Page 1

1 INDEX

CHAPTER 3

ENGINE

Models: J08C-TP and J08C-TR

TROUBLESHOOTING...............................................................3- 1-3

SPECIAL TOOLS ......................................................................3- 2-1

ENGINE 3-1-1Models J08C-TP and J08C-TR

3-228E-05

3

ENGINE OVERHAUL CRITERIA ..............................................3- 3-1

DISMOUNTING THE ENGINE ASSEMBLY ..............................3- 4-1

REMOVAL OF THE ENGINE COMPONENT PARTS ...............3- 5-1

CAMSHAFT HOUSING AND CYLINDER HEAD......................3- 6-1

CRANKSHAFT FRONT END, OIL PAN, FLYWHEEL AND

FLYWHEEL HOUSING ..............................................................3- 7-1

TIMING GEAR ...........................................................................3- 8-1

PISTON, CRANKSHAFT AND CYLINDER BLOCK.................3- 9-1

LUBRICATING SYSTEM ...........................................................3-10-1

COOLING SYSTEM...................................................................3-11-1

FUEL SYSTEM ..........................................................................3-12-1

AIR INTAKE AND EXHAUST SYSTEM ....................................3-13-1

ENGINE CONTROL SYSTEM...................................................3-14-1

ELECTRICAL PARTS................................................................3-15-1

AIR COMPRESSOR AND POWER STEERING PUMP............3-16-1

INSTALLATION OF THE ENGINE COMPONENT PARTS .......3-17-1

ENGINE TUNE-UP ....................................................................3-18-1

MOUNTING THE ENGINE ASSEMBLY ....................................3-19-1

LIQUID GASKET AND APPLICATION POINTS.......................3-20-1

POWER TAKE-OFF (IF FITTED) ..............................................3-21-1

Page 2

1 page 1

3-1-2 ENGINE

Models J08C-TP and J08C-TR

TROUBLESHOOTING

(ENGINE)

Symptom Possible cause Remedy/Prevention

Engine overheating Coolant

● Insufficient coolant ........................................Add coolant

`

● Defective thermostat ..................................... Replace the thermostat

● Overflow of coolant due to leakage of ..........Repair

exhaust into cooling system

● Damaged rubber hose ..................................Replace rubber hose

● Coolant leakage due to deteriorated.............Replace rubber hose

rubber hose

● Coolant leakage from coolant pump .............Replace the coolant pump

● Coolant leakage from rubber hose ...............Retighten or replace clamp

connection

● Coolant leakage from cylinder head ............. Replace gasket

gasket

Coolant pump

● Bearing seizure .............................................Replace

● Damaged (corroded) vane ............................Replace vane

Radiator

● Clogged with rust and scale..........................Clean radiator

● Clogged with iron oxide due to leakage ........ Clean coolant passage and

of exhaust into cooling system correct exhaust leakage

● Coolant leakage ............................................Repair or replace radiator

● Damaged cooling fan .................................... Replace cooling fan

● Clogged radiator core due to mud or ............Clean radiator

other debris

● Defective radiator cap pressure valve ..........Replace radiator cap

Abnormal combustion

● Incorrect injection timing ...............................Adjust injection timing

● Reduced injection pressure .......................... Adjust injection pressure

● Poor fuel........................................................Use good quality fuel

● Poor nozzle spray .........................................Adjust or replace nozzle

● Unsatisfactory automatic timer......................Repair or replace timer

advance angle

Page 3

1 page 1

ENGINE 3-1-3Models J08C-TP and J08C-TR

Symptom Possible cause Remedy/Prevention

Engine overheating Other problems

● Defective or deteriorated engine oil ..............Change engine oil

● Unsatisfactory operation of oil pump ............Replace or repair

● Insufficient oil ................................................Add oil

● Brake drag .................................................... Adjust

Severe operating conditions

● Lugging the engine ....................................... Operate engine properly

Excessive oil consumption Pistons, cylinder liners and piston rings

● Wear of piston rings and cylinder liner..........Replace piston rings and

● Worn, sticking or broken piston rings............Replace piston rings and

● Insufficient tension on piston rings................Replace piston rings and

● Unsatisfactory break-in of piston rings..........Replace piston rings and

● Unsuitable oil (viscosity too low) ................... Change oil as required and

●

Incorrectly fitted piston rings (upside down)..

● Gaps of piston rings in line with each other ..Reassemble piston rings

Valves and valve guides

● Worn valve stem ...........................................Replace valve and valve guide

● Worn valve guide ..........................................Replace valve guide

● Incorrectly fitted valve stem seal...................Replace the stem seal

● Excessive lubricant on rocker arm ................ Check clearance of rocker arm

cylinder liner

cylinder liner

cylinder liner

cylinder liner

replace piston rings and

cylinder liner

Replace piston rings

and shaft

Excess oil feed

● Defective oil level gauge ............................... Replace oil level gauge

● Oil level too high ........................................... Drain excess oil

Page 4

1 page 1

3-1-4 ENGINE

Symptom Possible cause Remedy/Prevention

Excessive oil consumption Oil leakage from miscellaneous parts

● Oil leakage from oil seal................................Replace oil seal

● Cracks or blowhole in cylinder block.............Replace cylinder block

● Oil leakage from connections of oil lines ......Tighten connections of oil lines

● Oil leakage from oil cooler ............................ Replace oil cooler

● Oil leakage from oil pan gasket ....................Replace oil pan gasket

● Oil leakage from O-ring.................................Replace O-ring

●

Models J08C-TP and J08C-TR

Other problems

Overcooled engine ........................................

(low temperature wear)

Warm up engine before moving

vehicle

Check cooling system

NOTE: If oil consumption is excessive, the problems above will occur. Complaints from the

customer are often related to such problems.

1. White smoke is emitted continuously when the engine is run at high speed.

2. White smoke is emitted only immediately after the engine speed is abruptly raised

when idling.

3. The tail pipe is blackened with oil.

4. Oil leaks from the flanges of the exhaust manifold.

5. Lack of power.

6. Excessive blow-by gas.

Piston seizure Pistons, cylinder liners and piston rings

● Incorrect clearance between piston ..............Replace piston, piston rings

and cylinder liner and cylinder liner

● Unsatisfactory installation of piston pin.........Replace piston, piston rings,

cylinder liner and piston pin as

required

● Broken piston ring ......................................... Replace piston, piston rings

and cylinder liner

● Difference in expansion due to use of...........Replace piston, piston rings

wrong piston and cylinder liner

Page 5

1 page 1

ENGINE 3-1-5Models J08C-TP and J08C-TR

Symptom Possible cause Remedy/Prevention

Piston seizure Coolant

● Reduction in capacity of coolant pump .........Replace the coolant pump

(due to vane corrosion)

● Leakage of coolant........................................Repair

● Insufficient coolant ........................................Add coolant

● Dirty coolant ..................................................Clean and replace coolant

● Defective radiator..........................................Repair or replace the radiator

(coolant leakage, clogging)

● Defective rubber hose (leakage)...................Replace rubber hose

● Defective thermostat ..................................... Replace the thermostat

● Leakage of exhaust into cooling system ....... Repair

Operation

● Abrupt stoppage of engine after running ......Operate engine properly

at high speed

● Hill climbing using unsuitable gear ...............Select suitable gear

Oil

● Insufficient oil ................................................Add oil

● Dirty oil ..........................................................Change oil

● Poor quality oil .............................................. Replace with proper engine oil

● High oil temperature......................................Repair

● Low oil pressure............................................Repair

● Defective oil pump ........................................ Repair oil pump

● Reduced performance due to worn ..............Replace oil pump

oil pump

● Suction strainer sucking air...........................Add oil and/or repair strainer

Abnormal combustion

● Use of defective fuel ..................................... Change fuel

● Incorrect injection timing ...............................Adjust injection timing

● Engine overheating .......................................See Symptom: “Engine

overheating”

Page 6

1 page 1

3-1-6 ENGINE

Models J08C-TP and J08C-TR

NOTE: If piston seizure occurs, the problems above will occur. Complaints from the customer

are often related to these problems.

1. White smoke is emitted.

2. Lack of power

3. Excessive blow-by gas

Symptom Possible cause Remedy/Prevention

Lack of power Injection pump ............................................Refer to “FUEL INJECTION

PUMP”

Intake

● Clogged air cleaner.......................................Clean element or replace

element

Overheating ...............................................See Symptom: “Engine

overheating”

Fuel and nozzle

● Poor nozzle spray .........................................Adjust or replace injection

nozzle

● Nozzle clogged with carbon .......................... Clean nozzle

● Wear or seizure of nozzle .............................Replace nozzle

● Air in fuel system...........................................Repair and bleed air from fuel

system

● Clogged fuel filter .......................................... Replace element

● Use of poor fuel.............................................Use good quality fuel

Pistons, cylinder liners and piston rings

● Seized or wear of piston ............................... Replace the piston, piston rings

and liner

● Worn or broken piston rings,.........................Replace piston rings, piston

piston and cylinder liner and liner

Page 7

1 page 1

ENGINE 3-1-7Models J08C-TP and J08C-TR

Symptom Possible cause Remedy/Prevention

Lack of power Other problems

● Exhaust brake butterfly valve stuck...............Replace or repair exhaust

in half-open position brake

● Connecting rod bent......................................Replace or repair connecting

rod

● Exhaust pipe or muffler crushed ...................Replace exhaust pipe or

(increased back-pressure) muffler

● Breakage of turbine or blower.......................Refer to TURBOCHARGER in

CHAPTER 51

Leakage of exhaust Head gasket

● Fatigued gasket (aging) ................................Replace gasket

● Damage.........................................................Replace gasket

● Improper installation......................................Replace gasket

Head bolts

● Loose bolts....................................................Tighten bolts

● Elongated bolts .............................................Replace bolts

● Improper tightening torque or........................Tighten properly

tightening sequence

Cylinder block

● Cracking........................................................Replace cylinder block

● Surface distortion .......................................... Repair or replace

● Fretting of cylinder liner insertion portion ...... Replace cylinder block

(insufficient projection of cylinder liner)

Cylinder head

● Cracking........................................................Replace cylinder head

● Surface distortion .......................................... Repair or replace

Cylinder liners

● Cracking........................................................Replace cylinder liner

● Corrosion.......................................................Replace cylinder liner

● Insufficient projection of cylinder liner ........... Replace cylinder liner

Page 8

1 page 1

3-1-8 ENGINE

Symptom Possible cause Remedy/Prevention

Leakage of exhaust Other problems

● Incorrect injection timing ...............................Adjust injection timing

Models J08C-TP and J08C-TR

NOTE: If leakage of the exhaust occurs, the problems above will occur. Complaints from the

customer are often related to these problems.

1. Lack of power.

2. The engine overheats.

3. The coolant is discolored.

Difficulty starting engine Electrical system

● Discharged battery........................................Charge battery

● Defective wiring in starter-circuit ................... Repair wiring of starter

● Loose or open-circuit battery cable...............Tighten battery terminal

● Breakdown of starter.....................................Replace starter

● Broken glow plug .......................................... Replace

Injection pump .............................................Refer to “FUEL INJECTION

Air cleaner

● Clogged element...........................................Clean the element or replace

Fuel system

● No fuel in tank ...............................................Supply fuel

● Clogged fuel line ...........................................Clean fuel line

● Air sucked into fuel system through .............. Tighten fuel line connections

fuel line connections

● Clogged fuel filter .......................................... Replace element

● Loose connection in high-pressure line ........ Tighten sleeve nut of high

● Water in fuel..................................................Drain and clean fuel system

connections or replace battery

cable

PUMP”

the element

pressure line

Page 9

1 page 1

ENGINE 3-1-9Models J08C-TP and J08C-TR

Symptom Possible cause Remedy/Prevention

Difficulty starting engine Nozzles

● Seized nozzle................................................Replace nozzle

● Broken or fatigued nozzle spring .................. Replace spring

Oil system

● Oil viscosity too high .....................................Use proper viscosity oil, or

install an oil immersion heater

and warm up oil

Other problems

● Seized piston ................................................ Replace piston, piston rings,

and liner

● Seized bearing .............................................. Replace bearing and crankshaft

● Reduced compression pressure ...................Overhaul engine

● Ring gear damaged or worn ......................... Replace the ring gear and/or

accelerator cable starter pinion

● Improperly adjusted or broken ......................Adjust or replace the

accelerator cable

Rough idling Injection pump ............................................Refer to “FUEL INJECTION

PUMP”

Nozzles

● Uneven injection pressure ............................ Adjust

● Poor nozzle spray .........................................Adjust or replace nozzle

● Carbon deposit on nozzle tip ........................ Remove carbon

● Seized needle valve......................................Replace nozzle

Engine proper

● Improper valve clearance .............................Adjust valve clearance

● Improper contact of valve seat......................Replace or repair valve and

valve seat

● Idling speed too low ......................................Adjust idling speed

● Coolant temperature too low.........................Warm up engine

● Compression pressure of cylinders...............Overhaul engine

markedly different from one another

Page 10

1 page 1

3-1-10 ENGINE

Symptom Possible cause Remedy/Prevention

Rough idling Other problems

● Clogged high pressure injection line ............. Replace line

● Leakage due to improper tightening ............. Tighten sleeve nut

● Improperly adjusted or broken ......................Adjust or replace accelerator

● Engine seizure ..............................................Replace pistons, piston rings

● Incorrect valve timing ....................................Replace camshaft

Models J08C-TP and J08C-TR

of high pressure injection line

accelerator cable cable

and liners

Diesel knock Injection pump...............................................Refer to “FUEL INJECTION

PUMP”

Nozzles

● Incorrect injection pressure...........................Adjust

● Poor nozzle spray .........................................Adjust or replace nozzle

● Sticking of nozzle .......................................... Check and/or replace

● Fatigued or broken nozzle spring .................Replace spring

Fuel system

● Use of poor fuel.............................................Use good quality fuel

● Fuel leakage into combustion chamber ........Adjust nozzles

(during engine starting)

Other problems

● Excessively cooled or heated engine ...........Warm up or cool engine

● Insufficient air intake .....................................Correct

● Insufficient compression pressure ................ Repair

● Compression pressure leaks at .................... Replace head gasket

cylinder head gasket

● Improper valve clearance or valve sticking ... Adjust or repair

● Tappet sticking .............................................. Replace tappet and camshaft

Page 11

1 page 1

ENGINE 3-1-11Models J08C-TP and J08C-TR

Symptom Possible cause Remedy/Prevention

Unusual engine noise Piston

● Wear of piston pin boss or piston pin............Replace piston and/or piston

pin

● Seized, damaged, or worn piston pin ...........Replace piston pin bushing.

bushing

● Worn pistons or cylinder liners......................Replace piston or cylinder liner

● Damaged or seized piston ............................Replace piston and cylinder

liner

● Foreign matter on top surface of the piston ..

Remove foreign matter and

repair or replace piston, cylinder

liner, and/or cylinder head

Valve mechanism

● Incorrect valve clearance .............................. Adjust valve clearance

● Valve cotter out of place................................Replace valve cotter

● Seized valve stem.........................................Replace valve and valve guide

● Broken valve .................................................Replace valve

● Damaged rocker arm support .......................Replace rocker arm support

● Broken valve spring ...................................... Replace valve spring

Bearings seizure

● Insufficient lubricating oil...............................Add oil

● Excessive or insufficient tightening of ........... Retighten to specified torque

bearing housings

● Pits and scratches on bearing surface..........Replace bearing and crankshaft

● Oil film formed on back of bearing ................Replace bearing

● Improper installation of bearing ....................Replace bearing

● Reduction of spread dimension of bearing ... Replace bearing

● Distorted bearing housing ............................. Replace or correct bearing

housing

● Excessive oil clearance.................................Replace bearing

Page 12

1 page 1

3-1-12 ENGINE

Symptom Possible cause Remedy/Prevention

Unusual engine noise Various other parts

● Exhaust gas leakage from exhaust...............Retighten joints

● Loosen or missing intake manifold ...............Retighten or replace

● Intake valve seating is not concentric ...........Replace or correct the valve

● Intake gas leakage........................................Retighten

● Loose cooling fan mounting bolts or .............Tighten the fan and

● Lack of lubricating oil .................................... Lubricate

● Worn timing gear...........................................Replace the timing gear

● Breakage of turbine or blower.......................Refer to TURBOCHARGER in

Models J08C-TP and J08C-TR

pipe joints

flange gasket

and valve seat

Other problems

fan pulley nut crankshaft pulley

(coolant pump, valves, etc.)

