Page 1

8 Remote Support

• Callme@HP Configuration .................................................................................. 792

• Installation................................................................................................. 792

• Troubleshooting the setup ............................................................................ 793

• Callme@HP Operation....................................................................................... 794

• How to launch a call from Customer Printer.................................................... 794

• How to access a call from the Customer ........................................................ 794

• How to receive a file from a customer............................................................ 795

• How to Video stream and make snapshots..................................................... 795

• How to initiate a Remote Connection ............................................................ 796

• How to terminate a call ............................................................................... 797

• How to look for an old service request .......................................................... 797

Remote Support

Safety 791

Page 2

Callme@HP Configuration

Installation

This information is also included in the Printer´s Installation guide.

During installation process, specific information must be introduced into the IPS preferences to correctly

route the Remote Support Calls to the Support Agent (HP or Authorized Service Provider approved to

provide this Remote Support Service).

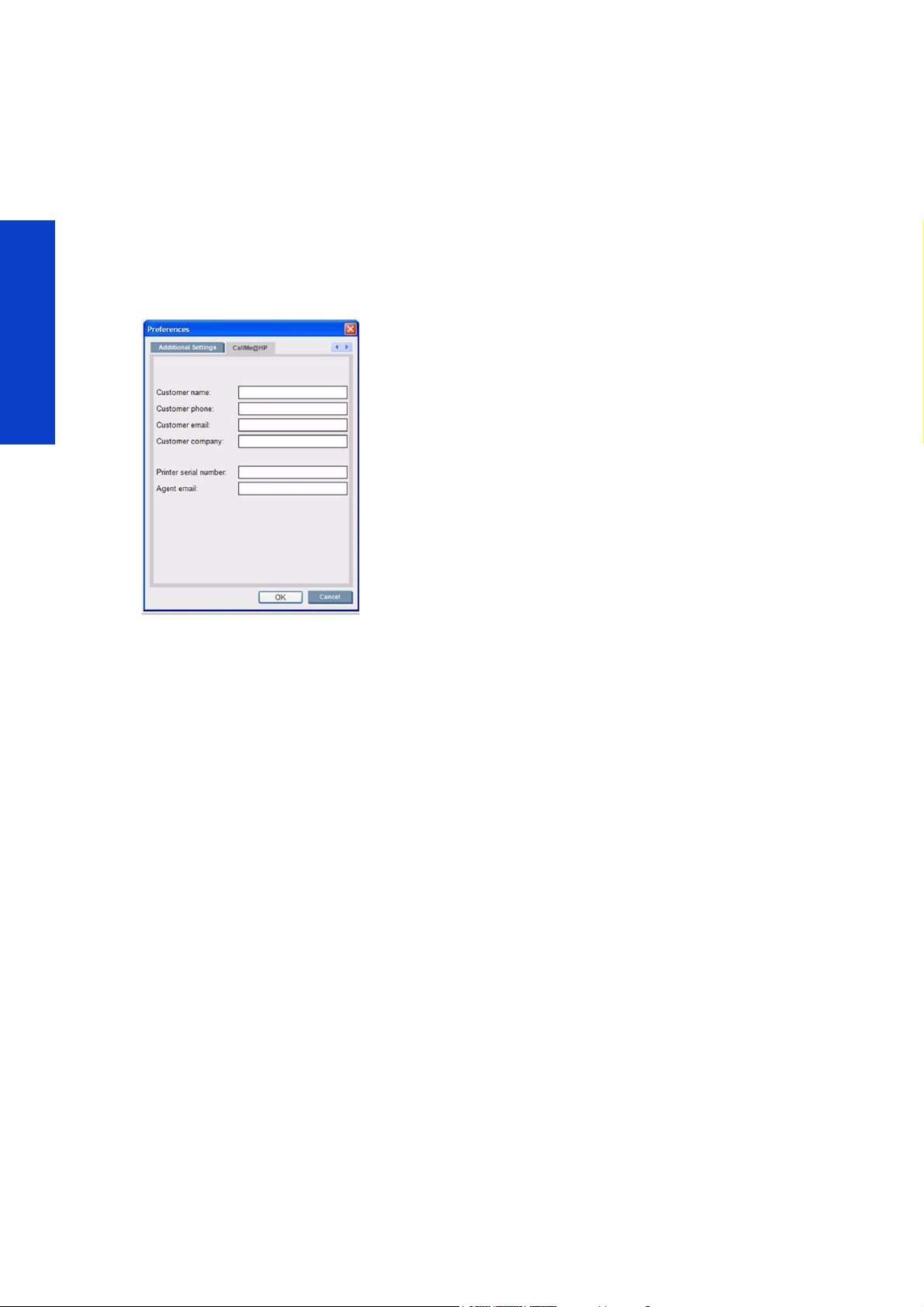

1. Go to the IPS menu “Tools”, then press “Preferences” and look for the tab “Callme@HP”.

Remote Support

2. Enter in information into all 6 fields:

The first four fields are related to customer data. They can be generic and are intended to be automatically

loaded as default data into the Remote Support Application.

a. Printer Serial Number: Check that the serial number is correctly entered into the text field.

b. Agent E-mail: This parameter is VERY important as it establishes the call routing to the

appropriate support organization. If the configuration of this field is not correct any support

calls made will not reach the intended recipient.

- If the Reseller partner is going to provide the support for the unit AND has been approved for

using this tool and has the account setup and permissions setup, enter in this field the E-mail

of the reseller engineer supporting this printer, using the reseller's domain used for creating

the account.

- If the reseller is not entitled to use the “Callme@hp” remote troubleshooting tool, then leave

the default value: printcare@hp.com.

3. Launch the “callme@HP” application under the “tools” menu option and verify the information entered

loads correctly into the template.

