Page 1

May 1998 Edition

HP Color LaserJet and

HP Color Laser Jet 5/5M Printer

Quick Reference Service Guide

Page 2

Page 3

HP Color LaserJet and

HP Color LaserJet 5/5M

Printer Quick Reference

Service Guide

Page 4

© Copyright Hewlett-Packard

Company 1998

All Rights Reserved.

Reproduction, adaptation, or

translation without prior written

permission is prohibited, except

as allowed under the copyright

laws.

Publication number

5041-9258

First edition, May 1998

Warranty

The information contained in this

document is subject to change

without notice.

Hewlett-Packard makes no

warranty of any kind with respect

to this information.

HEWLETT-PACKARD

SPECIFICALLY DISCLAIMS

THE IMPLIED WARRANTY OF

MERCHANTABILITY AND

FITNESS FOR A PARTICULAR

PURPOSE.

Hewlett-Packard shall not be

liable for any direct, indirect,

incidental, consequential, or other

damage alleged in connection

with the furnishing or use of this

information.

Trademark credits

Adobe and PostScript are registered

trademarks of Adobe Systems, Inc.,

which may be registered in certain

jurisdictions.

®

Microsoft

trademark of Microsoft Corporation.

MS-DOS

trademark of Microsoft Corporation.

UNIX is a registered trademark in the

United States and other countries,

licensed exclusively through X/Open

Company Limited.

is a U.S. registered

®

is a U.S. registered

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 5

Ordering other manuals

This

HP Color LaserJet and HP Color LaserJet 5/5M Printer Quick

Reference Service Guide

service engineer quickly troubleshoot common printer problems. While

this reference is intended to pr ovide information the service engineer

will need for on-site repair of HP LaserJet color products, it is not

intended to replace the service manual for any HP LaserJet color

product. For detailed information about the HP LaserJet color products

described in this guide, see the user guide or service manual for that

product.

Service manuals for HP LaserJet products are available from

Hewlett-Packard. The phone number for the Service Parts Order

Desk is:

(800) 227-8164 (U.S. only)

If you are located outside of the U.S., contact your local HP Sales and

Service Office. See “Training and support resources” in chapter 9.

has been created to help the HP LaserJet

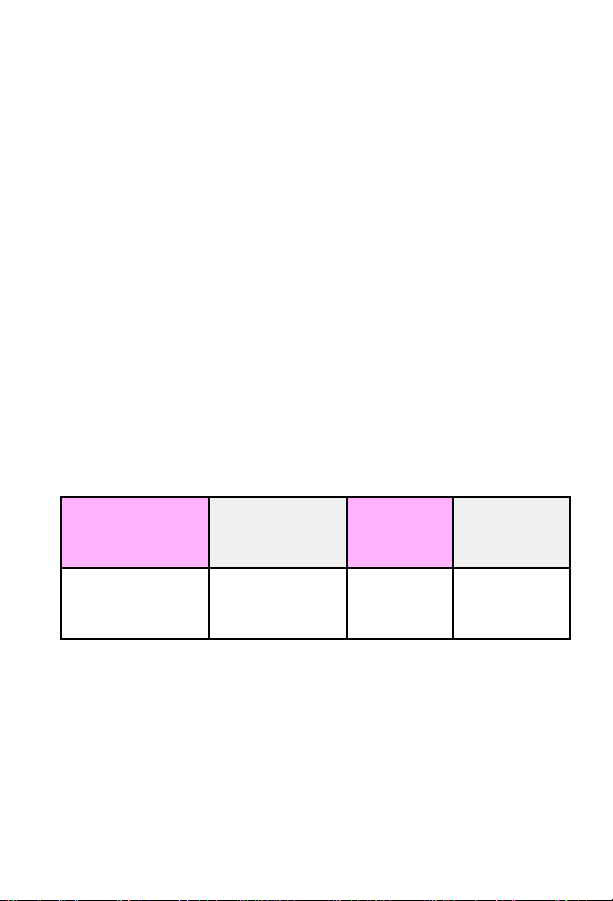

Supported products

Name used in

this guide

HP Color LaserJet/

HP Color LaserJet

5/5M

Model

number

C3100A

C3961A/C3962A/

Maximum

pages per

month

30K C3100-90916/

Service

manual part

number

C3961-90955

Note

This guide will be updated as the service needs change, as new

products are introduced, or as information becomes available.

EN

iii

Page 6

Contents

1 Troubleshooting control panel messages. . . . . . . . . . . . . 1

2 Cleaning and maintenance. . . . . . . . . . . . . . . . . . . . . . . 73

3 Service Mode and diagnostics . . . . . . . . . . . . . . . . . . . . 85

4 Media specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

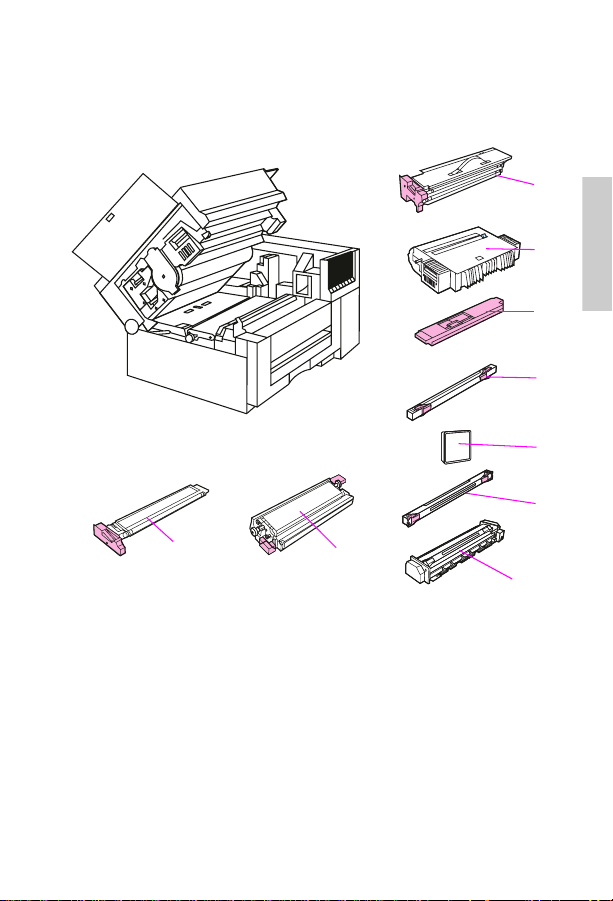

5 Printer options and replaceable parts. . . . . . . . . . . . . . 121

6 Parts and part locations . . . . . . . . . . . . . . . . . . . . . . . . 125

7 Image quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

8 Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

9 Training and support resources . . . . . . . . . . . . . . . . . . 205

A Acronyms and abbreviations. . . . . . . . . . . . . . . . . . . . . 213

iv

EN

Page 7

Troubleshooting

1

control panel

messages

Overview

This chapter contains the following sections:

Pretroubleshooting checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contains a list of questions to address bef ore troubleshootin g printer

problems

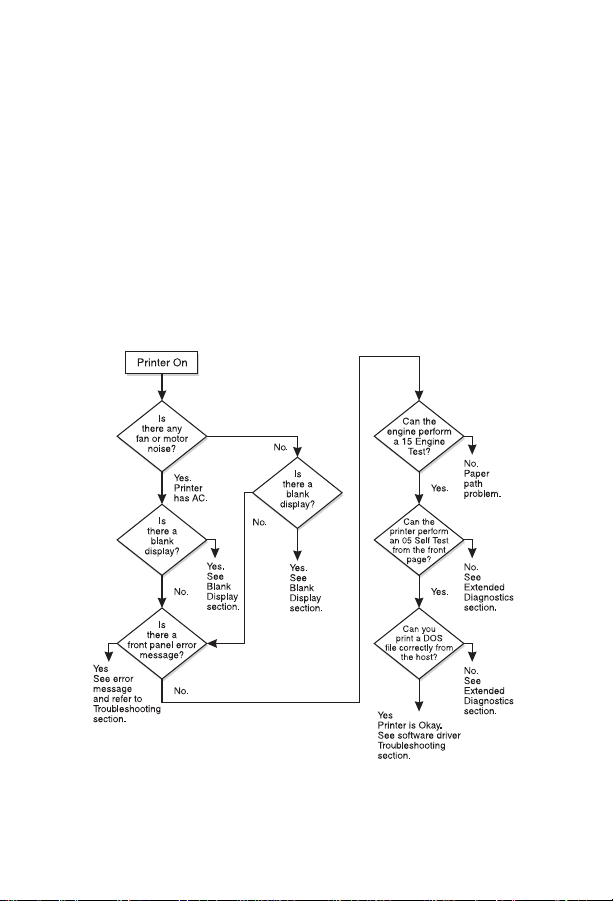

Basic troubleshooting process . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Includes a flowchart that provides help in solving printer hardware

problems

Control panel messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Provides a list of control panel messages along with solutions.

Alphabetical messages are listed first, followed by numerical

messages. Self-explanatory messages are not included.

Aids to troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Provides tools to help isolate the cause of many printer failures,

including troubleshooting by part swapping and a self-test printout

Troubleshooting paper feed problems. . . . . . . . . . . . . . . . . . . . . . 68

Provides preventive and troubleshooting techniques for paper and

paper path jams

Note

If you need more detailed information, see the printer service manual.

EN

Overview

1

Page 8

Pretroubleshooting checklist

WARNING!

Always unplug the printer before servicing. Current is present in the

main body cooling fan (M4), the noise filter board (Color LaserJet

only), the AC driver board (Color LaserJet only), and the DC power

supply whenever the printer is plugged in.

Before troubleshooting any specific printer problem, check the following:

• Has the printer been maintained on a regular basis (as described in

Chapter 2, “Cleaning and maintenance”)?

– Note the location of spilled or accumulated toner before

troubleshooting. Toner contamination may be an indication of

another problem.

Note

The customer is responsible for ensuring that the maintenance units

are in good condition.

• Are all of the maintenance units within their rated life?

• Is the customer using media as specified in Chapter 4, “Media

specifications” and the

Guide

?

• Is the media stored correctly and within environmental limits?

• Is the printer installed on a solid, level surface?

• Has the line voltage been chec ked to ma ke sure that it does not v ary

more than 20% from the nominal rated v alue specified on the po w er

rating label?

