Hino 238, 258LP, 268, 338, 358 Workshop Manual

MENU

FOREWORD

This workshop manual has been prepared to provide information regarding repair procedures on Hino Trucks.

Applicable for HINO 238, 258LP, 268, 338 series, equipped with J08E-VB and J08E-VC engine

When making any repairs on your vehicle, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Driver’s / Owner

All information and specifications in this manual are based upon the latest product information available at the time of printing.

Hino Motors Sales U.S.A., Inc. reserves the right to make changes at any time without prior notice.

Please note that the publications below have also been prepared as relevant workshop manuals for the components and

systems in these vehicles.

Manual Name Pub. No.

Chassis Workshop Manual

J08E-VB, VC Engine Workshop Manual S5-UJ08E10A

Trouble Shooting Workshop Manual

's Manual.

S1-UNAE10A 1/2

S1-UNAE10A 2/2

S7-UNAE10C 1/4

S7-UNAE10C 3/4

S7-UNAE10C 4/4

CHAPTER REFERENCES REGARDING THIS WORKSHOP MANUAL

Use this chart to the appropriate chapter numbers for servicing your particular vehicle.

MANUAL NO. S7-UNAE10C 2/4 (U.S.A.), S7-CNAE10C 2/4 (CANADA)

CHAPTER

GENERAL INTRODUCTION 1-001

TROUBLE SHOOTING - COMPONENTS 2-001

TROUBLE SHOOTING ELECTRICAL CONTROL SYSTEM

ENGINE CONTROL SYSTEM (J08E) 4-001

DEF SCR SYSTEM (DCU) 5-001

BURNER CONTROL SYSTEM (BCU) 6-001

BRAKE CONTROL SYSTEM

VEHICLE CONTROL SYSTEM (VCS) 11-001

CAN COMMUNICATION 12-001

DX MANUAL DX01-001 DX02-001 DX03-001 DX04-001 DX06-001 DX07-001

This manual does not contain items on half-tone dot meshing.

MODELS HINO 238, 258LP, 268, 338, 358

Production Code NE8J, NF8J, NJ8J, NV8J

3-001

9-001

(ABS:HYDRAULIC (E VERSION))

(ABS:FULL AIR)

9-002

INDEX: TROUBLE SHOOTING

GENERAL INTRODUCTION

TROUBLE SHOOTING - COMPONENTS

TROUBLE SHOOTING ELECTRICAL CONTROL SYSTEM

WORKSHOP

MANUAL

ENGINE CONTROL SYSTEM (J08E)

DEF SCR SYSTEM (DCU)

BURNER CONTROL SYSTEM (BCU)

BRAKE CONTROL SYSTEM

VEHICLE CONTROL SYSTEM (VCS)

CAN COMMUNICATION

ENGINE CONTROL SYSTEM (J08E) 4–1

ENGINE CONTROL SYSTEM (J08E)

4

ENGINE CONTROL SYSTEM......................................4-3

PRECAUTIONS FOR DIAGNOSIS.........................4-3

SYSTEM BLOCK DIAGRAM...................................4-5

SYSTEM DIAGRAM................................................4-6

PRECAUTIONS ......................................................4-8

SENSOR LOCATION ............................................4-11

COMPUTER (ECU) PIN ASSIGNMENT............... 4-20

ENGINE ECU CONNECTOR................................4-24

INSPECTION ........................................................ 4-28

DIAGNOSIS USING THE PC DIAGNOSIS

TOOL.....................................................................4-29

DIAGNOSTIC TROUBLE CODE (DTC)

