Page 1

https://truckmanualshub.com/

MENU

FOREWORD

This workshop manual has been prepared to provide information regarding repair procedures on Hino Trucks.

Applicable for J05E engine

When making any repairs on your vehicle, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owner’s Manual.

All information and specifications in this manual are based upon the latest product information available at the time of printing.

Hino Motors Sales U.S.A. , Inc. reserves the right to make changes at any time without prior notice.

Page 2

https://truckmanualshub.com/

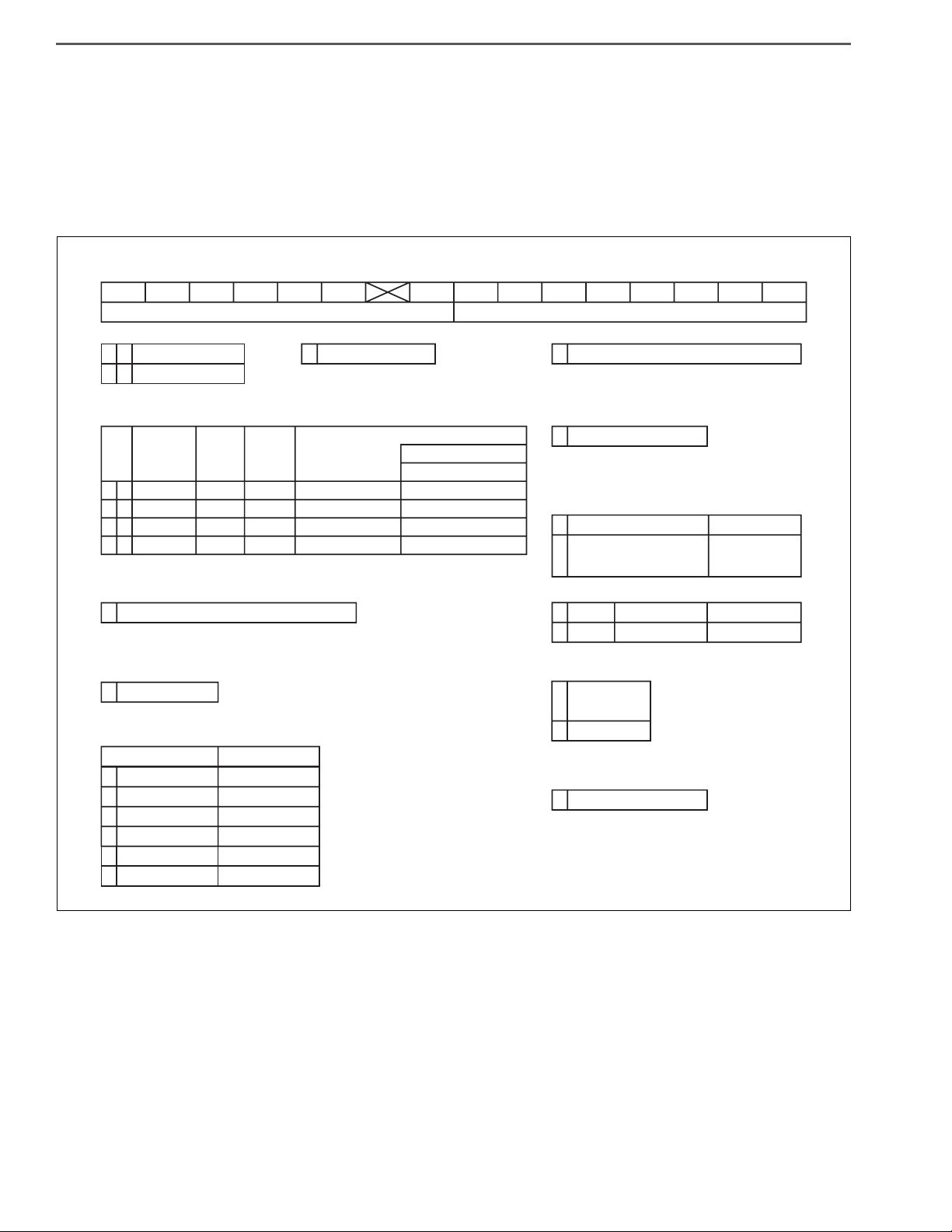

CHAPTER REFERENCES REGARDING THIS WORKSHOP MANUAL

Use this chart to the appropriate chapter numbers for servicing your particular truck.

CHAPTER

MANUAL NO.

MODEL J05E

GENERAL INTRODUCTION 1-001

STANDARD VALUE 2-001

REQUIRED ITEMS 3-001

MOUNTING AND DISMOUNTING THE ENGINE 5-001

ENGINE CONTROL 6-001

FUEL SYSTEM 7-001

EMISSION CONTROL 8-001

S5-LJ05E04A (U.S.A.), S5-LJ05E05A (CANADA)

INTAKE 9-001

ENGINE MECHANICAL 10-001

EXHAUST 11-001

COOLING 12-001

LUBRICATION 13-001

STARTING/CHARGING 16-001

TURBOCHARGER 17-001

Page 3

https://truckmanualshub.com/

INDEX: ENGINE GROUP 1/2

GENERAL INTRODUCTION

STANDARD VALUE

REQUIRED ITEMS

WORKSHOP

MANUAL

TROUBLESHOOTING

MOUNTING AND DISMOUNTING THE ENGINE

ENGINE CONTROL

FUEL SYSTEM

EMISSION CONTROL

INTAKE

ENGINE MECHANICAL

EXHAUST

All rights reserved. This manual may not be

reproduced or copied in whole in part, without the written consent of Hino Motors, Ltd.

COOLING

LUBRICATION

SPEED CONTROL SYSTEM

IGNITION

STARTING/CHARGING

TURBOCHARGER

AIR COMPRESSOR

Page 4

https://truckmanualshub.com/

INDEX: ENGINE GROUP 2/2

ENGINE PTO

(POWER TAKE-OFF)

Page 5

GENERAL INTRODUCTION 1–1

https://truckmanualshub.com/

GENERAL INTRODUCTION

1

HOW TO IDENTIFY VEHICLE TYPE...........................1-2

VEHICLE MODEL ...................................................1-2

VEHICLE IDENTIFICATION NUMBER (VIN)

STRUCTURE ..........................................................1-3

APPEARANCE OF VEHICLE ......................................1-4

APPEARANCE OF VEHICLE .................................1-4

SAFETY INSTRUCTIONS AND READINESS

TO WORK.....................................................................1-5

WARNING...............................................................1-5

IDENTIFICATION INFORMATION ..........................1-9

SAFETY INSTRUCTIONS FOR WORK................1-12

INTRODUCTION TO WORKSHOP MANUAL.......1-15

TIGHTENING OF BOLTS AND NUTS ..................1-19

HANDLING OF LIQUID GASKET.........................1-29

GLOSSARY................................................................1-30

DEFINITION OF ABBREVIATION

IN THIS MANUAL..................................................1-30

LUBRICANTS ............................................................1-36

RECOMMENDED LUBRICANTS .........................1-36

1-001

Page 6

GENERAL INTRODUCTION1–2

X

Ԙ

J

ԙ

C

Ԛ

7

ԛ

0

Ԝ

0

ԝԞ

L

ԟ

H

Ԡ

K

ԡ

T

Ԣ

Q

ԣ

M

Ԥ

A

ԥ

3

Ԧ

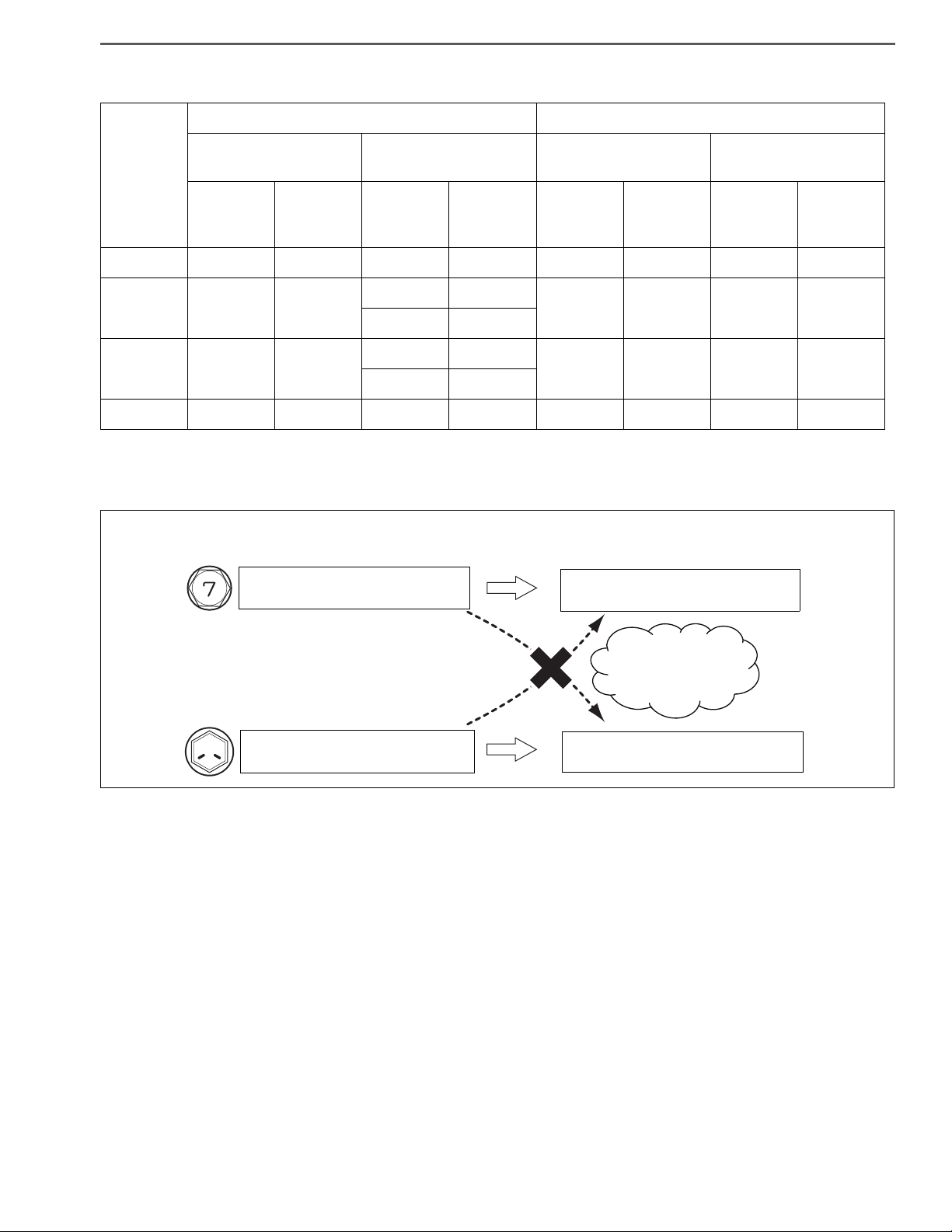

CLASSIFICATION

REPORTED MODEL

Ԙԙ

㧦ENGINE MODEL

Ԛ

C

㧦VEHICLE MODEL

HEAVY DUTY TRACK

ԛ

㧦CAB WIDTH, DRIVE, FRAME FORM, WHEEL BASE

Ԝ

70

71

72

74

CAB WIDTH

DRIVE WHEEL BASE

FRAME ASSEMBLY WIDTH

FRAME

FORM

WIDE 2WD MEDIUMOPEN

WIDE 2WD LONGOPEN

WIDE 2WD SUPER LONGOPEN

WIDE 2WD SUPER LONGOPEN

840 mm {33 in.}

2,900 mm {114 in.}

3,500 mm {138 in.}

3,800 mm {150 in.}

4,400 mm {173 in.}

ԝ

0

㧦TYPE OF SUSPENSION

FRONT RIGID, REAR RIGID

Ԡ

CAB FORM BRAKE TYPE

㧦CAB FORM, BRAKE TYPE

ԟ

㧦STEERING WHEEL POSITION

L

LEFT HAND DRIVE

H

Q

SINGLE CAB VACUUM

CREW CAB VACUUM

C

D

SINGLE CAB HYDRAULIC

CREW CAB HYDRAULIC

K

L

SINGLE CAB VACUUM

SINGLE CAB HYDRAULIC

ԡ

㧦DECK HEIGHT

K

HIGH FLOOR

Ԣ

㧦TRANSMISSION

T

6AT

Ԧ

㧦DECK FORM

3

CHASSIS WITH CAB

Ԥ

㧦ENGINE HORSEPOWER, FUEL

FUEL

HORSEPOWER EXHAUST

VERY HIGH US10

DIESEL OIL

M

ԣ

㧦LOADING CAPACITY, GVW, REAR TIRES

ԥ

㧦DESTINATION

DESTINATION

A

U.S., CANADA

6.58 t {14,500 lbs}

8.14 t {17,950 lbs}

8.85 t {19,500 lbs}

Q

T

REAR DOUBLE

REAR DOUBLE

J05E-UG (HV)

XF

J05E-TP (Diesel)

XJ

SHTS01ZZZ0000001

https://truckmanualshub.com/

GENERAL INFORMATION

HOW TO IDENTIFY VEHICLE TYPE

VEHICLE MODEL

EN01F01ZZZ000102001001

Page 7

GENERAL INTRODUCTION 1–3

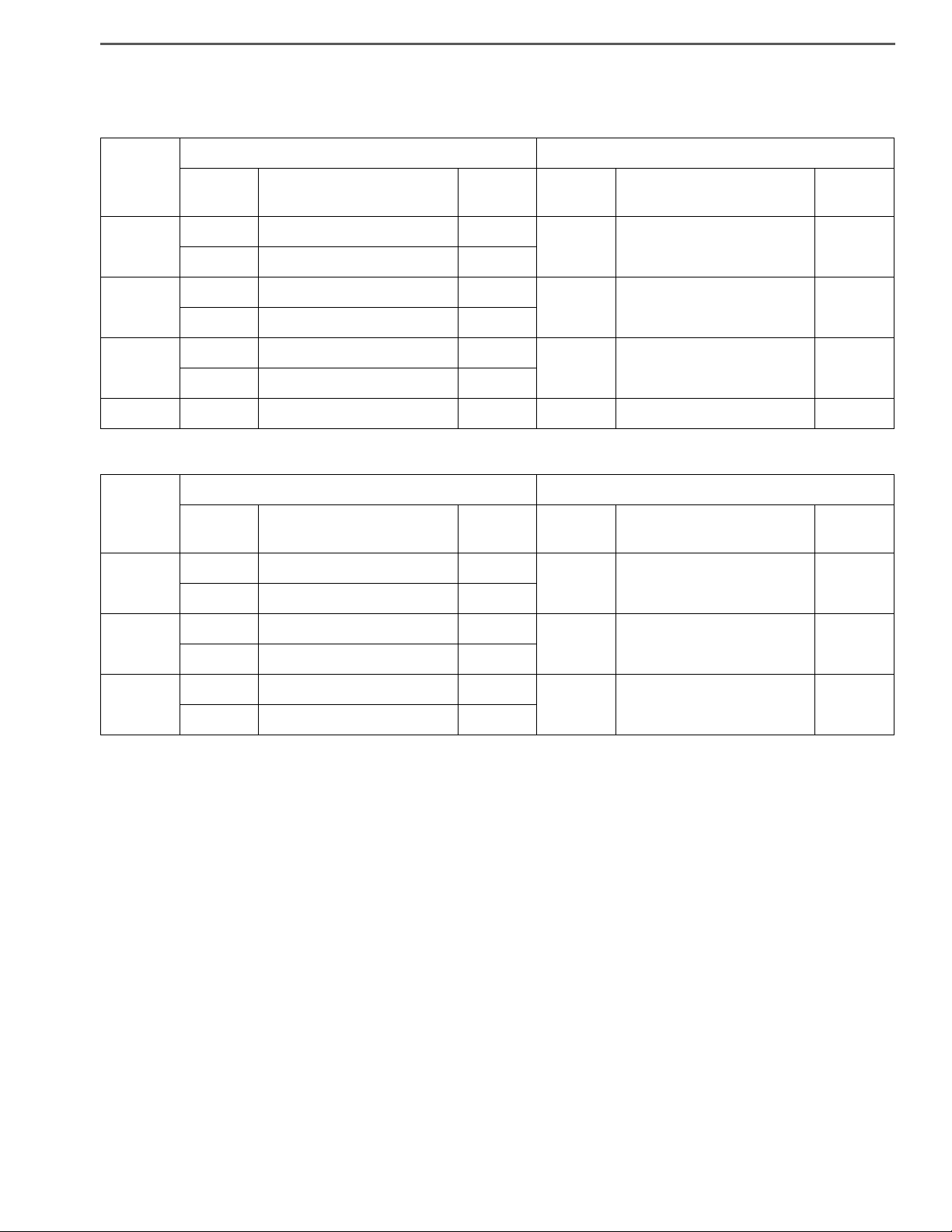

WMI VDS CD VIS

(1) (2) (3) (4) (5) (6) (7) (8) (9)

(10) (11) (12) (13) (14) (15) (16)

JHH KDM2H 5 E K00100

(17)

1

MANUFACTURER ,TYPE

MODEL, CAB TYPE,

WHEEL BASE,

BRAKE SYSTEM

MODEL YEAR

ENGINE MODEL

ASSEMBLY PLANTSERIES

MAKE

CHECK DIGIT

SEQUENTIAL NUMBER

CODE

JHN INCOMPLETE VEHICLE

TYPEMANUFACTURER

HINO MOTORS, LTD.

