Husqvarna PT26 D User Manual

Oper ator ′ s manual

PT26 D

Please r ead the operator’s manual carefully and make sure you

understand the instructions bef

ore using the machine.

EEEEnnnngggglllliiiisssshh

hh

Contents

Introduction ................................................ 3

Congratulations ............................................

Driving and Transport on Public Roads .......3

Towing ..........................................................3

Use ...............................................................3

Proper Service .............................................4

Serial Number ..............................................4

Symbols and Decals .................................. 5

Safety Instructions .....................................7

General Use .................................................7

Driving on slopes .......................................... 9

Children ........................................................10

Maintenance .................................................10

Transport ......................................................13

Environment protection ................................ 13

User responsibility ........................................14

Presentation ............................................... 15

1-2. Speed control ........................................17

3. Parking brake ...........................................17

4. Control panel ............................................18

5-9. Seat ....................................................... 18

10. Steering wheel and steering wheel console 19

11. Differential Lock .....................................19

12. Adjusting the cutting height ....................19

13. Fuelling ................................................... 19

21-37. Controls on the control panel ............20

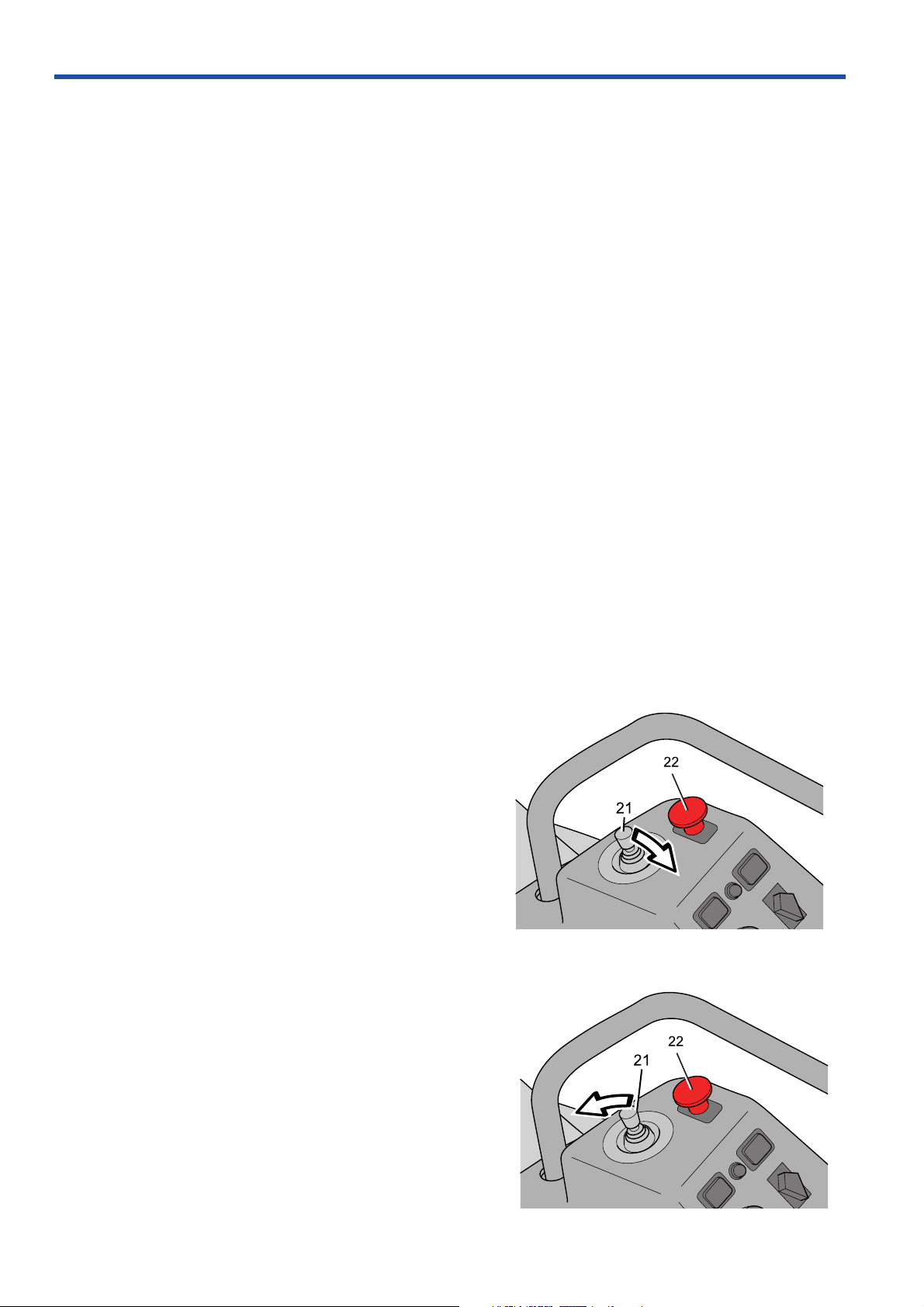

21. Control lever hydraulics .......................... 20

22. Switch for operation of cutting unit .........21

23. Switch for extra hydraulic function (hydraulic kit op-

tion) .............................................................. 21

24. Push button for horn (traffic kit option) ...21

25. Indicators (traffic kit option) ....................21

26. Starter switch .........................................22

27. Headlight ................................................22

28. Throttle control ....................................... 22

29. High speed .............................................22

30. Weight transfer .......................................23

31. Rotating warning light (traffic kit option) .23

32. Parking lights (traffic kit option) ..............23

33. Spare ...................................................... 23

34-35.Power outlet .......................................23

36. Chronometer .......................................... 24

40-51. Warning lamps ..................................24

49. Lever for steering wheel console angle .. 24

Adjusting the steering wheel setting ............. 24

Rops .............................................................25

Cooling system ............................................. 26

Cutting unit ...................................................27

Accessories ..................................................28

Towing ..........................................................28

Driving ......................................................... 29

Mowing Tips ................................................29

Before Starting ............................................. 30

Starting the engine .......................................31

Driving the machine .....................................33

Braking ......................................................... 34

Cutting the engine ........................................34

Bleeding in the event of fuel stoppage. ........34

Engine stop .................................................. 34

Maintenance ............................................... 35

Maintenance Schedule ................................. 35

Cleaning ....................................................... 37

Removing the machine’s covers .................. 38

3

Checking radiatorgrilles ............................... 38

Cleaning the radiator's heat exchanger ....... 38

Adjusting the pump and generator drive belts 38

Replacing the pump and generator drive belts 39

Checking and adjusting the throttle control ..39

Checking the exhaust system ...................... 39

Adjusting the parking brake ......................... 39

Servicing the air filter ................................... 40

Cleaning the cyclone filter ............................40

Replacing the air filter .................................. 40

Bleeding the fuel system ..............................41

Servicing the fuel filter .................................. 41

Checking the Tyre Pressures ....................... 41

Servicing the battery .................................... 42

Fuses ........................................................... 42

Checking the Safety System ........................43

Replacing the bulb in the headlight ..............44

Light setting .................................................. 45

The Cutting Unit Components ...................... 45

Attaching and removing the cutting unit .......45

Side shifting the cutting unit ......................... 45

Setting the cutting height and tilt angle ........ 47

The Cutting Unit’s Service Position .............. 48

Cutting Unit Model ....................................... 49

Checking the Blades .................................... 50

Replacing the power take-off belts ............... 50

Adjusting the power take-off belts ................51

Replacing the cutting unit belt ......................51

Removal of BioClip Plug .............................. 52

Lubrication ................................................. 53

Lubrication Schedule ................................... 53

General ........................................................ 53

Lubricating the cables .................................. 53

Accessories .................................................. 54

Lubricating in Accordance with the Lubrication

Schedule ...................................................... 54

Trouble Shooting Guide ............................ 61

Storage ........................................................ 65

Winter Storage ............................................. 65

Service ......................................................... 66

Electrical system ........................................ 67

Hydraulic System .......................................68

Fuel system ................................................ 70

Technical Data ............................................ 71

Design standards .......................................75

1

2

Introduction

Chapter 1: Introduction

Congratulations

Thank you for purchasing a Husqvarna PT 26D. Husqvarna PTs have been designed according to a unique

concept with a front mounted cutting unit and Husqvarna's unique rear wheel steering. The machine is built to giv e

maximum efficiency even in small and difficult areas. Collected controls and a hydrostatic transmission controlled

by pedals also contribute to the machine’s performance.

This Operator’s Manual is a valuable document. Following the instructions (use, service, maintenance, etc.) can

considerably increase the service life of your machine and even increase its resale value.

When you sell your machine, make sure to give the operator’s manual to the new owner.

A service journal is available for the machine. Ensure that service and repair work is documented. A well-kept

service journal reduces service costs for the season-based maintenance and affects the machine’s resale value.

Take the service journal along when the machine is taken to the workshop for service.

Driving and Transport on Public Roads

Check applicable road traffic regulations before driving and transport on public roads. You should always use

approved load retainers during transport and ensure that the machine is well secured.

Towing

The PT 26D is equipped with hydrostatic transmission and a bypass valve must be used when towing.

Use

This machine is designed to mow grass on ordinary lawns and other open and level ground surfaces without

obstacles such as stones, stumps and the like. All other types of use are incorrect. The man ufacturer’s instructions

with regard to driving, maintenance and repair must be followed precisely, even when the machine is equipped with

special accessories supplied by the manufacturer for which operating instructions accompany the delivery.

This machine should be operated, serviced and repaired only by persons who are familiar with its particular

characteristics and who are acquainted with the relevant safety instructions.

Accident prevention regulations, other general safety regulations, occupational safety rules, and traffic regulations

must be observed.

Unauthorised modifications to the design of the machine may absolve the manufacturer from liability for any

resulting personal injury or property damage.

3

Introduction

Proper Service

Husqvarna’s products are sold all over the world and only by specialised retail traders offering complete service.

This ensures that you as a customer receive only the best support and service. Before the product is delivered, the

machine has, for example, been inspected and adjusted by your dealer, see the certificate in the Service Journal.

When you need spare parts or support concerning service, warranty issues, etc., please consult the following

professional:

This operator’s manual belongs to the

machine bearing serial number:

Engine Transmission

Serial Number

The serial number can be found on the printed plate attached on the right-hand side under the seat. The plate

includes the following information:

• The machine’s type designation.

• Weight.

• The manufacturer's type number.

• The machine’s serial number.

• Manufacturer.

Please state the type designation and serial number when ordering spare parts.

The engine’s serial number is on the engine block above the injection pump.

Please state this when ordering spare parts.

The hydraulic pump and h ydraulic motors are equipped with rating plates that indicate type designation and serial or

manufacture numbers.

Please state these when ordering spare parts.

4

Symbols and Decals

Chapter 2: Symbols and Decals

These symbols are found on the machine and in the operator’ s man ual. Symbols for control units and warning lamps

are displayed in chapter “Presentation”, see page 42 and following pages.

Study them carefully so you understand their significance.

Read the

operator's manual

Engine off

Tyre

pressure

Read the

Operator's manual

Warning

Fuel Fast

CE conformity

marking

Parking brake

Use hearing

protection

Slow

Use protective

gloves

Cutting

Danger. Keep your hands and

feet away

Use protective

glasses

Poisonous

Hazardous to

health

Starting instructions:

Activate the parking brake

Read the operator’s manual

Hydrostat pedals in neutral

position

Do not insert

your hands

or feet under

the cover

when the

engine is

running

Warning!

Rotating

blades

Only for

attached

cutting unit

Oil level

Noise emission to

surroundings in

accordance with the

directive of the

European Community.

The machine’s

emission is indicated in

the TECHNICAL DATA

chapter and on the

decal.

Never carry

passengers

on the

machine

or on its tools.

10 - 61 93 445

Pedal forwards

Pedal backwards

Differential lock

Warning!

Risk of the

machine

overturning

Drive very

slowly

without the

cutting unit

Never

drive

directly

across a

slope

Never use the

machine if

there are

people,

especially

children, or

pets, in the

immediate

vicinity.

