Husqvarna PP 455 E Manual

GB ES

DE FR

Operator’s manual

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

Manual de |

PP 455 E |

instrucciones |

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

Bedienungsanweisung

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen

Sie sich mit dem Inhalt vertraut,bevor Sie das Gerät benutzen. GB ES DE FR

Manuel d’utilisation

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

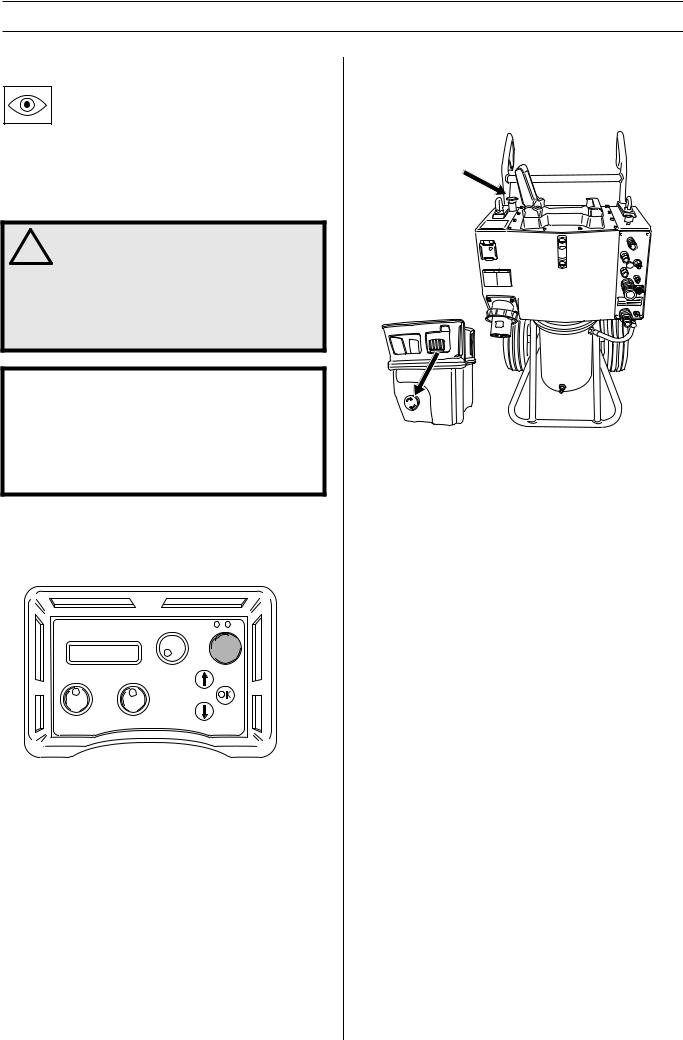

KEY TO SYMBOLS

Symbols on the machine:

WARNING! The machine can be a dangerous tool if used incorrectly or carelessly, which can cause serious or fatal injury to the operator or others.

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

Always wear:

• Approved protective helmet

• Approved hearing protection

•Protective goggles or a visor

•Breathing mask

This product is in accordance with applicable EC directives.

WARNING! High current.

Environmental marking.

Symbols on the product or its packaging indicate that this product cannot be handled as domestic waste. It must instead be submitted to an appropriate recycling station for the recovery of electrical and electronic equipment.

By ensuring that this product is taken care of correctly, you can help to counteract the potential negative impact on the environment and people that can otherwise result through the incorrect waste management of this product.

For more detailed information about recycling this product, contact your municipality, your domestic waste service or the shop from where you purchased the product.

Symbols in the operator’s manual:

Inspection and/or maintenance should be carried out with the motor switched off and the plug disconnected.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be worn.

2 – English

|

CONTENTS |

Contents |

|

KEY TO SYMBOLS |

|

Symbols on the machine: ............................................. |

2 |

Symbols in the operator’s manual: ............................... |

2 |

CONTENTS |

|

Contents ...................................................................... |

3 |

WHAT IS WHAT? |

|

What is what on the hydraulic unit? ............................. |

4 |

SAFETY INSTRUCTIONS |

|

Steps before using a new hydraulic unit ..................... |

5 |

Personal protective equipment ..................................... |

5 |

Machine′s safety equipment ........................................ |

6 |

General safety precautions .......................................... |

7 |

General working instructions ....................................... |

8 |

PRESENTATION |

|

PP 455 E ...................................................................... |

9 |

ASSEMBLY |

|

Assembling/Installing equipment ................................. |

10 |

SETTINGS AND ADJUSTMENTS |

|

Menu functions ............................................................. |

12 |

Start menu ................................................................... |

12 |

Operations menu ......................................................... |

12 |

Settings ........................................................................ |

14 |

STARTING AND STOPPING |

|

Wall sawing .................................................................. |

18 |

Wire cutting .................................................................. |

19 |

MAINTENANCE |

|

Error messages ............................................................ |

21 |

Service ......................................................................... |

22 |

Maintenance ................................................................ |

22 |

TECHNICAL DATA |

|

PP 455 E ...................................................................... |

23 |

EC-declaration of conformity ........................................ |

24 |

English – 3

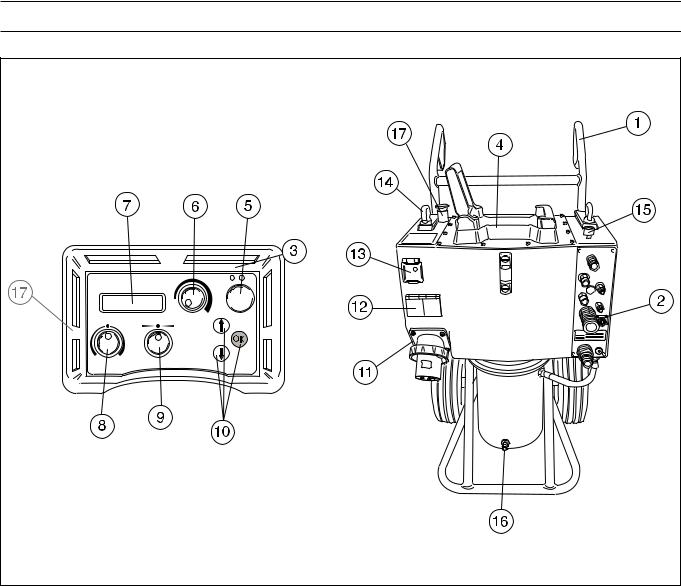

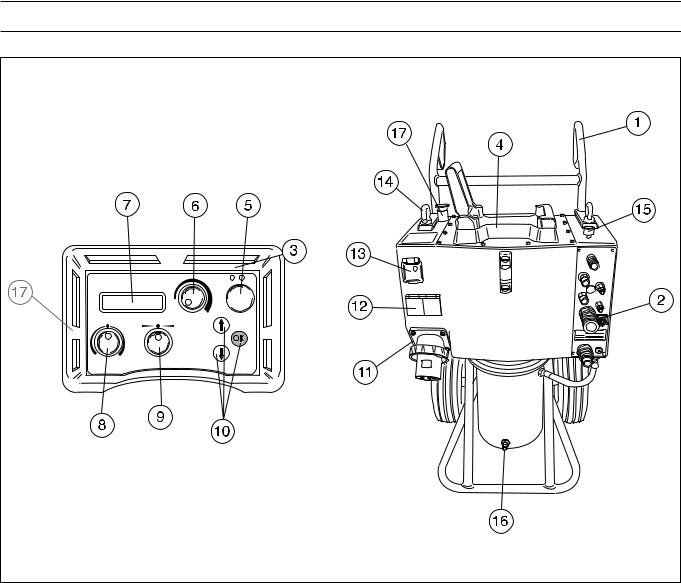

WHAT IS WHAT?

What is what on the hydraulic unit?

1 |

Handle |

10 |

Option keys |

2 |

Hydraulic hose connections |

11 |

Electrical socket |

3 |

Remote control |

12 |

230 V single phase socket |

4 |

Saw attachment |

13 |

Personal protection/Fuses |

5 |

Electric motor On/Off |

14 |

Lifting eye |

6 |

Blade rotation and start water coolant |

15 |

Water flow valve |

7 |

Display |

16 |

Water connector |

8 |

Depth feed |

17 |

Emergency stop |

9 |

Travel feed |

|

|

4 – English

SAFETY INSTRUCTIONS

Steps before using a new hydraulic unit

•Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

•This machine is only intended for use together with a Husqvarna WS 355, WS 463, WS 462, WS 460 and CS 2512. All other use is forbidden.

•Read through the manual supplied with the hydraulic tool before starting to use the machine.

•The machine can cause serious personal injury. Read the safety instructions carefully. Learn how to use the machine.

Always use common sense

It is not possible to cover every conceivable situation you can face. Always exercise care and use your common sense. Avoid all situations which you consider to be beyond your capability. If you still feel uncertain about operating procedures after reading these instructions, you should consult an expert before continuing.

Do not hesitate to contact your dealer if you have any more questions about the use of the machine. We will willingly be of service and provide you with advice as well as help you to use your machine both efficiently and safely.

Let your Husqvarna dealer regularly check the machine and make essential adjustments and repairs.

All information and all data in the Operator’s Manual were applicable at the time the Operator’s Manual was sent to print.