Important: The application will ask for software to be installed, select yes to all the requirements.

If no window is displayed, go to the Site Preparation document under the section where the network

requirements are described, and check that all the requirements for network connectivity have been met.

4. Submit a Testing Call including the following text in the comment box: “Customer Name Installation Call.

Remote Support Configuration Check”.

792

Page 3

Troubleshooting the setup

If after the Callme@HP software is installed the calls are not reaching the desired queue, verify that the

agent email field is correct. If the email address ends in ‘hp.com’ the call will be routed to the generic

GBU queue.

NOTE: If the agent is qualified to support the printer through the remote tool, the email can be different

from the default ‘printcare@hp.com’.

The reseller is qualified if the following is true

• The reseller has been trained to support the printer.

• An HP digital badge has been supplied.

• Access to ‘Callme@hp’.

• A reseller queue has been created

If the reseller queue has not been created and the agent’s email does not end in ‘hp.com’, the call will be

sent to an incorrect queue and the call will be lost.

Remote Support

Safety 793

Page 4

Callme@HP Operation

How to launch a call from Customer Printer

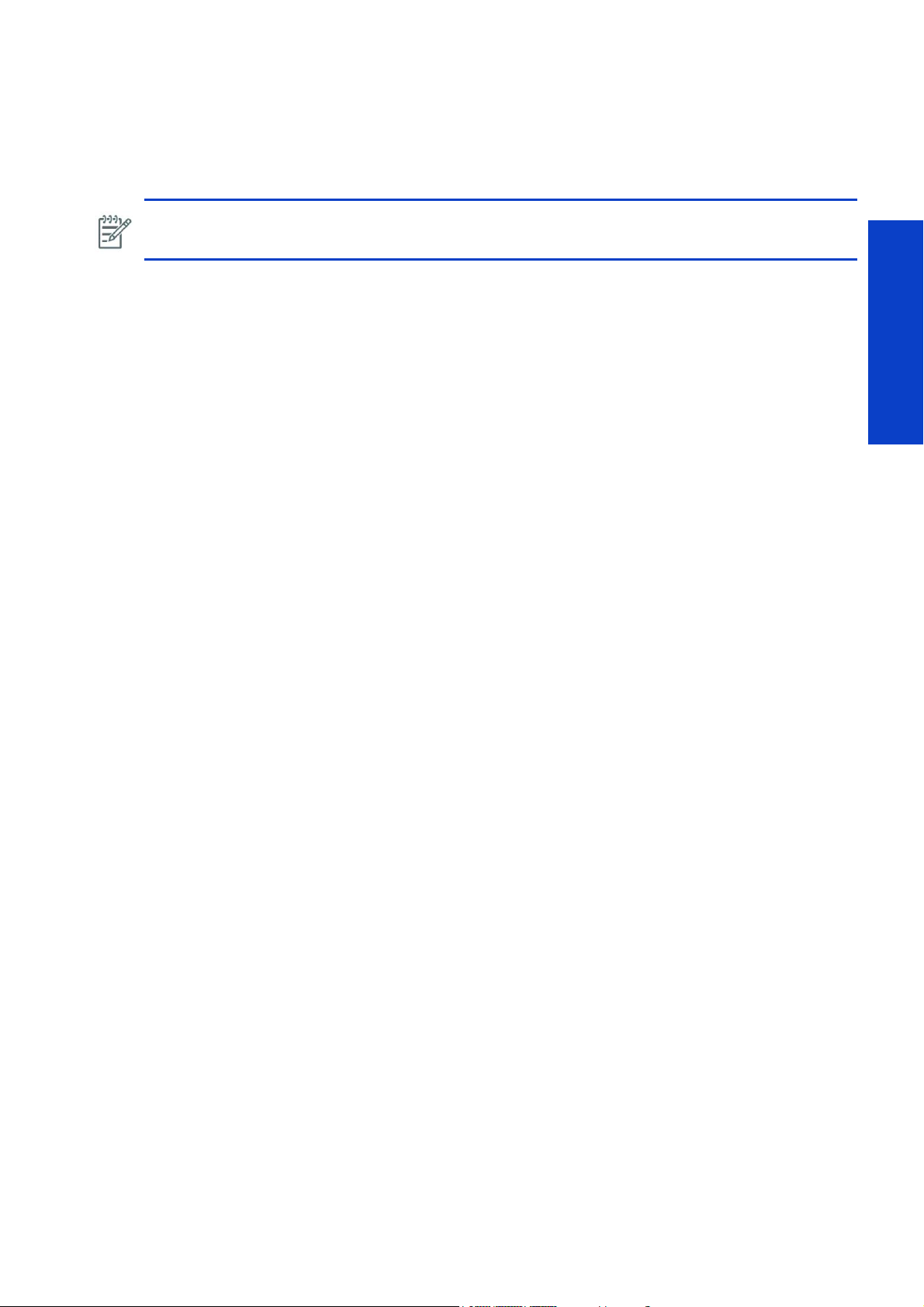

1. Go to the Callme@HP option in the “Tools” drop-down menu in the IPS.

Remote Support

2. Accept all requirements to install additional software.

3. If correctly configured, the web page will open with all parameters filled. Special attention should be

made to the Agent e-mail option. The mail domain MUST match the Reseller Domain (“@hp.com” for HP

direct supported units). If not correctly configured, please go to the appropriate chapter in the installation

guide.

4. HP agents have access to all reseller queues. There is no need to modify parameters. In second level esca-

lations, use the reseller queue.

5. Please make sure the customer fills in correctly the comments field with the issue description.

6. Press the ‘Accept’ button.

How to access a call from the Customer

1. Login to Callme@Hp page: https://ispe4p.houston.hp.com/AgentWeb/login.aspx

2. After login, identify the corresponding call from the list and select “Assign SR”.

794

Page 5

How to receive a file from a customer

To receive files go to the Callme@HP customer screen, ask the customer to select the “send file” option,

or do it yourself in a Remote IPS PC Control session. Browse the IPS PC folders and select the files.

