Page 1

HP Designjet L65500 Printer & HP Scitex

LX Printer family

Installation guide (third edition)

Page 2

Legal notices

Trademarks

© 2009 Hewlett-Packard Development

Company, L.P.

The information contained herein is subject

to change without notice.

The only warranties for HP Products and

services are set forth in the express warranty

statement accompanying such products and

services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Microsoft® and Windows Vista® are U.S.

registered trademarks of Microsoft

Corporation.

Page 3

Table of contents

1 Safety precautions

General safety guidelines ..................................................................................................................... 1

Electric shock hazard ........................................................................................................... 1

Heat hazard ......................................................................................................................... 2

Fire hazard ........................................................................................................................... 2

Mechanical hazard ............................................................................................................... 2

Heavy substrate hazard ....................................................................................................... 3

Ink handling ......................................................................................................................... 3

Warning and Cautions ......................................................................................................... 3

Warning labels ..................................................................................................................... 3

Emergency stop buttons ...................................................................................................... 5

2 Introduction

Installation guide overview ................................................................................................................... 6

Manpower required .............................................................................................................................. 6

Tools required for installation ............................................................................................................... 6

Inbox content ........................................................................................................................................ 7

3 Receive the shipment

Unload the crate ................................................................................................................................... 9

Move the printer over ramps .............................................................................................................. 10

Remove the crate packaging .............................................................................................................. 10

Remove the printer from the pallet ..................................................................................................... 11

Lift the printer to a second floor using a crane ................................................................................... 13

4 Set up the printer in the final position

How to push the printer ...................................................................................................................... 15

Choose the final position .................................................................................................................... 15

Remove additional packaging ............................................................................................................ 17

Lower the feet ..................................................................................................................................... 22

5 Connect the power cables

Requirements ..................................................................................................................................... 23

ENWW iii

Page 4

Tri-phase AC Power Cord .................................................................................................................. 23

Protective Earth conductors (grounding) ............................................................................................ 26

6 Configure the electrical system

Install the fuses and power jumper ..................................................................................................... 27

Choose delta or star (Y) configuration ................................................................................................ 29

Check resistances .............................................................................................................................. 31

Check connections ............................................................................................................................. 31

Connect mains power ......................................................................................................................... 32

Power on the printer ........................................................................................................................... 32

7 Purge the ink system

8 Prepare the printer

Install the printhead cleaning roll and aerosol filters .......................................................................... 50

Install the computer, monitor, LAN switch, tray, keyboard and mouse .............................................. 53

Create a shared folder on the HP Internal Print Server computer ...................................................... 55

Configure the printer’s IP address ...................................................................................................... 58

9 Prepare for printing

Install the printheads .......................................................................................................................... 59

Callme@HP Setup Process .............................................................................................................. 62

Antivirus Registration ........................................................................................................................ 63

Web Cam Installation ......................................................................................................................... 63

Load a substrate ................................................................................................................................. 63

Connect the air supply ........................................................................................................................ 63

Configure the RIP ............................................................................................................................... 64

Install the covers ................................................................................................................................ 66

Print the HP test images ..................................................................................................................... 68

Appendix A Prepare the HP Internal Print Server (Japan and Russia only)

Appendix B Manually configure the printer’s IP address

Appendix C Change the Windows Vista language

iv ENWW

Page 5

1 Safety precautions

Before installing the printer, read the following safety precautions.

General safety guidelines

No operator serviceable parts inside. Refer servicing to qualified service personnel.

●

Turn off the printer, using both Branch Circuit Breakers located in the building's Power Distribution

●

Unit (PDU), and call your service representative in any of the following cases:

The power cord is damaged.

◦

Liquid has entered the printer.

◦

There is smoke or an unusual smell coming from the printer.

◦

The printer has been dropped or the drying or curing module damaged.

◦

The printer's built-in Residual Current Circuit Breaker (Ground Fault Circuit Interrupter) has

◦

repeatedly tripped.

Fuses have blown.

◦

The printer is not operating normally.

◦

Turn off the printer using both Branch Circuit Breakers in either of the following cases:

●

During a thunderstorm

◦

During a power failure

◦

Electric shock hazard

WARNING! The internal circuits and drying and curing modules operate at hazardous voltages

capable of causing death or serious personal injury.

Turn off the printer using both Branch Circuit Breakers located in the building's Power Distribution Unit

(PDU) before servicing the printer. The printer must be connected to earthed mains outlets only.

To avoid the risk of electric shock, do not attempt the following actions:

Do not attempt to dismantle the drying and curing modules or the electrical control cabinet.

●

Do not remove or open any other closed system covers or plugs.

●

Do not insert objects through slots in the printer.

●

ENWW General safety guidelines 1

Page 6

NOTE: A blown fuse may indicate malfunctioning electrical circuits within the system. Call your service

representative, and do not attempt to replace the fuse yourself.

Heat hazard

The drying and curing subsystems of the printer operate at high temperatures and can cause burns if

touched. To avoid personal injury, take the following precautions.

Do not touch the internal enclosures of the printer's drying and curing modules.

●

Take special care when accessing the substrate path.

●

Fire hazard

The drying and curing subsystems of the printer operate at high temperatures. Call your service

representative if the printer's built-in Residual Current Circuit Breaker (Ground Fault Circuit Interrupter)

is repeatedly tripped.

To avoid the risk of fire, take the following precautions.

Do not insert objects through slots in the printer.

●

Take care not to spill liquid on the printer.

●

Do not use aerosol products that contain flammable gases inside or around the printer.

●

Do not block or cover the openings of the printer.

●

Do not attempt to dismantle the drying or curing module, or the electrical control cabinet.

●

Load substrates that can be used at an operating temperature of up to 125°C (257°F), and have

●

auto-ignition temperatures above 250°C (482°F).

Mechanical hazard

The printer has moving parts that can cause injury. To avoid personal injury, take the following

precautions when working close to the printer.

Keep your clothing and all parts of your body away from the printer's moving parts.

●

Avoid wearing necklaces, bracelets and other hanging objects.

●

If your hair is long, try to secure it so that it will not fall into the printer.

●

Take care that sleeves or gloves do not get caught in the printer's moving parts.

●

Avoid standing close to the fans, which could cause injury and could also affect print quality (by

●

obstructing the air flow).

Do not touch gears or moving rolls during printing.

●

2 Chapter 1 Safety precautions ENWW

Page 7

Heavy substrate hazard

Special care must be taken to avoid personal injury when handling heavy substrates.

Handling heavy substrate rolls always requires at least two people. Care must be taken to avoid

●

back strain and/or injury.

Always use a forklift, pallet truck or other handling equipment to lift substrates.

●

Always wear personal protective equipment including boots and gloves.

●

Ink handling

Your printer does not use solvent inks and does not have the traditional problems associated with them.

However, HP recommends that you wear gloves when handling ink cartridges or printhead cleaner rolls.

Warning and Cautions

The following symbols are used in this manual to ensure the proper use of the printer and to prevent

the printer from being damaged. Follow the instructions marked with these symbols.

WARNING! Failure to follow the guidelines marked with this symbol could result in serious personal

injury or death.

CAUTION: Failure to follow the guidelines marked with this symbol could result in minor personal injury

or damage to the product.

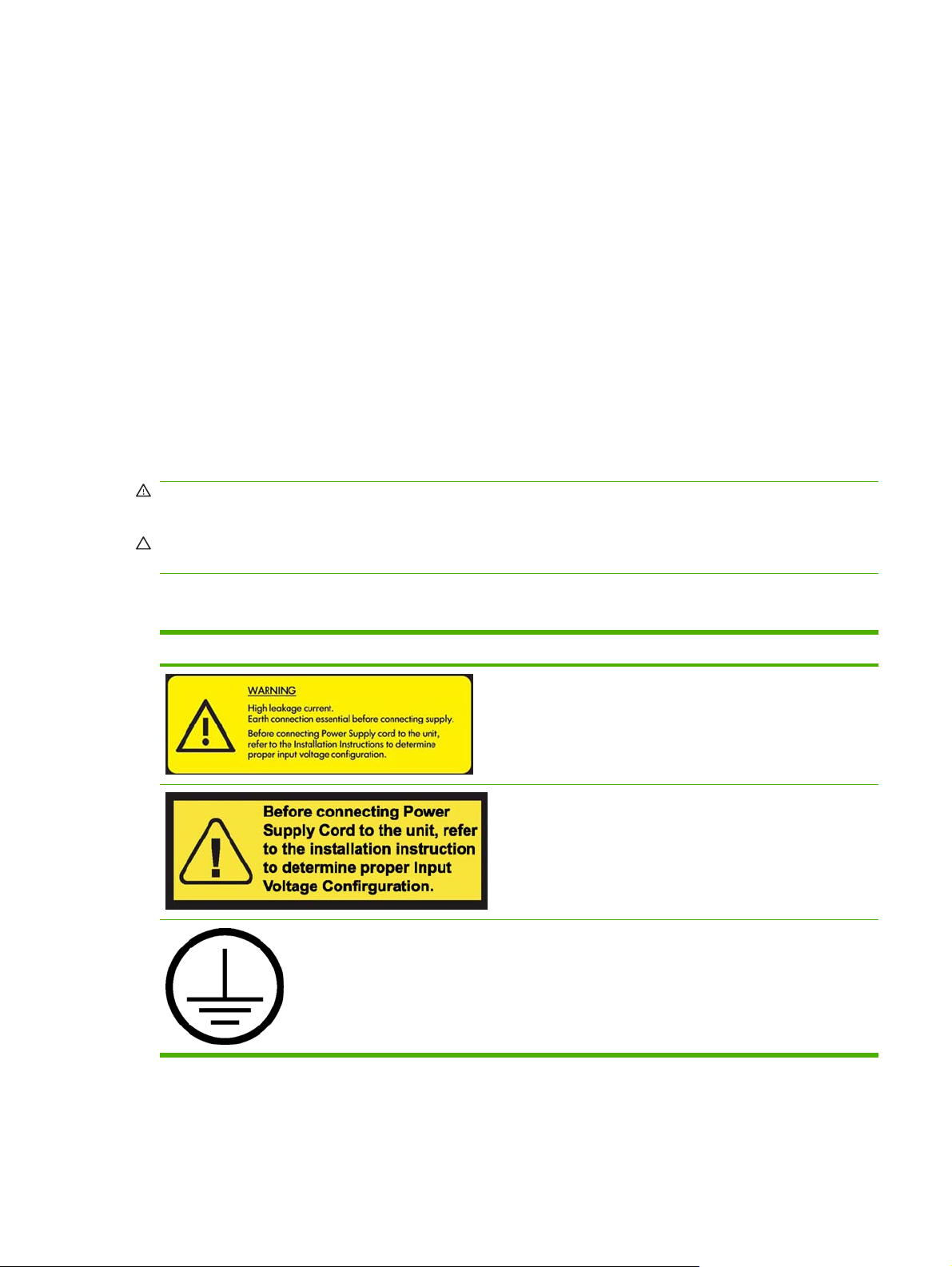

Warning labels

Label Explanation

Current leakage may exceed 3.5 mA.

The printer can be connected to power supplies at different

voltages.

Identifies the Protective Earth (PE) terminal. It is located inside

the electrical control cabinet.

ENWW General safety guidelines 3

Page 8

Label Explanation

Electric shock hazard. The printer has two mains supplies.

There are no operator-serviceable parts inside the printer. In

case of operation of the fuse, parts of the printer that remain

energized may represent a hazard during servicing. Refer

servicing to qualified service personnel. Turn off the printer

using both Branch Circuit Breakers located in the building's

Power Distribution Unit (PDU) before servicing. See

installation instructions before connecting to the supply.

Danger of electric shock. In case of operation of the fuse, parts

of the printer that remain energized may represent a hazard

during servicing. Therefore, ensure that the printer is

completely turned off before servicing.

Risk of burns. Do not touch the internal enclosures of the

printer's drying and curing modules.

You are recommended to wear gloves when handling ink

cartridges, printhead cleaning cartridges and the printhead

cleaning container.

When substrate has been loaded, the carriage descends into

its normal position, and could crush your hand or anything else

left underneath it.

Danger that your hands may become trapped between

gearwheels

When the printer is printing, the printhead carriage travels back

and forth across the substrate.

Beware of this moving part.