! |

WARNING! Under no circumstances should |

you modify the original design of the |

|

machine without approval from the |

|

|

manufacturer. Always use original spare |

|

parts. Unauthorised modifications and/or |

|

accessories may lead to serious injury or |

|

death to the user or others. |

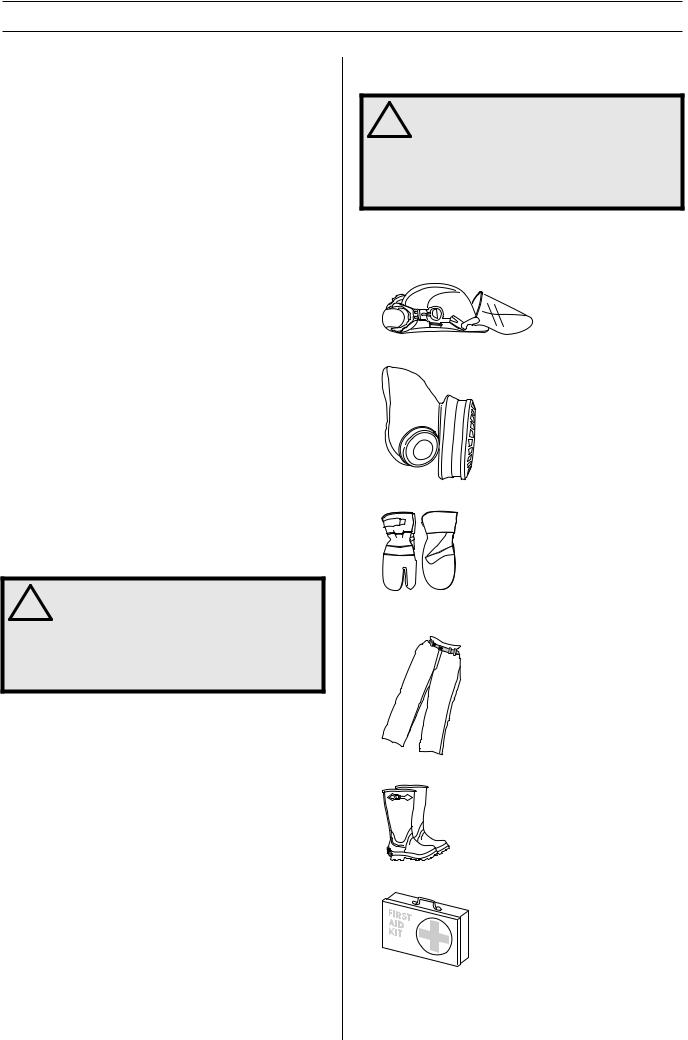

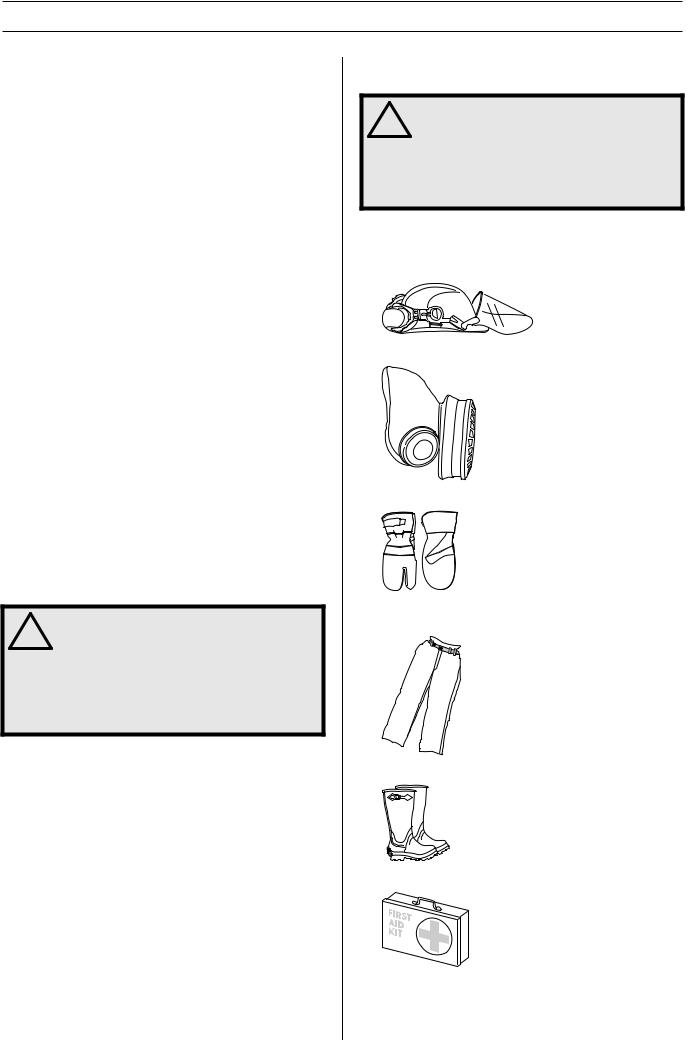

Personal protective equipment

! |

WARNING! You must use approved personal |

protective equipment whenever you use the |

|

machine. Personal protective equipment |

|

|

cannot eliminate the risk of injury but it will |

|

reduce the degree of injury if an accident |

|

does happen. Ask your dealer for help in |

|

choosing the right equipment. |

•Protective helmet

•Hearing protection

•Protective goggles or a visor

•Breathing mask

•Heavy-duty, firm grip gloves.

•Tight-fitting, heavy-duty and comfortable clothing that permits full freedom of movement.

•Boots with steel toe-caps and non-slip sole.

•Always have a first aid kit nearby.

English – 5

SAFETY INSTRUCTIONS

Machine′s safety equipment

This section describes the machine′s safety equipment, its purpose, and how checks and maintenance should be carried out to ensure that it operates correctly. See the ”What is what?” section to locate where this equipment is positioned on your machine.

! |

WARNING! Never use a machine that has |

faulty safety equipment! Safety equipment |

|

must be inspected and maintained. See |

|

|

instructions under the heading Checking, |

|

maintaining and servicing the machine’s |

|

safety equipment. If your machine does not |

|

pass all the checks, take it to a service |

|

workshop for repair. |

IMPORTANT! All servicing and repair work on the machine requires special training. This is especially true of the machine′s safety equipment. If your machine fails any of the checks described below you must contact your service agent. When you buy any of our products we guarantee the availability of professional repairs and service. If the retailer who sells your machine is not a servicing dealer, ask him for the address of your nearest service agent.

Start button

The start button must be pushed and held to be able to start the blade rotation.This in order to prevent unintended starting of the blade rotation.

Checking the start button

•Turn the knob for blade rotation without pushing and holding the start button. The blade rotation must not start.

•Push and hold the start button and turn the knob for blade rotation. Now the blade rotation shall start.

Emergency stop and stop button

The hydraulic unit is equipped with an emergency stop and the remote control with a stop button. These are used to be able to quickly shut down the hydraulic unit.

Check the emergency stop and stop button

•Start blade rotation

•Push the emergency stop on the hydraulic unit and check that the blade rotation stops. Check the stop button on the remote control in the same way.

6 – English

SAFETY INSTRUCTIONS

General safety precautions

Do not use the machine without first reading and understanding the contents of this Operator’s Manual.

! |

WARNING! There is always a risk of shocks |

from electrically powered machines. Avoid |

|

unfavourable weather conditions and body |

|

|

contact with lightning conductors and metal |

|

objects. Always follow the instructions in the |

|

Operator’s manual to avoid damage. |

•Never use the machine if you are tired, if you have drunk alcohol, or if you are taking medication that could affect your vision, your judgement or your co-ordination.

•Wear personal protective equipment. See instructions under the heading Personal protective equipment.

•Never carry the machine by means of the cord and never pull out the plug by pulling the cord.

•Keep all cords and extension cords away from water, oil and sharp edges. Make sure the cord is not pinched in doors, fences or the like. Otherwise it can cause the object to become live.

•Check that the cord and extension cord are intact and in good condition.

•Never use the machine if the cord is damaged, hand it in to an authorized service workshop for repair.

•Do not use an extension cord while it is rolled up to avoid overheating.

•The machine should be connected to an earthed outlet socket.

•Check that the mains voltage corresponds with that stated on the rating plate on the machine.

•Keep all parts in good working order and ensure that all fixtures are properly tightened.

•Never use a machine that is faulty. Carry out the checks, maintenance and service instructions described in this manual. Some maintenance and service measures must be carried out by trained and qualified specialists. See instructions under the heading Maintenance.

•Do not modify safety equipment. Check regularly that they function as they should.The machine must not be run with defective or disassembled safety equipment.

•Never allow anyone else to use the machine without first ensuring that they have understood the contents of the operator’s manual.

•People and animals can distract you causing you to lose control of the machine. For this reason, always remain concentrated and focused on the task.

•Be careful as clothing, long hair, and jewellery can get caught in moving parts.

•Observe care when lifting. You are handling heavy parts, which implies the risk of pinch injuries or other injuries.

Transport and storage

•Always switch off the power to the hydraulic unit and pull out the electric cable before moving the equipment.

•Store the equipment in a lockable area so that it is out of reach of children and unauthorised persons.

•Use the cases provided to store the equipment.

English – 7

SAFETY INSTRUCTIONS

General working instructions

WARNING! This section describes basic

!safety directions for using a wall saw. This information is never a substitute for professional skills and experience. If you get into a situation where you feel unsafe, stop and seek expert advice. Contact your dealer, service agent or an experienced user. Do not attempt any task that you feel unsure of!

•All operators shall be trained in the use of the machine. The owner is responsible for ensuring that the operators receive training.

•Check that all couplings, connections and hydraulic hoses are in full working order.

•Keep the hydraulic hoses and couplings free from dirt.

•Do not misuse hoses.

•Do not use hoses that are distorted, worn or damaged.

•Make sure that all hoses and electrical cables are connected to the machine correctly before you start the machine.

•Check that the hoses are connected correctly to the machine and that the hydraulic couplings lock as intended before pressurising the hydraulic system. The couplings are locked by turning the outer sleeve on the female coupling so that the slot moves away from the ball.

The pressure hoses in the system must always be connected to the tool’s intake. The return hoses in the system must always go to the tool’s outlet. Confusing the connections can cause the tool to work in reverse, which can result in personal injury.

•Never use the hydraulic hoses to lift the machine.

•Check the machine, couplings and hydraulic hoses daily for leakage. A rupture or leak can cause a ”hydraulic fluid injection” in the body or result in other serious physical injury.

•Never disconnect the hydraulic hoses without first shutting off and disconnecting the hydraulic unit and ensuring the motors have stopped completely.

•If despite all precautions an emergency situation should arise, press the red emergency stop button on the top of the unit or press the green start/stop button on the remote control.

•Do not exceed the specified hydraulic fluid flow or pressure for the tool being used. Excessive pressure or flow can result in rupturing.

•Do not check for leakage with your hands. Contact with the leak can result in serious personal injury caused by the high pressure in the hydraulic system.

•Check that power cables and the Canbus cable are not damaged or can be damaged while working.

•Working close to power lines:

Hoses that are marked and approved as electrically non conductive must be used when using hydraulic tools on or in the vicinity of electrical cables. The use of other types of hoses can result in serious physical injury or even death.

When replacing hoses, hoses marked non-conducting dielectric” must be used. The hoses must be regularly checked for their electrical conductive insulation in accordance with special instructions.

•Working close to gas conduits:

Always check and mark out where gas pipes are routed. Cutting close to gas pipes always entails danger. Make sure that sparks are not caused when cutting in view of the risk of explosion. Remain concentrated and focused on the task. Carelessness can result in serious personal injury or death.

