INSTALLATION INSTRUCTIONS

Adjustable Rear Stabilizer Bar

2011+ F-250/F-350 Super Duty Except Dual Wheels

4WD Models ONLY

Thank you for purchasing a quality Hellwig Product.

PLEASE READ THISINSTRUCTION SHEET COMPLETELY BEFORE STARTING YOUR INSTALLATION

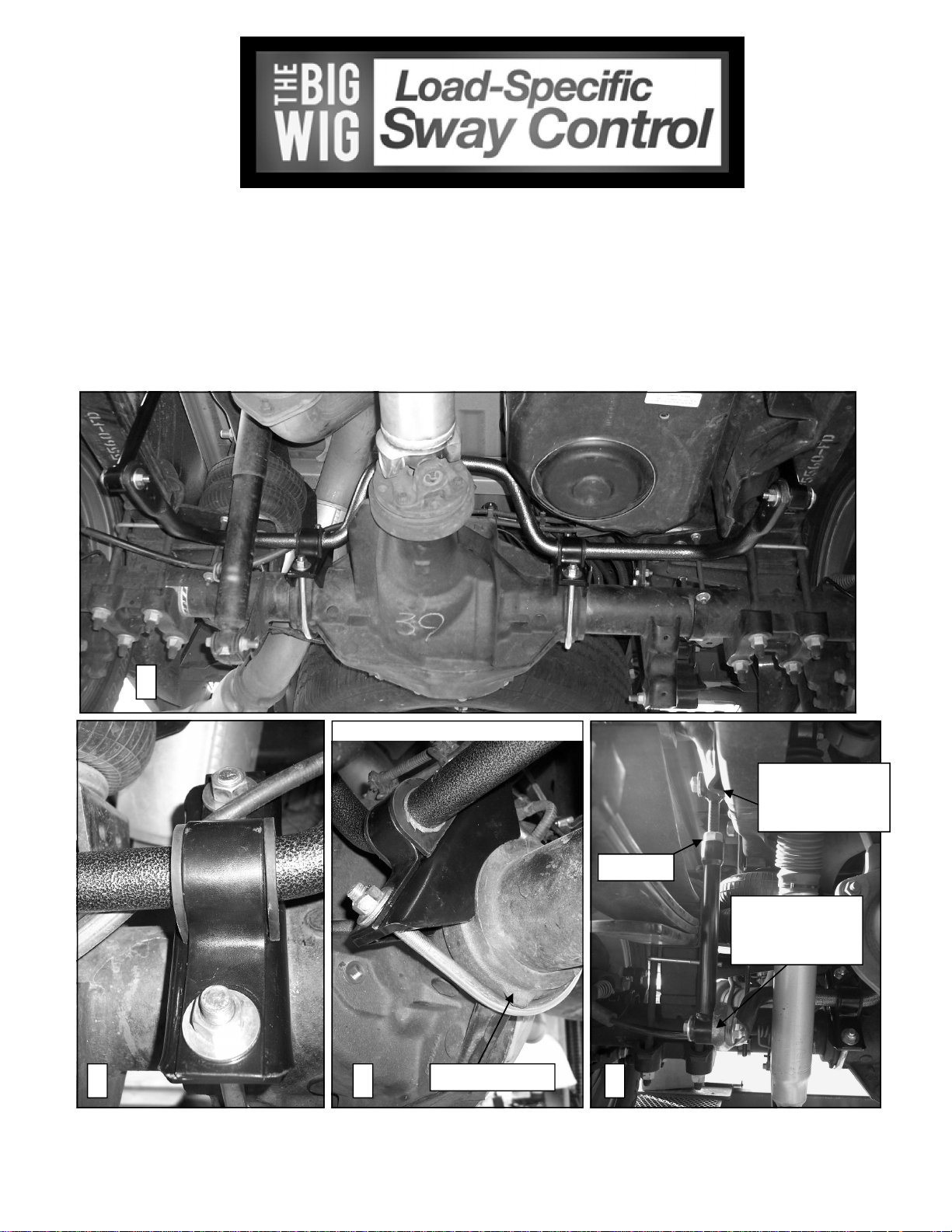

1 2 3

1

9/16” Nut

2 3 4

Half Round Lug

3/4” ID Hourglass

Bushings on frame

end.

5/8” ID Hourglass

Bushings on sway

bar end.