5

Symbols and Decals

WARNING:

Xxxxxx x xxxx xxxxx xxxxx xxxxx Xxxxxxxxxxx xxx

xxxxxx. Xxxx xxxxxxx xxx xx xxxx

Used in this publication to notify the reader of a risk of serious personal injur

neglect to follow instructions given in the manual.

y , particularly if the reader should

IMPORTANT INFORMATION:

Xxx xxx xxxx xxxxxxxxx xxx xxxxx xxx xxxx xx

xxxxx xx xxxxx. Xxx xxxxxxxx xx x x xxxxxxx xx

xxxx xxxx.

Used in this publication to notify the reader of a risk of material damage , particularly if the reader should neglect to

follow instructions given in the manual. Used also when there is a potential for misuse or misassembly.

Avoid hosing the decals with high pressure washers. Replace damaged decals before the machine is used.

6

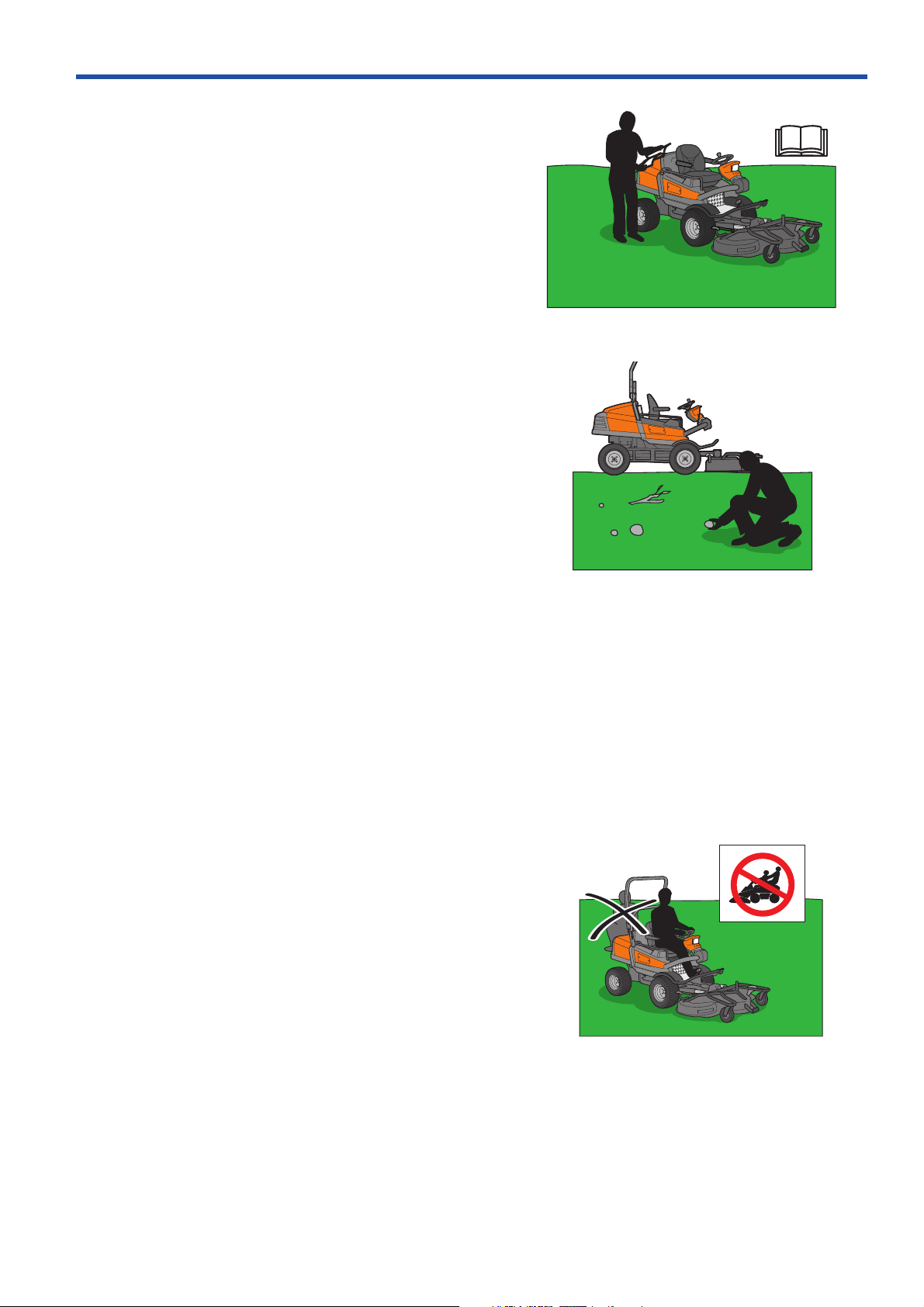

Read the operator’s manual before starting the machine

Clear the area of objects before mowing

Never take passengers

Safety Instructions

Chapter 3: Safety Instructions

These instructions are for your safety. Read them

carefully.

General Use

• Read all instructions in this operator’s manual and

on the machine before starting it. Ensure you

understand them and then observe them.

• Learn how to use the machine and its controls

safely and learn how to stop quickly. Also learn to

recognise the safety decals.

• If you get into a situation where you feel unsure

about how to progress, stop and seek expert

advice. Contact your Husqvarna retailer, service

agent or an experienced user. Avoid all usage that

you consider to be beyond your capability.

• Only allow the machine to be used by adults who

are familiar with its use.

• Make sure nobody else is in the vicinity of the

machine when you start the engine, engage the

drive, or run the machine.

• Clear the area of objects such as stones, toys,

steel wire, etc. that may become caught in the

blades and thrown out.

• Beware of the rear ejector and do not point it at any

one.

• Stop the engine and prevent it from starting before

you clean the cutting unit.

• Remember that the driver is responsible for

dangers or accidents.

• Never carry passengers. The machine is only

intended to be used by one person.

• Always look down and behind before and during

reversing manoeuvres. Keep watch for both large

and small obstacles.

• Slow down before turning.

7

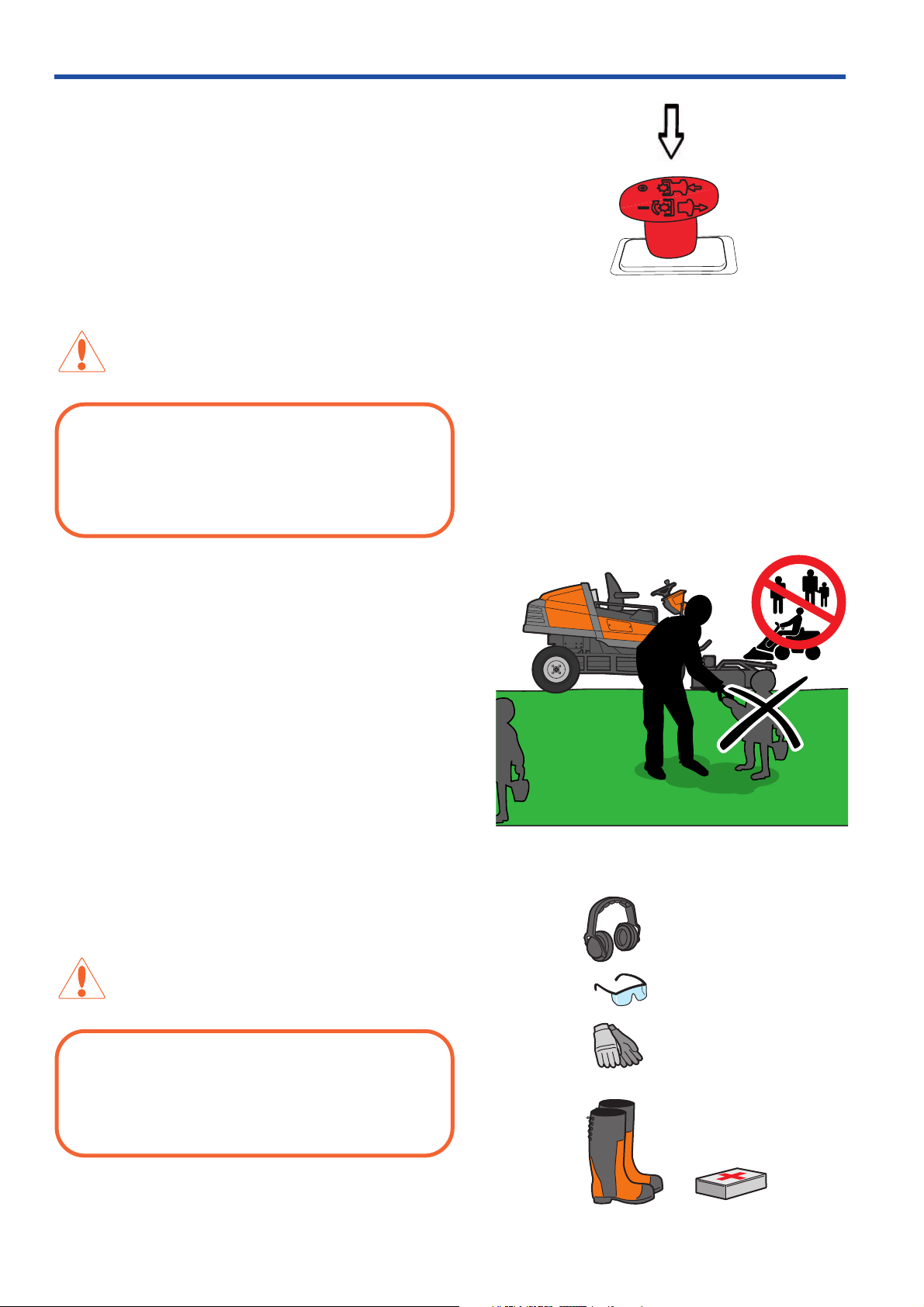

Shut down the blades

Keep children away from the work area

Personal protective equipment

Safety Instructions

• Shut down the blades when not mowing. The

lades must only be running when the cutting unit

b

is lowered and active when used for mowing.

• Be careful when rounding fixed objects, so that the

blades do not hit them. Nev er run the machine ov er

foreign objects.

• Never drive close to objects or other machines.

Remember that “Brake pedal reflex” from driving a

car has the opposite effect if you press on the

forward pedal.