•Run the hydraulic system until it reaches its operation temperature of 30°C before starting to saw, to reduce return pressure and other wear.

•Never leave the machine unsupervised with the engine running.

•Always saw in a manner that permits easy access to the emergency stop.

•Make sure that there is always another person close at hand when you use the machines, so that you can call for help if an accident should occur.

•People that need to be in close proximity of the machine must wear hearing protection as the sound level when cutting exceeds 85 dB(A).

•The safety distance is 4 meters (15 ft) from the machine.

•Do not use the machine in bad weather, such as dense fog, rain, strong wind, intense cold, etc. Working in bad weather is tiring and can lead to dangerous conditions, e.g. slippery surfaces.

•Ensure that the working area is sufficiently illuminated to create a safe working environment.

•Always ensure you have a safe and stable working position.

•Observe care when lifting. You are handling heavy parts, which implies the risk of pinch injuries or other injuries.

8 – English

|

PRESENTATION |

PP 455 E |

PP 455E is supplied with the following equipment: |

|

• 1 x hydraulic unit |

|

• 1 x remote control with radio control* |

|

• 1 x charging adapter (12 V/230 V)* |

|

• 1 x bag for the radio unit with accessories* |

|

• 1 x hose assembly, 8 m |

|

• 1 x Canbus cable, 8 m |

|

*The machine is only equipped with a radio on some markets. |

It is our wish that you will be satisfied with your product and that it will be your companion for a long time. Think of this operator′s manual as a valuable document. By following its′ content (using, service, maintenance etc) the life span and the second-hand value of the machine can be extended. If you will sell this machine, make sure that the buyer will get the operator′s manual.

A purchase of one of our products gives you access to professional help with repairs and services whenever this may be necessary. If the retailer who sells your machine is not one of our authorised dealers, ask him for the address of your nearest service workshop.

Husqvarna Construction Products has a policy of continuous product development. Husqvarna reserves the right to modify the design and appearance of products without prior notice and without further obligation introduce design modifications.

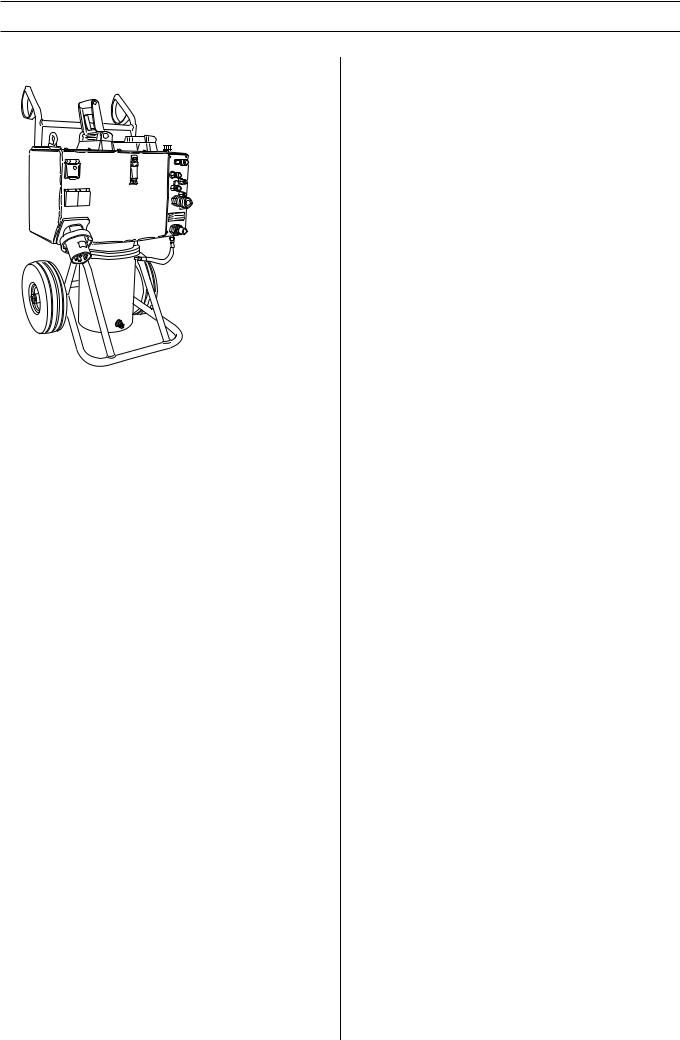

General

Husqvarna PP 455E is the latest hydraulic unit from Husqvarna. The unit is a further developed of the former unit PP 355E and has been produced to match the new Hsqvarna products and products to be launched in the future.

PP 455 is a very compact hydraulic unit, only 970 mm high.

Among the new major features is the water cooled motor, which means the user can use more power for longer periods than before. New improved software, adjustable handle and the possibility to attach a wall saw from the WS 400 series on the unit are other new features that facilitate the daily use of the product.

English – 9

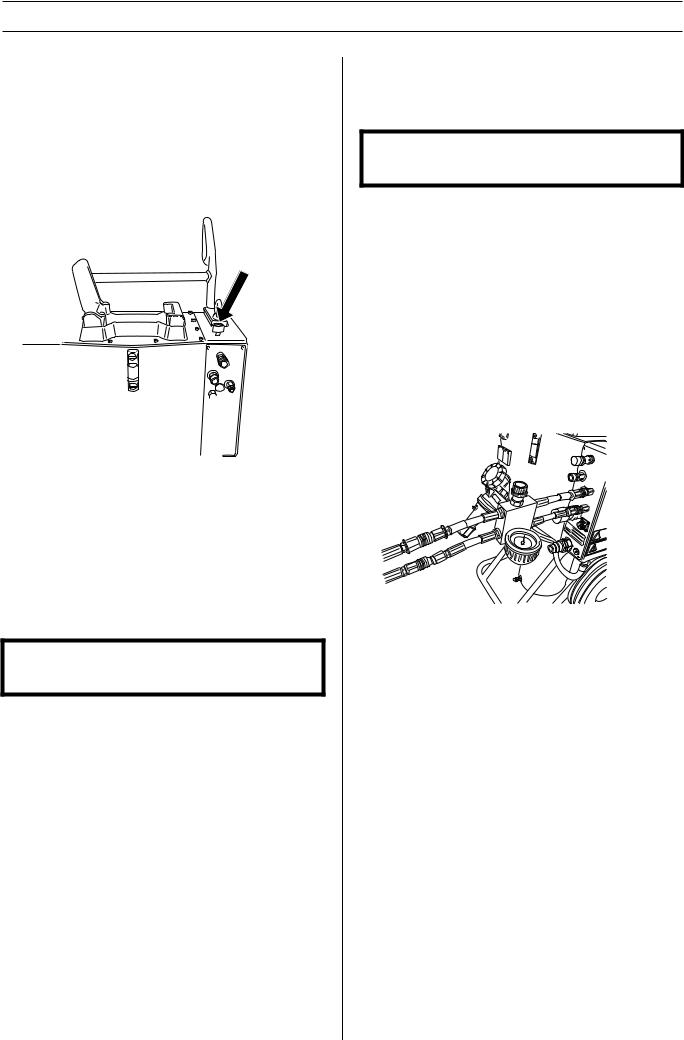

ASSEMBLY

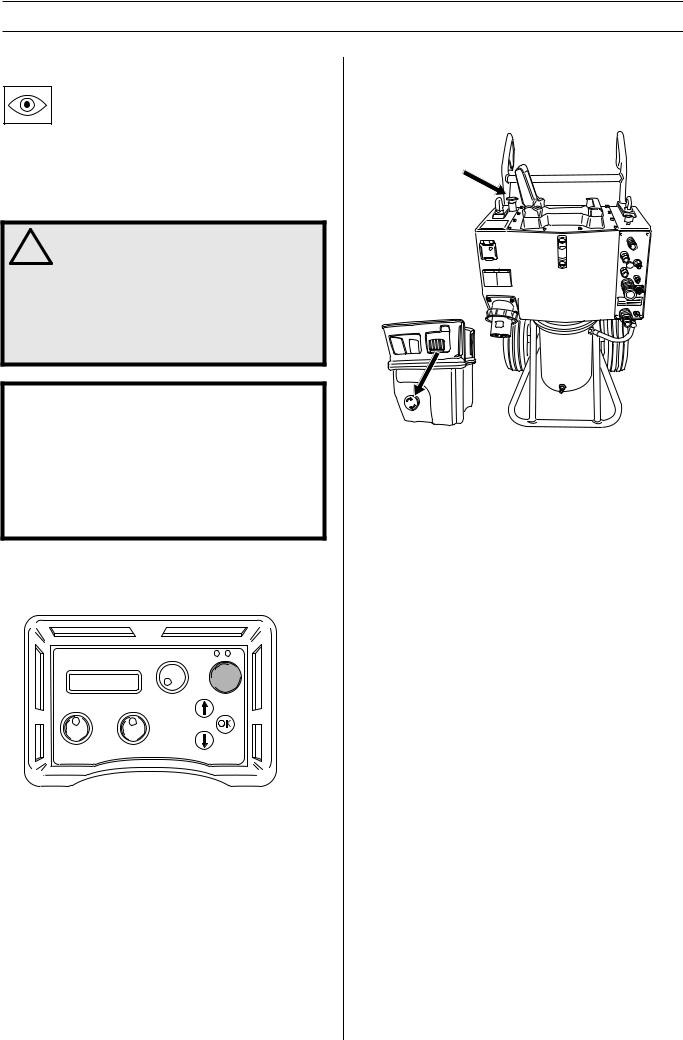

Assembling/Installing equipment

When the machine has been transported to a suitable site, it should be connected:

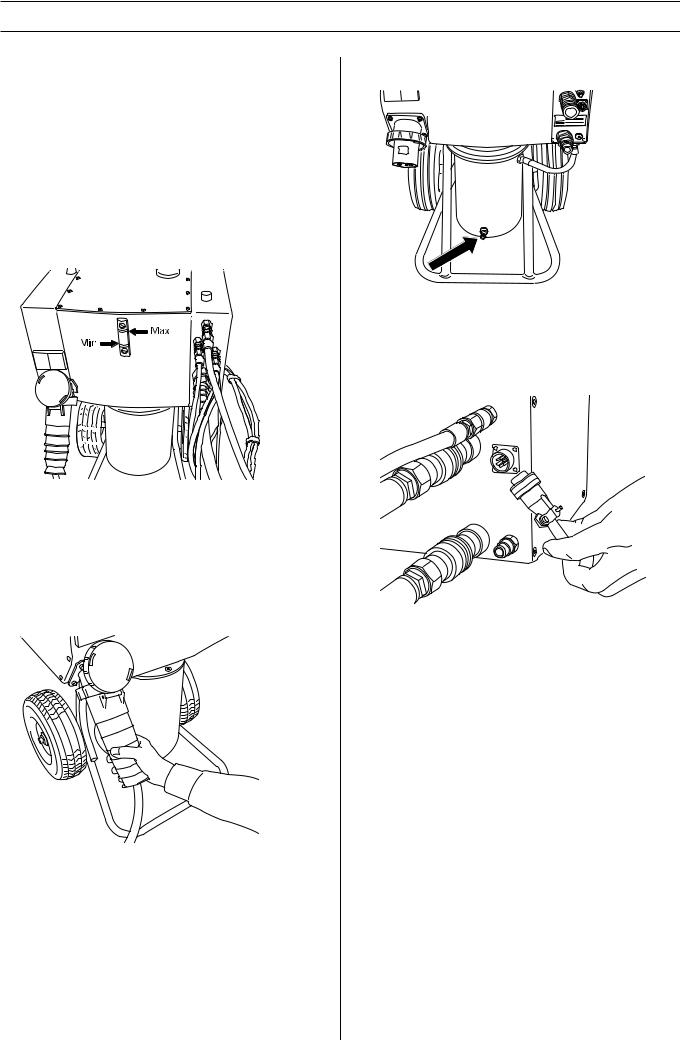

1Check the hydraulic fluid level in the power unit. This is checked with the level indicator.

Min. level = red line Max. level = black line

Do not exceed the max. level when filling the tank with hydraulic fluid. The hydraulic fluid expands when it gets hot and can overflow if the level is too high. Tank volume 16 l (4.2 US gallons).

2Connect the incoming power cable (400 V, 63 A or 400 V, 32 A European connector).The cable must be threephase and earthed. When the machine is equipped with a single phase socket there must also be a neutral otherwise the single phase socket on the distribution box will not work.

3The power unit must be connected through a 63 A fuse in order to use maximum power. If connected through a 32 A fuse, the saw must be operated at low pressure, and with that cut less effectively to avoid overloading the fuse.

4Connect the incoming water hose to the water coupling on the bottom of the motor front on the hydraulic unit.

5Connect the remote control using the supplied Canbus cable. Tighten the cable connector screws by hand.

When the machine is equipped with a radio, a radio antenna can be connected instead of a Canbus cable. This is screwed into the same socket as where the Canbus cable should have been fitted.

6Check that the emergency stop button on the power unit and the stop button on the remote control are not pressed by turning the them clockwise.

7The display now shows SELECT FUSE 32A”. If the available fuse is 32 A, confirm this by pressing the membrane key marked OK”. If there is a 63 A fuse available, press the membrane key marked up arrow”.The display now indicates SELECT FUSE 63A”. Confirm this by pressing the membrane key marked OK”. ( Menu functions / 2. Select fuse”.)

10 – English

ASSEMBLY

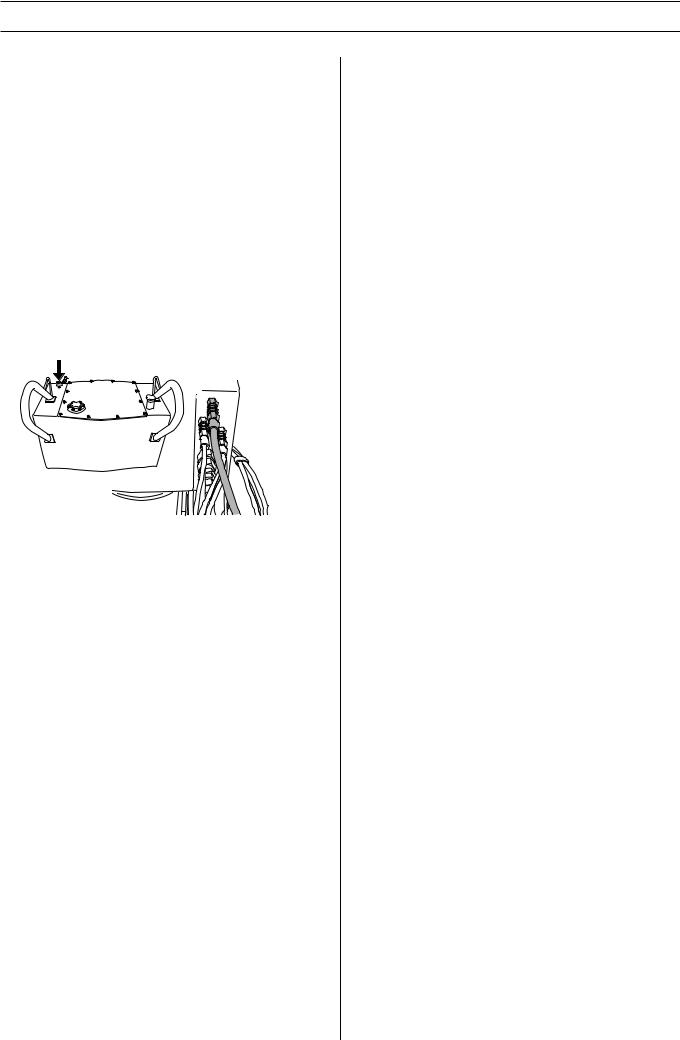

8Connect the hose assembly. In this position, connect the hydraulic hoses. A pressure equalizing function making it easier to connect the hoses is now activated. This spares the seals in the hydraulic couplings.

There are two types of hydraulic hoses for the unit:

-On a wall saw in the WS 400 series, the four thin hoses control the saw’s motion motors, i.e. the saw’s blade motion and the saw’s trolley motion. The two thick hoses drive the blade.

-When a wire saw CS 2512 is connected to the unit, the two thin hoses control the tension on the magazine arm while the two thick hoses drive the wire.

Some couplings on the unit have a red marking sign on the coupling. The hoses with red discs should be connected to these couplings.

9Connect the water hose between the unit and the saw’s water connector and open the water flow valve on top of the unit by turning the handwheel anticlockwise.

When the power cable and water hoses and hose assembly are connected, the machine can be started.

- Press OK to confirm the selection.

10The hydraulic output must be set according to which machine is connected to the hydraulic unit. Select one of the following:

-25 kW, 230 bar, 65 l/min

-15 kW, 210 bar, 45 l/min or

-9 kW, 140 bar, 40 l/min

11The display now shows HUSQVARNA PP 455E START ELECTRIC MOTOR”. If the display does not show this, follow the instructions shown on the display.

English – 11

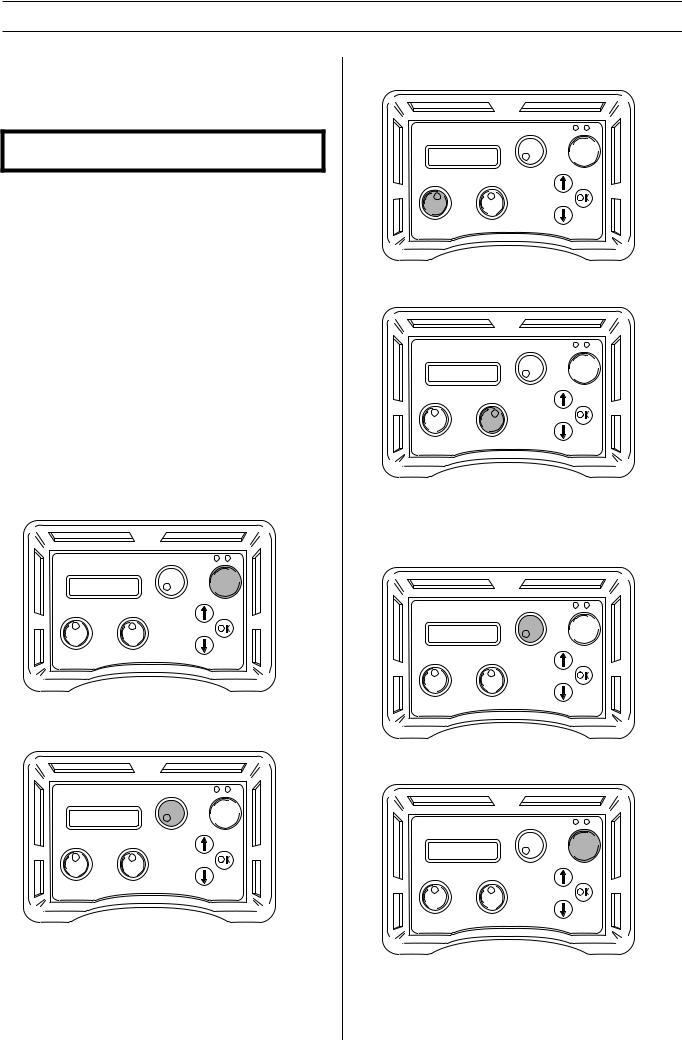

SETTINGS AND ADJUSTMENTS

Menu functions

The menus, shown on the display, are grouped in menus, sub-menus (Settings”) and part menus. The menus are divided into two sections:

•Start menu: Here you can select under which conditions the hydraulic unit shall work.

•Operations menu: Information concerning the operating status is shown here.

Start menu

The start menu is shown each time the power to the hydraulic unit is switched on. The menu consists of three steps:

Select fuse

The fuse rating must be set according to the fuse the hydraulic unit is connected to.

Select 16 A, 32 A or 63 A.

•Press OK to confirm the selection. Step three is then displayed.

Select the output

The hydraulic output must be set depending on the machine connected to the hydraulic unit. Select one of the following options:

•25 kW, 230 bar, 65 l/min (3300 psi, 17 US gpm)

•15 kW, 210 bar, 45 l/min (3000 psi, 12 US gpm)

•9 kW, 140 bar, 40 l/min (2000 psi, 10 US gpm) Press OK to confirm the selection.

Husqvarna PP 455E Connect hose assembly

•Press OK when all hoses are connected.

Operations menu

The operations menu starts after step 3 in the start menu. All information about operations and all setting options are accessed from this menu.

The operations menu consists of eight menus:

1a. Husqvarna PP-455, b Status

2Water coolant ON/OFF?

3Phase 1, Phase 2, Phase 3

4Settings

5Time

6Total machine time

7Battery status (only machines equipped with a radio)

8Radio channel (only machines equipped with a radio)

1.a Husqvarna PP-355, Start electric motor

Press the green button on the remote control to start the electric motor.