4 Chapter 1 Safety precautions ENWW

Page 9

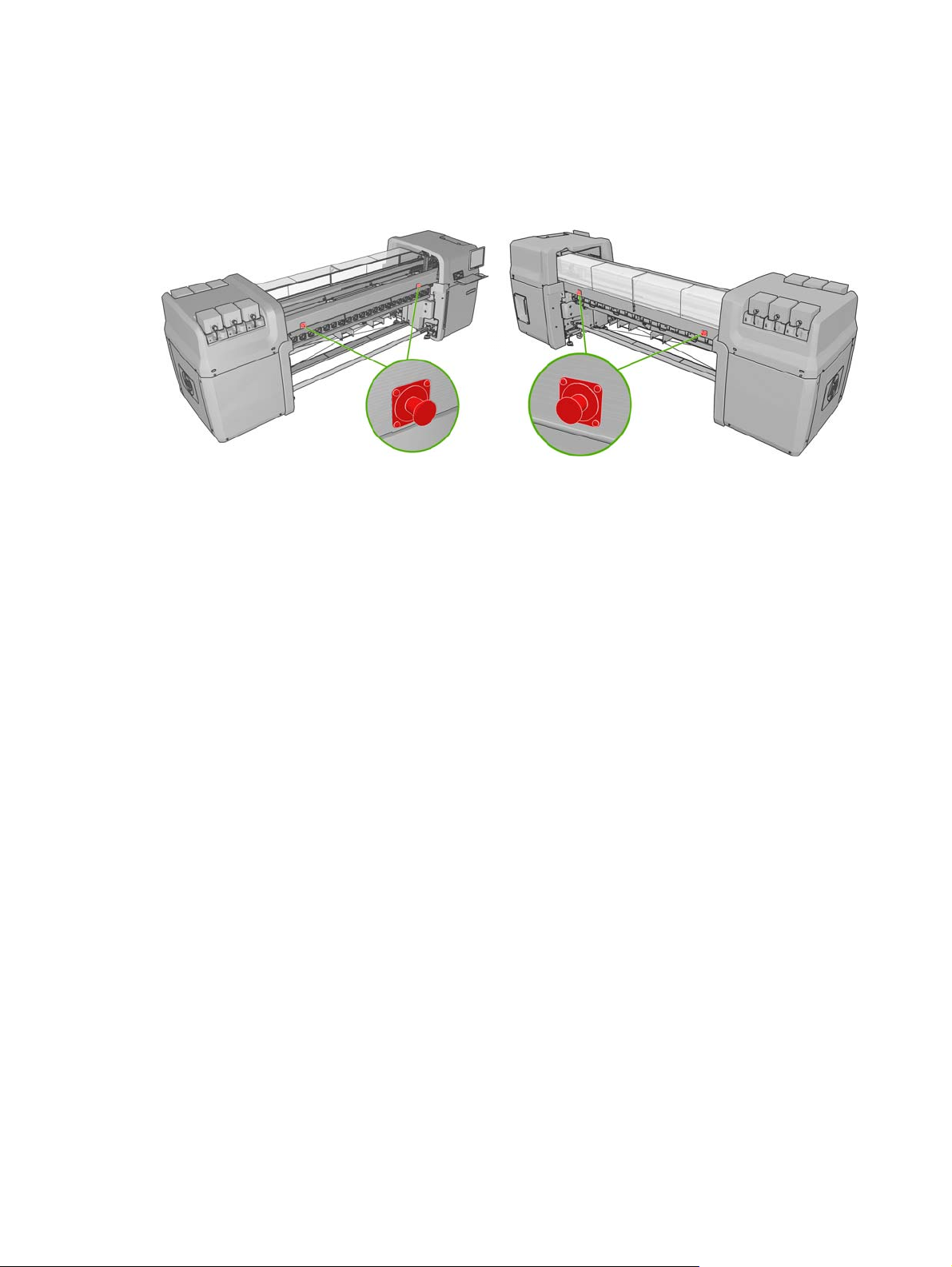

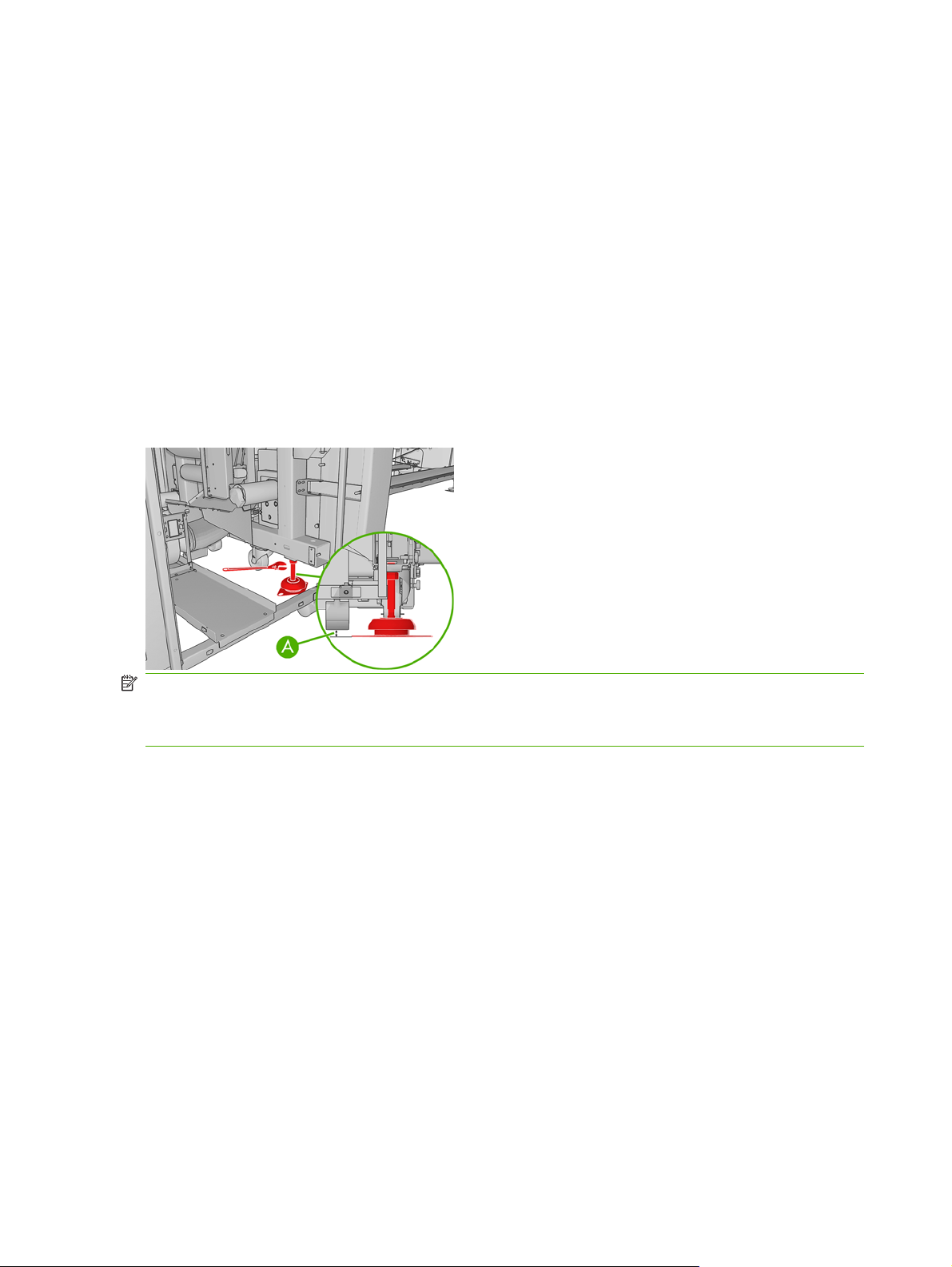

Emergency stop buttons

There are four emergency stop buttons distributed around the printer. If an emergency occurs, simply

push one of the emergency stop buttons to stop all printing processes. A system error message is

displayed on the front panel, and the fans turn at maximum speed. Ensure that all emergency stop

buttons are released before restarting the printer.

ENWW General safety guidelines 5

Page 10

2 Introduction

Installation guide overview

This installation guide provides you with step by step procedures for the installation process. This guide

is organized in chronological order and should be followed from beginning to end.

Manpower required

Installation of your HP Designjet L65500 & HP Scitex LX600/LX800 requires the following manpower:

HP Installation Specialist

●

Customer

●

Certified electrician

●

Moving specialist

●

Tools required for installation

TIP: Without a heavy-duty electric screwdriver, it could take up to two hours just to disassemble the

crate.

Installation of your HP Designjet L65500 HP Scitex LX600/LX800 requires the following tools:

Step ladder

●

Cutting pliers

●

Cutter

●

Heavy-duty electric screwdriver with two batteries

●

Phillips screwdrivers

●

T8, T10, T15, T20, T25 and T30 torx screwdrivers

●

Long torx extension pins that have a diameter of approximately 2–3 mm and are more than 15 cm

●

in length to be able to access all screws

Two Flathead screwdrivers (two sizes)

●

Socket wrench, extension and 17 mm socket

●

7 mm, 15 mm and two 30 mm open-end wrenches

●

6 Chapter 2 Introduction ENWW

Page 11

Inbox content

NOTE: The shipment items should be verified during installation.

NOTE: Ink cartridges do not come with the printer and should have been ordered by the customer

prior to installation. Make sure that the ink cartridges are available.

The shipment should include the following items:

The HP Printer

●

Documentation CD including the Legal Information , the Maintenance and Troubleshooting Guide

●

and the User's Guide

Maintenance and troubleshooting guide

●

Operating System Recovery CD

●

Pneumatic gun

●

L65500 only: 1 substrate roll

●

2 spindles (the front spindle is mounted on the printer with ties, the rear spindle is attached to the

●

pallet)

1 empty substrate core

●

L65500 only:

●

HP 786 Yellow/Magenta Designjet Printhead

◦

HP 786 Cyan/Black Designjet Printhead

◦

HP 786 Lt Magenta/ Lt Cyan Designjet Printhead

◦

LX600/LX800 only:

●

HP 786 Yellow/Magenta Scitex Printhead

◦

HP 786 Cyan/Black Scitex Printhead

◦

HP 786 Lt Magenta/ Lt Cyan Scitex Printhead

◦

LX800 only: Ink Collector Kit

●

8 collector plates (in one box)

◦

2 Diverters

◦

LX800 only: Dual Roll Kit

●

2 spindles with differential

◦

Edge Holders

◦

Allen Keys 4,6

◦

1 HP Internal Print Server computer (includes keyboard, mouse and power cord)

●

1 LAN switch (includes power cord)

●

ENWW Inbox content 7

Page 12

1 Flat screen monitor (includes power cord)

●

Ethernet cables (computer to LAN switch)

●

Keyboard Tray

●

Sliding Door Handle

●

Covers (with screws)

●

Product name label

●

Fuse and cable kit

●

6 fuses, 1 extra fuse

◦

Set of power jumpers includes 200V, 240/230V, 220V, 127V/120V and 115V/100V/110V

◦

Two electrical cabinet keys

●

Printer Cleaning Kit

●

Maintenance Kit

●

2 aerosol filters

◦

1 printhead cleaner roll

◦

Purge kit

●

7 syringes and needles (extra syringe/needle set is included)

◦

6 purge bags

◦

1 purger quick connector (already installed)

◦

4 air purgers (extra air purger is included)

◦

Protective gloves and cloth

◦

12 intermediate tanks and labels

●

NOTE: The Russian printer configuration includes two 2 MB memory cards.

8 Chapter 2 Introduction ENWW

Page 13

3 Receive the shipment

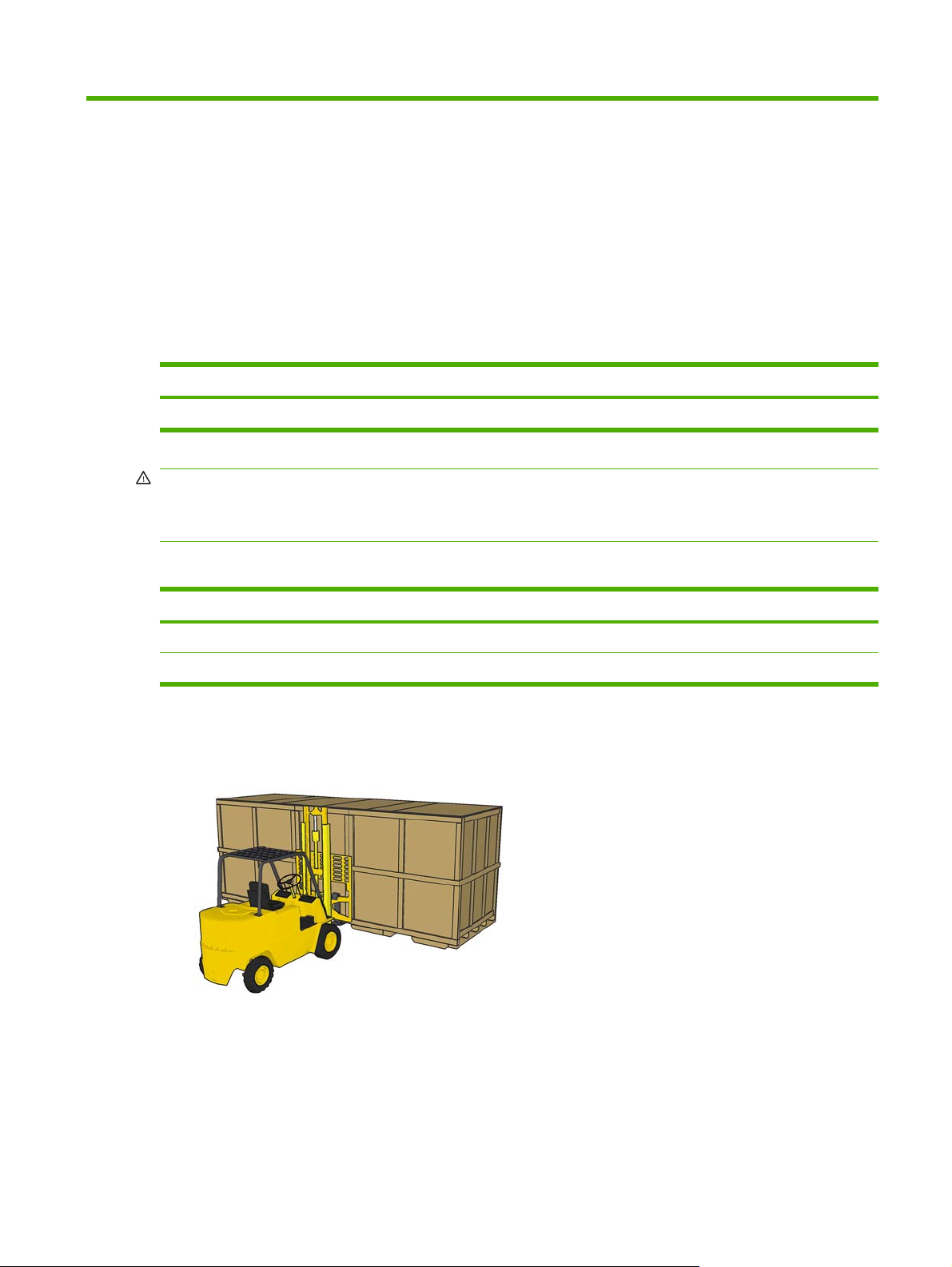

Unload the crate

Manpower Tools Time

2 persons Forklift, skates 15 minutes

WARNING! The crate must be lifted with a forklift from the front side of the crate. The front side of

the crate will be marked Front. This is important because of the weight distribution inside the crate.

WARNING! Do not stand on top of the crate.

Shown below are the recommended specifications of the forklift that should be used to move the crate.

