Page 1

HINO 300 SERIES

Body Mounting Manual

TRUCK CHASSIS

TRUCK CHASSIS

XZU

XKU

(Hybrid vehicle)

&

MODEL

SERIES

KK-XZU215C

Page 2

KK-XZU215C

No part of this manual may be reproduced or transmitted in any form without the

express written permission of Hino Motors, Ltd.

© 2010, All rights reserved. Printed in Japan.

PRODUCT PLANNING DIVISION

3-1-1, HINO-DAI, HINO-SHI, TOKYO, 191-8660 JAPAN

Telephone : 042-586-5249

Facsimile : 042-586-5868

2010 - 02

Page 3

KK-XZU215C

We have published the new revised edition of Body Mounting Manual with

the following changes.

Consequently, please discard the current Body Mounting Manual

CD-ROM NO.KK-XZU215B, and use the new CD-ROM NO.KK-XZU215C

from now on.

CONTENTS OF CHANGES

The information about XKU417L-HKFQB3 (Hybrid vehicle) has been added.

RECORD OF CHANGES

Page 4

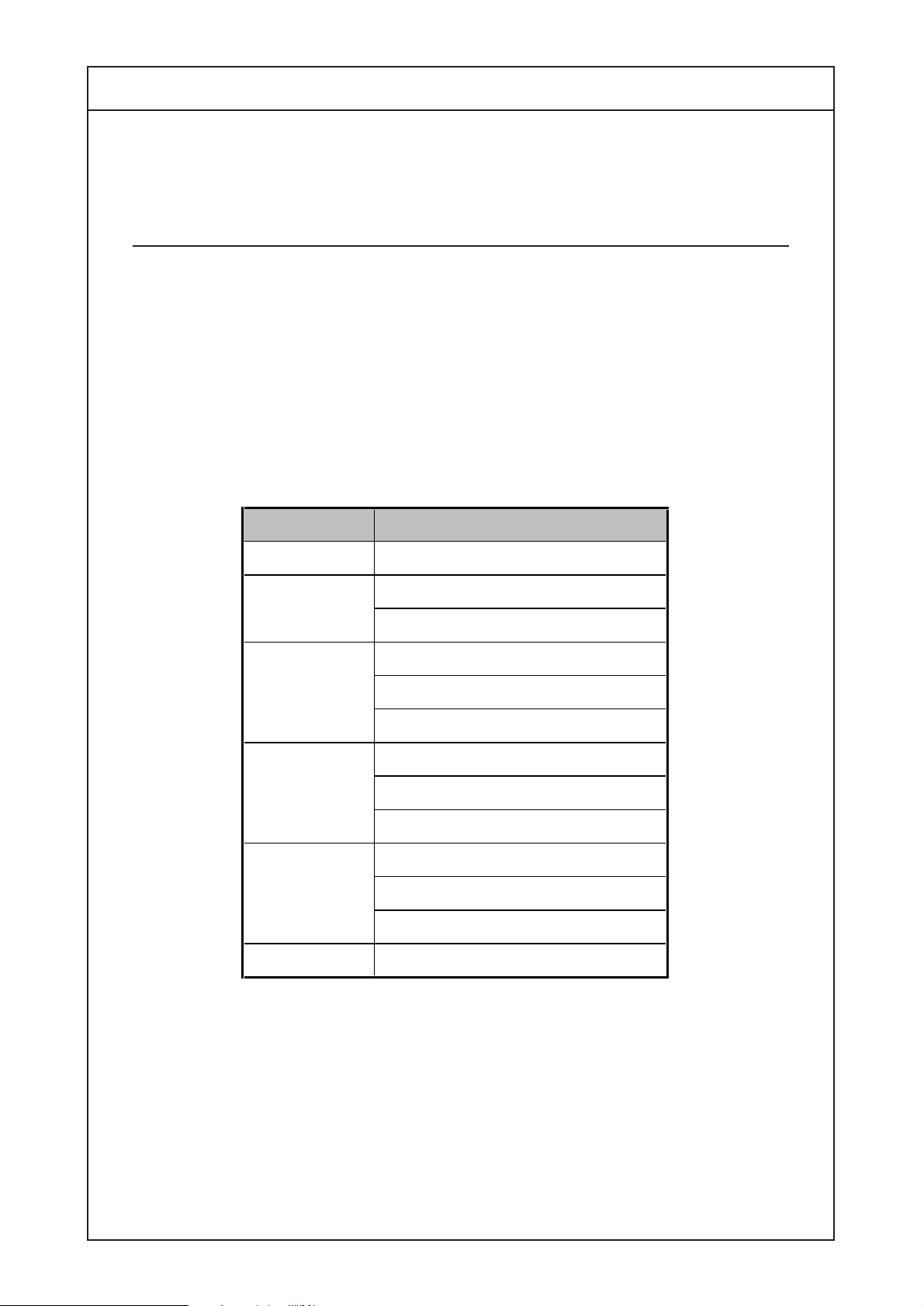

KK-XZU215C

WARNING

Request for alteration to make when reading MODEL NAME.

• The MODEL NAME in this manual of BODY MOUNTING MANUAL is

described according to the “PRODUCTION CODE” name.

• When making use of the BODY MOUNTING MANUAL, use the MODEL

NAME after replacing it in accordance with the following table.

(MODEL) (PRODUCTION CODE)

HINO 3414

XZU307L-HKMLB3

XZU307L-HKMMB3

XZU347L-HKMMB3

XZU407L-HKMMD3

XZU407L-HKMQD3

XZU417L-HKMMD3

XZU407L-HKFQD3

XZU417L-HKFQD3

XZU427L-HKFQD3

XZU407L-HKFRD3

XZU417L-HKFRD3

XZU427L-HKFRD3

HINO 3714

XKU417L-HKFQB3

AUSXZU201 00T001

HINO 3614

HINO 3616

HINO 3716

HINO 3816

Page 5

- 1 -

KK-XZU215C

Purpose

This manual is provided the Body and Equipment

Manufacturers, including inter-mediate and/or final stage

manufacturers (hereinafter collectively referred to as Body and

Equipment Manufacturers), to provide :

(1) Technical instructions for Hino truck chassis with cab for

modification and mounting of bodies.

(2) An aid to Body and Equipment Manufacturers for producing

safe vehicles under their own discretion and responsibility.

(3) Other general advice for installation, modification or

alteration.

When Body and Equipment Manufacturers install any body

or other equipment or device on Hino truck chassis with

cab (hereinafter collectively referred to as Hino Chassis), or

modify or alter a Hino Chassis.

Content

This manual contains chassis specifications and instructions

particular to model 300 series with US-04 emission control in

the Hino light duty trucks.

Important

This instruction manual must be used in combination

with the Common Manual, No. KC-AA102.

• For more information on mounting of bodies and equipments

or on chassis modifications, refer to the appropriate workshop

manuals, parts catalogs, and maintenance guides and

owner's or driver's manual.

• The information in this manual is accurate to the best of

Hino's Knowledge at the time of going to press.

Hino reserves the right to modify any and all information

without notice and without obligation.

• Should more detailed data or information be needed, please

contact authorized Hino distributor.

ABOUT THIS MANUAL

Page 6

- 2 -

KK-XZU215C

Warning

• It is the responsibility of Body and Equipment Manufacturers

or modification companies to make sure that the completed

vehicle with body and equipment, or after modification,

conforms to all applicable laws and regulations of the country

in which the vehicle is to be used (e. g. regulations on

lighting, tilt, overall size, axle load, external noise control etc.)

• This manual does not guarantee the safety of a Hino chassis

once a body or equipment has been mounted or modification

has been made by a Body and Equipment Manufacturers or a

modification company.

• This manual does not affect that ultimate responsibility for the

manufacture and mounting of the body, installation,

modification or alteration on Hino Chassis devolves upon the

Body and Equipment Manufacturer.

• Each individual Body and Equipment Manufacturer has the

sole responsibility for the design, functions, materials and

work concerning the body and equipment.

• Hino Motors, Ltd. does not assume any liability whatsoever

for any injury to persons or damage to property caused as a

result of the utilization of this manual.

ABOUT THIS MANUAL

Page 7

KK-XZU215C

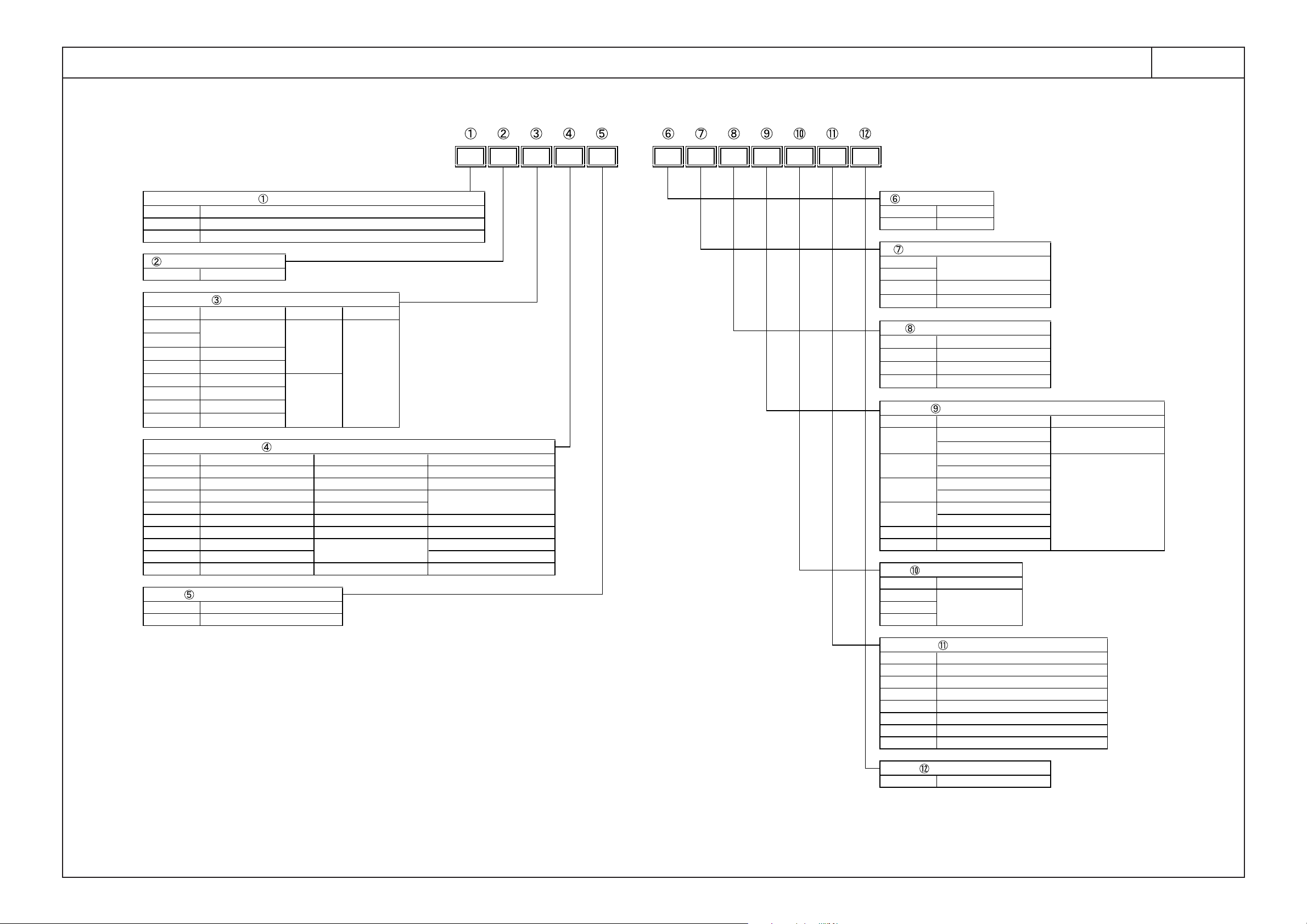

1. VEHICLE SUMMARY

2. GENERAL PRECAUTIONS

3. CHASSIS MASS & FRAME SECTION MODULUS

4. SPRING & REAR AXLE

5. PTO AND CONTROL

6. ELECTRICAL SYSTEMS

7. PAINTING

8. CHASSIS DRAWINGS

9. CHASSIS FRAME DRAWINGS

10. MOUNTING OF CHASSIS EQUIPMENT

CONTENTS

Page 8

KK-XZU215C

1. VEHICLE SUMMARY

PRODUCTION CODE・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1 - 1

IDENTIFICATION NUMBER

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1 - 2

CHASSIS SPECIFICATIONS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 1 - 3

Page 9

PRODUCTION CODE

1. VEHICLE SUMMARY

1 - 1

KK-XZU215C

XZ U 41 4 L - H K F R D W 3

AUSXZU201 01T001

DOUBLE

CODE

L

M

Q

R

S

7.5

6.5

4.495(FOR AUS.)

3870

4200

M

P

T

5 SPEEDS (MECH.)

4 SPEEDS (AUTO.)

6 SPEEDS (AUTO.)

M

DUMP

TRANSMISSION CODE

F

6 SPEEDS (MECH.)

BODY DECK HEIGHT CODE

B

K

Q

HIGH FLOOR

LOW FLOOR

300 SERIES

CAB DRIVEWHEEL BASE

2800

3400

L

R

LEFT HAND DRIVE

RIGHT HAND DRIVE

CHASSIS TYPE CODE

41

MODEL SERIES CODE

CODE

30

32

4 X 2

NARROW

WIDE

2810

3430

CAB TYPE CODE

HSINGLE

DOUBLEQ

42

43

5.5

4.495(FOR AUS.)

GVMR (ton)

GVMR AND REAR TIRE TYPE CODE

4.8-5.1

4.495(FOR AUS.)

REAR TIRE TYPE

SINGLE

4.495(FOR AUS.)

8.0

8.5

ENGINE CODE

T

NA

W/TURBO

DESTINATION CODE

NIL

S

A

B

D

D

N

Q

R

T

V

W

EXPORT STANDARD

INDONESIA

SOUTH AFRICA

AUSTRALIA & NEW ZEALAND

TAIWAN

THAI

GCC

EURO

SHIPPING CODE

CAB WITH CHASSIS3

34

40

U

VEHICLE MODEL CODE

2525

33

XZ

XK

N04C-TR/TS/TT, N04C-TP/TW, N04C-TU/TV

ENGINE TYPE CODE

N04C-TN/TU (N04C-H1)

W W04D, W04D-TM, W04D-TN

6

EMISSION CONTROL

EURO-1/2

-

EURO-1/2

EURO-3

-

-

EURO-4

3

4

5

ENGINE AND SUSPENSION CODE

CODE

0

1

2

RIGID

INDEPENDENT

8

ENGINE

W04D

-

W04D-TM/TN

N04C-TR/TS/TT

-

N04C-TP/TW

FRONT SUSPENSION

RIGID

-

-

RIGID

RIGID

D

US04

N04C-TU

N04C-TN

7 RIGIN04C-TU/TV

Page 10

1 - 2

KK-XZU215C

IDENTIFICATION NUMBER

Located at the side

member of chassis frame.

FXZ1 C No

CHASSIS

ENGINE

Page 11

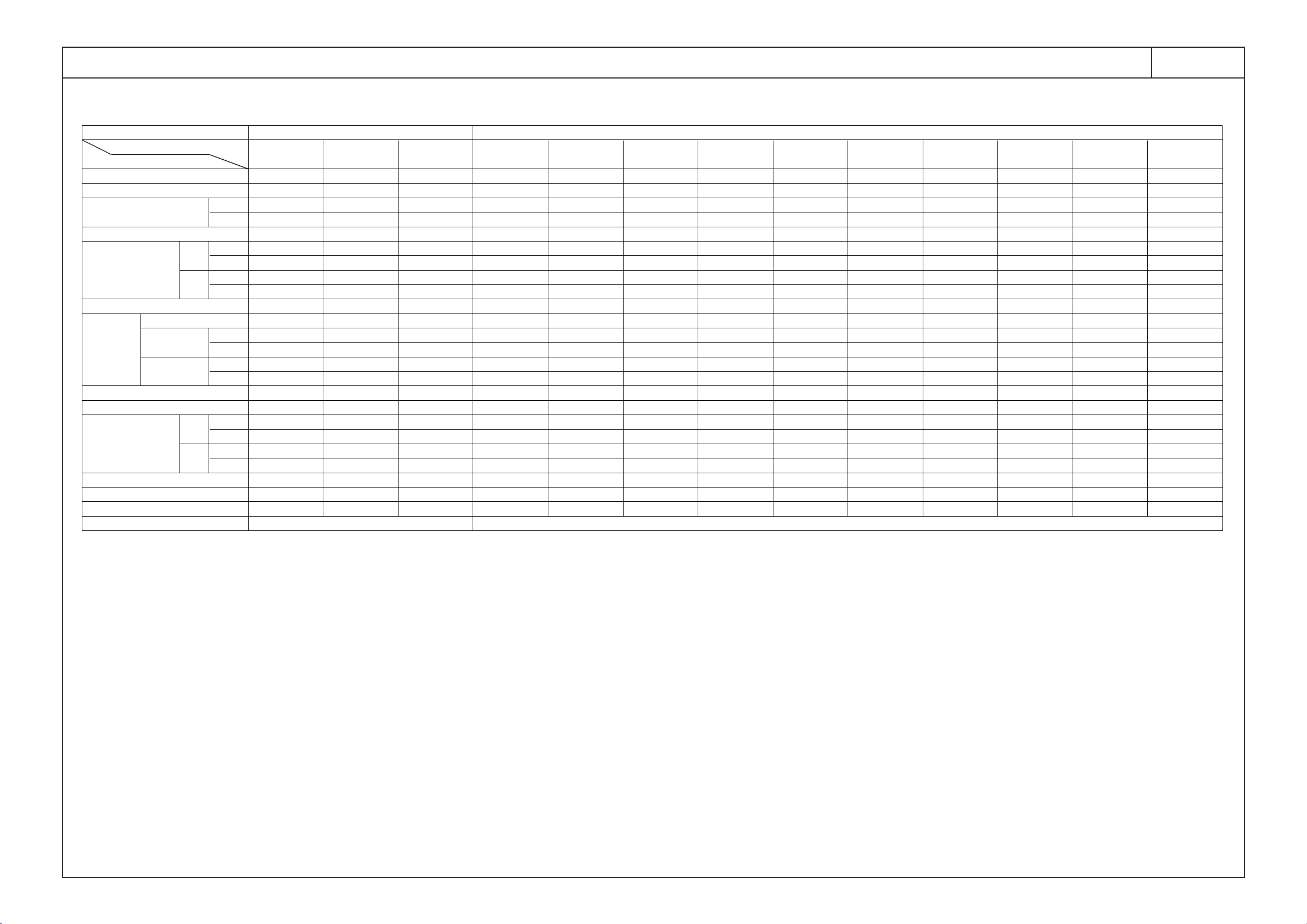

CHASSIS SPECIFICATIONS

1 - 3

KK-XZU215C

[NOTE]

• Permissible axle capacity and GVM or GCM capacity listed above table must not be exceeded.

• The front axle load must exceed 30% of the gross vehicle mass under full loaded condition.

• The height of center of gravity from ground on the unloaded vehicle with body mounted should be 0.82m (XZU307L-HKMLB3 only) or less.

• The height of center of gravity from ground on the unloaded vehicle with body mounted should be 0.88m (STANDARD CAB SERIES), 1.00m (WIDE CAB SERIES) or less.

