Page 1

HP LaserJet P3010 Series Printers

Service Manual

Additional product information:

www.hp.com/support/ljp3010series

Page 2

Page 3

HP LaserJet P3010 Series Printers

Service Manual

Page 4

Copyright and License

© 2009 Copyright Hewlett-Packard

Development Company, L.P.

Trademark Credits

®

Adobe

is a trademark of Adobe Systems

Incorporated.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CE524-90909

Edition 1, 7/2009

Microsoft®, Windows®, Windows® XP, and

Windows Vista® are U.S. registered

trademarks of Microsoft Corporation.

ENERGY STAR and the ENERGY STAR

mark are registered U.S. marks.

Page 5

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging the

product.

WARNING! Warnings alert you to specific procedures that you should follow to avoid personal injury,

catastrophic loss of data, or extensive damage to the product.

ENWW iii

Page 6

iv Conventions used in this guide ENWW

Page 7

Table of contents

1 Theory of operation

Basic operation ..................................................................................................................................... 2

Major printer systems .......................................................................................................... 2

Printer block diagram ........................................................................................................... 2

Sequence of operation ......................................................................................................... 3

Normal sequence of operation ............................................................................ 3

Formatter-control system ..................................................................................................................... 4

Sleep mode .......................................................................................................................... 4

Input/output .......................................................................................................................... 4

CPU ..................................................................................................................................... 4

Memory ................................................................................................................................ 5

Optional hard disk ............................................................................................... 5

Firmware ............................................................................................................. 5

Nonvolatile memory ............................................................................................ 5

PJL overview ....................................................................................................................... 5

PML ..................................................................................................................................... 5

Control panel ....................................................................................................................... 5

Engine-control system .......................................................................................................................... 6

Motors, fans, clutches, solenoids, switches, and sensors ................................................... 7

DC controller operations .................................................................................................... 14

Fuser-control circuit ........................................................................................................... 16

Fuser failure detection ....................................................................................... 17

Fuser temperature control ................................................................................. 18

Fuser protective function ................................................................................... 19

Low-voltage power supply ................................................................................................. 20

Overcurrent/overvoltage protection ................................................................... 21

High-voltage power supply ................................................................................................ 22

Formatter ........................................................................................................................... 23

Formatter heartbeat LED .................................................................................. 23

DIMM slots ........................................................................................................ 23

Laser/scanner system ........................................................................................................ 24

Laser failure detection ....................................................................................... 25

Image-formation system ..................................................................................................................... 26

Electrophotographic process ............................................................................................. 26

ENWW v

Page 8

Image formation process ................................................................................................... 27

Latent-image formation stage ........................................................................... 28

Primary charging .............................................................................. 28

Laser beam exposure ....................................................................... 28

Developing stage .............................................................................................. 29

Print cartridge ................................................................................... 29

Transfer stage ................................................................................................... 30

Fusing stage ..................................................................................... 30

Cleaning stage .................................................................................. 31

Toner detection .................................................................................................................. 32

Pickup, feed, and delivery system ...................................................................................................... 33

Paper trays ........................................................................................................................ 33

Photo sensors and switches .............................................................................................. 34

Solenoids and clutches ...................................................................................................... 36

Tray 1 or Tray 2 .................................................................................................................................. 38

Pickup and feed unit .......................................................................................................... 38

Cassette paper size detection/cassette paper detection ................................... 38

Cassette pickup ................................................................................................. 38

Tray 1 paper pickup ........................................................................................................... 38

Paper pickup and feed ....................................................................................................... 39

Jam detection .................................................................................................................... 40

Additional tray ..................................................................................................................................... 41

Tray driver PCA ................................................................................................................. 41

Paper pickup and feed ....................................................................................................... 42

Media level and size detection ........................................................................................... 43

Jam detection .................................................................................................................... 43

2 Removal and replacement

Removal and replacement strategy ................................................................................................... 46

General cautions during removal and replacement ........................................................... 46

Electrostatic discharge ...................................................................................... 46

Required tools ................................................................................................... 46

Types of screws ................................................................................................ 47

Service approach ............................................................................................................................... 48

Before performing service .................................................................................................. 48

After performing service ..................................................................................................... 48

Post-service test ................................................................................................................ 48

Print-quality test ................................................................................................ 48

Parts removal order ........................................................................................................... 50

Removal and replacement procedures .............................................................................................. 52

Print cartridge, cassettes, and sub cover ........................................................................... 52

Print cartridge .................................................................................................... 52

Tray cassette (Tray 2, Tray 3, or Tray 4) .......................................................... 54

vi ENWW

Page 9

Sub cover .......................................................................................................... 55

External panels, covers, doors, formatter PCA, DIMM, and EIO disk ............................... 56

EIO disk ............................................................................................................. 56

DIMM cover and DIMM ..................................................................................... 57

Reinstall the DIMM ........................................................................... 58

Formatter cover and formatter PCA .................................................................. 60

Rear-door assembly .......................................................................................... 62

Left cover .......................................................................................................... 66

Right-rear cover ................................................................................................ 68

Tray 1 (multipurpose tray) cover ....................................................................... 69

Cartridge-door assembly ................................................................................... 71

Top-right cover .................................................................................................. 73

Control panel ..................................................................................................... 74

Front-right and right-side cover assembly ......................................................... 76

Lower-right cover and bracket ........................................................................... 80

Reinstall the lower-right cover .......................................................... 82

Top cover .......................................................................................................... 84

Main assemblies ................................................................................................................ 86

Tray 1 (multipurpose tray) pickup roller ............................................................. 86

Tray 1 (multipurpose tray) separation pad ........................................................ 87

Tray 2, Tray 3, or Tray 4 pickup roller ............................................................... 88

Tray 2, Tray 3, or Tray 4 separation pad ........................................................... 90

Tray 2, Tray 3, or Tray 4 base-plate roller assembly ........................................ 91

Transfer roller .................................................................................................... 92

USB port PCA ................................................................................................... 94

Power-switch assembly ..................................................................................... 96

Main fan, fan duct, and environmental sensor .................................................. 98

Fuser ............................................................................................................... 100

Registration assembly ..................................................................................... 102

Duplex media-feed assembly .......................................................................... 104

Laser/scanner ................................................................................................. 107

Engine control unit (ECU) ............................................................................... 110

Cassette pickup (Tray 2) solenoid or Tray 1 (multipurpose tray) pickup

solenoid ........................................................................................................... 115

Fuser motor ..................................................................................................... 117

Sub fan and fan duct ....................................................................................... 118

High-voltage power supply (HVPS) ................................................................. 121

3 Solve problems

Solve problems checklist .................................................................................................................. 128

Menu map ........................................................................................................................................ 130

Troubleshooting process .................................................................................................................. 131

Determine the problem source ........................................................................................ 131

Power subsystem ............................................................................................................ 132

ENWW vii

Page 10

Power-on checks ............................................................................................. 132

Tools for troubleshooting .................................................................................................................. 133

Individual component diagnostics .................................................................................... 133

LED diagnostics .............................................................................................. 133

LED indicators ................................................................................ 133

Formatter heartbeat LED ................................................................ 133

HP Jetdirect LEDs .......................................................................... 134

Engine diagnostics .......................................................................................... 134

Engine-test button .......................................................................... 134

Fuser test page ............................................................................................... 135

Paper-path test (and automatic sensors test) ................................................. 136

Sensor test (interactive) .................................................................................. 137

A TOP (Top-of-Page) sensor .......................................................... 140

B Fuser output sensor .................................................................... 141

C Duplex sensor ............................................................................. 142

D Paper width sensor 1 .................................................................. 143

E Tray 3 feed sensor ...................................................................... 144

F Tray 4 feed sensor ...................................................................... 145

G FD tray full sensor ....................................................................... 146

H Face up detect sensor ................................................................ 147

I Cartridge-door open switch .......................................................... 148

J Rear cover open sensor .............................................................. 149

K Tray 1 paper sensor .................................................................... 150

L Tray 2 paper sensor .................................................................... 151

M Tray 2 detect switch .................................................................... 152

N Tray 3 paper sensor .................................................................... 153

O Tray 3 detect switch .................................................................... 154

P Tray 4 paper sensor .................................................................... 155

Q Tray 4 detect switch .................................................................... 156

Print/stop test .................................................................................................. 157

Component tests ............................................................................................. 158

Half self-test .................................................................................... 158

Drum rotation test check ................................................................. 158

Diagnostics menu components test ................................................ 158

Diagrams ......................................................................................................................... 160

Block diagrams ................................................................................................ 160

Plug/jack locations .......................................................................................... 162

Location of connectors .................................................................................... 163

ECU controller connections ............................................................ 163

Locations of major components ...................................................................... 165

General timing charts ...................................................................................... 169

General circuit diagram ................................................................................... 170

Internal print quality test pages ........................................................................................ 171

Cleaning page ................................................................................................. 172

viii ENWW

Page 11

Configuration page .......................................................................................... 172

Print quality troubleshooting tools .................................................................................... 173

Repetitive image-defect ruler .......................................................................... 173

Control-panel menus ....................................................................................................... 174

Use the menus ................................................................................................ 174

Show Me How menu ....................................................................................... 174

Retrieve job menu ........................................................................................... 175

Information menu ............................................................................................ 176

Paper handling menu ...................................................................................... 177

Manage supplies menu ................................................................................... 177

Configure device menu ................................................................................... 178

Printing menu ................................................................................. 178

Print Quality menu .......................................................................... 180

System setup menu ........................................................................ 183

I/O menu ......................................................................................... 187

Resets menu .................................................................................. 194

Diagnostics menu ............................................................................................ 194

Service menu .................................................................................................. 196

Interpret control-panel messages .................................................................................... 197

Control-panel message types ......................................................................... 197

Control-panel messages ................................................................................. 197

Event-log messages ........................................................................................................ 215

Print an event log ............................................................................................ 215

Show an event log ........................................................................................... 215