TABLE ...................................................................4-30

GROUP SHARING THE SENSOR POWER SUPPLY

TERMINAL ............................................................4-45

GROUP SHARING THE SENSOR GND

TERMINAL ............................................................4-46

ENGINE BASIC INSPECTION SHEET

(ENGINE INSPECTION CHECK SHEET) ............4-47

NO DTC ................................................................4-50

DTC: P0016 ..........................................................4-53

DTC: P003A ..........................................................4-57

DTC: P0045 ..........................................................4-64

DTC: P0047 ..........................................................4-71

DTC: P0048 ..........................................................4-78

DTC: P006E ..........................................................4-85

DTC: P006F ..........................................................4-90

DTC: P007B ..........................................................4-95

DTC: P007C and P007D.....................................4-113

DTC: P0088 ........................................................4-122

DTC: P0096 ........................................................4-146

DTC: P0097 and P0098 ......................................4-161

DTC: P00AF........................................................4-170

DTC: P0101 ........................................................4-175

DTC: P0104 ........................................................4-187

DTC: P0106 ........................................................4-195

DTC: P0108 ........................................................4-202

DTC: P0112 and P0113 ......................................4-210

DTC: P0115 ........................................................4-219

DTC: P0117 and P0118 ......................................4-231

DTC: P011A ........................................................4-241

DTC: P011C........................................................4-252

DTC: P0122 and P0123 ......................................4-260

DTC: P0128 ........................................................4-273

DTC: P016E and P016F .....................................4-280

DTC: P0182 and P0183 ......................................4-304

4-001

DTC: P0191 ........................................................4-313

DTC: P0192 and P0193 ......................................4-335

DTC: P01A5 ........................................................4-346

DTC: P01A6 ........................................................4-355

DTC: P0200 ........................................................4-364

DTC: P0201, P0202, P0203, P0204, P0205 and

P0206..................................................................4-367

DTC: P0217 ........................................................4-376

DTC: P0219 ........................................................4-383

DTC: P0222 and P0223 ......................................4-390

DTC: P0234 ........................................................4-402

DTC: P0237 ........................................................4-409

DTC: P0263, P0266, P0269, P0272, P0275 and

P0278..................................................................4-418

DTC: P026C and P026D.....................................4-434

DTC: P0299 ........................................................4-452

DTC: P0300 ........................................................4-459

DTC: P0301, P0302, P0303, P0304, P0305 and

P0306..................................................................4-469

DTC: P0335 ........................................................4-481

DTC: P0336 ........................................................4-489

DTC: P0340 ........................................................4-497

DTC: P0341 ........................................................4-504

DTC: P0381 ........................................................4-512

DTC: P0401 ........................................................4-519

DTC: P0402 ........................................................4-537

DTC: P0404 ........................................................4-550

DTC: P0405 and P0406 ......................................4-557

DTC: P041B ........................................................4-564

DTC: P041C and P041D.....................................4-579

DTC: P0420 ........................................................4-589

DTC: P0489 and P0490 ......................................4-596

DTC: P049D........................................................4-603

DTC: P04D5 and P04D6.....................................4-610

DTC: P0500 and P0501 ......................................4-619

DTC: P0504 ........................................................4-627

DTC: P0519 ........................................................4-635

DTC: P0524 ........................................................4-639

DTC: P0562 and P0563 ......................................4-646

DTC: P05F1 ........................................................4-654

DTC: P0605 ........................................................4-664

DTC: P0606 ........................................................4-667

DTC: P0607 ........................................................4-670

DTC: P0610 ........................................................4-673

DTC: P0611 ........................................................4-677

DTC: P0617 ........................................................4-680

ENGINE CONTROL SYSTEM (J08E)4–2

DTC: P0628 and P0629 ......................................4-685

DTC: P062F ........................................................4-694

DTC: P0630.........................................................4-699

DTC: P0642.........................................................4-703

DTC: P0643.........................................................4-710

DTC: P064C ........................................................4-718

DTC: P0652.........................................................4-725

DTC: P0653.........................................................4-731

DTC: P0671, P0672, P0675 and P0676 .............4-738

DTC: P0683.........................................................4-750

DTC: P0686.........................................................4-757

DTC: P06D3 and P06D4 .....................................4-762

DTC: P0704.........................................................4-770

DTC: P073D ........................................................4-776

DTC: P081A ........................................................4-783

DTC: P081B ........................................................4-788

DTC: P0850.........................................................4-793

DTC: P1133.........................................................4-800

DTC: P119F ........................................................4-808

DTC: P141F ........................................................4-815

DTC: P1426.........................................................4-818

DTC: P1427.........................................................4-826

DTC: P1428.........................................................4-834

DTC: P1458.........................................................4-843

DTC: P1459.........................................................4-850

DTC: P14B0 ........................................................4-857

DTC: P14B2 ........................................................4-862

DTC: P14B3 and P14B4 .....................................4-867

DTC: P14B7 and P14B8 .....................................4-874

DTC: P14BC and P14BD ....................................4-881

DTC: P14BF ........................................................4-888

DTC: P1515.........................................................4-895

DTC: P1530.........................................................4-901

DTC: P1601.........................................................4-906

DTC: P200C ........................................................4-911

DTC: P203F ........................................................4-922

DTC: P204F ........................................................4-927

DTC: P207F ........................................................4-931

DTC: P20EE........................................................4-943

DTC: P2100.........................................................4-955

DTC: P2101.........................................................4-962

DTC: P2103.........................................................4-970

DTC: P2120.........................................................4-977

DTC: P2122 and P2123 ......................................4-982

DTC: P2127 and P2128 ......................................4-991

DTC: P2135.......................................................4-1002

DTC: P2138.......................................................4-1009

DTC: P2146.......................................................4-1015

DTC: P2147 and P2148 ....................................4-1023

DTC: P2149.......................................................4-1032

DTC: P2150 and P2151 ....................................4-1040

DTC: P2184 and P2185 ....................................4-1049

DTC: P2214.......................................................4-1058

DTC: P2227.......................................................4-1072

DTC: P2228 and P2229 ....................................4-1077

DTC: P2269.......................................................4-1082

DTC: P226C ......................................................4-1088

DTC: P22D3 ......................................................4-1097

DTC: P240F ......................................................4-1102

DTC: P242B ......................................................4-1115

DTC: P242C and P242D ...................................4-1125

DTC: P244A ......................................................4-1135

DTC: P244B ......................................................4-1161

DTC: P2457.......................................................4-1190

DTC: P2459.......................................................4-1207

DTC: P2463.......................................................4-1210

DTC: P246F ......................................................4-1224

DTC: P2470 and P2471 ....................................4-1234

DTC: P2563.......................................................4-1244

DTC: P2564 and P2565 ....................................4-1251

DTC: P259E ......................................................4-1260

DTC: P259F ......................................................4-1267

DTC: P2635.......................................................4-1274

DTC: P268A and P2696....................................4-1296

DTC: P2BA9......................................................4-1303

DTC: U0073 ......................................................4-1309

DTC: U010A ......................................................4-1313

DTC: U010C......................................................4-1316

DTC: U010E ......................................................4-1319

DTC: U029D......................................................4-1322

DTC: U029E ......................................................4-1325

DTC: U02A2 ......................................................4-1328

DTC: U0301 ......................................................4-1331

DTC: U1001 ......................................................4-1335

DTC: U110A ......................................................4-1338

DTC: U111E ......................................................4-1341

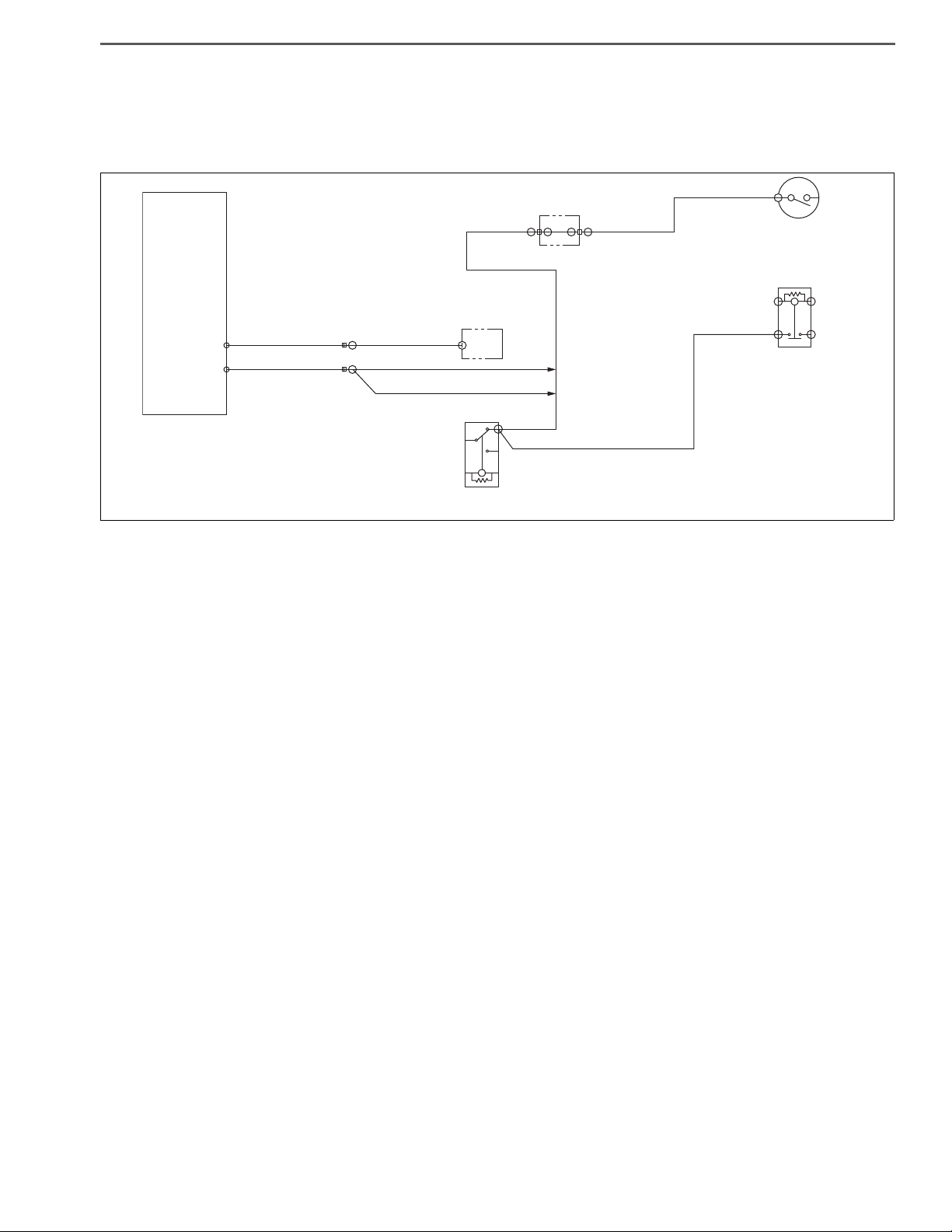

ENGINE CONTROL SYSTEM (J08E) 4–783

%L9

(STA)