CHAPTER 51

NOTE: The items on this page concern unusual engine noise which is due to causes other than

those given for diesel knock.

Page 13

1 page 1

(FUEL INJECTION PUMP)

Symptom Possible cause Remedy

Engine does not start Fuel not reaching injection pump

● Fuel lines clogged or damaged.....................Clean or replace fuel lines

● Fuel filter clogged .........................................Clean or replace the filter

element

● Air in fuel caused by improper ...................... Repair connections

connections of fuel line between

fuel tank and feed pump

● Filter incorporated in inlet side ...................... Remove foreign material

of feed pump clogged

● Faulty feed pump check valve ...................... Repair or replace it

● Feed pump piston spring broken .................. Replace it

● Feed pump push rod or tappet sticking ........Repair or replace it

ENGINE 3-1-13Models J08C-TP and J08C-TR

Fuel reaching injection pump

● Faulty connection of accelerator cable ......... Repair connection

to pump adjusting lever

● Control rack faulty or sticking........................Repair it

● Damaged camshaft bearing..........................Repair it

● Plunger worn or sticking................................Correct or replace it

● Faulty connection of engine .......................... Repair it

stop cable to pump stop lever

Nozzle faulty

● Fuel leakage caused by loosened ................ Inspect and tighten it

nozzle holder

● Low opening pressure of nozzle ...................Adjust it

● Nozzle pressure spring broken .....................Replace it

● Nozzle needle sticking to nozzle body .......... Correct or replace it

Pump out of timing

● Improperly retarded injection timing..............Correct injection timing

● Incorrect timing caused by improper.............Check engine timing and

installation of pump correct it

● Woodruff key for pump camshaft cut off. ......Replace it

● Improper pre-stroke adjustment....................Correct it to obtain specified

injection timing

Page 14

1 page 1

3-1-14 ENGINE

Symptom Possible cause Remedy

Engine starts and stops Fuel lines clogged.........................................Clean or replace fuel lines

Engine has low power Pump out of timing

● Excessive advanced timing...........................Check and correct it

● Excessively retarded timing ..........................Check and correct it

● Defective injection pump overflow valve ....... Repair or replace it

● Feed pressure too low .................................. Repair the feed pump

● Improper accelerator cable adjustment ........Adjust it

Models J08C-TP and J08C-TR

Air in fuel caused by damaged ..................... Repair fuel lines or replace fuel

fuel lines or improper connection of lines and gaskets

fuel lines

resulting in loud knocking

resulting in black smoke

Nozzle faulty

● Fuel leakage from nozzle holder...................Check and repair nozzle holder

● Bad nozzle spray characteristic ....................Repair or replace it

● Loosened adjusting screw in nozzle .............Adjust it

holder, resulting in low opening pressure

● Nozzle pressure spring broken .....................Replace it

Pump faulty

● Fuel leakage from delivery valve .................. Retighten the delivery valve

holder

holder if it is loosened or replace

O-ring if the O-ring is defective

● Defective seat of delivery valve assembly ....Repair or replace it

● Delivery valve spring broken.........................Replace the spring

● Plunger worn.................................................Replace it

● Large spread in fuel delivery.........................Adjust it

● Wear of tappet roller ..................................... Replace the roller

● Camshaft bearing worn or broken.................Replace it

● Improper adjustment of governor..................Adjust it

full load stopper screw

Page 15

1 page 1

Symptom Possible cause Remedy

Excessive smoke Black smoke

● Excessive fuel delivery caused by ................

incorrect adjustment of full load

stopper screw

● Excessively advanced injection timing..........Correct it

● Large spread in fuel delivery.........................Adjust it

● Bad nozzle fuel spray characteristics ...........Check and correct them

White smoke

● Unused after glow system.............................Use it

● Improperly retarded injection timing..............Advance injection timing

● Water in fuel..................................................Check and clean fuel lines

● Glow plug not operating ................................ Check glow plug circuit. Refer

Adjust fuel delivery on test stand

to ELECTRICAL EQUIPMENT

in CHAPTER 20

ENGINE 3-1-15Models J08C-TP and J08C-TR

Low idle speed

Improper adjustment of throttle control knob ..

Correct it

irregular Bad fuel spray characteristic of nozzles. ...... Check and repair them

Incorrect injection timing ............................... Correct it

Incorrect initial tension setting of...................Adjust or replace it

idling spring or the spring broken.

Control rack does not move smoothly...........Disassemble pump and repair it

Large spread in fuel delivery.........................Adjust it

Plunger worn.................................................Replace it

Governor linkage does not move smoothly...Correct it

Defective feed pump .....................................Disassemble and repair it

Engine always runs Accelerator cable sticking .............................Check and correct it

at high speed Governor linkage sticking .............................Disassemble and repair the

governor

Control rack sticking......................................Check and correct it

Loud knocking Improper injection timing...............................Correct it

Bad fuel nozzle spray pattern . .....................Check and correct it

after-dribble

High nozzle opening pressure ......................Adjust the opening pressure

Incorrect fuel deliveries to.............................Readjust the fuel deliveries

some nozzles.

Page 16

1 page 1

Models J08C-TP and J08C-TR

SPECIAL TOOLS

Prior to starting an engine overhaul, it is necessary to have the following.

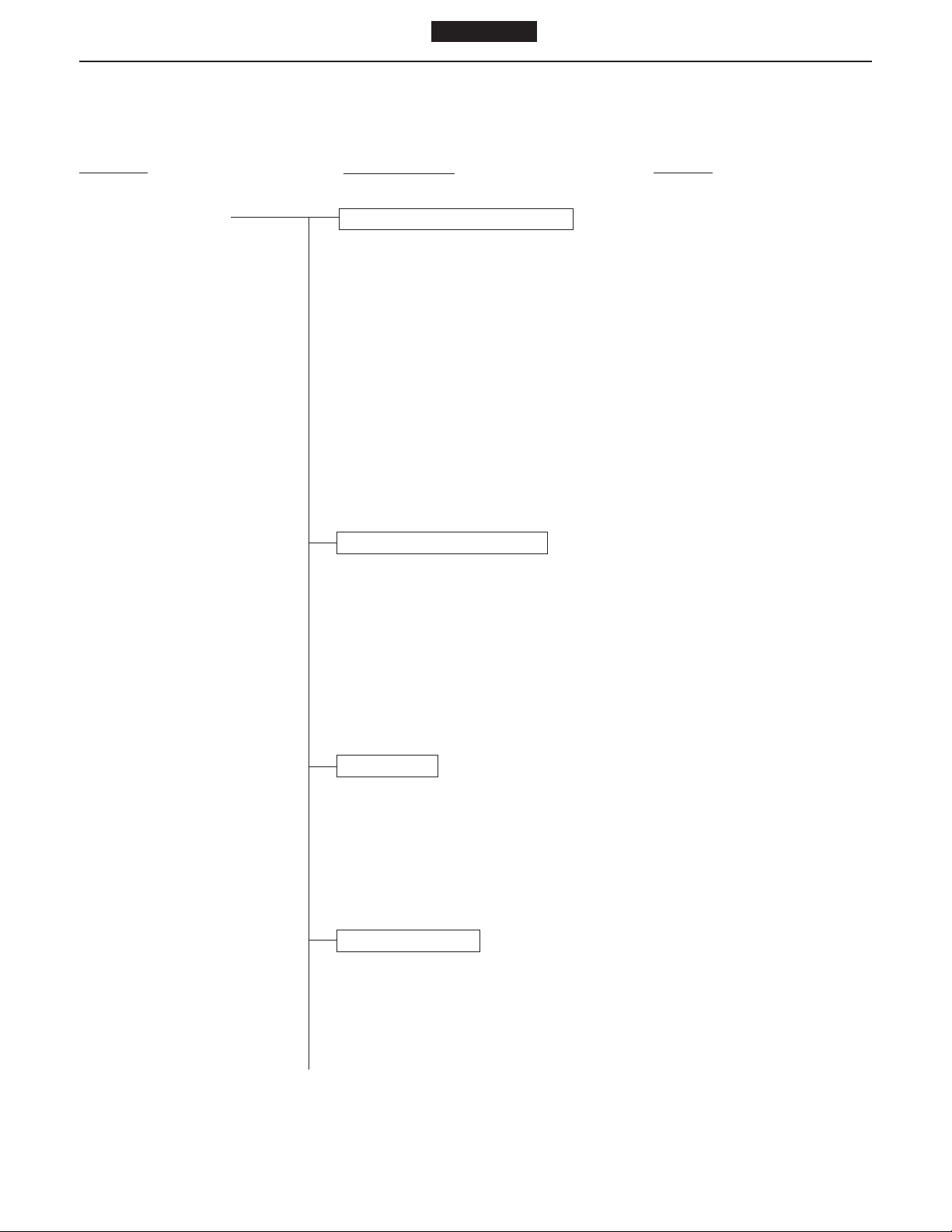

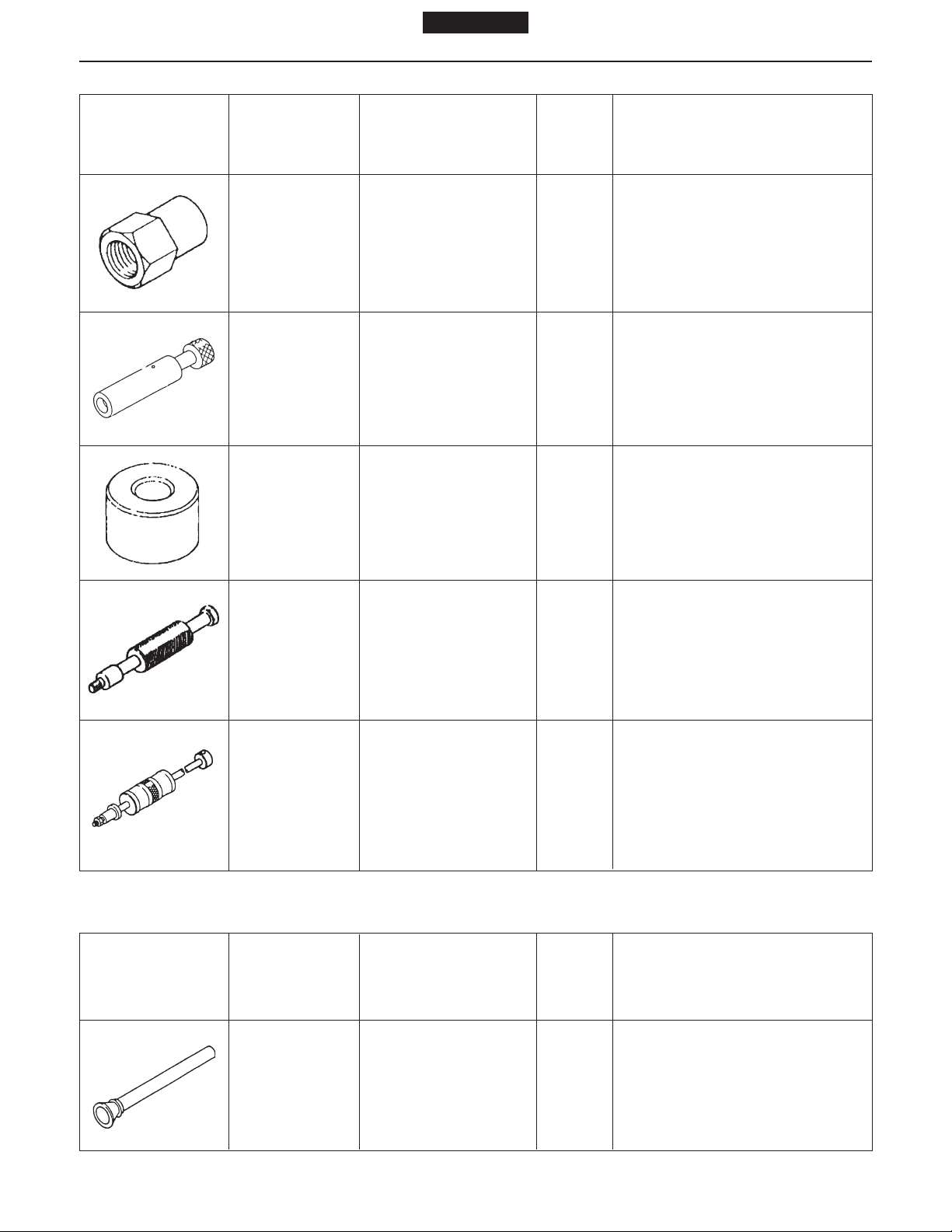

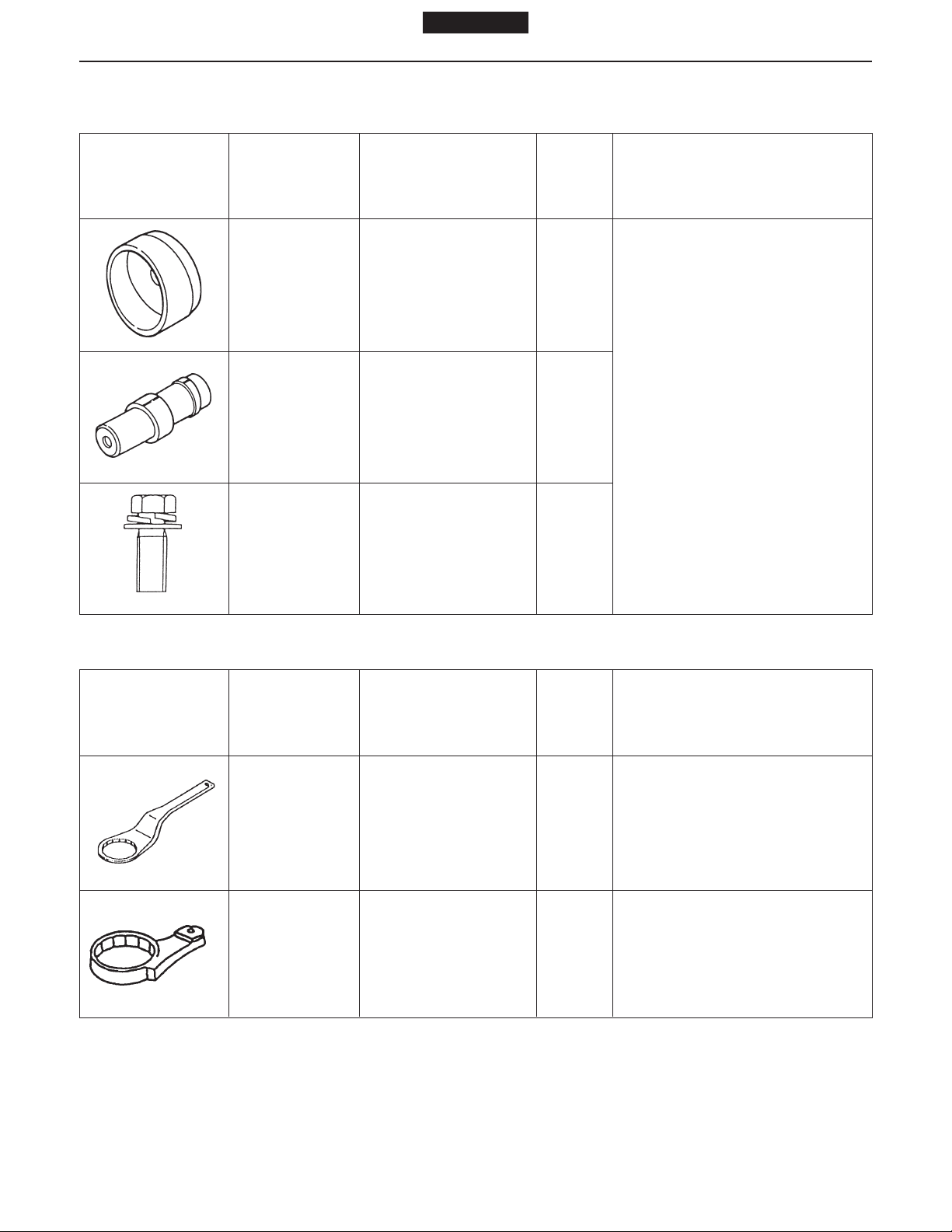

(1) Lifting parts

Shape Parts No. Parts name No./unit Application

09491 - 1010 Wire cable 1 Lifting engine

SM3-J052

ENGINE 3-2-1

09433 - 1070 Eye bolt 2 Lifting cylinder head

SM3-J048

(2) Related parts of cylinder head

Shape Parts No. Parts name No./unit Application

09472 - 1210 Bar 1

SM3-J050

9800-06100 (Steel ball) 1

Caulking nozzle seat

(Use together with 9800 - 06100)

