Page 1

Service Manual

Page 2

Page 3

HP Color LaserJet CP2020 Series

Service Manual

Page 4

Copyright information

Safety information

Trademark credits

© 2008 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number CB493-90948

Edition 1, 09/2008

WARNING!

Potential Shock Hazard

Always follow basic safety precautions when

using the product to reduce risk of injury from

fire or electric shock.

Read and understand all instructions in the

user guide.

Observe all warnings and instructions

marked on the product.

Use only a grounded electrical outlet when

connecting the product to a power source. If

you do not know whether the outlet is

grounded, check with a qualified electrician.

Do not touch the contacts on the end of any

of the sockets on the product. Replace

damaged cords immediately.

Unplug the product from wall outlets before

cleaning.

Do not install or use the product near water

or when you are wet.

Install the product securely on a stable

surface.

Microsoft® and Windows® are U.S.

registered trademarks of Microsoft

Corporation.

Windows Vista® is either a registered

trademark or trademark of Microsoft

Corporation in the United States and/or other

countries or regions.

Linux is a U.S. registered trademark of Linus

Torvalds.

UNIX® is a registered trademark of The

Open Group.

PostScript® is a trademark of Adobe

Systems Incorporated.

ENERGY STAR and the ENERGY STAR

mark are registered U.S. marks.

Install the product in a protected place where

no one can step on or trip over the power

cord and where the power cord will not be

damaged.

If the product does not operate normally, see

the online user guide.

Refer all servicing questions to qualified

personnel.

Information regarding FCC Class B, Parts 15

and 68 requirements can be found in the user

guide.

Page 5

Table of contents

1 Product basics

Quick access to product information .................................................................................................... 2

Product comparison ............................................................................................................................. 3

Product features ................................................................................................................................... 3

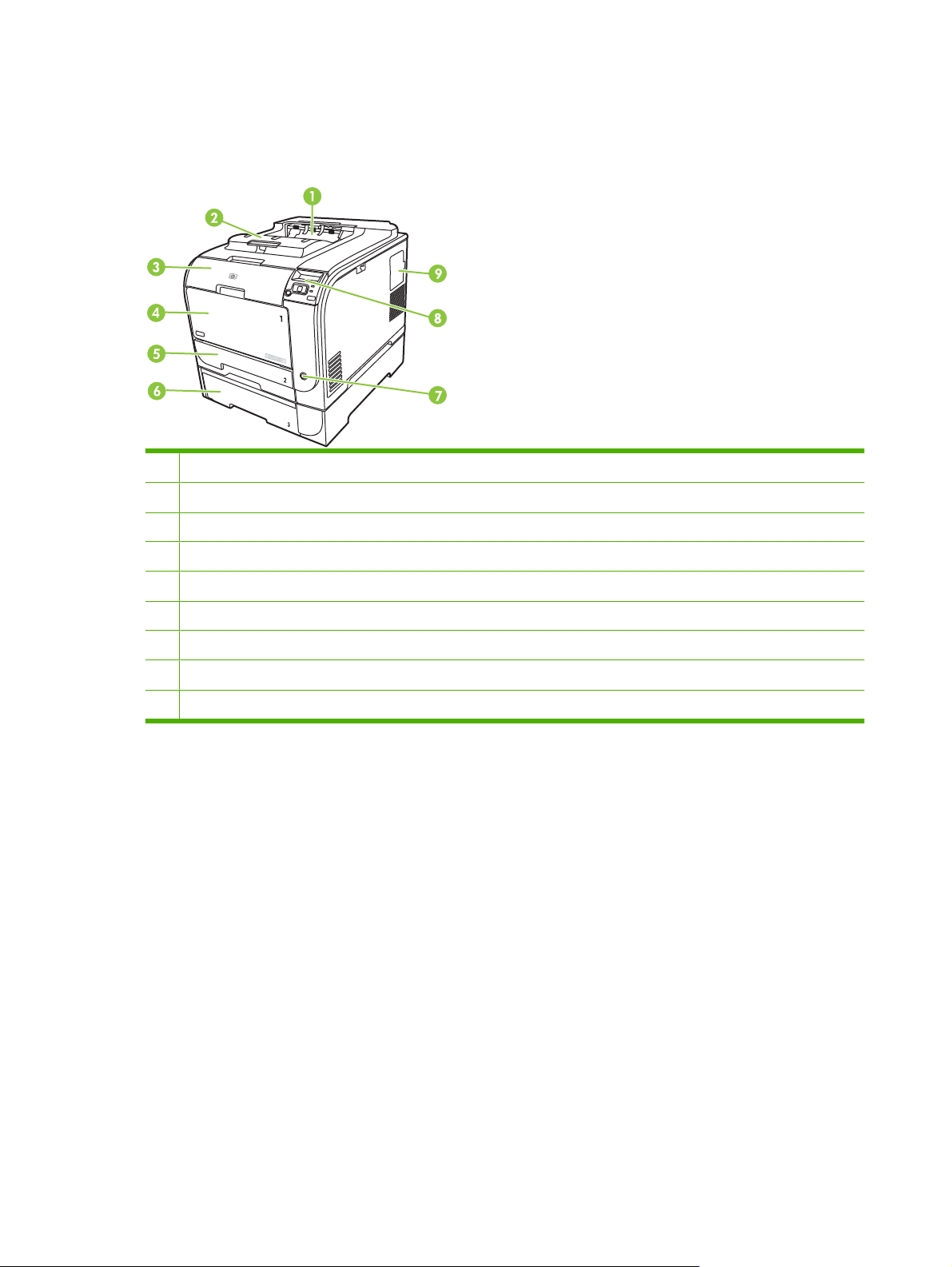

Walkaround .......................................................................................................................................... 4