Weight Fork Length Distance between forks

Forklift for L65500/LX600 2721 kg (5999 lb) 2 m (78.74 in) 800 mm (31.5 in)

Forklift for LX800 3500 kg (7716 lb) 2 m (78.74 in) 800 mm (31.5 in)

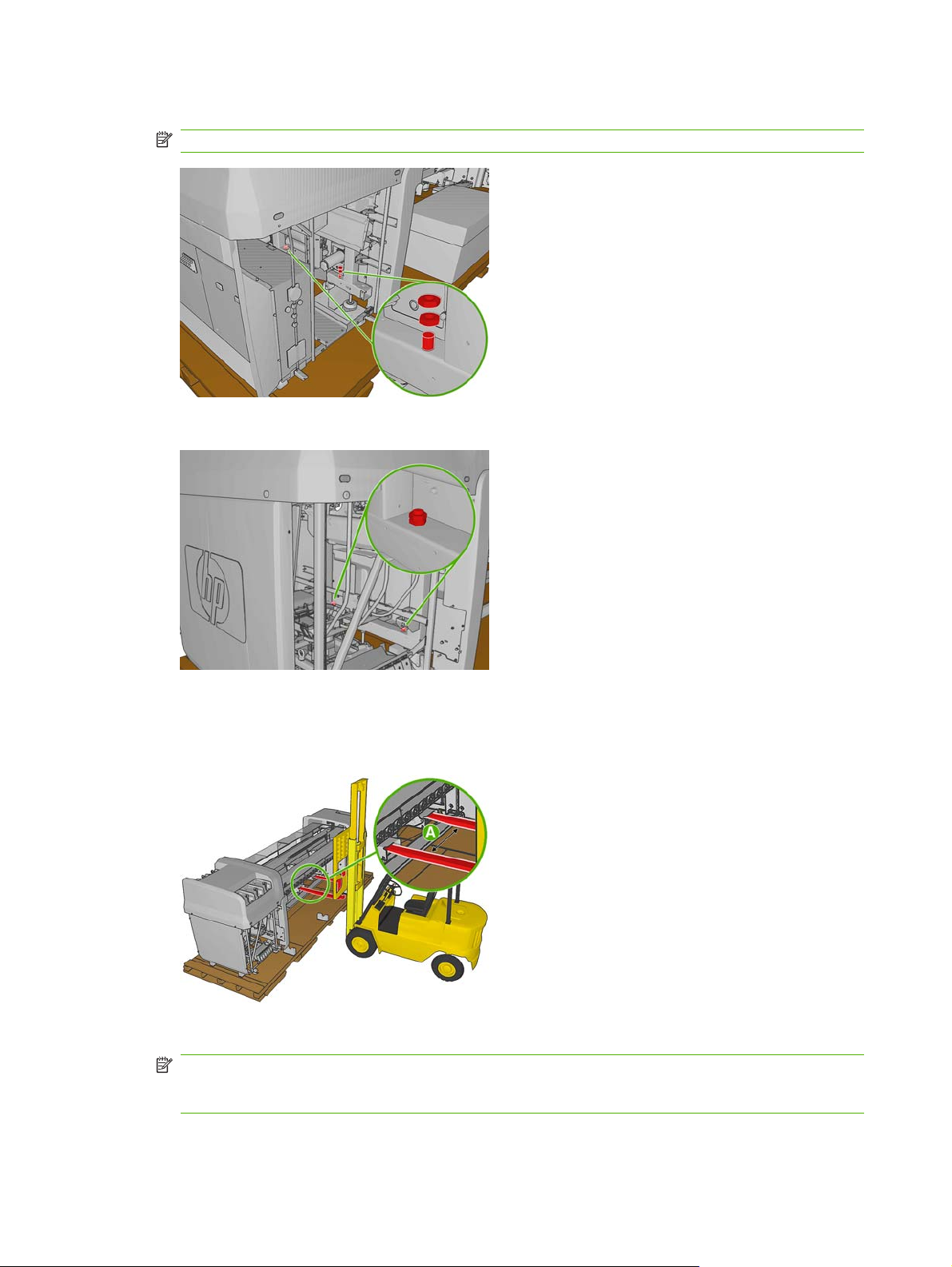

1. To move the crate with a forklift, insert the forks in the designated slots on the crate. Always lift the

crate from the front and center.

ENWW Unload the crate 9

Page 14

2. You can also use skates to maneuver the crate around tight corners or to move the crate laterally.

Move the printer over ramps

WARNING! Do not exceed the maximum incline if you must move the printer up or down a ramp.

Failure to respect the maximum incline could damage the printer.

CAUTION: Slopes steeper than 5% may cause serious damage to the printer.

Once the crate packaging has been removed from the printer, the maximum incline of a ramp used to

move the printer is 5%.

If you must move the printer over a ramp that exceeds the maximum incline (5%), do not remove the

printer from the pallet. The pallet will help prevent damage to the printer.

Remove the crate packaging

Manpower Tools Time

2 persons M17 socket wrench, Phillips screwdriver,

NOTE: Approximately 16 bolts and 100 Phillips screws secure the crate.

In some cases, it may be necessary to leave the printer inside the crate packaging to go up ramps or

make second story deliveries. Plan accordingly.

1. Beginning with the top, left corners, remove the Phillips screws securing the top panels and remove

them.

pliers, ladder

40 minutes

10 Chapter 3 Receive the shipment ENWW

Page 15

2. Remove the four support beams. Be careful that the support beams do not fall into the crate.

3. Use a Phillips screwdriver to remove the remaining screws that secure the side panels.

4. Carefully remove the panels and open the plastic bag surrounding the printer and free it from the

printer.

Remove the printer from the pallet

Manpower Tools Time

1 person Two M30 sockets, M17 socket wrench,

cutter, forklift

1. Remove the 8 Phillips screws that secure the items box and remove it.

NOTE: The starter kit weighs 60 kg. Two people are needed to lift it.

2. Remove the PC box and the disassembled covers.

3. LX800 only: Remove the Ink Collector Ink.

4. Use the 17 mm socket wrench to remove the spindle.

5. Lift the spindle away from the pallet.

NOTE: If you must lift the printer with a crane or perform difficult maneuvers, use tape to prevent

the door from opening accidentally.

ENWW Remove the printer from the pallet 11

10 minutes

Page 16

6. Remove the two 30 mm nuts attaching the left side of the printer to the pallet.

NOTE: Use a second M30 wrench to hold the second 30 mm nut in place.

7. Remove the two 30 mm nuts attaching the right side of the printer to the pallet.

8. Make sure that the feet are up and the sliding door is secured with the tape used for transportation.

9. Locate the forklift guides underneath the printer and make sure that the forks on the forklift are

spaced 80 cm apart (A).

10. Carefully lift the printer, move it away from the pallet and set it on the floor.

NOTE: The printer weighs more on the right side than the left side. Make sure that it does not tilt

toward the right hand side when you lift the printer. Make sure you lift the printer high enough so

the screws that attach the printer to the pallet do not touch the printer.

12 Chapter 3 Receive the shipment ENWW

Page 17

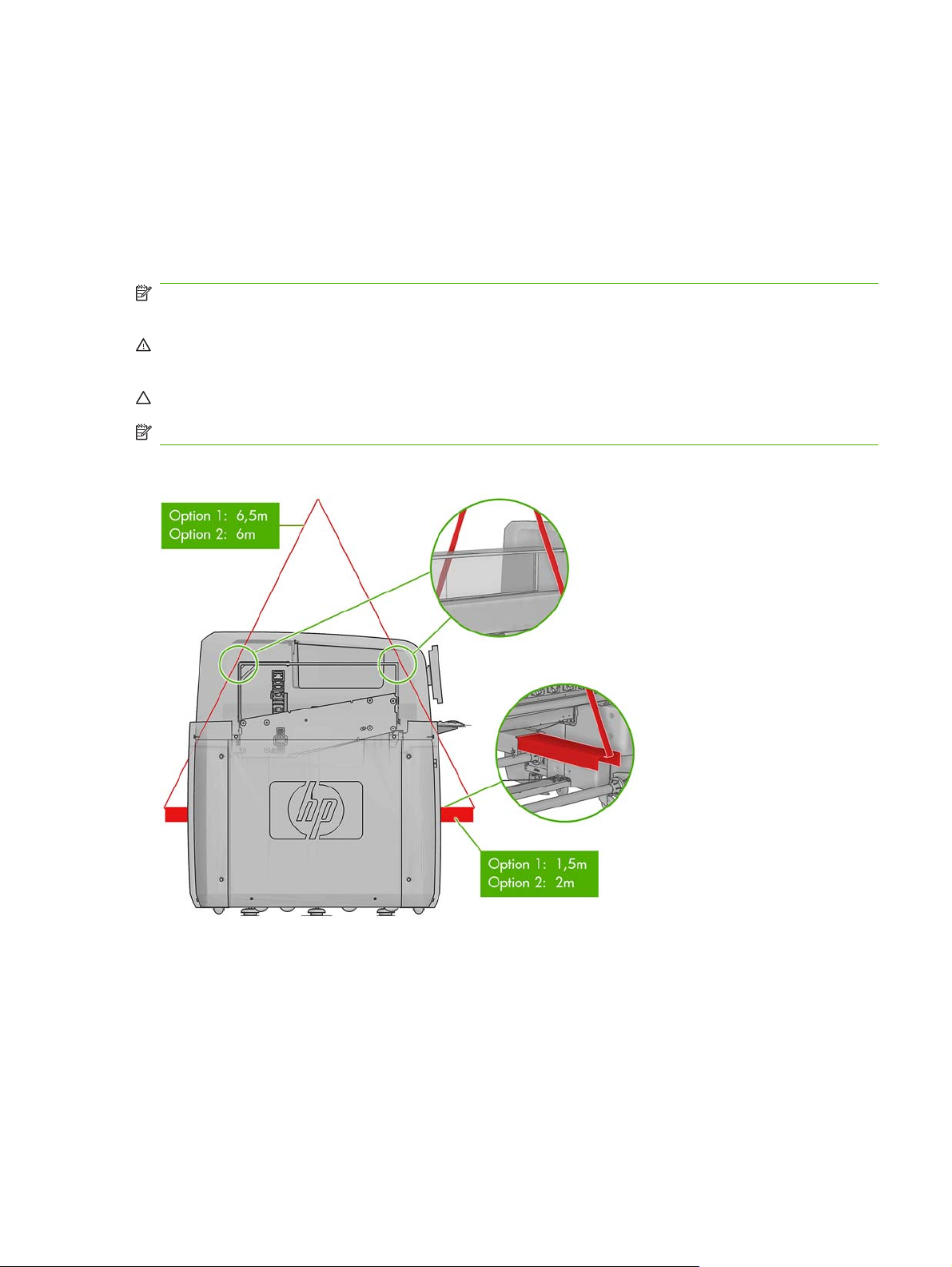

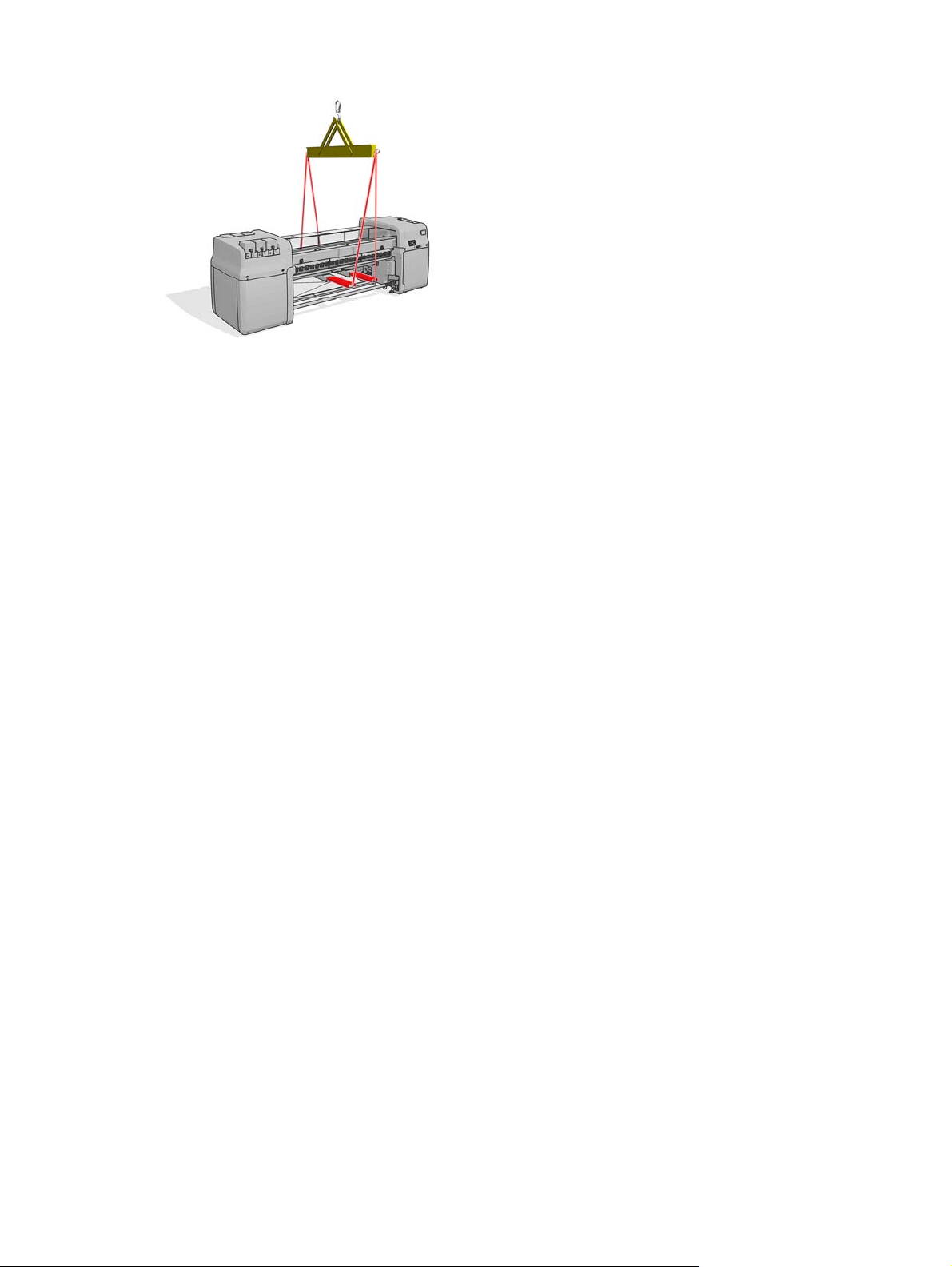

Lift the printer to a second floor using a crane

At this point, normally you would push the printer to the final location. However, if you need to make a

second floor installation, a crane will be needed to lift the printer. The same guides used to lift the printer

with a forklift should be used to lift the printer with a crane. To do so, lifting bars must be inserted into

the forklift guides. The lifting cables can either be attached to a spreader beam or directly to the crane.