• Weight distribution on the left and right wheels should be balanced.

• Both front axle and rear axle loads must not exceed the permissible load based on the tire load capacity according to the tire standards in your country.

• The dimension of tires to be mentioned in above chassis specification shows design figure according to JATMA or ETRTO standard.

Cab type

Chassis model

Item

Drive system (number of wheels) 4x2 (4) 4x2 (6) 4x2 (6) 4x2 (6) 4x2 (6) 4x2 (6) 4x2 (6) 4x2 (6) 4x2 (6) 4x2 (6) 4x2 (6) 4x2 (6) 4x2 (6)

Wheel base (mm) 2525 2525 3400 2810 2810 2810 2810 3430 3430 3430 3870 3870 3430

Tread

Max. GVM Rating (kg) 4300 5500 5500 5500 5500 6500 7500 5500 6500 7500 6500 7500 6500

Capacity (kg) Rear 4400 4400 4400 4400 5100 5100 5500 4400 5100 5500 5100 5500 5100

(On std. Spec.) Front 2300 2300 2300 2300 2800 2800 3200 2300 2800 3200 2800 3200 2430

Chassis mass (kg) Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1

Model N04C-TU N04C-TU N04C-TU N04C-TV N04C-TV N04C-TV N04C-TV N04C-TV N04C-TV N04C-TV N04C-TV N04C-TV N04C-UK

Max. Out put JIS gross 103{140}/2700 103{140}/2700 103{140}/2700 114{155}/2700 114{155}/2700 114{155}/2700 114{155}/2700 114{155}/2700 114{155}/2700 114{155}/2700 114{155}/2700 114{155}/2700 103{140}/3000

Engine (kW{PS}/rpm) ISO net 100{136}/2700 100{136}/2700 100{136}/2700 110{150}/2700 110{150}/2700 110{150}/2700 110{150}/2700 110{150}/2700 110{150}/2700 110{150}/2700 110{150}/2700 110{150}/2700 100{136}/3000

Max. Torque JIS gross 364{37.1}/1800 364{37.1}/1800 364{37.1}/1800 404{41.2}/1800 404{41.2}/1800 404{41.2}/1800 404{41.2}/1800 404{41.2}/1800 404{41.2}/1800 404{41.2}/1800 404{41.2}/1800 404{41.2}/1800 359{36.6}/1600

(N·m{kgf·m}/rpm) ISO net 358{36.5}/1800 358{36.5}/1800 358{36.5}/1800 397{40.5}/1800 397{40.5}/1800 397{40.5}/1800 397{40.5}/1800 397{40.5}/1800 397{40.5}/1800 397{40.5}/1800 397{40.5}/1800 397{40.5}/1800 353{36.05}/1600

Emission US04 US04 US04 US04 US04 US04 US04 US04 US04 US04 US04 US04 US04

Height of gravity from ground (m) Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1 Refer to page 3-1

Tire and disc

Fuel tank (L) 70 70 100 100 100 100 100 100 100 100 100 100 100

Battery 12-216{60}x2 12-216{60}x2 12-216{60}x2 12-216{60}x2 12-216{60}x2 12-216{60}x2 12-216{60}x2 12-216{60}x2 12-216{60}x2 12-216{60}x2 12-216{60}x2 12-216{60}x2 12-288{80}x2

Alternator V - A 24-60 24-60 24-60 24-60 24-60 24-60 24-60 24-60 24-60 24-60 24-60 24-60 24-80

Body width (See notes.) (mm)

(mm)

Front 1400 1400 1400 1660 1665 1665 1655 1660 1665 1655 1655 1655 1655

Rear 1350 1435 1435 1480 1520 1520 1520 1480 1520 1520 1520 1520 1520

Front 2600 2600 2600 2600 3100 3100 3100 2600 3100 3100 3100 3100 3100

Axle

Tire

Disc

V - kC {Ah} - No.

Rear 2300 4360 4360 4360 5280 5280 6200 4360 5280 6200 5280 6200 4480

Front 205/75R16C 205/75R16C 205/75R16C 205/75R16C 215/85R16 215/85R16 215/75R17.5 205/75R16C 215/85R16 215/75R17.5 215/85R16 215/75R17.5 215/85R16

Tire

Rear 205/75R16C 205/75R16C 205/75R16C 205/75R16C 215/85R16 215/85R16 215/75R17.5 205/75R16C 215/85R16 215/75R17.5 215/85R16 215/75R17.5 215/85R16

Front 16x5.5K-115mm 16x5.5K-115mm 16x5.5K-115mm 16x5.5K-115mm 16x5.5K-122mm 16x5.5K-122mm 17.5x6.00-127mm 16x5.5K-115mm 16x5.5K-122mm 17.5x6.00-127mm 16x5.5K-122mm 17.5x6.00-127mm 16x5.5K-122mm

Rear 16x5.5K-115mm 16x5.5K-115mm 16x5.5K-115mm 16x5.5K-115mm 16x5.5K-122mm 16x5.5K-122mm 17.5x6.00-127mm 16x5.5K-115mm 16x5.5K-122mm 17.5x6.00-127mm 16x5.5K-122mm 17.5x6.00-127mm 16x5.5K-122mm

XZU307L-HKMLB3 XZU307L-HKMMB3 XZU347L-HKMMB3 XZU407L-HKMMD3 XZU417L-HKMMD3 XZU427L-HKFRD3XZU407L-HKFQD3

STANDARD CAB SERIES

XZU407L-HKMQD3 XZU407L-HKFRD3

1896

WIDE CAB SERIES

2095

XZU427L-HKFQD3XZU417L-HKFQD3 XZU417L-HKFRD3

XKU417L-HKFQB3

AUSXZU201 01T002

Page 12

KK-XZU215C

2. GENERAL PRECAUTIONS

FIRE SHIELD ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2 - 1

CLEARANCE BETWEEN CAB AND REAR BODY OR

・・・・・・・・・・・・ 2 - 2

EQUIPMENT

RECOMMENDED POSITIONS OF U-BOLTS

・・・・・・・・・・・・・・・・・・・・ 2 - 3

RECOMMENDED POSITIONS OF REAR FENDERS AND

・・・・・・・・・・ 2 - 4

MUDGUARDS

ELECTRIC WELDING WORK

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 2 - 5

NOTES ON ADDITIONAL WIRING IN THE ENGINE

・・・・・・・・・・・・・・ 2 - 6

COMPARTMENT

NOTES ON ENGINE CONTROL, BRAKE ABS SYSTEM

・・・・・・・・・・ 2 - 7

COMPUTERS AND DC-DC CONVERTER

HANDLING OF PARTS FOR MEETING THE EXTERNAL

・・・・・・・・・・ 2 - 8

NOISE CONTROL REGULATION

PRECAUTION ON BODY MOUNTING WORK

・・・・・・・・・・・・・・・・・・・・ 2 - 9

THE NOISE MEASURES OF THE AM RADIO

・・・・・・・・・・・・・・・・・・・・ 2 - 10

Peculiar to XKU417L-HKFQB3

*

*

*

Page 13

2 - 1

2. GENERAL PRECAUTIONS

FIRE SHIELD

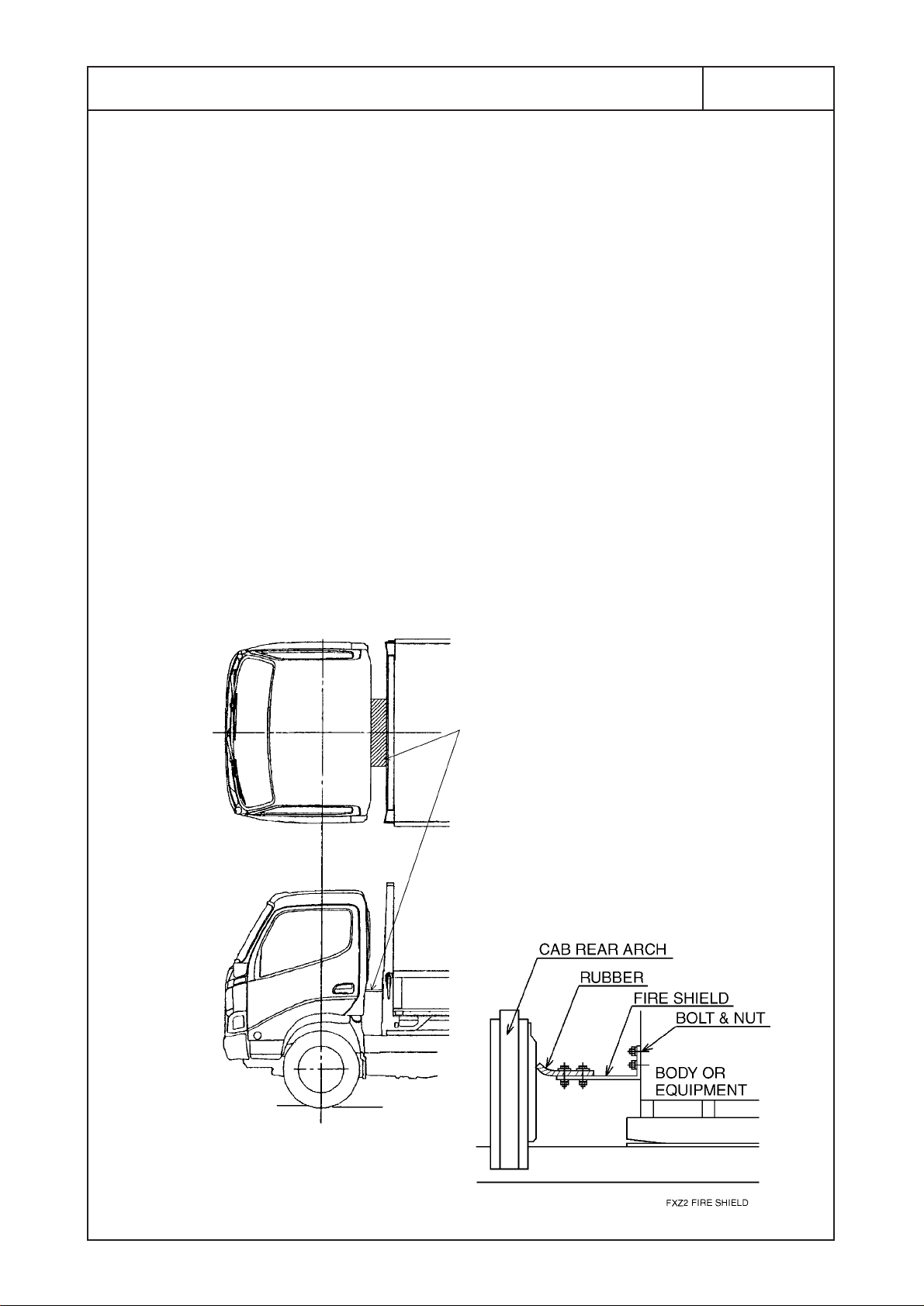

1) Gap Between Cab Rear End and Body

When a flat bed or similar body has been mounted, a fire

shield should be fitted across the gap between the cab rear

end and the front end of the load platform frame to prevent fires

that may be caused by flammable materials

falling off from the load platform onto the exhaust pipe (see

figure below).

A fire shield is not necessary if the body is fitted with a sheet

carrier attached directly to the top of the front guard.

A fire shield is also not necessary for such bodies as dump

trucks, mixers, tankers, and aluminum vans, where there is no

danger of flammable materials falling off.

[NOTE] When you mount the fire shield, use bolts, etc., that

can be taken out to allow for replacement of the

chassis parts which are located at the rear part of cab.

KK-XZU215C

• For approximately 50 mm from the front

edge of fire shield (the cab side), use

rubber to match the shape of the fire

shield to that of the cab rear end such

as rear arch cover.

• You may also install the fire shield so

that it covers only the exhaust pipe.

Page 14

2 - 2 - 1

KK-XZU215C

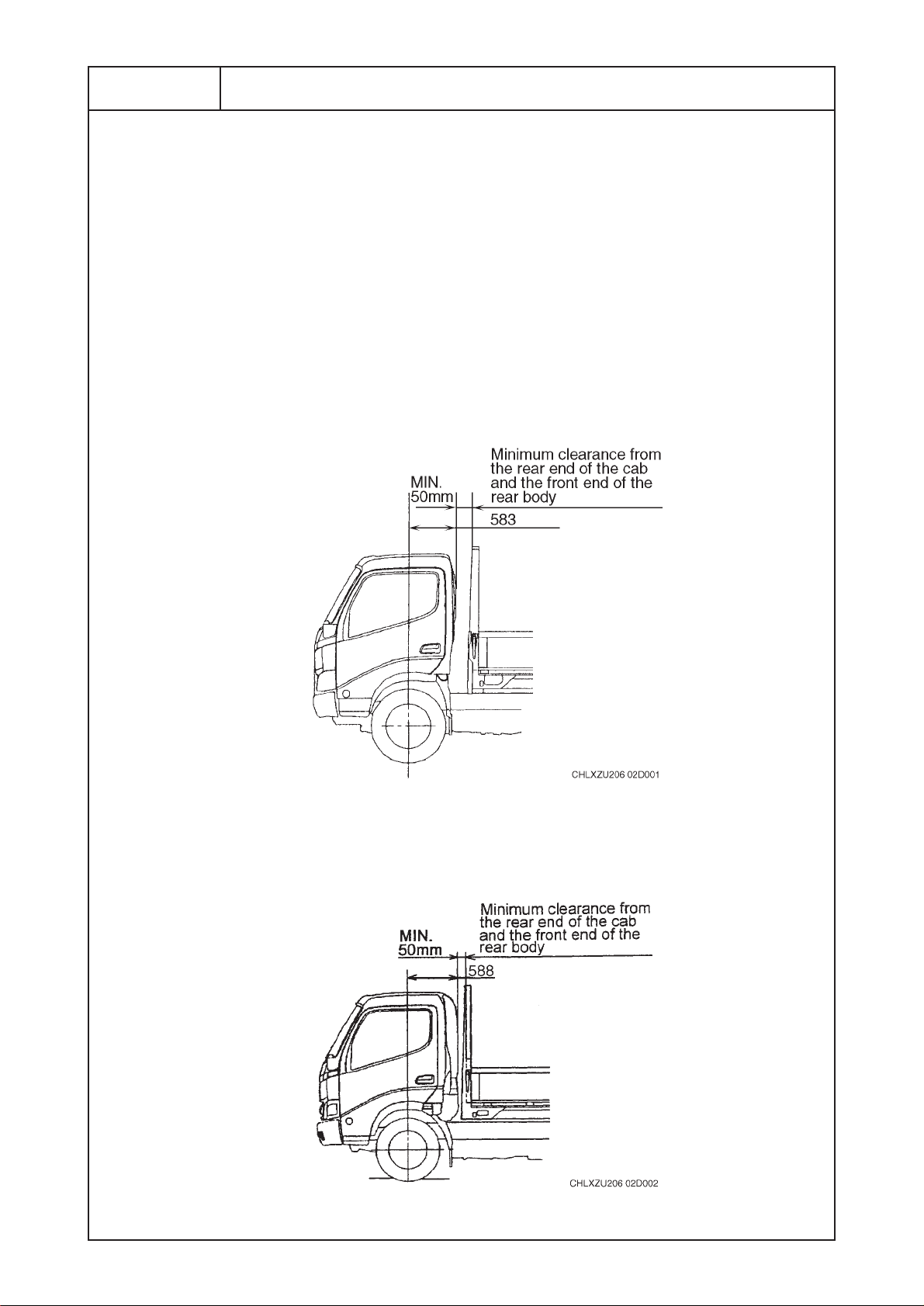

CLEARANCE BETWEEN CAB AND REAR BODY OR EQUIPMENT

The rear part of the cab contains the cab lock mechanism or

stack exhaust pipe as well as the engine cylinder block.

When mounting the rear body or equipment, allow at least the

minimum clearance between the rear end of the cab or stack

exhaust pipe and the front end of the rear body, to avoid

obstructing the operation of cab lock mechanism or avoiding

fire.

1) Minimum Clearance with Cab Rear End

(1) STANDARD CAB series

Unit : mm

(2) WIDE CAB series

Page 15

2 - 2 - 2

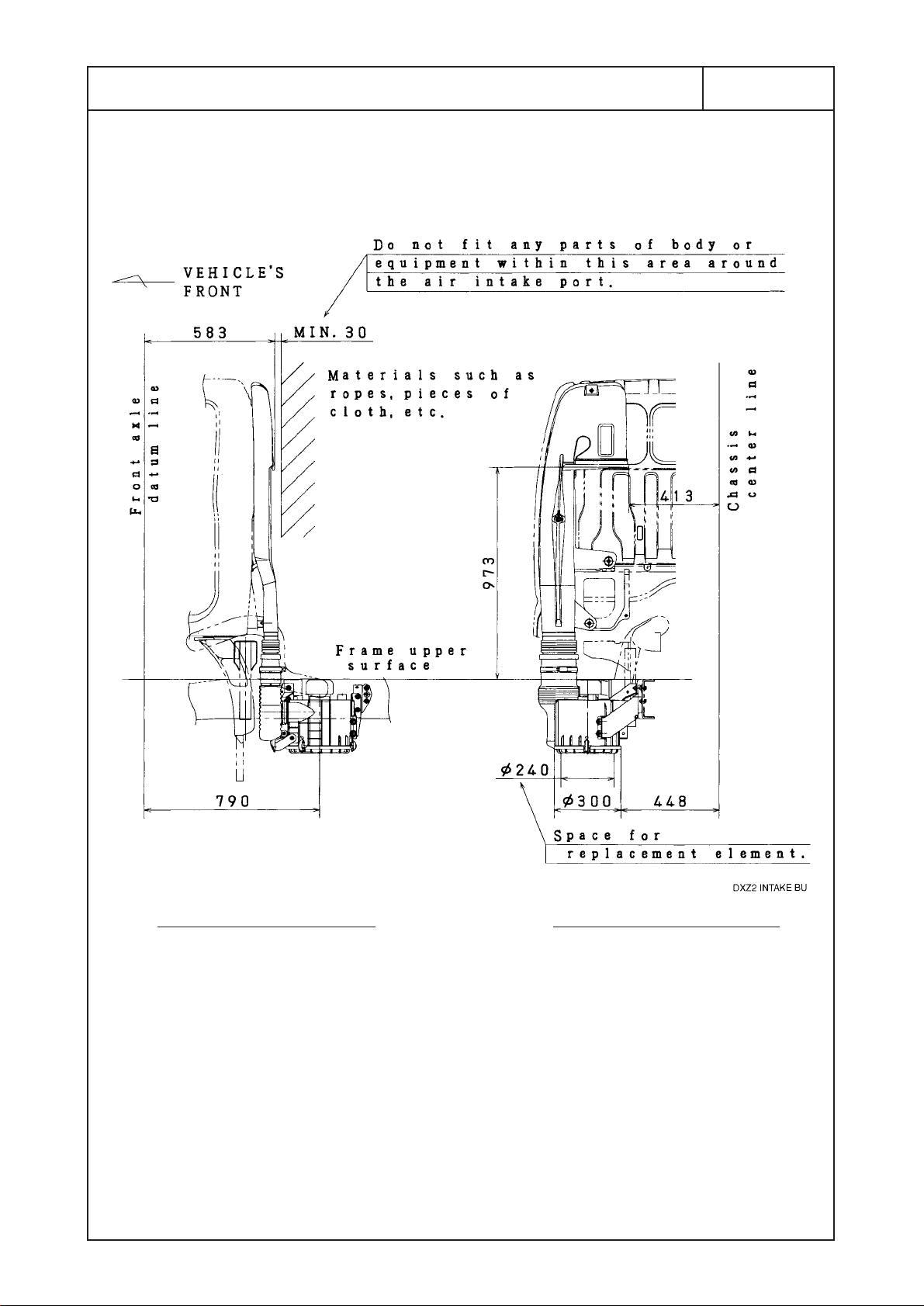

2) Measurement of the Engine Air Intake Port

• STANDARD CAB series Unit : mm

SIDE VIEW ( LEFT SIDE )

