Husky HRDC-U750-061205 User Manual

Nozzle Selection |

Ultra 750 |

ULTRA 750 DESIGN INFORMATION

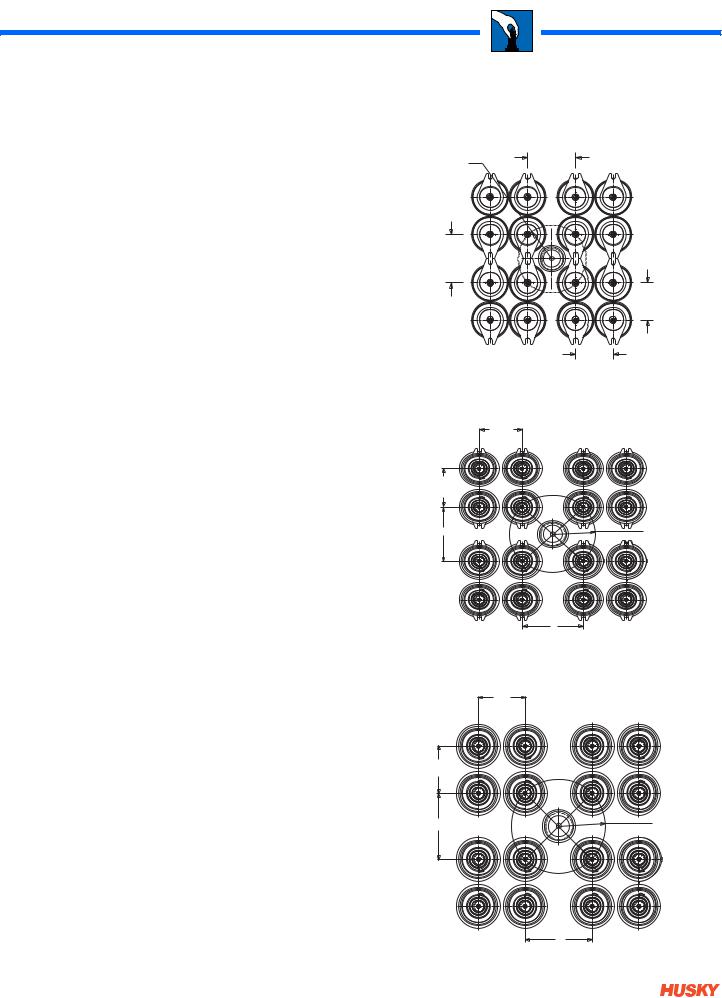

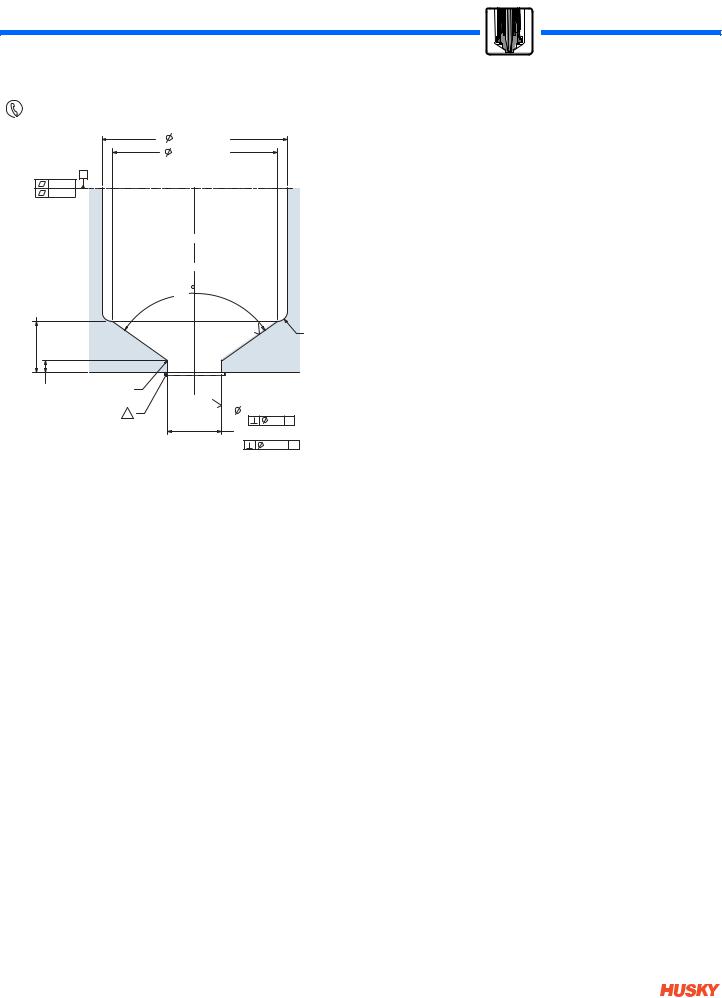

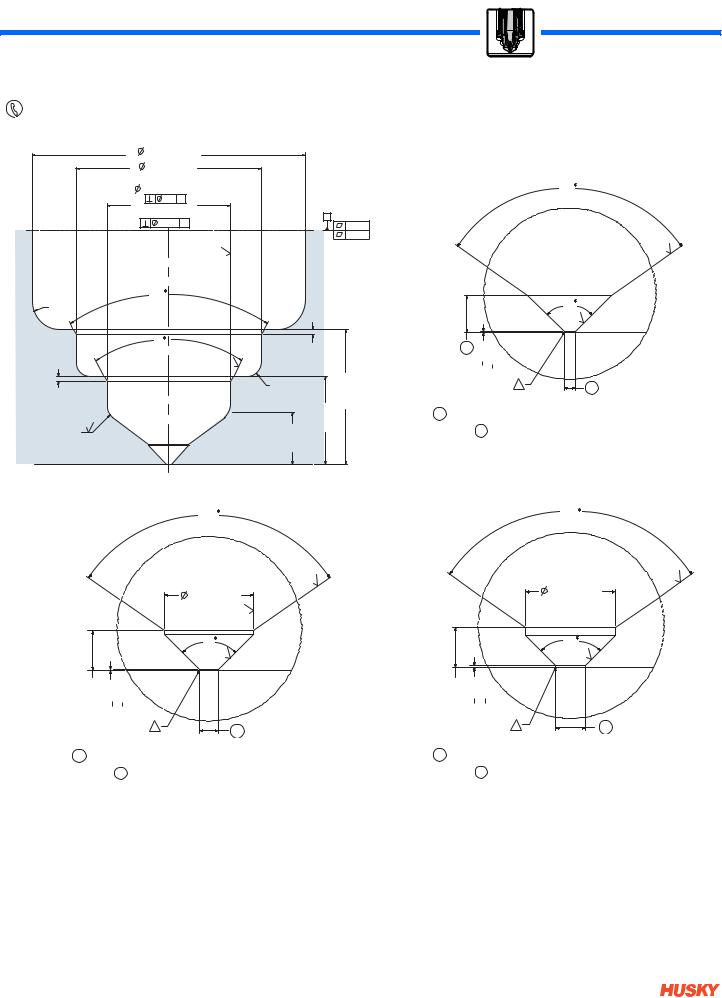

Ultra 750 Nozzle Pitch

Minimum nozzle pitch dimensions for the Ultra 750 nozzle are provided on the right and below. For applications that exceed 16 drops,  .

.

Thermal Gate

NOTE:The sprue minimum radius 40.4 mm (1.60") and the X and Y minimum distances must all be satisfied.

•For 8 or fewer drops x and y must be greater than 45.0 mm (1.77").

•For 12 drops and greater, x and y must be greater than 76.2 mm (3.00").

•For 48 drops and greater, click here.

Large Pitch Valve Gate (VG-LX)

NOTE:The sprue minimum radius 50.0 mm (1.97") and the X and Y minimum distances must all be satisfied.

•X and Y must be greater than 71.0 mm (2.80").

Large Piston Valve Gate (VG-EX)

NOTE:The sprue minimum radius 65.0 mm (2.559") and the X and Y minimum distances must all be satisfied.

X and Y must be greater than 92.0 mm (3.622").

NOTE: Minimum distance between outermost nozzle drop center to outer edge of the manifold plate is 125mm (4.921”). If reduced distance is required, contact Husky.

Thermal Gate

R 40.4 |

X |

|

[1.60] |

||

|

||

min. |

|

Y

44.5 [1.75]

44.5

[1.75]

Large Pitch Valve Gate (VG-LX)

|

|

50.0 |

|

|

|

[1.97] |

|

50.0 |

[1.97] |

|

|

Y |

50.0 |

[1.97] |

|

X

Large Piston Valve Gate (VG-EX)