2AY

INCOMPLETE VEHICLE

HINO MOTORS

CANADA, LTD.

CODE CODE YEARYEAR

H 2017

J 2018

K 2019

L 2020

M 2021

C 2012

D 2013

E 2014

F 2015

G 2016

CODE

PM Hybrid

APPLICATIONENGINE MODEL

J05E

DM DieselJ05E

CODE

1

1

2

ASSEMBLY PLANT

HINO MOTORS, LTD.

HINO PLANT IN JAPAN

HINO MOTORS, LTD.

Hamura Plant in Japan

3 Canada Plant

4

K

W.V Plant

CODE

CODE

H

MAKE

SERIES GVWR

HINO

6,580 kg

{14,500 lbs.}

8,140 - 8,850 kg

{17,950 - 19,500 lbs.}

CODE CLASS MODEL

R

S

T

PRODUCTION

CODE

CAB TYPE WHEEL BASE

BRAKE

SYSTEM

U

V

W

X

Y

P

H

K

L

HINO 195h

HINO 195

HINO 195

HINO 195

HINO 155

HINO 155

HINO 155

HINO 155

HINO 195

HINO 195

HINO 155

HINO 155

5

5

5

5

4

4

5

5

4

4

4

4

XFC710

HINO 155h

XFC720

HINO 155h

XFC740

HINO 195h

XFC720

HINO 195h

XFC740

HINO 155h

XFC710

HINO 195h

XFC720

HINO 195h

XFC740

HINO 155h

XFC740

HINO 155h

XFC720

HINO 195 XJC710

COE

SINGLE CAB

COE

SINGLE CAB

COE

SINGLE CAB

COE

SINGLE CAB

COE

SINGLE CAB

COE

SINGLE CAB

COE

SINGLE CAB

COE

SINGLE CAB

COE

CREW CAB

COE

CREW CAB

COE

CREW CAB

COE

CREW CAB

3500mm{138 in.}

3500mm{138 in.}

2900mm{114 in.}

2900mm{114 in.}

3800mm{150 in.}

3800mm{150 in.}

3800mm{150 in.}

3800mm{150 in.}

4400mm{173 in.}

4400mm{173 in.}

4400mm{173 in.}

4400mm{173 in.}

XJC700

XJC700

XJC710

XJC720

XJC740

XJC740

XJC720

XJC720

XJC740

XJC720

XJC740

HYDRAULIC

HYDRAULIC

HYDRAULIC

HYDRAULIC

HYDRAULIC

HYDRAULIC

VACUUM

VACUUM

VACUUM

VACUUM

VACUUM

VACUUM

SHTS01ZZZ0000002

https://truckmanualshub.com/

VEHICLE IDENTIFICATION NUMBER (VIN) STRUCTURE

EN01F01ZZZ000102001002

Page 8

GENERAL INTRODUCTION1–4

SHTS01ZZZ0000003

https://truckmanualshub.com/

APPEARANCE OF VEHICLE

APPEARANCE OF VEHICLE

EN01F01ZZZ000102002001

Page 9

GENERAL INTRODUCTION 1–5

https://truckmanualshub.com/

SAFETY INSTRUCTIONS AND READINESS TO WORK

WARNING

EN01F01ZZZ000102003001

GENERAL PRECAUTIONS

Some recommended and standard maintenance services for your vehicle are included in this section. When performing

maintenance on your vehicle be careful not to get injured by improper work. Improper or incomplete work can cause a malfunction of the vehicle which may result in personal injury and/or property damage. If you have any question about performing maintenance, please consult your Hino dealer.

WARNING

When working on your vehicle, observe the following general precautions to prevent death, personal injury and/

or property damage in addition to the particular DANGERS, WARNINGS, CAUTIONS and NOTICES in each chapter.

• Always wear safety glasses or goggles to protect your eyes.

• Remove rings, watches, ties, loose hanging jewelry and loose clothing before starting work on the vehicle.

• Bind long hair securely behind the head.

• When working on the vehicle, apply the parking brake firmly, place the gear shift lever in "Neutral" or "N"

and block the wheels.

• Always turn off the starter switch to stop the engine, unless the operation requires the engine running.

Removing the key from the switch is recommended.

• To avoid serious burns, keep yourself away from hot metal parts such as the engine, exhaust manifold,

radiator, muffler, exhaust pipe and tail pipe.

• Do not smoke while working on the vehicle since fuel, and gas from battery are flammable.

• Take utmost care when working on the battery. It contains corrosive sulfuric acid.

• Large electric current flows through the battery cable and starter cable. Be careful not to cause a short

which can result in personal injury and/or property damage.

• Read carefully and observe the instructions specified on the jack before using it.

• Use safety stands to support the vehicle whenever you need to work under it. It is dangerous to work under

a vehicle supported only by a jack.

• If it is necessary to run the engine after the hood is raised (tilted), make sure that the parking brake is

firmly applied, the wheels are blocked, and the gear shift lever is positioned in "Neutral" before staring the

engine.

• Run the engine only in a well-ventilated area to avoid inhalation of carbon monoxide.

• Keep yourself, your clothing and your tools away from moving parts such as the cooling fan and V-belts

when the engine is running.

• Be careful not to damage lines and hoses by stepping or holding your feet on them.

• Be careful not to leave any tool in the engine compartment. The tool may be hit by moving parts, which can

cause personal injury.

Page 10

GENERAL INTRODUCTION1–6

! WARNING

B

F

E

G

SHTS01ZZZ0000004

https://truckmanualshub.com/

PRECAUTIONS IN TILTING AND LOWERING THE CAB

Be sure to observe the following when tilting and lowering the cab to reduce the risk of an accident which may

result in death, serious injury and/or property damage.

• Park the vehicle on a level place and ensure ample space around the cab before tilting the cab.

• Apply the parking brake firmly and place the gearshift lever in “N” position (“P” position if your vehicle is

equipped with automatic transmission).

• Stop the engine and block the wheels.

• Remove any articles in or over the cab and close the doors firmly.

• Make sure there is no one in or around the cab and there are no obstacles in front of the vehicle or above the

cab.

• The catch (E), stopper (F), stay (G) and other parts such as the engine, radiator, and exhaust pipe can be very

hot while your vehicle is operated. Be sure to confirm they have been cooled down before you start working

under the cab.

• Never raise or lower the cab only by yourself if your cab is equipped with heavy component such as a roof

rack.

• Never put your body under the cab while raising or lowering the cab.

• Make sure the cab stopper stay is securely locked by the catch (E) and raise the stopper (F) to lock the catch

(E) completely after raising the cab.

• Before lowering the cab, make sure that any object such as hand tools, gloves or cloth are not left under the

cab.

• Make sure the handle (B) is caught by the catch after lowering the cab.

Read the Owner’s manual for details.

DEFINITION OF SAFETY TERMS

Indicates an extremely hazardous situation if proper procedures are not followed and

could result in death or serious injury.

Indicates a potential hazardous situation if proper procedures are not followed and

could result in death or serious injury.

Indicates a hazardous situation if proper procedures are not followed and could result

in serious injury or damage to parts/equipment.

Indicates the need to follow proper procedures and to pay attention to precautions so

that efficient service is provided.

Provides additional information to help you to perform the repair efficiently.

Page 11

GENERAL INTRODUCTION 1–7

https://truckmanualshub.com/

TOWING

• When being towed, always place the gear shift lever in "Neutral" and release the parking brake completely. In order to

protect the bumper, fit a protection bar against the lower edge of the bumper and put a wood block under the frame

near the No. 1 cross member when attaching the towing chain. Never lift or tow the vehicle if the chain is in direct contact with the bumper.

1. Towing procedures

(1) Make sure that the propeller shaft of the vehicle to be towed is removed. When the differential gear or rear axle shaft

is defective, remove both right and left rear axle shafts, then cover the hub opening to prevent loss of axle lubricant

and entry of dirt or foreign matter.

(2) Use a heavy duty cable or rope when towing the vehicle. Fasten the cable securely to the towing hook on the frame.

(3) The angle of pulling direction of the cable fastened to the towing hook must not exceed 15° in horizontal and vertical

directions from the straight ahead, level direction. Avoid using the hook in a way that subjects it to jerk, as in towing a

vehicle trapped in a gutter.

(4) Keep the gear shift lever in Neutral.

(5) Make sure that the starter switch is kept in the "ON" position, if the engine is not running.

(6) Make sure that the engine of the towed vehicle is kept running. If the engine is off, no compressed air/ no vacuum will

be available for the brake. This is dangerous, as the brake system does not function if the engine is not running.

In addition, the power steering system will not function. The steering wheel, therefore, will become unusually hard to

turn, making it impossible to control the vehicle.

(7) Note that the engine brake and exhaust brake cannot be applied, if the propeller shaft is removed.

(8) Make a slow start to minimize shock. Towing speed should be less than 30 km/h {18 mile/h}.

2. If the engine of the towed vehicle is defective, make sure that the vehicle is towed only by a tow truck

designed for that purpose.

(1) Front end towing (with front wheels raised off the ground)

When towing from the front end with the front wheels raised off the ground, remove the rear axle shafts to protect the

transmission and differential gears from being damaged. The hub openings should be covered to prevent the loss of

axle lubricant or the entry of dirt or foreign matter. The above-mentioned precautions should be observed for vehicles

equipped with either manual or automatic transmission, and for even short distance towing. After being towed, check

and refill the rear axle housing with lubricant if necessary.

(2) Rear end towing

When being towed with the rear wheels raised off the ground, fasten and secure the steering wheel in a straight-

ahead position.

CLEAN AIR ACT

1. Heavy-duty engine rebuilding practices.

§ 86.004-40

• The provisions of this section are applicable to heavy-duty engines subject to model year 2004 or later standards and

are applicable to the process of engine rebuilding (or rebuilding a portion of an engine or engine system). The pro-

cess of engine rebuilding generally includes disassembly, replacement of multiple parts due to wear, and reassembly,

and also may include the removal of the engine from the vehicle and other acts associated with rebuilding an engine.

Any deviation from the provisions contained in this section is a prohibited act under section 203(a) (3) of the Clean Air

Act (42 U.S.C. 7522(a) (3)).

(1) When rebuilding an engine, portions of an engine, or an engine system, there must be a reasonable technical basis

for knowing that the resultant engine is equivalent, from an emissions standpoint, to a certified configuration (i.e., tol-

erances, calibrations, specifications) and the model year(s) of the resulting engine configuration must be identified. A

reasonable basis would exist if:

a. Parts installed, whether the parts are new, used, or rebuilt, are such that a person familiar with the design and

function of motor vehicle engines would reasonably believe that the parts perform the same function with respect

to emissions control as the original parts; and

b. Any parameter adjustment or design element change is made only:

• In accordance with the original engine manufacturer's instructions; or

• Where data or other reasonable technical basis exists that such parameter adjustment or design element change,

when performed on the engine or similar engines, is not expected to adversely affect in-use emissions.

(2) When an engine is being rebuilt and remains installed or is reinstalled in the same vehicle, it must be rebuilt to a con-

figuration of the same or later model year as the original engine. When an engine is being replaced, the replacement

engine must be an engine of (or rebuilt to) a configuration of the same or later model year as the original engine.

Page 12

GENERAL INTRODUCTION1–8

https://truckmanualshub.com/

(3) At time of rebuild, emissions-related codes or signals from on-board monitoring systems may not be erased or reset

without diagnosing and responding appropriately to the diagnostic codes, regardless of whether the systems are

installed to satisfy requirements in § 86.004-25 or for other reasons and regardless of form or interface. Diagnostic

systems must be free of all such codes when the rebuilt engine is returned to service. Such signals may not be rendered inoperative during the rebuilding process.

(4) When conducting a rebuild without removing the engine from the vehicle, or during the installation of a rebuilt engine,

all critical emissions-related components listed in § 86.004-25(2) not otherwise addressed by paragraphs (1) through

(3) of this section must be checked and cleaned, adjusted, repaired, or replaced as necessary, following manufacturer recommended practices.

(5) Records shall be kept by parties conducting activities included in paragraphs (1) through (4) of this section. The

records shall include at minimum the mileage and/or hours at time of rebuild, a listing of work performed on the

engine and emissions-related control components including a listing of parts and components used, engine parameter adjustments, emissions-related codes or signals responded to and reset, and work performed under paragraph

(4) of this section.

a. Parties may keep records in whatever format or system they choose as long as the records are understandable

to an EPA enforcement officer or can be otherwise provided to an EPA enforcement officer in an understandable

format when requested.

b. Parties are not required to keep records of information that is not reasonably available through normal business

practices including information on activities not conducted by themselves or information that they cannot reasonably access.

c. Parties may keep records of their rebuilding practices for an engine family rather than on each individual engine

rebuilt in cases where those rebuild practices are followed routinely.

d. Records must be kept for a minimum of two years after the engine is rebuilt.

2. Maintenance instructions.

§ 86.010-38

(1) For each new diesel-fueled engine subject to the standards prescribed in § 86.007-11, as applicable, the manufac-

turer shall furnish or cause to be furnished to the ultimate purchaser a statement that

"This engine must be operated only with ultra low-sulfur diesel fuel (meeting EPA specifications for highway

diesel fuel, including a 15 ppm sulfur cap)."