Front and side view .............................................................................................................. 4

Back view ............................................................................................................................. 5

Model and serial numbers ................................................................................................... 5

Supported operating systems ............................................................................................................... 6

Supported product software ................................................................................................................. 7

Software included with the product ...................................................................................... 7

Recommended Installation for Windows ............................................................. 7

Express Installation ............................................................................................. 7

Macintosh software ............................................................................................. 7

Printer driver ........................................................................................................................ 7

Other software provided ...................................................................................................... 8

Software for Windows ......................................................................................... 8

HP ToolboxFX .................................................................................... 8

Software for Macintosh ....................................................................................... 8

PostScript Printer Description (PPD) files .......................................... 8

Configure the product using a Macintosh ........................................... 8

Status Alerts software ......................................................................................... 8

Software for networks ......................................................................................... 8

HP Web Jetadmin ............................................................................... 8

Embedded Web server ....................................................................... 9

Linux ................................................................................................... 9

System requirements ........................................................................................................... 9

Windows requirements ........................................................................................ 9

Macintosh requirements ...................................................................................... 9

Connectivity ........................................................................................................................................ 10

Supported network operating systems .............................................................................. 10

Printer sharing disclaimer .................................................................................. 10

Supported network protocols ............................................................................................. 10

ENWW iii

Page 6

2 Control panel

Control-panel walkaround .................................................................................................................. 14

Control-panel menus .......................................................................................................................... 15

Use the menus ................................................................................................................... 15

Reports menu .................................................................................................................... 16

System setup menu ........................................................................................................... 17

Service menu ..................................................................................................................... 19

Network config. menu ........................................................................................................ 20

3 Paper and print media

Understand paper and print media use .............................................................................................. 22

Supported paper and print media sizes .............................................................................................. 23

Supported paper types and tray capacity ........................................................................................... 25

Special paper or print media guidelines ............................................................................................. 27

Load paper and print media ............................................................................................................... 28

4 Manage and maintain

Information pages ............................................................................................................................... 32

HP ToolboxFX .................................................................................................................................... 33

Open HP ToolboxFX .......................................................................................................... 33

Status ................................................................................................................................. 33

Alerts .................................................................................................................................. 34

Product information ............................................................................................................ 34

Set password ..................................................................................................................... 34

Help ................................................................................................................................... 35

Device Settings .................................................................................................................. 36

Network Settings ................................................................................................................ 39

Shop for Supplies .............................................................................................................. 39

Event log ........................................................................................................... 33

Set up Status Alerts .......................................................................................... 34

Set up E-mail Alerts .......................................................................................... 34

Device Information ............................................................................................ 36

Paper Handling ................................................................................................. 37

Printing .............................................................................................................. 37

PCL5c ............................................................................................................... 37

PostScript .......................................................................................................... 37

Print Quality ....................................................................................................... 38

Print Density ...................................................................................................... 38

Paper Types ...................................................................................................... 38

System Setup .................................................................................................... 38

Save/Restore Settings ...................................................................................... 38

Password .......................................................................................................... 38

Service .............................................................................................................. 39

iv ENWW

Page 7

Other Links ........................................................................................................................ 39

Embedded Web server ....................................................................................................................... 40

View the HP embedded Web server .................................................................................. 40

Embedded Web server sections ........................................................................................ 41

HP Web Jetadmin .............................................................................................................................. 43

Manage supplies ................................................................................................................................ 44

Supplies life ....................................................................................................................... 44

Print-cartridge storage ....................................................................................................... 44

HP policy on non-HP print cartridges ................................................................................. 44

HP fraud hotline and Web site ........................................................................................... 44

Print when cartridge is out ................................................................................................. 45

Replace print cartridges ..................................................................................................................... 46

Memory and font DIMMs .................................................................................................................... 50

Product memory ................................................................................................................ 50

Install memory and font DIMMs ......................................................................................... 50

Enable memory .................................................................................................................. 54

Enable memory for Windows ............................................................................ 54

Check DIMM installation .................................................................................................... 54

Clean the product ............................................................................................................................... 54

Firmware updates ............................................................................................................................... 55

5 Theory of operation

Basic operation ................................................................................................................................... 58

Major product systems ....................................................................................................... 58

Product components .......................................................................................................... 59

Sequence of operation ....................................................................................................... 60

Engine control system ........................................................................................................................ 61

DC controller ...................................................................................................................... 62

Low-voltage power supply ................................................................................................. 62

High-voltage power supply ................................................................................................ 63

Laser/scanner system ........................................................................................................................ 65

Laser failure detection ....................................................................................................... 65

Image-formation system ..................................................................................................................... 66

Image-formation process ................................................................................................... 66

Latent-image formation stage ............................................................................................ 67

Developing stage ............................................................................................................... 68

Transfer stage .................................................................................................................... 69

Step 1: primary charging ................................................................................... 67