K01

(S+)

K04

(NC)

NK0

(NO)

(ST)

N6E

(CL2-)

%L7

(STA)

ATM starter relay

Starter cut relay

Starter cut relay

LL1K01

K0G%D7

K0G

(STCR)

LL1

Engine

ECU

SAPH16F010300632

DTC: P081A

P081A: Starter Disable Circuit Low

INFORMATION

EN01H16F01030F03001098

1. Technical description

• The starter cut relay prevents further rotations of the starter when the starter switch is turned after start of the engine.

<Description of malfunction>

• Harness GND short-circuit or disconnection and relay unit failure are detected.

2. DTC set condition

(1) Check conditions

• Engine speed of 500 r/min or more. (Request starter cut relay operation)

• Starter switch ON.

• Battery voltage is in the range of 10 V to 16 V.

The conditions described above remain for 5 seconds or longer.

(2) Judgement criteria

• Output of the starter cut relay remains at 10 V or less for 3 seconds or longer.

3. Reset condition

• Just after restoration to normal condition.

4. Indication, warning or system control regulation when the DTC is set.

• MIL: OFF

• Diag lamp: OFF

5. Symptoms on the vehicle when the DTC is set

<Symptoms on the vehicle due to backup control (fail safe function)>

• –

<Symptoms on the vehicle due to malfunction>

• Starter operates even when the engine is running.

6. Pre-inspection work

• Check that the battery voltage is in the normal range.

ENGINE CONTROL SYSTEM (J08E)4–784

7. After-inspection work

• Clear all past DTCs.

• Check that no DTC is stored after test drive.