– Large motors used near the printer can cause temporary voltage

changes.

• Is the operating environment within the parameters listed in the

printer service manual?

• Is the printer protected from substances such as office cleaning

materials and the ammonia gas that is produced by diazo copiers?

HP LaserJet Family Paper Specification

2 Chapter 1 – Troubleshooting control panel messages

EN

Page 9

• Is the printer protected from direct sunlight?

• Have all non-HP components (toner, typeface cartridges, memory

boards, and MIO cards) been removed from the printer?

CAUTION

Using non-HP components, such as toner, may cause permanent

damage to the printer.

• Has the printer hardware or software configuration changed?

Or could the problem be associated with any specific software?

– Contact the Customer Care Center for software-related problems

(see Chapter 9, “Training and support resources”).

• Could the problem be related to network configuration changes?

– Remove the printer from the network and make sure that the

failure is associated with the printer before beginning

troubleshooting.

1

EN

Pretroubleshooting checklist

3

Page 10

Basic troubleshooting process

The troubleshooting flowchart shown below highlights the process that

most quickly solves printer hardware problems. During its power-on

sequence, the printer verifies that its components are operating

correctly. If the printer fails to turn on correctly, use the steps shown in

the flowchart to troubleshoot the failure.

Note

User-accessible parts are blue-coded in the Color LaserJet and

purple-coded in the Color LaserJet 5/5M.

Troubleshooting flowchart

4 Chapter 1 – Troubleshooting control panel messages

EN

Page 11

Control panel messages

Alphabetical messages

Blank display

• Remove the cover over the display and look in the upper right-hand

corner of the vacuum florescent display (VFD). The dot should be

dark. If it is white, the vacuum in the display has been lost. Replace

the front panel.

• Turn off the printer. Then unplug and plug in the printer before

turning the printer on again.

• Check the 5 VDC on Fuse 1 on the control PCA, as shown in

“Voltage checks” in the printer service manual. The 5 VDC may be

missing.

• Reseat the display connections.

• Reseat the formatter.

• Check the fuses and connectors and listen for running fans and

motors when turning the printer on.

– If no fans or motors are running, there is no AC voltage to the

unit.

• Check the voltage at the test connector.

• Replace the formatter.

Config language

• Do not interrupt this installation sequence.

• This message is displayed when pressing and holding

turning the printer on. When the power-on self-test is completed, the

display language menu is available for configuration. This message

is not localized.

[Enter]

while

1

EN

Control panel messages

5

Page 12

Drum inst./drum number = xxx

• This message indicates that the printer has detected a new drum

and is waiting for the user to enter the number that is printed on the

bar-code label on the front of the drum. Press the [+] and [-] keys to

enter this information. The number xxx is a whole number between

1 and 127.

Note

The drum number (or drum ID) should match the number shown on

the self-test printout. (See “Understanding the self-test printout” on

page 64.)

Note

If the incorrect number was entered when the

number = xxx

message appeared, it can be corrected now.

Drum inst./drum

Error log

• To display this message, press and hold [Form Feed] while

power-cycling the printer.

• When the power-on self-test is completed, the error log is available

to use. See Chapter 7 in the printer service manual for instructions

on entering the Error Log Mode. This message is not localized.

Extended diagnostics

• Use extended diagnostics to test the printer when formatter,

memory (DRAM only), and MIO-related errors persist. The extended

diagnostics test exercises the ability of the f ormatter to communicate

across the MIO and with the memory. To perform the extended

diagnostics tests, see “Extended diagnostics” on page 110.

6 Chapter 1 – Troubleshooting control panel messages

EN

Page 13

FE font cart err/cycle power

Color LaserJet only

• The font cartridge was removed while the printer was online.

– This error occurs whether or not the cartridge was being

accessed.

– Power cycle the printer to clear this error.

Initializing NVRAM

• This message occurs when NVRAM must be initialized because one

or more values are incorrect.

• After the initialization is complete, the printer self-test message

appears.

Note

This message should only appear when the printer is turned on. It

should never appear during normal printer operation.

Installing new developer

Note

Do not interrupt this installation sequence.

• The new developer sequence has started.

– The installation sequence lasts about 3 minutes for the black

developer and 9 minutes for the color developer.

No fonts top/bottom/both font cartridge

1

Color LaserJet only

• The printer is not reading some (or all) of the indicated cartridges.

– To clear this error, reinsert the specified font cartridge and press

.

[Online]

• If the message persists, the indicated cartridge is bad and should be

replaced.

EN

Control panel messages

7

Page 14

Please verify drum number = xxx

• Re-enter the drum number for verification.

– Press the [+] and [-] keys to change the displayed number. If the

incorrect number was entered when the Drum inst. drum

number + xxx message appeared, it can be corrected now.

– This verifies that the correct number was entered.

Reinsert top/bottom/both font cartridge

Color LaserJet only

• Any or all of the font cartridges were removed while the printer was

offline and contained buffered data.

• Clear this error by reinserting the specified cartridge(s) and pressing

[Online].

Service Mode

• Service Mode is used to test printer functions by issuing commands

to the control PCA through the control panel. For more information

on this display panel message, see “Accessing Service Mode” on

page 87.

8 Chapter 1 – Troubleshooting control panel messages

EN

Page 15

Numerical messages

11.x Front tray empty

• The paper tray is not installed, or the tray is empty.

– Load paper.

– Check the paper-size detect board.

– Check that the switch actuators (on the tray) are not damaged.

11.4 Front tray empty

• The paper-out photosensor (PS8) senses an empty tray.

• If paper is in the tray, the sensor arm could be stuck or broken.

Troubleshoot PS8 as follows:

Remove the paper tray and open the top cover.

1

Check that the paper-size switch actuators on the tray are not damaged.

2

Check that PS8 is free throughout its entire range of travel and is properly

3

located in its mount.

Check that connector CN802 (on the controller) is fully seated.

4

If the error persists, perform the PS8 Service Mode Test as described

5

below.

PS8 Service Mode test

• PS8, the paper-out photosensor, can be tested in Service Mode as

follows:

Enter Service Mode (see “Accessing Service Mode” on page 87) and

1

select the Status Test Mode.

Enter the PS8 test address (10) and press

2

With no tray installed, the display will read

3

Open the printer, lift the paper guide, and move the sensor shaft through

4

its range of motion.

The display should change from low to high (

5

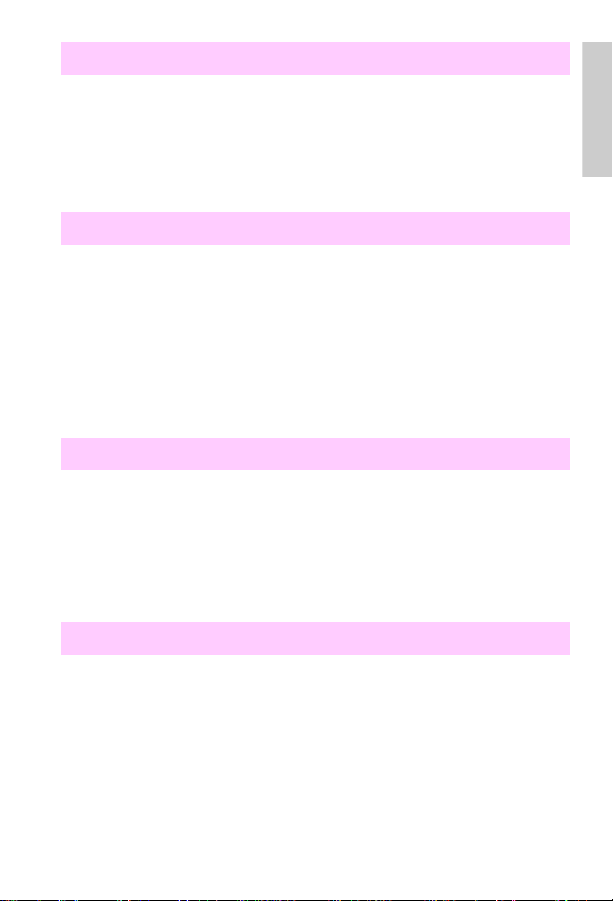

activated. If it does not change, check that the PS8 connector on the highvoltage power supply (HVPS) is fully seated, as shown in the figure below.

(The connectors are on the back of the HVPS.)

Replace the photosensor.

6

.

[Enter]

for paper tray empty.

0

to 1) as the photosensor is

0

1

EN

Control panel messages

9

Page 16

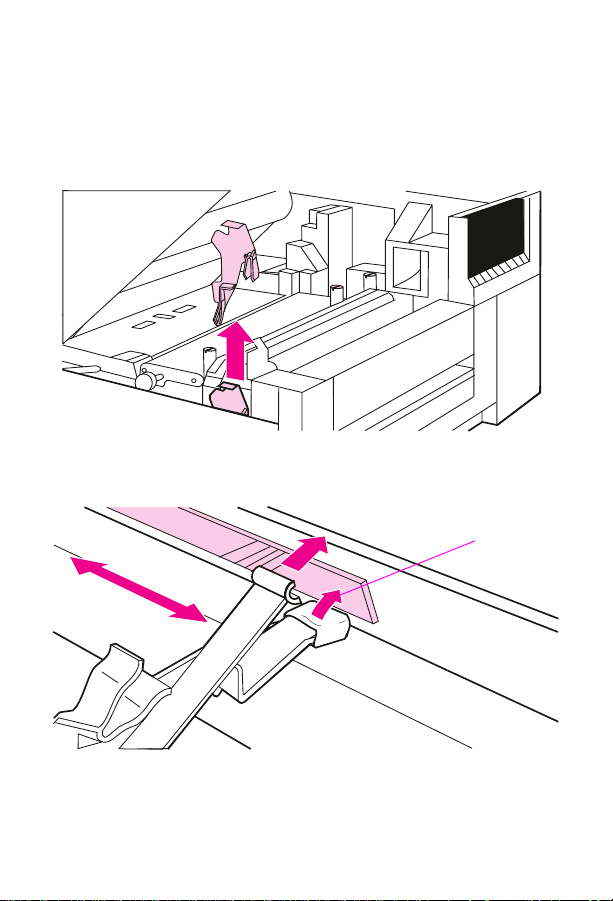

Photosensor PS8 connections on HVPS (HVPS inverted)

11.X Rear tray empty

• Check that the rear feed unit (RFU) is installed and that it has paper

in it.