REAR VIEW ( LEFT SIDE )

KK-XZU215C

Page 16

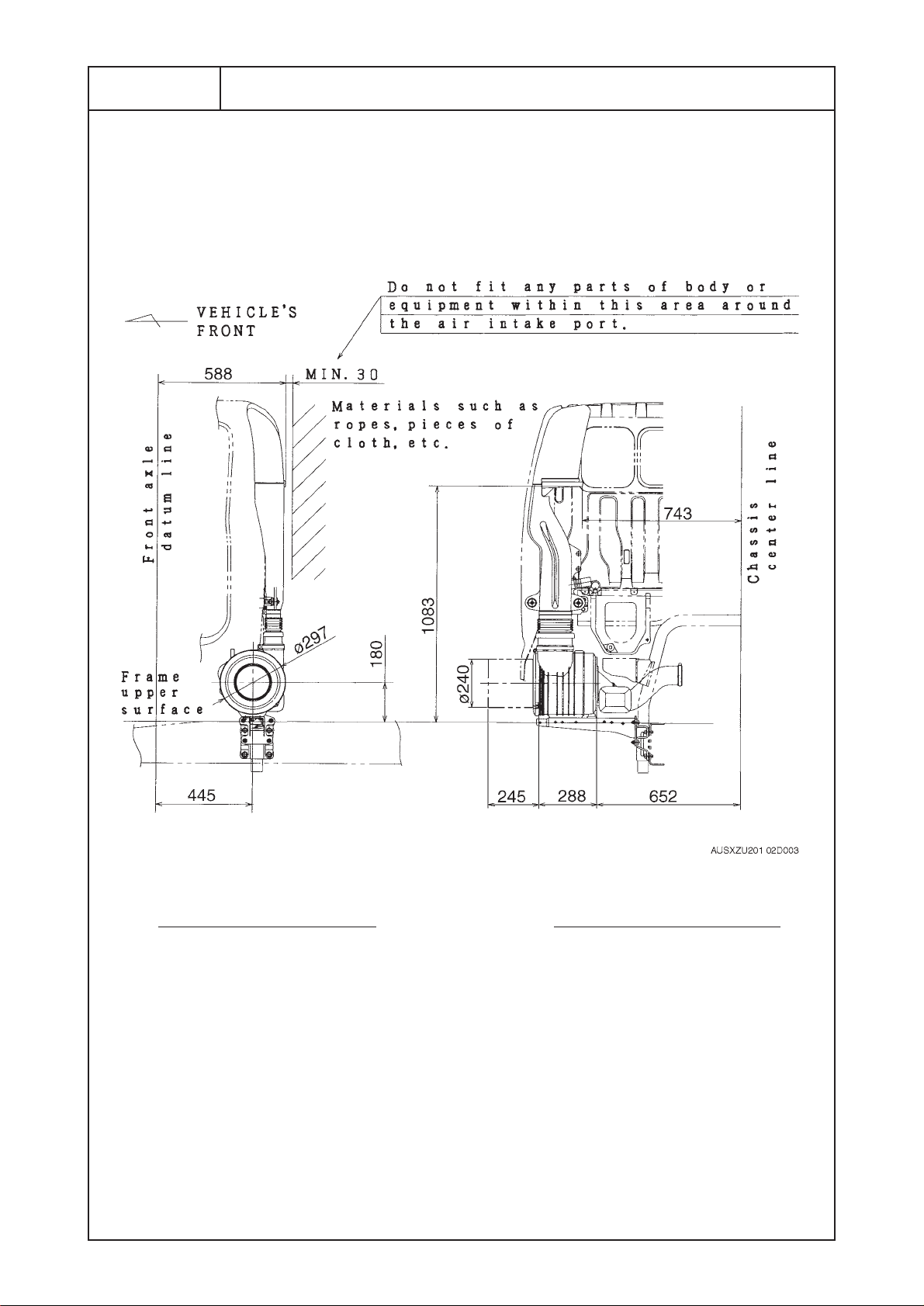

2 - 2 - 3

KK-XZU215C

• WIDE CAB series Unit : mm

SIDE VIEW ( LEFT SIDE )

REAR VIEW ( LEFT SIDE )

Caution

The blocking of the smooth flow of air into the air intake pipe caused by

any materials such as ropes, pieces of cloth, etc. leads to the increase

of exhaust temperature if driven long intervals. The increase in exhaust

temperature is caused by the decreased efficiency in the combustion

process, as the proportion of air in the combustion chamber is also

decreased by the above mentioned factor. This situation will lead to

major malfunctions such as the cracking of the exhaust manifold and

the breaking down of the turbocharger. To avoid such malfunctions,

please keep the air intake pipe free from any blocking materials at all

times.

Page 17

2 - 2 - 4

KK-XZU215C

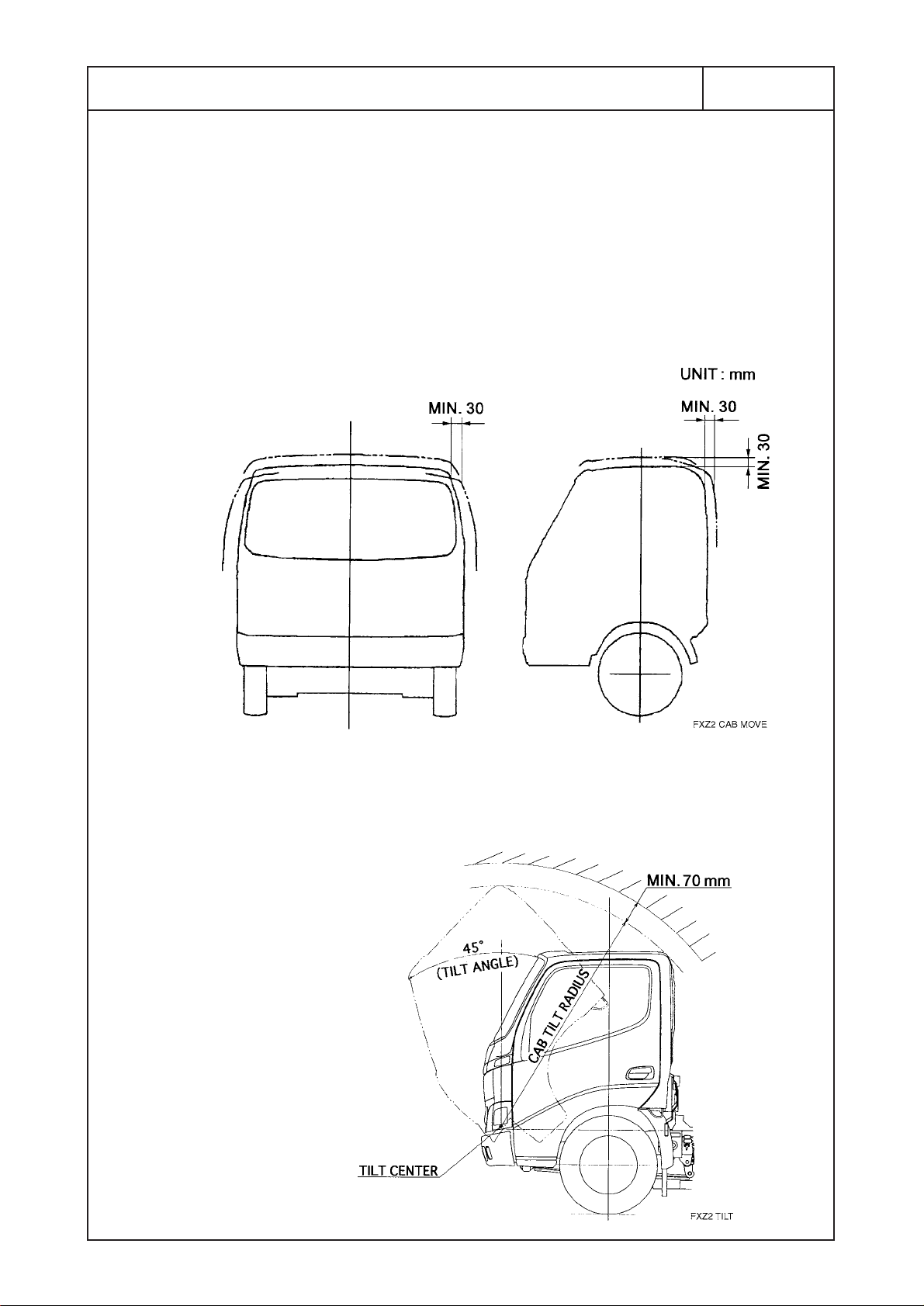

3) Minimum Clearance with Cab Outer Shell

• Even under normal driving conditions, when the cab is not

tilted, it moves back and front, right and left, and up and

down. The body or equipment must not interfere with cab

movement.

• Allow at least 30 mm clearance between the cab and rear

body or equipment.

• When cab tilt, allow at least 70 mm clearance the cab and

rear body or equipment. For details of cab tilt dimensions, see

the Body Mounting Manual for the respective model series.

Page 18

2 - 2 - 5

KK-XZU215C

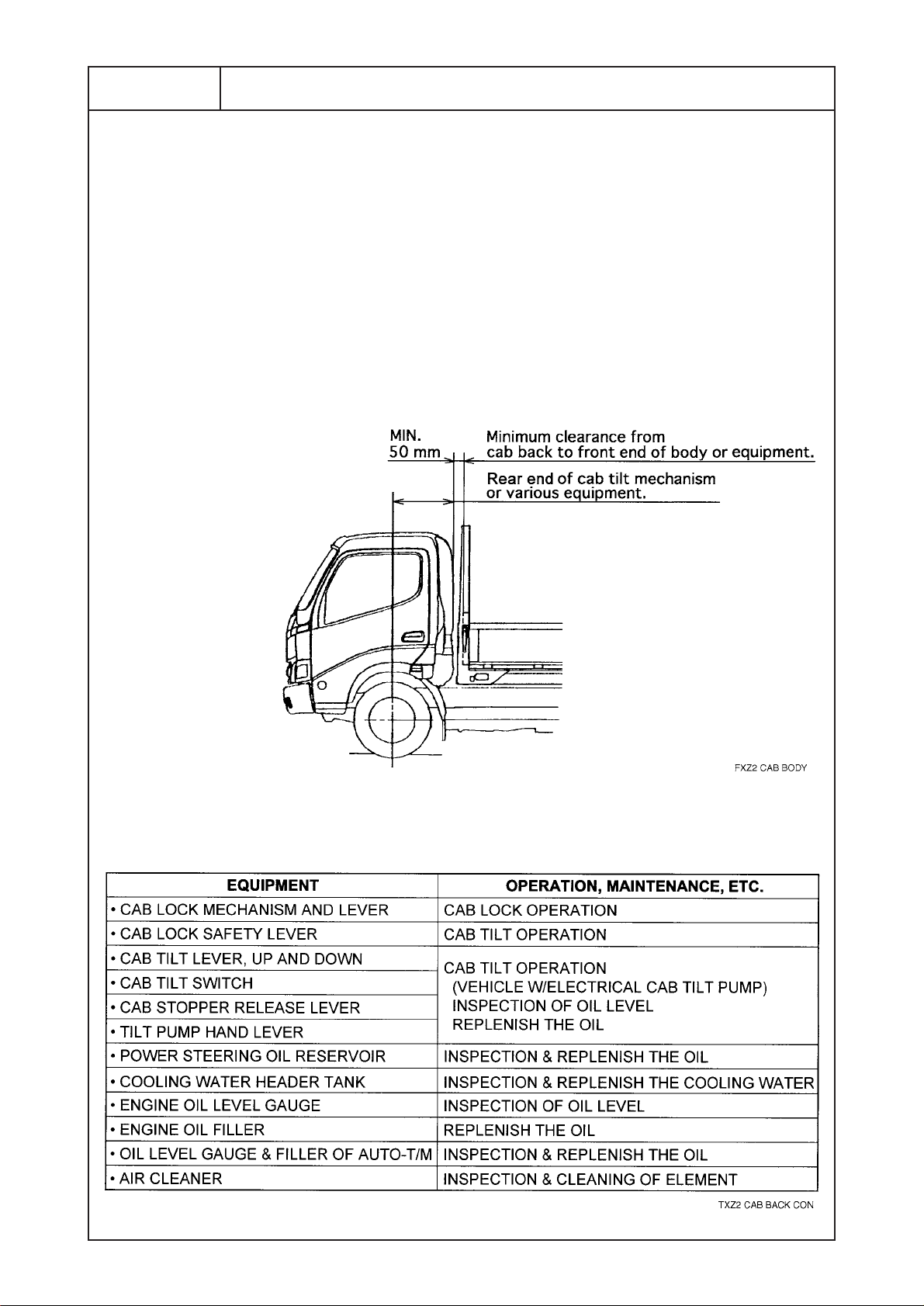

4) Contained Equipment of Cab Rear End

The rear part of the cab contains the cab lock mechanism and

the tilt mechanism, as well as the engine cylinder block or

other various equipment.

When mounting the body or equipment, allow at least the

minimum clearance between the rear end of the cab and the

front end of the rear body or equipment, to avoid obstructing

the operation and maintenance of these mechanisms or

various equipment.

For details of cab dimensions, see chassis drawings.

[ EXAMPLE ]

Page 19

2 - 3

KK-XZU215C

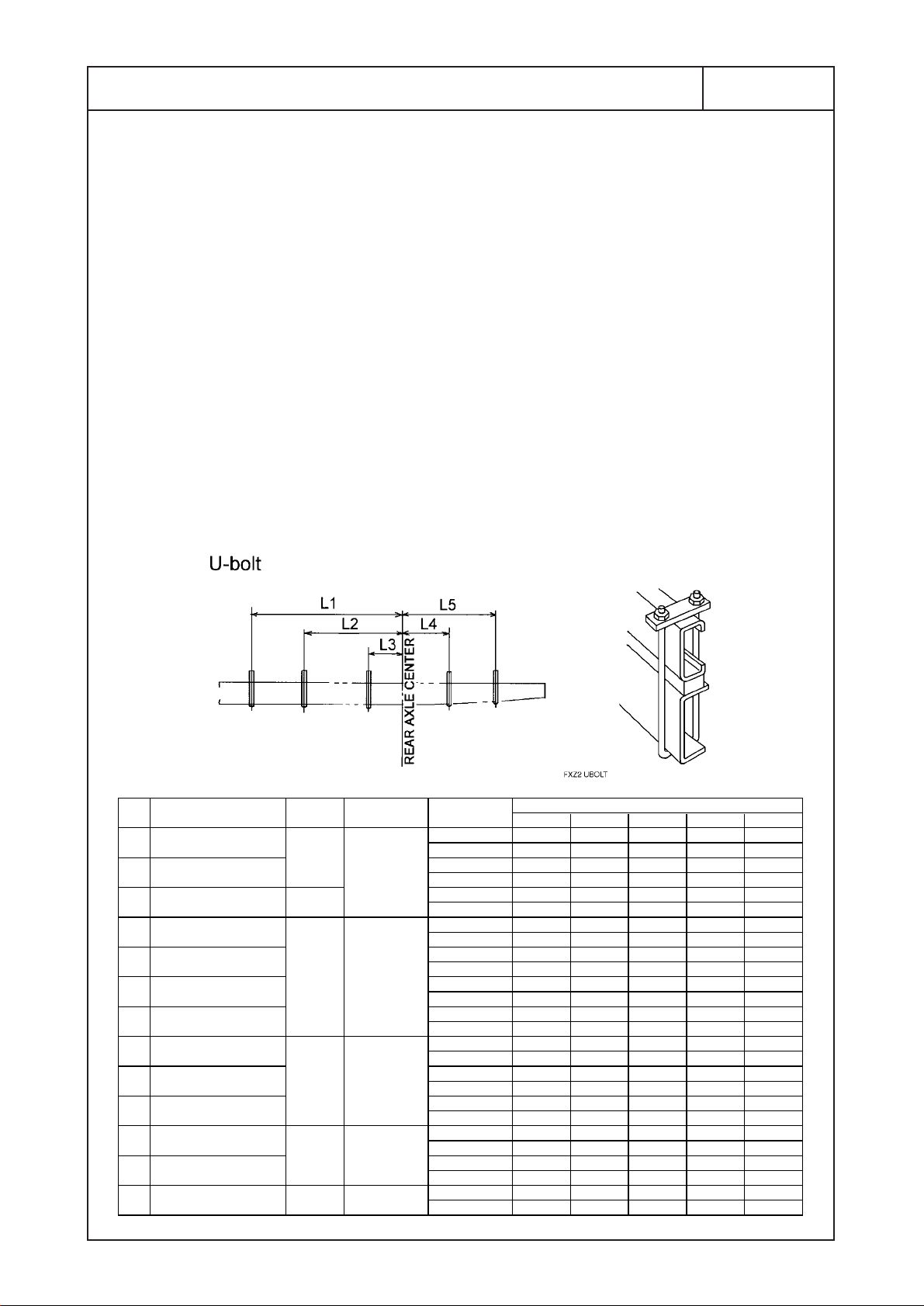

RECOMMENDED POSITIONS OF U-BOLTS

[NOTES]

(1) The details of setting positions of the U-bolt are shown in

following figure.

Fasten the U-bolt as much as possible to the positions

described in following figure when a body or equipment are

going to be mounted to the chassis.

(2) If the U-bolt positions are to be altered according to the

constructions or kinds of the body, determine the place where

U-bolt to be fastened after carefully studies the condition of the

chassis to prevent contact with the brake pipes, hoses and

harness wires.

(3) The position of U-bolts at forward of No.3 crossmember

should be observed according to the figure shown next page

due to structure and layout of each component parts of the

chassis.