Caulking nozzle seat

(Use together with 09472-1210)

SM3-J054

SM3-J021

09552-1090

Compression gauge

adaptor (for size PF3/8)

1

Measuring compression

Page 17

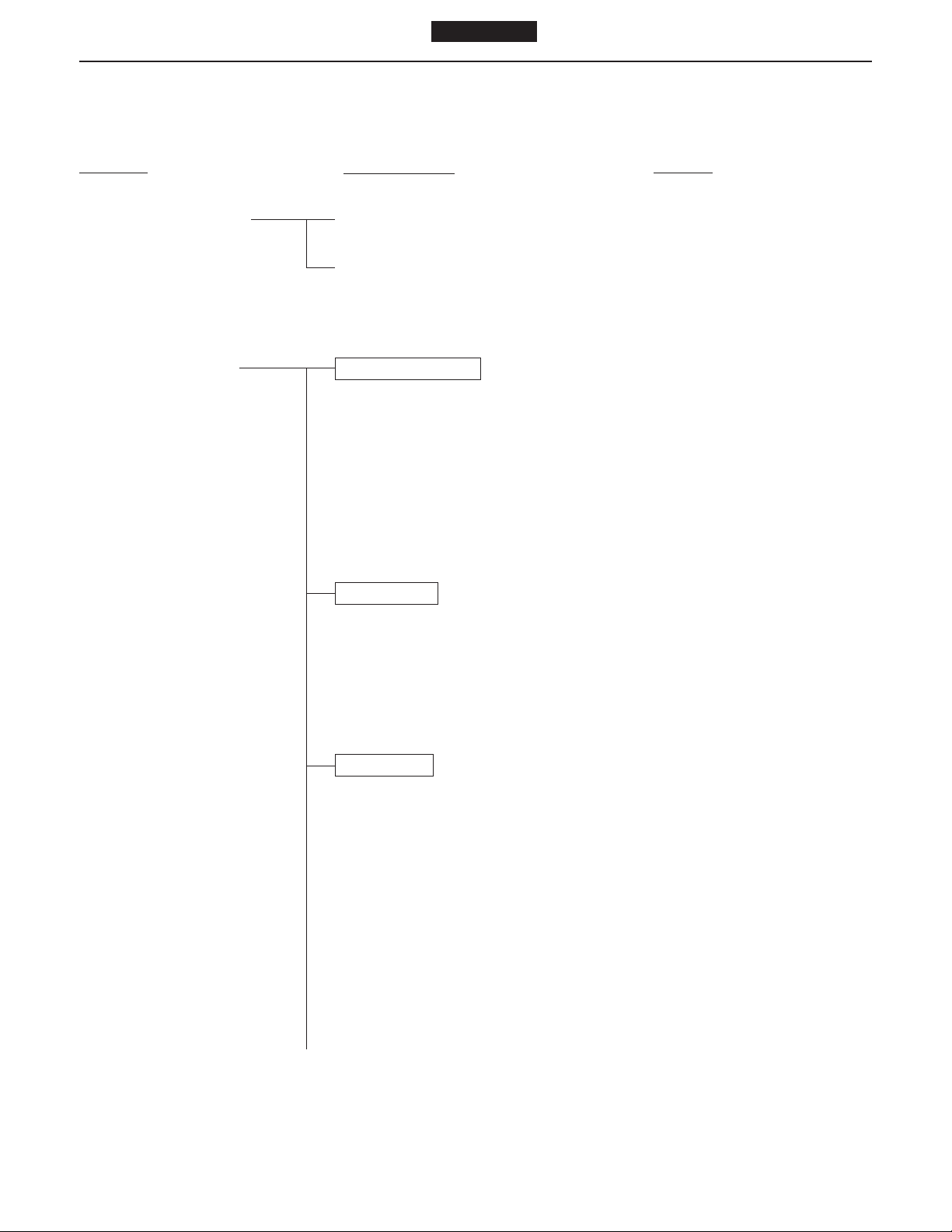

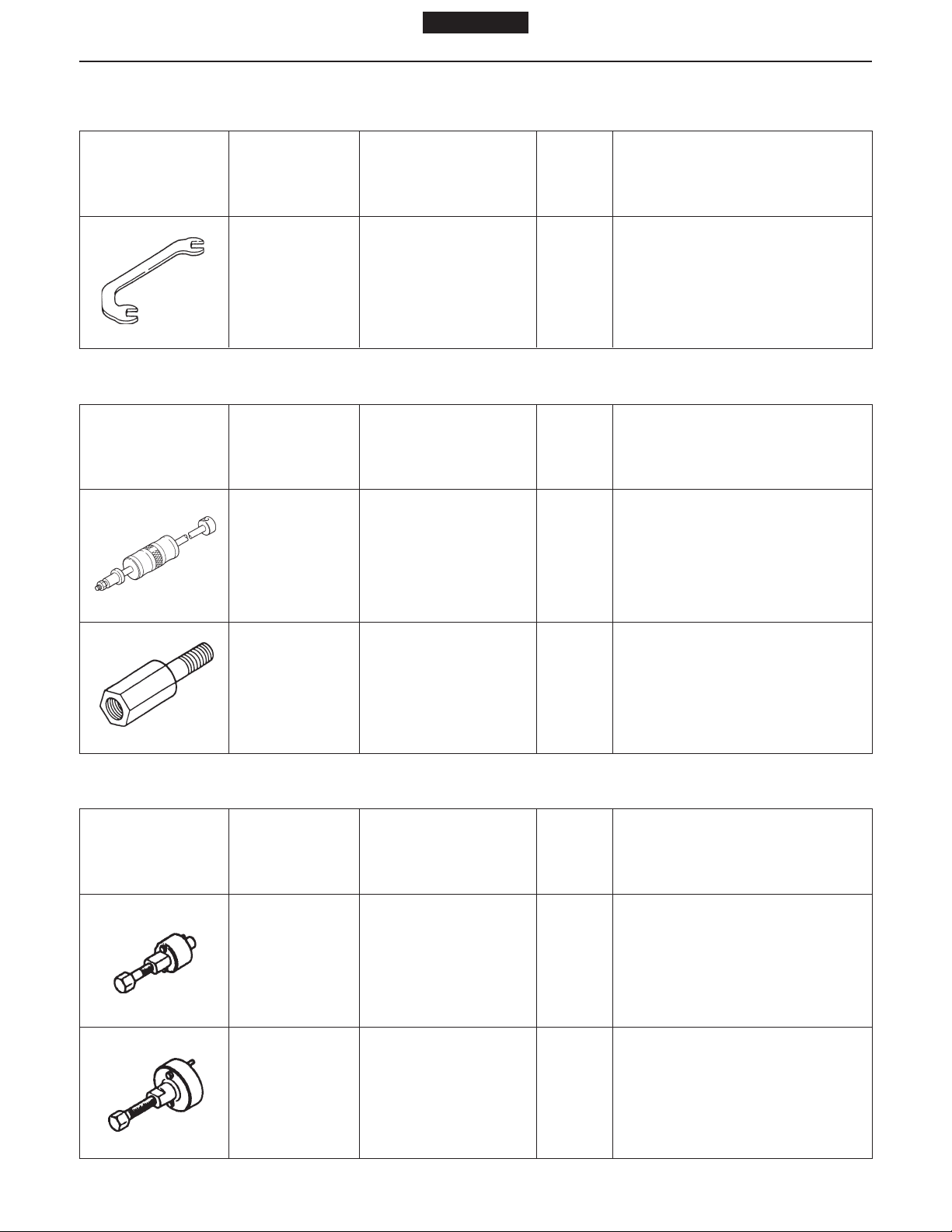

3-2-2 ENGINE

Shape Parts No. Parts name No./unit Application

SM3-J022

SM3-J055

1 page 1

Models J08C-TP and J08C-TR

09552 - 1060

Press gauge adaptor 1 Measuring compression

09552 - 1030

09472 - 2100 Bar 1 Strike-fitting valve stem seal

09471 - 1520 Guide 1 Strike-fitting valve guide

SM3-J051

09420 - 1100 Sliding hammer 1 Removing main idle gear shaft

SM3-J131

09420 - 1442

(Same as tool

for pulling out

injection nozzle)

SM3-J132

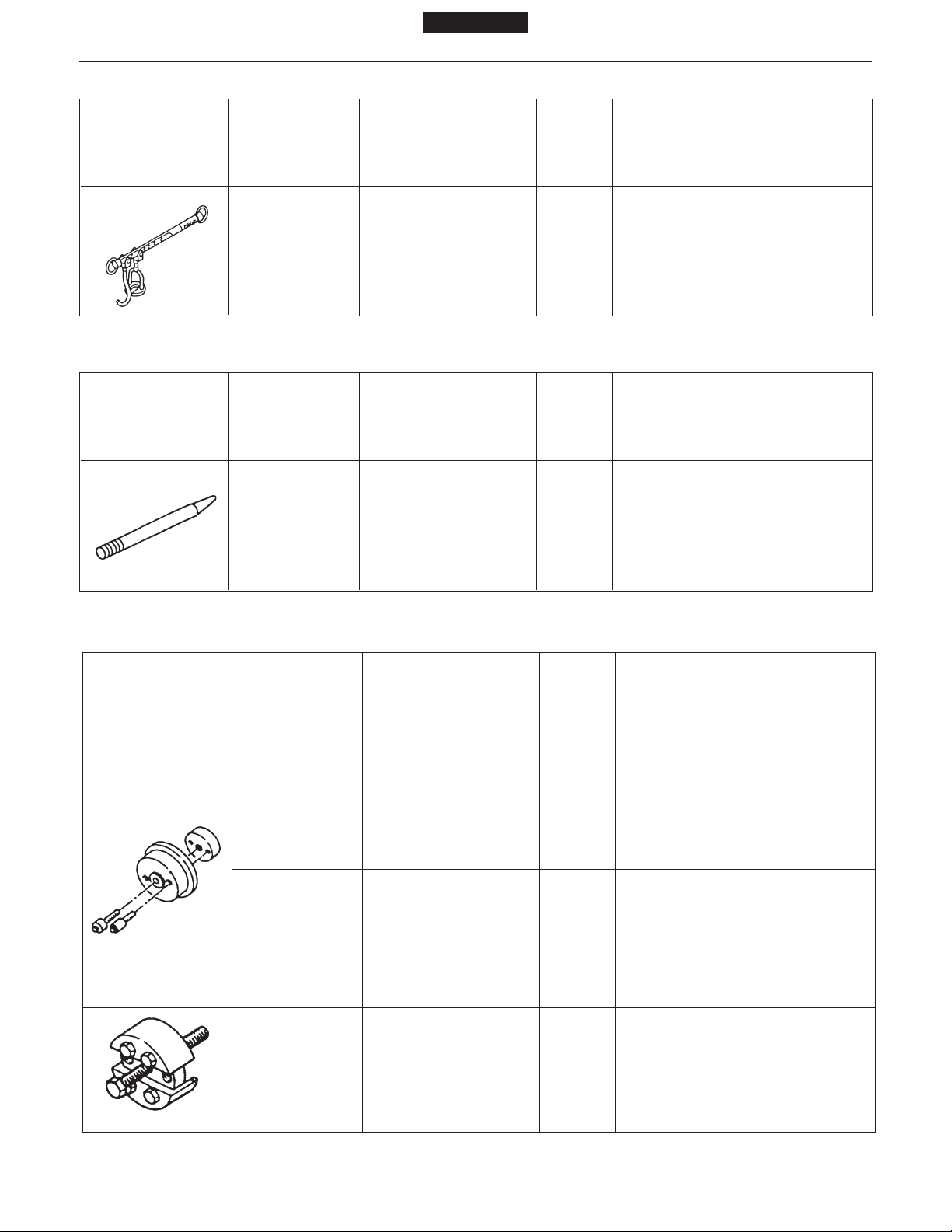

(3) Related parts of valve

Removing sub- and cam idle

Sliding hammer 1 gear shafts (Remove the

adaptor from the top before use)