• Remove the RFU and check that the connector is not damaged.

• Remove and reseat the RFU if paper is present.

Note

Do not remove or install the RFU when the power is on. The printer

only checks for the prese nce of the RFU when the printer is turned on.

10 Chapter 1 – Troubleshooting control panel messages

EN

Page 17

12 Close top or side door

• The printer’s top or side door is open or the door sensor has failed.

– Close the top or side door or replace the door sensor.

• One of the two interlock switch es (MS2 or MS3) m ay be defective . If

the following test proves that the switches are defective, replace the

interlock switch assembly as shown in Chapter 6 of the printer

service manual.

Note

Power cycle the printer and re-close both doors to confirm the

message before troubleshooting.

Test the interlock switch

WARNING!

Do not inhibit the free movement of the interlock switch. If this

mechanism is blocke d, voltage ma y be present when the top cove r is

open.

Open and close the top cover. If the message remains, open and

1

close the side door.

Open the side door and push the interlock mechanism with a flat-

2

blade screwdriver (see “Testing the interlock switches” on page 7-21

of the service manual), while running test 41 from Service Mode

(see Chapter 3).

If the message persists, remove the top cover and check that the

3

switch linkage is not bent.

Check that the switch connectors are in good repair. Toggle the

4

switches by pressing down on the metal tab over the switches.

If the linkage is not damaged, remove the switch assembly and test

5

it with an ohmmeter.

Replace the assembly if it is defective.

6

1

EN

Control panel messages

11

Page 18

13.1 Clear drum winding jam

Note

The locations of all sensors are identified on page 139.

• Paper is detected in the out of limit area of the print drum. The

drum-winding jam sensor indicates that paper is beginning to wrap

around the print drum.

– Turn the paper stack over end-to-end.

– Check that the paper meets HP paper specifications for the

printer.

– Check that media is not being re-fed into the printer.

– Check that the drum-wrap sensor is not blocked by opening the

side door and checking for paper wrapped around the drum.

• If no paper is seen, calibrate the drum-winding jam sensor by

entering into Service Mode (see “Accessing Service Mode” on

page 87“) and running test 47.

• See “Troubleshooting paper feed problems” on page 68.

13.2 Clear output jam

Note

The locations of all sensors are identified on page 139.

• Print media is jammed in the exit assembly because it failed to clear

the exit sensor (PS1) in the allotted time.

– Check that the sensor flag moves freely and that the sensor is

free of paper dust.

– Check that media is not in the sensor when the printer is turned

on.

– Te st th e operation of the sensors by entering Service Mode (see

“Accessing Service Mode” on page 87“) and running test 22.

• See “Troubleshooting paper feed problems” on page 68.

12 Chapter 1 – Troubleshooting control panel messages

EN

Page 19

13.4 Clear front tray input jam

Note

The locations of all sensors are identified on page 139.

• The printer detects a paper jam in the front tray area.

– Clear the front tray area.

• The paper failed to arrive at PS7 within the allotted time after SL1

(the paper feed solenoid) was engaged.

– Inspect the input an d registrati on area f or media . Transparencies

can be especially difficult to see.

– Test the operation of the sensors by entering Service Mode (see

“Accessing Service Mode” on page 87“) and running test 20.

• See “Troubleshooting paper feed problems” on page 68.

13.5 Clear fuser jam (CLJ)

13.5 Clear paper jam (CLJ5)

• Paper did not arrive at PS1 (exit sensor) in the allotted time. (See

the diagram on page 141 for the location of PS1.)

– Check that PS1 is free throughout its entire range of travel and

that media is not at the sensor when the printer is turned on.

– Check for paper dust in the sensor.

– Chec k to see if me dia has cleared the reg istra tion pl ate. If media

is present, check the operation of the registration plate solenoid

by running test 25 from the status and test section of the printer

service manual.

• Check to see if the transfer assembly is installed correctly.

• Test the interlock switch. (For instructions, see the section called “To

test the interlock switch” under erro r message 12 on page 11.)

• See “Troubleshooting paper feed problems” on page 68.

1

EN

Control panel messages

13

Page 20

13.6 Clear rear tray input jam

• The printer detects paper in the rear input area.

– Clear the RFU.

• The sensor (PS4) did not activate within the allotted time after M7

started. (See the diagram on page 142 for the location of PS4.)

– Repair the sensor.

– Check that PS4 is not blocked.

• Sensor PS4, the RFU paper sensor, failed to detect paper media

within the allotted time.

– Check that the sensor is not stuck.

– Check if media has been picked from the tray.

• Verify that the RFU is properly adjusted for the loaded media.

• See “Troubleshooting paper feed problems” on page 68.

13.7 Clear rear tray paper jam

Note

The locations of all sensors are identified on page 140.

• The printer detects a paper jam at the rear input area. This message

indicates that the paper was picked, but did not arrive at the

registration area (PS7), in the allotted time.

– Clear the jam and check the paper feed rollers.

– Check that sensor PS4 is not defective and that it is free

throughout its travel.

• See “Troubleshooting paper feed problems” on page 68.

13.8 Clear paper jam

• Paper is jammed in the paper registration area.

– Open the printer and remove the jammed paper.

• Paper may be on PS7 when the printer is turned on. (See the

diagram on page 141 for the location of PS7.)

– Check that PS7 is free.

• See “Troubleshooting paper feed problems” on page 68.

14 Chapter 1 – Troubleshooting control panel messages

EN

Page 21

13.8 Internal paper jam during warm-up

• Media was detected in the printer during warm up.

– Open the top cover and clear any media found inside the printer.

– If no media is found in the printer, check all sensors by running

the tests described under error messages 13.1, 13.2, 13.4,

and 13.5.

• Verify that all paper path sensors are not blocked and that the

detection flags are free throughout their travel.

• See “Troubleshooting paper feed problems” on page 68.

14.5 Replace collection box

16.5 Replace collection box

• Remove the toner collection box from the OPC drum assembly and

inspect the flexible diaphragm (in the top surface of the collection

box).

– If the diaphragm has been pushed above the collection box

surface by accumulated toner, the box is full. In this case, the

collection box must be replaced. Do not attempt to push the

diaphragm down to correct this condition.

• The excess toner collection box is monitored by PS3. (See the

diagram on page 141 for the location of PS3.) Perform the sensor

checks below to isolate the problem.

Toner collection box full sensor tests

Power cycle the printer.

1

Open the top cover and lower the print drum.

2

Pull the toner collection box out of the drum assembly.

3

Verify that the toner-full flag is moving freely (it should raise up as

4

you are pulling the toner collection box out of the assembly and drop

down once the collection box is remo ved).

Check to see if the toner collection box is full. If the toner collection

5

box is full, the diaphragm will be pushed out. If it is pushed out, then

the collection box is full and needs to be replaced.

1

EN

Control panel messages

15

Page 22

CAUTION

Do not try to continue using the toner collection box by pushing the

diaphragm down.

6 Check that the PS3 sensor is fully seated, clean, and connected

properly. (See the diagram on page 141 for the location of PS3.)

If these tests are not effective, perform the PS3 Service Mode test

described below.

Note

If the collection box is overfilled, the printer may need a thorough

cleaning. In addition, the excess toner auger (inside the print drum)

may be compacted or broken. The print drum may have to be

replaced.

PS3 Service Mode test

Note

The PS3 sensor flag is not accessible to toggle by hand. You must

have an empty collection box to perform this test.

1 P o wer cycle the printer and enter the Service Mode (see “Accessing

Service Mode” in Chapter 3.)

2 Select the status and test Mode of the Service menu.

3 Enter the PS3 test address (55), and press [Enter].

4 Install the empty collection box. If the display is high (1), the sensor

is stuck or defective.

5 If the display is low (0), pull out the collection box about an inch to

make the sensor flag rise. If the displa y does not change from 0 to 1,

the sensor flag is stuck or brok en or the sensor (PS3) is disl odged or

defective .

6 Check connector CN904 on the toner sensor PCA (Color LaserJet

only).

16 Chapter 1 – Troubleshooting control panel messages

EN

Page 23

14.6 Replace coating kit

• If this message does not clear when the coating pad kit is replaced,

the fusible link in the coating pad may not be contacting the leaf

spring in the fusing assembly or a coating kit with a blown fuse has

been installed.

– Reseat the coating pad.

Color LaserJet only

• If a new style fusing assembly with a purple handle has been

installed, then the fusible-link contacts are not making proper

electrical contact with the contact fusing spring assembly.

– Reseat the cleaning roller.

CAUTION

The printer should continue to print when returned online. The fuser

and main drive may be damag ed if the oil pad and cleaning roller are

not replaced as soon as possible.

16.5 Replace collection box

• See “14.5 Replace collection box.”

17.1 Install developer

17.2 Install developer

• The printer failed to detect either the black developer (for the 17.1

message) or the color developer (for the 17.2 message).

– If the developer is not installed, install it.

Power cycle the printer.

1

If the message persists, remove the suspected developer and

2

inspect the blade connectors that insert into the toner sensor PCA.

Check that they are clean and straight. Also check the toner sensor

PCA connectors.

Re-install the developer.

