Hino J08C-TP, J08C-TR Service Manual

Models |

1INDEX |

|

ENGINE 3-1-1 |

J08C-TP and J08C-TR |

|||

|

|

|

3-228E-05 |

3

CHAPTER 3

ENGINE

Models: J08C-TP and J08C-TR

TROUBLESHOOTING ............................................................... |

3- 1-3 |

SPECIAL TOOLS ...................................................................... |

3- 2-1 |

ENGINE OVERHAUL CRITERIA .............................................. |

3- 3-1 |

DISMOUNTING THE ENGINE ASSEMBLY .............................. |

3- 4-1 |

REMOVAL OF THE ENGINE COMPONENT PARTS ............... |

3- 5-1 |

CAMSHAFT HOUSING AND CYLINDER HEAD ...................... |

3- 6-1 |

CRANKSHAFT FRONT END, OIL PAN, FLYWHEEL AND |

|

FLYWHEEL HOUSING .............................................................. |

3- 7-1 |

TIMING GEAR ........................................................................... |

3- 8-1 |

PISTON, CRANKSHAFT AND CYLINDER BLOCK ................. |

3- 9-1 |

LUBRICATING SYSTEM ........................................................... |

3- 10-1 |

COOLING SYSTEM ................................................................... |

3- 11-1 |

FUEL SYSTEM .......................................................................... |

3- 12-1 |

AIR INTAKE AND EXHAUST SYSTEM .................................... |

3- 13-1 |

ENGINE CONTROL SYSTEM ................................................... |

3- 14-1 |

ELECTRICAL PARTS ................................................................ |

3- 15-1 |

AIR COMPRESSOR AND POWER STEERING PUMP ............ |

3- 16-1 |

INSTALLATION OF THE ENGINE COMPONENT PARTS ....... |

3- 17-1 |

ENGINE TUNE-UP .................................................................... |

3- 18-1 |

MOUNTING THE ENGINE ASSEMBLY .................................... |

3- 19-1 |

LIQUID GASKET AND APPLICATION POINTS ....................... |

3- 20-1 |

POWER TAKE-OFF (IF FITTED) .............................................. |

3- 21-1 |

|

|

|

|

3-1-2 ENGINE |

Models |

1 page 1 |

|

J08C-TP and J08C-TR |

|||

TROUBLESHOOTING (ENGINE)

Symptom |

|

|

Possible cause |

Remedy/Prevention |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine overheating |

|

|

Coolant |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

|

Insufficient coolant ........................................ |

Add coolant |

|||||||

` |

|

● |

|

Defective thermostat ..................................... |

Replace the thermostat |

|||||||

|

|

● Overflow of coolant due to leakage of .......... |

Repair |

|||||||||

|

|

|

|

exhaust into cooling system |

|

|

|

|||||

|

|

● |

|

Damaged rubber hose .................................. |

Replace rubber hose |

|||||||

|

|

● Coolant leakage due to deteriorated ............. |

Replace rubber hose |

|||||||||

|

|

|

|

rubber hose |

|

|

|

|||||

|

|

● Coolant leakage from coolant pump ............. |

Replace the coolant pump |

|||||||||

|

|

● Coolant leakage from rubber hose ............... |

Retighten or replace clamp |

|||||||||

|

|

|

|

connection |

|

|

|

|||||

|

|

● Coolant leakage from cylinder head ............. |

Replace gasket |

|||||||||

|

|

|

|

gasket |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

Coolant pump |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||

|

|

● |

|

Bearing seizure ............................................. |

Replace |

|||||||

|

|

● |

|

Damaged (corroded) vane ............................ |

Replace vane |

|||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

Radiator |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|||||

|

|

● Clogged with rust and scale .......................... |

Clean radiator |

|||||||||

|

|

● Clogged with iron oxide due to leakage ........ |

Clean coolant passage and |

|||||||||

|

|

|

|

of exhaust into cooling system |

correct exhaust leakage |

|||||||

|

|

● |

|

Coolant leakage ............................................ |

Repair or replace radiator |

|||||||

|

|

● |

|

Damaged cooling fan .................................... |

Replace cooling fan |

|||||||

|

|

● Clogged radiator core due to mud or ............ |

Clean radiator |

|||||||||

|

|

|

|

other debris |

|

|

|

|||||

|

|

● Defective radiator cap pressure valve .......... |

Replace radiator cap |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

Abnormal combustion |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||

|

|

● |

|

Incorrect injection timing ............................... |

Adjust injection timing |

|||||||

|

|

● |

|

Reduced injection pressure .......................... |

Adjust injection pressure |

|||||||

|

|

● |

|

Poor fuel........................................................ |

Use good quality fuel |

|||||||

|

|

● |

|

Poor nozzle spray ......................................... |

Adjust or replace nozzle |

|||||||

|

|

● |

|

Unsatisfactory automatic timer...................... |

Repair or replace timer |

|||||||

|

|

|

|

advance angle |

|

|

|

|||||

1 page 1 |

|

Models J08C-TP and J08C-TR |

ENGINE 3-1-3 |

Symptom |

Possible cause |

Remedy/Prevention |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Engine overheating |

|

|

Other problems |

|

|

|

|

||||

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|||||

|

|

|

● |

Defective or deteriorated engine oil .............. |

Change engine oil |

||||||

|

|

|

● |

Unsatisfactory operation of oil pump ............ |

Replace or repair |

||||||

|

|

|

● |

Insufficient oil ................................................ |

Add oil |

||||||

|

|

|

● |

Brake drag .................................................... |

Adjust |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Severe operating conditions |

