Page 1

For DENSO Authorized

ECD Service Dealer Only

Diesel Injection Pump

SERVICE MANUAL

Common Rail System for HINO

J05D/J08E Type Engine

OPERATION

October, 2003

-1

00400041E

Page 2

TABLE OF CONTENTS

1. Product Application ------------------------------------------------------------------------------------- 1

1.1 Application ------------------------------------------------------------------------------------------------------------------- 1

1.2 System Components Parts Numbers --------------------------------------------------------------------------------- 1

2. Outline ------------------------------------------------------------------------------------------------------ 2

2.1 Features of System ------------------------------------------------------------------------------------------------------- 2

[1] System Characteristics ------------------------------------------------------------------------------------------------ 2

[2] Comparison to the Conventional System ------------------------------------------------------------------------- 3

2.2 Outline of System ----------------------------------------------------------------------------------------------------------4

[1] Composition -------------------------------------------------------------------------------------------------------------- 4

[2] Operation ----------------------------------------------------------------------------------------------------------------- 4

2.3 Fuel System and Control System -------------------------------------------------------------------------------------- 5

[3] Fuel System -------------------------------------------------------------------------------------------------------------- 5

[4] Control System ---------------------------------------------------------------------------------------------------------- 5

3. Construction and Operation--------------------------------------------------------------------------- 6

3.1 Description of Main Components ------------------------------------------------------------------------------------- 6

[1] Supply Pump (HP3, HP4) --------------------------------------------------------------------------------------------- 6

[2] Description of Supply Pump Components ------------------------------------------------------------------------ 13

[3] Rail -------------------------------------------------------------------------------------------------------------------------- 16

[4] Injector (G2 Type) ------------------------------------------------------------------------------------------------------- 17

[5] Engine ECU (Electronic Control Unit) ------------------------------------------------------------------------------ 22

3.2 Description of Control System Components ------------------------------------------------------------------------ 22

[1] Engine Control System Diagram ------------------------------------------------------------------------------------ 22

[2] Sensor and Relays ----------------------------------------------------------------------------------------------------- 23

3.3 Various Types of Controls ----------------------------------------------------------------------------------------------- 29

[1] Fuel Injection Rate Control ------------------------------------------------------------------------------------------- 30

[2] Fuel Injection Quantity Control --------------------------------------------------------------------------------------- 31

[3] Fuel Injection Timing Control ----------------------------------------------------------------------------------------- 35

3.4 Other Relevant Engine Control ----------------------------------------------------------------------------------------- 36

[1] EGR Control -------------------------------------------------------------------------------------------------------------- 36

3.5 Engine ECU -----------------------------------------------------------------------------------------------------------------37

[1] Diagnosis Codes -------------------------------------------------------------------------------------------------------- 37

[2] ECU External Wiring Diagram --------------------------------------------------------------------------------------- 44

[3] ECU Connector Diagram ---------------------------------------------------------------------------------------------- 45

0

Page 3

1. Product Application

1.1 Application

Vehicle Name Vehicle Model Engine Model Exhaust Volume Reference

HINO145, HINO165,

HINO185

J05D 4.73L

Medium Truck

HINO238, HINO268,

HINO308, HINO338

J08E 7.68L

1.2 System Components Parts Number

Part Name

Supply Pump

Vehicle

Name

DENSO Part

Number

294050-0011 22730-1311A

Car Manufacturer

Part Number

Injector 095000-5281 23910-1360A

Rail 095440-0480 22760-1180A

Engine ECU 102758-3010 89560-6540A

Accelerator Position Sensor 198800-3160 78010-1200A

Coolant Temp. Sensor 071560-0110 83420-1250A

Crankshaft Position Sensor 029600-0570 89410-1280A

Cylinder Recognition Sensor 949979-1360 89410-1590A

Medium Truck

HINO238,

HINO268,

HINO308,

HINO338

Sales from

Early ’04

Reference

Intake Air Pressure Sensor 079800-5890 89390-1080A

EGR Valve 135000-7091 17350-1220A

Air Flow Meter 197400-2000 22204-21010B

Supply Pump

294000-0251 22730-1321A

Injector 095000-5391 23910-1310A

Rail 095440-0530 22760-1220A

Engine ECU 102758-3010 89560-6540A

Accelerator Position Sensor 198800-3160 78010-1200A

Coolant Temp. Sensor 071560-0110 83420-1250A

Crankshaft Position Sensor 029600-0570 89410-1280A

Medium Truck

HINO145,

HINO165,

HINO185

Cylinder Recognition Sensor 949979-1360 89410-1590A

Intake Air Pressure Sensor 079800-5890 89390-1080A

EGR Valve 135000-7071 17350-1210A

Air Flow Meter 197400-2000 22204-21010B

For EGR

Control

For EGR

Control

1

Page 4

2. Outline

2.1 Features of System

The common rail system was developed primarily to cope with exhaust gas regulations for

diesel engines, and aimed for 1. further improved fuel economy; 2. noise reduction; and 3.

high power output.

[1] System Characteristics

The common rail system uses a type of accumulation chamber called a rail to store pressurized fuel, and injectors that contain electronically controlled solenoid valves to spray the pressurized fuel into the cylinders. Because the engine ECU controls the injection system

(including the injection pressure, injection rate, and injection timing), the system is unaffected

by the engine speed or load. This ensures a stable injection pressure at all times, particularly

in the low engine speed range, and dramatically decreases the amount of black smoke ordinarily emitted by a diesel engine during start-up and acceleration. As a result, exhaust gas

emissions are cleaner and reduced, and higher power output is achieved.

(1) Injection Pressure Control

a. Enables high-pressure injection, even in the low engine speed range.

b. Optimizes control to minimize particulate matter and NOx emissions.

(2) Injection Timing Control

a. Optimally controls the timing to suit driving conditions.

(3) Injection Rate Control

a. Pilot injection control sprays a small amount of fuel before the main injection.

Common Rail System

Injection Pressure Control

Optimization, High Pressurization

Common Rail System

Conventional

Injection Pressure

Pump

Speed

Particulate

Injection

Pressure

Injection Timing Control

Optimization

Common Rail System

NOx

Injection Timing

Conventional

Pump

Speed

Injection Rate Control

Pilot Injection

Injection Rate

Crankshaft Angle

Injection Quantity Control

Cylinder Injection

Volume Correction

Speed

㧝㧟㧠㧞

Main

Injection

(4) EGR (Exhaust Gas Recirculation) Control

a. By recirculating the exhaust gas into the intake side of the engine, the combustion

temperature is reduced and NOx is decreased.

2

QD0734E

Page 5

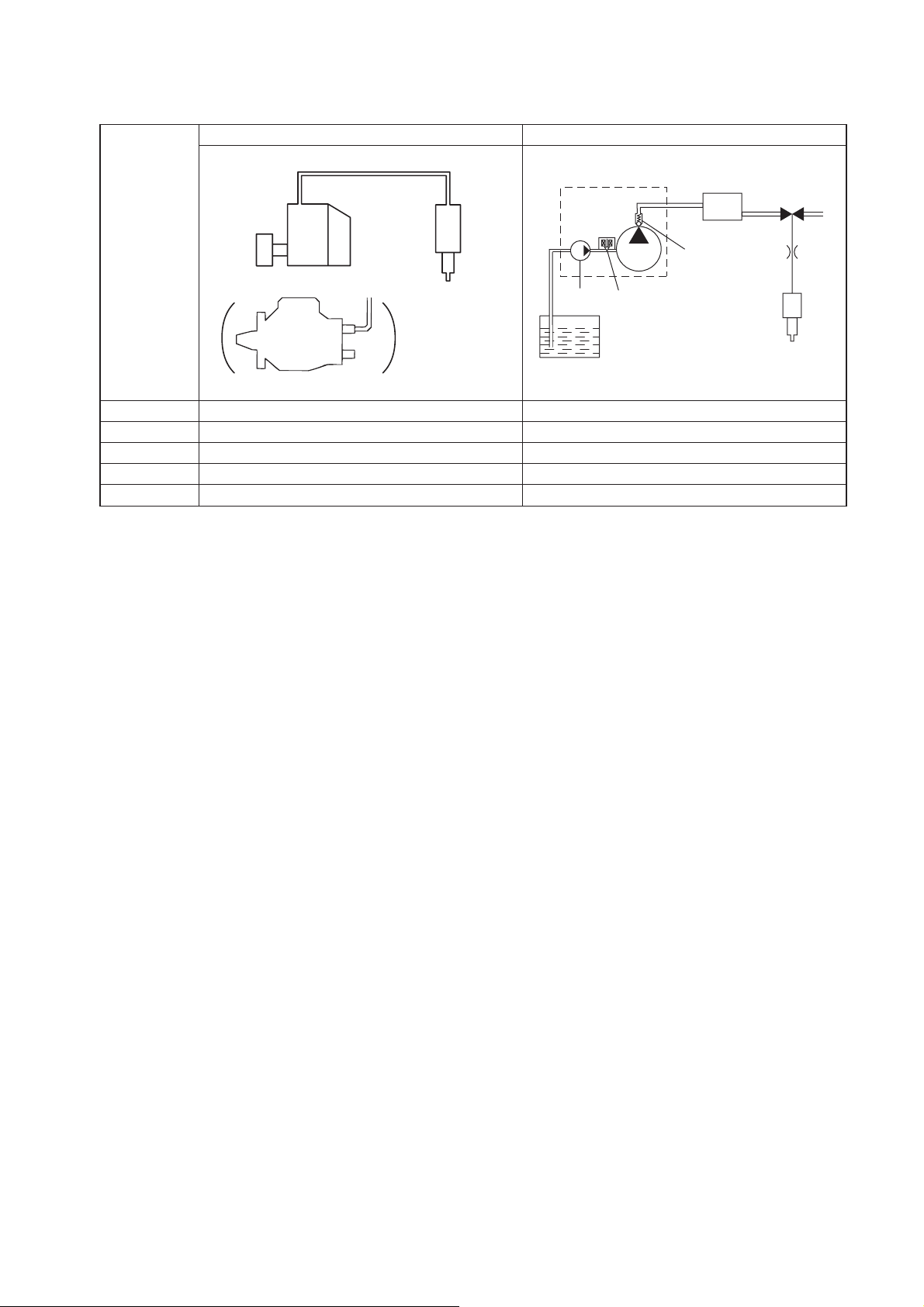

[2] Comparison to the Conventional System

In-line, VE Pump

High-pressure Pipe

Momentary High Pressure

Timer

System

In-line Pump

VE Pump

Injection Quantity Control

Injection Timing Control

Pump (Governor)

Pump (Timer)

Rising Pressure

Distributor Pump

Injection Pressure Control

Dependent upon Speed and Injection Quantity

Governor

Pump

Common Rail System

Rail

Nozzle

Supply Pump

Usually High Pressure

Delivery Valve

Feed Pump

SCV (Suction Control Valve)

Injector

Fuel Tank

Engine ECU, Injector (TWV)*

Engine ECU, Injector (TWV)*

1

1

Engine ECU, Supply Pump

Engine ECU, Rail

Engine ECU, Supply Pump (SCV)*

*1 TWV: Two Way Valve *2 SCV: Suction Control Valve

TWV

2

QD2341E

3

Page 6

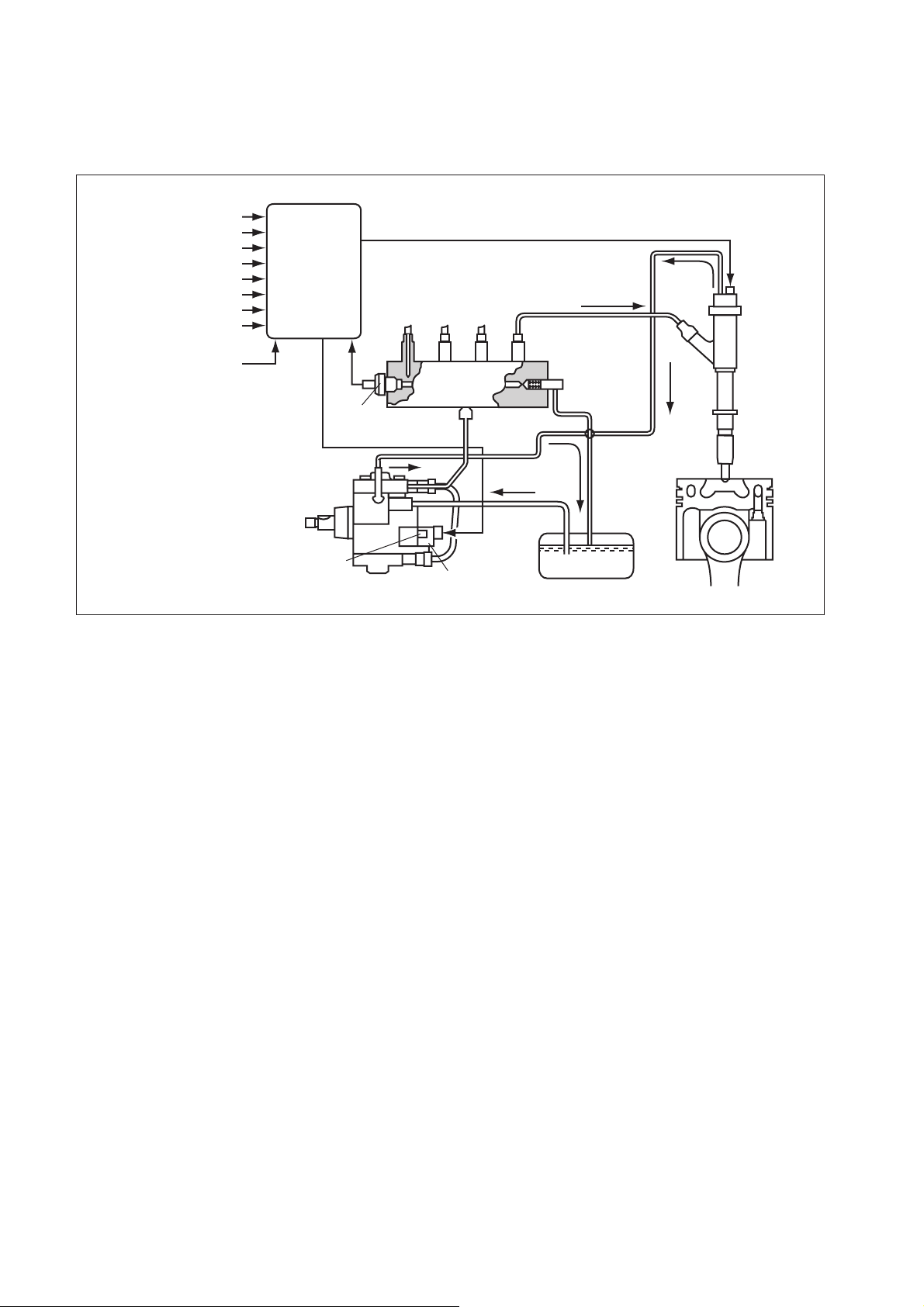

2.2 Outline of System [1] Composition

The common rail system consists primarily of a supply pump, rail, injectors, and engine ECU.

Fuel Temperature Sensor

Vehicle Speed

Accelerator Opening

Intake Air Pressure

Intake Air Temperature

Coolant Temperature

Crankshaft Position

Cylinder Recognition Sensor

Intake Airflow Rate

Engine ECU

Rail Pressure

Sensor

Rail

Pressure

Limiter

Injector

Fuel Temperature Sensor

Supply Pump

SCV (Suction

Control Valve)

Fuel Tank

[2] Operation

(1) Supply pump (HP3)

a. The supply pump draws fuel from the fuel tank, and pumps the high pressure fuel to the

rail. The quantity of fuel discharged from the supply pump controls the pressure in the

rail. The SCV (Suction Control Valve) in the supply pump effects this control in

accordance with the command received from the ECU.

(2) Rail

a. The rail is mounted between the supply pump and the injector, and stores the high-

pressure fuel.

(3) Injector (G2 type)

a. This injector replaces the conventional injection nozzle, and achieves optimal injection by

effecting control in accordance with signals from the ECU. Signals from the ECU

determine the length of time and the timing in which current is applied to the injector. This

in turn, determines the quantity, rate and timing of the fuel that is injected from the

injector.

Q000144E

(4) Engine ECU

a. The engine ECU calculates data received from the sensors to comprehensively control

the injection quantity, timing and pressure, as well as the EGR (exhaust gas

recirculation).

