Page 1

hp Color 9850mfp

Service

Manual

Page 2

Copyright and License

© 2004 Copyright Hewlett-Packard Development Company, L.P.

Reproduction, adaptation, or translation without prior written permission

is prohibited, except as allowed under the copyright laws.

The information contained herein is subject to change without notice.

The only warranties for HP products and services are set forth in the

express warranty statements accompanying such products and services.

Nothing herein should be construed as constituting an additional

warranty. HP shall not be liable for technical or editorial errors or

omissions contained herein.

Part number: Q3225-90935

Edition 1: 03/ 2004

FCC Regulations

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses,

and can radiate radio frequency energy. If this equipment is not installed

and used in accordance with the instructions, it may cause harmful

interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures:

Reorient or relocate the receiving antenna. Increase separation between

equipment and receiver.

Connect equipment to an outlet on a circuit different from that to which

the receiver is located.

Consult your dealer or an experienced radio/TV technician.

Any changes or modifications to the printer that are not expressly

approved by HP could void the user's authority to operate this

equipment. Use of a shielded interface cable is required to comply with

the Class A limits of Part 15 of FCC rules. For more regulatory

information, see the hp 9085mfp user's guide. Hewlett-Packard shall not

be liable for any direct, indirect, incidental, consequential, or other

damage alleged in connection with the furnishing or use of this

information.

Trademark Credits

PostScript® is a trademark of Adobe Systems Incorporated.

Windows® is a U.S. registered trademark of Microsoft Corporation.

Page 3

hp Color 9850mfp

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

IMPORTANT NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

DESCRIPTION ITEMS FOR DANGER, WARNING AND CAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-1

SAFETY WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-2

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-10

IMPORTANT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-10

SAFETY CIRCUITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-11

INDICATION OF WARNING ON THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-13

I OUTLINE

PRODUCT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.

1.1 Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Product specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4 Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.5 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.6 Media specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.7 Media assessment tools and suppliers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1.8

1.9 Maintenance and life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

CENTER CROSS SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

2.

PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

3.

DRIVE SYSTEM DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

4.

4.1 Drum drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

4.2 Transfer belt conveyance/pressure drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

4.3 Developing drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

4.4 Toner supply drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

4.5 Toner collection drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

4.6 Fixing drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-30

4.7 Paper feed drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

4.7.1

4.7.2 Vertical conveyance drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

4.8 ADU drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

4.8.1 By-pass tray drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-34

4.8.2 Registration drive/loop drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

4.8.3 ADU conveyance drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

4.8.4 Reverse paper exit drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

4.9

4.10 Scanner drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

5. IMAGE CREATION PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

5.1 Image creation flow and function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

5.2 Charging process (Step 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

5.3 Laser exposure process (Step 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-41

Paper feed tray 1 to 3 drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Engine paper exit drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

I OUTLINEII UNIT EXPLANATIONIII DIS./ASSEMBLY

i

Page 4

CONTENTS

I OUTLINE

II UNIT EXPLANATION

1. SCANNER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

II UNIT EXPLANATION

2. WRITE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

III DIS./ASSEMBLY

3. DRUM UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

4. DEVELOPING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

5. TRANSFER BELT UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

hp Color 9850mfp

5.4 Developing process (Step 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-42

5.5 1st transfer process (Step 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-43

5.6 2nd transfer process (Step 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

5.7 Separation process (Step 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

5.8 Drum cleaning (Sub step 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-45

5.9 Pre-charging exposure (Sub step 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-45

5.10 Transfer belt cleaning (Sub step 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-46

2nd transfer roller L cleaning (Sub step 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-46

5.11

5.12 Toner collection (Sub step 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

5.13 Process speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-47

1.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

1.2.1 Home position search in the exposure unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

1.2.2 Shading correction reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

1.2.3 Original reading mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

1.2.4 Original reading control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

1.2.5 APS control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

1.2.6 AE control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

1.2.7 Image processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.2.1 Image writing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.2.2

3.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

3.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

3.2.1 Image formation timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

4.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

4.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

4.2.1 Flow of developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

4.2.2 Developing control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

4.2.3 Toner supply control to the developing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

4.2.4 Developing bias control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

4.2.5 Durability of the developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

5.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

5.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

5.2.1 Transfer belt pressure/release mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

5.2.2 Image correction unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

5.2.3 1st transfer control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

5.2.4 2nd transfer control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Color registration correction control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

ii

Page 5

hp Color 9850mfp

6. TONER SUPPLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

6.1 Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

6.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

6.2.1 Toner supply control to the toner hopper section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

6.2.2 Toner supply control to the developing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

6.2.3 Copy/print operation stop control due to no toner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

7. TONER COLLECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

7.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

7.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

7.2.1 Toner collection control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

7.2.2 Waste toner full detection control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

PAPER FEED TRAY 1 TO 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

8.

8.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

8.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

8.2.1 Paper feed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

8.2.2 Up/down plate control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

8.2.3 Remaining paper detection control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

8.2.4 Paper size detection control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

9. BY-PASS FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

9.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

9.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

9.2.1 Tray up drive control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

9.2.2 Paper feed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

9.2.3 Paper size detection control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

10. VERTICAL CONVEYANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

10.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

10.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

10.2.1 Vertical conveyance control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

11. REGISTRATION/ADU/REVERSE/PAPER EXIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

11.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

11.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

11.2.1 Switching control of the paper exit/ADU conveyance path. . . . . . . . . . . . . . . . . . . . . . . . . 2-53

11.2.2 Reverse/exit control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

11.2.3 ADU conveyance control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

11.2.4 Paper reverse control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

11.2.5 ADU pre-registration control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

11.2.6 Registration control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

11.2.7 2nd transfer control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

11.2.8 Paper exit full detection control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

12. FIXING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

12.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

12.2 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

12.2.1 Fixing drive control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

12.2.2 Pressure/release control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

12.2.3 Web control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

12.2.4 Temperature control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-68

CONTENTS

I OUTLINEII UNIT EXPLANATIONIII DIS./ASSEMBLY

iii

Page 6

CONTENTS

13. INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

14. IMAGE STABILIZATION CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

I OUTLINE

15.OTHER CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

II UNIT EXPLANATION

III DIS./ASSEMBLY

hp Color 9850mfp

13.1 Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

14.1 Toner density control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

14.2 Dmax control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

14.3 Charging potential control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

14.3.1 Correction of the reference value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

14.3.2 Low humidity environment correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

14.4 Dot diameter adjustment control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-72

14.5 Gamma correction control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-73

15.1 Parts to which power is supplied even when the reset switch is turned off . . . . . . . . . . . . . . . . . 2-74

15.2 Parts that operate only when the power switch is turned on . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-75

15.2.1 Parts that operate when the reset switch is turned on . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-75

15.2.2 Parts that operate when the main switch is turned on . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-75

15.3 Fan control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

15.3.1 Fan composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

15.4 Operation board control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-77

15.4.1 Operation board composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-77

15.5 Counter control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

15.5.1 Counter composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

15.5.2 Counter operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

15.6 ACS control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-80

15.6.1 Switching between the color mode and the black and white mode . . . . . . . . . . . . . . . . . . 2-80

15.6.2 Copy count when using ACS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-80

III DISASSEMBLY/ASSEMBLY

1. EXTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Replacing the dust filter 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1

Replacing the dust filter 1 and the ozone filter 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

1.2

1.3 Replacing the toner collection box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

1.4 Angle adjustment of the operation board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

1.5 Removing and reinstalling the main board unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

2. SCANNER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

2.1 Screws that must not be removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Removing and reinstalling the scanner glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

2.2

2.3 Removing and reinstalling the CCD unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

2.4 Removing and reinstalling the exposure unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

2.5 Removing and reinstalling the exposure lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

2.6 Removing the scanner wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

2.7 Reinstalling the scanner wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3. WRITING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.1 Screw that must not be removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.2 Removing and reinstalling the write unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

4. PROCESS UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

4.1 Flow of the disassembly of the process unit section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

4.2 Cleaning the charging corona unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

iv

Page 7

hp Color 9850mfp

4.3 Cleaning/replacing, removing and reinstalling the charging wire assy

/the charging grid plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

4.4 Pulling out the process unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

4.5 Removing and reinstalling the transfer belt unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

4.6 Replacing the belt cleaning brush unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

4.7 Replacing the belt cleaning blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

4.8 Replacing the toner collection sheet 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

4.9 Replacing the belt separation claw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

4.10 Replacing the transfer belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

4.11 Replacing the 1st transfer roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

4.12

Replacing the 2nd transfer roller U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

4.13 Replacing the drum cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

4.14 Removing and reinstalling the drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

4.15 Replacing the developing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

4.16 Replacing the developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

4.17 Replacing the belt separation claw solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

4.18 Removing and reinstalling the process unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

4.19 Removing and reinstalling the image correction unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

5. TONER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

5.1 Opening and closing the toner supply section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

5.2 Replacing the charging dust filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

6.

PAPER FEED TRAYS 1 to 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

6.1 Removing and reinstalling the paper feed unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

6.2

Removing and reinstalling the paper feed trays 1 to 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

6.3 Replacing the paper feed roller and the feed rubber. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60

6.4 Replacing the double feed prevention rubber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

6.5

Replacing the paper feed clutch and the pre-registration clutch . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

6.6

Removing and reinstalling the tray up/down wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64

7. BY-PASS TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-68

7.1 Replacing the paper feed roller and the feed roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-68

7.2 Replacing the double feed prevention roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-70

7.3

Replacing the paper feed clutch BP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-71

8. VERTICAL CONVEYANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-73

8.1 Removing and reinstalling the vertical conveyance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-73

8.2

Replacing the intermediate conveyance clutch 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-76

9. FIXING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-77

9.1 Screws that must not be removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-77

9.2 Removing and reinstalling the fixing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-78

9.3

Replacing the fixing upper heater lamps 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-79

9.4 Replacing the fixing lower heater lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-81

9.5

Replacing the fixing roller U, ball bearing U and the heat insulating sleeve U . . . . . . . . . . . . . . 3-84

9.6

Replacing the fixing roller L, ball bearing L and the heat insulating sleeve L . . . . . . . . . . . . . . . 3-86

9.7

Replacing the fixing temperature sensor 3, and removing and reinstalling

the fixing temperature sensor 1 and the thermostat 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-88

9.8

Replacing the fixing temperature sensor 4, and removing and reinstalling

the fixing temperature sensor 2 and the thermostat L. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-93

9.9 Replacing the fixing drive gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-98

9.10 Replacing the fixing cleaning unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-100

CONTENTS

I OUTLINEII UNIT EXPLANATIONIII DIS./ASSEMBLY

v

Page 8

CONTENTS

10. REGISTRATION/ADU/REVERSE/PAPER EXIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-104

I OUTLINE

II UNIT EXPLANATION

hp Color 9850mfp

9.11 Replacing the fixing torque limiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-102

10.1 Removing and reinstalling the ADU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-104

10.2 Replacing the registration cleaning sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-106

Replacing the separation corona unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-107

10.3

Replacing the transfer ground plate unit and the 2nd transfer roller L . . . . . . . . . . . . . . . . . . . 3-108

10.4

10.5

Replacing the registration roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-109

10.6

Replacing the intermediate conveyance clutches 2 and 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-111

10.7

Replacing the ADU conveyance clutches 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-112

10.8 Replacing the ADU pre-registration clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-113

10.9 Replacing the decurler roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-114

III DIS./ASSEMBLY

vi

Page 9

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the Safety and Important Warning Items described below to understand them before doing ser-

vice work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this MFP as well as the risk of damage to

the MFP, hp strongly recommends that all servicing be performed only by hp-trained service technicians.

Changes may have been made to this MFP to improve its performance after this Service Manual was

printed. Accordingly, hp does not warrant, either explicitly or implicitly, that the information contained in this

Service Manual is complete and accurate.

The user of this Service Manual must assume all risks of personal injury and/or damage to the MFP while

servicing the MFP for which this Service Manual is intended.

Therefore, this Service Manual must be carefully read before doing service work both in the course of techni-

cal training and even after that, for performing maintenance and control of the MFP properly.

Keep this Service Manual also for future service.

DESCRIPTION ITEMS FOR DANGER, WARNING AND

CAUTION

In this Service Manual, each of three expressions “

defined as follows together with a symbol mark to be used in a limited meaning.

When servicing the MFP, the relevant works (disassembling, reassembling, adjustment, repair, maintenance,

etc.) need to be conducted with utmost care.

DANGER

WARNING

CAUTION

Symbols used for safety and important warning items are defined as follows:

:Precaution when using the MFP.

:Action having a high possibility of suffering death or serious injury

:Action having a possibility of suffering death or serious injury

:Action having a possibility of suffering a slight wound, medium trouble, and

property damage

General precaution Electric hazard High temperature

DANGER”, “ WARNING”, and “ CAUTION” is

:Prohibition when using the MFP.

:Direction when using the MFP.