7271 ( R-7271) 04/25/2011

TORQUETABLE

BOLT SIZE: 3/8” = 20-30 ft. lbs. – 7/16” = 35-45 ft. lbs. – ½” = 50-70 ft. lbs. – 9/16” = 70-90 ft. lbs.

SAFETY: BEFORE STARTING YOUR INSTALLATION, BE SURE TO SET PARKINGBRAKE ANDCHOCK THE WHEELS.

NOTE: TO EASE INSTALLATIONAND TOPROPERLY ADJUSTBAR, THE WEIGHTOFTHEVEHICLE MUSTBE ON THE SUSPEN-

SION, AS IF DRIVING DOWNTHE ROAD. DO NOT RAISE THE VEHICLE BY FRAME.

NOTE: THIS UNIT IS DESIGNED TO REPLACE THEFACTORY INSTALLED REARANTI-SWAY BAROR AS AN ADDITIONIF THE

REAR ANTI-SWAY IS NOT FACTORY SUPPLIED.

NOTE: THIS KIT INCLUDES LOCK NUTSWHICH REQUIRE TIGHTENING WITH A WRENCH AFTER BEING STARTED BY HAND.

1. Remove the factory installed rear anti-sway bar (if equipped) and all factory supplied hardware. See note 7 for

removal of factory installed end link.

2. Locate the half round cast lugs on the differential housing at each side near the axle tubes. Install the U-bolts on

the axle between these lugs and install the saddles over the legs of the U-bolts. Orient the saddle brackets as

shown in photos (2&3).

3. Lubricate and place the D-shaped poly-bushings onto the straight areas of the bar on each side of the center

clearance hump. Place the U-plates over the bushings on the bar, position the U-plates and poly-bushings as

close as possible to the center of the hump.

4. Disconnect the emergency cable bracket located on the passenger side shock mount. Save bolt to reattach the

bracket later. Move emergency brake cable out of the way to ease sway bar installation.

5. Place the bar with the bushings and U-plates up over the top of the differential housing. Align the bushings and

U-plates so that they align with the U-bolts on the differential. Place the bar bushings and U-plates onto the Ubolts and saddles , attach them with the flat washers and locknuts provided. Leave loose at this time to allow

for adjustment later.

6. Locate the end links and assemble with the poly bushings and 9/16” nut as in photo (4). Insert the 3/4” ID hourglass bushings and matching inserts in the loops of the end link that will attach to the frame rail. Insert the 5/8”

ID hourglass bushings and matching inserts in the loops of the end link that will attach to the sway bar. Lubricate hourglass bushings and insert first and then insert sleeve.