4

Page 7

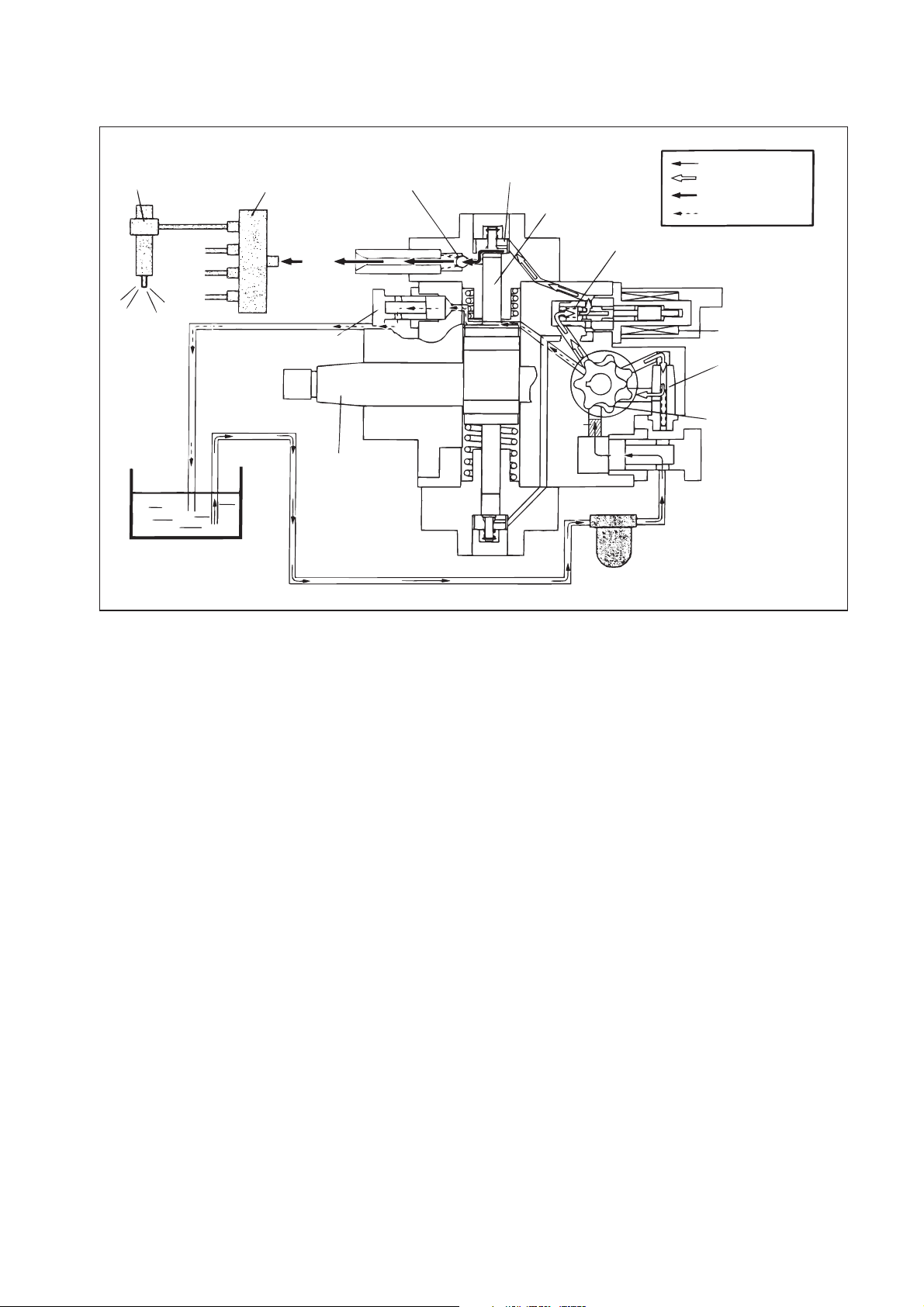

2.3 Fuel System and Control System [1] Fuel System

This system comprises the route through which diesel fuel flows from the fuel tank to the supply pump, via the rail, and is injected through the injector, as well as the route through which

the fuel returns to the tank via the overflow pipe.

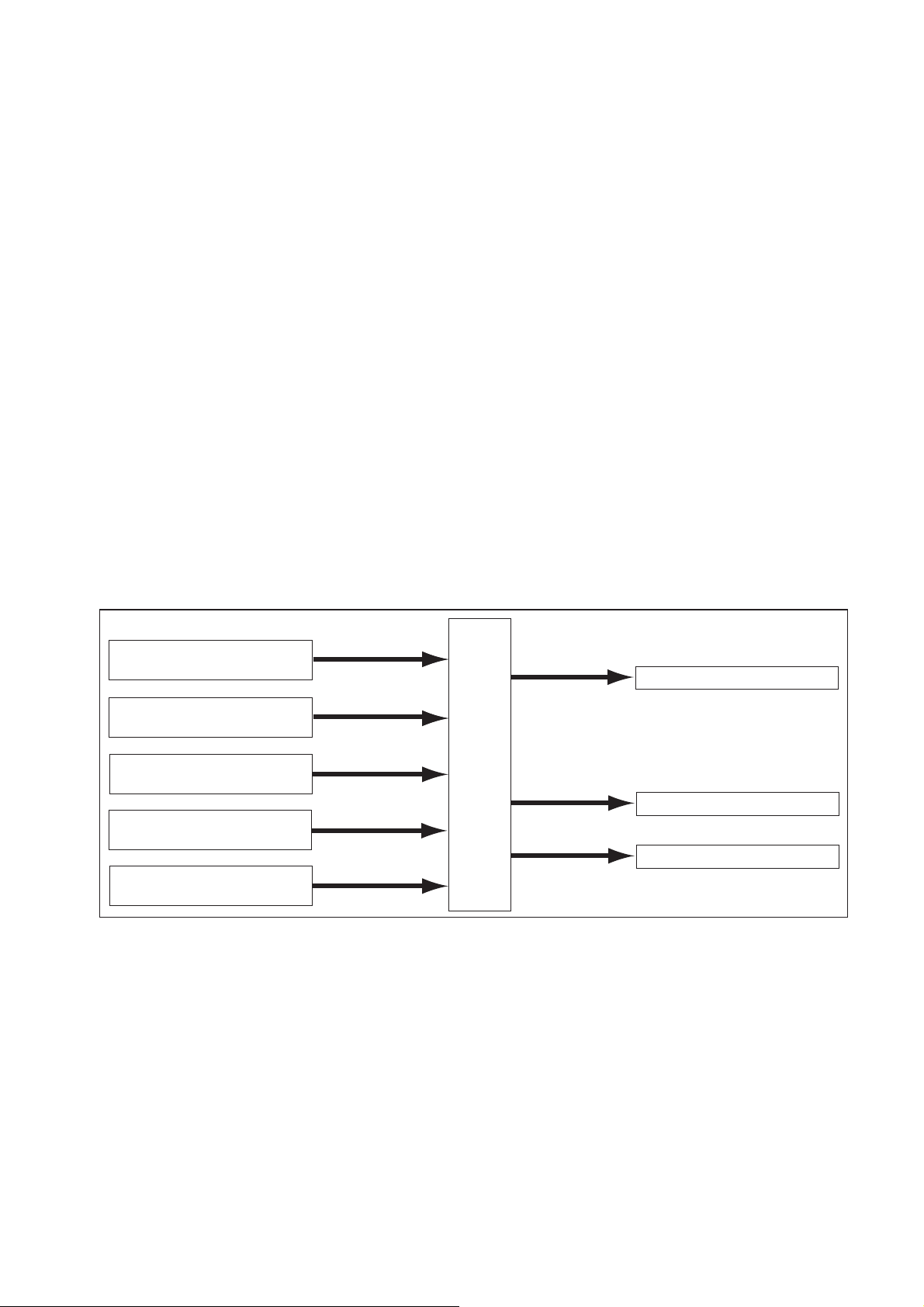

[2] Control System

In this system, the engine ECU controls the fuel injection system in accordance with the signals received from various sensors. The components of this system can be broadly divided

into the following three types: (1) Sensors; (2) ECU; and (3) Actuators.

(1) Sensors

a. Detect the engine and driving conditions, and convert them into electrical signals.

(2) Engine ECU

a. Performs calculations based on the electrical signals received from the sensors, and

sends them to the actuators in order to achieve optimal conditions.

(3) Actuators

a. Operate in accordance with electrical signals received from the ECU. Injection system

control is undertaken by electronically controlling the actuators. The injection quantity

and timing are determined by controlling the length of time and the timing in which the

current is applied to the TWV (Two-Way Valve) in the injector. The injection pressure is

determined by controlling the SCV (Suction Control Valve) in the supply pump.

Sensor

Crankshaft Position Sensor NE

Cylider Recognition Sensor G

Accelerator Position Sensor

Rail Pressure Sensor

Other Sensors and Switches

Engine Speed

Cylinder Recognition

Load

Actuator

Injector

•Injection Quantity Control

•Injection Timing Control

Engine

ECU

Supply Pump (SCV)

•Injection Pressure Control

EGR, Engine Warning Light

Q000282E

5

Page 8

3. Construction and Operation

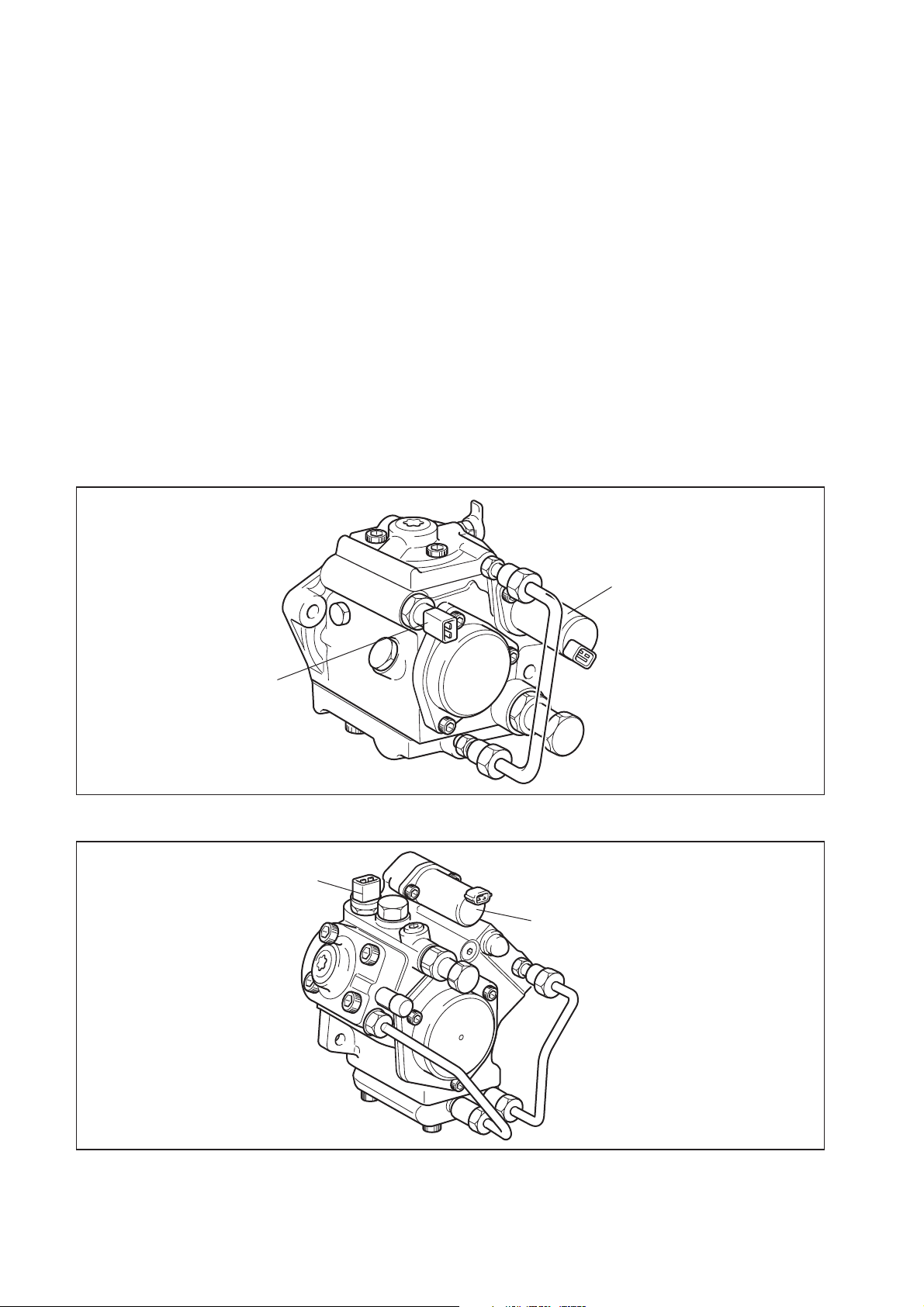

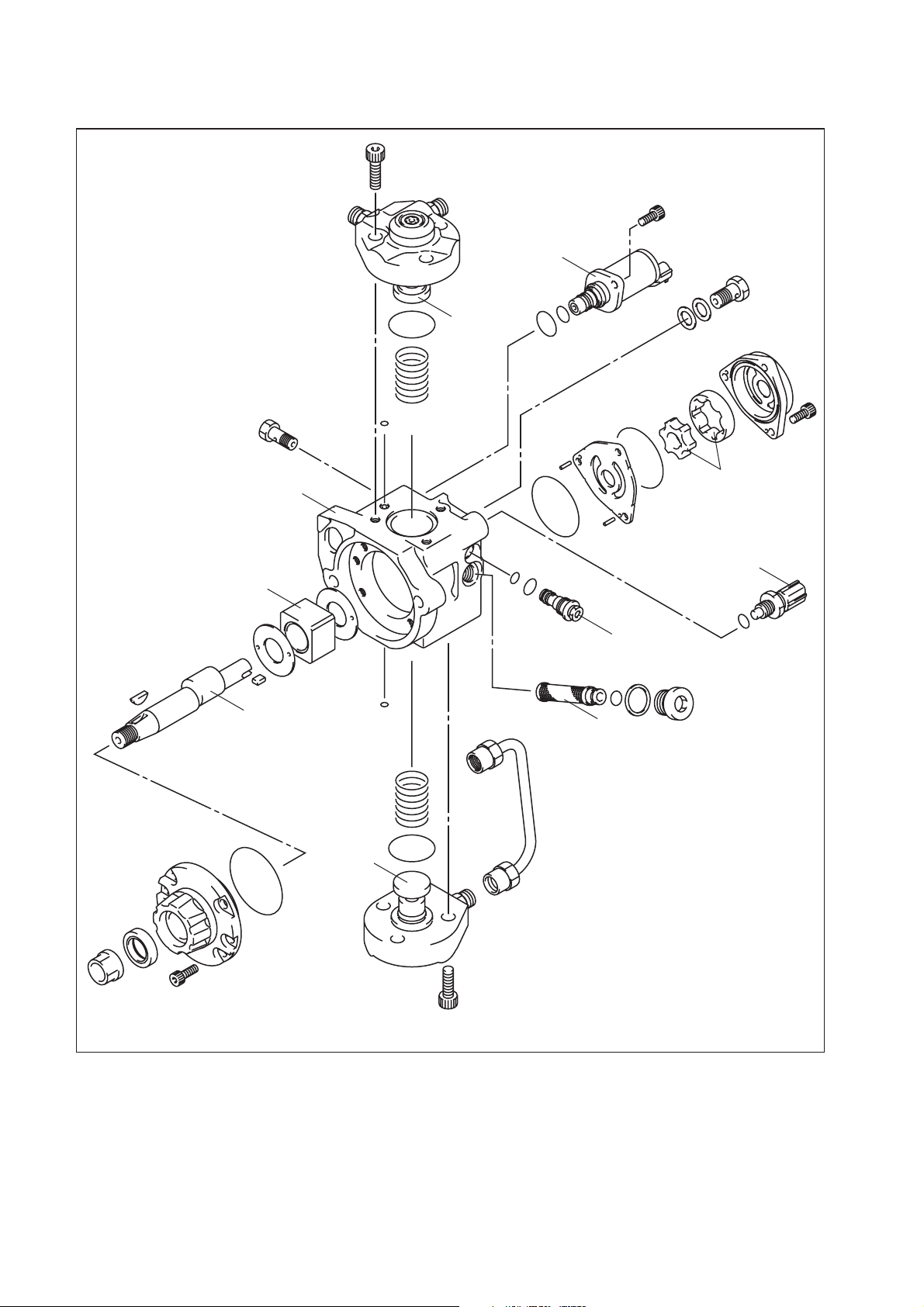

3.1 Description of Main Components [1] Supply Pump (HP3, HP4)

(1) Outline

a. The supply pump consists primarily of the pump body (cam shaft, ring cam, and

plungers), SCV (Suction Control Valve), fuel temperature sensor, and feed pump.

b. The two plungers for HP3 or the three plungers for HP4 are positioned vertically on the

outer ring cam for compactness.

c. The engine drives the supply pump at a ratio of 1:1. The supply pump has a built-in feed

pump (trochoid type), and draws the fuel from the fuel tank, sending it to the plunger

chamber.

d. The internal camshaft drives the two plungers, and they pressurize the fuel sent to the

plunger chamber and send it to the rail. The quantity of fuel supplied to the rail is

controlled by the SCV, using signals from the engine ECU. The SCV is a normally

opened type (the intake valve opens during de-energization).

HP3

Fuel Temperature Sensor

HP4

Fuel Temperature Sensor

SCV

Q000252E

SCV

Q000253E

6

Page 9

Injector

Rail

Discharge Valve

Intake Valve

Plunger

Intake Pressure

Feed Pressure

High Pressure

Return Pressure

Return Spring

Fuel Tank

Return

Fuel Overflow

Camshaft

Filter

SVC

Regulating Valve

Feed Pump

Fuel Inlet

Intake

Fuel Filter (with Priming Pump)

QD0704E

7

Page 10

HP3

Pump Body

Ring Cam

SCV

Plunger

Feed Pump

Fuel Temperature

Sensor

Drive Shaft

Regulating

Valv e

Filter

Plunger

Q000254E

8

Page 11

HP4

SCV

Plunger

Fuel Temperature

Sensor

Ring Cam

Drive Shaft

Filter

Feed Pump

Regulating

Valv e

Pump Body

Plunger

Q000255E

9

Page 12

(2) Supply Pump Internal Fuel Flow

a. The fuel that is drawn from the fuel tank passes through the route in the supply pump as

illustrated, and is fed into the rail.