Page 13

GENERAL INTRODUCTION 1–9

A

B

SHTS01ZZZ0000010

https://truckmanualshub.com/

IDENTIFICATION INFORMATION

EN01F01ZZZ000102003002

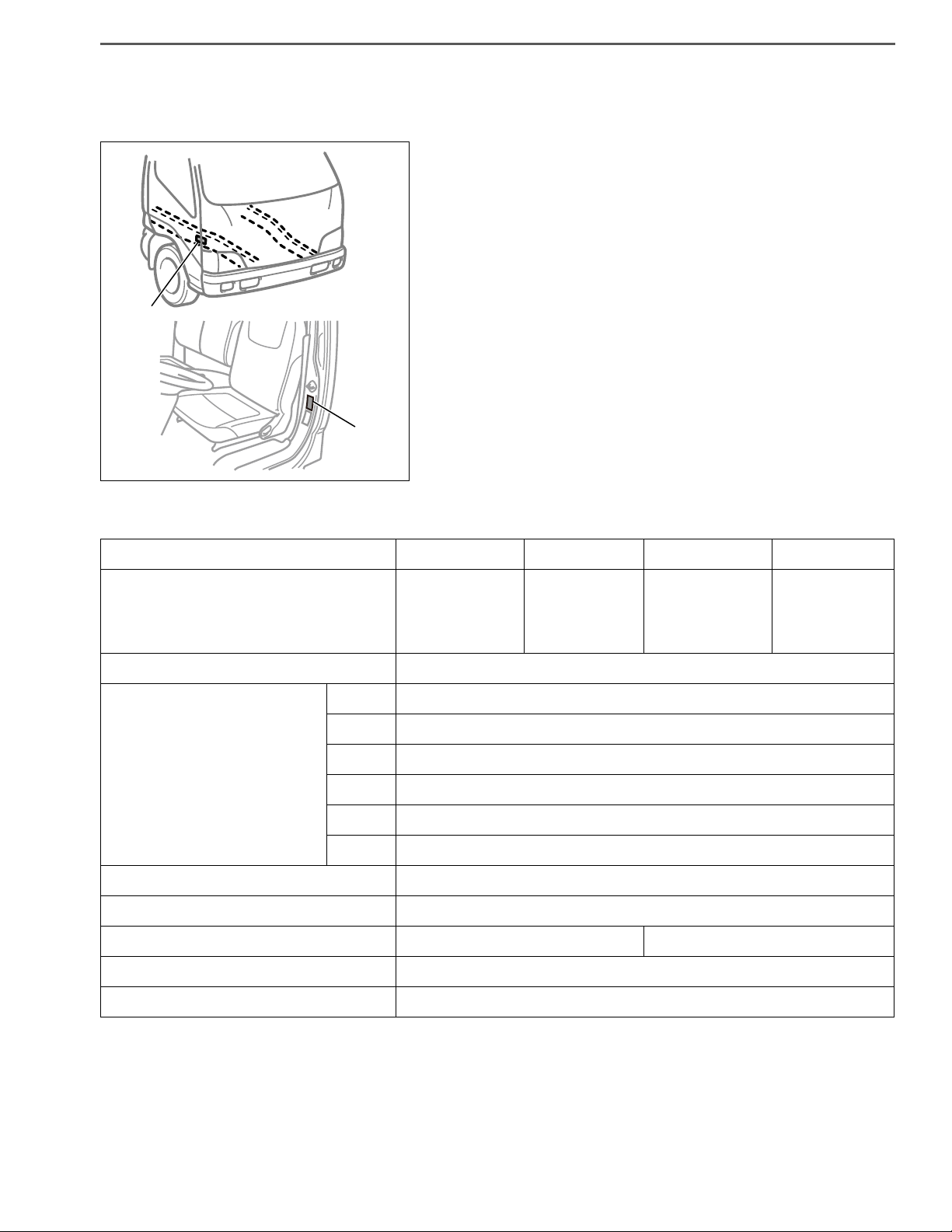

1. VEHICLE IDENTIFICATION NUMBER

(1) The vehicle identification number (VIN) is stamped on the right

frame, as shown in the illustration. This number has also been

stamped on the manufacture's label.

A: Vehicle Identification Number (VIN)

B: Manufacturer's Label

(2) VIN

See VEHICLE IDENTIFICATION NUMBER (VIN) STRUCTURE

on the following page.

(3) PRODUCTION CODE AND VEHICLE COMPONENTS

MODEL (CLASS) HINO 155h (4) HINO 155 (4) HINO 195h (5) HINO 195 (5)

XJC700

XJC710

XJC720

XJC740

PRODUCTION CODE

XFC710

XFC720

XFC740

TRANSMISSION SERIES A465

1st 3.742

2nd 2.003

3rd 1.343

TRANSMISSION RATIO

4th 1.000

5th 0.773

6th 0.634

REAR AXLE SERIES SH13

REAR AXLE RATIO 4.333 / 4.625 / 4.875 / 5.142 / 5.571 / 5.857

SERVICE BRAKE Vacuum Hydraulic

PARKING BRAKE ACTING ON DIFFERENTIAL OUTPUT SHAFT

SUSPENSION LEAF

XFC710

XFC720

XFC740

XJC700

XJC710

XJC720

XJC740

Page 14

GENERAL INTRODUCTION1–10

FOR ALL MODELS

SHTS01ZZZ0000011

A

SHTS01ZZZ0000012

A

SHTS01ZZZ0000013

SHTS01ZZZ0000014

https://truckmanualshub.com/

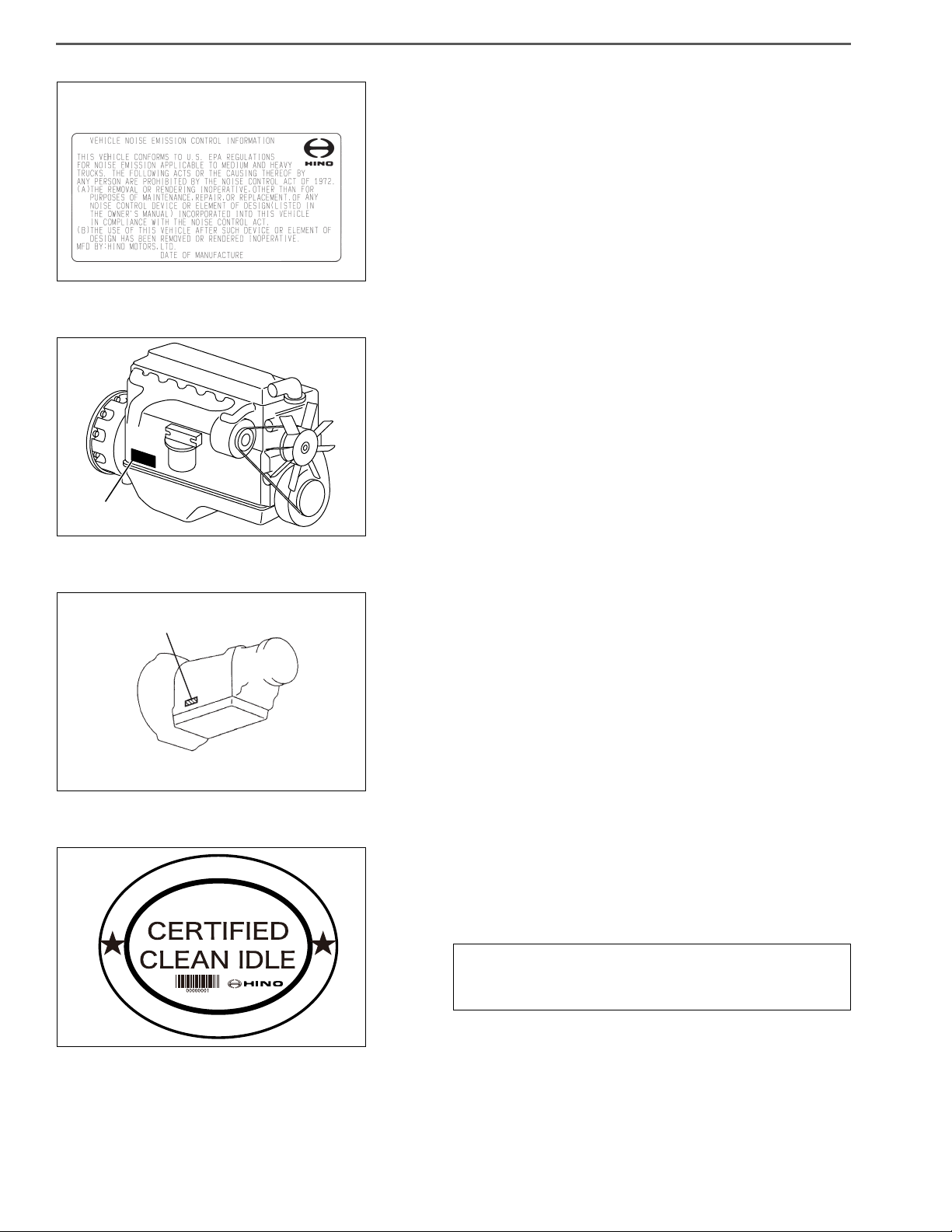

2. VEHICLE NOISE EMISSION CONTROL INFORMATION

• The Vehicle Noise Emission Control Information is affixed to the

left pillar of the cab. The name of manufacturer, production year

and month, and noise emission applicable to medium and heavy

trucks in conformity with U.S. EPA Regulations are displayed.

3. ENGINE SERIAL NUMBER

(1) The engine serial number is stamped on the cylinder block, as

shown in the illustration.

A: J05E

4. TRANSMISSION SERIAL NUMBER

(1) The transmission serial number is stamped on the transmission,

as shown in the illustration.

A: A465

5. CLEAN IDLE CERTIFIED LABEL FOR U.S.

• Make sure that the following clean engine idling certified label is

affixed to the outside of the left door. By the CARB below, the

label must be affixed there to prove that the new vehicle with diesel engine manufactured from Jan., 2008 conforms to this low.

CARB § 1956.8. Exhaust Emission Standard and Test

Procedure (a) (b) Heavy-Duty Diesel Engine Idling

Requirements

Page 15

GENERAL INTRODUCTION 1–11

EXEMPTION LABEL

SHTS01ZZZ0000015

https://truckmanualshub.com/

6. EXEMPTION LABEL FOR US GHG REGULATION

HINT

Exemption label fuel economy comes in paste right side of the

front passenger seat.

However, this label is limited to one year.

Page 16

GENERAL INTRODUCTION1–12

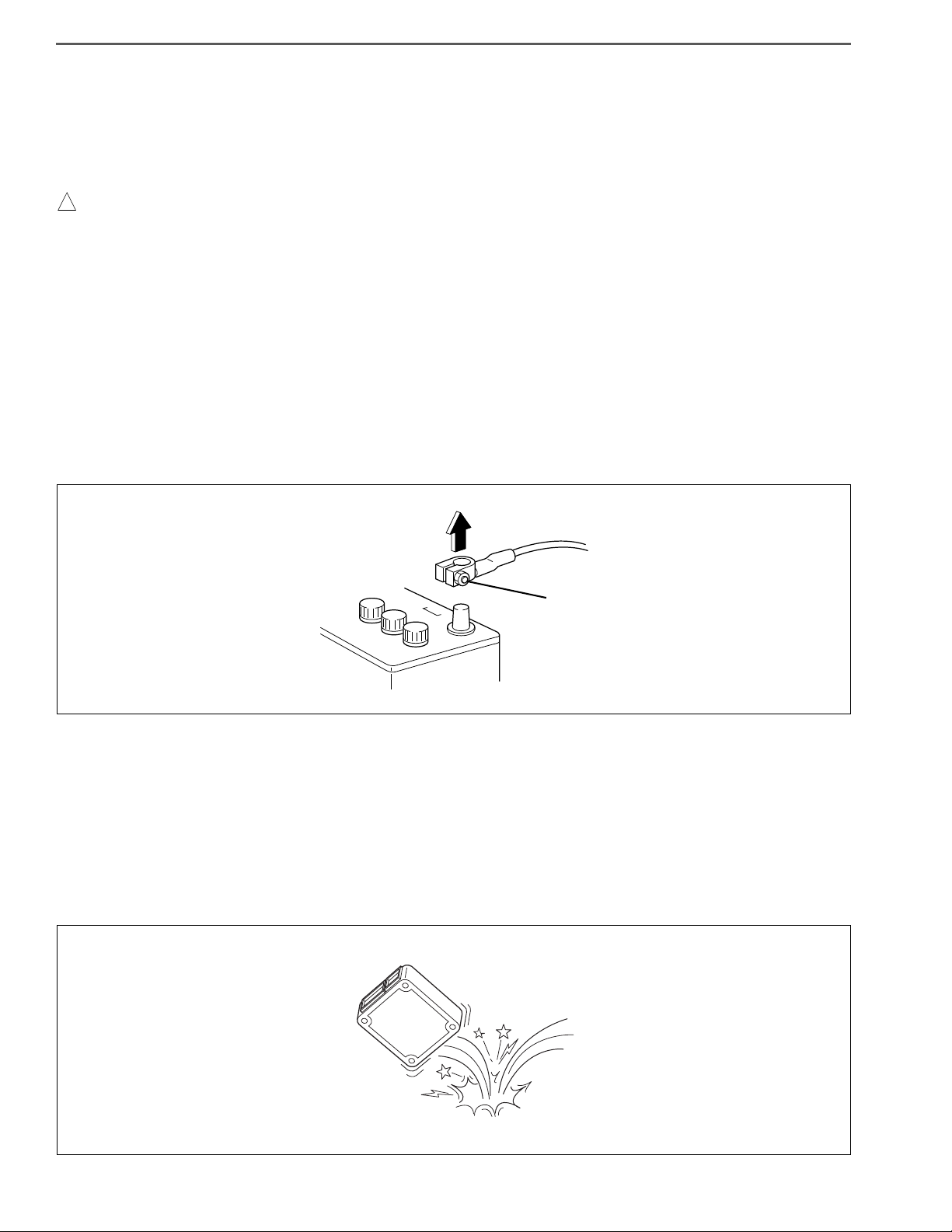

! WARNING

SHTS01ZZZ0000016

LOOSEN

SHTS01ZZZ0000017

https://truckmanualshub.com/

SAFETY INSTRUCTIONS FOR WORK

EN01F01ZZZ000102003003

PRECAUTIONS

1. SAFETY INSTRUCTIONS FOR HANDLING ELECTRICAL SYSTEMS

(1) Remove the battery cable

• Be sure to wait for at least ten minutes after the starter key is turned to "LOCK" position before you discon-

nect the battery terminals from the battery, as the vehicle data is recorded on ECU and DCU starts working

for the exhaust gas after treatment after the starter key is turned to "LOCK" position. Otherwise, the vehicle

data will not be recorded on ECU properly and DCU will not complete working properly, which may result in

the malfunction of DPR system and DEF-SCR system.

• The MIL (malfunction indicator light) may come on when the starter key is turned to "ON" position again,

even if you wait for at least ten minutes before disconnecting the battery terminals from the battery after the

starter key is turned to "LOCK" position. In this case, use HINO-DX to clear the DTC (P204F and P068A), to

turn off the MIL and to conduct DPR regeneration manually.

a. Before electrical system work, remove the cable from the minus terminal of the battery in order to avoid burning

caused by short-circuiting.

b. To remove the battery cable, fully release the nut to avoid damage to the battery terminal. Never twist the termi-

nal.