|

|

59.0 |

|

|

|

[2.323] |

|

59.0 |

[2.323] |

|

|

Y |

65.0 |

[2.559] |

|

X

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

2006.08 |

79 |

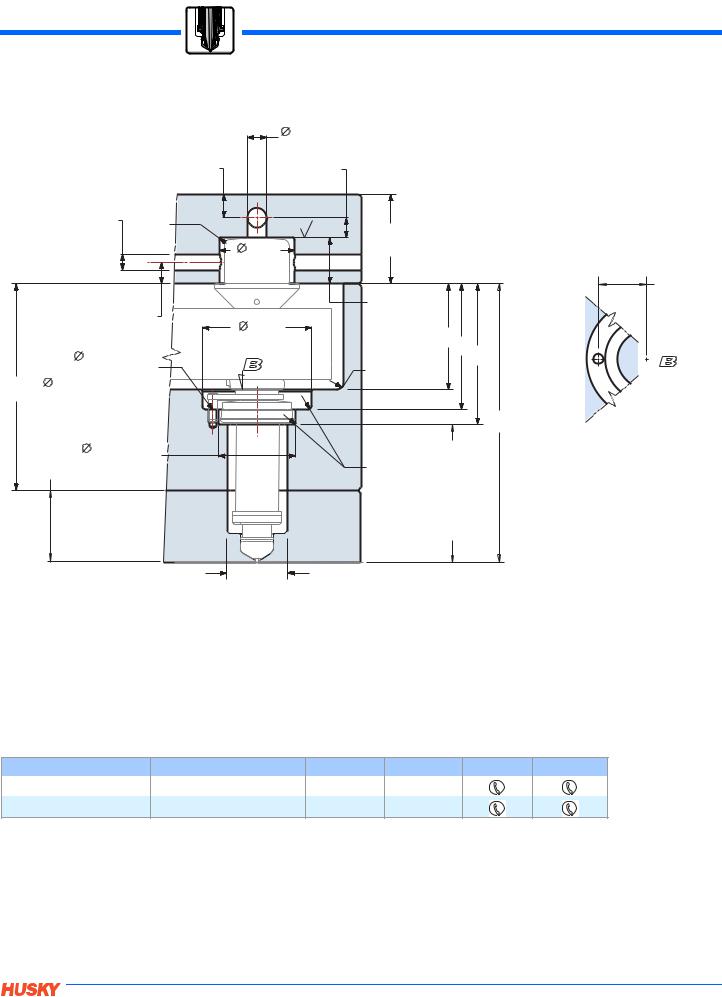

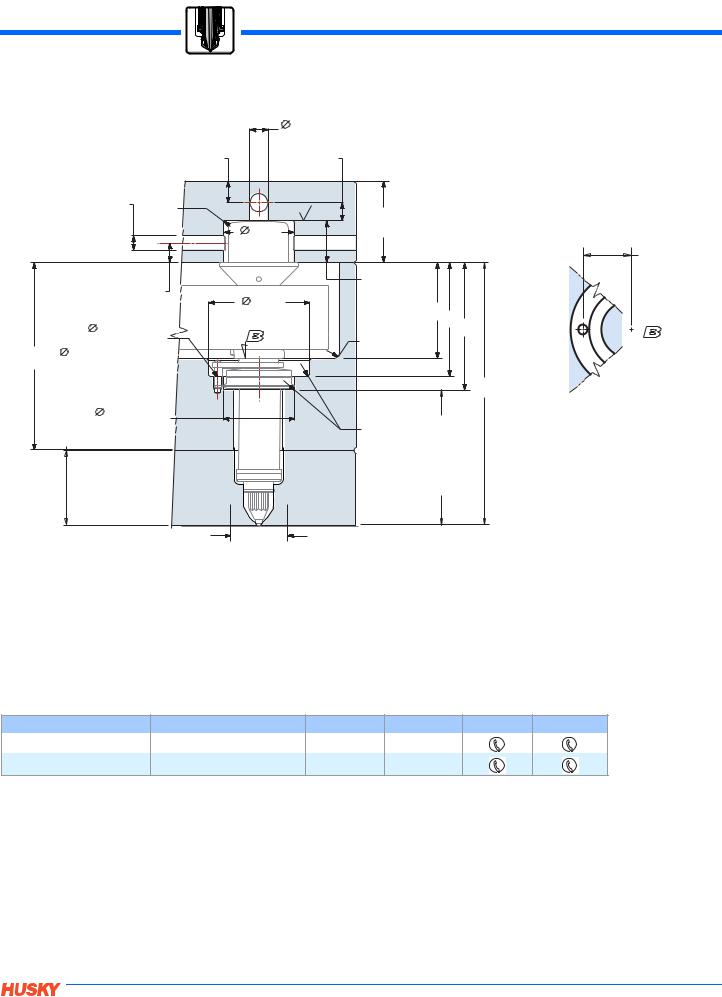

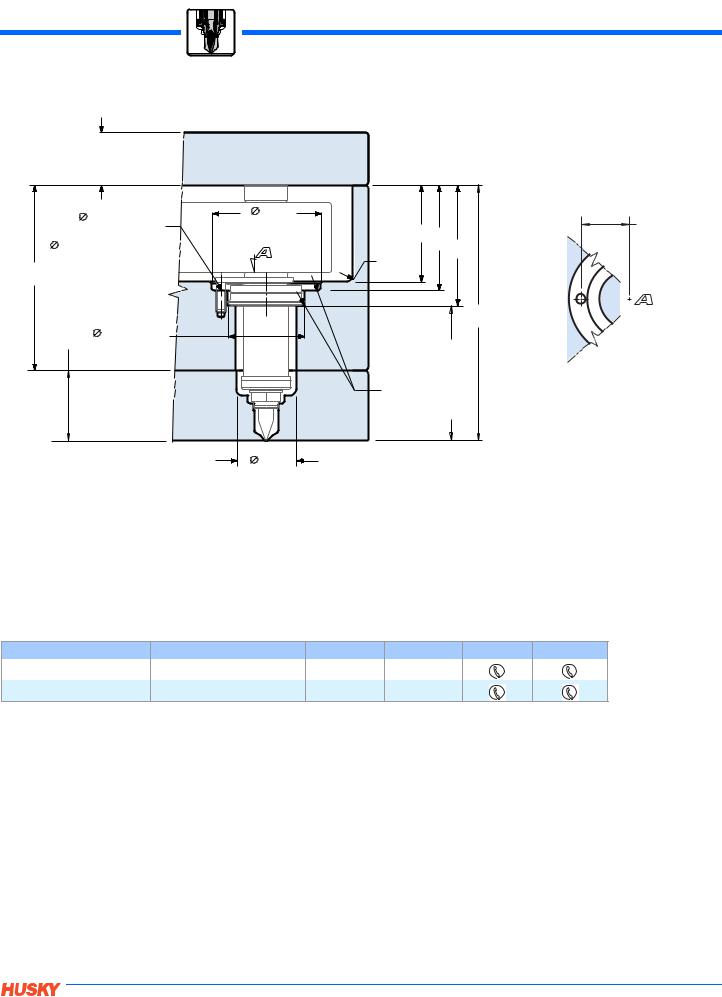

Ultra 750 VG

Sizing - Pocket Detail

|

|

|

|

11.11 |

|

|

|

|

|

|

[0.437] |

|

|

|

|

|

> 10.0 |

> 10.0 |

|

|

|

|

|

[0.39] |

|

[0.39] |

|

|

|

8.73 |

R 1.5 |

|

|

|

|

|

[0.344] |

0.8 |

[32] |

|

|

|

|

[0.06] |

60.00 |

|||

|

|

|

|

|

||

|

|

|

|

43.0 |

|

[2.362] |

|

|

|

|

|

|

|

|

|

|

|

[1.69] |

|

|

|

|

|

|

|

|

25.60 + 0.03 |

|

|

|

> 10.0 |

62.0 |

|

[1.01 + 0.001] |

|

|

|

[0.39] |

|

J |

|

|

|

|

|

[2.44] |

|

|

|

|

|

|

|

|

S |

|

|

4.8 x 10.4 DP. |

|

|

K |

|

|

|

|

|

R 3.0 |

||

|

|

[0.189 x 0.410] |

|

|

||

|

|

|

|

[0.12] |

||

|

5.03 + 0.03 x 7.5 DP. |

|

|

|||

N |

|

|

|

|||

[0.198 + 0.001 x 0.30] |

|

|

|

|||

|

|

|

|

|||

L - 141.0 |

- 5.55] |

44.01 + 0.03 |

|

|

SL |

|

27.4 |

[1.08 |

|

|

BL 163.67-63.67 6.444]-[2.507 |

||

[1.733 + 0.001] |

|

|

||||

|

|

|

|

R 1.5 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

[0.06] |

31.0 [1.22]

31.0 [1.22]

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Nozzle Selection

25.5

[1.00]

For more than 16 drops

For more than 16 drops

Thermal Calculations

BL / K / L / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html - OR -

Contact  Husky for plate thickness and critical bore depths.

Husky for plate thickness and critical bore depths.