Supply Pump Interior

Regulating Valve

Feed Pump

Overflow

Fuel Tank

SCV (Suction Control Valve)

Intake Valve

Pumping Portion (Plunger)

Rail

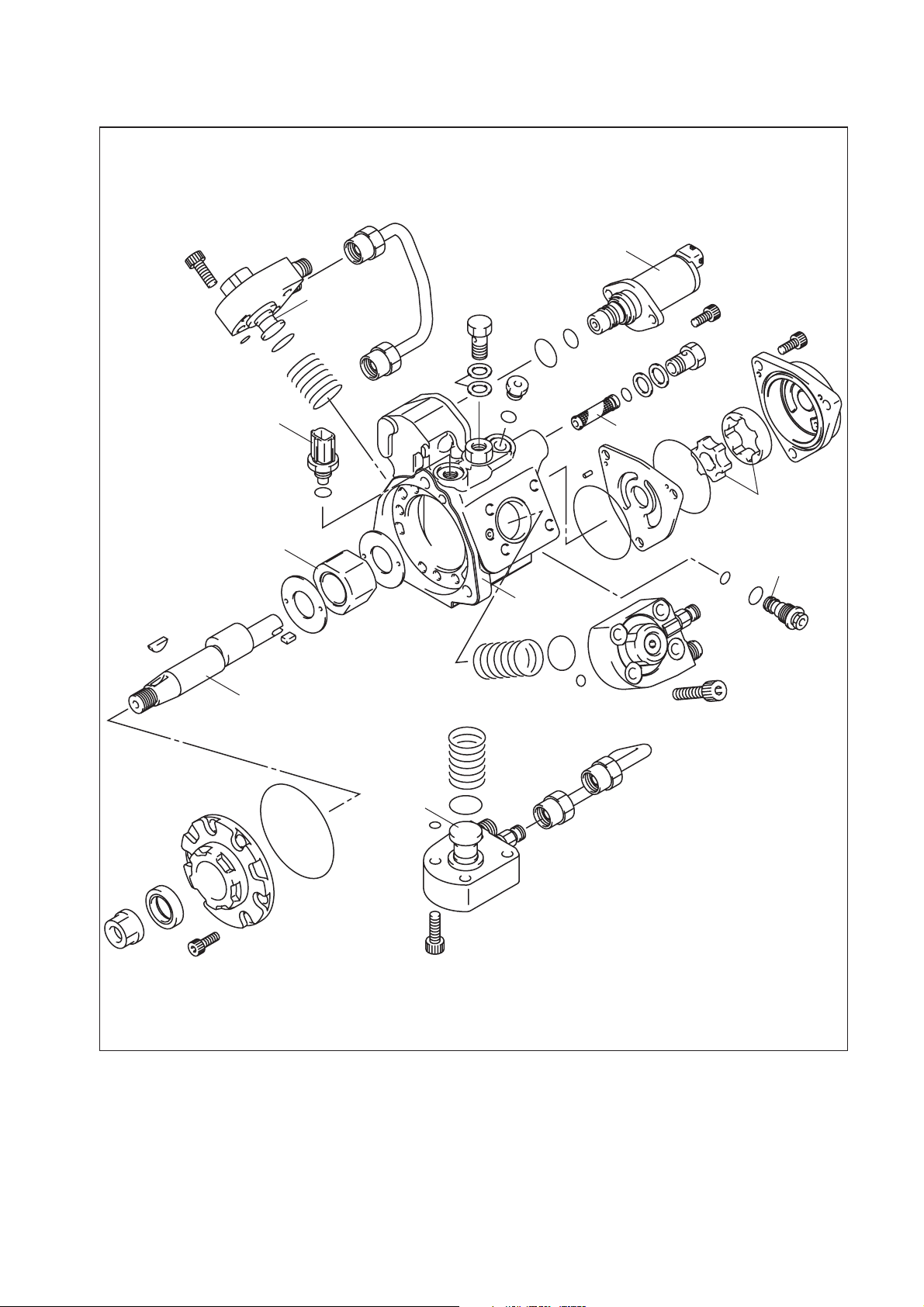

(3) Construction of Supply Pump (in case of HP3 pump)

a. The eccentric cam is attached to the cam shaft. The eccentric cam is connected to the

ring cam.

Cam Shaft

Eccentric Cam

Ring Cam

b. As the cam shaft rotates, the eccentric cam rotates eccentrically, and the ring cam moves

up and down while rotating.

Q000283E

QD0706E

Plunger

Eccentric Cam

Cam Shaft

Ring Cam

10

QD0727E

Page 13

c. The plunger and the suction valve are attached to the ring cam. The feed pump is

connected to the rear of the cam shaft.

Plunger A

Ring Cam

Feed Pump

Plunger B

QD0728E

11

Page 14

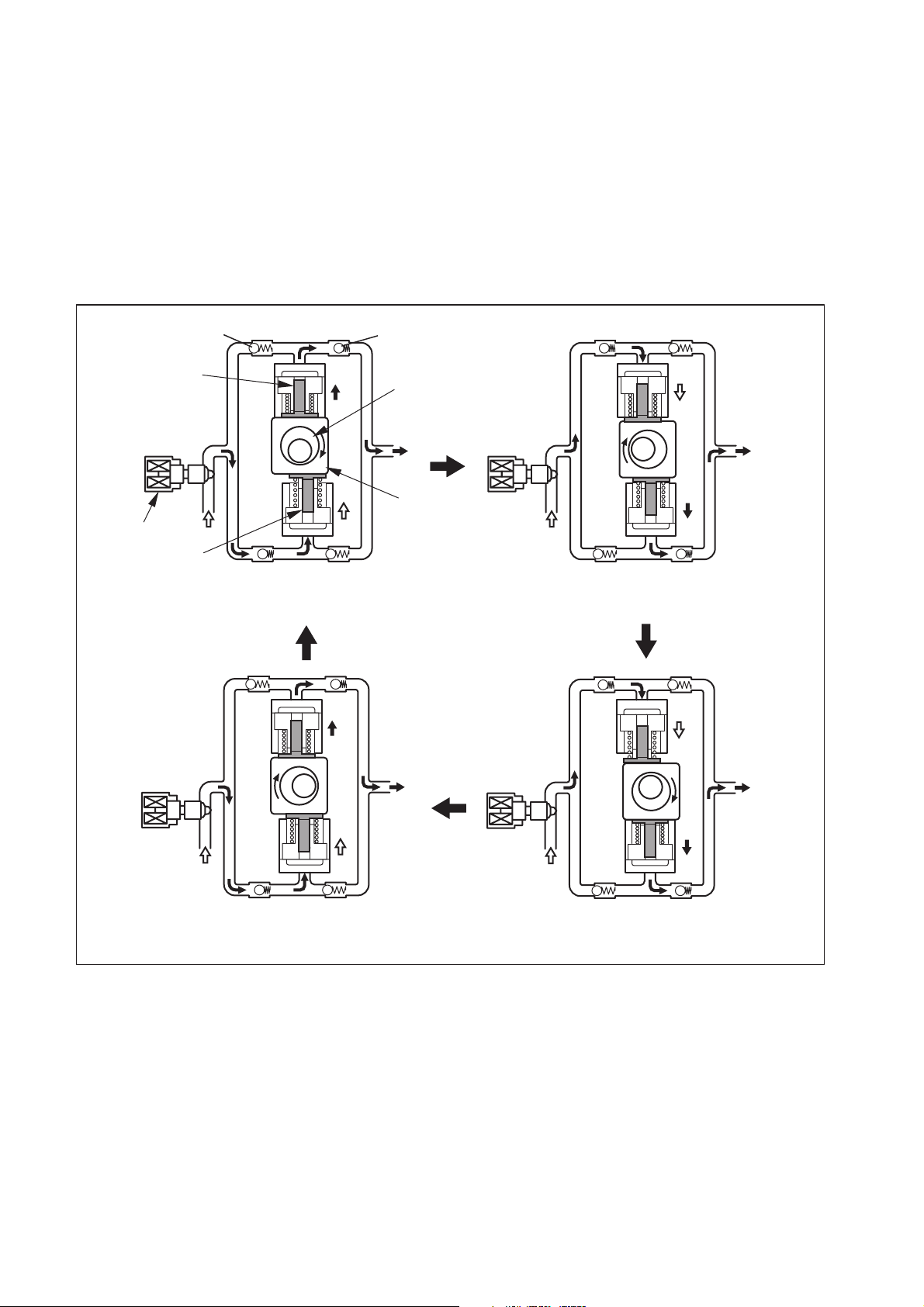

(4) Operation of the Supply Pump

a. As shown in the illustration below (in case of HP3 pump), the rotation of the eccentric cam

causes the ring cam to push Plunger A upwards. Due to the spring force, Plunger B is

pulled in the opposite direction to Plunger A. As a result, Plunger B draws in fuel, while

Plunger A pumps it to the rail. In the case of the 4-cylinder engine used with the HP3

pump, each plunger pumps fuel in a reciprocal movement during the 360° cam rotation.

Conversely, in the case of the 6-cylinder engine used with the HP4 pump, 3 plungers

pump fuel in a reciprocal movement for each one rotation of the cam.

Suction Valve

Plunger A

SCV

Plunger B

Delivery Valve

Eccentric Cam

Ring Cam

Plunger A: Complete Compression

Plunger B: Complete Intake

Plunger A: Begin Intake

Plunger B: Begin Compression

Plunger A: Begin Compression

Plunger B: Begin Intake

NOTE:

There are 3 plungers for the HP4.

Plunger A: Complete Intake

Plunger B: Complete Compression

QD0707E

12

Page 15

[2] Description of Supply Pump Components

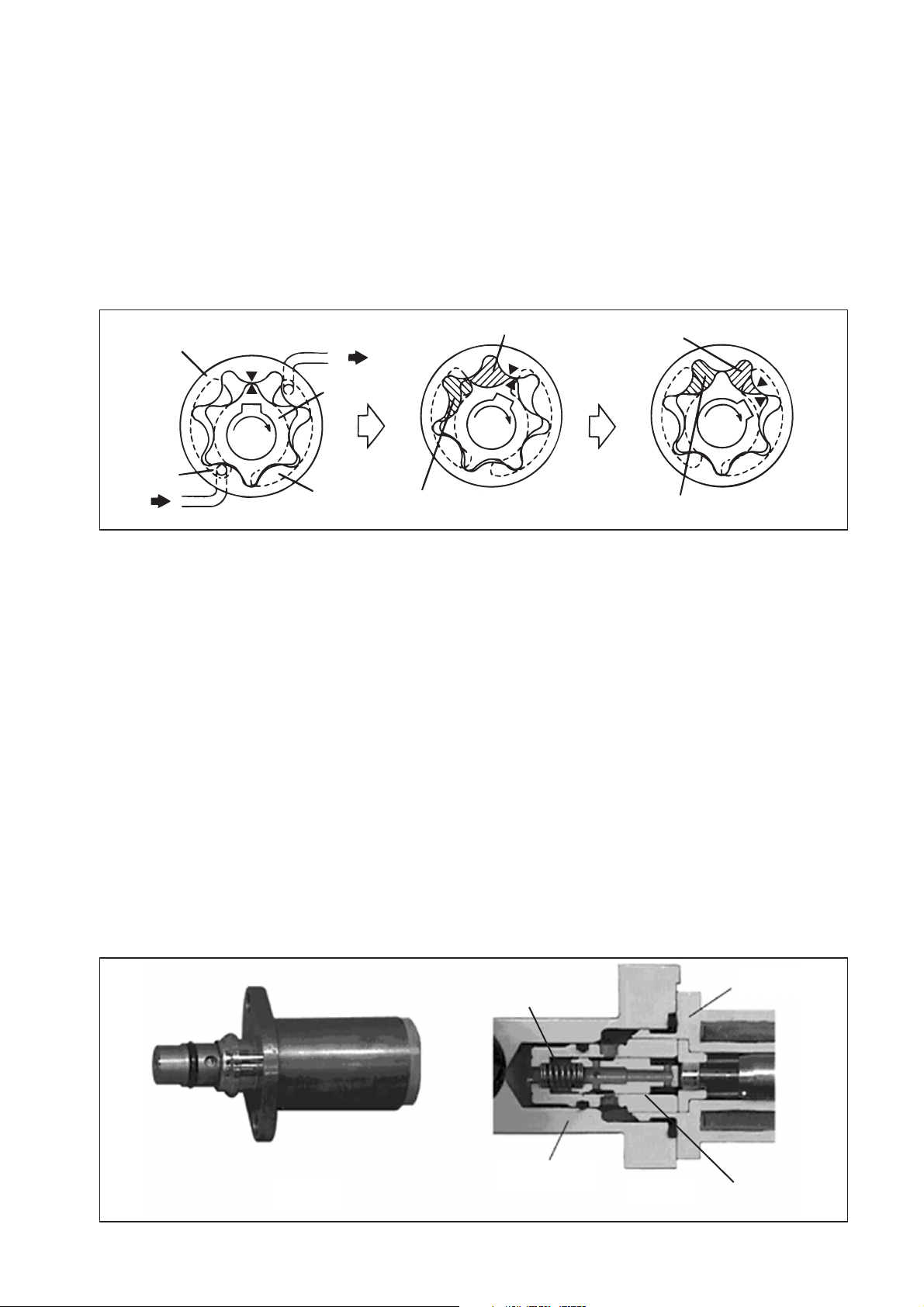

(1) Feed Pump

a. The trochoid type feed pump, which is integrated in the supply pump, draws fuel from the

fuel tank and feeds it to the two plungers via the fuel filter and the SCV (Suction Control

Valve). The feed pump is driven by the drive shaft. With the rotation of the inner rotor,

the feed pump draws fuel from its suction port and pumps it out through the discharge

port. This is done in accordance with the space that increases and decreases with the

movement of the outer and inner rotors.

Outer Rotor

Intake Port

from Fuel Tank

to Pump Chamber

Inner Rotor

Discharge

Port

Quantity Decrease

Quantity Increase

Quantity Decrease (Fuel Discharge)

Quantity Increase (Fuel Intake)

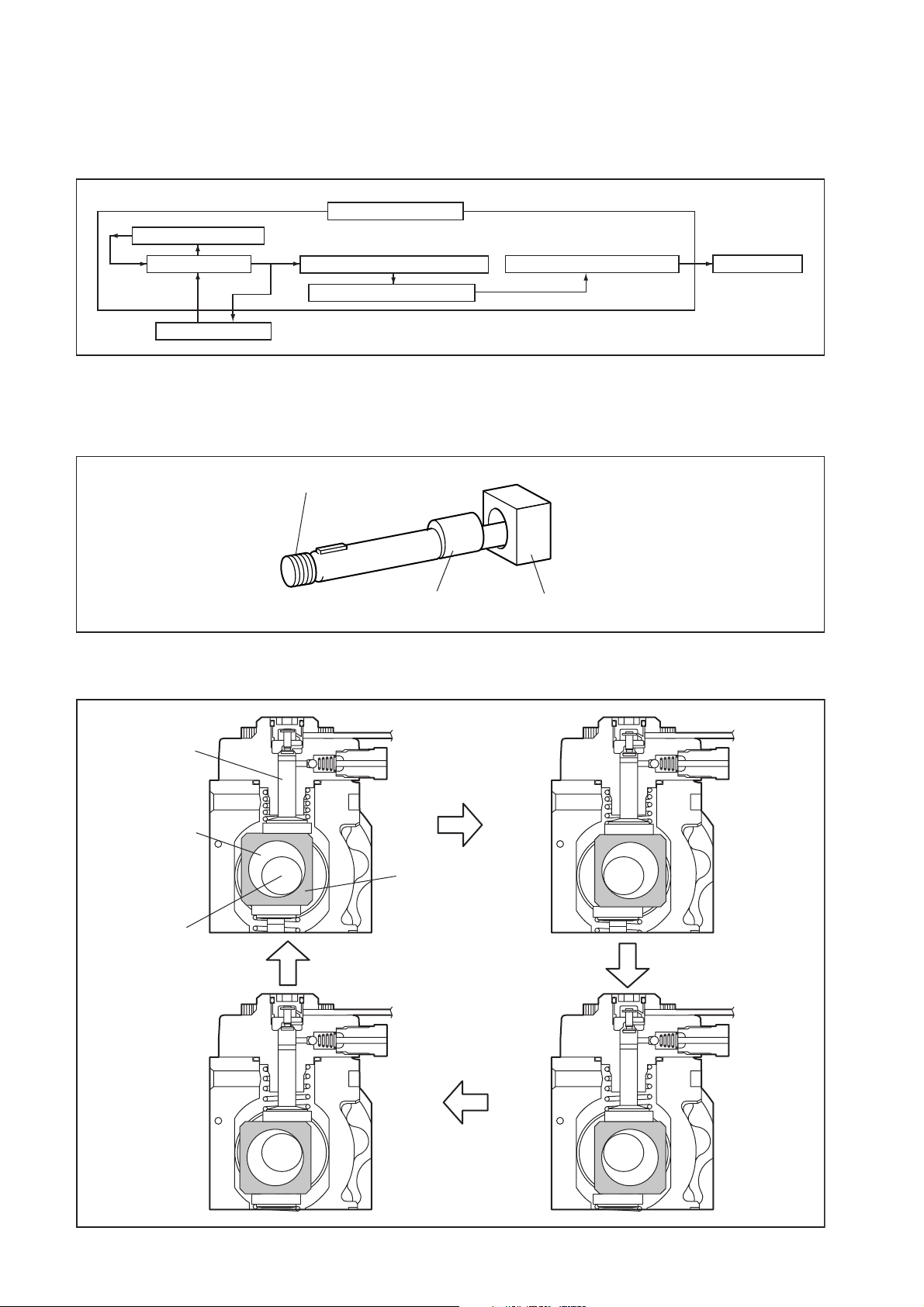

(2) SCV: Suction Control Valve (Normally open type)

a. A linear solenoid type valve has been adopted. The ECU controls the duty ratio (the

duration in which current is applied to the SCV), in order to control the quantity of fuel

that is supplied to the high-pressure plunger.

b. Because only the quantity of fuel that is required for achieving the target rail pressure is

drawn in, the actuating load of the supply pump decreases.

c. When current flows to the SCV, variable electromotive force is created in accordance with

the duty ratio, moving the armature to the left side. The armature moves the cylinder to

the left side, changing the opening of the fuel passage and thus regulating the fuel

quantity.

d. With the SCV OFF, the return spring contracts, completely opening the fuel passage and

supplying fuel to the plungers. (Full quantity intake and full quantity discharge)

e. When the SCV is ON, the force of the return spring moves the cylinder to the right, closing

the fuel passage (normally opened).

f. By turning the SCV ON/OFF, fuel is supplied in an amount corresponding to the actuation

duty ratio, and fuel is discharged by the plungers.