Step 2: laser-beam exposure ............................................................................ 68

Step 3: development ......................................................................................... 68

Step 4: primary transfer ..................................................................................... 69

Step 5: secondary transfer ................................................................................ 69

Step 6: separation from the drum ...................................................................... 70

ENWW v

Page 8

Fusing stage ...................................................................................................................... 70

ITB cleaning stage ............................................................................................................. 71

Drum cleaning stage .......................................................................................................... 72

Pickup-and-feed system ..................................................................................................................... 73

Jam detection .................................................................................................................... 75

6 Removal and replacement

Removal and replacement strategy ................................................................................................... 78

General cautions during removal and replacement ........................................................... 78

Electrostatic discharge ....................................................................................................... 78

Required tools ................................................................................................................... 79

Types of screws ................................................................................................................. 79

Before performing service .................................................................................................. 80

After performing service ..................................................................................................... 80

Post-service test ................................................................................................................ 81

Print cartridges ................................................................................................................................... 82

Tray 2 cassette ................................................................................................................................... 83

Rollers and pads ................................................................................................................................ 84

Transfer roller .................................................................................................................... 84

Paper-pickup roller ............................................................................................................. 85

Separation roller ................................................................................................................ 87

Paper-pickup roller (Tray 1) ............................................................................................... 90

Separation pad (Tray 1) ..................................................................................................... 92

Components and major assemblies ................................................................................................... 93

Link guide .......................................................................................................................... 93

DIMM cover ....................................................................................................................... 94

Print-cartridge drawer ........................................................................................................ 95

Intermediate transfer belt (ITB) .......................................................................................... 97

Paper-feed guide assembly ............................................................................................. 101

Rear-door stopper and link caps (simplex product) ......................................................... 103

Rear door (simplex product) ............................................................................................ 104

Rear door (duplex product) .............................................................................................. 106

Right cover ....................................................................................................................... 108

Rear-upper cover (duplex product) .................................................................................. 111

Rear cover and feed guide (simplex product) .................................................................. 112

Rear-lower cover and rear-door links (duplex product) ................................................... 116

Step 7: fusing .................................................................................................... 70

Step 8: ITB cleaning .......................................................................................... 71

Step 9: drum cleaning ....................................................................................... 72

Print-quality test ................................................................................................ 81

Reinstall the separation roller ............................................................................ 89

Reinstall the ITB .............................................................................................. 100

Reinstall the right cover ................................................................................... 110

vi ENWW

Page 9

Rear-door rib assembly (duplex product) ........................................................................ 119

Upper-cover assembly ..................................................................................................... 121

Reinstall the upper cover ................................................................................ 123

Control-panel assembly ................................................................................................... 124

Left cover ......................................................................................................................... 126

Reinstall the left cover ..................................................................................... 127

High-voltage power-supply PCA ...................................................................................... 129

Color-misregistration sensor assembly PCA ................................................................... 132

Reinstall the color-misregistration sensor assembly ....................................... 135

Right panel ....................................................................................................................... 136

Motors (M1 and M2) ........................................................................................................ 140

DC controller PCA ........................................................................................................... 142

Special considerations .................................................................................... 142

Remove the DC controller PCA ...................................................................... 142

Formatter PCA ................................................................................................................. 144

Special considerations .................................................................................... 144

Remove the formatter PCA ............................................................................. 144

Fan ................................................................................................................................... 146

Intermediate PCA ............................................................................................................ 147

Right-front cover and power button ................................................................................. 148

Power-supply sub PCA .................................................................................................... 150

Fuser motor assembly ..................................................................................................... 154

Reinstall the fuser motor assembly ................................................................. 158

Duplex reverse-drive assembly ....................................................................................... 159

Fuser ................................................................................................................................ 162

Reinstall the fuser ........................................................................................... 167

Paper-delivery assembly ................................................................................................. 168

Front-door assembly ........................................................................................................ 171

Reinstall the front-door assembly .................................................................... 176

7 Problem solve

Introduction ....................................................................................................................................... 180

Solve problems checklist .................................................................................................................. 181

Menu map ........................................................................................................................................ 181

Troubleshooting process .................................................................................................................. 182

Pretroubleshooting checklist ........................................................................................... 182

Power-on checks ............................................................................................................. 184

Tools for troubleshooting .................................................................................................................. 185

Print-quality troubleshooting tools .................................................................................... 185

Calibrate the product ....................................................................................... 185

Problem-solve diagrams ................................................................................................................... 186

Repetitive image defects ................................................................................................. 186

Interface ports .................................................................................................................. 187

ENWW vii

Page 10

DC controller PCA ........................................................................................................... 188

Major components ........................................................................................................... 190

Solenoids, clutches, and sensors .................................................................................... 191

Rollers .............................................................................................................................. 192

Motors and fans ............................................................................................................... 193

PCAs ................................................................................................................................ 194

Timing diagram ................................................................................................................ 195

Circuit diagram ................................................................................................................. 195

Control-panel messages .................................................................................................................. 197

Pages and reports ............................................................................................................................ 201

Diagnostic page ............................................................................................................... 201

Configuration page .......................................................................................................... 201

Supplies status page ....................................................................................................... 201

Event log .......................................................................................................................... 202

Paper-handling problems ................................................................................................................. 204

Clear jams ........................................................................................................................ 204