Ultra 750 VG Plate Sizing

Number of Drops |

Manifold Height |

J |

S |

K |

N |

2 - 4 |

40.00 (1.574") |

59.1 (2.33") |

70.0 (2.76") |

|

|

6 - 16 |

60.00 (2.362") |

79.1 (3.11") |

90.0 (3.54") |

|

|

Contact Husky for more information

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

80 2006.08

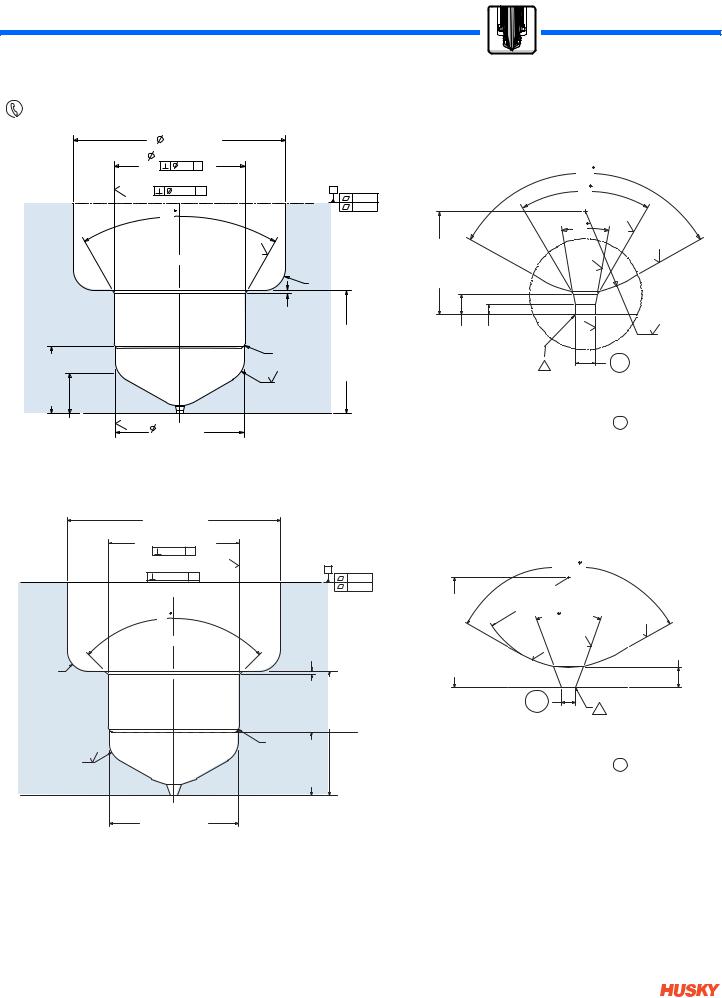

Nozzle Selection |

Ultra 750 VG |

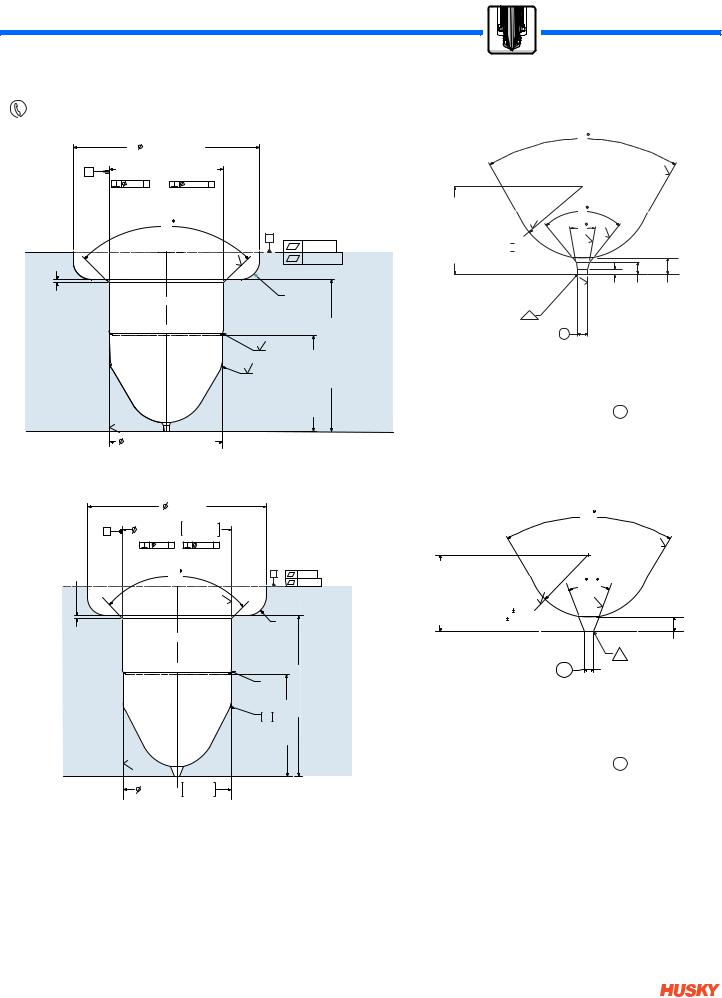

Gate Detail (Plunger)

Contact Husky with any gate insert backup concerns

|

|

|

31.0 [1.22] |

|

|

|

|

|

|

|

|

|

|

|

|

|

19.060 +0.010 |

|

|

|

|

|

|

|

|

|

|

|

|

|

0.01 |

A |

|

|

|

|

|

120 |

|

|

|

|

|

|

[0.7504 +0.0004] |

|

|

|

|

|

|

|

|

||

|

|

.0 |

|

A |

|

|

|

60 |

|

|

|

||

|

|

4 |

0.0004 |

A |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

0.005 |

METRIC |

|

|

|

|

|

|

|

|

|

60 |

|

|

0.0002 |

IMPERIAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

0 |

. 8 |

|

|

|

|

|

|

|

[0.199]5.06 |

CenterSR |

|

|

|

|

|

|

|

|

|

0 |

. 8 |

|

|

|

|

|

.8 |

||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

. |

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

R 3.0 [0.12] |

|

|

|

|

|

|

|

|

|

|

|

|

|

1.5 [0.06] |

[0.68] |

|

[0.039] |

[0.020] |

0.4 |

|

|

0.8 |

|

|

|

|

|

|

|

|

[0.156] |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

SR3.96 |

[0.385] |

|

|

|

|

R 0.8 [0.03] |

17.3 |

|

1.00 |

0.50 |

|

|

|

|

|

|

|

|

0.8 |

|

S |

G |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9.78 |

|

|

|

|

R 3.0 [0.12] |

|

1.000 (0.039"), 1.500 (0.059"), 1.800 (0.0708") and |

||||||

|

|

|

|

|

|

2.500 (0.0984") dia. gates are standard, other sizes |

|||||||

|

|

|

|

|

|

|

|||||||

5.91 |

[0.233] |

8.0 |

18.80 +0.10 |

|

|

require customized parts. Obtain |

G |

|

for the specific |

||||

|

|

|

application from Husky prior to machining. |

||||||||||

|

|

|

[0.740 +0.004] |

|

|

|

|||||||

Gate Detail (Taper)

31.0 [1.22]

19.060 +0.005

0.01 A

0.01 A

[0.7504 +0.0002]

0.0004 A

0.0004 A

60

R 3.0 [0.12]

0.8

R 3.0 [0.12]

18.80 +0.10 [0.740 + 0.004]

0.4

R 0.8 [0.03]

A

0.005 METRIC 0.0002 IMPERIAL

1.5 [0.06]

17.3 [0.68]

9.1 [0.36]

|

|

|

120 |

|

|

[0.3145]7.99REF |

CenterSR |

SR 6.50 |

|

|

[0.059]1.49 TangentSR |

[0.256] |

|

|

|||

|

|

|

|

|

|

|

|

40 +0 -15' |

|

|

|

|

|

|

|

.8 |

|

|

|

|

|

0 |

|

|

|

0. |

4 |

|

|

|

|

. |

|

|

|

|

|

8 |

0 |

|

|

G

S

1.000 (0.039"), 1.500 (0.059"), 1.800 (0.0708") and

2.500 (0.0984") dia. gates are standard, other sizes require customized parts. Obtain G for the specific application from Husky prior to machining.