General prohibition Do not touch with wet hand Do not disassemble

General instruction

S-1

Unplug

Ground/Earth

Page 10

SAFETY AND IMPORTANT WARNING ITEMS

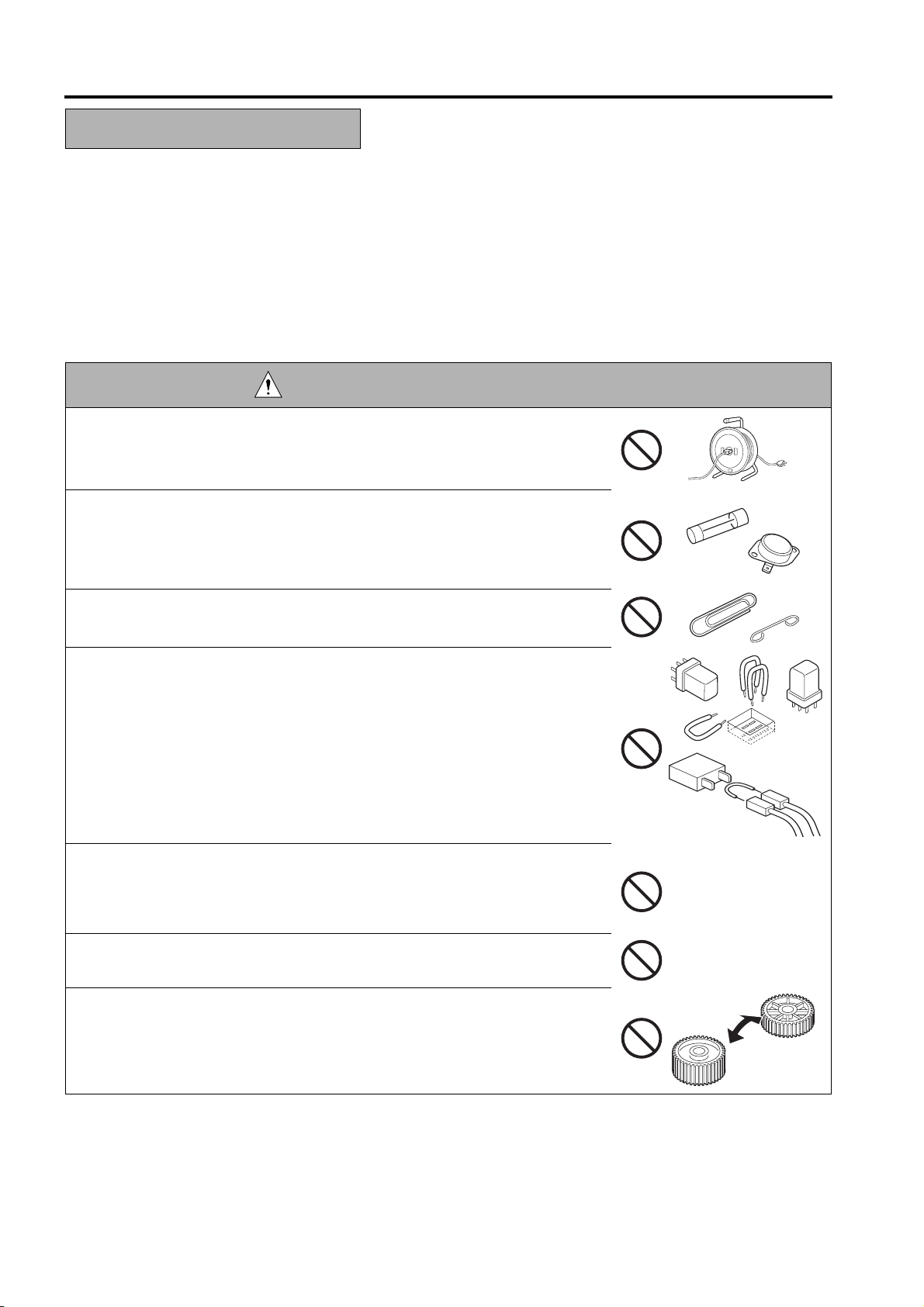

SAFETY WARNINGS

MODIFICATIONS NOT AUTHORIZED BY hp

1.

HP MFP's are renowned for their high reliability. This reliability is achieved through high-quality design

and a solid

MFP design is a highly complicated and delicate process where numerous mechanical, physical, and

electrical aspects

factors. For this reason, unau-thorized modifications involve a high risk of degradation in performance and

safety. Such modifications are thereforestrictly prohibited. The points listed below are not exhaustive, but they

illustrate the reasoning behind this policy.

Using any cables or power cord not specified by hp.

•

Using any fuse or thermostat not specified by hp. Safety will not be

•

assured, leading to a risk of fire and injury.

service network.

have to be taken into consideration, with the aim of arriving at proper tolerances and safety

DANGER : PROHIBITED ACTIONS

• Disabling fuse functions or bridging fuse terminals with wire, metal clips, sol-

der or similar object.

• Disabling relay functions (such as wedging paper between relay contacts)

• Disabling safety functions (interlocks, safety circuits, etc.) Safety will not be

assured, leading to a risk of fire and injury.

Making any modification to the MFP unless instructed by hp

•

Using parts not specified by hp

•

S-2

Page 11

SAFETY AND IMPORTANT WARNING ITEMS

2. CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE

HP MFP's are extensively tested before shipping, to ensure that all applicable safety standards are met, in order

to pro-

tect the customer and customer engineer (hereafter called the CE) from the risk of injury. However, in daily

use, any electri-cal equipment may be subject to parts wear and eventual failure. In order to maintain safety

and reliability, the CE mustperform regular safety checks.

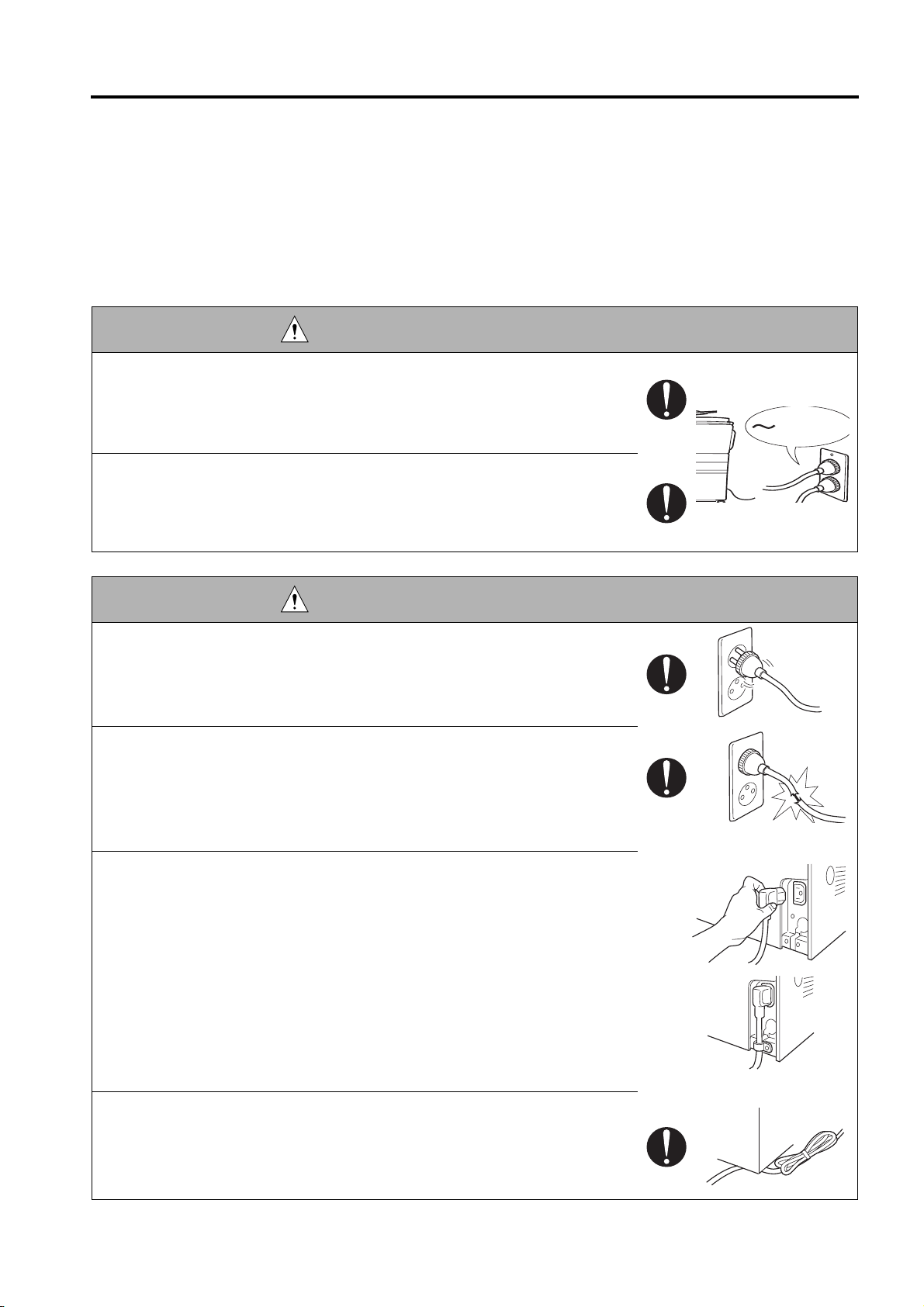

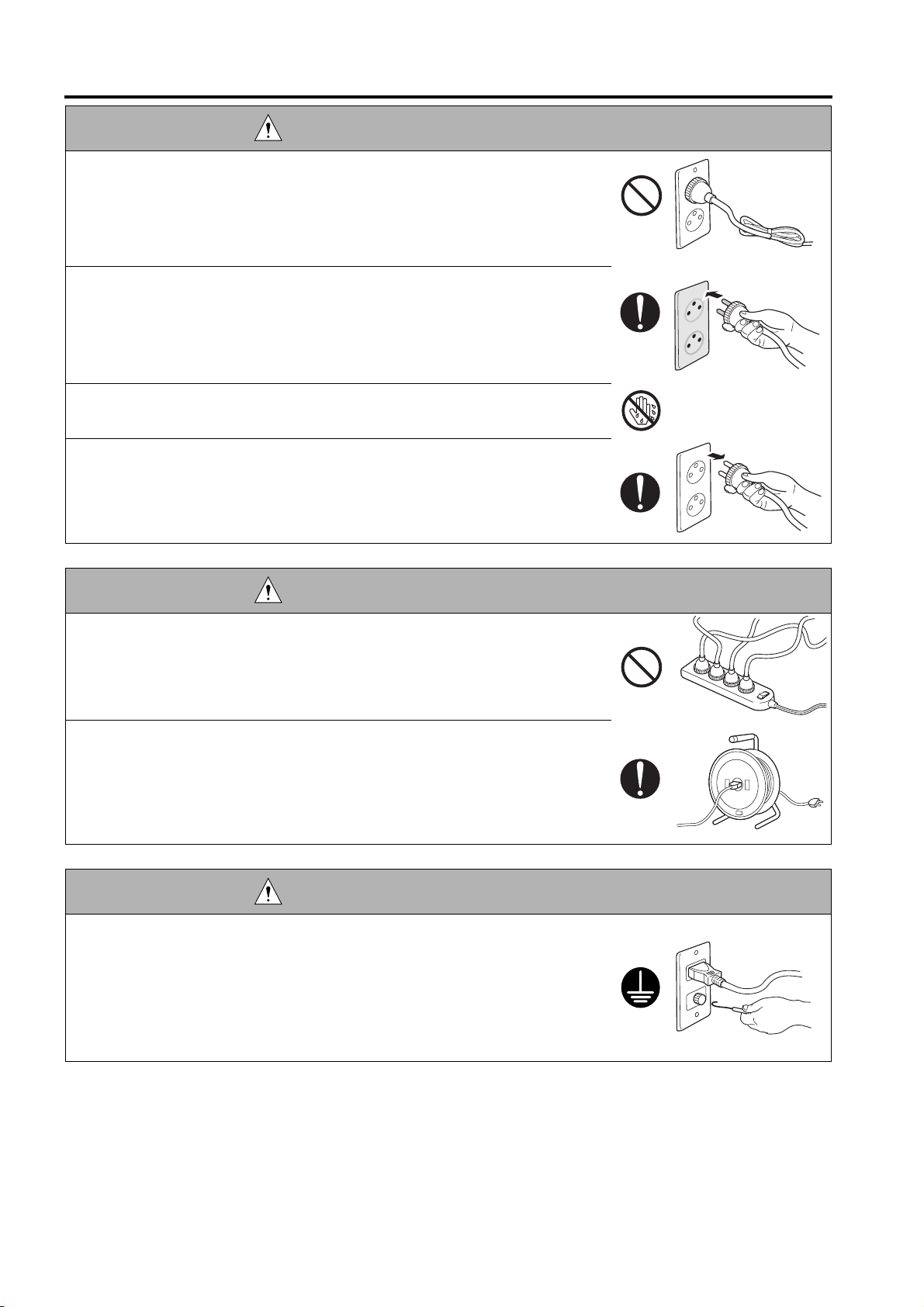

2.1 Power Supply

WARNING: Wall Outlet

Check that main voltage is as specified. Plug the power cord into the dedi-

•

cated wall outlet with a capacity greater than the maximum power consump-

tion.

If excessive current flows in the wall outlet, fire may result.

• If two or more power cords can be plugged into the wall outlet, the total load

must not exceed the rating of the wall outlet.

If excessive current flows in the wall outlet, fire may result.

kw

WARNING: Power Plug and Cord

• Make sure the power cord is plugged in the wall outlet securely.

Contact problems may lead to increased resistance, overheating, and the

risk of fire.

• Check whether the power cord is damaged. Check whether the sheath is

damaged.

If the power plug, cord, or sheath is damaged, replace with a new power

cord (with plugs on both ends) specified by hp. Using the damaged

power cord may result in fire or electric shock.

When using the power cord (inlet type) that came with this MFP, be sure to

•

observe the following precautions:

Make sure the MFP-side power plug is securely inserted in the socket

a.

on the rear panel of the MFP.

Secure the cord with a fixture properly.

b. If the power cord or sheath is damaged, replace with a new power cord

(with plugs on both ends) specified by hp.

If the power cord (inlet type) is not connected to the MFP securely, a

contact problem may lead to increased resistance, overheating, and risk

of fire.

• Check whether the power cord is not stepped on or pinched by a table and

so on.

Overheating may occur there, leading to a risk of fire.

S-3

Page 12

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Power Plug and Cord

• Do not bundle or tie the power cord.

Overheating may occur there, leading to a risk of fire.

• Check whether dust is collected around the power plug and wall outlet.

Using the power plug and wall outlet without removing dust may result in

fire.

• Do not insert the power plug into the wall outlet with a wet hand.

The risk of electric shock exists.

• When unplugging the power cord, grasp the plug, not the cable.

The cable may be broken, leading to a risk of fire and electric shock.

WARNING: Wiring

• Never use multi-plug adapters to plug multiple power cords in the same out-

let.

If used, the risk of fire exists.

• When an extension cord is required, use a specified one.

Current that can flow in the extension cord is limited, so using a too long

extension cord may result in fire.

Do not use an extension cable reel with the cable taken up. Fire may

result.

WARNING: Ground Lead

•

Check whether the MFP is grounded properly.