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||

|

|

|

● |

Lugging the engine ....................................... |

Operate engine properly |

||||||

Excessive oil consumption |

|

|

Pistons, cylinder liners and piston rings |

|

|

||

|

|

|

|||||

|

|

|

|

|

|

||

|

|

● |

Wear of piston rings and cylinder liner .......... |

Replace piston rings and |

|||

|

|

|

|

|

|

|

cylinder liner |

|

|

● |

Worn, sticking or broken piston rings ............ |

Replace piston rings and |

|||

|

|

|

|

|

|

|

cylinder liner |

|

|

● |

Insufficient tension on piston rings ................ |

Replace piston rings and |

|||

|

|

|

|

|

|

|

cylinder liner |

|

|

● |

Unsatisfactory break-in of piston rings .......... |

Replace piston rings and |

|||

|

|

|

|

|

|

|

cylinder liner |

|

|

● |

Unsuitable oil (viscosity too low) ................... |

Change oil as required and |

|||

|

|

|

|

|

|

|

replace piston rings and |

|

|

|

|

|

|

|

cylinder liner |

|

|

● |

Incorrectly fitted piston rings (upside down) .. |

Replace piston rings |

|||

|

|

● |

Gaps of piston rings in line with each other .. |

Reassemble piston rings |

|||

|

|

|

|

|

|

|

|

|

|

|

Valves and valve guides |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

● |

Worn valve stem ........................................... |

Replace valve and valve guide |

|||

|

|

● |

Worn valve guide .......................................... |

Replace valve guide |

|||

|

|

● |

Incorrectly fitted valve stem seal ................... |

Replace the stem seal |

|||

|

|

● |

Excessive lubricant on rocker arm ................ |

Check clearance of rocker arm |

|||

|

|

|

|

|

|

|

and shaft |

|

|

|

|

|

|

|

|

|

|

|

Excess oil feed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

Defective oil level gauge ............................... |

Replace oil level gauge |

|||

|

|

● |

Oil level too high ........................................... |

Drain excess oil |

|||

|

|

|

|

3-1-4 ENGINE |

Models |

1 page 1 |

|

J08C-TP and J08C-TR |

|||

Symptom |

|

|

Possible cause |

|

Remedy/Prevention |

|||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

Excessive oil consumption |

|

|

Oil leakage from miscellaneous parts |

|

|

|

|

|||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

||||

|

|

|

● Oil leakage from oil seal................................ |

Replace oil seal |

||||||

|

|

|

● Cracks or blowhole in cylinder block ............. |

Replace cylinder block |

||||||

|

|

|

● Oil leakage from connections of oil lines ...... |

Tighten connections of oil lines |

||||||

|

|

|

● Oil leakage from oil cooler ............................ |

Replace oil cooler |

||||||

|

|

|

● Oil leakage from oil pan gasket .................... |

Replace oil pan gasket |

||||||

|

|

|

● Oil leakage from O-ring ................................. |

Replace O-ring |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other problems |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

|

Overcooled engine ........................................ |

Warm up engine before moving |

||||

|

|

|

|

|

(low temperature wear) |

vehicle |

||||

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

Check cooling system |

||

NOTE: If oil consumption is excessive, the problems above will occur. Complaints from the customer are often related to such problems.

1.White smoke is emitted continuously when the engine is run at high speed.

2.White smoke is emitted only immediately after the engine speed is abruptly raised when idling.

3.The tail pipe is blackened with oil.

4.Oil leaks from the flanges of the exhaust manifold.

5.Lack of power.

6.Excessive blow-by gas.

Piston seizure |

|

|

Pistons, cylinder liners and piston rings |

|

|

|

|

||

|

|

|

|

|

|

|

● Incorrect clearance between piston .............. |

Replace piston, piston rings |

|

|

|

|

and cylinder liner |

and cylinder liner |

|

|

● Unsatisfactory installation of piston pin ......... |

Replace piston, piston rings, |

|

|

|

|

|

cylinder liner and piston pin as |

|

|

|

|

required |

|

|

● |

Broken piston ring ......................................... |

Replace piston, piston rings |

|

|

|

|

and cylinder liner |

|

|

● Difference in expansion due to use of ........... |

Replace piston, piston rings |

|

|

|

|

wrong piston |

and cylinder liner |

|

|

|

||

1 page 1 |

|

Models J08C-TP and J08C-TR |

ENGINE 3-1-5 |

Symptom |

|

Possible cause |

Remedy/Prevention |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Piston seizure |

|

|

Coolant |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

|

Reduction in capacity of coolant pump ......... |

Replace the coolant pump |

|||||||

|

|

|

|

|

(due to vane corrosion) |

|

|

|

|||||

|

|

|

● |

|

Leakage of coolant........................................ |

Repair |

|||||||

|

|

|

● |

|

Insufficient coolant ........................................ |

Add coolant |

|||||||

|

|

|

● |

|

Dirty coolant .................................................. |

Clean and replace coolant |

|||||||

|

|

|

● |

|

Defective radiator .......................................... |

Repair or replace the radiator |

|||||||

|

|

|

|

|

(coolant leakage, clogging) |

|

|

|

|||||

|

|

|

● |

|

Defective rubber hose (leakage) ................... |

Replace rubber hose |

|||||||

|

|

|

● |

|

Defective thermostat ..................................... |

Replace the thermostat |

|||||||

|

|

|

● |

|

Leakage of exhaust into cooling system ....... |

Repair |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Operation |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

