Page 1

4 Service Tests, Utilities & Calibrations

Introduction............................................................................................................. 268

• Phone Support ........................................................................................... 268

• Overview of Diagnostic Tests, Service Utilities & Service Calibrations ................ 268

• Diagnostic Tests ................................................................................. 268

• Service Utilities and Calibrations.......................................................... 270

• Service Menu Key Combinations ...................................................................271

• Diagnostic mode ................................................................................271

• Service Menu.................................................................................... 272

0. Purge & Setup Menu .............................................................................................274

• 0.1 Purge ISM .............................................................................................274

• 0.2 Fill Intermediate Tanks ........................................................................... 279

• 0.3 Purge Printer Tubes ................................................................................281

• 0.4 Purge Ink Used Menu ............................................................................ 284

• 0.5 3ph AC Volt Setup Menu....................................................................... 284

• 0.5.6 Voltage Configuration................................................................ 286

• 0.6 Force Normal Boot ............................................................................... 286

• 0.6 Force Normal Boot ............................................................................... 286

• 0.7 Prepare for transport ............................................................................. 287

• 0.8 Set ISM as Purged ................................................................................ 288

• 0.9 Set TRS as Purged................................................................................. 289

1.0 User Interface Menu ........................................................................................... 289

• 1.1 Front Panel............................................................................................ 289

2. Electrical Systems Menu .........................................................................................291

• 2.1 ECabinet...............................................................................................291

• 2.2 Main Electronics Menu.......................................................................... 295

• 2.2.1 Electronics Control ..................................................................... 295

• 2.2.2 Hard Disk Drive ........................................................................ 300

• 2.2.3 IO Information .......................................................................... 302

• 2.2.4 Unit Information ........................................................................ 303

• 2.2.5 71.X:19 Recovery ....................................................................... 304

• 2.2.6 Set SN and PN......................................................................... 304

• 2.3 Main PSU/OFF .................................................................................... 305

• 2.4 ECabinet Fault Signals........................................................................... 306

3. Substrate Path Menu............................................................................................. 306

• 3.1 Spindle Motors burning ......................................................................... 306

• 3.2 Front Spindle System ............................................................................. 307

• 3.3 Rear Spindle System............................................................................... 310

• 3.4 Drive Roller........................................................................................... 312

• 3.5 Pinch Switches....................................................................................... 313

• 3.6 Vacuum................................................................................................ 313

• 3.7 OMAS................................................................................................. 314

• 3.8 Free Fall Pinch Switch Test....................................................................... 315

• 3.9 Free Fall System..................................................................................... 316

• 3.10 Free Fall Relays .................................................................................... 316

• 3.11 Take Up Reel System.............................................................................. 317

• 3.11 Take Up Reel System.............................................................................. 317

4. Ink system............................................................................................................ 318

• 4.1 ISS Electronics ....................................................................................... 318

• 4.2 Air Pressure System................................................................................ 319

• 4.3 Ink Supply Connector ............................................................................ 320

• 4.4 IT Broken Bag Recovery..........................................................................321

• 4.5 Ink System Leakage............................................................................... 322

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 265

Page 2

• 4.6 ISS Electrovalves ...................................................................................323

• 4.7 Recovery from Ink Leakage .....................................................................324

• 4.9 Intermediate Tank Change Process ..........................................................324

• 4.10 Ink Cartridge LEDs ...............................................................................326

• 4.11 Ink Pres. Sen. Calib...............................................................................326

• 4.12 Ink Pressure At Pen. ..............................................................................328

• 4.13 Force Filling Tanks ................................................................................330

• 4.14 No Flow Error Recovery ........................................................................330

• 4.15 ISS Components Test Menu.................................................................... 331

• 4.15.1 Entry Front Valves...................................................................... 331

• 4.15.2 Entry Rear Valves...................................................................... 331

• 4.15.3 Inter Front Valves ......................................................................332

• 4.15.4 Inter Rear Valves.......................................................................332

• 4.15.5 Front (1) Air Pumps ....................................................................333

• 4.15.6 Rear (1) Air Pumps ....................................................................333

• 4.15.7 Relief Valves.............................................................................333

• 4.15.8 Air Pressure Sens ......................................................................334

• 4.15.9 Ink Pressure Sens ......................................................................334

• 4.15.10 Int T Front Brk Bag ...................................................................335

• 4.15.11 Int T Rear Brk Bag ....................................................................335

• 4.16 ISS Flushing Menu................................................................................335

• 4.16.1 Auxiliary Tool Pump...................................................................335

• 4.16.2 Operate Front Valves.................................................................336

• 4.16.3 Operate Rear Valves .................................................................336

• 4.17 Int Tanks Ink Life Cycles.........................................................................337

• 4.18 Int Tanks Ink Amount.............................................................................337

• 4.19 Int Tanks time refill................................................................................338

• 4.20 Check Ink Supplies..............................................................................339

Test, Utilities & Calibrations

5. Scan Axis Menu...................................................................................................339

• 5.1 Impelling system ....................................................................................339

• 5.2 PPS Menu.............................................................................................342

• 5.2.1 Move to Home Position ...............................................................342

• 5.2.2 Move to Load Position ............................................................... 343

• 5.2.3 Move to Printing Position ............................................................ 344

• 5.2.4 PPS Motor Check.......................................................................345

• 5.2.5 PPS Switch ............................................................................... 348

• 5.2.6 PPS Shims Values.......................................................................349

• 5.2.1 Move to Home Position ...............................................................342

• 5.3 Service Station......................................................................................349

• 5.2 PPS Menu.............................................................................................342

• 5.2.1 Move to Home Position ...............................................................342

• 5.2.2 Move to Load Position ............................................................... 343

• 5.2.3 Move to Printing Position ............................................................ 344

• 5.2.4 PPS Motor Check.......................................................................345

• 5.2.5 PPS Switch ............................................................................... 348

• 5.2.6 PPS Shims Values.......................................................................349

• 5.3 Service Station......................................................................................349

• 5.3.1 Shuttle Open Loop......................................................................349

• 5.3.2 Shuttle Close Loop ..................................................................... 351

• 5.3.3 Drop Detector Test......................................................................352

• 5.3.4 Service Station Cal.................................................................... 354

• 5.3.5 Drop Detector 12V On/Off .........................................................355

• 5.3.6 Drop Detector signals.................................................................356

6. Carriage Menu ....................................................................................................357

• 6.0 Trailing Cable test .................................................................................357

• 6.1 Carriage System Test ..............................................................................358

• 6.2 Move to Repair Position..........................................................................362

• 6.4 Line Sensor check..................................................................................363

• 6.5 Aerosol Fans.........................................................................................363

266 Service Tests, Utilities & Calibrations

Page 3

• 6.6 Force Priming Menu.............................................................................. 364

• 6.6.1 Force Priming Left ............................................................................... 364

• 6.6.2 Force Priming Centre.......................................................................... 366

• 6.6.3 Force Priming Right ............................................................................ 367

7. Print Head cleaning Menu..................................................................................... 369

• 7.1 PH Roll Adv Open Loop.......................................................................... 369

• 7.2 PH Roll Adv Close Loop ..........................................................................371

• 7.3 PH Roll End Open Loop ......................................................................... 372

• 7.4 PH Roll End Close Loop.......................................................................... 373

• 7.5 PH High Calib Default ............................................................................374

8. Heating and Curing Menu.................................................................................... 375

• 8.1 Heating ............................................................................................... 375

• 8.2 Curing ................................................................................................ 377

• 8.3 Heating Temp Profile............................................................................. 379

• 8.4 Curing Temp Profile .............................................................................. 383

• 8.5 Temperature Controller Calibration.......................................................... 387

9. Covers Menu....................................................................................................... 390

10. Diagn. Utilities menu ...........................................................................................391

Service Utilities........................................................................................................ 396

1. Service Utilities Menu ........................................................................................... 396

• 1.0 Force Diagnostic Mode.......................................................................... 396

• 1.1 Report Test Version................................................................................. 396

• 1.2 Electrical Systems Menu ......................................................................... 397

• 1.3 Substrate Path Menu.............................................................................. 402

• 1.4 Ink system Menu ................................................................................... 407

• 1.5 Scan Axis Menu ................................................................................... 408

• 1.6 Carriage Menu...................................................................................... 413

• 1.8 Heating and Curing Menu ...................................................................... 417

2. Service Prints Menu............................................................................................... 418

• 2.0 Printhead Alignment............................................................................... 418

• 2.3 Substrate Path Menu............................................................................... 418

• 2.5 Scan Axis Menu .................................................................................... 418

• 2.6 Carriage Menu ..................................................................................... 419

• 2.10 For Escalation Menu .............................................................................419

3. Reset Life Counters ............................................................................................... 420

4. Service Calibrations............................................................................................. 425

• 4.3 Substrate Path Menu ............................................................................. 425

• 4.3.1 Drive Roller Encoder Calibration.................................................. 425

• 4.3.2 OMAS Calibration.................................................................... 426

• 4.3.3 OMAS temp Calibration ............................................................ 427

• 4.3.4 Roller Calibration...................................................................... 428

• 4.3.5 Check Roller Calibration ............................................................ 429

• 4.3.6 Reset Roller Calibration.............................................................. 429

• 4.3.7 View Roller Calibration .............................................................. 430

• 4.5 Scan Axis Menu................................................................................... 430

• 4.5.1 Drop Detector Calibration........................................................... 430

• 4.5.2 Ser. Sta Compensation .............................................................. 432

• 4.6 Carriage menu..................................................................................... 433

• 4.6.1 Line Sensor Cal ......................................................................... 433

• 4.7 Print Head Cleaning ............................................................................. 436

• 4.7.1 PH Cleaner Height Calibration .................................................... 436

• 4.7.2 PH Cleaner Horizontal Calibration............................................... 438

• 4.7.3 PH Cleaner Measurement Tool .................................................... 439

5. Service Test Menu................................................................................................ 443

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 267

Page 4

Introduction

The objective of this chapter is to guide you through the procedures for diagnostic tests, service utilities,

and service calibrations. If you need to troubleshoot a problem with the printer, see page 87.

Phone Support

The customer can be guided to perform nearly all diagnostic tests, utilities, and calibrations. However,

there are some procedures that the customer should not do. The customer cannot perform the following:

• Save Factory Defaults

• Restore Factory Defaults

• Reset Maintenance Kit Usage

• Reset Life Counters

Overview of Diagnostic Tests, Service Utilities & Service Calibrations

Diagnostic Tests

Diagnostic tests are used to identify the root cause of a problem, and can be performed in response to

printer problems or a system error code being displayed. When performing a diagnostic test, the

objective is to find the failure and get a system error code or message that will help you with

troubleshooting.

Whenever you get a system error code, check it up in the System Error Codes section of Troubleshooting.

Most system error codes correspond to a specific fault in the printer, and in this section you will find the

Test, Utilities & Calibrations

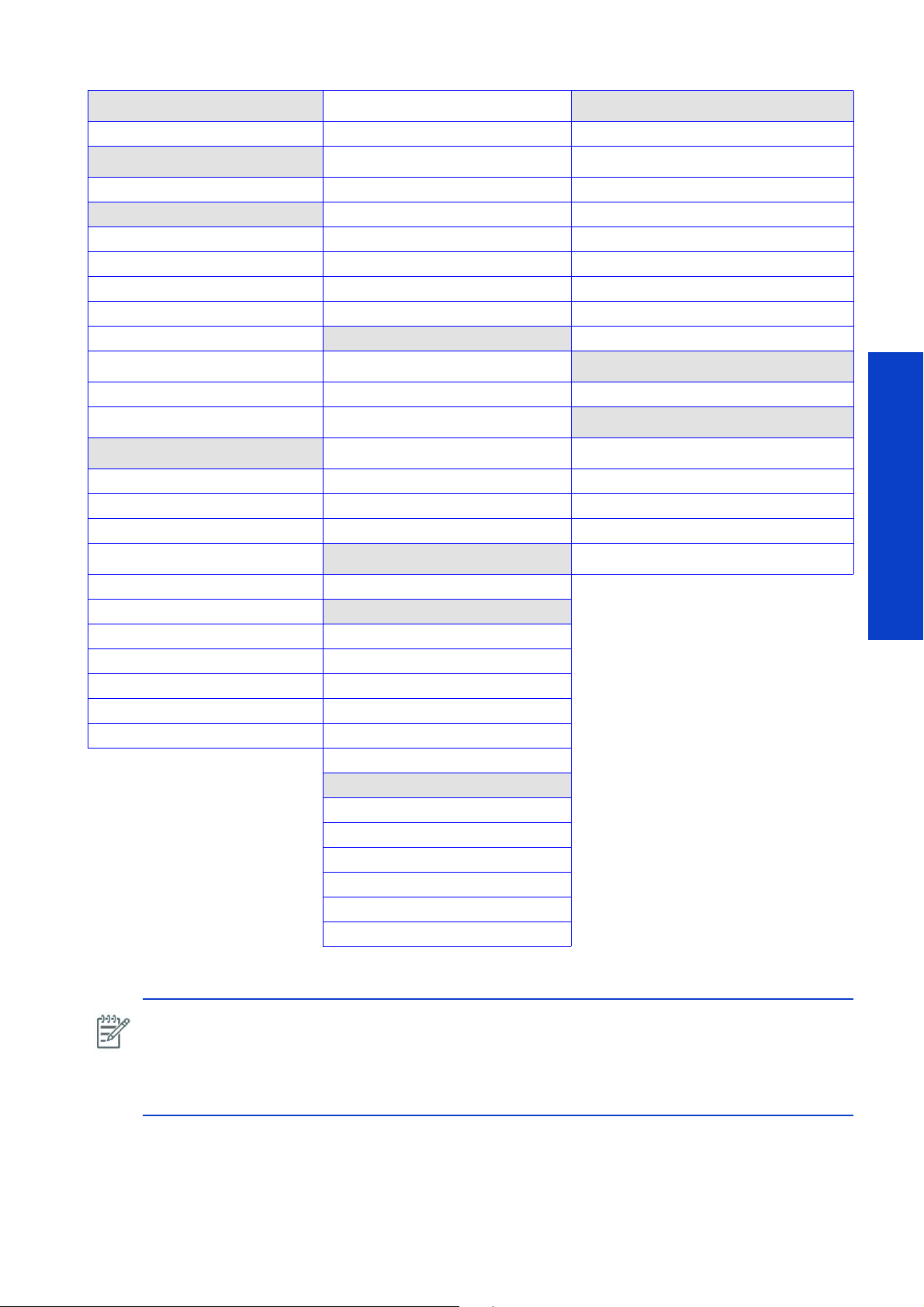

0. Purge & Setup Menu 4. Ink System Menu 6. Carriage Menu

0.1 Purge ISM 4.1 ISS Electronics 6.0 Trailing Cable test

0.2 Fill Intermediate Tanks 4.2 Air Pressure System 6.1 Carriage system test

0.3 Purge Printer Tubes 4.3 Ink Supply Connector 6.2 Move to Repair Position

0.4 Purge Ink Used Menu 4.4 IT Broken Bag Recovery 6.4 Line Sensor Check

0.5 3ph AC Volt Setup Menu 4.5 Ink System Leakage 6.5 Aerosol Fans

0.5.0 3ph AC Voltage 200V 4.6 ISS Electro valves

0.5.1 3ph AC Voltage 208V 4.7 Recovery Ink Leakage 6.6.1 Force Priming Left

0.5.2 3ph AC Voltage 220V 4.9 I Tank Change Process 6.6.2 Force Priming Centre

0.5.3 3ph AC Voltage 380V 4.10 Ink Cartridge LEDs 6.6.3 Force Priming Right

0.5.4 3ph AC Voltage 400V 4.11 Ink Pres. Sen. Calib. 6.6.4 Force Priming All

actions you need to perform to fix the problem, it may be a calibration to perform or you may need to

replace a part, see page 90.

For specific information and procedures regarding diagnostic tests, see page 274.

overview of the Diagnostic tests available, print this out and use it as a quick reference to the tests

available.

Shown below is an

Diagnostics

6.6 Force Priming Menu

0.5.5 3ph AC Voltage 415V 4.12 Ink Pressure At Pen

0.5.6 Voltage Configuration 4.13 Force filling I Tanks 7.1 PH Roll Adv Open Loop

0.6 Force Normal Boot 4.14 No Flow Error Recovery 7.2 PH Roll Adv Close Loop

0.7 Prepare for transport

0.8 Set ISM as Purged 4.15.1 Entry Front Valves 7.4 PH Roll Eng Close Loop

0.9 Set TRS as Purged 4.15.2 Entry Rear Valves 7.5 Calib std values

4.15 ISS Components test Menu 7.3 PH Roll Eng Open Loop

7.Print Head Cleaning Menu

268 Service Tests, Utilities & Calibrations

Page 5

1. User Interface Menu 4.15.3 Inter Front Valves 8. Heating and Curing Menu

1.1 Front Panel 4.15.4 Inter Rear Valves 8.1 Heating

2. Electrical Systems Menu 4.15.5 Front (1) Air Pumps 8.2 Curing

2.1 Ecabinet 4.15.6 Rear (2) Air Pumps 8.3 Heating Temp profile

2.2 Main Electronics Menu 4.15.7 Relief valves 8.4 Curing Temp profile

2.2.1 Electronics Control 4.15.8 Air Pressure Sens 8.5 Temp Controllers Calib Menu

2.2.2 Hard Disk Drive 4.15.9 Ink Pressure Sens 8.5.1 Heating Current Cali

2.2.3 Conectivity Check 4.15.10 Int T Front Brk Bag 8.5.2 Curing Current Calib

2.2.4 Unit Information 4.15.11 Int T Rear Brk Bag 8.5.3 Reset Heating Calib

2.2.5 SE 71.X:19 Recovery

4.16 ISS Flushing Menu 8.5.4 Reset Curing Calib

2.2.6 Set SN and PN 4.16.1 Auxiliary Tool Pump

2.3 Main PSU ON/OFF 4.16.2 Operate Front valves 9.1 Cover/Switch Sensor

2.4 e-Cabinet Fault signals 4.16.3 Operate Rear valves

3.Substrate Path Menu 4.17 Int Tanks Ink Life Cycles 10.0 Enable/Diasable Logs

3.1 Spindle sys 4.18 Int Tanks Ink amount 10.1 Force Normal Boot

3.2 Front Spindle System 4.19 Int Tanks time refill 10.2 Report Tests Version

3.3 Rear Spindle System 4.20 Check Ink Supplies 10.3 Save NVM To File

3.4 Drive Roller

3.5 Pinch Switches 5.1 Impelling System

3.6 Vacuum

3.7 OMAS 5.2.1 MoveTo Home Position

3.8 Free Fall Pich Switch Test 5.2.2 MoveTo Load Position

3.9 Free Fall system 5.2.3 MoveTo Printing Pos

3.10 Free Fall Relays 5.2.4 PPS Motor Check

3.11 Take up Reel System 5.2.5 PPS Switch

5. Scan Axis Menu 10.4 Restore NVM From File

5.2 PPS Menu

5.2.6 PPS Shims Values

5.3 Service Station

5.3.1 Shuttle Open Loop

5.3.2 Shuttle Close Loop

5.3.3 Drop Detector test

5.3.4 Service Station Cal

5.3.5 Drop detector 12V On/Off

5.3.6 Drop detector signals

9. Covers Men u

10.Diagn. utilities menu

Tests, Utilities & Calibrations

NOTE: Most diagnostic tests are only available when you start the printer in Diagnostic Mode. This

special bootmode does not require full initialization of the printer, and it’s only function is to allow you to

perform the tests.