Shape Parts No. Parts name No./unit Application

09431 - 1020 Valve wrapping tool 1 Valve wrapping

SM3-J053

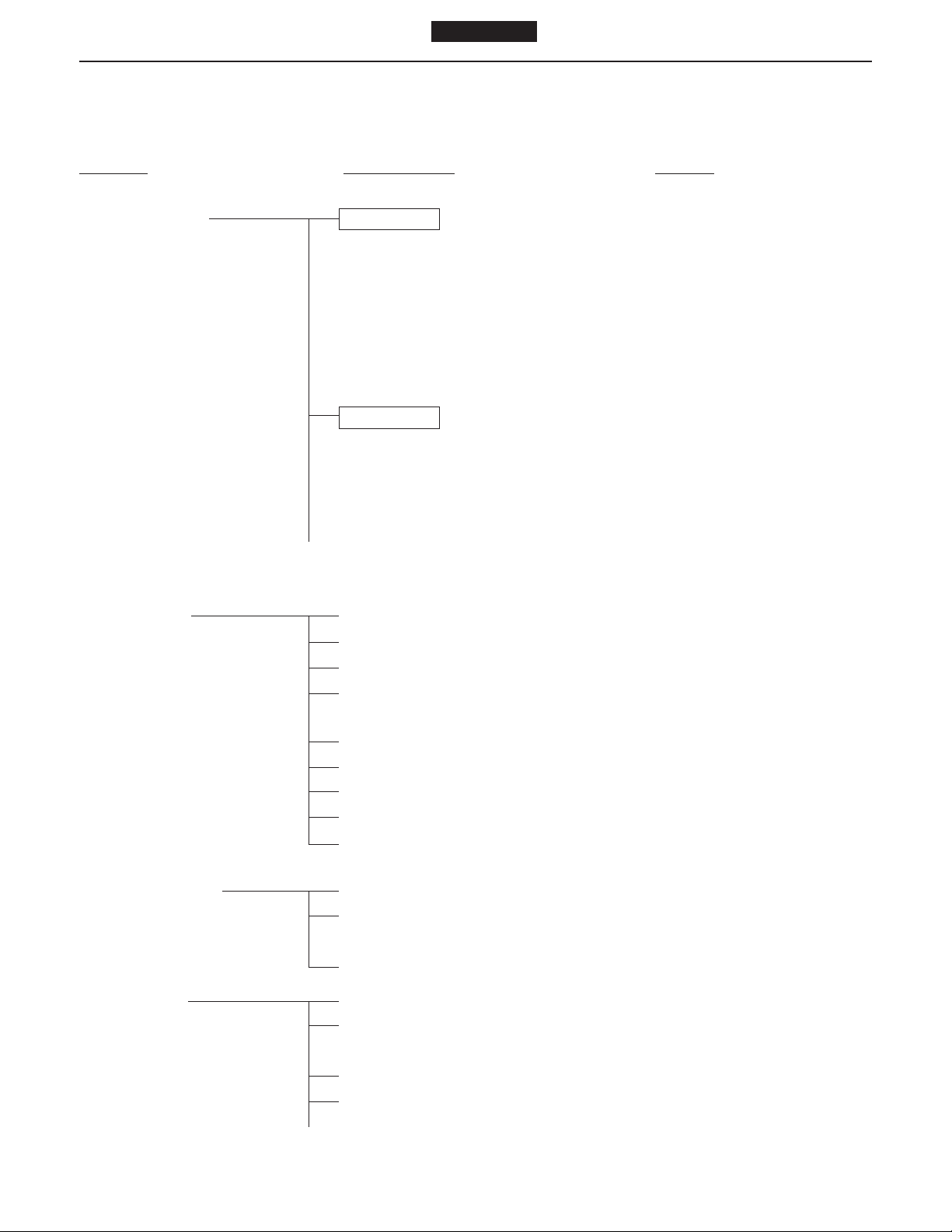

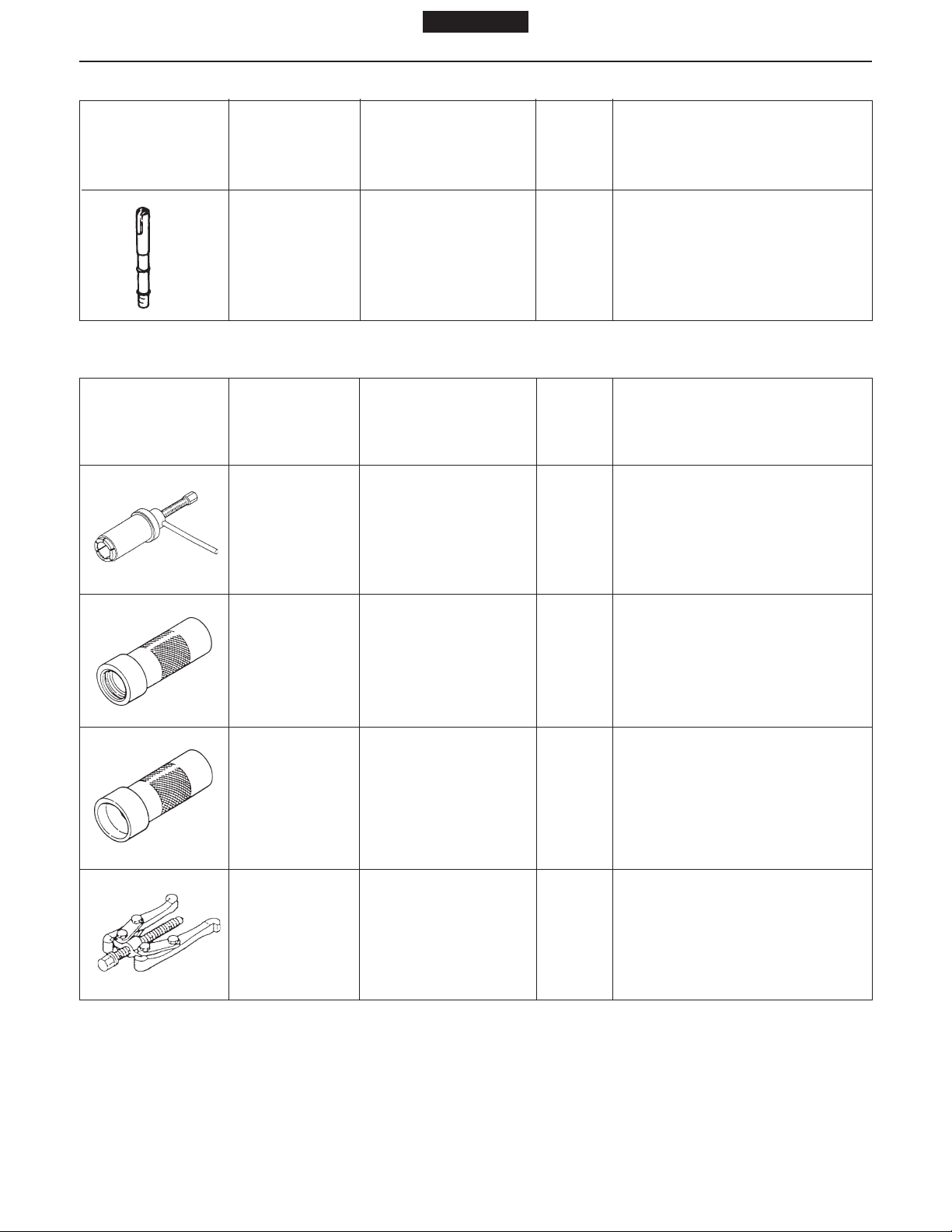

Page 18

1 page 1

Models J08C-TP and J08C-TR

Shape Parts No. Parts name No./unit Application

ENGINE 3-2-3

09470 - 1170 Valve spring press 1

SM3-J049

(4) Related parts of flywheel

Shape Parts No. Parts name No./unit Application

09481 - 1340 Guide 1

SM3-J116

(5) Related parts of cylinder block

Removing and installing valve

spring

Removing and installing

flywheel

Shape Parts No. Parts name No./unit Application

09407 - 1030 Oil seal press 1 Press-fitting front oil seal

09407 - 1040 Oil seal press 1 Press-fitting rear oil seal

SM3-J118

09420 - 1731 Oil seal puller 1 Pulling out front oil seal

SM3-J115

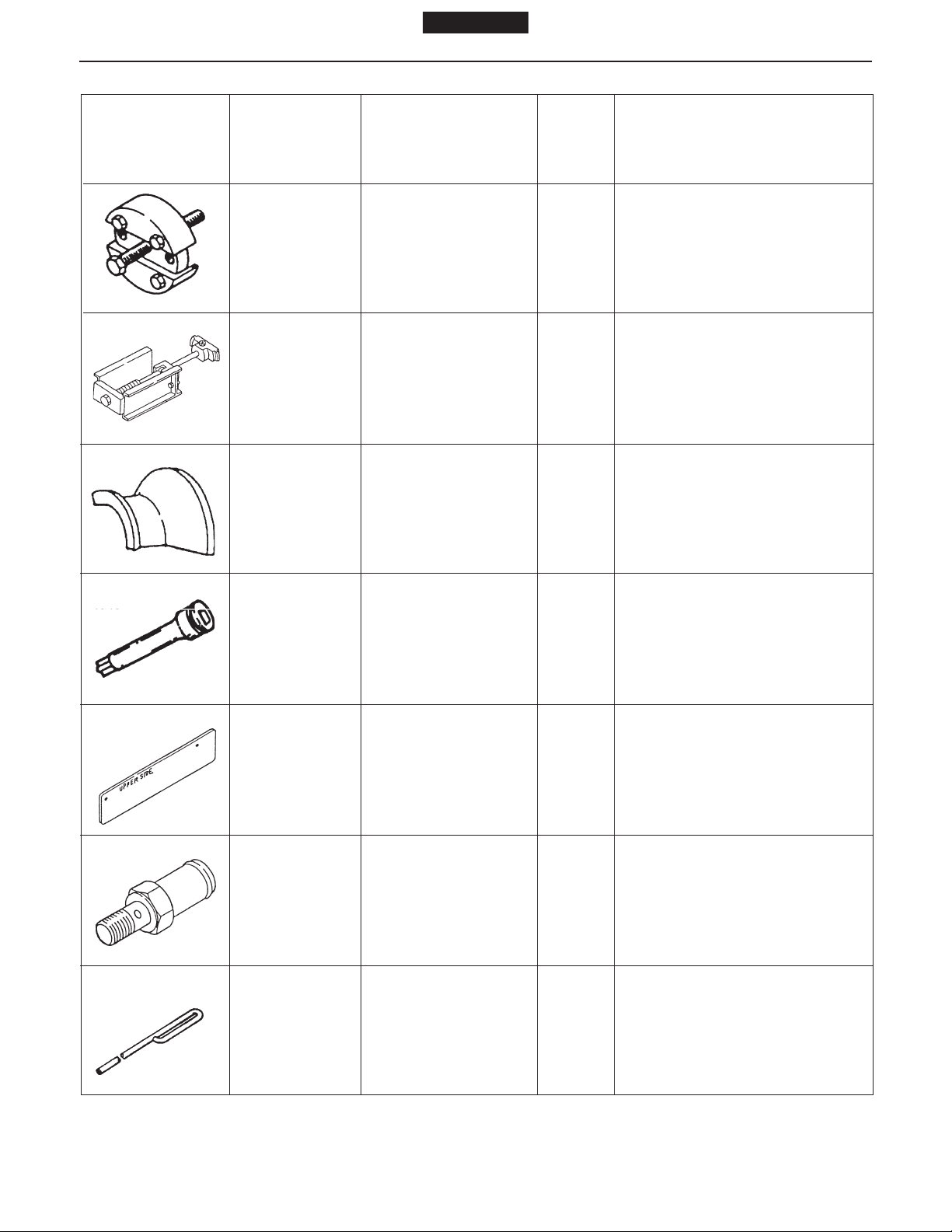

Page 19

3-2-4 ENGINE

Shape Parts No. Parts name No./unit Application

SM3-J117

SM3-J148

1 page 1

Models J08C-TP and J08C-TR

09420 - 1742 Oil seal puller 1 Pulling out rear oil seal

09420 - 1720 Cylinder liner puller 1 Pulling out cylinder liner

SM3-J149

SM3-J133

SM3-J146

SM3-J151

09471 - 1490 Guide 1 Insert guide for cylinder liner

09411 - 1300 Socket wrench 1 Rear end plate TORX® bolt

09444 - 1630 Gauge 1 Cooling jet check

9001 - 24262 Check bolt 1 Cooling jet check

SM3-J780

09472 - 1620 Tool 1

Cooling jet check (Fixture for

correction)

Page 20

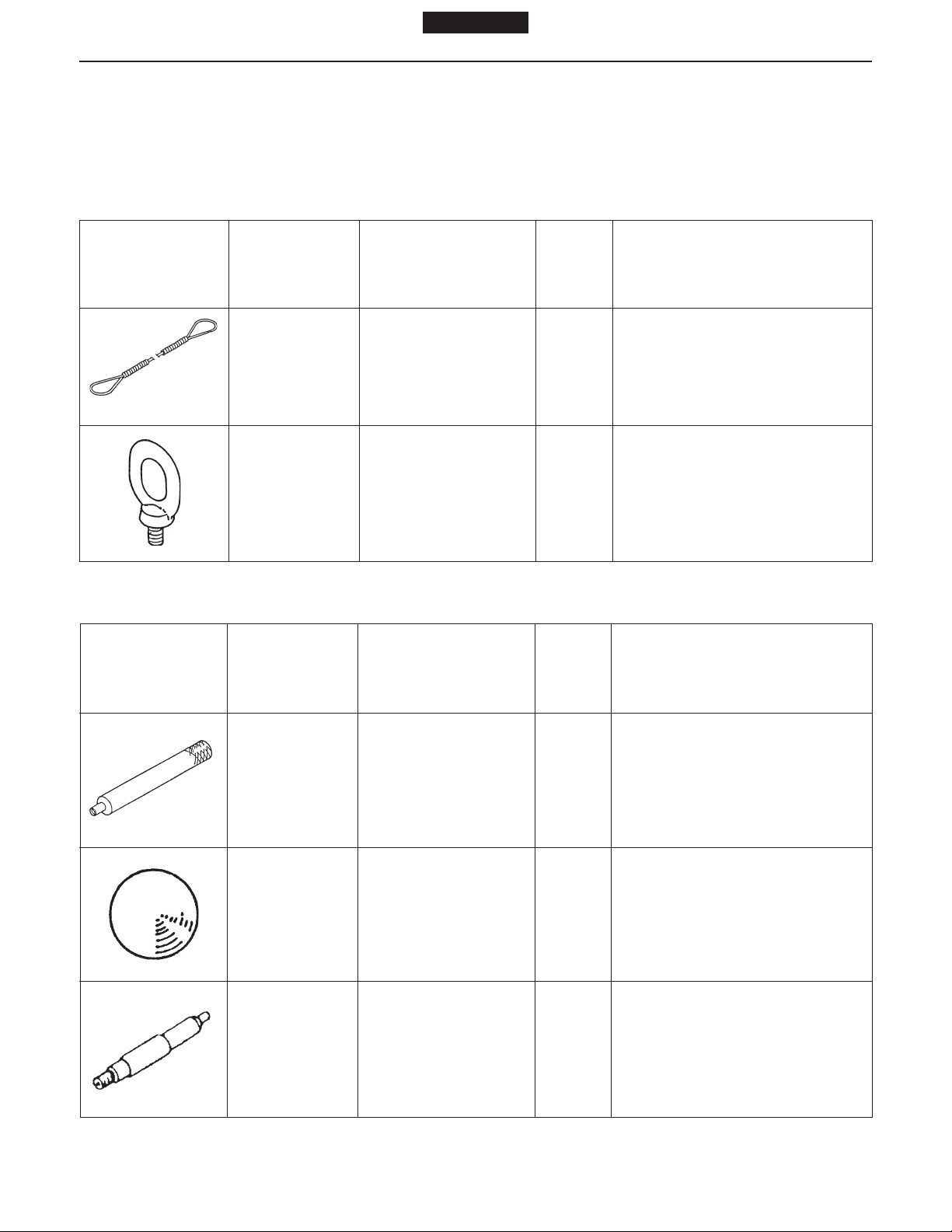

(6) Related parts of piston

Shape Parts No. Parts name No./unit Application

1 page 1

Models J08C-TP and J08C-TR

ENGINE 3-2-5

SM3-J153

SM3-J145

SM3-J781

09441 - 1320 Piston ring holder

09442 - 1011 Piston ring expander 1

09481-1130 Guide 1

09402-1530 Press sub assembly 1

1

Used when inserting piston into

cylinder block

Removing and installing piston

ring

For replacing the piston pin

bushing

SM3-J782

SM3-J783

9233-10360 Wing nut 1

Page 21

3-2-6 ENGINE

(7) Related parts of connecting rod

Shape Parts No. Parts name No./unit Application

09481 - 1540 Guide 1

SM3-J147

1 page 1

Models J08C-TP and J08C-TR

09402-1540

SM3-J152

9191 - 08252 Bolt 1

SM3-J150

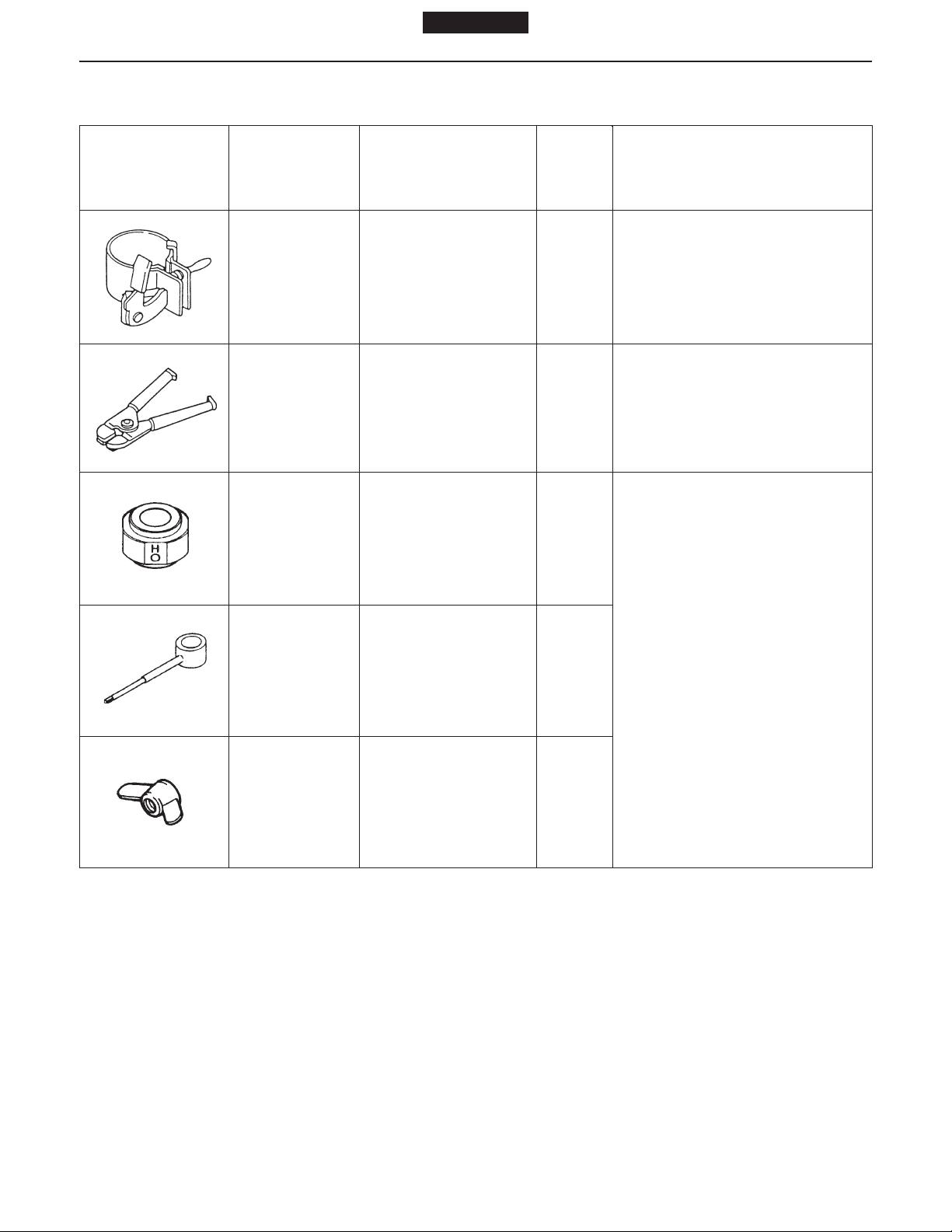

(8) Related parts of filter

Shape Parts No. Parts name No./unit Application

09553 - 1021 Oil filter wrench 1 Removing and installing oil filter

Press sub assembly 1

Replacing connecting rod

bushing

SM3-J784

SM3-J785

09553 - 1010

Fuel filter wrench 1

Removing and installing fuel filter

Page 22

(9) Related parts of injection pump

Shape Parts No. Parts name No./unit Application

09511 - 2500 Wrench 1 Injection pump coupling

SM3-J200

(10) Related parts for injection nozzle

Shape Parts No. Parts name No./unit Application

1 page 1

Models J08C-TP and J08C-TR

ENGINE 3-2-7

09420 - 1442

(Same as the

parts to remove

idler gear shaft)