(2) Handling of electronic parts

a. Never give an impact to electronic parts of a computer or relay.

b. Keep electronic parts away from high temperatures and humidity.

c. Never splash water onto electronic parts in washing the vehicle.

d. Do not remove the harness connector, electric component box, and cover except for repair and inspection.

If removal is necessary, pay attention that water and foreign matters do not attach or enter to the connector, terminals, electric component box, and cover.

In restoration, make sure there is no attachment or entry of water and foreign matters and mount them properly,

because it causes degradation of waterproof function.

INCORRECT

Page 17

GENERAL INTRODUCTION 1–13

SHTS01ZZZ0000018

INCORRECT

INCORRECT

CORRECT

SHTS01ZZZ0000019

https://truckmanualshub.com/

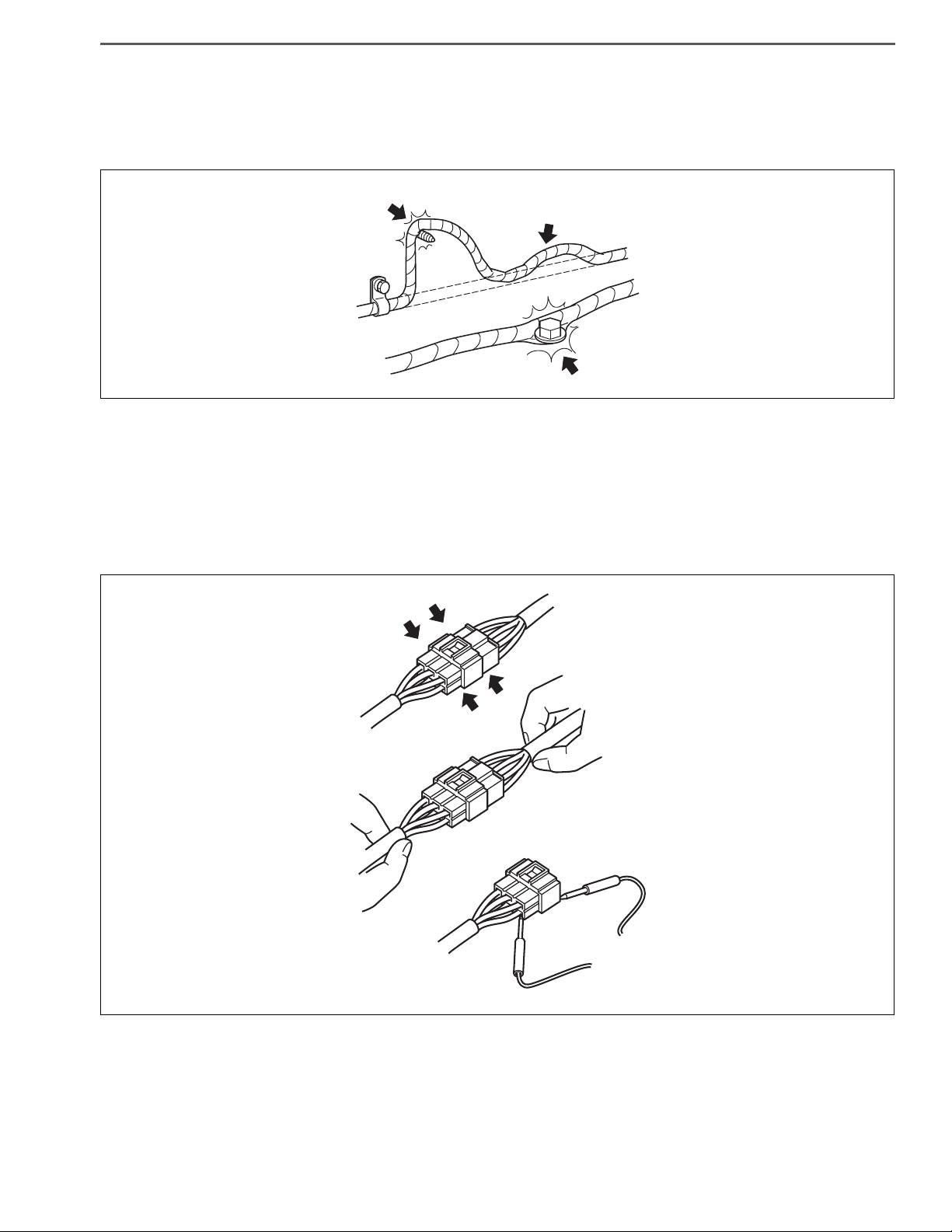

(3) Handling of wire harness

a. Perform marking on a clamp and a clip and secure then in original position so that the wire harness will not inter-

fere with the end and acute angle section of the body and a bolt.

b. To attach a part, take care not to bite the wire harness.

INCORRECT

INCORRECT

INCORRECT

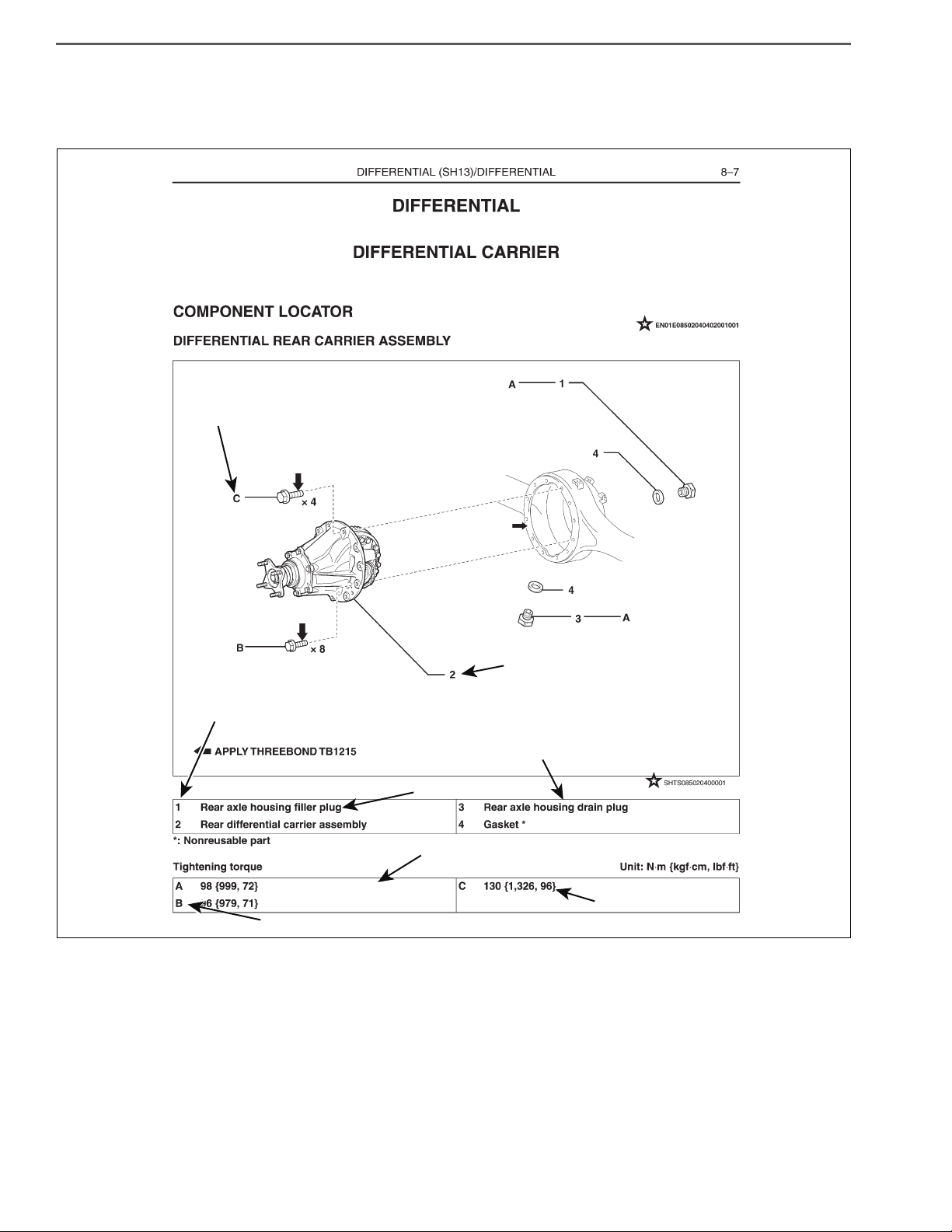

(4) Handling of connectors

a. When removing a connector, hold a connector (area shown in an arrow in the figure) and then pull it off. Do not

pull wire harnesses.

b. Pull off a lockable connector after unlocking.

c. When connecting a lockable connector, make sure to insert a lockable connector until it makes a click sound.

d. When inserting a test lead, insert it from the back of a connector.

e. If it is difficult to insert a test lead from the back of a connector, make and use an inspection harness.

Page 18

GENERAL INTRODUCTION1–14

! WARNING

! WARNING

SHTS01ZZZ0000020

Connect the ground of the ARC welding

machine near the place on the frame to be

welded but not connect it to plated parts such

as fuel pipes, brake pipes and leaf spring.

Disconnect the ground terminal for

battery at the connecting point on the

frame and disconnect the ground for

computer as well.

CHASSIS FRAME

CHASSIS FRAME

BATTERY

ALTERNATOR

ETC.

COMPUTER

ARC WELDING

MACHINE

https://truckmanualshub.com/

(5) Installation of battery disconnect switch

• Installation of the battery disconnect switch on the power supply circuit for the dosing control unit of DEF-

SCR (DCU) may damage or result in the malfunction of DEF-SCR system.

• Be sure to read and follow the procedures and instructions on the service bulletin before the installation of

the battery disconnect switch.

(6) Handling of battery disconnect switch

• Wait for at least ten minute before using the battery disconnect switch after the starter key is turned to

"LOCK" position.

Otherwise, the vehicle data will not be recorded on ECU properly, which may result in the malfunction of DPR

system.

2. PRECAUTION FOR ELECTRIC WELDING

Electrical components such as the alternator and tachograph are directly connected to the battery and one

end is earthed to the chassis frame. Under these conditions, welding current will flow back along the earth

circuit if electric welding is carried out and damage may be caused to the alternator, tachograph, electrical

components, etc. Consequently, the following precautions are always to be taken during welding.

(1) Disconnect the earth terminal of the battery at the frame fitment and earth the welding equipment securely to the

frame itself. (Do not fit the welding equipment earth to such things as the tire rims, brake pipes or fuel pipes and leaf

spring, etc.)

a. Turn the starter switch off.

b. Disconnect the battery’s negative terminal of the battery.

c. Earth welding equipment securely, near to the area to be welded.

d. Put back battery negative ground as original condition.

e. Finally check the functioning of all instruments.

(2) In order to prevent damage to ancillary equipment components from sparks during welding, take steps such as put-

ting fire-resistant covers over things like the engine, meters, steering wheel, hoses, leaf spring and tires.

Page 19

GENERAL INTRODUCTION 1–15

https://truckmanualshub.com/

INTRODUCTION TO WORKSHOP MANUAL

EN01F01ZZZ000102003004

GENERAL

1. SCOPE OF REPAIR DESCRIPTIONS

(1) There are three major processes in repair work: i.e. "troubleshooting," "removal/installation, replacement, overhaul,

assembly, inspection and adjustment" and "final inspection".

(2) This document covers only the first process (troubleshooting) and the second process (removal/installation, replace-

ment, overhaul, assembly, inspection and adjustment) and omits the third process (final inspection).

(3) The element tasks listed below are omitted from this document but must be done in actual repair work.

a. Jacking and lifting

b. Cleaning and washing of removed parts as required

c. Visual check

2. STANDARD VALUE

(1) Standard values, limits, required actions and tightening torques are tabulated in this document.

3. REQUIRED ITEMS

(1) Special tools, tools, instruments, oil and grease and other items to be prepared before starting work are listed in the

section titled "REQUIRED ITEMS". Note that general tools, jacks, rigid racks and other required items supposedly

available at a general service shop are omitted from the list.

4. REPRESENTATION OF SECTION AND TITLE

(1) Under a title containing a system name such as "ENGINE CONTROL SYSTEM", the descriptions cover "INSPEC-

TION", "ADJUSTMENT", "REPLACEMENT" and "OVERHAUL" of components.

(2) Under a title containing a part name such as "AIR COMPRESSOR ASSEMBLY", the descriptions cover "REPLACE-

MENT" and "OVERHAUL".

Page 20

GENERAL INTRODUCTION1–16

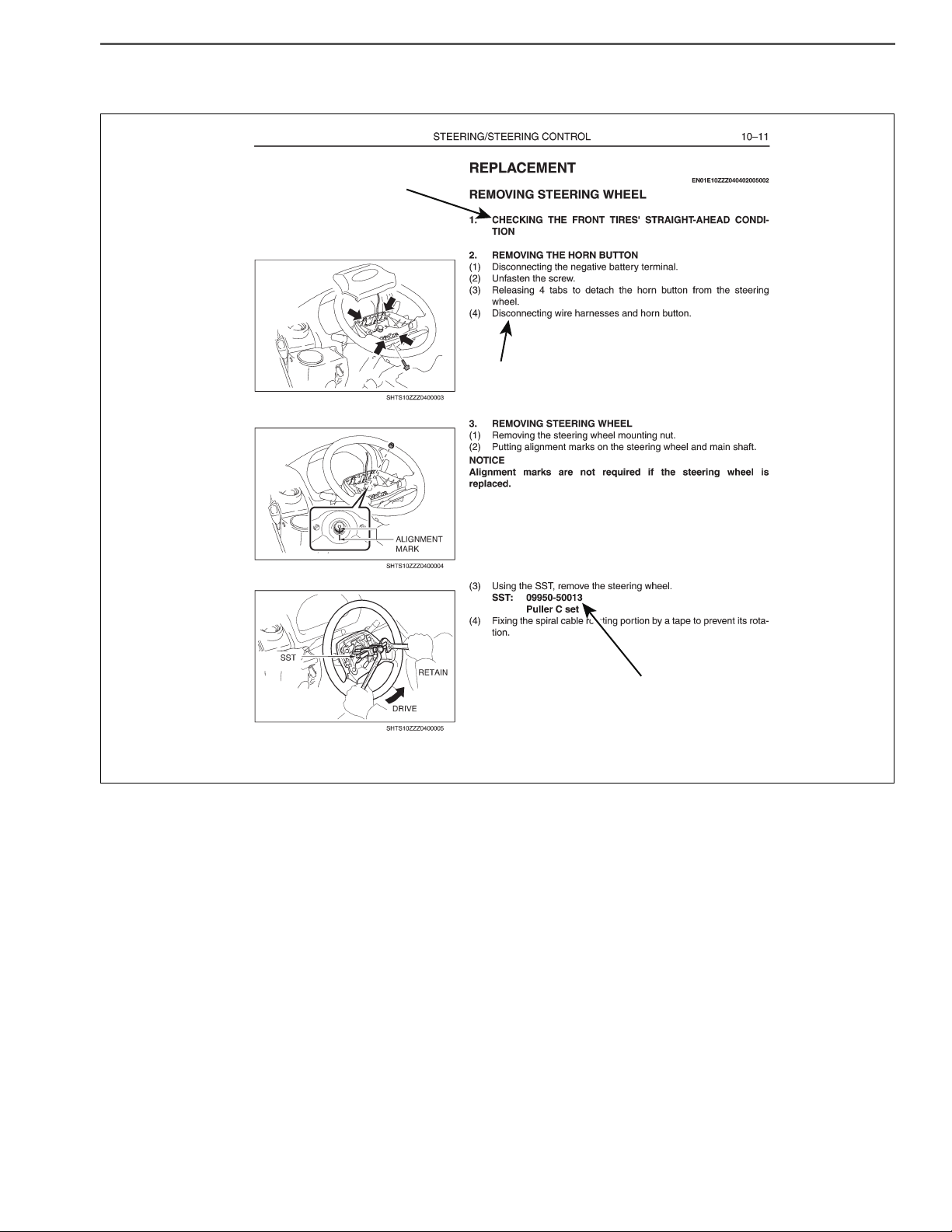

Alphabetical mark indicating the

tightening torque in the following

tightening torque table

Numerical order indicating the

part name in the following part

name table

Numerical order

Part name

Part name table

Tightening torque table

Tightening torque

Alphabetical mark

SHTS01ZZZ0000021

INTRODUCTION TO DESCRIPTIONS

1. COMPONENT LOCATOR

https://truckmanualshub.com/

☆ : The ID number is given to required items for the purpose of preparing electronic data and is not needed

in repair work.