In some cases, the printer can be lifted by the crane without removing the crate. If the unloading area

for the crate has enough space to disassemble the crate safely, this situation is ideal.

NOTE: The lifting bars, spreader beam and any other crane attachment must be supplied by the

customer. For the exact specifications of the crane attachments, see the Site Preparation Guide.

WARNING! When lifting the printer with a crane, extra caution should be taken to ensure that the

cables do not apply pressure to the center covers or carriage beam.

CAUTION: The printer weight is not evenly distributed, and it may tilt to the right side.

NOTE: The printer will bend as you lift it.

The following graphic illustrates how to lift the printer using lifting bars.

If you use a spreader beam to lift the printer, make sure that the spreader beam and lifting bars are wide

enough so the lifting cables do not touch the center covers or carriage beam. The following graphic

illustrates how to lift the printer with a spreader beam.

ENWW Lift the printer to a second floor using a crane 13

Page 18

14 Chapter 3 Receive the shipment ENWW

Page 19

4 Set up the printer in the final position

How to push the printer

Manpower Time

2 persons Varies

NOTE: Do not remove the ISM or electrical cabinet straps until the printer is in the final position.

When you set the printer on the floor, the printer wheels allow you to easily roll the printer.

Only push the printer from the outside corners of the top covers on either side of the printer.

Choose the final position

Your HP Designjet L65500 printer requires enough space to perform the following tasks:

Print

●

Use the HP Internal Print Server

●

Replace a substrate roll

●

Service the printer or replace printer components

●

Ensure the printer is well ventilated

●

The printer has the following dimensions:

ENWW How to push the printer 15

Page 20

Printer Length Width Height

HP Designjet L65500 5 m (16 ft, 5 inches) 1.6 m (5 ft, 3 inches) 1.8 m (5 ft, 11 inches)

HP Designjet LX600 5 m (16 ft, 5 inches 1.6 m (5 ft, 3 inches) 1.6 m (5 ft, 3 inches)

HP Designjet LX800 5.7 m (18 ft, 11 inches) 1.6 m (5 feet, 3 inches) 1.6 m (5 feet, 3 inches)

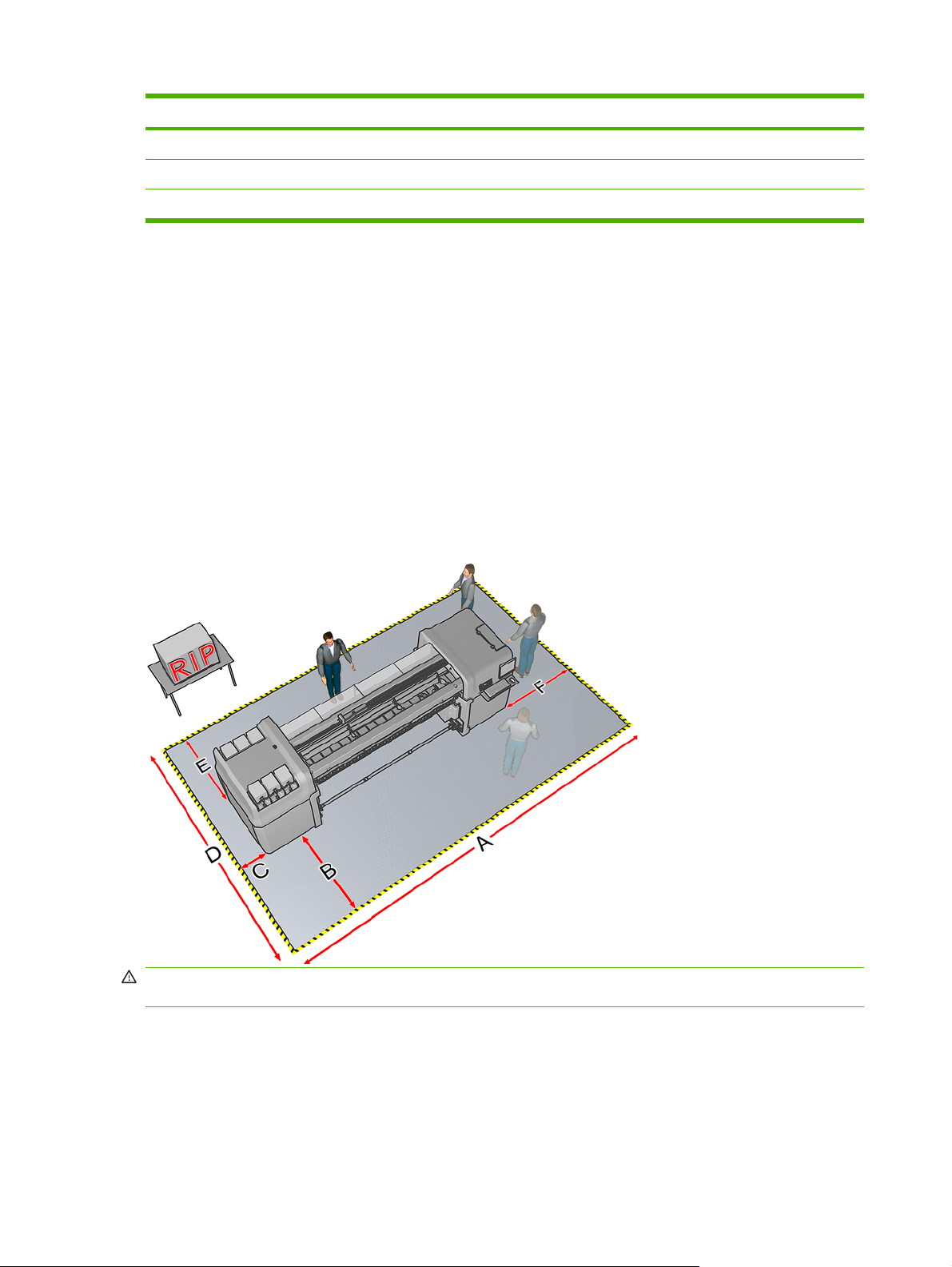

The following table and illustration shows the minimum space required for the printer.

Measurement

A L65500/LX600: 7m (23ft)

LX800: 8m (26ft 3 in)

B 1.5 m (5ft)

C 0.6 m (2 ft) minimum

D 4 m (13 ft, 2 in)

E 1.5 m (5 ft)

F 1.5 m (5 ft)

WARNING! The zone surrounding the HP Designjet L65500 printer should be considered a restricted

access area and signaled accordingly. Only trained personnel should be operating within this area.

16 Chapter 4 Set up the printer in the final position ENWW

Page 21

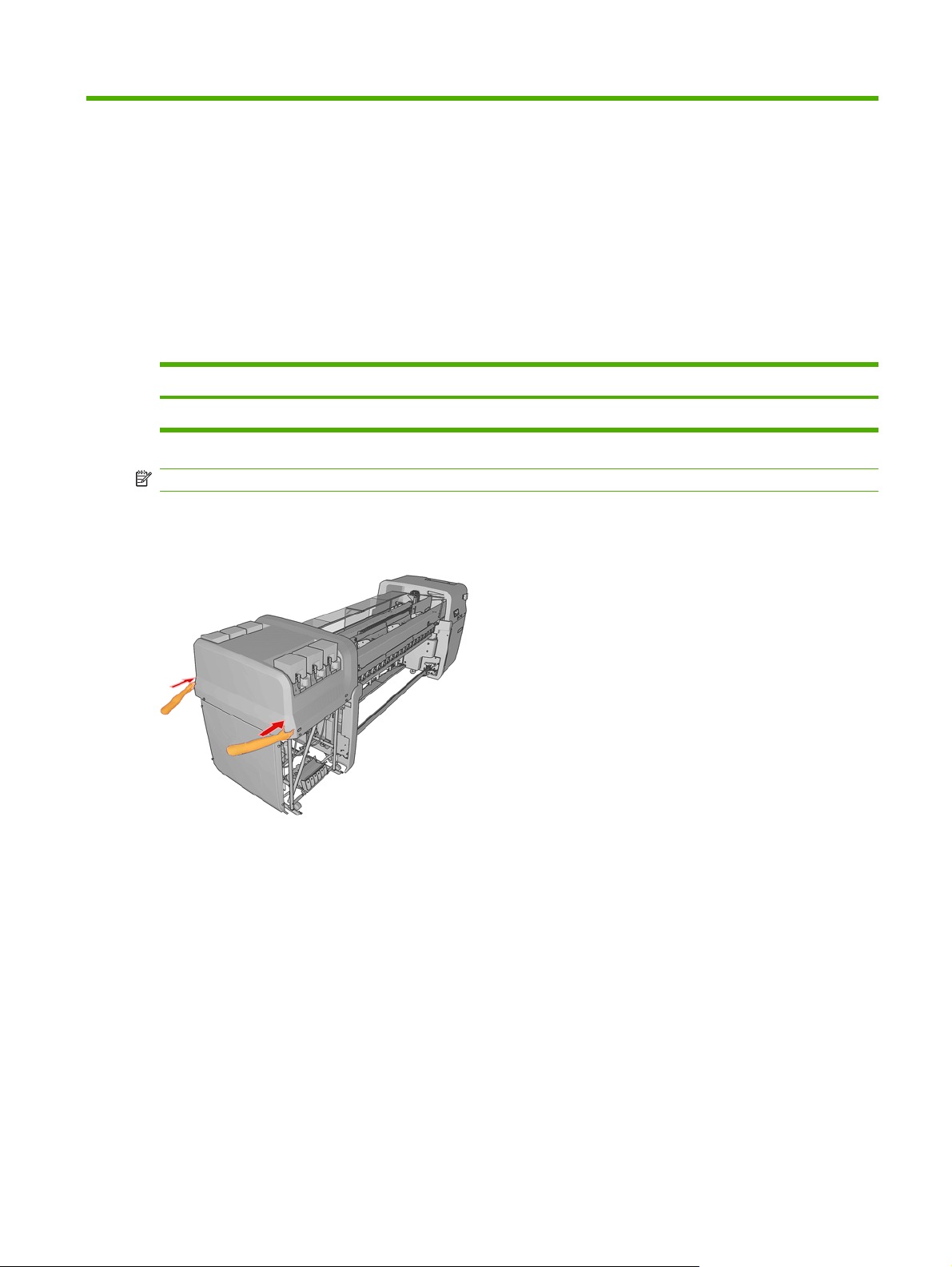

Remove additional packaging

Manpower Tools Time

1 person Cutting Pliers, Allen keys, T20 and T25

screwdrivers

15 minutes

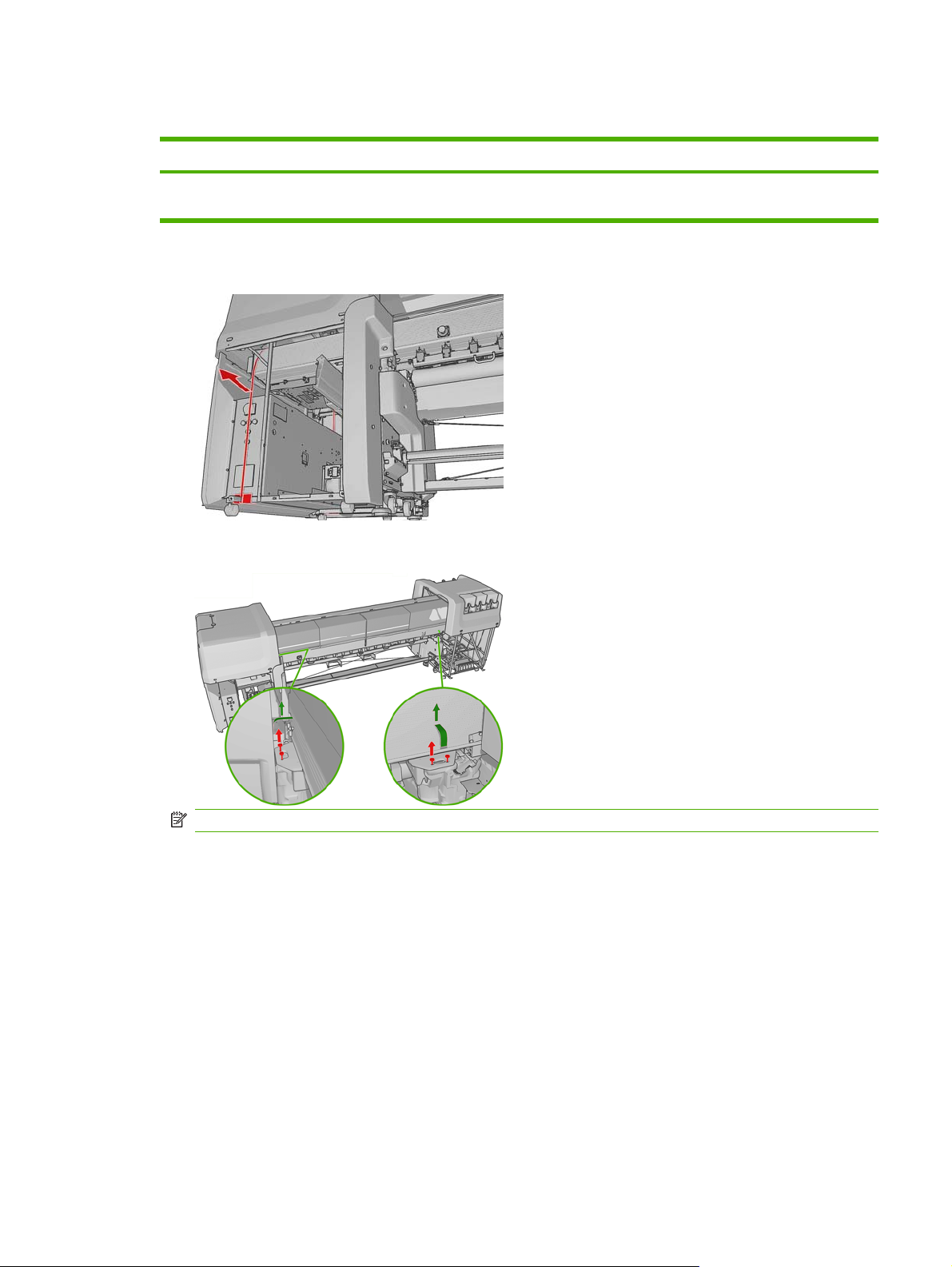

1. From the back, remove the electrical cabinet straps and foams from the printer.

2. Remove the straps from the sliding doors.

NOTE: The keys to the electrical cabinet are located on top of the cabinet.