● |

|

Abrupt stoppage of engine after running ...... |

Operate engine properly |

|||||||

|

|

|

|

|

at high speed |

|

|

|

|||||

|

|

|

● |

|

Hill climbing using unsuitable gear ............... |

Select suitable gear |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Oil |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||||||

|

|

|

● |

|

Insufficient oil ................................................ |

Add oil |

|||||||

|

|

|

● |

|

Dirty oil .......................................................... |

Change oil |

|||||||

|

|

|

● |

|

Poor quality oil .............................................. |

Replace with proper engine oil |

|||||||

|

|

|

● |

|

High oil temperature...................................... |

Repair |

|||||||

|

|

|

● |

|

Low oil pressure ............................................ |

Repair |

|||||||

|

|

|

● |

|

Defective oil pump ........................................ |

Repair oil pump |

|||||||

|

|

|

● |

|

Reduced performance due to worn .............. |

Replace oil pump |

|||||||

|

|

|

|

|

oil pump |

|

|

|

|||||

|

|

|

● |

|

Suction strainer sucking air ........................... |

Add oil and/or repair strainer |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Abnormal combustion |

|

|

|

|

||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

● |

|

Use of defective fuel ..................................... |

Change fuel |

|||||||

|

|

|

● |

|

Incorrect injection timing ............................... |

Adjust injection timing |

|||||||

|

|

|

● |

|

Engine overheating ....................................... |

See Symptom: “Engine |

|||||||

|

|

|

|

|

|

|

|

|

|

|

overheating” |

||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

3-1-6 ENGINE |

Models |

1 page 1 |

|

J08C-TP and J08C-TR |

|||

NOTE: If piston seizure occurs, the problems above will occur. Complaints from the customer are often related to these problems.

1.White smoke is emitted.

2.Lack of power

3.Excessive blow-by gas

Symptom |

|

Possible cause |

Remedy/Prevention |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lack of power |

|

|

|

Injection pump |

|

|

Refer to “FUEL INJECTION |

|||||

|

|

............................................ |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

PUMP” |

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Intake |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

|

Clogged air cleaner ....................................... |

Clean element or replace |

||||||

|

|

|

|

|

|

|

|

|

|

element |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overheating |

|

|

|

See Symptom: “Engine |

|||

|

|

|

|

............................................... |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

overheating” |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel and nozzle |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||||

|

|

|

● |

|

Poor nozzle spray ......................................... |

Adjust or replace injection |

||||||

|

|

|

|

|

|

|

|

|

|

nozzle |

||

|

|

|

● Nozzle clogged with carbon .......................... |

Clean nozzle |

||||||||

|

|

|

● Wear or seizure of nozzle ............................. |

Replace nozzle |

||||||||

|

|

|

● Air in fuel system........................................... |

Repair and bleed air from fuel |

||||||||

|

|

|

|

|

|

|

|

|

|

system |

||

|

|

|

● |

|

Clogged fuel filter .......................................... |

Replace element |

||||||

|

|

|

● Use of poor fuel............................................. |

Use good quality fuel |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pistons, cylinder liners and piston rings |

|

|

|

||||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● Seized or wear of piston ............................... |

Replace the piston, piston rings |

||||||||

|

|

|

|

|

|

|

|

|

|

and liner |

||

|

|

|

● Worn or broken piston rings, ......................... Replace piston rings, piston |

|||||||||

|

|

|

|

|

piston and cylinder liner |

and liner |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

1 page 1 |

|

Models J08C-TP and J08C-TR |

ENGINE 3-1-7 |

Symptom |

|

|

Possible cause |

|

Remedy/Prevention |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Lack of power |

|

|

|

|

Other problems |

|

|

|

|

|||||

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

● Exhaust brake butterfly valve stuck............... |

Replace or repair exhaust |

||||||||

|

|

|

|

|

|

|

in half-open position |

brake |

||||||

|

|

|

|

|

● |

Connecting rod bent ...................................... |

Replace or repair connecting |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

rod |

||

|

|

|

|

|

● Exhaust pipe or muffler crushed ................... |

Replace exhaust pipe or |

||||||||

|

|

|

|

|

|

(increased back-pressure) |

muffler |

|||||||

|

|

|

|

|

● Breakage of turbine or blower ....................... |

Refer to TURBOCHARGER in |

||||||||

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

CHAPTER 51 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

Leakage of exhaust |

|

|

Head gasket |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

● |

Fatigued gasket (aging) ................................ |

Replace gasket |

|||||||

|

|

|

|

|

● |

Damage......................................................... |

Replace gasket |

|||||||

|

|

|

|

|

● |

Improper installation ...................................... |

Replace gasket |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Head bolts |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

● |

Loose bolts .................................................... |

Tighten bolts |

|||||||

|

|

|

|

|

● |

Elongated bolts ............................................. |

Replace bolts |

|||||||

|

|

|

|

|

● Improper tightening torque or ........................ |

Tighten properly |

||||||||

|

|

|

|

|

|

|

tightening sequence |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cylinder block |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