NOTE: Except for internal service prints, you cannot use the printer in the normal way when the printer

is in diagnostic mode.

Service Tests, Utilities & Calibrations 269

Page 6

Service Utilities and Calibrations

Service utilities are a set of operations that help you service, clean, and maintain the printer, and can

occasionally assist you with troubleshooting.

For specific information and procedures regarding service utilities, see page 396.

Service calibrations allow you to calibrate printer components and settings to ensure optimal

performance, and are performed after removing or replacing components or in response to system error

codes or image quality problems. For specific information and procedures regarding service utilities, see

page 425.

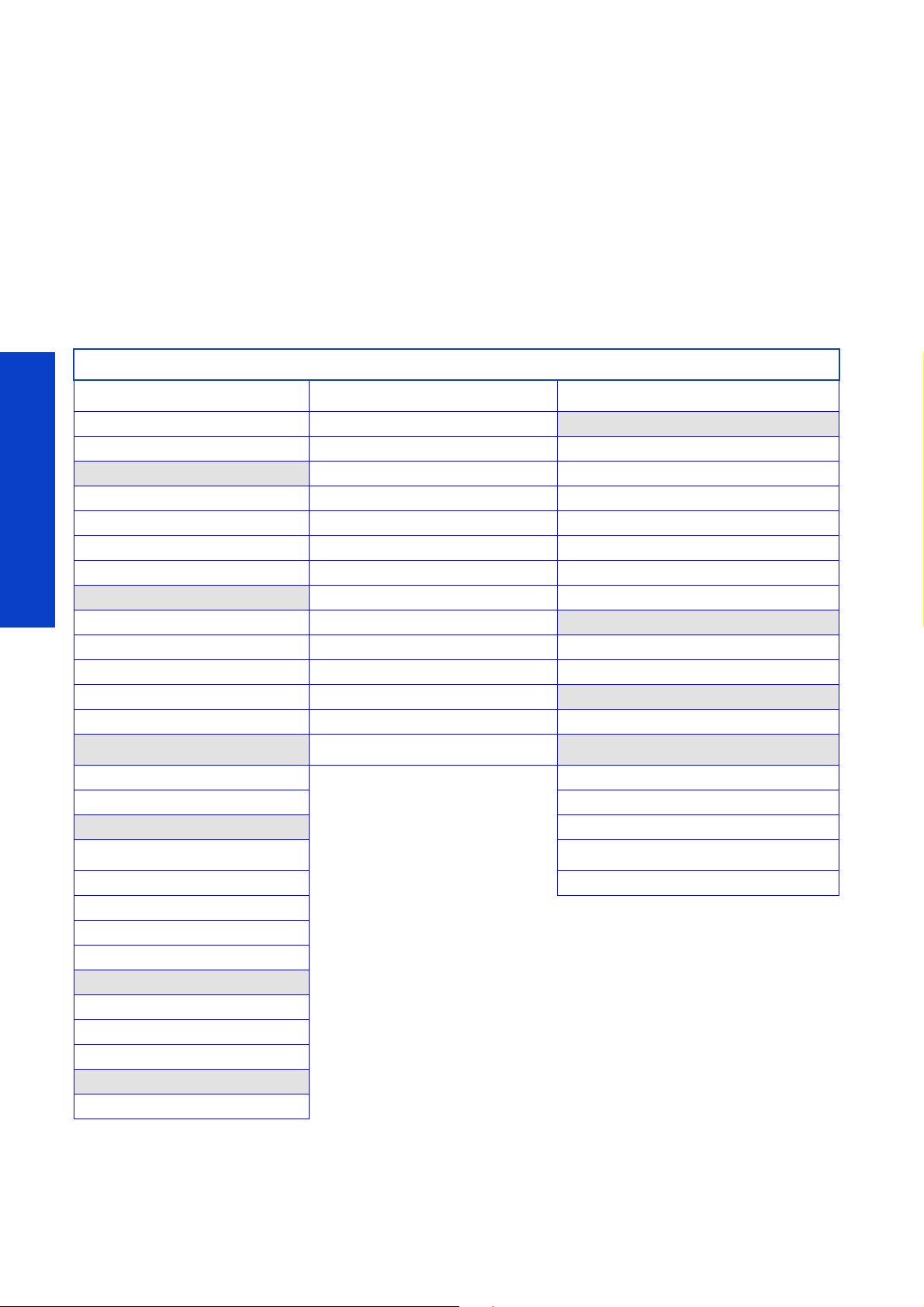

Shown below is an overview of the Service Utilities and Calibrations available, print this out and use it as

a quick reference to the features available to you.

Service

1. Service Untilities Menu 2. Service Prints Menu 4. Serv. Calibrations Menu

1.0 Force Diagnostics Mode 2.0 Printhead Alignment

1.1 Report Test Version 2.0.1 40 ips 600x1200 4.3.1 Drive Roller encoder Calib

1.2 Electrical systems menu 2.3 Substrate Path Menu 4.3.2 OMAS Calibration

1.2.1 Set Date and Time 2.3.4 Substrate Expansion Check 4.3.3 OMAS temp Calibration

1.2.2 Enable/Disable Firewall 2.5 Scan Axis Menu 4.3.4 Roller Calibration

1.2.3 Enable/Disable Logs 2.5.1 Scan Axis Check 4.3.5 Check Roller Calibration

1.2.4 Input/Output 2.5.2 PPS Check 4.3.6. Reset Roller Calibration

1.3 Substrate Path Menu 2.6 Carraige Menu 4.3.7 View Roller Calibration

Test, Utilities & Calibrations

1.3.1 Turn Drive Roller 2.6.1 Nozzle Check

1.3.2 Enable/Disable SCAPA 2.10 For Escalation Menu 4.5.1 Drop Detector Cal

1.3.3 Enable/Disable OMAS 2.10.1 Odd 2 Even Sad 4.5.2 Ser. Sta Compensation

1.3.4 OMAS Sensor Check 2.10.2 Pen2PenSad No Adv

1.3.6 OMAS led Check 2.10.3 Pen2PenPad No Adv 4.6.1 Line Sensor Cal

1. 4 In k S ys t em M e n u 3. Reset Life Counters Menu 4.7 Print Head Cleaning

1. 4 .1. I n k P re s su r e va l u e s 4 . 7.1 P H Cl e a n e r H e i g ht C a l ib

1.4.2 Air Pressure sensors 4.7.2 PH Cleaner Horizontal Calib

1.5 Scan Axis Menu 4.7.3 PH Cleaner PH Measurment Tool

1.5 .1 SA X Fr i ct i o n T e st 5. Service Tests Menu

4.3 Substrate Path Menu

4.5 Scan Axis Menu

4.6 Carriage Menu

1.5.2 Force Drop Detection 5.0 Show Test Messages

1.5 . 3 G h o st D r o p D e t e ct i o n

1.5.4 PH Stability Check

1.5 . 5 R e se t E r ro r H id i n g

1. 6 Ca r ri a g e Me n u

1.6.1 Open/Close Color sensor

1.6.2 Color Sensor Check

1. 6. 3 Ae r o so l Fa n s

1.8 Heating & Curing Menu

1.8.1 Heating Curing Temp

270 Service Tests, Utilities & Calibrations

Page 7

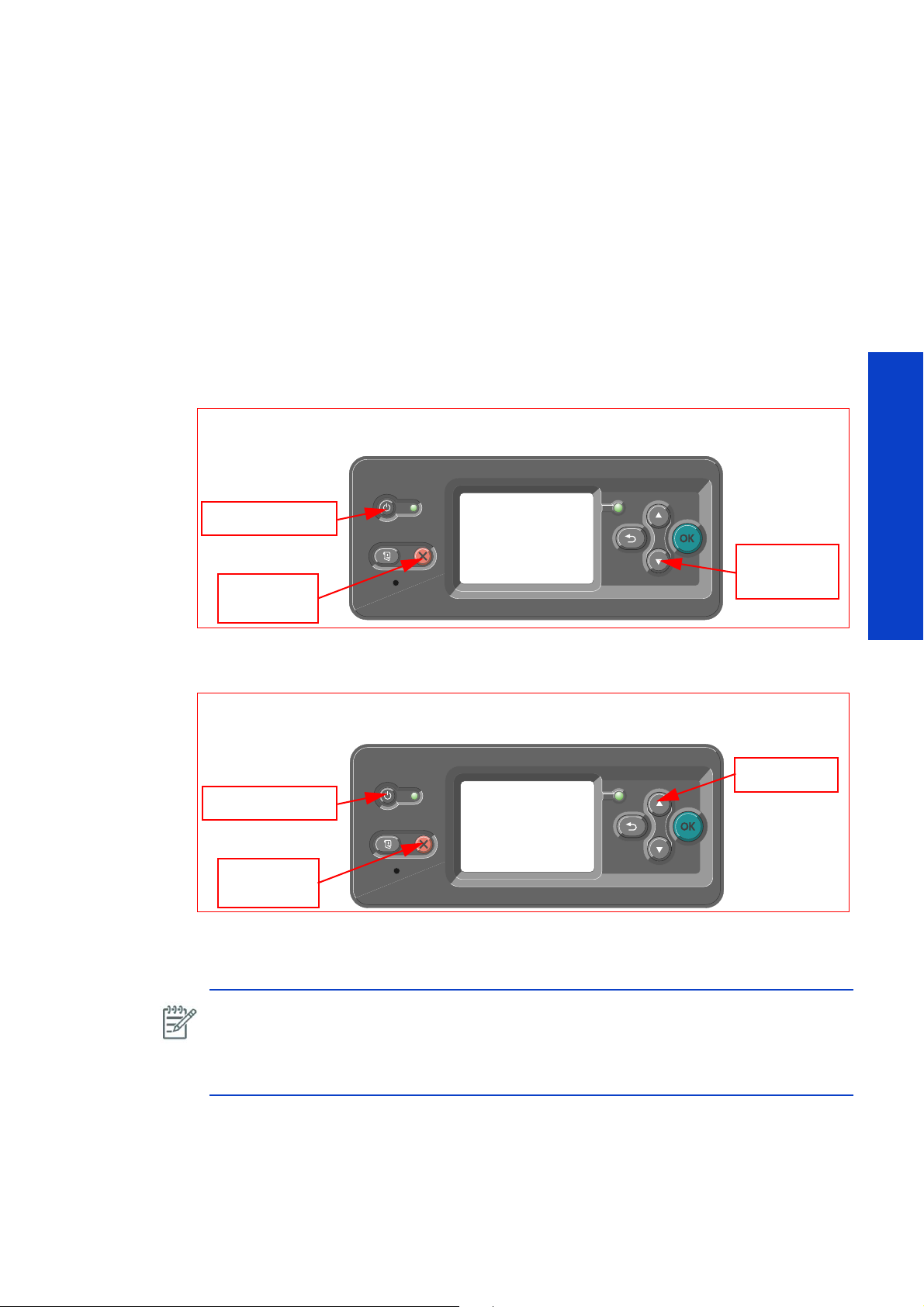

About the Service Menu

Hold Cancel

key

Switch Printer ON

Hold DOWN

key

P

H

O

N

E

SU

P

P

O

R

T

Hold Cancel

key

Switch Printer ON

O

N-

S

I

T

E

R

EPA

I

R

Hold UP key

The Service Utilities, Reset Life Counters, and Service Calibration menus are only available from the

service menu.

This special menu is ‚’hidden’ and requires a special access key combination to access it. Two menus

exist, one for the user and one for the service engineer, in order to prevent the user from changing

important settings like life counters or factory defaults.

Service Menu Key Combinations

Diagnostic mode

1. For Call Agents who will request the User to Perform certain troubleshooting action, hold the Down

arrow key and the Cancel key down and switch the printer ON using the front power switch. Watch the

LED light on the Front Panel.

Tests, Utilities & Calibrations

2. For On-Site Engineers, hold the Up arrow key and the Cancel key down and switch the printer ON

using the front power switch.

3. First it will be red for short time, then green for a longer time, then it will be off, and finally it will start

flashing green. As soon as it lights up green after being off, quickly release all three keys.

NOTE: If you restart the printer from the ACB-1 breaker switch or you do not press the service

key combination in time, press and hold the ON key for 1 second and release the key, the

printer will switch off within the coming 3-5 seconds. Do NOT leave the ON key pressed too

long, or the printer will restart again immediately. If this occurs, just press again the ON key

for 1 second and release it => the printer will switch off within the coming 3-5 seconds.

Service Tests, Utilities & Calibrations 271

Page 8

4. Once inside the Service Tests Menu use the Arrow keys to scroll through the Diagnostics menu. Press the

Enter key to begin a specific test when the required Service Test is highlighted.

Common reasons for failing to boot in diagnostic mode

It is important to press and hold the buttons exactly as described here.

1. With the Down (customer) or UP (CE) and Cancel keys already pressed and kept down, press the

On/Off button and keep it pressed until you see the green light switching on for the 2nd time..

2. A moment after pressing the On/Off button the green light comes on. Do not release the On/Off

button at this time. If you do then the diagnostic menu does not open and the printer starts normally.

• Keep all three buttons pressed down until you hear the beep sound.

• Only at the end of the boot process do you know if the printer has booted in diagnostic mode or in

normal mode.

• In case you do not have enough time, after having turned ON the big ON/OFF switch, to press the

3 keys -> hold down on the ON/OFF button (#3) for 1 second and release it; the printer will

switch off within the coming 3-5 seconds, and then you can start again the sequences (by pressing

on 3 buttons).

Test, Utilities & Calibrations

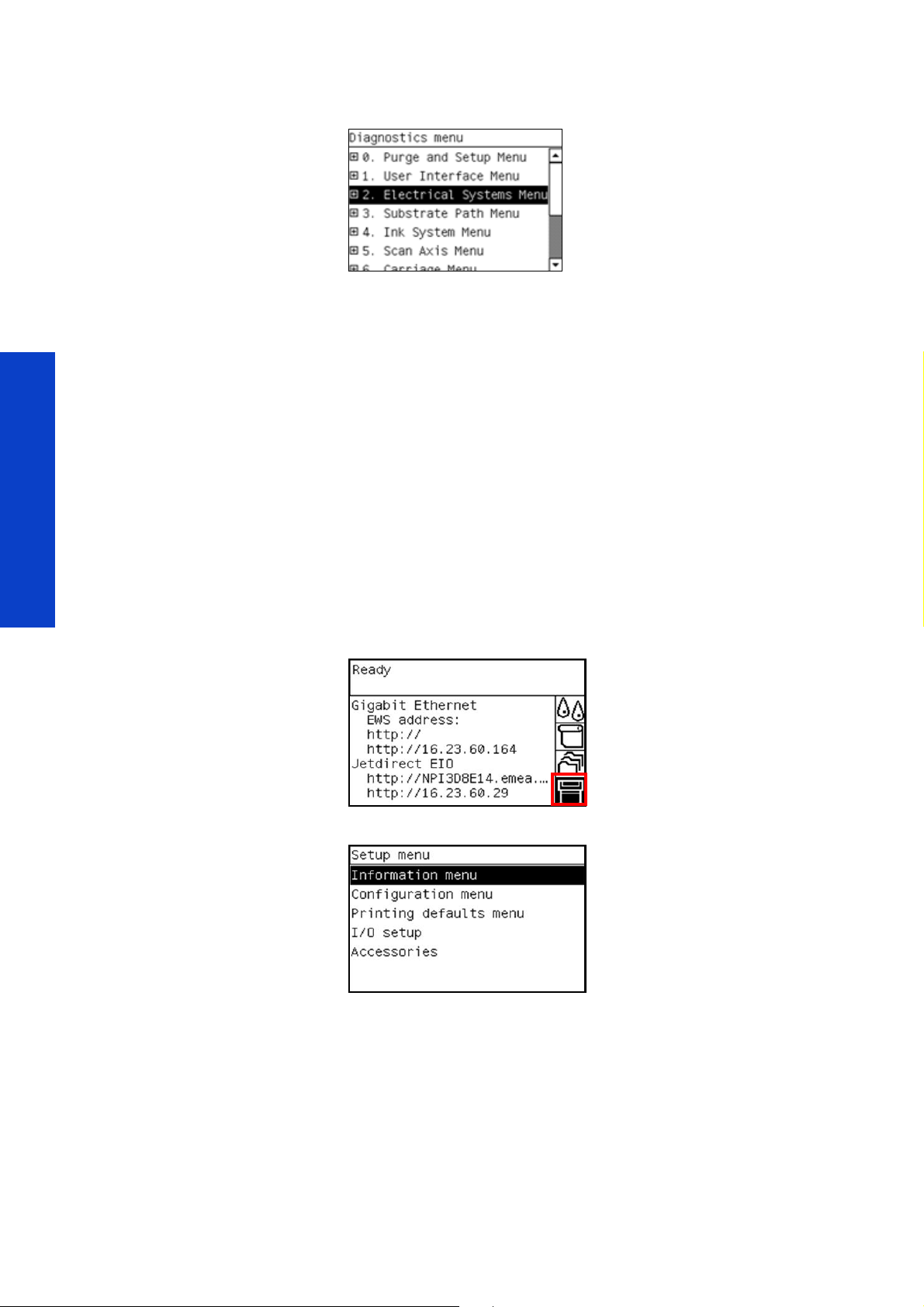

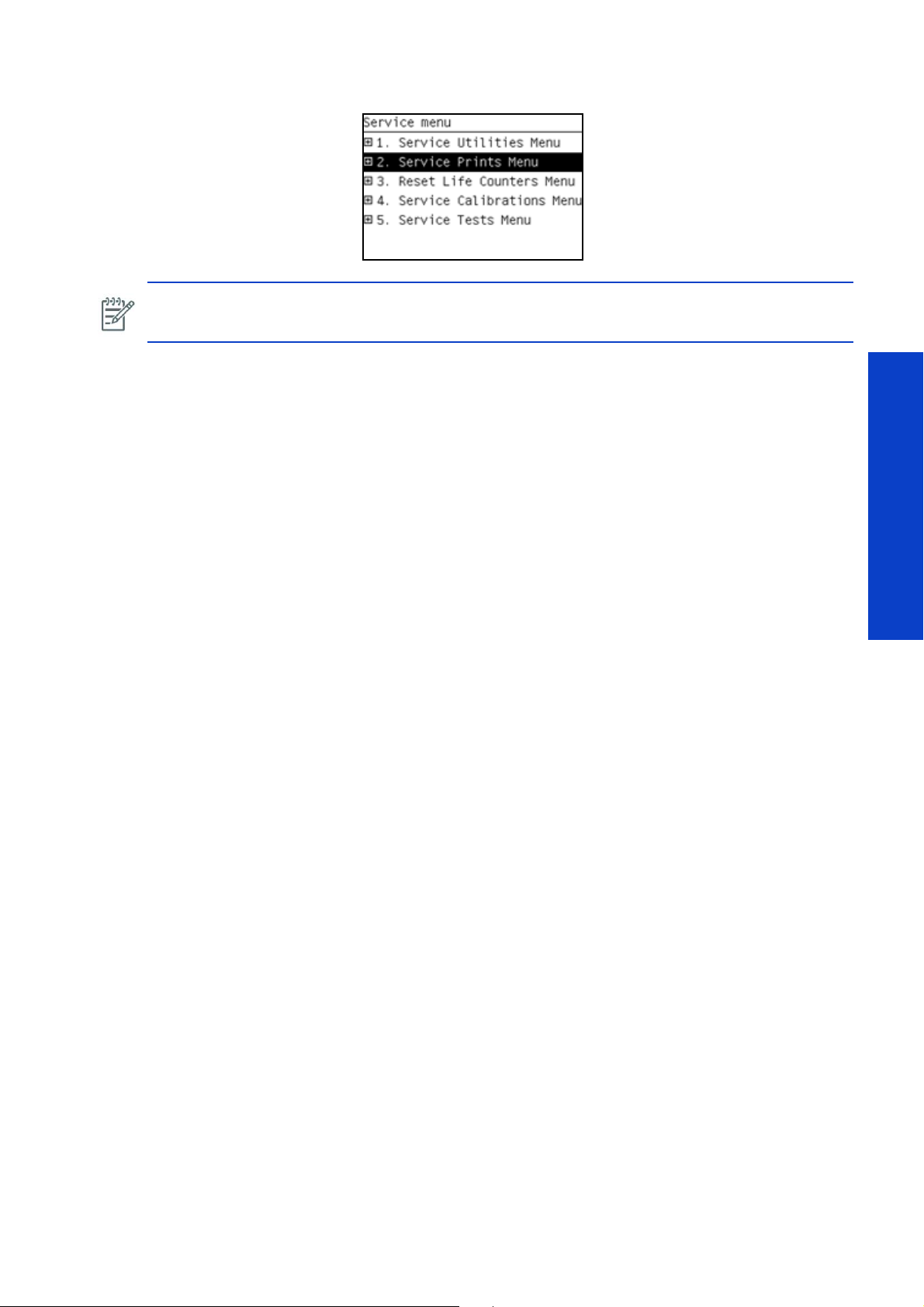

Service Menu

1. Select the setup icon from the Front Panel and press Enter.

The Printer displays the following menu:

2. Depending on the situation:

• Phone Support: Press and hold the Down key, and press the Cancel key at the same time.