Common causes of jams ................................................................................. 204

Jam locations .................................................................................................. 205

Change Jam Recovery setting ........................................................................ 205

Clear jams in Tray 1 ........................................................................................ 206

Clear jams in Tray 2 ....................................................................................... 208

Clear jams in Tray 3 ....................................................................................... 209

Clear jams in fuser area .................................................................................. 210

Clear jams in output bin .................................................................................. 211

Clear jams in duplexer (duplexing models only) ............................................. 212

Image defects ................................................................................................................................... 214

General print quality issues ............................................................................................. 214

Solve issues with color documents .................................................................................. 218

Solve connectivity problems ............................................................................................................. 220

Solve direct-connection problems .................................................................................... 220

Solve network problems .................................................................................................. 220

Service mode functions .................................................................................................................... 222

Service menu ................................................................................................................... 222

Service menu settings ..................................................................................... 222

Restore the factory-set defaults ...................................................................... 222

Secondary service menu ................................................................................................. 222

Open the secondary service menu ................................................................. 222

Secondary service menu structure .................................................................. 222

Engine resets ................................................................................................................... 224

Engine test page ............................................................................................. 224

Cold reset ........................................................................................................ 224

NVRAM initialization ........................................................................................ 225

Performance problems ..................................................................................................................... 226

Print speeds ..................................................................................................................... 227

viii ENWW

Page 11

8 Parts and diagrams

Order parts, accessories, and supplies ............................................................................................ 230

Order directly from HP ..................................................................................................... 230

Part numbers .................................................................................................................................... 230

Supplies ........................................................................................................................... 230

Memory ............................................................................................................................ 230

Cable and interface accessories ...................................................................................... 231

Paper-handling accessories ............................................................................................ 231

User-replaceable parts .................................................................................................... 231

Whole unit replacement ................................................................................................... 231

Screws .............................................................................................................................................. 232

How to use the parts lists and diagrams .......................................................................................... 233

External components ........................................................................................................................ 234

Covers, panels, and doors ............................................................................................... 234

Internal components ......................................................................................................................... 236

Internal components (1 of 7) ............................................................................................ 236

Internal components (2 of 7) ............................................................................................ 238

Internal components (3 of 7) ............................................................................................ 240

Internal components (4 of 7) ............................................................................................ 242

Internal components (5 of 7) ............................................................................................ 244

Internal components, simplex products (6 of 7) ............................................................... 246

Internal components, duplex products (7 of 7) ................................................................ 248

Major assemblies ............................................................................................................................. 250

Cassette (Tray 2) ............................................................................................................. 250

Fuser assembly ............................................................................................................... 252

PCAs ................................................................................................................................ 254

Optional 250-sheet paper cassette .................................................................................................. 256

Alphabetical parts list ....................................................................................................................... 258

Numerical parts list ........................................................................................................................... 261

Appendix A Service and support

Hewlett-Packard limited warranty statement .................................................................................... 266

Customer self repair warranty service .............................................................................................. 267

Print cartridge limited warranty statement ........................................................................................ 268

Customer support ............................................................................................................................. 269

Repack the product .......................................................................................................................... 270

Service information form .................................................................................................................. 271

Appendix B Specifications

Physical specifications ..................................................................................................................... 274

Electrical specifications .................................................................................................................... 275

Acoustic emissions ........................................................................................................................... 276

Environmental specifications ............................................................................................................ 276

ENWW ix

Page 12

Appendix C Regulatory information

FCC regulations ............................................................................................................................... 278

Declaration of conformity .................................................................................................................. 279

Safety statements ............................................................................................................................. 280

Laser safety ..................................................................................................................... 280

Canadian DOC regulations .............................................................................................. 280

VCCI statement (Japan) .................................................................................................. 280

Power cord statement (Japan) ......................................................................................... 280

EMC statement (Korea) ................................................................................................... 280

Laser statement for Finland ............................................................................................. 281

Substances Table (China) ............................................................................................... 282

Certificate of Volatility ...................................................................................................... 283

Types of memory ............................................................................................ 283

Volatile memory .............................................................................. 283

Non-volatile memory ....................................................................... 283

Index ................................................................................................................................................................. 285

x ENWW

Page 13

List of tables

Table 1-1 Product guides ................................................................................................................................... 2

Table 1-2 Printing ............................................................................................................................................. 10

Table 1-3 Network product discovery ............................................................................................................... 10

Table 1-4 Messaging and management ........................................................................................................... 10

Table 1-5 IP addressing ................................................................................................................................... 11

Table 3-1 Supported paper and print media sizes ........................................................................................... 23

Table 3-2 Supported envelopes and postcards ............................................................................................... 23

Table 3-3 Tray 1 ............................................................................................................................................... 25

Table 3-4 Tray 2 and Tray 3 ............................................................................................................................. 26

Table 5-1 Sequence of operation ..................................................................................................................... 60

Table 7-1 Repetitive image defects ................................................................................................................ 186

Table 7-2 DC controller connectors ................................................................................................................ 188

Table 7-3 Major components .......................................................................................................................... 190

Table 7-4 Solenoid, clutches, and sensors .................................................................................................... 191

Table 7-5 Rollers ............................................................................................................................................ 192

Table 7-6 PCAs ............................................................................................................................................. 194

Table 7-7 Event-log messages ....................................................................................................................... 202