QD0708E

Exterior View of SCV

Cross-section of SCV

Return Spring

Pump Body

13

SCV

Cylinder

Q000270E

Page 16

[In case of short time ON duty]

Short time ON duty → large valve opening → maximum intake quantity

Plunger

SCV

Feed Pump

Cylinder

Large Opening

Cylinder

Q000051E

14

Page 17

[In case of long time ON duty]

Long time ON duty → small valve opening → minimum intake quantity

Plunger

SCV

Feed Pump

Cylinder

Small Opening

Cylinder

Q000052E

15

Page 18

[3] Rail

(1) Outline

a. Stores pressurized fuel (0 to 150 MPa {0 to 1528.5 kg/cm2}) that has been delivered from

the supply pump and distributes the fuel to each cylinder injector. A rail pressure sensor

and a pressure limiter are adopted in the rail.

b. The rail pressure sensor (Pc sensor) detects the fuel pressure in the rail and sends a

signal to the engine ECU, the pressure limiter prevents the rail pressure from being

abnormally high. This ensures optimum combustion and reduces combustion noise.

Pressure Limiter

Pressure Sensor

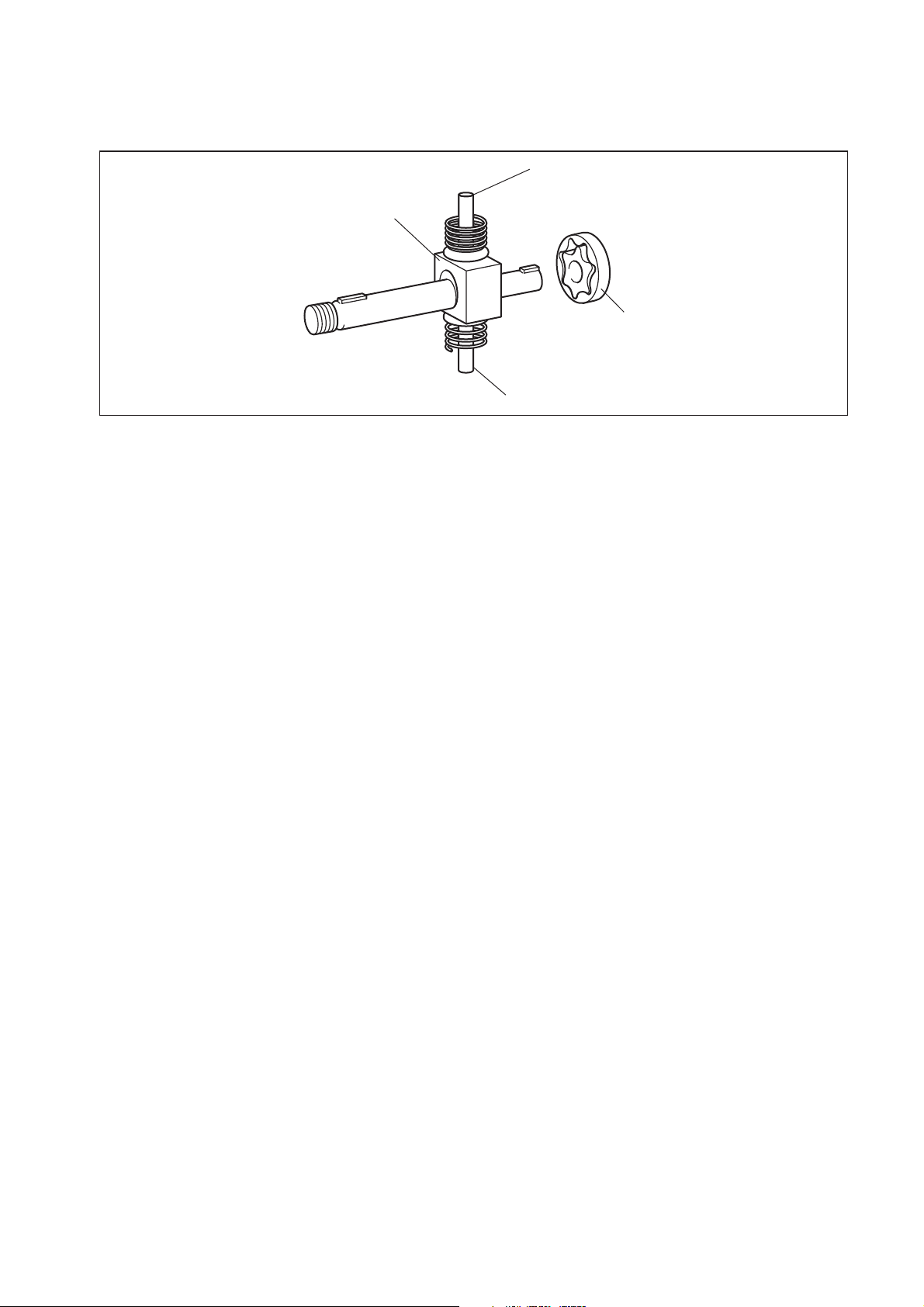

(2) Pressure Limiter

a. The pressure limiter opens to release the pressure if an abnormally high pressure is

generated.

b. When the rail pressure reaches approximately 200 MPa (2038 kg/cm2), it trips the

pressure limiter (the valve opens). When the pressure drops to approximately 50 MPa

(509.5 kg/cm2), the pressure limiter returns to its normal state (the valve closes) in order

to maintain the proper pressure.

Valve Open

Valve Close

50 MPa (509.5 kg/cm

200 MPa (2038 kg/cm

2

)

Q000256E

2

)

Q000257E

Q000271E

16

Page 19

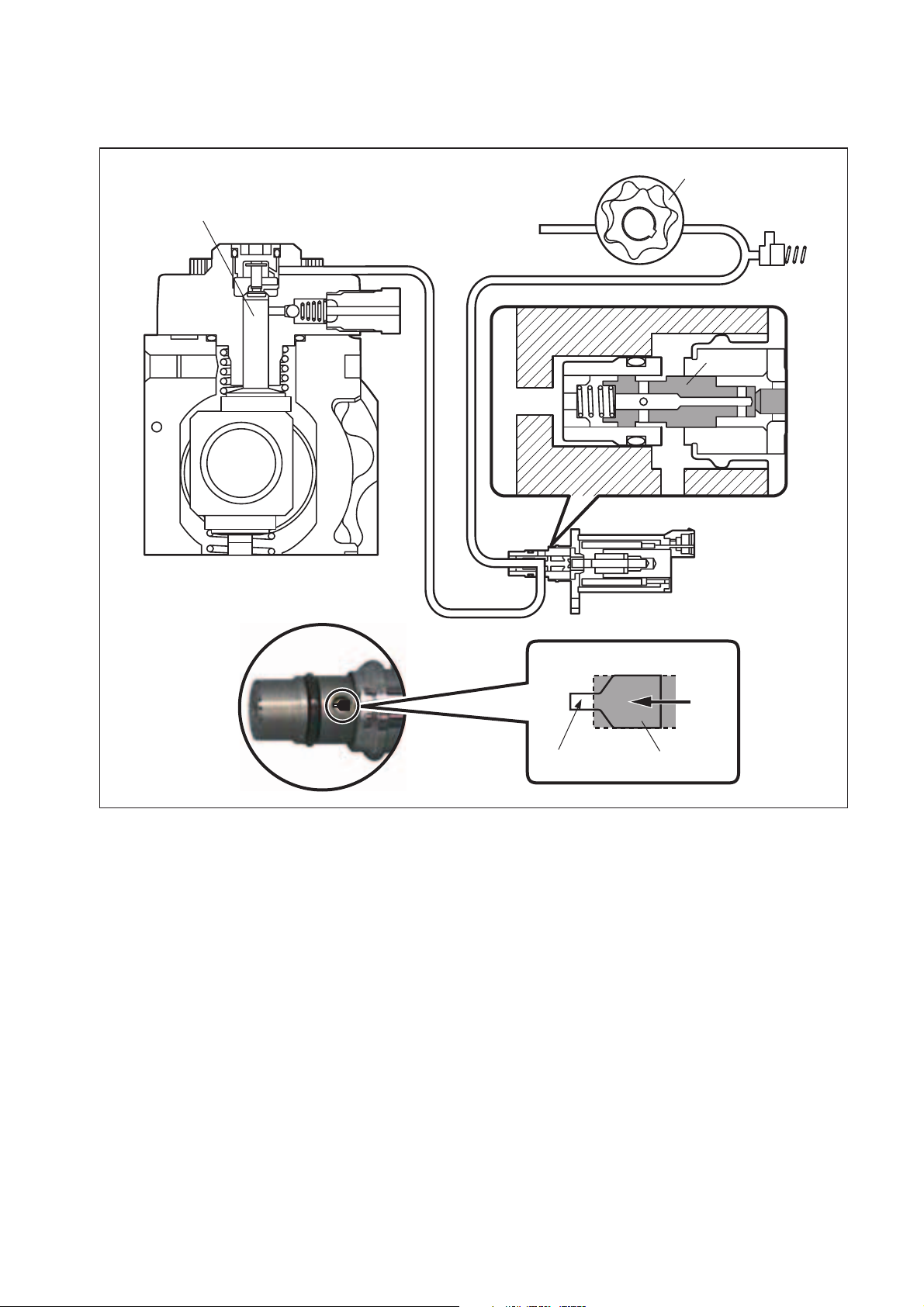

(3) Pressure Sensor

a. The rail pressure sensor (Pc sensor) is attached to the rail in order to detect the fuel

pressure.

b. It is a semiconductor type pressure sensor that utilizes the characteristics of silicon,

whereby the electrical resistance changes when pressure is applied to it.

4.2 V

VC VOUT GND

Q000258E

1.0 V

0 200 MPa (2038 kg/cm

Q000272E

REFERENCE:

It is necessary to reset the ECU default value using the Hino diagnosis tool at the time of

supply pump service replacement. In addition, the ECU has a function enabling it to learn

the performance of the supply pump at the time of ECU service replacement, so ensure

sufficient time (several minutes) is available.

2

)

17

Page 20

[4] Injector (G2 Type)

(1) Outline

a. The injectors inject the high-pressure fuel from the rail into the combustion chambers at

the optimum injection timing, rate, and spray condition, in accordance with commands

received from the ECU.

(2) Characteristics

a. A compact, energy-saving solenoid-control type TWV (Two-Way Valve) injector has been

adopted.

b. QR codes displaying various injector characteristics and the ID codes showing these in

numeric form (30 alphanumeric figures) are engraved on the injector head. The J05/J08

engine common rail system optimizes injection volume control using this information.

When an injector is newly installed in a vehicle, it is necessary to enter the ID codes in

the engine ECU using the HINO Diagnostic tool.

(3) Construction

30 Alphanumeric Figures

Control Chamber

Pressurized Fuel

(from Rail)

Command Piston

A

A

BCD

A

BCD

A

BCD

BCD

EF

EFGH

EFGH

E

FGH

QR Codes

Solenoid Valve

Nozzle Spring

Pressure Pin

Nozzle Needle

Q000259E

18

Page 21

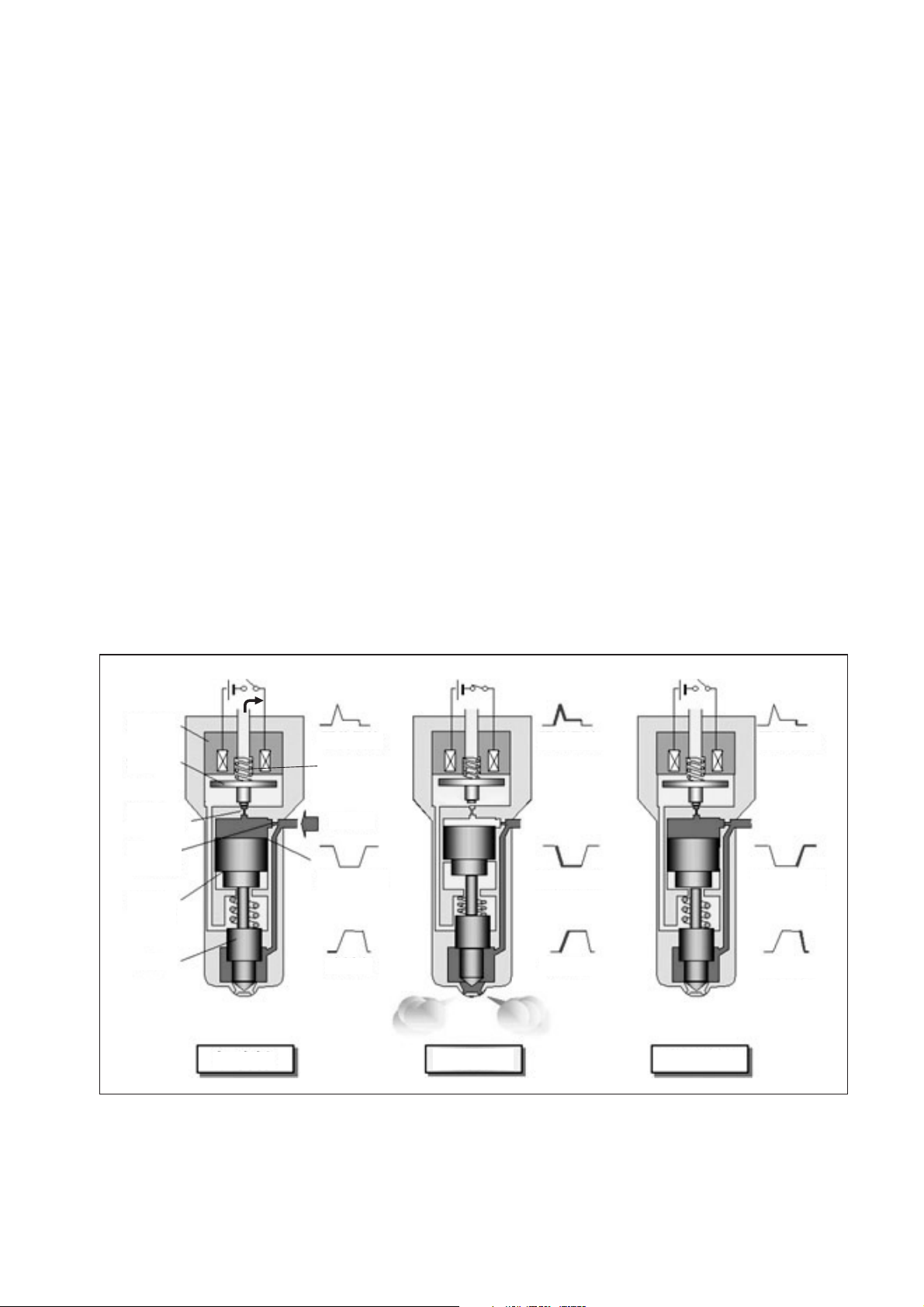

(4) Operation

a. The TWV (Two-Way Valve) solenoid valve opens and closes the outlet orifice to control

both the pressure in the control chamber, and the start and end of injection.

[No injection]

• When no current is supplied to the solenoid, the spring force is stronger than the hydraulic

pressure in the control chamber. Thus, the solenoid valve is pushed downward, effectively

closing the outlet orifice. For this reason, the hydraulic pressure that is applied to the

command piston causes the nozzle spring to compress. This closes the nozzle needle, and

as a result, fuel is not injected.

[Injection]

• When current is initially applied to the solenoid, the attraction force of the solenoid pulls the

solenoid valve up, effectively opening the outlet orifice and allowing fuel to flow out of the

control chamber. After the fuel flows out, the pressure in the control chamber decreases,

pulling the command piston up. This causes the nozzle needle to rise and the injection to

start.

• The fuel that flows past the outlet orifice flows to the leak pipe and below the command

piston. The fuel that flows below the piston lifts the piston needle upward, which helps

improve the nozzle's opening and closing response.

• When current continues to be applied to the solenoid, the nozzle reaches its maximum lift,

where the injection rate is also at the maximum level. When current to the solenoid is turned

OFF, the solenoid valve falls, causing the nozzle needle to close immediately and the

injection to stop.

Solenoid

TWV

Outlet orifice

Inlet orifice

Command

piston

Nozzle

needle

Leak pipe

No injection

Actuation

current

Valve spring

Rail

Control chamber

pressure

Injection rate

Injection

Actuation

current

Control chamber

pressure

Injection rate

Actuation

current

Control chamber

pressure

Injection rate

End of injection

Q000149E

19

Page 22

(5) QR Codes

a. In order to minimize performance tolerance of injectors at replacing them, QR*1 (Quick

Response) codes have been adopted to enhance correction precision.

b. Using QR codes has resulted in a substantial increase in the number of fuel injection

quantity correction points, and thus the injection quantity control precision has improved.

The characteristics of the engine cylinders have been further unified, contributing to

improvements in combustion efficiency, reductions in exhaust gas emissions and so on.

[QR code correction points]

Injection quantity Q

*1: Location of QR codes

QR code on the injector connector

Pressure Parameter

Actuating pulse width TQ

QR Codes ( 9.9mm)

ID Codes

(30 alphanumeric figures)

16 figure alphanumeric notations of

fuel injection quantity correction

information for market service use.

Q000260E

20

Q000261E

Page 23

(6) Repair Procedure Changes

a. Differences in comparison with the conventional method of replacing injectors assembly

are as shown below.

NOTE:

When replacing injectors with QR codes, or the engine ECU, it is necessary to record the

ID codes (QR codes) in the ECU. (If the ID codes of the installed injector are not registered

correctly, engine failure such as rough idling and noise will result.)