SM3-J132

09462 - 1 130 Adaptor 1

SM3-J172

(11) Related parts of coolant pump

Shape Parts No. Parts name No./unit Application

09420 - 1820 Puller assembly 1 Coolant pump vane

Sliding hammer 1

Pulling out injection nozzle

(Use together with 09462 - 1 130)

Pulling out injection nozzle

(Use together with 09420 - 1442)

SM3-J786

SM3-J787

09420 - 1810 Puller assembly 1 Coolant pump pulley center

Page 23

1 page 1

3-2-8 ENGINE

Shape Parts No. Parts name No./unit Application

09444 - 1210 Belt tension gauge 1 Adjusting V-belt tension

SM3-J788

(12) Related parts of air compressor

Shape Parts No. Parts name No./unit Application

Models J08C-TP and J08C-TR

SM3-J002

SM3-J003

SM3-J004

09420 - 1670 Puller assembly 1

09482 - 2220 Press 1

Pulling out air compressor

sleeve

Strike-fitting air compressor

sleeve

09482 - 2230 Press 1

seal

Strike-fitting air compressor oil

09420 - 1680 Puller assembly 1 Pulling out air compressor gear

SM3-J005

Page 24

1 page 1

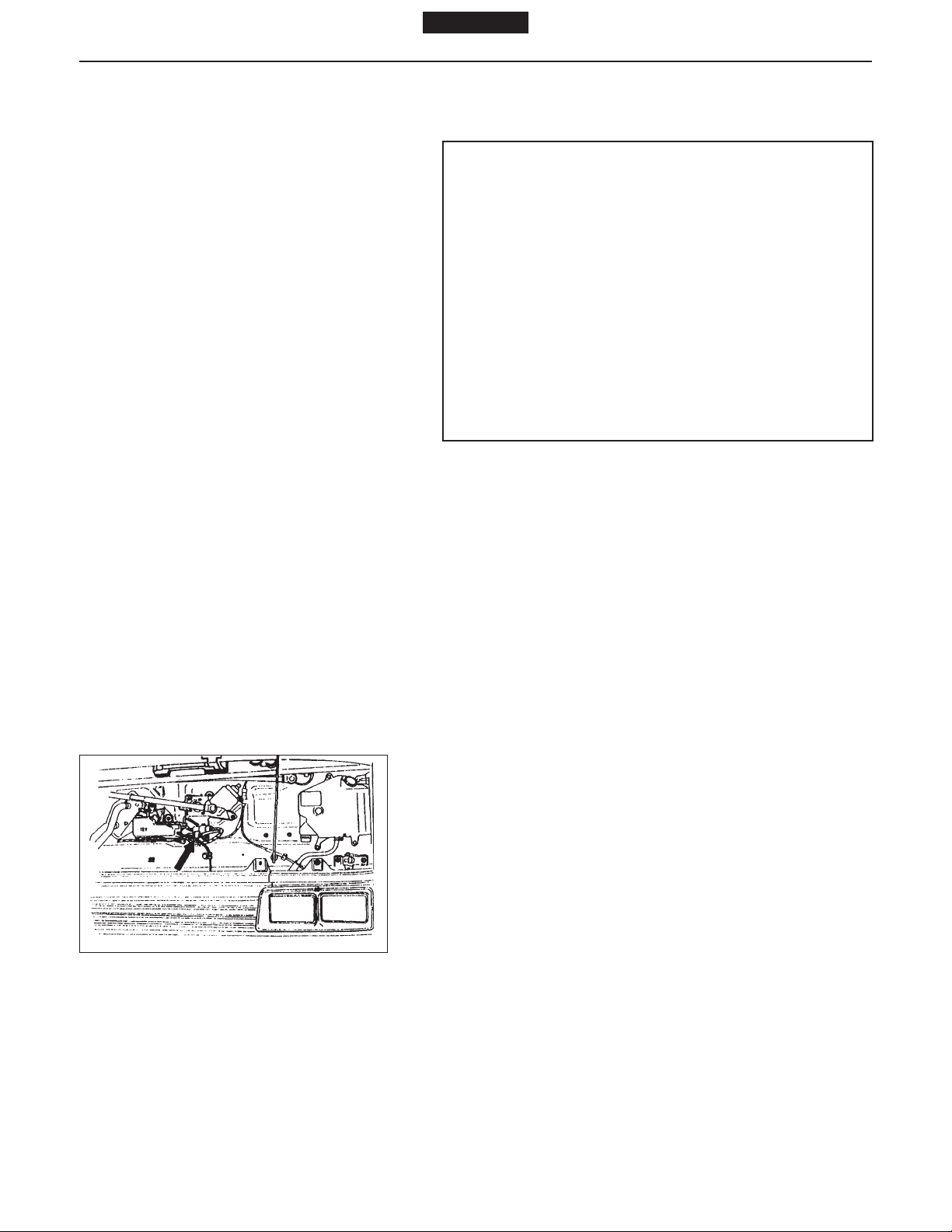

Models J08C-TP and J08C-TR ENGINE 3-3-1

GENERAL

WARNING

The following items should be observed to prevent

injury to yourself and others when servicing the

engine or vehicle;

● Stop the engine and keep the engine off during

checks and adjustments.

● Place the starter key in the “LOCK” position.

● Leave the engine stop knob pulled out fully.

(For model equipped with manual engine stop

control)

● Place the transmission shift lever in “NEUTRAL”.

● Apply the parking brake firmly.

● Block the wheels.

Fig. 1

SM3-J580

ENGINE OVERHAUL CRITERIA

FACTORS TO DETERMINE THE ENGINE

OVERHAUL

1. LOW COMPRESSION PRESSURE

(1) Before measurement

1. Charge the battery completely.

2. Set the valve clearance to the correct value.

Intake : 0.30 mm (0.0118 in.)

Exhaust : 0.45 mm (0.0177 in.)

(when engine is cold)

NOTE: Refer to page 3-18-4.

3. Idle the engine (to 80 °C {176°F}).

4. While the starter switch is at the LOCK position, disconnect the engine stop motor.

5. Remove all nozzle holders.

NOTE: Refer to page 3-6-3.

6. Remove the air cleaner hose.

Page 25

1 page 1

3-3-2 ENGINE

Models J08C-TP and J08C-TR

(2) Measurement

1. Insert the gauge adaptor into the nozzle holder hole.

Special tool: Compression gauge adaptor

(09552 - 1090)

(09552 - 1060)

(09552 - 1030)

2. Run the engine with the starter and measure the

compression pressure.

SM3-J581

Fig. 2

NOTE: Do not operate the starter for more than 15 sec-

onds.

3. Measure the compression pressure of each cylinder.

NOTE: Do not allow gas leakage from the seal face.

Unit: kg/cm2 (lb/sq.in.)

Assembly standard Assembly limit Difference among Engine speed

individual cylinders (rpm)

35 - 38 (498-540) 28 (398) Less than 3 (43) 180 - 220

Fig. 3

SM3-J580

(3) After measurement

1. Install the removed parts.

WARNING

Do not connect the electric harness with the engine stop motor while the engine starter key is at

ON position as this may operate the engine stop

motor instantaneously and the link lever of the

engine stop motor and the engine stop lever of the

fuel injection pump will move, resulting in your

fingers caught by the lever.

Page 26

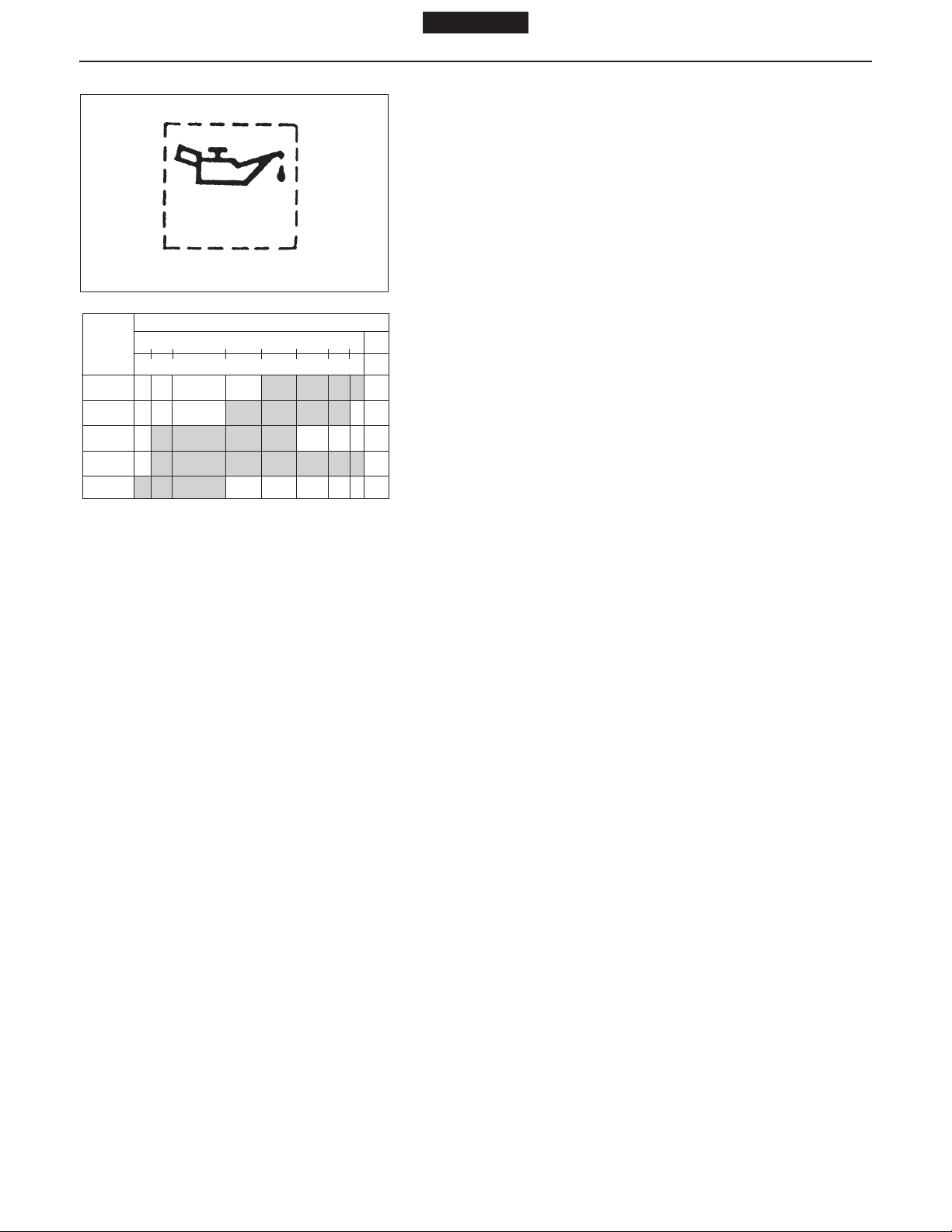

Fig. 4

S.A.E.

GRADE

40

30

20W/20

15W/40

10W/30

Fig. 5

OIL

SM3-J024

ATMOSPHERIC TEMPERATURE

-10 0 32 50 70 90 100 ˚F

-23 -18 0 10 21 32 39 ˚C

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-3-3

2. DECREASED OIL PRESSURE

Check the oil pressure warning lap when the oil and coolant temperature is hot [about 80°C (176°F)].

a. If the warning lamp is lit, check the oil level.

b. Check oil deterioration.

If oil quality is poor, replace with a suitable grade oil.

c. Remove the oil pressure switch and install the oil

pressure gauge.

d. Measure the oil pressure at oil temperature 100°C

(212°F).

Standard oil Pressure:

2

At 2,500 (rpm) 5.7 kg/cm

(81.05 lb/sq.in.)

Service Limit:

At idle speed 0.5 kg/cm

2

(7.11 lb/sq.in.)

3. OTHER FACTORS

a. Blow-by gas increases.

b. Engine does not start easily.

c. Engine output decreases.

d. Fuel consumption increases.

e. Engine makes greater noise.

f. Excessive oil consumption.

Page 27

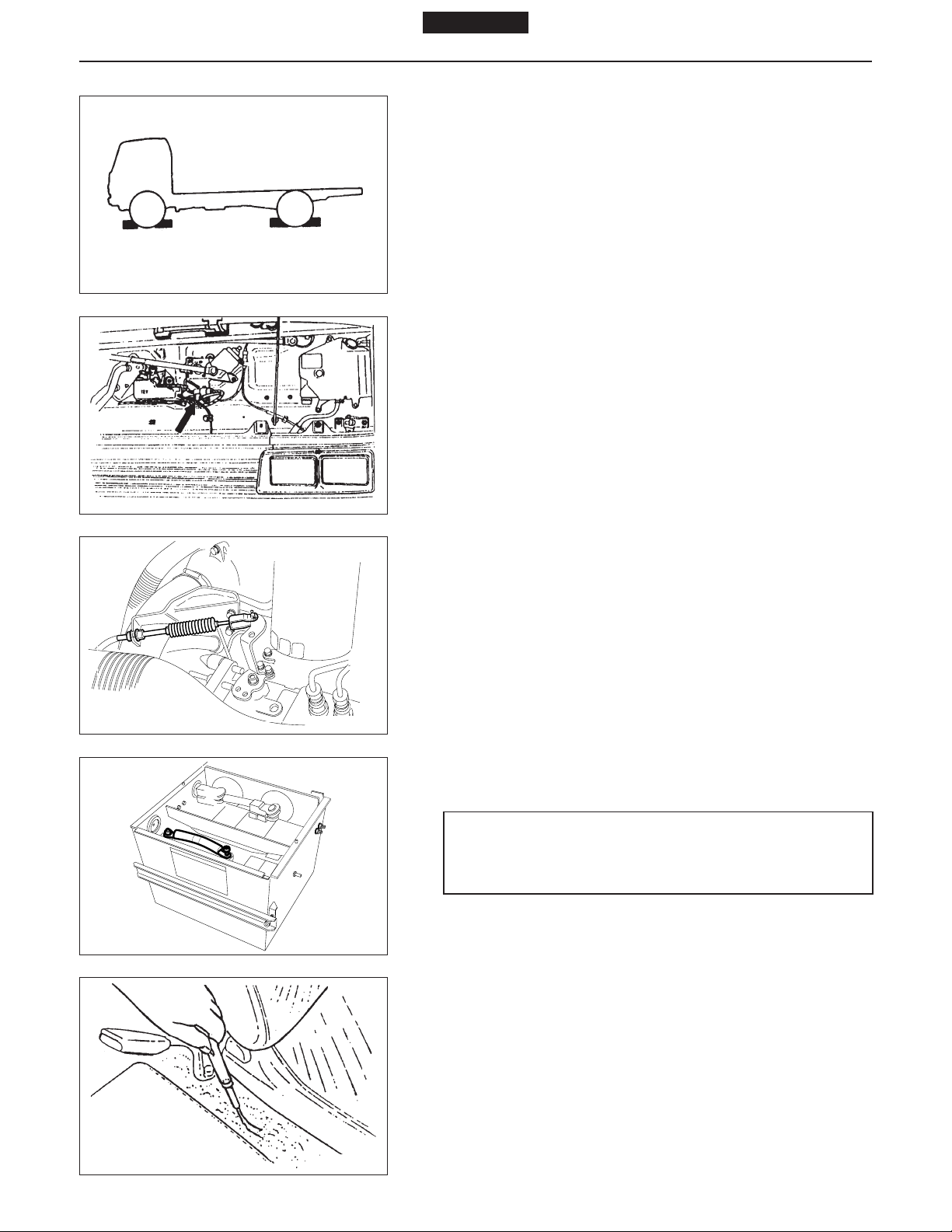

Fig. 1

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-4-1

DISMOUNTING THE ENGINE ASSEMBLY

1. BLOCK THE WHEELS OF THE VEHICLE.

1. Park the vehicle on level ground.

2. Block the wheels.

SM3-J500

2. DISCONNECT THE ENGINE CONTROL AND THE STOP

CABLE.