Table 7-8 2ndary Service menu ..................................................................................................................... 222

Table 8-1 Common fasteners ........................................................................................................................ 232

Table 8-2 Covers, panels, and doors ............................................................................................................. 235

Table 8-3 Internal components (1 of 7) .......................................................................................................... 237

Table 8-4 Internal components (2 of 7) .......................................................................................................... 239

Table 8-5 Internal components (3 of 7) .......................................................................................................... 241

Table 8-6 Internal components (4 of 7) .......................................................................................................... 243

Table 8-7 Internal components (5 of 7) .......................................................................................................... 245

Table 8-8 Internal components, simplex products (6 of 7) ............................................................................. 247

Table 8-9 Internal components, duplex products (7 of 7) ............................................................................... 249

Table 8-10 Cassette (Tray 2) ......................................................................................................................... 251

Table 8-11 Fuser assembly ............................................................................................................................ 253

Table 8-12 PCAs ............................................................................................................................................ 255

Table 8-13 250-sheet paper cassette ............................................................................................................ 257

Table 8-14 Alphabetical parts list ................................................................................................................... 258

Table 8-15 Numerical parts list ....................................................................................................................... 261

Table B-1 Physical specifications ................................................................................................................... 274

ENWW xi

Page 14

Table B-2 Electrical specifications .................................................................................................................. 275

Table B-3 Power consumption (average, in watts), ....................................................................................... 275

Table B-4 HP Color LaserJet CP2020 Series, ............................................................................................... 276

Table B-5 Operating-environment specifications ........................................................................................... 276

xii ENWW

Page 15

List of figures

Figure 5-1 Product systems ............................................................................................................................. 58

Figure 5-2 Product components ....................................................................................................................... 59

Figure 5-3 Engine control system components ................................................................................................ 61

Figure 5-4 DC controller circuit diagram ........................................................................................................... 62

Figure 5-5 Low-voltage power supply .............................................................................................................. 63

Figure 5-6 High-voltage power supply .............................................................................................................. 64

Figure 5-7 Laser/scanner system ..................................................................................................................... 65

Figure 5-8 Image-formation system ................................................................................................................. 66

Figure 5-9 Image-formation process ................................................................................................................ 67

Figure 5-10 Primary charging ........................................................................................................................... 67

Figure 5-11 Laser-beam exposure ................................................................................................................... 68

Figure 5-12 Development ................................................................................................................................. 68

Figure 5-13 Primary transfer ............................................................................................................................ 69

Figure 5-14 Secondary transfer ........................................................................................................................ 69

Figure 5-15 Separation from the drum ............................................................................................................. 70

Figure 5-16 Fusing ........................................................................................................................................... 70

Figure 5-17 ITB cleaning .................................................................................................................................. 71

Figure 5-18 Drum cleaning ............................................................................................................................... 72

Figure 5-19 Pickup-and-feed system ............................................................................................................... 73

Figure 6-1 Phillips and pozidrive screwdriver comparison ............................................................................... 79

Figure 6-2 Remove the print cartridge .............................................................................................................. 82

Figure 6-3 Remove the Tray 2 cassette ........................................................................................................... 83

Figure 6-4 Remove the pickup roller (1 of 2) .................................................................................................... 86

Figure 6-5 Remove the pickup roller (2 of 2) .................................................................................................... 86

Figure 6-6 Remove the separation roller (1 of 3) ............................................................................................. 87

Figure 6-7 Remove the separation roller (2 of 3) ............................................................................................. 88

Figure 6-8 Remove the separation roller (3 of 3) ............................................................................................. 88

Figure 6-9 Reinstall the separation roller ......................................................................................................... 89

Figure 6-10 Remove the Tray 1 paper-pickup roller (1 of 3) ............................................................................ 90

Figure 6-11 Remove the Tray 1 paper-pickup roller (2 of 3) ............................................................................ 91

Figure 6-12 Remove the Tray 1 paper-pickup roller (3 of 3) ............................................................................ 91

Figure 6-13 Remove the Tray 1 separation pad (1 of 2) .................................................................................. 92

Figure 6-14 Remove the Tray 1 separation pad (2 of 2) .................................................................................. 92

Figure 6-15 Replace the link guide (simplex products) .................................................................................... 93

ENWW xiii

Page 16

Figure 6-16 Replace the link guide (duplex products) ...................................................................................... 93

Figure 6-17 Remove the DIMM cover ............................................................................................................. 94

Figure 6-18 Remove the print-cartridge drawer (1 of 3) ................................................................................... 95

Figure 6-19 Remove the print-cartridge drawer (2 of 3) ................................................................................... 95

Figure 6-20 Remove the print-cartridge drawer (3 of 3) ................................................................................... 96

Figure 6-21 Remove the ITB (1 of 6) ................................................................................................................ 97

Figure 6-22 Remove the ITB (2 of 6) ................................................................................................................ 97

Figure 6-23 Remove the ITB (3 of 6) ................................................................................................................ 98

Figure 6-24 Remove the ITB (4 of 6) ................................................................................................................ 98

Figure 6-25 Remove the ITB (5 of 6) ................................................................................................................ 99

Figure 6-26 Remove the ITB (6 of 6) ................................................................................................................ 99

Figure 6-27 Reinstall the ITB .......................................................................................................................... 100