New (Injector with QR Codes)

30 alphanumeric figures-sixteen figure alphanumeric notations of fuel injection

quantity correction information displaed for market service use

ID Code

Replacing the Injector

Q000284E

"No correction resistance, so no electrical recognition capability"

Spare Injector

Replacing the Engine ECU

"No correction resistance, so no electrical recognition capability"

Vehicle-side Injector

Engine ECU

* Necessary to record the injector ID codes in Engine ECU

QD1536E

Spare Engine ECU

* Necessary to record the injector ID codes in the engine ECU

QD1537E

21

Page 24

[5] Engine ECU (Electronic Control Unit)

(1) Outline

a. This is the command center that controls the fuel injection system and engine operation

in general.

Outline Diagram

Sensor

Detection

Engine ECU

Calculation

3.2 Description of Control System Components [1] Engine Control System Diagram

Intake Air Temperature Sensor

Mass Airflow Meter

Inter-Cooler

Intake Air Pressure Sensor

Actuator

Actuation

QD2352E

EGR Valve

(J08E-double, J05D-single)

G2 Injector

EGR Cooler

VGT

Controller

EGR Valve Lift

Sensor

VGT Actuator

Coolant

Oxidation Catalyst

Q000262E

22

Page 25

[2] Sensor and Relays

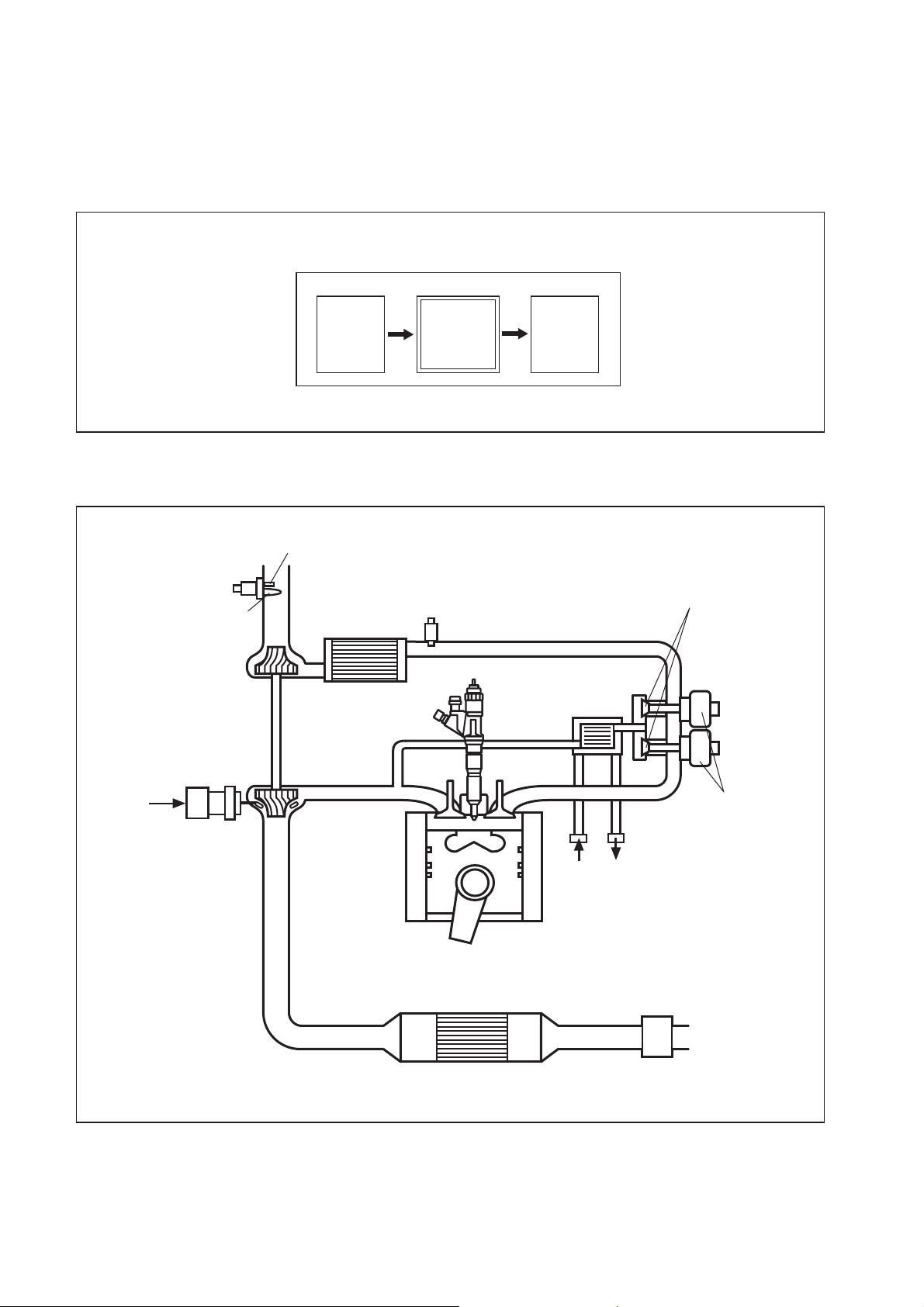

(1) NE Sensor (Crankshaft Position Sensor)

a. When the signal holes on the flywheel move past the sensor, the magnetic line of force

passing through the coil changes, generating alternating voltage.

b. The signal holes are located on the flywheel at 6.5-degree intervals. There are a total of

56 holes, with holes missing in three places. Therefore, every two revolutions of the

engine outputs 112 pulses.

c. This signal is used to detect the engine speed and the crankshaft position in 7.5-degree

intervals.

NE (Crankshaft Position) Sensor

Q000263E

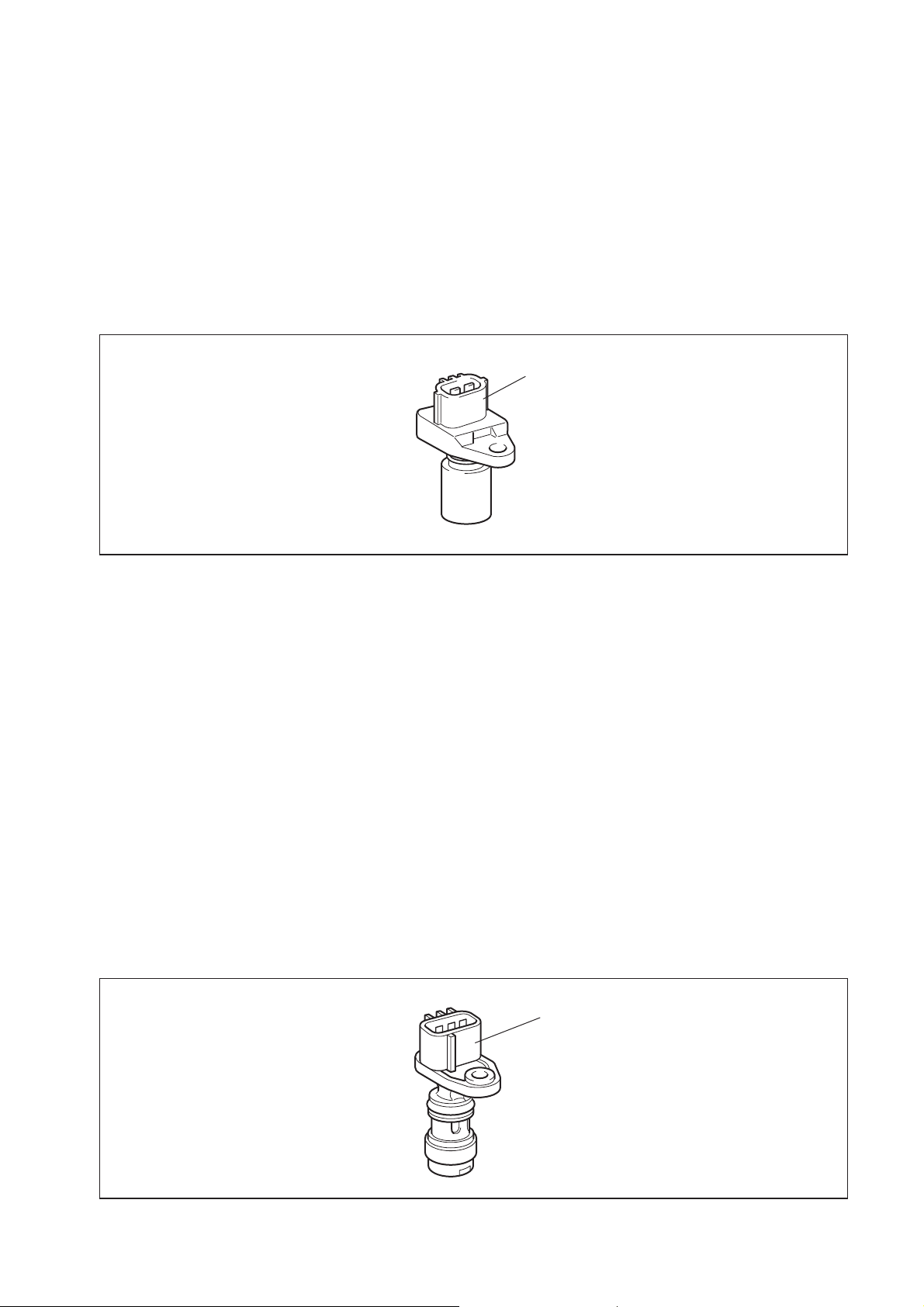

(2) TDC Sensor (Cylinder Recognition Sensor)

a. Unlike the NE sensor, the TDC sensor is an MRE (magnetic resistance element) sensor.

As the pulsar near the sensor revolves, the magnetic field changes. This causes

variations in the generated current, which are amplified in the internal circuits of the

sensor unit before a signal is output to the engine ECU.

b. The engine camshaft gear (one revolution for every two revolutions of the engine) is used

as a pulsar. The J05D and J08E use different types of gear, so the signal outputs differ

as follows.

For the J05D:

In addition to four knock pins located at 90-degree intervals, there is an extra signal hole on

the gear. Therefore every revolution of the gear, i.e. two revolutions of the engine, outputs

4 + 1 = 5 TDC signal pulses.

For the J08E:

In addition to six knock pins located at 60-degree intervals, there is an extra signal hole on

the gear. Therefore every revolution of the gear, i.e. two revolutions of the engine, outputs

6 + 1 = 7 TDC signal pulses.

TDC (Cylinder Recognition) Sensor

23

Q000264E

Page 26

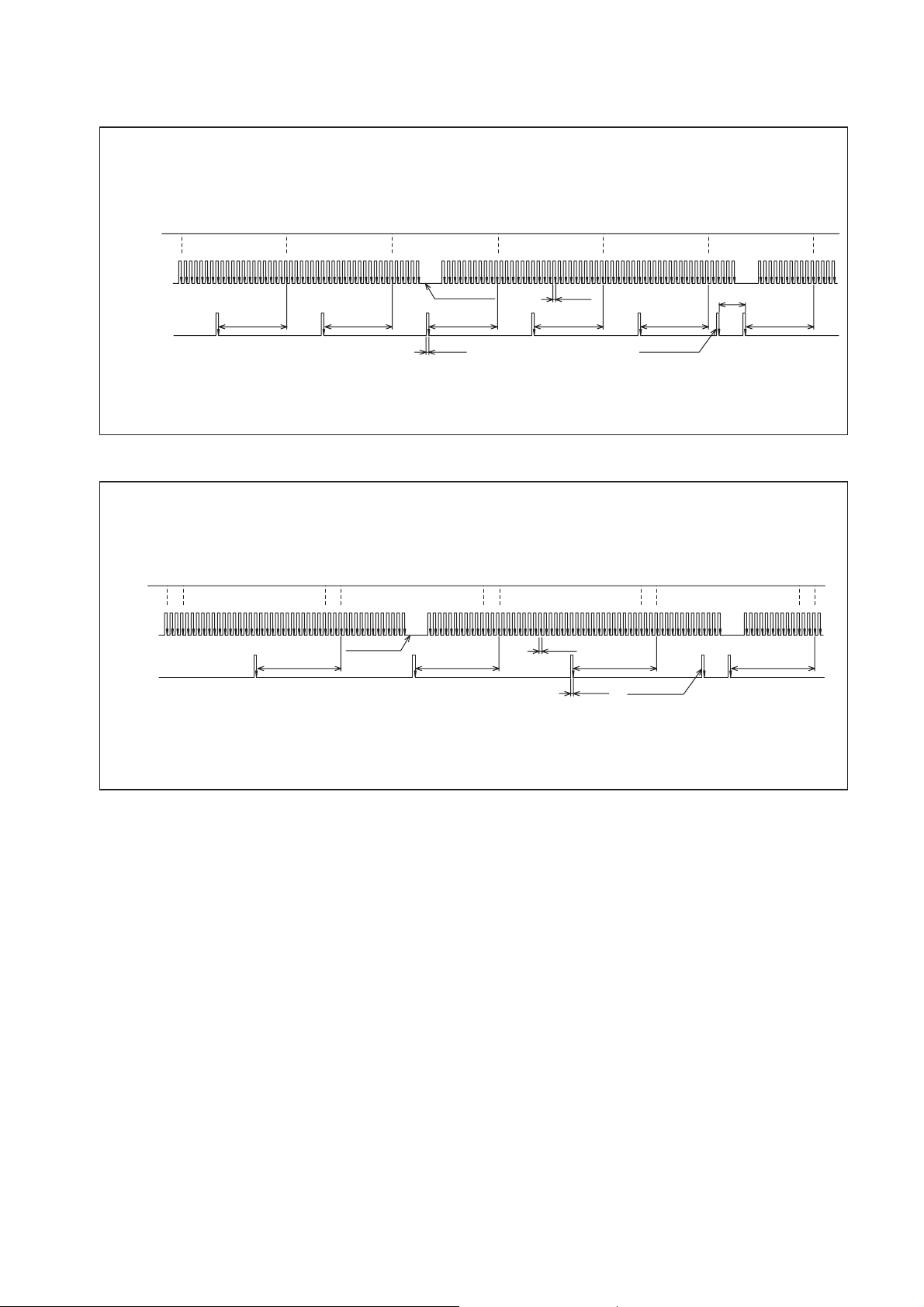

c. A combination of the NE pulse and the TDC pulses are used for the cylinder reference

pulse, and the irregular pulse is used to determine the No. 1 cylinder.

For the J08E engine

The cylinder at a rotation of 78° following the No. 1 TDC reference signal after the irregular

pulse is the number one cylinder TDC (refer to the chart on the following page).

For J08E

VCC

TDC

GND

NE

GND

ECU

VCC

Input circuit

Input circuit

Q000273E

For the J05D engine

The cylinder at a rotation of 96° following the No. 1 TDC reference signal after the irregular

pulse is the number one cylinder TDC (refer to the chart on the following page).

For J05D

VCC

TDC

ECU

VCC

Input circuit

GND

NE

GND

Input circuit

Q000274E

24

Page 27

For J08E

0°CA 120°CA 240°CA 360°CA 480°CA 600°CA 720°CA

NE+

11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56

(NE- Standard)

G

(G-GND Standard)

For J05D

0°CA 180°CA 360°CA 540°CA 0°CA

#1TDC

NE+

(NE- Standard)

G

(G- Standard)

11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56

#5TDC

#3TDC

4th Missing Tooth

#6TDC

3°CA

#2TDC

#4TDC

30°CA

78°CA 78°CA 78°CA 78°CA 78°CA 78°CA

#3TDC

4th Missing Tooth

3°CA

#4TDC

3°CA

Extra Tooth

#2TDC

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

96°CA 96°CA 96°CA 96°CA

Extra Tooth

3°CA

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

#1TDC

Q000275E

#1TDC

Q000276E

25

Page 28

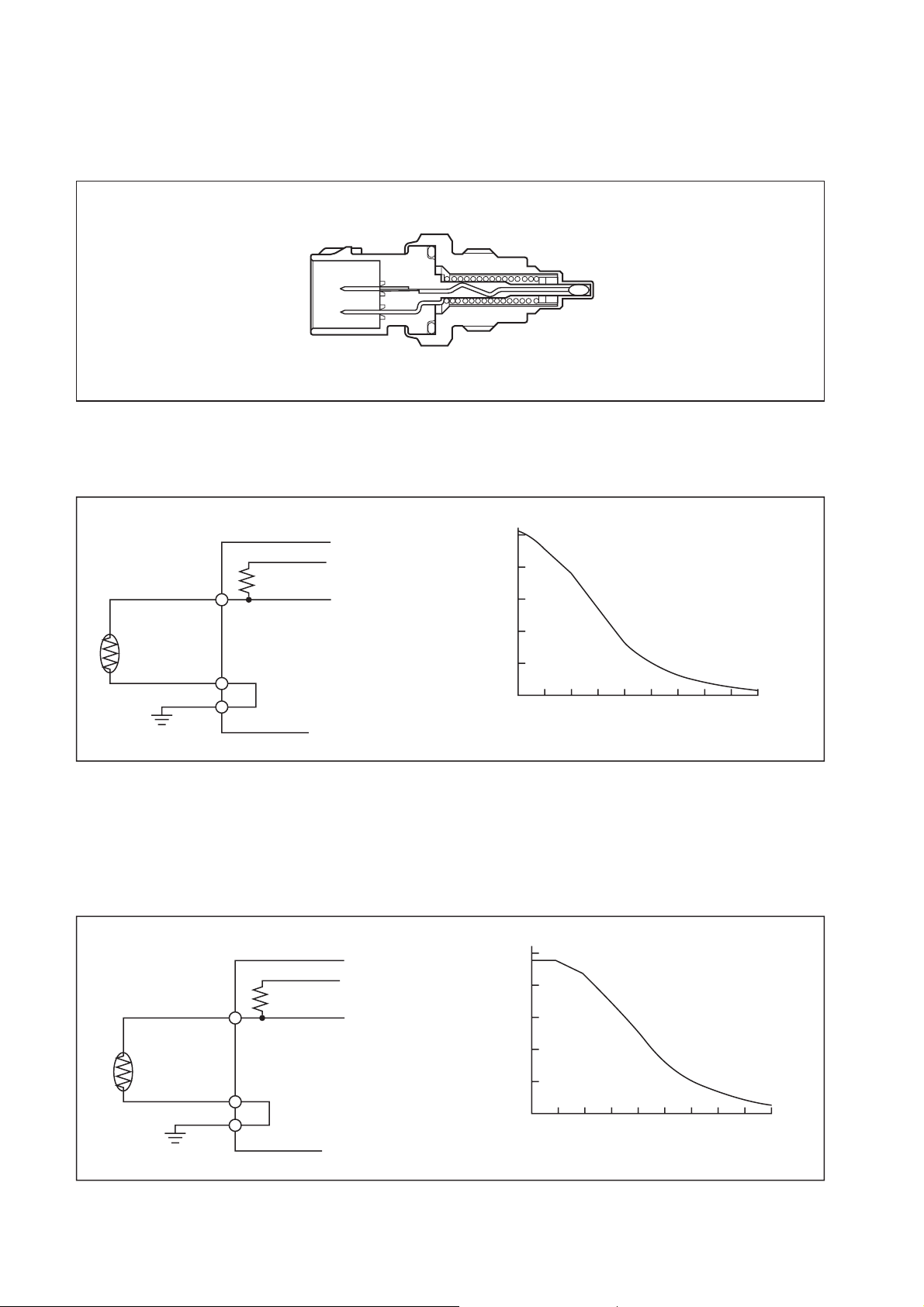

(3) Coolant Temperature Sensor

a. The coolant temperature sensor detects the temperature of the engine coolant and

outputs it to the ECU.

b. The sensor uses a thermistor, which varies resistance according to temperature. As the

ECU applies voltage to the thermistor, it uses a voltage resulting from the division of the

computer internal resistance and the thermistor resistance to detect the temperature.