• Onsite repair: Press on the Up key, and press on the Cancel key at the same time.

272 Service Tests, Utilities & Calibrations

Page 9

3. The Service menu is displayed.

NOTE: In case of 'phone support', the 'reset life counters Menu' is not displayed.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 273

Page 10

Diagnostic Tests

If you need to troubleshoot a problem with the printer, see page 87.

Diagnostic tests help you determine which component is failing when you have a problem. This section

guides you through the diagnostic test procedures and provides information about each test.

0. Purge & Setup Menu

0.1 Purge ISM

Description

This is used to purge the Ink Supply Module. The test guides step by step the user to fill the tubes of the

ISM side with ink by one of two ways. This procedure is only performed during the installation process,

further details are available in the ‘Installation Guide’.

• Follow the user with instructions to fill the column of ink between Ink Cartridge connector and the

purge port.

• Opening the entry electrovalves and letting the ink fill the ISM system up to the quick connector.

NOTE: The printer can tolerate up to 20cm of air (the length of the bubble) in the tubes per

color, from the main ink electrovalve to the printhead, small pockets of bubbles are okay.

CAUTION: From the cartridge connector to the main ink electrovalve: NO bubble is accept-

able, or the printer can display an error message ‘unexpected empty cartridge’ (while there is

Test, Utilities & Calibrations

ink in the cartridge). The tube from the ISM ink tray to the ink cartridges are not transparent. In

case of any doubt, do not hesitate to refill the ink within the tubes (only this portion of tube).

CAUTION: Do not apply too much force the syringe or any tube or connection. Gently

manipulate the syringe during insertion to ink cartridges, purging ports, or printhead connec

tions.

Procedure

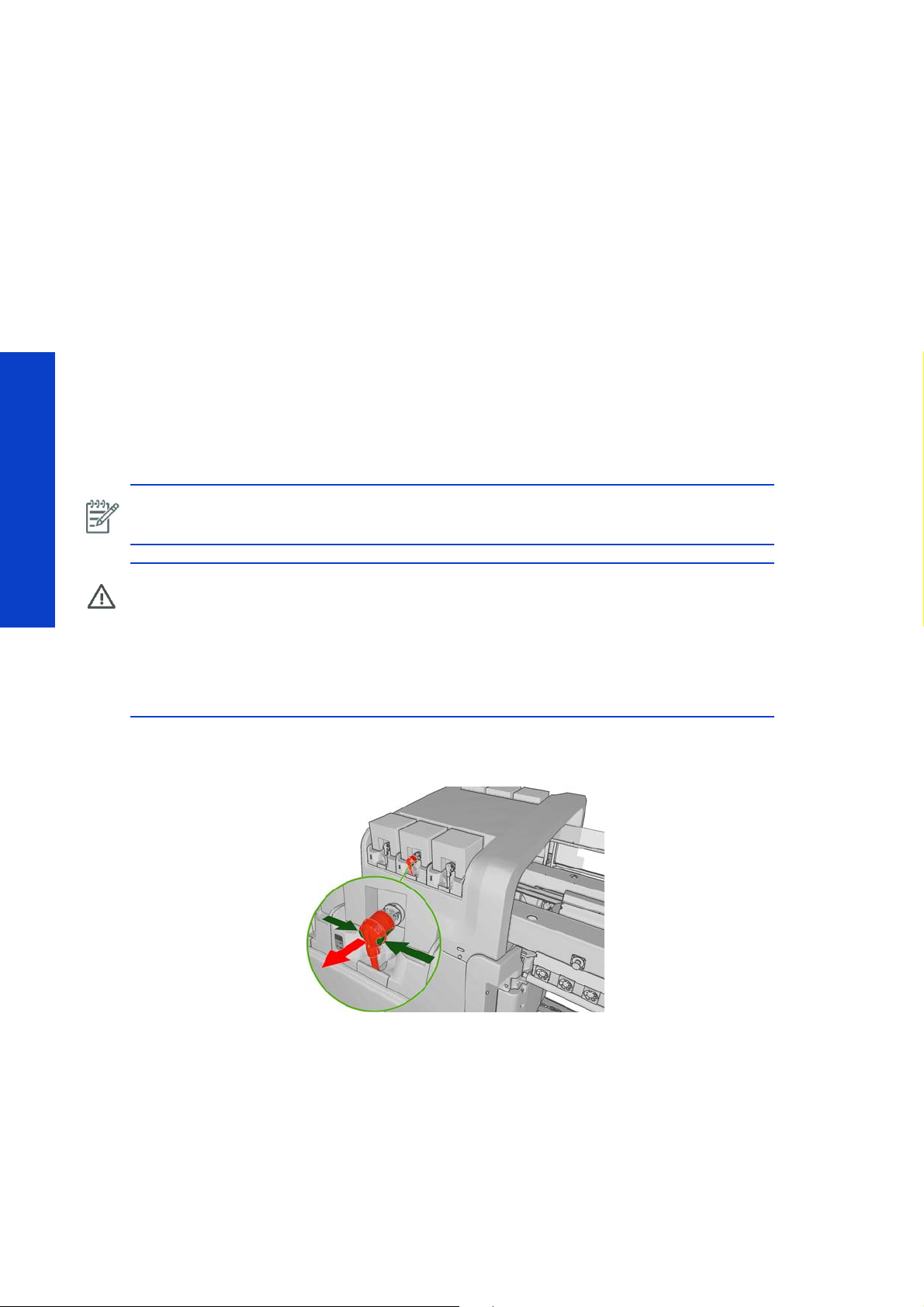

1. Disconnect the ink cartridges.

-

2. Connect the purge bags to the printer.

274 Service Tests, Utilities & Calibrations

Page 11

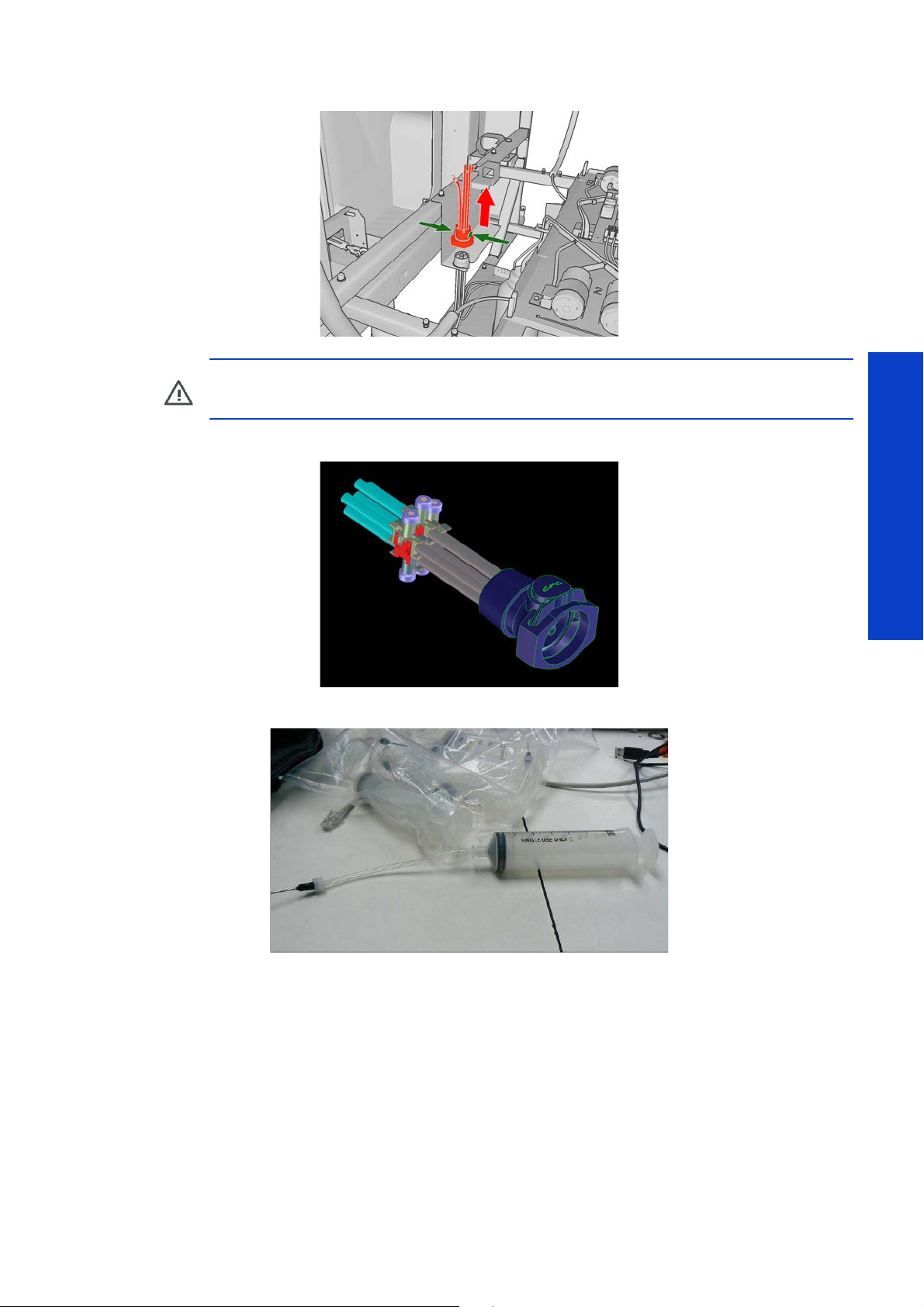

3. Disconnect the quick connector from the ISM..

CAUTION: The quick connector should always be handled with care and held by the pro-

vided protective tube, so as to avoid any over-stress on its internal fittings.

4. Connect the Purger Quick Connector to the ISM.

5. Screw the needles into all the syringes.

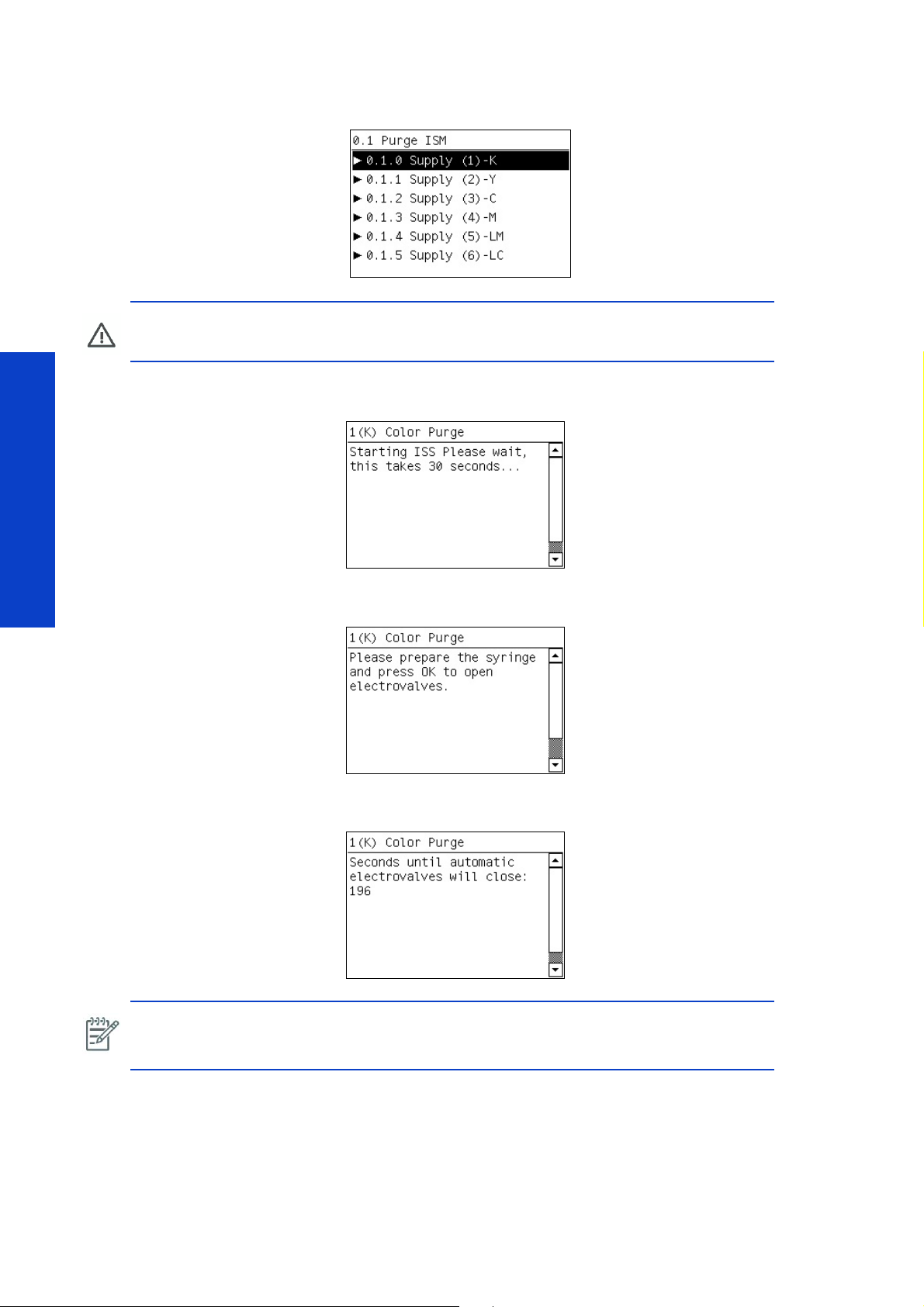

6. Go to the Diagnostics menu> 0. Purge Menu & Set Up Menu> 0.1 Purge ISM.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 275

Page 12

7. There is a special menu selection for each color line, each has the same identical operation, press ok to

select the color to purge

CAUTION: When selecting the option in the following procedure, do not push the ok button

more than once per selection.

8. The front panel will display the following message, in the initialization period, the electrovalve of the color

selected will open

.

and close several times to ensure it is functional.

9. The front panel displays the following message, press the ok key to open the electrovalve of the selected

Test, Utilities & Calibrations

color.

10. The front panel displays the time remaining that the electrovalve is open and beeps to indicate the open

status (in total 200 seconds)

NOTE: At this moment the EV will open if ink does not go beyond the EV, the part might

require a repair procedure. Try to open and close it several times using the 4.15.X service

procedure.

.

276 Service Tests, Utilities & Calibrations

Page 13

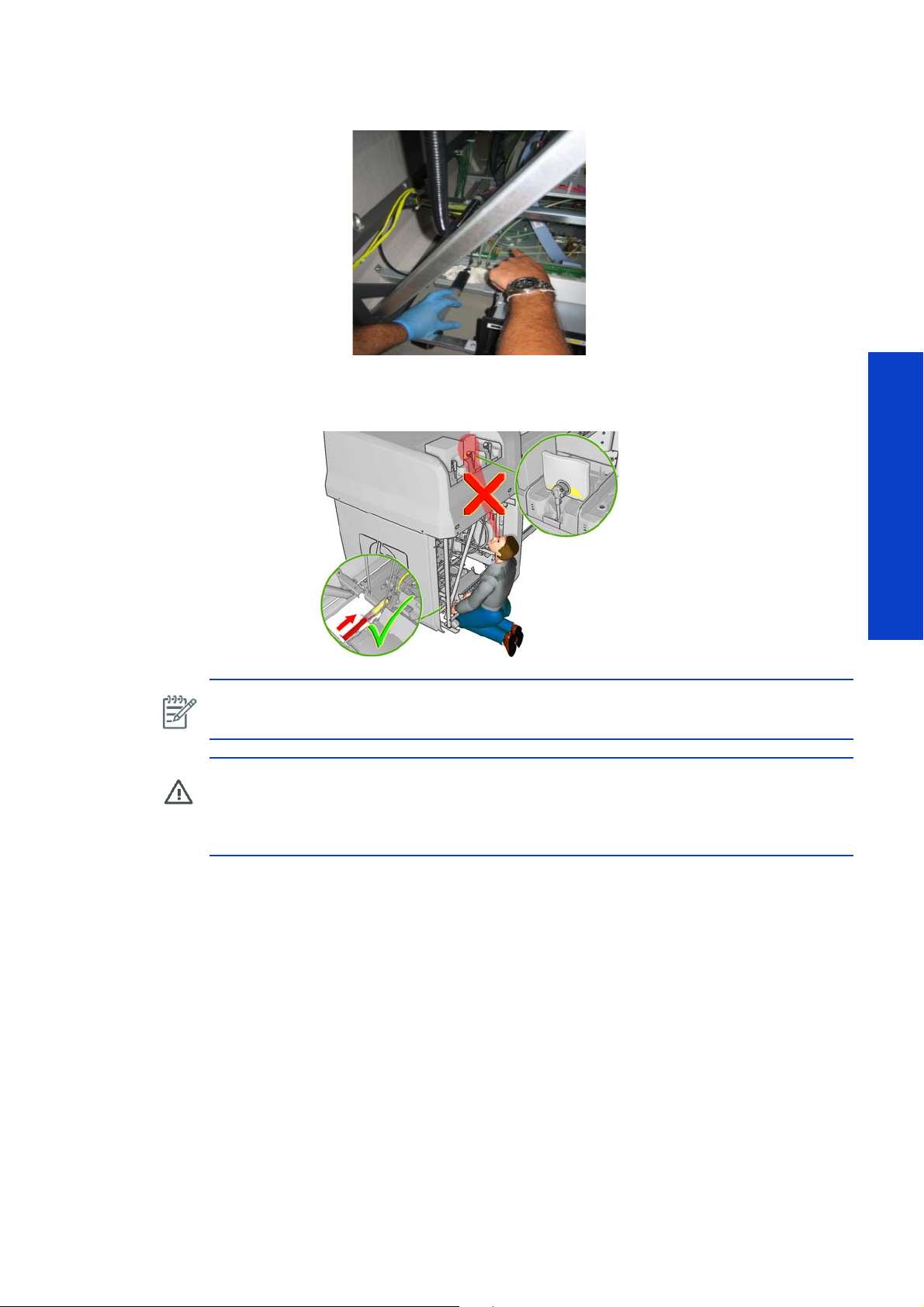

11 . Insert the syringe in the purging port (next to the ink pressure sensor) for the color selected, and slowly

push the ink until it clearly reaches the quick connector purger (first) and the purge bags (second).