Click here for taper / plunger comparison.

Gate Steel:Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344 provide a good combination of strength and ductility. Note: These steels may not offer the desired resistance to abrasive and/or corrosive resins, fillers and/or additives.

|

|

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining. |

|

2006.08 |

81 |

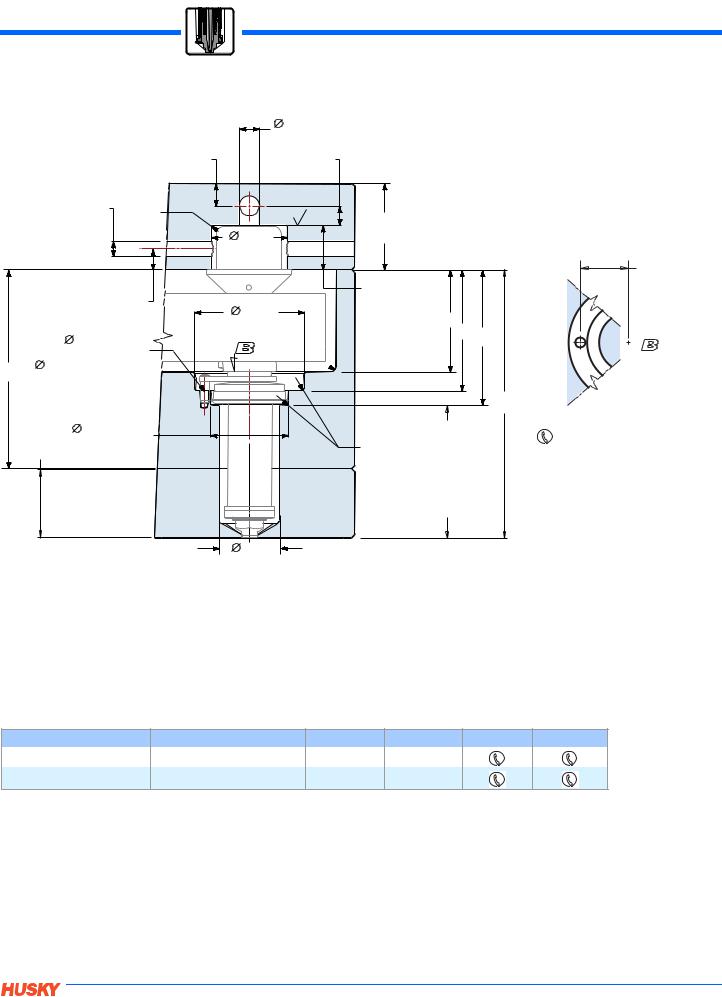

Ultra 750 VX |

Nozzle Selection |

Plate Sizing - Pocket Detail

> 10.0 [0.39]

8.73 |

R 1.5 |

|

[0.344] |

||

[0.06] |

||

|

43.0

[1.69]

> 10.0 [0.39] 62.0

[2.44]

|

|

4.8 x 10.4 DP. |

|

|

|

[0.189 x 0.410] |

|

N |

5.03 + 0.03 x 7.5 DP. |

||

[0.198 + 0.001 x 0.30] |

|||

|

|||

L - 131.0 |

- 5.16] |

44.01 + 0.03 |

|

27.4 |

[1.08 |

||

[1.733 + 0.001] |

|||

|

|

||

31.0

[1.22]

11.11

[0.437]

> 10.0 [0.39]

0.8 |

[32] |

60.00 |

|

|

|

|

|

[2.362] |

|

25.5 |

25.60 + 0.03 |

[1.00] |

|

|

[1.01 + 0.001] |

|

J |

|

S |

K |

R 3.0

[0.12]

[0.12]

SL

BL |

153.67-53.67 |

6.05]-[2.113 |

For more than 16 drops |

R 1.5 |

|

|

|

[0.06] |

|

|

|

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Thermal Calculations

BL / K / L / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html - OR -

Contact  Husky for plate thickness and critical bore depths.

Husky for plate thickness and critical bore depths.

Ultra 750 VX Plate Sizing

Number of Drops |

Manifold Height |

J |

S |

K |

N |

2 - 4 |

40.00 (1.574") |

59.1 (2.33") |

70.0 (2.76") |

|

|

6 - 16 |

60.00 (2.362") |

79.1 (3.11") |

90.0 (3.54") |

|

|

Contact Husky for more information

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

82 2006.08

Nozzle Selection |

Ultra 750 VX |

Gate Detail

Contact Husky with any gate insert backup concerns

31.0[1.22]

24.7[.97] Int Pt

A

METRIC 0.005

IMPERIAL 0.0002

[0.30] |

|

|

110 |

|

|

7.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

.4 |

R 1.5 |

|

|

|

|

0 |

|

|

|

|

|

|

[0.06] |

|

[0.078] |

R 0.10 + 0.10 |

|

|

|

Land |

[0.004 +0.004] |

|

|

|

|

S |

0.4 |

9.005 + 0.005 |

|||

|

2.00 |

|

|

0.01 |

A |

|

|

|

[0.3545 +0.0002] |

||

|

|

|

|

|

|

|

|

|

|

0.0004 |

A |

Clearance required in this area > 0.50mm (0.020”). Front face of nozzle tip cannot make contact.

NOTE:Extra tip stock available for contouring.

Gate Steel: Hardened tool steel such as 49-51 Rc AISI H13 / DIN 1.2344 provide a good combination of strength and ductility. Note: These steels may not offer the desired resistance to abrasive and / or corrosive resins, fillers and / or additives.