(V)

ECU

+5V

VTHW

Output Voltage

VTHW

5

4

3

2

Q000277E

A-GND

1

0

-40 -20

-40 -4

0 20

40 60

32

68 104 140 176 212 248 (°F)

80 100 120 (°C)

Coolant Temperature

(4) Fuel Temperature Sensor (THL)

a. The fuel temperature sensor detects the fuel temperature and outputs it to the ECU. The

sensor uses a thermistor, which varies resistance according to temperature. As the ECU

applies voltage to the thermistor, it uses a voltage resulting from the division of the

computer internal resistance and the thermistor resistance to detect the temperature.

VTHL

ECU

+5V

VTHL

Output Voltage

A-GND

(V)

5

4

3

2

1

0

-40 -20

-40 -4

0 20

40 60

32

68 104 140 176 212 248 (°F)

Fuel Temperature

80 100 120 (°C)

THW

Q000105E

THL

Q000106E

26

Page 29

(5) Atmospheric Air Pressure Sensor (Built-in ECU)

a. This sensor converts the atmospheric air pressure into an electrical signal to correct full-

load injection volume.

VPATM

Output Voltage (V)

3.8

107 {1.09}

Atmospheric Air Pressure (kPa {kg/cm2})

(6) Accelerator Position Sensor

a. This sensor converts the angle of the pedal effort applied to the accelerator pedal into

electrical signals and sends them to the ECU. The accelerator sensor uses hall

elements. A magnet is mounted on the shaft that moves in unison with the accelerator

pedal, and the magnetic field orientation changes with the rotation of the shaft. The

changes in the magnetic field orientation generate voltage.

VPA1 GND1 VC1 VPA 2 GND2 VC2

Q000278E

Hall elements

(2 pieces)

Magnets

(1 pair)

VPA1

GND1

VC1

V

PA2

GND2

VC2

V

PA1

GND1

VC1

V

PA2

GND2

VC2

Output Voltage

5

4

3

2

1.6 V

0.8 V

1

0 5 10 15 20

Q000266E

VPA2

4.0 V

PA1

V

3.2 V

Accelerator Opening Angle (°)

Q000265E

27

Page 30

(7) Boost Pressure Sensor

a. In order to correct the full-load injection volume, this sensor converts the intake air

pressure (absolute pressure) into an electrical signal, then amplifies it into a voltage

signal to the computer.

A-VCC

VPIM

A-GND

ECU

+5V

Output Valtage (V)

VPIM

4.0

3.45

2.0

0.5

0

100 200 300

{1.019}

{2.038} {3.057}

Intake Air Pressure PIM (kPa {kg/cm2})

(8) Air Flow Sensor

a. Detects the intake airflow (mass flow rate) in the hot-wire type airflow meter.

b. The intake airflow is converted to a voltage value and this signal is transmitted to the ECU.

E2 THA VG E2G +B

Q000279E

Airflow Sensor

Intake Air Temperature

Sensor

Q000280E

c. The airflow sensor is installed to the rear of the air cleaner, and consists of a heater,

thermometer, intake air temperature sensor, and control circuit (base). It diverts a portion

of the intake air from the air cleaner and measures the intake airflow at the hot-wire

measuring part.

Outline Diagram of Hot-Wire Type Airflow Meter

Throttle Body

Temperature Compensating Resistor

(Hot-Wire)

Heating Resistor

(Hot-Wire)

Intake Air from

Air Cleaner

Intake Air Temperature Sensor

Bypass Flow

28

Q000285E

Page 31

3.3 Various Types of Control

This system controls the fuel injection quantity and injection timing more optimally than the

mechanical governor or timer used in conventional injection pumps.

For system control, the ECU makes the necessary calculations based on signals received

from sensors located in the engine and on the vehicle in order to control the timing and duration in which current is applied to the injectors, thus realizing optimal injection timing.

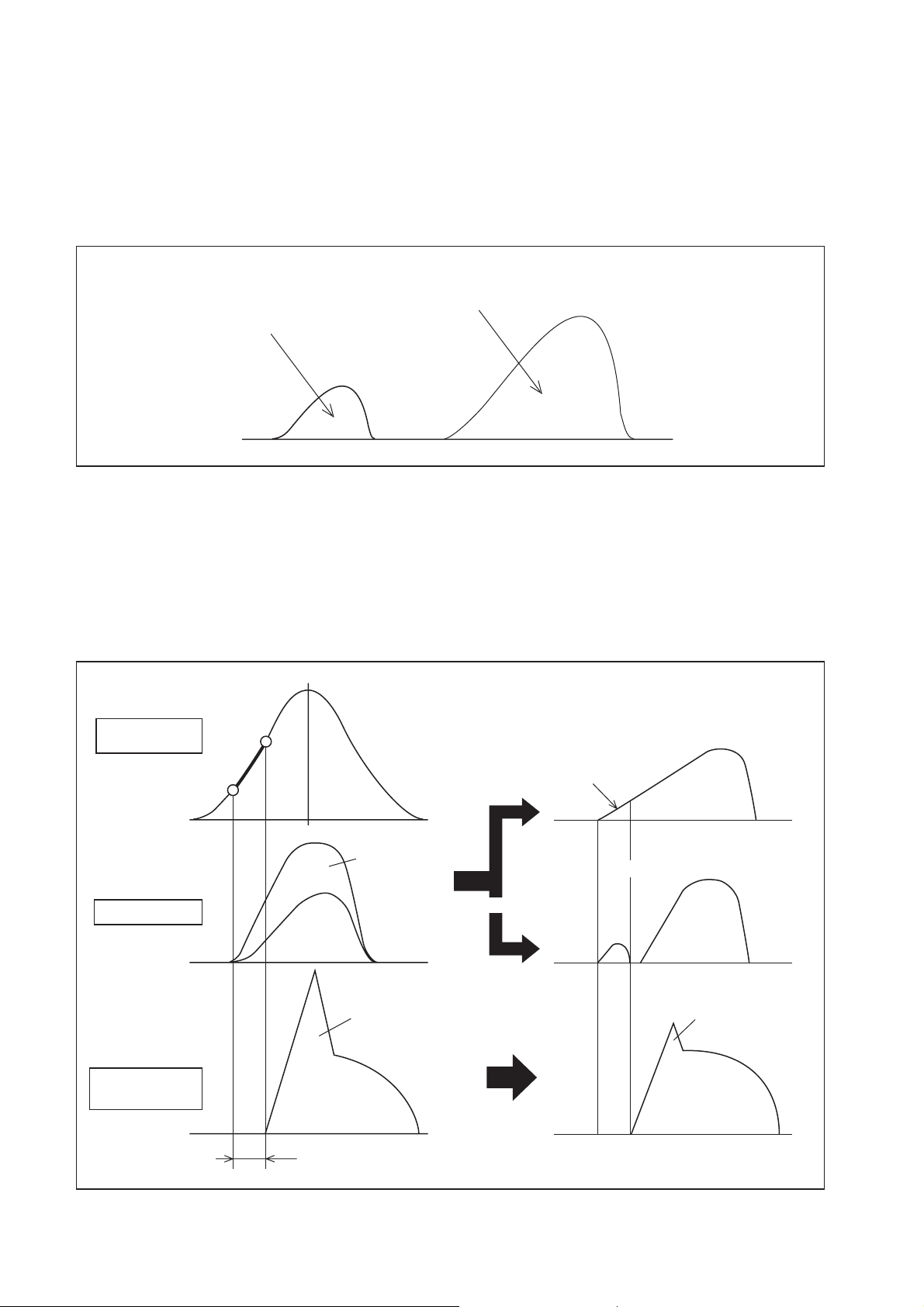

(1) Fuel Injection Rate Control Function

a. The fuel injection rate control function controls the ratio of the quantity of fuel that is

injected through the nozzle hole during a specified period.

(2) Fuel Injection Quantity Control Function

a. The fuel injection quantity control function, replaces the conventional governor function,

and controls fuel injection to achieve an optimal injection quantity based on the engine

speed and the accelerator opening.

(3) Fuel Injection Timing Control Function

a. The fuel injection timing control function, replaces the conventional timer function, and

controls the fuel injection to achieve an optimal injection timing according to the engine

speed and the injection quantity.

(4) Fuel Injection Pressure Control Function (Rail Pressure Control Function)

a. The fuel injection pressure control function (rail pressure control function) uses a rail

pressure sensor to measure fuel pressure, and feeds this data to the ECU to control the

pump discharge quantity.

b. Pressure feedback control is implemented to match the optimal quantity (command

quantity) set according to the engine speed and the fuel injection quantity.

Input Signal

Accelerator sensor

NE Sensor

(Crankshaft Position Sensor)

TDC Sensor

(Cylinder Recognition Sensor)

Rail Pressure Sensor

Various Sensors

·Water Temperature Sensor

·Fuel Temperature Sensor

·Atmospheric Air Temperature

Sensor etc.

Fuel Control Computer

(ECU)

Atmospheric Air

Pressure Sensor

Control Output

Fuel Injection Rate Control

Fuel Injection Quantity Control

Fuel Injection Timing Control

Fuel Injection Pressure Control

Diagnosis

29

Q000109E

Page 32

[1] Fuel Injection Rate Control

(1) Main Injection

a. Same as conventional fuel injection.

(2) Pilot Injection

a. Pilot injection is the injection of a small amount of fuel prior to the main injection.

Main Injection

Pilot Injection

b. While the adoption of higher pressure fuel injection is associated with an increase in the

injection rate, the lag (injection lag) that occurs from the time fuel is injected until

combustion starts cannot be reduced below a certain value. As a result, the quantity of

fuel injected before ignition increases, resulting in explosive combustion together with

ignition, and an increase in the amount of NOx and noise. Therefore, by providing a pilot

injection, the initial injection rate is kept to the minimum required level dampening, the

explosive first-period combustion and reducing NOx emissions.

Q000110E

Combustion

Process

Injection Rate

Heat Generation

Rate

TDC

High Injection

Rate

Large Pre-mixture

Combustion

(NOx, Noise)

Small Injection Amount

Prior to Ignition

Pilot Injection

Improvement

Small Pre-mixture

Combustion

Ignition Delay

Q000111E

30

Page 33

(3) Split Injection

a. When the rotation is low at starting time, a small amount of fuel is injected several times

prior to main injection.

Split Injection

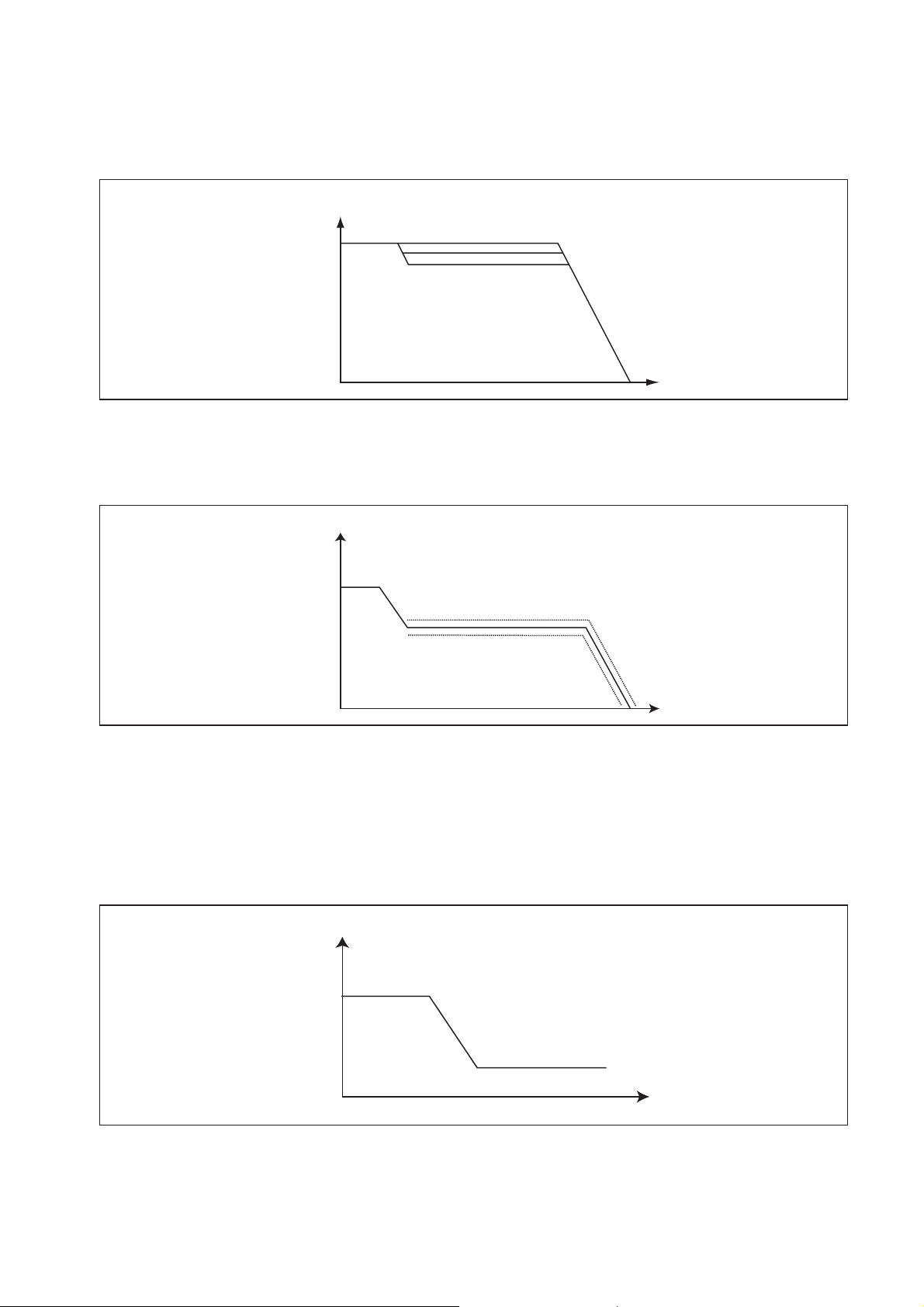

[2] Fuel Injection Quantity Control

(1) Starting Injection Quantity

a. The injection quantity is determined based on the engine speed (NE) and water

temperature while starting.

Starting Injection Quantity

Q000112E

Water

Temperature

Engine Speed

(2) Transient Injection Quantity Correction

a. When the changes in the accelerator opening are great during acceleration, the increase

in fuel volume is delayed to inhibit the discharge of black smoke.

Injection Quantity

Change in Accelerator Opening

Injection Quantity after Correction

Delay Time

Time

Q000127E

Q000128E

31

Page 34

(3) Basic Injection Quantity

a. This quantity is determined in accordance with the engine speed (NE) and the accelerator

opening.

b. Increasing the accelerator opening while the engine speed remains constant causes the

injection quantity to increase.

Basic Injection Quantity

Accelerator Opening

Engine Speed

(4) Injection Quantity for Maximum Speed Setting

a. The injection quantity is regulated by a value that is determined in accordance with the

engine speed.

Injection Quantity for Maximum Speed Setting

Engine Speed

(5) Maximum Injection Quantity

a. Is determined in accordance with the engine speed and corrected by the coolant

temperature signal.