8. Estimated failure factors

• Harness disconnection or short-circuit

• Looseness or poor contact of connector

• starter cut relay failure

• Engine ECU failure

ENGINE CONTROL SYSTEM (J08E) 4–785

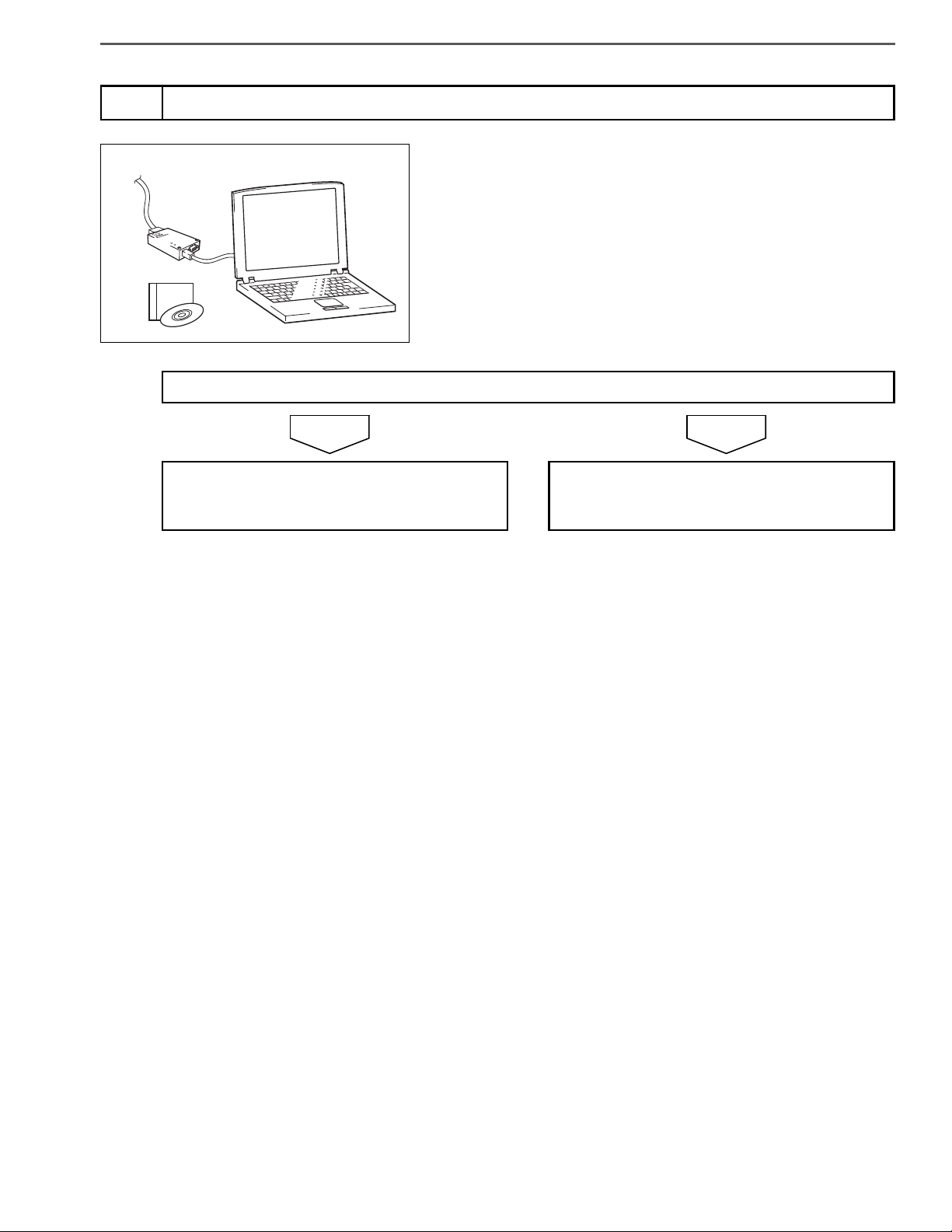

NOYES

NOYES

Select

Engine

SAPH16F010300633

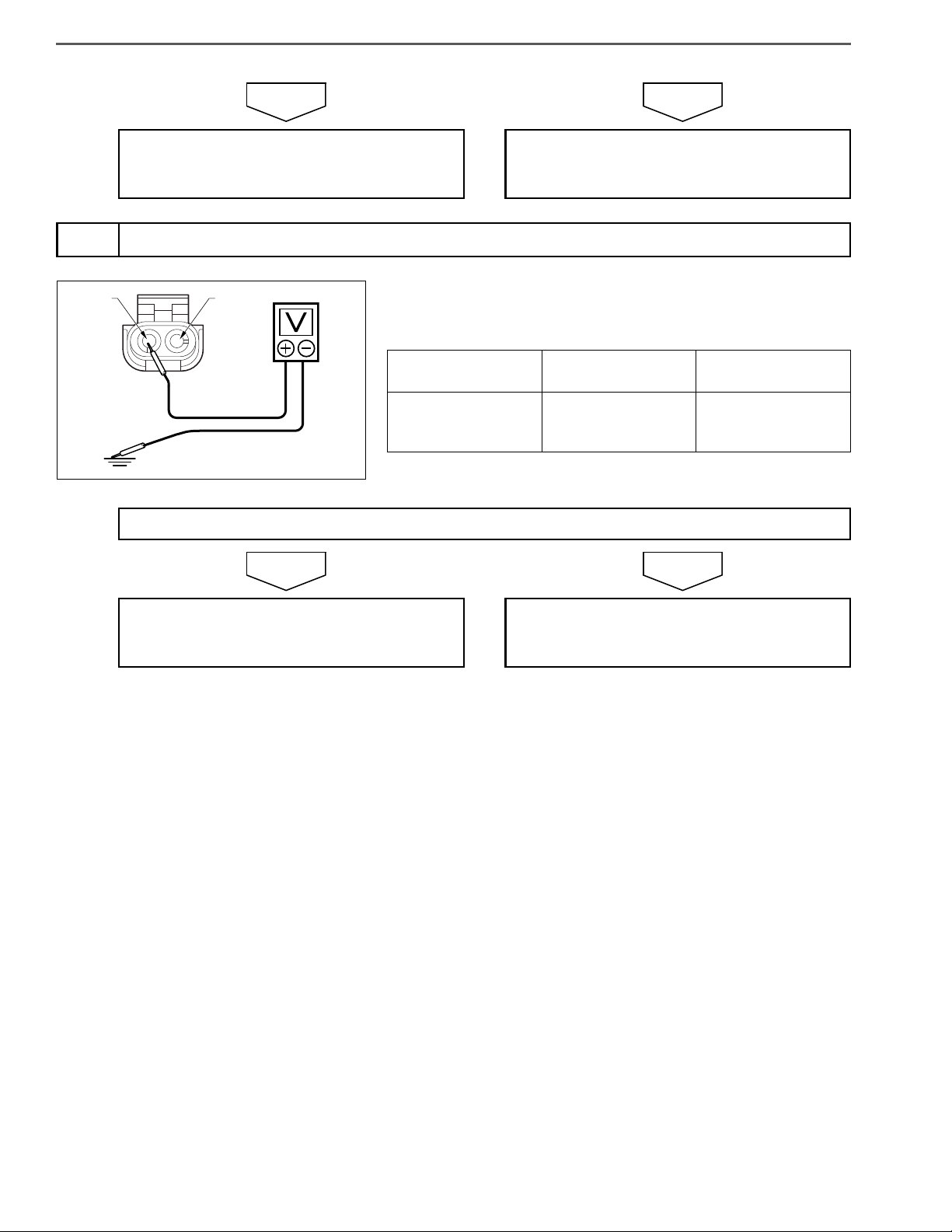

INSPECTION PROCEDURE: P081A

Check the DTC detected (Engine ECU) [Hino-DX]

1

Has DTC P081A been detected?

1. Set the starter switch to the "LOCK" position.

2. Disconnect the starter cut relay.

3. Set the starter switch to the "ON" position.

4. Select [Engine] and check if P081A has been detected in [Fault

Information].

Go to step 2. Replace the starter cut relay.

Perform "After-inspection work" of INFORMATION section.

Inspect the starter cut relay connector

2

1. Check the connection of the starter cut relay connector (Looseness and poor contact).

Was any failure found?

Connect securely, repair if needed.

Go to step 3.

Perform "After-inspection work" of INFORMATION section.

ENGINE CONTROL SYSTEM (J08E)4–786

NOYES

NOYES

A B

V2

V80

SAPH16F010300634

SAPH16F010300635

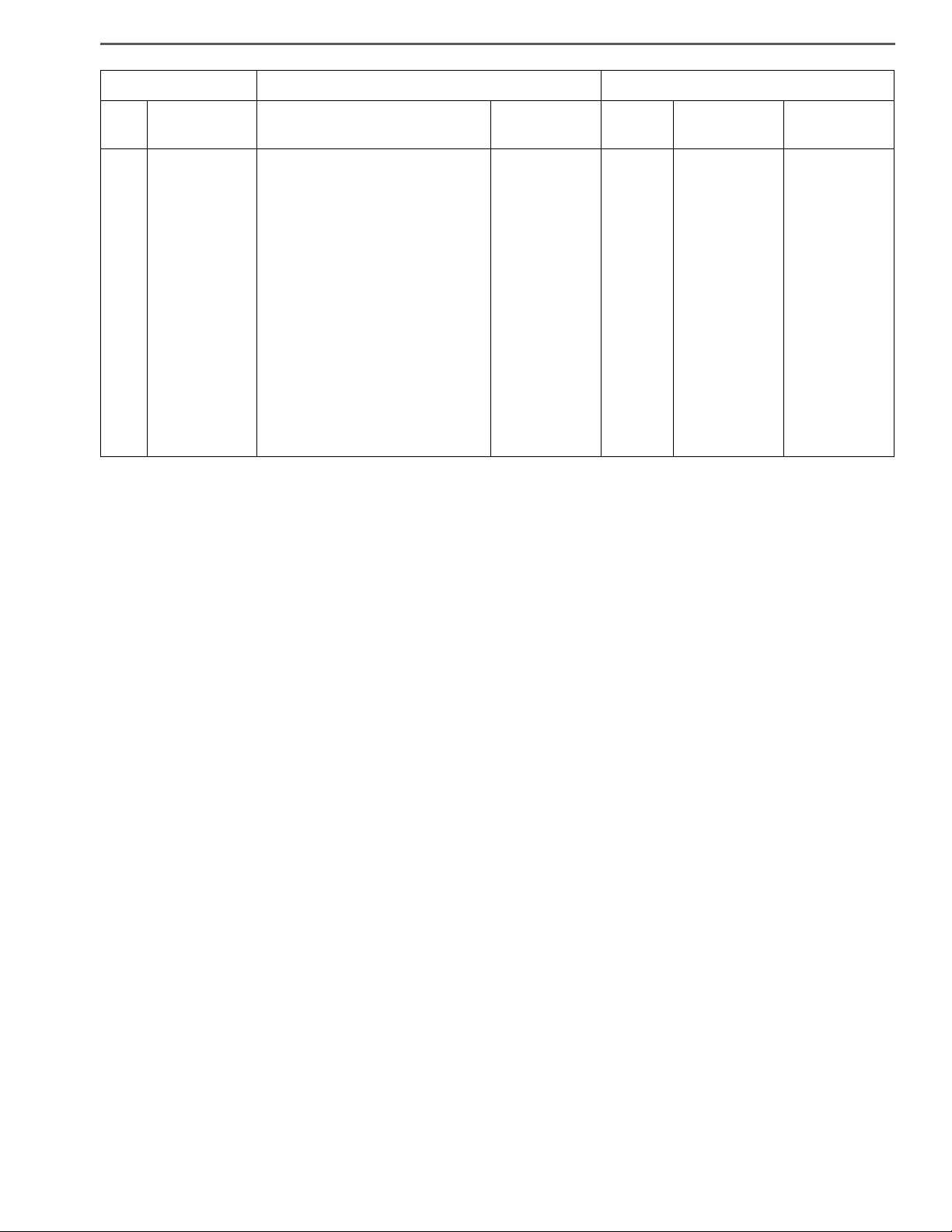

Inspect for disconnection in wire harness of starter cut relay

3

1. Set the starter switch to the "LOCK" position.

2. Connect the signal check harness to the engine ECU.

3. Set the starter switch to the "ON" position.

4. Use the electrical tester to measure the resistance between the

terminals of the engine ECU (signal check harness).