3

1

EN

Control panel messages

17

Page 24

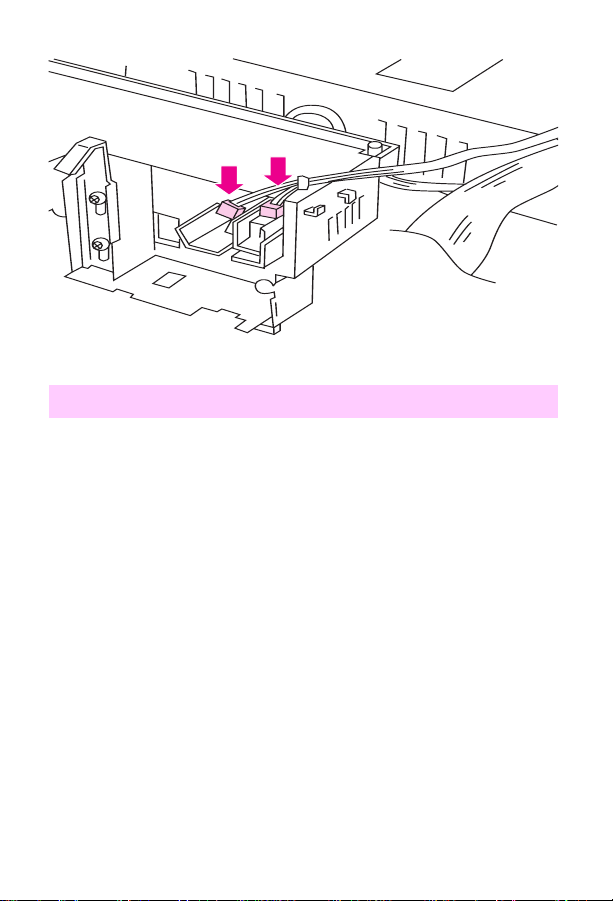

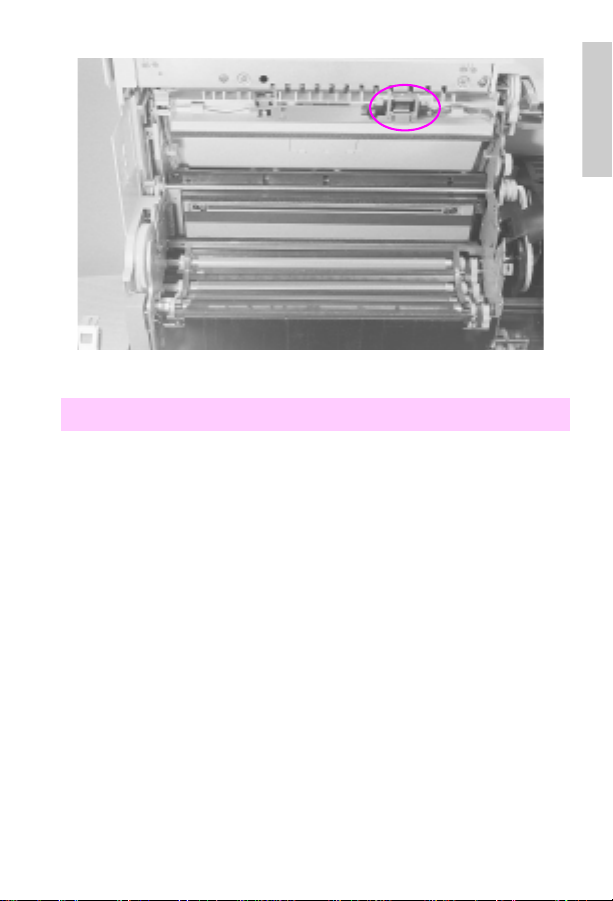

Ton er sensor PCA connections (circled)

4 Check all the connectors on the toner sensor PCA. Ensure that they

are all fully seated.

5 Check the wiring behind the power supply drawer for nicks or cuts

that may cause the signal line to short to ground. Reseat the

connectors if any are suspect.

6 Replace the toner sensor PCA if necessary.

7 If steps 1 through 6 do not resolve the problem, replace the

developer.

17.4 Install fuser

• The fuser is not installed, or the printer failed to detect the fuser.

1 Power cycle the printer.

2 If the message persists, remove and reseat the fuser.

3 Check that the fuser connectors are not damaged (no bent or

broken pins).

4 Check that nothing prevents the fuser from fully seating into its plug.

5 Check the connector (CN105) at the control PCA.

18 Chapter 1 – Troubleshooting control panel messages

EN

Page 25

Replace the fuser.

6

Replace the control PCA if necessary.

7

17.6 Install collection box

• The toner collection box or the print drum is not installed or is not

detected. The switches that post this message are inside the print

drum cartridge and cannot be tested directly.

Power cycle the printer to clear the message.

1

With the printer turned off and unplugged, inspect the print drum

connector (see the figure under “17.8 Reinstall drum”). Ensure that the

connections are not bent and that both the male and female ends are in

good repair and clean.

Ensure that nothing inhibits the print drum from fully seating into the

2

connection.

Check that CN101 on the control PCA and CN 254 on top of the

3

developer bias supply are fully seated.

Reseat the collection box and listen for an audible click.

4

If the collection box does not click into place, the leaf spring inside

5

the housing may be defective. Replace the print drum.

Remove the drum and very carefully clean the inside of the sensor,

6

using a cotton swab and isopropyl alcohol.

Re-install the drum.

7

1

EN

Control panel messages

19

Page 26

17.7 Remove drum cover

• The protective shipping cover for the print drum has not been

removed.

– Remove the drum cover (see the printer service manual for

instructions) or clear the drum wrap sensor.

• If the error persists, perform the status and test checks (see the

printer service manual) to test the drum wrap sensor.

• If the error still persists, perform the drum reflectance calibration

(Service Mode status and test address 47). Also see the procedures

for the 66.1 Jam sensor service message.

17.8 Reinstall drum

• This message indicates that the drum-winding sensor output is

abnormal during printing (see 66.1 Jam sensor error message).

• A jam sensor could be broken or defective, or a connection could be

loose.

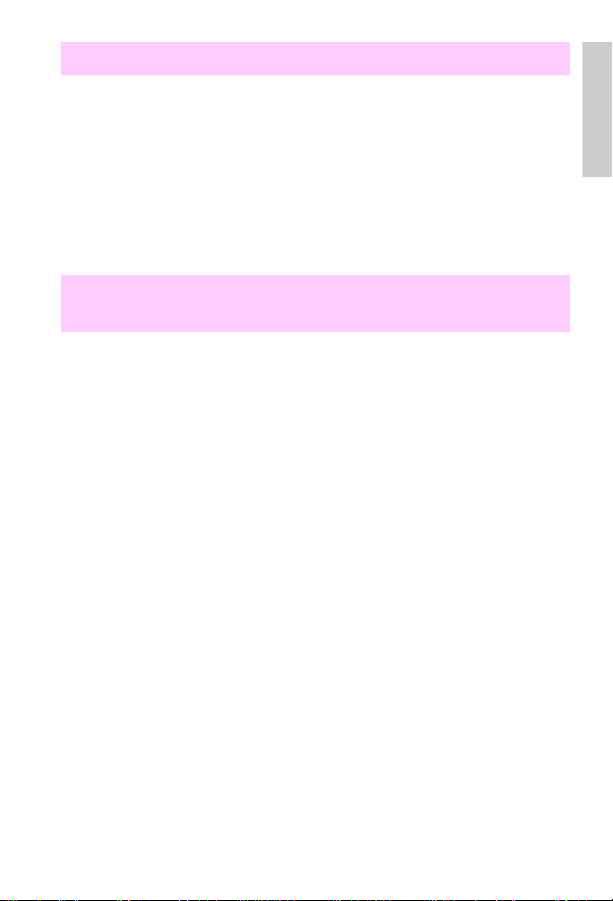

1 Remove the print drum and inspect both sides of the connector as

shown in the “Print drum connector” figure below.

2 Re-install the print drum. Check that nothing prevents the print drum

from being fully seated into the printer.

Note

If the drum assembly is for a Color LaserJet 5/5M (the assembly will

be purple-coded), you will need to make sure the corona cleaning

lever on the drum is fully seated to the right.

3 Power cycle the printer.

4 Run test 47 in Service Mode (see Chapter3 for information on

accessing Service Mode).

5 Replace the drum cartridge assembly.

20 Chapter 1 – Troubleshooting control panel messages

EN

Page 27

Print drum connector (circled).

17.9 Reinstall fuser

• The fuser did not warm up correctly.

– Reseat the fuser.

• The fuser connection is not stable.

WARNING!

The fuser is HOT. Turn off the printer to allow the fuser to cool for at

least 30 minutes before beginning this procedure.

– Power cycle the printer to clear the message.

• If the message persists:

– Remove the fuser. Check that all the connectors are strai ght an d

clean.

– Reseat the fuser, being certain that all the connectors make

contact.

• If the message persists, replace the fuser.

1

EN

Control panel messages

21

Page 28

18.1 Clean transfer corona wire

• The paper-charging brush or the bias roller in the transfer assembly

is arcing.

– Power cycle the printer.

– Clean the transfer corona wire (see Chapter 2, “Cleaning and

maintenance”).

– Check connector CN701 on the control PCA and connector

CN702 on the HVPS.

– Replace the transfer assembly and try another test print.

– Replace the HVPS.

18.2 Reinstall drum

• The printer sensed a high-voltage leak in the print drum neutralizing

corona.

– Power cycle the printer to clear this error.

– Remove and reinstall the print drum. Try a test print.

– Check connector CN731 on the control PCA and connector

CN730 on the HVPS.

– Check the neutralizing corona contact for damage or

contamination. (see the “Neutralizing corona contacts” figure

below.)

– Replace the print drum.

– Replace the HVPS.

• The neutralizing corona may have arced.

– Clean the printer.

22 Chapter 1 – Troubleshooting control panel messages

EN

Page 29

Neutralizing corona contacts (circled)

18.3 Reinsert developers

• The printer detected a high-voltage leak in the de v elo per bias po wer

supply. (Although this is a developer bias fault, the print drum is

often the root cause of this failure.)

• The developer is not turning.

Remove each developer and check their pin contacts.

1

Check that each of the high voltage contacts on the developer bias

2

assembly is clean and located correctly.

Print several self-tests and look for repetitive defects. Replace the

3

print drum if repetitive defects appear.

Remove the print drum and check its surface for any bright metallic

4

spots, dents, or def ects that may indicate an arcing point (anywhere

in the green area). Replace the print drum if any defects are found.

Check CN601 on the developer bias supply and CN600 on the

5

control PCA.

Try a test print.

6

1

EN

Control panel messages

23

Page 30

• If the message persists, replace the print drum f ollo w e d b y the color

developer and the black developer if necessary.

7 Replace the developer bias power supply.

18.4 Clean transfer corona

• There is a high-voltage leak in the transf er belt, print drum, or HVPS.

– Power cycle the printer.

Note

If the problem will not repeat dependably , print transparencies in color.

Transparencies print at a slower speed with a higher transf er current.

• Clean the transfer corona (see Chapter 2, “Cleaning and

maintenance”).

• Check that the print drum contacts are clean.

• Remove the transfer belt assembly and print a test page.