If current leakage occurs in an ungrounded MFP, you may suffer electric

shock while operating the MFP. Connect the ground lead to one of the

following points:

a. Ground terminal of wall outlet

b. Ground terminal for which Class D work has been done

S-4

Page 13

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Ground Lead

• Pay attention to the point to which the ground lead is connected.

Connecting the ground lead to an improper point such as the points listed

below results in a risk of explosion and electric shock:

a. Gas pipe (A risk of explosion or fire exists.)

b. Lightning rod (A risk of electric shock or fire exists.)

c. Telephone line ground (A risk of electric shock or fire exists in the case

of lightning.)

d. Water pipe or faucet (It may include a plastic portion.)

2.2. Installation Requirements

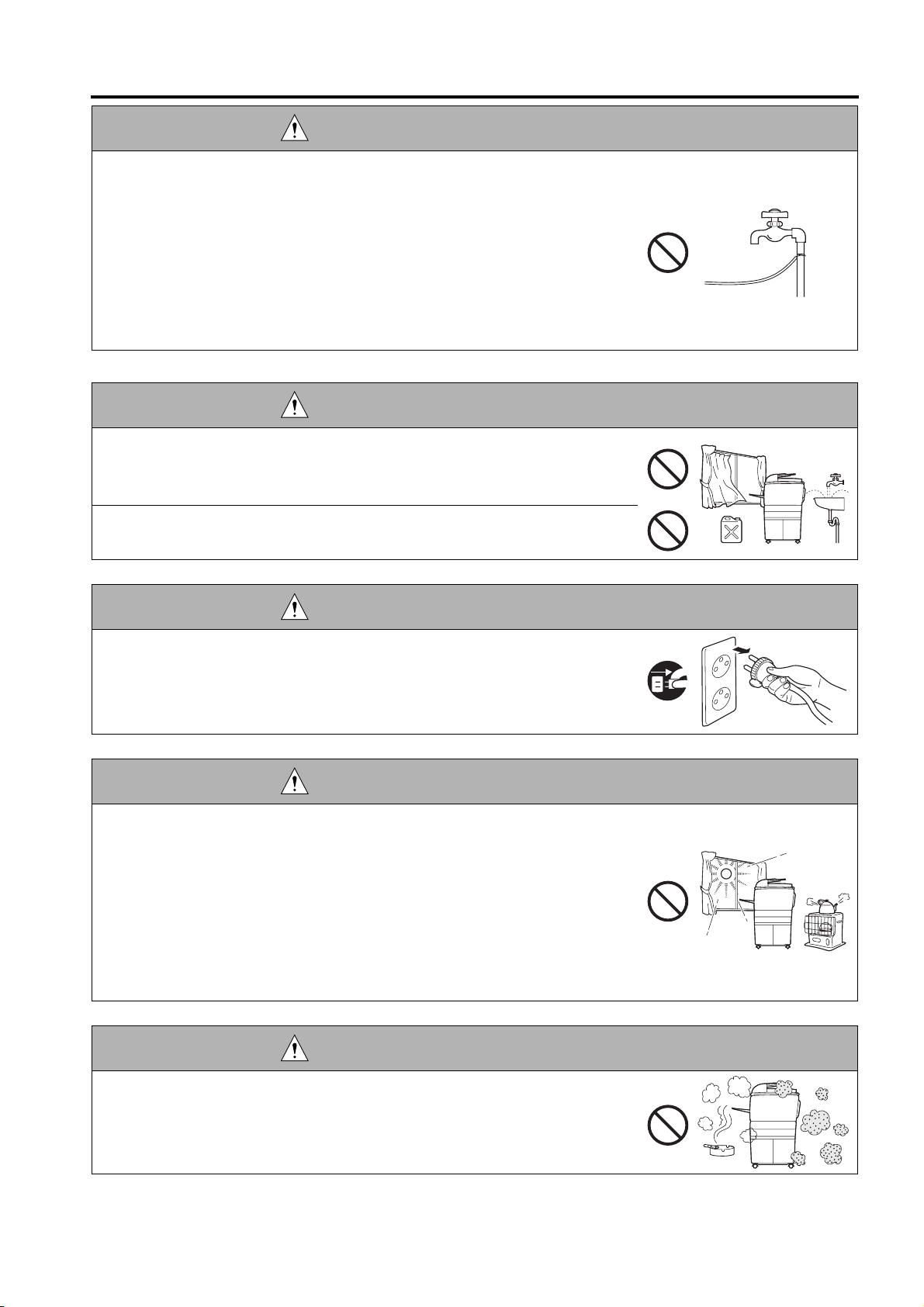

WARNING: Prohibited Installation Place

•

Do not place the MFP near flammable materials such as curtains or volatile

materials that may catch fire.

A risk of fire exists.

Do not place the MFP in a place exposed to water such as rain water.

•

A risk of fire and electric shock exists.

WARNING: Nonoperational Handling

•

When the MFP is not used over an extended period of time (holidays, etc.),

switch it off and unplug the power cord.

Dust collected around the power plug and outlet may cause fire.

CAUTION: Temperature and Humidity

•

Do not place the MFP in a place exposed to direct sunlight or near a heat

source such as a heater.

A risk of degradation in MFP performance or deformation exists.

Do not place the MFP in a place exposed to cool wind.

Recommended temperature and humidity are as follows:

Temperature: 10

Humidity: 10% to 80% (no dew condensation)

Avoid other environments as much as possible.

°C

to 30

°C

CAUTION: Ventilation

•

Do not place the MFP in a place where there is much dust, cigarette

smoke, or ammonia gas.

Place the MFP in a well ventilated place to prevent engine problems

and image faults.

S-5

Page 14

SAFETY AND IMPORTANT WARNING ITEMS

CAUTION: Ventilation

•

The MFP generates ozone gas during operation, but it is not sufficient to be

harmful to the human body.

If a bad smell of ozone is present in the following cases, ventilate the

room.

a. When the MFP is used in a poorly ventilated room

b. When taking a lot of copies

c. When using multiple MFPs at the same time

CAUTION: Vibration

•

When installing the MFP, read the Installation Guide thoroughly. Be sure to

install the MFP in a level and sturdy place.

Constant vibration will cause problems.

• Be sure to lock the caster stoppers.

In the case of an earthquake and so on, the MFP may slide, leading to a

injury.

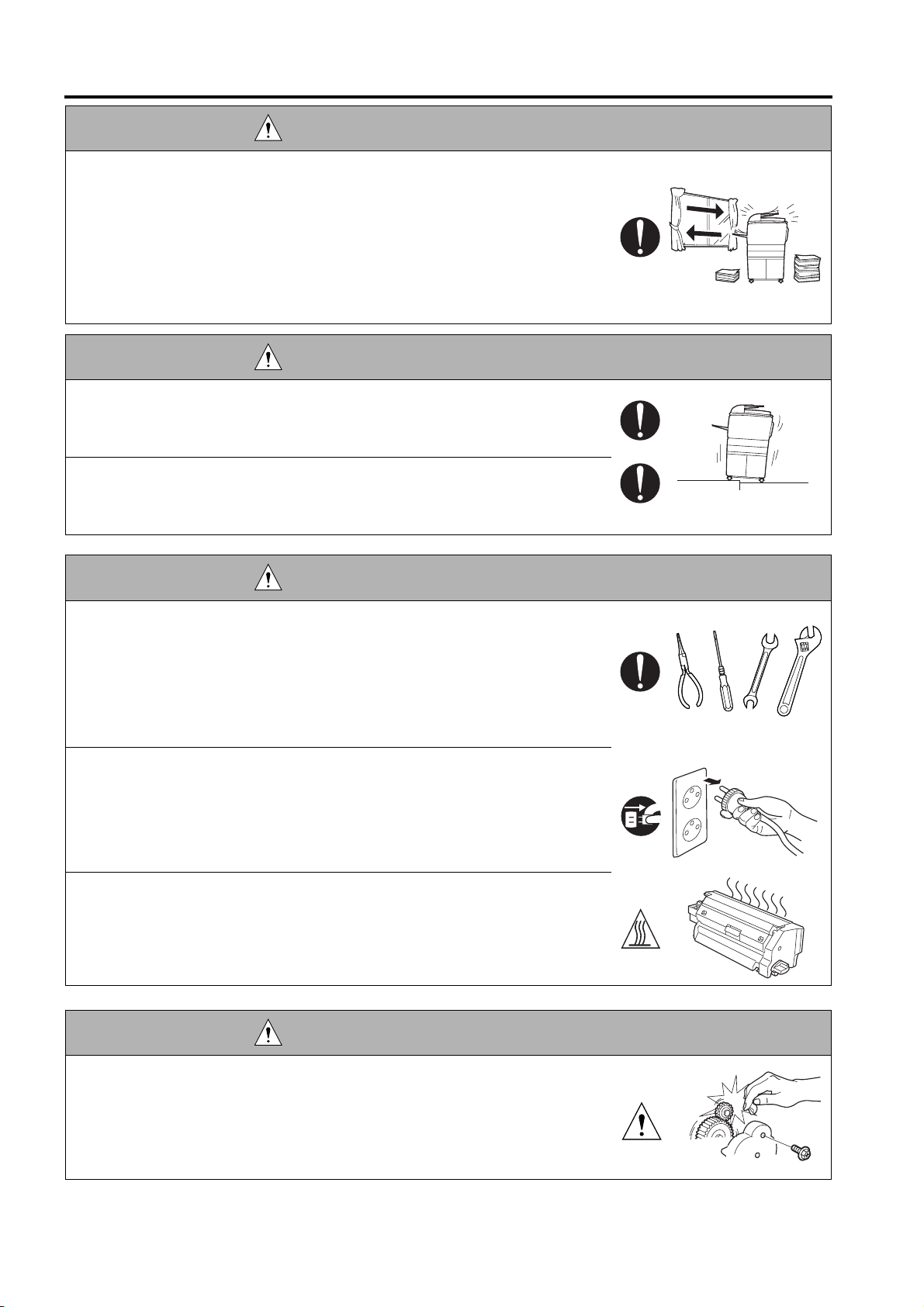

CAUTION: Inspection before Servicing

• Before conducting an inspection, read all relevant documentation (service

manual, technical notices, etc.) and proceed with the inspection following

the prescribed procedure in safety clothes, using only the prescribed tools.

Do not make any adjustment not described in the documentation.

If the prescribed procedure or tool is not used, the MFP may break and a

risk of injury or fire exists.

• Before conducting an inspection, be sure to disconnect the power plugs from

the MFP and options.

When the power plug is inserted in the wall outlet, some units are still pow-

ered even if the POWER switch is turned OFF. A risk of electric shock

exists.

• The area around the fixing unit is hot.

You may get burned.

DANGER: Work Performed with the MFP Powered

• Take every care when making adjustments or performing an operation check

with the MFP powered.

If you make adjustments or perform an operation check with the external

cover detached, you may touch live or high-voltage parts or you may be

caught in moving gears or the timing belt, leading to a risk of injury.

S-6

Page 15

SAFETY AND IMPORTANT WARNING ITEMS

DANGER: Work Performed with the MFP Powered

• Take every care when servicing with the external cover detached.

High-voltage exists around the drum unit. A risk of electric shock exists.

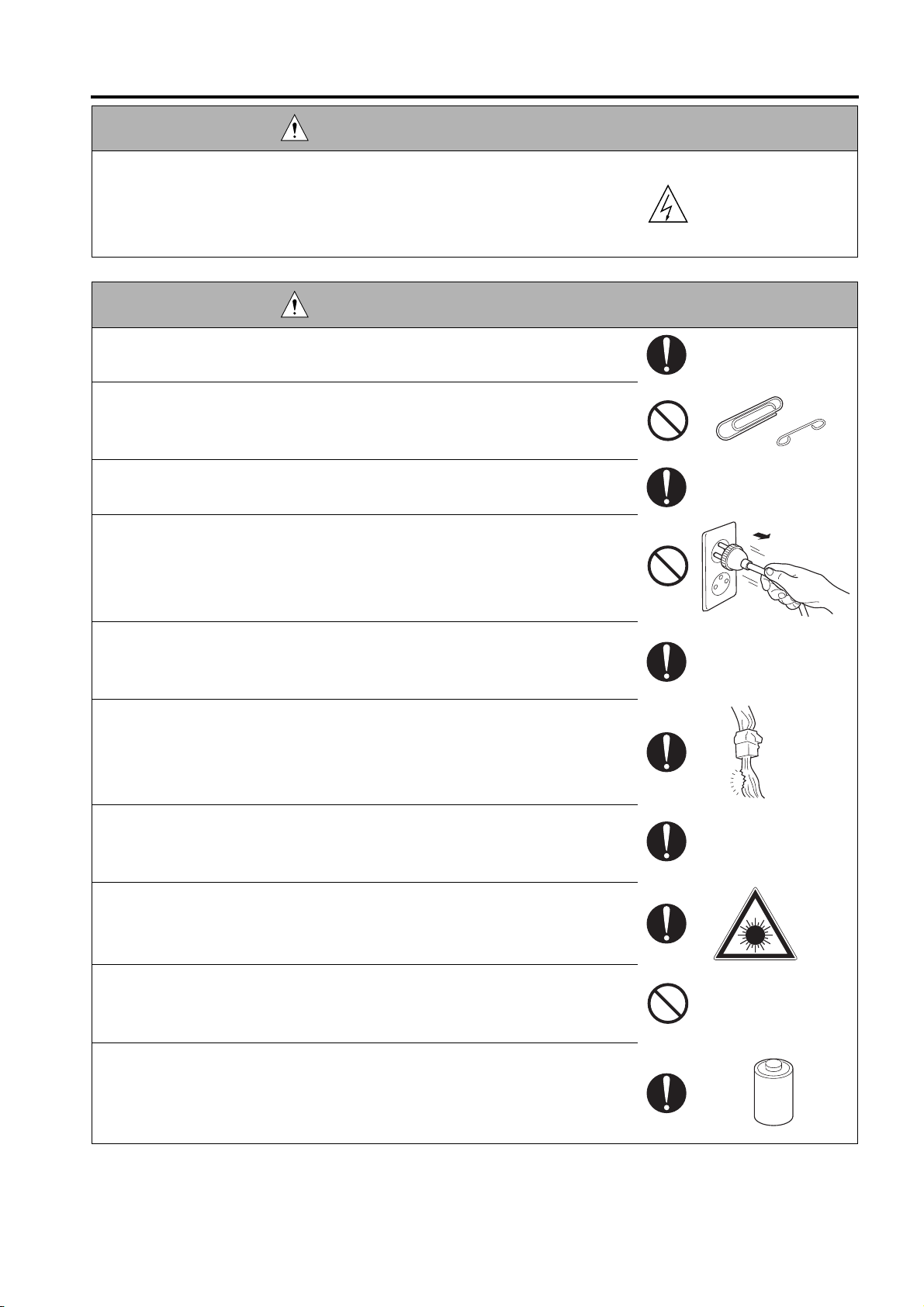

WARNING: Safety Checkpoints

• Check the exterior and frame for edges, burrs, and other damages.