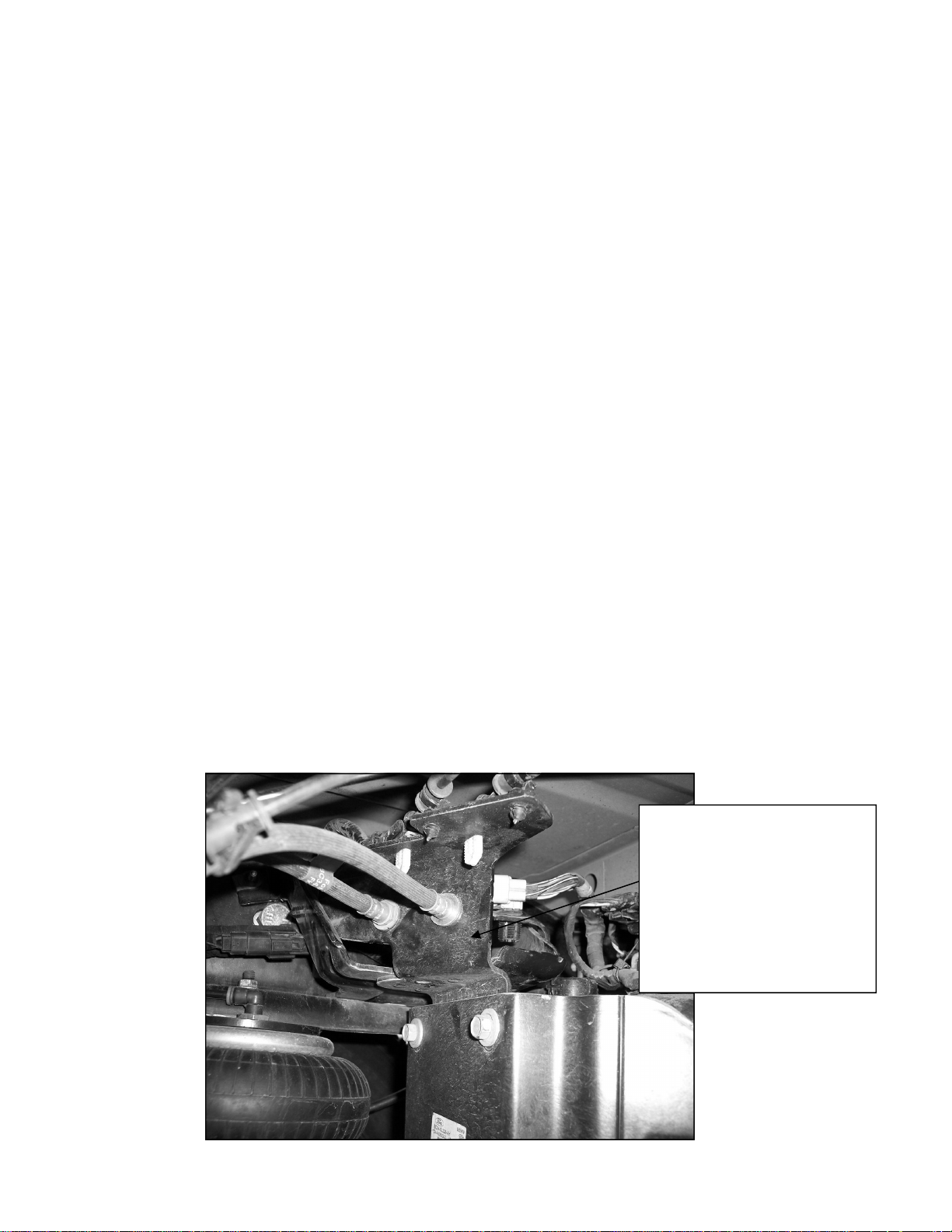

7. Installation of driver side end link will be easer if bracket in photo below is unbolted from fuel tank support.

DO NOT DISCONNECT BRAKE LINES OR ELECTRICAL CONNECTIONS, ONLY UNBOLT THE

BRACKET TO ALLOWEASIER ACCESS TO END LINK BOLT ON DRIVER SIDE.

Removal of stock end link and installation of new end link on driver

side will be easier if this bracket is

unbolted and moved away from

frame rail. Do not disconnect hoses

or electrical lines. Take care not

to damage brake line or hoses.

Replace bracket after installing end

link.

7271 ( R-7271) 04/25/2011

7. Attach the end links to the frame rail as shown in photos (4,5&6) using the 1/2 X 2 –1/2” bolt, washers and locknut.

8. Center sway bar on the differential and move the axle mounting hardware so the bar is aligned properly. Be sure

to move any lines, wires or hoses on the axle or the inside of the frame to avoid any damage. Rotate bar up and

down to make sure there is adequate clearance to all axle and undercarriage components as the suspension articulates. When bar is centered and proper clearances verified, tighten axle U-bolt locknuts to 60 ft-lb.

9. Attach lower end of end link to outer hole of swaybar as shown in photo six (6) using 7/16 X 2-3/4” bolt, washer

and locknut. Adjust end links so that end link bolt will clear fuel tank. Tighten 1/2” bolt to 50-60 ft-lb and 7/16”

bolt to 35-40 ft-lb. Tighten 9/16” adjustment nut on end link to 70 ft-lb.

10. Reattach emergency brake bracket and torque to factory specification.

11. Bounce the vehicle checking for clearance on all undercarriage components shocks, exhaust etc… test drive the

vehicle and recheck your installation. Recheck periodically on a regular basis thereafter.

12. The sway bar arms have three mounting holes. Mounting the sway bar on the outer hole is the nominal position.

For firmer settings, use the inner holes. We recommend starting with the outer mounting hole as in photo ( 2 )

until you are accustomed to the vehicles new handling characteristics. Then select the mounting point that best

fits your driving style

ATTENTION INSTALLER: BE SURE THE CUSTOMERRECEIVES THIS INSTRUCTIONSHEET, ALL WARNING

AND NOTE CARDSANDTHE WARRANTYFORM.

Attach end link to

end hole for initial

3/4” ID Houglass

Bushings on frame

end. Attach with 1/2”

Hardware and torque

to 50-60 ft-lb.

adjustment.

6

5

7271 ( R-7271) 04/25/2011

Loading...

Loading...