On each Remote Troubleshooting Session, always capture the Service Plot and send to the HP Division

Customer Assurance contact.

Remote Support

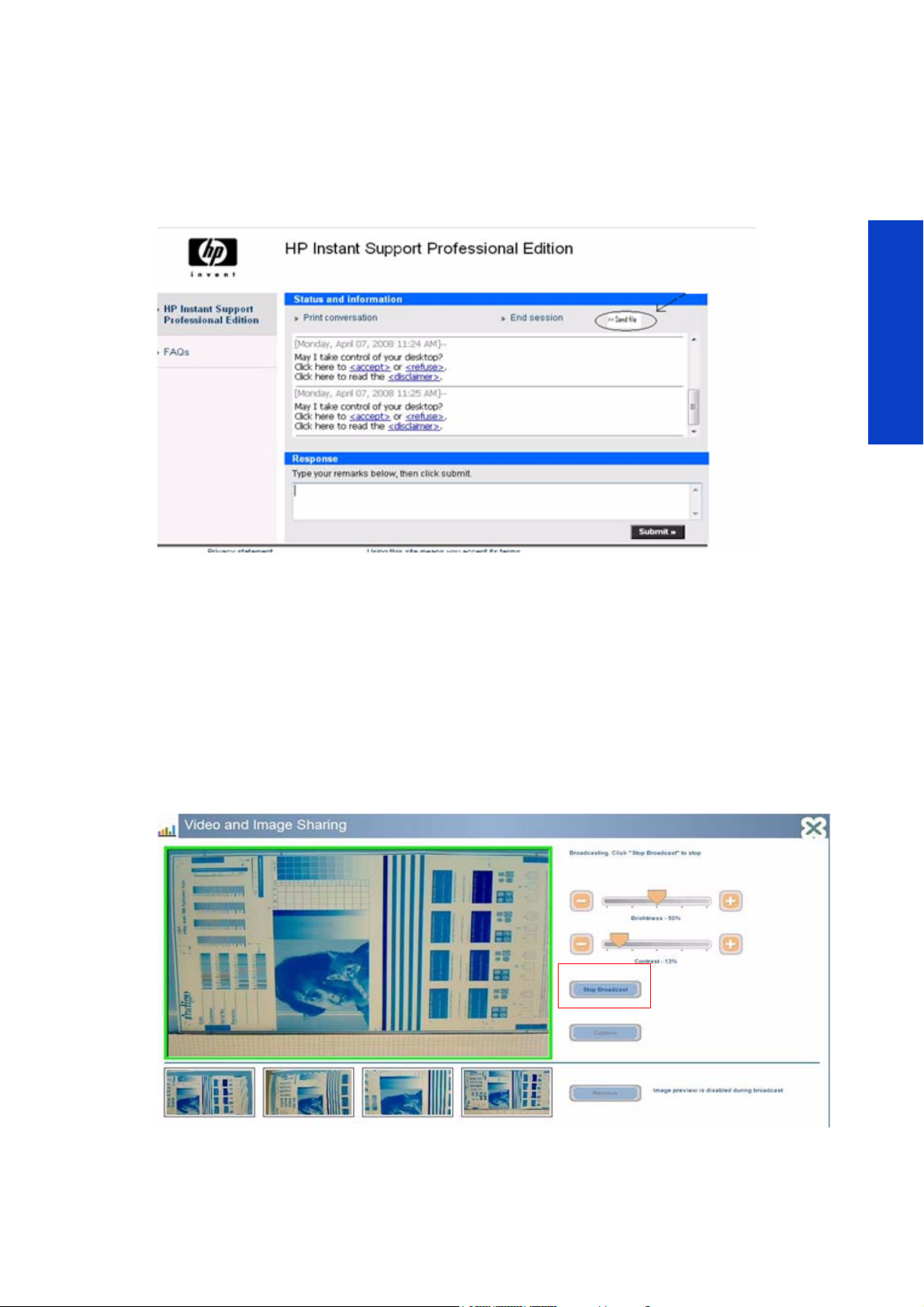

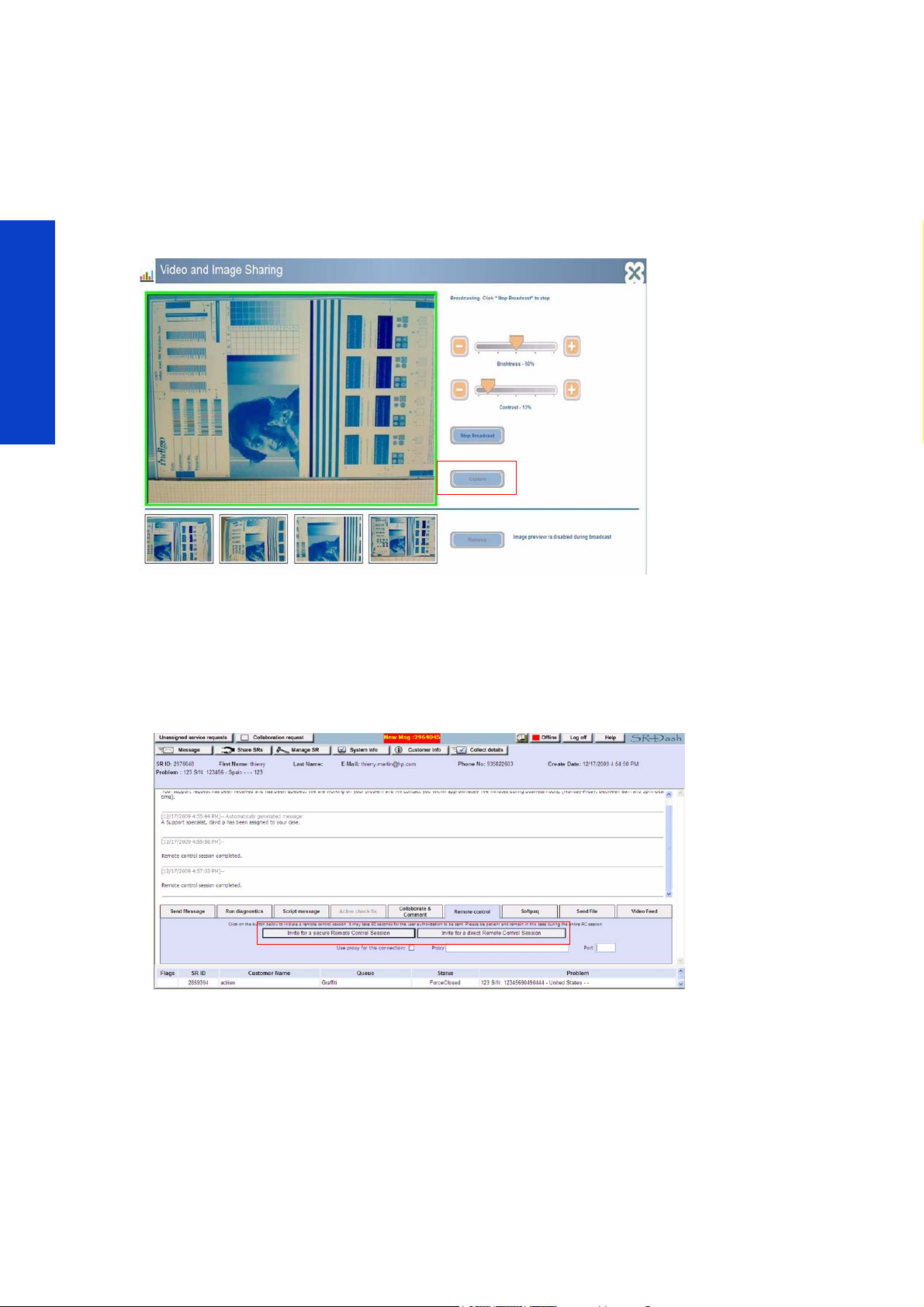

How to Video stream and make snapshots

Video Streaming

LX Series printers come equipped with an HP Web Cam and 5m of USB extension cable.

1. Connect the USB extension cable to the IPS PC and the web cam to the USB extension cable.

2. Click on the ‘video’ tab in the Callme@HP tool.

3. The customer must start the ‘Print Care Webcam’ application in ‘Start> All Programs’

4. Customer must select ‘Start Broadcast’.

5. The HP Support engineer must select ‘Receive video’. A video screen will open and after a few seconds it

will start to buffer the video.

Safety 795

Page 6

• Note that there is around 5 seconds of delay on the video.

• Avoid video streaming and using the remote IPS PC at same time.

• To reinstall the camera software refer to page 775.

Taking snapshots

1. With the ‘Print Care Webcam’ tool activated, select the ‘Capture’ button.

2. Images can be seen in the small windows below Web Cam display.

Remote Support

3. You can transfer the pictures through the ‘send file option’. The snapshots are placed in the following path:

C:\Program Files\PrintCare\webcam\images.