The user or CE may be injured.

• Do not allow any metal parts such as clips, staples, and screws to fall into the

MFP.

They can short internal circuits and cause electric shock or fire.

• Check wiring for squeezing and any other damage.

Current can leak, leading to a risk of electric shock or fire.

• When disconnecting connectors, grasp the connector, not the cable.

(Specifically, connectors of the AC line and high-voltage parts)

Current can leak, leading to a risk of electric shock or fire.

• Carefully remove all toner remnants and dust from electrical parts and elec-

trode units such as a charging corona unit.

Current can leak, leading to a risk of MFP trouble or fire.

• Check high-voltage cables and sheaths for any damage.

Current can leak, leading to a risk of electric shock or fire.

• Check electrode units such as a charging corona unit for deterioration and

sign of leakage.

Current can leak, leading to a risk of trouble or fire.

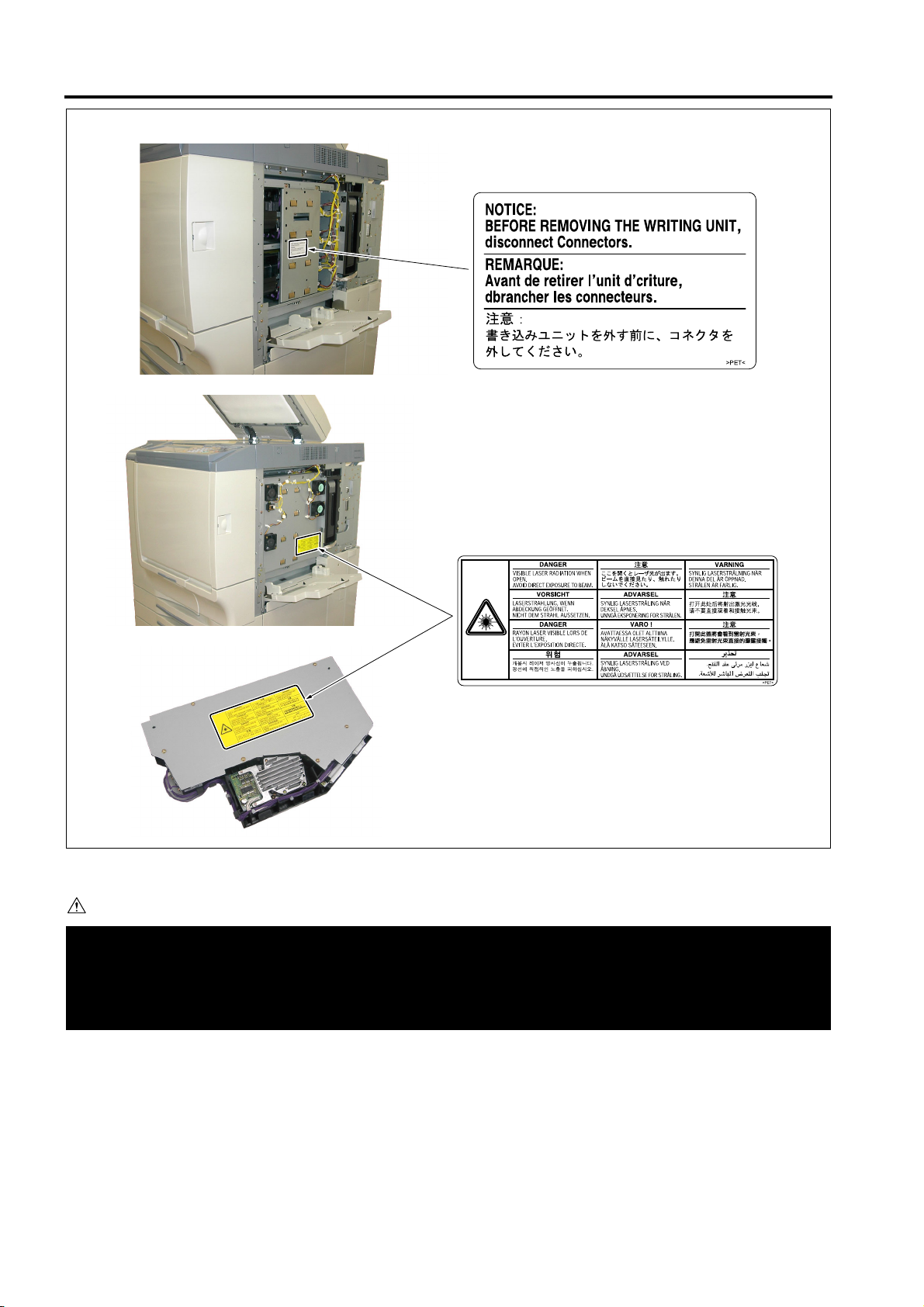

• Before disassembling or adjusting the write unit incorporating a laser, make

sure that the power cord has been disconnected.

The laser light can enter your eye, leading to a risk of loss of eyesight.

• Do not remove the cover of the write unit. Do not supply power with the write

unit shifted from the specified mounting position.

The laser light can enter your eye, leading to a risk of loss of eyesight.

• When replacing a lithium battery, replace it with a new lithium battery speci-

fied in the Parts Guide Manual. Dispose of the used lithium battery using the

method specified by local authority.

Improper replacement can cause explosion.

S-7

Page 16

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Safety Checkpoints

• After replacing a part to which AC voltage is applied (e.g., optical lamp and

fixing lamp), be sure to check the installation state.

A risk of fire exists.

• Check the interlock switch and actuator for loosening and check whether the

interlock functions properly.

If the interlock does not function, you may receive an electric shock or be

injured when you insert your hand in the MFP (e.g., for clearing paper

jam).

• Make sure the wiring cannot come into contact with sharp edges, burrs, or

other pointed parts.

Current can leak, leading to a risk of electric shock or fire.

• Make sure that all screws, components, wiring, connectors, etc. that were

removed for safety check and maintenance have been reinstalled in the orig-

inal location. (Pay special attention to forgotten connectors, pinched cables,

forgotten screws, etc.)

A risk of MFP trouble, electric shock, and fire exists.

DANGER: HANDLING OF SERVICE MATERIALS

• Toner and developer are not harmful substances, but care must be taken not

to breathe excessive amounts or let the substances come into contact with

eyes, etc. It may be stimulative.

If the substances get in the eye, rinse with plenty of water immediately.

When symptoms are noticeable, consult a physician.

• Never throw the used cartridge and toner into fire.

You may be burned due to dust explosion.

S-8

Page 17

SAFETY AND IMPORTANT WARNING ITEMS

DANGER : HANDLING OF SERVICE MATERIALS

• Unplug the power cord from the wall outlet.

Drum cleaner (isopropyl alcohol) and roller cleaner (acetone-based) are

highly flammable and must be handled with care. A risk of fire exists.

•

Do not replace the cover or turn the MFP ON before any solvent remnants

on the cleaned parts have fully evaporated.

A risk of fire exists.

• Use only a small amount of cleaner at a time and take care not to spill any

liquid. If this happens, immediately wipe it off.

A risk of fire exists.

• When using any solvent, ventilate the room well.

Breathing large quantities of organic solvents can lead to discomfort.

3. MEASURES TO TAKE IN CASE OF AN ACCIDENT

•

If an accident has occurred, the distributor who has been notified first must immediately take emergency

measures toprovide relief to affected persons and to prevent further damage.

If a report of a serious accident has been received from a customer, an on-site evaluation must be carried

•

out quicklyand hp must be notified.

To determine the cause of the accident, conditions and materials must be recorded through direct on-site

•

checks, inaccordance with instructions issued by hp.

For reports and measures concerning serious accidents, follow the regulations given in “Serious

•

Accident Report/Follow-up Procedures”.

4. CONCLUSION

•

Safety of users and customer engineers depends highly on accurate maintenance and administration.

Therefore,safety can be maintained by the appropriate daily service work conducted by the customer

engineer.

•

When performing service, each MFP on the site must be tested for safety. The customer engineer must

verify thesafety of parts and ensure appropriate management of the equipment.

S-9

Page 18

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY INFORMATION

IMPORTANT INFORMATION

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration implemented

regulations for laser products manufactured since August 1, 1976. Compliance is mandatory for products mar-

keted in the United States.

This MFP is certified as a “Class 1” laser product under the U.S.

Department of Health and Human Services (DHHS) Radiation Performance Standard according to the Radiation

Control for Health and Safety Act of 1968. Since radiation emitted inside this MFP is completely confined within

protective housings and external covers, the laser beam cannot escape during any phase of normal user opera-

tion.

S-10

Page 19

SAFETY AND IMPORTANT WARNING ITEMS

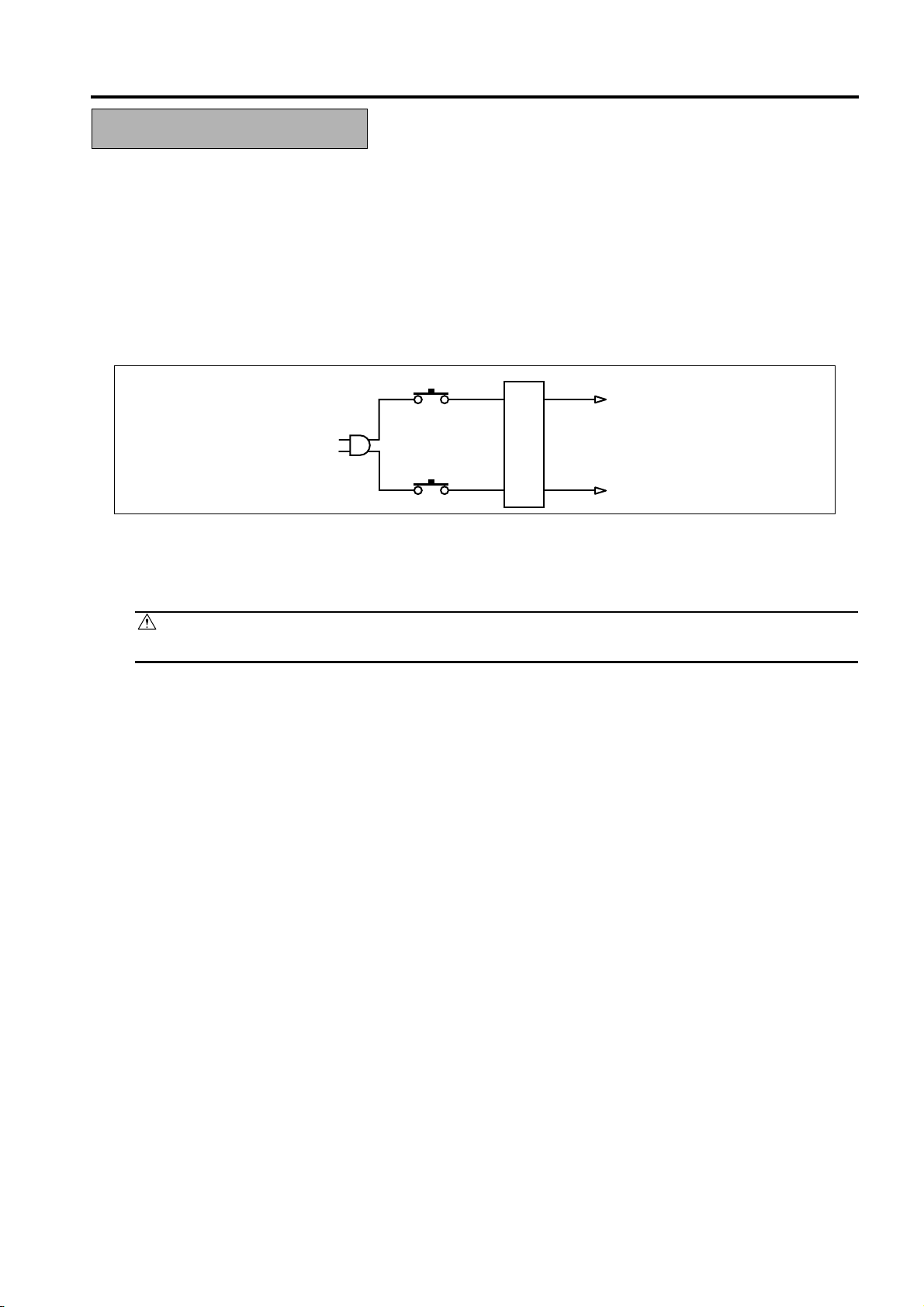

SAFETY CIRCUITS

This engine is provided with the following safety circuits to prevent engine faults from resulting in serious

accidents.

• Overall protection circuit

Fixing upper lamp 1 (L2), Fixing upper lamp 2 (L3), Fixing lower lamp (L4) overheating prevention circuit

•

These safety circuits are described below to provide the service engineer with a renewed awareness of them in

order to pre-vent servicing errors that may impair their functions.

1. Overall protection circuit

CBR1

NF

CBR2

1.1 Protection by circuit breaker /1 (CBR1) and circuit breaker /2 (CBR2)

CBR1 and CBR2 interrupt the AC line instantaneously when an excessive current flows due to a short

in the ACline.

CAUTION:

The CBR1 and CBR2 functions must not be deactivated under any circumstances.