ENWW Remove additional packaging 17

Page 22

3. Remove the eight T20 screws attaching the scan path assembly to the frame. Use a screwdriver

extension for easier screw access.

WARNING! Failure to remove the screws attaching the scan path assembly to the frame could

seriously damage the printer.

NOTE: The screws located at the back, are less accessible and may require a longer screwdriver.

4. Remove tape from the window and open the carriage access door, remove the T30 screw securing

the carriage.

18 Chapter 4 Set up the printer in the final position ENWW

Page 23

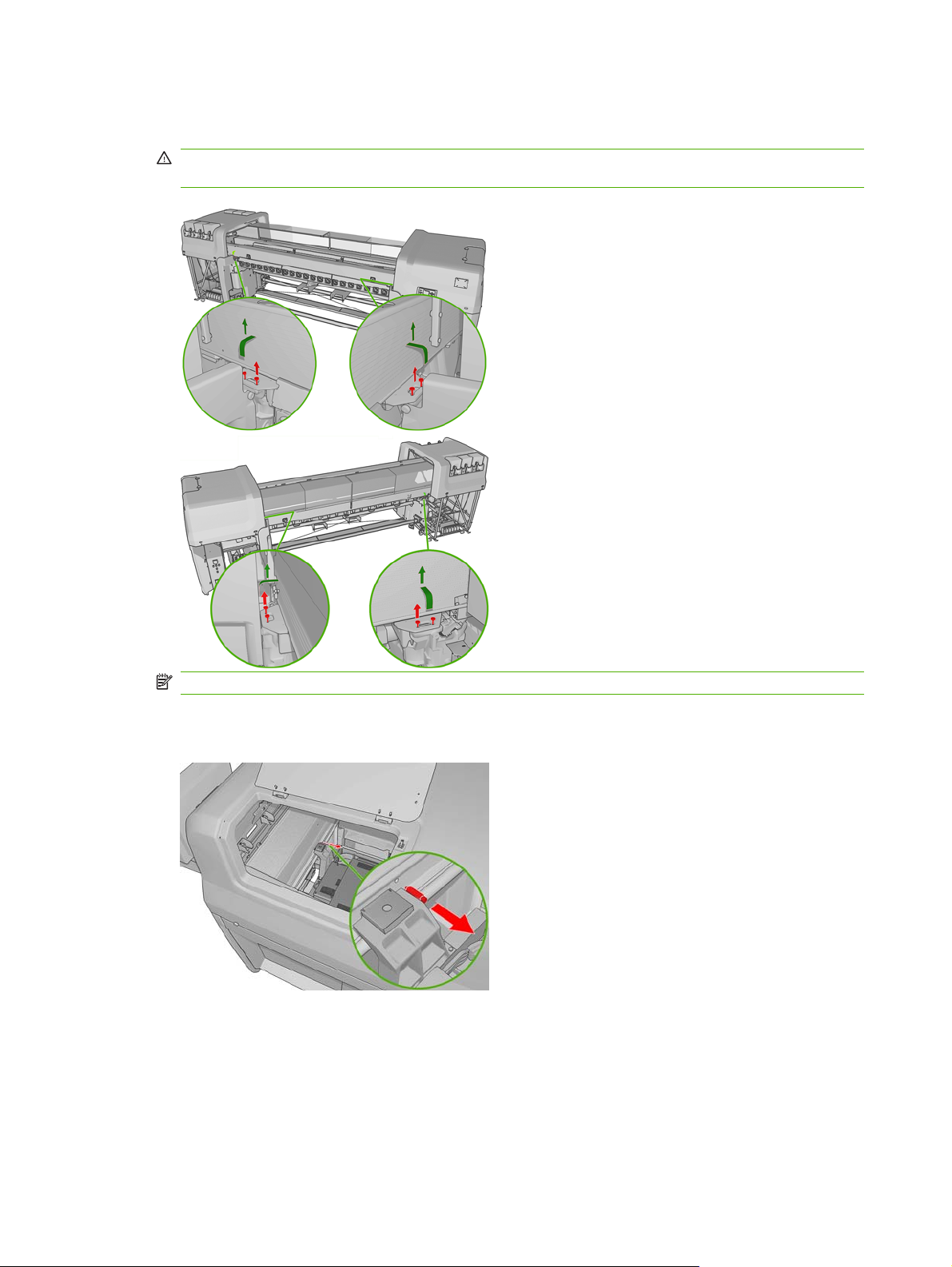

5. Remove the tie and 2 foam pieces that secure the service station.

6. Remove the four foam pieces that secure the top cover.

7. Remove the two T20 screws securing the printhead cleaning assembly.

8. Remove the substrate pressure handle straps (pinches).

9. Remove the plastic ties securing the diverter.

ENWW Remove additional packaging 19

Page 24

10. Remove the plastic tie securing the spindle and the tape covering the air valve.

11. Remove the ink system compartment strap from the printer.

12. Remove the plastic coverings from the ink cartridge connectors.

13. Remove the intermediate tank plastic bags, foams and straps.

14. Remove the plastic ties securing the tri-phase and single-phase power cables.

15. Remove any other plastic ties that you can see inside the printer.

20 Chapter 4 Set up the printer in the final position ENWW

Page 25

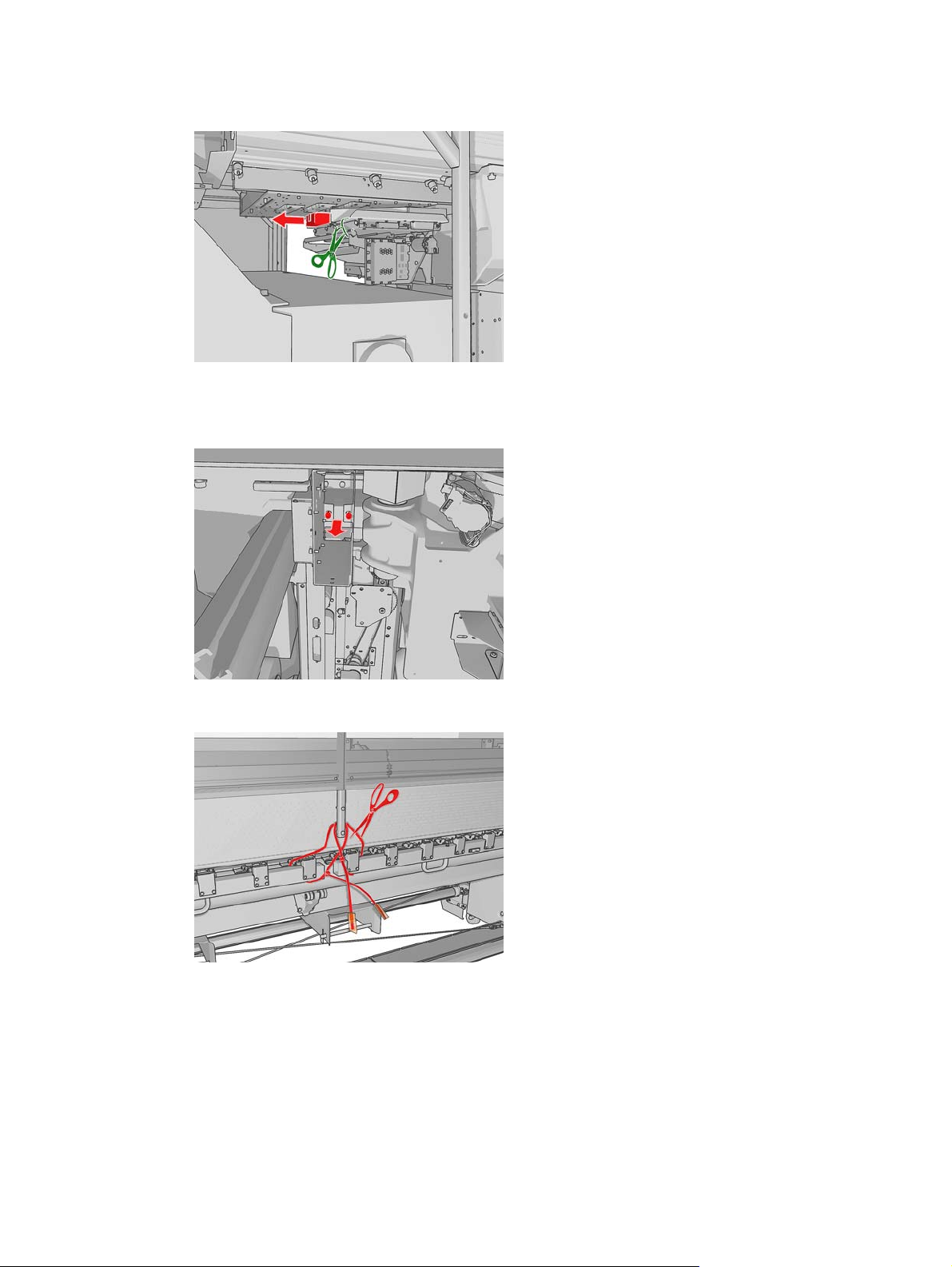

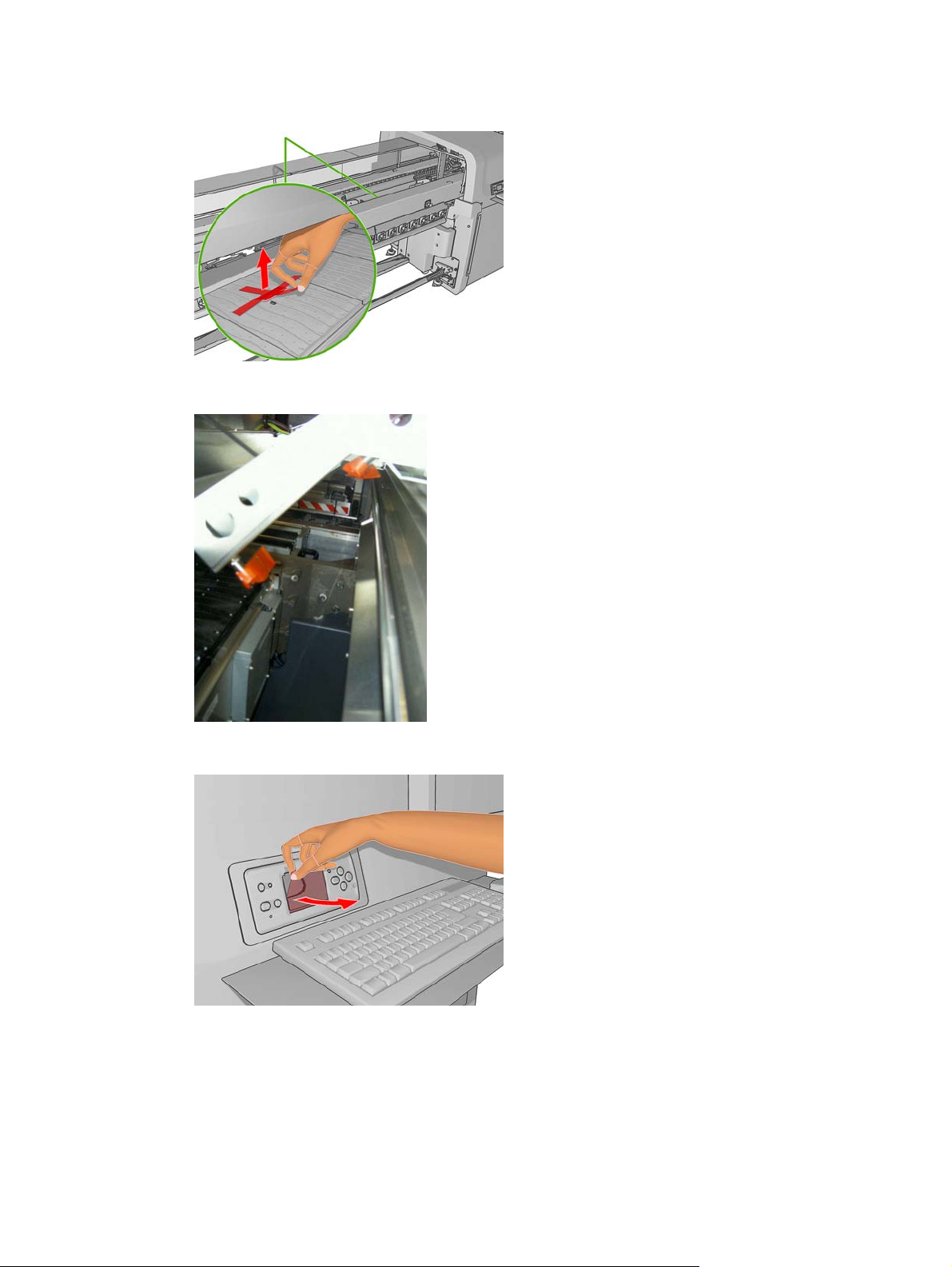

16. Remove the tape covering the OMAS window on the print platen.

17. Remove the tapes covering the temperature sensors.

18. Remove the plastic covering from the carriage access door , front panel and central cover.

19. Remove tape from the Curing Plate.

20. Remove foam pieces from the left and right.

21. Remove foam pieces from the rear beam structure.

ENWW Remove additional packaging 21

Page 26

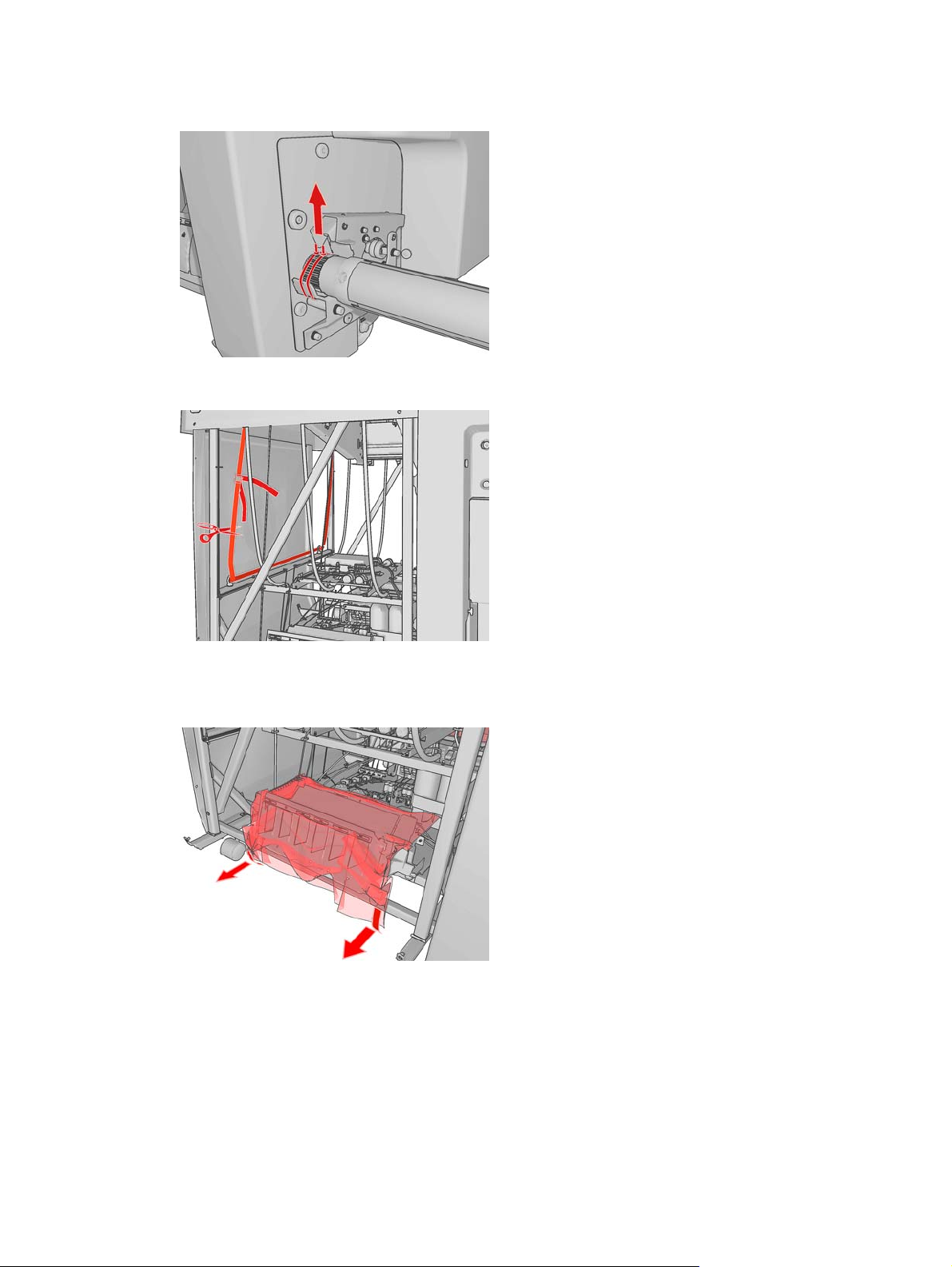

22. Remove 4 plastic ties from the left side cover.

23. Remove plastic ties from the top covers.

Lower the feet

1. Use a 30 mm wrench to unlock the nut at the top of the foot.

2. Rotate the nut manually down the bolt. Leave about 0.8 inches (2 cm) of clearance at the bottom

between nut and foot.

3. Use a 15 mm wrench to rotate the foot downwards. Use the flat faces at the bottom of the bolt to

fit the wrench.

4. Lower the foot as far as the bolt allows.

5. Once the wheels are 15 mm (A) off the ground, tighten the 30 mm locking nut against the printer

structure

NOTE: The right side of the printer is heavier than the left side. Therefore, the feet on the right side

will be more difficult to lower.

NOTE: The position of the feet must be parallel with the spindle.

22 Chapter 4 Set up the printer in the final position ENWW

Page 27

5 Connect the power cables

Requirements

An electrician is required for the setup and configuration and building of the electrical system used to

power the printer and also for printer installation. Make sure that your electrician is appropriately certified

according to local regulations and supplied with all the information regarding the electrical configuration.

Configure the building's electrical system used to power the printer to meet the printer's requirements

and the Electrical Code requirements of the local jurisdiction of the country where the equipment is

installed. A qualified electrician is required.

Your printer requires the following electrical components to be supplied and installed by the customer,

according to the Electrical Code requirements of the local jurisdiction of the country where the equipment

is installed.

Remember that you are required to follow the local laws, regulations, and standards that pertain to the

electrical installation of your printer.

Tri-phase AC Power Cord

The cable must meet the requirements of the printer and should be in accordance with the Electrical

Code requirements of the local jurisdiction of the country where the equipment is installed.

Printer's tri-phase line specifications High-voltage systems Low-voltage systems

Input voltage (line to line) 3 x 380–414 V~ (-10% +6%) 3 x 200–220 V~ (±10%)

Input frequency 50 Hz 60 Hz (1)

Power Consumption 15 KW 15 KW

Maximum Load Current 30 A 50 A

1

Japan may have input frequencies of 50 Hz or 60 Hz

Power Cord Specification

Configuration 4 Wires, L1/L2/L3/PE

Minimum cross-sectional area

The power cord must enter into the printer through the AC power gland, and securely fit into it, in order

to avoid any slip even when the cord suffers a pull force of 100N.

High-voltage systems High-voltage systems

AWG6, 16mm

2

AWG6

ENWW Requirements 23

Page 28

Tri-phase Power Cord attachment

1. The Tri-phase AC power cord must be attached to the back of the Main Switch.

2. Back of the Main Switch is shown below:

This Main Switch is made by two blocks of identical size, each one having three contacts. The left

block is dedicated to tri-phase lines, so the three contacts are used. The block on the right side is

dedicated to single-phase lines, so only two contacts form the total of three are used.

24 Chapter 5 Connect the power cables ENWW

Page 29

The AC power cords (tri-phase and single-phase) have to be screwed to the bottom terminals of the

switch. Add adequate ferrules on power cord cable terminations. In total there are 6 terminals to attach

wires, and only 5 of them are to be used. They are labeled (from left to right): L1, L2, L3, (blank), L0 and

N. Each wire must be securely attached to the terminals of the power switch.

Label on Switch Wire Power Cord

L1 Phase Tri-phase

L2 Phase Tri-phase

L3 Phase Tri-phase

Blank — —

L0 Phase Single-phase

N Neutral Single-phase

ENWW Tri-phase AC Power Cord 25

Page 30

Protective Earth conductors (grounding)

The printer must be connected to a good quality, dedicated ground line in order to avoid electrical risk.

Please note your obligation to comply with the Electrical Code requirements of the local jurisdiction of

the country where the equipment is installed.

Protective Earth attachment

The ground wires coming from the tri-phase power cord and from the single-phase power cord

▲

must be fitted with round terminals suitable for attaching into M6 pillar terminal. Reliable screw

attachment must be used. They are close to Protective Earth (PE) terminal marking which are

located in the Cabinet on the right as shown on the picture below.

Protective Earth (PE) terminal markings:

26 Chapter 5 Connect the power cables ENWW

Page 31

6 Configure the electrical system

Install the fuses and power jumper

Manpower Time

1 person 5 minutes

NOTE: The electrical system inside the printer must be configured by the service engineer during

installation.

CAUTION: If there are any doubts regarding the proper installation of the fuse or power jumper,

consult the certified electrician that knows the voltage of the electrical installation.

TIP: The electrical cabinet key is located in a plastic bag secured to the top of the electrical cabinet.