(mm)

(mm)

W/B CAB

1

XZU307L-HKMLB3

2

XZU307L-HKMMB3

3

XZU347L-HKMMB3

4

XZU407L-HKMMD3

5

XZU407L-HKMQD3

6 XZU407L-HKFQD3

7

XZU407L-HKFRD3

8

XZU417L-HKMMD3

9

XZU417L-HKFQD3

10

XZU417L-HKFRD3

11 XZU427L-HKFQD3

12 XZU427L-HKFRD3

13 XKU417L-HKFQB3 3430 WIDE

2525

3400

2810

3430

3870

TYPE L1 L2 L3 L4 L5

STD

WIDE

WIDE

WIDE

POSITIONNo. MODEL

RH 1595 – 264 – 1000

LH 1495 – 264 – 1035

RH 1595 – 264 – 1000

LH 1495 – 264 – 1035

RH 2470 935 – – 1410

LH 2362 935 – – 1410

RH 1780 – 236 – 950

LH 1780 – 236 – 950

RH 1780 – 236 – 950

LH 1780 – 236 – 950

RH 1780 – 236 – 950

LH 1780 – 236 – 950

RH 1780 – 236 – 950

LH 1780 – 236 – 950

RH 2400 – 233 – 1360

LH 2400 – 233 – 1360

RH 2400 – 233 – 1360

LH 2400 – 233 – 1360

RH 2400 – 233 – 1360

LH 2400 – 233 – 1360

RH 2820 1120 – – 1560

LH 2820 900 – – 1560

RH 2820 1120 – – 1560

LH 2820 900 – – 1560

RH 2400 – 233 – 1360

LH 2400 – 233 – 1360

DIMENSION

AUSXZU201 02T002

Page 20

2 - 4 - 1

KK-XZU215C

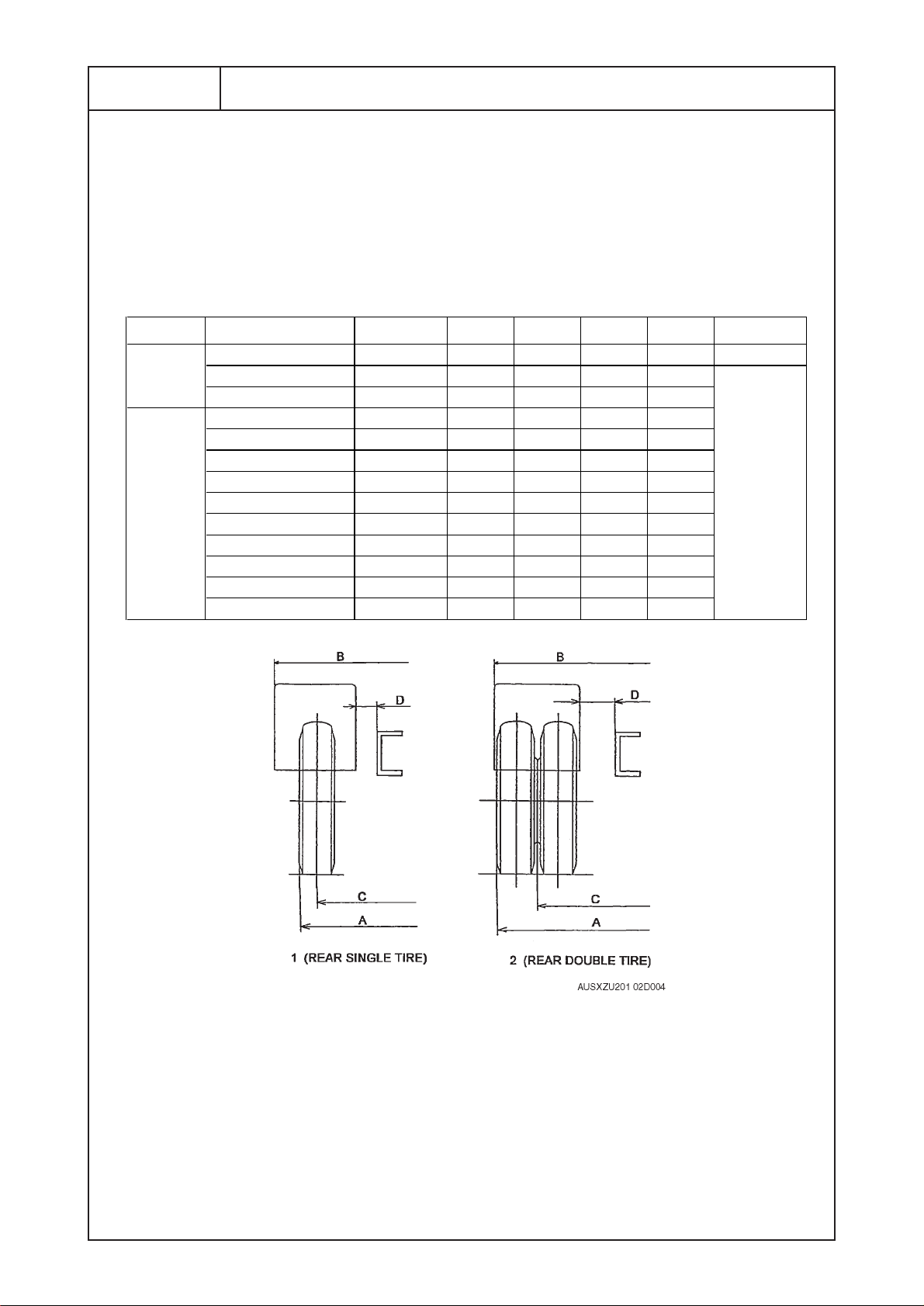

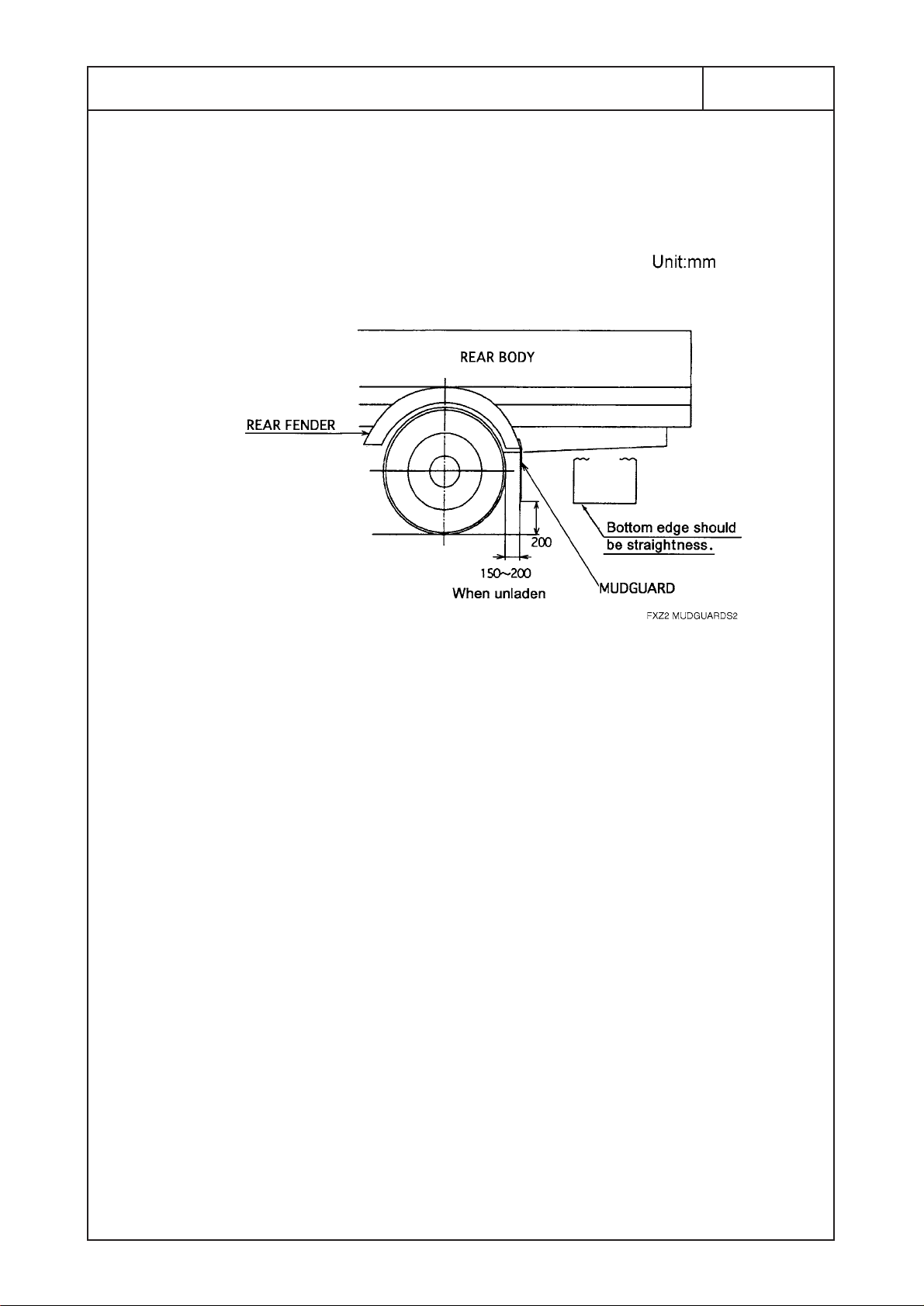

RECOMMEND POSITIONS OF REAR FENDERS AND MUDGUARDS

When mounting rear fenders and mudguards, determine

required clearances with reference to the following table and

figures of "MAXIMUM VERTICAL DEFLECTION OF REAR

WHEEL" in 4-2.

1) Rear Fender Unit : mm

[NOTE]

The dimension of tire to be mentioned in above table shows design figure according

to JATMA or ETRTO standard.

CAB TYPE MODEL TIRE SIZE A B C D REAR TIRE

XZU307L-HKMLB3 205/75R16C 1636 1656 1350 210 SINGLE

STD

WIDE

XZU307L-HKMMB3 205/75R16C 1876 1896 1435 137

XZU347L-HKMMB3 205/75R16C 1876 1896 1435 137

XZU407L-HKMMD3 205/75R16C 1921 1941 1480 135

XZU407L-HKMQD3 215/85R16 1986 2006 1520 142

XZU407L-HKFQD3 215/85R16 1986 2006 1520 142

XZU407L-HKFRD3 215/75R17.5 1994 2014 1520 138

XZU417L-HKMMD3 205/75R16C 1921 1941 1480 135

XZU417L-HKFQD3 215/85R16 1986 2006 1520 142

XZU417L-HKFRD3 215/75R17.5 1994 2014 1520 138

XZU427L-HKFQD3 215/85R16 1986 2006 1520 142

XZU427L-HKFRD3 215/75R17.5 1994 2014 1520 138

XKU417L-HKFQB3 215/85R16 1989 2009 1520 141

DOUBLE

AUSXZU201 02T003

Page 21

2 - 4 - 2

KK-XZU215C

2) Mudguards

Page 22

2 - 5 - 1

KK-XZU215C

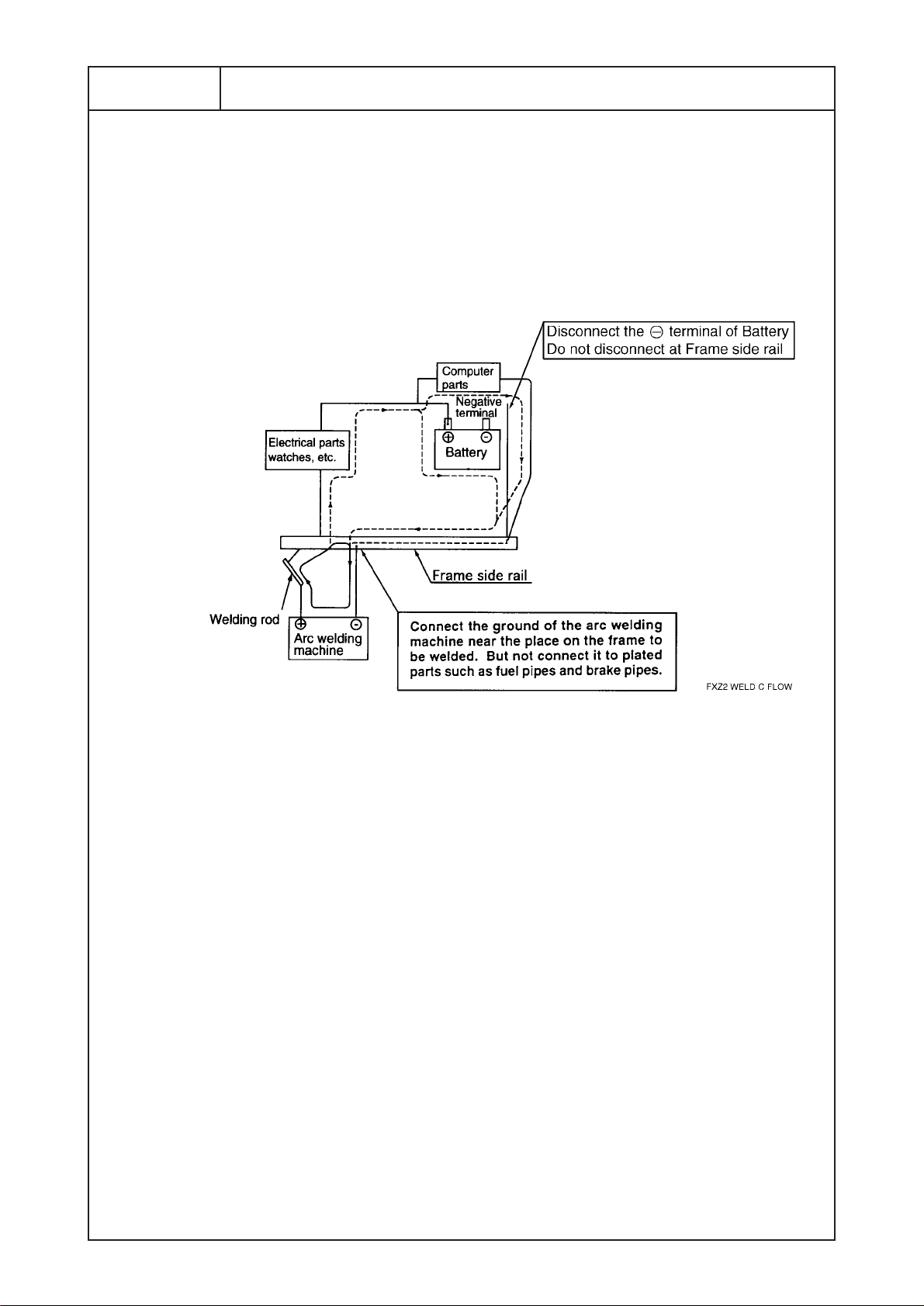

ELECTRIC WELDING WORK

Electrical components such as the alternator and tachograph

are directly connected to the battery and one end is grounded

to the chassis frame. Under these conditions, welding current

will flow back along the ground circuit if electric welding is

carried out and damage may be caused to the alternator,

tachograph, electrical components, etc.

Be sure to follow all instructions to be described to chapter 2,

2-9 PRECAUTION ON BODY MOUNTING WORK and

following precautions at performing any electric welding.

(1) procedure before welding

• Make sure to always wear the electric insulation

equipment(insulation rubber gloves .etc)while working.

•Turn the starter switch OFF.

• Pull out the SERVICE PLUG of PCU and wait more than 7

minutes.

• Disconnect the battery's negative terminal.

• Disconnect the connector of DC-DC Converter.

• Disconnect fuse of ECU of the each electronic instrument

(except DC-DC Converter).

• Dinconnect all signal circuit connectors in PCU, after taking

off the front under cover of PCU.

(See the page 2-5-3)

Peculiar to XKU417L-HKFQB3

*

*

*

*

*

Page 23

2 - 5 - 2

KK-XZU215C

DETAILS, RELAY & FUSE BLOCK

AUSXZU201 02D006

E/G CONTROL ECU

ABS ECU

DC-DC

CONVERTER

PASSENGER

SEAT SIDE

Page 24

2 - 5 - 3

KK-XZU215C

FRONT UNDER COVER

SIGNAL CIRCUIT

CONNECTOR

PCU

WIRE HARNESS

OF SIGNAL

CIRCUIT

UP

FR

CHASSIS

CENTER

Page 25

2 - 5 - 4

KK-XZU215C

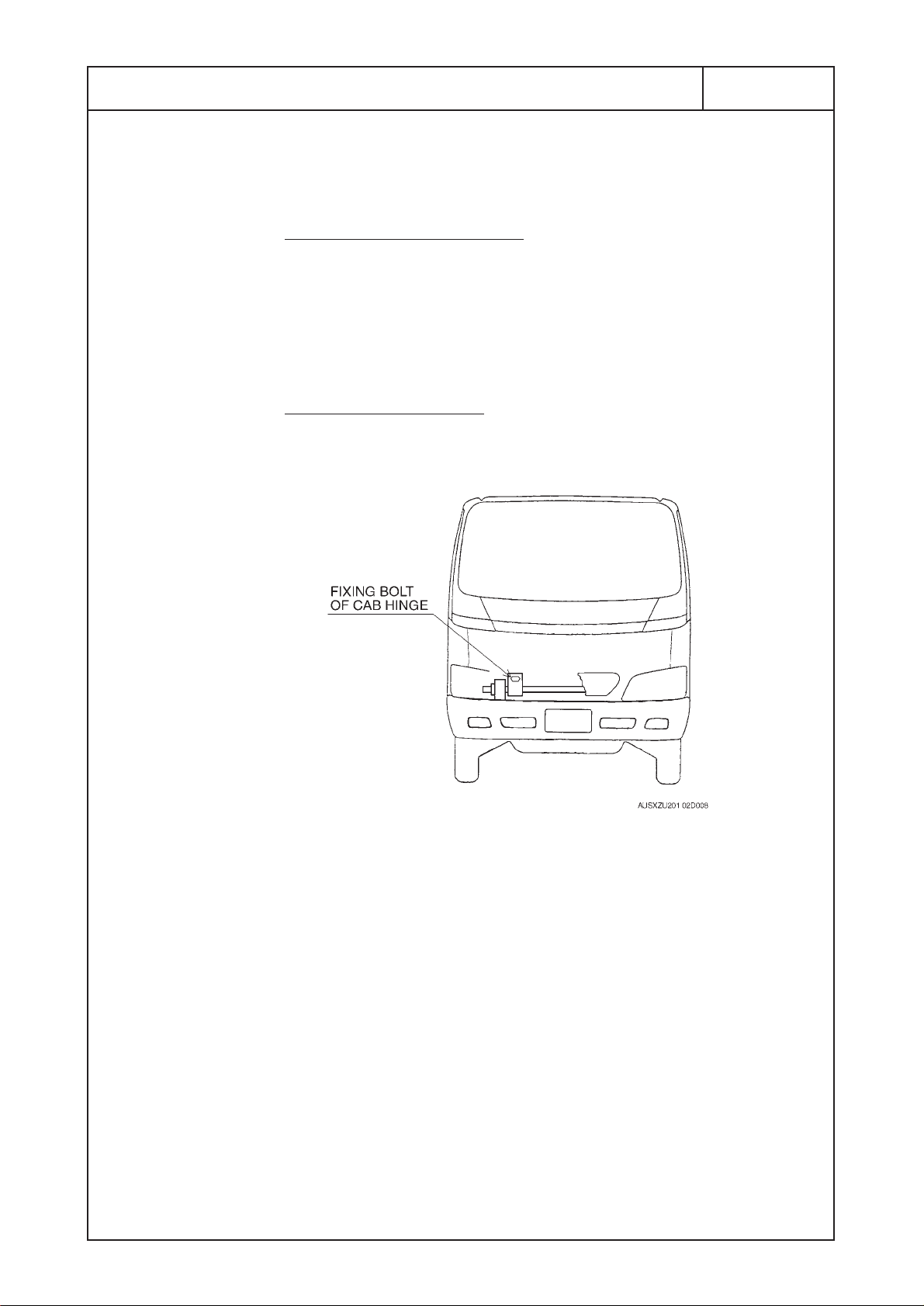

(2) Ground of the Welding Equipment

Connect the ground of the welding equipment near the place

where to be welded.

Welding to the chassis frame

• Connect the ground to the bolt (plating bolt) or chassis

frame near the place where to be welded.

• Peel off the paint where to be welded.

• Connecting the ground to the chassis spring is strictly

prohibited to prevent damage of the spring.