1. Set the starter switch to the ON position.

2. Disconnect the wires of the engine stop motor at the

connector.

3. Set the starter switch to the LOCK position.

Fig. 2

Fig. 3

Fig. 4

SM3-J580

4. Tilt up the cab.

5. Disconnect the engine control and the stop cable at

the injection pump.

SM3-J582A

3. DISCONNECT THE NEGATIVE TERMINAL OF THE

BATTERY.

WARNING

Always disconnect the battery cable when servicing the engine.

SM3-J583

4. DISCONNECT THE PARKING BRAKE CABLE (1).

1. Remove the center console.

2. Disconnect the parking brake cable at the lever.

Fig. 5

SM3-J584

Page 28

1 page 1

Models J08C-TP and J08C-TR3-4-2 ENGINE

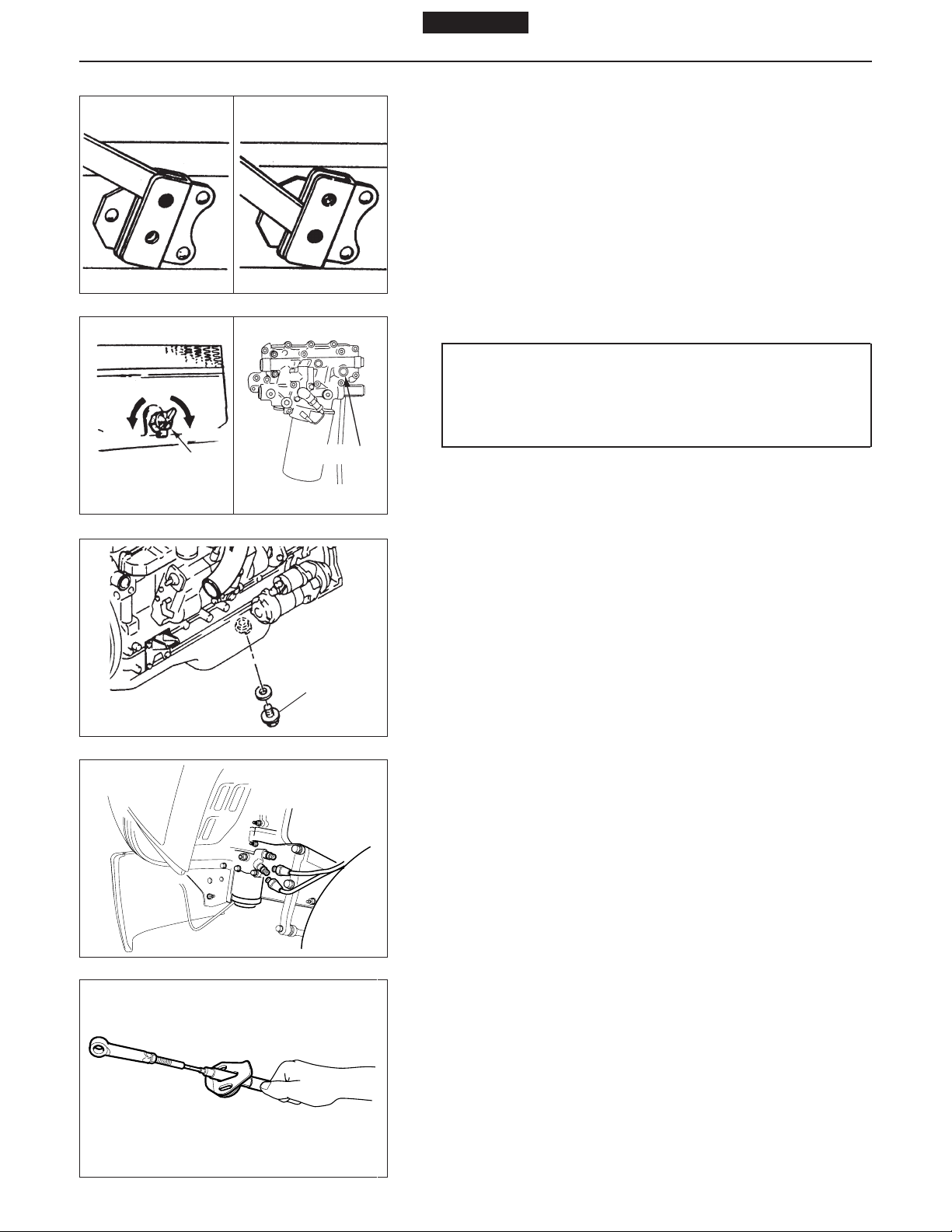

OVER-TILTING

POSITION

Fig. 6

OPEN

DRAINING PLUG

Fig. 7

CLOSE

NORMAL POSITION

DRAINING PLUG

SM3-J705B

Fig. 8

5. OVER-TILT THE CAB

NOTE: Refer to CAB in CHAPTER 19.

SM3-J585

6. DRAIN THE COOLANT AND ENGINE OIL.

WARNING

To avoid the danger of burns do not drain the engine oil and coolant while the engine and radiator

are still hot.

1. Drain the coolant from the radiator. (Fig. 7)

NOTE: The coolant can be drained more easily by

removing the filler cap.

Fig. 9

Fig. 10

DRAINING PLUG

SM3-J791

SM3-J587

2. Drain the coolant from the cylinder block. (Fig. 8)

Coolant capacity: 21 L (22.19 US qt)

23 L (24.30 US qt)

(with transmission oil cooler only)

3. Drain the engine oil through the drain plug.

Engine oil capacity: 13.5 L (14.27 US qt)

7. DISCONNECT THE POWER STEERING LINES A T THE

GEAR UNIT.

NOTE: Place a container under the gear unit.

8. DISCONNECT THE PARKING BRAKE CABLE (2).

1. Remove the bracket behind the cab, then pull out

the parking brake cable.

NOTE: Pull out the cable straight and slowly. If pulled out

forcefully, the gasket will crack. Cracked cables

must be replaced with new ones.

Fig. 11

SM3-J589

Page 29

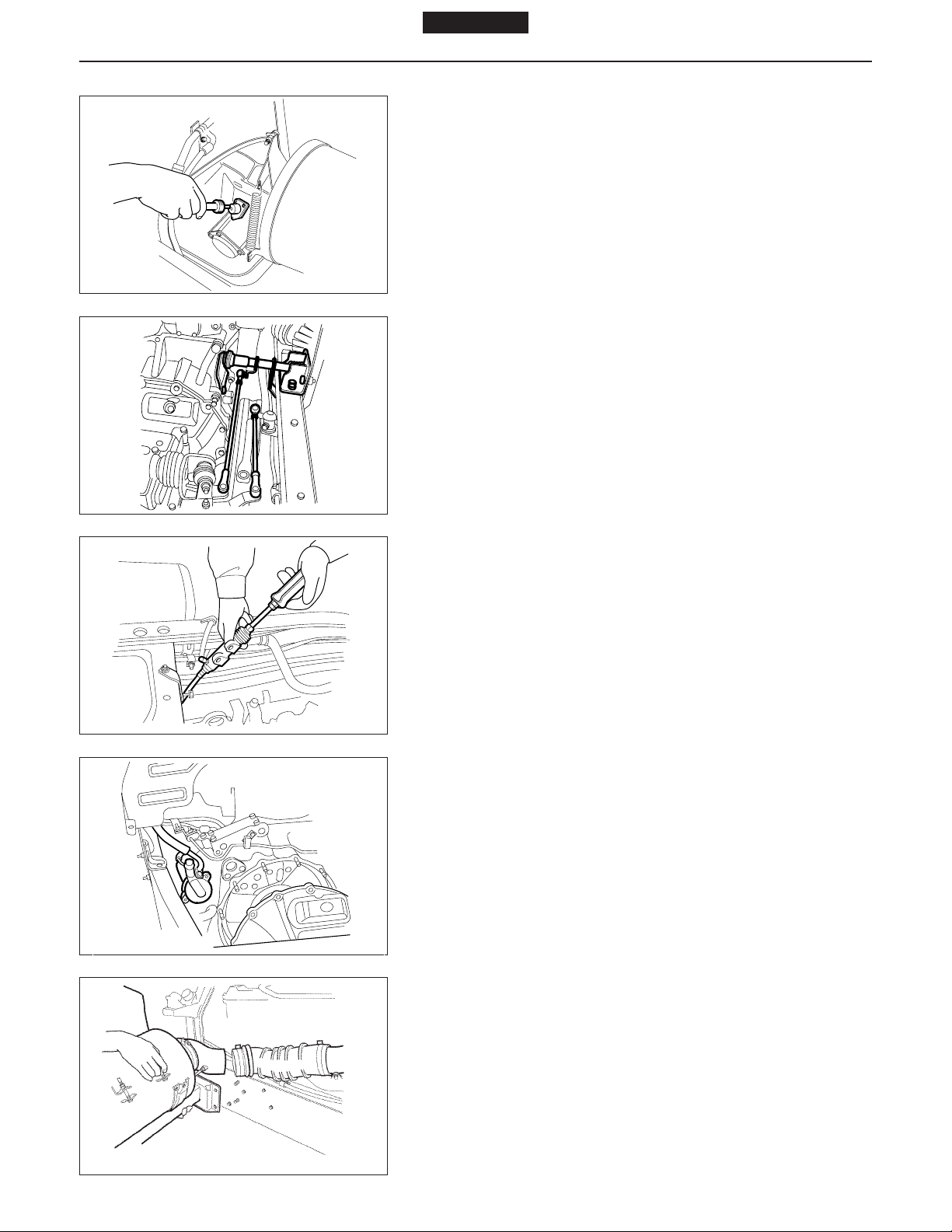

Fig. 12

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-4-3

9. DISCONNECT THE SPEEDOMETER CABLE AT THE

TRANSMISSION.

SM3-J590

10. REMOVE THE TRANSMISSION CONTROL ROD

TOGETHER WITH THE BRACKET A T THE TRANSMISSION.

Fig. 13

Fig. 14

Fig. 15

SM3-J796

11. REMOVE THE CLUTCH SLAVE CYLINDER.

1. Remove the connecting clip of the clutch hose.

2. Remove the return spring and the clevis of the lever.

3. Remove the slave cylinder together with the lines.

SM3-J593

12. DISCONNECT THE POWER STEERING LINES A T THE

PUMP.

NOTE: Be careful of oil leakage from the removed lines

at the gear unit

SM3-J594

13. DISCONNECT THE AIR HOSES WHICH CONNECT THE

AIR CLEANER AND ENGINE.

14. REMOVE THE SPLASH BOARD.

15. REMOVE THE AIR CLEANER TOGETHER WITH THE

BRACKET.

Fig. 16

SM3-J595

Page 30

Fig. 17

1 page 1

Models J08C-TP and J08C-TR3-4-4 ENGINE

16. DISCONNECT THE ELECTRICAL WIRES (1).

1. Engine speed sensor

2. Glow plug

3. Rack sensor, pre-stroke actuator

4. Starter terminals B and C and grounding (frame end)

SM3-J596A

17. REMOVE THE REAR CAB MOUNTING BRACKET.

Fig. 18

Fig. 19

Fig. 20

SM3-J597

18. DISCONNECT THE ELECTRICAL WIRES (2).

1. Water temperature sensor (2 parts)

2. Alternator

3. Magnetic clutch of the air conditioner

19. DISCONNECT THE HEATER HOSES.

SM3-J598

20. DISCONNECT THE GAS LINES OF THE AIR CONDITIONER.

1. Use the refrigerant collector to discharge refriger-

ant.

2. Disconnect the gas lines of the air conditioner at the

compressor.

SM3-J599

21. DISCONNECT THE RADIATOR FROM THE FRAME.

1. Disconnect the reservoir hose.

2. Remove the radiator mounting.

Fig. 21

SM3-J600A

Page 31

Fig. 22

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-4-5

22. REMOVE THE EXHAUST PIPE AND MUFFLER.

SM3-J601A

23. REMOVE THE PROPELLER SHAFT.

1. Remove the center bearing support.

NOTE: Attach a hoist to the propeller shaft.

2. Loosen the flange, then remove the propeller shaft.

Fig. 23

Fig. 24

SM3-J602

SM3-J502

24. REMOVE THE TRANSMISSION.

1. Place a jack under the bottom of the flywheel hous-

ing.

2. Place a transmission jack under the transmission.

WARNING

The engine must be suspended with a hoist until

completion of disassembly of the transmission

assembly.

3. Remove the mounting bolt of the mounting rubber

behind the transmission.

4. Remove the mounting bolt of the transmission at the

clutch housing, then remove the transmission.

NOTE: Jack up and align the transmission with the en-

gine, then pull the transmission straight out.

Page 32

Fig. 25

1 page 1

Models J08C-TP and J08C-TR3-4-6 ENGINE

25. REMOVE THE ENGINE ASSEMBLY.

1. Attach hoists to the engine hangers at the front and

rear ends of the engine, and lift slightly.

2. Remove the engine mounting at the frame.

3. Remove the engine assembly together with the ra-

diator and inter cooler.

4. Mount the engine assembly on a work stand.

SM3-J503

26. REMOVE THE RADIATOR AND INTER COOLER.

1. Loosen the tightening band of the fan shroud.

2. Disconnect the radiator hoses and inter cooler hoses

at the engine.

3. Remove the radiator and inter cooler.

NOTE: Attach a hoist to the radiator.

Fig. 26

Fig. 27

SM3-J604

27. REMOVE THE CLUTCH COVER AND CLUTCH DISC.

NOTE: Refer to CLUTCH in CHAPTER 5.

SM3-J746

28. REMOVE THE AIR CONDITIONER COMPRESSOR.

1. Loosen the tension pulley, then remove the V-belt.

2. Remove the air conditioner compressor.

Page 33

Fig. 1

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-5-1

REMOVAL OF THE ENGINE COMPONENT PARTS

1. PREPARATION

1. Loosen the coolant drain cock of the oil cooler, then

discharge coolant.

2. Loosen the oil drain plug of the oil filter, then dis-

charge oil.

SM3-J606

3. Clean the engine assembly.

a. Cover openings with tape.

b. Clean the engine assembly with a steam cleaner.

NOTE: Do not apply steam directly to the electrical com-

ponents. (Alternator, starter, etc.)

4. Mount the engine assembly on a work stand.

Fig. 2

Fig. 3

Fig. 4

SM3-J504

2. REMOVE THE POWER STEERING OIL PUMP.

SM3-J607

3. REMOVE THE STARTER.

1. Put alignment marks on the harness and the starter

terminal, then remove the harness.

