients for =

a 100.624

b -0.37679

c -20.5623

d 0.0348656

Where y(x) = pressure in Torr,

x= measured analog output in volts

Example: Measured analog output voltage is 0.3840 V.

From first table shown above use equation:

y(x) = a + bx + cx

2

+ dx3 + ex4 +fx5

x = 0.3840 volts

a = -0.02585, b=0.03767, c=0.04563, d=0.1151,

e=-0.04158, f=0.008738

y(x) = Pressure = 1.0E-03 Torr

The equations listed above are used to calculate the non-linear

voltage outputs for N

/air shown in the table below. Non-linear

2