W

elding to the cab body

• Connect the ground to the fixing bolt of cab hinge after

dismounting the front grille or to the cab body.

(3) Other Precautions

•To protect ancillary equipment from sparks during welding,

place fire-resistant covers over the rubber hoses, wire

harness, pipes, chassis spring and tires, etc.

• Perform to weld under most suitable conditions of the

welding, and minimize the heat influence to the circumference

where to be welded, and as far as possible to keep the

welding quality.

Page 26

2 - 5 - 5

KK-XZU215C

(4) After Welding

• Make sure to connect all signal circuit connectors in PCU.

• Put back fuses as original condition.

• Make sure to connect the DC-DC Converter.

• Make sure to connect the negative terminal of the battery.

And the terminal should be horizontally setting.

• Re-paint the place where to be peeled off the paint for

grounding the welding equipment by same color.

(5) Final Inspection after Welding

• Restore each electronic instrument and equipment to its

original site.

• Install the SERVICE PLUG.

(Refer the 2-9 PRECAUTION ON BODY MOUNTING WORK)

• Inspect the operation and function of all electronic instruments

and equipments.

• Consult to each Hino sales dealer or distributor for the details

of inspection’s procedure.

Peculiar to XKU417L-HKFQB3

BATTERY

A : B = SAME HEIGHT

GOOD

NO GOOD

BA TTER Y TERMINAL

A

B

FXZ2 BATTERY

*

*

*

Page 27

2 - 6

KK-XZU215C

NOTES ON ADDITIONAL WIRING IN THE ENGINE COMPARTMENT

Since the engines in HINO trucks are covered with sound

arrest plates, the engine compartment tends to heat up.

Avoid wiring in the engine compartment if possible.

Additional wiring harness or cable should be kept away from

heated elements, and should be wired along the main harness.

Page 28

2 - 7

KK-XZU215C

NOTES ON ENGINE CONTROL, BRAKE ABS SYSTEM

COMPUTERS AND DC-DC CONVERTER

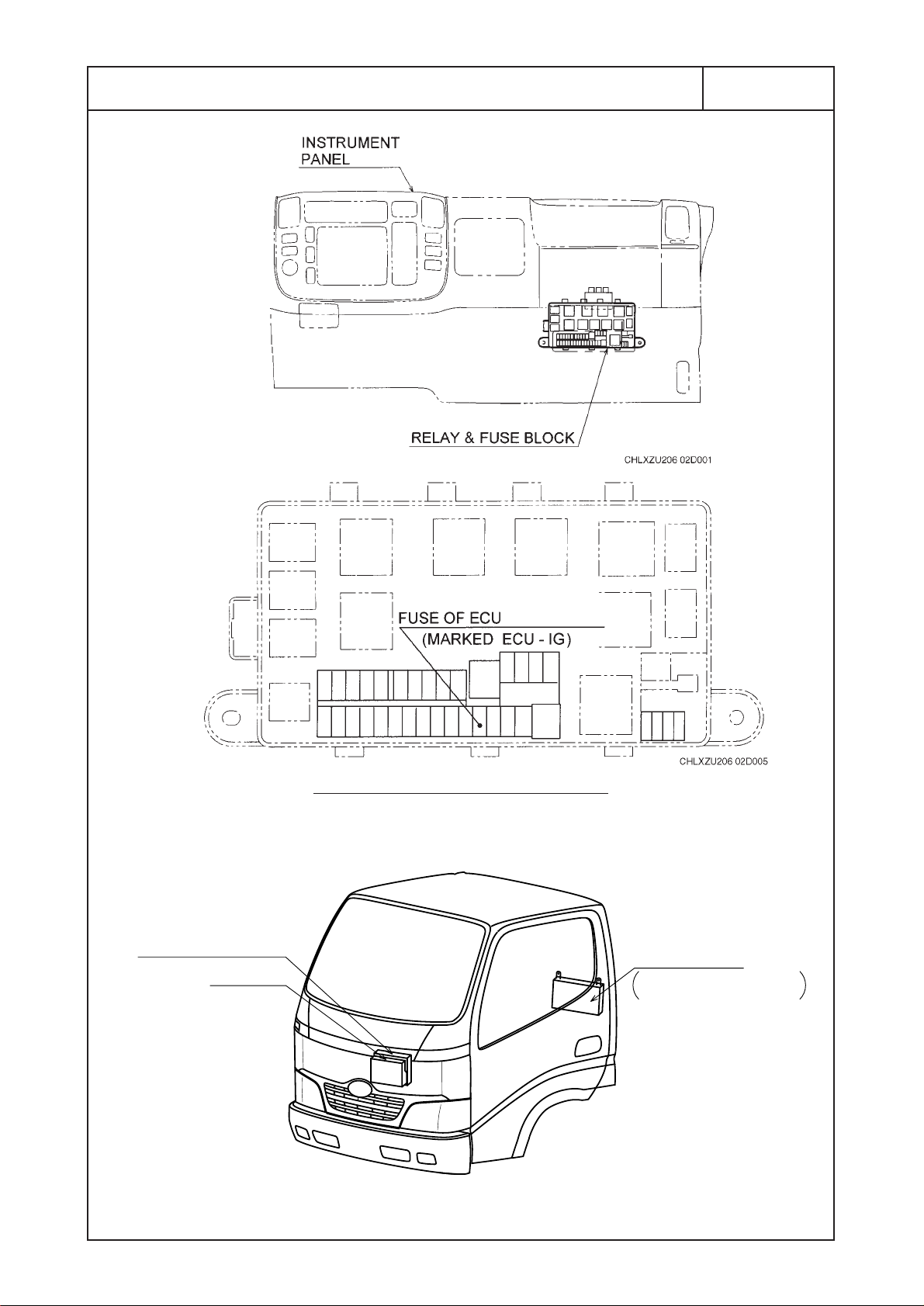

Engine control and brake ABS computers are installed center

part, inside of the instrument panel, and DC-DC converter is

installed on right side of the cab back panel as described

following figure.

Therefore, give great care to the computer and converter when

performing any body mounting work or modification as

following points.

(1) Be sure to follow the all instruction to be described to

chapter 2, 2-5 ELECTRIC WELDING WORK and 2-9

PRECAUTION ON BODY MOUNTING WORK (XKU417LHKFQB3 only) before peforming any electric welding.

(2) Be sure to cover the computer and converter to protect the

water penetration when performing cleaning up the inside

of cab.

(3) When mounting such devices as a radiophone, a wireless

communication device, be sure to use the devices that

conforms to the electric control act and install the devices

on the places which are as far as possible from the

computers and it's harness.

Do not install any high output (over 50w) device.

Be sure to check that no abnormal electric wave or

electromagnetic wave is found, after having installed the

device, which affects on the electronic signals passing

through in computer harness.

(4) Do not alter the computer and converter, harness wire or

sensors.

AUSXZU201 02D006

E/G CONTROL ECU

ABS ECU

DC-DC

CONVERTER

PASSENGER

SEAT SIDE

Page 29

2 - 8

KK-XZU215C

HANDLING OF PARTS FOR MEETING THE EXTERNAL NOISE

CONTROL REGULATION

To comply with the external noise control regulation, parts for

external noise reduction, such as sound-insulating materials

(cover, rubber) sound-absorbing materials, muffler etc., are

equipped on the cab, the engine and the chassis. Since the

parts for external noise reduction and their fitting locations are

depending on the vehicle model, refer to the corresponding

explanatory example drawing shown in the following. To ensure

external noise reductions, following items must be observed

when mounting a superstructure.

(1) The parts for external noise reduction must not be modified

or detached, since their specifications are determined to

comply with the limiting value of the external noise

regulation. The position and/or direction of the tail pipe

must also not be changed.

(2) If the parts for external noise reduction are temporarily

detached for mounting a superstructure, handle them

carefully to prevent their deformation and/or damage, and

be sure attach them on original position after completion of

mounting the superstructure.

If the parts for external noise reduction have been

deformed and/or damaged, replace them with genuine

parts and never use rectified parts.

Page 30

2 - 9 - 1

KK-XZU215C

PRECAUTION ON BODY MOUNTING WORK

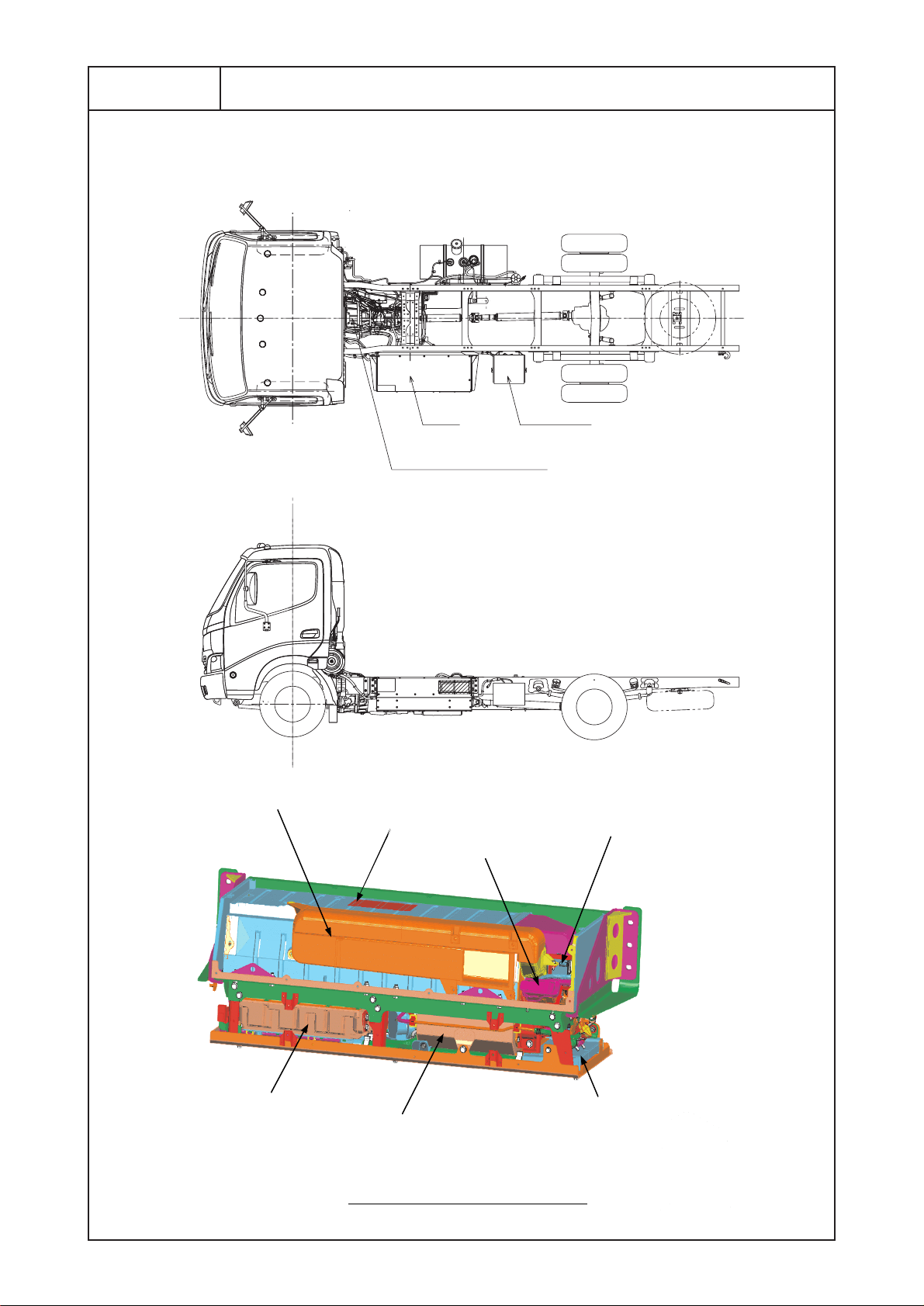

Installation position of hybrid related equipment.

BATTERYPCU

MOTOR GENERATOR

INVERTER

ECU BOX

(HV-ECU, BATTERY ECU,

KINDS OF RELAIES)

RADIATOR

FOR INVERTER

NICKEL METAL HYDRIDE (Ni-MH)

BATTERY

SERVICE PLUG

COOLING DUCT

COOLING FAN

FOR BATTERY

INNER STRUCTURE OF PCU

Page 31

2 - 9 - 2

KK-XZU215C

Precaution on body mounting work.

Before starting to mount a body please make sure to contact a

distributor and receive suitable advice.

Carry out mounting a body paying attention to following

precautions.

• Make sure to always wear the electric insulation equipment

(insulation rubber gloves .etc) while working.

• Prior to performing the body mounting, turn the starter switch

to OFF, pull out the SERVICE PLUG of PCU and wait more

than 7 minutes. (see following figures)

Strictly observe abouve precautions to avoid receiving electric

shock.

• Do not attach the SERVICE PLUG which removed till the end

of work.

It takes 7 minutes to discharge the electricity of high-voltage

condenser of the inverter.

SERVICE PLUG LID

PCU

SERVICE PLUG

Procedure of the SERVICE PLUG removal

Procedure of the SERVICE PLUG installation

y

p

*

Slide the lever.

Rais the lever and draw out the

SERVICE PLUG.

Slide the lever

certainl

till it is locked.

Insert the SERVICE PLUG

and

ush down the lever.

Page 32

2 - 9 - 3

KK-XZU215C

• Pay attention to handle high voltage harness wires which are

rolled by orange color tape.

• Never get on the hybrid system equipment such as the battery

and the inverter. You might get an electric shock or damage a

equipment.

• During work, protect PCU cover to prevent blemish and dirt

adheres.

• The SERVICE PLUG LID (hereinafter termed LID) is

directional.

When attaching the LID, the air intake port of LID must be

placed in the direction of vehicle front. (see following figures)

If the LID is placed in the wrong direction, the intake port of

Ni-MH BATTERY COOLING DUCT will be coverd and the

battery gets hot unusually.

It causes other faults.

Fr

OK

Place the intake port (wire net part) in

the direction of vehicle front.

NG

Fr

The state which attached the service plug lid in

the wrong direction.

The inner service plug can be seen from the

intake port (wire net part).

The intake port of cooling duct is coverd and

the battery can not be cooled.

Page 33

2 - 10 -1

KK-XZU215C

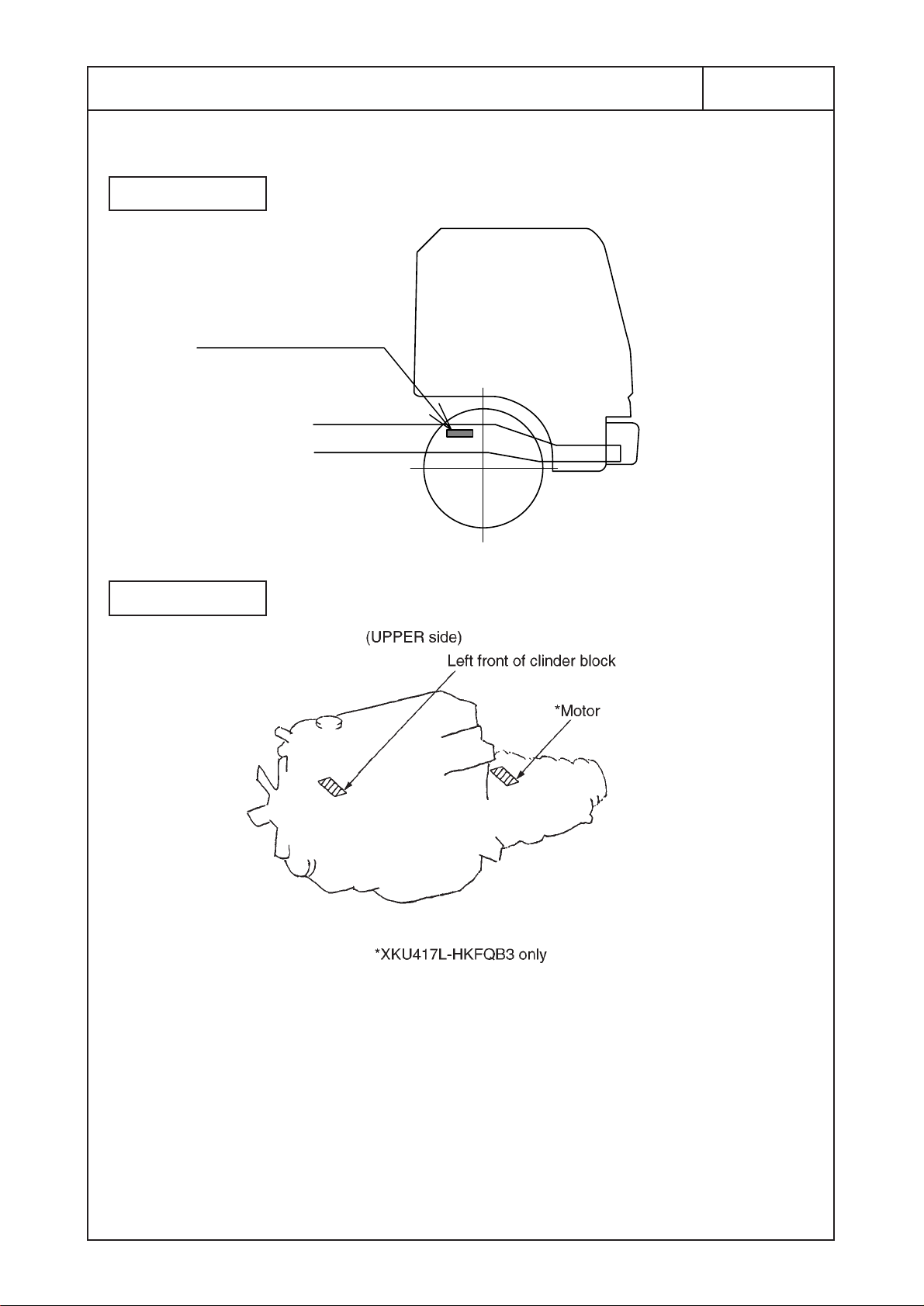

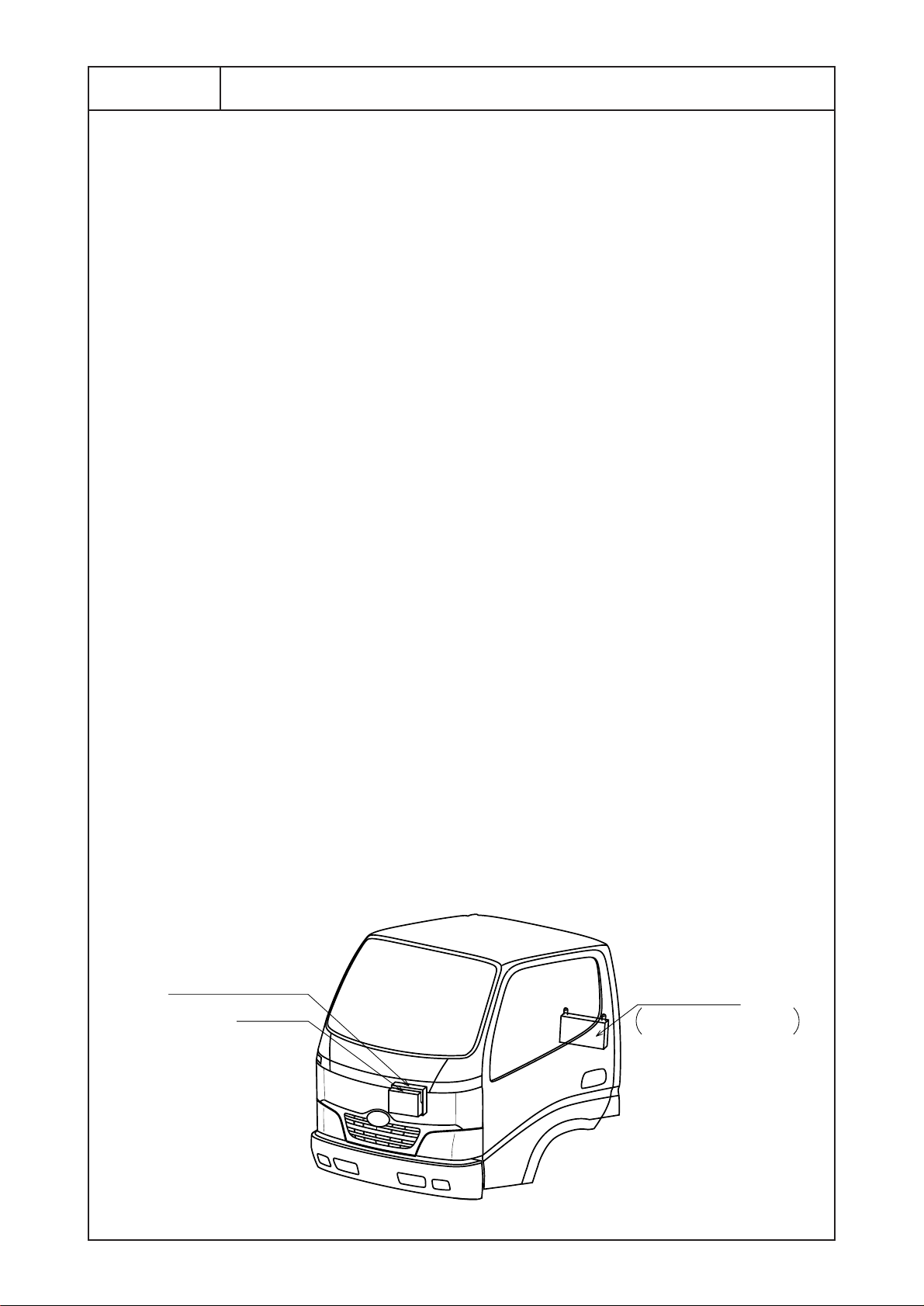

THE NOISE MEASURES OF THE AM RADIO

Make sure to connect 2 earth wires between body and / or

equipment(hereinafter termed body) and chassis frame for the

noise preventing of the AM radio by the hybrid system.