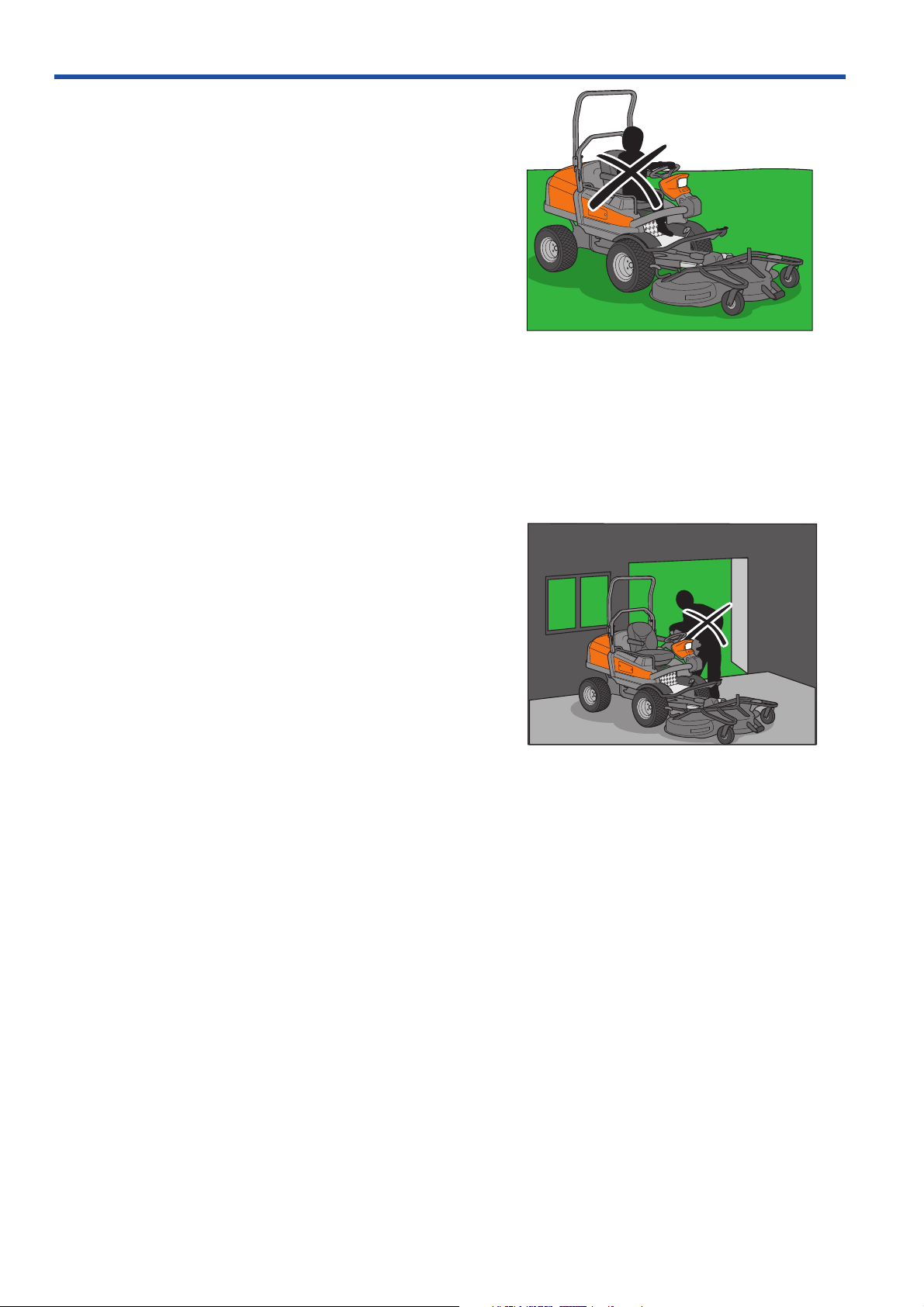

WARNING:

Engine exhaust, some of its constituents and certain

vehicle components contain or emit chemicals

considered to cause cancer, birth defects or other

reproductive impairment. The engine emits carbon

monoxide, which is a colourless, poisonous gas. Do

not use the machine in enclosed spaces.

• Only use the machine in daylight or in other well-lit

conditions. Keep the machine at a safe distance

from holes or other irregularities in the ground. P ay

attention to other possible risks.

• Never use the machine if you are tired, if you hav e

consumed alcohol, or if you are taking other drugs

or medication that can affect your vision,

judgement, or co-ordination.

• Beware of traffic when working near or crossing a

road.

• Never leave the machine unsupervised with the

motor running. Always stop the blades, apply the

parking brake, stop the engine and remove the

keys before leaving the machine.

• Never allo w children or other persons not trained in

the use of the machine to use or service it. Local

laws may regulate the age of the user.

WARNING:

You must use approved personal protective

equipment whenever you use the machine. Personal

protective equipment cannot eliminate the risk of

injury but it will reduce the degree of injury if an

accident does happen. Ask your dealer for help in

choosing the right equipment.

• Use hearing protection to minimise the risk of

hearing impairment.

• Wear approved protective goggles or a full visor

when driving.

8

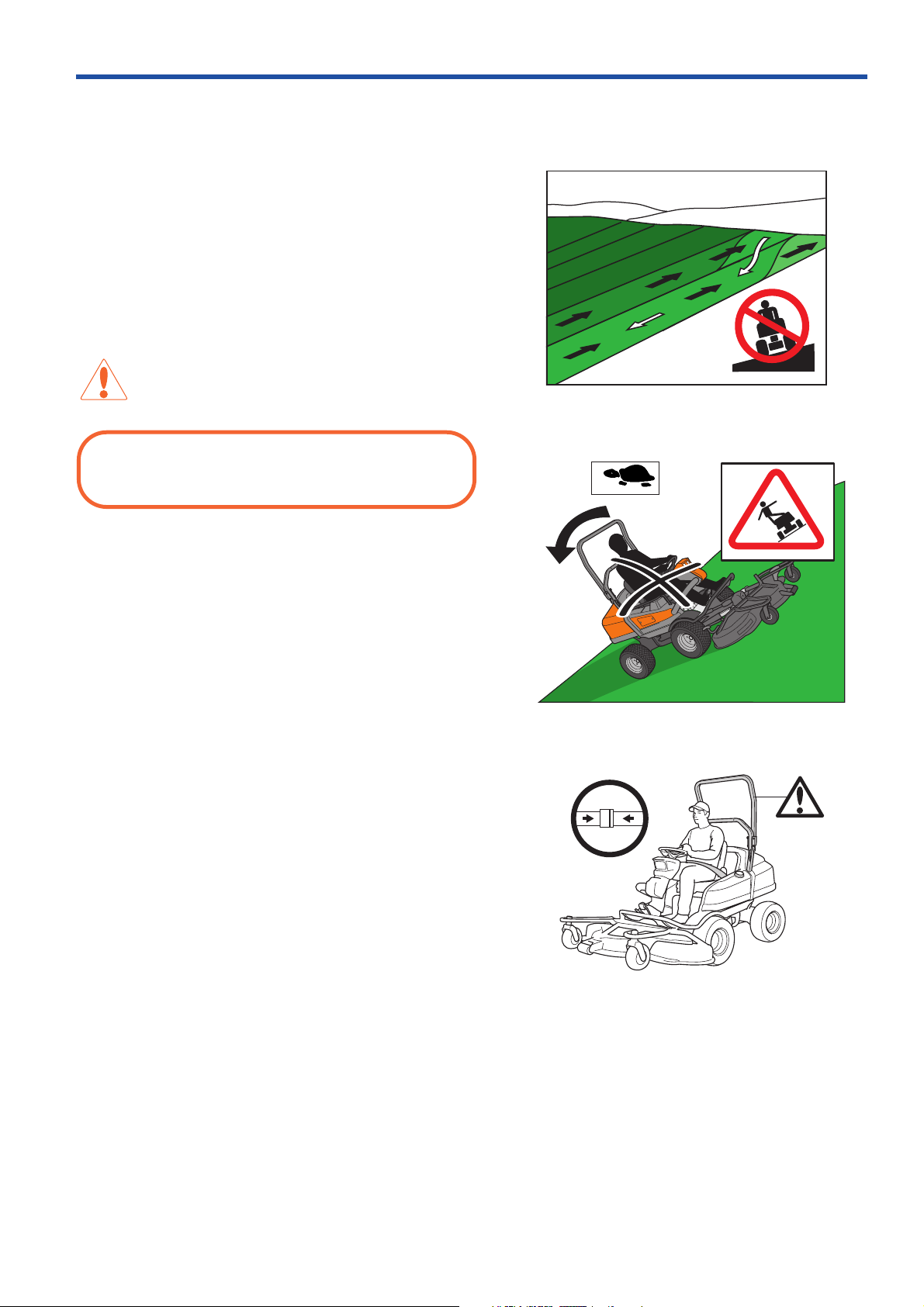

Mow upwards and downwards on slopes, not sideways.

Be extra cautious when driving on slopes

• Never use the machine when barefoot. Always

ear protective shoes or protective boots,

w

preferably with steel toes.

• Make sure that you have first aid equipment close

at hand when using the machine.

Driving on slopes

Driving on slopes is one of the operations where the

risk of the driver losing control of the machine or of it

overturning is the greatest; this can result in serious

injury or death. All slopes demand extra care. If you

cannot reverse up a slope or if you feel unsure, do not

mow it.

WARNING:

Do not drive down slopes with the unit raised.

Control can be reduced due to the changed centre of

gravity.

Safety Instructions

Do as follows

• Remove obstacles such as stones, tree branches, etc.

• Mow up and down, not side-to-side.

• The differential lock should also be used on slopes.

• Never drive the machine on terrain that slopes

more than 10°.

• Avoid starting or stopping on a slope. If the tyres

start to slip, stop the blades and drive slowly down

the slope.

• Always drive evenly and slowly on slopes.

• Always use rops and safety belt when driving on slopes

• Make no sudden changes in speed or direction.

• Avoid unnecessary turns on slopes, and if it proves

necessary , turn slowly and gradually do wnw ard, if possib le.

• Watch out for and avoid driving over furrows, holes, and

bumps. It is easier for the machine to overturn on uneven

ground. Tall grass can hide obstacles.

• Drive slowly. Do not turn the wheel sharply.

• Be extra cautious with any additional equipment, which can

alter the machine’s stability.

• Do not mow near verges, ditches, or banks. The machine

can suddenly overturn if one wheel comes over the edge of

a steep slope or a ditch, or if an edge gives way.

• Do not mow wet grass. It is slippery, and tyres can lose

their grip so that the machine skids.

• Try not to stabilise the machine by putting a foot on the

ground.

• When cleaning under the machine, it may never be driven

near verges or ditches.

9

Never fill the fuel tank indoors

Safety Instructions

Children

• Serious accidents may occur if you fail to be on

guard for children in the vicinity of the machine.

Children are often attracted to the machine and

mowing. Never assume that children will stay put

where you last saw them.

• Keep children away from the mowing area and

under close supervision by another adult.

• Keep an eye out and shut off the machine if

children enter the work area.

• Before and during a reversing manoeuvre, look

backward and downward for small children.

• Never allow a child to ride with you. They can fall

off and seriously injure themselves or be in the way

for safe manoeuvring of the machine.

• Never allow children to operate the machine.

• Be particularly careful near corners, bushes, trees

or other objects that block your view.

Never allow children to operate the machine

Maintenance

• Stop the engine. Remove the ignition key before

making any adjustments or carrying out

maintenance.

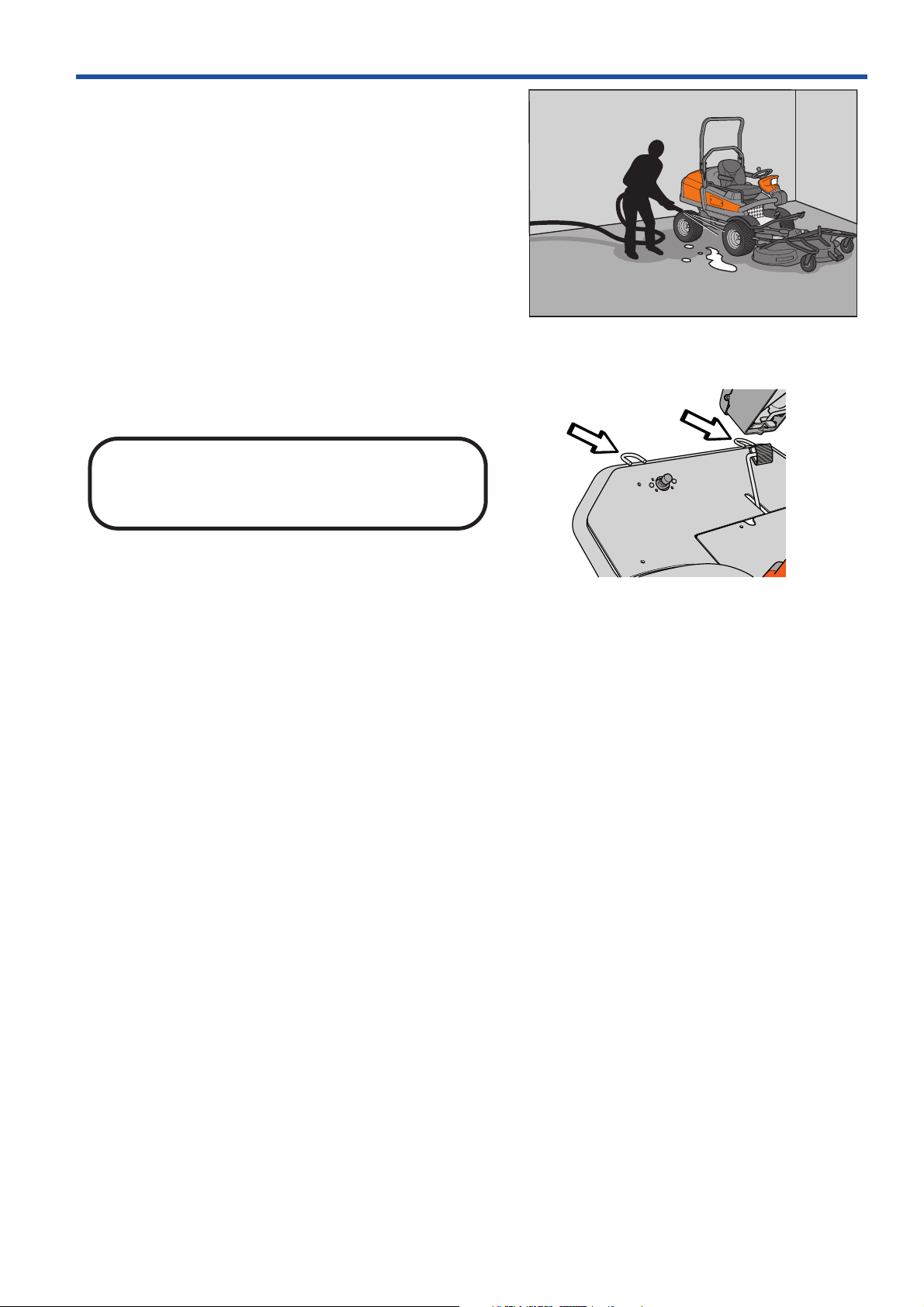

• Never fill the fuel tank indoors.