If you run out of ink in the syringe, it is okay to refill the syringe from the ink cartridge. Keep track of how

much ink you remove from the ink cartridge, because you will be asked to report the quantity of ink taken.

Make sure the electrovalves are still open.

NOTE: Make sure you insert the syringe far enough into the port so that the tip of the syringe

engages with a small spring inside the port.

CAUTION: Never look away from the syringe. If you need to look at the purge bags or some-

thing else in the room, set down the syringe first. The ink system components are easily broken.

CAUTION: Do not insert the syringe if the electrovalves are not open, this will be noticeable

as there will be too much resistance when inserting the syringe.

• 1 = K

• 2 = Y

• 3 = C

• 4 = M

• 5 = LM

• 6 = LC

12. Remove the syringe from the purge port with a cloth to prevent spills.

13 . Press OK on the Front Panel to close the electrovalves.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 277

Page 14

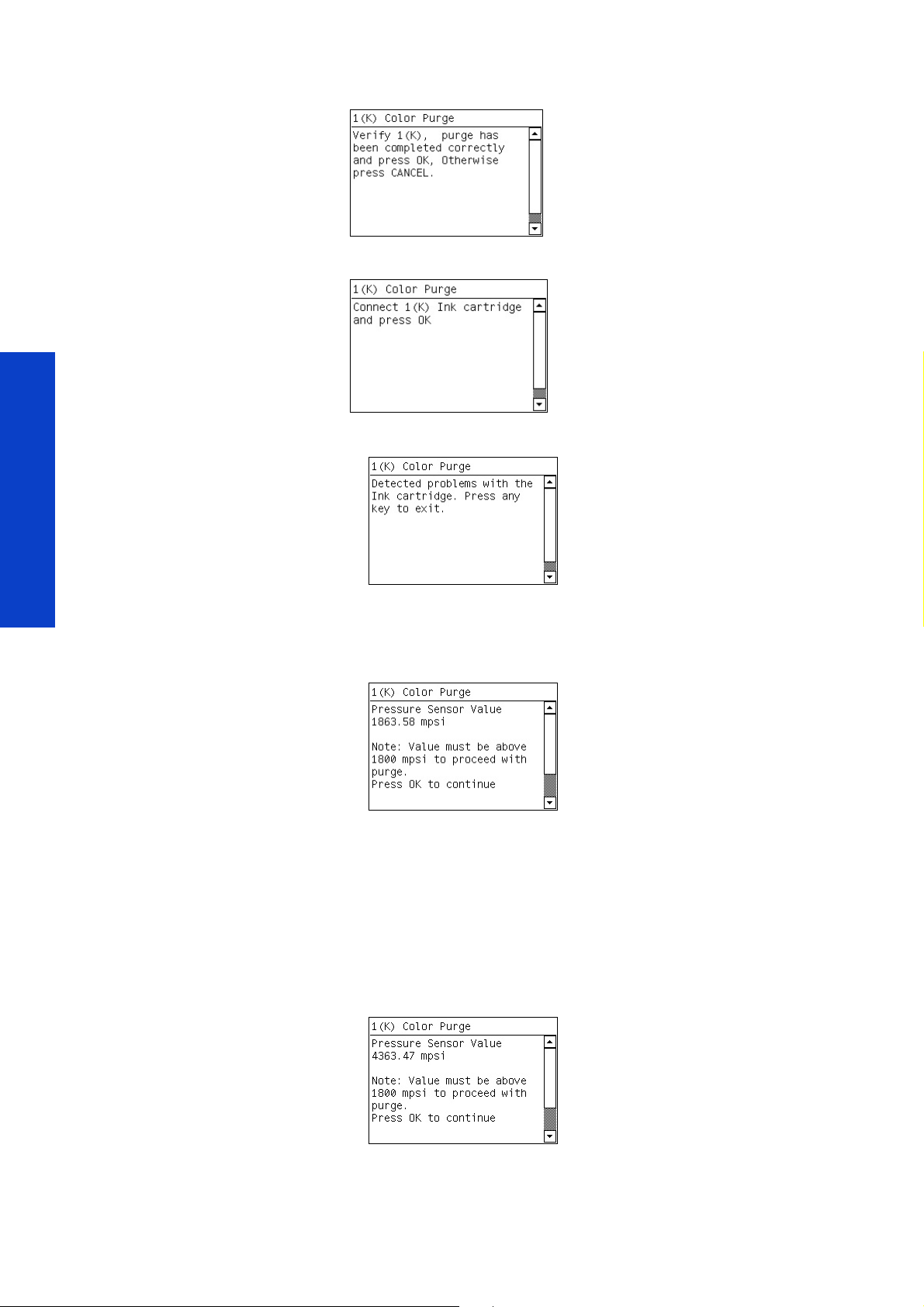

14 . Press OK to confirm that you have finished purging the ink tubes for the color selected.

15 . Disconnect the purge bag and connect the ink cartridge, and then press OK.

16 . If there is a connection error at this point the following message will be displayed.

Test, Utilities & Calibrations

Check the ink cartridge is correctly connected. Check the connector switch and cable connections (red

cable) to the ISM PCA

17. If there is no error at this point the following message is displayed.

The pressure must be above 1800 mpsi, this is to ensure that the ink pressure sensor is reading a good

value (1800mpsi is for a ink cartridge almost empty), this check prevents bubbles of air in the line (which

causes low ink pressure) which causes the system to mark the ink cartridge as empty. As in the next step

the printer will access the acumen and write it as empty if the pressure is very low.

For completely new ink cartridges the value should be around 2200-2300 mpsi. If the value does not

match the expected values, repeat the purging process of the column.

18 . If there is a failure with the Ink Pressure Sensor or a cable is disconnected, the front panel will display that

the ink pressure is above 3000 mspi, such as the message shown below.

278 Service Tests, Utilities & Calibrations

Page 15

If the above message is displayed, check the connections of the Ink Pressure Sensor cable. Check for any

similar problems with the other colors that share the same ink pressure sensor board, if these color also

have a problem, replace the board.

19. If there is no error at this point the following message is displayed.

20. Enter the quantity of ink that was extracted from the ink cartridge (typically this is 60ml), press the ok key

when this is done.

NOTE: Entering the amount of ink taken from the ink cartridge correctly will have an impact

on the precision of the remaining ink that is displayed to the customer. The out of ink message

is independent of this value, which is solely dependant on the value detected by the ink

pressure sensor.

21. The following screen is displayed when the values have been entered.

NOTE: Checks are made of the values of the ink pressure sensor before finishing the

procedure. The reason for this is to ensure correct calibration before writing to the supply

acumen as empty (pressure values too low which might be due to air in the column of ink

between the supply and the ink pressure sensor). This check prevents displaying the ink

cartridge with incorrect remaining ink.

22. Select the next color and repeat.

23. Remove the quick connector purger.

0.2 Fill Intermediate Tanks

Description

This procedure is used to fill a new set of intermediate tanks with ink and should only be performed during

the printer’s installation (refer to the installation guide for details). The procedure first pressurizes and then

depressurizes the tanks to check the condition of the inner bag of the intermediate tank. The procedure

then fills the intermediate tanks with ink. This second procedure is time based and performed on one side

(intermediate tanks X.1) after the other (intermediate tanks X.2). While one side is refilled the other is semipressurized to control the refill. For the procedure to be performed there must be at least 1.5L of ink in the

ink cartridges, otherwise the system will halt the procedure.

Tests, Utilities & Calibrations

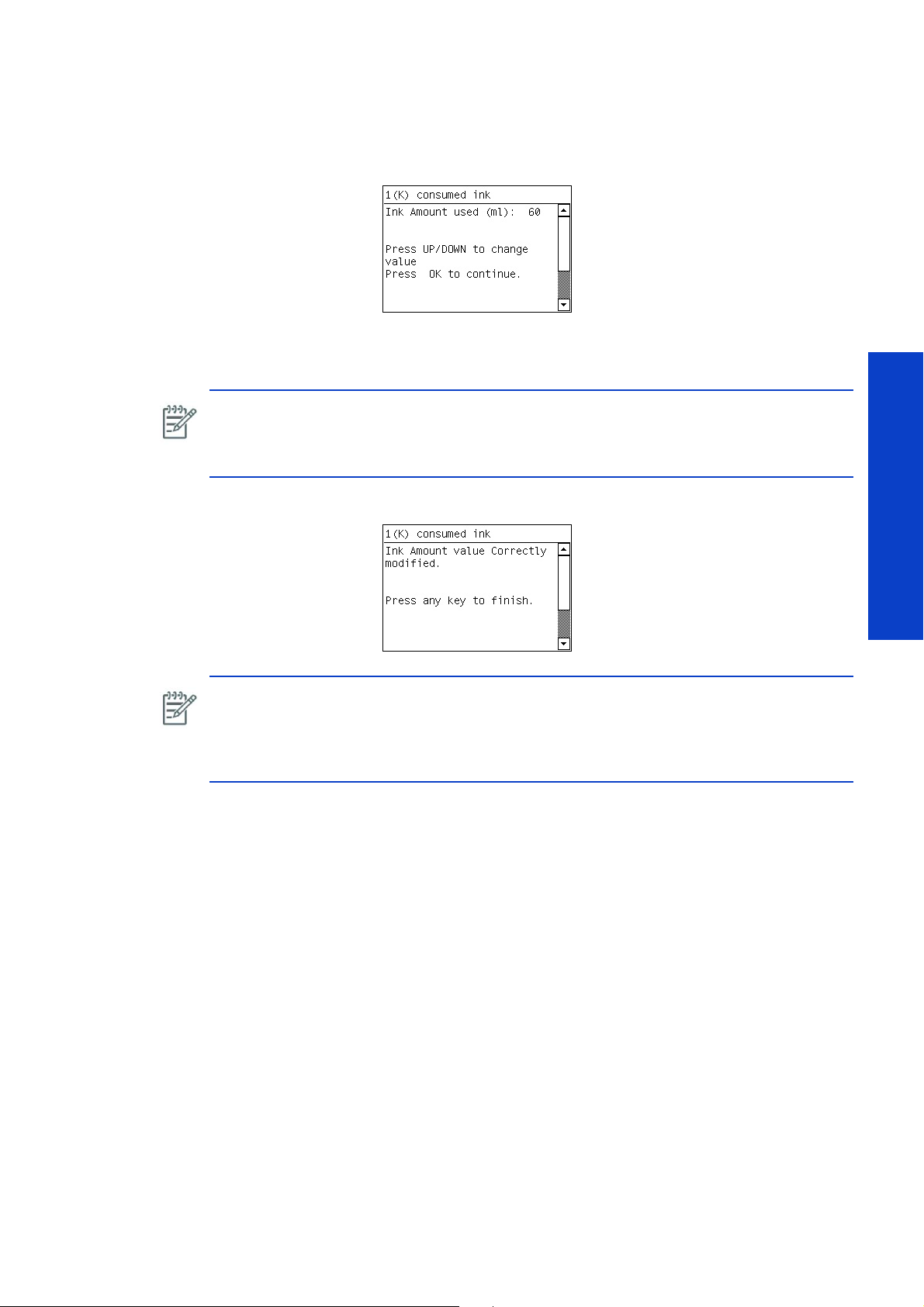

Procedure

1. Go to the Diagnostics menu 0. Purge and Setup Menu > 0.2 Fill intermediate tanks.

Service Tests, Utilities & Calibrations 279

Page 16

2. Ensure that all the intermediate ink tanks are installed, apply the labels (match them to the labels on the

printer), and confirm that they are installed from the Front Panel.

NOTE: This procedure sets the amount of ink in the intermediate tanks, if the process is

interrupted or not fully performed for any reason, the procedure is forced to run again until it is

successful.

3. The following messages are displayed while the printer starts the various subsystems in order to perform

the procedure.

The refill process takes approximately 25 minutes.

4. The printer unfolds the intermediate ink tanks. When the process is finished, press any key to continue.

Test, Utilities & Calibrations

5. The printer fills the intermediate ink tanks. When the process is finished, check that the ink cartridge LED

is green and press any key to continue.

280 Service Tests, Utilities & Calibrations

Page 17

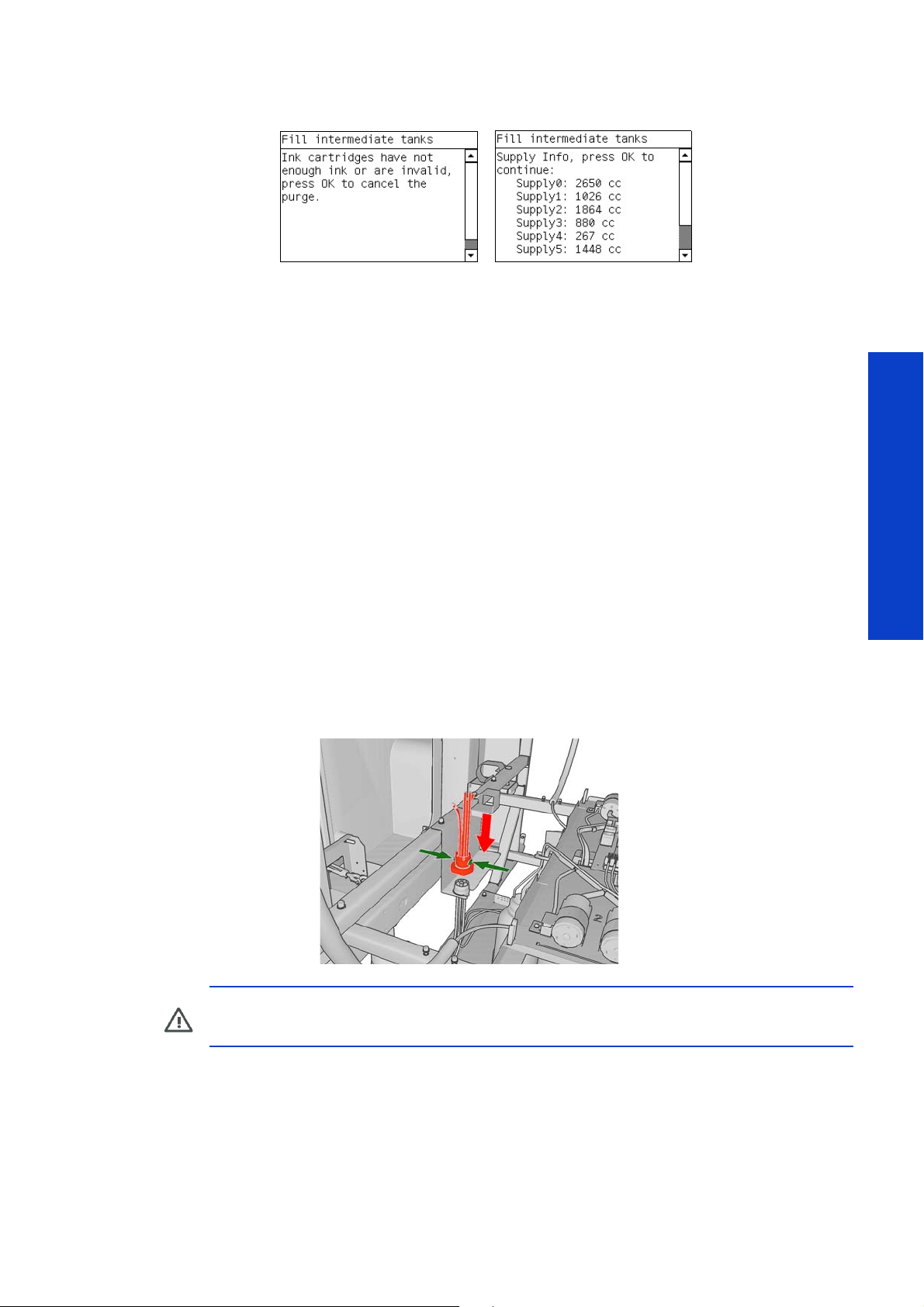

6. If there is a failure at this point because of insufficient ink in the ink cartridge, the following message is

displayed:

The supply ink information is obtained from the acumen of the supplies. If any of the values are 0 or

non-read, check the connections of the ink cartridges or replace them if they are not working.

Nomenclature used:

• Supply 0: Black Color Cartridge

• Supply 1: Yellow Color Cartridge

• Supply 2: Cyan Color Cartridge

• Supply 3: Magenta Color Cartridge

• Supply 4: Light Magenta Color Cartridge

• Supply 5: Light Cyan Color Cartridge

0.3 Purge Printer Tubes

Description

This process purges the TRS (Tube route system) from the ISM up to the print heads during the installation

process. Further details of the process cab be found in the installation guide. The system pressurizes the

ISM system to push ink into the tubes by placing the air purgers in the Printhead positions the air comes

out filling the tubes. The test pressurizes the tubes constantly until the user finishes the operation.

Procedure

1. Go to the Diagnostics menu and select 0. Purge and Setup Menu > 0.3 Purge Printer Tubes.

2. Connect the quick connector.

WARNING!: The quick connector should always be handled with care and held by the pro-

vided protective tube, so as to avoid any over-stress on its internal fittings.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 281

Page 18

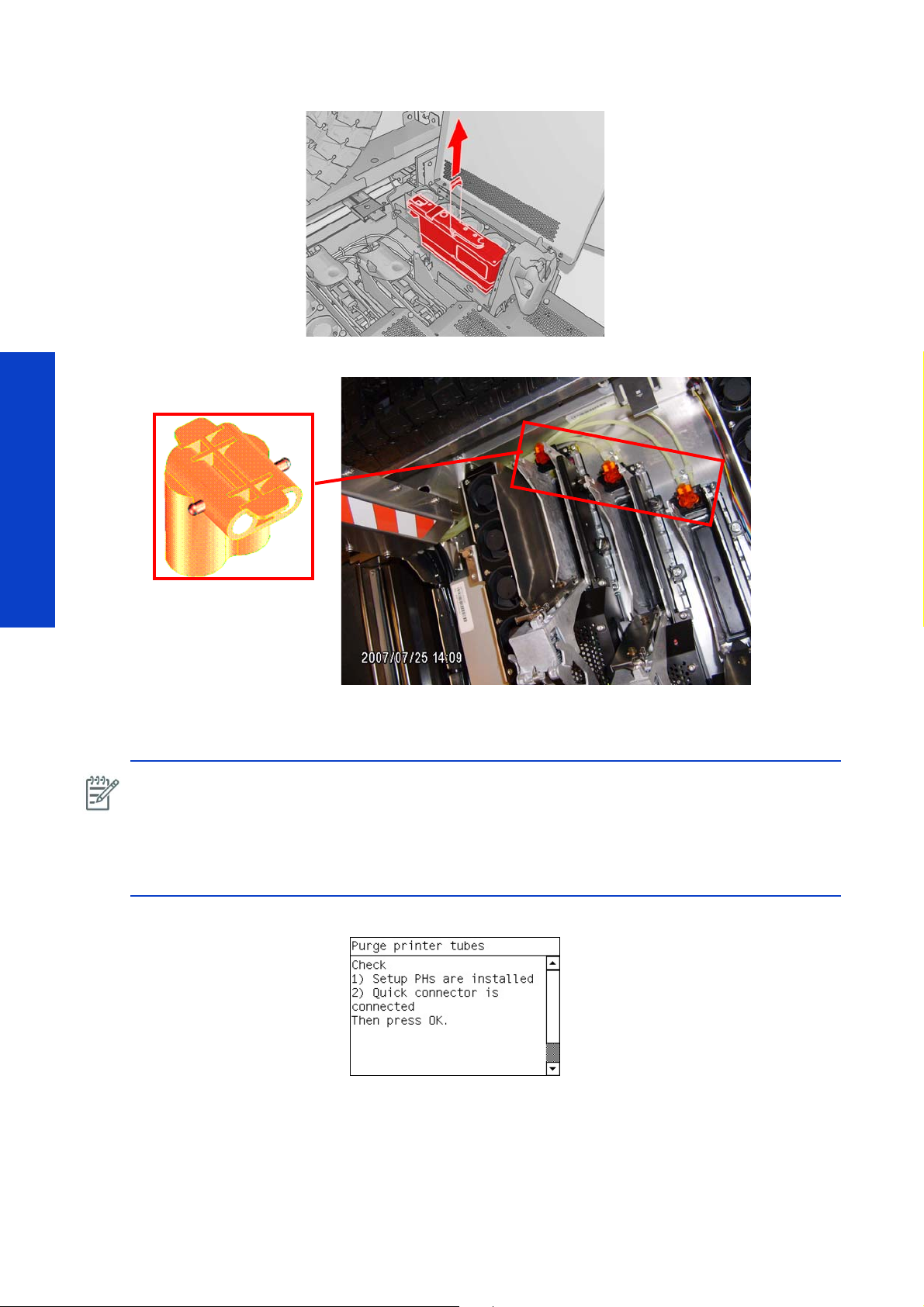

3. Printheads must not be present in the printer before at the start of the procedure. Remove the printheads.

4. Install the air purge connectors.

Test, Utilities & Calibrations

Ensure all purgers are placed in the FI connectors. The printer will then pressurize the system allowing ink

to flow through the tubes from the intermediate tanks. The filling of the tubes will take about 100cc of ink.