Page 21

2. WORK STEPS

Indicating the work

sequence

Descriptive text: Indicating the work

method which is gone into detail

Indicating the part number of

SST required for work

SHTS01ZZZ0000022

GENERAL INTRODUCTION 1–17

https://truckmanualshub.com/

Page 22

GENERAL INTRODUCTION1–18

https://truckmanualshub.com/

DEFINITION OF TERM

Terms used in this document are defined as follows.

DIRECTION

1. CHASSIS RELATED

(1) Longitudinal direction

a. The forward direction and the reverse direction of a vehicle are respectively defined as front and rear in the

installed position in a vehicle.

(2) Rotational direction

a. The clockwise direction and the counterclockwise direction viewed from the rear side of a vehicle are defined as

right-handed and left-handed respectively.

(3) Vertical direction

a. The upward direction and the downward direction in the installed position in a vehicle are defined as an upper

side and a lower side respectively.

(4) Lateral direction

a. The leftward direction and the rightward direction viewed from the back of a vehicle are respectively defined as a

left side and a right side in the installed position in a vehicle.

2. INDIVIDUAL DEVICES

(1) Longitudinal direction

a. The input side and the output side of motive power are defined as a front side and a rear side respectively.

(2) Rotational direction

a. The clockwise direction and the counterclockwise direction viewed from the back side are defined as right-

handed and left-handed respectively.

(3) Vertical direction

a. The upward direction and the downward direction of a device in its installed position in a vehicle (chassis) are

defined as an upper side and a lower side respectively.

(4) Lateral direction

a. The leftward direction and the rightward direction as viewed from the back side are defined as a left side and a

right side respectively.

STANDARD VALUE

Represents a basic dimension (excluding a tolerance), and a clearance arising from tolerances when two parts are assembled.

REPAIR LIMIT

Represents a numerical value indicating need of correction. A symbol "+" or "-" indicated next to a repair limit represents

an increase or a decrease from a standard value.

SERVICE LIMIT

Represents a numerical value indicating need of replacement. A symbol "+" or "-" indicated next to a repair limit represents

an increase or a decrease from a standard value.

Page 23

GENERAL INTRODUCTION 1–19

https://truckmanualshub.com/

TIGHTENING OF BOLTS AND NUTS

EN01F01ZZZ000102003005

BOLTS AND NUTS

More than hundreds of bolts/nuts are used in a vehicle and improper handling of them will cause damage and looseness.

Because tightening torque varies depending on tightening condition, strength class, and surface treatment, etc., make sure

to check the types and tightening torques of bolts/nuts and use them properly.

PURPOSES OF TIGHTENING TORQUE

Predefined tightening torque must be applied to ensure sufficient tightening by threads.

It also has purposes to prevent the adverse events below due to excessive or insufficient tightening.

Conditions Adverse events

• Stretch or fracture of bolt

• Depression of seat surface and looseness

Excessive tightening

Insufficient tightening

• Gasket damage

• Rounding and damage of hexagon part

• Opening of spring washer

• Looseness

• Gas and liquid Leakages

• Continuity failure

• Damage by fretting wear

NOTICE

Unique tightening torque may be specified for some parts.

Tighten with the tightening torque specified in the service manual.

HINT

Check the tightening torque list for general torques.

CAUTIONS TO PREVENT LOOSENESS.

When tightening, pay attention to the followings to prevent looseness after tightening.

• Insufficient tightening torque

• Inclusion of foreign matters (burrs and coatings) in the tightening surface.

• Sagging of coat

• Sinking into the seat surface hole by omitting attaching a plain washer.

• Defective seat surface flatness (wear-out during use)

Page 24

GENERAL INTRODUCTION1–20

SHTS01ZZZ0000023

SHTS01ZZZ0000024

FLANGE OUTER DIAMETER

GROOVES

GROOVES

SHTS01ZZZ0000025

FLANGE OUTER DIAMETER

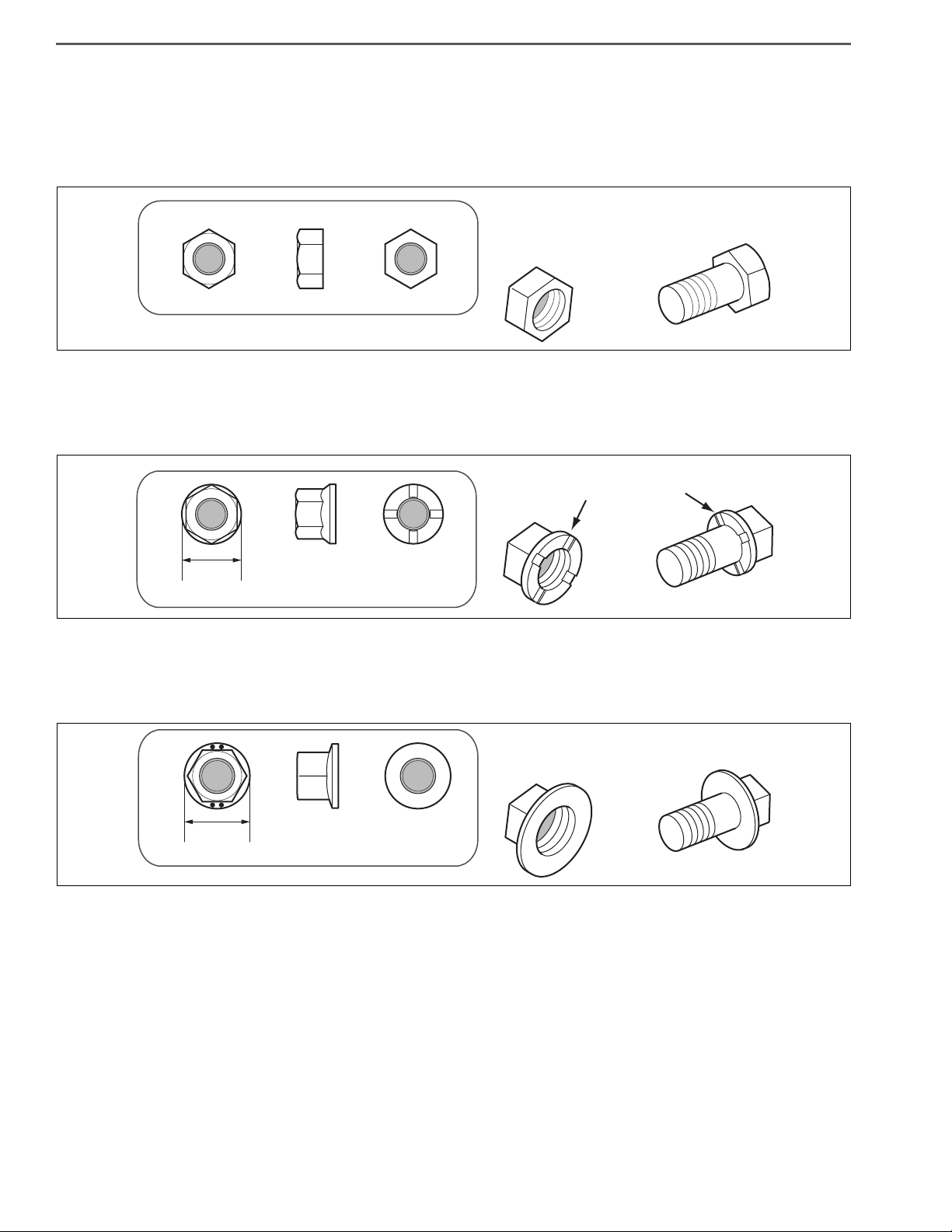

TYPES AND IDENTIFICATION

There are three types of bolts and nuts.

1. Standard (w/o flange)

• Bolts/nuts without flange

2. With old flange (w/grooves)

• Flange is small and has grooves on its back.

https://truckmanualshub.com/

3. With new flange (w/o grooves)

• Flange is big and does not have grooves on its back.

Page 25

SHTS01ZZZ0000026

SEAT SURFACE WITH OLD FLANGE

SEAT SURFACE WITH NEW FLANGE

NO COMPATIBILITY

BOLTS/NUTS WITH OLD FLANGE (W/GOOVES)

BOLTS/NUTS WITH NEW FLANGE (W/O GOOVES)

SEAT SURFACE WITH OLD FLANGE

SEAT SURFACE WITH NEW FLANGE

https://truckmanualshub.com/

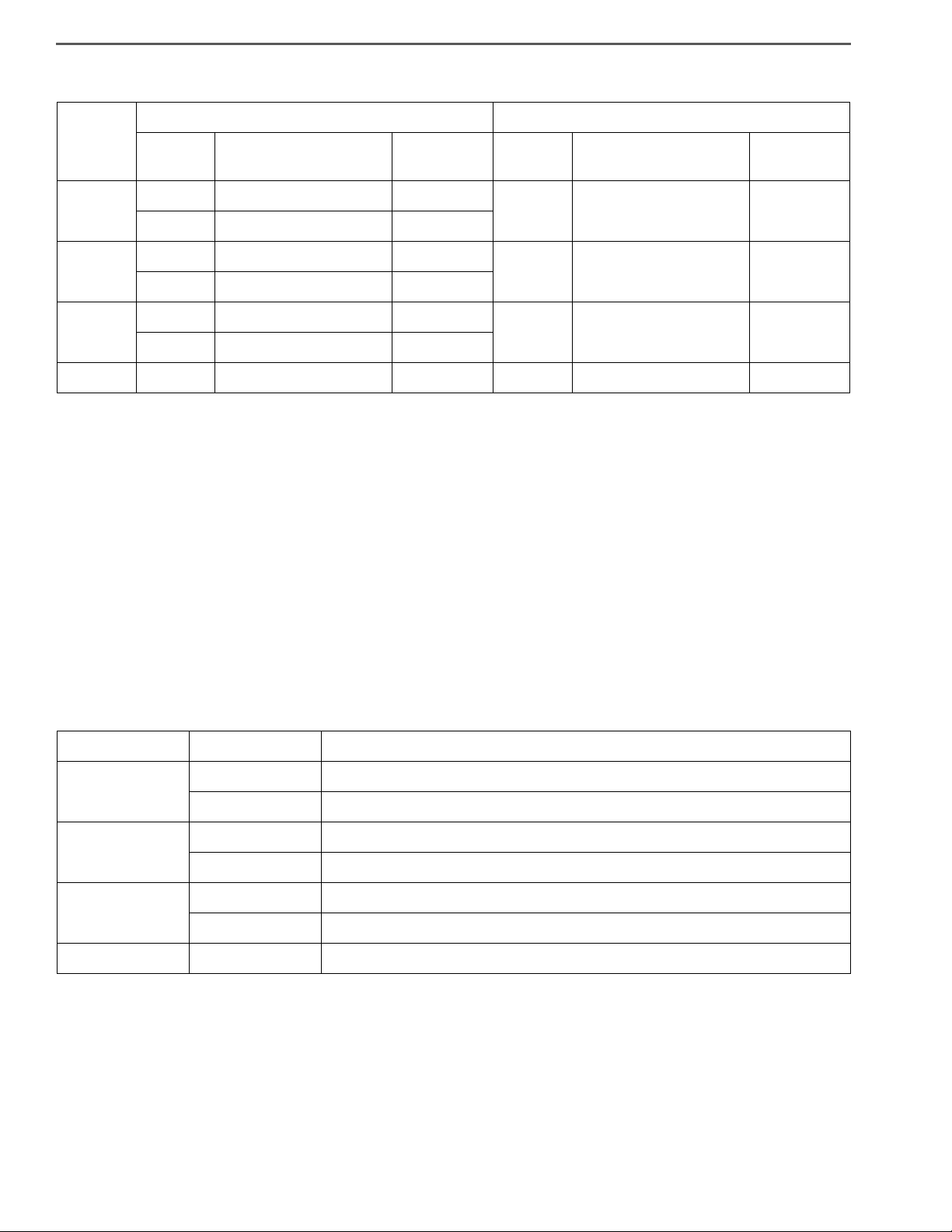

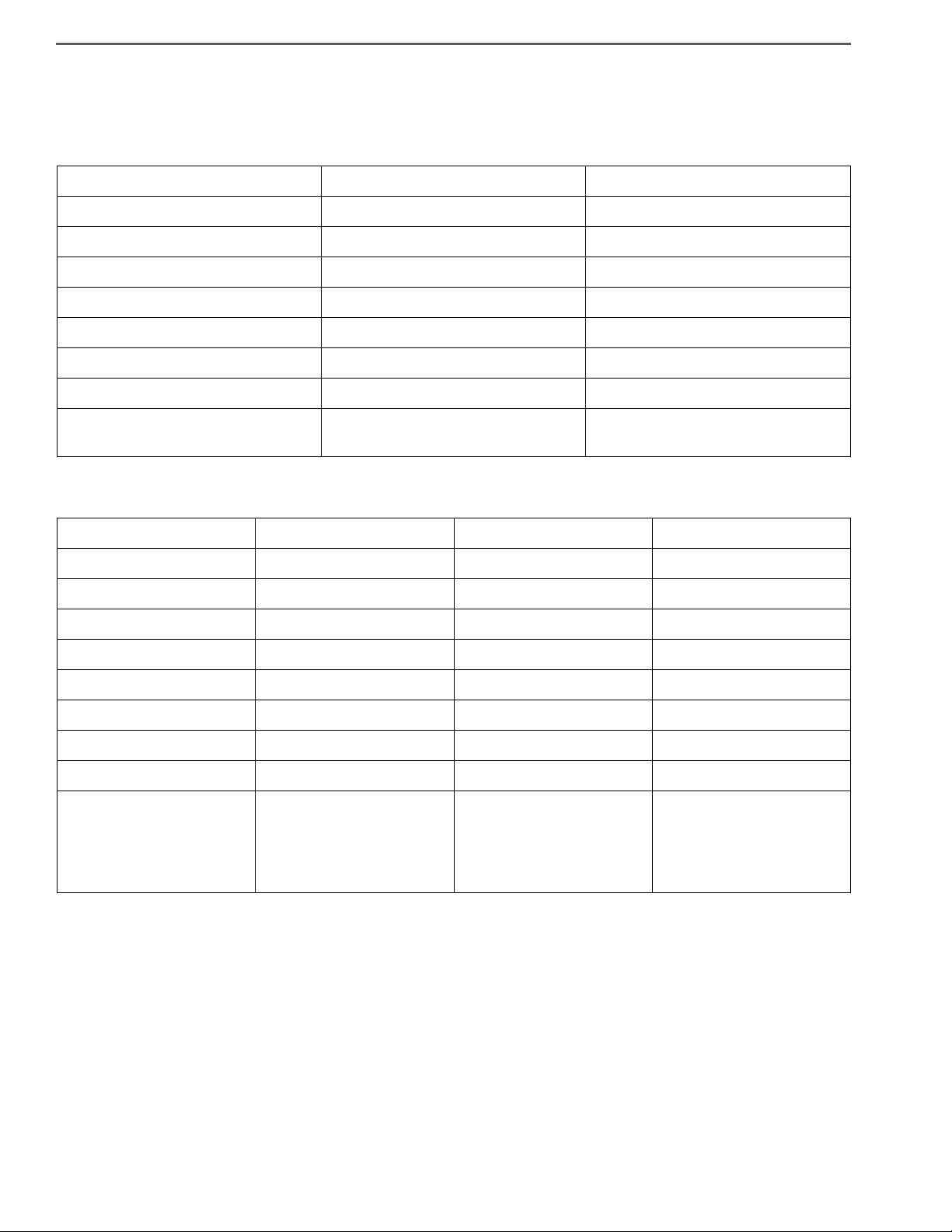

Comparison of flange outer diameters

Bolt Nut

GENERAL INTRODUCTION 1–21

Thread

diameter

With old flange

(w/grooves)

