Page 1

1 Printer systems

• Electrical system.....................................................................................................4

• Ecabinet.........................................................................................................5

• E-Box ........................................................................................................... 19

• ECabinet Circuit Diagrams ..................................................................... 10

• PCA Boards and connections..........................................................................20

• Formatter PCA...................................................................................... 20

• Hard disc drive..................................................................................... 20

• Upper and Lower Engine PCI Board ........................................................ 20

• Printmech Board ................................................................................... 21

• Main Interconnect Board connections ...................................................... 22

• Substrate path ..................................................................................................... 28

• Ink System........................................................................................................... 39

• Scan Axis ........................................................................................................... 45

• Carriage............................................................................................................. 57

• Printhead Cleaning System.................................................................................... 61

• Heating and Curing .............................................................................................66

• User Interface ...................................................................................................... 74

Printer Systems

Printer systems 3

Page 2

Electrical system

The electrical system is primarily housed in the electrical cabinet, inside this is the electronics box.

Electronics overview diagram

The following diagram explains the connections between components and electronic boards, the voltage,

Printer systems

or the type of data line.

4 Printer systems

Page 3

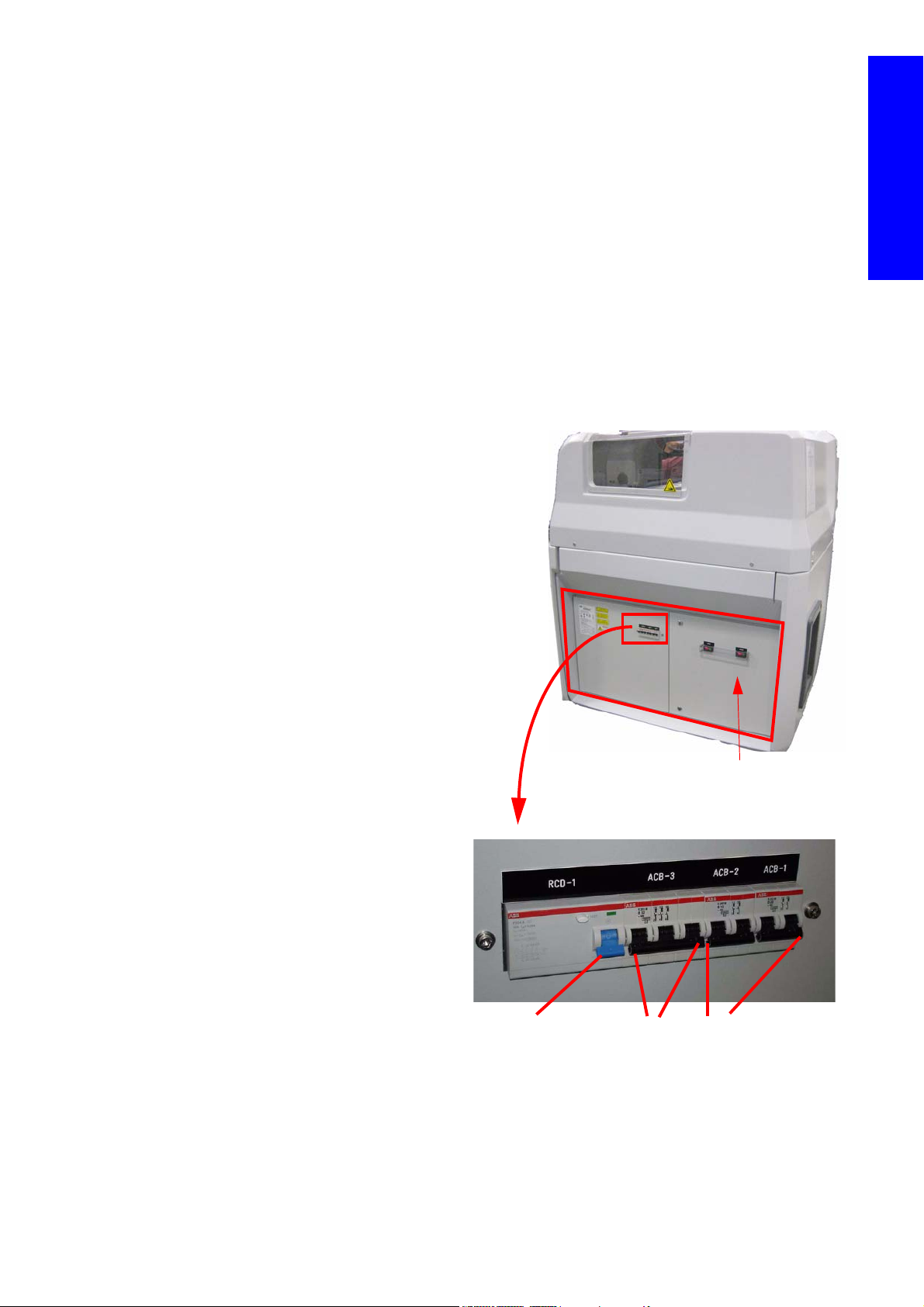

Ecabinet

The ECabinet

ACB-3

ACB-2

ACB-1

3 phase

Circuit

breaker

Single phase

Circuit breaker

RCD-1

Residual

Current

Circuit

Breaker

(RCCB)

The ECabinet located on the right side of the printer and is the enclosure where the main electronics

(Electronic Control System, E-box) and all the power electrical components of the printer are located. The

system if fed via two power lines, one single phase line and another tri-phase line see the Installation Guide

and Site Preparation guide for specifications.

The E-Cabinet responsible for distributing all the power lines to the functional areas, it includes the active

power elements of the heating and curing subsystem. It also performs safety cut-outs when any of the four

emergency stops are pushed

Some of the components inside the e-cabinet are independent units isolated from the electronics therefore

diagnosing any issues via Firmware is not possible.

To diagnose most electrical issues, voltage and continuity checks are required from the Service Engineer

by using multi-meter tools (Voltmeter, Amp meter, resistor meter, continuity checks)

Components

The Ecabinet contains the following

components:

• The Ebox

• Secondary 24v Power supply

• Secondary 42v Power supply

• Circuit breakers & Residual Current Circuit

• Contactor (Heating and Curing)

• Fuses (Heating and Curing)

• E-Box system (which includes a main

• Safety relay

• Fan

• Scan Axis break resistor

• Vacuum system transformer (110v)

• Main switch

• Power Enable button

• Light indication for Phases

• 3 Phase Line filter

• 1 Phase Line filter

Printer systems

breaker (RCCB)

power supply delivering ATX tensions and

also 24V and 42V)

Printer systems 5

Page 4

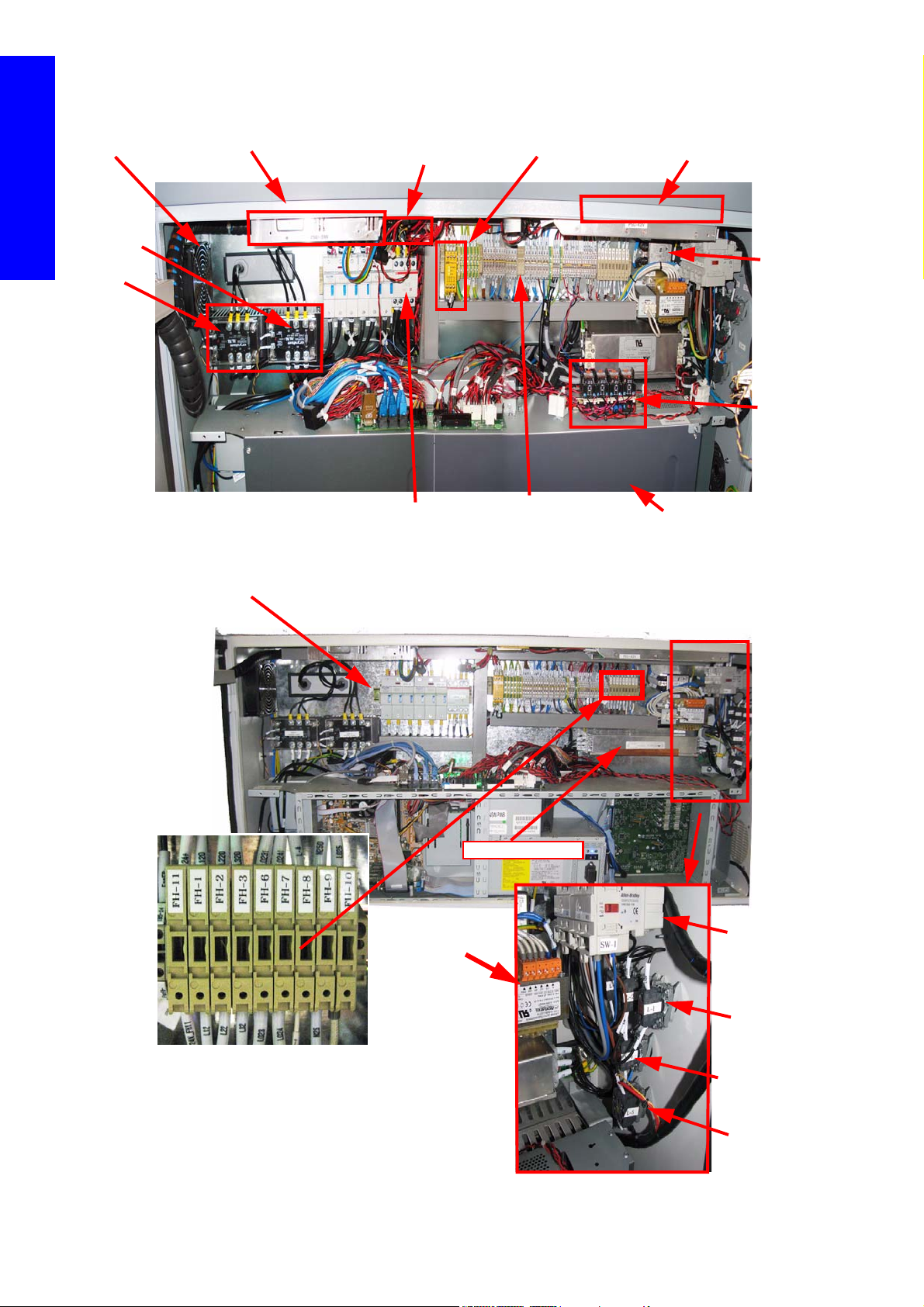

Inside the ECabinet (1 of 2)

Ebox

Secondary 24v supply

Secondary 42v supply

Heating

and

Curing

Power

Modules

(power

lines are

thicker in

the LX800)

Safety Relay

Contactor

RM 3 Phase

Terminal

Blocks

ECabinet

fan

1 Phase

Line filter

Line filter 42v

line +resistors

Roll to Free

Floor

control

system

LX800

Power fuses heating/

Curing

Fuse block (1A, 2A, 4A

3 Phase line filter

Power enable

button

Vacuum power

On

Vacuum

transformer 110v

Main switch

Light indicator

for phases

Printer systems

Inside the ECabinet (2 of 2)

6 Printer systems

Page 5

Ecabinet Fuse blocks

Fuse Application

• Fuses: 1,2,3 (1A) Indicator Lamps

• Fuses 6, 7 (1A): PID controllers

• Fuse 8 (2A): Phase 110 from Trafo to Pump

• Fuse 9 (2A): Neutral 0V from Trafo to Pump

• Fuse 10 (4A): protects 110V transformer

• Fuse 11 (2A): 24V from Main interconnect to e-cabinet

Functionality

1. The E-Cabinet is the power distribution centre for the whole printer

It is the central point where both input power lines (Single and tri-phase) are connected and then distributed

to the different power components.

Single Phase components powered through ACB1

• Heating Controller Module

• Curing Controller Module

• Secondary 42V power supply (SAX motor, Media Path Motors)

• Secondary 24V power supply (Curing Fans)

• Vacuum Fan

• E-Box

Printer systems

Single Phase components powered through ACB2

• Printer PC (Windows, IPS)

• Printer Monitor

• Printer Switch

Tri-Phase components powered through ACB3 and RCCB

• Heating and Curing Power modules – Heating and curing lamps

- Contains the Ebox

- Emergency stop mechanism for the machine.

- Heating and curing control and power distribution.