S-11

Page 20

SAFETY AND IMPORTANT WARNING ITEMS

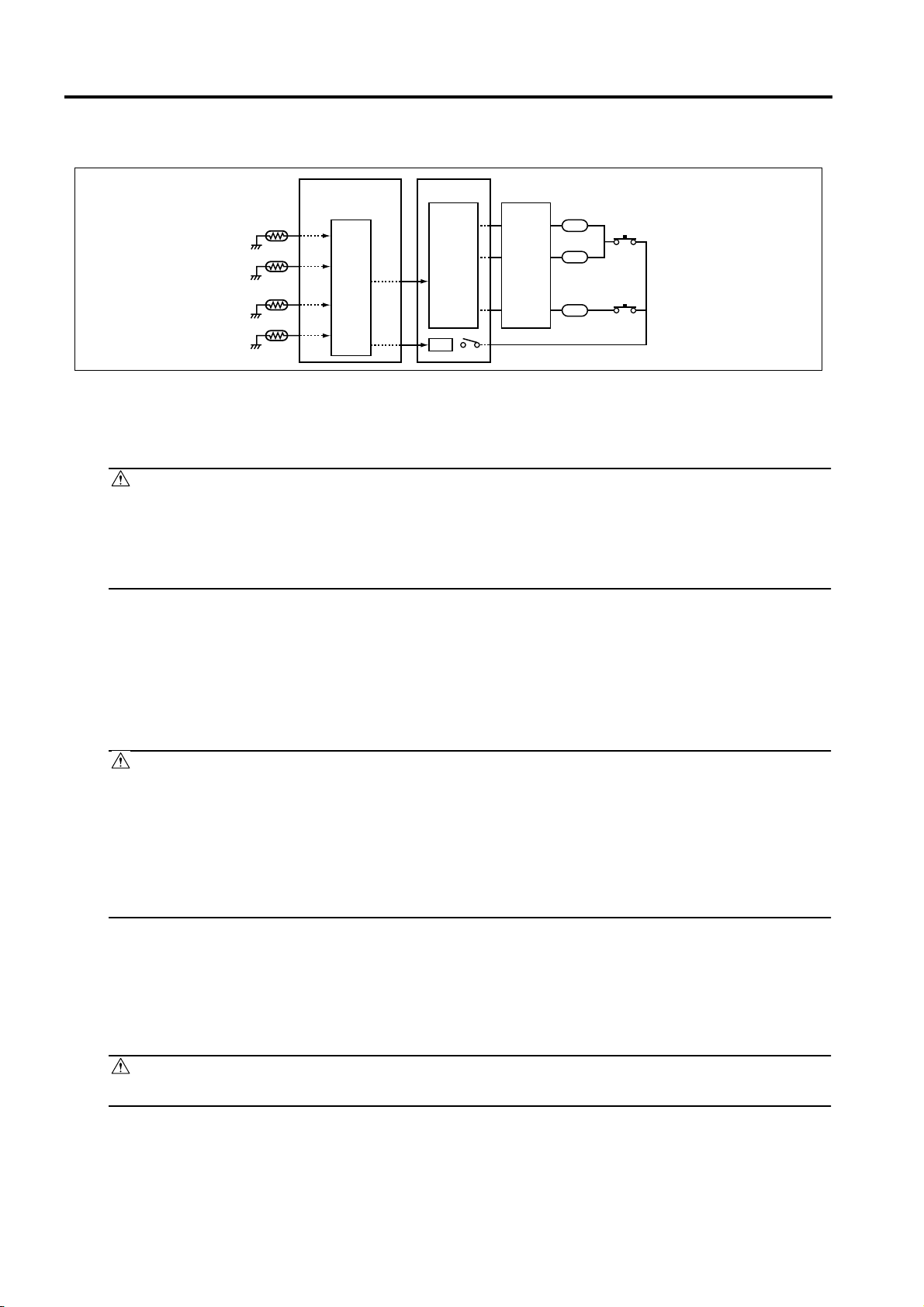

2.

Fixing upper lamp 1 (L2), Fixing upper lamp 2 (L3), Fixing lower lamp (L4) overheating

prevention circuit

PRCB ACDB

TH1

TH3

TH2

TH4

Control

section

AC driver

section

RL1

RL1

FHCB

L2

TS1

L3

TS2

L4

2.1 Protection by software

The output voltage from fixing temperature sensor 1 (TH1) and fixing temperature sensor 2 (TH2) is

read by theCPU. If this voltage is abnormal, L2, L3, and L4 are turned OFF by opening main relay (RL1).

CAUTION:

The clearance between the fixing upper roller and TH1 and the clearance between the fixing

•

lower roller and TH2 must not be changed. When replacing them, make sure to comply with

the specified clearances.

• The RL1 function must not be deactivated under any circumstances.

2.2 Protection by the hardware circuit

The output voltages from fixing temperature sensor 1 (TH1), fixing temperature sensor 2 (TH2), fixing

temperaturesensor 3 (TH3), and fixing temperature sensor 4 (TH4) are compared with the abnormality

judgment referencevalue in the comparator circuit. If the output voltage from TH1, TH2, TH3, or TH4

exceeds the reference value, L2,L3, and L4 are turned OFF by opening RL1.

CAUTION:

• The clearance between the fixing upper roller and TH1 and the clearance between the fixing

lower roller and TH2 must not be changed. When replacing them, make sure to comply with

the specified clearances.

• Periodically check the contact between the fixing upper roller and TH3 and the contact

between the fixing lower roller and TH4, and replace them if any abnormality is detected.

• The RL1 function must not be deactivated under any circumstances.

2.3

Protection by thermostat 1 (TS1) and thermostat 2 (TS2)

When the temperature of the fixing upper roller exceeds the specified value, TS1 is turned OFF, thus

interrupting thepower to L2 and L3 directly. When the temperature of the fixing lower roller exceeds the

specified value, TS2 isturned OFF, thus interrupting the power to L4 directly.

CAUTION:

Do not use any other electrical conductor in place of TS1 and TS2.

S-12

Page 21

SAFETY AND IMPORTANT WARNING ITEMS

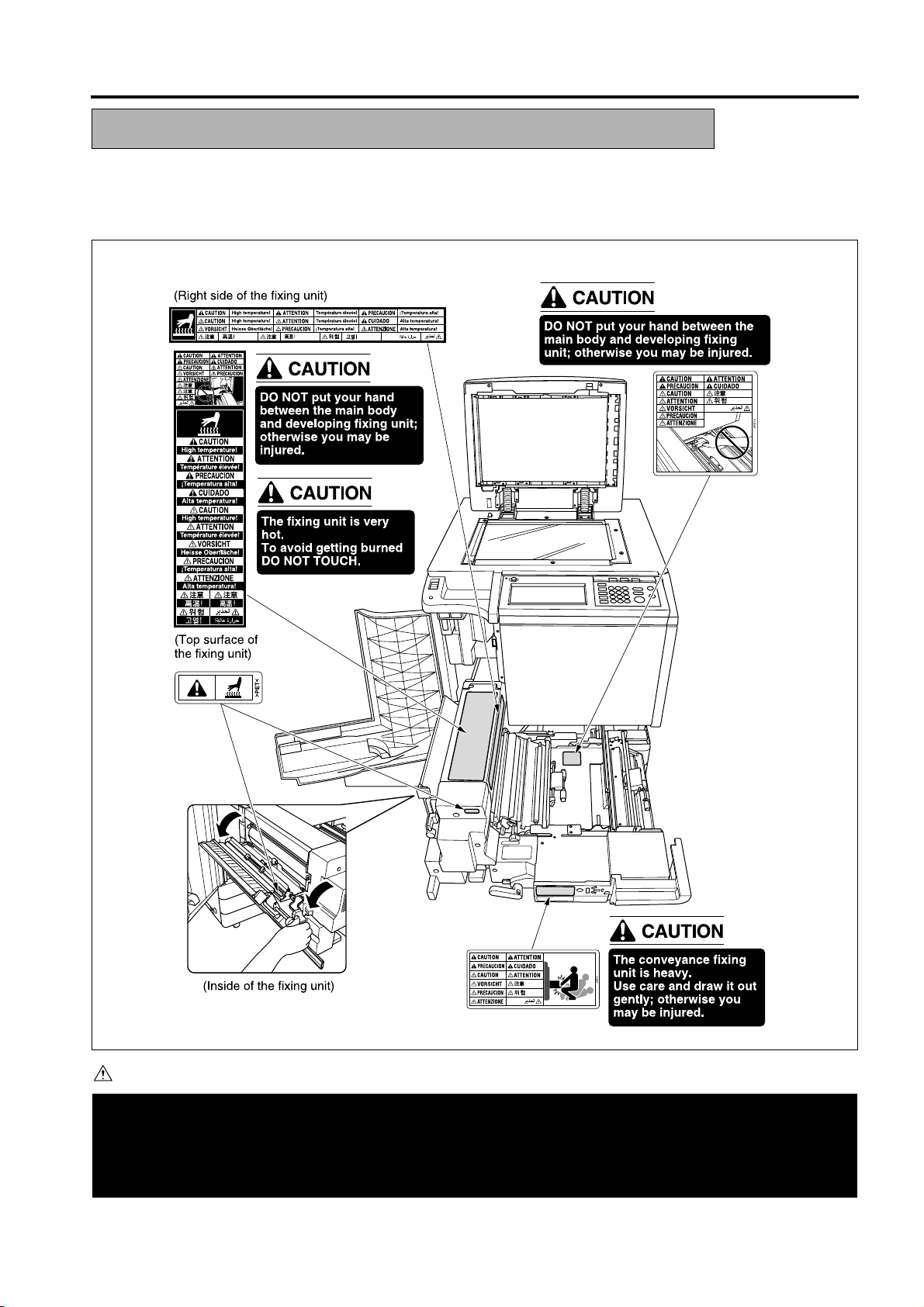

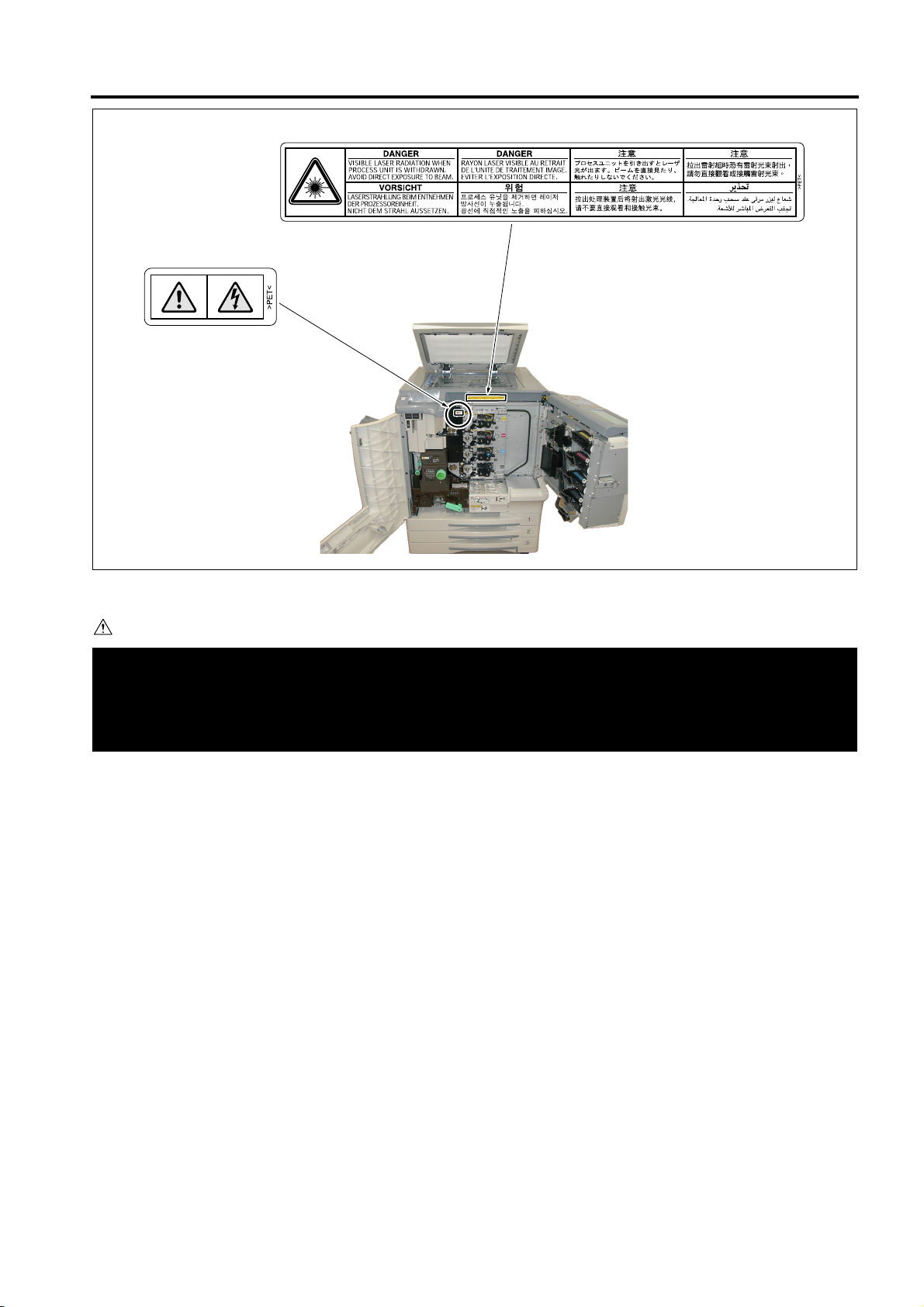

INDICATION OF WARNING ON THE ENGINE

Caution labels shown below are attached in some areas on/in the engine.

When accessing these areas for maintenance, repair, or adjustment, special care should be taken to avoid

burns and electricshock.