1b. Status

Status is the main information that is always shown on the display when the hydraulic unit with connected machine is operational:

•STATUS OK, signifies that the unit is operational and no warning messages have been issued.

•KV xx, where KV represents water coolant and xx ON or OFF. What is shown depends on whether the water coolant is switched on or off.

•yyy BAR, where yyy represents the instantaneous operating pressure.

•When time is switched on: mm:ss, is also shown, i.e. the time in minutes and seconds.

2. Water coolant ON/OFF?

Turn on and turn off the water coolant by pressing OK. The display then shows: STATUS OK KV OFF/ON yyy BAR. Now press arrow down to continue in the operations menu.

3. Phase 1, Phase 2, Phase 3

The instantaneous main voltage to the hydraulic unit is shown under each phase name.

When the voltage becomes low, an error message is shown on the display, see the section Error messages”.

IMPORTANT! Long electrical cables with a small core cross section can result in a voltage drop. The hydraulic unit can then warn of a too low voltage.

4. Settings

Via this sub-menu a number of values can be changed to affect the hydraulic unit’s characteristics.

To access the sub-menu: State the four digit PIN-code 0012 with the help of the arrow keys and the OK button.

To save the settings; select Save” in sub-menu 3 OUT SETTINGS”.

Refer to the SETTINGS” section for complete information about the setting options.

12 – English

SETTINGS AND ADJUSTMENTS

5. Time

The function is used to measure the amount of time a job takes. The time is counted from when the saw starts working.

Select:

•ON, to enable.

•OFF, to disable.

•RESET TIME, to reset.

Quit by pressing OK. The main information Status” is then shown on the display.

When you select time ON (and when the hydraulic unit is operational, see 1.b) 00:00 is also shown in the lower right corner of the display. Press arrow down to continue in the operations menu.

The total time that the hydraulic unit has been operational is shown here. The time is stated in hours and minutes (hhhh:mm).

7. Battery status (only machines equipped with a radio)

This function checks the remote control’s battery. Different messages are shown on the display, depending what is currently happening with the battery:

•0% BATTERY 100%

When the remote control is connected and the battery is being charged a horizontal column is shown below the 0 % - 100 % scale. The column length against the scale shows how much of the charge remains in the battery.

•CHARGING THE BATTERY

Shown when the remote control is connected and the battery is charging. The charging time from 0 % to 100 % is approximately 9 hours.

•BATTERY FULLY CHARGED

Shown when the battery is charged to 100 %.

•BATTERY DISENGAGED

Is shown when the battery is disengaged from the remote control.The message is also shown when the charging unit in the remote control has been damaged.

Charge the battery

IMPORTANT! This chapter only concerns machines equipped with a radio.

The remote control is equipped with a 7.2 volts battery. The emergency stop on the remote control should always be in the extended position when charging.

The battery can be charged as follows:

With the Canbus cable (Part No. 531 11 50-12)

With the charging cable to the 12 volts outlet in the car (Part No. 531 14 20-92)

With the charging cable to the battery charger (Part No. 531 11 72-54)

With the Canbus cable

Connect the Canbus cable between the remote control and the unit. Make sure that none of the emergency stops are pushed in and that the power unit is voltage fed.

Display CHARGING THE BATTERY”.

The power unit can be used during charging.

Charging takes approximately 10 hours.

With the charging cable

Connect the charging cable between the remote control and the 12 volt outlet in the car. Check that the emergency stop on the remote control is not pushed in. The display shows CHARGING THE BATTERY when charging is in progress.

The charging time is approximately 6 hours.

CAUTION! ONLY 12 V.

To charge with the battery charger

Connect the charging cable between the remote control and the battery charger. Now connect the battery charger to a 230 volts mains socket. Check that the emergency stop on the remote control is not pushed in. The display shows CHARGING THE BATTERY when charging is in progress.

The charging time is approximately 6 hours.

CAUTION! ONLY 230 V.

8. Radio channel (only machines equipped with a radio)

When the remote control is only used in battery mode, a radio antenna must first be connected to the unit:

Remove any cable connection.

Push in the antenna’s connector in the socket on the hydraulic unit. Make sure that the slot in the antenna connector aligns in the socket.

Screw on the connector’s ring on the socket.

A radio channel must be selected when the antenna is connected.

Select:

0, 1 or 2

Confirm the selection by pressing OK and then arrow down. The main information Status” is then shown on the display. Press arrow down again to continue in the operations menu.

English – 13

SETTINGS AND ADJUSTMENTS

Settings

All Setting options for the hydraulic unit and the remote control are accessed via this sub-menu.

A four digit code must be entered to access the settings submenu. This code is 0012.

The code is stated one digit at a time, from left to the right.The arrow keys scroll from 0-9 and the OK button confirms.

The SETTINGS” menu consists of seven sub-menus, which in turn consist of a number of part menus:

1.Select language

2.Adjust the hydraulic valve for the blade

3.Adjust the hydraulic valve for the feed

4.Sensor on/off calibrate

5.Hydraulic unit settings

6.Basic setting

7.Out settings

1. Select language

Using this sub-menu you can set the language you wish to use on the display.

The sub-menu always has the heading in English. The selected language is stated under heading.

To select the language:

•Scroll using the arrow keys until the required language is shown.

•Press OK to confirm the selection.

•Press the down arrow to continue to the next submenu.

2. Adjust the hydraulic valve for the blade

This sub-menu contains setting options for the rotation of the blade and consists of three part menus:

2.1Change the start point for the blade

2.2Change the end point for the blade

2.3Change the ramp time for the blade

2.1 Change the start point for the blade

The start point value should be adjusted so that the blade rotation is as low as possible when the blade rotation knob (pos. 2) is turned from its left-hand position.

A too low value results in the need to turn the knob before the blade starts to rotate.

A too high value results in the blade rotating too quickly when the knob is turned.

2.2 Change the end point for the blade

The end point value should be adjusted so that the blade rotation is as high as possible when the blade rotation knob is turned to the right.

A too low value results in full power from the hydraulic unit never being reached.

State the end point value:

•Press OK when the part menu is shown.

The display shows: CHANGE END POINT and a percentage value.

Scroll using the arrow keys to state the required end point. Hold the arrow key held down to increase the scrolling speed. The scale is graduated from 1-100 %.

•Press OK to confirm the selection.

•Press the down arrow to continue to the next part menu.

2.3 Change the ramp time for the blade

The ramp time value states how fast the blade’s speed of rotation shall change when the blade rotation knob is turned.

A too low value means the blade motor’s hydraulic system will start to self-oscillation.

State the ramp time value:

•Press OK when the part menu is shown.

The display shows: CHANGE RAMP TIME and the time in seconds.

•Scroll using the arrow keys to state the required ramp time. Hold the arrow key held down to increase the scrolling speed. The scale is graduated from 0.0 to 9.9 seconds.

•Press OK to confirm the selection.

•Press the down arrow to continue to Back to the menu”.

3. Adjust the hydraulic valve for the feed

This sub-menu contains setting options for blade feed, both horizontally and depth.

The sub-menu consists of five part menus:

3.1Change the start point for the trolley motion

3.2Change the end point for the trolley motion

3.3Change the start point for depth feeding

3.4Change the end point for depth feeding

3.5Change the ramp time for the feed

14 – English

SETTINGS AND ADJUSTMENTS

3.1 Change the start point for the trolley motion

The start point value should be adjusted so that the trolley motion is as low as possible when the trolley motion knob is in the zero position, i.e. in the middle of the left and right end positions.

A too low value results in the need to turn the knob further from the zero position before the trolley motion starts.

A too high value results in the trolley motion being too high when the knob is turned from the zero position.

IMPORTANT! Wear to the proportional valve and hydraulic motor can result in the need to adjust the start point value.

State the start point value:

•Press OK when the part menu is shown.

The display shows: CHANGE START POINT and a percentage value.

•Scroll using the arrow keys to state the required start point. Hold the arrow keys held down to increase the scrolling speed. The scale is graduated from 1-100 %.

•Press OK to confirm the selection.

•Press the down arrow to continue to the next part menu.

3.2 Change the end point for the trolley motion

The end point value should be adjusted so that the trolley motion speed is as high as possible when the trolley motion knob is turned to the right.

A too low end point value results in the full trolley motion speed never being reached.

State the end point value:

•Press OK when the part menu is shown.

The display shows: CHANGE END POINT and a percentage value.

•Scroll using the arrow keys to state the required end point. Hold the arrow key held down to increase the scrolling speed. The scale is graduated from 1-100 %.

•Press OK to confirm the selection.

•Press the down arrow to continue to the next part menu.

3.3 Change the start point for depth feeding

The start point value should be adjusted so that the depth feeding is as low as possible when the depth feeding knob is in the zero position, i.e. in the middle of the left and right end positions.

A too low value results in the need to turn the knob further from the zero position before the depth feeding starts.

A too high value results in the depth feeding being too high when the knob is turned from the zero position.

State the start point value:

•Press OK when the part menu is shown.

The display shows: CHANGE START POINT and a percentage value.

•Scroll using the arrow keys to state the required start point. Hold the arrow keys held down to increase the scrolling speed. The scale is graduated from 1-100 %.

•Press OK to confirm the selection.

•Press the down arrow to continue to the next part menu.

3.4 Change the end point for depth feeding

The end point value should be adjusted so that the depth feeding speed is as high as possible when the depth feeding knob is turned to the right.

A too low value results in the full blade feed speed never being reached.

State the end point value:

•Press OK when the part menu is shown.

The display shows: CHANGE END POINT and a percentage value.

•Scroll using the arrow keys to state the required end point. Hold the arrow key held down to increase the scrolling speed. The scale is graduated from 1-100 %.

•Press OK to confirm the selection.

•Press the down arrow to continue to the next part menu.

3.5 Change the ramp time for the feed

The ramp time value states how quickly the feeding speed shall change when the depth feeding knob or the travel feeding knob is turned.

The defined ramp time value for feeding applies to both for the depth feeding and the travel feeding speeds.

State the ramp time value:

•Press OK when the part menu is shown.

•The display shows: CHANGE RAMP TIME and the time in seconds.

•Scroll using the arrow keys to state the required ramp time. Hold the arrow key held down to increase the scrolling speed. The scale is graduated from 0.0 to 9.9 seconds.

•Press OK to confirm the selection.