Sample event-log page ................................................................................... 216

Clear an event log ........................................................................................... 216

Event-log messages ........................................................................................ 217

Clear jams ........................................................................................................................................ 219

Common causes of jams ................................................................................................. 219

Jam locations ................................................................................................................... 220

Clear jams from the input trays ........................................................................................ 222

Clear jams from the duplexer ........................................................................................... 226

Clear jams from the output areas .................................................................................... 231

Clear jams from inside the product .................................................................................. 234

Registration and transfer area ......................................................................... 234

Jam causes and solutions ............................................................................................... 236

Avoid repeated jams ....................................................................................................... 240

Change jam recovery ....................................................................................................... 241

Solve paper-handling problems ........................................................................................................ 242

Product feeds multiple sheets .......................................................................................... 242

Product feeds incorrect page size ................................................................................... 242

Product pulls from incorrect tray ...................................................................................... 243

Paper does not feed automatically .................................................................................. 243

Paper does not feed from Tray 2, 3, or 4 ......................................................................... 244

ENWW ix

Page 12

Transparencies or glossy paper will not feed .................................................................. 244

Envelopes jam or will not feed in the product .................................................................. 245

Output is curled or wrinkled ............................................................................................. 245

Product does not duplex or duplexes incorrectly (duplex models) .................................. 246

Solve image-quality problems .......................................................................................................... 247

Image defect examples .................................................................................................... 247

Clean the product ............................................................................................................................. 254

Solve performance problems ........................................................................................................... 257

Solve connectivity problems ............................................................................................................. 258

Solve direct-connect problems ........................................................................................ 258

Solve network problems .................................................................................................. 258

Service mode functions .................................................................................................................... 259

Service menu ................................................................................................................... 259

Product resets .................................................................................................................. 260

Restore factory settings .................................................................................. 260

Hard disk initialization ..................................................................................... 260

Skip disk-load .................................................................................................. 260

NVRAM initialization ........................................................................................ 260

Service ID ....................................................................................... 261

Restore service ID .......................................................................... 261

Convert the service ID to an actual date ........................................ 261

Reset serial number ....................................................................... 262

Reset page counts .......................................................................... 262

Product cold reset ........................................................................................... 262

Product updates ............................................................................................................................... 263

Determine the current firmware version ........................................................................... 263

Download new firmware from the HP Web site ............................................................... 263

Transfer the new firmware to the product ........................................................................ 263

Use the flash executable file to update the firmware ...................................... 263

Use FTP to upload the firmware through a browser ....................................... 264

Use FTP to upgrade the firmware on a network connection ........................... 264

Use HP Web Jetadmin to upgrade the firmware ............................................. 265

Use Microsoft Windows commands to upgrade the firmware ......................... 265

Upgrade the HP Jetdirect firmware .................................................................................. 265

4 Parts and diagrams

Order parts by authorized service providers .................................................................................... 268

Order parts, accessories, and supplies ........................................................................... 268

Related documentation and software .............................................................................. 268

Supplies part numbers ..................................................................................................... 268

Accessories part numbers ............................................................................................... 269

Whole-unit replacement part numbers ............................................................................. 270

How to use the parts lists and diagrams .......................................................................................... 271

x ENWW

Page 13

Assembly locations ........................................................................................................................... 272

Base product (no optional trays or accessories) .............................................................. 272

Base product (optional trays or accessories) ................................................................... 273

Covers .............................................................................................................................................. 274

Internal assemblies (1 of 6) .............................................................................................................. 276

Internal assemblies (2 of 6) .............................................................................................................. 278

Internal assemblies (3 of 6) .............................................................................................................. 280

Internal assemblies (4 of 6) .............................................................................................................. 282

Internal assemblies (5 of 6) .............................................................................................................. 284

Internal assemblies (6 of 6) .............................................................................................................. 286

Input devices .................................................................................................................................... 288

500-sheet input tray (Tray 3 and Tray 4) ......................................................................... 288

Alphabetical parts list ....................................................................................................................... 290

Numerical parts list ........................................................................................................................... 293

Appendix A Service and support

Hewlett-Packard limited warranty statement .................................................................................... 298

HP's Premium Protection Warranty: LaserJet print cartridge limited warranty statement ................ 299

End User License Agreement .......................................................................................................... 300

Customer self-repair warranty service .............................................................................................. 302

Customer support ............................................................................................................................. 303

Repack the product .......................................................................................................................... 304

Service information form .................................................................................................................. 305

Appendix B Specifications

Physical specifications ..................................................................................................................... 308

Electrical specifications .................................................................................................................... 308

Acoustic specifications ..................................................................................................................... 308

Environmental specifications ............................................................................................................ 309

Appendix C Regulatory information

FCC regulations ............................................................................................................................... 312

Environmental product stewardship program ................................................................................... 313

Protecting the environment .............................................................................................. 313

Ozone production ............................................................................................................ 313

Power consumption ......................................................................................................... 313

Toner consumption .......................................................................................................... 313

Paper use ........................................................................................................................ 313

Plastics ............................................................................................................................ 313

HP LaserJet print supplies ............................................................................................... 313

Return and recycling instructions ..................................................................................... 314

United States and Puerto Rico ........................................................................ 314

Multiple returns (more than one cartridge) ..................................... 314

ENWW xi

Page 14

Single returns ................................................................................. 314

Shipping .......................................................................................... 314

Non-U.S. returns ............................................................................................. 314

Paper ............................................................................................................................... 314

Material restrictions .......................................................................................................... 315

Disposal of waste equipment by users in private households in the European Union .... 315

Chemical substances ....................................................................................................... 315

Material Safety Data Sheet (MSDS) ................................................................................ 316

For more information ....................................................................................................... 316

Declaration of conformity .................................................................................................................. 317

Safety statements ............................................................................................................................. 318

Laser safety ..................................................................................................................... 318

Canadian DOC regulations .............................................................................................. 318

VCCI statement (Japan) .................................................................................................. 318

Power cord statement (Japan) ......................................................................................... 318

EMC statement (Korea) ................................................................................................... 318

Laser statement for Finland ............................................................................................. 319

Substances Table (China) ............................................................................................... 320

Index ................................................................................................................................................................. 321