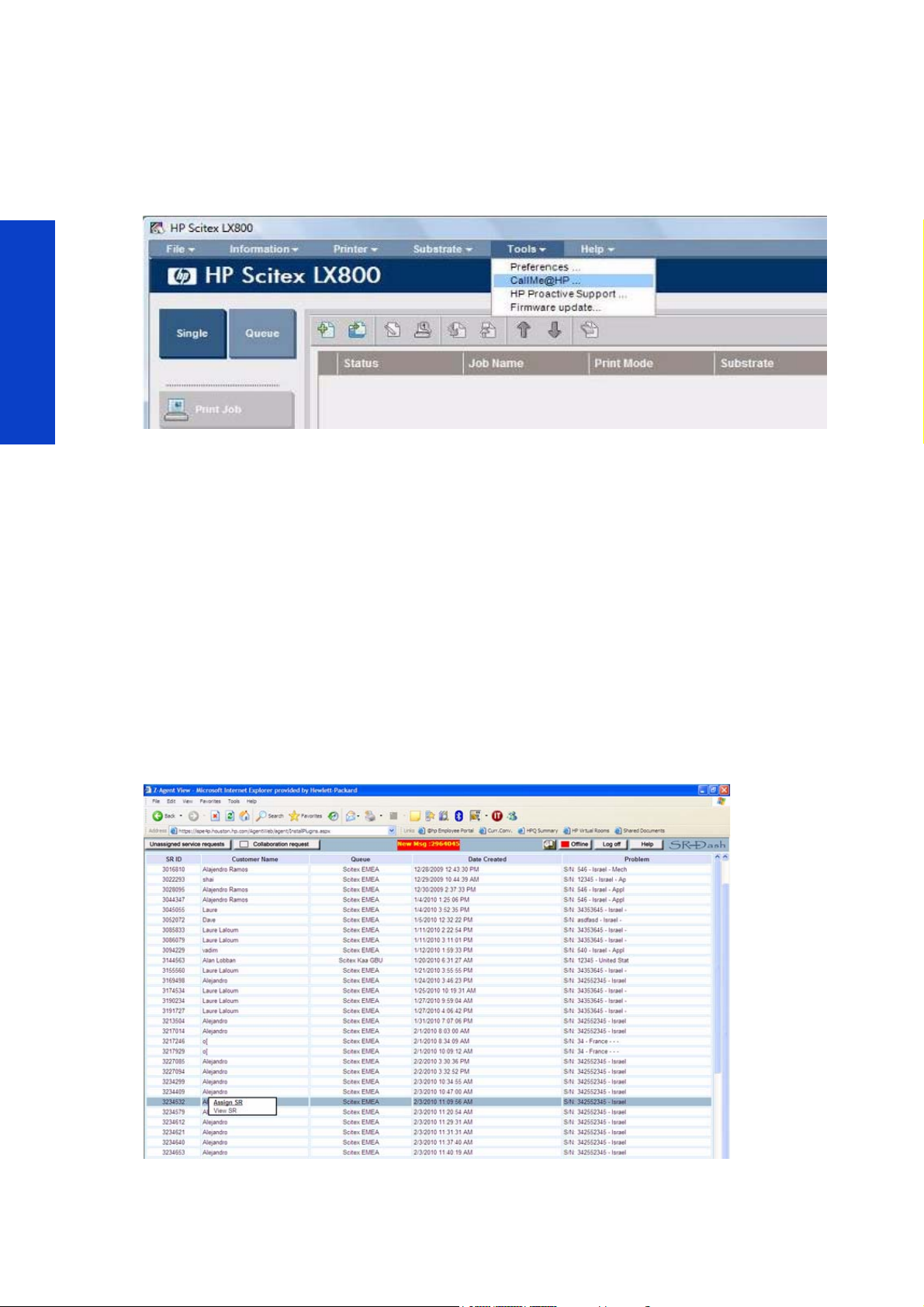

How to initiate a Remote Connection

1. Login to Callme@Hp page: https://ispe4p.houston.hp.com/AgentWeb/login.aspx.

2. Select ‘Invite for a secure remote control session’ or ‘Invite for a direct remote control session’, depending

on the level of security required.

3. The customer must accept the remote connection on the chat screen.

796

Page 7

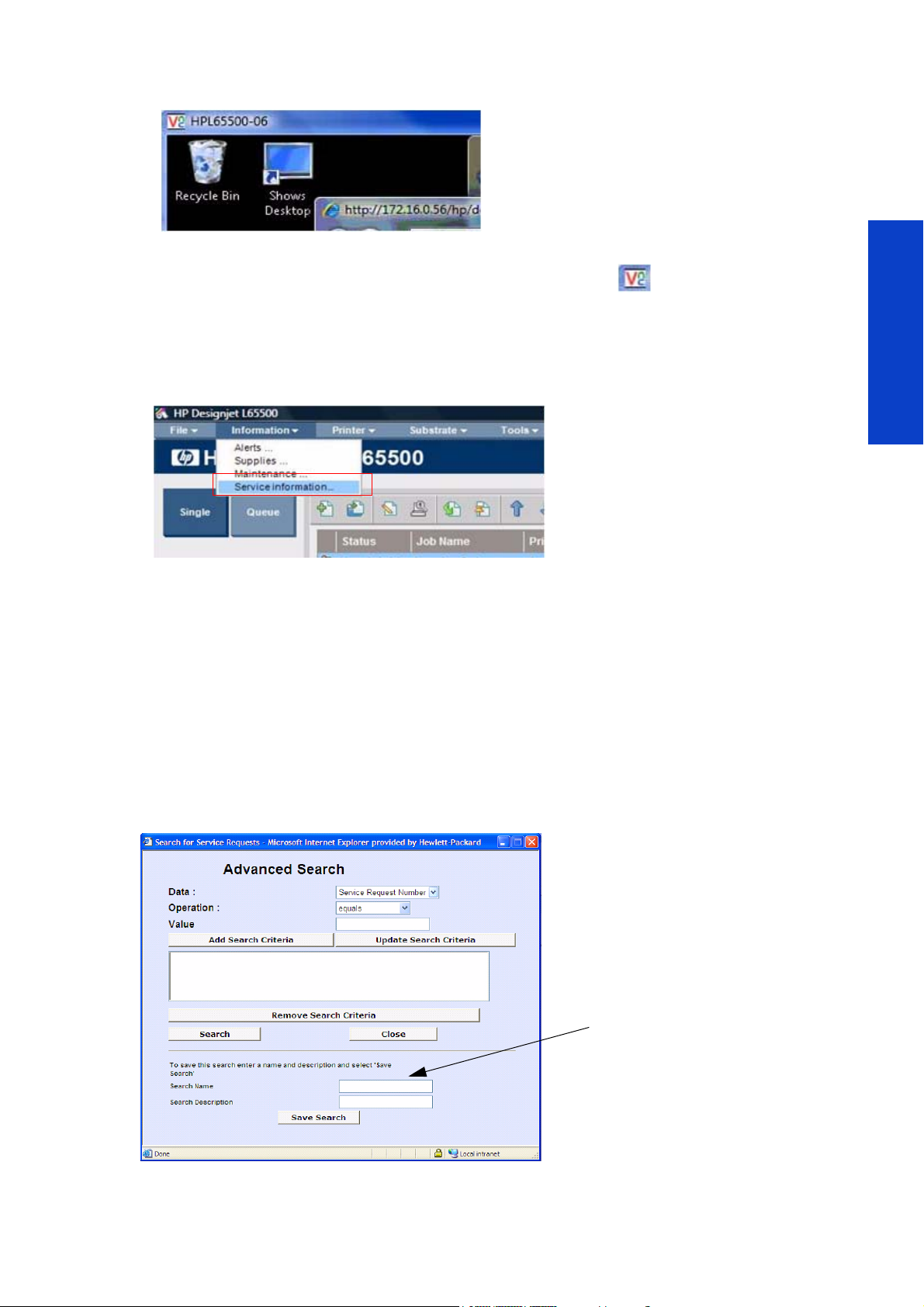

4. Once a remote session has started the customer’s IPS PC can be seen through window with VNC logo.

2. Select the search criteria, we recom-

mend by:

•By SR Queue

•By Queue name

•By Date

TIP: The most common searches can

be saved for later use.