Open the sliding door to find it.

1. Power fuse holder blocks

2. Vacuum transformer

NOTE: The Vacuum transformer is located in the purging kit box.

ENWW Install the fuses and power jumper 27

Page 32

Install the fuses

1. Use the key to access the electrical cabinet.

2. Open the two fuse holder blocks.

3. Insert the six fuses (three per fuse block) into the fuse holder with the piston facing you.

Printer Sites with high voltage supply (200–

HP Designjet L65500/LX600 20 A 32 A

HP Designjet LX800 25 A 40 A

1

Japan may have input frequencies of 50 Hz or 60 Hz

4. Close the fuse holder until you feel and hear a “click.” The red square above the fuse holder should

change color once all fuse holders have been inserted.

Install the power jumpers

290V)

Sites with low voltage supply (100–

120)

1. There are five power jumpers supplied. Select the appropriate power jumper according to the

single-phase power at the installation site. Inserting the wrong power jumper will cause the vacuum

pump to work incorrectly.

2. Insert the correct power jumper into the connector, located close to the transformer.

28 Chapter 6 Configure the electrical system ENWW

Page 33

Choose delta or star (Y) configuration

Manpower Tools Time

1 person T10 and M15 screwdriver, M7 wrench 5 minutes

There are two Delta/Star terminal blocks located on the printer that must be configured. Use the following

table to make the configuration, and follow the procedures below to access the two terminal blocks.

CAUTION: Both Delta/Star terminal blocks must use the same configuration.

Delta configuration

1

Use the delta configuration for tri-phase power supply voltages from 200–220 V (between phases).

2

Use the star configuration for tri-phase power supply voltages from 380–415 V (between phases).

Heating Module Configuration

1. Remove the six T10 screws securing the middle cover of the heating module and remove it.

TIP: The heating module cover you must remove is marked with orange tape.

1

Star configuration

2

ENWW Choose delta or star (Y) configuration 29

Page 34

2. To make the delta or star configuration, use the metal strips and configure them according to the

table. Use an M7 socket wrench to secure them.

Curing Module Configuration

1. Remove all the T10 screws securing the right cover of the curing module and remove the cover.

TIP: The heating module cover you must remove is marked with orange tape.

2. There is a strap that does not allow you to remove the terminal block. Remove this strap, taking

care that you replace it after making the configuration.

3. Remove the T15 screw securing the terminal block and pull it out for easy access.

4. To make the delta or star configuration, use the metal strips and configure them according to the

table. Use an M7 socket wrench to secure them.

30 Chapter 6 Configure the electrical system ENWW

Page 35

WARNING! The curing module terminal block must use the same configuration as the drying

module.

Check resistances

Check the resistance at the output of the static relay, as shown below, through the hole protecting the

static relay.

Also check the resistance between A2-B2, A2-C2, B2-C2 (marked on the static relay and on the heating

and curing cables: 1, 2, 3).

The acceptable values are as follows.

Triangle configuration (low input tri-phase, 200-220 V between phases): resistance should be

●

16 Ω (minimum: 15 Ω , maximum: 17 Ω).

Star configuration (high input tri-phase, 380-415 V between phases): resistance should be 32 Ω

●

(minimum: 30 Ω, maximum: 34 Ω).

Check connections

Check that the following items are correctly connected.

The main interconnect

●

The left remote controller board (remove the left trim)

●

The ink supply module board

●

The capping station's remote controller board

●

The printhead cleaning roll station

●

The tri-phase cables on the static relay: within the electrical cabinet, on the left, the two big black

●

relays)

The neutral or zero line of the tri-phase cables must not be connected.

ENWW Check resistances 31

Page 36

Connect mains power

Manpower Time

1 person 5 minutes

NOTE: This task must be performed by a certified electrician provided by the customer.

NOTE: Make sure to route the power cables under the electrical cabinet structure.

1. Use the key to access the electrical cabinet.

2. Connect both power cables to the AC mains using the appropriate connectors or by wiring them

directly to the PDU, according to the National Electrotechnical Code (NEC). For more information

about the HP Designjet L65500 electrical specifications, see the Site Preparation Guide.

Power on the printer

Manpower Time

1 person 5 minutes

Ground check

1. Check that the Protective Earth Conductor for the single-phase and tri-phase (green-and-yellow

2. Check that the Protective Bonding Conductor (green-and-yellow grounding cable) is well attached

grounding cable) is well attached to the back panel of electrical cabinet.

to the electrical cabinet doors.

32 Chapter 6 Configure the electrical system ENWW

Page 37

3. Check that the Protective Bonding Conductor (green-and-yellow grounding cable) is well attached

to the back panel of the electrical cabinet.

4. Check that the Protective Bonding Conductor (green-and-yellow grounding cable) is well attached

to the input single-phase filter.

ENWW Power on the printer 33

Page 38

5. Check that the Protective Bonding Conductor (green-and-yellow grounding cable) is well attached

to the printer structure.

6. Check that the Protective Bonding Conductor (green-and-yellow grounding cable) is well attached

to the drying system (at the resistor connection).

34 Chapter 6 Configure the electrical system ENWW

Page 39

7. Check that the Protective Bonding Conductor (green-and-yellow grounding cable) is well attached

to the curing system (at the resistor connection).

Turn power on

1. Make sure that the printer is ready to be turned on.

2. Turn the power switch ON.

3. Go the front panel and see if it is on. If it is not on, press and hold the Power key for a few seconds

Make sure that the emergency stop buttons are not pressed.

Make sure the ACB-1, ACB-2 and ACB-3 circuit breakers located on the electrical cabinet door are enabled (in

the UP position).

Make sure the electronics box switch is turned on.

Have you removed all the additional packaging?

Have you lowered the feet?

Is the correct power jumper installed?

Are the delta/star terminal blocks configured correctly?

Are the carriage access door and sliding door closed?

Are all tools and other objects clear from the printer?

Make sure that no people are touching the printer.

to start the printer.

ENWW Power on the printer 35

Page 40

4. Verify that all four LED lights on the rear side of the electrical cabinet are on (PH1, PH2, PH3,

Vacuum ON).

5. Wait for the printer to initialize.

NOTE: The printer will automatically start in diagnostic mode so you can purge the ink system.

When you first turn on the printer, you must set the voltage according to the country of installation.