● |

Cracking ........................................................ |

Replace cylinder block |

|||||||

|

|

|

|

|

● |

Surface distortion .......................................... |

Repair or replace |

|||||||

|

|

|

|

|

● Fretting of cylinder liner insertion portion ...... |

Replace cylinder block |

||||||||

|

|

|

|

|

|

(insufficient projection of cylinder liner) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cylinder head |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

● |

Cracking ........................................................ |

Replace cylinder head |

|||||||

|

|

|

|

|

● |

Surface distortion .......................................... |

Repair or replace |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Cylinder liners |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

● |

Cracking ........................................................ |

Replace cylinder liner |

|||||||

|

|

|

|

|

● |

Corrosion....................................................... |

Replace cylinder liner |

|||||||

|

|

|

|

|

● Insufficient projection of cylinder liner ........... |

Replace cylinder liner |

||||||||

|

|

|

|

3-1-8 ENGINE |

Models |

1 page 1 |

|

J08C-TP and J08C-TR |

|||

Symptom |

|

|

Possible cause |

Remedy/Prevention |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Leakage of exhaust |

|

|

Other problems |

|

|

|

|

|||

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|||

|

|

|

● |

|

Incorrect injection timing ............................... |

Adjust injection timing |

||||

NOTE: If leakage of the exhaust occurs, the problems above will occur. Complaints from the customer are often related to these problems.

1.Lack of power.

2.The engine overheats.

3.The coolant is discolored.

Difficulty starting engine |

|

|

Electrical system |

|

|

|||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

● |

Discharged battery ........................................ |

Charge battery |

||||

|

|

● Defective wiring in starter-circuit ................... |

Repair wiring of starter |

|||||

|

|

● Loose or open-circuit battery cable ............... |

Tighten battery terminal |

|||||

|

|

|

|

|

|

|

|

connections or replace battery |

|

|

|

|

|

|

|

|

cable |

|

|

● |

Breakdown of starter ..................................... |

Replace starter |

||||

|

|

● |

Broken glow plug .......................................... |

Replace |

||||

|

|

|

|

|

|

|

||

|

|

|

Injection pump |

............................................. |

Refer to “FUEL INJECTION |

|||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

PUMP” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Air cleaner |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

● |

Clogged element ........................................... |

Clean the element or replace |

||||

|

|

|

|

|

|

|

|

the element |

|

|

|

|

|

|

|

|

|

|

|

|

Fuel system |

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

● No fuel in tank ............................................... |

Supply fuel |

|||||

|

|

● |

Clogged fuel line ........................................... |

Clean fuel line |

||||

|

|

● Air sucked into fuel system through .............. |

Tighten fuel line connections |

|||||

|

|

|

fuel line connections |

|

||||

|

|

● |

Clogged fuel filter .......................................... |

Replace element |

||||

|

|

● Loose connection in high-pressure line ........ |

Tighten sleeve nut of high |

|||||

|

|

|

|

|

|

|

|

pressure line |

|

|

● |

Water in fuel .................................................. |

Drain and clean fuel system |

||||

|

|

|

|

|

|

|

|

|

1 page 1 |

|

Models J08C-TP and J08C-TR |

ENGINE 3-1-9 |

Symptom |

Possible cause |

Remedy/Prevention |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Difficulty starting engine |

|

|

Nozzles |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

● |

Seized nozzle................................................ |

Replace nozzle |

|||||||

|

|

|

|

● Broken or fatigued nozzle spring .................. |

Replace spring |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oil system |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● Oil viscosity too high ..................................... |

Use proper viscosity oil, or |

||||||||

|

|

|

|

|

|

|

|

|

|

|

install an oil immersion heater |

||

|

|

|

|

|

|

|

|

|

|

|

and warm up oil |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other problems |

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

Seized piston ................................................ |

Replace piston, piston rings, |

|||||||

|

|

|

|

|

|

|

|

|

|

|

and liner |

||

|

|

|

|

● |

Seized bearing .............................................. |

Replace bearing and crankshaft |

|||||||

|

|

|

|

● |

Reduced compression pressure ................... |

Overhaul engine |

|||||||

|

|

|

|

● Ring gear damaged or worn ......................... |

Replace the ring gear and/or |

||||||||

|

|

|

|

|

accelerator cable |

starter pinion |

|||||||

|

|

|

|

● Improperly adjusted or broken ...................... |

Adjust or replace the |

||||||||

|

|

|

|

|

|

|

|

|

|

|

accelerator cable |

||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

||||||||

Rough idling |

|

|

|

Injection pump |

............................................ |

Refer to “FUEL INJECTION |

|||||||

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

PUMP” |

||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Nozzles |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

● |

Uneven injection pressure ............................ |

Adjust |

|||||||

|

|

|

|

● |

Poor nozzle spray ......................................... |

Adjust or replace nozzle |

|||||||

|

|

|

|

● Carbon deposit on nozzle tip ........................ |

Remove carbon |

||||||||

|

|

|

|

● |

Seized needle valve ...................................... |

Replace nozzle |

|||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

Engine proper |

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

● |

Improper valve clearance ............................. |

Adjust valve clearance |

|||||||

|

|

|

|

● Improper contact of valve seat ...................... |

Replace or repair valve and |

||||||||

|

|

|

|

|

|

|

|

|

|

|

valve seat |

||

|

|

|

|

● Idling speed too low ...................................... |

Adjust idling speed |

||||||||

|

|

|

|

● Coolant temperature too low ......................... |

Warm up engine |

||||||||

|

|

|

|

● Compression pressure of cylinders............... |

Overhaul engine |

||||||||

|

|

|

|

|

markedly different from one another |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-1-10 ENGINE |