•Press the down arrow to continue to Back to the menu”.

4. Sensor on/off calibrate

This sub-menu contains the setting options for the hydraulic unit’s different pressure sensors.

The sub-menu consists of seven part menus:

4.1Temperature sensor for hydraulic oil

4.2Voltage sensor

4.3Pressure sensor for hydraulic pressure

4.4Calibrate pressure sensor for hydraulics

4.5Calibrate voltage sensor

4.6Calibrate potentiometer

English – 15

SETTINGS AND ADJUSTMENTS

4.1 Temperature sensor for hydraulic oil

A temperature sensor is fitted by the water coolant duct. The sensor ensures that the water coolant is connected to the hydraulic unit. The water coolant cools the hydraulic oil.

When the temperature sensor is on, the control system continuously reads the temperature.

IMPORTANT! The hydraulic unit can be damaged, if the temperature sensor is switched off.

Turn on/ turn off the temperature sensor:

•Press OK when the part menu is shown.

The display shows: TEMP. SENSOR FOR HYDR. OIL and ON or OFF.

•Press OK to switch between ON and OFF.

•Press the down arrow to continue to the next part menu.

4.2 Voltage sensor

A voltage sensor is connected to each phase, i.e. in total three sensors. These measure the phase voltage to hydraulic unit. Should the voltage be 10 % less than the nominal voltage, the hydraulic unit stops.

IMPORTANT! The electric motor risks overheating due to a too low voltage, if the voltage sensors are switched off.

Turn on / turn off the voltage sensors:

•Press OK when the part menu is shown.

The display shows: VOLTAGE SENSOR and ON or OFF.

•Press OK to switch between ON and OFF.

•Press the down arrow to continue to the next part menu.

4.3 Pressure sensor for hydraulic pressure

The pressure sensor measures the hydraulic pressure to the blade.

IMPORTANT! The hydraulic unit’s control system switches off, if the pressure sensor is switched off. The hydraulic system may then be difficult to control with a high load.

Turn on/ turn off the pressure sensor:

•Press OK when the part menu is shown.

The display shows: PRESSURE SENSOR FOR HYDRAULIC PRESSURE and ON or OFF.

•Press OK to switch between ON and OFF.

•Press the down arrow to continue to the next part menu.

4.4 Calibrate pressure sensor for hydraulics

The pressure sensor that measures the oil pressure for blade rotation is possible to calibrate.

The pressure sensor must be calibrated according to the order zero point and maximum point.

To calibrate the zero point:

1Connect the incoming power cable to 63 A.

2Connect an oil pressure reducing valve with a pressure gauge to the blade rotation’s hydraulic couplings.

3Select the sub-menu Sensor on/off calibrate” from the Settings” menu.

4Scroll using the arrow keys and press OK when Calibrate pressure sensor for hydraulics” is shown.

5Press OK again when the display shows CALIBRATE ZERO POINT.

6Start the hydraulic unit.

7Adjust the oil pressure reduction valve to 0 bar.

8Press arrow up/down until the value for the oil pressure is shown as 0 bar, i.e. the same value as on the pressure gauge on the oil pressure reduction valve.

9Press OK to execute calibration.

To calibrate the maximum point:

IMPORTANT! Calibrate the zero point (see previous page) before the maximum point. This is so you do not miss to start the hydraulic unit.

1Select the sub-menu Sensor on/off calibrate” from the Settings” menu.

2Scroll using the arrow keys and press OK when Calibrate pressure sensor for hydraulics” is shown.

3Press OK again when the display shows CALIBRATE MAX POINT.

4Adjust the oil pressure reduction valve to 215 bar.

5Press arrow up/down until the value for the oil pressure is shown as 215 bar, i.e. the same value as on the pressure gauge on the oil pressure reduction valve.

6Press OK to execute calibration.

7Press the down arrow to continue to the next part menu.

4.5 Calibrate voltage sensor

To calibrate the voltage sensor:

1Scroll using the arrow keys and press OK when Calibrate voltage sensor” is shown.

2Select the voltage sensor (1-3) with the arrow keys and press OK.

3Connect a voltmeter between the phase and the earth on the sensor to be calibrated.

4Press arrow up/down until the defined voltage value on the display is the same as the value on the voltmeter.

5Press OK to execute calibration.

6Press the down arrow to continue to the next part menu.

16 – English

SETTINGS AND ADJUSTMENTS

4.6 Calibrate potentiometer

1This function is used when calibrating the zero positions on the knobs for depth feeding and travel feeding.

To calibrate the zero positions:

1Scroll using the arrow keys and press OK when Calibrate potentiometers” is shown.

The display shows: CALIBRATE 0 0. The left-hand digit refers to the depth feeding and the right digit refers to the travel feeding.

When the knobs are turned from the zero position the zeros are shown and a number of >>>. The number of arrows depends on how far the knobs are from the zero positions.

1Remove the knobs by unscrewing the screws located on the side of each knob. Use an allen key.

2Turn the shafts until only two zeros are shown on the display.

3Fit the knobs again.

4Adjust the plastic washer.

5Confirm with OK”.

6Press the down arrow to continue to Back to the menu”.

5. Hydraulic unit settings

This sub-menu contains information about the hydraulic unit and functions for setting of units and the PIN code. The submenu consists of six part menus:

5.1Husqvarna PP 455E version

5.2AM (American) units

5.3Radio ID

5.4ID Hydraulic unit

5.5.PIN code

5.6.Change the PIN code

5.1 Husqvarna PP 455E version

The display shows the version number, for example 2.0, for the software.

•Press the down arrow to continue to the next part menu.

5.2 AM (American) units

AM units. The display shows: AM units and ON or OFF. When the function is ON American units are used in the menu system.

•Press the down arrow to continue to the next part menu.

5.3 Radio ID

In order to make radio contact with the remote control and the hydraulic unit, an ID number must be stated. The CAN cable must be connected between the remote control and the hydraulic unit to change the ID number.

•Press OK when the display shows RADIOID 0 0.

The left-hand digit refers to the high byte and the right digit refers to the low byte.

•State, with the arrow keys, the high byte and press OK.

•State, with the arrow keys, the low byte and press OK.

•Press the down arrow to continue to the next part menu.

5.4 ID Hydraulic unit

From the factory the ID number is the same as the machine number. If the remote control or the hydraulic unit are replaced or reprogrammed, an ID number must be stated. As a suggestion, change to the hydraulic unit’s ID number.

The display shows the identity number for the hydraulic unit. The identity number must be greater than 0.

•Press the down arrow to continue to the next part menu.

5.5. PIN code

When the function is activated, a four digit PIN code is requested each time the remote control is switched on. The first time the code is 0000.When the wrong PIN code is stated 4 times in succession the hydraulic unit is locked A PUK code (provided by Husqvarna) must then be stated to unlock the unit.

The display shows: PIN code and ON or OFF.

To activate or deactivate:

•Press OK to switch between ON and OFF.

6. Basic setting

This function restores all the menu settings to the factory settings. The PIN code is also restored.

The display shows: DEFAULT SETTING and ON or OFF. OFF is shown when a change has been made that differs from the default settings.

7. Out settings

This function confirms or rejects all settings made before the operations menu is shown again.

•Press OK when the display shows OUT SETTINGS. The display shows: SAVE? NO.

To not implement the made settings:

Confirm with OK”.

To implement the made settings:

• Press arrow up/down to select YES.

Confirm with OK”.

English – 17

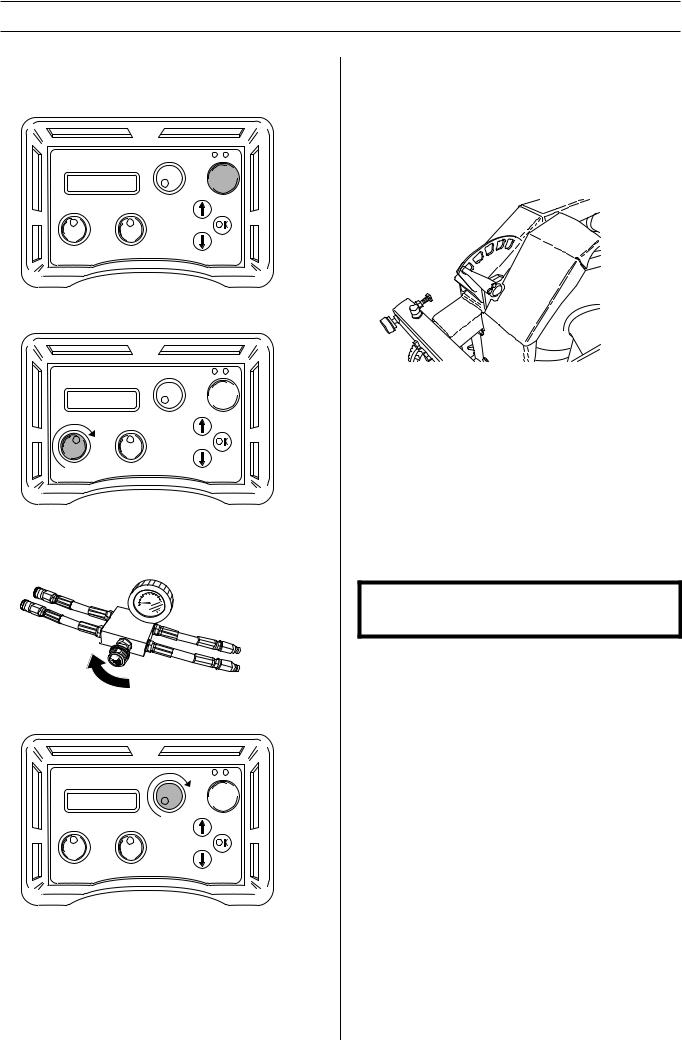

STARTING AND STOPPING

Wall sawing

Before starting

IMPORTANT! Make sure that the blade and blade guard are fitted correctly before turning on the hydraulic unit.

Before you start the motor, check that:

•The incoming electrical cable has been connected to a fuse rated at least 25 A.

•The 32 A or 63 A power setting is chosen.

If this is not done, a message in the display will prompt this when the start button is pushed.

•The hoses have been connected to a device.

•Run the hydraulic system until it reaches its operation temperature of 30°C before starting to saw, to reduce return pressure and other wear.

•All controls on the remote control have been set to zero position. If this is not done, a message in the display will prompt this when the start button is pushed.

Starting

1Start the electric motor by pressing the remote control’s green button once. The Y/D start takes place automatically. The rotation direction is always correct due to an automatic phase relay.