xii ENWW

Page 15

1 Theory of operation

Basic operation

●

Formatter-control system

●

Engine-control system

●

Image-formation system

●

Pickup, feed, and delivery system

●

Tray 1 or Tray 2

●

Additional tray

●

ENWW 1

Page 16

Basic operation

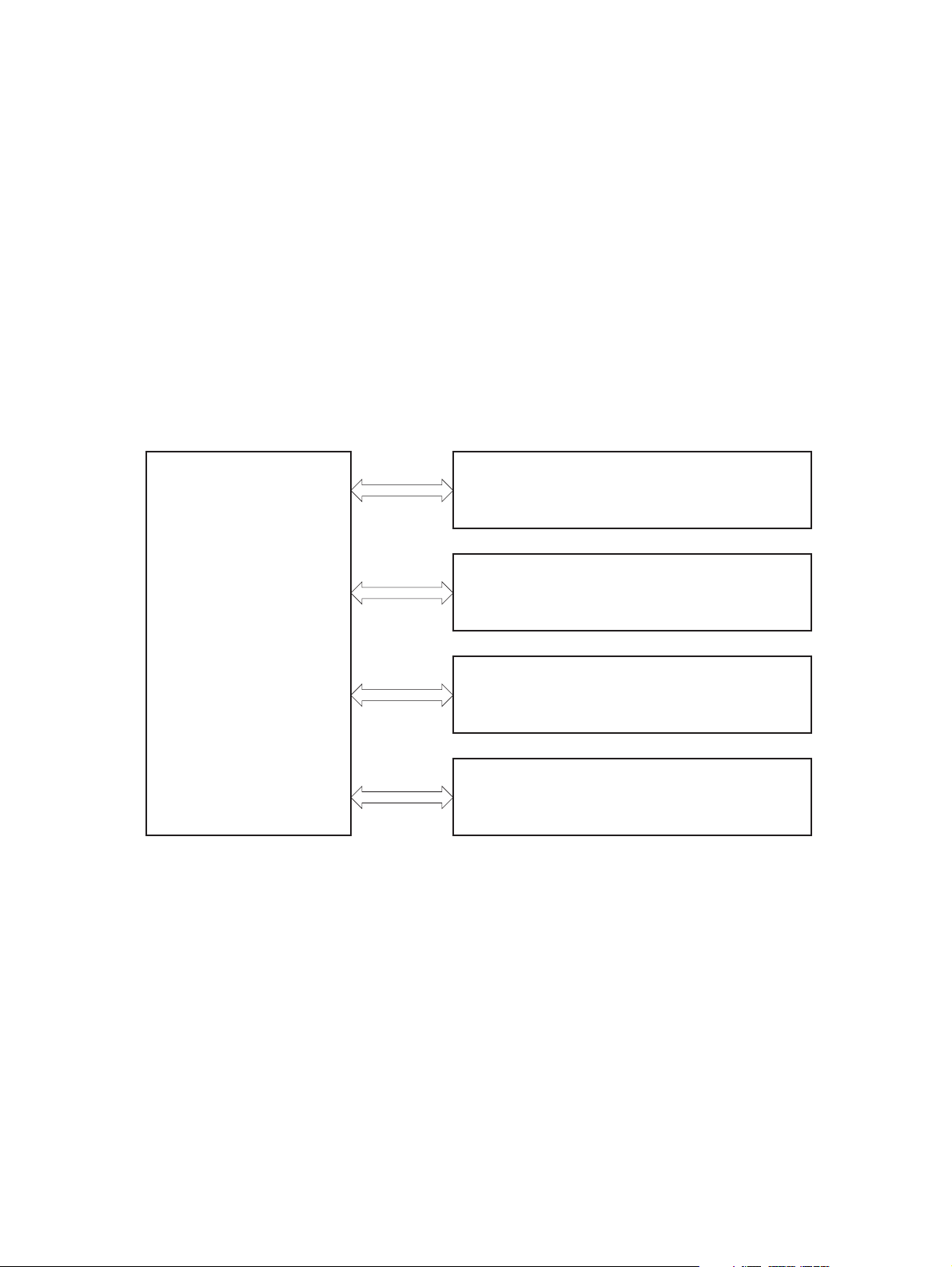

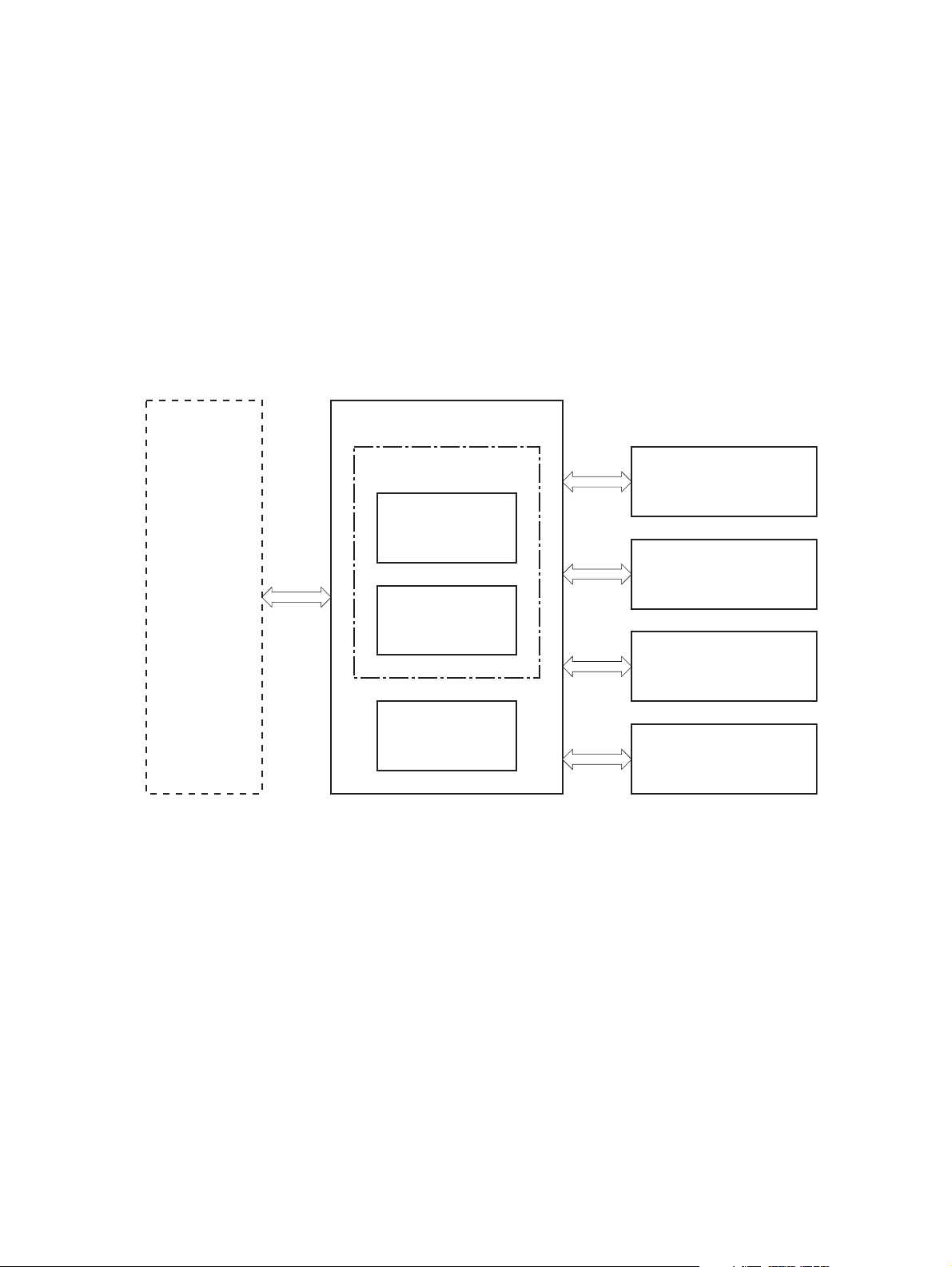

Major printer systems

The product contains the following five systems:

Engine-control system

●

Laser/scanner system

●

Image-formation system

●

Media feed system

●

Option

●

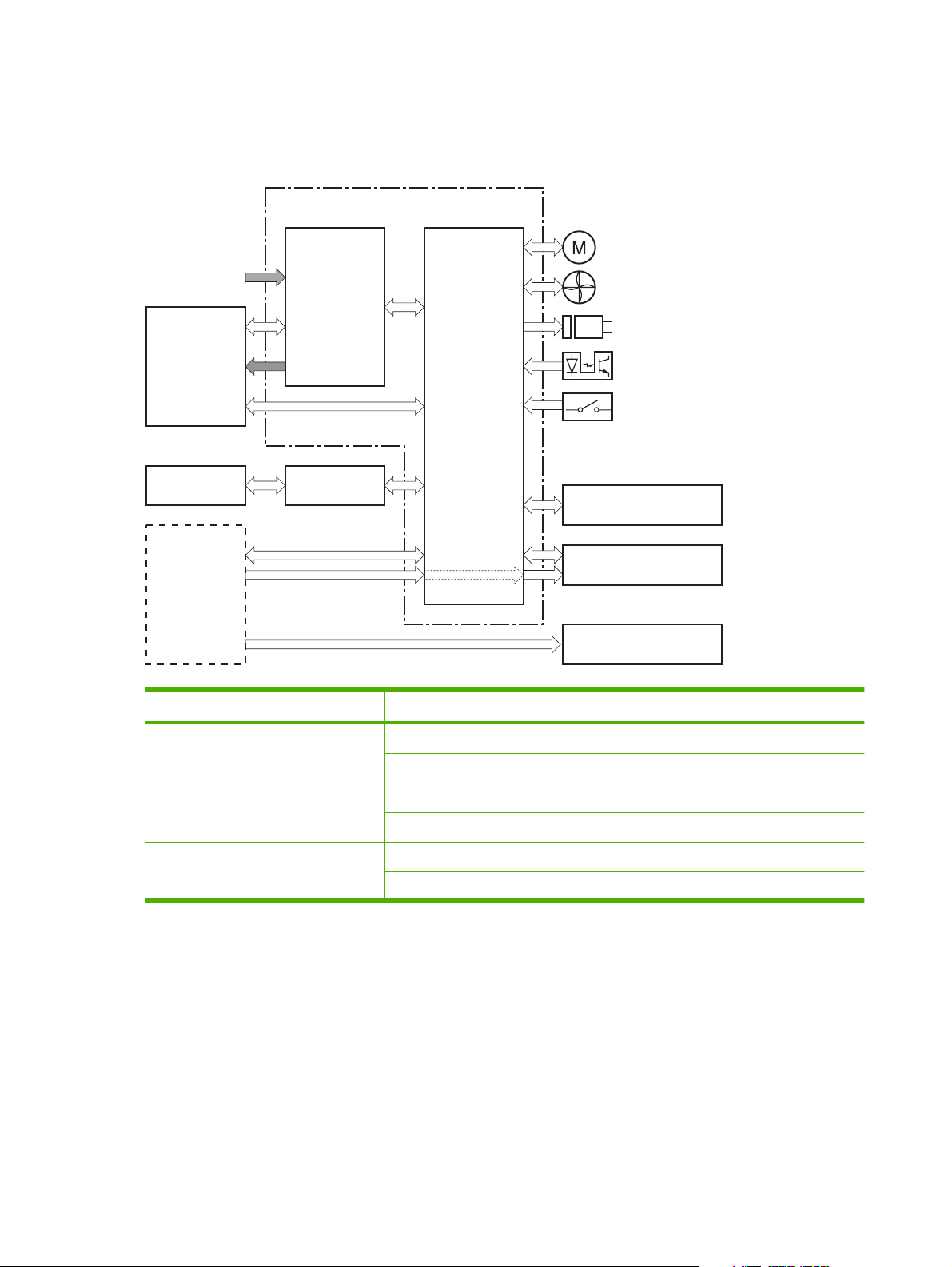

Printer block diagram

Figure 1-1 Printer block diagram

LASER SCANNER SYSTEM

ENGINE CONTROL SYSTEM

IMAGE-FORMATION SYSTEM

MEDIA FEED SYSTEM

OPTION

2 Chapter 1 Theory of operation ENWW

Page 17

Sequence of operation

The DC controller in the engine-control system controls the operational sequences of the printer. The

table below describes durations and operations for each period of a print operation from when the printer

is turned on until the motor stops rotating

Normal sequence of operation

Table 1-1 Sequence of operation

Name Timing Purpose

WAIT From the time the power switch is turned on or the

STBY (standby) From the end of the WAIT or LSTR period until either

INTR (initial

rotation)

PRINT From the end of the INTR period until the last sheet

LSTR (last

rotation)

door is closed until the printer is ready for a print

operation.

a print command is sent or the power switch is turned

off.

From the time the print command is received until the

temperature of the fuser unit reaches its targeted

temperature.

completes the fuser operation.

From the end of the PRINT period until the main motor

stops rotating.

Brings the product to printable condition. The product

performs the following during the operation:

Detects the print cartridge

●

Maintains the product in printable condition.

Starts up the high-voltage biases, the laser/scanner

and the fuser unit for printing.

Forms the image on the photosensitive drum based

on the VIDEO signals from the formatter. Transfers

and fuses the toner image to the paper.

Moves the last printed sheet out of the product.

The product enters the INTR period as the LSTR

period is completed, if the formatter sends another

print command.