Figure 6-28 Remove the feed assembly (1 of 2) ............................................................................................ 101

Figure 6-29 Remove the feed assembly (2 of 2) ............................................................................................ 102

Figure 6-30 Remove the rear-door stopper and link caps (simplex product) (1 of 2) ..................................... 103

Figure 6-31 Remove the rear-door stopper and link cap (simplex product) (2 of 2) ...................................... 103

Figure 6-32 Remove the rear door (simplex product) (1 of 4) ........................................................................ 104

Figure 6-33 Remove the rear door (simplex product) (2 of 4) ........................................................................ 104

Figure 6-34 Remove the rear door (simplex product) (3 of 4) ........................................................................ 105

Figure 6-35 Remove the rear door (simplex product) (4 of 4) ........................................................................ 105

Figure 6-36 Remove the rear door (duplex product) (1 of 4) ......................................................................... 106

Figure 6-37 Remove the rear door (duplex product) (2 of 4) ......................................................................... 106

Figure 6-38 Remove the rear door (duplex product) (3 of 4) ......................................................................... 107

Figure 6-39 Remove the rear door (duplex product) (4 of 4) ......................................................................... 107

Figure 6-40 Remove the right cover (1 of 5) .................................................................................................. 108

Figure 6-41 Remove the right cover (2 of 5) .................................................................................................. 108

Figure 6-42 Remove the right cover (3 of 5) .................................................................................................. 109

Figure 6-43 Remove the right cover (4 of 5) .................................................................................................. 109

Figure 6-44 Remove the right cover (5 of 5) .................................................................................................. 110

Figure 6-45 Reinstall the right cover .............................................................................................................. 110

Figure 6-46 Remove the rear-upper cover (1 of 2) ........................................................................................ 111

Figure 6-47 Remove the rear-upper cover (2 of 2) ........................................................................................ 111

Figure 6-48 Remove the rear cover and feed guide (simplex product) (1 of 6) ............................................. 112

Figure 6-49 Remove the rear cover and feed guide (simplex product) (2 of 6) ............................................. 112

Figure 6-50 Remove the rear cover and feed guide (simplex product) (3 of 6) ............................................. 113

Figure 6-51 Remove the rear cover and feed guide (simplex product) (4 of 6) ............................................. 114

Figure 6-52 Remove the rear cover and feed guide (simplex product) (5 of 6) ............................................. 115

Figure 6-53 Remove the rear cover and feed guide (simplex product) (6 of 6) ............................................. 115

Figure 6-54 Remove the rear-lower cover and rear-door links (duplex product) (1 of 6) ............................... 116

Figure 6-55 Remove the rear-lower cover and rear-door links (duplex product) (2 of 6) ............................... 116

Figure 6-56 Remove the rear-lower cover and rear-door links (duplex product) (3 of 6) ............................... 117

Figure 6-57 Remove the rear-lower cover and link-guides (duplex product) (4 of 6) ..................................... 117

Figure 6-58 Remove the rear-lower cover and link-guides (duplex product) (5 of 6) ..................................... 118

Figure 6-59 Remove the rear-lower cover and rear-door links (duplex product) (6 of 6) ............................... 118

xiv ENWW

Page 17

Figure 6-60 Remove the rear-door rib assembly (duplex product) (1 of 3) .................................................... 119

Figure 6-61 Remove the rear-door rib assembly (duplex product) (2 of 3) .................................................... 120

Figure 6-62 Remove the rear-door rib assembly (duplex product) (3 of 3) .................................................... 120

Figure 6-63 Remove the upper-cover assembly (1 of 4) ................................................................................ 121

Figure 6-64 Remove the upper-cover assembly (2 of 4) ................................................................................ 121

Figure 6-65 Remove the upper-cover assembly (3 of 4) ................................................................................ 122

Figure 6-66 Remove the upper-cover assembly (4 of 4) ................................................................................ 122

Figure 6-67 Upper-cover tabs not correctly seated ........................................................................................ 123

Figure 6-68 Upper-cover tabs correctly seated .............................................................................................. 123

Figure 6-69 Remove the control-panel assembly (1 of 3) .............................................................................. 124

Figure 6-70 Remove the control-panel assembly (2 of 3) .............................................................................. 125

Figure 6-71 Remove the control-panel assembly (3 of 3) .............................................................................. 125

Figure 6-72 Remove the left cover (1 of 3) ..................................................................................................... 126

Figure 6-73 Remove the left cover (2 of 3) ..................................................................................................... 126

Figure 6-74 Remove the left cover (3 of 3) ..................................................................................................... 127

Figure 6-75 Reinstall the left cover (1 of 2) .................................................................................................... 127

Figure 6-76 Reinstall the left cover (2 of 2) .................................................................................................... 128

Figure 6-77 Remove the high-voltage power-supply PCA (1 of 5) ................................................................. 129

Figure 6-78 Remove the high-voltage power-supply PCA (2 of 5) ................................................................. 130

Figure 6-79 Remove the high-voltage power-supply PCA (3 of 5) ................................................................. 130

Figure 6-80 Remove the high-voltage power-supply PCA (4 of 5) ................................................................. 131

Figure 6-81 Remove the high-voltage power-supply PCA (5 of 5) ................................................................. 131