Models |

1 page 1 |

|

J08C-TP and J08C-TR |

|||

Symptom |

|

Possible cause |

Remedy/Prevention |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Rough idling |

|

|

|

|

Other problems |

|

|

|||||

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

● Clogged high pressure injection line ............. |

Replace line |

|||||||

|

|

|

|

● Leakage due to improper tightening ............. |

Tighten sleeve nut |

|||||||

|

|

|

|

|

of high pressure injection line |

|

||||||

|

|

|

|

● Improperly adjusted or broken ...................... |

Adjust or replace accelerator |

|||||||

|

|

|

|

|

accelerator cable |

cable |

||||||

|

|

|

|

● |

Engine seizure .............................................. |

Replace pistons, piston rings |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

and liners |

|

|

|

|

● |

Incorrect valve timing .................................... |

Replace camshaft |

||||||

Diesel knock |

|

|

|

|

|

|

|

|

|

|

Refer to “FUEL INJECTION |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

Injection pump............................................... |

|

|

|||||||

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

PUMP” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nozzles |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

Incorrect injection pressure ........................... |

Adjust |

||||||

|

|

|

|

● |

Poor nozzle spray ......................................... |

Adjust or replace nozzle |

||||||

|

|

|

|

● |

Sticking of nozzle .......................................... |

Check and/or replace |

||||||

|

|

|

|

● Fatigued or broken nozzle spring ................. |

Replace spring |

|||||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Fuel system |

|

|

|

||||

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

● Use of poor fuel............................................. |

Use good quality fuel |

|||||||

|

|

|

|

● Fuel leakage into combustion chamber ........ |

Adjust nozzles |

|||||||

|

|

|

|

|

(during engine starting) |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other problems |

|

|

|||||

|

|

|

|

|

|

|

||||||

|

|

|

|

● Excessively cooled or heated engine ........... |

Warm up or cool engine |

|||||||

|

|

|

|

● |

Insufficient air intake ..................................... |

Correct |

||||||

|

|

|

|

● |

Insufficient compression pressure ................ |

Repair |

||||||

|

|

|

|

● Compression pressure leaks at .................... |

Replace head gasket |

|||||||

|

|

|

|

|

cylinder head gasket |

|

||||||

|

|

|

|

● Improper valve clearance or valve sticking ... |

Adjust or repair |

|||||||

|

|

|

|

● |

Tappet sticking .............................................. |

Replace tappet and camshaft |

||||||

1 page 1 |

|

Models J08C-TP and J08C-TR |

ENGINE 3-1-11 |

Symptom |

|

Possible cause |

Remedy/Prevention |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Unusual engine noise |

|

|

|

Piston |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

● |

|

Wear of piston pin boss or piston pin ............ |

Replace piston and/or piston |

||||||

|

|

|

|

|

|

|

|

|

|

|

pin |

||

|

|

|

|

● |

|

Seized, damaged, or worn piston pin ........... |

Replace piston pin bushing. |

||||||

|

|

|

|

|

|

bushing |

|

|

|

||||

|

|

|

|

● |

|

Worn pistons or cylinder liners ...................... |

Replace piston or cylinder liner |

||||||

|

|

|

|

● |

|

Damaged or seized piston ............................ |

Replace piston and cylinder |

||||||

|

|

|

|

|

|

|

|

|

|

|

liner |

||

|

|

|

|

● |

|

Foreign matter on top surface of the piston .. |

Remove foreign matter and |

||||||

|

|

|

|

|

|

|

|

|

|

|

repair or replace piston, cylinder |

||

|

|

|

|

|

|

|

|

|

|

|

liner, and/or cylinder head |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Valve mechanism |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

● |

|

Incorrect valve clearance .............................. |

Adjust valve clearance |

||||||

|

|

|

|

● |

|

Valve cotter out of place ................................ |

Replace valve cotter |

||||||

|

|

|

|

● |

|

Seized valve stem ......................................... |

Replace valve and valve guide |

||||||

|

|

|

|

● |

|

Broken valve ................................................. |

Replace valve |

||||||

|

|

|

|

● |

|

Damaged rocker arm support ....................... |

Replace rocker arm support |

||||||

|

|

|

|

● |

|

Broken valve spring ...................................... |

Replace valve spring |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Bearings seizure |

|

|

|

|

|||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

● |

|

Insufficient lubricating oil ............................... |

Add oil |

||||||

|

|

|

|

● |

|

Excessive or insufficient tightening of ........... |

Retighten to specified torque |

||||||

|

|

|

|

|

|

bearing housings |

|

|

|

||||

|

|

|

|

● |

|

Pits and scratches on bearing surface .......... |

Replace bearing and crankshaft |

||||||

|

|

|

|

● |

|

Oil film formed on back of bearing ................ |

Replace bearing |

||||||

|

|

|

|

● |

|

Improper installation of bearing .................... |

Replace bearing |

||||||

|

|

|

|

● |

|

Reduction of spread dimension of bearing ... |

Replace bearing |

||||||

|

|

|

|

● |

|

Distorted bearing housing ............................. |

Replace or correct bearing |

||||||

|

|

|

|

|

|

|

|

|

|

|

housing |

||

|

|

|

|

● |

|

Excessive oil clearance................................. |

Replace bearing |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-1-12 ENGINE |