ENWW Basic operation 3

Page 18

Formatter-control system

The formatter is responsible for the following procedures:

Controlling sleep mode

●

Receiving and processing print data from the various product interfaces

●

Monitoring control-panel functions and relaying product-status information (through the control

●

panel and the network or bidirectional interface)

Developing and coordinating data placement and timing with the DC controller PCA

●

Storing font information

●

Communicating with the host computer through the network or the bidirectional interface

●

The formatter receives a print job from the network or bidirectional interface and separates it into image

information and instructions that control the printing process. The DC controller PCA synchronizes the

image-formation system with the paper-input and -output systems, and then signals the formatter to

send the print-image data.

The formatter also provides the electrical interface and mounting locations for one EIO card and an

additional DIMM.

Sleep mode

NOTE: In the SYSTEM SETUP menu, this item is termed SLEEP DELAY.

This feature conserves power after the product has been idle for an adjustable period of time. When the

product is in SLEEP DELAY, the control-panel backlight is turned off, but the product retains all settings,

downloaded fonts, and macros. The default setting is for SLEEP DELAY to be enabled, and the product

enters SLEEP DELAY after a 30-minute idle time.

The product exists SLEEP DELAY and enters the warm-up cycle when any of the following events

occur:

A print job, valid data, or a PML or PJL command is received

●

A control-panel button is pressed

●

A cover is opened

●

A paper tray is opened

●

The engine-test switch is pressed

●

NOTE: Product error messages override the Sleep message. The product enters SLEEP DELAY at

the appropriate time, but the error message continues to appear.

Input/output

The product receives print data primarily from the embedded HP Jetdirect print server. The product also

has a USB 2.0 port for connecting directly to a computer.

CPU

The formatter incorporates a 540 MHz Coldfire processor.

4 Chapter 1 Theory of operation ENWW

Page 19

Memory

The random access memory (RAM) on the formatter PCA contains the page, I/O buffers, and the font

storage area. It stores printing and font information received from the host system, and can also serve

to temporarily store a full page of print-image data before the data is sent to the print engine. Memory

capacity can be increased by adding a DIMM to the formatter. Note that adding memory might also

increase the print speed for complex graphics.

NOTE: If the product encounters a problem when managing available memory, a clearable warning

message appears on the control-panel display.

Optional hard disk

This product supports an optional EIO hard disk or an optional secure hard disk as an accessory.

Firmware

The firmware is contained on NAND flash memory soldered on the formatter board. A remote firmware

upgrade process is available, which overwrites the firmware in the NAND flash.

Nonvolatile memory

The product uses nonvolatile memory (NVRAM) to store device and user configuration settings. The

contents of NVRAM are retained when the product is turned off or disconnected.

PJL overview

The printer job language (PJL) is an integral part of configuration, in addition to the standard printer

command language (PCL). With standard cabling, the product can use PJL to perform a variety of

functions such as these:

Two-way communication with the host computer through a network connection or a USB

●

connection. The product can inform the host about such things as the control-panel settings, and

the control-panel settings can be changed from the host.

Dynamic I/O switching. The product uses this switching to be configured with a host on each I/O.

●

The product can receive data from more than one I/O simultaneously, until the I/O buffer is full.

This can occur even when the product is offline.

Context-sensitive switching. The product can automatically recognize the personality (PS or PCL)

●

of each job and configure itself to serve that personality.

Isolation of print environment settings from one print job to the next. For example, if a print job is

●

sent to the product in landscape mode, the subsequent print jobs print in landscape mode only if

they are formatted for landscape printing.

PML

The printer management language (PML) allows remote configuration and status read-back through the

I/O ports.

Control panel

The formatter sends and receives product status and command data to and from the control-panel PCA.

ENWW Formatter-control system 5

Page 20

Engine-control system

The engine-control system coordinates all product functions, according to commands that the formatter

sends. The engine-control system drives the laser/scanner system, the image formation system, and

the pickup/feed/delivery system.

The engine control system contains the following major components:

Engine-control unit (ECU)

●

DC controller

◦

Low-voltage power supply

◦

High-voltage power supply

●

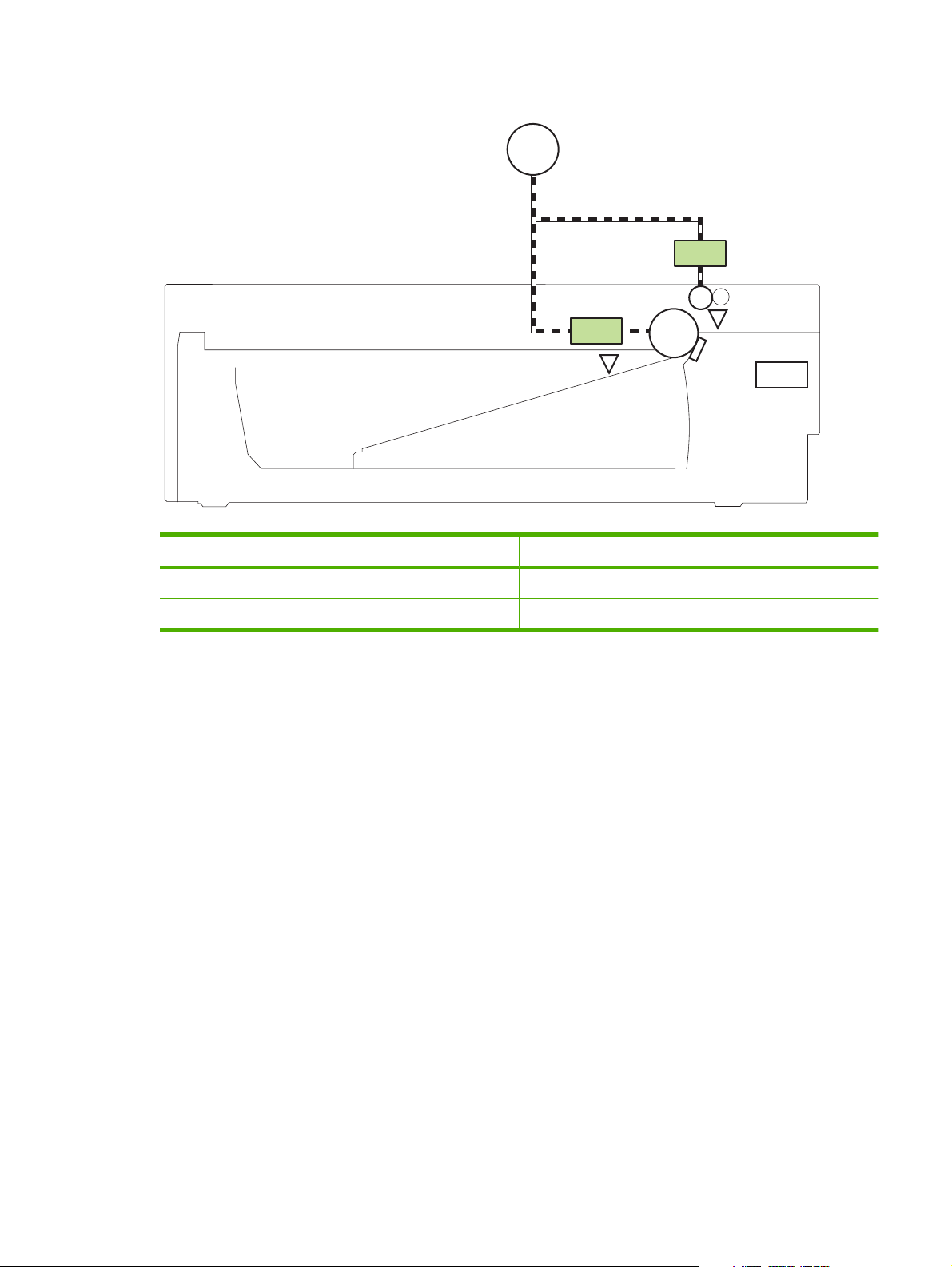

Figure 1-2 Engine-control system

ENGINE CONTROL SYSTEM

Formatter

Engine controller

LASER SCANNER SYSTEM

DC controller

IMAGE-FORMATION SYSTEM

Low-voltage

power supply

MEDIA FEED SYSTEM

High-voltage

power supply

OPTION

6 Chapter 1 Theory of operation ENWW

Page 21

Motors, fans, clutches, solenoids, switches, and sensors

Figure 1-3 Motors

Fuser motor

Main motor

Table 1-2 Motors

Description Components driven Fault detection

Main motor (M8001)

Fuser motor (M8002)

Pickup roller

●

Feed roller

●

Transfer roller

●

Photosensitive drum

●

Developing roller

●

Duplex repickup roller (duplex models only)

●

Pressure roller

●

Delivery roller

●

Fuser-delivery roller

●

Duplex-feed roller (duplex models only)

●

Yes

Yes

ENWW Engine-control system 7

Page 22

Figure 1-4 Fans

Main fan

Sub fan

Table 1-3 Fans

Description Area cooled Type Speed

Main fan (FM1) Inside the product Intake Full

Sub fan (FM2) Inside the product Intake Full

Figure 1-5 Solenoids and clutches (product)

PS4

PS1

M8001

SW501

PS8001

M8002

PS2

PS502

PS225

SL2

PS215

PS3

SL1

PS205

SW235

Table 1-4 Solenoids and clutches (product)

Item Description

SL1 Tray 1 (multipurpose tray) pickup solenoid

SL2 Cassette (Tray 2) pickup solenoid

8 Chapter 1 Theory of operation ENWW

Page 23

Figure 1-6 Solenoids and clutches (Tray 3 and Tray 4)

M8001

CL1

SL3

PS451

Table 1-5 Solenoids and clutches (Tray 3 and Tray 4)

Item Description

SL3 Paper feeder pickup solenoid

CL1 Paper feeder pickup clutch

1

Tray 3 and Tray 4 are identical 500-sheet input trays.