Figure 6-82 Remove the color-misregistration sensor assembly PCA (1 of 5) .............................................. 132

Figure 6-83 Remove the color-misregistration sensor assembly PCA (2 of 5) .............................................. 133

Figure 6-84 Remove the color-misregistration sensor assembly PCA (3 of 5) .............................................. 133

Figure 6-85 Remove the color-misregistration sensor assembly PCA (4 of 5) .............................................. 134

Figure 6-86 Remove the color-misregistration sensor assembly PCA (5 of 5) .............................................. 134

Figure 6-87 Reinstall the color-misregistration sensor assembly PCA (1 of 2) .............................................. 135

Figure 6-88 Reinstall the color-misregistration sensor assembly PCA (2 of 2) .............................................. 135

Figure 6-89 Remove the right panel (1 of 8) .................................................................................................. 136

Figure 6-90 Remove the right panel (2 of 8) .................................................................................................. 136

Figure 6-91 Remove the right panel (3 of 8) .................................................................................................. 137

Figure 6-92 Remove the right panel (4 of 8) .................................................................................................. 137

Figure 6-93 Remove the right panel (5 of 8) .................................................................................................. 138

Figure 6-94 Remove the right panel (6 of 8) .................................................................................................. 138

Figure 6-95 Remove the right panel (7 of 8) .................................................................................................. 139

Figure 6-96 Remove the right panel (8 of 8) .................................................................................................. 139

Figure 6-97 Remove motor M1 or motor M2 (1 of 3) ...................................................................................... 140

Figure 6-98 Remove motor M1 or motor M2 (2 of 3) ...................................................................................... 140

Figure 6-99 Remove motor M1 or motor M2 (3 of 3) ...................................................................................... 141

Figure 6-100 Remove the DC controller PCA (1 of 2) .................................................................................... 143

Figure 6-101 Remove the DC controller PCA (2 of 2) .................................................................................... 143

Figure 6-102 Remove the formatter PCA (1 of 2) .......................................................................................... 145

Figure 6-103 Remove the formatter PCA (2 of 2) .......................................................................................... 145

ENWW xv

Page 18

Figure 6-104 Remove the fan (1 of 2) ............................................................................................................ 146

Figure 6-105 Remove the fan (2 of 2) ............................................................................................................ 146

Figure 6-106 Remove the Intermediate PCA (1 of 2) ..................................................................................... 147

Figure 6-107 Remove the Intermediate PCA (2 of 2) ..................................................................................... 147

Figure 6-108 Remove the right-front cover and power button (1 of 2) ........................................................... 148

Figure 6-109 Remove the right-front cover and power button (2 of 2) ........................................................... 149

Figure 6-110 Remove the power-supply sub PCA (1 of 6) ............................................................................ 150

Figure 6-111 Remove the power-supply sub PCA (2 of 6) ............................................................................ 151

Figure 6-112 Remove the power-supply sub PCA (3 of 6) ............................................................................ 151

Figure 6-113 Remove the power-supply sub PCA (4 of 6) ............................................................................ 152

Figure 6-114 Remove the power-supply sub PCA (5 of 6) ............................................................................ 152

Figure 6-115 Remove the power-supply sub PCA (6 of 6) ............................................................................ 153

Figure 6-116 Remove the fuser motor assembly (1 of 8) ............................................................................... 154

Figure 6-117 Remove the fuser motor assembly (2 of 8) ............................................................................... 155

Figure 6-118 Remove the fuser motor assembly (3 of 8) ............................................................................... 155

Figure 6-119 Remove the fuser motor assembly (4 of 8) ............................................................................... 156

Figure 6-120 Remove the fuser motor assembly (5 of 8) ............................................................................... 156

Figure 6-121 Remove the fuser motor assembly (6 of 8) ............................................................................... 157

Figure 6-122 Remove the fuser motor assembly (7 of 8) ............................................................................... 157

Figure 6-123 Remove the fuser motor assembly (8 of 8) ............................................................................... 158

Figure 6-124 Reinstall the fuser motor assembly ........................................................................................... 158

Figure 6-125 Remove the duplex reverse-drive assembly (1 of 4) ................................................................ 159

Figure 6-126 Remove the duplex reverse-drive assembly (2 of 4) ................................................................ 160

Figure 6-127 Remove the duplex reverse-drive assembly (3 of 4) ................................................................ 160

Figure 6-128 Remove the duplex reverse-drive assembly (4 of 4) ................................................................ 161

Figure 6-129 Remove the fuser (1 of 8) ......................................................................................................... 162

Figure 6-130 Remove the fuser (2 of 8) ......................................................................................................... 163

Figure 6-131 Remove the fuser (3 of 8) ......................................................................................................... 163

Figure 6-132 Remove the fuser (4 of 8) ......................................................................................................... 164

Figure 6-133 Remove the fuser (5 of 8) ......................................................................................................... 164

Figure 6-134 Remove the fuser (6 of 8) ......................................................................................................... 165

Figure 6-135 Remove the fuser (7 of 8) ......................................................................................................... 165

Figure 6-136 Remove the fuser (8 of 8) ......................................................................................................... 166

Figure 6-137 Reinstall the fuser ..................................................................................................................... 167

Figure 6-138 Remove the paper-delivery assembly (1 of 4) .......................................................................... 168

Figure 6-139 Remove the paper-delivery assembly (2 of 4) .......................................................................... 169