Printer systems 7

Page 6

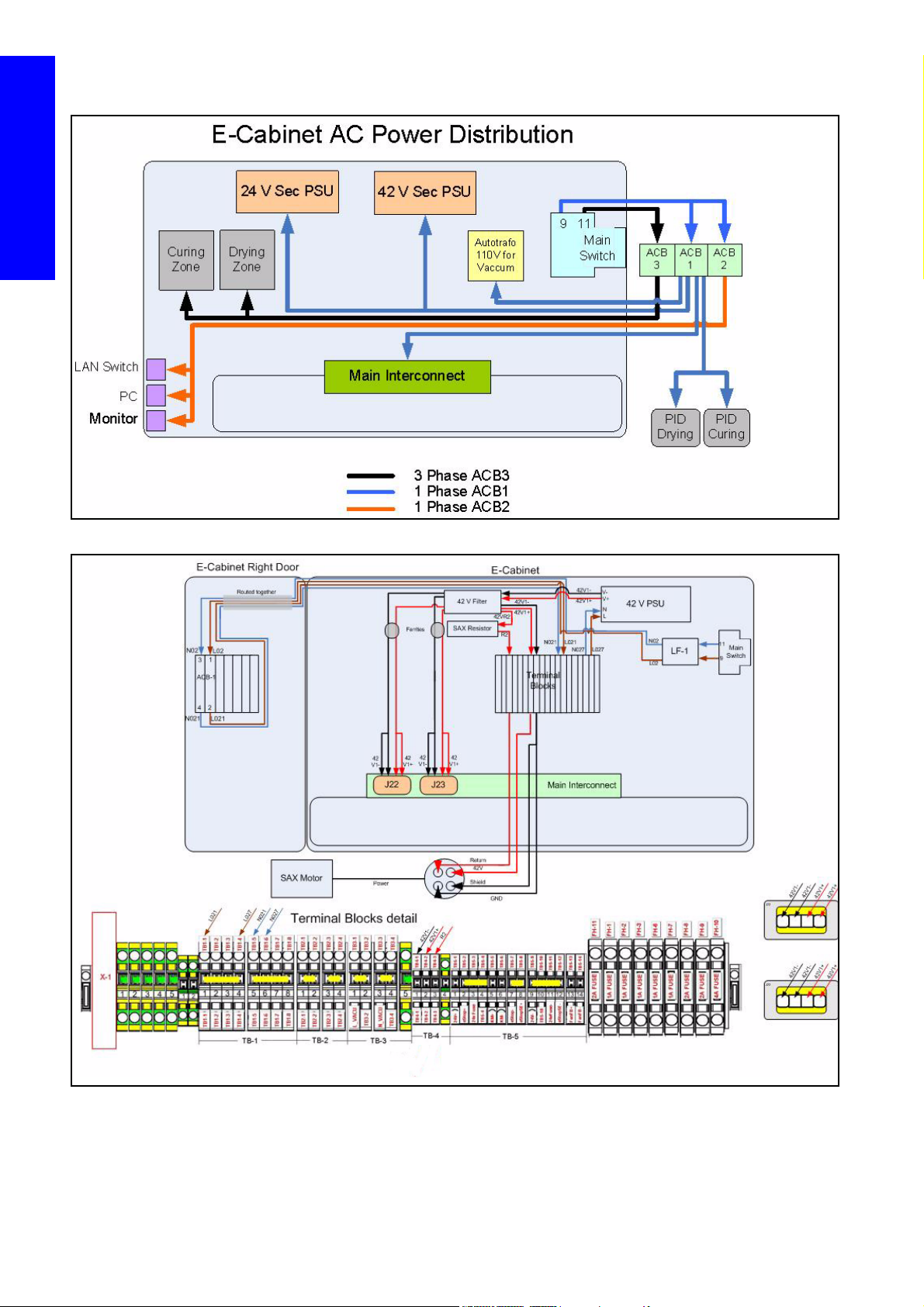

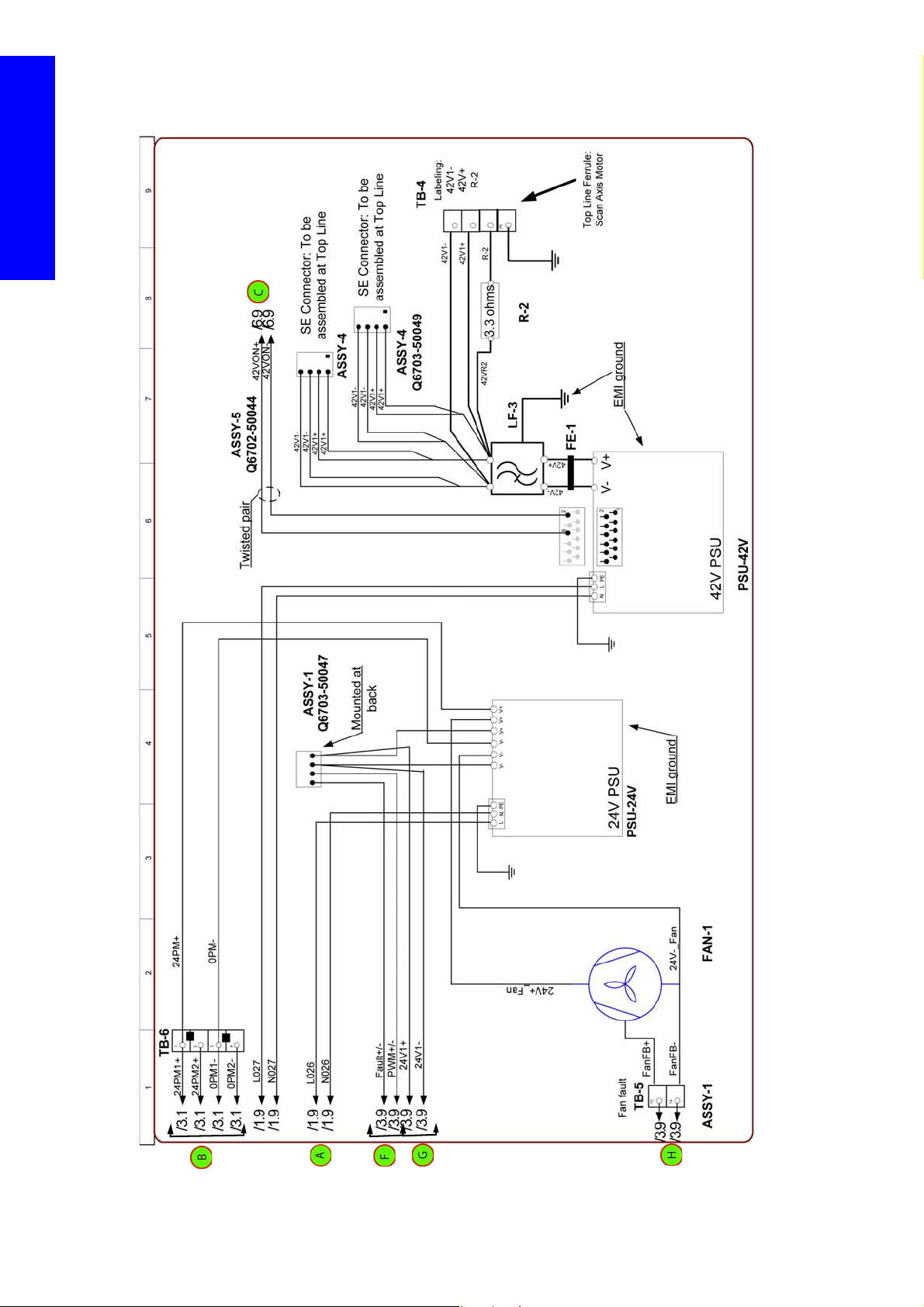

ECabinet electrical overview

Printer systems

42v Secondary Power Supply, Power distribution diagram

8 Printer systems

Page 7

Functionality interlinked between diagrams

Power

Fuses

Heating

Line

Filter

Main

Switch

Circuit

Breaker

Contactor

KM SW-1

Power

Module

Heating

Heating

Configuration Block

(star/triangle)

Lamps

Heating

Power

Fuses

Curing

Power

Module

Curing

Curing

Configuration Block

(star/triangle)

Lamps

Curing

A. 3 phase power supplied to the Heating and curing Modules through the power fuse blocks (FH4,

FH5):

B. Single phase power distribution.

C. 42v secondary power supply actuation (by safety relay)

D. Power modules control signals from PID controllers.

E. Safety line connections (cuts connector of the 3 phase line).

F. PWM signal and fault from curing fan array to Main Interconnect (24v power is directly supplied

from 24 volt secondary PSU).

G. 24v fault signal to the Main Interconnect (this line is used to detect if the 24v secondary power

supply is providing 24v or not).

H. E-cabinet internal fan fault signal to Main Interconnect (fault reported when fans do not rotate when

powered).

Printer systems

I. 24v fused line arrival to the e-cabinet from the Main Interconnect.

J. E-stop 24v power line (these 24v activate the safety relay).

K. Feedback to the Main Interconnect safety relay is active (with negative logic). This indicates the

printer is armed from the circuit breakers.

L. KM Contact active (closed). Feedback to the Main Interconnect.

In the following pages are the printers circuit diagrams. Refer to the circled numbers and letters to jump

from one circuit diagram to another.