NOTE: If the tubes have been cleaned before it is possible that some remaining water in the tubes can

trap the purgers, not allowing the air to come out. In this case used a syringe to extract the remaining

air and ensure the ink reaches the Fluid interconnects.

NOTE: In case you do not have the purge connector, you can use a syringe as described before, but

if you need to have the air pressure set for a long time, perform the following other diagnostic tool

'4.12 Ink Pressure At Pen refer to page 328.

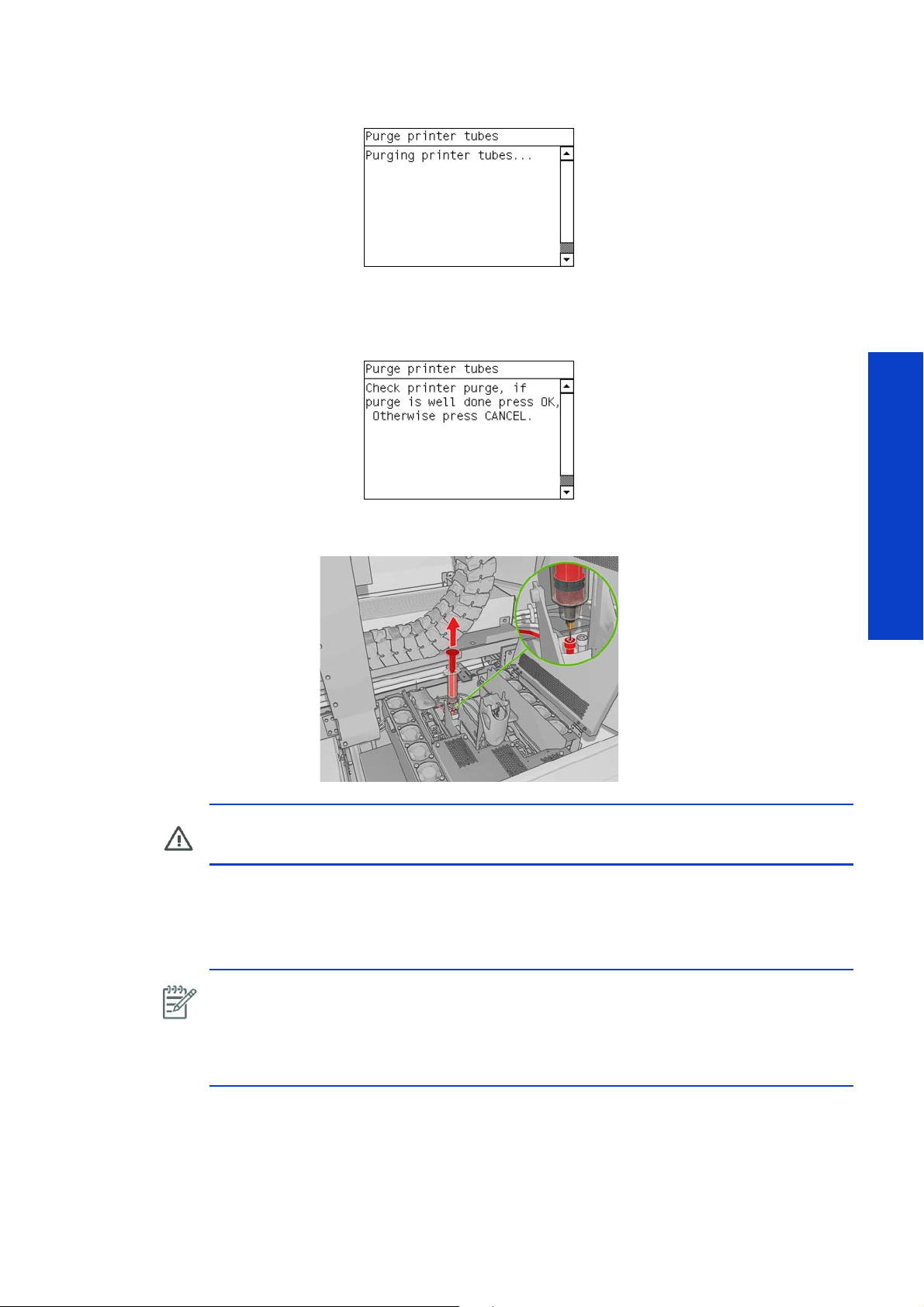

5. Press OK to purge the tubes.

282 Service Tests, Utilities & Calibrations

Page 19

6. At this point, the printer sends ink to the carriage purging the tubes, this process takes approximately 5

minutes.

7. After a few minutes the following message is displayed, the Front Panel prompts you to confirm that ink

has reached the air purge connectors. Look at the air purge connectors and confirm that each color has

arrived to the connector.

pressurize the tubes system by pressing Cancel.

8. If the ink did not arrive to the air purge connector successfully, remove the air purge connector and insert

a syringe of the same color. When the ink reaches the syringe, the printer tubes are purged.

Press ok if the purge was completed successfully. At this point it is possible to re-

WARNING!: Do not pull on the plunger of the syringe. The pressure in the tubes will force

the ink into the syringe itself.

9. If the ink does not arrive to the syringe, press CANCEL and repeat Purge Menu > Purge Printer

Tubes.

10. If the tubes are purged correctly, remove the air purge connectors and press OK to finish.

NOTE: Wear latex gloves and use a cloth when you remove the air purge connectors.

NOTE: The printer can be pressurized manually using other methods available in the

diagnostics (such as starting up the printer’s air pumps. Use this procedure if problems appear

and additional troubleshooting required (such as verification that the system is pressurizing

correctly). However ensure the TRS purged flag is reset (diagnostics ‘0.9 TRS as purged’.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 283

Page 20

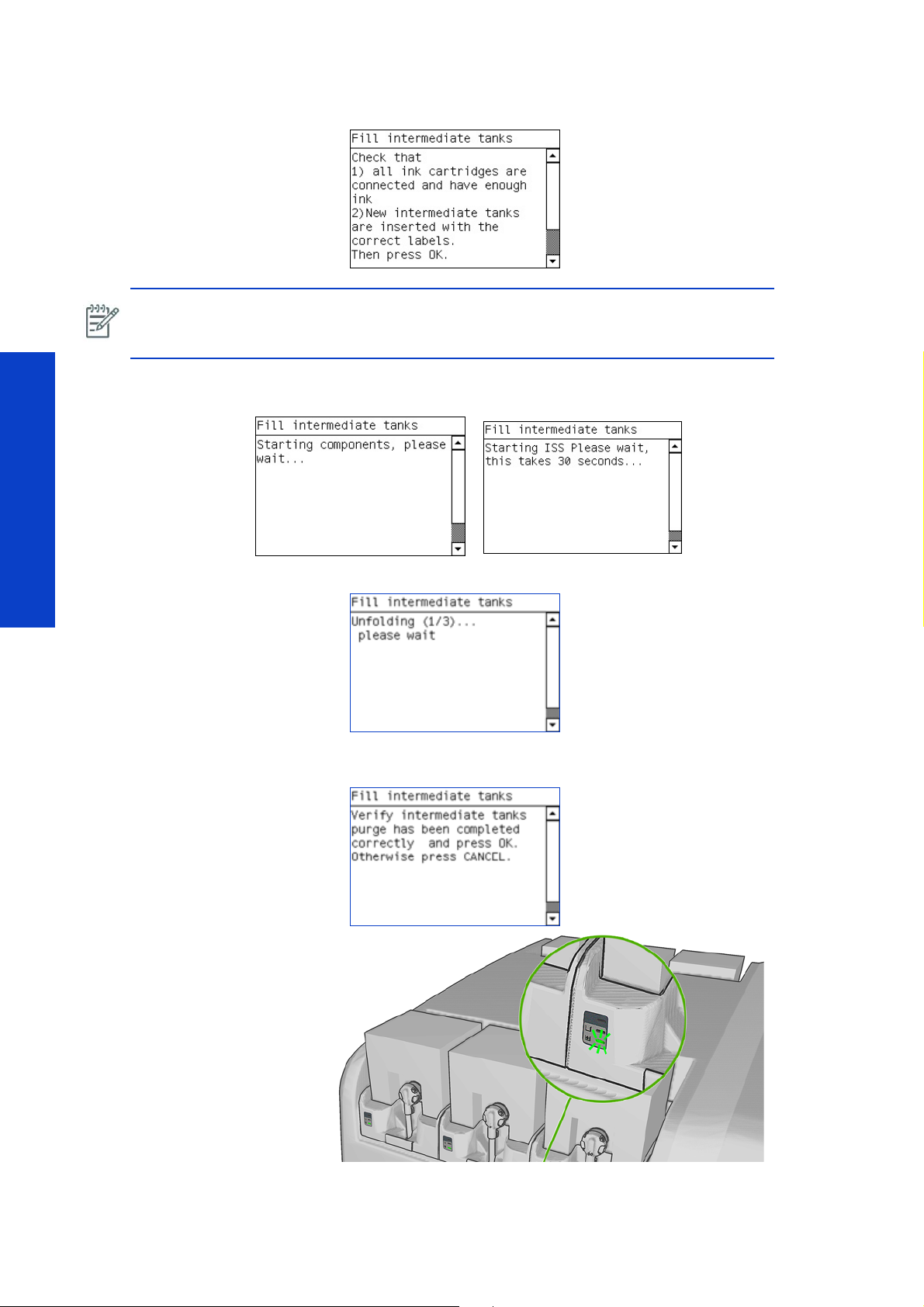

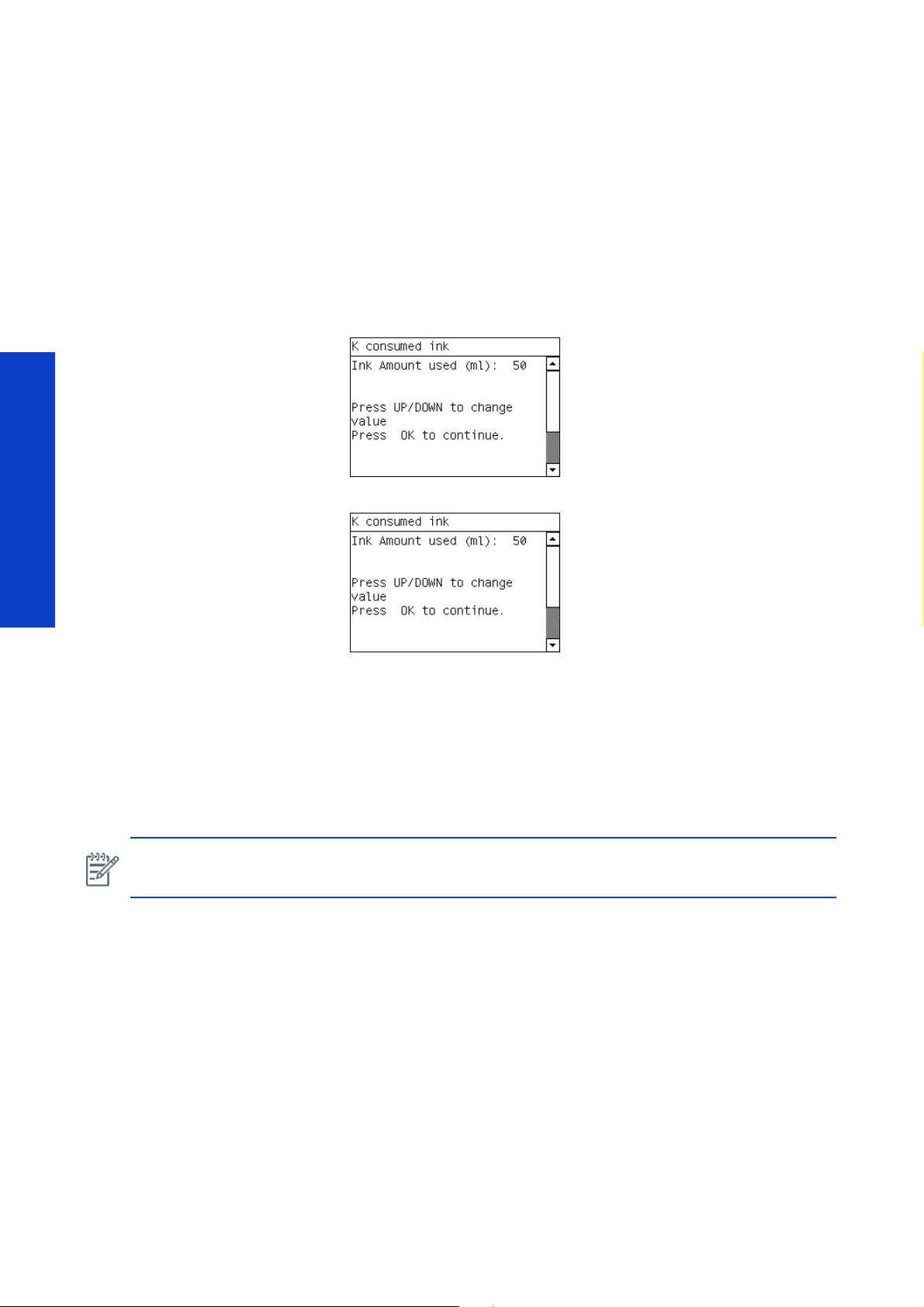

0.4 Purge Ink Used Menu

Description

In the case where ink is removed from the ink supplies to purge additional purging operations, this menu

enables the user to take into account the quantity of removed ink from the supply memory, this gives a

more precise measure of the ink accounted for in the IPS of the printer. The procedure can be applied to

each color line.

Procedure

1. Go to the Diagnostics menu and select 0. Purge and Setup Menu > 0.4 Purge Ink Used Menu.

2. The front panel displays the following message, use the up and down keys to change the value displayed

to the amount of ink that was removed from the ink cartridge for purging purposes.

3. The front panel displays the following message and confirms the amount entered, press ok to finish.

Press the ok key.

Test, Utilities & Calibrations

If the above confirmation screen is not displayed, this could indicate an error writing the value to the

acumen of the ink cartridge, in this case check the connections to the ink cartridge.

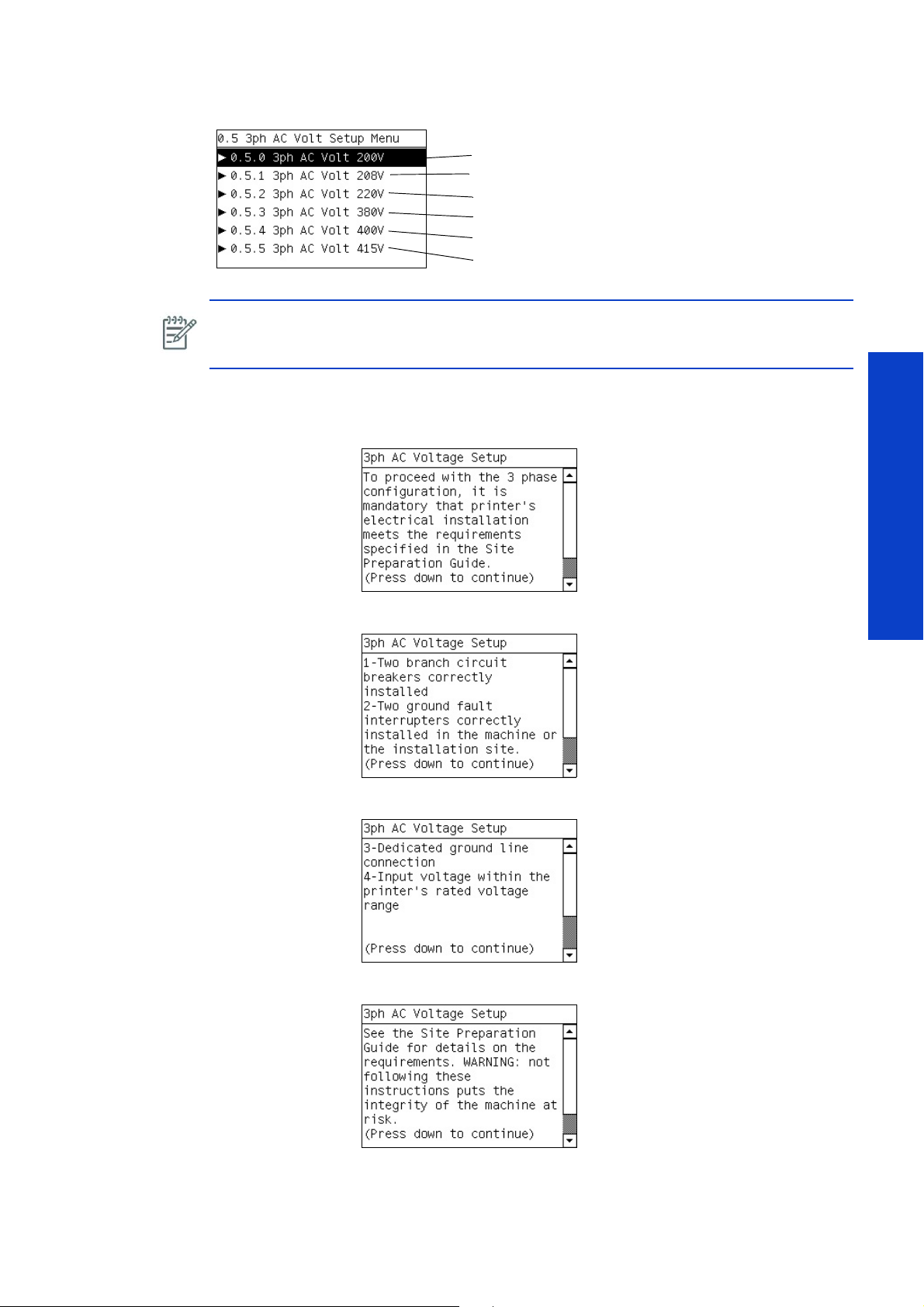

0.5 3ph AC Volt Setup Menu

Description

This menu sets the voltage of the 3 phase (phase to phase) voltage in the printer. This value must be set

correctly for the heating and curing systems in the printer to work correctly.