Strength

class

Flange

outer

diameter

With new flange

(w/o grooves)

Strength

class

Flange

outer

diameter

With old flange

(w/grooves)

Strength

class

Flange

outer

diameter

With new flange

(w/o grooves)

Strength

class

M8 7T, 9T 15.5 8.8, 10.9 17 7N 15.5 8 17

8.8 20

M10 7T, 9T 18.5

7N 18.5 8 21.5

10.9 21.5

8.8 24

M12 7T, 9T 21.5

7N 21.5 8 26

10.9 26

M14 ——10.9 30.5 ——12 30

COMPATIBILITY (NO COMPATIBILITY IN BOLTS AND NUTS)

Flange

outer

diameter

NOTICE

[Bolt/nuts with new flange (w/o grooves)] can not be used on the place where [bolts/nuts with old flange (w/

grooves)] were used. In addition, use care to avoid misassembly because even when nominal sizes and pitches

are same, there is no compatibility in strength if types are different.

Page 26

GENERAL INTRODUCTION1–22

https://truckmanualshub.com/

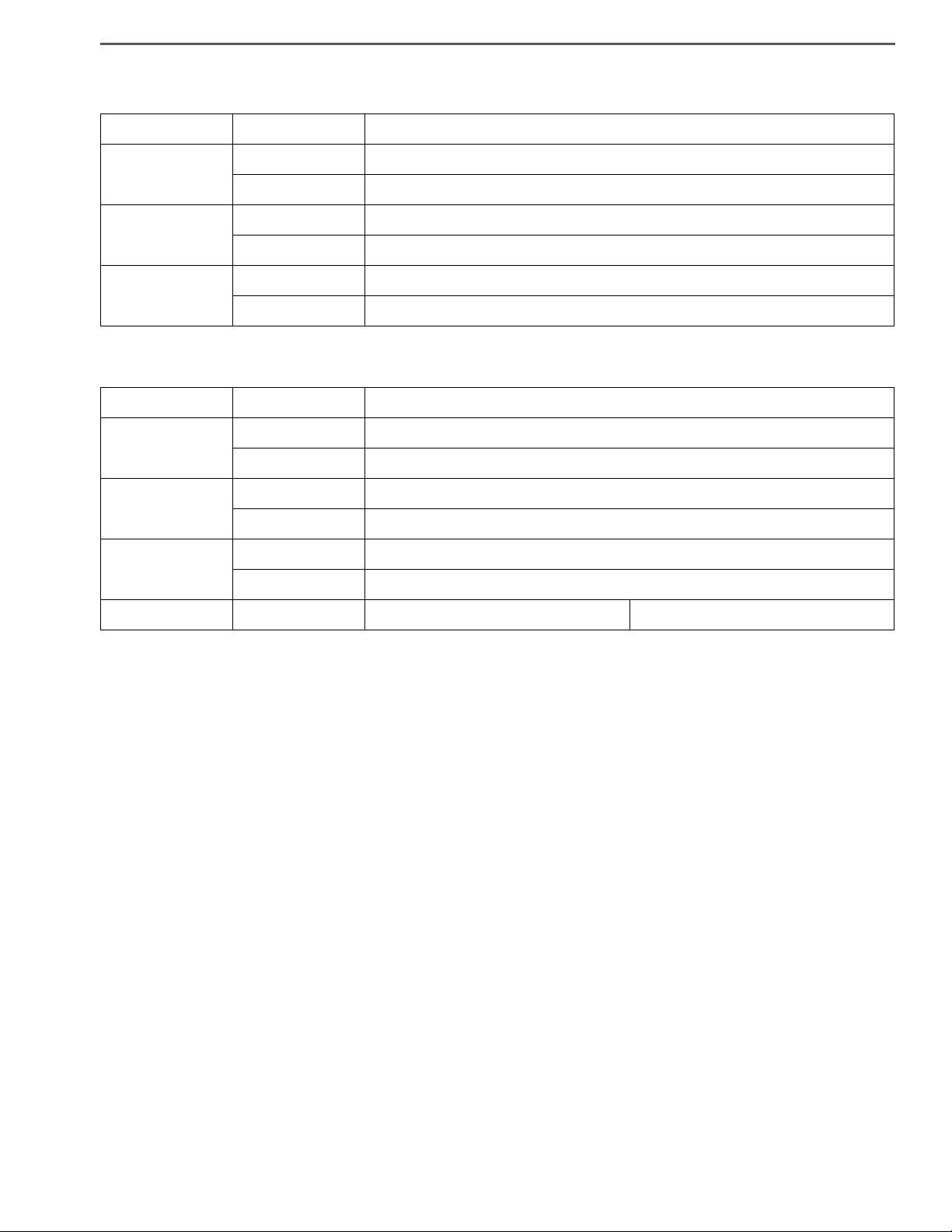

STRENGTH CLASSES AND SYMBOLS

1. With old flange (w/grooves)

Bolt Nut

Strength

class

4T —

9T

2. With new flange (w/o grooves)

Strength

class

Carbon steel Boron steel

Carbon steel Boron steel

Symbols

Bolt Nut

Symbols

Strength

class

7N7T

Strength

class

Symbols

Symbols

8.8 8

10.9 12

Page 27

PAR T N O.

1. Standard (w/o flange)

GENERAL INTRODUCTION 1–23

https://truckmanualshub.com/

Thread

diameter

M8

M10

M12

M14 9T SH112-**** Plating 8N SL113-01411 Plating

2. With old flange (w/grooves)

Thread

diameter

M8

Strength

class

7T SH111-**** Plating

9T SH112-**** Plating

7T SH111-**** Plating

9T SH112-**** Plating

7T SH111-**** Plating

9T SH112-**** Plating

Strength

class

7T SH562-**** Plating

9T SH562-**** Plating

Bolt Nut

Par t No.

Bolt Nut

Par t No.

Surface

treatment

Surface

treatment

Strength

class

8N SL113-00807 Plating

8N SL113-01008 Plating

8N SL113-01210 Plating

Strength

class

7N SL151-00809 Plating

Par t No.

Par t No.

Surface

treatment

Surface

treatment

M10

M12

7T SH562-**** Torquer

7N SL151-01011 Plating

9T SH562-**** Torquer

7T SH562-**** Torquer

7N SL151-01213 Plating

9T SH562-**** Torquer

Page 28

3. With new flange (w/o grooves)

GENERAL INTRODUCTION1–24

https://truckmanualshub.com/

Thread

diameter

M8

M10

M12

M14 10.9 91552-F14** Neotorquer 12 94151-21401 Neotorquer

NOTICE

Some bolts/nuts are applied friction stabilizer on thread surface. Note that their tightening torques are different

from those of plated-only bolts/nuts even if the strength class is same. (Threads with Neotorquer are colored in

light red.)

HINT

The * below the hyphen of a part number shows a thread diameter and length under head, so the numbers vary

depending on type.

Strength

class

8.8 91551-808** Plating

10.9 91551-008** Plating

8.8 91552-E10** Neotorquer

10.9 91552-F10** Neotorquer

8.8 91552-E12** Neotorquer

10.9 91552-F12** Neotorquer

Bolt Nut

Par t No.

Surface

treatment

Strength

class

8 94151-80800 Plating

8 94151-81001 Neotorquer

8 94151-81201 Neotorquer

Par t No.

Surface

treatment

LIST OF TIGHTENING TORQUE

Apply a tightening torque specified in the strength class of the bolt/nut used.

NOTICE

Refer to the service manual because tightening torques of some parts do not conform to it due to their tightening

conditions, strength classes, and surface treatments.

1. Standard (w/o flange)

Unit: Nm {kgfcm, lbfft}

Thread diameter Strength classes Tightening Torque

M8

M10

M12

M14 9T 160.032.0 {1,630326, 117.923.5}

7T 22.04.0 {22445, 16.22.9}

9T 29.05.5 {29656, 23.14.0}

7T 43.08.5 {43886, 31.76.2}

9T 57.011.0 {581112, 42.08.1}

7T 76.015.0 {774152, 56.011.0}

9T 100.020.0 {1,019203, 73.714.7}

Page 29

GENERAL INTRODUCTION 1–25

https://truckmanualshub.com/

2. With old flange (w/grooves)

Thread diameter Strength classes Tightening Torque

Unit: Nm {kgfcm, lbfft}

M8

M10

M12

3. With new flange (w/o grooves)

Thread diameter Strength classes Tightening Torque

M8

M10

M12

7T 22.04.0 {22445, 16.22.9}

9T 29.05.5 {29656, 23.14.0}

7T 51.510.0 {525101, 37.97.3}

9T 68.513.5 {698137, 50.59.9}

7T 91.018.0 {927183, 67.013.2}

9T 120.024.0 {1,223224, 88.417.6}

8.8 31.09.3 {31694, 22.86.8}

10.9 39.011.7 {397119, 28.78.6}

8.8 35.010.5 {356107, 25.87.7}

10.9 46.513.8 {474140, 34.210.1}

8.8 63.018.9 {642

10.9 82.024.6 {836250, 60.418.1}

192, 46.413.9}

Unit: Nm {kgfcm, lbfft}

M14 10.9 130.039.0 {1,325397, 95.828.7} 130.026.0 {1,325265, 95.819.1}*

HINT

*: Value is for usage in the fuel tank.

Page 30

GENERAL INTRODUCTION1–26

https://truckmanualshub.com/

TIGHTENING OF ENGINE BOLTS AND NUTS

1. TIGHTENING TORQUE FOR GENERAL STANDARD BOLTS

(1) Representative tightening torque for shouldered bolts

Unit: Nm {kgfcm, lbfft}

Thread diameter X pitch 7T 9T

M8 X 1.25 (coarse thread) 28.5 {290, 21} 36 {370, 27}

M10 X 1.25 (fine thread) 60 {610, 44} 74.5 {760, 55}

M10 X 1.5 (coarse thread) 55 {560, 40} 68.5 {700, 51}

M12 X 1.25 (fine thread) 108 {1,100, 80} 136 {1,390, 101}

M12 X 1.75 (coarse thread) 97 {990, 72} 125 {1,280, 93}

M14 X 1.5 (fine thread) 171.5 {1,750, 127} 216 {2,210, 160}

M14 X 2 (coarse thread) 154 {1,570, 114} 199 {2,030, 147}

Remark

(2) Representative torque for washer bolt

Thread diameter X pitch 4T 7T 9T

M6 X 1 (coarse thread) 6 {60, 4.3} 10 {100, 7.2} 13 {130, 9.4}

M8 X 1.25 (coarse thread) 14 {140, 10} 25 {250, 18} 31 {320, 23}

M10 X 1.25 (fine thread) 29 {300, 22} 51 {520, 38} 64 {650, 47}

M10 X 1.5 (coarse thread) 26 {270, 20} 47 {480, 35} 59 {600, 43}

M12 X 1.25 (fine thread) 54 {550, 40} 93 {950, 69} 118 {1,200, 87}

M12 X 1.75 (coarse thread) 49 {500, 36} 83 {850, 61} 108 {1,100, 80}

M14 X 1.5 (fine thread) 83 {850, 61} 147 {1,500, 108} 186 {1,900, 137}

M14 X 2 (coarse thread) 74 {750, 54} 132 {1,350, 98} 172 {1,750, 127}

Bolt with a numerical

character "4" indicated on

Remark

the head Projection bolt.

Stud with a rounded free

end.

Bolt with a numerical character "7"

indicated on the head

Bolt with a numerical

character "7" indicated on

the head. Stud with a

chamfered free end.

Bolt with a numerical character "9"

indicated on the head

Unit: Nm {kgfcm, lbfft}

Bolt with a numerical

character "9" indicated on

the head

Page 31

GENERAL INTRODUCTION 1–27

SHTS01ZZZ0000040

SEAL LOCKING AGENT

SHTS01ZZZ0000041

EXAMPLE OF WORK

ONE TURN BY 90

ONE TURN BY 90

ONE TURN BY 45

TIGHTEN

BY 90

TIGHTEN BY 90

(1ST TURN)

TIGHTEN BY 45

(2ND TURN)

TWO TURNS BY 90

TIGHTEN BY 90

(1ST TURN)

TIGHTEN BY 90

(2ND TURN)

https://truckmanualshub.com/

2. PRECOAT BOLT

(1) Reapply locking agent if:

a. a precoat bolt has been removed, or

b. a precoat bolt has been turned during a tightening check or other activities. (loosened or tightened)

HINT

• A precoat bolt is a bolt of which threads are applied with seal locking agent.

• Conduct a torque check with the lower limit of a permissible tightening torque range. If a bolt has been

turned or rotated, follow the procedures below to retighten a bolt.

(2) Steps for reusing precoat bolt lock

a. Clean a bolt and a screw hole. (Also clean a screw hole if replacement is made.)

b. Use air blower to dry out.

c. Apply specified seal locking agent to bolt threads.

3. PLASTIC-REGION TIGHTENING METHOD (TURNING ANGLE CONTROL)

NOTICE

• Some of engine parts employ the plastic-region tightening method.

• Said tightening method is different from the conventional tightening method. Follow the instructions

(1) Applicable parts

NOTICE

Prior to installation, measure a total length of a bolt. If a measurement reading of a total length exceeds the service limit, replace the bolts.

In installation work, apply engine oil to a bolt seat surface and bolt threads.

(2) Tightening after tightening with seating torque

described in this document for tightening.

Cylinder head bolt, crankshaft main bearing cap bolt, connecting rod bearing cap bolt, and etc.

Tighten to the angle specified in this document: i.e. tighten another 90, 135 (90 once and then 45 once) or 180

(90 twice).

Page 32

GENERAL INTRODUCTION1–28

https://truckmanualshub.com/

TIGHTENING OF FLARE NUTS AND HOSES

1. TIGHTENING TORQUE FOR PIPE FLARE NUTS

HINT

Steel pipes and copper pipes (excluding power steering pipe).