Printer systems 9

Page 8

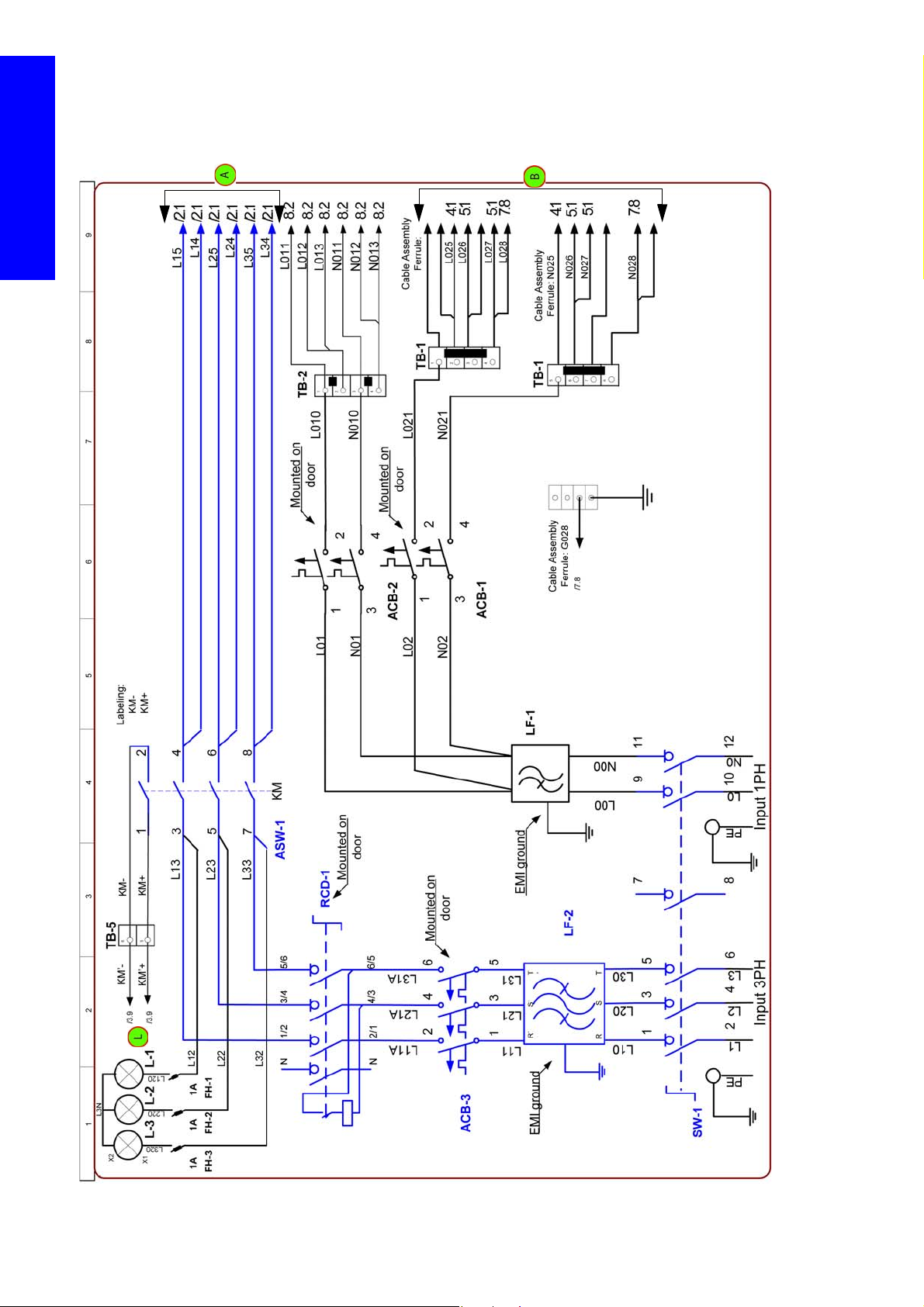

ECabinet Circuit Diagrams

Circuit Diagram 1: Power in distributing

Printer systems

10 Printer systems

Page 9

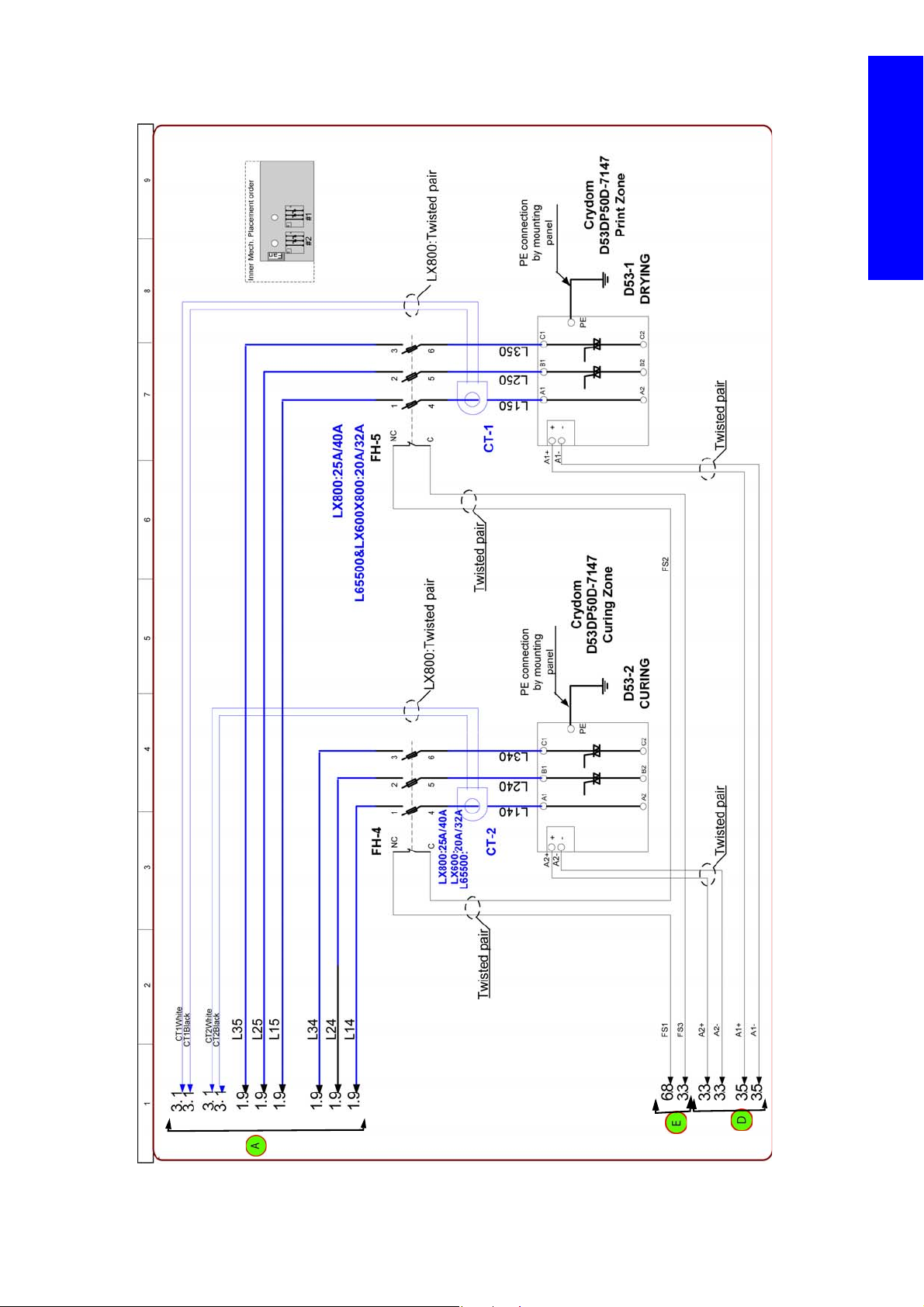

Circuit Diagram 2: Power modules, power control lines

Printer systems

Printer systems 11

Page 10

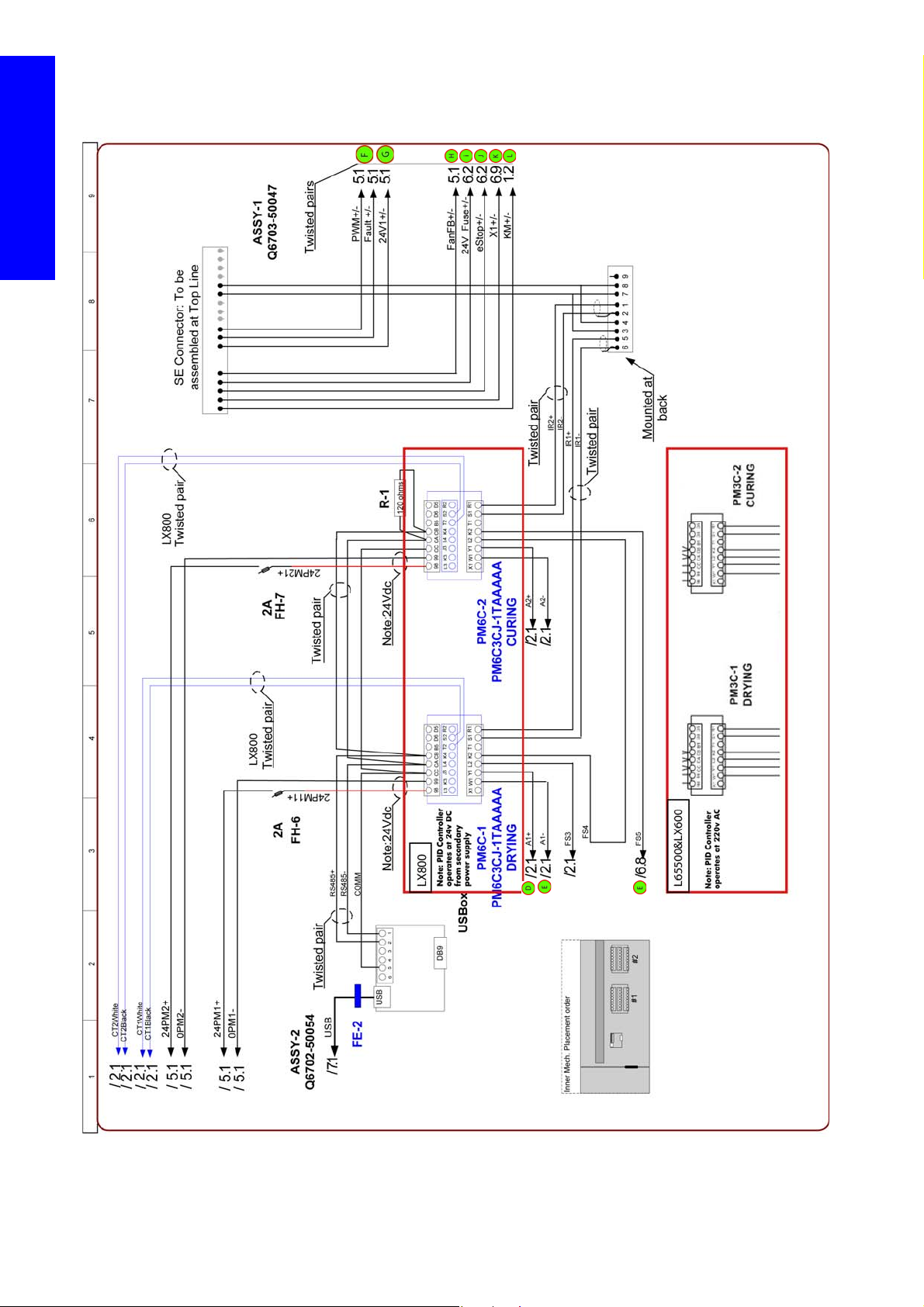

Circuit Diagram 3: Temperature Controllers

Printer systems

12 Printer systems

Page 11

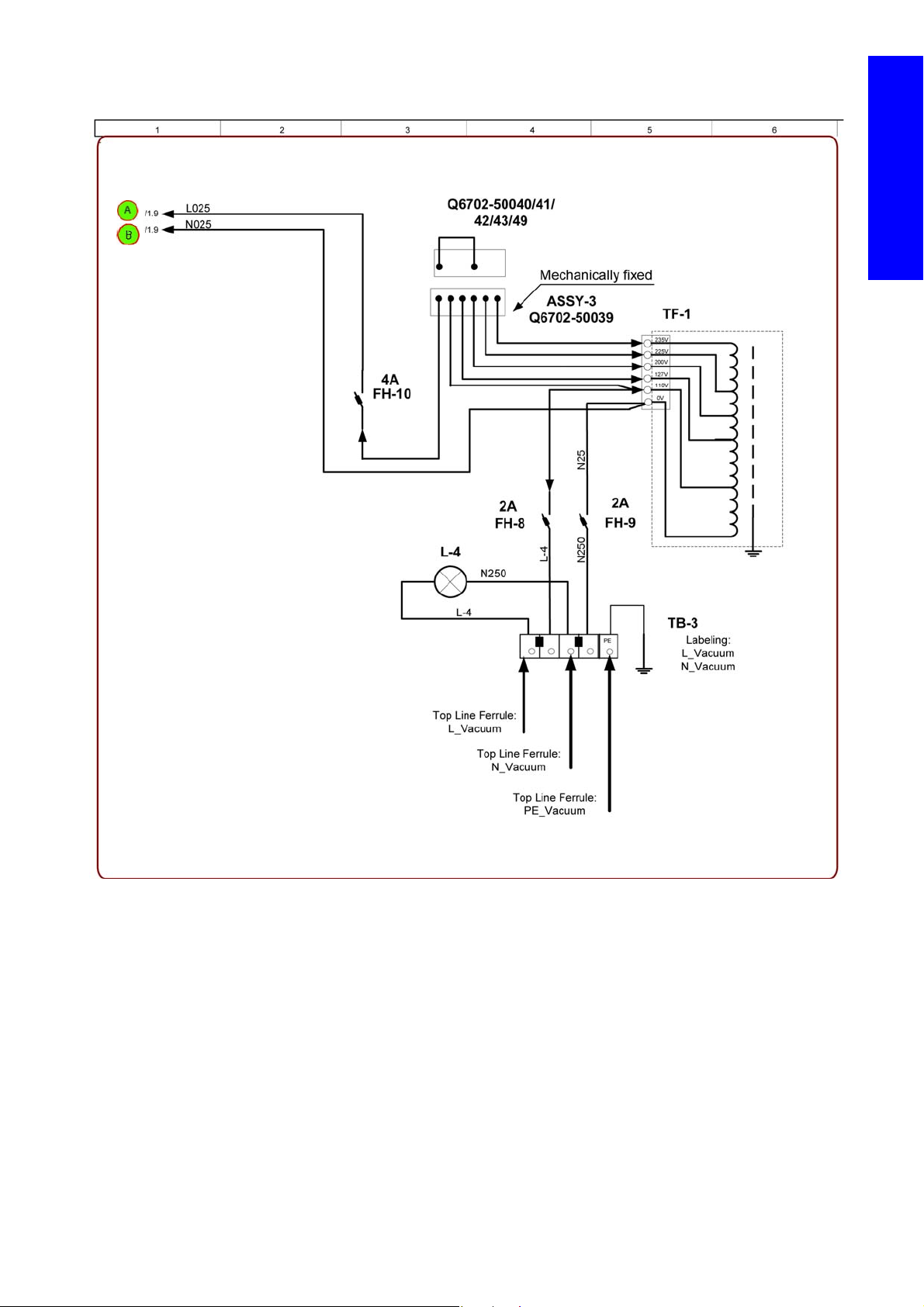

Circuit Diagram 4: Vacuum Transformer

Printer systems

Printer systems 13

Page 12

Circuit Diagram 5: Secondary Power Supplies and Internal Ecabinet Fan

Printer systems

14 Printer systems

Page 13

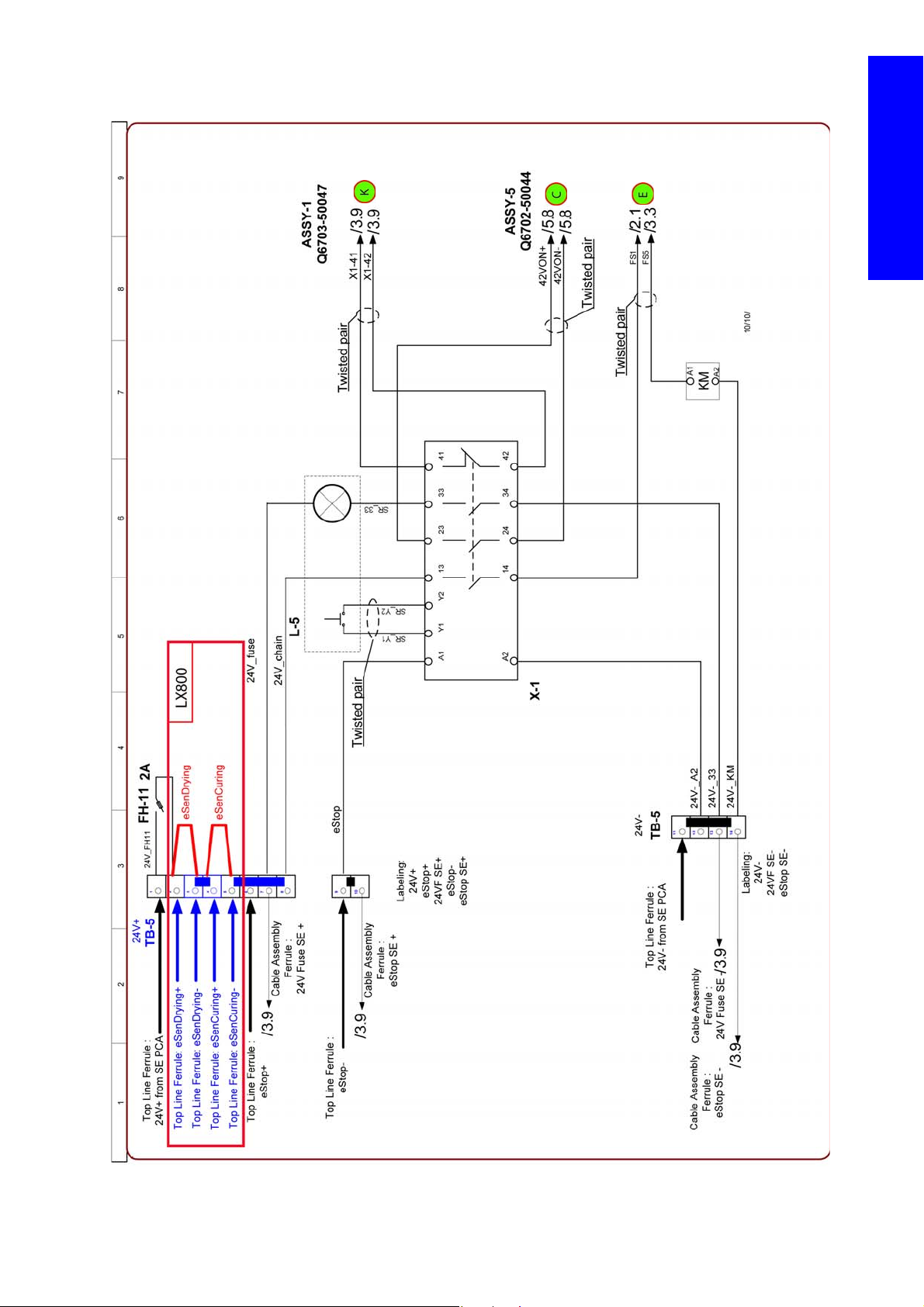

Circuit Diagram 6: Safety Control system

Printer systems

Printer systems 15

Page 14

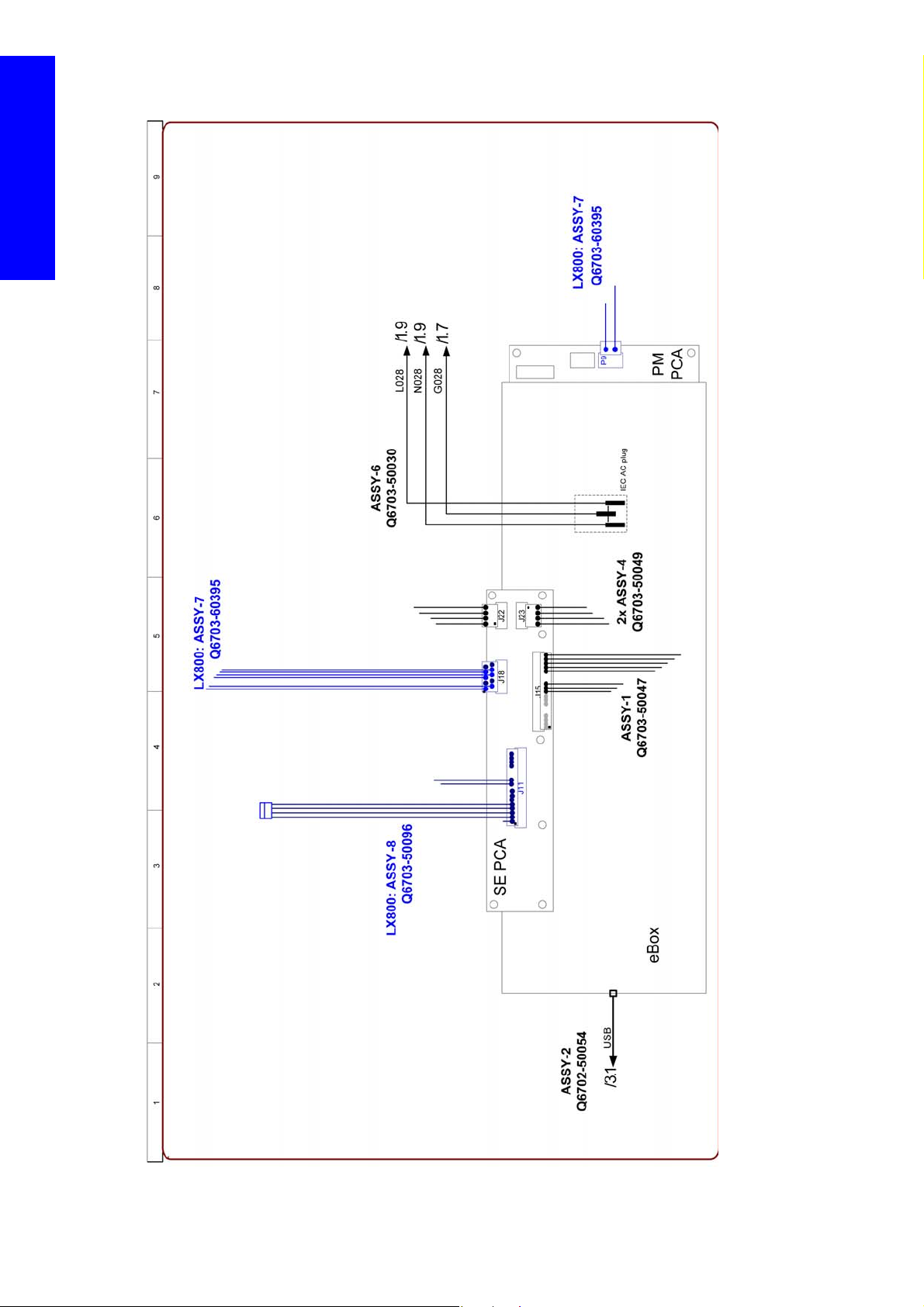

Circuit Diagram 7: Ebox Connections

Printer systems

16 Printer systems

Page 15

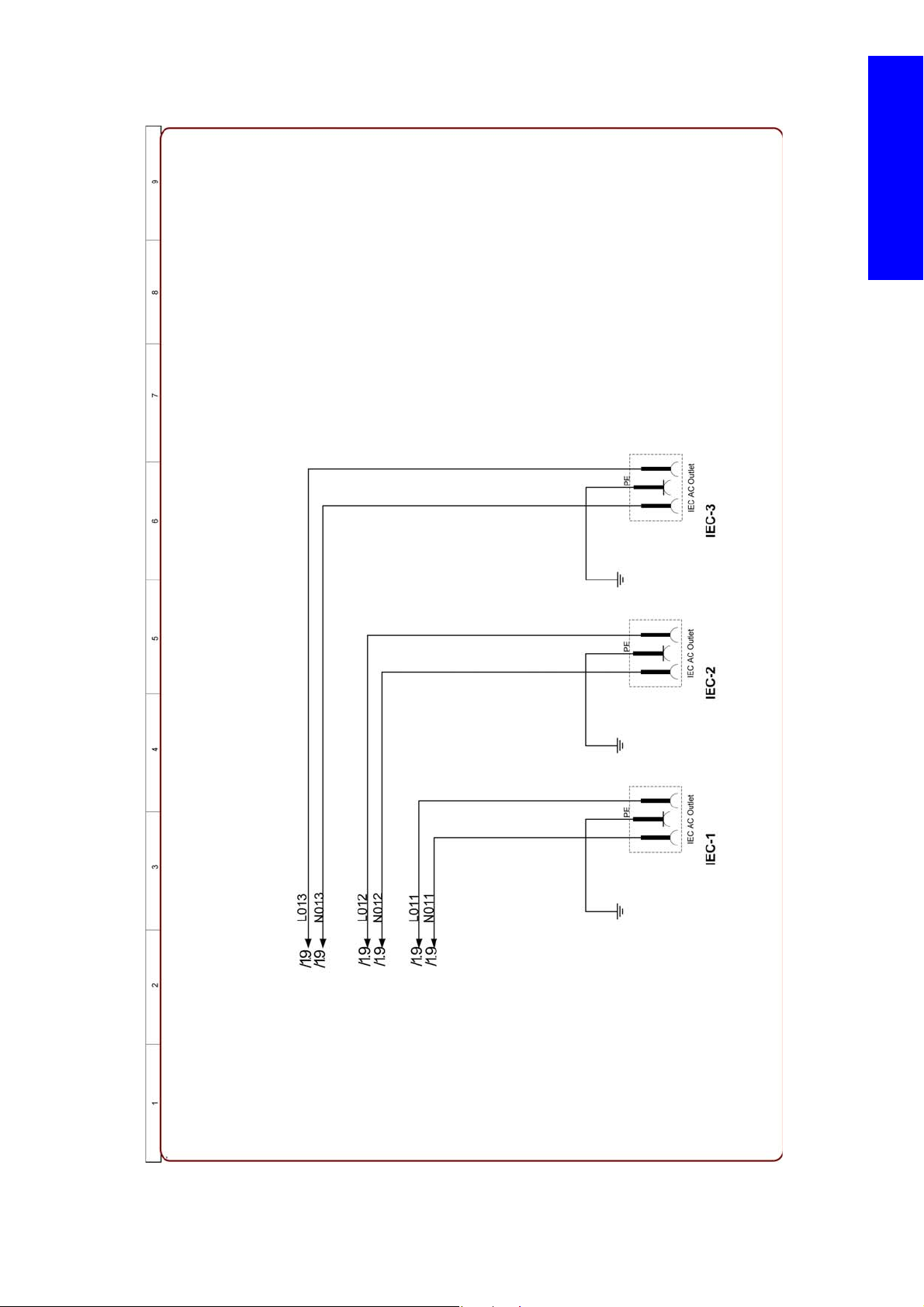

Circuit Diagram 8: PC Monitor Switch power connections

Printer systems

Printer systems 17

Page 16

Related tests, utilities, and calibrations

• Electrical cabinet diagnostic test Page 306.

Service parts

Printer systems

• Electrical Cabinet Page 451.