• Between body and chassis frame

Connect one side of the earth wire to the center part of front

end of body and the other side to the chassis frame with the

fitting nut of parking brake cable bracket.

Tightening torque of nut : 18±5N·m

In order to secure an electric conductivity remove the paint of

the fixing part.

Make sure to give anti-rust treatment to the fixing part after

installing the each wire.

The above figure is the example witch connected the earth

wire to the center part of front end of aluminum van and

the right side of chassis frame.

Fixing part of body

Earth wire

Remove the paint of

fixing part

Page 34

2 - 10 -2

KK-XZU215C

• Between body and motor generator

Connect one side of the earth wire to the center part of front

end body and the other side to the grounding terminal of the

motor generator together with the earth wire of the motor

generator with the existing bolt.(See the following figure)

Tightening torque of bolt : 24±7.2N·m

Tie the additional earth wire to the nearby cable with tie-rap.

Additional earth wires are contained in the package in the

cab.

Part number of earth cable (Assembly part number : 82046-

37160)

Prepare bolts, nuts and washers to needed for mounting body

by body builder.

Grounding terminal

Earth wire of

motor generator

FR

Place ti be fitted Part number

Between body and parking brake cable bracket

Between body and motor generator

82284-37160

Page 35

3. CHASSIS MASS & FRAME SECTION MODULUS

CHASSIS MASS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 3 - 1

FRAME SECTION MODULUS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 3 - 2

KK-XZU215C

Page 36

3. CHASSIS MASS & FRAME SECTION MODULUS

3 - 1 - 1

KK-XZU215C

MODEL

GRAVITY GRAVITY GRAVITY GRAVITY GRAVITY

MASS POSITION MASS POSITION MASS POSITION MASS POSITION MASS POSITION

FROM F.A.C FROM F.A.C FROM F.A.C FROM F.A.C FROM F.A.C

(kg) (m) (kg·m) (kg) (m) (kg·m) (kg) (m) (kg·m) (kg) (m) (kg·m) (kg) (m) (kg·m)

FRONT BUMPER 7 -0.920 -6.440 7 -0.920 -6.440 7 -0.920 -6.440 13 -0.970 -12.610 13 -0.970 -12.610

CAB FRONT 211 -0.827 -174.497 211 -0.827 -174.497 211 -0.827 -174.497 205 -0.867 -177.735 205 -0.867 -177.735

CAB FRONT MTG. 23 -0.827 -19.021 23 -0.827 -19.021 23 -0.827 -19.021 23 -0.867 -19.941 23 -0.867 -19.941

STEERING GEAR BOX 19 -0.715 -13.585 19 -0.715 -13.585 19 -0.715 -13.585 20 -0.755 -15.100 20 -0.755 -15.100

RADIATOR 16 -0.220 -3.520 16 -0.220 -3.520 16 -0.220 -3.520 16 -0.220 -3.520 16 -0.220 -3.520

STEERING CONTROL 2 -0.200 -0.400 2 -0.200 -0.400 2 -0.200 -0.400 3 -0.190 -0.570 3 -0.190 -0.570

ENGINE FRONT 373 0.175 65.275 363 0.175 63.525 373 0.175 65.275 377 0.175 65.975 377 0.175 65.975

CONTROL 7 0.440 3.080 7 0.440 3.080 7 0.440 3.080 7 0.480 3.360 7 0.480 3.360

ENGINE ROOM (COVER) 1.4 0.000 0.000 1.4 0.000 0.000 1.4 0.000 0.000 1.4 0.000 0.000 1.4 0.000 0.000

AIR CLEANER 7 0.790 5.530 7 0.790 5.530 7 0.790 5.530 11 0.385 4.235 11 0.385 4.235

CAB REAR 104 0.455 47.320 104 0.455 47.320 104 0.455 47.320 164 0.465 76.260 164 0.465 76.260

CAB REAR MTG. 30 0.455 13.650 30 0.455 13.650 30 0.455 13.650 35 0.465 16.275 35 0.465 16.275

ENGINE REAR 112 1.114 124.768 112 1.114 124.768 112 1.114 124.768 113 1.180 133.340 113 1.180 133.340

REAR SPLASH 2 0.450 0.900 2 0.450 0.900 2 0.450 0.900 4 0.460 1.840 4 0.460 1.840

BRAKE SYSTEM 4 -0.600 -2.400 4 -0.600 -2.400 4 -0.600 -2.400 4 -0.600 -2.400 7 -0.600 -4.200

ELECTRIC SYSTEM 14 0.400 5.600 14 0.400 5.600 14 0.400 5.600 15 0.500 7.500 15 0.500 7.500

EXHAUST SYSTEM 27 1.261 34.047 31 1.545 47.895 27 1.261 34.047 27 1.269 34.263 27 1.269 34.263

BATTERY 32 1.157 37.024 32 1.157 37.024 32 1.157 37.024 38 1.207 45.866 38 1.207 45.866

FUEL TANK 76 1.335 101.460 76 1.335 101.460 104 2.140 222.560 104 1.325 137.800 104 1.325 137.800

FUEL TANK (SUB)

A/C

PROPELLER SHAFT (FRONT)

PROPELLER SHAFT (REAR) 12 1.800 21.600 12 1.800 21.600 25 2.240 56.000 14 2.090 29.260 14 2.090 29.260

FRAME ETC. 184 1.335 245.640 217 1.270 275.590 258 1.870 482.460 211 1.360 286.960 211 1.360 286.960

SPARE TIRE CARRIER 7 3.160 22.120 7 3.370 23.590 7 4.295 30.065 7 1.850 12.950 7 1.850 12.950

SPARE TIRE 32.4 3.160 102.384 33.2 3.370 111.884 32.4 4.295 139.158 32.4 1.850 59.940 38.4 1.850 71.040

FRONT SUSPENSION 60 0.000 0.000 83 0.000 0.000 73 0.000 0.000 72 0.000 0.000 72 0.000 0.000

REAR SUSPENSION 112 2.525 282.800 96 2.525 242.400 134 3.400 455.600 128 2.810 359.680 128 2.810 359.680

TOOL BOX

TORSION BAR & SUPPORT (4WD)

REAR BUMPER

P.T.O

CAB TILT

PCU

AIR BUG

STABILIZER (FRONT)

STABILIZER (REAR)

DISCHARGE HEAD LAMP

TOOL 10 0.500 5.000 10 0.500 5.000 10 0.500 5.000 10 0.500 5.000 10 0.500 5.000

TOTAL 1484.8 0.605 898.335 1519.6 0.599 910.953 1634.8 0.923 1508.174 1654.8 0.634 1048.628 1663.8 0.636 1057.928

WHEEL BASE (m) 2.525 2.525 3.400 2.810 2.810

FRONT REAR TOTAL FRONT REAR TOTAL FRONT REAR TOTAL FRONT REAR TOTAL FRONT REAR TOTAL

(kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg)

SPRUNG MASS 1,129 356 1,485 1,159 361 1,520 1,191 444 1,635 1,282 373 1,655 1,287 376 1,664

UNSPRUNG MASS 189 249 438 189 344 533 189 344 533 213 337 550 229 361 590

CHASSIS MASS 1,318 605 1,923 1,348 705 2,053 1,380 788 2,168 1,495 710 2,205 1,516 737 2,254

GRAVITY POSITION FROM F.A.C (m)

GRAVITY HEIGHT FROM GROUND (m)

AUSXZU201 03T002

CHASSIS MASS

CHASSIS MASS : On Std. spec, filled with lubricants, coolant and fuel, with spare tire and Std. tool sets.

XZU307L-HKMLB3 XZU307L-HKMMB3

MOMENT

ITEMS

FROM

F.A.C

MOMENT

FROM

F.A.C

MOMENT

FROM

F.A.C

XZU407L-HKMMD3 XZU407L-HKMQD3XZU347L-HKMMB3

MOMENT

FROM

F.A.C

MOMENT

FROM

F.A.C

0.794

0.524

1.235

0.565 0.555

0.9050.867

0.919

0.6670.628

Page 37

3 - 1 - 2

KK-XZU215C

CHASSIS MASS : On Std. spec, filled with lubricants, coolant and fuel, with spare tire and Std. tool sets.

MODEL

GRAVITY GRAVITY GRAVITY GRAVITY GRAVITY

MASS POSITION MASS POSITION MASS POSITION MASS POSITION MASS POSITION

FROM F.A.C FROM F.A.C FROM F.A.C FROM F.A.C FROM F.A.C

(kg) (m) (kg·m) (kg) (m) (kg·m) (kg) (m) (kg·m) (kg) (m) (kg·m) (kg) (m) (kg·m)

FRONT BUMPER 13 -0.970 -12.610 13 -0.970 -12.610 13 -0.970 -12.610 13 -0.970 -12.610 13 -0.970 -12.610

CAB FRONT 205 -0.867 -177.735 205 -0.867 -177.735 205 -0.867 -177.735 205 -0.867 -177.735 205 -0.867 -177.735

CAB FRONT MTG. 23 -0.867 -19.941 23 -0.867 -19.941 23 -0.867 -19.941 23 -0.867 -19.941 23 -0.867 -19.941

STEERING GEAR BOX 20 -0.755 -15.100 20 -0.755 -15.100 20 -0.755 -15.100 20 -0.755 -15.100 20 -0.755 -15.100

RADIATOR 16 -0.220 -3.520 16 -0.220 -3.520 16 -0.220 -3.520 16 -0.220 -3.520 16 -0.220 -3.520

STEERING CONTROL 3 -0.190 -0.570 3 -0.190 -0.570 3 -0.190 -0.570 3 -0.190 -0.570 3 -0.190 -0.570

ENGINE FRONT 387 0.175 67.725 387 0.175 67.725 377 0.175 65.975 387 0.175 67.725 387 0.175 67.725

CONTROL 7 0.480 3.360 7 0.480 3.360 7 0.480 3.360 7 0.480 3.360 7 0.480 3.360

ENGINE ROOM (COVER) 1.4 0.000 0.000 1.4 0.000 0.000 1.4 0.000 0.000 1.4 0.000 0.000 1.4 0.000 0.000

AIR CLEANER 11 0.385 4.235 11 0.385 4.235 11 0.385 4.235 11 0.385 4.235 11 0.385 4.235

CAB REAR 164 0.465 76.260 164 0.465 76.260 164 0.465 76.260 164 0.465 76.260 164 0.465 76.260

CAB REAR MTG. 35 0.465 16.275 35 0.465 16.275 35 0.465 16.275 35 0.465 16.275 35 0.465 16.275

ENGINE REAR 121 1.180 142.780 121 1.180 142.780 113 1.180 133.340 121 1.180 142.780 121 1.180 142.780

REAR SPLASH 4 0.460 1.840 4 0.460 1.840 4 0.460 1.840 4 0.460 1.840 4 0.460 1.840

BRAKE SYSTEM 7 -0.600 -4.200 7 -0.600 -4.200 4 -0.600 -2.400 7 -0.600 -4.200 7 -0.600 -4.200

ELECTRIC SYSTEM 15 0.500 7.500 15 0.500 7.500 15 0.500 7.500 15 0.500 7.500 15 0.500 7.500

EXHAUST SYSTEM 27 1.269 34.263 27 1.269 34.263 27 1.269 34.263 27 1.269 34.263 27 1.763 47.601

BATTERY 38 1.207 45.866 38 1.207 45.866 38 1.207 45.866 38 1.207 45.866 38 1.207 45.866

FUEL TANK 104 1.325 137.800 104 1.325 137.800 104 1.945 202.280 104 1.945 202.280 104 1.945 202.280

FUEL TANK (SUB)

A/C

PROPELLER SHAFT (FRONT)

PROPELLER SHAFT (REAR) 14 2.090 29.260 14 2.090 29.260 26 2.400 62.400 26 2.400 62.400 26 2.400 62.400

FRAME ETC. 211 1.360 286.960 234 1.360 318.240 268 1.790 479.720 268 1.790 479.720 268 1.790 479.720

SPARE TIRE CARRIER 7 1.850 12.950 7 1.850 12.950 7 4.400 30.800 7 4.400 30.800 7 4.400 30.800

SPARE TIRE 38.4 1.850 71.040 46.5 1.850 86.025 32.4 4.400 142.560 38.4 4.400 168.960 46.5 4.400 204.600

FRONT SUSPENSION 72 0.000 0.000 72 0.000 0.000 72 0.000 0.000 72 0.000 0.000 81 0.000 0.000

REAR SUSPENSION 128 2.810 359.680 128 2.810 359.680 128 3.430 439.040 128 3.430 439.040 128 3.430 439.040

TOOL BOX

TORSION BAR & SUPPORT (4WD)

REAR BUMPER

P.T.O

CAB TILT

PCU

AIR BUG

STABILIZER (FRONT)

STABILIZER (REAR)

DISCHARGE HEAD LAMP

TOOL 10 0.500 5.000 10 0.500 5.000 10 0.500 5.000 10 0.500 5.000 10 0.500 5.000

TOTAL 1681.8 0.636 1069.118 1712.9 0.651 1115.383 1723.8 0.881 1518.838 1750.8 0.888 1554.628 1767.9 0.907 1603.606

WHEEL BASE (m) 2.810 2.810 3.400 3.430 3.430

FRONT REAR TOTAL FRONT REAR TOTAL FRONT REAR TOTAL FRONT REAR TOTAL FRONT REAR TOTAL

(kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg)

SPRUNG MASS 1,301 380 1,682 1,316 397 1,713 1,281 443 1,724 1,298 453 1,751 1,300 468 1,768

UNSPRUNG MASS 229 361 590 256 415 671 213 337 550 229 361 590 256 415 671

CHASSIS MASS 1,530 741 2,272 1,572 812 2,384 1,494 780 2,274 1,527 814 2,341 1,556 883 2,439

GRAVITY POSITION FROM F.A.C (m)

GRAVITY HEIGHT FROM GROUND (m)

AUSXZU201 03T003

XZU407L-HKFQD3 XZU417L-HKMMD3

MOMENT

ITEMS

FROM

F.A.C

MOMENT

FROM

F.A.C

MOMENT

FROM

F.A.C

MOMENT

FROM

F.A.C

XZU417L-HKFRD3XZU407L-HKFRD3 XZU417L-HKFQD3

MOMENT

FROM

F.A.C

0.917

0.667

1.1930.957

0.660 0.660

0.628 0.667

1.2411.176

Page 38

3 - 1 - 3

KK-XZU215C

CHASSIS MASS : On Std. spec, filled with lubricants, coolant and fuel, with spare tire and Std. tool sets.