Models |

1 page 1 |

|

J08C-TP and J08C-TR |

|||

Symptom |

|

Possible cause |

Remedy/Prevention |

|||||

|

|

|

|

|

|

|

|

|

Unusual engine noise |

|

|

|

Various other parts |

|

|

||

|

|

|

|

|||||

|

|

● Exhaust gas leakage from exhaust ............... |

Retighten joints |

|||||

|

|

|

|

pipe joints |

|

|||

|

|

● Loosen or missing intake manifold ............... |

Retighten or replace |

|||||

|

|

|

|

flange gasket |

|

|||

|

|

● Intake valve seating is not concentric ........... |

Replace or correct the valve |

|||||

|

|

|

|

|

|

|

|

and valve seat |

|

|

● |

|

Intake gas leakage ........................................ |

Retighten |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Other problems |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

● Loose cooling fan mounting bolts or ............. |

Tighten the fan and |

|||||

|

|

|

|

fan pulley nut |

crankshaft pulley |

|||

|

|

● Lack of lubricating oil .................................... |

Lubricate |

|||||

|

|

|

|

(coolant pump, valves, etc.) |

|

|||

|

|

● |

|

Worn timing gear ........................................... |

Replace the timing gear |

|||

|

|

● Breakage of turbine or blower ....................... |

Refer to TURBOCHARGER in |

|||||

|

|

|

|

|

|

|

|

CHAPTER 51 |

NOTE: The items on this page concern unusual engine noise which is due to causes other than those given for diesel knock.

1 page 1 |

|

Models J08C-TP and J08C-TR |

ENGINE 3-1-13 |

(FUEL INJECTION PUMP)

Symptom |

|

Possible cause |

Remedy |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Engine does not start |

|

|

|

Fuel not reaching injection pump |

|

|

|||||

|

|

|

|

|

|||||||

|

|

● Fuel lines clogged or damaged ..................... |

Clean or replace fuel lines |

||||||||

|

|

● |

|

Fuel filter clogged ......................................... |

Clean or replace the filter |

||||||

|

|

|

|

|

|

|

|

|

|

|

element |

|

|

● Air in fuel caused by improper ...................... |

Repair connections |

||||||||

|

|

|

|

|

connections of fuel line between |

|

|||||

|

|

|

|

|

fuel tank and feed pump |

|

|||||

|

|

● Filter incorporated in inlet side ...................... |

Remove foreign material |

||||||||

|

|

|

|

|

of feed pump clogged |

|

|||||

|

|

● Faulty feed pump check valve ...................... |

Repair or replace it |

||||||||

|

|

● Feed pump piston spring broken .................. |

Replace it |

||||||||

|

|

● Feed pump push rod or tappet sticking ........ |

Repair or replace it |

||||||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Fuel reaching injection pump |

|

|

||||

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||

|

|

● Faulty connection of accelerator cable ......... |

Repair connection |

||||||||

|

|

|

|

|

to pump adjusting lever |

|

|||||

|

|

● Control rack faulty or sticking ........................ |

Repair it |

||||||||

|

|

● |

|

Damaged camshaft bearing .......................... |

Repair it |

||||||

|

|

● Plunger worn or sticking................................ |

Correct or replace it |

||||||||

|

|

● Faulty connection of engine .......................... |

Repair it |

||||||||

|

|

|

|

|

stop cable to pump stop lever |

|

|||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Nozzle faulty |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● Fuel leakage caused by loosened ................ |

Inspect and tighten it |

||||||||

|

|

|

|

|

nozzle holder |

|

|||||

|

|

● Low opening pressure of nozzle ................... |

Adjust it |

||||||||

|

|

● Nozzle pressure spring broken ..................... |

Replace it |

||||||||

|

|

● Nozzle needle sticking to nozzle body .......... |

Correct or replace it |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pump out of timing |

|

|

|

|

||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● Improperly retarded injection timing .............. |