- Circuit Breaker

- Internal Fan

- Secondary Power Supplies

- Power Fuse Holder Block

- Safety Relay

- Scan Axis Brake Motor

- Vacuum Fan Power Transformer

- Main Power Switch

- Heating and Curing Temperature Sensor

- Power Fuses

- 3 Phase line filter

- Main Power Breaker

- Heating and Curing Power Module

-

Removal and installation

• Electrical Cabinet Page 522.

18 Printer systems

Page 17

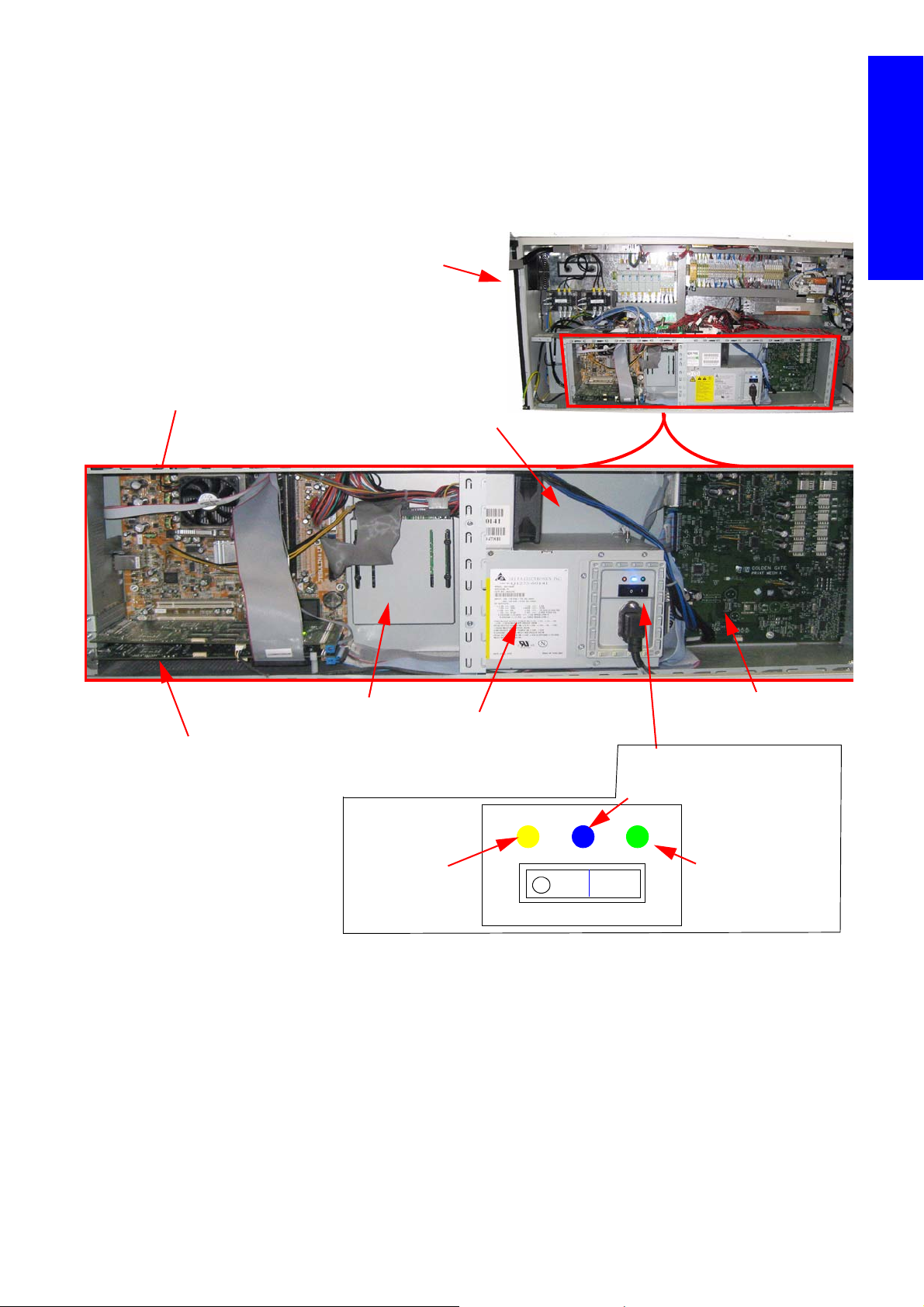

E-Box

Formatter PCA

Upper and Lower PCI PCA

Main Power Supply

ATX +24/42 PSU)

ECabinet

PrintMech PCA

ATX

On/Off switch

Hard Disk

1

Yellow led: Power

on>Stand by ON

Blue led: ATX On > Formatter

powered

Main Power Supply

Green led: 24/42

Printer On

The Ebox contains the main electrical control system in the printer. The e-box is the main processing and

control element of the machine where all main electronic units are comprised.

Components

The Ebox is inside the Ecabinet and contains the following components:

Printer systems

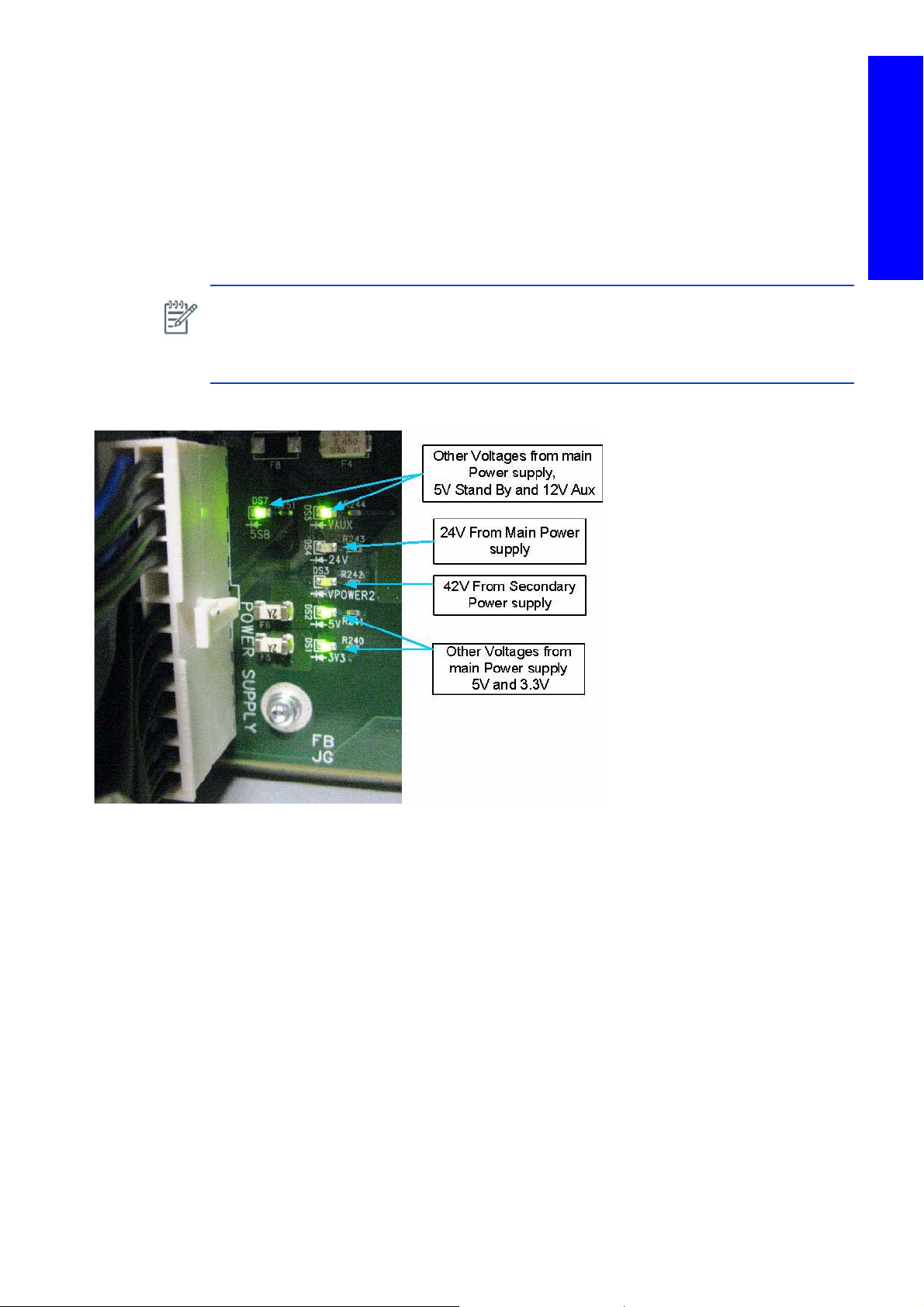

• Orange ON: System is powered (ACB 1 ON), System with Stand by power in the formatter waiting

• Blue ON: Formatter Power system (ATX) Active.Internal computer system running

• Green ON: 24/42V of the second part of the main power supply activated. These 24 Volts are the

for the Front Panel power ON button to be pressed to start up the system.

Check this led when the printer is not powering on by pressing the front panel button to ensure the

failure is not in the main power supply. If the led is Off AC power is not arriving to the main power

supply or Main power supply switch in the main power supply is off or the Main power supply is

faulty.

main source for the complete system to work. Without these 24 Volts the e-cabinet electrical system

will not work and the system will be impossible to be armed.

Printer systems 19

Page 18

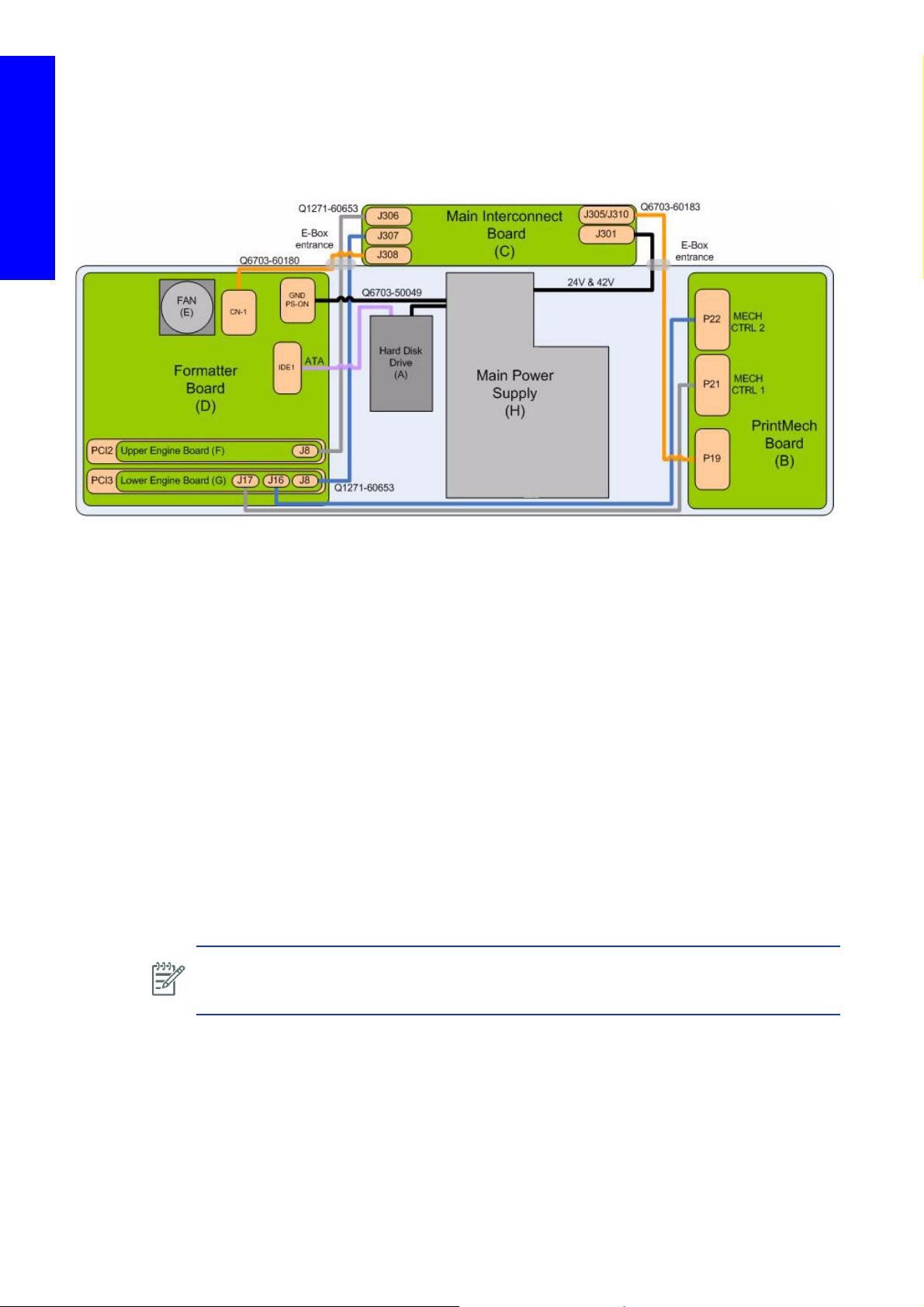

Functionality

The E-box contains the primary electrical systems of the printer in one area.

Circuit Diagram: PCAs in the Ebox

Printer systems

PCA Boards and connections

Components

Formatter PCA

The formatter is the motherboard of the printer, with an Intel microprocessor of 256 MB RAM memory

runs the operating system of the printer.

Hard disc drive

The HDD contains the main Firmware of the printer.

• The operating system is based on Montevista, an HP developed system.

• All calibration values, product number, serial number etc, are stored on the Hard Disc Drive. In

order to make sure that this information is not lost in the case of a failure of the HDD, a backup

is made:

- In the Main Interconnect Board for all the other information (other calibrations, total ink con-

sumption etc).

- In the ISM board for information related with the ISM area (calibrations of the ink sensors,

level of ink in the intermediate tanks, etc).

NOTE: In order to prevent the loss of calibration values, never replace the Hard disc system

and the ISS Main Board or the Hard disc system and the Main Interconnect Board at

the same time.

Upper and Lower Engine PCI Board

These two boards are the main controllers of the printer. They are responsible for all real-time

processing and are the ultimate controllers of all electromechanical systems.

The Lower Engine PCI Board controls all substrate path components (Drive Roller, Spindle Motors,

OMAS, etc.), and the link to the following controllers: Controllers of the PH cleaning roller (situated

on the main interconnect board). The one connected to the remote controller board controlling the

capping station movement motor. Both controllers are connected through the same bus (MICC).

20 Printer systems

Page 19

The Upper Engine PCI Board controls all non-substrate path components (carriage, scan axis motor,

scan beam height/PPS, PH cleaning assembly, service station, etc).

Printmech Board

The Printmech Board is mainly used to drive the four substrate advance motors.

• 2 Front Spindle motors (connected in series)

• 1 Rear Spindle motor.

• 1 Media advance motor (the drive roller motor)

NOTE: The motors are driven by 42V obtained from the secondary power supply which is

located inside the electrical cabinet.

NOTE: To check that the 42V power supply arrives from the secondary power supply, see the

V Power 2 LED located on the Printmech Board.