Unit: Nm {kgfcm, lbfft}

Outer diameter

of pipe

Tightening

torque

TIGHTENING TORQUE FOR POWER STEERING PIPE FLARE NUTS

Typ es

Feed pipe

(high pressure)

Return pipe

(low pressure)

4.76 6.35 8 10 12 15

Brake:15

{153,11}

Except brake:

150.5

{1535.1,

110.37}

Material quality and

shape

Copper (Outer diame-

ter 10) (Wall thick-

ness t=1.4)

Copper (Outer diame-

ter 10) (Wall thick-

ness t=1)

Clutch:24

{245,18}

Except

clutch:

211

{21410,

150.7}

Flare configuration Identification Tightening torque

323

{32631,

242.2}

Single flare Red 44±5 {44951,323.7}

Single flare — 44±5 {44951,323.7}

445

{44951,

323.7}

645

{65351,

473.7}

Unit: Nm {kgfcm, lbfft}

662.5

{67325,

491.8}

2. TIGHTENING TORQUE FOR HOSES

Unit: Nm {kgfcm, lbfft}

Outer diameter of hose13

fittings

Brake hose — 462.5 {46925,341.8} —

Power steering

oil hose

3. TIGHTENING TORQUE FOR STEEL JOINT LOCK NUTS

Nominal des-

ignation of

thread

Tightening

torque

M14 M16 M20 M22 M24

4810

{489102, 357.3}

——44±5 {44951,323.7}

6613

{673204, 499.5}

Outer diameter of hose13,

20, 22, packing unit fittings

12036

{1,224367,

26.5}

89

{1,346306,

Outer diameter of hose

PF 3/8 fittings

Unit: Nm {kgfcm, lbfft}

13030

9722.1}

15030

{1,530306,

11122.1}

Page 33

GENERAL INTRODUCTION 1–29

SHTS01ZZZ0000042

SPRAY GUN

CARTRIDGE

WINDING TOOL

TUBE

SHTS01ZZZ0000043

21

NOZZLE OF THE TUBE

https://truckmanualshub.com/

HANDLING OF LIQUID GASKET

EN01F01ZZZ000102003006

LIQUID GASKET

1. PROCEDURES FOR APPLYING LIQUID GASKET AND ASSEMBLING PARTS

(1) Thoroughly remove old liquid gasket remaining on individual parts and mating parts. Use clean cloth to remove oil,

moisture, dirt or other contaminants.

Make sure to overlap the start and end points of liquid gasket.

(2) Use care to avoid misalignment with a mating part when assembling a gasket-applied part. If misalignment is found,

reapply liquid gasket.

(3) Install parts within 20 minutes after applying liquid gasket.

If 20 minutes or longer time has elapsed, remove and reapply liquid gasket.

(4) Wait at least 15 minutes after assembling parts and then start the engine.

2. REMOVAL OF PARTS

(1) When removing individual parts, alternately winkle two or more portions in a gap or a collar of a flange. Avoid one-

point winkling. When removing a gasket, use care to avoid entry of gasket fragments into the engine.

3. OTHERS

(1) If liquid gasket is contained in a tube, use a supplied squeezer. If liquid gasket is contained in a cartridge, use a appli-

cator gun.

If liquid gasket is contained in a tube, the nozzle tip can be cut off to the desired application width.

1: Cut off the first block will form a application width of approximately 2 mm {0.079 in.}.

2: Cut off the second block will form a application width of approximately 5 mm {0.197 in.}.

1

Page 34

GENERAL INTRODUCTION1–30

https://truckmanualshub.com/

GENERAL INFORMATION

GLOSSARY

DEFINITION OF ABBREVIATION IN THIS MANUAL

LIST OF ABBREVIATION

Abbreviations Meaning, or Official Name

A/C Air Conditioner

ABS Anti-lock Brake System

ACC Accessory

AMT Automated Manual Transmission

ATC After Turbo Catalyst

ATF Automatic Transmission Fluid

CA Crank Angle

CAN Controller Area Network

CD-ROM Compact Disc Read Only Memory

CPU Central Processing Unit

dB Decibel

DC Direct Current

EN01F01ZZZ000102006001

D-CAT Diesel-Clean Advanced Technology System

DC motor Direct Current Motor

DCU Dosing Control Unit

DEF Diesel Exhaust Fluid

DPR Diesel Particulate active Reduction system

DSS Driving Support System

ECU Electronic Control Unit

EEPROM Electronically Erasable and Programmable Read Only Memory

EGR Exhaust Gas Recirculation

ELR Emergency Locking Retractor

ENG Engine

ES START Easy and Smooth start system

F/A Front Axle

FCCB Fuel Control Cylinder Balance

FCV Fuel Cutoff Valve

FF shift Feather touch & Finger shift

FL Fusible link

Page 35

GENERAL INTRODUCTION 1–31

https://truckmanualshub.com/

Abbreviations Meaning, or Official Name

Fr Front

FRP Fiber Reinforced Plastic

FUP Front Underrun Protector

GCU Glow Control Unit

GND Ground

GVW Gross Vehicle Weight

Hi High

HINO-DX HINO Diagnostic eXplorer

HV Hybrid Vehicle

HVAC Heating, Ventilating and Air-Conditioning unit

I.S.C. Idle Speed Control

IC Integrated Circuits

ID Identification

IPD Intelligent Power Device

IS Idle Stop

ISO International Organization for Standardization

JIS Japanese Industrial Standards

LED Light Emitting Diode

LEV Low Emission Vehicle

LH Left Hand

LLC Long Life Coolant

Lo Low

MAX Maximum

MIN Minimum

MS evaporator Multi-tank and Super slim structure evaporator

MT Manual Transmission

No. Number

NOx Nitrogen Oxide

NMR No load Maximum Revolution

OHC Over Head Camshaft

PC Personal Computer

PCD Pitch Circle Diameter

PCS Pre-Crash Safety

PCV Pump Control Valve

PCV valve Positive Crankcase Ventilation valve

Page 36

GENERAL INTRODUCTION1–32

https://truckmanualshub.com/

Abbreviations Meaning, or Official Name

PM Particulate Matter

PPG Glass-fiber-reinforced Polypropylene

ppm Parts Per Million

PS pump Power Steering Pump

PTO Power Take-Off

PVD Physical Vapor Deposit

PWR Power

QR code Quick Response Code

R/A Rear Axle

RH Right Hand

SCR Selective Catalytic Reduction

SST Special Service Tool

SW Switch

T/M Transmission

Page 37

GENERAL INTRODUCTION 1–33

https://truckmanualshub.com/

GLOSSARY OF SAE AND HINO TERMS

This glossary lists all SAE-J2403 terms and abbreviations used in this manual in compliance with SAE recommendation,

as well as their HINO equivalents.

SAE ABBREVIATIONS SAE TERMS HINO TERMS( )--ABBREVIATIONS

A/T AUTOMATIC TRANSMISSION Automatic transmission

AAT AMBIENT AIR TEMPERATURE Ambient Air Temperature

ACL AIR CLEANER Air cleaner

ACL Element ACL (Air Cleaner) Element Air Cleaner element

ACL Element AIR CLEANER Element Air Cleaner element

ACL Housing AIR CLEANER Housing Air cleaner body assembly

ACL Housing Cover AIR CLEANER Housing Cover Air Cleaner Housing Cover

AFTDEF

AFTDEFDU

AFTDOC

AFTDOS AFTERTREATMENT DOSER AFTDOS Dosing

AFTDPF

AFTDPFDP

AFTEGT

AP ACCELERATOR PEDAL Accelerator pedal

AP Sensor ACCELERATOR PEDAL Sensor Accelerator Pedal Position Sensor

APP ACCELERATOR PEDAL POSITION Accelerator Pedal Position

CAC CHARGE AIR COOLER Intercooler

CPP Switch CLUTCH PEDAL POSITION Switch Clutch Switch

AFTERTREATMENT DIESEL EXHAUST

FLUID

AFTERTREATMENT DIESEL EXHAUST

FLUID DOSING UNIT

AFTERTREATMENT DIESEL OXIDATION

CATALYST

AFTERTREATMENT DIESEL PARTICULATE FILTER

AFTERTREATMENT DIESEL PARTICULATE FILTER DIFFERENTIAL PRESSURE

AFTERTREATMENT EXHAUST GAS TEMPERATURE

DEF

DCU

DOC (Diesel Oxidation Catalyst)

DPR filter

DPR differential pressure

Exhaust gas temperature

DCC DIAGNOSTIC CONNECTOR, Cab Diagnosis connector

DCU DIAGNOSTIC CONNECTOR, Underhood Diagnosis connector

DRIVER DRIVER Driver

DTC DIAGNOSTIC TROUBLE CODE Diagnosis Trouble Code

DTM Switch DIAGNOSTIC TEST MODE Switch Diagnosis switch

EBP EXHAUST BACK PRESSURE Back pressure

EBP EXHAUST BACK PRESSURE Exhaust back pressure

EBP Sensor EXHAUST BACK PRESSURE Sensor Back Pressure Sensor

EBPR Valve

EC ENGINE CONTROL Engine control

EXHAUST BACK PRESSURE REGULATOR

Val ve

Exhaust control valve

Page 38

GENERAL INTRODUCTION1–34

https://truckmanualshub.com/

SAE ABBREVIATIONS SAE TERMS HINO TERMS( )--ABBREVIATIONS

ECT ENGINE COOLANT TEMPERATURE Coolant Temperature

ECT ENGINE COOLANT TEMPERATURE Water Temperature

EFT ENGINE FUEL TEMPERATURE Fuel temperature

EFT Sensor ENGINE FUEL TEMPERATURE Sensor Fuel temperature sensor

EGR EXHAUST GAS RECIRCULATION EGR

EGR Valve EXHAUST GAS RECIRCULATION Valve EGR valve

EGRT

EGRT Sensor

EGT EXHAUST GAS TEMPERATURE Exhaust gas temperature

EI ELECTRONIC IGNITION Ignition coil

EOP ENGINE OIL PRESSURE Oil Pressure

EOT ENGINE OIL TEMPERATURE Oil Temperature

FP FUEL PUMP Fuel pump

FUEL PRESSURE

Sensor

GLOW PLUG GLOW PLUG Glow plug

GND GROUND GROUND

IA INTAKE AIR Air Intake

IA System INTAKE AIR System Air Intake System

IAT INTAKE AIR TEMPERATURE Intake temperature

IAT Sensor INTAKE AIR TEMPERATURE Sensor Intake temperature sensor

EXHAUST GAS RECIRCULATION TEMPERATURE

EXHAUST GAS RECIRCULATION TEMPERATURE Sensor

FUEL PRESSURE Sensor Fuel Pressure sensor

EGR temperature

EGR exit temperature sensor

IDLE IDLE Idle

IMAT INTAKE MANIFOLD AIR TEMPERATURE Intake manifold Air temperature sensor

IMAT INTAKE MANIFOLD TEMPERATURE Intake manifold temperature sensor

INJ INJECTOR Injector

MAF Sensor MASS AIR FLOW Sensor Air flow sensor

MIL MALFUNCTION INDICATOR LIGHT Check engine

OSS Sensor OUTPUT SHAFT SPEED Sensor Output Speed Sensor

OSS Sensor OUTPUT SHAFT SPEED Sensor Speed Sensor

PC Solenoid Valve PRESSURE CONTROL Solenoid Valve Solenoid control valves

PCV POS CRANKCASE VENTILATION PCV (Positive Crankcase Vent)

PCV Valve POS CRANKCASE VENTILATION Valve PCV (Positive Crankcase Vent) Valve

PCV Valve POS CRANKCASE VENTILATION Valve PCV Valve

PCV Valve POSITIVE CRANKCASE VENT Valve PCV Valve

Page 39

GENERAL INTRODUCTION 1–35

https://truckmanualshub.com/

SAE ABBREVIATIONS SAE TERMS HINO TERMS( )--ABBREVIATIONS

PNP PARK/NEUTRAL POSITION Neutral position

PNP Switch PARK/NEUTRAL POSITION Switch Neutral switch

RFP RAIL FUEL PRESSURE Common rail Pressure

RFP Sensor RAIL FUEL PRESSURE Sensor Common rail pressure sensor

SPARK PLUG SPARK PLUG Spark plug

SRI SERVICE REMINDER INDICATOR Check engine

ST SCAN TOOL Diagnostic tool

TC TURBOCHARGER Turbocharger

TCC TORQUE CONVERTER CLUTCH Torque Converter

TP Sensor THROTTLE POSITION Sensor Throttle Sensor

TSS Sensor TURBINE SHAFT SPEED Sensor Turbine Speed Sensor

VAF Sensor VOLUME AIR FLOW Sensor Air flow sensor

VLS VEHICLE LIMITING SPEED Speed Limiter Upper Limit

VSS VEHICLE SPEED SENSOR Vehicle Speed sensor

Page 40

GENERAL INTRODUCTION1–36

10 32

0

90 °F

-12

SAE 90

32 °C

https://truckmanualshub.com/

1

SAFETY INFORMATION

LUBRICANTS

RECOMMENDED LUBRICANTS

EN01F01ZZZ000101007001

No. POSITION LUBRICANTS VISCOSITY RECOMMENDATIONS (SAE)

1 Cylinder block Engine oil

(JASO: DH-2)

(API: CJ-4)

(ACEA: E-6, E-9)

2 Transmission:

A465 Automatic

Transmission

3 Differential: SH13 HINO GENUINE SERIES Differential

Toyota genuine ATF Type T-IV

(ATF: JWS3309)

gear oil for Hypoid gear

(API: GL-5)

No. POSITIONS LUBRICANTS

4 Integral power steering gear HINO GENUINE SERIES Power steering fluid or

ATF DE X RO N

5 Brake HINO GENUINE SERIES Brake and clutch fluid or

Brake fluid (DOT-3)

6 Wheel bearing

Propeller shaft

7 Front and rear suspension spring bracket pins and

shackle pins

HINO GENUINE SERIES Bearing grease or Bearing

grease (NLGI No.2 LITHIUM-SOAP)

HINO GENUINE SERIES Multipurpose grease

(NLGI No.2 LITHIUM-SOAP)

8 Chassis grease fitting HINO GENUINE SERIES Chassis grease or

Chassis grease (MIL-G-17740)

9 Engine, Radiator HINO GENUINE SERIES Long life coolant

(NILGI No.1 CALCIUM or LITHIUM-SOAP)

Page 41

STANDARD VALUE (J05E) 2–1

https://truckmanualshub.com/

STANDARD VALUE (J05E)