2Turn the controls for blade rotation and water coolant to their maximum positions to start blade rotation and the water coolant.

The amount of water can be adjusted manually with the knob on the top of the unit.

3Start the depth feeding by turning the depth feeding knob on the remote control in the desired direction.

4Start the horizontal motion by turning the horizontal motion knob in the desired direction.

Stopping

1After the work is completed, turn off the blade rotation and water flow by turning the blade rotation and water coolant start knobs on the remote control back to 0”.

2Turn off the electric motor by pressing the remote control’s green button.

18 – English

STARTING AND STOPPING

Water valve

When the power to the hydraulic unit is disconnected, the water valve opens so that the cooling system can be drained prior to transport and to avoid the risk of the cooler and motor freezing in sub-zero temperatures. The unit can be transported vertically or horizontally. If the power is cut during sawing, the water can be turned off by turning the water flow valve on top of the power unit clockwise to the stop position. The water flow connected to the hydraulic tool can also be reduced by turning the water flow valve.

Dismantling the equipment

1Allow the motor to stop completely.

2Disconnect the power supply cable before disconnecting the water hoses.

3Disconnect the hydraulic hoses.

4If there is a risk of freezing, drain the water from the oil cooler by disconnecting both hoses, opening the water flow valve, and tilting the unit forwards.

IMPORTANT! Always clean all the equipment at the end of the working day. Do not use a high pressure washer to clean the machine.

Wire cutting

Before starting

IMPORTANT! Do not connect the two thick hydraulic hoses to the wire saw before the cable is correctly fitted and tensioned, and all guards are correctly fitted.

•Before you start the motor, check that:

-The incoming electrical cable has been connected to a fuse rated at least 25 A.

-The 32 A or 63 A power setting is chosen. If this is not done, a message in the display will prompt this when the start button is pushed.

•Assemble the pressure reduction block supplied with the wire saw on the hydraulic unit according to the instructions on the block.

•Connect the two smaller hydraulic hoses to the pressure reduction block. The hoses in the hose assembly marked with a red disc by the coupling shall be connected to the hose on the pressure reduction block that is also fitted with a disc.

•Close the valve on the pressure reduction block by turning the knob anti-clockwise until it stops and then two turns back.

English – 19

STARTING AND STOPPING

Starting

1Start the electric motor by pressing the remote control’s green button once.

2Set the feeding flow on the unit to max by turning the control on the remote control clockwise.

3Tension the wire by carefully turning the knob on the pressure reduction block clockwise until the wire is tensioned sufficiently. Make sure to always check that the wire is seated correctly in all the wheels on the saw.

4Start the wire drive by turning the control for motor rotation on the remote control clockwise.

5Carefully increase the motor speed by turning the control for motor rotation. A suitable working pressure when cutting usually lies between 100 and 130 bar, but varies depending on how many wheel sets are used in the magazine, how much wire is in use and the hardness of the material to be cut.

6As the material is cut away the working pressure drops, which is shown on the display, and the magazine must then be tensioned. Do this by turning the knob on the pressure reduction block clockwise.

7The output tension on the magazine is shown by an indicator on the machine (shown in the min position). When the magazine cylinder is fully tensioned, the machine must be stopped and the wire must be wound around a new wheel set. Then continue to cut as above.

Stopping

•Lower the speed on the wire and allow the motor to stop completely.

•Turn off the electric motor by pressing the remote control’s green button.

•Disconnect the incomming cables from the hydraulic unit.

•Disconnect the hydraulic hoses and the water hose from the saw unit.

•The other steps are done in the reverse order to assembling.

IMPORTANT! Always clean all the equipment at the end of the working day. Do not use a high pressure washer to clean the machine.

20 – English

MAINTENANCE

Error messages

Nine different error messages can be shown on the display:

•NOTE! LOW VOLTAGE (1A) CHECK THE VOLTAGE SUPPLY AND THE CABLE TO THE HYDRAULIC UNIT

•LOW VOLTAGE PHASE X (1B) LOW POWER 32A

•MOTOR PROTECTION TRIPPED (2)

•MOTOR OVERHEATED (3) COOLING IN PROGRESS. DO NOT SWITCH OFF THE ELECTRIC MOTOR

•OIL TEMP. HIGH (4) CHECK THE WATER TO THE HYDRAULIC UNIT

•PRESSURE SENSOR OUT OF (5) ORDER

•HIGH HYDR PRESSURE (6) CHECK UNIT

•NO CONTACT CHECK THE CAN CABLE (7)

•NO RADIO CONTACT (8)

Error message (1A)

IMPORTANT! Low voltage Check the voltage supply and the cable to the hydraulic unit.

Too low voltage, caused by:

•Long mains cable.

•Too small core size (cross-section) on the mains cable. One or more phases down, caused by:

•A fuse has blown in the distribution box.

•Cable breakage.

•No voltage to one or more phases in the distribution box.

Action (1A)

Press OK to acknowledge the error message.

The hydraulic unit will match the maximum power output to 32 A.

Error message (1B)

Low voltage Phase x low output. 32 A”, where x represents phase 1, 2 or 3.

Action (1B)

Press OK to acknowledge the message. It states on the display that the maximum power output is set to 32 A. If the voltage is still low, the electric motor is turned off and the low voltage error message is shown.

By pressing OK, the unit returns to the maximum power you selected at start up.To switch between 63 A and 32 A, the unit must be turned off and then on again.

Read the supply voltage on the operations menu Phase 1, Phase 2, Phase 3”. If the voltage, before the motor is started, is:

•Below 340 V, check that none of the cores in the cable are broken and that there is voltage up to distribution box.

•Above 340 V, check the cable’s core dimensions and length.

Error message (2)

Motor protection tripped”

Cause (2)

The electric motor has been overload or a phase is down. This is why the motor cut-out, which is there to protect the electric motor, has tripped.

Action (2)

Press OK to acknowledge the error message. Check that there is voltage to the hydraulic unit on all three phases.

Read the supply voltage on the operations menu Phase 1, Phase 2, Phase 3”.

If the voltage to one phase is down: Check the mains cable and the voltage to the distribution box. The motor protection is reset automatically within three minutes.

If the voltage to all phases is higher than 340V: Wait for the motor cut-out to reset. Now restart the hydraulic unit.

If the motor cut-out trips frequently you should call the service personnel.

Error message (3)

Motor overheated cooling in progress. Do not turn off the electric motor!”

IMPORTANT! Do not turn off the motor, as this can damaged it. When the motor has cooled it is turned off automatically.

Cause (3)

The motor temperature sensor is too high.

Action (3)

Press OK to acknowledge the error message.

If after all it is necessary to turn off the engine, the error message must still be acknowledged by first pressing OK.

The display shows: COOLING. The hydraulic valves for blade and trolley motion are turned off. The blade motion can also be restarted.

When the motor temperature sensor drops below the limit level the display shows: MOTOR COOLED PRESS OK.

If the motor frequently overheats you should call the service personnel.

Error message (4)

Oil temp. high Check water to the hydraulic unit”

Cause (4)

Failure to cool the hydraulic oil.

Action (4)

When the error message is shown, the electric motor is turned off. Press OK to acknowledge the error message. Check that the water coolant is connected to the hydraulic unit and that the water runs to the blade when you turn the knob for blade rotation.

English – 21

MAINTENANCE

Error message (5)

Pressure sensor not working”

Cause (5)

The pressure sensor for measuring the hydraulic pressure to the blade rotation is not working.

Action (5)

Press OK to acknowledge the error message. If the error message is shown repeatedly, replace the pressure sensor.

Error message (6)

High hydr pressure check unit”

Cause (6)

The blade has jammed, which causes a high hydraulic pressure.

Action (6)

Press OK to acknowledge the error message. If the error message is shown frequently, you should call the service personnel.

Error message (7)

No contact Check the CAN cable”

Cause (7)

The CAN cable, or its connector is damaged, which results in the hydraulic unit not being possible to control via the remote control.

Action (7)

Press OK to acknowledge the error message. Check the cable and connector and replace if damaged. Contact the service personnel if the fault remains.

Error message (8) - applies to units equipped with a radio system

No radio contact”

Cause (8)

The radio contact between the hydraulic unit and remote control is not working.

Action (8)

Several actions may be necessary to rectify the fault:

•Ensure (via the operations menu - settings - radio id) that the identity number is greater than 0.

•Make sure that the hydraulic unit has been started.

•Move closer to the hydraulic unit to prevent long distances or reinforced walls.

Restart the remote control. Contact the service personnel if the fault remains.

Service

IMPORTANT! All types of repairs may only be carried out by authorised repairmen. This is so that the operators are not exposed to great risks.

After 100 hours of operation, the message "Time for servicing" is displayed. The entire equipment shall then be taken to an authorized Husqvarna dealer for servicing.

Maintenance

IMPORTANT! Inspection and/or maintenance should be carried out with the motor switched off and the plug disconnected.

Oil change hydraulic unit

There is a magnetic plug on the underside of the tank for draining the hydraulic fluid. Clean the magnet.

! |

WARNING! Remember that oil can pose a |

|

hazard to health and the environment. |

||

|

Open the screw cap on the tank and fill with hydraulic oil with a viscosity of 68. Make sure that the fluid level is about 10 mm below the max. mark on the level indicator.

About 16 litres of hydraulic fluid is required when changing.

Filter replacement

To change the filter, remove the tank cap after loosening the twelve screws. Loosen the three screws for the filter housing cover and remove it as well. Lift out the old filter cartridge and press in the new one, making sure it engages with the end of the tube in the bottom of the housing.

Daily maintenance

Regularly check:

•The hydraulic fluid level in the hydraulic power unit, to make sure it lies between the marks on the level glass.

•Check the tyre pressures.

•Any abnormal noises.