Printmech leds

Printer systems

Printer systems 21

Page 20

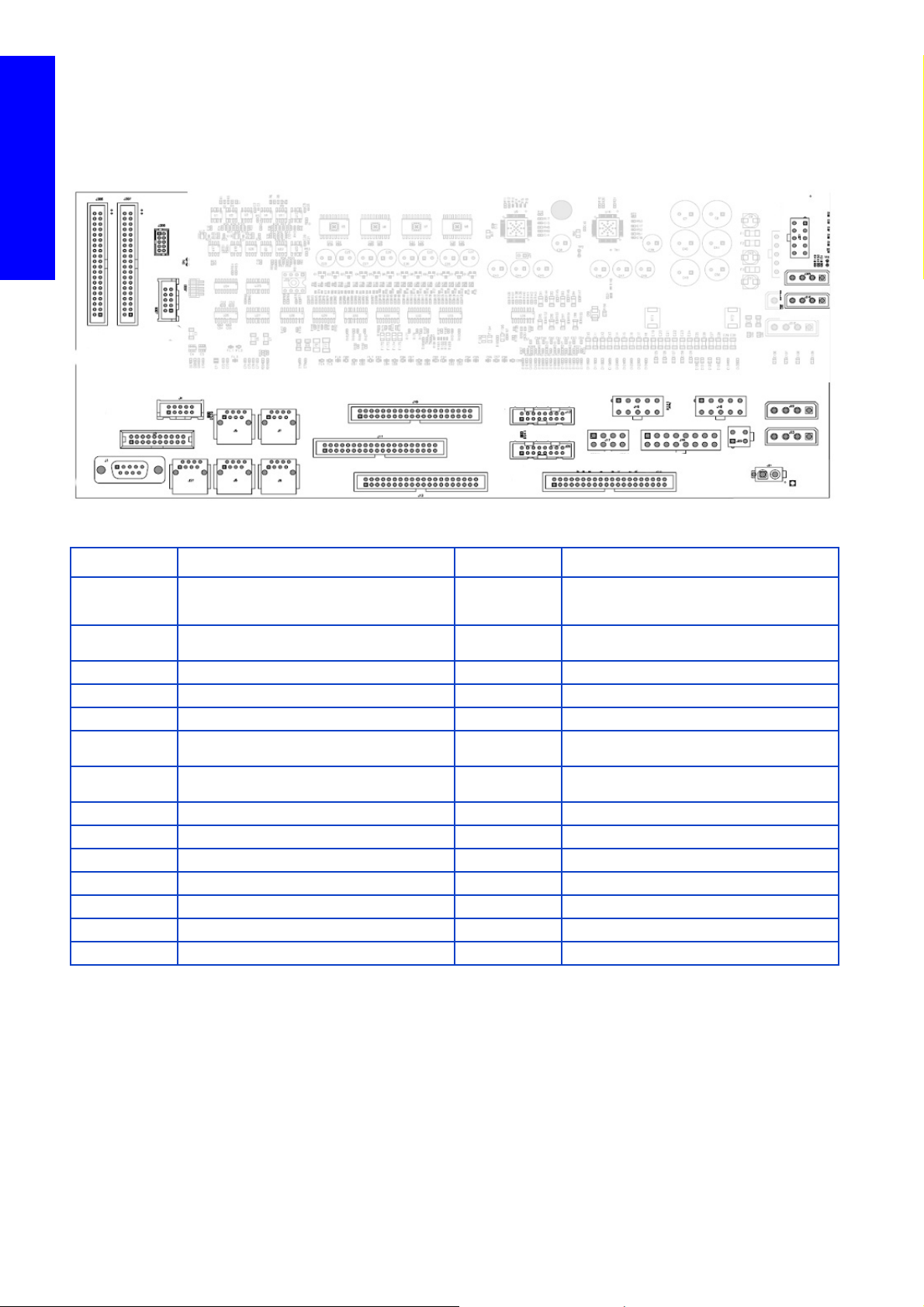

Main Interconnect Board connections

J306

J307

J3

J308

J4

J1

J27

J6

J8

J7

J5

J10

J12

J13

J26

J19

J22

J23

J15

J16

J17

J11

J310

J305

J301

J21

J20

J300

J18

Printer systems

Most of the signals to or from the electronics box pass through the interconnect board. All of the

cables connected to the Main Interconnect Board have labels indicating to which connection it

should be connected.

J Plug Description J Plug Description

J1 Scan Axis Motor data J16

J3 Drop Detector J17

J4 Front Panel J18 Roll to Free Floor Control/power

J5 Remote Control Board (Service Station) J19 Power 24v (E-Cabinet, PPS, ISS)

J6 Remote Control Board (PPS) J22, J23 From secondary power supply 42v

J10 Media Input (Rear Spindle System) J300

J7 ISM 1 (Ink system Module: data 1) J301

J8 ISM 2 (Ink system Module: data 2) J306 To upper engine PCI Board

J12 PH Cleaning System data (Encoders) J307 To lower engine PCI Board

J13 Front Right PPS (data) Encoder+switch J308 Front Panel Intermediate cable

J26 Rear Right PPS (data) Encoder+switch J305/J310 To Printmech 42v

J15 Ecabinet Faulty Signals J20 Power supply to Carriage 24v

J11 Media Output (Front spindle system Encoder) J21 Power supply to Carriage 42v

J27 OMAS/Vacuum control data

Power& Control for PPS rear right motor PH

Cleaning Roller motors & Capping Station 24v

power to remote controller

Power & Motor control for PPS front right motor &

vacuum controller (24v & 5v)

Encoder readers from the Printhead cleaning

Rollers to the Upper Engine PCI board

42v from secondary 42 v power supply to

PrintMech

22 Printer systems

Page 21

Main Interconnect Board LEDs

2

1

3

4

5

6

8

7

9

10

11

12

Number Description Number Description

1 24 LEDs (DS6 to DS29) 7 From PPS encoder (rear, right)(DS36)

2

3Not used 9

4 Power temperature sensor 10 24v to Scan Axis motor (DS40)

5 5v for the PPS encoder (rear, right)(DS41) 11 Scan Axis motor comms signal (DS32-33)

6 5v for the PPS encoder (front, right)(DS37) 12 From Scan Axis Motor (DS34)

ATX from Main Power Supply+12v, +5 (including

5v stand-by)

8 From PPS encoder (front, right) (DS35)

12v from main power supply going to Front

Panel (DS39)

Printer systems

Photo detail of Main Interconnect

Printer systems 23

Page 22

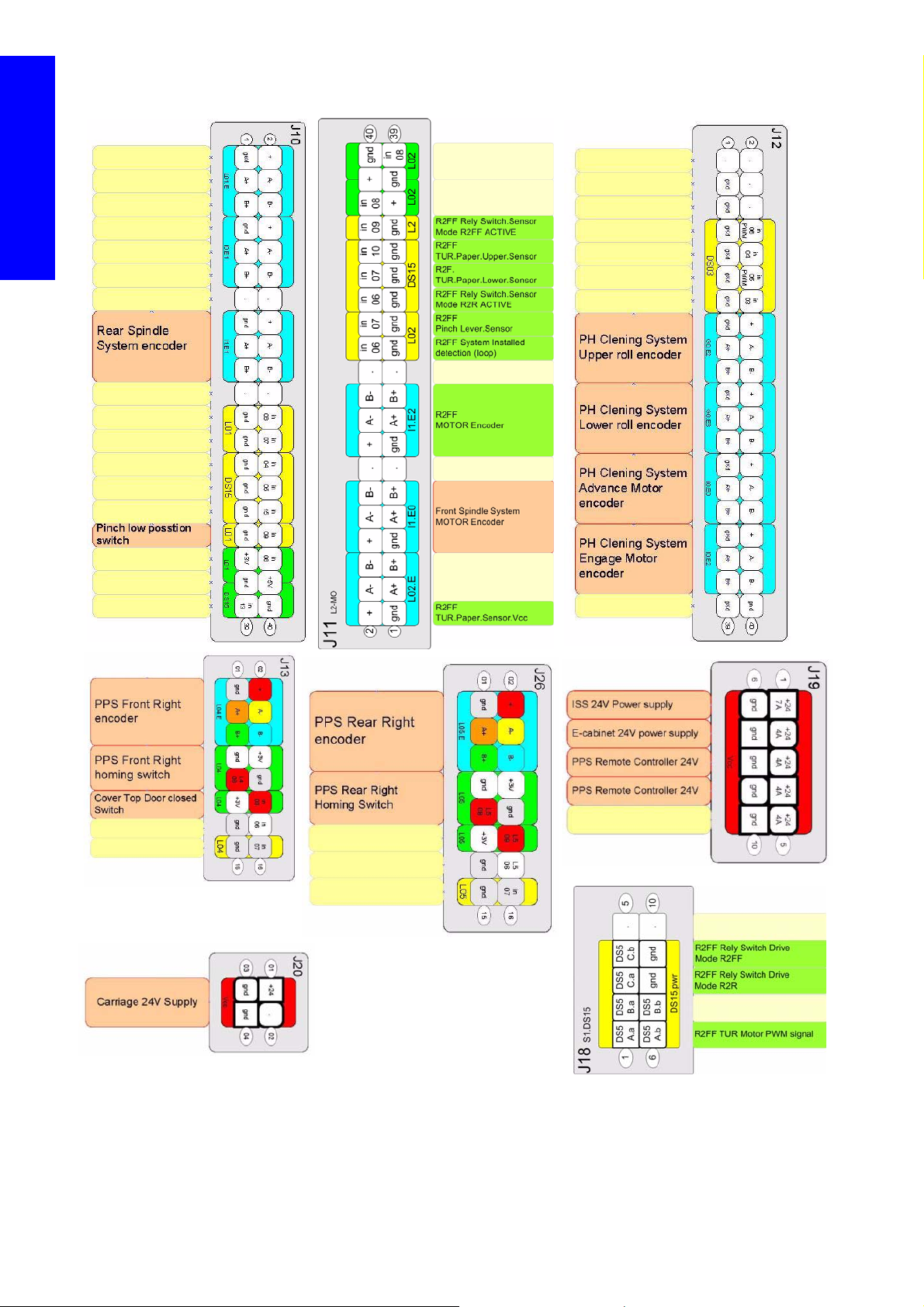

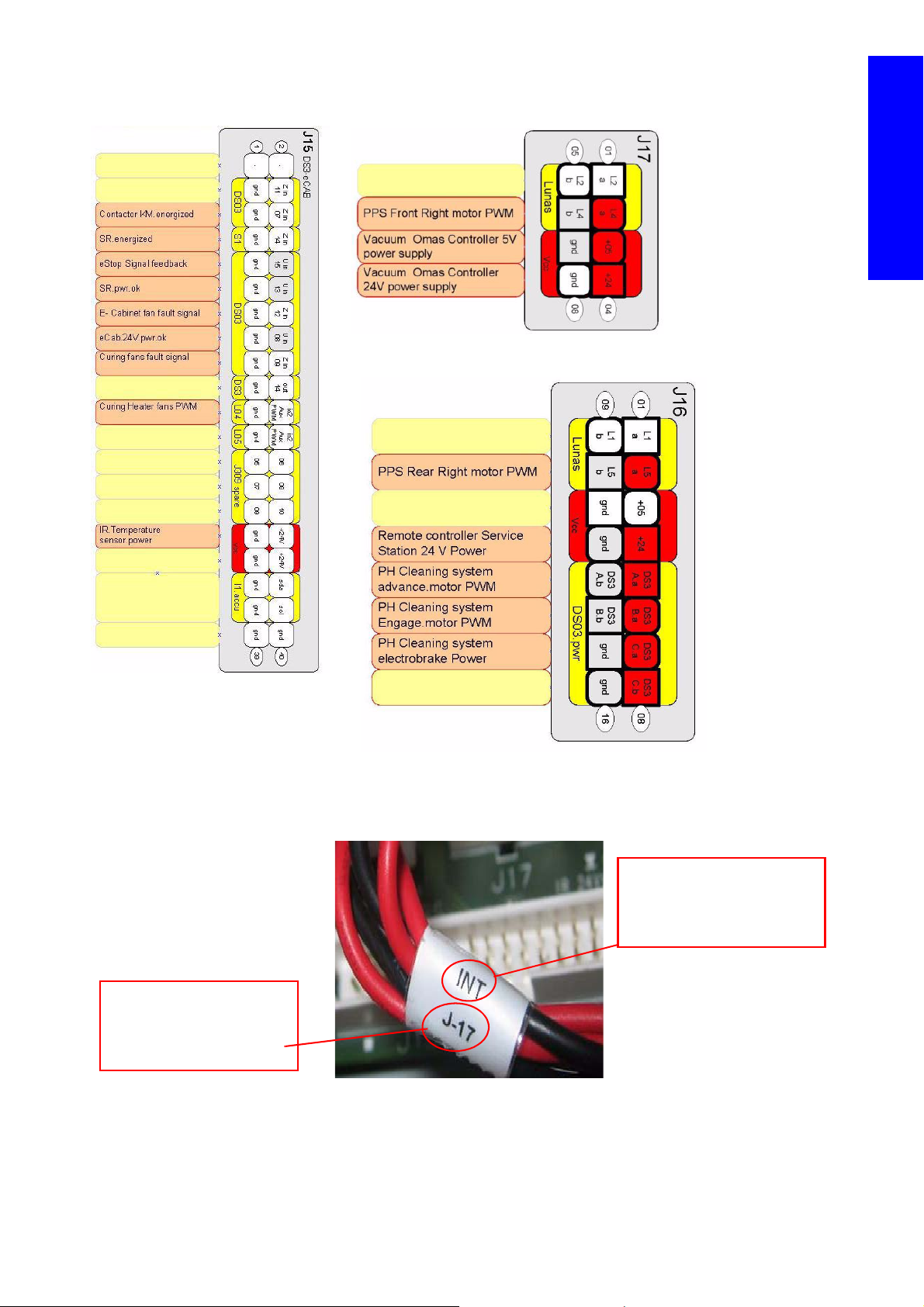

Pin outs of the Main Interconnect

Printer systems

24 Printer systems

Page 23

Pin outs of the Main Interconnect

The’ J17’ on the label

identifies the J17 connector

on the Main Interconnect

Board.

The ‘INT’ on the label

signifies Main INTerconnect

Board, which this cable is

connected to

Printer systems

Labels on the cables

Labels are attached to the cables to identify where the cables go to, and in some cases identify the

functionality of the cable.

Printer systems 25

Page 24

Label abbreviations

Related part Abbreviation on label

Switch SW

Encoder ENC

Printer systems

Power PWR

Lan LAN

Cover CV

Main Interconnect Board INT

Engine upper PCI board ENG 0

Engine lower PCI board ENG 1

PrintMech board PM

Hard Disk Drive HDD

Main Power Supply PWR

Powe r Cabinet PWR CAB

Secondary 24V Power supply PWR CAB SEC 24V

Secondary 42V Power supply PWR CAB SEC 42V

E-cabinet 24V intermediate connection PWR CAB 24V Out

IR temperature Sensor - Left (Curing) SAX TS - LEFT

CUR IR temperature Sensor - Right SAX TS - RIGHT PZ - H

Print zone lamps power SAX PZ - H PWR

Curing lamps power SAX CURING PWR

Curing fans CURING FANS

Front Spindle Motor FSM - T/B ( Top/Botto m)

Rear Spindle Motor RSM

Drive Roller Motor MA (media advance)

Carriage Lid Switch C Lid SW

Printhead Board C PH1/2/3

Note: SAX=Scan Axis

L65500/LX600 Power lines specifications: 3 phase line

High Voltage system Low voltage systems

Input voltage 3 x 380-415V~ (-10%+6%) 3 x 200-220V~ (-10%)

Circuit Breaker 20A 32A

Input frequency 50Hz 60Hz

Power consumption 12kW 12kW

maximum load current (per phase) 32A 32A

L65500/LX600 Power lines specifications: Single phase line

High Voltage system Low voltage systems

Input voltage (phase to neutral) 3 x 220-240V~ (-10%+6%) 115-127 V~ (-10%) (Japan 200 V~)

Input frequency 50Hz 60Hz

26 Printer systems

Page 25

High Voltage system Low voltage systems

Power consumption 1kW 1kW

maximum load current (per phase) 10A 10A

LX800 Power lines specifications: 3 phase line

High Voltage system Low voltage systems

Input voltage (line to line) 3 x 380-415V~ (-10%+6%) 3 x 200-220V~ (-10%)

Input frequency 50Hz 60Hz

Power consumption 15kW 15kW

maximum load current (per phase) 30A 50A

LX800 Power lines specifications: Single phase line

High Voltage system Low voltage systems

Input voltage (line to line) 200-240V~ (-10%+6%) 115-127 V~ (-10%) (Japan 200 V~)

Input frequency 50Hz 60Hz

Power Consumption 1kW 1kW

Maximum load current (per phases) 10A 10A

Related tests, utilities, and calibrations

• From diagnostic mode: Electronics Page 291.

• Service Utilities: Electrical system Page 291.

Service parts

• Electrical Cabinet Page 451.

Printer systems

Removal and installation

Electronics Page 509.

Printer systems 27

Page 26

Substrate path

Drive Roller Encoder disc

Drive Roller Motor Assembly

Pinch mechanism

Drive Roller

Rear Spindle

Drive

Roller

Encoder

sensor

The media roll is mounted on the rear spindle and is collected on the front spindle. Media goes from the rear

spindle over the drive roller, over the print platen, over the diverter and onto the front spindle.

Each of the spindles has its own motor system. Vacuum is applied at the level of the print platen to keep the

substrate flat.

Printer systems

Components

The advance of the media is applied by the motor of the drive roller. There is a pinch mechanism to prevent

the substrate slipping against the drive roller.