PS8008

SW461

ENWW Engine-control system 9

Page 24

Figure 1-7 Switches (product)

PS4

PS1

M8001

SW501

PS8001

PS2

PS502

M8002

PS225

SL2

PS215

PS3

Table 1-6 Switches (product)

Item Description

SW235 Cassette presence switch

SW501 Cartridge-door switch

SL1

PS205

SW235

10 Chapter 1 Theory of operation ENWW

Page 25

Figure 1-8 Switches (Tray 3 and Tray 4)

M8001

CL1

SL3

PS451

Table 1-7 Switches (Tray 3 and Tray 4)

Item Description

SW461 Paper feeder cassette presence switch

1

Tray 3 and Tray 4 are identical 500-sheet input trays.

PS8008

SW461

ENWW Engine-control system 11

Page 26

Figure 1-9 Sensors

PS4

PS1

PS8001

PS2

PS502

PS225

PS215

PS205

PS3

PS8008

PS451

PS8008

PS451

Table 1-8 Sensors

Item Description Item Description

PS1 Face-up sensor PS225 Media width sensor

PS2 Fuser delivery sensor PS502 Duplex media-feed sensor (duplex models only)

PS3 Cassette media-presence sensor PS451 Paper feeder cassette media-presence sensor

NOTE: PS451 is used in Tray 3, and Tray 4

12 Chapter 1 Theory of operation ENWW

Page 27

Table 1-8 Sensors (continued)

Item Description Item Description

PS4 Face-down tray media-full sensor PS8001 Rear door sensor

PS205 Tray 1 (multipurpose tray) media-presence

sensor

PS215 Top-of-Page (TOP) sensor

PS8008 Paper feeder media-feed sensor

NOTE: PS8008 is used in Tray 3, and Tray 4

ENWW Engine-control system 13

Page 28

DC controller operations

The DC controller controls the operational sequences of the product systems.

Figure 1-10 DC controller block diagram

Engine controller

Motor

AC input

Fuser

Print cartridge

Formatter

Low-voltage

power supply

High-voltage

power supply

DC controller

Fan

Solenoid

Photointerrupter

Switch

Optional paper-feeder

Laser/scanner

Control panel

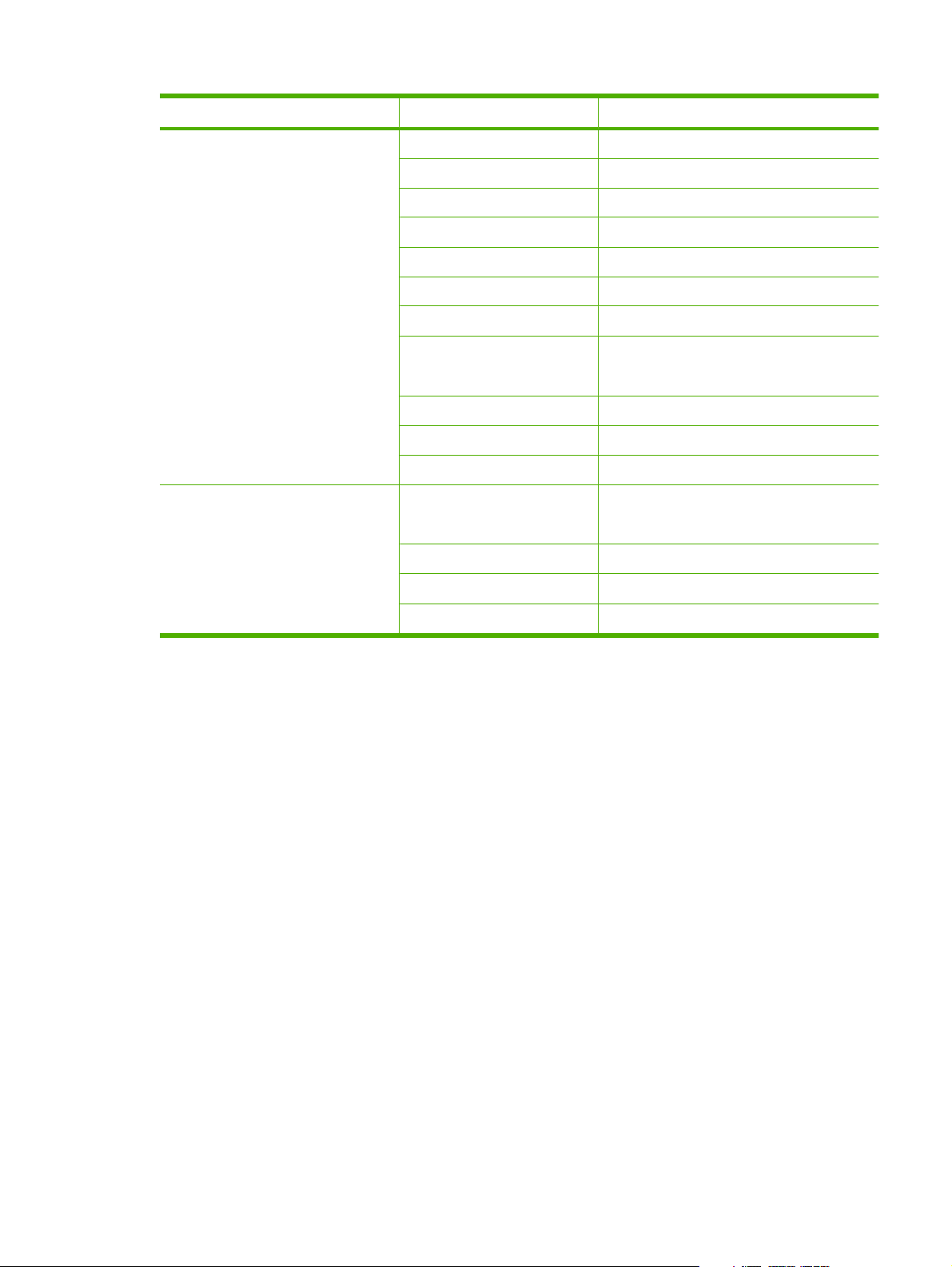

Table 1-9 DC controller controlled components

Component Designator Description

Motor M8001 Main motor

M8002 Fuser motor

Fan FM1 Main fan

FM2 Sub fan

Solenoid SL1 Tray 1 (multipurpose tray) pickup solenoid

SL2 Cassette (Tray 2) pickup solenoid

14 Chapter 1 Theory of operation ENWW

Page 29

Table 1-9 DC controller controlled components (continued)

Component Designator Description

Photointerrupter PS1 Face-up sensor

PS2 Fuser delivery sensor

PS3 Cassette media presence sensor

PS4 Face-down tray (output bin) media-full sensor

PS205 Tray 1 (multipurpose tray) presence sensor

PS215 Top-Of-Page (TOP) sensor

PS225 Media width sensor

PS451 Paper feeder cassette media-presence sensor

NOTE: PS451 is used in Tray 3, and Tray 4

PS502 Duplex media-feed sensor (duplex models only)

PS8001 Rear door sensor

PS8008 Paper feeder media-feed sensor

Switch SW235 Cassette-presence switch

NOTE: PS8008 is used in Tray 3, and Tray 4

SW240 Power switch

SW250 Test Print switch

SW501 Cartridge-door switch

ENWW Engine-control system 15

Page 30

Fuser-control circuit

The fuser-control circuit monitors and controls the temperature in the fuser. The product uses ondemand fusing. The fuser-control circuit consists of the following major components:

Fuser heater (H1); heats the fusing film

●

Thermistor (TH1 and TH2); detects the fuser temperature (contact type)

●

Main thermistor (TH1); controls the temperature in the fuser (contact type)

◦

Sub thermistor (TH2); detects a one-sided temperature rise in the fuser and controls the

◦

temperature in the fuser (contact type)

Thermoswitch (TP1); prevents abnormal temperature rise in the fuser (contact type)

●

Figure 1-11 Fuser control circuit

TP1

H1

Fuser film

TH2

DC controller

TH1

FUSER HEATER CONTROL signal

Fuser heater control

circuit

Engine controller unit

Pressure roller

FUSER TEMPERATURE signal

Fuser heater safety

circuit

Fuser control circuit

16 Chapter 1 Theory of operation ENWW

Page 31

Fuser failure detection

The DC controller determines a fuser unit failure, deactivates the FUSER HEATER CONTROL signal,

releases the relay to interrupt power supply to the fuser heater and notifies the formatter of a failure

state when it encounters the following conditions:

Start-up failure

●

If the main thermistor does not detect a specified temperature during the start-up process of

◦

the heater in the wait period.

If the main thermistor does not detect a specified temperature during the heater temperature

◦

control in the initial rotation period.

Abnormal low temperature

●

If the main thermistor detects an abnormal low temperature of the fuser unit during the printing

◦

operation.

If the sub thermistor detects an abnormal low temperature of the fuser unit during the printing

◦

operation.

Abnormal high temperature

●

If the main thermistor detects an abnormal high temperature of the fuser unit.

◦

If the sub thermistor detects an abnormal high temperature of the fuser unit.

◦

Frequency detection circuit failure

●

If a specified frequency of the ZERO CROSSING signal is not detected within a specified

◦

period after the product is turned on.

ENWW Engine-control system 17

Page 32

Fuser temperature control

The fuser temperature control maintains the temperature of the fuser heater at its targeted temperature.

The DC controller monitors the FUSER TEMPERATURE (FSRTH1, FSRTH2) signals and sends the

FUSER HEATER CONTROL (FSRD) signal according to the detected temperature. The fuser heater

control circuit controls the fuser heater depending on the signal so that the heater remains at the targeted

temperature.

Figure 1-12 Fuser-heater control circuit

Fuser control circuit

Engine controller unit

DC controller

RL1002

Fuser heater

control circuit

Fuser film

TP1

RL1001

TH2

TH1

Frequency

detection circuit

Relay control

circuit

Fuser heater

safety circuit

ZEROX

RLYD

FSRTH2

FSRTH1

FSRD

H1

Pressure roller

Fuser

H1: Fuser heater

TP1: Thermoswitch

TH1: Main thermistor

TH2: Sub thermistor

18 Chapter 1 Theory of operation ENWW

Page 33

Fuser protective function

The protective function detects an abnormal temperature rise of the fuser unit and interrupts power

supply to the fuser heater.