Figure 6-140 Remove the paper-delivery assembly (3 of 4) .......................................................................... 169

Figure 6-141 Remove the paper-delivery assembly (4 of 4) .......................................................................... 170

Figure 6-142 Remove the front-door assembly (1 of 10) ............................................................................... 171

Figure 6-143 Remove the front-door assembly (2 of 10) ............................................................................... 172

Figure 6-144 Remove the front-door assembly (3 of 10) ............................................................................... 172

Figure 6-145 Remove the front-door assembly (4 of 10) ............................................................................... 173

Figure 6-146 Remove the front-door assembly (5 of 10) ............................................................................... 173

Figure 6-147 Remove the front-door assembly (6 of 10) ............................................................................... 174

xvi ENWW

Page 19

Figure 6-148 Remove the front-door assembly (7 of 10) ............................................................................... 174

Figure 6-149 Remove the front-door assembly (8 of 10) ............................................................................... 175

Figure 6-150 Remove the front-door assembly (9 of 10) ............................................................................... 175

Figure 6-151 Remove the front-door assembly (10 of 10) ............................................................................. 176

Figure 6-152 Reinstall the front-door assembly (1 of 2) ................................................................................. 176

Figure 6-153 Reinstall the front-door assembly (2 of 2) ................................................................................. 177

Figure 7-1 DC controller connectors .............................................................................................................. 188

Figure 7-2 Major components ........................................................................................................................ 190

Figure 7-3 Solenoid, clutches, and sensors ................................................................................................... 191

Figure 7-4 Rollers ........................................................................................................................................... 192

Figure 7-5 Motors and fans ............................................................................................................................ 193

Figure 7-6 PCAs ............................................................................................................................................. 194

Figure 7-7 Timing diagram ............................................................................................................................. 195

Figure 7-8 Circuit diagram ............................................................................................................................. 196

Figure 7-9 Engine test button location ........................................................................................................... 224

Figure 8-1 Covers, panels, and doors ............................................................................................................ 234

Figure 8-2 Internal components (1 of 7) ......................................................................................................... 236

Figure 8-3 Internal components (2 of 7) ......................................................................................................... 238

Figure 8-4 Internal components (3 of 7) ......................................................................................................... 240

Figure 8-5 Internal components (4 of 7) ......................................................................................................... 242

Figure 8-6 Internal components (5 of 7) ......................................................................................................... 244

Figure 8-7 Internal components, simplex products (6 of 7) ............................................................................ 246

Figure 8-8 Internal components, duplex products (7 of 7) ............................................................................. 248

Figure 8-9 Cassette (Tray 2) .......................................................................................................................... 250

Figure 8-10 Fuser assembly ........................................................................................................................... 252

Figure 8-11 PCAs ........................................................................................................................................... 254

Figure 8-12 Optional 250-sheet paper cassette ............................................................................................. 256

ENWW xvii

Page 20

xviii ENWW

Page 21

1 Product basics

Quick access to product information

●

Product comparison

●

Product features

●

Walkaround

●

Supported operating systems

●

Supported product software

●

Connectivity

●

ENWW 1

Page 22

Quick access to product information

Use the following Web site to find information about the product:

www.hp.com/support/ljcp2020series

●

Table 1-1 Product guides

Guide Description

Getting Started Guide Provides step-by-step instructions for installing and setting up the product.

User Guide Provides detailed information for using the product and for problem solving. Available on

HP ToolboxFX To check the product status and settings, and to view problem solving information and online

Embedded Web server Use the embedded Web server to view product and network status and manage printing

Online Help Provides information about options that are available in the printer drivers. To view a Help

the product CD or in ui.message>Program Group if the software is installed on a computer.

documentation, use HP ToolboxFX. You must have performed a recommended software

installation to use HP ToolboxFX. See the user guide for more information about software

installation.

functions from your computer. See

file, open the online Help through the printer driver.

Embedded Web server on page 9

2 Chapter 1 Product basics ENWW

Page 23

Product comparison

HP Color LaserJet CP2020 Series

Prints up to 21 pages per minute (ppm) on letter-size media (20 ppm on A4-size media).

●

50-sheet multipurpose tray (Tray 1) and 250-sheet input tray (Tray 2)

●

Optional 250-sheet input tray (Tray 3) (standard on the x model)

●

Hi-Speed universal serial bus (USB) 2.0 port

●

Built-in networking to connect to 10Base-T/100Base-TX networks (n, dn, and x models only)

●

Automatic duplexer (d, dn, and x models only)

●

Product features

Print

Memory

Paper handling

Printer driver features

Interface connections

Environmental features

Prints up to 21 pages per minute (ppm) on letter-size media (20 ppm on A4-size media).

●

Prints at 600 dots per inch (dpi).

●

Includes adjustable settings to optimize print quality.

●

The print cartridges use HP ColorSphere toner. For information about the number of pages

●

the cartridges can print, see

use.

Offers automatic duplexing (d, dn, and x models only).

●

Includes 128-megabyte (MB) random-access memory (RAM).

●

Tray 1 (multipurpose tray) holds up to 50 sheets of print media or 10 envelopes.

●

Tray 2 holds up to 250 sheets of print media.

●

Optional Tray 3 holds up to 250 sheets of print media (standard tray with the x model).