The accuracy of the substrate advance is controlled with two components:

• The Driver Roller Encoder disc.

• The OMAS: This is an optical sensor which works like a camera taking pictures of the media’s fibre,

the pictures are then compared, measuring actual distances during movements in order to apply

small corrections in the advancement of the substrate.

28 Printer systems

Page 27

LX800: Roll to Free Fall Assembly functionality

OMAS Sensor Assembly

Diverter Assembly

Vacuum unit

Side plate Spindle Assembly

OMAS Vacuum Connector

This is a feature which comes with the LX800, it provides the user a method to be able to collect media

and cut it as the printer prints dynamically.

Printer systems

In addition to the Roll to Free Fall there is also a Media Collector (front spindle). The added functionality

can be activated on demand by the user.

Printer systems 29

Page 28

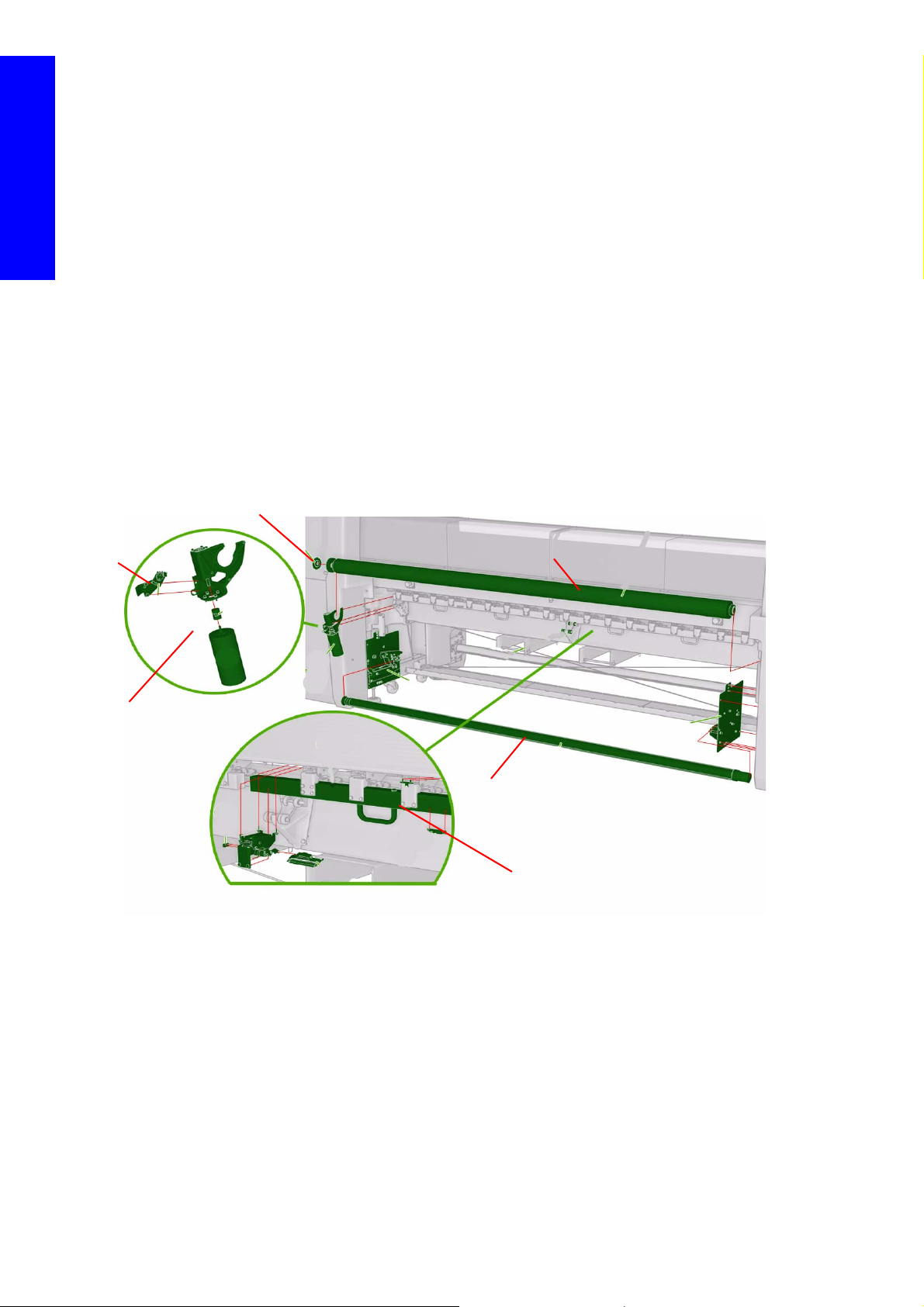

LX800: Roll to Free Fall Assembly mechanical system

The Roll to Free Fall assembly is located on the front of the printer between the Diverter and the Front

Spindle assembly. The whole assembly is held in place by left and right plates, secured to the structure of

the legs.

Printer systems

The drive plate of the Roll to Free Fall is located on the right side of the printer and

operates in an analogue system to the Front Spindle with a drive motor and encoder

system. The motor transmits the torque directly to the roll to Free Fall roller via a

transmission belt.

Dual Roll Functionality

The dual roll enables the printer to print on two different rolls of substrate at the same

time, significantly improving the productivity of the printer.

30 Printer systems

Page 29

A differential mechanical system is used to keep the same tension in both rolls of media mounted on the

Core supported by the end hubs

Media Core

Differential gears

Point of attachment

of transmission bar with

differential

which are suspended on the

ball bearings

Media Core

Core held on to

by the rubber system,

the end hubs

Transmission Bar

Gear

Gear

Gear

where the torque is transmitted from

the differential

transmission bar by

End Hub

1. Dual Roll Gear (Differential)

2. Dual Roll Tool and Screw Pro-

tection kit

3. Dual Roll End Hub

4. Dual Roll Spindle 104

5. Dual Roll Rubber Kits

7. Dual Roll Cap Left

8. Dual Roll Cap Right

same spindle, regardless of the type of media or diameter of each roll. The gear connection allows

movement until torque on the both sides is the same. This allows the usage of different diameters of media

rolls.

Printer systems

The left core is linked to the right core via the differential. The whole assembly is mounted on the spindle

via ball bearings, this enables the assembly to turn on the spindle easily, but at different rates, while

maintaining the same tension between the left and right sides.

Pinch Mechanism

The Roll to Free Fall beam holds an array of pinches. All the pinches are interlinked by a bar, which

Printer systems 31

transmits any open or closing movement from the Pinchwheel lever, to all the pinches. Underneath the

Page 30

pinchwheel system is a sensor which detects the open and close state of the pinches. The system contains

Pinchwheel switch

Shock absorber

a shock absorber system which prevents damage to the printer and/or the media.

Printer systems

NOTE: There are two types of Pinchwheel mechanism: 18 inner and 2 outer types. The two

outer pinchwheels act as reference points of the system.

Media collector

On the front right hand side, underneath the Roll to Floor main beam is the media collector system. The

system comprises of two sensor and a PCA in an enclosed U shaped structure. A cosmetic cover is secured

over the whole system as further protection.

32 Printer systems

Page 31

Media Collector sensors

The sensors are two distance detecting sensors which create a beam of infrared light on the media to sense

the upper and lower position of the paper. The system will operate the collector motor (front spindle system)

to keep the bottom area of the media loop within the area defined by the sensors.

The Loop shaper

The loop shaper is part of the media collection system and gives shape to the loop of media that hangs

down from the media paper path, it also gives added tension to the media as its being collected. The length

of the loop shaper can be changed by removing and/or adding sections to it in order to work with various

widths of media.

Drive Roller Assembly

The driver roller system contains the following:

Printer systems

• Roller

• Pinch Wheels

• Motor

• Encoder Disc

• Encoder PCA

The Drive Roller system advances the substrate under control. The Encoder Disc and Encoder PCA

provide feedback on the advance of the substrate. The Pinch Wheels ensure that the substrate does

not slip and moves the same distance. There are separated into two modules that are manually

opened and closed while loading the substrate.

Diverter

The Diverter Assembly makes sure that the substrate exits the substrate path correctly, and prevent

the substrate from becoming damaged.

The OMAS

The OMAS consists of an optical sensor is located

underneath the print platen. It has a dedicated controller

board, which is connected to the Main Control board

through a CAN bus.

The optical sensor takes pictures of the back of the substrate

as it moves across the platen. These pictures evaluate the

precision of the substrate movement. The evaluations result

in a set of values that describe the substrate advance error.

The values obtained are then used to feed the substrate into

the printer, correcting the movement, and making on-going precision adjustments that avoid any

possible substrate skew.

The OMAS temperature sensor detects the heat around the OMAS sensor, which comes from the

Heating and curing system, the system can then make small adjustments to compensate.

The Vacuum system

Printer systems 33

Page 32

The vacuum is used to keep the substrate flat on the print platen. There are different Vacuum levels

Vacuum

sensor

Drive roller

Rear spindle

Diverter

Front spindle

Vacuum

Pinchwheels

Drive roller

Diverter

Front spindle

Vacuum

Pinchwheels

depending on the substrate used. The level of vacuum is determine automatically during the loading

of the media.

The vacuum pump is a 110V pump. It receives power from a transformer in the power cabinet. This

transformer need to be configured according the input voltage during the installation. The amount

of Vacuum is measured by a sensor. The sensor is located in the vacuum controller PCA.

Printer systems

Functionality

Substrate path workflow overview LX600, L65500 & LX800 (Roll to Roll)

The following steps describe the substrate path workflow.

1. The substrate passes from the rear spindle, over the drive roller (and under the pinches), over the diverter,

and is collected on the front spindle.

2. The rear spindle system maintains tension on the media.

3. The drive roller’s motor advances the substrate. The substrate is pressed against the drive roller by the

pinchwheels, to ensure a correct substrate advance.

34 Printer systems

Page 33

4. The Print Platen is designed for minimal resistance against the substrate’s advance, and includes suc-

Diverter

Front spindle

Vacuum

Drive roller

Rear spindle

Diverter

Front spindle

Vacuum

OMAS sensor

Pinchwheels

Diverter

Front spindle

Vacuum

Diverter

Front spindle

tion holes for the vacuum.

5. The substrate passes over the OMAS sensor which is able to detect very small errors in the advance-

ment of the media. These advancement errors are communicated to the motors on the drive rollers and

very small correction adjustments are applied to the movement of the substrate.

Printer systems

NOTE: The OMAS sensor camera cannot see the fibers on some substrates, such as

transparent media or very dark substrates. In these cases, the OMAS sensor can be

disabled. To disable the OMAS sensor

6. The Vacuum level is set according to the substrate type and print options, it sucks the substrate to the

print platen, making sure that the substrate is flat.

7. The substrate exits the print zone and passes over the passive diverter (no motor), this enables the sub-

strate exit correctly, undamaged, friction is reduced and controlled.

See page 404.

Printer systems 35

Page 34

8. The front spindle has two motors that pull the substrate through the print path to maintain tension and

Front spindle

Substrate collector

Pinches

Roll to Free Fall

Substrate collector

Pinches

Roll to Free Fall

to roll up the printed image.

Printer systems

9. LX800 only:

a. Roll to Free Fall: The pinches & Roll to Free Fall Roller keep the paper in tension while the

end of the paper is free to pass over the Substrate Collector and fall to the floor, or be cut as

the printer prints.

b. Substrate Collector: The pinches & Roll to Free Fall Roller keep the paper in tension while

the substrate collector rolls up the printed media as it prints.

Related tests, utilities, and calibrations

• Diagnostic mode

• 2.3 Substrate path diagnostic test: Page 418 .

• 3.2 Front spindle diagnostic test: Page 307.

• 3.3 Rear spindle diagnostic test: Page 31 0 .

• 3.4 Drive roller diagnostic test: Page 312 .

• 3.5 Pinch switches diagnostic test: Page 313 .

• Service utilities

• 1.3.1 Turn drive roller service utility: Page 402.

• 1.3.3 Enable/disable OMAS service utility: Page 404.

• 1.3.2 Enable/disable SCAPA service utility: Page 403.

• 1.5 Scan axis check: Page 408.

• 4.3.2 OMAS calibration: Page 426.

Service parts

• Front Substrate Path (1of 2) Page 454.

36 Printer systems

Page 35

• Front Substrate Path (2 of 2) Page 455.

Refer to following

photo

• Rear Substrate Path Page 456.

• Rear Substrate Path Page 457.

• Dual Roll Assembly Page 458.

• Roll to Floor Page 459.

Removal and installation

• Substrate Path: Page 547.

Substrate Path Circuit Diagram

Printer systems

Printer systems 37

Page 36

Vacuum Controller Connectors

2 motors of the Roll to Roll (or Collector)

To set & control the status of the relays

Motor of the Roll to Free Floor

Part detecting the substrate loop position

1

2

3

1. Cable detection, a way for the printer to check that the cable is correctly connected, if it is not a system error will display.

2. From the encoder reader placed at the back of the Roll to Free floor motor

3. The lever switch of the Tension Roller, detects if it is raised of lowered.

Printer systems

LX800: roll to Free Floor and Media Collection Electrical system

38 Printer systems

Page 37

Ink System

The ink system is located in the left compartment of the printer (inside the left covers) and delivers a

continuous supply of ink to the printheads. It can detect an ink leakage anywhere in the system, including

inside an Ink Cartridge. It also tracks and determines when an Ink cartridge needs replacing.

In addition the system is designed to allow Ink Cartridge replacement while printing (Hot Swap

functionality)

Components

• Ink Cartridges

• Printheads.

• TRS

• The twelve Intermediate ink tanks (two for each color), located at the bottom front and rear of

the ink system compartment.

• The ISM Air Circuit Module, located on the first tray from the top, provides the air pressure

needed to pressurize the intermediate ink tanks and send ink to the printheads.

• The two Air Pressure Bottles prevent cross contamination of ink when a broken bag occurs

inside an intermediate ink tank. It also works as cushion device for the air pressurization system

• The ISM Ink Circuit Module, located on the lower tray, manages the flow of ink using a complex

set of valves.

• There are two Ink sensors boards, each with three ink pressure sensors. Each board comes

calibrated from the factory with unique values. New service parts require a service procedure to

manually enter in calibration values. Ink Pressure Sensor Calibration:

• The Ink Cartridge Connector Set connects to the ink system to the ink cartridges. The ink

connectors include read the acumen data from the cartridges, and also an internal switch to detect

whether or not the connector is correctly inserted.

• The ISS Main Board controls the entire ink system.

Printer systems

Page 339.

Functionality

Ink supply hot swap

• The printer allows the user to change the Ink Cartridge while the printer is printing, as it is actually

using the ink stored in the intermediate tanks.

Printer systems 39

Page 38

Intermediate tank set swap

Ink Pressure Sensor

Higher column of ink

= higher pressure

Lower column of ink

= lower pressure

• While one of the Intermediate tanks is refilling, the other intermediate tank is pressurized to enable

the correct ink flow to the printheads.

• Once the quantity of ink falls below a certain threshold, the printer calculates the amount of ink fired

from the printheads and resupply the intermediate tank with ink, while at the same time swapping

the amount of pressurization supplying ink from the other set of intermediate tanks.

Printer systems

Low ink carriage detection

Control of ink to the Intermediate Tanks

Intermediate tank set swap

• While one of the Intermediate tanks is refilling, the other intermediate tank is pressurized to enable

• Once the quantity of ink falls below a certain threshold, the printer calculates the amount of ink fired

The pressure sensor detects the amount of pressure of the column of ink above. When the column is

low (empty cartridge), the sensor triggers the empty condition. The pressure of a fluid mainly

depends on the height of the column of fluid.

Once the main electrovalves open the ink falls into the intermediate tanks by gravity. When an

intermediate tank is full, the ink flows stops, which generates a pressure difference which is detected

by the pressure sensor.

the correct ink flow to the printheads.

from the printheads and resupply the intermediate tank with ink, while at the same time swapping

the amount of pressurization supplying ink from the other set of intermediate tanks.

Air System Functionality: The Intermediate tanks push the ink to the printheads

The system has two air pumps for each set of intermediate ink tanks (four total). The air pressure is distributed

using an air pressure bottle (one for each tank set) with air tubes going out to the tanks.

Each tank has a bag inside which holds the ink. In order to send the ink to the printheads, the air pumps push

air into the enclosed space of the tanks around the bags to pressurize them and force ink out.