Q000129E

Q000130E

Basic Maximum Injection Quantity

32

Engine Speed

Q000131E

Page 35

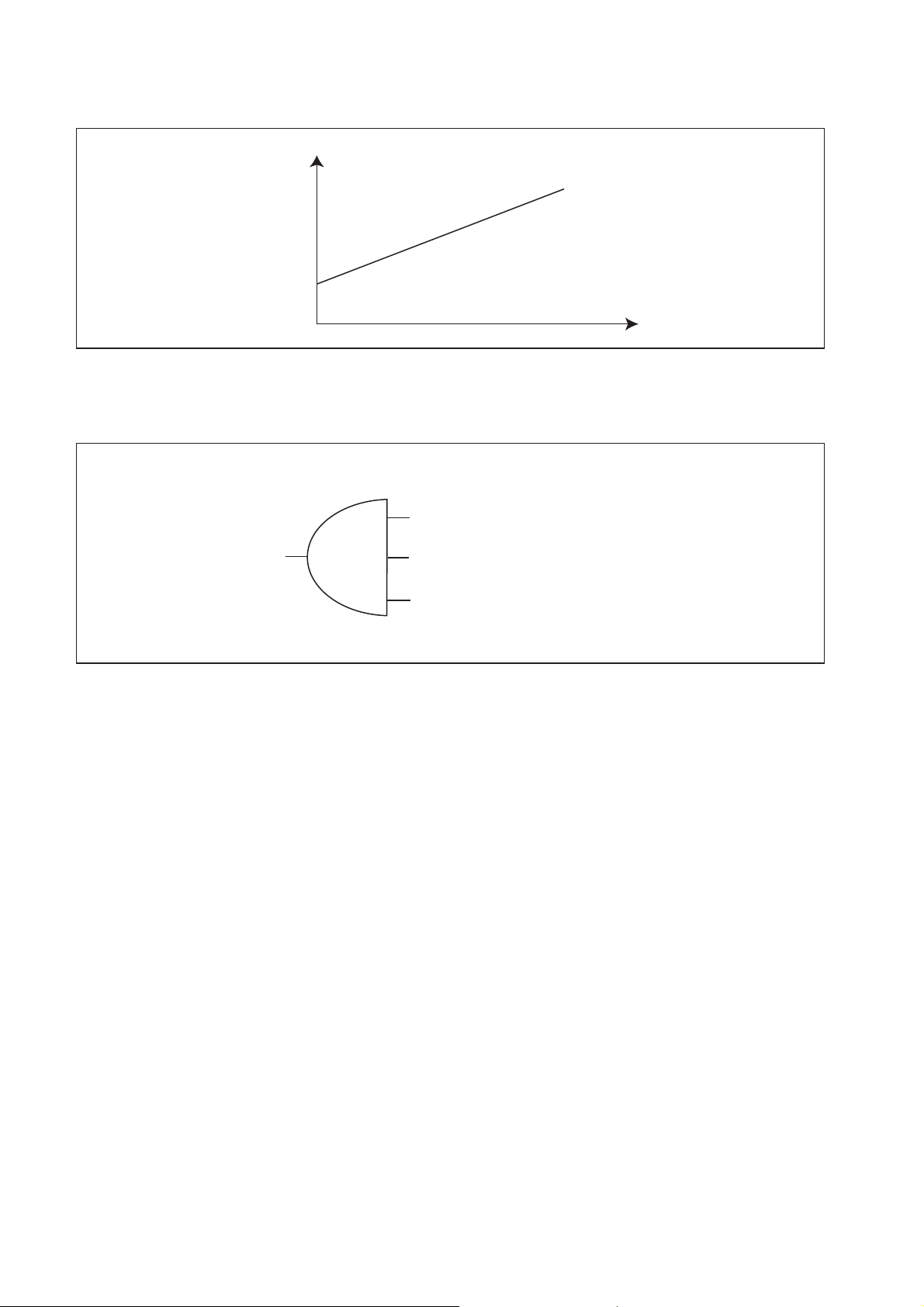

(6) Amount of Injection Quantity Intake Pressure Correction

a. Limits the maximum injection quantity in accordance with the intake pressure, in order to

minimize the discharge of smoke when the intake air pressure is low.

Amount of Intake Air Pressure Correction

Engine Speed

(7) Amount of Injection Quantity by Atmospheric Air Pressure Correction

a. With using atmospheric air pressure sensor signal, the maximum injection quantity curve

is corrected as shown in the right figure.

Amount of Atmospheric Air Pressure Correction

Engine Speed

(8) Idle Speed Control System (ISC)

a. Controls the idle speed by regulating the injection quantity in order to match the target

speed, which has been calculated by the computer, with the actual speed. The functions

of the ISC can be broadly divided into the following two items:

• Auto ISC

Controls the idle speed in accordance with the water temperature.

Q000133E

Q000134E

Target Speed

Water Temperature

Q000135E

• Manual ISC

Controls the idle speed in accordance with the idle speed indicated on the manual idle setting

33

Page 36

knob provided at the driver's seat.

Target Speed

ISC Knob Terminal Voltage

Q000136E

• Air Conditioner Idle-up Control

When the conditions shown in the chart on the right are realized, bring the idle-up speed to

constant rpm.

Conditions

Air Conditioning SW = "ON"

Clutch SW = "ON" (Clutch Connection)

Neutral SW = "ON" (Neutral)

(9) Auto Cruise Control

a. Controls the actual vehicle speed by regulating the injection quantity in order to match

the target speed that has been calculated by the computer with the actual speed.

b. The CRS ECU controls the injection quantity in accordance with signals from the cruise

control computer.

Q000137E

34

Page 37

[3] Fuel Injection Timing Control

The characteristics of the fuel injection timing vary depending on whether it is the main injection or the pilot injection. Although either the NE sensor or the auxiliary NE sensor is the reference for controlling the injection timing, the NE sensor is ordinarily used for this purpose.

(1) Main Injection Timing

a. The basic injection timing is calculated in accordance with the final injection quantity, the

engine speed, and the water temperature (with map correction).

b. While starting, it is calculated in accordance with the water temperature and the engine speed.

Basic Injection Timing

Final Injection Quantity

Engine Speed

Q000138E

(2) Pilot Injection timing (Pilot Interval)

a. The pilot injection timing is controlled by adding the pilot interval to the main injection timing.

b. The pilot interval is calculated in accordance with the final injection quantity, the engine

speed, and the water temperature (with map correction).

c. While starting, it is calculated in accordance with the water temperature and the engine speed.

Pilot Interval

Final Injection Quantity

Engine Speed

(3) Fuel Injection Pressure

a. A value is calculated as determined in accordance with the final injection quantity and the

engine speed.

b. While starting, it is calculated in accordance with the water temperature and the engine speed.

Q000139E

Rail Pressure

Final Injection Quantity

Engine Speed

Q000140E

35

Page 38

3.4 Other Relevant Engine Control [1] EGR Control

(1) Control System

EGR Target Opening

EGR Deviation Compensation

Control

ECU

Final EGR Target

Opening Calculation

Processing/Duty Ratio

Calculation

Feed Back

EGR Valve Lift Sensor

(Detects Actual Opening)

EGR Valve Assy

EGR Valve Actuation

Q000267E

(2) Related Sensors

The related sensors are as follows:

• Air volume sensor: Detects the volume of air flowing into the engine.

• Coolant temperature sensor: Detects the engine coolant temperature.

• Atmospheric pressure sensor: Detects the atmospheric pressure around the engine (built

into the ECU).

(3) EGR Valve

a. An EGR valve is utilized as the system actuator for the electric exhaust gas recirculation

(E-EGR) system. It is constructed of an upper section and a lower section. The upper

section receives output signals from the engine ECU, and contains a solenoid that

generates electromagnetic force. The lower section is constructed of a nozzle that

moves up and down in response to the electromagnetic force, and a valve with an

opening that alters in response to the nozzle position.

For J05D

Q000268E

For J08E

Q000281E

36

Page 39

(4) Control Operation

Operation Start Conditions: During engine warm-up, other than start-up, when not overheating (etc.).

EGR Operating Range: During medium engine load.

Q

NE

3.5 Engine ECU [1] Diagnosis Codes

P-Code DST-1 Display Remarks Description

P0045 VNT Malfunction For the VNT. The VNT actuator has a malfunction.

Q000269E

P0049

P0088

P0093

P0102

P0103

P0108

P0112

Turbo Charger Turbine

Over speed

Common Rail

Pressure -Too high

Fuel System Leak

Detected

Mass Air Flow Sensor

Malfunction (LO)

Mass Air Flow Sensor

Malfunction (HI)

Boost Pressure Sensor

Malfunction (HI)

Intake Air Temperature

Sensor Malfunction (LO)

The turbine rotation

sensor has been

detected.

The pump does not

work properly. (Fuel

leak)

Integrated in the mass

air flow sensor.

Over speed of the turbo has been detected.

High fuel pressure has been detected.

There is a possibility of the fuel leakage.

Perform the fuel leakage check.

"The mass air flow sensor has a malfunction.

There are possibilities of the sensor malfunction,

open and short circuit to ground in the harness."

The mass air flow sensor has a malfunction.

There are possibilities of the sensor malfunction and

short circuit to +B in the harness.

The boost pressure cannot be detected properly.

There are possibilities of the sensor malfunction and

short circuit in the harness.

"The temperature cannot be detected properly.

There are possibilities of the sensor malfunction,

short circuit to ground in the harness."

P0113

P0117

P0118

Intake Air Temperature

Sensor Malfunction (HI)

Engine Coolant

Temperature Sensor

Malfunction (LO)

Engine Coolant

Temperature Sensor

Malfunction (HI)

Integrated in the mass

air flow sensor.

37

"The temperature cannot be detected properly.

There are possibilities of the sensor malfunction,

open and short circuit to +B in the harness."

The temperature cannot be detected properly.

There are possibilities of the sensor malfunction and

short circuit to ground in the harness.

"The temperature cannot be detected properly.

There are possibilities of the sensor malfunction,

open and short circuit to +B in the harness."

Page 40

P-Code DST-1 Display Remarks Description

P0182

P0183

P0191

P0192

P0193

P0200

P0201 Injector 1 Open Circuit

P0202 Injector 2 Open Circuit

Fuel Temperature

Sensor Malfunction (LO)

Fuel Temperature

Sensor Malfunction (HI)

Rail Pressure Sensor

Malfunction

Rail Pressure Sensor

Malfunction (LO)

Rail Pressure Sensor

Malfunction (HI)

ECU Charge Circuit

Malfunction (HI)

Integrated in the supply

pump.

Integrated in the supply

pump.

Characteristic malfunction

"The temperature cannot be detected properly.

There are possibilities of the sensor malfunction,

short circuit to ground in the harness."

"The temperature cannot be detected properly.

There are possibilities of the sensor malfunction,

open and short circuit to +B in the harness."

The rail pressure cannot be detected properly.

There is a possibility of the sensor malfunction.

The rail pressure cannot be detected properly.

There are possibilities of the sensor malfunction and

short circuit to ground in the harness.

"The rail pressure cannot be detected properly.

There are possibilities of the sensor malfunction,

open and short circuit to +B in the harness."

The voltage for the injector activation is too high.

Replace the ECU.

There is a possibility of the Injector 1 malfunction or

open circuit in the harness.

There is a possibility of the Injector 2 malfunction or

open circuit in the harness.

P0203 Injector 3 Open Circuit

P0204 Injector 4 Open Circuit

P0205 Injector 5 Open Circuit

P0206 Injector 6 Open Circuit

P0217

P0219

P0234

P0237

P0263

Over Temperature

Condition

Engine Over speed

Condition

Turbo Charger

Overboost Condition

Boost Pressure Sensor

Malfunction (LO)

Correction Error

Between Cylinders #1

There is a possibility of the Injector 3 malfunction or

open circuit in the harness.

There is a possibility of the Injector 4 malfunction or

open circuit in the harness.

There is a possibility of the Injector 5 malfunction or

open circuit in the harness.

There is a possibility of the Injector 6 malfunction or

open circuit in the harness.

The over temperature condition has been detected.

Check the cooling system.

The engine speed exceeded the rated value.

The boost pressure is too higher than the specified

value.

"The intake air pressure cannot be detected properly.

There are possibilities of the sensor malfunction,

open and short circuit in the harness."

The rotation fluctuation in the cylinder 1 became bigger than other cylinders.

There is a possibility that the flow damper is operating.

P0266

Correction Error

Between Cylinders #2

The rotation fluctuation in the cylinder 2 became bigger than other cylinders.

There is a possibility that the flow damper is operating.

38

Page 41

P-Code DST-1 Display Remarks Description

The rotation fluctuation in the cylinder 3 became big-

P0269

P0272

P0275

P0278

Correction Error

Between Cylinders #3

Correction Error

Between Cylinders #4

Correction Error

Between Cylinders #5

Correction Error

Between Cylinders #6

ger than other cylinders.

There is a possibility that the flow damper is operating.

The rotation fluctuation in the cylinder 4 became bigger than other cylinders.

There is a possibility that the flow damper is operating.

The rotation fluctuation in the cylinder 5 became bigger than other cylinders.

There is a possibility that the flow damper is operating.

The rotation fluctuation in the cylinder 6 became bigger than other cylinders.

There is a possibility that the flow damper is operating.

P0335

P0340

P0404 EGR Valve 1 Clogged

P0405

P0406

P0407

P0408

Crankshaft Position

Sensor Malfunction

Engine Speed Sensor

Malfunction

EGR Lift Sensor 1

Malfunction (LO)

EGR Lift Sensor 1

Malfunction (HI)

EGR Lift Sensor 2

Malfunction (LO)

EGR Lift Sensor 2

Malfunction (HI)

"In case that the NE

and G sensor have

malfunctions, this P

code will be output."

Clogging has been

detected by the lift sensor.

The pulse from the crankshaft position sensor cannot be detected.

There are possibilities of the sensor and harness

malfunctions.

The pulse from the engine speed sensor cannot be

detected.

There are possibilities of the sensor and harness

malfunctions.

The EGR valve 1 is clogged in the open state.

"The EGR lift sensor 1 has a malfunction.

There are possibilities of the sensor malfunction,

open and short circuit to ground in the harness."

The EGR lift sensor 1 has a malfunction.

There are possibilities of the sensor malfunction and

short circuit to +B in the harness.

"The EGR lift sensor 2 has a malfunction.

There are possibilities of the sensor malfunction,

open and short circuit to ground in the harness."

The EGR lift sensor 2 has a malfunction.

There are possibilities of the sensor malfunction and

short circuit to +B in the harness.

P0489

P0490

P0500

EGR Solenoid Valve 1

Malfunction

EGR Solenoid Valve 1

Malfunction

Vehicle Speed Sensor

Malfunction (LO)

Open circuit

"The EGR solenoid valve 1 has a malfunction.

There are possibilities of the solenoid valve malfunction, open and short circuit to ground in the harness."

The EGR solenoid valve 1 has a malfunction.

There are possibilities of the solenoid valve malfunction and short circuit to +B in the harness.

The pulse from the vehicle speed sensor cannot be

detected .

There are possibilities of the sensor and harness

malfunctions.

39

Page 42

P-Code DST-1 Display Remarks Description

The pulse from the vehicle speed sensor has an

P0501

Vehicle Speed Sensor

Malfunction (HI)

Noise

error.

There are possibilities of the sensor and harness

malfunctions.

P0510 Idle Switch Malfunction

P0524

P1401 EGR Valve Clogged

P0540

P0545

P0546

P0605 Flash ROM Malfunction

P0606

Engine Oil Pressure Too

Low

Preheating System

Malfunction

Exhaust Gas Temperature Sensor 1

Malfunction (LO)

Exhaust Gas Temperature Sensor 1

Malfunction (HI)

CPU Malfunction (Hardware Detected)

Clogging has been

detected by the lift

sensor.

The idle switch does not function properly.

Monitor the state and check the ON/OFF judgment.

The engine oil pressure became too low.

The EGR valve 2 system is clogged in the open

state.

The intake heater relay has a malfunction.

There are possibilities of the relay and harness malfunctions.

The temperature cannot be detected properly.

There are possibilities of the sensor malfunction and

short circuit to ground in the harness.

"The temperature cannot be detected properly.

There are possibilities of the sensor malfunction,

open and short circuit to +B in the harness."

There is an internal malfunction in the ECU.

Replace the ECU.

There is an internal malfunction in the ECU.

Replace the ECU.

P0607

P0611

P0617

P0686 Main Relay Malfunction

P0704

P0850

P1132

P1133

CPU Monitoring ID

Malfunction

ECU Charge Circuit

Malfunction

Starter Switch

Malfunction

Clutch Switch

Malfunction

Neutral Switch

Malfunction

Accelerator Position

Sensor for Operation

(LO)

Accelerator Position

Sensor for Operation

(HI)

There is an internal malfunction in the ECU.

Replace the ECU.

The voltage for the injector activation is too low.

Replace the ECU.

There is a short in the starter switch circuit.

Monitor the state and check the ON/OFF judgment.

The main relay cannot be turned OFF.

Check the relay.

The clutch switch cannot be detected properly.

Monitor the state and check the ON/OFF judgment.

The neutral switch cannot be detected properly.

Monitor the state and check the ON/OFF judgment.

The accelerator position sensor for operation cannot

be detected properly.

Check the sensor voltage.

There are possibilities of open and short circuit to

ground.

The accelerator position sensor for operation cannot

be detected properly.

Check the sensor voltage.

There is a possibility of short circuit to +B.

40

Page 43

P-Code DST-1 Display Remarks Description

The idle volume cannot be detected properly. Check

P1142 Idle Volume (LO)

P1143 Idle Volume (HI)

the sensor voltage.

There are possibilities of open and short circuit to

ground.

The idle volume cannot be detected properly. Check

the sensor voltage.

There is a possibility of short circuit to +B.

P1211

P1212

P1214

P1215

P1427

P1428

P1472

P1473

Injector Common 1

Malfunction

Injector Common 1

Malfunction

Injector Common 2

Malfunction

Injector Common 2

Malfunction

Exhaust Pressure

Sensor Malfunction (LO)

Exhaust Pressure

Sensor Malfunction (HI)

Transmission Retarder

Relay Malfunction

Transmission Retarder

Relay Malfunction

Transmission retarder

relay linked with the

cruise control system

for the large- and

medium-size vehicles

Transmission retarder

relay linked with the

cruise control system

for the large- and

medium-size vehicles

There is a possibility of short circuit to ground.