Measurement

conditions

Starter switch:

ON

Tester connections Standard values

Engine ECU (signal

check harness)

STCR(V2) – PGD4(V80)

Do the measurements meet the standard value?

Go to step 4. Repair or replace the harness.

Perform "After-inspection work" of INFORMATION section.

Check the DTC detected (Engine ECU) [Hino-DX]

4

1. Set the starter switch to the "ON" position.

2. Select [Engine] and check if P081A has been detected in [Fault

Information].

Has DTC P081A been detected?

Replace the engine ECU.

Perform "After-inspection work" of INFORMATION section.

Select

Engine

Procedure completed.

Perform "After-inspection work" of INFORMATION section.

ENGINE CONTROL SYSTEM (J08E) 4–787

CHECKLIST: P081A

DTC: P081A Starter Disable Circuit Low Inspection procedure

Step Action Description Judgement

DTC P081A

has been

detected: Go

to YES.

No DTC has

Check the

DTC detected

1

(Engine ECU)

[Hino-DX]

1. Disconnect the starter cut

relay.

2. Check if P081A has been

detected in [Engine].

been detected:

Go to NO.

Failure found:

Inspect the

starter cut

2

relay connector

Check the connection of the

starter cut relay connector

(Looseness and poor contact).

Go to YES.

No failure

found: Go to

NO.

Inspect for disconnection in

3

wire harness

of starter cut

relay

Connect the signal check harness

to the engine ECU and measure

the resistance between the terminals of the engine ECU (signal

check harness).

<Tester connections>

Engine ECU (signal check harness)

STCR(V2) – PGD4(V80)

<Standard values>

The measure-

ments meet

the standard

value: Go to

YES.

The measure-

ments do not

meet the stan-

dard value: Go

to NO.

Check

(Yes/No)

Yes No

Go to step 2.

Connect

securely,

repair if

needed.

Perform "Afterinspection

work" of

INFORMATION section.

Go to step 4.

Replace the

starter cut

relay.

Perform "Afterinspection

work" of

INFORMATION section.

Go to step 3.

Repair or

replace the

harness.

Perform "Afterinspection

work" of

INFORMATION section.

Check the

DTC detected

4

(Engine ECU)

[Hino-DX]

Check if P081A has been

detected in [Engine].

DTC P081A

has been

detected. Go

to YES.

No DTC has

been detected.

Go to NO.

Replace the

engine ECU.

Perform "Afterinspection

work" of

INFORMATION section.

Procedure

completed.

Perform "Afterinspection

work" of

INFORMATION section.

ENGINE CONTROL SYSTEM (J08E)4–788

%L9

(STA)

K01

(S+)

K04

(NC)

NK0

(NO)

(ST)

N6E

(CL2-)

%L7

(STA)

ATM starter relay

Starter cut relay

Starter cut relay

LL1K01

K0G%D7

K0G

(STCR)

LL1

Engine

ECU

SAPH16F010300636

DTC: P081B

P081B: Starter Disable Circuit High

INFORMATION

EN01H16F01030F03001099

1. Technical description

• The starter cut relay prevents further rotations of the starter when the starter switch is turned after start of the engine.

<Description of malfunction>

• Harness +B short-circuit is detected.

2. DTC set condition

(1) DTC detection condition

• Request for deactivation of starter block is in progress (while engine is stopped).

• Starter switch ON.

• Battery voltage is 10 V – 16 V.

Above conditions continue for at least 5 seconds.

(2) Judgement criteria

• Output of the starter cut relay remains at 10 V or more for 3 seconds or longer.

3. Reset condition

• After restoration to normal condition.

4. Indication, warning or system control regulation when the DTC is set.

• MIL: OFF

• Diag lamp: OFF

5. Symptoms on the vehicle when the DTC is set

<Symptoms on the vehicle due to backup control (fail safe function)>

• –

<Symptoms on the vehicle due to malfunction>

• Starter may not turn over. (If the starter turns over it will not interfere with engine operation.)

6. Pre-inspection work

• Check that the battery voltage is in the normal range.

ENGINE CONTROL SYSTEM (J08E) 4–789

7. After-inspection work

• Clear all past DTCs.

• Check that no DTC is stored after test drive.

8. Estimated failure factors

• Harness disconnection or short-circuit

• Looseness or poor contact of connector

• Starter cut relay failure

• Engine ECU failure

ENGINE CONTROL SYSTEM (J08E)4–790

NOYES

NOYES

A B

V2

V80

SAPH16F010300637

INSPECTION PROCEDURE: P081B

Inspect the starter cut relay connector

1

Was any failure found?

1. Check the connection of the starter cut relay connector (Looseness and poor contact).

Connect securely, repair if needed.

Perform "After-inspection work" of INFORMATION section.

Inspect for disconnection in wire harness of starter cut relay

2

1. Set the starter switch to the "LOCK" position.

2. Connect the signal check harness to the engine ECU.

3. Set the starter switch to the "ON" position.

4. Use the electrical tester to measure the resistance between the

terminals of the engine ECU (signal check harness).

Measurement

conditions

Starter switch:

ON

Do the measurements meet the standard value?

Go to step 2.

Tester connections Standard values

Engine ECU (signal

check harness)

STCR(V2) – PGD4(V80)

3 V or less

Go to step 3. Repair or replace the harness.

Perform "After-inspection work" of INFORMATION section.

ENGINE CONTROL SYSTEM (J08E) 4–791

NOYES

Select

Engine

SAPH16F010300638

Check the DTC detected (Engine ECU) [Hino-DX]

3

1. Set the starter switch to the "ON" position.

2. Select [Engine] and check if P081B has been detected in [Fault

Has DTC P081B been detected?

Information].

Replace the engine ECU.

Perform "After-inspection work" of INFORMATION section.

Procedure completed.

Perform "After-inspection work" of INFORMATION section.

ENGINE CONTROL SYSTEM (J08E)4–792

CHECKLIST: P081B

DTC: P081B Starter Disable Circuit High Inspection procedure

Step Action Description Judgement

Failure found:

Inspect the

starter cut

1

relay connector

Inspect for disconnection in

2

wire harness

of starter cut

relay

Check the

DTC detected

3

(Engine ECU)

[Hino-DX]

Check the connection of the

starter cut relay connector

(Looseness and poor contact).