The following three protective components prevent an abnormal temperature rise of the fuser heater:

DC controller

●

The DC controller interrupts power supply to the fuser heater when it detects an abnormal

◦

temperature of the fuser heater.

Fuser heater safety circuit

●

The fuser heater safety circuit interrupts power supply to the fuser heater when the detected

◦

temperature of the main and sub thermistors is abnormal.

Thermoswitch

●

The contact of the thermoswitch is broken to interrupt power supply to the fuser heater when

◦

the thermoswitch detects an abnormal temperature of the fuser heater.

ENWW Engine-control system 19

Page 34

Low-voltage power supply

The low-voltage power supply (LVPS) converts ac input voltage to dc voltage. The LVPS has two fuses

on the PCA. The LVPS 24 V output is interrupted to the fuser and the high-voltage power supply if the

cartridge-door interlock switch (SW501) is in the off position (cover open).

WARNING! The product power switch only interrupts dc voltage from the LVPS. The ac voltage is

present in the product when the power cord is plugged into a power receptacle and the power switch is

in the off position. You must unplug the product power cord before servicing the product.

Figure 1-13 Low-voltage power supply (LVPS)

Fuse(FU1001)

Low-volt age power supply

Noise filter

Engine controller unit

Fuser control

circuit

Fuser

Noise filter

Protection

circuit

Fuse(FU1002)

+24V generation

circuit

REM24

+3.3V generation

circuit

+5V generation

circuit

+24V

+3.3V

/FDOORSNS

DC controller

Power-switch

control circuit

Power switch

(SW240)

High-voltage

power supply

+24R

Door switch

(SW501)

+24U

+3.3V

+5V

20 Chapter 1 Theory of operation ENWW

Page 35

Overcurrent/overvoltage protection

The low-voltage power supply has a protective function against overcurrent and overvoltage to prevent

failures in the power supply circuit. If an overcurrent or overvoltage condition occurs, the system

automatically cuts off the output voltage.

If the DC power is not being supplied from the low-voltage power supply, the protective function might

be running. In such case, turn off the power switch and unplug the power cord. Do not plug in the power

cord or turn on the power switch again until the cause is found.

WARNING! If you believe the overcurrent or overvoltage protection circuits have been activated, do

not plug in the product power cord or turn on the product power until the cause of the failure is found

and corrected.

In addition, two fuses in the low-voltage power supply protect against overcurrent. If overcurrent flows

into the AC line, the fuses melt and cut off the power distribution.

ENWW Engine-control system 21

Page 36

High-voltage power supply

The high-voltage power supply (HVPS) applies biases to the following components:

Primary charging roller

●

Developing roller

●

Transfer roller

●

Fusing film

●

Figure 1-14 High-voltage power supply

Engine controller unit

DC controller

High-voltage power supply

Fuser film bias

charging bias

circuit

Primary

circuit

FSRB

FILMB

PRI

Fuser

Fuser film

Pressure roller

Cartridge

To primary charging roller

To developing roller

Developing

bias circuit

Transfer bias

circuit

DEV

Photosensitive drum

Transfer roller

TR

22 Chapter 1 Theory of operation ENWW

Page 37

Formatter

Formatter heartbeat LED

The heartbeat LED indicates that the formatter is functioning correctly. While the product is initializing

after you turn the product on, the LED blinks rapidly, and then turns off. When the product has finished

the initialization sequence, the heartbeat LED pulses on and off. For more information abut the heartbeat

LED see

DIMM slots

CAUTION: Single inline memory modules (SIMMs) used in previous HP LaserJet products are not

compatible with the product.

The formatter has one dual inline memory module (DIMM) slot for upgrading the product with more

memory.

To find out how much memory is installed in the product, print a configuration page. For more information

about memory, see

Formatter heartbeat LED on page 133.

DIMM cover and DIMM on page 57.

ENWW Engine-control system 23

Page 38

Laser/scanner system

The laser/scanner system receives VIDEO signals from the ECU and the formatter and converts the

signals into latent images on the photosensitive drum.

The main components of the laser/scanner are the laser unit and the scanner motor unit. The DC

controller sends signals to the laser/scanner to control the functions of these components.

Figure 1-15 Laser/scanner system

Engine controller unit

Formatter

DC controller

BDI signal

VIDEO signal

LASER CONTROL signal

SCANNER MOTOR CONTROL signal

Scanning mirror

BD sensor

Scanner motor unit

Photosensitive drum

Laser unit

24 Chapter 1 Theory of operation ENWW

Page 39

Laser failure detection

The DC controller determines an optical unit failure and notifies the formatter, if the laser/scanner

encounters the following conditions:

The scanner motor does not reach a specified rotation within a specified period of the scanner

●

motor start up.

The rotation of the scanner motor is out of specified range for a specified period during the scanner

●

motor drive.

The BD interval is out of a specified value during a print operation.

●

ENWW Engine-control system 25

Page 40

Image-formation system

Electrophotographic process

The electrophotographic process forms an image on the paper. Following are the major components

used in the process:

Print cartridge

●

Transfer roller

●

Fuser

●

Laser/scanner

●

The DC controller uses the laser/scanner and HVPS to form the toner image on the photosensitive drum.

The image is transferred to the print media and then fused onto the paper.

Figure 1-16 Electrophotographic process block diagram

Laser scanner

Laser beam

Cartridge

Fuser

Transfer roller

High-voltage power supply

DC controller

Engine controller unit

26 Chapter 1 Theory of operation ENWW

Page 41

Image formation process

Each of the following process function independently and must be coordinated with the other product

processes. Image formation consists of the following processes:

Latent-image formation block

●

Step 1: primary charging

◦

Step 2: laser-beam exposure

◦

Developing block

●

Step 3: developing

◦

Transfer block

●

Step 4: transfer

◦

Step 5: separation

◦

Fusing block

●

Step 6: fusing

◦

Drum cleaning block

●

Step 7: drum cleaning

◦

Figure 1-17 Image formation process

: Media path

: Direction of drum rotation

: Block

: Step

1. Primary charging

Delivery

Drum cleaning

6. Fusing (Fixing)

Fusing (Fixing)

7. Drum cleaning

Latent image formation

2. Laser-beam exposure

5. Separation

Transfer

3. Developing

4. Transfer

Developing

Pickup

ENWW Image-formation system 27

Page 42

Latent-image formation stage

During the latent-image formation stage, the laser/scanner forms an invisible image on the

photosensitive drum in the print cartridge.

Primary charging

Step 1: DC and AC biases are applied to the primary charging roller, which transfers a uniform negative

potential to the photosensitive drum.

Figure 1-18 Primary charging

Primary charging roller

Photosensitive drum

Laser beam exposure

Step 2: The laser beam scans the photosensitive drum to neutralize negative charges on parts of the

drum surface. An electrostatic latent image is formed on the drum where negative charges were

neutralized.

Figure 1-19 Laser beam exposure

Primary charging bias

Laser beam

Unexposed area Exposed area

28 Chapter 1 Theory of operation ENWW

Page 43

Developing stage

Print cartridge

Step 3: In the print cartridge, the developing cylinder comes in contact with the photosensitive drum to

deposit toner onto the electrostatic latent image.

Figure 1-20 Print cartridge

Blade

Exposed area Unexposed area

Unexposed area

Toner acquires a negative charge from the friction that occurs when the developing roller rotatesagainst

the developing blade. The developing bias is applied to the developing roller to make a potential

difference between the developing roller and the photosensitive drum. The negatively charged toner is

attracted to the latent image on the photosensitive drum because the drum surface has a higher

potential.

Developing roller

Photosensitive drum

Exposed area

Developing bias

ENWW Image-formation system 29

Page 44

Transfer stage

Step 4: The transfer charging roller, to which a DC positive bias is applied, imparts a positive charge

on the print media. When the print media comes in contact with the photosensitive drum, the toner is

transferred to the print media.

Figure 1-21 Transfer

Step 5: The elasticity of the print media causes its separation from the photosensitive drum. A static

charge eliminator aids separation by weakening any electrostatic adhesion.

Photosensitive

drum

Media

Transfer roller

Transfer bias

Figure 1-22 Separation

Static charge eliminator

Fusing stage

Step 6: The DC negative bias applied to the fusing film strengthens the holding force of the toner on the

print media and prevents the toner from scattering.

Photosensitive

drum

Media

Transfer roller

30 Chapter 1 Theory of operation ENWW

Page 45

The product uses an on-demand fuser method. The toner image is permanently affixed to the printing

paper by heat and pressure.

Figure 1-23 Fusing

Cleaning stage

Fuser heater

Brush

Fuser film

Toner

Media

Pressure roller

Fuser bias

Step 7: The cleaning blade scrapes the residual toner off of the photosensitive drum and deposits it into

the waste toner case.

Figure 1-24 Drum cleaning

Cleaning blade

Toner collection box

Photosensitive

drum

ENWW Image-formation system 31

Page 46

Toner detection

The product uses a nonvolatile memory tag built into the print cartridge. Print-cartridge detection

happens when the engine controller detects the presence of a genuine HP print-cartridge that contains

a memory tag. Toner detection happens as the engine controller reads or writes the data that is stored

on the memory tag. The engine controller renews the information in the prescribed timing and reads or

writes it from or to the memory tag.

The engine controller commands the memory tag to read or write with the following conditions:

Read

●

Power is on

◦

The cartridge door is closed

◦

A command is received from the formatter

◦

Write

●

A page of media is printed

◦

A command is received from the formatter

◦

When the engine controller fails to read or write three times in a row, it determines that the memory tag

is abnormal and sends a cartridge memory abnormality warning to the formatter.