40 Printer systems

Page 39

While one tank sends ink to the printheads, the other is being refilled. In this way, continuous printing is

Air Circuit

Printhead

Intermediate Tank

Ink Circuit

Air Pump

Air Pressure

Sensor (in

ISM board)

Relief valve

Air pumps

Air Pressure

bottle

Relief valve

Broken bag in

intermediate

tank

Intermediate ink

tanks

Air Pressure

sensor

possible while changing ink cartridges.

•Air pressure is constantly

monitored by an Air Pressure

Sensor located on the ISS PCA

•The system is able to

depressurize with the relief valve

located in the Air System.

Broken bag in an Intermediate Tank

In the event of a broken bag in an

intermediate ink tank, the ink

system uses the air pressure bottle

to prevent cross contamination of

inks.

Printer systems

When a broken bag is detected by the sensor located inside the intermediate ink tank, the relief valve opens

to release the air pressure of the system. The ink going through into the air system can at maximum flow and

fall into the bottom of the bottle, preventing cross contamination of colors.

Printer systems 41

Page 40

Ink Cartridge LEDs Indicators

• Red: Connector connected to the cartridge, but communication issue with the

• Yellow blinking: Ink Cartridge empty

• Green blinking: Filling intermediate ink tank or reading acumen. Do not

Printer systems

• Green: Functioning correctly, no issue

• No LED: Connector not connected

Acumen. Cannot use

disconnect!

the cartridge.

Related tests, utilities, and calibrations

• Diagnostic mode

• 4.1 ISS Electronics diagnostic test: Page 318 .

• 4.2 Air Pressure System diagnostic test: Page 319 .

• 4.3 Ink Supply Connector diagnostic test: Page 320.

• 4.4 Broken bag recovery: Page 321.

• 4.5 Ink System Leakage diagnostic test: Page 322.

• 4.6 ISS Electrovalves diagnostic test. Page 323.

• 4.7 Recover ink leakage: Page 324.

• 4.9 Intermediate tank change: Page 324.

• 4.10 Ink cartridge LEDs diagnostic test: Page 326.

• 4.11 Ink Pressure Sensors calibration: Page 326.

• 4.12 Ink pressure at Pen: Page 328.

• 4.13 Force Filling Tanks: Page 330.

• 4.14 No flow Error recovery: Page 330.

• 4.15 ISS Test components Menu: Page 331.

• 4.16 Flushing Menu: Page 335.

• 4.17 Intermediate Tank Ink Life Cycles: Page 337.

• 4.18 Intermediate Tank Ink Amount: Page 337.

• 4.19 Intermediate Tank Refill Time: Page 338.

• 4.20 check Ink Supplies: Page 339.

Service parts

• Ink System: Page 460

Removal and installation

• Ink system: Page 598

42 Printer systems

Page 41

Ink System Circuit Diagram

Printer systems

Further information about the two 'LAN' cables linking the ISS board to the main interconnect:

• The cable linking J36 (ISS board) to J8 (Main Interconnect) contain the specific bus to communicate

with the cartridge ACUMEN and one specific interruption line (the line is activated for some events,

such as when a connector of a cartridge is disconnected or connected back). All the signals are

moved down to the upper engine PCI board.

• The cable linking J37 (ISS board) to J7 Main Interconnect) mainly contain lines of an 'I2C' bus, that

the printer can get the detailed status from the main elements of the ISS area (Ink Pressure Sensor,

Air Pressure Sensor, Broken Bag, ...) and can also set the main elements of the ISS area (Air Pump,

Ink Electrovalves, ...)

Printer systems 43

Page 42

ISS PCA with leds and connectors

Printer systems

44 Printer systems

Page 43

Scan Axis

carriage

Belt Tensioner

Scan Axis motor

Scan Axis Belt

The Scan Axis system can be separated into three different subsystems:

• Scan Axis: Carriage Impelling System (Carriage Movement)

• Scan Axis: PPS System (Print to Paper Space)

• Scan Axis: Service Station (Capping)

Scan Axis Impelling System

The Scan Axis Impelling System is designed to move the Carriage Assembly across the scan axis under

control, for the purpose of printing and moving the printheads into a position where they can be serviced/

maintained.

Components

Scan Axis Motor

The Scan Axis Motor, located on the right side of the printer, drives the belt that moves the carriage.

Scan Axis Impelling Belt

The Scan Axis Belt is connected to the carriage on both sides, and runs from the Scan Axis Motor to

the Scan Axis Belt Tensioner. The motor drives the belt, which in turn moves the carriage back and

forth.

Printer systems

Scan Axis Belt Tensioner

Scan Axis Encoder Strip and Encoder Sensor

Carriage Chain Assembly (TRS system)

Functionality

Carriage movement

The Scan Axis Belt Tensioner, located on the left side of the printer, acts as a pulley for the Scan Axis

Impelling Belt opposite the motor. Two springs mounted between the pulley and scan axis sideplate

maintain tension on the belt.

The Scan Axis Encoder Strip is a metal strip running the length of the scan axis. As the carriage is

moved back and forth by the Scan Axis Impelling System, an encoder sensor mounted on the carriage reads the encoder to determine the speed and position of the carriage. This feedback is then

used to control the Scan Axis Motor movements

The Carriage Chain Assembly contains the ink tubes and trailing cables that connect to the carriage,

it is designed using a ‘chain system’ that enables the Carriage Chain Assembly to bend while the

carriage moves back and forth. The chain system also protects the ink tubes and data lines housed

inside.

A belt is attached to each side of the carriage. The belt is driven by the scan axis motor mounted on

the right side of the printer. On the left side of the printer, the scan axis belt tensioner acts as a pulley

for the belt which uses a simple spring mechanism to maintain tension on the belt.

Printer systems 45

Page 44

Tension of the belt

Left side (outside)

Left side (inside)

Springs exert a force against the belt

maintaining tension

A screw on the other side of the wall enables the

belt to be adjusted or tension released for removal.

Printer systems

Force is applied to the belt via springs on the left side of the printer.

To ensure the correct tension of the belt, make sure the side face the tensioner is located between

the two marks located on the tension poles

Related tests, utilities, and calibrations

• 5.1 Impelling system diagnostic test: Page 339.

• Move the position of the carriage.

- 5.2.1 Move to home position: Page 342.

- 5.2.2 Move to load position: Page 343.

- 5.2.3 Move to Printing position: Page 344.

• 1.5.1 SAX Friction analysis. Page 408.

Service parts

• Scan Axis (A): Page 463

Removal and installation

• Scan Axis Impelling System: Page 619 .

46 Printer systems

Page 45

Scan Axis Impelling System Circuit Diagram

Pin 1

Pin 4

Pin 3

Pin 2

Pin 4: Earth

Pin 1: +42V

Pin 2: Resistor cable

Pin 3: GND

Printer systems

Identify the pins of the power cables from the Scan Axis motor.

Printer systems 47

Page 46

The pins shown above go to the location on the fuse block in the E-Cabinet (after having identified them

Capping post

Capping Module bottom

Capping Module top

Rubber cap

Springs

Capping

Module base

with an multimeter):

• Pin 1 connects to TB4-2

• Pins 2 connects to TB4-3

• Pin 3 connects to TB4-1

• Pin 4 connects to Earth

Printer systems

Scan Axis Service Station (capping and drop detection)

The Capping of the printheads is performed in the Service Station, the process seals them while they are not

in use, to keep the printhead’s nozzles in good condition while the printer is not printing. The assembly is

located on the right side of the printer, beneath the carriage path. The Service Station also contain s the drop

detector sensors which determine possible nozzles out, which then have the appropriate automatic

maintenance routines applied.

Components

Service Station Motor

The Service Station Motor with its Encoder is mounted on the rear sideplate of the service station

chassis. The motor drives the screw that moves the service station.

Service Station Screw Assembly

The Service Station Screw Assembly rotates by the action of the Service Station motor.The assembly

includes a nut and pin system which is inserted into the shuttle.

Printhead Capping Module

The Printhead Capping Module is the mechanical part that seals the printheads.

NOTE: If the Carriage is moved while the Service station is in the capped position, the

capping post may become damaged and the capping module will be unable to

perform the capping procedure on the printhead. Image quality will begin to

deteriorate and the life of the printhead will be affected.

Drop Detectors Set

There is one detector for every printhead. Drop detection: Page 50 for a detailed explanation of

how drop detectors work.

Service Station Encoder Strip and Sensor

48 Printer systems

The encoder strip and sensor is used during drop detection to ensure that the drops of ink are fired

in the correct place. The strip is located under the shuttle and from side to side of the Service Station.

Page 47

Service Station Connection Board

M

o

v

e

s

i

n

b

o

t

h

s

c

a

n

d

i

r

e

c

t

i

o

n

s

Left slide rod

Right slide rod

Service Station Remote Controller Board

Functionality

Moving the service station

The bottom structure attaches the Service Station to the right structure of the printer, it includes the driver

mechanism and the linear encoder strip. The top shuttle moves back and forth over the bottom structure, held

by two bushings which are attached to the left slide rod and two support points over the right slide rod.

The Service Station Connection Board links the three drop detectors and the service station linear

encoder with the Main interconnect board. The board is located on the rear right corner on the top

of the Service Station.

For more information refer to Service Station Connection Board: Page 51 .

The Remote Controller Board controls the movements of the Service Station Motor. It provides power

to the motor and encoder. The Remote Controller Board is located on the back of the rear sideplate

of the service station structure.

Printer systems

The movement is driven by the Service Station motor, which is located at the rear of the Service Station. This

motor contains its own encoder, which detects and controls the movement. The motor signals and readings

are managed by the Remote Controller Board, which is located at the back of the Service Station.

To maintain accuracy while performing the drop detection procedure, the Service Station also has an

additional linear encoder, which is located underneath the Service Station shuttle.

NOTE: While the printer is turned off and the printheads are in the capped position, it is not

possible to move the carriage. To uncap the printheads manually rotate the shuttle

screw with a screw driver, this can be accessed from the front of the Service Station.

The Capping Procedure

The printheads must be sealed when they are not printing to prevent ink from drying and clogging

the nozzles.

Printer systems 49

Page 48

1. The Printheads are capped by moving the capping station into position underneath the carriage.

Capping Station

Carriage Bottom

Printhead base plate

Movement of

capping station

Movement of

capping station

Capping module post

Carriage Bottom

Printhead base plate

Movement of

capping station

Printer systems

2. The capping station moves until the capping module posts come into contact with the carriage bottom

base plate, underneath the printheads.

3. The upper part of the capping station raises into position (shown in red below), pushing the rubber caps

up to seal the printheads.

The Capping Station is forced upwards, capping the printheads.

4. The service station continues to move, pushing the capping head up to seal the printheads.

Drop detection

The Service Station system contains three drop detector modules, one for each printhead. Each drop

detector has a window with a sender LED on one side and a receiver on the other.

The printer fires sequentially drops of ink from each nozzle into the window, through the signal path.

This generates a disturbance in the signal which detects if the nozzle was fired correctly.

Any nozzles that did not fire correctly are then disabled, allowing the printer to compensate and

maintain print quality by using the other nozzles.

50 Printer systems

Page 49

Scan Axis Service Station

5V LED (DS1) PWR

Drop detectors

From encoder sensor

of linear encoder strip

12V LED (DS2) PWR Only active

when performing drop detection

diagnostic tests

Data and Power cable

to Main Interconnect

Printer systems

Service Station Connection Board

Printer systems 51

Page 50

Related tests, utilities, and calibrations

• 3.5.6 Service Station Drop Detectors diagnostic test: Page 424.

• 5.3.1 Service Station Open Loop diagnostic test: Page 349.

• 5.3.2 Service Station Closed Loop diagnostic test: Page 351.

• 5.3.3 Drop Detectors diagnostic test: Page 352.

• 5.3.4 Service Station Calibration Page 354.

Printer systems

• 5.3.5 Drop Detector 12v On/Off Page 355.

• 5.3.6 Drop Detector Signals Page 356.

• 5.4.1 Drop Detector Calibration Page 430.

• 4.5.2 Service station Compensation Page 432.

• 1.5.2 Force Drop Detection service utility: Page 410 .

• 1.5.3 Ghost Drop Detection service utility: Page 411.

Service parts

• Scan Axis (A):Page 463

Removal and installation

• Scan Axis Service Station: Page 634

52 Printer systems

Page 51

Scan Axis Print to paper space (PPS)

Limiter

Rear left PPS

Front left PPS

Front right PPS

Rear right PPS

The Scan Axis PPS system raises and lowers the complete Scan Axis, (the pinchwheels, carriage, service

station, printhead cleaning system, and printheads). This increases the distance between the substrate path

and the carriage assembly, enabling the user to load substrate and print on different types of substrate

thickness.

• PPS Standard height: 2.3mm (Printhead to Platen)

• PPS (Printhead to Platen).

• PPS Custom. To a user selectable height.

There are four PPS units which are all synchronized to move at the same time

Components

PPS Motor Assembly and PPS Motor Mount Assembly

PPS Low Position Switch

Remote Controller Board (PPS)

Printer systems

The printer has four PPS Motors and motor mount assemblies, each

located on a corner of the scan axis. These four systems always raise

and lower the scan axis at exactly the same rate. If the motors were to

raise or lower the scan axis at different rates, a system error will be

generated.

The PPS Low Position Switch detects when its PPS unit has reached its

lowest position. The switches are attached to the four side walls of the

printer.

The two right hand PPS units are connected and controlled by the Main

interconnect Board. The two left hand PPS units are connected and

controlled by the main interconnect board via the Remote Control

Boards (refer the PPS circuit diagram).

Printer systems 53

Page 52

Functionality

The PPS Positioning

The PPS system has three positions in the printer:

• Print position: This is the nominal printing position and is calibrated and set at the manufacturing site

Printer systems

• Custom print position: This setting is a high printing position, used for the thicker types of substrates,

• Load position (highest position): This is used to load substrate. The default setting is 120mm

PPS Lowering Alignment

1. The four PPS units are lowered until they reach the PPS Low Position Switch.

2. The four PPS units are raised until they reach the scan axis.

When the motor reaches the scan axis, the system detects an increase the PWM (signal), which stop the

movement

at 2.3mm (0.09inchs). When the Scan axis is in this position the complete assembly is set onto the

side walls.

this is a customer selectable setting.

(4.7inchs), this movement can be cancelled.

In order to maintain consistent movement and positioning of the PPS system, the PPS performs the

following alignment procedure:

NOTE: When lowering the PPS, if any of the four low position switches fail, the affected PPS

unit will continue to lower until it reaches a servo shutdown position, this will triggers

a system error. This type of unknown position error can be solved following the

procedures in the utilities and calibration section of this service manual.

Related tests, utilities, and calibrations

• PPS Diagnostics Page 342

• 5.2.1 Move to Home Position: Page 342

• 5.2.2 Move to Load Position: Page 343

• 5.2.3 Move to Printing Position: Page 344

• 5.2.4 PPS Motor check: Page 345

• 5.2.5 PPS Switch: Page 348

• 5.2.6 PPS Shims Values: Page 349

• 5.2.6 PPS Shims Values: Page 349

Service parts

• Scan Axis (A): Page 463

Removal and installation

• Scan Axis PPS: Page 648

• PPS Columns and Bushing Page 749

54 Printer systems

Page 53

Print to Paper space (PPS) Circuit Diagram

Printer systems

Printer systems 55

Page 54

Remote Controller leds

Printer systems

56 Printer systems

Page 55

Carriage

The carriage performs the actual printing of the printer. It contains the printheads, together with the

printhead control electronics. the printhead primer system, two arrays of aerosol fans, the SAX encoder,

and the sensor box which contains the Spectrophotometer, as well as a line sensor.

Components

Printheads

Primer Assembly

Carriage Printhead Interconnect

Printer systems

The printheads fire ink onto the substrate to perform the actual printing. The printheads are controlled

by the dedicated Carriage Printhead Interconnect PCAs.

• Each printhead contains two colors

• Each printhead prints a maximum swath width of 4.25 inches (108mm).

• The printheads have five dies, and each die has 2112 nozzles (10,560 total nozzles per print-

head). The dies are divided into two arrays of nozzles (1056 nozzles per array, one for each

color.

Each printhead houses a Primer Assembly that is responsible for squeezing ink out of the printhead

nozzles to remove clogging and maintain printhead health (for more information about priming

Page 64).

Each primer assembly includes an air pump that pushes air into a bag inside the printhead regulator.