Correct injection timing |

||||||||

|

|

● Incorrect timing caused by improper ............. |

Check engine timing and |

||||||||

|

|

|

|

|

installation of pump |

correct it |

|||||

|

|

● Woodruff key for pump camshaft cut off. ...... |

Replace it |

||||||||

|

|

● |

|

Improper pre-stroke adjustment .................... |

Correct it to obtain specified |

||||||

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

injection timing |

|

|

|

|

3-1-14 ENGINE |

Models |

1 page 1 |

|

J08C-TP and J08C-TR |

|||

Symptom |

|

|

Possible cause |

|

Remedy |

||||||

Engine starts and stops |

|

|

|

Fuel lines clogged ......................................... |

Clean or replace fuel lines |

||||||

|

|

||||||||||

|

|

|

|

|

|

Air in fuel caused by damaged |

Repair fuel lines or replace fuel |

||||

|

|

|

|

|

|||||||

|

|

|

|

|

|

fuel lines or improper connection of |

lines and gaskets |

||||

|

|

|

|

|

|

fuel lines |

|

||||

|

|

|

|

|

|

|

|

|

|

||

Engine has low power |

|

|

|

Pump out of timing |

|

|

|||||

|

|

|

|

|

|||||||

|

|

|

● |

|

|

Excessive advanced timing........................... |

Check and correct it |

||||

|

|

|

|

|

|

resulting in loud knocking |

|

||||

|

|

|

● |

|

|

Excessively retarded timing .......................... |

Check and correct it |

||||

|

|

|

|

|

|

resulting in black smoke |

|

||||

|

|

|

● Defective injection pump overflow valve ....... |

Repair or replace it |

|||||||

|

|

|

● Feed pressure too low .................................. |

Repair the feed pump |

|||||||

|

|

|

● Improper accelerator cable adjustment ........ |

Adjust it |

|||||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Nozzle faulty |

|

|

|||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|||||

|

|

|

● Fuel leakage from nozzle holder ................... |

Check and repair nozzle holder |

|||||||

|

|

|

● Bad nozzle spray characteristic .................... |

Repair or replace it |

|||||||

|

|

|

● Loosened adjusting screw in nozzle ............. |

Adjust it |

|||||||

|

|

|

|

|

|

holder, resulting in low opening pressure |

|

||||

|

|

|

● Nozzle pressure spring broken ..................... |

Replace it |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pump faulty |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● Fuel leakage from delivery valve .................. |

Retighten the delivery valve |

|||||||

|

|

|

|

|

|

holder |

holder if it is loosened or replace |

||||

|

|

|

|

|

|

|

|

|

|

|

O-ring if the O-ring is defective |

|

|

|

● Defective seat of delivery valve assembly .... |

Repair or replace it |

|||||||

|

|

|

● Delivery valve spring broken ......................... |

Replace the spring |

|||||||

|

|

|

● |

|

|

Plunger worn ................................................. |

Replace it |

||||

|

|

|

● Large spread in fuel delivery ......................... |

Adjust it |

|||||||

|

|

|

● Wear of tappet roller ..................................... |

Replace the roller |

|||||||

|

|

|

● Camshaft bearing worn or broken................. |

Replace it |

|||||||

|

|

|

● Improper adjustment of governor .................. |

Adjust it |

|||||||

|

|

|

|

|

|

full load stopper screw |

|

||||

1 page 1 |

|

Models J08C-TP and J08C-TR |

ENGINE 3-1-15 |

Symptom |

|

Possible cause |

Remedy |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Excessive smoke |

|

|

|

Black smoke |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

● Excessive fuel delivery caused by ................ |

Adjust fuel delivery on test stand |

||||||

|

|

|

|

|

|

|

|

incorrect adjustment of full load |

|

|

|

||

|

|

|

|

|

|

|

|

stopper screw |

|

|

|

||

|

|

|

|

|

|

● Excessively advanced injection timing. ......... |

Correct it |

||||||

|

|

|

|

|

|

● Large spread in fuel delivery ......................... |

Adjust it |

||||||

|

|

|

|

|

|

● Bad nozzle fuel spray characteristics ........... |

Check and correct them |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

White smoke |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

● Unused after glow system............................. |

Use it |

||||||

|

|

|

|

|

|

● Improperly retarded injection timing .............. |

Advance injection timing |

||||||

|

|

|

|

|

|

● |

|

Water in fuel .................................................. |

Check and clean fuel lines |

||||

|

|

|

|

|

|

● Glow plug not operating ................................ |

Check glow plug circuit. Refer |

||||||

|

|

|

|

|

|

|

|

|

|

|

to ELECTRICAL EQUIPMENT |

||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

in CHAPTER 20 |

||

Low idle speed |

|

|

|

|

|

Improper adjustment of throttle control knob |

Correct it |

||||||

|

|

|

|

|

|||||||||

irregular |

|

|

Bad fuel spray characteristic of nozzles. ...... |

Check and repair them |

|||||||||

|

|

||||||||||||

|

|

|

|

|

|

|

|

Incorrect injection timing ............................... |

Correct it |

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

Incorrect initial tension setting of................... |

Adjust or replace it |

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

idling spring or the spring broken. |

|

|

|

||

|

|

|

|

|

|

|

|

Control rack does not move smoothly........... |

Disassemble pump and repair it |

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

Large spread in fuel delivery ......................... |

Adjust it |

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

Plunger worn ................................................. |

Replace it |

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

Governor linkage does not move smoothly... |

Correct it |

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

Defective feed pump ..................................... |

Disassemble and repair it |

||||

|

|

|

|

|

|

|

|

||||||

Engine always runs |

|

|

|

Accelerator cable sticking ............................. |

Check and correct it |

||||||||

|

|

|

|||||||||||

at high speed |

|

|

Governor linkage sticking ............................. |

Disassemble and repair the |

|||||||||

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

governor |

||

|

|

|

|

|

|

|

|

Control rack sticking...................................... |

Check and correct it |

||||

|

|

|

|

|

|

|

|

||||||

Loud knocking |

|

|

|

|

|

Improper injection timing ............................... |

Correct it |

||||||

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

Bad fuel nozzle spray pattern . ..................... |

Check and correct it |

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

after-dribble |

|

|

|

||

|

|

|

|

|

|

|

|

High nozzle opening pressure ...................... |

Adjust the opening pressure |

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

Incorrect fuel deliveries to ............................. |

Readjust the fuel deliveries |

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

some nozzles. |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|||

1 page 1

Models J08C-TP and J08C-TR |

ENGINE 3-2-1 |

SPECIAL TOOLS

Prior to starting an engine overhaul, it is necessary to have the following.