22 – English

TECHNICAL DATA

PP 455 E

Specified hydraulic output, kW/hp |

25/33,5 |

|

|

|

|

|

|

Max. hydraulic oil flow (at 63 A), l/min / gal/min |

65/17 |

|

|

|

|

|

|

Weight hydraulic unit incl. oil, kg/lbs |

140/310 |

|

|

|

|

|

|

|

|

|

|

Power supply |

|

|

|

|

|

|

|

Europe + Australia 5-pin |

400V |

(32-63A), 50Hz |

|

|

|

|

|

Europe + Asia 4-pin |

400V |

(32-63A), 50Hz |

|

|

|

|

|

Norway 5-pin |

400V |

(32-63A), 50Hz |

230V (80A), 50Hz |

|

|

|

|

Japan 4-pin |

200V |

(80A) 50, 60 Hz |

|

|

|

|

|

USA 4-pin |

480V |

(63-32A), 60 Hz |

|

|

|

|

|

Canada 4-pin |

600V |

(20-40A), 60Hz |

|

|

|

|

|

Optional equipment |

2 x 230 V wall socket |

|

|

|

|

|

|

|

|

|

|

Noise emissions (see note 1) |

|

|

|

|

|

|

|

Sound power level, measured dB(A) |

97 |

|

|

|

|

|

|

Sound power level, guaranteed dB(A) |

101 |

|

|

|

|

|

|

Sound levels (see note 2) |

|

|

|

|

|

|

|

Sound pressure level at the operators ear, dB(A) |

78 |

|

|

|

|

|

|

IMPORTANT! The higher ampere rating applies for maximum output.

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive 2000/14/EC.

Note 2: Noise pressure level according to EN ISO 11201. Reported data for noise pressure level has a typical statistical dispersion (standard deviation) of 1.0 dB(A).

English – 23

TECHNICAL DATA

EC-declaration of conformity

(Applies to Europe only)

Husqvarna AB, SE-433 81 Göteborg, Sweden, tel: +46-31-949000, declares under sole responsibility that the hydraulic unit Husqvarna PP 455 E from 2010´s serial numbers and onwards (the year is clearly stated in plain text on the type plate with subsequent serial number) is in conformity with the requirements of the COUNCIL’S DIRECTIVES:

•of May 17, 2006 "relating to machinery" 2006/42/EC

•of December 12, 2006 ”relating to electrical equipment” 2006/95/EC.

•of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

•of May 8, 2000 ”relating to the noise emissions in the environment” 2000/14/EC.

The following standards have been applied: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-3-11:2000, EN 982/A1:2008, EN 60204-1:2006.

Göteborg December 29, 2009

Henric Andersson

Vice President, Head of Power Cutters and Construction Equipment

Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

24 – English

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina:

¡ATENCIÓN! La máquina, si se utiliza de forma errónea o descuidada, puede ser una herramienta peligrosa que puede causar daños graves e incluso la muerte al usuario y a otras personas.

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

Utilice siempre:

• Casco protector homologado

• Protectores auriculares homologados

•Gafas protectoras o visor

•Máscara respiratoria

Este producto cumple con la directiva CE vigente.

¡ATENCIÓN! Corriente intensa.

Etiquetado ecológico.

El símbolo en el producto o en su envase indica que no se puede tratar este producto como desperdicio doméstico. Deberá por lo tanto depositarse en un centro de recogida adecuado para el reciclado de equipos eléctricos y electrónicos.

Haciendo que este producto sea manipulado adecuadamente, se ayuda a evitar consecuencias negativas potenciales para el medio ambiente y las personas, lo que puede ocurrir con la manipulación inadecuada como residuos del producto.

Para obtener información más detallada sobre el reciclado de este producto, contacte con la oficina municipal local, con el servicio de eliminación de desperdicios domésticos o con la tienda donde compró el producto.

Símbolos en el manual de instrucciones:

El control y/o mantenimiento de la máquina debe hacerse con el motor parado y el enchufe desenchufado.

Utilice siempre guantes protectores homologados.

La máquina debe limpiarse regularmente.

Control visual.

Debe utilizarse gafas protectoras o visor.

Spanish – 25

|

ÍNDICE |

Índice |

|

ACLARACIÓN DE LOS SÍMBOLOS |

|

Símbolos en la máquina: ............................................. |

25 |

Símbolos en el manual de instrucciones: .................... |

25 |

ÍNDICE |

|

Índice ........................................................................... |

26 |

¿QUÉ ES QUÉ? |

|

¿Qué es qué en la unidad hidráulica? ......................... |

27 |

INSTRUCCIONES DE SEGURIDAD |

|

Antes de utilizar una nueva unidad hidráulica ............. |

28 |

Equipo de protección personal .................................... |

28 |

Equipo de seguridad de la máquina ............................ |

29 |

Instrucciones generales de seguridad ......................... |

30 |

Instrucciones generales de trabajo .............................. |

31 |

PRESENTACIÓN |

|

PP 455 E ...................................................................... |

32 |

MONTAJE |

|

Montaje / instalación del equipo .................................. |

33 |

REGLAJES Y AJUSTES |

|

Menú de arranque ........................................................ |

35 |

Menú de arranque ........................................................ |

35 |

Menú de funcionamiento ............................................. |

35 |

Ajustes ......................................................................... |

37 |

ARRANQUE Y PARADA |

|

Serrado de pared ......................................................... |

42 |

Cortado con alambre ................................................... |

43 |

MANTENIMIENTO |

|

Mensajes de fallo ......................................................... |

45 |

Servicio ........................................................................ |

46 |

Mantenimiento ............................................................. |

46 |

DATOS TECNICOS |

|

PP 455 E ...................................................................... |

47 |

Declaración CE de conformidad .................................. |

48 |

26 – Spanish

¿QUÉ ES QUÉ? |

¿Qué es qué en la unidad hidráulica?

1 |

Mango |

10 |

Teclas de selección |

2 |

Conexiones de las mangueras hidráulicas |

11 |

Toma eléctrica |

3 |

Mando a distancia |

12 |

Toma monofásica de 230 V |

4 |

Fijación de sierra |

13 |

Protección personal / fusible |

5 |

Motor eléctrico, Conexión / Desconexión |

14 |

Cáncamo de elevación |

6 |

Rotación de la hoja y activación del agua refrigerante |

15 |

Válvula de flujo de agua |

7 |

Display |

16 |

Conexión de agua |

8 |

Avance de entrada |

17 |

Parada de emergencia |

9 |

Avance longitudinal |

|

|

Spanish – 27

INSTRUCCIONES DE SEGURIDAD

Antes de utilizar una nueva unidad hidráulica

•Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

•Esta máquina está destinada únicamente a utilizar junto con Husqvarna WS 355, WS 463, WS 462, WS 460 y CS 2512. Está prohibida cualquier otra aplicación.

•Lea el manual de instrucciones suministrado con la unidad hidráulica antes de utilizar la máquina.

•La máquina puede ocasionar lesiones graves. Lea atentamente las instrucciones de seguridad. Aprenda a utilizar la máquina.

Emplee siempre el sentido común.

Es imposible abarcar todas las situaciones en las que puede encontrarse. Utilice siempre el equipo con cuidado y sentido común. Evite todas aquellas situaciones que considere que sobrepasan sus capacidades. Si, después de leer estas instrucciones, no está seguro del procedimiento que debe seguir, consulte a un experto antes de utilizar el equipo.

No dude en ponerse en contacto con su distribuidor si tiene preguntas acerca del uso de la máquina. Estaremos encantados de poder aconsejarle y ayudarle a utilizar la máquina de manera eficaz y segura.

Diríjase a su distribuidor de Husqvarna para que revise la máquina regularmente y para que realice ajustes y reparaciones básicas.

Toda la información y todos los datos contenidos en este manual de instrucciones son vigentes en la fecha de impresión del manual.

! |

¡ATENCIÓN! No está permitido modificar el |

diseño original de la máquina, por ningún |

|

motivo, sin la autorización del fabricante. |

|

|

Utilice siempre accesorios originales. Las |

|

modificaciones y/o el uso de accesorios no |

|

autorizados comportan riesgo de daöos |

|

personales graves y peligro de muerte para |

|

el usuario y otras personas. |

Equipo de protección personal

! |

¡ATENCIÓN! Para trabajar con la máquina |

debe utilizarse un equipo de protección |

|

personal homologado. El equipo de |

|

|

protección personal no elimina el riesgo de |

|

lesiones, pero reduce su efecto en caso de |

|

accidente. Pida a su distribuidor que le |

|

asesore en la elección del equipo. |

•Casco protector

•Protectores auriculares

•Gafas protectoras o visor

•Máscara respiratoria

•Guantes resistentes de agarre seguro.

•Prendas de vestir ceñidas, resistentes y cómodas que permitan una libertad de movimientos total.

•Botas con puntera de acero y suela antideslizante.

•Tenga siempre a mano el equipo de primeros auxilios.

28 – Spanish

INSTRUCCIONES DE SEGURIDAD

Equipo de seguridad de la máquina

En este capítulo se describen los componentes de seguridad de la máquina, su función y el modo de efectuar el control y el mantenimiento para garantizar un funcionamiento óptimo. En cuanto a la ubicación de estos componentes en su máquina, vea el capítulo Qué es qué.

! |

¡ATENCIÓN! Nunca utilice una máquina con |

componentes de seguridad defectuosos. El |

|

equipo de seguridad se debe controlar y |

|

|

mantener. Ver las instrucciones del capítulo |

|

Control, mantenimiento y servicio del |

|

equipo de seguridad de la máquina. Si el |

|

control de la máquina no da resultado |

|

satisfactorio, hay que acudir a un taller de |

|

servicio para la reparación. |

¡IMPORTANTE! Todos los trabajos de servicio y reparación de la máquina requieren una formación especial. Esto es especialmente importante para el equipo de seguridad de la máquina. Si la máquina no pasa alguno de los controles indicados a continuación, acuda a su taller de servicio local. La compra de alguno de nuestros productos le garantiza que puede recibir un mantenimiento y servicio profesional. Si no ha adquirido la máquina en una de nuestras tiendas especializadas con servicio, solicite información sobre el taller de servicio más cercano.

Botón de arranque

Mantenga pulsado el botón de arranque para que la hoja empiece a girar. Así evitará que la hoja gire por accidente.

Control del botón de arranque

•Gire el pulsador para activar la rotación de la hoja sin mantener pulsado el botón de arranque. La rotación de la hoja no debería accionarse.

•Mantenga pulsado el botón de arranque y gire el pulsador para que la hoja rote. La rotación de la hoja se pondrá en marcha.

Parada de emergencia y botón de parada

La unidad hidráulica dispone de parada de emergencia y el control remoto tiene un botón de parada. Se utilizan para parar rápidamente la unidad hidráulica.

Verifique la parada de emergencia y el botón de parada

•Activar la rotación de la hoja

•Pulse la parada de emergencia de la unidad hidráulica y compruebe que la rotación del disco se detiene. Compruebe de igual modo el botón de parada situado en el control remoto.

Spanish – 29

Loading...

Loading...