NOTE: 3 Phase voltage values below 190V and above 430V are not supported by the printer.

Procedure

1. Go to Diagnostics menu and select 0. Purge and Setup Menu > 0.5 AC Volt Setup Menu.

284 Service Tests, Utilities & Calibrations

Page 21

2. The following screen is displayed, select the correct voltage of the line voltage of the customers site, and

• Select this for line voltages below 204V

• Select this for line voltages below 205V-214V

• Select this for line voltages below 215V-240V

• Select this for line voltages below 360V - 390V

• Select this for line voltages below 391V-407V

• Select this for line voltages below 408V and above

select the ok key.

NOTE: It is possible to check the current voltage setting of the printer via the service plot by

going to ‘IPS Select information>Service Information’ (available from firmware version

14.2.2.1 and IPS 3.5 and greater)

3. The following messages are displayed in order to confirm that the appropriate safety requirements have

been met when installing the printer and selecting the voltage value. Read each message and press the

down arrow to continue only when you are sure the corresponding safety requirement has been met.

4. The following message is displayed, press the down arrow to continue.

5. The following message is displayed, press the down arrow to continue.

6. The following message is displayed, press the down arrow to continue.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 285

Page 22

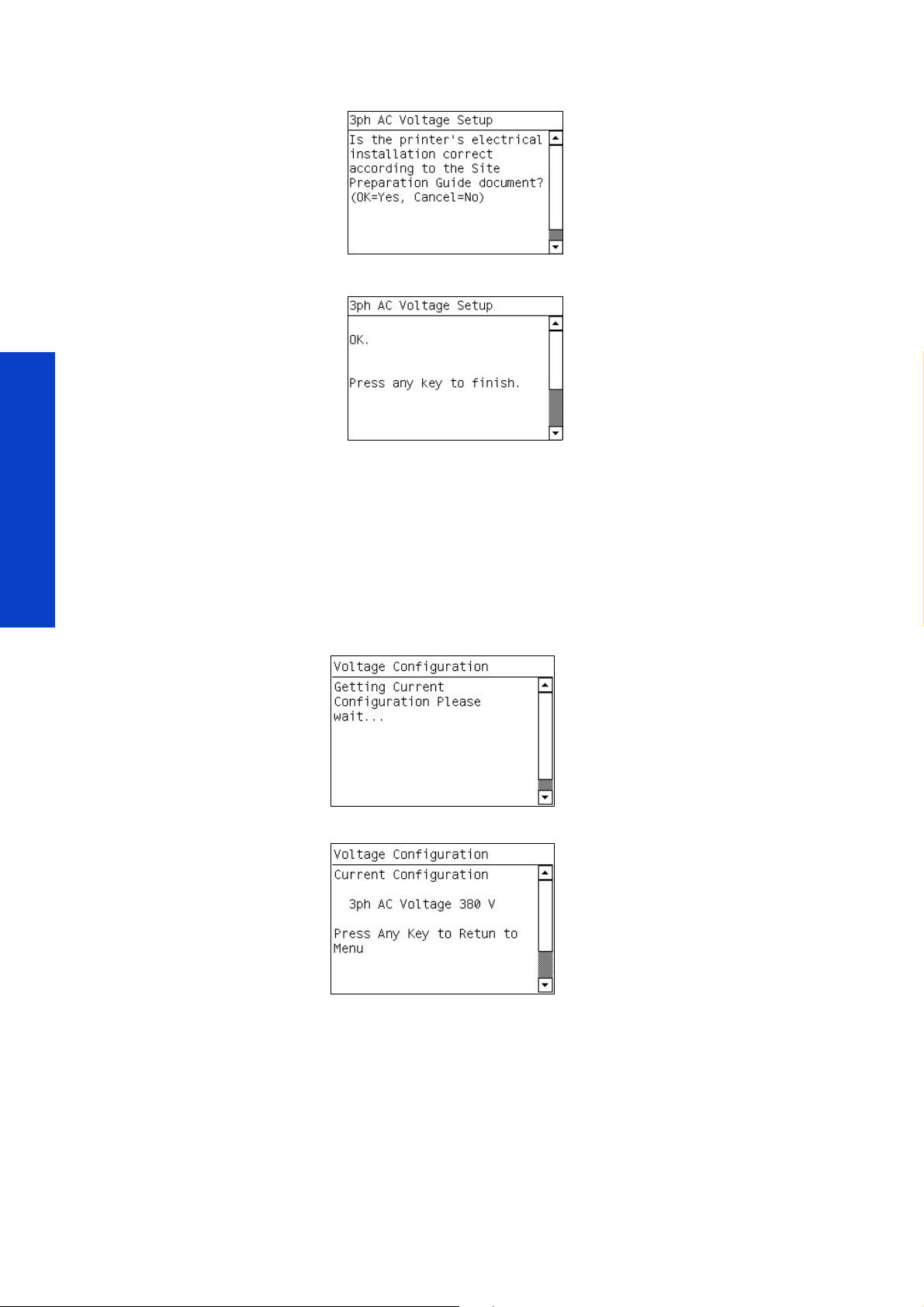

7. The following message is displayed, press the down arrow to continue.

8. The following message is displayed, press the down arrow to continue.

0.5.6 Voltage Configuration

Description

This menu enables you to see the current voltage configuration selected.

Procedure

1. Go to Diagnostics menu and select 0. Purge and Setup Menu > 0.5 AC Volt Setup Menu >

Test, Utilities & Calibrations

0.5.6 Voltage Configuration

2. The following screen is displayed.

3. The current voltage selected is displayed.

The values displayed will be 200, 208, 220, 380, 400 or 415 depending on the current configuration. If

the printer does not have any configration selected the display will show NO CONFIGURATION. To set a

voltage configuration refer to page 284.

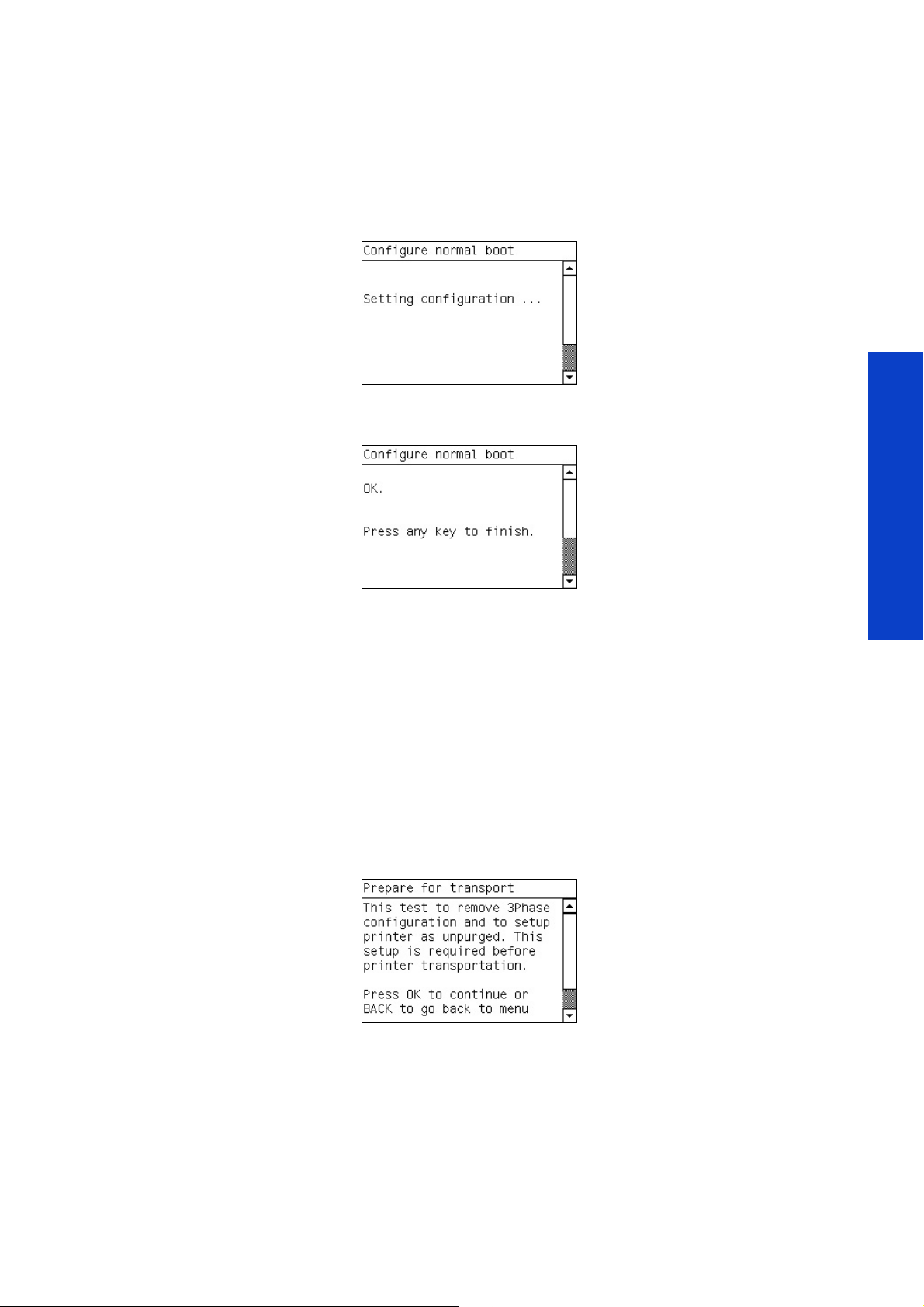

0.6 Force Normal Boot

Description

This test changes the boot up parameter of the printer to start up in normal mode (also known as printer

mode)

286 Service Tests, Utilities & Calibrations

Page 23

After initial set up of the printer in Diagnostics boot up, this procedure is selected to start up the printer

normally. This procedure is required to reset the printer back to normal boot mode operation after ‘1.0

Force diagnostics boot mode’ has been performed.

Procedure

1. Go to Diagnostics menu and select 0. Purge and Setup Menu> 0.6 Force Normal Boot

2. The following screen is displayed while the system is changed to boot up in Normal Boot mode.

3. When the process has finished, the following screen is displayed confirming the printer will now automat-

ically boot up in normal printer mode., press ok to finish.

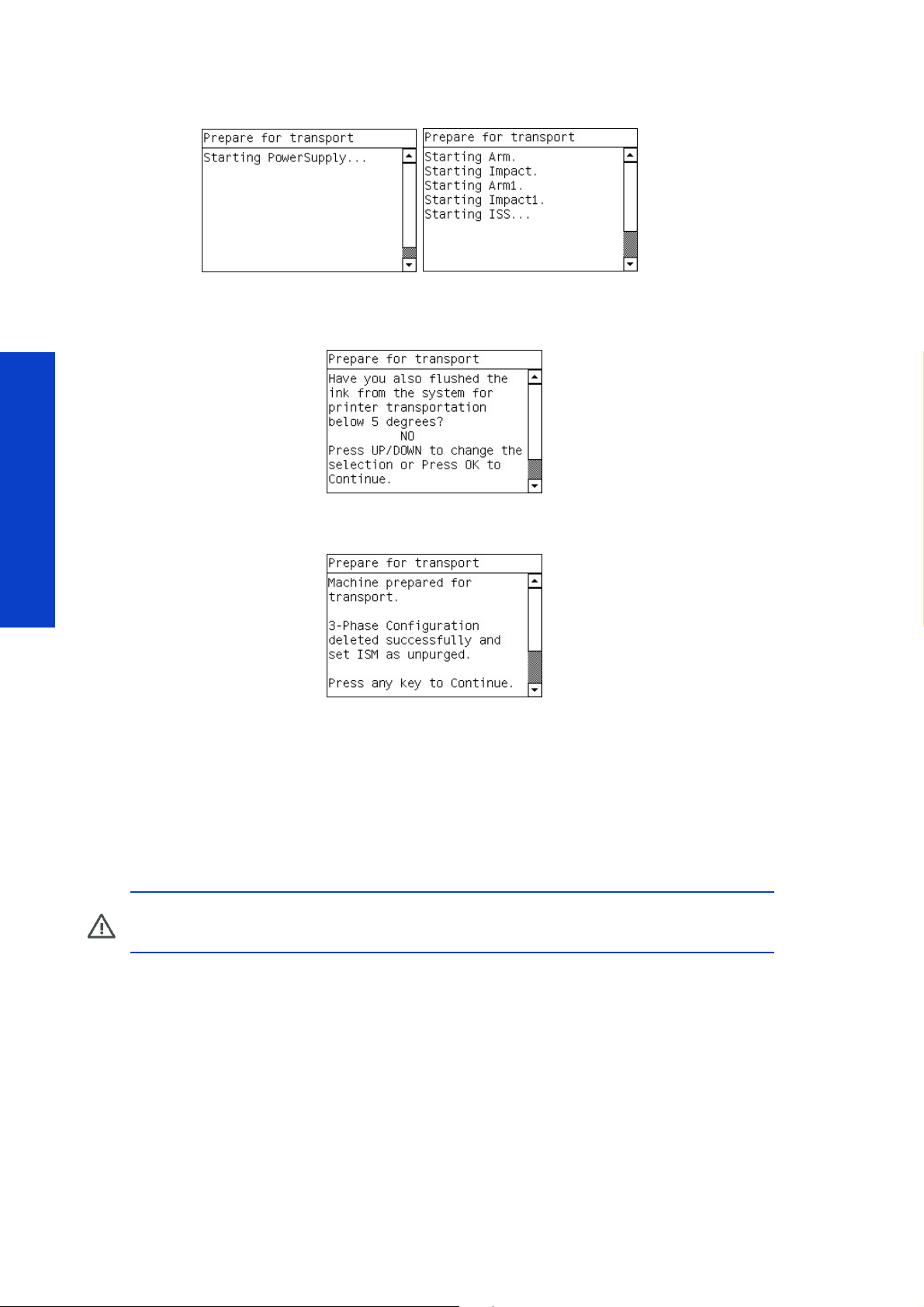

0.7 Prepare for transport

Description

This procedure is used to prepare the printer for transportation.

The procedure deletes the 3Phase configuration parameter, forcing the selection again of the 3 Phase

configuration once in the customer new premises. In addition where the transportation environment was

below 5 degrees and ink flushing was performed, the procedure enables the user to remove the ISM and

TRS purged status which allows a re-purging of the printer.

Procedure

1. Go to Diagnostics menu and select 0. Purge and Setup Menu> 0.7 Prepare for transport

2. The front panel displays the following message, press ok to continue.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 287

Page 24

3. The front panel displays the following messages, and the 3 phase power configuration is reset in the

printer.

4. The front panel displays the following message. If yes is selected, the ISM and TRS purge status is reset to

0, forcing the purging procedure to be performed again, (this can be reversed using the procedure 0.8

and 0.9).

5. The following message is displayed confirming the printer’s voltage setting has been reset and the purge

status of the printer has been reset to 0 (Unpurged), press any key to finish the procedure.

If no is selected at this point the procedure will finish.

Test, Utilities & Calibrations

0.8 Set ISM as Purged

Description

This procedure is used to set the ISM purged status in the NVM. The test is used if the standard ISM purging

procedure failed (0.1 Purge ISM page 274) and the purging process was manually performed and the

status needs to be set using this procedure to ‘Purged’.

CAUTION: If this procedure is performed and the printer has not actually been purged, print-

ing failures and possible printhead damage will probably occur.

Procedure

1. Go to Diagnostics menu and select 0. Purge and Setup Menu> 0.8 Set ISM as Purged

288 Service Tests, Utilities & Calibrations

Page 25

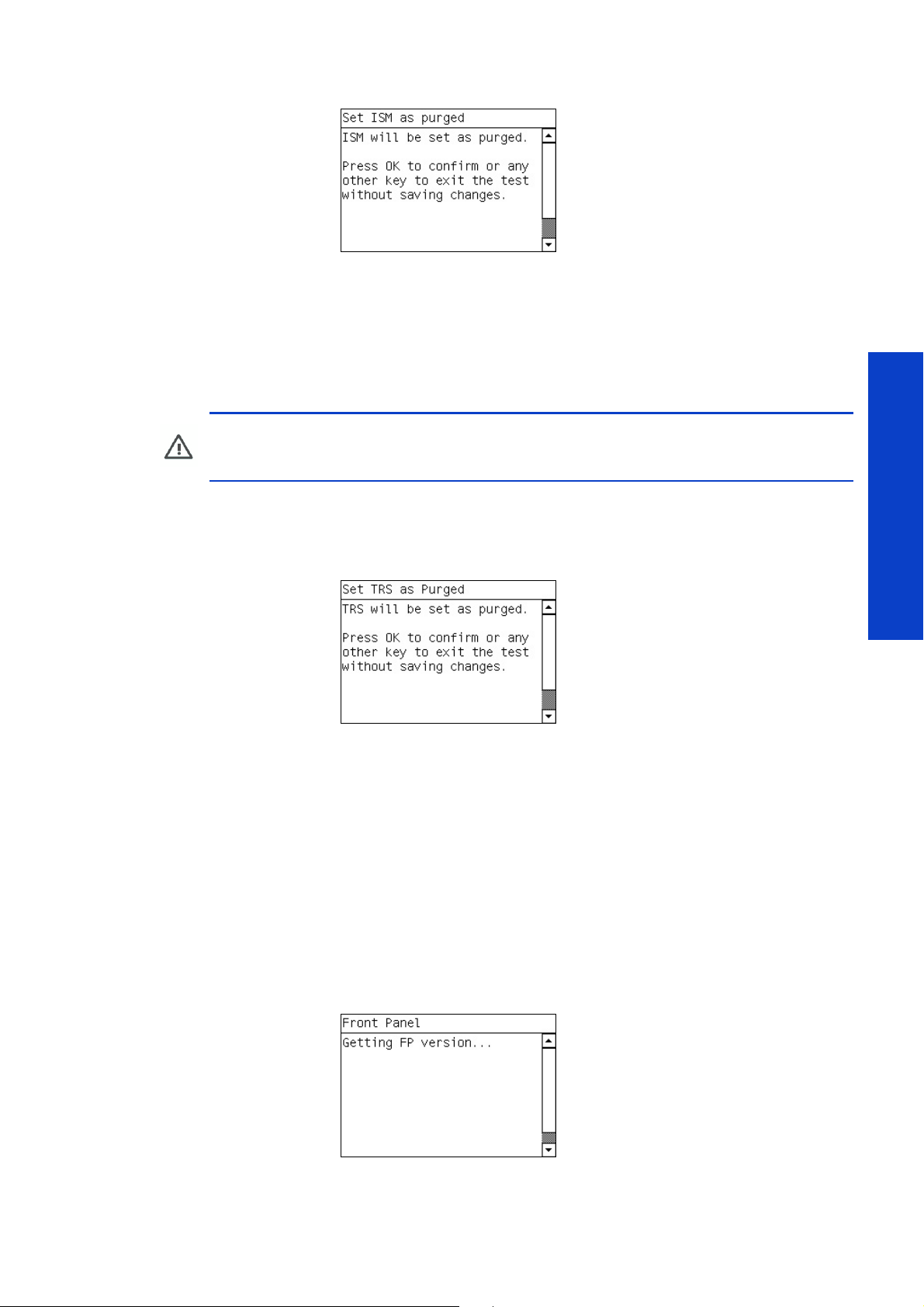

2. The following message will be displayed, press the ok key to set the ISM status as ‘Purged’.

0.9 Set TRS as Purged

Description

This procedure is used to set the TRS purged status in the NVM. The test is used if the standard TRS purging

procedure failed (0.3 Purge ISM page 281) and the purging process was manually performed and the

status needs to be set using this procedure to ‘Purged’.