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

2006.08 |

83 |

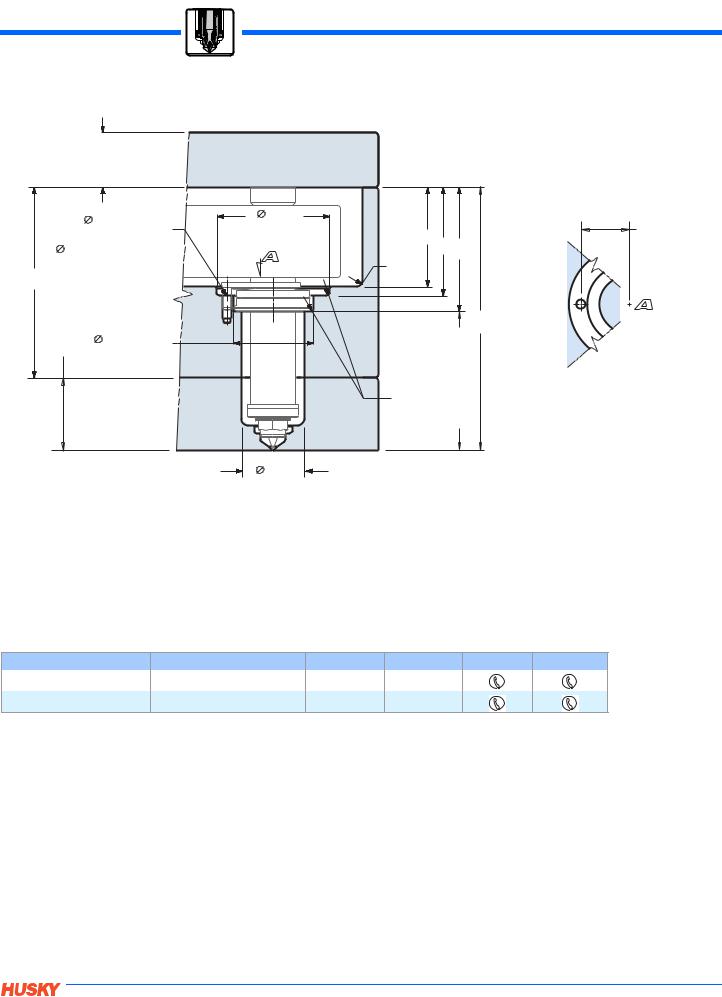

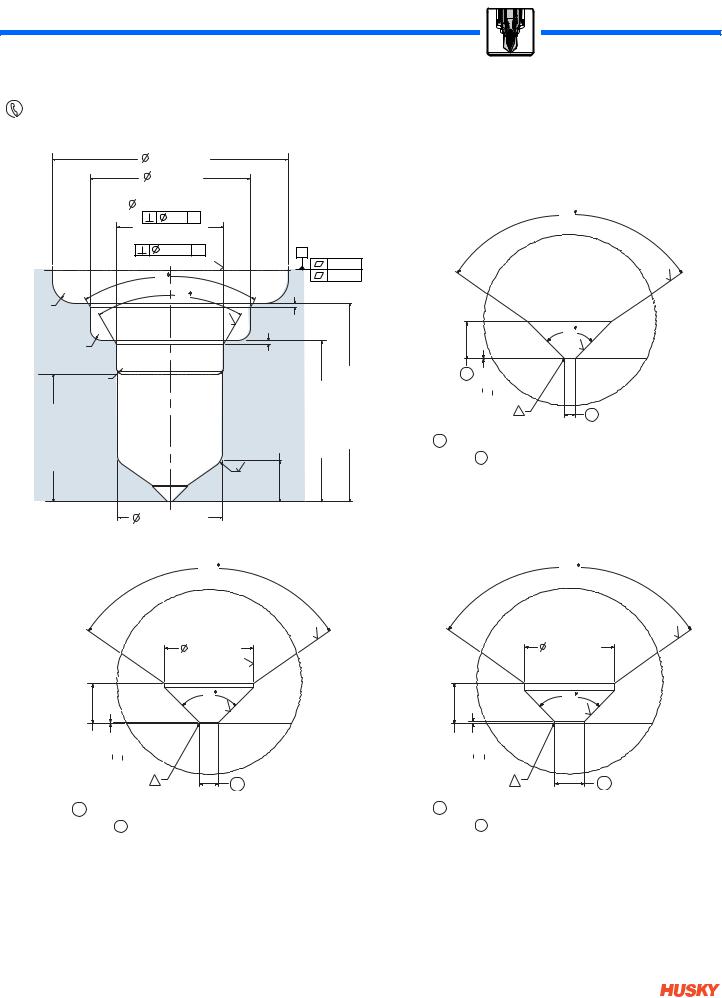

U750 VG-R

Plate Sizing - Pocket Detail

|

|

11.11 |

|

||

|

|

[0.437] |

|

||

|

> 10.0 |

> 10.0 |

|

||

|

[0.39] |

|

[0.39] |

|

|

8.73 |

R 1.5 |

|

|

|

|

[0.344] |

0.8 |

[32] |

|

||

[0.06] |

60.00 |

||||

|

|

|

|||

|

|

43.0 |

|

[2.362] |

|

|

|

|

|

||

|

|

[1.69] |

|

|

|

|

|

|

30.60 + 0.03 |

|

> 10.0 |

62.0 |

[1.20 + 0.001] |

|

[0.39] |

J |

|

|

|

[2.44] |

|

|

|

|

S |

|

4.8 x 10.4 DP. |

|

K |

|

|

R 3.0 |

|

|

[0.189 x 0.410] |

|

|

|

|

[0.12] |

|

|

5.03 + 0.03 x 7.5 DP. |

|

|

N |

|

|

|

[0.198 + 0.001 x 0.30] |

|

|

|

|

|

|

148.9 |

5.86] |

44.01 + 0.03 |

|

|

SL |

- - |

|

|

|

||

L 35.3 |

[1.39 |

[1.733 + 0.001] |

R 1.5 |

BL 168.6 |

6.64]- |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

[0.06] |

|

|

|

|

|

|

64 - |

[2.52 |

31.0 [1.22]

31.0 [1.22]

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

Nozzle Selection

25.5

[1.00]

For more than 16 drops

For more than 16 drops

Thermal Calculations

BL / K / L / N / SL - Refer to the plate claculator at http://www.husky.ca/hotrunners/content-316-219.html - OR -

Contact  Husky for plate thickness and critical bore depths.

Husky for plate thickness and critical bore depths.