• Only store fuel in clean containers approved f or the

purpose.

• Never remove the fuel cap or fill the fuel tank with

fuel while the engine is running.

• Allow the engine to cool before refuelling. Do not

smoke.

• Handle oil, oil filters, fuel and the battery carefully,

of environmental considerations. Observe

applicable recycling regulations.

• Do not allow compressed air to come into contact

with skin. If compressed air penetrates the skin,

seek medical advice immediately.

• Seek medical advice immediately if skin comes into

contact with fuel, which that is under high pressure.

• The combustible material in some of the engine’s

components (e.g. certain seals) can be very

dangerous if ignited. Never allow burnt material to

come into contact with skin or eyes.

• Do not remove the filler cap or any other

component on the cooling system when the engine

is hot or under pressure, as hazardous hot coolant

can spray out.

10

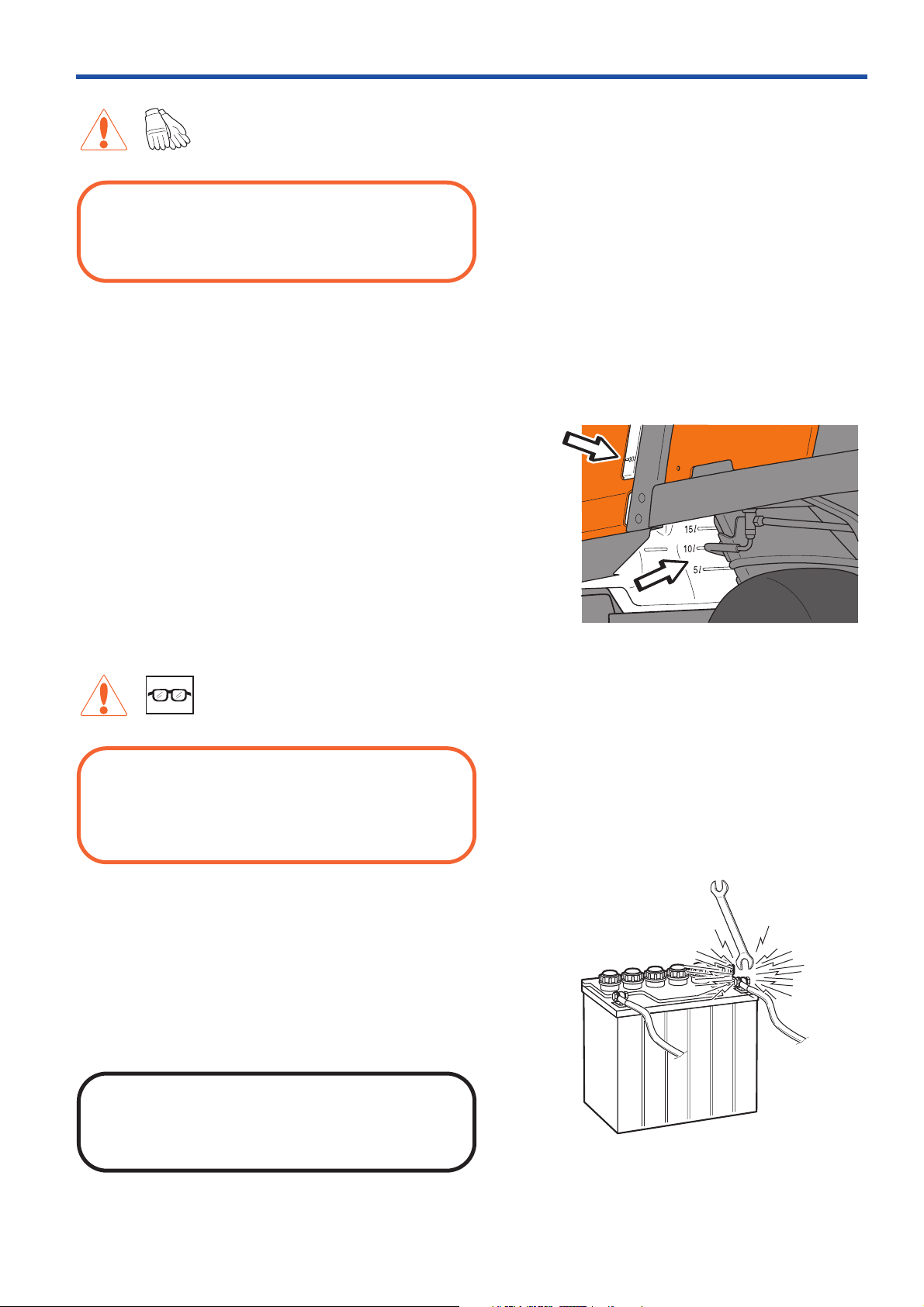

Tank with level window

Risk of sparking

WARNING:

The engine, exhaust system, cooling system and

hydraulic system components become extremely hot

during operation. Risk of burn injuries if touched.

Wear protective gloves

• If leaks arise in the fuel system, the engine must

not be star

• Store the machine and fuel in such a way that

there is no risk of leaking fuel or fuel vapour

leading to damages.

• Check the fuel level before each use and leave

space for the fuel to expand, because the heat

from the engine and the sun may otherwise cause

the fuel to expand and overflow.

ted until the problem has been resolved.

Safety Instructions

• Avoid overfilling. In the event of spilling fuel on the

machine, wipe it up before starting the engine. If y ou

spill petrol on your clothing, change your clothing.

• Material that has been contaminated by fuel must be

moved to a fire proof and environmentally safe place.

• Allow the machine to cool before taking any

actions in the engine room.

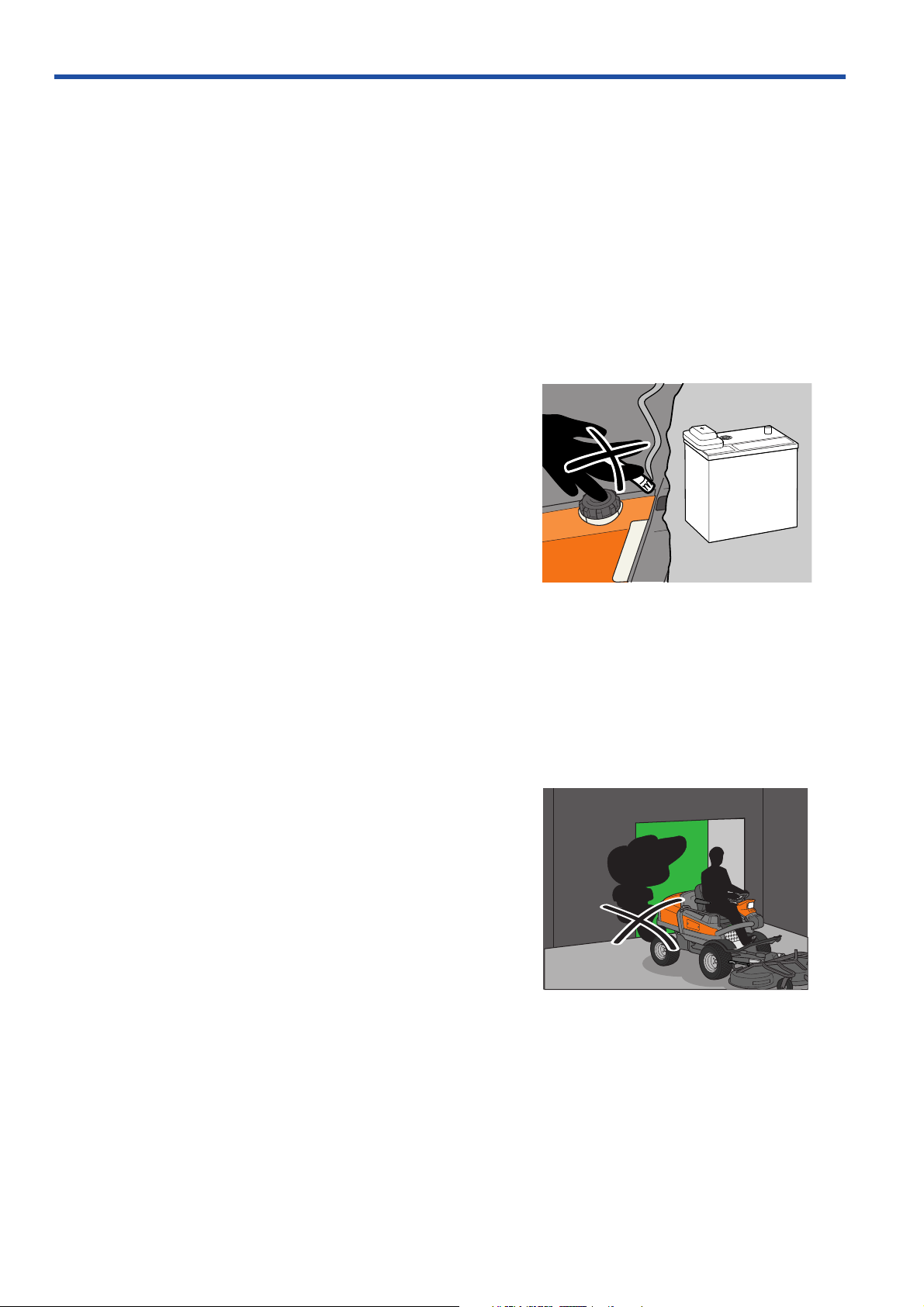

WARNING:

The battery contains lead and lead compounds,

chemicals that are considered to cause cancer, birth

defects, and other reproductive system damage.

Wash you hands after touching the battery. Use

protective goggles when working with the battery.

• Sparking can occur when working with the battery

and the thick cables in the starter motor circuit.

This can cause the battery to explode, fire or eye

injuries.

Sparking in the circuit can not occur once the

battery's power connection cable (usually the black

negative cable) has been disconnected.

Avoid sparking and its consequences by:

Wearing protective glasses.

Make sure that the fuel cap is fitted and that no

IMPORTANT INFORMATION:

11

Safety Instructions

Do not smoke when carrying out maintenance

Never drive the machine in an enclosed space

flammable liquids are stored in an open container.

Do not w

ork on the starter motor circuit in the vicinity of

spilt fuel.

Disconnect the battery's power connection cable (usually

the black negative cab le) first and connect it last.

Exercise care with tools so that short circuiting does

not occur.

Do not short circuit across the starter relay's

connections to run the starter motor.

• Be especially careful when handling battery acid.

Acid on the skin can cause serious corrosive

injuries. In the event of spillage on the skin wash

immediately with water.