CAUTION: If this procedure is performed and the printer has not actually been purged, print-

ing failures and possible printhead damage will probably occur, (because there is air within

the tubes and no ink).

Procedure

1. Go to Diagnostics menu and select 0. Purge and Setup Menu> 0.9 Set TRS as Purged

2. The following message will be displayed, press the ok key to set the TRS status as ‘Purged’.

1.0 User Interface Menu

1.1 F ron t P a nel

Description

This procedure checks the correct functionality of the keys on the front panel and the correct operation of

the pixels in the display. The procedure also performs a quick front panel internal electronics check.

Procedure

1. Go to Diagnostics menu and select 1.0 User Interface Menu> 1.1 Front Panel

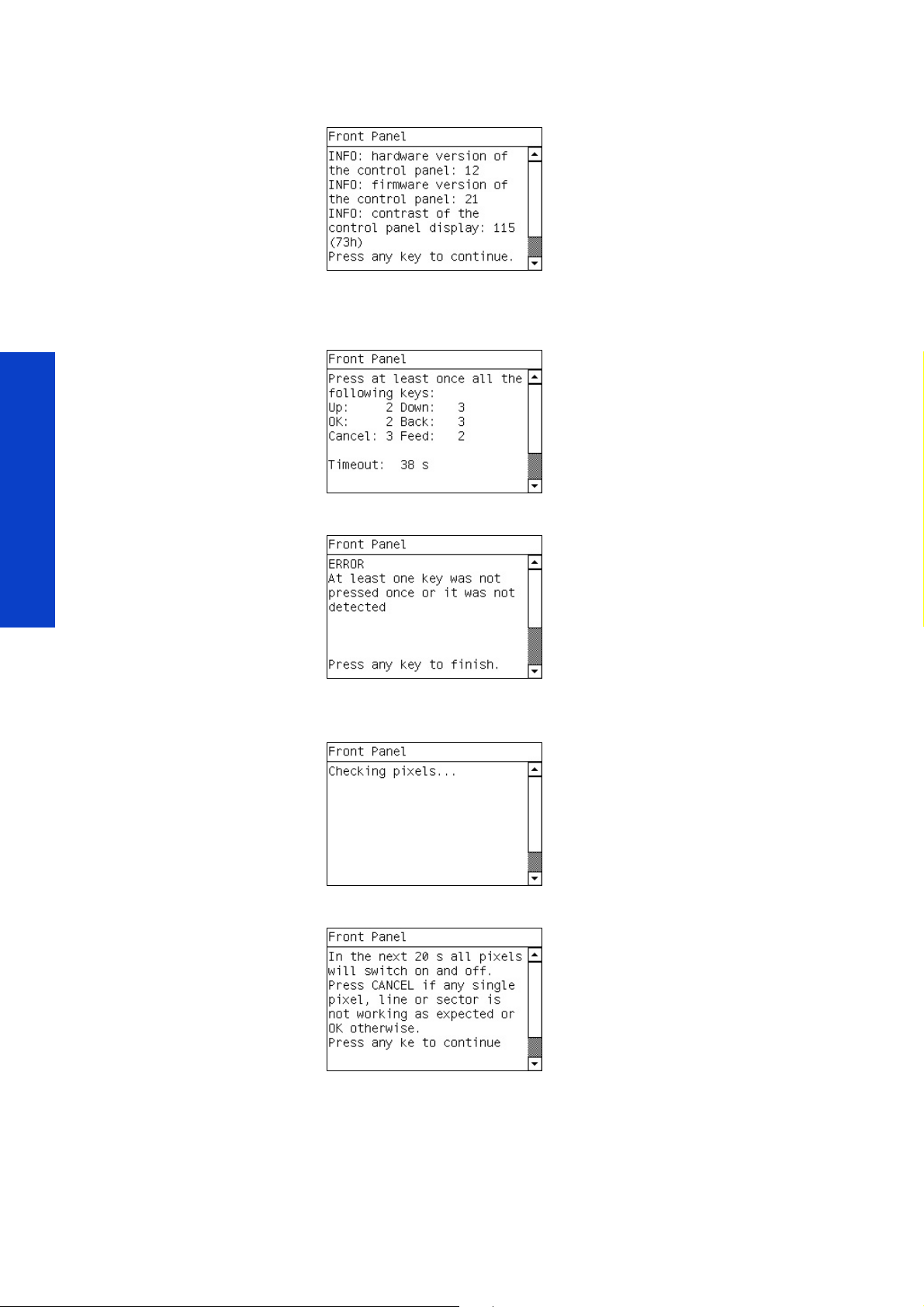

2. The following message will be displayed, the version of the firmware is checked and the hardware ver-

sion.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 289

Page 26

3. If this is displayed correctly, as shown here, this would indicate that the electronics of the front panel are

functioning correctly,

4. Press all the keys of the front panel, multiple times, each press of the key is recorded in the message dis-

played. Make sure the keys are pressed firmly, so that they can be registered correctly on the display. The

procedure times-out after a while.

If any of the keys are register as 0 presses, an error message is displayed and the test fails.

press any key to continue

Test, Utilities & Calibrations

5. If there is no error at this point the test continues, the front panel displays the following screen which tests

all the pixels on the screen of the front panel.

6. The front panel displays the following message, wait for 20 seconds to elapse for the start of the pixel test.

290 Service Tests, Utilities & Calibrations

Page 27

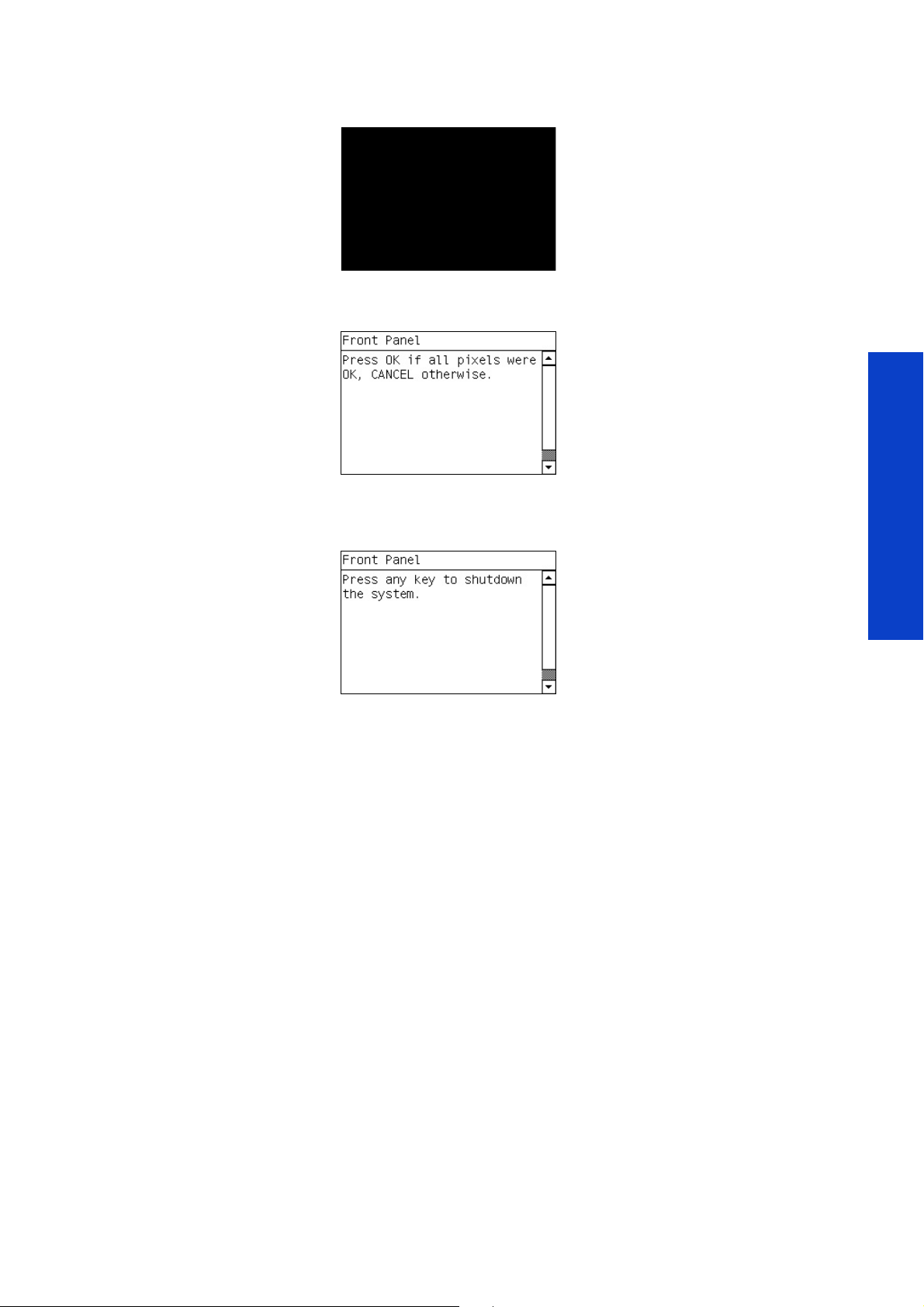

7. The front panel screen will go completely black, check to see if there are any white pixels showing, which

would indicate a failure of one or multiple pixels on the screen.

8. The front panel will display the following message, if there were no white pixels showing and the screen

was completely black, press the ok key.

If there were white pixels showing on the screen, press cancel to fail the test and replace the front panel.

9. If the screen passes the test, the following message is displayed, press any key to shutdown the printer.

2. Electrical Systems Menu

2.1 ECabinet

Description

This procedure checks the functionality of electronics in the ECabinet. The following are turn on for the

purposes of the functionality:

• Power Supply Voltage test (main power supply)

• Vacuum Transformer test

• Curing System Fans test

• Temperature Sensors test (communication temperature values)

• Heating and curing modules configuration

Procedure

1. Go to Diagnostics menu and select 2. User Electrical Systems Menu> 2.1 ECabinet

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 291

Page 28

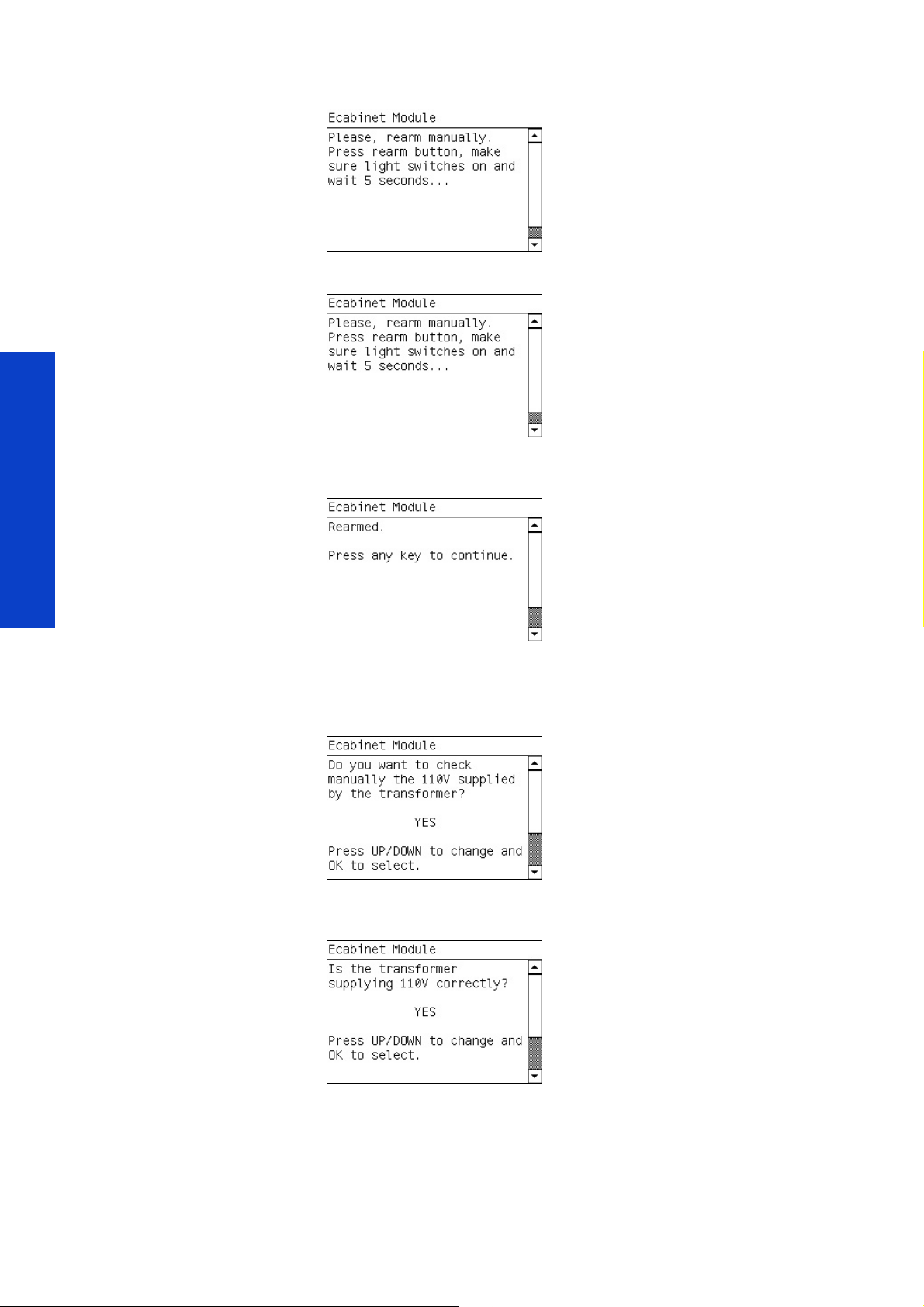

2. The following screen is displayed, reset the circuit breakers and make sure there is a light showing.

3. The following screen is displayed, reset the circuit breakers and make sure there is a light showing.

4. When the circuit breakers have been reset the front panel displays the following message, press any key

to continue.

Test, Utilities & Calibrations

The printer starts the various subsystems required to perform the tests, if there are any system errors at this

point refer the troubleshooting chapter.

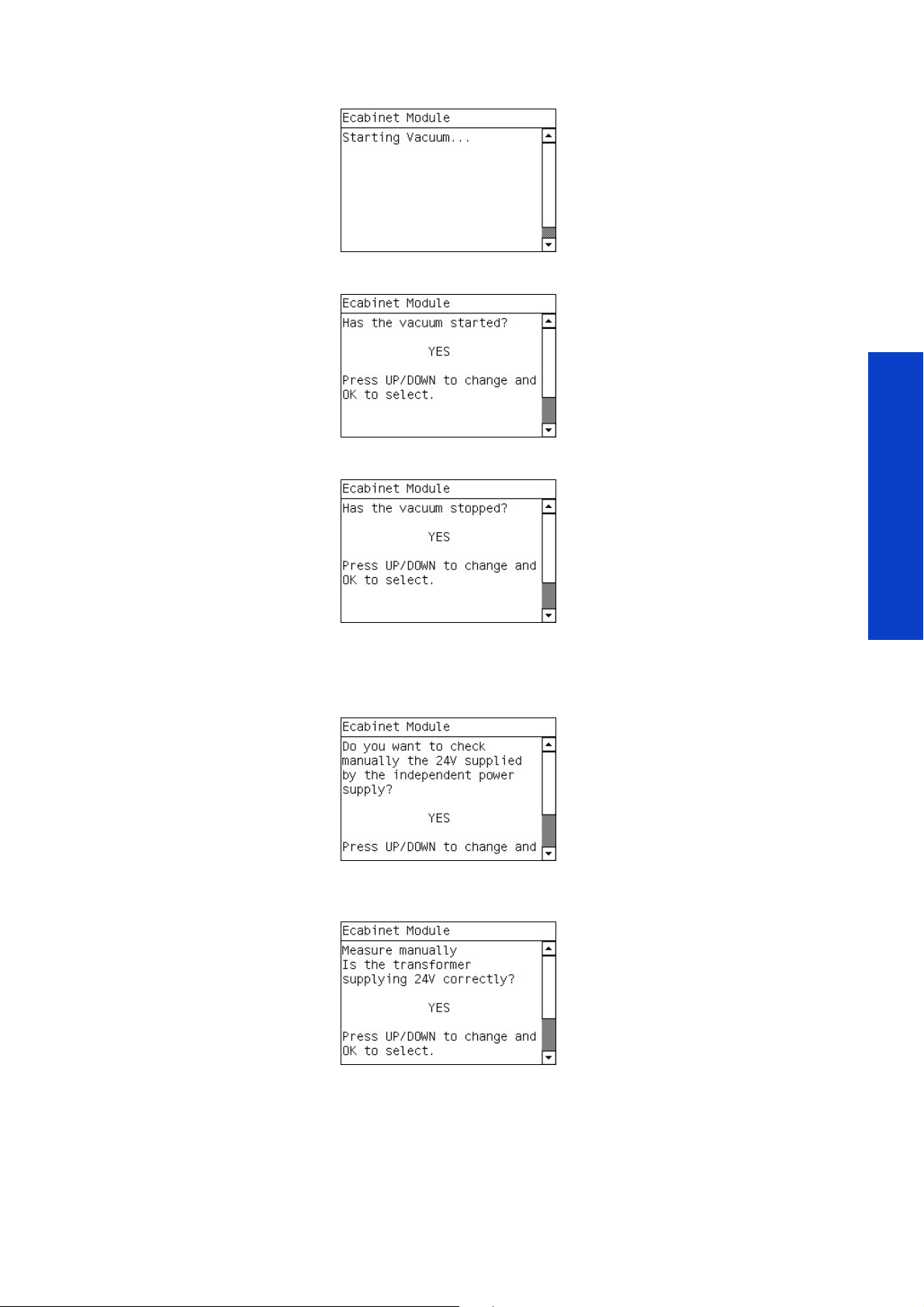

5. The front panel will display the following message, select yes and press ok.

6. Use a voltameter to test for 110v in the output voltage point of the transformer or the terminal blocks to the

vacuum pump, if there is 110v present, select yes and press ok.

If 110v is not present, select no and press ok. The printer will shut down and the failure can be repaired.

292 Service Tests, Utilities & Calibrations

Page 29

7. If there is no failure, the front panel displays the following message, and the vacuum system is turned on.

8. The front panel displays the following message, press yes if the vacuum has started.

9. The front panel displays the following message, press yes if the vacuum has stopped.

If there is an error with the Vacuum functionality, this would indicate an error with the Vacuum

Transformer, press no and the printer will shut down so the appropriate repair can be made.

10. If there is no error at this point the following message is displayed, select yes and press the ok key.

11 . Use a voltameter to test for 24v in the output voltage point of the 24v Secondary PSU, if there is 24v

present, select yes and press ok.

Tests, Utilities & Calibrations

If 24v is not present, select no and press ok. The printer will shut down and the failure can be repaired.