When this bag is inflated, the ink channel is opened, the ink pressure received in the printhead

pushes the ink out of printhead through the nozzles. This is called ‘priming’.

The three Carriage Printhead Interconnects receive signals from the Upper Engine PCI Board and

then finally control the printheads.

Each Carriage Printhead Interconnect receives 42 V power from the Carriage Interconnect Board.

Additionally two of the boards have a data connection from the Carriage Interconnect Board.

• The Carriage Printhead Interconnect #1, controls the Y/M printhead, it processes signals com-

ing from the sensor box (line sensor, color sensor and color sensor shutter) via the Carriage

Interconnect Board. The sax encoder signal also passes through the two Printheads

• The Carriage Printhead Interconnect #2, controls the Lc/Lm printhead, processed signals that

control the three Primers and the two Aerosol Fans via the Carriage Interconnect Board. It also

has the carriage lid switch and the SAX encoder signals.

• The Carriage Printhead Interconnect number 3 controls the K/C Printhead

Carriage Interconnect Board

The Carriage Interconnect Board receives 24 V and 42 V power supply via the Main Interconnect

from the Main Power Supply. The 42 V supply is relayed to the Carriage Printhead Interconnect s,

while the 24 V is used to power the remaining components housed in the carriage. All control data

for this board goes through the Printhead Interconnect PCAs as described above. The 3 primer

pumps the two aerosol fan arrays are powered by this board. THe board is also interfaces for the

Carriage lid switch, the sensor box and the sax encoder.

Sensor Box

• Carriage Sensors PCA

The Carriage Sensors PCA is embedded within the sensor box and, relays data from the line sensor

and color sensor and also controls the shutter motor for the Color Sensor. For more information, see

the circuit diagram later in this section.

• Line Sensor Assembly

Printer systems 57

Page 56

Printer systems

• SOL Spectrophotometer performs the Color Calibration.

Carriage Encoder

Carriage Lid Switch

The line sensor has three different colored LEDs and one receptor. By shining these three LEDs into

the print path, the line sensor is able to:

• Detect the edge of the substrate.

• Detect printed line positions in order to perform various calibrations:

- Automatic Printhead Alignment

- OMAS Calibrations

- Service Station calibration

•

The Carriage Encoder Set reads the scan axis encoder strip to determine the position of the carriage

on the Scan Axis, refer to the Scan Axis Encoder Strip and Encoder sensor:

connection with the printer is through the carriage board + PH interconnect board of Y/M + trailing

cable + upper engine PCI board.

These signals are not tested during the trailing cable test (on the PH interconnect board, the 2 signals

from the encoder reader is converted to 4 lines, differential signals).

The Carriage Lid Switch reads when the carriage lid is opened or closed in order to prevent damage

to the printer by leaving the lid open. Connection with the printer is through the carriage board + PH

interconnect board of Y/M + trailing cable + upper engine PCI board.

Page 45. The

Aerosol Fans Assembles and Aerosol Filters

There are two arrays of five fans at both side of the printheads. The fans and filters remove aerosol

(ink dust) from the print path to maintain good image quality and components health. Connection to

the printer: This should transit through the carriage board -> PH interconnect board of the Light Cyan

/ Light magenta -> trailing cable -> upper engine PCI board.

Carriage Oiling Foam Retainers

The carriage oiling foams lubricate the rods and bushings that support the carriage. There are two

units located at the front and rear of the carriage.

Related tests, utilities, and calibrations

• Diagnostic mode

• 6.1 Carriage assembly diagnostic test: Page 358.

• 6.2 Move the carriage to repair position from diagnostic mode: Page 362.

• 6.4 Line sensor diagnostic test: Page 363.

• 6.5 Aerosol fans diagnostic test: Page 363.

• 6.6 Force Priming Menu: Page 364

• Service utilities

• 1.6.1 Open/Close color sensor: Page 413

• 1.6.2 Color sensor check: Page 416 .

• 1. 6 .3 Ae r o s o l f a ns ch e ck : Page 417 .

Service parts

• Scan Axis (B): Page 465

Removal and installation

• Carriage: Page 654

58 Printer systems

Page 57

Carriage Circuit Diagram

Printer systems

Printer systems 59

Page 58

Carriage Interconnect Connection and leds

Printer systems

60 Printer systems

Page 59

Printhead Cleaning System

Output

roller

Input roller

Wiping

area

Pinch & roll

advance

Latching

system

The printhead cleaning system is designed to clean the printheads and absorb ink during the priming and

ink spitting procedures. The subsystem absorbs ink and cleans the printheads with a cloth roll that is

impregnated with non-volatile PEG liquid. This roll is moved from an input (Top roller) to an output collecting

roller (bottom roller), while the cloth is impelled by the advance of the delivery system pressed with the

pinch roll, in a similar way to the substrate path.

Components

Input roll

The input roll holds the new printhead cleaner roll before it is fed through the roll path. The input roll

is not powered by any motor, and instead uses an electromechanical brake to maintain tension.

The cleaner roll cores are easily fastened into place and removed

using the blue lock at the end of

Output roll

The output roll receives the used printhead cleaner roll. The output

roll is powered by the advance motor and belt system, and works

together with the drive roller to pull the roll through the roll path.

The cleaner roll cores are easily fastened into place and removed

using the blue lock at the end of the roller.

the roller.

Printer systems

Input encoder

The input roll features an encoder that provides the feedback

necessary to control the rolls (encoder counts tell the printer how

much the roll is advancing). This feedback determines if the system

is in a Jam condition triggering a system error.

NOTE: A jam condition system error is displayed when the Drive System is moving and the

Electromechanical brake

The input roll includes an electromechanical brake to apply tension to the cloth, keeping it flat and

under controlled tension.

Pinchwheel and Drive roller

The printhead cleaner roll is moved through the roll path by the output roll and the drive roller. The

pinchwheel mechanism presses the roll against the drive roller to ensure good contact. The drive

roller includes teeth that grip the roll to help pull it through the path. The Drive Roller is powered by

the advance motor and belt system.

The pinchwheel mechanism must be opened and closed in order to load and unload a roll. It is

critical to ensure that the pinchwheels are correctly closed to avoid the system displaying false

substrate jams/crashes.

Advance motor and belts

A single advance motor and encoder controls the drive roller and the output roller using a belt

system.

Upper Roller Encoder does not detect the appropriate cloth roll movement.

Rubber roller and roller up motor (engage system)

Printer systems 61

Page 60

The rubber roller is a star shaped rubber wheel that moves up and down, lifting the cleaner roll to

This part is no

longer installed,

and is no longer

required in the

printers, in printers

with serial number

SG93xxx this part

is no longer

installed

ensure that the printheads make proper contact with the cloth, in order to perform the Printhead

cleaning.

The up/down motion has two main positions. The engage position (is the upper position calibrated

for correct Printhead Cleaning operation) and the disengage position, which is the lowest resting

position of the rubber roller.

Printer systems

Electronic control

Rear of the Printhead cleaning system

The Upper Engine PCI Board controls the following Printhead Cleaning Assembly components

through the Main Interconnect Board:

• Advance motor and Advance motor encoder.

• Rubber Roller up/Down motor and up/down motor encoder.

• Electromechanical brake

• Input Roller encoder signal.

Functionality

Static wipe

A static wipe is a printhead cleaning procedure which is performed when the carriage is not moving.

The carriage is moved into the wipe position for each printhead, the rubber roller is set to the correct

height, and the cleaning roll is advanced under the printheads.

The following describes the process:

62 Printer systems

Page 61

1. The carriage is moved into position below the cleaning system.

Printhead Cleaning

System

Carriage

Printhead

Engage

position

Wiper cloth is

moved

Printhead nozzles

are cleaned by the

wiping action

2. The rubber roller is moved up to the printhead and presses the cloth wiping over the nozzle area.

Printer systems

3. The cleaner roll is advanced performing the operation of cleaning the nozzles by friction. while mov-

ing the cloth.

4. The cleaner roll continues to advance until it reaches the end position, after having advanced a total

o f 3.3cm.

5. The rubber roller is moved back to the down position (disengage position).

Dynamic wipe

A dynamic wipe is a printhead cleaning performed while printing. The rubber roller is set to the

correct height, and the carriage passes over the printhead cleaner, from right to left, without stopping

(but still making contact and being cleaned).

Printer systems 63

Page 62

Printer systems

1. Carriage movement

2. Printhead is wiped 3. Carriage moves away

Spitting

• If an image printing is larger than (152cm) (60 inches), a dynamic wipe is performed every 2

swaths.

• If image to print smaller than 60 inches, a dynamic wipe is performed every 4 swaths.

In order to ensure the good health of the nozzles, the carriage is moved over the printhead cleaning

assembly, and the system performs a spitting operation where all the nozzles spit a small amount of

ink over the surface of the wiping cloth. There are two spitting modes:

• One static spit, when the carriage stops over the cleaning assembly, and is performed while

the heating and curing system warms to the target temperature and again before the first swath

of each job.

• One flying spit is performed with every swath of the carriage.

Priming

Priming is performed in order to ensure good health of the nozzles and to prevent the nozzles from

becoming blocked with dried ink. Ink floods out of the printhead onto the wiper cloth. This procedure

can be performed by selecting the option in the IPS of the printer.

The priming procedure is also performed on new printheads once it is installed or a hard cleaning

or clean and check is launched from the IPS.

Related tests, utilities, and calibrations

• 4.7.1 Printhead Cleaner Roll Height calibration: Page 436.

64 Printer systems

Page 63

• 4.7.2 Printhead Cleaner Horizontal Calibration Page 438

• 4.7.3 Printhead Cleaner Measurement Tool Page 439

• Printhead Cleaner menu: Page 369.

• 7.1 Printhead Cleaner Roll Advance Open Loop: Page 369.

• 7.2 Printhead Cleaner Roll Advance Close Loop: Page 371.

• 7.3 Printhead Cleaner Roll End Open Loop: Page 372.

• 7.4 Printhead Cleaner Roll End Close Loop: Page 373.

• 7.5 Printhead Cleaner High Calibration Default: Page 374

Service parts

• Printhead Cleaning Assembly: Page 467

Removal and installation

• Printhead Cleaning System: Page 703

Printhead Cleaner Roll Circuit Diagram

The following diagram explains the power and data connections needed to control the active components of the printhead cleaning assembly.

Printer systems

Printer systems 65

Page 64

Heating and Curing

Print Zone heating area

The heating (also known as drying) and curing system provide heat to the printing zone of the printer, this is

used in conjunction with the HP Latex inks in this printer. This is done by heating two sets of metal lamps

(resistors).

The 3 phase line is used exclusively to power this system

Printer systems

Heating

Curing

Components

• Three module support structure and reflecting plates

• One heating resistor for each heating module

66 Printer systems

Page 65

• Thermal safety switches for each heating module

• Temperature sensors

• Fan Array System:

Functionality

The Latex Inks

The ink vehicle is a blend of water (~70%), co-solvents for aqueous inks (<30%), and additives. The heating

and curing system is designed to work with the ink to make accurate, durable images.

Printing process

1. The printheads fire ink from the nozzles

2. The heating system evaporates water from the ink vehicle.

3. The curing system causes latex particles to form a continuous film on the media.

Printer systems

• An ink drop makes a colored dot on the media surface.

• Ink vehicle softens vinyl for good film adhesion.

• Ink forms a thin liquid film on the substrate surface.

• Pigment particles are dispersed throughout the film.

• Dot is ‘fixed’ to prevent color bleed and dot coalescence.

• Co-solvents evaporate.

• Latex particles coalesce.

• Pigments are encapsulated.

Curing System Fans

In front of each Curing module there is an array of seven fans which ensure the correct flow of air along

the printing and curing areas. The fans distribute the air evenly, avoiding image quality issues. The fans

also reduce the heat of the substrate once it is printed, avoiding any liquid condensation.

This air flow is required to:

• Improve the heat distribution of the lamps, which improves image quality (bleed/coalescence/

banding).

• Quickly reduce heat in the substrate when the printer has finished printing.

• Remove any possible liquid condensation.

NOTE: One or two non-consecutive failing fans can be compensated for by the others, but

when there are three, the customer will notice IQ issues in the area where the fans

are not functioning.

NOTE: Blocking the air path of the fans can also cause some image quality artifacts. This

can typically occur as the operations leans on the fans to see the PrintZone.

Printer systems 67

Page 66

• LX800 printer: The curing fans have a switch off system located on the front of the printer between

Printer systems

the curing fans and the left emergency stop. The switch turns on and off the two fans located on the

left and the fans located between the curing heaters (marked in red). This switch should only be used

when troubleshooting issues with the Curing.

Due to the high risk of the customer using the switch in error and causing a significant increase in

the temperature of the printhead without knowing it, the final implementation of this switch has been

changed (refer to the support tips document available in the support zone for further information of

this issue). The switch is now situated behind the metal protection bar (switch shown below). When

opening the switch, the fault signal is cut switching off the power to the FAN cable, this cable goes

to the 6 FANs described before.

Delta/Star Configuration

At installation the engineer must define the type of 3 phase connection, which will be based on the voltage

supplied in the country.

This configuration distributes the voltage from the 3 phase power line among the heating and curing

systems. If the set up is incorrect and the power is too high or not enough to able to provide sufficient heat,

it can damage or reduce the life of the lamps.

68 Printer systems

Page 67

Thermostats

Star/Wye Triangle connection

Delta connection

Ensure line adaptors are in

this side, otherwise the

circuit will short-circuit

Countries with a

high voltage

configuration (Star)

Countries with

a low voltage

configuration

(Triangle)

Thermostat

Thermostat Thermostat

V

R=

V

L

√

3

Example: VR=

380

V3

=220v

In Star configuration:

In Triangle configuration:

V

R=VL

V

R

V

L

380-400v

V

R

V

L

200v-240v

Each Heating and Curing module has a safety thermostat that cuts the power to the lamp if it exceeds a

certain temperature.

For more information, see the Installation Guide or refer to the Delta/Star configuring in Removal and

replace chapter: Page 727.

Printer systems

The tri-phase power cable is going from the static relay and connected to the star/delta configuration to

the point L22, L32 and L12 (connected at the top of the cables going towards the resistance).

The lamps are designed to work at 200-240v, the 3ph configuration performs the appropriate setup to

obtain this voltage to each resistor.

Printer systems 69

Page 68

Control circuit

1. Three phase power

arrives from the

customers installation

2. The temperature

control sensors sends

the control signal to the

power module

3. Power module sends

power to the lamp

system according to the

signals received from

the controller

4. Heat is

created and

applied to the

substrate

5. The temperature sensor

detects the heat of the media

and sends a signal to the

temperature controller

6. The temperature control

sensors adjust the control

signals according to the

values received from the

temp. sensor. This achieves/

maintains the expected temp

levels. Each substrate has a

preset value for the heating

and curing zones.

1. Indicates control signal to the

power module

2. Indicates control signal of the

safety line. This line must be

On to be able to have 3 phase

power in the power module

(contactor)

Up and down keys:

In the Home Page, this adjusts the set

point in the lower display. In other

pages, it changes the upper display to

a higher or lower value, or changes a

parameter selection.

Infinity key:

Press to back up on a level, or

press and hold to for two

seconds to return to the Home

Page

Left (Upper) Display:

In the home page, displays

the incoming temperature

value from the temp. sensor,

it also displays the value of

the parameter in the lower

display during menu

navigation

Percent units Indicator:

Light when the controller

is displaying values as

a percentage

Right (Lower) Display:

Indicates the set point or

output power value

during operation, (or the

parameter of the value

that is displayed

in the upper display

during menu navigation

Stand-by and printing

target temperature.

Warm-up % of power

supplied to the resistors.

Note: This value is then

scaled internally

according to the 3

phase AC voltage

configuration set in the

printer

Advance key:

Advances through

parameter prompts

Important note: The PID Controllers operate at 220 volts AC directly from the e-cabinet

The following diagram describes the temperature control system in the Heating and Curing modules.

Printer systems

Temperature PID controllers L65500/LX600

The temperature controllers (PID Controllers) use the readings from the Temperature Sensors to achieve and

sustain the target temperature. Whenever a PID controller is replaced, it has to be minimally configured to

enable communication with the printer.

70 Printer systems

Page 69

Temperature PID controllers LX800

Temperature units:

Indicates whether

the temperature is

displayed in

Fahrenheit or

Celsius

Advance key:

Advances through

parameter prompts