2

MOUNTING AND DISMOUNTING THE ENGINE........2-3

ENGINE ASSEMBLY ..............................................2-3

ENGINE CONTROL .....................................................2-4

ENGINE ECU..........................................................2-4

ENGINE SPEED MAIN SENSOR...........................2-4

ENGINE SPEED SUB SENSOR.............................2-4

IDLE SET VOLUME................................................2-4

ACCELERATOR PEDAL .........................................2-5

BLOCK HEATER .....................................................2-5

FUEL SYSTEM.............................................................2-6

FUEL TANK .............................................................2-6

FUEL SENDER GAUGE .........................................2-6

ENGINE-SIDE FUEL FILTER & CASE ...................2-7

WATER LEVEL WARNING SWITCH ......................2-7

SUPPLY PUMP .......................................................2-8

INJECTOR ..............................................................2-8

COMMON RAIL ......................................................2-9

VEHICLE-SIDE FUEL FILTER................................2-9

FUEL COOLER.......................................................2-9

EMISSION CONTROL................................................2-10

EGR VALVE & COOLER .......................................2-10

CLOSED VENTILATOR ........................................2-10

INTAKE.......................................................................2-11

INTAKE MANIFOLD ..............................................2-11

DIESEL THROTTLE..............................................2-11

INTAKE PIPE (EXHAUST SIDE)...........................2-11

STACK DUCT........................................................2-11

AIR CLEANER ......................................................2-12

INTAKE TEMPERATURE SENSOR......................2-12

BOOST PRESSURE SENSOR.............................2-12

AIR FLOW SENSOR.............................................2-12

ENGINE MECHANICAL.............................................2-13

HEAD COVER.......................................................2-13

ROCKER ARM ASSEMBLY ..................................2-13

CAMSHAFT ASSEMBLY.......................................2-14

CYLINDER HEAD ASSEMBLY .............................2-15

VALVE SYSTEM ...................................................2-16

CRANKSHAFT PULLEY.......................................2-17

FRONT OIL SEAL RETAINER ..............................2-17

FLYWHEEL ASSEMBLY .......................................2-17

FLYWHEEL HOUSING..........................................2-17

TIMING GEAR & CAM IDLE GEAR......................2-18

PISTON & CONNECTING ROD ...........................2-19

CRANKSHAFT......................................................2-20

2-001

CYLINDER LINER ................................................2-21

CYLINDER BLOCK...............................................2-21

ENGINE MOUNTING AND BRACKET .................2-21

GLOW PLUG.........................................................2-21

EXHAUST...................................................................2-23

EXHAUST MANIFOLD..........................................2-23

EXHAUST PIPE ....................................................2-23

EXHAUST PIPE (ATC) ..........................................2-23

DEF-SCR ..............................................................2-24

DPR CLEANER.....................................................2-24

FUEL ADDITION VALVE .......................................2-25

FUEL CUTOFF VALVE..........................................2-25

DEF PUMP............................................................2-25

DEF INJECTOR ....................................................2-26

DEF TANK .............................................................2-26

COOLANT CUTOFF VALVE .................................2-26

DCU ......................................................................2-26

DPR DIFFERENTIAL PRESSURE SENSOR ....... 2-27

SCR UPSTREAM NOx SENSOR .........................2-27

SCR DOWNSTREAM NOx SENSOR...................2-27

ATC DOWNSTREAM TEMPERATURE

SENSOR ...............................................................2-27

DOC UPSTREAM TEMPERATURE SENSOR .....2-28

DPR UPSTREAM TEMPERATURE SENSOR...... 2-28

DPR DOWNSTREAM TEMPERATURE

SENSOR ...............................................................2-28

SCR UPSTREAM TEMPERATURE SENSOR ...... 2-29

EXHAUST BRAKE ................................................2-29

EXHAUST BRAKE MAGNETIC VALVE ................2-29

COOLING ...................................................................2-30

RADIATOR ............................................................2-30

RADIATOR CAP....................................................2-30

RESERVE TANK ...................................................2-30

INTERCOOLER ....................................................2-31

THERMOSTAT CASE & THERMOSTAT ...............2-31

COOLANT PUMP .................................................2-31

COOLING FAN & FAN CLUTCH...........................2-32

COOLANT TEMPERATURE SENSOR .................2-32

LUBRICATION ...........................................................2-33

OIL COOLER ........................................................2-33

OIL PUMP .............................................................2-33

OIL PAN ................................................................2-34

OIL STRAINER .....................................................2-34

OIL PRESSURE SWITCH ....................................2-34

Page 42

STANDARD VALUE (J05E)2–2

https://truckmanualshub.com/

STARTING/CHARGING..............................................2-35

STARTER ..............................................................2-35

V-BELT ..................................................................2-35

ALTERNATOR (130 A) ..........................................2-36

TURBOCHARGER .....................................................2-37

TURBOCHARGER ASSEMBLY ............................2-37

Page 43

STANDARD VALUE (J05E) 2–3

https://truckmanualshub.com/

BASIC VALUE

MOUNTING AND DISMOUNTING THE ENGINE

ENGINE ASSEMBLY

STANDARD VALUE, LIMIT AND ACTION

Inspection item Standard value Permissible limit Action

Compression pressure

(Per cylinder: Engine revolution 190 r/min)

Intake 0.30 mm {0.012 in.}

Valve clearance (when cold)

Exhaust 0.45 mm {0.018 in.}

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Rocker arm lock nut 25 {255, 18}

Crosshead lock nut 25 {255, 18}

Oil pan drain plug 41 {418, 30}

Engine hanger mounting bolt (front) 125 {1,275, 92}

3.0 MPa

{31 kgf/cm

435 lbf/in

2

,

.2

}

{28 kgf/cm

392 lbf/in.

EN01F02127010701001001

2.7 MPa

2

,

2

}

Overhaul

– Adjustment

Unit: Nm {kgfcm, lbfft}

Engine hanger mounting bolt (rear) 85 {867, 63}

Engine mounting nut 96-144 {979-1,468, 71-106}

Cab mounting bracket bolt 38.4-57.9 {392-587, 29-42}

Engine side cover bolt 11.5 {117, 8}

Page 44

STANDARD VALUE (J05E)2–4

https://truckmanualshub.com/

ENGINE CONTROL

ENGINE ECU

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Engine ECU mounting bolt 28.5 {290, 21}

ENGINE SPEED MAIN SENSOR

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Engine speed main sensor mounting bolt 10 {102, 7}

ENGINE SPEED SUB SENSOR

TIGHTENING TORQUE

EN01F02127010701002001

Unit: Nm {kgfcm, lbfft}

EN01F02127010701002002

Unit: Nm {kgfcm, lbfft}

EN01F02127010701002003

Unit: Nm {kgfcm, lbfft}

Tightening part Tightening torque Remarks

Engine speed sub sensor mounting bolt 4-6 {41-61, 3.0-4.4}

IDLE SET VOLUME

EN01F02127010701002004

STANDARD VALUE, LIMIT AND ACTION

Inspection item Standard value Action

Resistance between terminals 1,180-1,620 Replace

Page 45

STANDARD VALUE (J05E) 2–5

https://truckmanualshub.com/

ACCELERATOR PEDAL

STANDARD VALUE, LIMIT AND ACTION

Inspection item Standard value Action

Accelerator sensor 1 output voltage

Accelerator sensor 2 output voltage

Accelerator fully-closed 0.6-1.0 V Replace

Accelerator fully open 2.8-3.6 V Replace

Accelerator fully-closed 1.4-1.8 V Replace

Accelerator fully open 3.6-4.4 V Replace

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Accelerator pedal assembly mounting nut 5.5 {56, 4}

BLOCK HEATER

TIGHTENING TORQUE

EN01F02127010701002005

Unit: Nm {kgfcm, lbfft}

EN01F02127010701002006

Unit: Nm {kgfcm, lbfft}

Tightening part Tightening torque Remarks

Block heater socket mounting bolt 1.4-1.7 {14-17, 1.0-1.3}

Page 46

STANDARD VALUE (J05E)2–6

https://truckmanualshub.com/

FUEL SYSTEM

FUEL TANK

EN01F02127010701003001

TIGHTENING TORQUE

Unit: Nm {kgfcm, lbfft}

Tightening part Tightening torque Remarks

Fuel tank drain plug 24.5-34.3 {250-349, 19-26}

Fuel tank bracket mounting bolt 96-144 {979-1,468, 71-106} For 30 gallon

Fuel tank band 10.2-15.0 {105-152, 8-11} For 33 gallon

FUEL SENDER GAUGE

EN01F02127010701003002

STANDARD VALUE, LIMIT AND ACTION

Inspection item Standard value Action

Resistance between

terminals

Float height

TIGHTENING TORQUE

E 107.5-112.5 Replace

F3-5 Replace

Unit: Nm {kgfcm, lbfft}

Tightening part Tightening torque Remarks

Fuel sender gauge mounting bolt 1.5-2.5 {16-25, 1.2-1.8}

Page 47

STANDARD VALUE (J05E) 2–7

https://truckmanualshub.com/

ENGINE-SIDE FUEL FILTER & CASE

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Fuel filter drain plug 5-9 {51-91, 3.7-6.6}

Fuel filter air bleeding plug 5-9 {51-91, 3.7-6.6}

Fuel filter center bolt 23.1-32.9 {236-335, 18-24}

Fuel filter mounting bolt 55 {561, 41}

Fuel feed pipe No.3 mounting union

bolt

Fuel feed pipe No.1 mounting union

bolt

Fuel filter

side

Supply pump

side

Fuel shutoff

valve side

Supply pump

side

Fuel filter

side

14.8-19.6 {151-199, 11-14}

30 {306, 22}

19.6 {200, 14}

25 {255, 18}

30 {306, 22}

EN01F02127010701003003

Unit: Nm {kgfcm, lbfft}

Fuel feed pipe No.2 mounting union

bolt

Return pipe No.2 mounting union

bolt

Supply pump

side

Fuel filter

side

Fuel filter

side

Intake manifold side

25 {255, 18}

30 {306, 22}

30 {306, 22}

24.5 {250, 18}

WATER LEVEL WARNING SWITCH

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Fuel filter drain plug 5-9 {51-91, 3.7-6.6}

Water level warning switch 2-3 {21-30, 1.5-2.2}

EN01F02127010701003004

Unit: Nm {kgfcm, lbfft}

Page 48

STANDARD VALUE (J05E)2–8

https://truckmanualshub.com/

SUPPLY PUMP

STANDARD VALUE, LIMIT AND ACTION

Inspection item Standard value Action

Resistance between terminals of

suction control valve

Resistance between terminals of

combustion temperature sensor

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Fuel filter drain plug 5-9 {51-91, 3.7-6.6}

Bearing holder case mounting bolt 28.5 {291, 21}

Coupling flange mounting nut 64 {653, 47}

20C {68F} 1.6-2.6 Replace

–20C {–4F} 13.84-16.33 k Replace

20C {68F} 2.32-2.59 k Replace

80C {176F} 0.310-0.326 k Replace

110C {230F} 0.1399-0.1435 k Replace

EN01F02127010701003005

Unit: Nm {kgfcm, lbfft}

Coupling and supply pump mounting bolts 28.5 {291, 21}

Pressure feed pipe 44 {449, 32}

INJECTOR

EN01F02127010701003006

STANDARD VALUE, LIMIT AND ACTION

Inspection item Standard value Action

Insulation resistance of injector

(Between one side of terminal and upper body of

injector)

Resistance value between injector terminals 0.37-0.57 (at 20C {68F}) Replace

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Injector clamp mounting bolt 25 {255, 18}

Injection pipe 44 {449, 32}

10 M or more

(at room temperature)

Replace

Unit: Nm {kgfcm, lbfft}

Refer to this

document.

Page 49

STANDARD VALUE (J05E) 2–9

https://truckmanualshub.com/

COMMON RAIL

STANDARD VALUE, LIMIT AND ACTION

Inspection item

12

Resistance between terminals of common

rail pressure sensor

56 Replace

23

45 Replace

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Common rail mounting bolt 28.5 {291, 21}

Injection pipe 44 {449, 32}

Pressure

limiter side

Standard value

(At 20 C {68 F})

1.05-3.55 k

6.7-18.7 k

20 {204, 15}

EN01F02127010701003007

Action

Replace

Replace

Unit: Nm {kgfcm, lbfft}

Refer to this docu-

ment.

Return pipe No.1

Cluster connector side

Cylinder head

side

20 {204, 15}

13 {133, 10}

VEHICLE-SIDE FUEL FILTER

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Vehicle-side fuel filter mounting bolts 17.5 {178, 13}

FUEL COOLER

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Fuel cooler mounting bolts 25 {255, 18}

EN01F02127010701003008

Unit: Nm {kgfcm, lbfft}

EN01F02127010701003009

Unit: Nm {kgfcm, lbfft}

Page 50

STANDARD VALUE (J05E)2–10

https://truckmanualshub.com/

EMISSION CONTROL

EGR VALVE & COOLER

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

EGR cooler mounting bolt 68.5 {699, 51}

Bracket mounting bolt 28.5 {291, 21}

EGR pipe mounting bolt 55 {561, 41}

Bracket mounting bolt and nut 28.5 {291, 21}

CLOSED VENTILATOR

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Closed ventilator mounting bolt 31 {316, 23}

Ventilator hose A mounting bolt 31 {316, 23}

EN01F02127010701004001

Unit: Nm {kgfcm, lbfft}

EN01F02127010701004002

Unit: Nm {kgfcm, lbfft}

Page 51

STANDARD VALUE (J05E) 2–11

https://truckmanualshub.com/

INTAKE

INTAKE MANIFOLD

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Intake manifold mounting bolt and nut 28.5 {291, 21}

DIESEL THROTTLE

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Diesel throttle mounting bolt and nut 28.5 {291, 21}

INTAKE PIPE (EXHAUST SIDE)

TIGHTENING TORQUE

EN01F02127010701005001

Unit: Nm {kgfcm, lbfft}

EN01F02127010701005002

Unit: Nm {kgfcm lbfft}

EN01F02127010701005003

Unit: Nm {kgfcm lbfft}

Tightening part Tightening torque Remarks

6.25 {64, 4.6} Turbocharger side

Primary intake pipe mounting clamp

2.4-5.0 {25-50, 1.8-3.6} Air cleaner side

Secondary intake pipe mounting bolt 28.5 {291, 21}

STACK DUCT

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Duct to bracket mounting bolt 19.5 {199, 14}

Duct to cab mounting bolt 19.5 {199, 14}

Stack duct mounting clamp 2.4-5.0 {25-50, 1.8-3.6}

Stack duct mounting nut 13 {133, 10}

EN01F02127010701005004

Unit: Nm {kgfcm lbfft}

Page 52

STANDARD VALUE (J05E)2–12

https://truckmanualshub.com/

AIR CLEANER

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Air cleaner housing mounting nut 19.5 {199, 14}

Intake hose clamp 2.4-5.0 {25-50, 1.8-3.6}

INTAKE TEMPERATURE SENSOR

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Intake temperature sensor 19.6 {200, 14}

BOOST PRESSURE SENSOR

TIGHTENING TORQUE

EN01F02127010701005005

Unit: Nm {kgfcm, lbfft}

EN01F02127010701005006

Unit: Nm {kgfcm, lbfft}

EN01F02127010701005007

Unit: Nm {kgfcm, lbfft}

Tightening part Tightening torque Remarks

Boost pressure sensor mounting bolt 5 {51, 3.7}

AIR FLOW SENSOR

TIGHTENING TORQUE

Tightening part Tightening torque Remarks

Air flow sensor mounting screw 0.56-0.82 {5.8-8.3, 0.42-0.60}

EN01F02127010701005008

Unit: Nm {kgfcm, lbfft}

Page 53

STANDARD VALUE (J05E) 2–13

https://truckmanualshub.com/

ENGINE MECHANICAL

HEAD COVER

EN01F02127010701006001

TIGHTENING TORQUE

Unit: Nm {kgfcm, lbfft}

Tightening part Tightening torque Remarks

Head cover mounting bolt 28.5 {291, 21}

ROCKER ARM ASSEMBLY

EN01F02127010701006002

STANDARD VALUE, LIMIT AND ACTION

Unit: mm {in.}