Connect the signal check harness

to the engine ECU and measure

the resistance between the terminals of the engine ECU (signal

check harness).

<Tester connections>

Engine ECU (signal check harness)

STCR(V2) – PGD4(V80)

<Standard values>

3 V or less

Check if P081B has been

detected in [Engine].

Go to YES.

No failure

found: Go to

NO.

The measure-

ments meet

the standard

value: Go to

YES.

The measure-

ments do not

meet the stan-

dard value: Go

to NO.

DTC P081B

has been

detected: Go

to YES.

No DTC has

been detected:

Go to NO.

Check

(Yes/No)

Yes No

Connect

securely,

repair if

needed.

Perform "Afterinspection

work" of

INFORMATION section.

Go to step 3.

Replace the

engine ECU.

Perform "Afterinspection

work" of

INFORMATION section.

Go to step 2.

Repair or

replace the

harness.

Perform "Afterinspection

work" of

INFORMATION section.

Procedure

completed.

Perform "Afterinspection

work" of

INFORMATION section.

ENGINE CONTROL SYSTEM (J08E) 4–793

SAPH16F010300639

DTC: P0850

P850: Neutral switch - rationality

INFORMATION

K45NRF

N1N

(NUSW)

Engine

ECU

K45

NRF

(-)

Neutral switch

#LH#LH

%DW

(NTSW)

NRE

(+)

NRE NRF

%G1

(NSIG)

%DX

(NTSW)

ON

OFF

#D4#D4

KSM

(SW+)

EN01H16F01030F03001100

Neutral switch

%17

(SIG)

Vehicle control ECU

L98

(NUSW)

A1J

(33LD)

DPR refresh switch

1. Technical description

• Through the neutral switch, the ECU senses neutral signals when the transmission lever is in the P or N range.

<Description of malfunction>

• The neutral switch cannot correctly sense.

2. DTC set condition

(1) Check conditions

After the starter switch is set to ON position, the status described below remains for 10 seconds.

• Vehicle speed is 31.25 miles/h or higher.

• Battery voltage is in the range of 10 V to 16 V.

• After that, vehicle speed is 0 miles/h.

(2) Judgement criteria

• The neutral switch cannot be switched twice.

3. Reset condition

• Immediately after normal operation is restored.

4. Indication, warning or system control regulation when the DTC is set.

• MIL: ON

• Diag lamp: OFF

• Cruise control is not available.

ENGINE CONTROL SYSTEM (J08E)4–794

5. Symptoms on the vehicle when the DTC is set

<Symptoms on the vehicle due to backup control (fail safe function)>

• Cruise control does not work.

<Symptoms on the vehicle due to malfunction>

• –

6. Pre-inspection work

• Check that the battery voltage is in the normal range.

7. After-inspection work

• Clear all past DTCs.

• Check that no DTC is stored after test drive.

8. Estimated failure factors

• Harness disconnection or short-circuit

• Malfunction of neutral switch

• Malfunction of ECU

ENGINE CONTROL SYSTEM (J08E) 4–795

NOYES

NOYES

NRF(-) NRE(+)

SAPH16F010300640

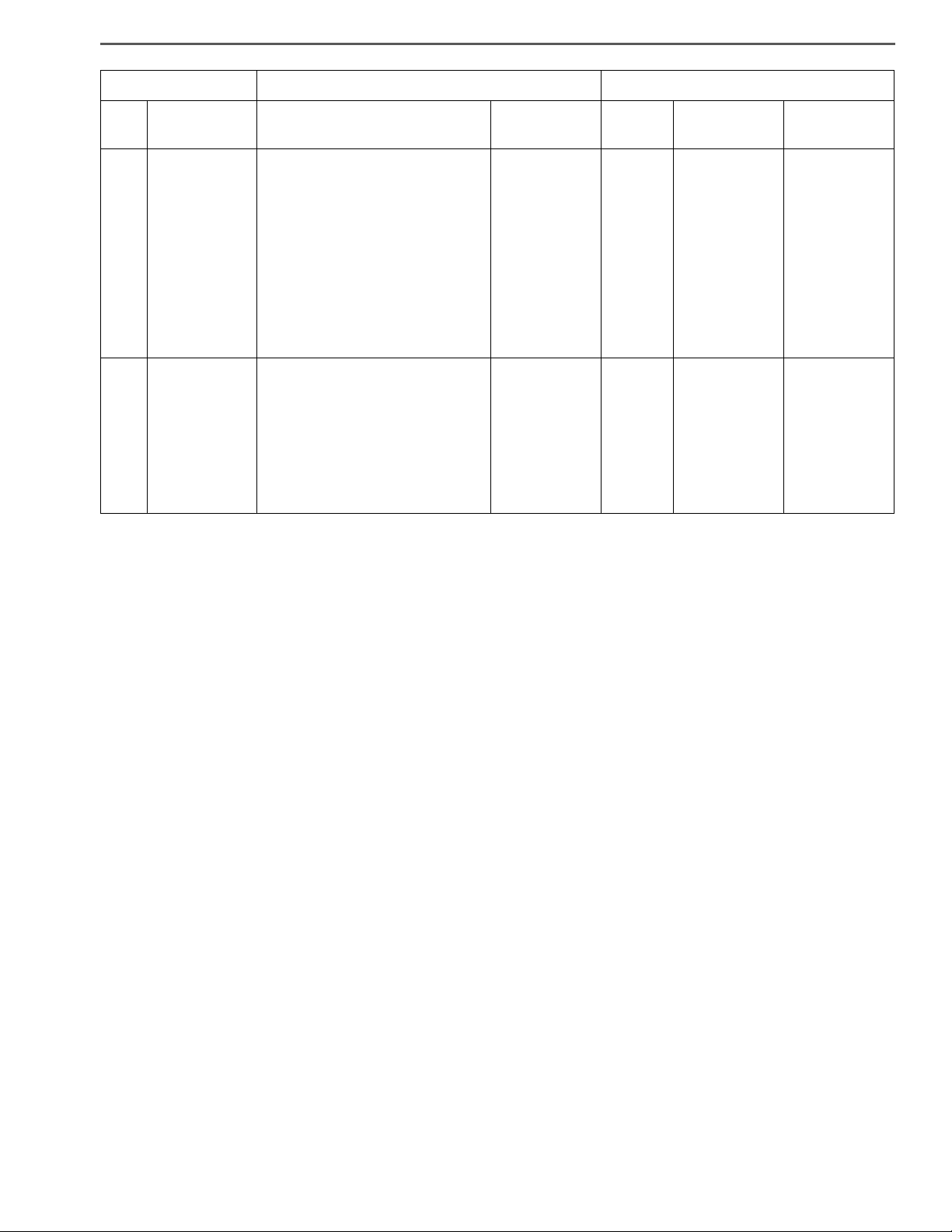

INSPECTION PROCEDURE: P0850

Inspect the neutral switch

1

Was any failure found?