• Acid in the eyes can cause blindness, contact a

doctor immediately.

• Be careful when servicing the battery. Explosive

gases form in the battery. Never perform

maintenance on the battery while smoking or in the

vicinity of open flames or sparks. This can cause

the battery to explode and cause serious injuries.

• Make sure all nuts and bolts are tightened correctly

and that the equipment is in good condition.

• Do not modify safety equipment. Check regularly to be

sure it works properly. The machine must not be driven

if protective plates, protective covers, safety switches or

other protective devices are not fitted or are defective.

• Do not change the settings of governors and avoid

running the engine with overly high engine speeds. If

you run too fast, you risk damaging the machine

components.

• Never use the machine indoors or in spaces lacking

proper ventilation. Exhaust fumes contain carbon

monoxide, an odourless, poisonous and highly

dangerous gas.

• Stop and inspect the equipment if you run over or into

anything. If necessary, make repairs before starting.

• Never make adjustments with the engine running.

• The machine is tested and approved only with the

equipment originally provided or recommended by the

manufacturer.

• The blades are sharp and can cause cuts and gashes.

Wrap the blades or wear protective gloves when

handling them.

• Check the parking brake’ s functionality regularly. Adjust

and maintain as required.

• The mulching unit should only be used where better

quality mowing is required and in known areas.

12

• Reduce the risk of fire by removing grass, lea ves

Clean the machine regularly

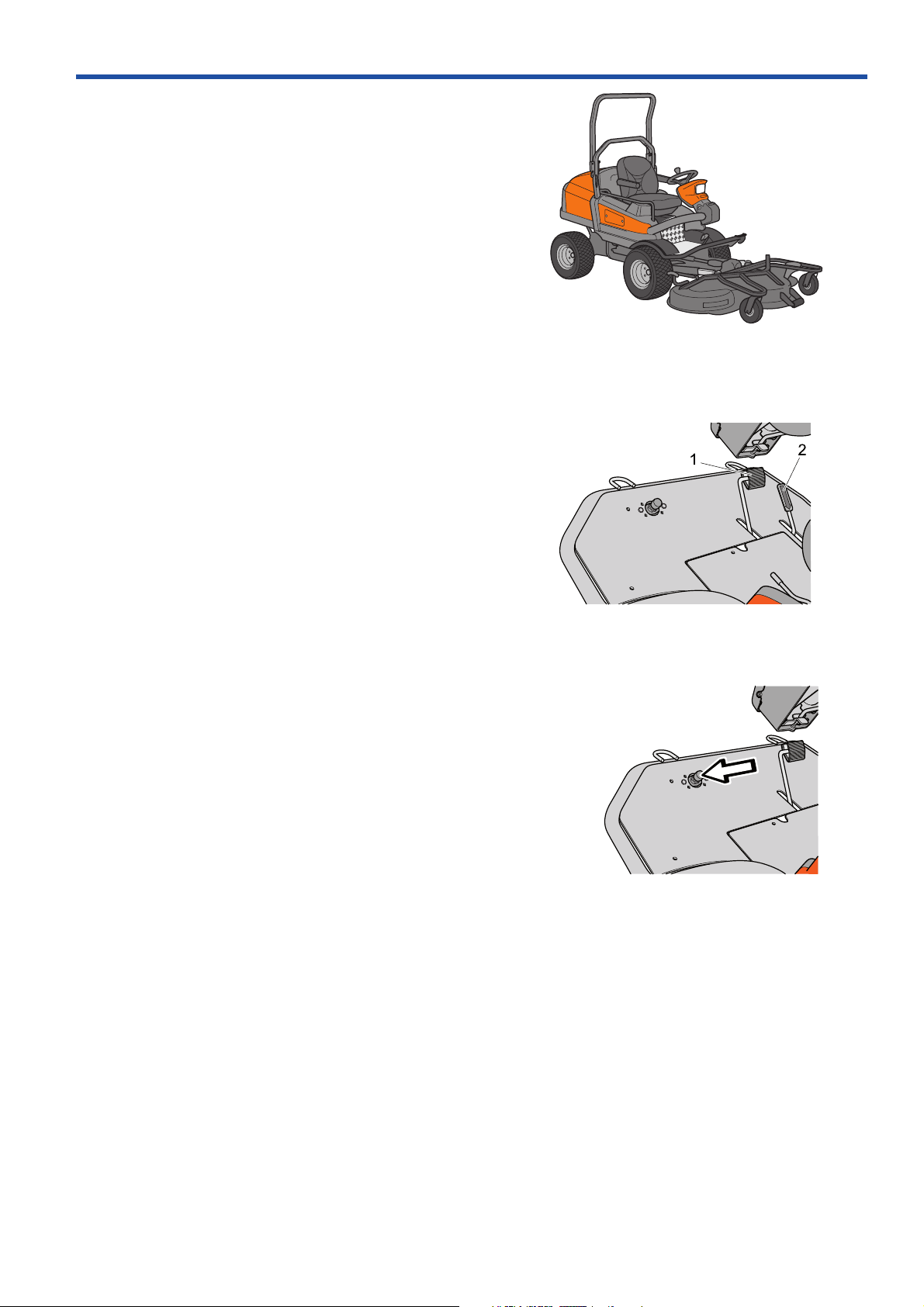

Front securing eyelets

and other debr

machine. Allow the machine to cool before

putting it in storage.

• Do not turn over the engine by hand without

preventing the engine from starting, which can be

done in different ways:

a. Remove the glow plug, no compression the

engine can therefore be easily turned over.

b. Loosen a pressure pipe connection on each jet

pipe a 1/2 turn.

c. Secure the injection pump stop arm in position for

zero supply.

is that may have fastened in the

Safety Instructions

Transport

IMPORTANT INFORMATION:

The parking brake is not sufficient to lock the

machine during transport. Ensure you secure the

machine firmly to the transporting vehicle.

The machine is heavy and can cause serious

crushing injuries. Be extra cautious when it is loaded

on or unloaded from a vehicle or trailer.

• Use an approved trailer to transport the machine.

Activate the parking brake and secure the

machine using approved fasteners, such as

straps, chains or ropes when transporting.

• Check and comply with laws and regulations

when driving on public roads, a traffic kit is

available as an option. This can be retrofitted on

PT 26D.

Environment protection

Take care of the environment, there are numerous

environmental risks especially when performing

maintenance on the machine. This particularly

applies when dealing with engine oil, hydraulic oil,

fuel, oil filters, hydraulic filters and fuel filters. You

must be attentive to ensure spillage does not occur

when you open a system that contains oil or fuel.

• Always wipe up spillage. When using cloths,

sawdust or oil absorbents, these should be

treated as environmental hazardous waste.

Follow local regulations.

• Choose an area, preferably with a concrete floor,

when you handle or store oils and fuel so that

you can clear up any spillage without it

penetrating into the ground.

• Avoid spillage, use a funnel and fill carefully.

• When draining, ensure that a suitably sized

container is placed correctly. Remember that the

oil does not always run straight down.

• Transfer the waste oil into a sealed container and

13

Safety Instructions

hand in for destruction. Remember to follow local

regulations

workshops or petrol stations that handle waste oil.

• Replaced oil and fuel filters are environmental

hazardous waste, handle them as waste oil.

• Do not spill fuel when refuelling. One litre of diesel

fuel can, according to the Swedish Rescue

Services Agency , destroy up to one million litres of

drinking water. Spilt fuel is a fire risk.

• Wash your hands thoroughly when the job is done.

• Coolant is poisonous and sweet. Ensure that

animals do not come into contact with open

containers or pools of fluid.

• Bear in mind the risk of grass fire when working in

dry vegetation. Never operate a machine with a

modified or damaged muffler, as sparks from the

exhaust fumes can set dry grass on fire.

. Gener ally you can deposit waste oil at

User responsibility

• Study and follow the safety instructions, see

“Safety Instructions” on page 7.

• Follow the maintenance schedule for care, see

“Maintenance Schedule” on page 71, lubrication

chart, see “Lubrication Schedule” on page 111 and

the instructions for operating the machine, see

“Presentation” on page 29 and “Driving” on

page 57.

• Follow the maintenance instructions, see

“Maintenance” on page 71, lubrication, see

“Lubrication” on page 111 and storage, see

“Storage” on page 133.

14

PT 26D

Speed control

Differential lock pedal

Presentation

Chapter 4: Presentation

Congratulations on your choice of an exceptionally

high quality product. This operator's manual describes

Husqvarna PT 26D.

It is fitted with a Perkins 3 cylinder diesel engine

developing 26 horse power.

PT 26D is equipped with hydraulic steering and

attachment lift. They are supplied with pressure from a

pump on the engine.

The machine is all wheel drive in low speed mode.

The power transmission from the engine is hydrostatic.

It is supplied with pressure by a pump under the

driver’s seat. A shaft with two flexible couplings powers

the pump. Flow and direction are regulated with the

pedals, so that forward and reversing speeds are

variably controlled. One pedal to drive f orwards (1) and

one pedal to reverse (2). The pump drives four

hydraulic motors in parallel, one for each wheel.

The power transmission is also used as service brake.

There are low and high speeds for driving. High or low

speed is selected using a switch.

The machine is equipped with an electro-hydraulic

differential lock, which is controlled by a pedal. The

differential lock only works longitudinally, which means

that you can turn the machine with the differential lock

activated.

The differential lock does not work in high speed.

Rear light, horn, direction indicators and rotating

warning lights are optional equipment (traffic kit).

The cutting unit takes power from the engine by means

of an electromagnetic clutch, two V-belts, apower takeoff shaft, a propeller shaft and a bevel gear.