Configure the voltage

1. From the front panel, enter the diagnostic menu and select Purge and Setup Menu > 3ph AC Volt

Setup Menu to display a list of voltages.

2. Select the correct voltage according to the country of installation and press OK.

NOTE: Select the tri-phase nominal mains voltage (line to line) according to the Electrical

Installation section of the Site Preparation checklist.

3. Press the Power enable button on the rear side of the printer. It should light up orange.

36 Chapter 6 Configure the electrical system ENWW

Page 41

7 Purge the ink system

Manpower Tools Time

1 person Syringe, Gloves, Clean cloth 60 minutes

Do the purging process one color at a time. Always double check to make sure you are inserting the

right color of ink into the purging port. Before installing the purge bags, check that the electrical

connectors are not bent or damaged.

The purge process requires at least 1.7 liters of ink per ink cartridge.

Purge the ISM tubes

NOTE: From the ink cartridge to the purging port, no air can be tolerated. From the purging port to the

printhead, the printer can tolerate a cumulative total of 20 cm of air (the length of the bubble) in the tubes

per color. Small pockets of bubbles are acceptable.

CAUTION: To avoid damaging the printer, do not force any tube or connection. Gently manipulate the

syringe during insertion and purging.

1. Install the six purge bags.

2. Begin connecting the purger quick connector. To do so, hold each end of the quick connection with

your hands.

3. Press and hold the green button on the ISM side of the quick connector.

4. If not already installed (some printers may have this part already installed), insert the purger quick

connector until both sides of the connection are perfectly aligned, and release the green button on

the ISM side of the quick connector, complete the coupling, until you hear a click.

ENWW 37

Page 42

5. Release the green button on the ISM side of the quick connector and complete the coupling. You

should hear a click.

CAUTION: Use only moderate force to make the connection. If it is difficult to make the

connection, do not continue. Instead, start the process again. Using too much force could damage

the internal fittings of the connectors.

6. Test the connection by gently pulling both connectors away from each other.

7. From the diagnostic menu on the front panel, select Purge and Setup Menu > Purge ISM.

8. Select the color you want to purge.

Ink Supply Legend

●

●

●

●

●

●

NOTE: The printer starts up the procedure, which may take a couple of minutes.

TIP: Do not press the OK button more than once.

9. Place the cartridge on a flat surface and turn it four times (rotating it through 360 degrees) as

indicated on the label, to ensure that the ink is well mixed before use.

1 = K

2 = Y

3 = C

4 = M

5 = LM

6 = LC

38 Chapter 7 Purge the ink system ENWW

Page 43

10. Insert a clean syringe into the ink cartridge and fill it with 60 cc of ink for the color selected.

11. From the front panel, press OK to open the electrovalves. You now have 200 seconds to feed the

remaining ink into the purging port before the electrovalve closes.

NOTE: The printer will beep during these 200 seconds.

12. Check that all of the electrovalves have opened (you can hear a clicking sound). If not, perform the

4.6 ISS Electrovalves diagnostic procedure described in the Service Manual. While the test is in

progress, tap vigorously on the body of the electrovalve with a tool such as a screwdriver.

13. Check that there is no air in the syringe by hitting it a few times. If there is air, hold the syringe

vertically with the needle up, so that the bubble of air rises to the top. Put a cloth around the needle,

and press gently on the piston to remove the air from the syringe.

14. Insert the syringe in the purging port (next to the ink pressure sensor) for the color selected, and

slowly push the ink until it clearly reaches the purger quick connector and the purge bags.

TIP: Make sure to insert the syringe far enough into the port. In order to insert the ink correctly,

the tip of the syringe must engage a small spring inside the port.

CAUTION: If you apply too much force to the syringe, you may damage the ink system. If there

seems to be too much resistance, stop pushing the ink with the syringe and try to identify possible

problems.

CAUTION: Never look away from the syringe. If you need to look at the purge bags or something

else in the room, set down the syringe first. The ink system components are easily broken.

ENWW 39

Page 44

Ink Supply Legend

●

●

●

●

●

●

CAUTION: Do not push the ink from the syringe if the electrovalves are not open. You will notice

too much resistance if the electrovalves are not open.

TIP: If you run out of ink in the syringe, you can refill the syringe from the ink cartridge. Keep track

of how much ink you remove from the ink cartridge, because you will be asked to report the quantity

of ink taken. Make sure the electrovalves are still open.

15. Remove the syringe from the purge port with a cloth around the needle to prevent spills.

16. Press OK on the front panel to close the electrovalves.

17. Check that the ink has arrived as far as the purging bag and purger.

18. Press OK to confirm that you have finished purging the ink tubes for the color selected.

1 = K

2 = Y

3 = C

4 = M

5 = LM

6 = LC

19. Disconnect the purge bag and connect the ink cartridge. If the ink cartridge is connected correctly,

the cartridge LED will show a constant green light.

40 Chapter 7 Purge the ink system ENWW

Page 45

20. When the ink cartridge has been installed correctly, press OK.

21. Press OK to confirm that you have installed the ink cartridge.

22. The printer checks the pressure sensors.

If the pressure is correct, press OK to continue.

If the pressure sensor value is below the limits or is negative then follow the steps in Problems with

the ink sensor value on page 42.

23. Enter the quantity of ink you extracted from the ink cartridge. If you extracted ink from the cartridge

twice and purged the ISM in two steps, enter the total sum of the ink extracted.

24. Select the next color and repeat.

ENWW 41

Page 46

25. Remove the purger quick connector.

Problems with the ink sensor value

1. There are three different cases that can cause a problem.

The pressure sensor value is below a limit, which may vary depending on the volume of the

●

supply. Probably there is an air bubble inside the cartridge connector tube column. Prepare

the syringe again. Press OK and continue with step 2.

The ink volume of the cartridge is too low to register on the pressure sensor. To ensure there

●

are no air bubbles in the tube, you are recommended to purge again. Press BACK and

continue with step 2. If you think there are no air bubbles, press OK and continue the process

of purging the ISM tubes from where you were.

42 Chapter 7 Purge the ink system ENWW

Page 47

The pressure sensor gives a negative value. If the pressure is negative, there may be an error

●

in the ink pressure PCA or in the ink pressure sensor cable. Check both by looking at the

connection of the cable to the ISS PCA and at the pressure sensor PCA. Press OK to cancel

the purge process.

2. If the pressure is positive, probably there is an air bubble inside the cartridge connector tube

column. Prepare the syringe again, then press OK.

3. Insert the same syringe into the ink cartridge and fill it with 20 cc of ink for the color selected.

4. Check that there is no air in the syringe by hitting it a few times. If there is air, hold the syringe

vertically with the needle up, so that the bubble of air rises to the top. Put a cloth around the needle,

and press gently on the piston to remove the air from the syringe.

ENWW 43

Page 48

5. Insert the syringe in the purging port (next to the ink pressure sensor) for the color selected, and

slowly push the ink until it clearly reaches the quick connector purger and the purge bags.

TIP: Make sure to insert the syringe far enough into the port. In order to insert the ink correctly,

the tip of the syringe must engage a small spring inside the port.

CAUTION: If you apply too much force to the syringe, you may damage the ink system. If there

seems to be too much resistance, stop pushing the ink with the syringe and try to identify possible

problems.

CAUTION: Never look away from the syringe. If you need to look at the purge bags or something

else in the room, set down the syringe first. The ink system components are easily broken.

TIP: You will notice more resistance than before because the electrovalves are not open.

TIP: If you run out of ink in the syringe, you can refill the syringe from the ink cartridge. Keep track

of how much ink you remove from the ink cartridge, because you will be asked to report the quantity

of ink taken.

6. Remove the syringe from the purge port with a cloth around the needle to prevent spills.

7. Press OK to confirm that you have finished purging the ink tubes for the color selected.

8. Disconnect the purge bag and connect the ink cartridge. If the ink cartridge is connected properly,

the ink cartridge LED shows a continuous green.

9. Continue with step

20 in the process of purging the ISM tubes. If the problem is not solved after

trying this twice, perform the 4.5 ISS Ink Pressure Sensors diagnostic procedure found in the

Service Manual.

44 Chapter 7 Purge the ink system ENWW

Page 49

Fill the intermediate ink tanks

1. From the front panel, select Purge and Setup Menu > Fill intermediate tanks.

2. Install all the intermediate ink tanks, apply the labels (match them to the labels on the printer) and

confirm that they are installed from the front panel.

The printer unfolds the intermediate ink tanks. This process takes approximately 25 minutes.

NOTE: During this time, you can install the printhead cleaner roll, aerosol filters, HP Internal Print

Server and switch. See

the computer, monitor, LAN switch, tray, keyboard and mouse on page 53.

3. When the printer finished unfolding the intermediate ink tanks, press OK to continue.

Install the printhead cleaning roll and aerosol filters on page 50 and Install

The printer fills the intermediate ink tanks. This takes a few minutes.

4. When the process is finished, check that the ink cartridge LED is green and press any key to

continue.

ENWW 45

Page 50

Purge the tubes from the ISM to the printheads

1. Install the three air purgers into the three empty printhead ink ports.

2. From the front panel, enter the diagnostic menu and select Purge and Setup Menu > Purge

Printer Tubes.

3. Begin connecting the quick connector. To do so, hold each end of the quick connection with your

hands.

WARNING! Always handle the quick connector by the protective tubing to avoid damaging the

internal fittings.

4. Press and hold the green button on the ISM side of the quick connector.

46 Chapter 7 Purge the ink system ENWW

Page 51

5. Partially insert the quick connector until both sides of the connection are perfectly aligned.

6. Release the green button on the ISM side of the quick connector and complete the coupling. You

should hear a "click".

CAUTION: Use only moderate force to make the connection. If it is difficult to make the

connection, do not continue. Instead, start the process again. Using too much force could damage

the internal fittings of the connectors or result in an incorrect color matching of the ink tubes.

7. Test the connection by gently pulling both connectors away from each other.

8. Make sure the quick connector is placed in the holding panel.

9. Press OK to start the purge.

At this point, the printer sends ink to the carriage. This process takes approximately 5 minutes.

10. The front panel prompts you to confirm that ink has reached the air purgers. Look at the air purgers

and confirm that each color arrived to the air purger.

11. If ink did not reach one of the air purgers, use a syringe to complete the operation. For instructions,

Use a syringe to purge the tubes from the ISM to the printheads on page 49.

see

ENWW 47

Page 52

12. Wear gloves and use a cloth to remove the air purgers, as some ink may spill. When you have

finished removing the air purgers, close the carriage cover and access window. Press OK to finish.

13. At this point, check to make sure that the rear ink leakage sensor is correctly placed at the bottom

of the tray (it should be touching the tray).

14. From the front panel, enter the diagnostic menu and select Purge and Setup Menu > Force

Normal Boot .

15. The printer sets the boot configuration.

48 Chapter 7 Purge the ink system ENWW

Page 53

16. The printer displays OK when the configuration is set. Press any key to finish.

17. Switch the ACB-1 breaker switch ON and OFF again to restart the printer in normal boot mode.

NOTE: The printer performs a complete system check during start up. If a failure is detected

during start up, follow the troubleshooting instructions in the Service Manual.

18. When the printer finishes initializing, select the preferred language in the front panel.

Use a syringe to purge the tubes from the ISM to the printheads

If the ink does not arrive to any of the air purgers, you must use a syringe to complete the purging

operation. This procedure is only necessary if the ink did not arrive to one or more of the air purgers.

1. Fill the printhead pockets with paper or cloth to prevent spilled ink or dirt from dirtying the printhead

interconnect contacts.

2. Use a cloth to remove the air purger to which ink did not arrive.

3. Insert an empty syringe into the ink port where you removed the air purger. Make sure the syringe

plunger is pushed all the way into the syringe before you insert it into the ink port.

4. Enter the service menu and select Purge and Setup Menu > Purge Printer Tubes to perform the

purge again.

5. The air will pass from the tubes into the syringe until the ink reaches the syringe. The syringe

plunger will move by itself.

NOTE: If the syringe plunger does not move at all, pull it out no more than 1 mm. Otherwise,

never manually pull the syringe plunger out.

6. When the purge operation is finished, put a cloth around the needle and remove the syringe quickly.

NOTE: Wait until the purge operation is completely finished before you remove the syringe.

7. Continue from step 6 of the previous procedure.

ENWW 49

Page 54

8 Prepare the printer

Install the printhead cleaning roll and aerosol filters

Install the printhead cleaning ro ll

NOTE: You should install the printhead cleaning roll during the purging process to save time. You can

install the printhead cleaning roll when the printer is off or in diagnostic mode. Otherwise, when the

printer starts in normal boot mode, it will detect that the printhead cleaner roll is missing and you can

install it at that time.

1. In order to replace the printhead cleaning roll, open the door on the front right of the printer.

2. Grip the handle and pull the whole printhead cleaning roll assembly out through the door.

3. Slide both rolls off their axles and dispose of the roll with the used cleaning material according to

the instructions provided with the new roll. Keep the empty core to use as a takeup core.

4. Slide the new roll onto the upper axle. It clicks into place.

5. Pull the black knob on the upper left and move the pinch system aside.

50 Chapter 8 Prepare the printer ENWW

Page 55

6. Pass the leading edge of the roll over the upper rollers, and thread the cleaning material through

the rollers on the left.

7. There is a strip of polyester film on the leading edge of the cleaning material. Insert it into the hole

in the takeup core, which takes hold of it.

8. Slide the takeup core onto the lower axle. It clicks into place.

NOTE: If the cleaner roll has not been properly installed, you may see a message about clearing

a printhead cleaning roll jam. Pull the whole assembly out, wind a little of the roll forward, then slide

it back in again. The printer will check the roll again

9. Restore the pinch system by moving the black knob back into place. If you feel resistance because

the cleaning roll is too tight, turn the roll slightly counter-clockwise.

10. Grip the handle and push the whole printhead cleaning roll assembly back into the printer.

11. Close the door.

ENWW Install the printhead cleaning roll and aerosol filters 51

Page 56

Install the aerosol filters

1. Open the printhead access door in the side of the printer, and lift the carriage cover.

2. The aerosol filter containers are on the near and the far sides of the printheads.

3. Lift up the right-hand side of the filter container; it pivots on the left.

4. Pull the old filter out of the bottom of its container and dispose of it according to the instructions

provided with the new filter.