MODEL

GRAVITY GRAVITY GRAVITY

MASS POSITION MASS POSITION MASS POSITION

FROM F.A.C FROM F.A.C FROM F.A.C

(kg) (m) (kg·m) (kg) (m) (kg·m) (kg) (m) (kg·m)

FRONT BUMPER 13 -0.970 -12.610 13 -0.970 -12.610 13 -0.970 -12.610

CAB FRONT 205 -0.867 -177.735 205 -0.867 -177.735 205 -0.867 -177.735

CAB FRONT MTG. 23 -0.867 -19.941 23 -0.867 -19.941 23 -0.867 -19.941

STEERING GEAR BOX 20 -0.755 -15.100 20 -0.755 -15.100 20 -0.755 -15.100

RADIATOR 16 -0.220 -3.520 16 -0.220 -3.520 16 -0.220 -3.520

STEERING CONTROL 3 -0.190 -0.570 3 -0.190 -0.570 3 -0.190 -0.570

ENGINE FRONT 387 0.175 67.725 387 0.175 67.725 402 0.175 70.350

CONTROL 7 0.480 3.360 7 0.480 3.360 7 0.480 3.360

ENGINE ROOM (COVER) 1.4 0.000 0.000 1.4 0.000 0.000 3 0.000 0.000

AIR CLEANER 11 0.385 4.235 11 0.385 4.235 11 0.385 4.235

CAB REAR 164 0.465 76.260 164 0.465 76.260 164 0.465 76.260

CAB REAR MTG. 35 0.465 16.275 35 0.465 16.275 35 0.465 16.275

ENGINE REAR 121 1.180 142.780 121 1.180 142.780 148 1.293 191.364

REAR SPLASH 4 0.460 1.840 4 0.460 1.840 4 0.460 1.840

BRAKE SYSTEM 7 -0.600 -4.200 7 -0.600 -4.200 7 -0.600 -4.200

ELECTRIC SYSTEM 15 0.500 7.500 15 0.500 7.500 20 0.500 10.000

EXHAUST SYSTEM 27 1.903 51.381 27 1.903 51.381 33 1.500 49.500

BATTERY 38 1.207 45.866 38 1.207 45.866 51 2.461 125.511

FUEL TANK 104 2.385 248.040 104 2.385 248.040 104 1.945 202.280

FUEL TANK (SUB)

A/C

PROPELLER SHAFT (FRONT)

PROPELLER SHAFT (REAR) 28 2.620 73.360 28 2.620 73.360 25 2.400 60.000

FRAME ETC. 280 2.030 568.400 280 2.030 568.400 241 1.780 428.980

SPARE TIRE CARRIER 7 4.815 33.705 7 4.815 33.705 7 4.390 30.730

SPARE TIRE 33.1 4.815 159.377 46.5 4.815 223.898 38.4 4.815 184.896

FRONT SUSPENSION 72 0.000 0.000 81 0.000 0.000 72 0.000 0.000

REAR SUSPENSION 128 3.870 495.360 161 3.870 623.070 128 3.430 439.040

TOOL BOX

TORSION BAR & SUPPORT (4WD)

REAR BUMPER

P.T.O

CAB TILT

PCU 122 1.300 158.600

AIR BUG

STABILIZER (FRONT)

STABILIZER (REAR)

DISCHARGE HEAD LAMP

TOOL 10 0.500 5.000 10 0.500 5.000 10 0.500 5.000

TOTAL 1759.5 1.004 1766.788 1814.9 1.079 1959.019 1912.4 0.954 1824.545

WHEEL BASE (m) 3.870 3.870 3.430

FRONT REAR TOTAL FRONT REAR TOTAL FRONT REAR TOTAL

(kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg) (kg)

SPRUNG MASS 1,303 457 1,760 1,309 506 1,815 1,380 532 1,912

UNSPRUNG MASS 229 361 590 256 415 671 229 361 590

CHASSIS MASS 1,532 818 2,350 1,565 921 2,486 1,609 893 2,502

GRAVITY POSITION FROM F.A.C (m)

GRAVITY HEIGHT FROM GROUND (m)

AUSXZU201 03T004

XZU427L-HKFQD3

MOMENT

ITEMS

FROM

F.A.C

XZU427L-HKFRD3

MOMENT

FROM

F.A.C

XKU417L-HKFQB3

MOMENT

FROM

F.A.C

1.347

0.667

1.434

1.224

0.6670.660

Page 39

FRAME SECTION MODULUS (MAIN FRAME ON BOTH SIDE)

3 - 2 - 1

KK-XZU215C

MODEL : XZU307L-HKMLB3

Page 40

FRAME SECTION MODULUS (MAIN FRAME ON BOTH SIDE)

3 - 2 - 2

KK-XZU215C

MODEL : XZU307L-HKMMB3

Page 41

FRAME SECTION MODULUS (MAIN FRAME ON BOTH SIDE)

3 - 2 - 3

KK-XZU215C

MODEL : XZU347L-HKMMB3

Page 42

FRAME SECTION MODULUS (MAIN FRAME ON BOTH SIDE)

3 - 2 - 4

KK-XZU215C

MODEL : XZU407L-HKMMD3

XZU407L-HKMQD3

XZU407L-HKFQD3

XZU407L-HKFRD3

Page 43

FRAME SECTION MODULUS (MAIN FRAME ON BOTH SIDE)

3 - 2 - 5

KK-XZU215C

MODEL : XZU417L-HKMMD3 XKU417L-HKFQB3

XZU417L-HKFQD3

XZU417L-HKFRD3

Page 44

FRAME SECTION MODULUS (MAIN FRAME ON BOTH SIDE)

3 - 2 - 6

KK-XZU215C

MODEL : XZU427L-HKFQD3

XZU427L-HKFRD3

Page 45

4. SPRINGS & REAR AXLES

SPRING CHARACTERISTICS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 4 - 1

MAXIMUM VERTICAL DEFLECTION OF REAR WHEELS

・・・・・・・・ 4 - 2

TRAVEL RANGE OF REAR SPRING

・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 4 - 3

KK-XZU215C

Page 46

4 - 1 - 1

KK-XZU215C

4. SPRINGS & REAR AXLES

SPRING CHARACTERISTICS

1) SPRING COMBINATION

Refer to SPRING CHARACTERISTICS CHART based on

following table.

SPRING CHARACTERISTICS

MODEL

XZU307L-HKMLB3 F1 R1

XZU307L-HKMMB3 F2 F6 R2 R5

XZU347L-HKMMB3 F2 F6 R2 R5

XZU407L-HKMMD3 F3 F7 R3 R4

XZU407L-HKMQD3 F4 F5 R3 R4

XZU407L-HKFQD3 F4 F5 R3 R4

XZU407L-HKFRD3 F5 F8 R4 R6

XZU417L-HKMMD3 F3 F7 R3 R4

XZU417L-HKFQD3 F4 F5 R3 R4

XZU417L-HKFRD3 F5 F8 R4 R6

XZU427L-HKFQD3 F4 F5 R3 R4

XZU427L-HKFRD3 F5 F8 R4 R6

XKU417L-HKFQB3 F4 F5 R3 R4

FRONT REAR

STD OPT STD OPT

AUSXZU201 04T001

Page 47

2) FRONT LEAF SPRING

(1) SPRING CHARACTERISTICS CHART "F1"

(2) SPRING CHARACTERISTICS CHART "F2"

4 - 1 - 2

KK-XZU215C

Page 48

(3) SPRING CHARACTERISTICS CHART "F3"

(4) SPRING CHARACTERISTICS CHART "F4"

4 - 1 - 3

KK-XZU215C

Page 49

(5) SPRING CHARACTERISTICS CHART "F5"

(6) SPRING CHARACTERISTICS CHART "F6"

4 - 1 - 4

KK-XZU215C

Page 50

(7) SPRING CHARACTERISTICS CHART "F7"

(8) SPRING CHARACTERISTICS CHART "F8"

4 - 1 - 5

KK-XZU215C

Page 51

3) REAR LEAF SPRING

(1) SPRING CHARACTERISTICS CHART "R1"

4 - 1 - 6

KK-XZU215C

Page 52

(2) SPRING CHARACTERISTICS CHART "R2"

4 - 1 - 7

KK-XZU215C

Page 53

4 - 1 - 8

KK-XZU215C

(3) SPRING CHARACTERISTICS CHART "R3"

Page 54

4 - 1 - 9

KK-XZU215C

(4) SPRING CHARACTERISTICS CHART "R4"

Page 55

(5) SPRING CHARACTERISTICS CHART "R5"

4 - 1 - 10

KK-XZU215C

Page 56

4 - 1 - 11

KK-XZU215C

(6) SPRING CHARACTERISTICS CHART "R6"

Page 57

4 - 2

KK-XZU215C

MAXIMUM VERTICAL DEFLECTION OF REAR WHEELS

Measurements for the maximum deflection for on tire and for

simultaneous left and right deflection are shown below.

When you mount the body, allow a clearance of at least 30mm so

as not to obstruct tire deflection.

D

A

BC

D

A

BC

F4 RTIRES2

Deflection of rear tires

Maximum deflection for

one side wheels.

Maximum simultaneous deflection

right and left wheels.

With tire chain : Dimensions A and B are added 50mm.

1.SINGLE TIRE

2.DOUBLE TIRE

MODEL TIRE SIZE A B C D REAR TIRE

XZU307L-HKMLB3 205/75R16C 139 132 42 198 SINGLE

XZU307L-HKMMB3 205/75R16C 137 97 96 120

XZU347L-HKMMB3 205/75R16C 137 97 96 120

XZU407L-HKMMD3 205/75R16C 100 54 125 113

XZU407L-HKMQD3 215/85R16 124 79 128 127

XZU407L-HKFQD3 215/85R16 124 79 128 127

XZU407L-HKFRD3 215/75R17.5 120 75 134 123

XZU417L-HKMMD3 205/75R16C 100 54 125 113

XZU417L-HKFQD3 215/85R16 124 79 128 127

XZU417L-HKFRD3 215/75R17.5 120 75 134 123

XZU427L-HKFQD3 215/85R16 124 79 128 127

XZU427L-HKFRD3 215/75R17.5 120 75 134 123

XKU417L-HKFQB3 215/85R16C 124 79 128 127

DOUBLE

Page 58

4 - 3

KK-XZU215C

TRAVEL RANGE OF REAR SPRING

During driving, the shackle of the main spring slides beyond the end of the rear

bracket.

REAR SHACKLE

REAR LEAF SPRING

A

Do not mount any parts of

body inside of the this range.

FRONT

Unit : mm

MODEL A (min.)

XZU307L-HKMMB3

XZU347L-HKMMB3

XZU407L-HKMMD3

XZU407L-HKMQD3

XZU407L-HKFQD3

XZU407L-HKFRD3

XZU417L-HKMMD3

XZU417L-HKFQD3

XZU417L-HKFRD3

XZU427L-HKFQD3

XZU427L-HKFRD3

XKU417L-HKFQB3

AUSXZU201 04T003

MODEL : XZU307L-HKMLB3

100

130

Page 59

5. PTO AND CONTROL

LAYOUT OF POWER LINE ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5 - 1

TRANSMISSION SIDE POWER TAKE OFF (OPT) ・・・・・・・・・・・・・・・・ 5 - 2

ENGINE CONTROL FOR BODY OR EQUIPMENT ・・・・・・・・・・・・・・・・ 5 - 3

REAR BODY CONTROL LEVER (OPT) ・・・・・・・・・・・・・・・・・・・・・・・・ 5 - 4

KK-XZU215C

Page 60

LAYOUT OF POWER LINE

5. PTO AND CONTROL

5 - 1

KK-XZU215C

MODEL

XZU307L-HKMLB3

XZU307L-HKMMB3

XZU347L-HKMMB3

XZU407L-HKMMD3

XZU407L-HKMQD3

XZU407L-HKFQD3

XZU407L-HKFRD3

XZU417L-HKMMD3

XZU417L-HKFQD3

XZU417L-HKFRD3

XZU427L-HKFQD3

XZU427L-HKFRD3

E/G

MODEL

N04C-TU M550

N04C-TU M550

N04C-TU M550

N04C-TV M550 240 153 4° 436 287 944 0 0° 1

N04C-TV M550 240 153 4° 436 287 944 0 0° 1

N04C-TV MYY6 240 153 4° 357 221 860 0 0° 2

N04C-TV MYY6 240 153 4° 357 221 860 0 0° 2

N04C-TV M550 240 153 4° 436 287 944 0 0° 1

N04C-TV MYY6 240 153 4° 357 221 860 0 0° 2

N04C-TV MYY6 240 153 4° 357 221 860 0 0° 2

N04C-TV MYY6 240 153 4° 357 221 860 0 0° 2

N04C-TV MYY6 240 153 4° 357 221 860 0 0° 2

T/M

MODEL

ABCDEFGH

247 180

247 180

247 180

436 287 944

3°

436 287 944

3°

436 287 944

3°

00° – –

00° 1

00° 1

PTO

T/M

No.

REAR

BODY

CONTROL

(OPT)

DUMP

LEVER

DUMP

LEVER

DUMP

LEVER

DUMP

LEVER

DUMP

LEVER

DUMP

LEVER

DUMP

LEVER

DUMP

LEVER

DUMP

LEVER

DUMP

LEVER

DUMP

LEVER

AUSXZU201 05T001

Page 61

5 - 2 - 1

KK-XZU215C

TRANSMISSION SIDE POWER TAKE OFF (OPT)

When the body require transmission Power Take Off (PTO),

genuine PTO equipment and related parts should be supplied

as shown below.

[T/M PTO No.1]

1) Transmission Series by Vehicle Model

2) Data of the PTO Output Shaft

3) Necessary Parts

[NOTE]

1. Parts mentioned above table shows transmission PTO unit only.

2. Other related parts of transmission PTO control, please contact each Hino

sales dealer or distributor.

Model Transmission series

XZU307L-HKMMB3

XZU347L-HKMMB3

XZU407L-HKMMD3

XZU407L-HKMQD3

XZU417L-HKMMD3

M550

AUSXZU201 05T006

Transmission

series

Permissible torque

(N·m{kgf·m} at r/min)

PTO control

type

Direction of

rotation

M550 245 {25} / 1,000

Vacuum

control

Reverse to

engine

Nut

Stud bolt

Bolt

Gasket, PTO case

Power take off assy

Parts name

Rev.

5th

4th

3rd

2nd

1st

Transmission gear ratio

Transmission model

94130-61000

92132-81025

90119-10372

33162-37030

36610-37280

Parts No.

4.625

0.738

1.000

1.556

2.911

4.981

M550

05

05

01

01

01

Lockwasher 94512-01000 05

PTO control type Vacuum

Q'ty /

unit

AUSXZU201 05T007

Page 62

5 - 2 - 2

KK-XZU215C

4) PTO Installation Procedure

(1) Drain the transmission oil.

(Do not remove the drain plug while the oil is hot, or you will

scaled yourself.)

(2) Remove the PTO cover which is at the left of the transmission.

( Do not reuse the bolts and gasket that you remove at this

time.)

(3) Clean the PTO mounting surface on the transmission side.

(4) Prepare the necessary parts, referring to paragraph "3")

(5) Install the stud bolts to the PTO mounting of the transmission

case.

(6) Fit the gasket and PTO on the PTO mounting position and

tighten the fitting bolts and nuts.

Tightening torque for stud bolts : 36.3N·m {370kgf·cm}

(7) After attaching the PTO, turn the output shaft coupling a few

revolutions to be sure that it turns freely.

(8) When you refill the transmission oil, increase the amount by

0.3 liters to allow for the PTO.

5) Gear Layout and Gear Ratio

Gear ratio : i = N2/N1 x N3/N2 x N5/N4

[NOTES]

1. Number of revolutions of PTO output shaft

= number of revolutions of engine x1/ i

2. The PTO output shaft turns in the opposite direction to the engine.

M550 32 35 34 31 40 1.371

Transmission N1 N2 N3 N4 N5 i

Page 63

5 - 2 - 3

KK-XZU215C

6) Detail of M550 Transmission

Unit : mm

DRIVE GEAR SPECIFICATION (T/M SIDE /3rd COUNTER GEAR)

TO T/M CASE

FRONT SURFACE 149

130

108

124 ±0.1

70

16 ±0.1

142

164

54

101

MAINSHAFT CENTER LINE

6-M10x1.25

DEPTH 24

DRIVE GEAR

(C)

1.5

+0.05

0

AUSXZU201 05F001

Tooth profile

Number of teeth

Normal module

Normal pressure angle

Helix angle (and direction)

Standard pitch circle diameter

Base circle diameter

Normal circular thickness

Over ball diameter

Used ball diameter

Face width

Rotation backlash

Addendum modification coefficient

Gear layout

Outside diameter

Whole depth

Semi-topping

Helical gear

35

2.650

17˚

29˚ (Right)

106.046

3.9171

113.403

5.000

20 ±0.2

0.05

-0.1515

100.106

112.750

8.1

0.2

Tooth

thickness

0

-0.1

0

-0.1

INPUT

SHAFT

PTO

35

32

AUSXZU201 05T005

Page 64

5 - 2 - 4

KK-XZU215C

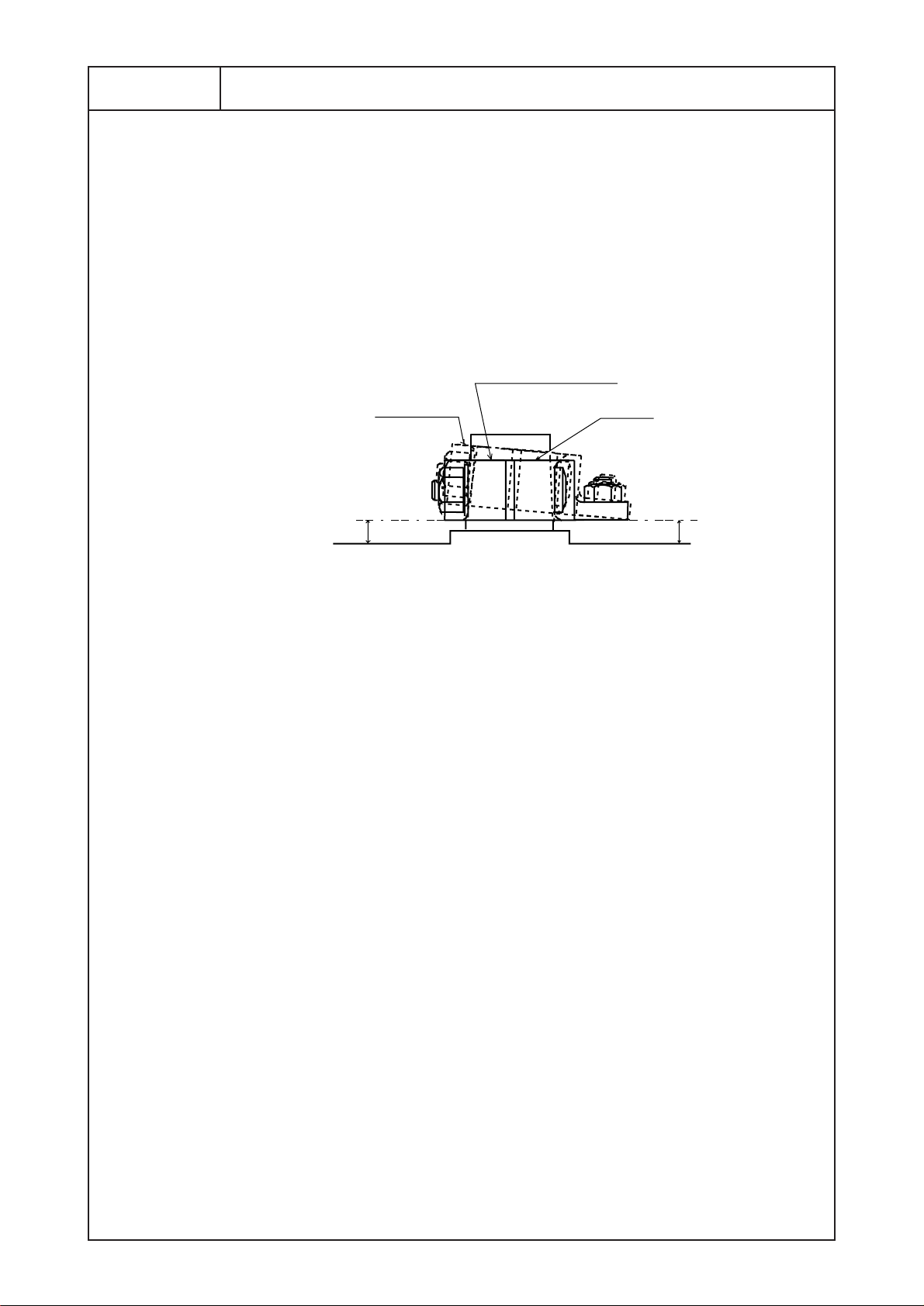

7) Transmission PTO mounting (M550)

Vacuum control type

Unit : mm

[NOTE] 1) The devices on the body or equipment side (e. g. oil pump)

must be mounted at the same angle as engine to the body.

(Direct mounting the devices to the PTO output flange is

strictly prohibited.)

2) The three-dimensional angle of the universal joint of the

drive shaft should be less than 6˚.

Page 65

5 - 2 - 5

KK-XZU215C

• Detail of PTO Flange

Unit : mm

• Detail of PTO Output Shaft

Page 66

5 - 2 - 6

KK-XZU215C

[T/M PTO No.2]

1) Transmission Series by Vehicle Model

2) Data of the PTO Output Shaft

3) Necessary Parts

[NOTE]

1. Parts mentioned above table shows transmission PTO unit only.

2. Other related parts of transmission PTO control, please contact each Hino

sales dealer or distributor.