15

Presentation

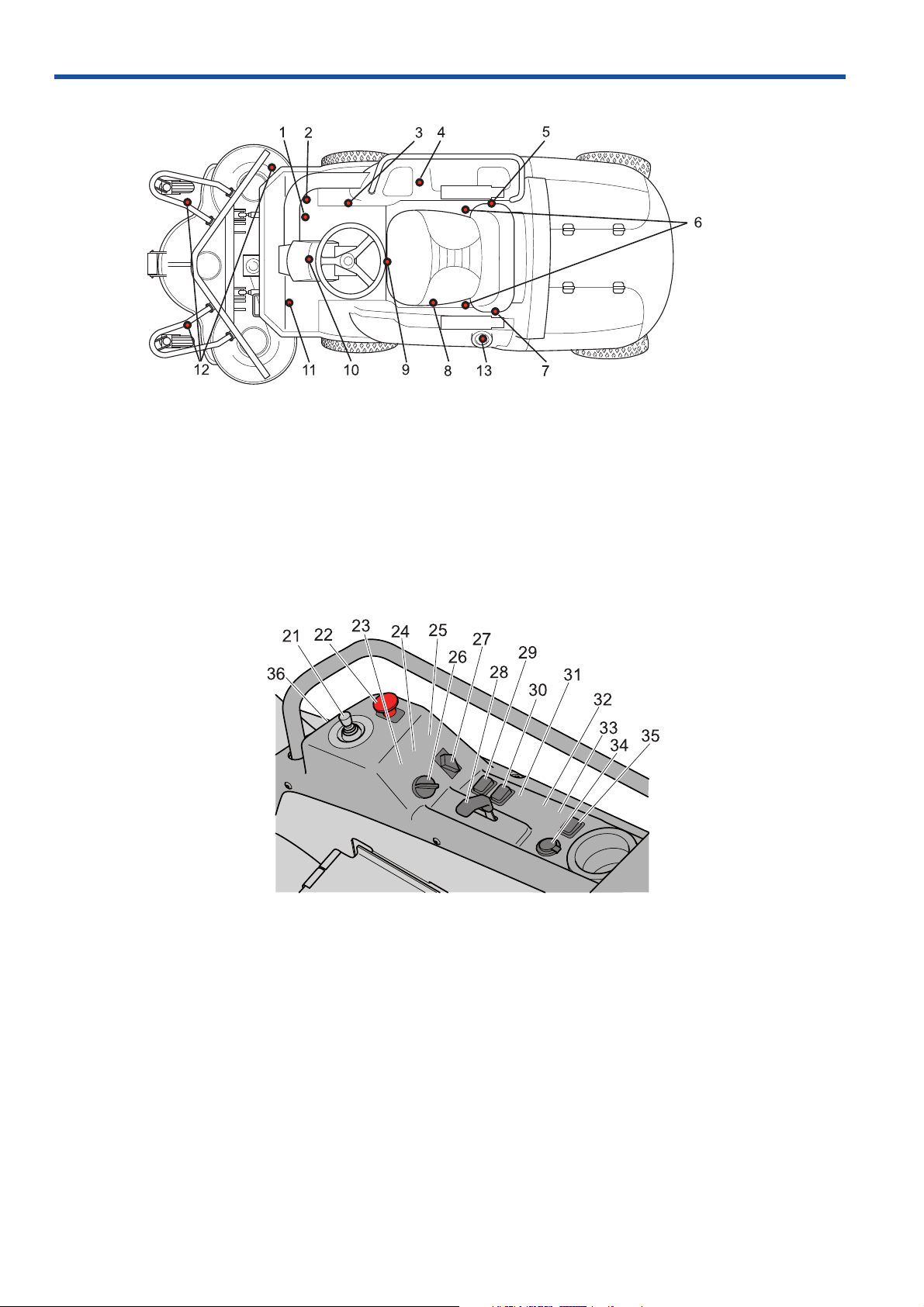

Placement of controls

1. Speed control for driving forwards page 17

2. Speed control for reversing page 17

3. Parking brake page 17

4. Control panel page 16

5. Knob for the backrest rake page 18

6. Catch for seat folding page 18

7. Knob for the lumbar support page 18

8. Lever for lateral seat adjustment page 18

9. Knob for seat suspension page 18

10. Steering wheel console page 17

11. Pedal for differential lock page 19

12. Cranks for setting cutting height page 19

13. Fuel tank cover page 19

16

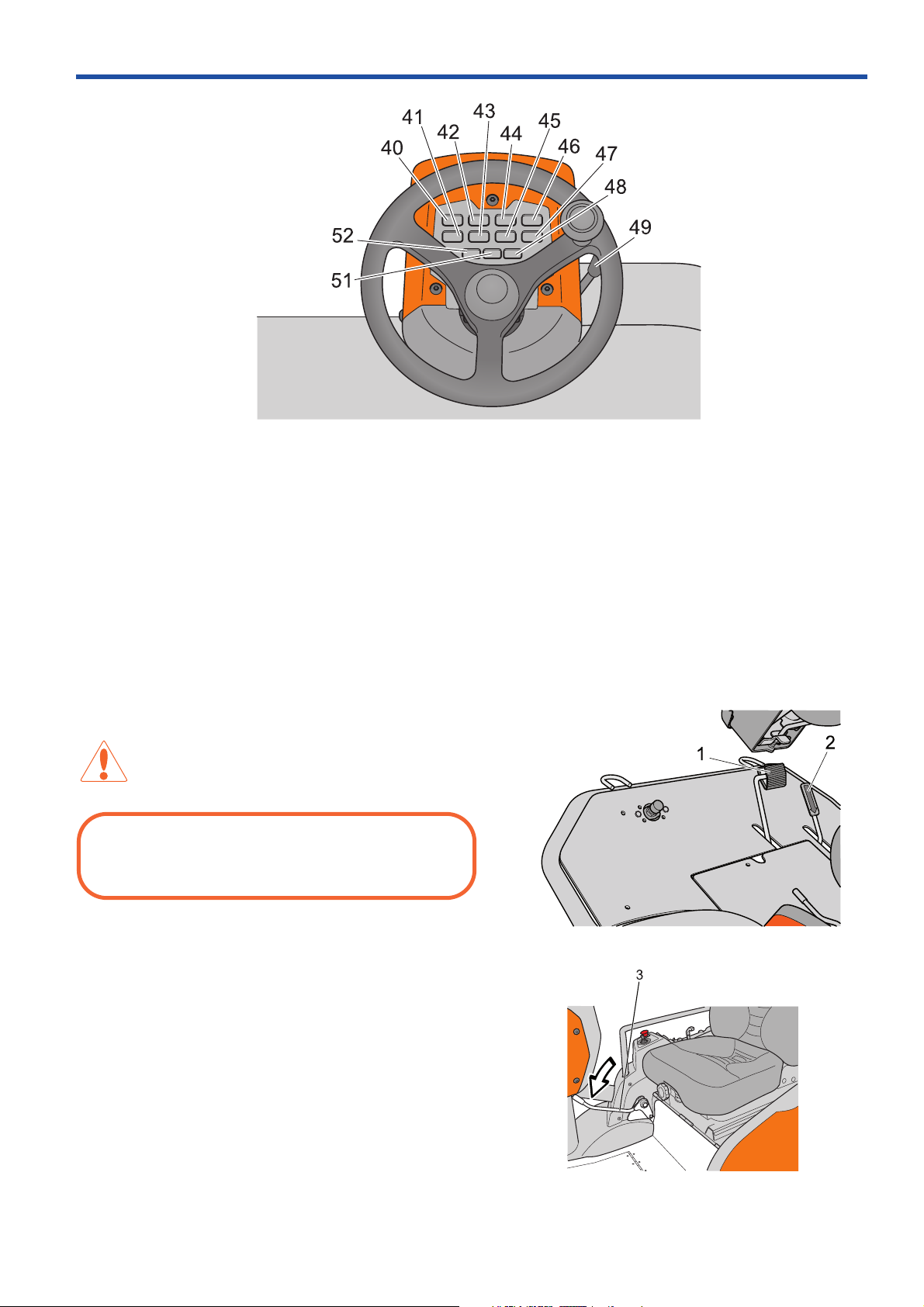

Control panel

21. Control lever hydraulics page 20

22. Switch for operating the cutting unit page 21

23. Switch for 2nd hydraulic function (option) page 21

24. Horn switch (option) page 21

25. Turn signal lights switch (option) page 21

26. Starter switch page 22

27. Switch for the lights page 22

28. Throttle control page 22

29. Switch for high and low speed page 22

-

30. Switch for weight transfer page 23

31. Rotating warning light (option) page 23

32. Parking lights (option) page 23

33. Spare

34. Power outlet page 23

35. Mains switch power outlet page 23

36. Chronometer page 24

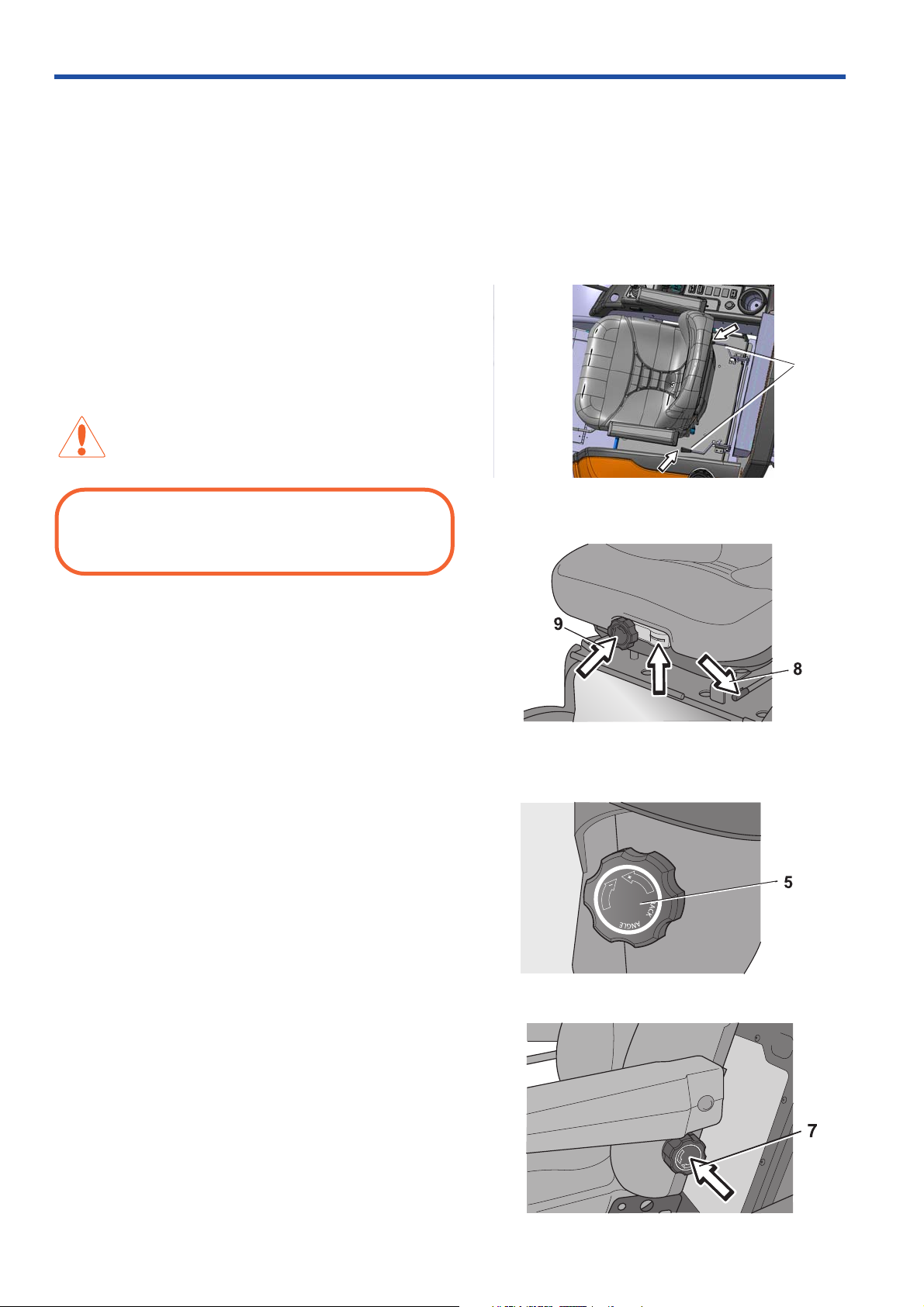

Steering wheel console

Speed control

Parking brake

Presentation

40. Warning lamp Battery charging page 24

41. Warning lamp Differential lock page 24

42. Warning lamp Coolant temperature page 24

43. Warning lamp Glow plug heating page 24

44. Warning lamp Engine oil pressure page 24

45. Warning lamp Cutting unit operation page 24

46. Warning lamp Parking brake page 24

1-2. Speed control

The speed of the machine is variably controlled using

two pedals. Pedal (1) is used to travel forwards and

pedal (2) to reverse.

WARNING:

Make sure that no branches can interfere with the

pedals when mowing under bushes.

47. Warning lamp High speed page 24

48. Warning lamp Right-hand indicator page 24

49. Lever for tilting the steering wheel console page 24

50. Warning lamp Full beam page 24

51. Warning lamp Left-hand indicator page 24

3. Parking brake

Apply the parking brake by moving the handle forward.

Release the parking brake by moving the handle back.

17

Presentation

Seat lock

6

Lateral adjustment and adjusting suspension

4. Control panel

There are controls and switches on the control panel

on the right-hand side of the driver that are used when

operating the machine. The lower section of the panel

is equipped with a cover over the machine’s fuses and

relays. See “21-37. Controls on the control panel” on

page 20.