Check the injector and wiring.

There is a possibility of open or short circuit to +B.

Check the injector and wiring.

There is a possibility of short circuit to ground.

Check the injector and wiring.

There is a possibility of open or short circuit to +B.

Check the injector and wiring.

"The exhaust pressure cannot be detected properly.

There are possibilities of the sensor malfunction,

open and short circuit to ground in the harness."

The exhaust pressure cannot be detected properly.

There are possibilities of the sensor malfunction and

short circuit to +B in the harness.

"The transmission retarder relay has a malfunction.

There are possibilities of the relay malfunction, open

and short circuit to ground in the harness."

The transmission retarder relay has a malfunction.

There are possibilities of the relay malfunction and

short circuit to +B in the harness.

Transmission retarder

P1477

P1478

P1530

P1565

P1601 QR Code Error The QR code has an error. Check the QR code.

Cruise Control Retarder

Relay Malfunction

Cruise Control Retarder

Relay Malfunction

Engine Stop Switch

Close Malfunction

Cruise Control Switch

Malfunction

relay linked with the

cruise control system

for the medium-size

vehicle

Transmission retarder

relay linked with the

cruise control system

for the medium-size

vehicle

"The cruise control retarder relay has a malfunction.

There are possibilities of the relay malfunction, open

and short circuit to ground in the harness."

The cruise control retarder relay has a malfunction.

There are possibilities of the relay malfunction and

short circuit to +B in the harness.

The engine stop switch has a malfunction or there is

short circuit in the wiring.

Monitor the state and check the ON/OFF judgment.

The cruise control switch has a malfunction and

remains ON.

Monitor the state and check the ON/OFF judgment.

41

Page 44

P-Code DST-1 Display Remarks Description

"The exhaust brake solenoid valve has a malfunc-

P1681

Exhaust Brake Solenoid

Valve Malfunction

tion. There are possibilities of the solenoid valve

malfunction, open and short circuit to ground in the

harness."

P1682

P2002

P2032

P2033

P2120

P2121

P2122

Exhaust Brake Solenoid

Valve Malfunction

DPR System

Malfunction

Exhaust Gas Temperature Sensor 2

Malfunction (LO)

Exhaust Gas Temperature Sensor 2

Malfunction (HI)

Accelerator Position

Sensor 1&2 Malfunction

Accelerator Position

Sensor 1 Malfunction

Accelerator Position

Sensor 1 Malfunction

(LO)

The exhaust brake solenoid valve has a malfunction.

There are possibilities of the solenoid valve malfunction and short circuit to +B in the harness.

The DPR system has a malfunction.

There are possibilities of the melt down and clogging. Perform the DPR system check.

The temperature cannot be detected properly.

There are possibilities of the sensor malfunction and

short circuit to ground in the harness.

"The temperature cannot be detected properly.

There are possibilities of the sensor malfunction,

open and short circuit to +B in the harness."

Both the accelerator sensor 1 and 2 have malfunctions. There are possibilities of the sensor and harness malfunctions.

The accelerator position sensor 1 cannot be

detected properly. Check the sensor voltage.

The accelerator position sensor 1 cannot be

detected properly. Check the sensor voltage.

P2123

P2126

P2127

P2128

P2228

P2229

U0073

U0101

Accelerator Position

Sensor 1 Malfunction

(HI)

Accelerator Position

Sensor 2 Malfunction

Accelerator Position

Sensor 2 Malfunction

(LO)

Accelerator Position

Sensor 2 Malfunction

(HI)

Atmospheric Air Pressure Sensor

Malfunction (LO)

Atmospheric Air Pressure Sensor

Malfunction (HI)

CAN Communication

Malfunction (Engine)

Lost Communication

(Transmission)

For middle-sized VNT

Communication error

between pro-shift and

AT-ECU

The accelerator position sensor 1 cannot be

detected properly. Check the sensor voltage. There

is a possibility of short circuit to +B.

The accelerator position sensor 2 cannot be

detected properly. Check the sensor voltage.

The accelerator position sensor 2 cannot be

detected properly. Check the sensor voltage. There

are possibilities of open and short circuit to ground.

The accelerator position sensor 2 cannot be

detected properly. Check the sensor voltage. There

is possibility of short circuit to +B.

"The atmosphere pressure sensor (in ECU) has a

malfunction. If the malfunction occurs frequently, it is

necessary to repair or replace the ECU."

"The atmosphere pressure sensor (in ECU) has a

malfunction. If the malfunction occurs frequently, it is

necessary to repair or replace the ECU."

There is a malfunction of communication with the

VNT.

Communication with the transmission ECU is lost.

U0104

Lost Communication

(Cruise control)

Communication with the auto cruise ECU is lost.

42

Page 45

P-Code DST-1 Display Remarks Description

U0121

U0132

U0155

U1001

TBD

TBD

TBD

TBD

Lost Communication

(ABS)

Lost Communication

(Air suspension)

Lost Communication

(Meter)

CAN Communication

error (Vehicle)

EGR Solenoid 1

Malfunction

EGR Solenoid 1

Malfunction

EGR Solenoid 2

Malfunction

EGR Solenoid 2

Malfunction

CAN communication

bus OFF judgment

When linear solenoid

specific P code is

obtained

When linear solenoid

specific P code is

obtained

When linear solenoid

specific P code is

obtained

When linear solenoid

specific P code is

obtained

Communication with the ABS ECU is lost.

Communication with the air suspension ECU is lost.

Communication with the meter ECU is lost.

There is a malfunction of communication with other

computers equipped in vehicle.

"The EGR solenoid 1 has a malfunction.

There are possibilities of solenoid valve malfunction,

open and short circuit to ground in the harness."

The EGR solenoid 1 has a malfunction.

There are possibilities of solenoid valve malfunction

and short circuit to +B in the harness.

"The EGR solenoid 2 has a malfunction.

There are possibilities of solenoid valve malfunction,

open and short circuit to ground in the harness."

The EGR solenoid 2 has a malfunction.

There are possibilities of solenoid valve malfunction

and short circuit to +B in the harness.

43

Page 46

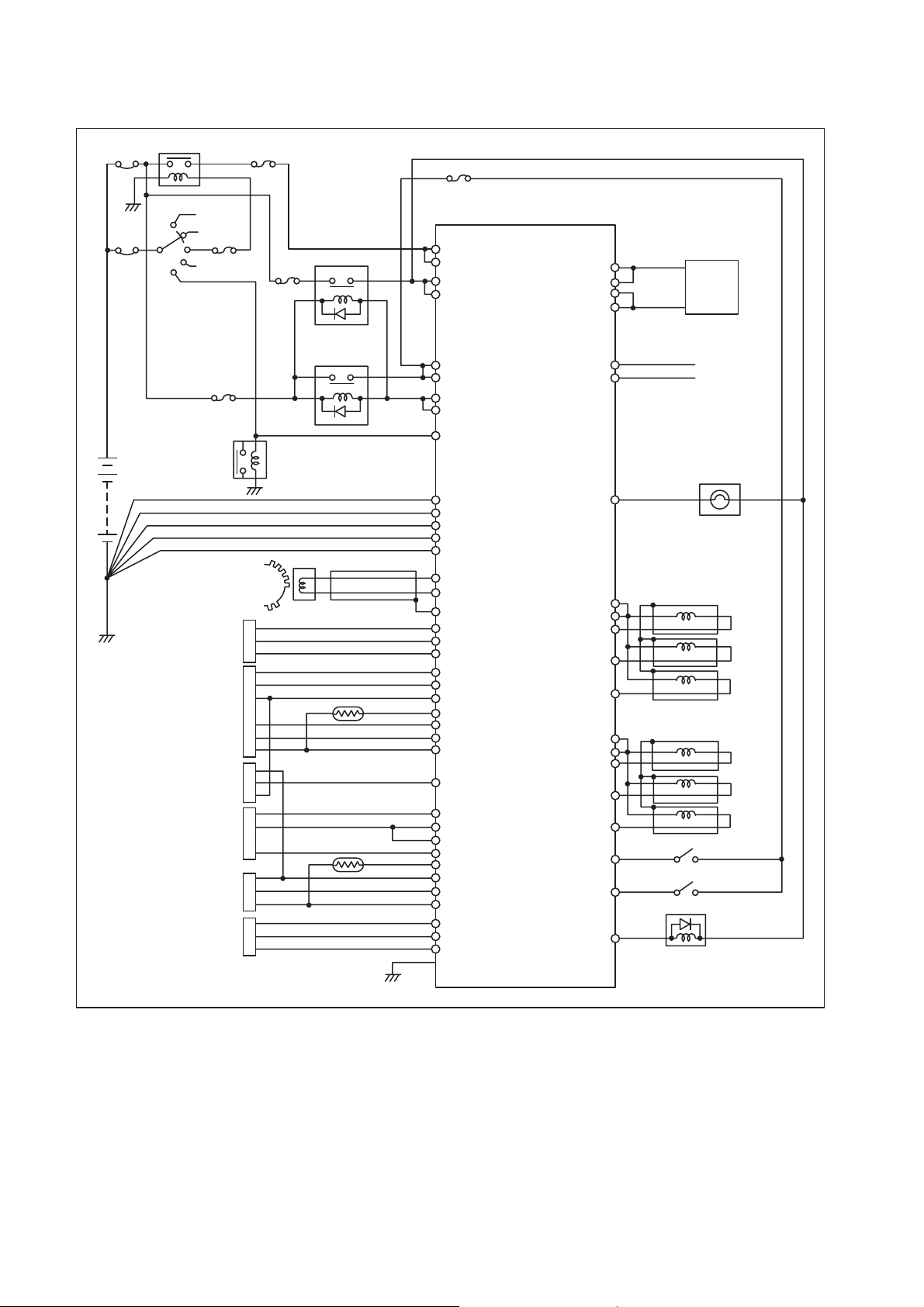

[2] ECU External Wiring Diagram

Power 4 relay

50 A

30 A

Battery

12 V

Engine speed sensor

Accelerator position sensor

Accelerator position sensor

Rail pressure sensor

Idle controller

Boost pressure sensor

5 A

15 A

TDC sensor

ACT power relay

15 A

Main relay

Starter relay

KEY/SW

KEY/SW

+BF

+BF

+BP

+BP

M-REL

M-REL

ST/SW

GND

GND

P-GND

P-GND

P-GND

NE [+]

NE [-]

NE-SLD

G-VCC

G

G-GND

A-VCC

ACCP1

Water temp. sensor

Fuel temp. sensor

A-GND

THW

ACCP2

A-GND

SCASC

A-VCC

VPC

VPC

A-GND

THL

A-VCC

VIMC

A-GND

A-VCC

PIM1

A-GND

Case GND

SCVHI

SCVHI

SCVLO

SCVLO

CANH

CANL

Lights

COMMON1

COMMON1

TWV1

TWV3

TWV5

COMMON2

COMMON2

TWV2

TWV4

TWV6

Switches

Actuators

SCV

For CAN wire

(Twist pair wire etc.)

Injector L6 (x6)

NOTE:

Dashed lines in the illustration show shield line.

Q000441E

44

Page 47

[3] ECU Connector Diagram

(1) ECU Connector Terminal Layout

34 P 35 P 32 P 35 P 31 P

2 3 4 5 6

1

8 9 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 27

28 29 30 31 32 33 34

7 35 36 37 38 39 40

42 43 44 45 46 47 48 49 50 51 52

54

55

56

62

57 58 59 60 61 87 88 89 90 91 92 93 94 95 96

63

64

65

66 67 68 69

41

70 71 72 73

53

77 78 79 80 81 82 83 84 85

97

98

74 75

99

76

86

100 101

102

108 109 110 111 112 113 11 4 115 116 117 144

118 119 120 121 122 123 124 125 126 127 128 154

129 130 131 132 133

103

104 105 106 107

134 135 136

137 138 139

140

145 146 147 148 149 150 151 152 153

155

156 157 158 159 160 161

162 163

164 165 166

(2) Terminal Connections

No.

Pin Symbol

1 (GND) ECU ground (spare) 18

2 (GND) ECU ground (spare) 19 KWP2000 ISO9141-K

3 IN3 spare 20 IN1 —

4 IN3- spare 21 AD1 Accelerator position sensor 1

5 +B Power 22 AD2 Accelerator position sensor 2

6 +B Power 23 AD10

7 +B Power 24 AD12 spare

8 TAC1 spare 25 AD19 spare

9 TAC2 Tachometer signal (SINK) 26 AD20 spare

10 POUT1 spare 27 VS1 Vehicle speed sensor

11 POUT2 spare 28

12 POUT3 spare 29 IN2 —

13 POUT4 spare 30 AD14 IMC volume

14 PIN1 spare 31 AD15 spare

15 PIN2 spare 32 AD16

16 — — 33 AD17 spare

17 (BATT) — 34 AD18 spare

35 +BF +BF 53 SW7 Brake switch

36 OUT5 Exhaust brake solenoid valve 54 A-GND4 Sensor ground 4

37 OUT6 spare 55 A-GND5 Sensor ground 5

38 OUT7 spare 56 SW1 Key switch

39 NE-SLD Engine RPM shield ground 57 A-VCC4 Sensor (Power supply) 4

40 NE+ Engine RPM + 58 SW8 Accelerator pedal switch

41 NE- Engine RPM - 59 SW10 spare

42 OUT1 spare 60 SW12 Constant-speed switch

43 OUT2 spare 61 SW17 Stop lamp switch

44 OUT3 Exhaust brake light 62 AD21 spare

45 OUT4 Glow indicator light 63 AD22 EGR valve lift sensor 2

46 SW1 Key switch 64 — —

47 OUT8 spare 65 A-VCC5 Sensor (Power supply) 5

48 SW2 Starter switch 66 SW9 Neutral switch

49 SW3 Exhaust brake switch 67 SW11 spare

50 SW4 spare 68 SW16 Diag. switch

51 SW5 spare 69 SW18 spare

52 SW6 spare

Connections No.

Pin Symbol

(CASE GND)

CASE GND

Connections

Case ground (spare)

Accelerator position sensor for operation

Case ground

Intake air temp. sensor (Build-in Airflow meter)

141

142

143

Q000442E

167

45

Page 48

No.

Pin Symbol

70 OUT19 Glow relay 86 — —

71 OUT20 Glow relay 87 SW31 AT identification signal

72 GND ECU ground 88 SW20 PTO2 switch

73 GND ECU ground 89 SW21 PTO switch

74 OUT17 ECU main relay 90 SW25 spare

75 OUT18 ECU main relay 91 SW26 spare

76 +BF +BF 92 SW13 Cruise switch 1

77 SW27 Clutch switch 93 SW28 Clutch stroke switch

78 SW spare 94 SW29 spare

79 SW Cruise switch 2 95 CANH CAN2 HI

80 SW Stop lamp switch 2 96 CANL CAN2 LOW

81 SW spare 97 SW32 Hydraulic pressure switch

82 S-OUT1 Check engine light 1 98 SW22 Warm-up switch

83 S-OUT2 spare 99 SW23 spare

84 S-OUT3 spare 100 SW30 spare

85 S-OUT4 spare 101 CAN-SLD CAN2 Shield ground

102 P-GND Power ground 120 G Cam angle

103 TWV1 Injector drive signal 1 121 AD4 Rail pressure sensor 1

104 TWV3 Injector drive signal 3 122 AD11 Airflow meter

105 TWV5 Injector drive signal 5 123 A-VCC3 Sensor (Power supply) 3

106

COMMON1

COMMON1

107

108 OUT9 EGR linear solenoid drive 1 126 A-VCC1 Sensor (Power supply) 1

109 OUT10 EGR linear solenoid drive 2 127 AD13 EGR valve lift sensor 1

110 OUT11 spare 128 AD3 Boost pressure sensor

111 OUT12 spare 129 (GND) ECU ground (spare)

112 OUT13 Cruise lamp 130 (GND) ECU ground (spare)

113 OUT14 Constant-speed lamp 131 G-GND CAM angle ground

114 OUT15 spare 132 AD5 Rail pressure sensor 2

115 OUT16 spare 133 G-VCC Cam angle VCC (5V)

116 — — 134 A-GND1 Sensor ground 1

117 — — 135 A-GND2 Sensor ground 2

118 A-GND6 Airflow ground 136 A-GND3 Sensor ground 3

119

NE (MRE)

Injector drive power 1 124 NE-VCC spare

Injector drive power 1 125 A-VCC2 Sensor (Power supply) 2

Connections No.

Pin Symbol

Connections

46

Page 49

No.

Pin Symbol

137 TWV2 Injector drive signal 2 153 PCV1 spare

138 TWV4 Injector drive signal 4 154 AD6 spare

139 TWV6 Injector drive signal 6 155 AD7 Water temp. sensor

140 P-GND Power ground 156 — —

141 P-GND Power ground 157 CAN1H CAN1 HI

142

COMMON2

COMMON2

143

144 SCVLO

145 SCVLO

146 SCVHI HP 3 or 4 pump control valve power 162 AD8 spare

147 SCVHI HP 3 or 4 pump control valve power 163 AD9 Fuel temp. sensor 2

148 — — 164 — —

149 — — 165

150 PCV2 spare 166 — —

151 PCV2 spare 167

152 PCV1 spare

Built-in

PATM Atmospheric air pressure sensor

Injector drive power 2 158 CAN1L CAN1 LOW

Injector drive power 2 159 — —

HP 3 or 4 pump control valve drive signal

HP 3 or 4 pump control valve drive signal

Connections No.

160 — —

161

Pin Symbol

(CASE GND)

CAN1-SLD

(CASE GND)

Connections

Case ground (spare)

spare

Case ground (spare)

47

Page 50

48

Loading...

Loading...