1. Check if the neutral switch is properly adjusted.

Adjust the neutral switch.

Perform "After-inspection work" of INFORMATION section.

Inspect the neutral switch connector

2

Was any failure found?

Connect securely, repair if needed.

Perform "After-inspection work" of INFORMATION section.

Inspect the neutral switch unit

3

Go to step 2.

1. Check the connection of the neutral switch connector (Looseness

and poor contact).

Go to step 3.

1. Set the starter switch to the "LOCK" position.

Do the measurements meet the standard value?

2. Disconnect the neutral switch connector.

3. Use the electrical tester to measure the resistance between the

terminals of the neutral switch.

Measurement

conditions

Starter switch:

LOCK

Tester connections Standard values

Shift lever in N posiNeutral switch

NRE – NRF

tion: < 1

Shift lever in any

other position:

ENGINE CONTROL SYSTEM (J08E)4–796

NOYES

NOYES

NRE(+) NRF(-)

SAPH16F010300641

Go to step 4. Replace the neutral switch.

Perform "After-inspection work" of INFORMATION section.

Inspect the power supply of the neutral switch

4

1. Set the starter switch to the "ON" position.

2. Use the electrical tester to measure the voltage between the NRE

terminal in the neutral switch vehicle-side connector and ground.

Measurement

conditions

Starter switch: ON

Tester connections Standard values

Neutral switch vehicle-side connector

NRE – Ground

More than 10 V

Do the measurements meet the standard value?

Go to step 5. Repair the neutral switch power circuit.

Perform "After-inspection work" of INFORMATION section.

NOYES

Inspect the neutral switch harness

A

V11

SAPH16F010300642

5

ENGINE CONTROL SYSTEM (J08E) 4–797

1. Set the starter switch to the "LOCK" position.

2. Connect the neutral switch connector.

3. Connect the signal check harness to the engine ECU vehicle-side

harness. (Do not connect the harness to the ECU.)

4. Set the starter switch to the "ON" position.

5. Use the electrical tester to measure the voltage between the terminals of the engine ECU (signal check harness) and ground.

Measurement

conditions

Starter switch:

ON

Do the measurements meet the standard value?

Replace the engine ECU.

Perform "After-inspection work" of INFORMATION section.

Tester connections Standard values

Engine ECU (signal

check harness)

NUSW(V11) – Ground

Shift lever in N position: ≥ 10 V

Shift lever in any

other position: ≤ 0.5 V

Repair or replace the harness.

Perform "After-inspection work" of INFORMATION section.

ENGINE CONTROL SYSTEM (J08E)4–798

CHECKLIST: P0850

DTC: P0850 Neutral switch - rationality Inspection procedure

Step Action Description Judgement

Failure found:

Go to YES.

Inspect the

1

neutral switch

Inspect the

2

neutral switch

connector

Inspect the

3

neutral switch

unit

Check if the neutral switch is

properly adjusted.

Check the connection of the neutral switch connector (Looseness

and poor contact).

Measure the resistance between

the terminals of the neutral

switch.

<Tester connections>

Neutral switch

NRE – NRF

<Standard values>

Shift lever in N position: < 1

Shift lever in any other position:

No failure

found: Go to

NO.

Failure found:

Go to YES.

No failure

found: Go to

NO.

The measurements meet

the standard

value: Go to

YES.

The measurements do not

meet the standard value: Go

to NO.

Check

(Yes/No)

Yes No

Adjust the

neutral switch.

Perform "Afterinspection

work" of

INFORMATION section.

Connect

securely.

repair if

needed.

Perform "Afterinspection

work" of

INFORMATION section.

Go to step 4.

Go to step 2.

Go to step 3.

Replace the

neutral switch.

Perform "Afterinspection

work" of

INFORMATION section.

Inspect the

power supply

4

of the neutral

switch

Measure the voltage between the

NRE terminal in the neutral switch

vehicle-side connector and

ground.

<Tester connections>

Neutral switch vehicle-side connector

NRE – Ground

<Standard values>

More than 10 V

The measurements meet

the standard

value: Go to

YES.

The measurements do not

meet the standard value: Go

to NO.

Go to step 5.

Repair the

neutral switch

power circuit.

Perform "Afterinspection

work" of

INFORMATION section.

ENGINE CONTROL SYSTEM (J08E) 4–799

DTC: P0850 Neutral switch - rationality Inspection procedure

Step Action Description Judgement

1. Connect the neutral switch

connector.

Inspect the

5

neutral switch

harness

2. Connect the signal check

harness, and measure the

voltage between the terminals of the engine ECU (signal check harness) and

ground.

<Tester connections>

Engine ECU (signal check harness)

NUSW(V11) – Ground

<Standard values>

The measurements meet

the standard

value: Go to

YES.

The measurements do not

meet the standard value: Go

to NO.

Shift lever in N position: ≥ 10 V

Shift lever in any other position: ≤

0.5 V

Check

(Yes/No)

Yes No

Replace the

engine ECU.

Perform "Afterinspection

work" of

INFORMATION section.

Repair or

replace the

harness.

Perform "Afterinspection

work" of

INFORMATION section.

ENGINE CONTROL SYSTEM (J08E)4–800

SAPH16F010300643

DTC: P1133

P1133: PTO accelerator sensor (Hi)

INFORMATION

PTO

accelerator sensor

(VCC)

K95

Exhaust gas

temperature

sensor

(DOC outlet)

KSE

(TEX1)

KSF

(GND1)

Differential

pressure

sensor

KSJ

(VCC)

KSK

(VOUT)

KSL

(GND)

EN01H16F01030F03001101

Exhaust gas

temperature

sensor

(DOC inlet)

LCY

(TEX3)

LCZ

(GND3)

KSE KR4

KSE KR4

LCG

(ET4+)

KSJ KUQ

KSJ KUQ

KUQ

(AVC5)

KSK KUH

KSK KUH

KUH

(EXPS)

KSF LCT

KSF LCT

LCT

(ADG9)

Engine

ECU

LCY LCG

LCY LCG

KR4

(ET2+)

1. Technical description

• The operational accelerator sensor measures accelerator opening if PTO (power take off) is used. (This applies only

to PTO-equipped vehicles.)

<Description of malfunction>

• The operational accelerator sensor cannot correctly sense.

• +B short-circuit is likely to have occurred.

2. DTC set condition

(1) Check conditions

• Starter switch ON.

• Battery voltage is in the range of 10 V to 16 V.

The conditions described above remain for 5 seconds or longer.

(2) Judgement criteria

• Sensor voltage remains at 4.82 V or higher for 3 seconds or longer.

3. Reset condition

• After normal operation is restored and starter switch is turned LOCK.

ENGINE CONTROL SYSTEM (J08E) 4–801

4. Indication, warning or system control regulation when the DTC is set.

• MIL: OFF

• Diag lamp: OFF

• Body mounting control is not available.