2. Remove the starter from the engine.

SM3-J608

4. REMOVE THE FUEL FILTER AND FUEL LINES.

Remove the fuel lines, oil lines and fuel leakage lines.

NOTE:

● Cover openings to prevent foreign matter from enter-

ing.

● Refer to page 3-12-1.

Fig. 5

SM3-J609

Page 34

1 page 1

3-5-2 ENGINE

Fig. 6

Models J08C-TP and J08C-TR

5. REMOVE THE INTAKE MANIFOLD.

SM3-J613

6. REMOVE THE INJECTION PUMP.

1. Remove the through bolt of the coupling.

Fig. 7

Fig. 8

Fig. 9

Fig. 10

SM3-J610A

SM3-J611C

SM3-J612

SM3-J614

2. Use the following special tool and loosen the adjust-

ing bolt.

Special tool: Injection pump coupling wrench

(09511 - 2500)

3. Remove the mounting bolt of the injection pump, then

remove the pump assembly.

NOTE: Cover openings to prevent foreign matter from

entering.

7. REMOVE THE AIR COMPRESSOR.

1. Remove the oil lines, refrigerant lines and air lines.

2. Remove the air compressor.

3. Remove the mounting bolt of the air compressor, then

remove the air compressor.

NOTE: Do not remove the air compressor forcefully. The

spigot may be damaged, or oil leakage may occur due to removal of liquid gasket between the

flywheel housing and the rear end plate.

Page 35

Fig. 11

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-5-3

8. REMOVE THE TURBOCHARGER.

NOTE: Refer to TURBOCHARGER in CHAPTER 51.

SM3-J615

9. REMOVE THE OIL FILTER AND OIL COOLER.

1. Remove the oil lines.

2. Remove the oil filter.

Special tool: Oil filter wrench (09553 - 1021)

3. Remove the oil cooler.

Fig. 12

Fig. 13

Fig. 14

SM3-J616

10. REMOVE THE EXHAUST MANIFOLD.

SM3-J617

11. REMOVE THE V-BELT AND THE ALTERNATOR.

1. Loosen the V-belt adjustment bolt.

2. Loosen the through bolt.

3. Remove the V-belt, then remove the alternator.

SM3-J619A

12. REMOVE THE FAN CLUTCH TOGETHER WITH THE

COOLING FAN.

Fig. 15

SM3-J620

Page 36

1 page 1

3-5-4 ENGINE

Fig. 16

Models J08C-TP and J08C-TR

13. REMOVE THE THERMOSTAT CASE.

SM3-J621

14. REMOVE THE COOLANT PUMP.

Fig. 17

SM3-J622

Page 37

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-6-1

CAMSHAFT HOUSING AND CYLINDER HEAD

1

2

7

12

3

4

13

16

8

9

5

6

14

11

10

15

Fig. 1

17

30

31

21

22

23

24

25

26

27

32

33

28

29

18

18

20

19

SM3-J264A

Page 38

34

1 page 1

Models J08C-TP and J08C-TR3-6-2 ENGINE

35

Fig. 2

1. Oil filler cap

2. Cylinder head cover

3. Silent block

4. Spacer

5. Head cover gasket

6. Valve rocker shaft

7. Lock nut

8. Valve rocker arm

9. Adjusting screw

10. Nozzle clamp

11. Valve rocker support

12. Camshaft bearing

13. Camshaft bearing cap

14. Camshaft

15. Camshaft drive gear

16. Camshaft housing

17. Camshaft housing gasket

18. Idler gear thrust plate

19. Camshaft idler gear

20. Idler gear shaft

21. Cross head

22. Valve spring retainer

23. Valve spring seat upper

24. Valve spring outer

25. Valve spring inner

26. Valve stem seal

27. Valve spring seat lower

28. Cross head adjusting screw

29. Lock nut

30. Cylinder head

31. Cylinder head gasket

32. Valve seat

33. Valve

34. Valve stem guide

35. Nozzle seat

SM3-J265

Page 39

Fig. 3

NOZZLE CLAMP BOLT

SM3-J623

LEAKAGE PIPE

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-6-3

DISMOUNTING

1. REMOVE THE CYLINDER HEAD COVER.

NOTE: Clean all dust from around the cylinder head

cover before removing it to prevent foreign particles from getting in.

2. REMOVE THE INJECTION NOZZLE.

1. Remove the leakage pipe.

2. Loosen the injection pipe nut.

3. Remove the injection pipe seal mounting bolts. Re-

move the injection pipe seal together with the injection pipe out of the cam housing.

4. Remove the nozzle clamp bolt.

Fig. 4

Fig. 5

CAM HOUSING

O-RING

NOZZLE HOLDER

ASSEMBLY

SM3-J178

5. Pull out the nozzle holder assembly, avoiding any

interference.

NOTE: If difficult, use a special tool, sliding hammer

(09420 - 1442), for easier removal.

6. Remove the O-ring.

NOTE: Replace the O-ring with a new one.

SM3-J624

Page 40

Fig. 6

LOCK NUT

ADJUSTING

SCREW

ROCKER ARM SUPPORT

124 675 3

1 page 1

Models J08C-TP and J08C-TR3-6-4 ENGINE

3. LOOSEN THE VALVE CLEARANCE ADJUSTING

SCREW.

1. Loosen the lock nut at the top of the rocker arm, then

wind up the adjusting screw completely.

NOTE: If the adjusting screw is left unwound, the rocker

shaft may bend when the rocker arm support is

loosened.

SM3-J056

4. REMOVE THE ROCKER ARM ASSEMBLY.

1. Remove the rocker arm support bolt in the order as

shown in the figure.

NOTE: When the rocker arm assembly is removed, the

rocker arm and rocker arm support tend to come

off the rocker shaft. Be careful in handling.

Fig. 7

Fig. 8

Fig. 9

SM3-J266

5. REMOVE THE CAMSHAFT.

1. Remove the cam bearing cap bolt.

2. Remove the camshaft together with the gear.

NOTE: Be extremely careful not to drop any part into the

interior of the engine.

SM3-J625

6. REMOVE THE CAM HOUSING.

1. Remove the cam housing bolts.

2. Tap and remove the cam housing with a plastic ham-

mer.

SM3-J626

7. REMOVE THE CYLINDER HEAD BOLTS.

Remove the cylinder head bolts in the order as shown in the figure.

Fig. 10

SM3-J276B

Page 41

Fig. 11

SM3-J627

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-6-5

8. LIFT AND REMOVE THE CYLINDER HEAD FROM THE

CYLINDER BLOCK.

Special tool: Eye bolt (09433 - 1070)

NOTE:

● Place a piece of wood between the cylinder head and

table.

● When removing the cylinder head together with the

injection nozzle, avoid contact between the injection

nozzle and a piece of wood.

● Check that there is no oil, water or gas leakage in the

cylinder head gasket if overheated or not.

Page 42

Fig. 12

1 page 1

Models J08C-TP and J08C-TR3-6-6 ENGINE

DISASSEMBLING

REMOVE THE CAM IDLER GEAR.

1. Remove the cam idler gear.

SM3-J628

2. Using the special tool, remove the cam idler gear.

Special tool: Sliding hammer (09420 - 1830)

Fig. 13

Fig. 14

IN

EX

Fig. 15

SM3-J629

SM3-J060

SM3-J061A

DISASSEMBLE THE VALVE SYSTEM.

1. Using the special tool, press fit the valve spring seat

upper, then remove the valve spring retainer.

Special tool: Valve spring press (09470 - 1170)

2. Remove the valve spring seat upper, valve spring

outer and inner.

3. Remove the intake and exhaust valves from the cyl-

inder head.

NOTE:

● Do not remove the valve guide and valve spring seat

lower unless they need to be replaced.

● Align the removed parts in the order of the cylinder

No.

Page 43

Fig. 16

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-6-7

INSPECTION AND REPAIR

CYLINDER HEAD

NOTE:

● Clean the cylinder head thoroughly with a commercial

cleaning agent before inspection.

● Do not damage the lower surface of the cylinder head.

SM3-J062

INSPECT THE CYLINDER HEAD FOR CRACKS.

Check the head surface and intake and exhaust valve

seats, for cracks, using a dye penetrant. If cracks are found,

replace the cylinder head.

Fig. 17

Fig. 18

B

C

D

A

Fig. 19

SM3-J103

CHECK THE CYLINDER HEAD FLATNESS.

1. Check the cylinder head surface for flatness with a

straight edge and a thickness gauge. If the measurements exceed service limits, replace the cylinder

head.

Standard: 0.06 mm (0.0024 in.) or less for longitudinal di-

rection

0.03 mm (0.0012 in.) or less for lateral direc-

SM3-J630

tion

Service limit: 0.20 mm (0.0079 in.)

E’

E

F’

F

G’

G

SM3-J505

A’

C’

D’

B’

2. Check the flatness of the intake and exhaust mani-

folds mounting surfaces.

Standard: 0.06 mm (0.0024 in.) or less for longitudinal di-

rection

0.03 mm (0.0012 in.) or less for lateral direction

Service limit: 0.20 mm (0.0079 in.)

Fig. 20

SM3-J506

Page 44

Fig. 21

Fig. 22

1 page 1

Models J08C-TP and J08C-TR3-6-8 ENGINE

INSPECT THE V AL VE CONT ACT SURF ACES FOR PROPER

CONTACT.

1. Visually check valves for damage, burn marks, car-

bon accumulation, warpage, or cracks in valve heads,

valve stems, and valve stem grooves. Replace valves

which are excessively worn, burnt, warped or

cracked.

SM3-J631

2. Check the valve seating condition.

Lightly apply red lead marking compound to the valve

face. Install the valve with a special tool, tap and

rotate the valve against the seat. Check the valve

face and valve seat for seating. When the red lead

mark is not concentric or even all around the valve

face or seat, correct the valve face or the valve seat.

Special tool: Valve lapping tool (09431 - 1020)

SM3-J104

Fig. 23

Fig. 24

SM3-J507A

SM3-J632

SM3-J507

HAND-LAP THE VALVE AND VALVE SEAT.

Lightly apply lapping compound to the valve face. Install

the valve with a special tool, tap and rotate the valve against

the seat.

NOTE:

● Following completion of hand-lapping, clean off any

lapping compound which has adhered to the valves

and valve seats.

● Following hand-lapping, always recheck the seating

condition.

Special tool: Valve lapping tool (09431 - 1020)

GRIND VALVES

NOTE:

● Grinding of valves should only be performed when

hand-lapping does not result in proper seating.

● Following hand-lapping, always recheck the seating

condition.

WARNING

When grinding, a metal tip may fly off on impact.

Wear safety glasses to protect your eyes.

Page 45

Fig. 25

30˚

INTAKE

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-6-9

Assembly standard:

Valve seat (Intake): 30°00' - 30°35'

Valve face (Intake): 29°30' - 30°00'

Valve seat (Exhaust): 45°00' - 45°30'

Valve face (Exhaust): 44°30' - 45°00'

45˚

EXHAUST

SM3-J097

HAMMER

VALVE

Fig. 26

Fig. 27

C

INTAKE

BLOCK BRASS

VALVE SEAT

ELECTRIC WELDING

APPLIED

GRIND THIS POINT

WITH A GRINDER

SM3-J064

C

EXHAUST

SM3-J065

IF NECESSARY, REPLACE THE VALVE SEAT.

1. Cut three places on the circumference of an un-

wanted valve and weld it to the valve seat.

NOTE: To protect the lower surface of the cylinder head

from welding spatter, be sure to apply grease

before welding.

2. Place a back plate at the top of the valve stem and

strike it with a hammer to remove the valve seat.

NOTE: When striking, a metal tip may fly off on impact.

Wear safety glasses to protect your eyes.

3. Machine the valve seat according to the specified

valve seat dimensions.

Dimensions of the valve seat machining:

Clynder

head side

Valve seat

side

Intake

Unit:mm Unit:in. Unit:mm Unit:in.

A 41-41.016 1.6142-1.6148 39-39.016 1.5355-1.5360

B 9.4-9.6 0.3701-0.3779 8.6-8.8 0.3386-0.3464

C 41.085-41.1 1.6176-1.6181 39.12-39.135 1.5402-1.5407

D 7-7.2 0.2756-0.2834 6-6.2 0.2363-0.2440

Exhaust

Fig. 28

SM3-J066

4. Heat the cylinder head to approx. 80°C (176°F) 90°C (194°F) with hot water . Cool the valve seat with

dry ice for approx. 30 minutes. Hold the seat with

pincers and place it into the heated cylinder head.

The valve seat can be easily made to fit by lightly

hitting it.

WARNING

● Never touch the cooled valve seat with your bear

hands.

● When striking, a metal tip may fly off on impact.

Wear safety glasses to protect your eyes.

● Following valve grinding, always recheck the

seating condition.

Page 46

Fig. 29

Fig. 30

Fig. 31

VALVE

SINK

DIMENSION

90°

VALVE SEAT

CYLINDER

HEAD

VALVE

SM3-J508

SM3-J509

SM3-J510

1 page 1

Models J08C-TP and J08C-TR3-6-10 ENGINE

MEASURE THE VALVE SINK.

Assembly standard:

Intake: 0.55 - 0.85 mm (0.0217 - 0.0334 in.)

Exhaust: 1.05 - 1.35 mm (0.0414 - 0.0531 in.)

Repair limit:

Intake: 1.1 mm (0.0433 in.)

Exhaust: 1.6 mm (0.0630 in.)

NOTE:

● If the valve heads are protruding from cylinder head

surface, the valve heads may hit against the pistons

while the engine is running.

● Following replacement of valve and valve seat, always

recheck the seating condition.

MEASURE THE CLEARANCE BETWEEN THE V AL VE STEM

AND VALVE GUIDE.

1. Measure the outside diameter of the valve stem with

a micrometer. If the value exceeds the service limit,

replace the valve.

Nominal dimension: 7.0 mm (0.2756 in.)

Service limit: Intake 6.92 mm (0.2724 in.)

Exhaust 6.84 mm (0.2693 in.)

2. Calculate the clearance between the valve stem and

valve guide. If the clearance exceeds the service

limit, replace the valve or valve guide.

Nominal dimension:

Intake: 0.023 - 0.058 mm (0.0010 - 0.0022 in.)

Exhaust: 0.037 - 0.067 mm (0.0015 - 0.0026 in.)

Service limit:

Intake: 0.10 mm (0.0039 in.)

Exhaust: 0.12 mm (0.0047 in.)

IF NECESSARY, REPLACE THE VALVE GUIDE.

1. Remove the valve stem seal.

2. Strike the valve guide out with a brass bar and a

hammer.

Fig. 32

WARNING

When striking, a metal tip may fly off on impact.

Wear safety glasses to protect your eyes.

SM3-J51 1

Page 47

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-6-11

Fig. 33

VALVE STEM SEAL

VALVE SPRING SEAT

LOWER

Fig. 34

INTAKE

EXHAUST

VALVE

COAT OIL

SM3-J065

SPECIAL

TOOL

SM3-J068

3. Press fit a new valve guide straight allowing it to protrude as shown in the figure.

NOTE: Apply engine oil lightly to the valve guide outer

circumference before installation.

IF NECESSARY, REPLACE THE VALVE STEM SEAL.

Replace the valve stem seal when the valve guide is replaced or when seal clearance is excessive or the stem

seal has been worn or damaged.

First, install the lower spring seat and valve to the cylinder head (for guide of special tool), then apply engine oil

to the lip of the stem seal and drive the guide with a special tool.

Special tool: Valve stem seal press (09472 - 2100)

WARNING

When striking, a metal tip may fly off on impact.

Wear safety glasses to protect your eyes.

Fig. 35

Fig. 36

NOTE:

B

● After installing the valve stem seal, make sure there

is a gap (A) and (B) as shown in the figure.

A

SM3-J068

● Do not use the special tool if its surface contacting

the valve spring lower seat is deformed.

INSPECT THE VALVE SPRINGS.

1. Check the valve springs for squareness using a

square and a thickness gauge. If a spring is out of

square beyond the service limit, replace it.