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-13

Page 22

SAFETY AND IMPORTANT WARNING ITEMS

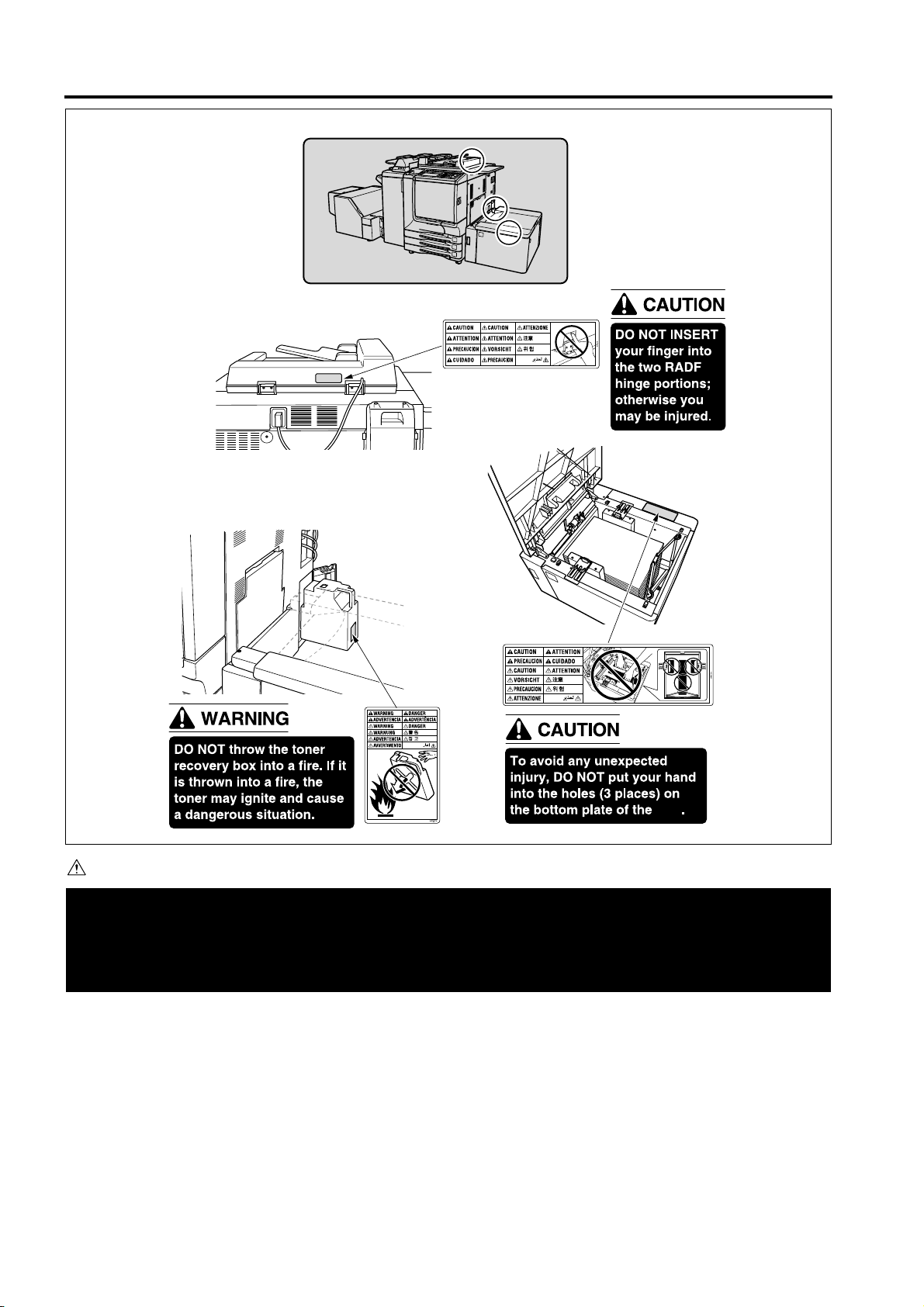

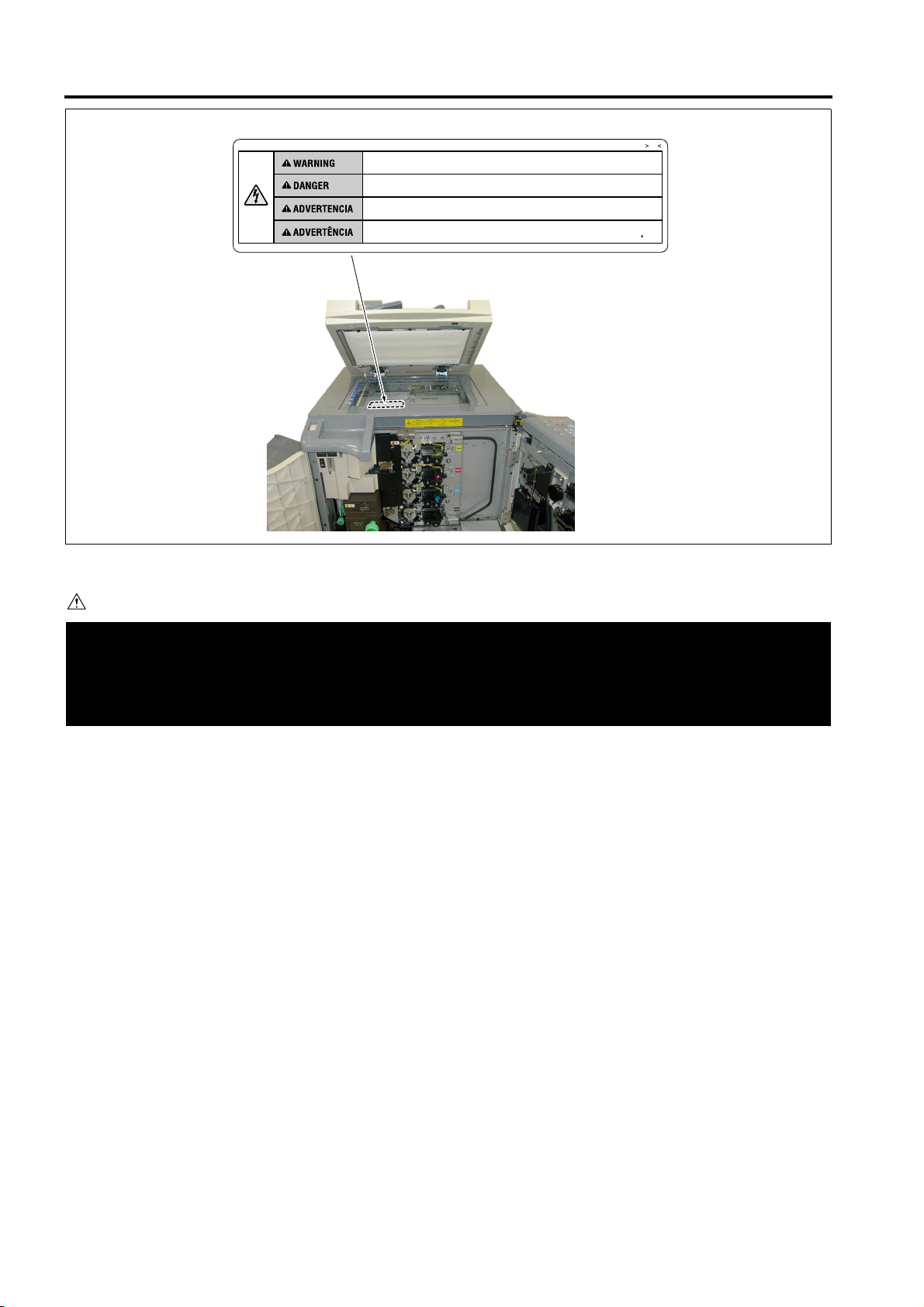

(Right rear side of the ADF)

(Right rear side

of the Engine)

(Inside of the HCI)

HCI

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-14

Page 23

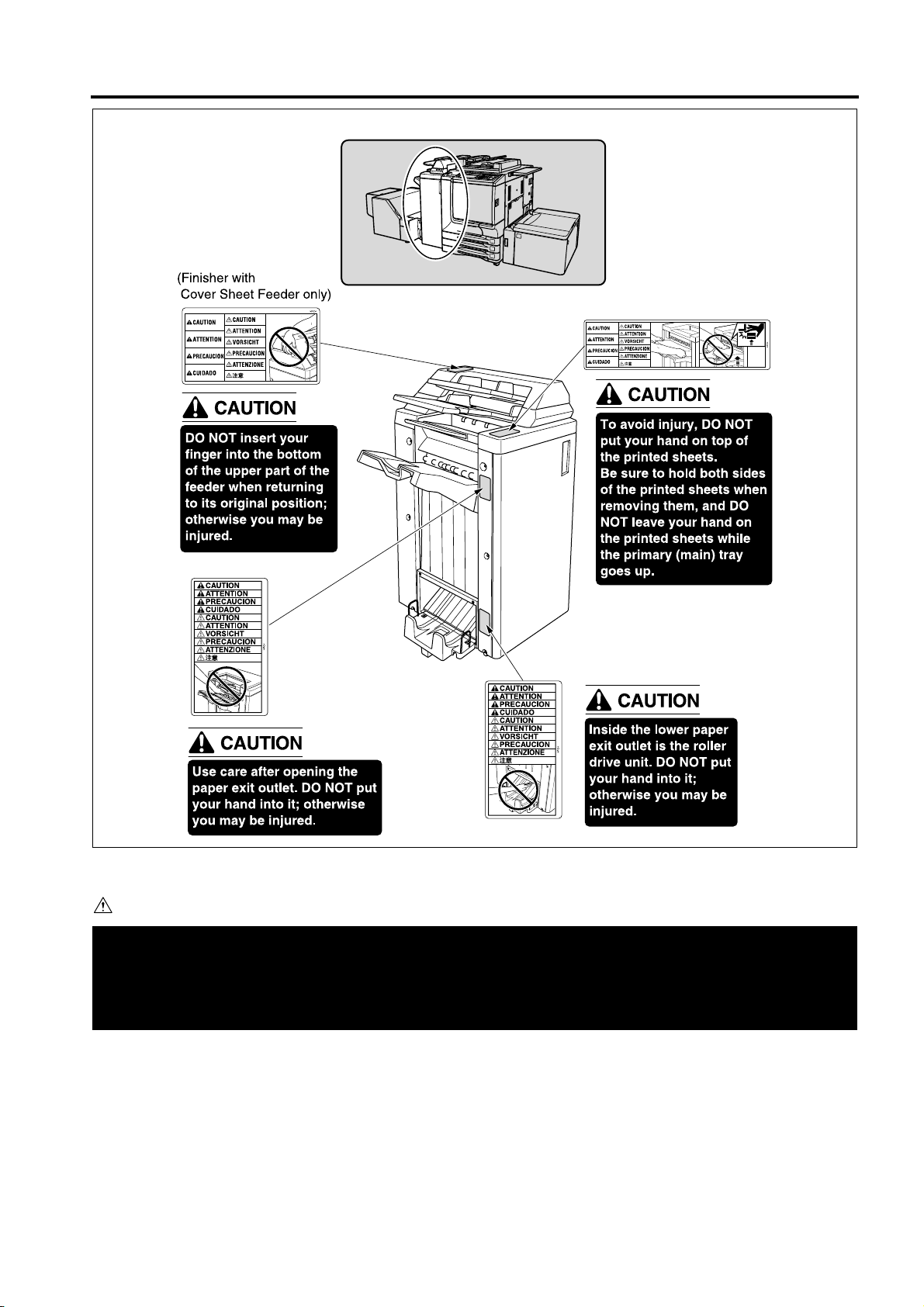

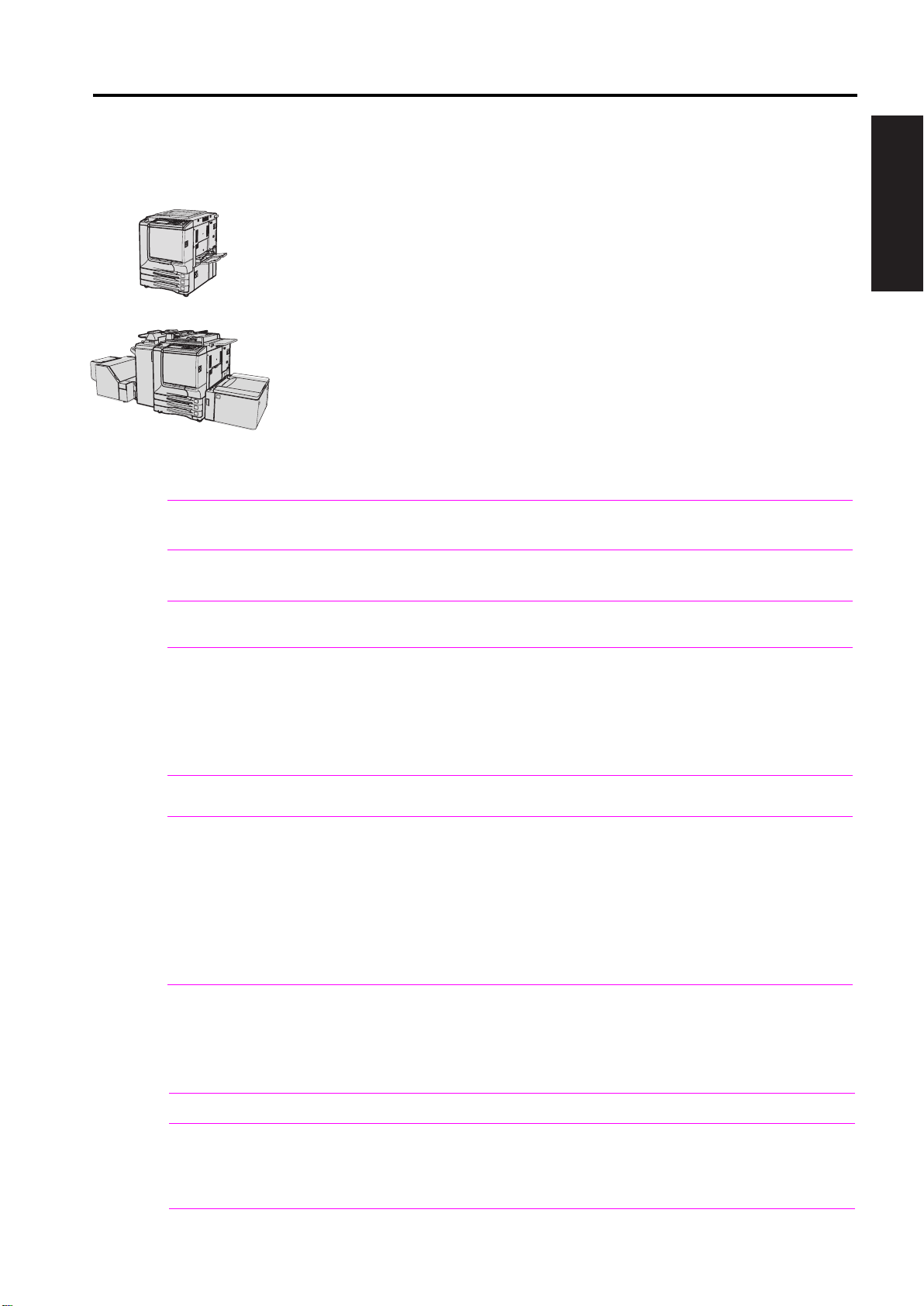

Q3636A

SAFETY AND IMPORTANT WARNING ITEMS

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-15

Page 24

SAFETY AND IMPORTANT WARNING ITEMS

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-16

Page 25

SAFETY AND IMPORTANT WARNING ITEMS

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-17

Page 26

SAFETY AND IMPORTANT WARNING ITEMS

Unplug the engine before removing scanner glass.