5. The customer can see the VNC icon at the bottom right of the screen.

How to view the Service Plot via a Remote Connection

1. From the IPS, click on Information -> Service information and an internet explorer window is opened with

the service plot.

Remote Support

2. The customer must accept the remote connection.

3. A copy of the service plot is placed on the desktop under folder ‘Service information’.

4. Always capture the service plot and send to the HP Division Customer Assurance contact.

How to terminate a call

The Customer can cut the remote control at any time by right-clicking on the VNC icon, and selecting ‘stop

session’. The remote support engineer can terminate the session by closing the VNC window.

How to look for an old service request

1. In the HP Support application, go to ‘Advance Search’.

Safety 797

Page 8

Remote Support

798

Page 9

9 Move the printer

• Related documents ........................................................................................... 800

• Moving the printer to the same site (no ramps, no steps).........................................801

• Moving the printer to the same site (with ramps or steps) ....................................... 802

• Moving the printer to a new site (transport temperature more than 5C/41F) ............. 806

• Moving the printer to a new site (transport temperature below 5C/41F).................... 816

Move the printer 799

Moving the Printer

Page 10

Related documents

• Site Preparation Guide

• Installation Guide

Moving the Printer

800 Move the printer

Page 11

Moving the printer to the same site (no ramps, no

steps)

If you wish to move the printer a short distance on the same site, across a horizontal floor with no steps

and no slopes, see the following instructions.

• To prepare the new installation site, see the Site Preparation Guide.

• Unmount and reinstall the printer, use the Installation Guide as a reference.

Procedure

1. Turn off the printer.

2. Disconnect all power and network cables from the printer.

3. Raise the feet so that the wheels (A) touch the ground. To raise a foot:

a. Use a 30 mm wrench to unlock the nut at the top of the foot.

b. Rotate the nut manually down the bolt. Leave about 2 cm (0.8 in) clearance at the bottom

between nut and foot.

c. Use a 15 mm wrench to rotate the foot upwards. Use the flat faces at the bottom of the bolt to

fit the wrench.

d. Raise the foot as far as the bolt allows.

e. Use the 30 mm wrench to relock the nut.

CAUTION: Take care to raise the feet as high as you can. They may break if they touch the ground

while the printer is in motion.

4. Push the printer from the outside corners of the top covers.

After moving the printer, you may in some cases need an electrician to reconnect the power cables. You

may also need to reconfigure the network: from the front panel, from the HP Internal Print Server computer,

and from the RIP computer. See the Installation Guide for more details.

Moving the Printer

Move the printer 801

Page 12

Moving the printer to the same site (with ramps or

steps)

If you need to move the printer within the same site but their are ramps or steps on the route, you will need

to lift the printer with a forklift or a crane

Some preparations must be made before the printer can be lifted (listed below), and failure to follow these

steps could cause irreversible damage to the printer.

Procedure

1. Check the Site Preparation Guide to make sure that the new site is well-prepared. For more details on

each procedure refer to the installation guide.

2. Turn off the printer.

3. Reboot the printer in diagnostic boot mode and '4.13: Force fill the intermediate ink tanks’ to prevent

broken bags, see

4. Disconnect the 3 phase and single phase power supply.

5. Remove the printheads and store them in their original caps.

6. Remove the two aerosol filters.

7. Remove the ink cartridges and store them in their initial packaging.

page 330'.

8. Remove the Printhead Cleaner Roll. You can cut the material, removing the used material of the lower

core, but important: KEEP THE LOWER COVER (can remove the used material around this core).

9. Remove the HP Internal Print Server and switch.

10. Remove the monitor, keyboard, mouse, and keyboard platform See page 505.

11 . Remove the Left Side Front Cover and Left Side Rear Cover See page 483.

12 . Force fill the intermediate ink tanks to prevent broken bagsSee page 339.

13 . Gently remove the intermediate ink tanks without shaking them.

Moving the Printer

14 . Remove the Right Side Rear Cover See page 485.

15 . Open the sliding door.

802 Move the printer

Page 13

16 . Secure the carriage in the travel position with the T25 screw.

Graphics taken from Installation Guide. For reference only.

17. Secure the scan axis to the printer chassis with the eight T20 screws.

Graphics taken from Installation Guide. For reference only.

Move the printer 803

Moving the Printer

Page 14

18 . Secure the Printhead Cleaning Assembly with two T20 screws.

Pass the strap under the printer frame

19. Secure the electrical cabinet with the strap.

NOTE: Make two loops if possible. The strap should be loose or have very little tension

during transportation.