Ultra 750 VG-R Plate Sizing

Number of Drops |

Manifold Height |

J |

S |

K |

N |

2 - 4 |

40.00 (1.574") |

55.1 (2.17") |

60.2 (2.37") |

|

|

6 - 16 |

60.00 (2.362") |

75.1 (2.96") |

80.3 (3.16") |

|

|

Contact Husky for more information

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

84 2006.08

Nozzle Selection |

U750 VG-R |

Gate Detail (Plunger)

Contact Husky with any gate insert backup concerns

|

31.0 |

[1.22] |

|

|

+.0002 |

B |

19.060+0.005 [.7504 -.0000] |

|

|

|

|

|

0.01 A |

0.0004A |

|

METRIC |

IMPERIAL |

60

[.06] |

|

|

|

A |

|

|

|

|

|

|

|

|

|

0.005 |

METRIC |

||

|

|

|

|

|

|

|||

1.5 |

|

|

|

.8 |

|

0.0002 |

IMPERIAL |

|

|

|

|

|

|

|

|

||

|

|

|

0 |

|

|

|

|

|

|

|

|

|

R 3.0 [.12] |

|

|

||

|

|

|

|

0.8 |

|

|

REF |

|

|

|

|

|

|

REF |

[0.98] |

|

|

|

|

|

|

R 0.8 |

[.03] |

|

||

|

|

|

|

|

|

|

||

|

|

|

|

0.8 |

|

[.65] |

25.0 |

|

|

|

|

|

R 3.0 [.12] |

|

|||

|

|

|

|

|

|

|

||

0.8 |

|

|

|

|

|

16.5 |

|

|

|

|

|

|

|

|

|

|

|

18.80 |

+0.10 |

[.740 |

+.004 |

] |

|

|

|

|

-0 |

-0.00 |

|

|

|

|

|||

60

0 |

.8 |

|

[.315]REF |

CENTER |

SR 6.50 + 0.04 |

80 |

0 |

|

|

|

|

4 |

|

|

||||

|

|

0.8 |

20 |

|

|

|

|

|

|

|

.4 |

|

|

||

8.00 |

SR |

|

. |

|

|

|

|

[.256 + .002] |

0 |

|

|

|

|

||

|

|

|

|

|

|

||

|

|

S |

4.0 |

[.020]0.50LAND |

1.13[.045] INT PT |

[.059]1.50 REF SRTAN PT |

|

G

1.000 (0.0394"), 1.800 (0.0708") and 2.500 (0.0984") dia. gates are standard, other sizes

require customized parts. Obtain G for the specific application from Husky prior to machining.

Gate Detail (Taper)

|

|

31.0 [1.22] |

|

|

|

||

|

19.060 |

+0.005 |

+.0002 |

|

|

|

|

B |

-0.000 |

.7504 |

-.0000 |

|

|

|

|

|

0.01A |

.0004 A |

|

|

|

||

[.06] |

METRIC |

IMPERIAL |

|

|

|

||

|

|

|

|

|

|

|

|

1.5 |

|

60 |

|

A |

|

0.005 |

METRIC |

|

|

|

|

|

|

0.0002 |

IMPERIAL |

|

|

|

|

0.4 |

|

|

|

|

|

|

|

|

R3.0 |

|

|

|

|

|

|

|

[.12] |

|

|

|

|

|

|

R0.8 |

|

REF |

|

|

|

|

|

REF[.65] |

[0.98]25.0 |

|

|

|

|

|

|

[.03] |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

R 3.0 |

|

|

|

|

|

|

|

.12 |

|

|

|

|

|

|

|

|

16.5 |

|

|

|

0.8 |

|

|

|

|

|

|

|

|

+0.10 |

+.004 |

|

|

|

|

|

18.80 -0.00 |

.740 |

-.000 |

|

|

|

|

|

|

|

60 |

|

|

|

|

|

|

|

|

|

|

0 |

. |

8 |

|

|

|

|

|

|

|

|

|

|

REF |

CENTER |

|

|

+0 |

|

|

|

|

[.315] |

|

40 |

|

|

|

|

||

|

|

|

-15’ |

|

|

|

|

|

|

|

|

0.8 |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

8.00 |

SR |

[.256 |

.002] |

. |

|

|

|

|

0 |

|

|

|

|

||||

|

|

SR 6.50 |

0.04 |

|

|

|

|

|

|

|

|

|

S |

|

|

REF |

PT |

|

|

|

|

|

|

[.059] |

TAN |

|

|

|

|

G |

|

|

|

||

|

|

|

|

|

|

|

1.50 |

SR |

1.000 (0.0394"), 1.800 (0.0708") and 2.500 (0.0984") dia. gates are standard, other sizes

require customized parts. Obtain G for the specific application from Husky prior to machining.

Click here for taper / plunger comparison.

Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344 provide a good combination of strength and ductility. Note: These steels may not offer the desired resistance to abrasive and/or corrosive resins, fillers and/or additives.

|

|

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining. |

|

2006.08 |

85 |

Ultra 750 HT-D

Plate Sizing - Pocket Detail

40.00

[1.574]

|

4.8 x 10.4 DP |

62.0 |

|

[2.44] |

|

|

[ .189 x 0.410] |

|

|

|

|

5.03 + 0.03 x 7.5 DP |

|

|

[0.198 + 0.001 x 0.30] |

|

|

N |

|

|

L - 134.3 - 5.29] |

|

|

27.4 [1.08 |

44.01 + 0.03 |

|

|

[1.733 + 0.001] |

|

31.0

[1.22]

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

K

S

J

R 3.0 [1.2]

SL

[0.06] |

BL - 156.88 |

- 6.176] |

56.87 |

[2.239 |

|

R 1.5 |

|

|

Nozzle Selection

25.5

[1.00]

For more than 16 drops

For more than 16 drops

Thermal Calculations

BL / K / L / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html - OR -

Contact  Husky for plate thickness and critical bore depths.

Husky for plate thickness and critical bore depths.