5. Symptoms on the vehicle when the DTC is set

<Symptoms on the vehicle due to backup control (fail safe function)>

• Body mounting control is not working.

<Symptoms on the vehicle due to malfunction>

• –

6. Pre-inspection work

• Check that the battery voltage is in the normal range.

7. After-inspection work

• Clear all past DTCs.

• Check that no DTC is stored after test drive.

8. Estimated failure factors

• Faulty harness (+B short-circuit)

• Malfunction of sensor

• Failure in engine ECU sensor power supply or internal circuit

ENGINE CONTROL SYSTEM (J08E)4–802

NOYES

NOYES

INSPECTION PROCEDURE: P1133

Inspect the PTO accelerator sensor connector

1

Was any failure found?

1. Check the connection of the PTO accelerator sensor connector

(Looseness and poor contact).

Connect securely, repair if needed.

Perform "After-inspection work" of INFORMATION section.

Inspect the PTO accelerator sensor

2

Was any failure found?

Clean the PTO accelerator sensor and install

it properly.

If damaged, replace the sensor.

Perform "After-inspection work" of INFORMATION section.

Go to step 2.

1. Check the installation of the PTO accelerator sensor.

2. Make sure there is no dirt or damage to the PTO accelerator sensor.

Go to step 3.

ENGINE CONTROL SYSTEM (J08E) 4–803

NOYES

VCCSIG

GND

SIG

SAPH16F010300644

Inspect the PTO accelerator sensor unit

3

1. Set the starter switch to the "LOCK" position.

2. Disconnect the PTO accelerator sensor connector.

3. Use the electrical tester to measure the resistance between the

terminals of the PTO accelerator sensor.

Measurement

conditions

Tester connections Standard values

PTO accelerator

Starter switch:

LOCK

sensor

SIG – VCC

More than 2

SIG – GND

Do the measurements meet the standard value?

Go to step 4. Replace the PTO accelerator sensor.

Perform "After-inspection work" of INFORMATION section.

ENGINE CONTROL SYSTEM (J08E)4–804

NOYES

B

B

V71

V68

V45

SAPH16F010300645

Inspect for short-circuit of the PTO accelerator sensor harness

4

1. Connect the signal check harness to the engine ECU. (Do not connect the harness to the ECU.)

2. Use the electrical tester to measure the resistance between the

terminals of the engine ECU (signal check harness) and ground.

Measurement

conditions

Starter switch:

LOCK

Tester connections Standard values

Engine ECU (signal

check harness)

ASCS(V68) – Ground

AVC5(V71) – Ground

ADG7(V45) – Ground

Do the measurements meet the standard value?

Go to step 5. Repair or replace the harness.

Perform "After-inspection work" of INFORMATION section.

ENGINE CONTROL SYSTEM (J08E) 4–805

NOYES

NOYES

B

B

V45

V68

V71

V68

SAPH16F010300646

Select

Engine

SAPH16F010300647

Inspect disconnection of the PTO accelerator sensor harness

5

1. Connect the PTO accelerator sensor connector.

2. Use the electrical tester to measure the resistance between the

terminals of the engine ECU (signal check harness).

Measurement

conditions

Starter switch:

LOCK

Tester connections Standard values

Engine ECU (signal

check harness)

ASCS(V68) – AVC5(V71)

ASCS(V68) – ADG7(V45)

More than 2

Do the measurements meet the standard value?

Go to step 6. Repair or replace the harness.

Perform "After-inspection work" of INFORMATION section.

Check the DTC detected (Engine ECU) [Hino-DX]

6

1. Connect the vehicle to Hino-DX.

2. Set the starter switch to the "ON" position.

3. Select [Engine] and check if P1133 has been detected in [Fault

Has DTC P1133 been detected?

Replace the engine ECU.

Perform "After-inspection work" of INFORMATION section.

Information].

Procedure completed.

Perform "After-inspection work" of INFORMATION section.

ENGINE CONTROL SYSTEM (J08E)4–806

CHECKLIST: P1133

DTC: P1133 PTO accelerator sensor (Hi) Inspection procedure

Step Action Description Judgement

Failure found:

Inspect the

PTO accelera-

1

tor sensor connector

Check the connection of the PTO

accelerator sensor connector

(Looseness and poor contact).

Go to YES.

No failure

found: Go to

NO.

Inspect the

2

PTO accelerator sensor

1. Check the installation of the

PTO accelerator sensor.

2. Make sure there is no dirt or

damage to the PTO accelerator sensor.

Failure found:

Go to YES.

No failure

found: Go to

NO.

Check

(Yes/No)

Yes No

Connect

securely,

repair if

needed.

Perform "Afterinspection

work" of

INFORMATION section.

Clean the PTO

accelerator

sensor and

install it properly.

If damaged,

replace the

sensor.

Perform "Afterinspection

work" of

INFORMATION section.

Go to step 2.

Go to step 3.

Inspect the

3

PTO accelerator sensor unit

Inspect for

short-circuit of

4

the PTO accelerator sensor

harness

Disconnect the PTO accelerator

sensor connector and measure

the resistance between the terminals of the PTO accelerator sensor.

<Tester connections>

PTO accelerator sensor

SIG – VCC

SIG – GND

<Standard values>

More than 2

Connect the signal check harness

to the engine ECU. (Do not connect harness to the ECU.)

Measure the resistance between

the terminals of the engine ECU

(signal check harness) and

ground.

<Tester connections>

Engine ECU (signal check harness)

ASCS(V68) – Ground

AVC5(V71) – Ground

<Standard values>

The measurements meet

the standard

value: Go to

YES.

The measurements meet

the standard

value: Go to

YES.

The measurements do not

meet the standard value: Go

to NO.

Go to step 4.

Go to step 5.

Replace the

sensor.

Perform "Afterinspection

work" of

INFORMATION section.

Repair or

replace the

harness.

Perform "Afterinspection

work" of

INFORMATION section.

ENGINE CONTROL SYSTEM (J08E) 4–807

DTC: P1133 PTO accelerator sensor (Hi) Inspection procedure

Step Action Description Judgement

The measurements meet

the standard

value: Go to

YES.

The measurements do not

meet the standard value: Go

to NO.

DTC P1133

has been

detected: Go

to YES.

No DTC has

been detected:

Go to NO.

Inspect disconnection of

5

the PTO accelerator sensor

harness

Check the

DTC detected

6

(Engine ECU)

[Hino-DX]

Connect the PTO accelerator

sensor connector and measure

the resistance between the terminals of the engine ECU (signal

check harness).

<Tester connections>

ASCS(V68) – AVC5(V71)

ASCS(V68) – ADG7(V45)

<Standard values>

More than 2

Check if P1133 has been

detected in [Engine].

Check

(Yes/No)

Yes No

Go to step 6.

Replace the

engine ECU.

Perform "Afterinspection

work" of

INFORMATION section.

Repair or

replace the

harness.

Perform "Afterinspection

work" of

INFORMATION section.

Procedure

completed.

Perform "Afterinspection

work" of

INFORMATION section.

Loading...

Loading...