• If a 13.x Paper jam message appears when printing without the

transfer assembly installed, the high-voltage leak is associated with

the transfer assembly.

– Check the transfer assembly contacts for proper alignment,

corrosion, etc. before replacing them.

• If the error persists, reseat the print drum. Then replace the print

drum followed by the HVPS if necessary.

24 Chapter 1 – Troubleshooting control panel messages

EN

Page 31

18.5 Reinsert developers

18.6 Reinsert developers

Note

18.5 Reinsert developers is for black developers.

18.6 Reinsert developers is for color developers.

Note

Do not replace devel opers until the actual cause h as been identified.

Replace the developers only if they are proven defective.

• The printer does not sense the changing output from the toner

concentration sensor that occurs with normal toner mo vement within

the developers.

– The developer is not selected.

– The developer drive gears are not engaging the developer.

– The developer drive gears do not rotate.

– The developer is not rotating.

• Reinsert the developer.

Note

If new developers are installed in the printer, toner compaction may

cause the toner concentration sensor to give an abnormal reading.

Remove the new dev eloper , shake it as described in Chapter 4 of the

printer service manual, and reinstall.

• Perform the following procedure to troubleshoot the 18.5 and 18.6

message:

Remove the developers and check that the drive and gears are not worn

1

and that no teeth are missing.

Remove the developer assemblies and print drum. Move the top cover up

2

and down. Check that the developer drive gears extend and retract and

are free throughout their travel. With the top cover partially closed, press

each developer drive gear and check that each has firm spring pressure.

Rotate the gears on each developer assembly by hand (this requires some

3

force). Check that they all hav e similar resistance. If the gears will not turn,

replace the developer.

Shake the developer as shown in chapter 4 of the service manual. Toner

4

may be compacted inside the developer.

1

EN

Control panel messages

25

Page 32

Examine the connectors on the developer and the toner sensor PCA for

5

damaged pins or connectors.

If symptoms still persist, follow the procedures listed below.

6

Service Mode tests

• Use Service Mode to check that the developers are rotating. This

test is especially useful because the status Mode displays the toner

concentration value while the developer augers rotate. To perform

this test, follow the steps below.

CAUTION

Do not perform this test with the RFU installed. Performing this test

with the RFU installed and the toner hopper cover removed will

damage the toner feed augers.

1 Enter Service Mode (see “Accessing Service Mode” in Chapter 3).

2 From the Status and Test Mode, select address 08.

3 Select subtest 0 for the 18.5 message, or address 1, 2, or 3 for the

18.6 message. Once selected, press [Online] to start the test. When

the test starts, the control panel displays the toner concentration

value for the selected developer. If the developer drive gear rotates,

the toner concentration sensor value displayed on the control panel

should fluctuate slightly.

4 If the gears do not rotate, check the developer rotation as follows:

A Remove the RFU, if installed.

B Remove the toner hopper cover.

C Run the Service Mode test again.

D Watch the developer drive gears at the rear of the printer. They

should turn when the test is started. Make sure you are looking

at the developer drive gear and the developer gear during this

test. (The black drive gear is the most difficult to see.)

E If the gears do not rotate, perform the mechanism alignment

checks.

5 If the gears rotate and the toner conce ntration sensor valu e does not

fluctuate, check the electrical connections between the developer

and the control PCA.

26 Chapter 1 – Troubleshooting control panel messages

EN

Page 33

If the electrical connections are OK, replace the toner sensor PCA.

6

If the message persists, replace the developer.

7

Mechanism alignment checks

• Misalignment between the developer drive assembly, the toner

hopper assembly, and the printer frame may cause 18.5 and 18.6

errors. Check the f ollowing items for a lignment when troub leshooting

this error.

Remove the developer and check to see if the developer casing is

1

bent. To do so, follow these instructions:

Place the developer on a flat surface with the back of the

A

developer toward you.

Push the developer forward inside the casing.

B

If the developers do not mov e f or ward un til the bias contact p in is

C

against the casing on the left side, the casing is bent.

Replace the developer assembly.

D

The printer frame has detents that position the developer drive

5

assembly correctly on the printer frame. Ensure that the assembly is

properly seated on these detents. Improper seating will misalign the

developer drive assembly with the developers and the toner hopper

assembly . If misa ligned, loosen the screw s, align the de ve loper drive

assembly on the detents, and then tighten the screws.

The developer drive assembly aligns with the toner hopper

6

assembly through an alignment pin located on the developer drive

assembly. Check that the alignment pin is straight and that the toner

hopper is fully seated. If the alignment pin is bent, replace the

developer drive assembly.

If the alignment pin is not damaged, remove the screws that hold the

7

toner hopper in place, and then:

Slide the toner hopper towards the left side of the printer (to the

A

right when viewed from the rear of the printer).

1

EN

Control panel messages

27

Page 34

B Check the gear cluster on the toner hopper for bent sheet metal.

If the toner hopper select shaft is out of its bushing or if the b u shing is not mounted correctly in the sheet metal, the sheet metal

may be bent. If the gear cluster is damaged, replace the toner

hopper assembly.

C Check to see if the activation arms for the toner hopper lockout

fingers are against the select cams. If the arms are on the cams,

check the toner hopper lock solenoid (SL6), located on the left

side of the toner hopper, for binding and correct operation.

D If the toner hopper assembly is functioning correctly, slide the

assembly back into position. Align it with the developer drive

assembly being careful not to damage the gear cluster. Reinstall

the toner hopper screws.

19.x User maintenance

• A printer consumable has exceeded its maximum life . Press [Online]

to continue. The printer will continue to print, but print quality will

degrade until the indicated consumable is replaced.

CAUTION

The main drive gears could become damaged if the fuse r is allo w ed

to remain past its maximum life in the printer.

• If the indicated consumable has been replaced:

Reseat the consumable.

1

Check both sides of the connector for bent pins.

2

Power cycle the printer.

3

Verify that the fuse for the consumable is not blown. The drum,

4

developers, transfer, fuser, and coating kit are fused. If the fuse is blown

when a new consumable is installed in the printer, the consumable will not

be detected as a “new” part.

Note

Do not return a consumable to stock once the fuse is blown.

Try another of the indicated consumables.

5

Check the self-test print for any value that is inconsistent with the

6

perceived actual cumulative usage. If a value is suspect, investigate the

possibility of a NVRAM problem. If necessary, contact your local response

center.

28 Chapter 1 – Troubleshooting control panel messages

EN

Page 35

20 Memory overflow

• More data has been received from the host than fits in internal

memory.

– Press

printer memory is printed.

• If the message persists, install more memory.

to continue printing. Only the data that fits in

[Online]

21 Memory out

• The printer has run out of memory. Imaging the current job cannot

continue until the engine clears memory.

– Press

• If this error persists, install additional memory.

to clear memory. This results in data loss.

[Online]

22 I/O config error

• The computer is not obeying the pacing mechanism of the MIO link.

This causes the printer’s receiving buffer to overflow during a busy

state.

23 MIO not ready

• The MIO card cannot accept data.

– Print the self-test page for more information.

– The MIO card could be defective.

• If the message persists, reseat the MIO card and ensure it is

properly connected to the network. If necessary, replace the MIO

card.

1

EN

Control panel messages

29

Page 36

24 Busy moving toner

• The printer is adding toner to the developers. If this message is

displayed frequently, check for faint print. If several pages of heavy

toner coverage are being printed, this message may not indicate an

error. If the message persists, the toner feed auger may not be

turning or a toner sensor may be defective.

1 Power cycle the printer.

2 Check the toner level in the toner hopper assembly by manually

opening each hopper. If any of the hoppers are completely empty,

the toner sensor for the empty hopper may be defective. Use the

Service Mode status and test (address 01) to test the toner level

sensors.

Note

The toner sensors on the hoppers are piezo -electric. When the toner

falls below the level of the sensor, the sensor output is audible.

However, the high-pitched sound may be out of hearing range for

some people.

3 If the hoppers have enough toner to cover the sensor, and the

message persists, check the toner hopper auger operation as

follows:

A Remove the RFU.

B Manually open the hoppers and watch the paddles while printing

the demo page.

C If the paddles turn, the problem is in the hopper augers . Replace

the toner hopper assembly.

D If the paddles do not turn, print the demo page 10 times. Watch

that the toner hopper supply shaft rotates, that the hopper select

shaft engages the hopper clutch, and that the toner supply

augers turn.

E If the toner supply shaft does not rotate, perform the toner supply

solenoid test as described below.

30 Chapter 1 – Troubleshooting control panel messages

EN

Page 37

Toner supply solenoid test

Test the toner supply solenoid (SL3) and supply augers as follows:

Enter the Service Mode (see “Accessing Service Mode” in

1

Chapter 3) and select test address 52.

Remove the RFU and the back cover. Listen for the solenoid to

2

actuate.

30 PostScript error xx

• The printer encountered a PostScript error indicated by XX.

– Press

to continue. The current job is canceled.

[Online]

Note

For PostScript errors, look at the program that is being sent, rather

than at the printer unless every Po stScript file comes up with the same

error.

30 PostScript error 00

• An attempt was made to add an item to a dictionary that is full. This

may be a driver incompatibility problem.

– Select a different PostScript driver and resend the print job.

30 PostScript error 01

• An attempt was made to place too many dictionaries on the

dictionary stack. This may be a driver incompatibility problem.

– Select a different PostScript driver and resend the print job.

1

30 PostScript error 02

• An attempt was made to remove more dictionaries from the

dictionary stack than were available. This may be a driver

incompatibility problem.

– Select a different PostScript driver and resend the print job.

EN

Control panel messages

31

Page 38

30 PostScript error 03

• The execution stack is too large. Procedure invocation is nested

deeper than PostScript allows. This may be a driver incompatibility

problem.

– Select a different PostScript driver and resend the print job.

30 PostScript error 04

• An attempt was made to access an array, dictionary, file, or string

object incorrectly.

30 PostScript error 05

• An incorrect exit was executed.

30 PostScript error 06

• An incorrect access string specification to the file operator occurred.

30 PostScript error 07

• The operand to make font or set font is not a well formed font

dictionary.

30 PostScript error 08

• An incorrect restore was attempted.

30 PostScript error 09

• An error occurred during the execution of one or more of the file

operators.

30 PostScript error 10

• A PostScript implementation limit was exceeded.