Figure 1-25 Print cartridge memory tag

32 Chapter 1 Theory of operation ENWW

Page 47

Pickup, feed, and delivery system

The pickup/feed/delivery system consists of several types of feed rollers and sensors. The ECU uses

a motor and two solenoids to drive the rollers. Three media-detection sensors detect paper as it passes

through the product. If media does not reach or pass each sensor within a specified time, the ECU

determines that a jam has occurred and alerts the formatter.

Paper trays

The product has the following paper trays:

Tray 1 (multipurpose tray; all models)

●

Tray 2 (500-sheet tray; all models)

●

Tray 3 (optional 500-sheet input tray; HP LaserJet P3015x)

●

Tray 4 (optional 500-sheet input tray)

●

ENWW Pickup, feed, and delivery system 33

Page 48

Photo sensors and switches

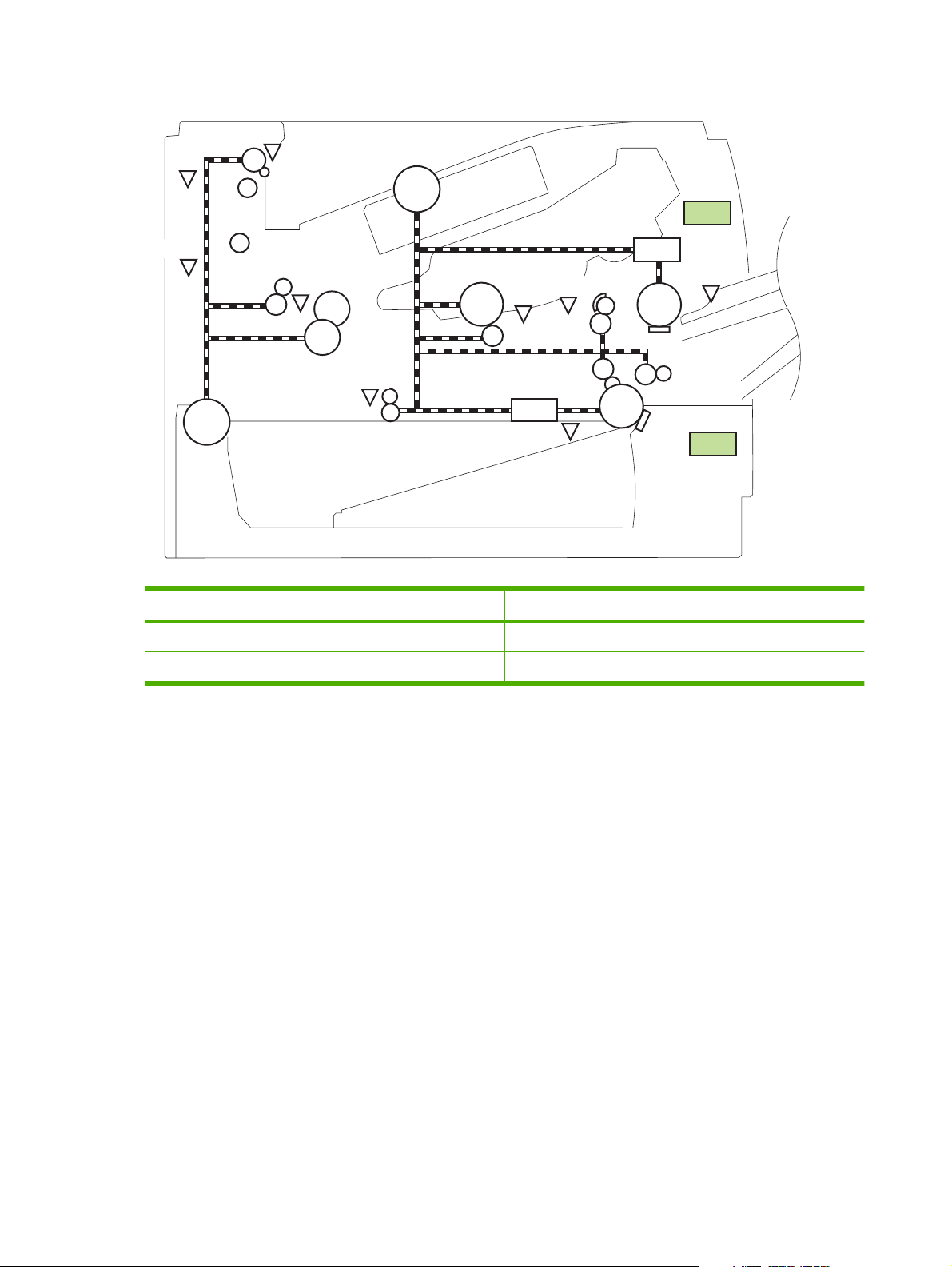

Figure 1-26 Photo sensors and switches (product)

PS4

PS1

M8001

SW501

PS8001

M8002

PS2

PS502

PS225

SL2

PS215

PS3

SL1

PS205

SW235

Table 1-10 Photo sensors and switches (product)

Item Description Item Description

PS1 Face-up sensor PS215 Top-of-Page (TOP) sensor

PS2 Fuser delivery sensor PS225 Media width sensor

PS3 Cassette media-presence sensor PS502 Duplex media-feed sensor (duplex models only)

PS4 Face-down tray media-full sensor PS8001 Rear door sensor

PS205 Tray 1 (MP tray) media-presence sensor SW235 Cassette presence sensor

34 Chapter 1 Theory of operation ENWW

Page 49

Figure 1-27 Photo sensors and switches (Tray 3 and Tray 4)

M8001

CL1

SL3

PS451

PS8008

SW461

Table 1-11 Photo sensors and switches (Tray 3 and Tray 4)

Item Description

PS451 Paper feeder cassette-media presence sensor

PS8008 Paper feeder media-feed sensor

SW461 Paper feeder cassette presence switch

1

Tray 3 and Tray 4 are identical 500-sheet input trays.

ENWW Pickup, feed, and delivery system 35

Page 50

Solenoids and clutches

Figure 1-28 Solenoids and clutches (product)

PS4

PS1

M8001

SW501

PS8001

M8002

PS2

PS502

PS225

SL2

PS215

PS3

SL1

PS205

SW235

Table 1-12 Solenoids and clutches (product)

Item Description

SL1 Tray 1 (multipurpose tray) pickup solenoid

SL2 Cassette (Tray 2) pickup solenoid

36 Chapter 1 Theory of operation ENWW

Page 51

Figure 1-29 Solenoids and clutches (Tray 3 and Tray 4)

M8001

CL1

SL3

PS451

Table 1-13 Solenoids and clutches (Tray 3 and Tray 4)

Item Description

SL3 Paper feeder pickup solenoid

CL1 Paper feeder pickup clutch

1

Tray 3 and Tray 4 are identical 500-sheet input trays.

PS8008

SW461

ENWW Pickup, feed, and delivery system 37

Page 52

Tray 1 or Tray 2

Pickup and feed unit

The pickup and feed unit uses the following components and processes.

Cassette paper size detection/cassette paper detection

NOTE: To find the following components, see Photo sensors and switches on page 34.

PS3; cassette media-presence sensor

●

PS225; media width sensor (detects media width after the media enters the paper path)

●

Cassette pickup

NOTE: To find the following components, see Solenoids and clutches on page 36.

SL2; cassette (Tray 2) pickup solenoid

●

Tray 1 paper pickup

NOTE: To find the following components, see Photo sensors and switches on page 34 and Solenoids

and clutches on page 36.