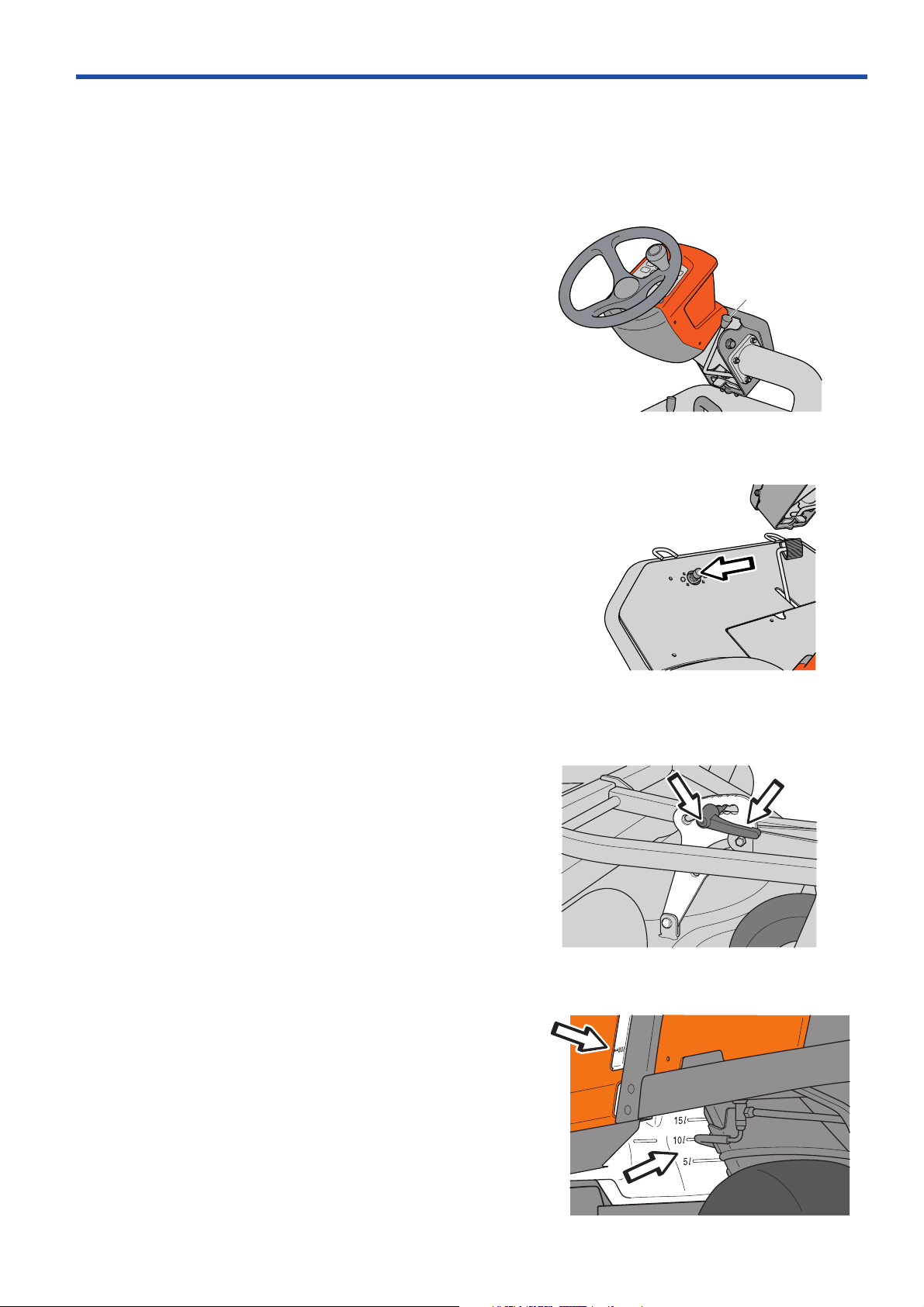

5-9. Seat

The seat has a hinged mounting on the front edge and

can be folded forwards.

To fold the seat forward, the steering wheel console

must be folded forwards and the lock (6) for the seat

operated.

WARNING:

Do not adjust the seat whilst driving. Risk of unsafe

operation.

The seat can also be adjusted lengthways:

• When making adjustments, the lever (8) under the

left-hand side of the seat is moved to the left, after

which the seat can be moved backwards or

forwards to the desired position.

• The seat’s suspension can be adjusted by turning

the knob (9) under the front edge of the seat. A

scale indicates the setting.

There are two knobs on the sides of the backrest:

• Backrest tilt is adjusted using the knob (5) on the

right-hand side of the seat.

• Lumbar support is adjusted using a knob (7) on the

left-hand side of the backrest.

18

Knob for the lumbar support

10. Steering wheel and steering wheel console

Steering wheel and steering wheel console

Differential lock pedal

Front cutting height adjustment

Tank with level window

The position of the steering wheel can be adjusted

vertically. The mounting for the steering unit in the

steering column can be adjusted vertically.

Depress the lever (49) and fold the steering wheel

console to one side to facilitate entering the driver’s

seat. The steering wheel console can be adjusted

lengthways.

See “40-51. Warning lamps” on page 24.

The headlights are set using the knob in the position

closest to the driver. In the second position the range

of the lighting will decrease.

Presentation

49

11. Differential Lock

The differential lock is electro-hydraulic. It is operated

by a pedal controlled switch. The differential lock only

works longitudinally, it ensures operation on at least

one front wheel and one rear wheel. This means that

you can turn the machine with engaged differential

lock without causing any interruptions in the power

transmission or damage to the lawn.

As the differential lock is not mechanical, it can be

engaged or disengaged without limitation, even when the

machine freewheels or in the ev ent of wheel spin. When

the pedal is released, the differential lock disengages

without the driver having to carry out any other

operations. The differential lock only works at low speed

and is active both up and down slopes.

12

.

Adjusting the cutting height

The cutting height adjustment allows the cutting height

to be adjusted in seven different positions 25.4 mm 127 mm (1” - 5”).

In order to obtain an even cutting height, it is important

that the settings are in the same positions and the air

pressure is the same in the front wheels, 100 kPa /

1.0 bar / 14.5 PSI and in the cutting unit’s pivot wheels

150 kPa / 1.5 bar / 21,7 PSI

When the adjustments have been made, the cr anks

should be released using the button in the crank and set

to a position that does not catch on any bushes or similar .

13. Fuelling

The fuel level in the tank is indicated in the sight glass.

Do not fill the tank completely , lea ve an area of at least 2.5 cm (1").

Fill the fuel tank with diesel. Do not use petrol under

any circumstances.

Use fuel with a cetane rating of above 45. Max RME

mixture 5 % in mineral oil based fuels. Aviation kerosene

(JP5, JP8 and Jet-A) can be used if lubricant additives

are used, but the starting ability may be affected. JP4 is

not recommended. Unmixed RME can be used.

19

Presentation

Raising the cutting unit with the lifting lever

Mowing Position

Do not smoke when filling the tank with fuel.

Diesel is less flammab

point. This varies depending on the type of diesel but is normally higher than +50 °C (120 °F).

Observe fuel hygiene. The diesel engine’s fuel injection system is very sensitive and can be damaged by

contaminants, which may be so small that they cannot be seen with the naked eye. Only use clean containers

(closed + dust-free funnel). Wipe away any dust before remo ving the fuel tank filler cap . There is a filter to protect the

fuel injection system, however if it becomes blocked operational malfunctions may occur. Rectifying damage,

operational malfunctions, filter replacement caused by poor hygiene are not repairs that are covered under warranty

Remember the environmental risks. See “Environment protection” on page 26.

Wipe up any spillages. Material that has been contaminated by fuel must be moved to a safe place.

If you spill fuel on your clothes, change to prevent skin irritations.

Winter fuel and paraffin precipitation

Malfunctioning can occur when driving in extremely

cold conditions on account of paraffin precipitation,

which can occur if using standard fuel. To avoid this,

winter fuel, diesel with additives to prev ent precipitation,

is sold in relevant climates . In certain regions different

types of summer and winter fuels are sold, in other

regions. winter fuel is sold all year round. Ask you fuel

supplier and only use winter fuel below 0 °C (+32 °F).

le than petrol at normal temperatures, but becomes very flammable if heated to the flash

21-37. Controls on the control panel

The control panel is prepared for optional extr as, which

are sold as accessories for PT 26D. Therefore, some

of the following control units may not be included with

your machine.

21. Control lever hydraulics

The lifting lever is used to put the cutting unit in either

the transport or mowing position when hydraulic

pressure is available.

Lifting the cutting unit (transport position)

Stop the blades by pressing in the s witch for driving the

cutting unit (22).

Pull the lever backward to engage the transport position.

The unit is then raised.

The cutting unit can be raised slightly with the blades

in operation. This is to facilitate work when cutting in

extremely tall grass or on uneven surfaces. The

machine is, however, equipped with an automatic

blade stop function, which is activated when the cutting

unit reaches the transport position. If the automatic

blade stop is activated, the switch (22) must be

pressed in and pulled out to restart.

Lowering the unit (mowing position)

Move the lifting lever forwards to engage the cutting

position. The unit is then lowered. The lever does not

need to be held in position, allow it to spring back to

the zero position when the unit has been lowered.

The blades are started with the switch for driving the

cutting unit (22).

Weight transf er can be activated, which means the cutting

unit follows the ground contour and une v enness on the

lawn more precisely. See “W eight tr ansf er” page 23

20

Other functions (option)

Switch for operation of cutting unit

When the le

operated to the 2nd hydraulic function, the terminals

are under the foot plate hatch.

ver is moved laterally, the oil pressure is

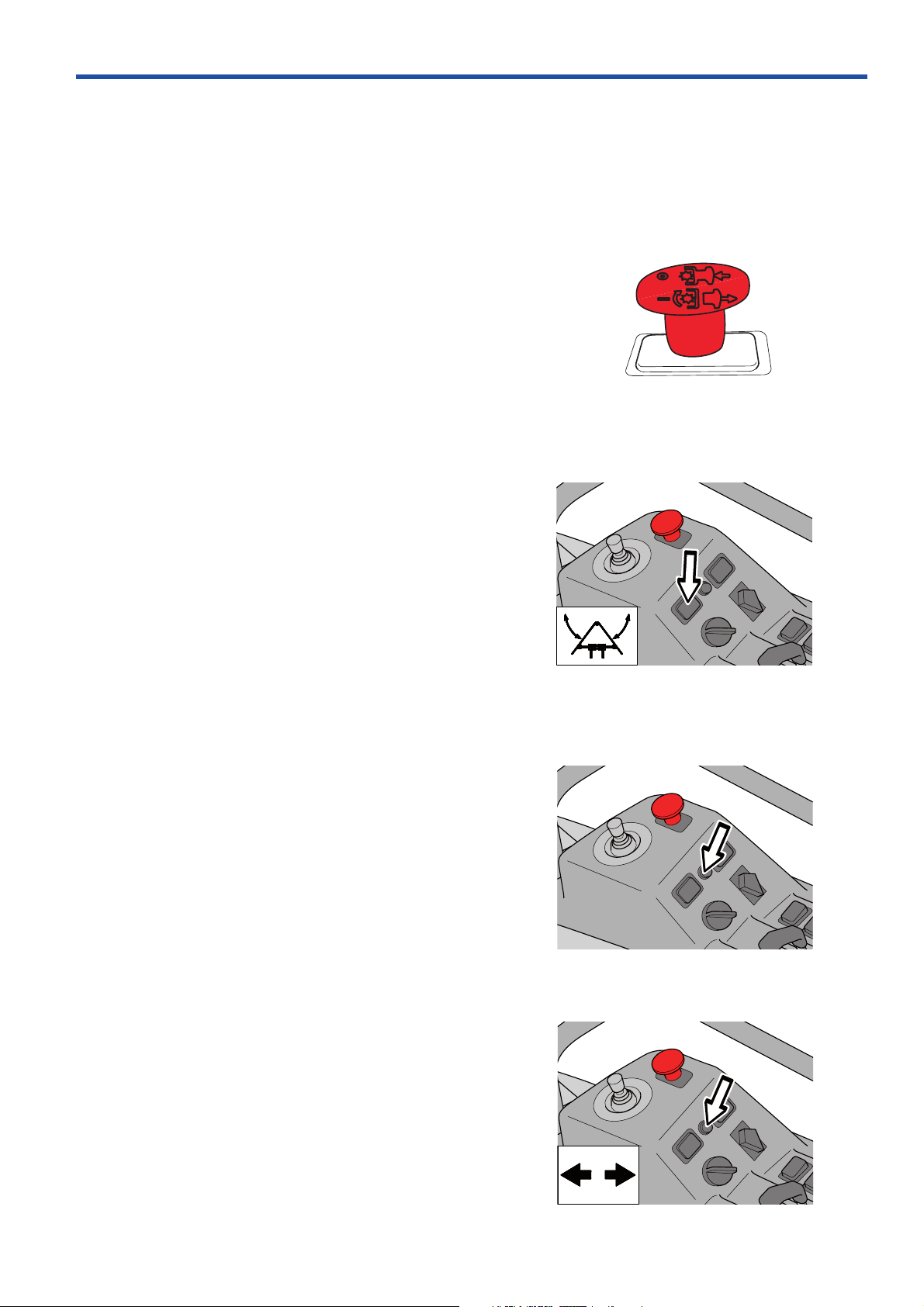

22. Switch for operation of cutting unit

The cutting unit can only be started when the driver is sitting in

the seat.