32 Chapter 1 – Troubleshooting control panel messages

EN

Page 39

30 PostScript error 11

• An operator requiring a current point was exceeded while the

current path was empty.

30 PostScript error 12

• A numeric operand’s value is out of range.

30 PostScript error 13

• An attempt was made to push too many objects on the operand

stack.

30 PostScript error 14

• An attempt was made to pop an item from an empty operand stack.

30 PostScript error 15

• The PostScript scanner encountered text that does not conform to

the PostScript syntax rules.

30 PostScript error 16

• The PostScript interpreter timed out waiting for the user to manually

feed paper, waiting for data from the computer, or because a job

took too long to complete.

1

30 PostScript error 17

• An operand was encountered that is not the correct type, such as a

number when a string is required.

30 PostScript error 18

• A name was encountered that cannot be found since it was

previously undefined.

EN

Control panel messages

33

Page 40

30 PostScript error 19

• A file identified by a name string operand of the file or run operators

cannot be found or opened.

30 PostScript error 20

• An overflow, underflow, or meaningless result of a numeric

calculation (such as division by zero) occurred.

30 PostScript error 21

• A clear-to-mark or count-to-mark operator could not find the

required mark on the stack.

30 PostScript error 22

• An operator object was executed for which the interpreter has no

built in action.

30 PostScript error 23

• An error occurred in virtual memory.

30 PostScript error 24

• The systemdict quit operator was executed causing the PostScript

interpreter to re-initialize virtual memory. All non-persistent

information was lost.

30 PostScript error 25

• A PostScript firmware failure occurred. This is associated with

normal error handling and not with hardware.

30 PostScript error 26

• A “setpagedevice” request cannot be satisfied.

34 Chapter 1 – Troubleshooting control panel messages

EN

Page 41

30 PostScript error 27

• An external interrupt request was received by the PostScript

interpreter.

30 PostScript error 28

• A named resource sought by the findresource operator does not

exist.

40 I/O data error

• A data error has occurred while receiving data from the computer.

Press

the printer and computer.

to continue printing. Check the connection between

[Online]

48 Invalid job/aborting job

• The printer does not recognize the language it is being switched to.

– This message remains in the display until it receives a valid

language.

50.x Fuser service

• The printer senses that the fuser temperature is incorrect for the

application. The voltage read at the upper fusing roller thermistor

momentarily exceeded the limit. Leave the printer on for 20 minutes

(this gives the internal clock time to count do wn and rese t) and th en

power cycle the printer to clear this message. This message can

also be reset by going into the service Mode, register adjust, and

setting address 47 to 00. If the message persists:

• Check that the fuser connector is in good repair (no bent or broken

pins).

• Open and close both doors during the warm-up period. If the

message appears immediately, replace the fuser.

• Make certain the fuser can be fully seated into the printer and that

toner has not accumulated around the fuser area.

1

EN

Control panel messages

35

Page 42

• Check the connectors on the fuser, and check the connectors in the

printer that interface with these fuser connectors.

• Check connector CN105. CN105 is labeled on the control PCA.

(See the main wiring diagram in Chapter 8).

• Replace the fusing assembly.

50.1 Fuser service error

• The fuser temperature is too high for the application.

– Leav e the pow er on f or 20 minutes while the printer counts down,

then power cycle the printer to clear this error or use address 47

in the register adjust section of the Service Mode to reset this

message.

– Check the fuser connections.

50.2 Fuser service error

• The fuser temperature is too low for the application.

– Leav e the pow er on f or 20 minutes while the printer counts down,

then power cycle the printer to clear this error or use address 47

in the register adjust section of the Service Mode to reset this

message.

– Check the fuser connections.

50.3 Fuser service error

• The fuser temperature sensor is open.

– Leav e the pow er on f or 20 minutes while the printer counts down,

then power cycle the printer to clear this error or use address 47

in the register adjust section of the Service Mode to reset this

message.

– Check the fuser connections.

36 Chapter 1 – Troubleshooting control panel messages

EN

Page 43

50.4 Fuser service error

• There is a fuser temperature error caused by erratic sensor values.

– Leave the power on for 20 minutes, and then power cycle the

printer to clear this error or use address 47 in the register adjust

section of the Service Mode to reset this message.

52.1 Engine NVRAM error

• This error indicates a fail ure to read the N VRAM on the control PCA.

To troubleshoot this problem:

Power cycle the printer.

1

If for some reason the NVRAM was remov ed from its soc k et, ensure

2

that there are no bent pins and that they are all in their correct

position.

If the error persists, contact your local response center for

3

assistance in evaluating NVRAM viability.

52.2 Engine NVRAM error

• A developer with a blown fuse is being installed into a new printer.

• The NVRAM data could be corrupt.

– The printer checks an address in NVRAM for the status of the

engine. If the status returned is new, then the printer checks the

developers to see if the fuses are ne w (clo sed). If the fuses ha ve

been blown, then the

fuses are blown on the developers use an ohmmeter across pins

5 and 6 on the color developer, and pins 4 and 6 on the black

developer (see the main wiring diagram in Chapter 8). (Pin 1 is at

the bottom of each connector.) If either developer has a blown

fuse, replace the developer.

• If the printer is new, replace the developer. If the printer is not new,

troubleshoot as 52.1 Engine NVRAM error.

52.2 error

is displayed. To check if the

1

EN

Control panel messages

37

Page 44

53 Laser error

• The printer has detected a laser diode error.

– Power cycle the printer.

• If the error persists, reseat connectors CN300 and CN101. (See

Chapter 8, “Wiring diagrams” for the locations of these connectors.)

• If the connectors are in good repair, replace the laser scanner

assembly.

53 Laser error/service

• The laser signal is unstable.

1 Press [Online] to continue.

2 Power cycle the printer.

3 Open, then close the side door.

4 Check the side door interlock.

54.x Engine error/service error

The engine reported one of five types of failures or errors as listed

below. Try to clear the errors by pressing [Online]. If the message

persists, perform the appropriate procedure described below for the

applicable 54 error message.

54.1 Engine error/service

• The scanner motor (M6) did not reach the correct speed in the

allotted time.

– Power cycle the printer.

• If the motor spins up and the error persists, perform the following

procedure.

1 Check CN104 and CN350 on the optics assembly.

2 Inspect the wires behind the power supply drawer for nicks or cuts

on the insulation.

3 Measure the 24V DC.

38 Chapter 1 – Troubleshooting control panel messages

EN

Page 45

Replace the laser scanner assembly.

4

Replace the control PCA.

5

54.2 Engine error/service

• The printer detected an error in the 24V DC supply.

– Power cycle the printer to clear the error.

• If the error persists, check the 24V DC line.

– If the 24V DC voltage is missing, replace the DC power supply.

Note

The actual measured voltage should be approximately 22V DC.

• A defective or misaligned interlock switch can also cause this error.

– Use a screwdriver to push the interlock mechanism in the

direction shown in the printer service manual, page 7-21, Figure

7-4.

• If the message clears, adjust the tab on the side door which

operates the interlock mechanism.

• If the message persists, turn off the printer and check the interlock

mechanism, connectors, and cabling.

• Check fuse F5 on the DC power supply and fuse F2 on the control

PCA.

54.3 Engine error/service

Note

Do not replace any dev elopers until the cause of the error is identi fied.

Replacing developers without identifying the cause of the error will

only mask the problem and could lead to an other service call from the

customer.

• A toner concentration error occurs when the toner concentration

sensor reading is at a minimum or maximum value. This error can

be caused by:

– a defective toner concentration sensor

– failure of the toner hopper sensor or toner supply mechanism

– too much or too little toner in the developer

1

EN

Control panel messages

39

Page 46

– a defective toner sensor PCA

– incorrect NVRAM values. Incorrect NVRAM values can be

caused by:

not installing the correct NVRAM on the control PCA

•

installing the NVRAM incorrectly

•

a defective NVRAM

•

installing a used devel o pe r.

•

Incorrect NVRAM values usually cause too much toner to be

delivered to the developer. Failure of the toner hopper sensor or

toner supply mechanism is usually associated with not enough ton er

being delivered to the developer. To determine the cause of this

error follow the steps below:

1 Power cycle the printer.

2 Run se v eral self-test pa ges to see if the e rror returns. You should be

able to print at least one self-test page before the 54.3 error

message reappears.

3 If the error returns, look at the self-test page and check for faded or

bold colors.

4 If a color looks fa ded, the problem will most lik ely be associated with

a defective toner hopp er sensor or the toner supply mechanism. If

any color looks bold, then too much toner may have been added to a

developer.

5 To identify which developer is reporting the error, run the toner

concentration test shown below. A value of 127 or 63 on the front

panel is an indicator for the developer reporting the error.

6 See “Faint print” on page 157 for the procedure to troubleshoot a

problem with faded print.

7 If a color looks bold on the self-test page, the problem can be

caused by one of the following:

– an incorrect NVRAM value

– the wrong NVRAM was installed on the control PCA

– a developer, which is not the most recent one to be initialized by

the printer, has been installed

40 Chapter 1 – Troubleshooting control panel messages

EN

Page 47

• The NVRAM values correspond to the last developer that was

initialized in the printer. Even if the developer currently installed was

initialized in the printer, if it was not the last de veloper initialized, the

NVRAM values are not correct.

If the wrong developer was installed, reinstall the correct developer.

8

If the wrong NVRAM was installed, reinstall the correct NVRAM.

9

If the correct NVRAM or the correct developer(s) is not available, a

10

new developer(s) must be initialized in the printer.

For other NVRAM associated problems, contact your local response

11

center.

Toner concentration test

Note

The toner concentration test is useful whenever the printed page

displays characteristics of having either low toner concentration or

high toner concentration. The procedures to correct low and high

toner concentration are discussed later in this chapter.

Print a self-test page and note the relative humidity reading.

1

Power cycle the printer and enter the Service MODE (see

2

“Accessing Service Mode” in Chapter 3). Select the Register Adjust

function of the Service Mode (see Chapter 3 for instructions on the

register adjust function) to obtain the data values contained in the

NVRAM addresses listed below.