(1) Lifting parts

Shape |

Parts No. |

|

Parts name |

No./unit |

Application |

|

|

|

|

|

|

|

09491 - 1010 |

|

Wire cable |

1 |

Lifting engine |

SM3-J052 |

|

|

|

|

|

|

09433 - 1070 |

|

Eye bolt |

2 |

Lifting cylinder head |

SM3-J048 |

|

|

|

|

|

|

|

|

|

|

|

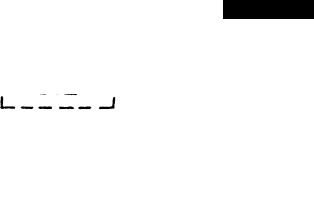

(2) Related parts of cylinder head |

|

|

|

||

|

|

|

|

|

|

Shape |

Parts No. |

|

Parts name |

No./unit |

Application |

|

|

|

|

|

|

|

09472 - 1210 |

|

Bar |

1 |

Caulking nozzle seat |

|

|

(Use together with 9800 - 06100) |

|||

|

|

|

|

|

|

SM3-J050 |

|

|

|

|

|

|

|

|

|

|

|

|

9800-06100 |

|

(Steel ball) |

1 |

Caulking nozzle seat |

|

|

(Use together with 09472-1210) |

|||

|

|

|

|

|

|

SM3-J054 |

|

|

|

|

|

|

09552-1090 |

|

Compression gauge |

1 |

Measuring compression |

|

|

adaptor |

(for size PF3/8) |

||

|

|

|

|

||

SM3-J021 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 page 1 |

|

|

|

3-2-2 ENGINE |

|

Models J08C-TP and J08C-TR |

|

|||

|

|

|

|

|

||

Shape |

Parts No. |

Parts name |

No./unit |

Application |

||

|

|

|

|

|

|

|

|

09552 - 1060 |

|

|

|

|

|

|

|

Press gauge adaptor |

1 |

Measuring compression |

||

|

09552 - 1030 |

|

|

|

|

|

SM3-J022 |

|

|

|

|

|

|

|

09472 - 2100 |

Bar |

1 |

Strike-fitting valve stem seal |

||

SM3-J055 |

|

|

|

|

|

|

|

|

|

|

|

||

|

09471 - 1520 |

Guide |

1 |

Strike-fitting valve guide |

||

SM3-J051 |

|

|

|

|

|

|

|

|

|

|

|

||

|

09420 - 1100 |

Sliding hammer |

1 |

Removing main idle gear shaft |

||

SM3-J131 |

|

|

|

|

|

|

|

09420 - 1442 |

|

|

|

|

Removing suband cam idle |

|

(Same as tool |

|

|

|

|

|

|

Sliding hammer |

1 |

gear shafts (Remove the |

|||

|

for pulling out |

|||||

|

|

|

|

|

adaptor from the top before use) |

|

|

injection nozzle) |

|

|

|

|

|

|

|

|

|

|

|

|

SM3-J132 |

|

|

|

|

|

|

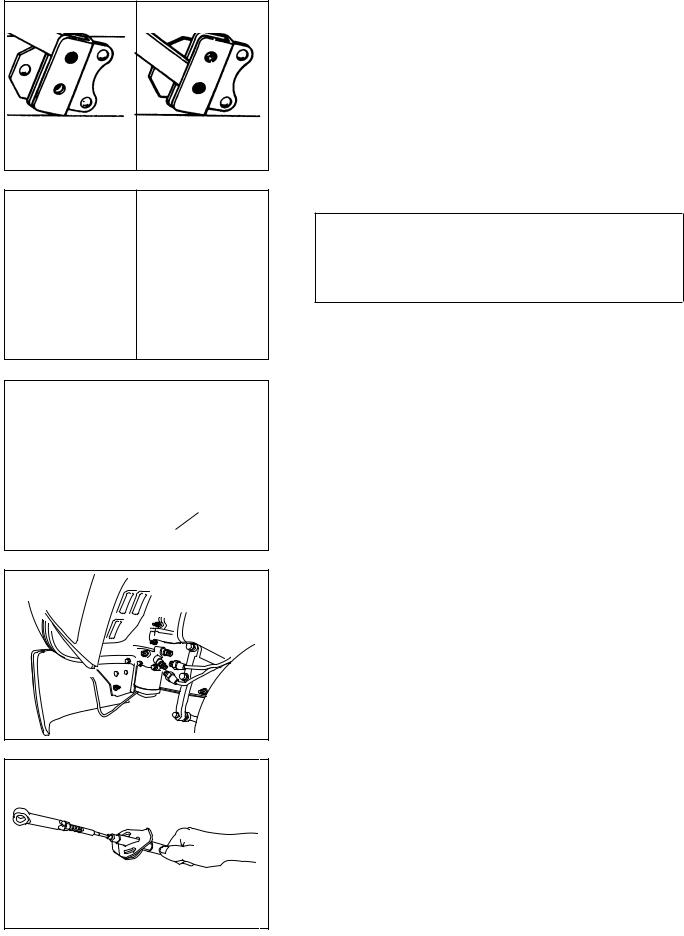

(3) Related parts of valve |

|

|

|

|

|

|

|

|

|

|

|

||

Shape |

Parts No. |

Parts name |

No./unit |

Application |

||

|

|

|

|

|

||

|

09431 - 1020 |

Valve wrapping tool |

1 |

Valve wrapping |

||

SM3-J053 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 page 1 |

|

|

|

|

|

|

|

|

|

Models J08C-TP and J08C-TR |

ENGINE 3-2-3 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shape |

|

Parts No. |

|

Parts name |

|

|

No./unit |

Application |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

09470 - 1170 |

|

Valve spring press |

|