Model Transmission series

XZU407L-HKFQD3

XZU407L-HKFRD3

XZU417L-HKFQD3

XZU417L-HKFRD3

XZU427L-HKFQD3

XZU427L-HKFRD3

MYY6S

AUSXZU201 05T012

Transmission

series

Permissible torque

(N·m{kgf·m} at r/min)

PTO control

type

Direction of

rotation

MYY6S 196 {20} / 1,000

Electronic

control

Reverse to

engine

AUSXZU201 05T013

Nut

Stud bolt

Power take off assy

Parts name

Rev.

6th

4th

3rd

2nd

1st

Transmission gear ratio

Transmission model

94130-61000

90031-16079

36610-37290

Parts No.

PTO control type Electronic

5.701

0.759

5th 1.000

1.297

1.862

3.434

5.979

MYY6S

06

06

01

Lockwasher 94512-01000 06

Q'ty /

unit

AUSXZU201 05T014

Page 67

5 - 2 - 7

KK-XZU215C

4) PTO Installation Procedure

(1) Drain the transmission oil.

(Do not remove the drain plug while the oil is hot, or you will

scaled yourself.)

(2) Remove the PTO cover which is at the left of the transmission.

( Do not reuse the bolts and gasket that you remove at this

time.)

(3) Clean the PTO mounting surface on the transmission side.

(4) Prepare the necessary parts, referring to paragraph "3")

(5) Install the stud bolts to the PTO mounting of the transmission

case.

(6) Apply liquid gasket 'THREEBOND

1215' or 'LOCKTITE 5127

(FMD-127)' to PTO sealing surface

of transmission case as shown.

Appling methods

1) Remove moisture and oils from

sealing surface before appling.

2) Dia of liquid gasket is 2 min.

3) Liquid gasket bead must be

continued all round.

(7) Fit the PTO on the PTO mounting position and tighten

nuts.

Tightening torque for nuts : 36.3N·m {370kgf·cm}

(8) After attaching the PTO, turn the output shaft coupling a few

revolutions to be sure that it turns freely.

(9) When you refill the transmission oil, increase the amount by

0.3 liters to allow for the PTO.

5) Gear Layout and Gear Ratio

Gear ratio : i =N2/N1xN4/N3xN5/N4

[NOTES]

1. Number of revolutions of PTO output shaft

= number of revolutions of engine x1/ i

2. The PTO output shaft turns in the opposite direction to the engine.

MYY6S 26 47 33 31 27 1.479

Transmission N1 N2 N3 N4 N5 i

AUSXZU201 05T015

Page 68

5 - 2 - 8

KK-XZU215C

6) Detail of MYY6S Transmission

Page 69

5 - 2 - 9

KK-XZU215C

7) Transmission PTO mounting (MYY6S)

Electronic control type

Unit : mm

[NOTE] 1) The devices on the body or equipment side (e. g. oil pump)

must be mounted at the same angle as engine to the body.

(Direct mounting the devices to the PTO output flange is

strictly prohibited.)

2) The three-dimensional angle of the universal joint of the

drive shaft should be less than 6˚.

Page 70

5 - 2 - 10

KK-XZU215C

• Detail of PTO Flange

Unit : mm

• Detail of PTO Output Shaft

Unit : mm

Page 71

5 - 3 - 1

KK-XZU215C

ENGINE CONTROL FOR BODY OR EQUIPMENT

1) Fuel Injection Pump Governor

• DUTRO vehicles use the following fuel injection pump

governor.

No.

XZU307L-HKMLB3

1

XZU307L-HKMMB3

2

XZU347L-HKMMB3

3

XZU407L-HKMMD3

4

XZU407L-HKMQD3

5

XZU407L-HKFQD3

6

XZU407L-HKFRD3

7

XZU417L-HKMMD3

8

XZU417L-HKFQD3

9

XZU417L-HKFRD3

10

XZU427L-HKFQD3

11

XZU427L-HKFRD3

12

E/G

MODEL

N04C-TU

N04C-TU

N04C-TU

N04C-TV

N04C-TV

N04C-TV

N04C-TV

N04C-TV

N04C-TV

N04C-TV

N04C-TV

N04C-TV

GOVERNOR TYPE

PUMP GOVERNOR

COMMON-RAIL

TYPE

COMMON-RAIL

TYPE

COMMON-RAIL

TYPE

COMMON-RAIL

TYPE

COMMON-RAIL

TYPE

COMMON-RAIL

TYPE

COMMON-RAIL

TYPE

COMMON-RAIL

TYPE

COMMON-RAIL

TYPE

COMMON-RAIL

TYPE

COMMON-RAIL

TYPE

COMMON-RAIL

TYPE

ELECTRONIC CONTROL TYPE DENSO

ELECTRONIC CONTROL TYPE DENSO

ELECTRONIC CONTROL TYPE DENSO

ELECTRONIC CONTROL TYPE DENSO

ELECTRONIC CONTROL TYPE DENSO

ELECTRONIC CONTROL TYPE DENSO

ELECTRONIC CONTROL TYPE DENSO

ELECTRONIC CONTROL TYPE DENSO

ELECTRONIC CONTROL TYPE DENSO

ELECTRONIC CONTROL TYPE DENSO

ELECTRONIC CONTROL TYPE DENSO

ELECTRONIC CONTROL TYPE DENSO

MANUFACTURERMODEL

AUSXZU201 05T016

Page 72

5 - 3 - 2

KK-XZU215C

2) Engine Accelerator

• Engine accelerator and extension harness for body control

are packed in cabin as optional equipment.

• Connect the connector of Engine accelerator with spare

connector which is provided behind the No.3 crossmember at

chassis frame LH side member.

• Should more detailed data or information with regard to

engine accelerator for body control be needed, consult

authorized Hino distributor.

Page 73

5 - 3 - 3

KK-XZU215C

Page 74

5 - 3 - 4

KK-XZU215C

3) HOW TO INSTALL ENGINE ACCELERATOR FOR BODY OR

EQUIPMENT

(1) Be sure to provide the body controller with the full speed

stopper for controlling the stroke of the sensor.

In that case, adjust the body side stroke in such a way that the

body side stopper comes in contact earlier than the sensor

side stopper.

The standard for adjustment is 1mm clearance between the

sensor side lever and stopper under the condition than the

body side lever touches the stopper. (See the following

illustration.)

• Be sure to set the sensor lever that sensor lever should be

contacted with idling stopper by adjusting body control lever

while body or equipment do not operate (while vehicle is

driving).

The clearance indicated for the stroke stopper of accelerator

stopper is just for reference. If the sensor side stopper comes

into contact earlier, a forcible stress will be imposed on the

sensor shaft and it may result in the damage of the part in

cause.

Moreover if sensor lever do not came into contact with idling

stopper may result in a bad condition of the engine while

vehicle to be driving.

Page 75

5 - 3 - 5

KK-XZU215C

(2) When fitting the cable on the sensor lever, define the direction

by pulling the cable parallelly to the direction of lever stroke so

that an imbalanced load may not be imposed on the sensor

shaft.

(See the following illustration.)

(3) Cautiones when installing the Engine accelerator sensor

(hereinafter termed the sensor).

• Never attempt to disassemble the sensor.

Do not drop the sensor or do not shock it.

Each above thing may lead malfunction and failure.

• The sensor is not integral waterproof type.

Therefore, when installing it, pay attention to avoid the direct

projection of vehicle washing water, tire splash etc.

• The usable range of temperature is -30~80°C. Use it in the

said range.

• Install the sensor in the position which can apply lubrication.

• Avoid such places where there is risk of receiving falling

matters or stones that give impact.

• Install the sensor where there is no possibility of exposing

dust, oil mist, humidity, chemical product or vibration.

If it is impossible to find such place, protect it with a cover.

• Install the wire harness certainly so that it may not twist or

not bend extremely.

• For fitting and clipping the harness wires,refer to the

COMMON manual.

• If the length of the sub-harness wire is too short, try to abtain

the same kind of the harness wire for extension.

Page 76

5 - 4

KK-XZU215C

REAR BODY CONTROL LEVER (OPT)

1) Mounting position of dump body control lever

Unit : mm

Page 77

KK-XZU215C

6. ELECTRICAL SYSTEM

FUSE BLOCK AND RELAY PANEL ・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6 - 1

ALTERNATOR OUTPUT CHARACTERISTIC

・・・・・・・・・・・・・・・・・・・・ 6 - 2

SPARE POWER TERMINALS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6 - 3

ADDITIONAL LAMPS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6 - 4

REAR COMBINATION LAMP

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6 - 5

LICENSE PLATE BRACKET AND LICENSE PLATE LAMP

・・・・・・・・ 6 - 6

BACK-UP BUZZER

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6 - 7

ELECTRICAL WIRING DIAGRAMS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6 - 8

Page 78

6 - 1 - 1

6. ELECTRICAL SYSTEM

KK-XZU215C

FUSE BLOCK AND RELAY PANEL

1) LOCATION

The fuse block and relay panel are located inside the instrument

panel as shown below.

Page 79

6 - 1 - 2

KK-XZU215C

2) FUSE BLOCK

Page 80

L

E12

+S

E29

-S

E13

L

E04

B

%4N

B

E01

L

#RC

L

K49

L

O0TLO0R

L

A04LA10LV02LH02LC08

B

C07B#CB

B

#HA

B

A03

L

E02

B

#RA

B

#OJ

L

I02

L

K04

L

C02

L

#PB

L

%4H

B

%4M

B

E11

E

Z24

-S

K19

+S

K18

B

O51

L

K17

-S

A21

+S

A74

L

A20

B

A19

B

%6A

L

%6B

+S

%6C

-S

%6D

-S

K7D

+S

K7C

B

K7B

L

K7E

S-

#NK

S+

#NJ

+B

#NL

+S

H71

E

Z4U

L

P88

B

P87

+S

C34

-S

Z96

L

C33

B

C32

+S

RN0

-S

RN1

L

RNZ

B

RNY

3

#R8

+S

C1A

L

C10

-S

C11

1

#R62#R7

3

#R5

1

#R32#R4

3

#R2

B

#SG

2

#SR

1

#SM

3

#SP

1

#SJ

2

#SK

3

#SL

HORN

L

X36

ECU

XD0

-S

Z23

B

X35

ENGINE

(N04C)

HEATER

IGNITION

POWER

WINDOW

FOG LAMP

HEAD LAMP ENGINE(N04C) A/C COMP

TAIL LAMP

ACCESSORY

15A

20A

10A

15A

10A

10A

10A

10A

10A

20A

20A

15A

10A

10A

10A

L

D02

10A

10A

15A

20A

30A

STOP

ENGINE

(12V)

WIPER AIR

CONDITIONING UNIT

L

%4G

10A

IGNITION

FOG

LAMP

DOME

L

#CA

10A

P-

TAIL

POWER

WINDOW

HAZ-

HORNP-ACC

AM2

HEAD LAMP

(LH) (RH)

GAUGE TAIL LAMP

ACC

FUSE

PULLER

SPARE FUSE

AM1

ECU

GENERAL

NAME AND FORM OF RELAY

FORM OF RELAY

FORM OF RELAY BLOCK

NAME OF RELAY

TERMINAL

SYMBOL

AUXILIARY

SYMBOL

L

E12

+S

E29

-S

E13

L

E11

HORN

6 - 1 - 3

KK-XZU215C

3) RELAY PANEL

(Except XKU417L-HKFQB3)

Page 81

L

E12

+S

E29

-S

E13

L

E04

B

%4N

L

E01

L

#RC

L

K49

L

O0TLO0R

L

A04LA10LV02LH02LC08

B

C07B#CB

B

#HA

B

A03

B

E02

B

#RA

B

#OJ

L

I02

L

K04

L

C02

L

#PB

L

%4H

L

%4J

B

%4M

B

E11

E

Z24

-S

K19

+S

K18

B

O51

L

K17

-S

A21

+S

A74

L

A20

B

A19

B

%6A

L

%6B

+S

%6C

-S

%6D

-S

K7D

+S

K7C

B

K7B

L

K7E

S-

#NK

S+

#NJ

+B

#NL

+S

H71

E

Z4U

L

P88

B

P87

+S

C34

-S

Z96

L

C33

B

C32

+S

RN0

-S

RN1

L

RNZ

B

RNY

3

#R8

+S

C1A

L

C10

-S

C11

1

#R62#R7

3

#R5

1

#R32#R4

1

#R2

2

#SG

3

#SR

1

#SM

2

#SN

3

#SP

1

#SJ

2

#SK

3

#SL

HORN

L

%6F

+S

%6G

-S

%6H

B

%6E

ENGINE-3

HEATER

IGNITION1-2

POWER

WINDOW

FOG LAMP

HEAD LAMP ENGINE-2 A/C COMP

TAIL LAMP

ACCESSORY

15A

15A

20A

10A

15A

10A

10A

10A

10A

10A

20A

20A

15A

10A

10A

10A

L

D02

10A

10A

15A

20A

30A

STOP

ENGINE

(12V)

HV

(12V)

WIPER AIR

CONDITIONING UNIT

L

%4G

10A

IGNITION1

FOG

LAMP

DOME

L

#CA

10A

TAIL

POWER

WINDOW

HAZ-

HORN

AM2

HEAD LAMP

(LH) (RH)

GAUGE TAIL LAMP

ACCP-

ACC

FUSE

PULLER

SPARE FUSE

AM1

ECU

GENERAL

NAME AND FORM OF RELAY

FORM OF RELAY

FORM OF RELAY BLOCK

NAME OF RELAY

TERMINAL

SYMBOL

AUXILIARY

SYMBOL

L

E12

+S

E29

-S

E13

L

E11

HORN

6 - 1 - 4

KK-XZU215C

RELAY PANEL

(XKU417L-HKFQB3 only)

Page 82

6 - 2

KK-XZU215C

ALTERNATOR OUTPUT CHARACTERISTIC

• Except XKU417L-HKFQB3

• XKU417L-HKFQB3 only

• The maximum power available for the whole vehicle is defined by the

capacity of the alternator.

Therefore, the electric power that is not consumed by electrical equipments

such as head lamps etc. can be available for the body side.

• Pay attention not to exceed the capacity of the alternator equipped on the

vehicle.

• In the event that you are obliged to carry out the body mounting exceeding

the capacity of the alternator, select the one available as an option or

consult your nearest Hino service dealer or distributor.

Page 83

6 - 3 - 1

KK-XZU215C

SPARE POWER TERMINALS

If you must take an electrical power supply for the body from

the chassis, take it from the spare power supply.

Spare power supplies and positions

[NOTE] (1) The permissible current to be taken from spare power terminal is determined from the capacity of the

fuse and wire size.

Make sure that the maximum load (current) of the installed equipment must be kept lower current

than the permissible capacity to be able to take from spare power terminal.

(2) Be sure to keep the lower current value than the alternator generated capacity when switched on the

original and additional equipment same time to avoid over discharging electricity of the battery.

(3) Using length show the wire length from fuse to each terminal (pole) of the spare outlet.

Be sure to make circuit using the appropriate kind, size and length of the wire followed by the table

described in this page.

Page 84

6 - 3 - 2

KK-XZU215C

1) Outlet Position Inside the Cab

Page 85

6 - 3 - 3

KK-XZU215C

2) Outlet Position on Chassis Side

HOW TO TAKE ELECTRICITY FROM POWER SUPPLY CIRCUIT

a. USING SUB-HARNESS TYPE

b. DIRECT CONNECTING TYPE

[NOTE] • As far as possible take power using sub-harness type.

• If you must take power using direct connecting type, be sure to

observe the precautions in described item "ELECTRICAL

EQUIPMENT AND WIRING".

Page 86

6 - 3 - 4

KK-XZU215C

3) Detail of Connector (Parts no. & pole arrangement)

• INSIDE THE CAB

• CHASSIS SIDE

[NOTE] FOR COUPLING CONNECTOR PROVIDED AS AN OPTIONAL

PARTS.

• Parts number of coupling connector is shown in parenthesis.

• Details of coupling connector are as follows.

• Each connector of the chassis side has individual color. Make

sure that do not connect wrong coupling with spare power

terminal (connector).

Page 87

6 - 4 - 1

KK-XZU215C

ADDITIONAL LAMPS

• The lamps installed to the chassis has already been complied

with the laws or regulations. Alteration and modification are

therefore strictly prohibited.

• If you must install additional lamps, be sure to observe the

following precautions.

• Moreover, installation of the additional lamps must be complied

with the laws or regulations and install the harness to be

observed the precautions of wire harness described in Common

Manual.

Page 88

6 - 4 - 2

KK-XZU215C

1) Drawing in the Wire Harness into the Cab

Penetration Hole of Wire Harness

• The penetration hole to draw the wire harness into the cab is

provided at the floor of cab as following figure.

• When draw the wire harness, replace the grommet and draw

it into the cab.

[NOTES]

(1) Make sure that the management should be taken such as

disposing the sharp edge of the penetration hole and fixing

the corrugated tube on the harness to prevent damage to

the wire and potential short circuit.

(2) Make sure that the clearance between wire and

penetration hole should be properly sealed by sealant to

prevent water coming in and abnormal noise.

(3) The penetration holes of wire marked A, B may be not

able to use according to the vehicle’s specification.

Be sure to confirm the actual vehicle before drawing the

harness (wire) and using empty hole.

(4) Using the chassis harness grommet together for drawing

the additional wire is strictly prohibited to prevent damage

of chassis harness when processing the grommet.

LEFT HAND DRIVE

Page 89

6 - 4 - 3

KK-XZU215C

2) Installation of Additional Equipment and Switches

Layout of Equipment and Switches

(1) Installing space of additional equipment

• Have been provided the installing space (H:150mm x W:180

mm ) at the center cluster which can be installed three kind of

additional equipment as a wireless radio, electrical equipment

and etc.

(2) Layout of switches and lamps

• Standard layout of switches and lamps are as following

figure.

• If you intend to install additional switches or lamps at

instrument panel for the convenience of body mounting, be

sure to install it at empty space after confirmation of original

condition of the actual vehicle.

Avoid using additional switches and lamps with

existing switches and lamps.

• If you install additional switches and lamps, fit a caution plate

showing the purpose of each switch, etc., to prevent

accidental operation or confirmation.

Page 90

6 - 4 - 4

LEFT HAND DRIVE

KK-XZU215C

No. DESCRIPTION APPLICATION

A TRAY TACHOGRAPH (OPT) AUDIO (OPT) OPT (1DIN SPACE)

B TRAY AUDIO (OPT) (WHEN TACHOGRAPH IS OPT.) OPT (1DIN SPACE)

C TRAY (1DIN SPACE)

a FRONT FOG LAMP SWITCH OPT

b ---- ---c COIN HOLDER STD

d ---- ---e PTO SWITCH OPT

f ---- ----

i WARM UP SWITCH STD

j ---- ----

k PEN HOLDER & HOOK STD

l IDLE STOP SWITCH STD

m HAZARD SWITCH STD

n ---- ---o ---- ---p ---- ----

Except XKU417L-HKFQB3

*

GEXZU208 06T001

Page 91

6 - 4 - 5

KK-XZU215C

Additional Switches

• If you intend to install the switch to the instrument panel, use

the switch mentioned hereinafter which is provided as a spare

parts.

Page 92

6 - 4 - 6

KK-XZU215C

3) Method of Taking Electrical Power