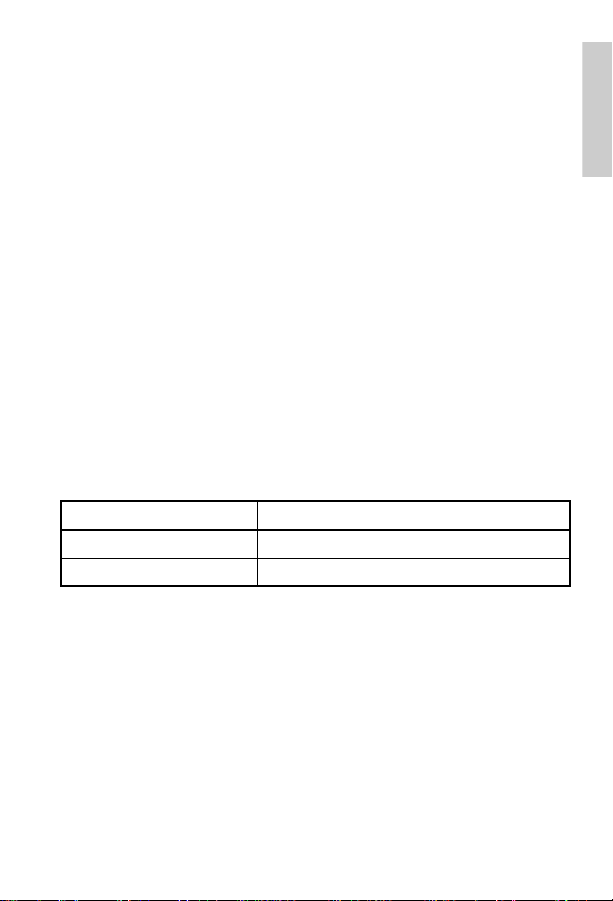

NVRAM addresses

1

Color Black Yellow Magenta Cyan

Address

Data

Example:

Page

count

EN

30 29 28 33 32 31 36 35 34 39 38 37

AA00BB16CC23AA00BB08CC28AA00BB08CC28AA00BB08CC

AABBCC AABBCC AABBCC AABBCC

Control panel messages

15

41

Page 48

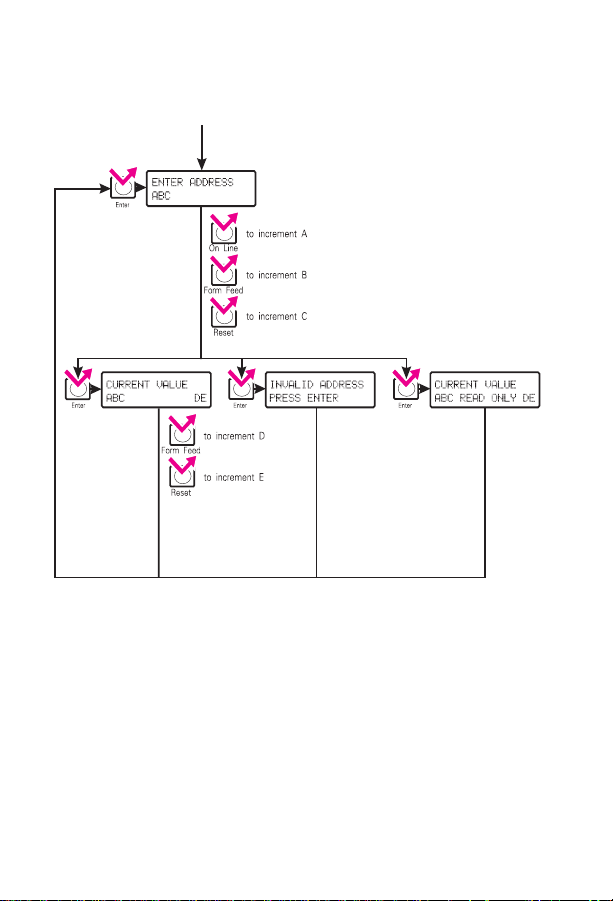

3 Press the [Form Feed] and [Reset] keys to select the desired

NVRAM address. When the desired NVRAM address is displayed,

press [Enter] to display the value held at that address. For example,

if the displayed NVRAM address is 29 and the value held at that

address is 18, then the display will read:

Current Value

029 ReadOnly 18

Record the address and the value it contains. To clear this display

and toggle back to

Enter Address xxx

, press [Enter] again.

Repeat this procedure until the NVRAM values for all of the

addresses in the “NVRAM addresses” table ha ve been obtained and

recorded.

4 The current cumulative page counts for each of the developers can

now be constructed from the data you have obtained. See the

following e x amples:

Examples

Address: 30=00, Address 29-16 and Address 28-23. The black page count is

001623.

Address 33=00. Address 32=08 and Address 31=28. The yellow page count is

000828.

Address 36=00. Address 35=08 and Address 34=28. The magenta page

count is 000828.

Address 39=00. Address 38=08 and Address 37=15. The cyan page count

:

is

000815.

Note

Do not use the black and color page counts from the self-test page

(these counts indicate the total cumulative page counts for the printer ,

which are usually different than the page counts for the developers).

5 Power cycle the printer and enter Service Mode again. Select the

status and test function from the Engine Service Status/Test Mode.

6 Follow the Status and Test Mode flow charts (pages 88 and 90 until

you come to the

Enter Address AB

several times to increment to AB = 08 (see the toner concentration

values table on page 43).This sets the system to select test number

08 (developer rotation).

display. Press [Form Feed]

42 Chapter 1 – Troubleshooting control panel messages

EN

Page 49

7

Press

[Enter]

to display:

Enter Subset #

08 0

Enter the value of the subset # that is appro priate for the developer;

select the number from the target toner concentration table below.

8

Press

[Enter]

to display:

Online to Start

AB x YYY

When

values of YYY will be displayed. After allo wing the rotation/update to

run for at least 30 seconds, record the

displayed. While the rotation/update is in progress, the following

message displays:

is pressed, the developer will rotate and updated

[Online]

value that is being

YYY

Reset to Cancel

AB x YYY

Make sure to record the displayed

developer. Press

Use the following table to convert the number displayed on the

9

control panel to the actual concentration value.

to end the rotation/update.

[Reset]

value for the appropriate

YYY

Toner concentration values

1

Displayed value (

Less than 64 Same as displayed value

64 or larger 64 minus the displayed value

Using the Internal Humidity reading from the self-test page and the

10

page count for the developer (from NVRAM), locate the target toner

concentration value for each developer from the target toner

concentration table.

If the toner concentration value (derived from step 10) is more than

11

12 points lower than the target value, then the toner concentration in

the developer is too low. If the toner concentration value is more

than 12 points higher than the target value, then the toner

concentration value is too high. Try the following techniques for

correcting low or high toner concentration problems.

EN

) Actual toner concentration value

YYY

Control panel messages

43

Page 50

Correcting toner concentration levels

Low toner level

Effective resolution of a low toner concentration problem r equires

correction of the root cause. Here are some likely causes:

• Poor distribution of the toner mix in the developer cartridge at the

time of its initial use in the printer.

– It is possib le that shipment or stor age of the de veloper resulte d in

some toner/carrier segregation. This can result in erroneous

calibration of the toner-concentration sensor when the new

developer is initialized in the printer. Toner/carrier segregation

can result in toner-rich compaction in the concentration-sensor

zone. This presents a worst-case condition f or sensor cali bration

error. Properly shaking new developer before initialization, as

prescribed in the installation instructions and in the user guide f or

the printer will usually prevent this condition. Correcting an

improper initialization is not practical. If print quality is noticeably

deficient, replace the developer.

• Use of a replacement developer that has not been properly

initialized in this printer.

– This can cause a toner concentration error. Short-term use of a

previously initialized developer for troubleshooting is acceptable,

but the original (properly initialized) developer should be

reinstalled after troubleshooting is completed ; otherwise, install a

new developer.

• Compaction of toner in the replenishment mechanism (auger

assembly or feed-in port).

– This can result in toner depletion.

• Empty auger tubes.

– If service efforts have resulted in replacing the toner hopper

assembly, the toner auger tubes may not have been filled. To

correct this problem:

Use Test 19 in Service Mode to unlock the hoppers.

1

Fill the hoppers with toner, if necessary.

2

Manually rotate (downwards) the large white gear on the side of each

3

hopper to fill the auger tubes. Do this while holding the auger tube

shutter open at the developer end of the auger tube with something in

place to catch any toner that escapes, such as a tissue or index card.

44 Chapter 1 – Troubleshooting control panel messages

EN

Page 51

• Incomplete toner fill in the auger tubes.

– Ensure a complete toner fill in the auger tube associated with

any developer (which has been revealed by the Toner

Concentration Test). This can be accomplished in the manner

described above (step 3).

• Incomplete toner concentration test.

– After completing any corrective action(s) for low toner

concentration, such as described above, run the Toner

Concentration Test again. Remember, it takes some time for the

replenished toner to be uniformly distributed through the

developer; the test should be allowed to run for at least 30

seconds before making the front panel reading (

resulting

return to normal toner concentration on its own during regular

operation. If it “errors out” or if the displayed value is greater than

100, manually feed toner (step 3, above) and repeat the Toner

Concentration Test. Failure to improve toner concentration

values with these measures may indicate failure of the toner

concentration detection circuitry or the toner replenishment

mechanisms. Installation of a new developer may appear to

correct the problem, but if the detection system, replenishment

system, or both are malfunctioning, the problem can return.

value is in the range 000 to 100, the printer will

YYY

value). If the

YYY

High toner level

• Recovering from this toner condition is not as easy as recovering

from a low toner level. It is important that the root problem for this

condition has been clearly identified; otherwise, the problem will be

masked for only a short time and the original problem will eventually

occur again.

Print a solid fill page for the color generating the error. Continue to

1

print this page until the error no longer appears.

If far too much toner is in the developer, the developer will need to

2

be replaced.