5. Unpack the new filters and ensure that the blue tabs at each end of each filter are at right angles

to the filter.

6. Insert the new filter into the container.

52 Chapter 8 Prepare the printer ENWW

Page 57

7. Ensure that the blue tabs on the filters are correctly engaged with the hooks on the containers,

otherwise the containers may not close completely.

8. Lower the container into position.

9. Lower the carriage cover and close the door. Press the OK key on the front panel.

10. When you finish the purging process and are ready to start the printer, select Check cleaner

roll from the Ink System menu

in normal printer mode.

Install the computer, monitor, LAN switch, tray, keyboard and mouse

Manpower Tools Time

1 person T20, T30 Phillips screwdriver 30 minutes

NOTE: Perform this task while you fill the intermediate ink tanks.

1. Install the keyboard platform with four T30 screws (two of which you will find already screwed into

the printer), and route the keyboard and mouse cables through the hole in the top cover.

NOTE: Use the longer of the two power cables (computer and monitor) to power the monitor.

WARNING! Do not route the keyboard, mouse or monitor cables over the front panel cable.

ENWW Install the computer, monitor, LAN switch, tray, keyboard and mouse 53

Page 58

2. Open the sliding door and check that all cables are routed above the sliding door support.

Otherwise, over the course of time the movement of the door will damage the cables.

Cables wrongly positioned: hanging over the sliding door support

Cables correctly positioned: supported above the sliding door support

3. Use a T20 screwdriver to remove the monitor holder on the printer.

4. Remove the Phillips screws that secure the monitor arm and remove it. Keep the screws.

5. Attach the holder to the monitor using the 4 Phillips screws from the monitor arm.

6. Attach the holder to the printer with the four T20 screws.

TIP: It is better to connect the power cable to the monitor before connecting it to the printer.

7. Connect the monitor, keyboard and mouse to the computer.

54 Chapter 8 Prepare the printer ENWW

Page 59

8. Plug the power cords of the computer, monitor and LAN switch into the outlets provided on the side

of the electrical cabinet facing the computer.

WARNING! The outlets are for the computer, monitor and switch only. Never plug any other

equipment into the outlets.

9. Place the HP Internal Print Server computer in the electrical compartment and secure it with the

two straps.

10. Put the switch inside the electrical compartment.

11. Route the customer LAN cable and connect it to the switch.

NOTE: The LAN cable, on the customer network side, must be connected to a hub/switch port

configured as autosense. Otherwise, there will be no communication between the HP switch

provided with the printer and the rest of the customer’s network. The HP Procurve 1400-8G switch

that is included with the printer supports one low-level communication protocol: autosense. If the

connector to which the switch is connected is set to any other protocol (such as half-duplex), no

communication can occur.

12. Connect the HP Internal Print Server computer to the switch using the cable included in the

shipment.

13. Connect the printer to the switch using the available cable.

14. Plug the power cord of the switch into the power strip.

NOTE: For Russian installations, you must also install the two 2 MB memory cards.

Create a shared folder on the HP Internal Print Server computer

A shared folder must be created on the HP Internal Print Server computer for the RIP to be able to send

jobs to the HP Internal Print Server and view the contents of the shared folder.

1. Log in to the HP Internal Print Server computer using the administrative user account that is already

set up on the computer.

HP Designjet L65500: User name hp65500, no password.

●

HP Designjet LX800/LX600: User name scitexlx, no password.

●

2. Create a folder called OutJobs.

ENWW Create a shared folder on the HP Internal Print Server computer 55

Page 60

3. Open the folder properties for the new OutJobs folder and navigate to the Sharing tab.

4. Click on Advanced Sharing to set the sharing properties.

5. Make sure that Share this folder is selected.

56 Chapter 8 Prepare the printer ENWW

Page 61

6. Set the other settings to your requirements, then click on Permissions.

7. Add any groups or users required, and set the permissions as required by the customer.

8. Navigate to Control Panel > Network and Internet > Network and Sharing Center on Windows

Vista, and make sure that File Sharing is turned on.

ENWW Create a shared folder on the HP Internal Print Server computer 57

Page 62

Configure the printer’s IP address

NOTE: If you cannot establish a connection between the printer and Internal Print Server, make sure

that no proxy is configured. See

1. To open the Internal Print Server, double-click the Internal Print Server icon on the desktop.

2. Set the printer IP address in the Internal Print Server, under Tools > Preferences.

Configure the proxy on page 75.

3. Configure HP Proactive Support and make sure the customer accepts all disclaimers, under

Tools -> Proactive support

58 Chapter 8 Prepare the printer ENWW

Page 63

9 Prepare for printing

Install the printheads

Manpower Time

1 person 5 minutes

After the initial power up of the printer in normal boot mode, the printer recognizes that the printheads

are not installed. Use the following procedure to install the printheads and also follow the instructions

on the front panel.

1.

At the front panel, select the Ink System icon

2. When requested by the front panel, open the printhead access door in the side of the printer.

3. Lift the carriage cover.

and then Replace printheads.

ENWW Install the printheads 59

Page 64

4. Check that the new printhead is of the correct colors.

NOTE: Each printhead has a unique shape and cannot be inserted into the wrong slot.

5. Remove its packaging and protective cap.

TIP: Keep the protective cap and do not lose it. It may be necessary to store the printheads in

the original protective caps for future servicing.

6. Shake the printhead according to the instructions on the packaging.

7. Put the new printhead into its correct place in the printer, and lower its handle.

CAUTION: Insert the printhead slowly and vertically, straight down. It may be damaged if you

insert it too fast, or at an angle, or if you rotate it as you insert it.

8. When you have inserted all the printheads, close the printhead latches.

9. Close the carriage cover.

10. Close the printhead access door.

60 Chapter 9 Prepare for printing ENWW

Page 65

If a printhead fails to work correctly, try the following recommendations.

1. Use the procedures in the Service Manual, described under “Large ink area missing or substantial

horizontal banding”.

2. Request a hard clean of the printhead, and illuminate the space between the printheads and the

printhead cleaning roll while the printhead is being cleaned.

Check that the primer is working correctly (first step of the hard cleaning): big dots should form

●

under the printhead.

Check that static spitting is functioning correctly (second step, seen as 'heavy rain').

●

3. Inspect the ink deposited on the printhead cleaning roll during printhead cleaning. You should see

a large area saturated with ink, followed by a pattern of smaller areas of ink. If the large saturated

area is missing, the primer is not working.

If the primer is not working:

1. Go to the front panel and start the process to replace the printhead in question.

2. After lifting the printhead cover, you will see two 'O' rings that seal the joints between the printhead

cover and the printhead. Apply a little oil, grease or water to the 'O' rings to improve their

performance.

3. Check the primer's electrical connections.

4. Close the printhead cover, the carriage cover and the printhead access door.

5. Request a hard clean of the printhead.

ENWW Install the printheads 61

Page 66

Callme@HP Setup Process

During installation process, specific information must be introduced into the IPS preferences to correctly

route the Remote Support Calls to the Support Agent (HP or Authorized Service Provider approved to

provide this Remote Support Service).

1. Go to the IPS menu “Tools”, then press “Preferences” and look for the tab “Callme@HP”.

2. Enter in information into all 6 fields

The first four fields are related to customer data. They can be generic and are intended to be

automatically loaded as default data into the Remote Support Application.

a. Printer Serial Number: Check that the serial number is correctly entered into the text field.

b. Agent e-mail: This parameter is VERY important as it establishes the call routing to the

appropriate support organization. If the configuration of this field is not correct any support

calls made will not reach the intended recipient.

If the Reseller partner is going to provide the support for the unit AND has been approved

●

for using this tool and has the account setup and permissions setup, enter in this field

the E-mail of the reseller engineer supporting this printer, using the reseller's domain

used for creating the account.

If the reseller is not entitled to use the “Callme@hp” remote troubleshooting tool, then

●

leave the default value: printcare@hp.com

3. Launch the “callme@HP” application under the “tools” menu option and verify the information

entered loads correctly into the template.

Important: The application will ask for software to be installed, select yes to all the requirements.

62 Chapter 9 Prepare for printing ENWW

Page 67

If no window is displayed, go to the Site Preparation document under the section where the network

requirements are described, and check that all the requirements for network connectivity have been

met.

4. Submit a Testing Call including the following text in the comment box: “Customer Name Installation

Call. Remote Support Configuration Check”.

Antivirus Registration

Antivirus software is pre-installed with the PC equipment. Antivirus license will be valid for 5 years.

License renewal will be the Customer's responsibility and it's a requirement for the use of the

Callme@HP tool.

Note that the installation and registration process may vary after this document has been generated.

Always keep updated with the installation notes.

Web Cam Installation

Unpack the web cam from the package and connect it to the PC of the printer. Wait until the operating

system displays “HW ready to use”.

Go to Windows Start>Print Care Webcam> and check the webcam function.

In case of any install issues,re install the drivers from the CD included with the Web cam.

Load a substrate

For information regarding loading and handling substrates, see the User's Guide.

Connect the air supply

1. Locate the airgun and adaptor that was included with the printer shipment.

ENWW Antivirus Registration 63

Page 68

2. The customer should have the correct air supply with the correct connection. Use the adaptor to

connect the airgun to the customer air supply.

Configure the RIP

A Raster Image Processor (RIP) should be run on a separate computer, In this section we describe how

to configure the RIP correctly for use with the printer.

L65500 only: RIP software is not provided with the printer, and cannot be installed on the same

●

computer as the HP Internal Print Server.

LX800/LX600 only: The RIP software is sold with the printer:

●

HP Scitex Onyx RIP Software CQ756A

◦

HP Scitex Caldera RIP Software CQ755A

◦

The customer's RIP for use with the HP Designjet L65500 Printer

The customer's RIP must be configured correctly to work with the HP Designjet L65500 Printer. Because

HP cannot support the customer's RIP, any troubleshooting must be done using the documentation and

service that accompany the RIP. However, generally three tasks must be done:

1. Configure the IP address or network name of the HP Designjet L65500 Printer.

2. Configure the RIP to recognize the shared output folder with the HP Internal Print Server.

3. Make any additional configurations required by the RIP.

64 Chapter 9 Prepare for printing ENWW

Page 69

HP Scitex Onyx RIP

The HP Scitex Onyx RIP is sold with the HP Scitex LX800/LX600 Printer. After the RIP software has

been installed and the printer has been added to the RIP, use the following procedure to configure the

RIP.

1. Following the installation process of the RIP, the screen 'Configure Printer Port' should

automatically be displayed. If not launch the RIP-Queue and select 'Configure the Printer'. The

following screen is displayed, select 'Print to HP Internal Printer Server' and click on the

'Configure' button.

2. The following screen is displayed. Enter or browse to the Internal Print Server shared folder.

3. Enter the IP address of the printer to enable the dynamic media list retrieval. Click Test to check

that it responds.

4. Click OK to confirm the printer configuration.

ENWW Configure the RIP 65

Page 70

HP Scitex Caldera RIP

The HP Scitex Caldera RIP is sold with the HP Scitex LX800/LX600 Printer. After the RIP software has

been installed and the printer has been added to the RIP, use the following procedure to configure the

RIP.

1. Go to the 'Special menu' in the RIP and click on 'Server Admin'.

2. Click on 'Configure' and select the 'Connection' tab, the following screen is displayed. Enter the

IP address of the printer (not the IP address of the IPS).

Install the covers

Manpower Tools Time

1 person T30 screwdriver 5 minutes

66 Chapter 9 Prepare for printing ENWW

Page 71

NOTE: The covers are wrapped in plastic, and the screws are inside the packaging. It is recommended

to install the covers last, in case of any issue that may require you to remove the covers. It is

recommended to wear gloves when removing the covers.

1. On the left side, replace the six T30 screws that secure each cover. The position of the screws is

the same on the rear cover as it is on the front cover.

2. On the right side, replace the four T30 screws that secure the rear cover.

3. On the right side, replace the four T30 screws that secure the sliding door, starting at the top.

ENWW Install the covers 67

Page 72

Print the HP test images

Test images are available with which you can check the print quality achieved once the printer has been

fully installed. From HP's Web site (

software & drivers, type the name of the printer, select Drivers, and download the pre-ripped images.

NOTE: L65500 only: The test prints are also available in the Internal Print Server computer if your

printer has a serial number beginning with SG95 or greater.

The following three images are available, each designed to test the print quality in a different way.

Filename: Petra Filename: Notatravel Filename: Fish

http://www.hp.com/), select Support & drivers, check Download

The main purpose of these pre-ripped files is to be able to check the print quality achieved by using files

that do not need to be ripped, and have been set up for the substrate supplied with the printer. This will

avoid any print-quality issues due to the RIP application or to a mismatch of substrate/RIP selections.

If any issues are found, the error can come only from the printer’s installation and setup. It is important

when selecting the print that the correct file is selected for the type of substrate loaded. There is a choice

of two, and the correct selection will depend on which type of substrate is loaded in the printer:

L65500 Printers only with serial numbers lower than SG96M1F002 are delivered with HP

●

Photorealistic substrate. The pre-ripped images are located in C:\Users\L65500\Documents\HP

IPS\Test Plot\ripped Photorealistic.

L65500 Printers only with serial numbers SG96M1F002 and greater are delivered with HP

●

Permanent Gloss Adhesive Vinyl. The pre-ripped images are located in C:\Users\L65500

\Documents\HP IPS\Test Plot\ripped SAV Gloss.

LX800 and LX600 Printers are delivered without substrate rolls. The pre-ripped images are

●

located in the following locations:

C:\Users\scitexlx\Documents\HP IPS\Test Plot\Ripped Photorealistic

◦

C:\Users\scitexlx\Documents\HP IPS\Test Plot\Ripped SAV Gloss

◦

Make sure before printing the files that the printer is ready to print at its best.

1. Load the roll of substrate provided with the printer.

2. Align the printheads (see the Maintenance and Troubleshooting Guide).

3. Check the printhead alignment.

68 Chapter 9 Prepare for printing ENWW

Page 73

4. Fine-tune the substrate advance with the print mode or modes that you intend to use. We