Service Tests, Utilities & Calibrations 293

Page 30

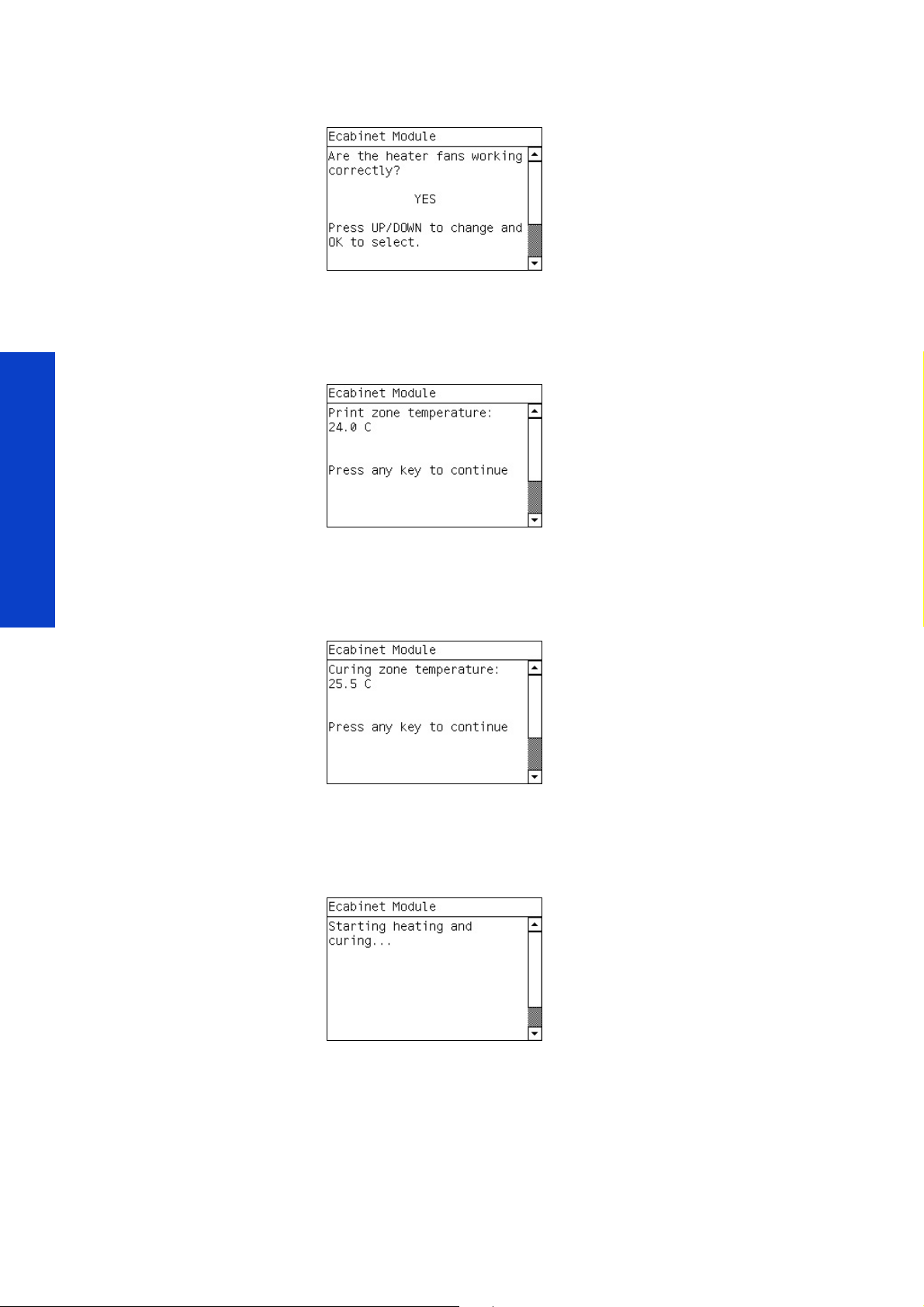

12. If there is no error at this point the following message is displayed, and the curing fans are turned on,

select yes and press the ok key if the curing ar functioning.

If the curing fans do not turn on, select no and press ok. The printer will shut down and the failure can be

repaired.

13 . If there is no error at this point the following message is displayed, and the heater is turned on to check if

the Print zone IR temperature sensor displayed is raised to an appropriate level, press any key to continue.

If the Print zone temperature is not displayed correctly on the front panel, this would indicate an error with

the connections or failure of the Print Zone IR temperature sensor.

Test, Utilities & Calibrations

14 . The following message is displayed, and the curing module is turned on to check if the Curing IR temper-

ature sensor displayed is raised to an appropriate level, press any key to continue.l.

If the Curing temperature is not displayed on the front panel, this would indicate a indicate an error with

the connections or failure of the Curing IR temperature sensor.

15 . The front panel displays the following message, and the Heating and Curing modules are turned on to

high.

294 Service Tests, Utilities & Calibrations

Page 31

16 . The front panel displays the following message, while the Heating and Curing modules are turned on and

the temperature is stabilized.

The Heating and Curing modules are turned on high (see warning below), check that they are heating

up, if they do not this would indicate an error with the heating and curing modules which must be

repaired.

WARNING!: This procedure will set the Heating and Curing modules to a very high temper-

ature of 100 Degrees, please careful as the media Loaded could be damaged at

100 degrees. It is recommended to use only a media strip for the curing temperature sensor

to be able to read, and under controlled circumstances, check the operation of the heating

and curing modules at 100 degrees.

2.2 Main Electronics Menu

2.2.1 Electronics Control

Description

This procedure is a test to check the various boards and communication buses of the printer, to ensure

they are installed/connected and functioning correctly. The following boards are checked:

• Formatter board

• Power Supply board

• Main interconnect (naming)

• PrintMech

• Engine Boards

• Carriage Board communication

• ISS Board communication

Procedure

1. Go to Diagnostics menu and select 2. User Electrical Systems Menu> 2.2 Main electronics

Menu> 2.2.1 Electronics Control.

1. The front panel displays the following message, select yes and press ok.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 295

Page 32

• The printer checks that the Formatter Board communicates correctly, press any screen to continue.

• The printer checks that the CPU fan is working correctly and the speed can be controlled by the

firmware on the Formatter board, press any key to continue.

• The printer checks that the main memory reads and writes correctly, and that the size (256 mb) is

correct, press any key to continue. If no is selected the test will finish and the printer will shut down.

Test, Utilities & Calibrations

2. The front panel displays the following message, select yes and press enter.

3. The front panel displays the following message. The printer verifies that the Main Non-Volatile Memory

(NVM), located on the Hard Disk System, and Main NVM backup, located on the Main Interconnect

Board, match.

If either the Hard Disk System or the Main Interconnect Board have been replaced, they may not match.

The printer also verifies that the serial number and part numbers are correct and use the correct format. If

the versions do not match, the printer displays the serial numbers and part numbers of the NVM and NVM

backup.

If necessary, the printer asks you if you want to force the NVM versions to synchronize. Press ok to

synchronize the NVM or cancel to leave them not synchronized.

296 Service Tests, Utilities & Calibrations

Page 33

4. If there is no problem at this point the following screen is displayed, press any key to continue.

5. The front panel displays the following message, select yes and press ok.

The electrical subsystems start up in order to perform the test.

6. The front panel displays the following message, select yes and press ok if you can see the LED located in

the Electronics box light up.

If the LED in the Electronics box does not light up, select no and the test will fail and the printer will shut

down in order to make the appropriate repair.

7. If there is no problem at this point the front panel will display the following message, select yes and press

ok.

Tests, Utilities & Calibrations

8. The printer checks that the Main Interconnect Board receives the correct voltage, can communicate with-

out failure, and receives the input signals correctly.

Service Tests, Utilities & Calibrations 297

Page 34

9. If there is no problem at this point the printer displays the following message. The printer checks the print-

head cleaning roll close position switch, the sliding door switch, and the top cover window switch. Press

any key to continue.

If there is a problem at this point the test will fail and the printer will shut down in order to make the repair.

10. If there is no problem at the point the front panel will display the following message, select yes and press

the ok.

11 . The front panel displays the following message, the printer checks that the Printmech Board receives the

correct voltage (42 V), can communicate without failure, and tries to connect to an element using the print

Test, Utilities & Calibrations

mech.

If there is a problem at this point the test will fail and the printer will shut down in order to make the repair.

12. If there is no problem at this point the front panel will display the following message, select yes and press

the ok.

-

298 Service Tests, Utilities & Calibrations

Page 35

13 . The printer checks the functionality, configuration, microprocessors operation and memory of the Upper

and Lower Engine PCI Board.

If there is a problem at this point the test will fail and the printer will shut down in order to make the repair.

14 . If there is no problem at this point the front panel will display the following message, select yes and press

the ok.

The printer starts the various subsystems required to perform the tests, if there are any system errors at this

point refer the troubleshooting chapter.

15 . If the printer successfully detects the Remote Controller Boards and Main interconnect board, the front

panel displays the following message.

If there is a problem at this point the test will fail and the printer will shut down in order to make the repair.

Tests, Utilities & Calibrations

16 . If there is no problem at this point the front panel displays the following message, select yes and press ok.

Service Tests, Utilities & Calibrations 299

Page 36

17. The printer checks that the carriage receives the correct voltage without failure and that the Trailing

Cables can communicate with the Carriage Printhead Board Assemblies.

18 . The printer sends a signal to the carriage and asks you to look at the 24 V Carriage LED to verify that the

LED is on and the signal arrives, select yes if the LED light up.

If the LED does not light up select no and the test will fail and the printer will shut down in order to make

the repair.

19. The printer asks you if you want to perform the ISS test, select yes and press ok.

20. The front panel displays the following messages and the printer checks the communications between the

printer and the Ink Supply System board. The printer reads and displays the IDS revision value to check

IDS connectivity with ADC. The printer asks you to verify that all the ink cartridges are connected cor

rectly. Verify that all ink cartridges are connected correctly. If an ink cartridge is not connected, connect it

now.

-

Test, Utilities & Calibrations

21. If the communications between the printer and the board are ok the front panel displays the following

message, press any key to finish the test and shutdown the printer.

If there is a problem at this point the test will fail and the printer will shut down in order to make the repair.

2.2.2 Hard Disk Drive

Description

This test checks the hard disc drive to make sure that it is working correctly, the checks include following:

• Protection status test (protected/not protected)

• Partition configuration test

• System file contents (sanity check for critical files)

Procedure

1. Go to Diagnostics menu and select 2. User Electrical Systems Menu> 2.2 Main electronics

Menu> 2.2.2 Hard disk Drive.

300 Service Tests, Utilities & Calibrations

Page 37

2. The front panel displays the following message, select yes and press ok.

3. The printer reads the protection status of the hard disc drive and displays it on the front panel. Press any

key to continue.

4. The front panel displays the following message, select yes and press ok.

5. The printer checks the hard disc drive partitions for faults and displays the results on the front panel, press

any key to continue.

6. The printer reads and displays the current file system contents of the formatted partitions of the hard disc

drive, press any key to continue.

7. The front panel displays the following message, select yes and press ok.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 301

Page 38

8. The printer performs a sanity check of the hard disc drive to check the hard disc drive consistency. A

progress value is displayed to indicate the percentage to completion.

9. If the status of the Disk is ok, the following screen is displayed, press any key to finish the test and shut

down the printer.

2.2.3 IO Information

Description

This test shows the LAN configuration data, and tests the communication, which can help when

troubleshooting or setting up a network. The information displayed is the following:

Test, Utilities & Calibrations

• IP address

• Gateway address

• Subnet mask

• Connectivity with the Internal Print Server

Procedure

1. Go to Diagnostics menu and select 2. User Electrical Systems Menu> 2.2 Main electronics

Menu> 2.2.3 Connectivity Check.

2. The front panel displays the following message, while the printer retrieves the IO information.

3. When the printer has retrieved the information it is displayed on the front panel.

302 Service Tests, Utilities & Calibrations

Page 39

4. The following message is displayed, select yes and press ok to check the connectivity between the printer

and the IPS (DFE).

5. The front panel displays the instructions on how to check the connectivity. From the IPS go to ‘Run’>enter

the word ‘CMD’>enter the following ‘Ping ‘the IP address of the PC’>Press enter.

6. If there is connectivity select OK, if any packets were lost, select No. If yes is selected the printer shut

down.

If there is a problem with the connectivity, the test fails.

2.2.4 Unit Information

Description

This procedure retrieves printer information and displays the results on the front panel. This information is

useful for obtaining internal printer information for use in networking or checking the firmware version etc.

• Firmware version

• Serial Number

• Par t Number

• Prototype Name

Procedure

1. Go to Diagnostics menu and select 2. User Electrical Systems Menu> 2.2 Main electronics

Menu> 2.2.4 Unit Information.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 303

Page 40

2. The printer reads and displays the printer unit information, press any key to finish the test and the printer

shuts down.

2.2.5 71.X:19 Recovery

Description

The SE 71.5:19 and SE 71.6:19 Recovery test resets the serial number and the part number in case the

Hard disk, Main Interconnect Board, and/or Ink System Main Board were replaced at the same time

which causes an SE 71.5:19 or SE 71.6:19.

Procedure

1. Go to Diagnostics menu and select 2. User Electrical Systems Menu> 2.2 Main electronics

Menu> 2.2.5 71.X:10 Recovery.

2. The printer reads and displays the serial number and part number of the HDD and the EEPROM, select

which ones are correct and press ok.

Test, Utilities & Calibrations

2.2.6 Set SN and PN

Description

This test displays and permits the engineer to set the Serial Number and Part Number of the printer. Use

this procedure only in case of critical failure of both NVM main and backup and loss of the Serial Number

and Part Number of the printer. Note: The Tests is protected with the code "NPI" to enter in order to prevent

the user performing this procedure.

Procedure

1. Go to Diagnostics menu and select 2. User Electrical Systems Menu> 2.2 Main electronics

Menu> 2.2.6 Set SN and PN.

304 Service Tests, Utilities & Calibrations

Page 41

2. The front panel displays the following message, enter the password in order to get access to this function-

ality. The password is NPI.

CAUTION: Changing the product number, could damage the printer. In case of any doubt

on the product number, it is marked on the top left side of the e-cabinet.

3. The Printer displays the current Serial Number, use the keys on the front panel to change the serial number

of the printer, and press ok.

4. The printer displays the new serial number and part numbers for confirmation. At this point, they are not

saved.

5. Double check that the values displayed are correct, press ok to confirm and shut down the printer.

2.3 Main PSU/OFF

This tests allows the user to start up the 24v and 42v of the main power supply. Use this test to diagnose

any electrical problem on the 24V and 42V supplied from the main Power supply.

NOTE: After any critical system error the 24V and 42v from the main power supply is cut, therefore this

test is required to diagnose any fault which is caused by an error with the root supply of electricity.

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 305

Page 42

2.4 ECabinet Fault Signals

Description

This tests displays in real time the input signals from the e-cabinet in the system electronics. The signals

displayed in real time and that can be used to troubleshoot are the following:

• KM contactor is active but the system reports the 3 phase power is off.

• Emergency stop buttons ON/OFF

• F11 Fuse 24V power signal from the main power supply reaching e-cabinet

• 24V input signal is not detected and physically arrives to the correct check point in the e-cabinet

• Printer seems reamed (light button on), but the printer does not react correctly.

• E-Cabinet internal fan is on but the printer reports it as faulty.

Procedure

1. Go to Diagnostics menu and select 2. User Electrical Systems Menu> 2.4 ECabinet

2. After the first part of the procedure, the following screen is displayed showing in real time the electrical

signal coming from the components.

Press ok to return to the previous menu.

Test, Utilities & Calibrations

3. Substrate Path Menu

3.1 Spindle Motors burning

Description

The procedure moves the front and rear spindle systems for a certain period of time at high speed. This

test is to ensure correct operation of the mechanical gears of the systems also performing auto lubrication

with the internal grease.

• As the systems operates in a torque based mechanism, if there is a long time without running or

there are low temperatures, this can cause media movement issues, which could be solved by

performing this procedure.

• Rear spindle: The tests runs the spindle 5 minutes in one direction and the 5minutes in the other. Test

duration 10 Minutes.

• Front spindle: The test runs the spindle 15 Minutes in one direction and 15 minutes in the other. Test

duration 30 Minutes.

Procedure

1. Go to Diagnostics menu and select 3. User Electrical Systems Menu> 3.1 Spindle Motors

Burning

306 Service Tests, Utilities & Calibrations

Page 43

2. The following screen is displayed, reset the circuit breakers and make sure there is a light showing.

3. The following screen is displayed, select which spindle you want to test and press ok.

4. The following information message is displayed, press ok to test the selected spindle in both directions.

5. While the test is in progress the following message is displayed.

6. When the test has completed the following message is displayed.

3.2 Front Spindle System

Description

The procedure checks the operation of the Front spindle system first in open loop (operating the Motor

system and showing the number of encoder units counted during the movement) and in close loop with a

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 307

Page 44

start stop detection procedure where the PWM to start the rotation movements is calculated to ensure

correct mechanical operation as well as servo control. The second part of the test takes about 30 min.

NOTE: Only one of the motors includes the encoder system. Both motors are set in series so the failure

of one can cause the failure of the other.

NOTE: Run this test to ensure correct operation of the Front spindle system or well after a system error

related with the system to perform the appropriate troubleshooting.

Procedure

1. Go to Diagnostics menu and select 3. User Electrical Systems Menu> 3.2 Front Spindle Sys-

tem

2. The following screen is displayed, reset the circuit breakers and make sure there is a light showing.

3. The front panel displays the following message, this test must be performed without media loaded, con-

firm there is no media loaded and press the ok key to continue.

Test, Utilities & Calibrations

4. The front spindle motor is turned continuously (open loop) in the ROLL direction, the results are then dis-

played on the front panel in encoder units, press any key to continue.

NOTE: Ensure the encoder is reading counts during the movement, if the value of the encoder units

counted is too low (in the hundreds range, this could indicate a faulty encoder or encoder signal path).

If the number of encoder units counted is 0, there is a complete lack of movement if the motor moved

(spindle turned) there is a failure in the coder system or signal path which requires a repair.

308 Service Tests, Utilities & Calibrations

Page 45

5. The front spindle motor is turned continuously (open loop) in the UNROLL direction, the results are then

displayed on the front panel in encoder units, press any key to continue.

6. The test can be performed again for the purposes of further troubleshooting, press ok to repeat, or cancel

to continue the spindle test.

7. The printer continues the test by displaying the following messages, press any key to continue

8. The front panel displays the following message while the front spindle moves in a start/stop method (close

loop).

NOTE: This part of the test may take a few minutes to complete, and it may not be obvious

that the test is in progress at times, as the printer may halt and do nothing.

9. The printer will apply gradually a value of PWM to the motor until the point where the motor starts rotat-

ing. This value will be the start of the movement point and it is a representation of the amount of friction in

Tests, Utilities & Calibrations

Service Tests, Utilities & Calibrations 309

Page 46

the system (amount of energy required for the motor to start moving). The test will be repeated 5 times forwards and backwards and a final PWM average value will be displayed, such as the one shown here.

NOTE: A good friction value of a system that is working correctly will be below 1400 eu PWM.

3.3 Rear Spindle System

Description

The procedure checks the operation of the Rear spindle system first in open loop (operating the Motor

system and showing the number of encoder units counted during the movement) and in close loop with a

start stop detection procedure where the PWM to start the rotation movements is calculated to ensure

correct mechanical operation as well as servo control. The second part of the test takes about 30 min.

NOTE: Run this test to ensure correct operation of the Rear spindle system or well after a system error

related with the system to perform the appropriate troubleshooting.

Test, Utilities & Calibrations

Procedure