Debrancher le copieur avant de retirer la vitre d'exposition.

Desenchufe la maquina antes de quitar el vidrio.

Desconecte a unidade da tomada antes de remover o vidro de exposicao.

PS

~

CAUTION

You may be burned or injured if you touch any area that you are advised by any caution label to keep your-

self away from.

Do not remove caution labels. If any caution label has come off or soiled and therefore the caution cannot

be read, contact our Service Office.

S-18

Page 27

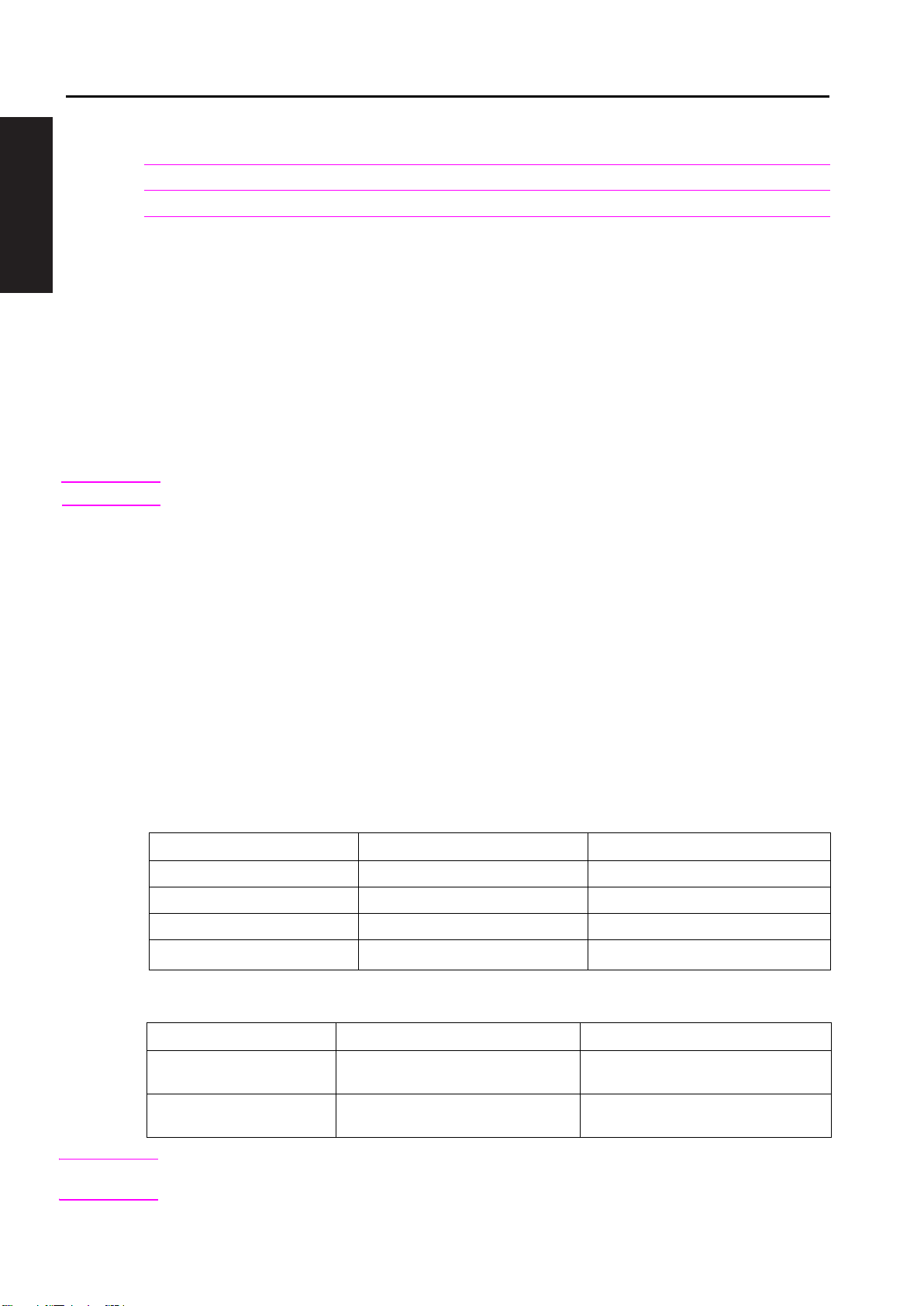

hp Color 9850mfp

I Product information

1.1 Product features

HP Color 9850mfp (Q3225A) basic configuration

The HP Color 9850mfp comes standard with 128-MB RAM for each color, wideformat standalone copying capability, trays 1, 2 and 3 (500-sheets each), a 250sheet multipurpose bypass tray and a Reversing Automatic Document Feeder

RADF.

HP Color 9850mfp (Q3225A) fully loaded

The fully loaded HP Color 9850mfp comes with 384-MB RAM for each color, a 20GB EIO hard disk, wide-format printing, copying and network printing capabilities,

trays 1, 2 and 3 (500-sheets each), a 250-sheet multipurpose bypass tray, tray 4

(a 2,500-sheet high capacity input HCI), a Reversing Automatic Document Feeder

RADF, an EFI print controller, a 3000-sheet Stapler-stacker or a Multifunction

Finisher with a Trimmming Unit at the output, a Post Insertion Unit for feeding

covers, and a Hole Punch Unit at the output.

Table 1. Features of the HP Color 9850mfp

OUTLINE OF SYSTEM

I OUTLINE

Speed

Resolution

Consumables

Language

and fonts

Memory expansion

Functions

Expandability z HP Color 9850mfp automatic document feeder (standard)

z Up to 50/51 pages per minute (ppm) for letter / A4-size media.

z First page out in 7.6 seconds for color and 6 seconds for B/W.

z 600-by-600 dots per inch (dpi).

z

600-by-1800 dots per inch (dpi) enhanced resolution mode (printing only).

z CMYK toner bottles.

z Staple cartridges.

z PCL6 EC (XL)

z PCL6e

z PCL5EC (with color)

z PCL6E (XL)

z PJL

Post Script 3

z

Basic 128 MB of RAM per color, expandable to 384 MB by using hp 256

z

MB memory module (Q6993A).

z Bypass tray supports up to 200 sheets of 28 lbs of custom-sized media up

to 13 by 19 in. (250 sheets of 20 lbs)

z Trays 1, 2 and 3 support up to 400 sheets of 28 lbs (500 sheets of 20 lbs)

Tray 4 supports up to 2,200 sheets of 28 lbs (2,500 sheets of 20 lbs)

z

z Two-sided printing (duplex printing)

z Wide-format printing

z Glossy printing

z Document finishing options (with stapler-stacker or multifunction finisher).

z 3,000-sheet stapler/stacker (optional)

z 3,000-sheet Multifunction finisher (optional)

z 4 DIMM slots for adding memory (standard)

z 20 GB hard disk drive (optional)

Wireless printing

Interface connection

z Not supported

Video interface for EFI print controller

z

z Parallel port (based on IEEE 1284, for service)

z Serial port (USB Type B, for service)

z RJ45 Ethernet connector (available with EFI print controller)

1-1

Page 28

PRODUCT SPECIFICATIONS hp Color 9850mfp

Table 1. Features of the HP Color 9850mfp (continued)

Networking

Maximum monthly duty cycle z 150,000 pages per month

z EFI print controller

I OUTLINE

1.2 Product specifications

Identification

A user-accessible label is located on the back cover of the engine. The model number is

alphanumeric, such as Q3225A.

The serial number contains information about the country of origin, product type, engine voltage,

revision number, and engine serial number. An example of a serial number is JPHCB00001. Please

refer to the 9850mfp Parts Manual, section How to use this manual for detailed information.

The identification label also contains electrical information and regulatory information.

Note The electrical information and regulatory information vary by country/region.

Specifications

Type:

Copying method: Tandem intermediate transfer type electrostatic method

Original table: Fixed

Original alignment: Rear left side as reference

Photosensitive material: OPC

Sensitizing method:

Paper feed trays: 3 trays method (500 sheets x 3, 80 to 90g/m

Console type (floor-mounted type)

Laser writing

Multisheet by-pass tray (250 sheets, 80 to 90g/m

Q5690A (2500 sheets, 80 to 90g/m , optional)

2

2

) (400 sheets x 3, 105g/m2)

2

) (200 sheets, 105g/m2)

WARNING!

Table 2. HP Color 9850mfp specifications

Specification Out-of-box Packaged

Height 1,179 mm (46.4 inches) 1,210 mm (47.6 inches)

Width 1,275 mm (50.2 inches) 950 mm (37.4 inches)

Depth 889 mm (35.0 inches) 1,258 mm (49.5 inches)

Weight

313 kg (690 lb) 361 kg (796 lb)

Table 3. Power requirements and circuit capacity

Power source for inch area Power source for metric area

Power requirements

Minimum recommended

circuit capacity

208 to 240 V (+/- 10%)

60 Hz 50 Hz

3600 Watts (dedicated circuit) 3450 Watts (dedicated circuit)

230 V, -14% +10.6%

Power requirements are based on the country/region where the MFP is sold. Do not convert operating

voltages. This can damage the MFP and void the product warranty.

1-2

Page 29

hp Color 9850mfp

Table 4. Power consumption

OUTLINE OF SYSTEM

MFP state

Switch off mode

Sleep mode

Low power mode

Continuous copying mode (A4) 1,618 W 1,603 W

Inch area consumption

0.2 W

12 W

172.4 W

568 WIdling mode

Metric area consumption

0.2 W

11 W

178.8 W

548 W

Environmental specifications

The environmental specifications must be maintained to ensure the proper operation of the MFP.

Consider the following points before installing the MFP:

z Install the MFP in a well-ventilated, dust-free area.

z Install the MFP on a level, flat surface that can support its size and weight. Do not install on

carpet or on other soft surfaces. Make sure that all four MFP feet are level.

z Install the MFP where temperature and humidity are stable, with no abrupt changes (away from

water sources, humidifiers, air conditioners, refrigerators, or other major appliances).

z Install the MFP away from direct sunlight, areas that experience vibration, open flames,

ammonia fumes, ultrasonic heaters, and devices that emit a magnetic field. If the MFP is

placed near a window, make sure that the window has a curtain or blind to block direct sunlight.

z Maintain enough space around the MFP for proper access and ventilation.

z Be sure to use a power source of the voltage and frequency indicated in the product

specifications. Ensure that the current carrying capacity of the power outlet is at least equal to

the current listed in the product specifications.

z Power the machine directly from a dedicated power outlet. (Do not use an extension cord.)

z Do not plug or unplug the power cord with wet or dirty hands, to prevent an electric shock.

I OUTLINE

Note

Table 5. Environmental specifications

Allowable condition Recommended condition

Operating temperature 10 to 30 C elsius (C)

(50 to 86 Fahrenheit [F])

Relative humidity 10 to 80 percent 40 to 60 percent

18 to 23 C (64 to 73 F)

Table 6. Noise level specifications

Acoustics Printing (50 ppm) Low power mode

Sound power level L

Sound pressure level, L

(Bystander position)

pAm

L

WAd

pAm

= 59 dB(A)

essentially inaudible = 7.7 B(A)

essentially inaudible

Testing per International Standards Organization (ISO) 9296 and (ISO) 7779.

1-3

Page 30

PRODUCT SPECIFICATIONS hp Color 9850mfp

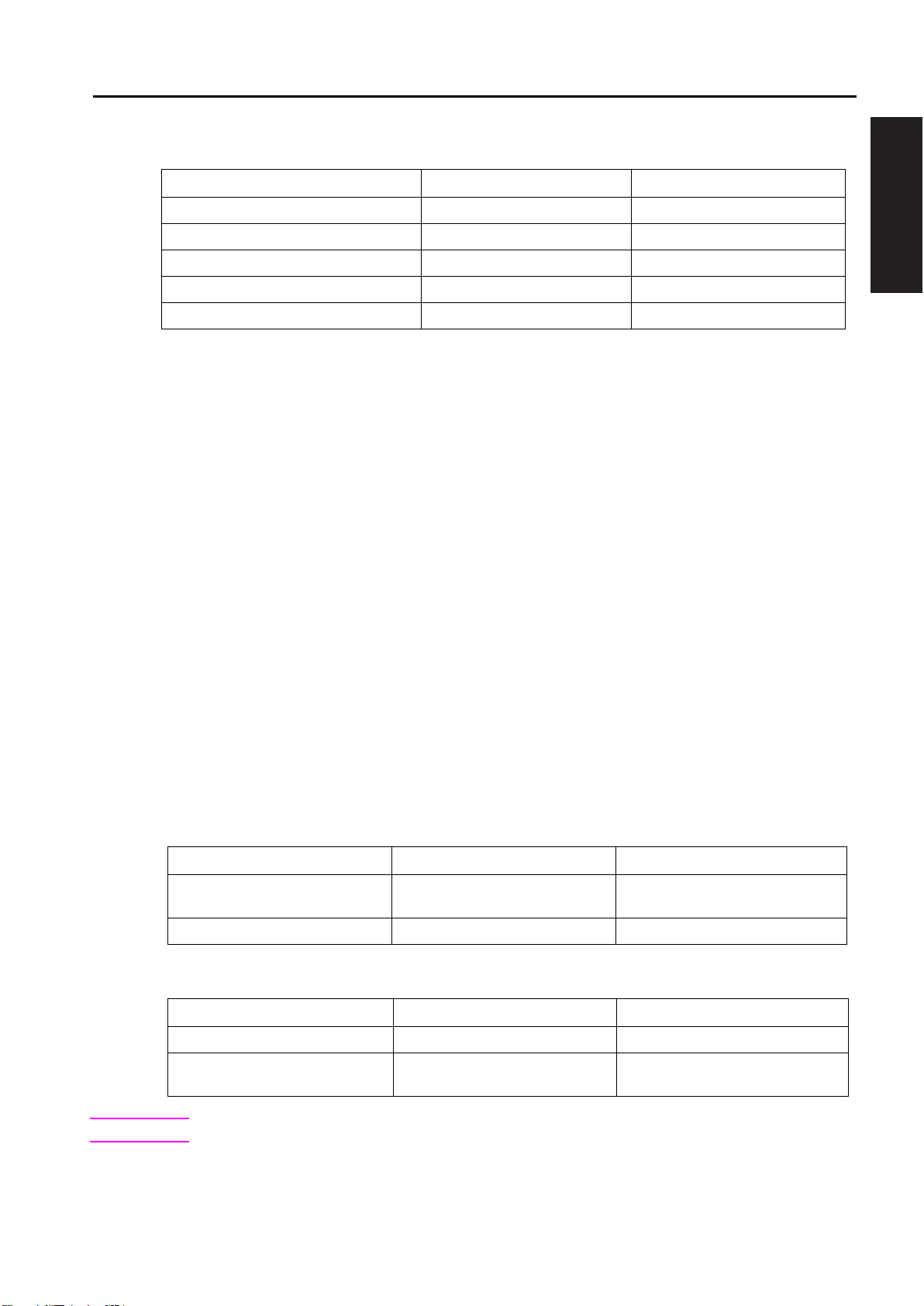

1.3 Product overview

External assembly locations

I OUTLINE

Control panel

LCD Touch screen

Power switch

Stapler/stacker

(option)