Limit: 2.0 mm (0.078 in.) or more

SM3-J098

Page 48

Fig. 37

1 page 1

Models J08C-TP and J08C-TR3-6-12 ENGINE

2. Measure the valve spring tension at a specified length

with the valve spring tester. If the spring force is lower

than the service limit, replace it.

SM3-J098

Outer spring

Inner spring

Fig. 38

Intake

Exhaust

Intake

Exhaust

Free length mm (in.)

Nominal dimension

75.7 (2.980) 75.4 (2.968) 46.8 (1.843) 46.4 (102.23) —

75.7 (2.980) 75.4 (2.968) 46.8 (1.843) 44.2 (97.44) —

64.6 (2.543) 64.3 (2.531) 44.8 (1.764) 21.7 (47.85) —

64.6 (2.543) 64.3 (2.531) 44.8 (1.764) 20.4 (44.98) —

Service limit

Setting height

mm (in.)

Nominal dimension

Setting load kg (lb)

3. Visually check the contact surface of the upper and

lower valve spring seats. Replacement is necessary

if damage such as wear and scratches is excessive.

SM3-J099

INSPECT THE CYLINDER HEAD COOLANT GALLERY FOR

LEAKS.

Close all coolant holes and apply air pressure of about

2

2.5 kg/cm

(36 lb/sq. in.) from one of the coolant holes.

Immerse the cylinder head into the water, then check for

air leakage. If any leakage is found, replace the cylinder

head.

Service limit

Fig. 39

IF NECESSARY, REPLACE THE NOZZLE SLEEVE.

1. Engage a tap to the nozzle sleeve from the bottom

of the cylinder head. Screw in an appropriate bolt,

then strike the bolt head with a hammer and drive

out the nozzle sleeve.

WARNING

When striking, a metal tip may fly off on impact.

SM3-J070SM3-J069

Wear safety glasses to protect your eyes.

Page 49

Fig. 40

SPECIAL

TOOL

SPECIAL

TOOL

CYLINDER HEAD

O-RING

NOZZLE SLEEVE

SM3-J071

NOZZLE

SLEEVE

CYLINDER

HEAD

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-6-13

2. Install an O-ring to the nozzle sleeve insert hole of

the cylinder head. Then apply liquid gasket (Three

Bond No. 121 1 or equivalent) to the bottom of a new

nozzle sleeve, and insert it to the nozzle sleeve insert hole of the cylinder head.

NOTE: Be sure to install a new O-ring. Reused O-rings

may cause water or gas leakage and lead to overheating or cracked heads.

3. Caulk the nozzle sleeve with the special tool.

Special tool: Sleeve bar (09472 - 1210)

Steel ball (9800 - 06100)

Fig. 41

Fig. 42

Fig. 43

Fig. 44

SM3-J072

CYLINDER HEAD

SM3-J100

SM3-J142

SM3-J634

4. Install the injection nozzle to the cylinder head. Then

measure the protrusion of the injection nozzle from

the lower surface of the cylinder head with a vernier

caliper. If the value exceeds the service limit, replace

the injection nozzle.

NOTE: Refer to page 3-12-5.

Assembly standard: 2.25 - 2.75 mm (0.0886 - 0.1082 in.)

Service limit: 2.75 mm (0.1082 in.)

MEASURE THE CLEARANCE BETWEEN THE CAM IDLER

GEAR SHAFT AND CAM IDLER GEAR BUSHING.

1. Measure the outside diameter of the cam idler gear

shaft with a micrometer. If the value exceeds the

service limit, replace the cam idler gear shaft.

Assembly standard: 34.0 mm (1.3386 in.)

Service limit: 33.95 mm (1.3366 in.)

2. Measure the inside diameter of the cam idler gear

bushing with a cylinder gauge. If the value exceeds

the service limit, replace the cam idler gear.

Assembly standard: 34.0 mm (1.339 in.)

Service limit: 34.025 mm (1.340 in.)

3. Calculate the clearance between the idler gear shaft

and idler gear bushing. If the value exceeds the service limit, replace the idler gear shaft and/or idler gear

bushing.

Assembly standard: 0.025 - 0.075 mm (0.0010-0.0029 in.)

Service limit: 0.20 mm (0.0079 in.)

Page 50

Fig. 45

Fig. 46

SM3-J635

SM3-J517

1 page 1

Models J08C-TP and J08C-TR3-6-14 ENGINE

INSPECT THE INTAKE AND EXHAUST MANIFOLDS.

NOTE: Clean the intake and exhaust manifolds with a

commercial cleaning agent before inspection.

1. Check the intake and exhaust manifolds for cracks,

using a dye penetrant. If cracks are found, replace

the manifold.

2. Measure the intake manifold flatness with a straight

edge and a thickness gauge. If the value exceeds

the service limit, replace the intake manifold.

Service limit: 0.2 mm (0.0079 in.)

3. Measure the exhaust manifold flatness with a straight

edge and a thickness gauge. If the value exceeds

the service limit, correct the exhaust manifold by

grinding it to become within 0.14 mm (0.006 in.) per

2 flanges or 0.1 mm (0.004 in.) per flange.

Service limit: 0.2 mm (0.0079 in.)

Fig. 47

Fig. 48

4. Visually check the seal ring of the exhaust manifold

for deformation or wear. Replacement is necessary

if damage such as deformation and wear is

excessive.

SM3-J570

INSPECT THE CAMSHAFT.

1. Visually check the camshaft surface for wear and

scratches.

SM3-J518

Page 51

Fig. 49

SM3-J636

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-6-15

2. Measure the cam height.

Measure the dimensions (A) shown in the figure with

a micrometer. If the value exceeds the service limit,

replace the camshaft.

Nominal dimension A : Intake = 50.0667 ± 0.15 mm

(1.9711 ± 0.0059 in. )

Exhaust = 52.1038 ± 0.15 mm

(2.0513 ± 0.0059 in.)

Service limit: –0.5 mm (–0.0197 in.)

Fig. 50

Fig. 51

Fig. 52

SM3-J519A

SM3-J637

SM3-J638

3. Measure the clearance of camshaft journal.

a. Measure the outside diameter of camshaft journal

with a micrometer. If the value exceeds the service

limit, replace the camshaft.

Nominal dimension: 40.0 mm (1.575 in.)

Service limit: 39.85 mm (1.569 in.)

b. Measure the inside camshaft bearing with a cylinder

gauge. If the value exceeds the service limit, replace

the camshaft bearing.

Nominal dimension: 40.0 mm (1.575 in.)

Service limit: 40.15 mm (1.581 in.)

c. Calculate the clearance from the above measure-

ment. If the clearance is greater than the limit, replace the camshaft or camshaft bearing.

Nominal dimension: 0.020 - 0.063 mm (0.0008 - 0.0024 in.)

Service limit: 0.1 mm (0.0039 in.)

Page 52

Fig. 53

1 page 1

Models J08C-TP and J08C-TR3-6-16 ENGINE

4. Measure the camshaft end play.

Support the camshaft with V -blocks and measure the

run out at the center journal with a dial gauge. If the

value exceeds the service limit, replace it.

Service limit: 0.10 mm (0.0039 in.)

SM3-J639

IF NECESSARY, REPLACE THE CAMSHAFT GEAR.

1. Measure the length of the cam gear bolts, if the length

is A or more, replace with new bolts.

A = 51 mm (2.0078 in.)

2. Make sure there is no dirt or scratch on the cam-

A

shaft gear or tightening surface of the camshaft.

Fig. 54

Fig. 55

Fig. 56

SM3-J080

90˚

SM3-J081 SM3-J082

SM3-J640

3. Apply clean engine oil to the bolt seating and bolt

thread, then tighten the bolt to the specified torque

below.

Tightening torque: 600 kg·cm (43 lb·ft)

4. Retighten them 90° (1/4 turn).

NOTE: When adding torque, never untighten the nuts,

even it they have been overtightened.

INSPECT THE ROCKER ARM ASSEMBLY AND ROCKER

ARM SHAFT.

1. Measure the inside diameter of the rocker arm bush-

ing with a cylinder gauge. If wear exceeds the service limit, replace it.

Nominal dimension: 22.0 mm (0.8661 in.)

Service limit: 22.08 mm (0.8693 in.)

NOTE: When installing a bushing into the rocker arm,

align the bushings with the oil holes of the rocker

arm.

Page 53

Fig. 57

Fig. 58

SM3-J641

SM3-J642

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-6-17

2. Measure the outside diameter of the rocker arm shaft

with a micrometer. If wear exceeds the service limit,

replace the rocker arm.

Nominal dimension: 22.0 mm (0.8661 in.)

Service limit: 21.92 mm (0.8630 in.)

3. Calculate the clearance between the rocker arm

bushing and rocker arm shaft. If the clearance is

greater than the specified limit, replace the rocker

arm bushing.

Assembly standard: 0.03 - 0.101 mm (0.0012 - 0.0039 in.)

Repair limit: 0.15 mm (0.0059 in.)

INSPECT THE ROCKER ARM AND CROSS HEAD.

Visually check the contact between the rocker arm and

cross head. Replace the rocker arm and the cross head

if damage such as wear and scratches is excessive. If

there is only a minimal amount of wear, correct the surface with a resurfacer.

Visually check the adjusting screw thread. Replace the

adjusting screw if damage such as wear and scratches is

excessive.

Page 54

Fig. 59

Fig. 60

SM3-J060

SM3-J643

1 page 1

Models J08C-TP and J08C-TR3-6-18 ENGINE

ASSEMBLING

ASSEMBLE THE VALVE SYSTEM.

NOTE: If parts are reused, install them to their initial

position.

1. Apply engine oil to the intake and exhaust valve

stems. Then insert them to the valve guide installed

to the cylinder head.

2. Install the valve inner and outer springs and valve

spring seat upper.

3. Press fit the valve spring seat upper with the special

tool, then securely fit the valve spring retainer.

Special tool: Valve spring press (09470 - 1022)

ASSEMBLE THE ROCKER ARM ASSEMBLY.

1. Make sure of the correct direction of the rocker arm

support and assemble the rocker arm assembly.

NOTE: Wrong mounting of the rocker arm support results

in seizure of the valve mechanism due to incorrect lubrication.

2. Wind up the adjusting screw of the rocker arm completely.

NOTE: If the adjusting screw is left unwound, the rocker

shaft may bend when the rocker arm support is

tightened.

Fig. 61

Fig. 62

SM3-J644

SM3-J645

INSTALL THE CAM IDLER GEAR.

1. Install the cam idler gear with the snap ring side facing the cylinder head.

2. Install the cam idler gear shaft through a thrust plate,

with the oil filler facing downward.

NOTE: Refer to page 3-6-1.

3. Tighten the idler gear shaft bolt to the specified torque

below.

Tightening torque: 1,100 kg·cm (80 lb·ft)

MEASURE THE CAM IDLER GEAR END PLAY.

After installing the cam idler gear, measure the clearance

between the cam idler gear and thrust bearing with a dial

gauge. If the clearance exceeds the service limit, replace

the thrust bearing.

Nominal clearance: 0.040 - 0.095 mm (0.0016 - 0.0037 in.)

Service limit: 0.30 mm (0.0118 in.)

Page 55

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-6-19

MATCHING SURFACE WITH HEAD END

LIQUID

GASKET

Fig. 63

HEAD

SIDE HOLE

SM3-J037

INSTALL THE IDLER GEAR COVER.

1. Clean the cylinder head mounting surface of the idler

gear cover.

2. Apply liquid gasket to the idler gear cover, then install it to the cylinder head within 20 minutes.

Liquid gasket: ThreeBond No.1207B

Coating width: 1.5 - 2.5 mm (0.06 - 0.10 in.)

NOTE:

● If left more than 20 minutes, clean off the liquid gas-

ket completely and reapply the liquid gasket.

● Refer to page 3-20-1.

Page 56

COOLANT

SEAL RING

Fig. 64

LIQUID GASKET

APPLICATION POINT

LIQUID GASKET

CYLINDER HEAD

CYLINDER

BLOCK

REAR END

PLATE

GEAR CASE

PRINTED SEAL

SM3-J268

PRINT SEAL

LIQUID GASKET

APPLICATION POINT

FLYWHEEL HOUSING

CORRECT

CLEARANCE

TOO POOR

1 page 1

Models J08C-TP and J08C-TR3-6-20 ENGINE

MOUNTING

1. INSTALL THE CYLINDER HEAD GASKET.

NOTE:

● Never reuse the cylinder head gasket as it may cause

engine damage.

● Before installing the cylinder head gasket, remove dirt,

moisture and oil on the cylinder head and cylinder

block surface.

● The coolant seal rings between the bores are easily

damaged. Do not touch them with your hands or other

objects. Make sure that the seal rings are not loose

or damaged.

● Since silicon material is used for the gear case print

seal, make sure that there is no peeling before assembly.

1. Install the cylinder head gasket on the cylinder block

and flywheel housing.

2. Fill the hole at the back of the cylinder head gasket

with liquid gasket.

NOTE: Make sure that the liquid gasket surface is flush

with the cylinder head gasket upper surface.

CLEARANCE

Fig. 65

Fig. 66

A-A SECTION

CLEARANCE

PROTRUDING

A

SM3-J075

2. INSTALL THE CYLINDER HEAD ON THE CYLINDER

BLOCK.

SM3-J627

3. INSTALL THE CYLINDER HEAD BOLT.

1. Preparation

a. Measure the length of the M12 head bolts, if the

length is A or more, replace with new bolts.

A = 126 mm (4.9606 in.)

b. Make sure that no dirt or scratch is on the tightening

surface of the cylinder head bolt.

Fig. 67

SM3-J076A

Page 57

Fig. 68

Fig. 69

PAINT

90˚

90˚

SM3-J078

1 page 1

Models J08C-TP and J08C-TR ENGINE 3-6-21

c. Apply clean engine oil to the bolt surface and bolt

threads.

NOTE: Since the cylinder head bolts are unique to this

engine, do not substitute ordinary bolts.

2. Tighten the cylinder head bolt.

a. Tighten No.1 - No.26 (M12)bolts in

the order shown in the figure to the

specified torque below.

Tightening torque: 600 kg·cm (43 lb.in.)

SM3-J269B

b. Mark the bolts with paint to indicate the same direc-

tions as shown in the figure.

c. Turn No.1 - No.26 bolts 90° (1/4 turn).

d. Retighten them 90° (1/4 turn).

NOTE: Total tightening amounts to 180°. It must not be-

come 200° or more.

e. Make sure that all paint marks face the same direc-

tion.

NOTE: When adding torque, never untighten the nuts,

even if they have been overtightened.

Fig. 70

Fig.71

FLYWHEEL HOUSING

FLYWHEEL

f. Tighten No.27 - No.29 (M10) bolts in

the order shown in the figure to the

specified torque below.

Tightening torque: 600 kg·cm (43 lb·ft)

SM3-J288A

4. INSTALL THE CAM HOUSING.

1. Using the timing line on the flywheel, align No.1 cyl-

inder with the upper dead point.

NOTE: Refer to page 3-18-1.

SM3-J009

Page 58

Fig. 72

ARROW OF

MARK

1 page 1

Models J08C-TP and J08C-TR3-6-22 ENGINE

2. Install the cam housing on the cylinder head.

NOTE: When installing the cam housing, make sure the

cam housing gasket is correctly fitted and is free

of uneven deformation.

SM3-J647

5. ASSEMBLE THE CAMSHAFT.

1. Install the camshaft into the cam housing so that the

arrow stamped on the front of the camshaft gear

faces upward and that the lower line is level.

NOTE: Incorrect installation may damage of the engine.

Fig. 73

Fig. 74

SCALE ETC...

SM3-J083

2. Install the camshaft bearing cap to the cam hous-

ing. Make sure there is no dirt or scratch on the tight-

ening surfaces.

3. Apply clean engine oil to the bolt seating and bolt

thread, then tighten the bolt to the specified torque

below.

Tightening torque: 320 kg·cm (23 lb·ft)

SM3-J648

6. MEASURE THE BACKLASH BETWEEN THE CAMSHAFT GEAR AND CAMSHAFT IDLER GEAR.

Measure the backlash between the camshaft gear and

camshaft idler gear with a dial gauge. If the value exceeds

the service limit, replace the camshaft gear.