Moving the Printer

20. The ISM must be secured with a strap.

804 Move the printer

Page 15

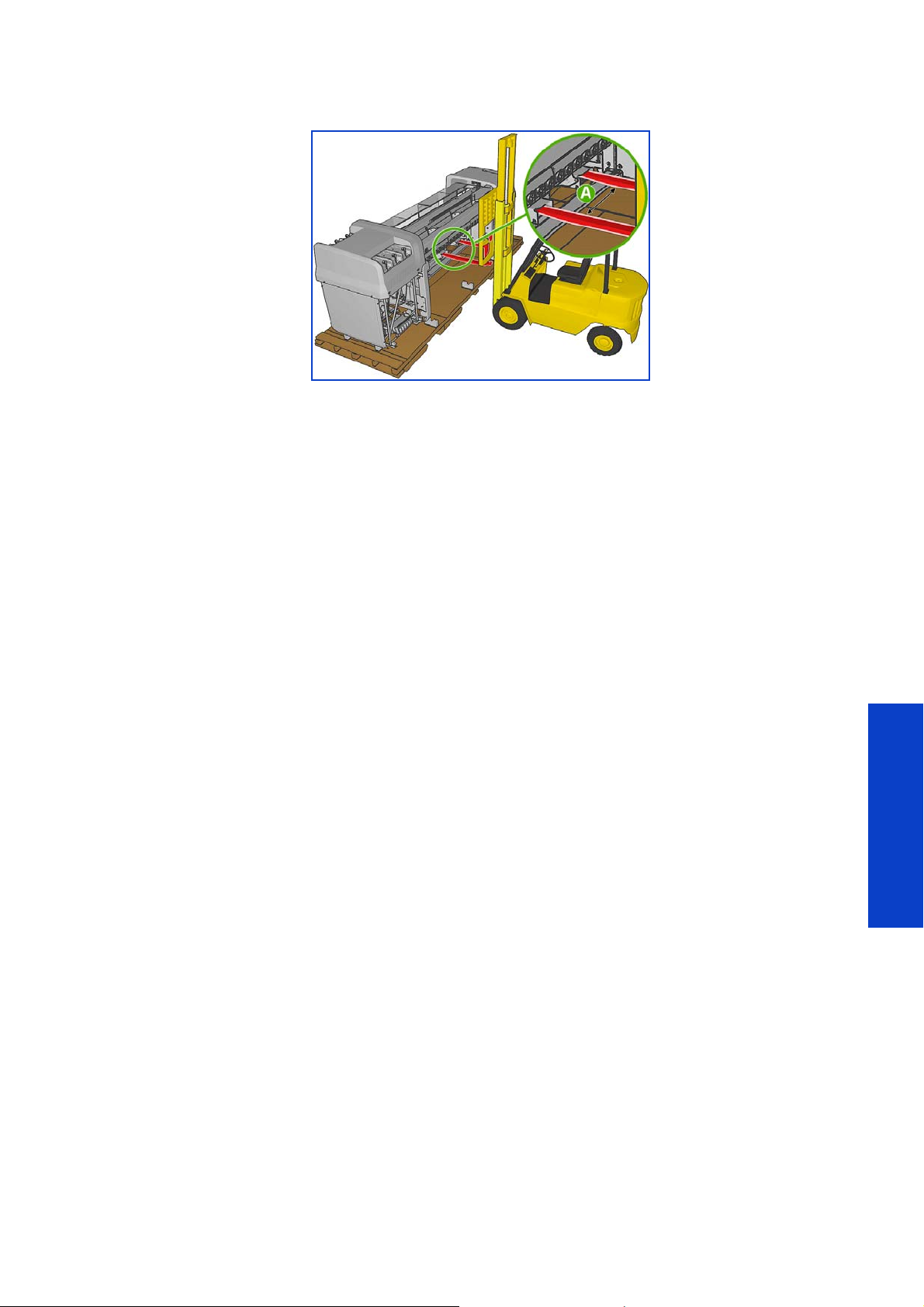

21. You can now lift the printer with a forklift, pallet jack, or crane using the forklift guides in the middle of the

printer. Use the recommendations in the Site Preparation Guide and Installation Guide.

Move the printer 805

Moving the Printer

Page 16

Moving the printer to a new site (transport

temperature more than 5C/41F)

If you need to move the printer to a new site, the printer must be fixed to a pallet. If the temperature will

not drop below 5° C/41° F, follow these instructions. Failure to follow these instructions could cause the

ink to freeze, which would damage the ink system and require heavy repair.

Procedure

1. The following steps are the main steps, refer to the installation guide (in reverse order) for a more detailed

explanation.

2. Lift the printer with a forklift, pallet jack, or crane, following the instructions in the Site Preparation Guide

and Installation Guide.

3. Remove the four bolts that secure the foot blocks to the pallet (16 total) and remove them.

4. To attach the foot block to the printer foot, remove the nut and washer.

5. Position the block and replace the nut and washer so that it is attached to the printer foot.

Moving the Printer

806 Move the printer

Page 17

6. Fix the two E-Cabinet Cushion Holders onto the right side of the shipping pallet.

Right side

Cushion holder

Long Tray

Short Tray

Short Tray

Long Tray

180

300

240

340

530

200

Front

Rear

7. Install four ISM Supports into the two ISM Support Trays (long and short).

8. Install ISM Supports and Trays onto the right side of the shipping pallet at the following dimensions:

9. Add new info from Excel sheet here (page 6 -7-9-10-11-12-13-15-19 and bottom line drawing page 21, 24,

blue shrink wrap picture on 25

Move the printer 807

Moving the Printer

Page 18

10. Place the forklift underneath the printer and make sure that the forks on the forklift are spaced 80 cm

apart (A). Place the printer on the pallet, and secure it with the four 24 mm nuts.

11 . Secure each foot block with the four bolts removed with the block earlier.

Moving the Printer

808 Move the printer

Page 19

12. Place tape around the Cusion holders as shown here:

13 . Secure the Inbox onto the pallet.

14 . Ensure the Inbox is secured between the ISM and the lifting bracket.

Moving the Printer

Move the printer 809

Page 20

15 . Ensure that the box with the PC inside in an upright position and secured the with strapping. Place next to

Important: The PC Box must be in an

uprigtht position

Use straapping to secure the covers (but not too tight)

Covers in wrapping

Secure support

foams herewith tape

Place the ID cover

box here

the Inbox

16 . L65500/LX600 only: Place the ID Covers on to the pallet on the right side of the E-Cabinet.

.

17. LX800 only: Place the ID Covers in their box and secure with strapping. Place onto the pallet at the rear

(close to the E-Cabinet).