• Pull out the switch to engage cutting unit operation.

• Press in the switch to disengage cutting unit

operation.

If the safety circuit trips cutting unit operation, the

switch must be pressed in and pulled out again.

The safety circuit trips and the cutting unit stops:

When the cutting unit is raised to the uppermost

position

When the driver leaves the seat. There is a brief delay to

prevent stoppages should the driver bounce in the seat

When high gear is engaged.

When the starter is activated.

Presentation

23. Switch for extra hydraulic function

(hydraulic kit option)

The switch is used, among others, when steering the

folding plough for individual control of the left or righthand plough-blades. Operate the plough blade using

the lever (21).

24. Push button for horn (traffic kit option)

Switch for extra 12 V outlet

Switch for horn

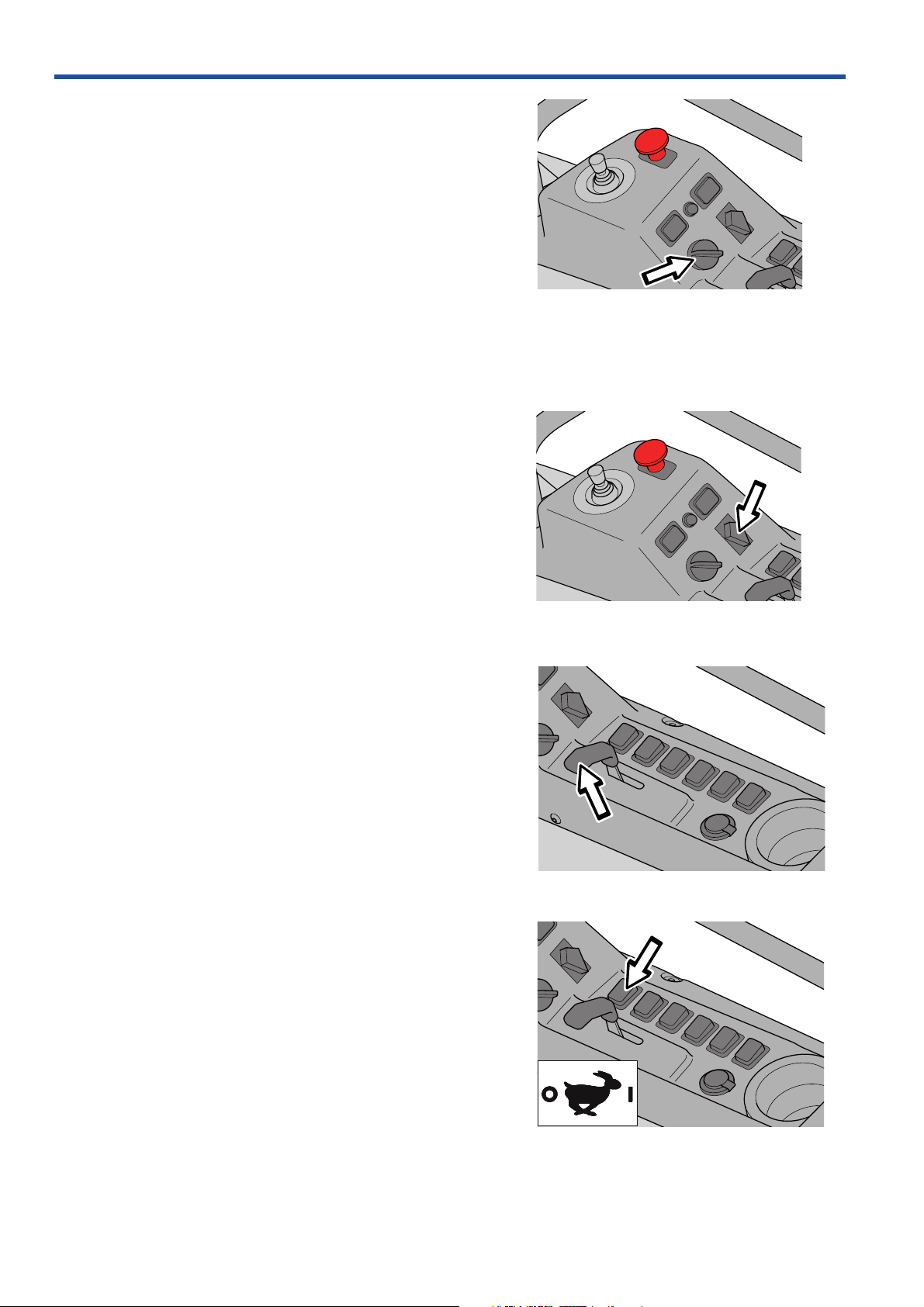

25. Indicators (traffic kit option)

Press for the left-hand or right-hand indicator. Blinkers

are switched off automatically after approximately

30 seconds or manually by pressing in the same

direction. A new 30 second period is activated if you

press after the blinkers have been switched off.

Pressing in the opposite direction while flashing,

activates the blinkers for the opposite side for

30 seconds.

Switch for indicators

21

Presentation

Throttle control

High speed

26. Starter switch

Three positions:

• OFF

All functions switched off. The engine is stopped. The

parking light can be switched on (traffic kit option).

•ON

Normal operating position.

• Start and Preheating

Keep the s witch in the glo w plug mode, when glow

plug heating is complete the starter is engaged.

During glow plug heating, light (43) on the indicator

panel comes on. Non-locking to position ON.

Turning again within 2 seconds gives starting

without glow plug heating.

27. Headlight

Three positions, clockwise in the following order:

Starter switch

• Off:

• Dipped beam

• Full beam

If the switch is moved to the Dipped beam position

automatic dipped beam mode, dipped beam is

switched on when the engine is running.

28. Throttle control

The accelerator is used to control the speed of the engine

and thereby also the rotation speed of the blades.

In order to increase or decrease the engine speed, the

control is moved forwards or backwards respectively.

29. High speed

Switch for headlight

Activated switch. This switch is used to select either

high or low speed.

The speed must drop to zero before the machine shifts

to low speed if high speed is actuated.

If the differential lock is actuated, the machine will not

shift to high speed until the pedal is released.

Front wheel drive is engaged in high speed mode.

All wheel drive is engaged in low speed mode.

The differential lock and cutting unit only work in low

speed mode.

22

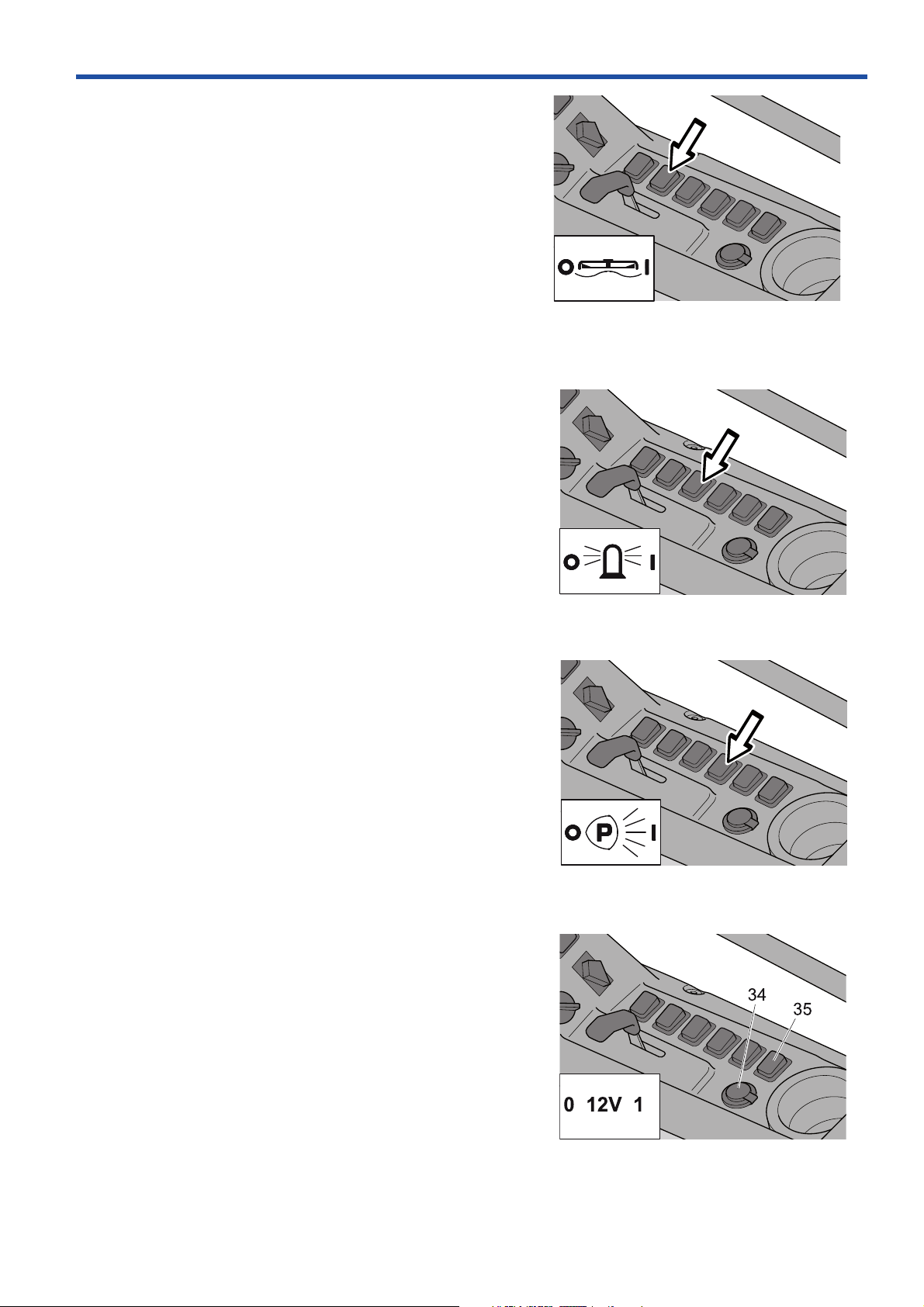

30. W eight transfer

Weight transfer

Rotating warning light

Parking lights

Power outlet with switch

Weight transf er is activated using this switch, transfers

a proportion of the unit’s weight to the machine. This

causes greater ground pressure on the machine’ s front

wheels and lower ground pressure on the unit’s pivot

wheels.

It is recommended to use weight transfer when lawn

mowing and sweeping. When snow clearing or

changing tools, the function should be off so that the

lifting arms can be lowered.

This function works when the lower position is selected

with control lever (21).

31. Rotating warning light (traffic kit option)

Observe any local traffic laws when using the warning

light.

Presentation

32. Parking lights (traffic kit option)

Can be lit using the switch even if the ignition switch is

not switched on. The battery will be completely drained

in approximately 20 hours.

The parking light is lit automatically when the engine is

running, even if the switch is not switched on.

33. Spare

34-35.Power outlet

A seat heater or mobile phone charger are examples

of articles that can be connected to the power socket (34).

The power outlet is switched on and off using power

switch (35) on the control panel.

The electrical outlet socket is fuse protected by its own

fuse FU11 (max. 10 A), which is located behind a

cover on the outside of the control panel.

23

Loading...

Loading...