PS205; Tray 1 (multipurpose tray) media-presence sensor

●

SL1; Tray 1 (multipurpose tray) pickup solenoid

●

38 Chapter 1 Theory of operation ENWW

Page 53

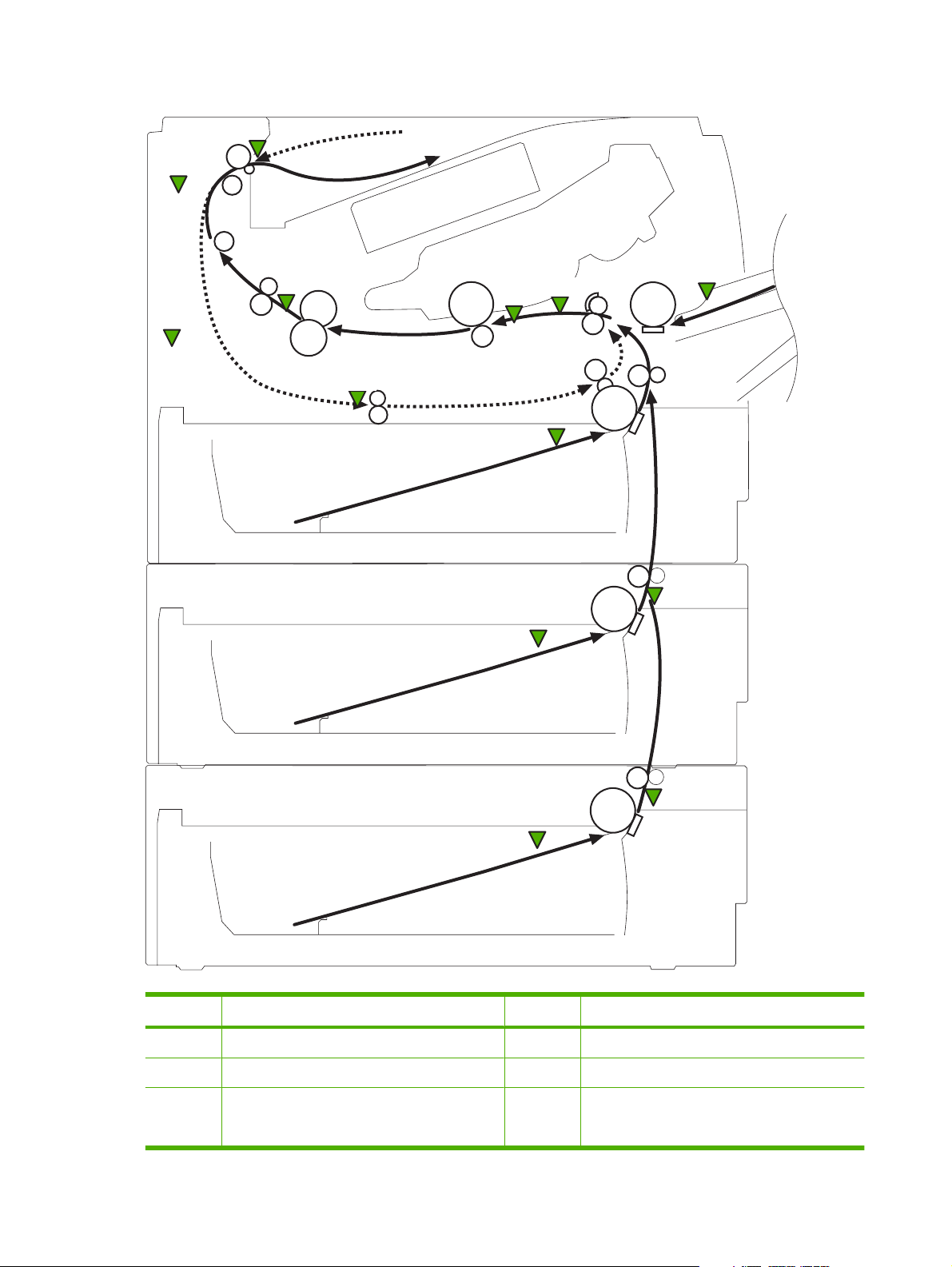

Paper pickup and feed

The following figure shows the pickup and feed paper path.

NOTE: Duplex models include a duplex media-feed path for automatic two-sided printing.

Figure 1-30 Pickup, feed, and delivery block diagram

Delivery roller

Fuser film

Pressure roller

Simplex media path

Duplex media path

Photosensitive drum

Transfer roller

Cassette pickup roller

MP tray pickup roller

MP tray separation pad

Cassette separation pad

ENWW Tray 1 or Tray 2 39

Page 54

Jam detection

The product uses the following sensors to detect the presence of media and to check for jams. If media

does not reach or pass each sensor within a specified time, the ECU determines that a jam has occurred

and alerts the formatter.

NOTE: To find the following components, see Photo sensors and switches on page 34.

PS2; fuser delivery sensor

●

PS4; face-down tray media-full sensor

●

PS215; Top-of-Page (TOP) sensor

●

PS225; media width sensor

●

PS502; duplex media-feed sensor (duplex models only)

●

PS8008; paper feeder media-feed sensor

●

NOTE: PS8008 is used in Tray 3 and Tray 4.

The product detects the following jams:

Pickup delay jam

●

Pickup stationary jam

●

Delivery delay jam

●

Delivery stationary jam

●

Fuser wrapping jam

●

Door open jam

●

Residual media jam

●

Duplex repickup jam (duplex models only)

●

40 Chapter 1 Theory of operation ENWW

Page 55

Additional tray

NOTE: This product supports identical 500-sheet input trays (Tray 3 and Tray 4).

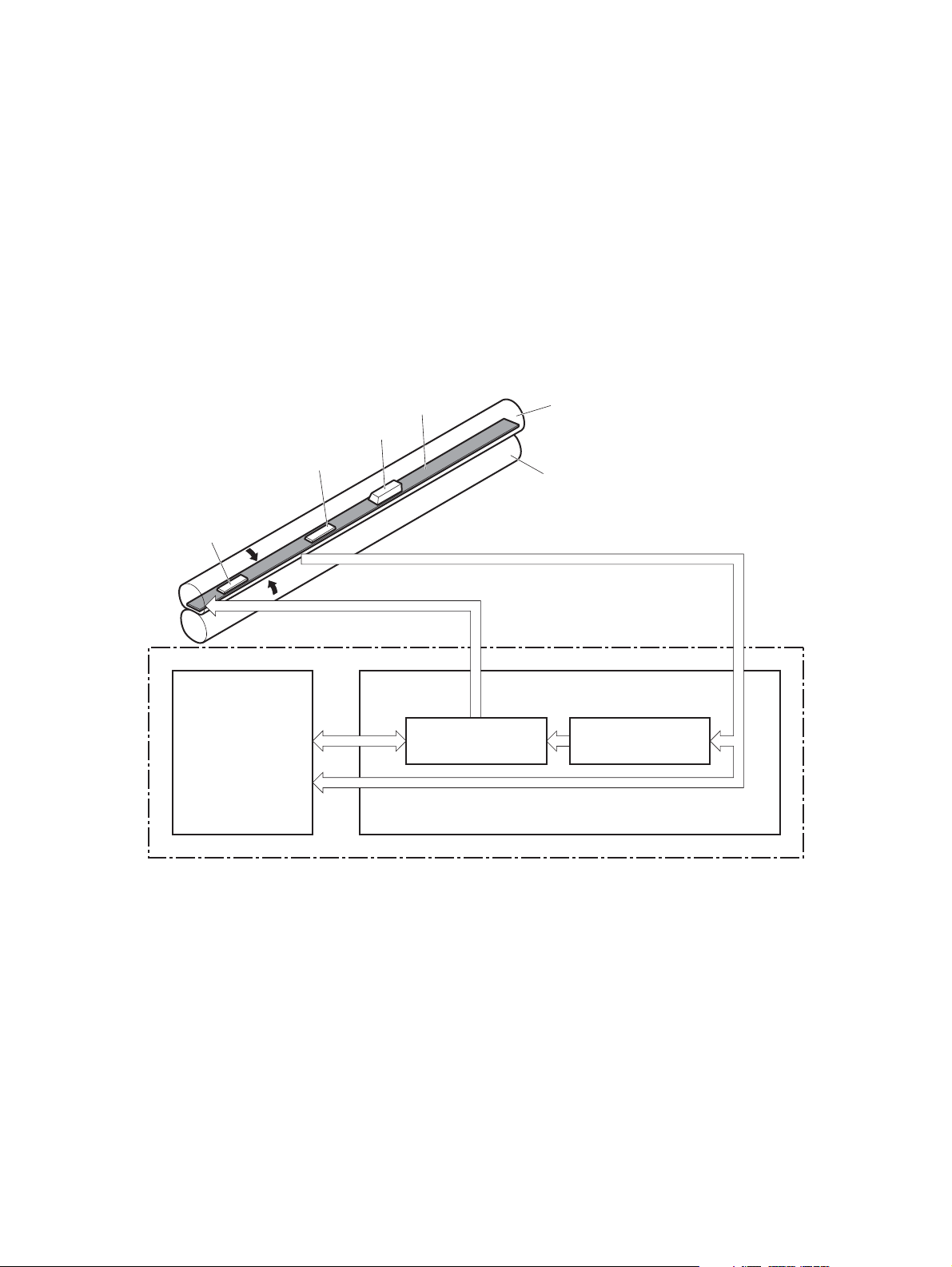

Tray driver PCA

The following figure shows the signals between the DC controller and the tray driver PCA.

Figure 1-31 Tray 3 and Tray 4 driver PCA block diagram

Optional paper feeder

Clutch

DC controller

+24V

Paper feeder

Solenoid

connector PCB

Photointerrupter

Switch

ENWW Additional tray 41

Page 56

Paper pickup and feed

NOTE: Tray 3 and Tray 4 are identical 500-sheet input trays.

The following figure shows the pickup and feed paper path (Tray 3 shown).

Figure 1-32 Tray 3 and Tray 4 pickup, feed, and delivery block diagram

Optional paper feeder

separation pad

Optional paper feeder

pickup roller

Optional paper feeder

feed roller

42 Chapter 1 Theory of operation ENWW

Page 57

Media level and size detection

PS451; paper feeder media-presence sensor detects if media is present in the tray.

●

NOTE: PS451 is used in Tray 3 and Tray 4.

Media size is detected after the page enters the product. See

●

cassette paper detection on page 38.

Jam detection

PS8008; paper feeder media-feed sensor detects jams in the paper feeder.

●

Cassette paper size detection/

ENWW Additional tray 43

Page 58

44 Chapter 1 Theory of operation ENWW

Page 59

2 Removal and replacement

Removal and replacement strategy

●

Service approach

●

Removal and replacement procedures

●

ENWW 45

Page 60

Removal and replacement strategy

General cautions during removal and replacement

This chapter describes the removal and replacement of field-replaceable units (FRUs) only.

Replacing FRUs is generally the reverse of removal. Occasionally, notes and tips are included to provide

directions for difficult or critical replacement procedures.

HP does not support repairing individual subassemblies or troubleshooting to the component level.

WARNING! Turn the product off, wait 5 seconds, and then remove the power cord before attempting

to service the product. If this warning is not followed, severe injury can result, in addition to damage to

the product. The power must be on for certain functional checks during troubleshooting. However,

disconnect the power supply during parts removal.

Never operate or service the product with the protective cover removed from the laser/scanner

assembly. The reflected beam, although invisible, can damage your eyes.

The sheet-metal parts can have sharp edges. Be careful when handling sheet-metal parts.

CAUTION: Do not bend or fold the flat flexible cables (FFCs) during removal or installation. Also, do

not straighten prefolds in the FFCs. You must fully seat all FFCs in their connectors. Failure to fully seat

an FFC into a connector can cause a short circuit in a PCA.

Incorrectly routed or loose wire harnesses can interfere with other internal components and can become

damaged or broken. Frayed or pinched harness wires can be difficult to find. When replacing wire

harnesses, always use the provided wire loops, lance points, or wire-harness guides and retainers.

NOTE: To install a self-tapping screw, first turn it counterclockwise to align it with the thread pattern,

and then carefully turn it clockwise to tighten. Do not overtighten. If a self-tapping screw-hole becomes

stripped, repair the screw-hole or replace the affected assembly.

Note the length, diameter, color, type, and location of each screw. Be sure to return each screw to its

original location during reassembly.