RADF

Toner supply unit

Toner access door

Toner recovery box

Multi-sheet

bypass tray

Trimmer unit

(option)

Front door

Tray 1

Cover insertion kit

(option)

Tray 2

Right side door

Tray 3

Work table

Tray 4 ( HCI High

capacity input) (option)

Trimmer kit (option)

Multifunction Finisher (option)

1-4

Page 31

hp Color 9850mfp

OUTLINE OF SYSTEM

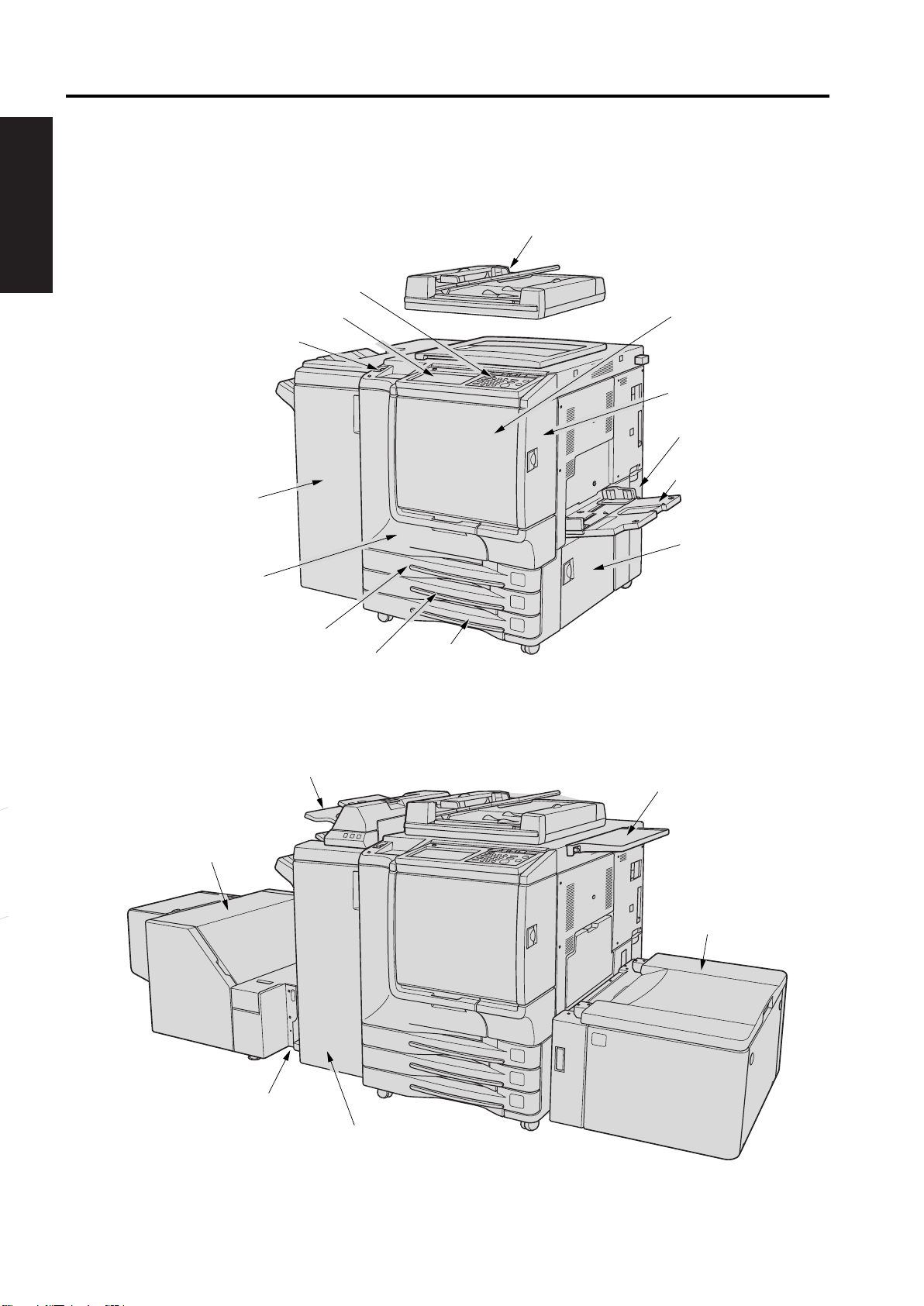

Accessories

1

Standard/optional equipment

I OUTLINE

2

3

4

5

7

6

8

9

11

10

12

13

1

HP 3 Hole Punch Kit

2

HP Post Insertion Kit

3

HP Automatic Document Feeder (RADF (ADF))

4Work table

5 HP 3000-Sheet Stapler/Stacker

6

HP Color 9850mfp (engine)

7 HP 2500-Sheet High Capacity Input (HCI)

8 HP 256 MB Memory Module

9 HP Copy Controller Hard Drive

10

HP 3000-Sheet Multifunction Finisher

11

EFI Print Controller Kit

12

HP Trimmer Adapter Kit connects the Finisher and HP Trimmer Unit.

13

HP Trimmer Unit

1-5

Page 32

PRODUCT SPECIFICATIONS hp Color 9850mfp

Internal engine parts

I OUTLINE

1

Lever A can be moved to withdraw the ADU for removal of misfed paper.

Fixing unit fuses the toner onto the copy paper.

2

3 Main power switch (used only by a service representative) turns the engine

power on and off.

4 Total counter indicates the total number of prints made.

5 Black print counter indicates the total number of the black prints made.

1.4 Space requirements

Printer with packaging

The shipping box that contains the HP Color 9850mfp is 950 mm (37.4 inches) wide, 1,258 mm

(49.5 inches) deep and 1,210 mm (47.6 inches) high. The in-box weight of the HP Color

9850mfp is 361 kg (796 lb) .The customer must locate a door or receiving area that is large

enough to accept delivery of the shipping box.

Note

Before removing the printer from the box, make sure that adequate space is available to

unpack the printer and to roll the product off of the shipping pallet. At least 10 feet of clearance

around the box is required to remove all of the shipping materials.

1-6

Page 33

hp Color 9850mfp

Printer physical dimensions

Install the MFP in an area with adequate space for performing all operations, replacing supply

items, and conducting preventive maintenance.

OUTLINE OF SYSTEM

I OUTLINE

HP Color 9850mfp plus HP Automatic Document

Feeder (Front) and 3000-sheet Stapler/Stacker

HP Color 9850mfp plus HP Automatic Document

Feeder, HP 3000-Sheet Multifunction Finisher,

HP Post Insertion Kit, and HP 2500-Sheet High

Capacity Input (HCI) (Front)

HP Color 9850mfp plus HP Automatic Document

Feeder (Right side)

HP Color 9850mfp plus HP Automatic Document

Feeder and HP 2500-Sheet High Capacity Input (HCI)

(Right side)

HP Color 9850mfp plus HP Automatic Document

Feeder, HP 3000-Sheet Multifunction Finisher,

HP Post Insertion Kit, HP 2500-Sheet High Capacity

Input (HCI), and HP Trimmer Unit, (Front)

1-7

Page 34

PRODUCT SPECIFICATIONS hp Color 9850mfp

1.5 Setup

The initial printer setup includes the following steps:

z Remove the printer from the box.

I OUTLINE

z Set up and install the printer. See the HP Color 9850 Install Guide.

z Set up and install the finishing devices. See the install guide that came with the finishing devices.

The shipping box contains the following items:

z HP Color 9850mfp

z Rear cover

z One Ozone filter

z

Four developers

Black

Yellow

Cyan

Magenta

z One developer charging funnel

z Four developing units

Black

Yellow

Cyan

Magenta

z Nails

z One transfer unit

z One belt cleaner unit

z One separation claw unit

z Three TP M3x6 screws

z One working table (shipped in Tray 2)

z HP Color 9850mfp System Administrator’s Guide

z One manual holder (shipped in Tray 3)

z HP Color 9850mfp Installation Guide

z One primary power switch label

z One secondary power switch label

Note The finishing devices are delivered in separate boxes.

1-8

Page 35

hp Color 9850mfp

1.6 Media specifications

Before purchasing large quantities of print media, make sure that it meets the requirements specified

in this service manual and in the HP Color 9850mfp System Administrator Guide. Always test the

print media before buying large quantities.

Hewlett-Packard neither warrants nor recommends the use of a particular brand of paper or print

media other than HP media. Media properties are subject to manufacturing changes, and HP has no

control over such changes. Although testing the media helps to characterize the performance and

the manufacturers process quality, the customer assumes all responsibility for the quality and

performance of media.

CAUTION

Using print media that does not meet HP specifications might cause problems for the printer,

requiring repair. Such repair is not covered by the Hewlett-Packard warranty or service

agreements.

The HP Color 9850mfp accepts a variety of media, such as cut-sheet paper, labels, and customsize paper. Properties such as weight, composition, grain, and moisture content are important

factors affecting printer performance and output quality. Media that does not meet the guidelines

outlined in this manual and in the print media guide can cause the following problems:

z poor print quality

z increased jams

z premature wear on the printer, requiring repair

OUTLINE OF SYSTEM

I OUTLINE

Note

Hint

Guidelines for selecting media

Selecting media by type and size at the control panel and in the MFP must be selected prior

to print/copy. Using the wrong setting can result in unsatisfactory print quality. Always print

by type for special print media such as labels.

Some print media might meet all of the guidelines in this manual and still not produce satisfactory

results. This might be the result of improper handling, unacceptable temperature and humidity

levels, or other variables over which HP has no control.

If you are unsure what type of paper you are loading (such as bond or recycled), check the label on

the package of paper.

See Basis weight field test on page 1-15 for information about measuring basis weight.

z

See Caliper field test on page 1-17 for information about measuring caliper.

z

See Paper finish field test on page 1-17 for information about smoothness.

z

Do not purchase more media than can be easily used in a short time (about 3 months). Media

that is stored for long periods experiences heat and moisture extremes that can be damaging.

Planning is important to prevent damage to a large supply of media.

1-9

Page 36

PRODUCT SPECIFICATIONS hp Color 9850mfp

Supported media and capacity for input and output

Note The leading edge is listed first in the dimension measurements.

Table 7. Supported standard media sizes

I OUTLINE

Bypass tray Tray 4 / HCIPrinting task Trays 1, 2 and 3

Simplex, and duplex

letter, letter R, legal,

z z

5.5 x 8.5R, A3, A4, A4R

A5R, B4, B5, B5R,

11 by 17, 12 by 18,

and 13 by 19 inches

zletter, letter R, legal,

5.5 x 8.5R, A3, A4

A4R, A5R, B4, B5,

B5R, B6R, 11 by 17,

12 by 18, 13 by 19 in

letter, letter R,

legal, A3, A4,

B4, B5, 11 by 17,

12 by 18 and 13

by 19 inches

Table 8. Maximum custom sizes

Printing task Trays 1, 2 and 3 Bypass tray Tray 4 / HCI

Simplex, and duplex

330 by 487 mm

z z

(13 by 19.2 inches)

z 330 by 487 mm

330 by 487 mm

(13 by 19.2 inches)(13 by 19.2 inches)

Table 9. Minimum custom sizes

Printing task Trays 1, 2 and 3 Bypass tray Tray 4 / HCI

Simplex and duplex

z210 by 140 mm

( 8.27 by 5.51 inches)

z100 by 148 mm

(3.9 by 5.8 inches)

z 257 by 210 mm

(10.1 by 8.3 inches)

Table 10. Supported media weights

Printing task Trays 1, 2 and 3 Bypass tray Tray 4 / HCI

Simplex and duplex

64 to 209 g/m

z

(17- to 115-lb)

2

64 to 256 g/m 64 to 256 g/m

z

(17- to 143-lb) (17- to 143-lb)

2

z

Table 11. Input tray capacities

2

CAUTION

Type of media Trays 1, 2 and 3 Bypass tray Tray 4 / HCI

Cut sheets z

Up to 400 sheets

28 lb paper

Up to 200 sheets

28 lb paper

Up to 2,200 sheets

28 lb paper

Table 12. Output bin capacities

2

Bin

Stapler/stacker

Multifunction finisher

Trimmer unit

Exit tray

75 g/m

z Up to 3000 sheets Up to 2400 sheets

z Up to 3000 sheets Up to 2400 sheets

z Up to 500 sheets

z up to 150 sheets

Do not use paper that is heavier than 200 g/m (53-lb bond) for duplex printing. Damage to the

(20-lb bond)

105 g/m (28-lb bond)

Up to 410 sheets

Up to 120 sheets

2

2

printer and jams might result.

Coated paper of 106g/m to 256g/m is fed one at a time by by-pass feed. However, it is possible to

2 2

feed it through H CI (optional).