Moving the Printer

810 Move the printer

Page 21

18 . LX800 only: Place the Gutter Assembly in the box, and place on the pallet next to the PC box

Gutter Assmbly

U-shaped foam block

Plywood Top clamp

Media Drive Input spindle

19. Secure the Media Drive Input spindle onto the pallet using two U-shaped foam blocks and Plywood Top

Clamps.

20. LX800 only: Assembly the clamps and supports on the left and right of the pallet (front).

Move the printer 811

Moving the Printer

Page 22

21. LX800 only: Install the two Dual Rolls onto the foam supports, and clamp the rolls in place with the Ply-

Ensure that the differentials of the two dual

rolls are placed at either ends of the spindles

to give balance

wood clamps.

22. LX800 only: Tighten the locking screws of the differentials and tape the wrench keys to the spindles.

Moving the Printer

23. LX800 only: Remove the End Caps of the Dual Rolls as they can cause damge to the side plates. Place

the End Caps in the Inbox

24. LX800 only: Add another layer of foam supports on top the the existing foam supports (see above).

812 Move the printer

Page 23

25. LX800 only: Install the two Wrinkle Deflectors onto the foam supports, and place foam stoppers ot

Foam stopper

Media Drive Input

Spindle

Plywood clamp

each end.

26. LX800 only: Install the Media Drive Input spindle into the foam supports and clamp in place with the

Plywood Clamps.

27. LX800 only: Install the Spindle Stoppers at both ends of the spindle.

Moving the Printer

Move the printer 813

Page 24

28. LX800 only: Install the Media Drive Output Spindle into the printer as per normal operation, and

secure it in place with a tie-wrap at both ends.

29. Wrap the complete printer with 3D VCI Bag as shown below. Make sure the printer is fully covered and is

sealed using packing tape.

30. If necessary, build the crate around the printer. You will need an electric screwdriver with a Philips head.

Moving the Printer

814 Move the printer

Page 25

31. Each panel is numbered, refer to the drawing below to help with assembling the panels.

2

8

1

5

6

4

12

7

3

10

11

9

32. Wrap the compete package with a plastic sheet.

33. Cover the package in heavy-duty wrapping and shrink-wrap.

Move the printer 815

Moving the Printer

Page 26

Moving the printer to a new site (transport

temperature below 5C/41F)

In this case, before switching off the printer, the ink must be removed from the tubes. You need to have

the ink system cleaning tubes and 5 liter of distilled water.

The procedure below shows how remove the ink from one line of color. This operation must be repeated

5 times (total of 5 hours).

ISM Flush and clean a single ink system line

Flushing the ink lines with distilled water and then with air removes the ink from the tubes, this enables you to remove

and replace parts of the ink system. The flushing procedure is done one ink line at a time.

1. Remove the printheads and store them in their caps.

2. Remove the Left Side Front Panel See page 483.

3. Remove the Left Side Rear Panel See page 483.

4. Remove the Left Side Lateral Panel See page 483.

5.Remove the Ink Cartridge.

Moving the Printer

6.Carefully remove the intermediate tanks of the color you are

going to flush

.

NOTE: Store the intermediate ink tanks vertically.

Failure to store them vertically can cause a broken

bag.

816 Move the printer

Page 27

7. Place the Flushing Tool in the space left when the ink cartridge

was removed, and connect the ink connector to the connection

port of the tool.

8. Connect cable from the Flushing Tool to J18 on the ISM Board.

9. From the Front Panel go to the Diagnostic Menu and select Ink System Menu 4.0>Flushing procedure>Activate

Flushing tool Pump.

10. Open the Entry Electrovalve of the color you are flushing Ink System Menu 4.0>Flushing procedure>Operate

Entry electrovalve-> “Color to flush”.

11 . Unscrew the top of the Cleaning Tool and fill the bottle with 500cc of distilled water.

12. Insert a needle into the tube coming from a waste bottle

13 . Insert the needle into the Printhead Ink Connector of the

Carriage assembly. Ensure you insert it into the correct color.

Moving the Printer

Move the printer 817

Page 28

14 . Ensure the path switch is in the horizontal position.

15 . Turn On the Flushing Tool with the switch located on top.

The Cleaning Tool slowly pumps the distilled water into the tubes and ink system of the color you are cleaning.

The pumping action cleans ink out of the tubes and into the draining bottle.

16 . When the level of distilled water is half finished:

a.Install the New Empty Intermediate Flushing Tank (that came

with the flushing kit) into the Left Intermediate slot, wait 10 sec

onds for the ink to be cleaned from this area and then remove

the tank.

-

b.Install the Intermediate Flushing Tank into the Right Intermedi-

ate slot, wait 10 seconds for the ink to be cleaned from this area

and then remove the tank.

NOTE: If the distilled water in the Cleaning

Tool bottle becomes low before the ink system

has been cleaned of ink, you must refill the

bottle with more water. You must stop the

Flushing tool to add more water.

17. When the Ink system has been cleaned of ink and the Flushing tool becomes empty of water, the pump of the

Cleaning Tool will then push air into the ink system tubes, which will push the water out into the draining

bottle of the Quick Connector Flushing Tool, this process will last for approximately 5 minutes.

18 . When five minutes has past:

a.Install the Intermediate Flushing Tank (that came with the flush-

Moving the Printer

ing kit) into the Left Intermediate slot, wait 10 seconds for the

water to be removed from this area and then remove the tank.

b.Install the Intermediate Flushing Tank into the Right Intermedi-

ate slot, wait 10 seconds for the water to be removed from this

area and then remove the tank.

19. When the Ink system has been cleaned of ink and the

Flushing tool becomes empty of water, the pump of the

Cleaning Tool will then push air into the ink system tubes, which

will push the water out into the draining bottle of the Quick Connector Flushing Tool, this process will last for

approximately 5 minutes.

818 Move the printer

Loading...

Loading...