Ultra 750 HT-D Plate Sizing

Number of Drops |

Manifold Height |

J |

S |

K |

N |

2 - 4 |

40.00 (1.574") |

55.1 (2.17") |

60.0 (2.36") |

|

|

6 - 16 |

60.00 (2.362") |

75.1 (2.96") |

80.0 (3.15") |

|

|

Contact Husky for more information

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

86 |

2006.08 |

Nozzle Selection |

Ultra 750 HT-D |

Gate Detail

Contact Husky with any gate insert backup concerns

31.0 |

[1.22] |

|

21.0 |

[0.83] |

|

14.010 + 0.005 |

|

|

0.01 A |

|

|

[0.5516 +0.0002] |

|

|

0.0004 A |

|

|

|

0.4 |

|

60 |

|

|

R 3.0 [.12] |

|

|

60 |

|

|

|

0 |

.8 |

|

|

|

1.0 |

[0.04] |

R 1.5 |

||

[0.06] |

||||

|

|

|||

|

R 1.5 |

0.8 |

[0.210] |

|

|

[0.06] |

5.34 |

||

|

|

|

||

A

0.005 METRIC 0.0002 IMPERIAL

0.5 |

[0.02] |

13.50 |

[0.531] |

Pt |

9.10 [0.358] |

Int |

|

Gate Diameter < 0.6mm (0.024”)

110

.8 0

90

.4 0

0.05+ 0.03 |

[0.002+ 0.001] |

|

V |

|

|

|

S |

G |

|

|

G is application specific, contact Husky prior to machining. V is variable according to gate diameter.

0.6mm (0.024”) <Gate Diameter < 1.2mm (0.047”) |

Gate Diameter > 1.2mm (0.047”) |

110 |

110 |

.8 0

|

|

4.54 [0.179] |

|

|

0.4 |

|

|

90 |

|

|

.4 |

|

|

0 |

2.02 [0.080] 0.05+ 0.03 [0.002+ 0.001] |

S |

G |

|

|

G is application specific, contact Husky prior to machining. V is variable according to gate diameter.

.8 0

|

|

4.54 [0.179] |

|

|

90 |

|

|

.4 |

|

|

0 |

2.02 [0.080] 0.10+ 0.03 [0.004 + 0.001] |

S |

G |

G is application specific, contact Husky prior to machining. V is variable according to gate diameter.

Gate Steel: Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344 provide a good combination of strength and ductility. Note: These steels may not offer the desired resistance to abrasive and/or corrosive resins, fillers and/or additives.

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

2006.08 |

87 |

Ultra 750 HT-DX

Plate Sizing - Pocket Detail

40.00

|

[1.574 ] |

|

|

4.8 x 10.4 DP |

62.0 |

|

[2.44] |

|

|

[0.189 x 0.410] |

|

|

|

|

5.03 + 0.03 x 7.5 DP |

|

|

[0.198 + 0.001 x 0.30] |

|

|

N |

|

|

L - 145.3 - 5.72] |

|

|

38.4 [1.51 |

44.01 + 0.03 |

|

|

[1.733 + 0.001] |

|

31.0

[1.22]

Nominal dimensions shown for layout purpose only.

Actual dimensions dependent on operating temperatures.

R 3.0 [1.2]

R 1.5 [0.06]

K

S

J

SL

BL - 167.84 |

- 6.61] |

67.84 |

[2.67 |

Nozzle Selection

25.5

[1.00]

For more than 16 drops

For more than 16 drops

Thermal Calculations

BL / K / L / N / SL - Refer to the plate calculator at http://www.husky.ca/hotrunners/content-316-219.html - OR -

Contact  Husky for plate thickness and critical bore depths.

Husky for plate thickness and critical bore depths.

Ultra 750 HT-DX Plate Sizing

Number of Drops |

Manifold Height |

J |

S |

K |

N |

2 - 4 |

40.00 (1.574") |

55.1 (2.17") |

60.0 (2.36") |

|

|

6 - 16 |

60.00 (2.362") |

75.1 (2.96") |

80.0 (3.15") |

|

|

Contact Husky for more information

Contact Husky for more information

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining.

88 2006.08

Nozzle Selection |

Ultra 750 HT-DX |

Gate Detail

Contact Husky with any gate insert backup concerns

31.0[1.22]

21.0[0.83]

|

14.010 + 0.005 |

|

|

|

|

|

|

|

0.01 |

A |

|

|

|

|

|

|

[0.5516 +0.0002] |

|

|

|

|

|

|

|

0.0004 |

A |

|

|

A |

0.005 |

METRIC |

|

|

0.4 |

|

|

|

||

|

60 |

|

|

|

0.0002 |

IMPERIAL |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

R 3.0 |

60 |

|

|

|

|

|

|

|

|

|

0.5 [0.02] |

|

|

||

[0.12] |

R 1.5 |

0 |

. 8 |

|

|

||

|

|

|

|

||||

|

|

|

|

|

|

||

|

|

|

[0.04] |

|

|

|

|

|

[0.06] |

|

1.0 |

|

|

|

|

|

R .8 |

|

|

|

|

||

[0.66]16.70 |

|

|

[0.210]5.34 PtsInt |

[0.831]21.10 |

[.984]25.00 |

|

|

[0.03] |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

0.8 R 1.5 |

|

|

|

|

|

|

|

[0.06] |

|

|

|

|

13.80 [0.543]

0.6mm (0.024”) <Gate Diameter < 1.2mm (0.047”)

110

.8 0

|

|

4.54 [0.179] |

|

|

0.4 |

|

|

90 |

|

|

.4 |

|

|

0 |

2.02 [0.080] 0.05+ 0.03 [0.002+ 0.001] |

S |

G |

|

|

G is application specific, contact Husky prior to machining.

V is variable according to gate diameter.

Gate Diameter < 0.6mm (0.024”)

110

.8 0

90

.4 0

0.05+ 0.03 |

[0.002+ 0.001] |

|

V |

|

|

|

S |

G |

|

|

G is application specific, contact Husky prior to machining. V is variable according to gate diameter.

Gate Diameter > 1.2mm (0.047”)

110

.8 0

|

|

4.54 [0.179] |

|

|

90 |

|

|

.4 |

|

|

0 |

2.02 [0.080] 0.10+ 0.03 [0.004 + 0.001] |

S |

G |

G is application specific, contact Husky prior to machining. V is variable according to gate diameter.

Gate Steel: Hardened tool steels such as 49 - 51 Rc AISI H13 / DIN 1.2344 provide a good combination of strength and ductility. Note: These steels may not offer the desired resistance to abrasive and/or corrosive resins, fillers and/or additives.

|

|

Please confirm all dimensions and nozzle/gating suitability with Husky prior to machining. |

|

2006.08 |

89 |

Loading...

Loading...