1

EN

Control panel messages

45

Page 52

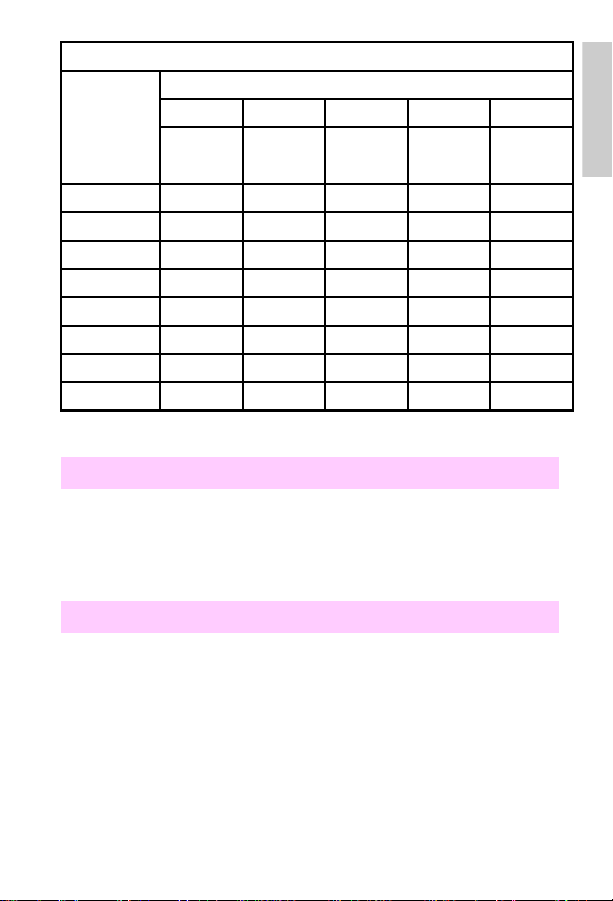

Target toner concentration

Target toner concentration

Developer

count

>0 4 4 3 3 2 2 2 1 2 0

>40 8 8 6 6 4 4 4 2 4 0

>80 12 12 9 9 6 6 6 3 6 0

>120 15 15 11 11 8 8 8 4 8 0

>160 18 18 13 14 9 9 9 5 9 0

>230 21 21 15 16 11 10 11 6 11 0

>310 24 24 17 18 12 12 12 6 12 0

>400 27 27 19 20 14 13 14 7 14 0

>500 30 30 22 23 16 14 16 8 16 0

>650 33 33 24 25 17 16 17 9 17 0

>800 36 36 26 27 19 17 19 9 19 0

>1000 39 39 28 29 20 19 20 10 20 0

>1250 42 42 30 32 22 20 22 11 22 0

>1500 45 45 32 34 23 22 23 12 23 0

>1750 48 48 35 36 25 23 25 12 25 0

>2000 50 50 38 36 26 24 26 11 26 0

>2750 47 47 34 35 24 23 24 10 24 0

>3500 44 44 32 33 23 21 23 9 23 0

>4250 41 41 30 31 21 20 21 8 21 0

>5000 38 38 27 29 20 18 20 6 20 0

>5750 35 35 25 26 18 17 18 4 18 -2

>6500 32 32 23 24 17 15 17 2 17 -4

20% or less 20-29% 30-39% 40-59% >60%

KY

M

C

Relative humidity

KY

M

C

KY

M

C

KY

M

C

KY

M

C

46 Chapter 1 – Troubleshooting control panel messages

EN

Page 53

Target toner concentration (continued)

Developer

count

>7000 28 28 20 21 16 13 16 0 16 -6

>7500 28 28 20 18 15 12 15 -2 15 -8

>8000 28 28 20 18 15 10 14 -4 14 -10

>8500 28 28 20 18 15 8 13 -6 13 -12

>9000 28 28 20 18 15 8 12 -6 12 -14

>9500 28 28 20 18 15 8 11 -6 11 -16

>10000 28 28 20 18 15 8 10 -6 10 -18

>14000 28 28 20 18 15 8 9 -6 9 -20

20% or less 20-29% 30-39% 40-59% >60%

KY

M

C

Relative humidity

KY

M

C

KY

M

C

KY

M

C

KY

54.4 Engine error/service

• A pressure cam home position sensor (PS2) error has occurred.

The pressure cam did not sense the home position with in 4 seconds

after the initial rotation of the pressure cam.

– Power cycle the printer.

54.4 Cam home position sensor

1

M

C

• The cam sensor (PS2) did not detect home position. This message

can also occur with general printer disassembly involving the control

PCA or the developer bias supply.

– Since PS2 is located on the back of the developer bias supply,

make sure it is reconnected if the developer bias supply was

removed. (See page 139 for the location of PS2.)

– Make sure that the connector (CN802) on the control PCA is fully

seated.

EN

Control panel messages

47

Page 54

• Other symptoms include the following:

– complete or partially blank pages

– smeared vertical line on the front of the page

– smeared toner image on the back of the page

Note

This message might appear as a result of the drive gears being

installed incorrectly causing a loss of cam timing. Follow the cam

timing procedure in Chapter 6 of the printer service manual to correct

the cam timing problem.

• To troubleshoot the 54.4 message:

1 Open the top cov er and locate the tab that activ ates the A C interlock

switch. The tab is located to the right and belo w th e black dev el oper

and is part of the developer drive assembly. If the tab is bent, bend

the tab until it is aligned with the plunger.

2 If the tab is stra ight, turn the printer on while chec king the 24V DC at

the test connector, which is located on the rear of the printer.

Note

The actual measured voltage will be approximately 22V DC.

3 If no voltage is present, check the interlock switches on the left side

of the printer and verify that they are working correctly. Replace the

switch mechanism if defective.

4 If the switch mechanism is oka y and the v oltage does not reach 22V

when the printer is turned on, replace the DC power supply.

5 If the DC voltage is OK, remove the right-side cover and watch the

AC motor (M2) to see if it turns as you turn on the printer.

6 If M2 does not turn, turn off the printer and unplug the power cord.

Disconnect the connector to M2 and connect a voltmeter.

WARNING!

With the printer turned on, there is 120/240V AC at this connector . Do

not cross the leads of your meter or touch them with your hand. Doing

so will cause damage to the printer or result in electrical shock.

7 Plug the power cord into the printer and turn the printer on. Watch to

see if the AC voltage is supplied.

48 Chapter 1 – Troubleshooting control panel messages

EN

Page 55

If power is available replace M2.

8

If no power is available, replace the AC power supply in the Color

9

LaserJet or the DC power supply in the Color LaserJet 5/5M.

If the power supply does not solve the problem, follow the

10

procedures for the cam service Mode test to verify that the sensor is

operating correctly.

Run test 53 in service Mode to verify that the solenoid is operating.

11

You should be able to hear when the solenoid turns on or off.

Replace the solenoid if defective. A good solenoid should have a

resistance value of approximately 56 ohms.

If the solenoid is okay when the resistance is measured and

12

everything else noted above has been checked, replace the control

PCA.

Cam Service Mode test

Enter the status and test section of the Service Mode (see

1

“Accessing Service Mode” in Chapter 3).

Select address 51.

2

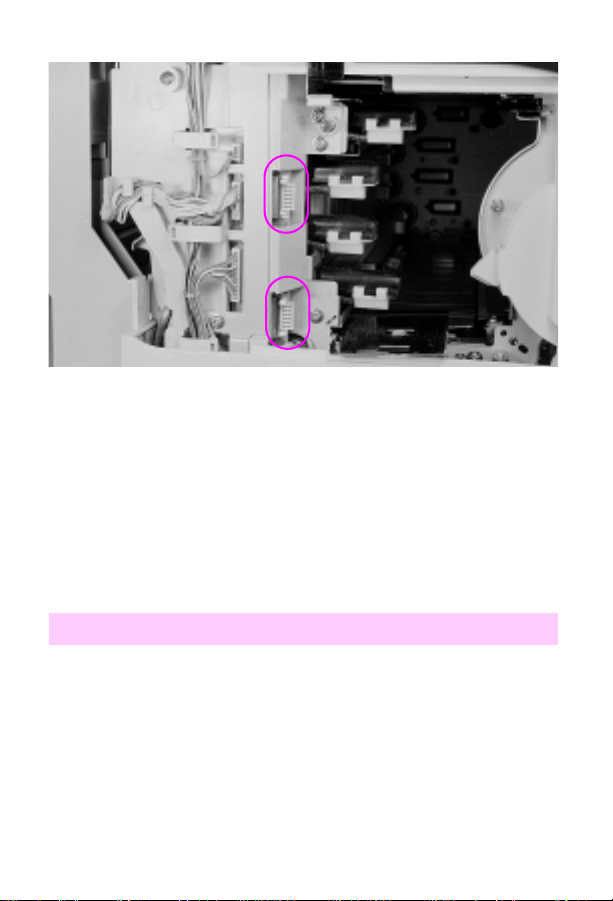

Open the top cover, remove the print drum, and release the cam

3

solenoid (SL4), as shown in the figure below.

Turn the gear train slowly, and watch the control panel display. The

4

status display will change from 000 to 001 when the cam home

sensor is activated.

If the home sensor reading does not change, check the following:

• The developer bias supply is fully seated.

• The cam home sensor is mounted in the printe r frame correctly.

• The sensor connector is in good repair.

• If all of the above are okay, replace the sensor PS2. (See page 141

for the location of PS2.)

• When checking the cam home solenoid, run a demo page. With the

top cover removed, check that the solenoid releases. If it does not,

replace solenoid (SL4) and its clutch, and then check th e cam timing

as shown in Chapter 6 of the printer service manual.

1

EN

Control panel messages

49

Page 56

Releasing the pressure cam home solenoid

54.5 Engine error/service

• A developer home position sensor (PS6) error has occurred. The

developing switch position sensor did not detect the home position

within 4 seconds after the initial motion of the pressure cam.

54.5 Developer home position sensor

• The printer failed to detect the developer cam home position within

4 seconds after the initial rotation of the pressure cam.

• The sensor (PS6) is defective. (See page 141 for the location of

PS6.)

Note

If this message occurs after general printer disassembly around the

control PCA, the sensor PS6 may be disconnected. See chapter 5

under “Sensors” in the printer service manual to locate PS6, and

check that it is plugged in both at the sensor and at the control PCA

(CN802).

50 Chapter 1 – Troubleshooting control panel messages

EN

Page 57

54.5 Service Mode test

Select the Service Mode Status and test address 51 and check that

1

the developer drive motor rotates.

If the developer drive motor (M2) does not rotate, check the

2

connectors. If the connectors are proper and M2 still does not rotate,

replace M2.

If the developer d rive mo tor rotates , use the status Mode test (50) to

3

test the developer home sensor. (It may be necessary to turn the

gear train by hand to activ ate this sensor .) The displa y changes from

00 to 01 when the sensor is activated.