559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLATION INSTRUCTIONS

FRONT STABILIZER BAR

2003+ GMC KODIAK 4500/5500

Thank you for purchasing a quality Hellwig Product.

PLEASE READ THIS INSTRUCTION SHEET

COMPLETELY BEFORE STARTING YOUR INSTALLATION

SAFETY: BEFORE STARTING YOURINSTALLATION, BE SURE TO SET PARKING BRAKE AND

CHOCK THE TIRES.

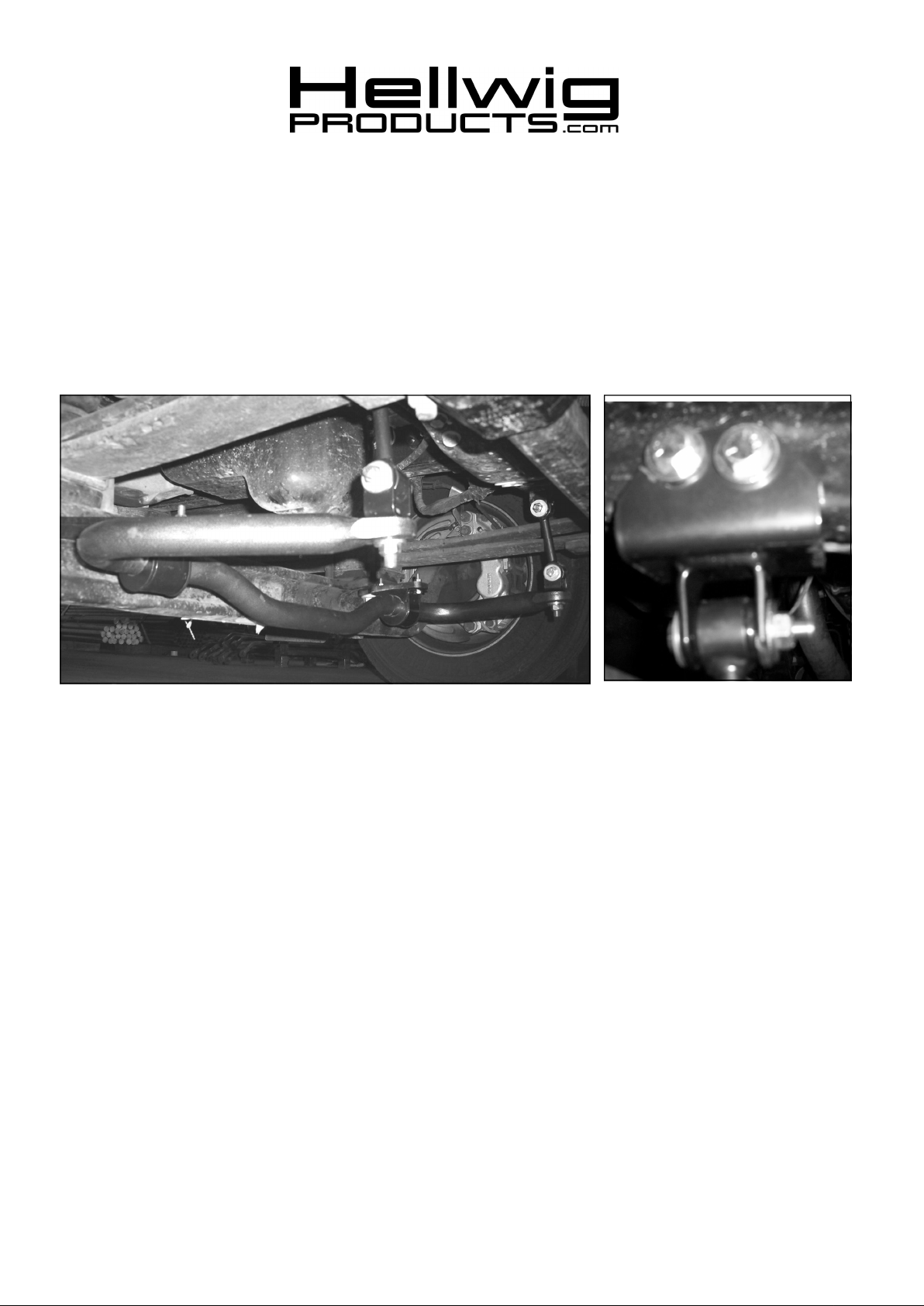

NOTE: THIS SWAY BAR IS TO BE MOUNTED ON THE FRONT OF THE FORWARD AXLE WITH

THE HUMP POINTING TOWARDS THE GROUND, AND THE ARMS POINTING TOWARDS

THE FRONT OF THE VEHICLE.

NOTE: THIS KIT INCLUDES LOCKNUTS WHICH REQUIRE TIGHTENING WITH A WRENCH

AFTER BEING STARTED BY HAND.

TORQUE TABLE

BOLT SIZE: 3/8” = 20-30 ft. lbs. – 7/16” = 35-45 ft. lbs. – ½” = 50-70 ft. lbs. – 9/16” = 70-90 ft. lbs.

1. Remove nuts from the axle u-bolts located on the forward side of the front axle. Do not remove nuts

from u-bolts on rearward side of axle.

2. Attach frame brackets to existing holes in frame crossmember using the 1/2X4-1/2” bolts, washers, and

locknuts as shown in photos. Orient brackets so that the clevis sits perpendicular to the ground and

torque bolts to 60 ft-lb.

7243 ( R-7243) 10/08/2007

559-734-7451 800-367-5480 FAX 559-734-7460

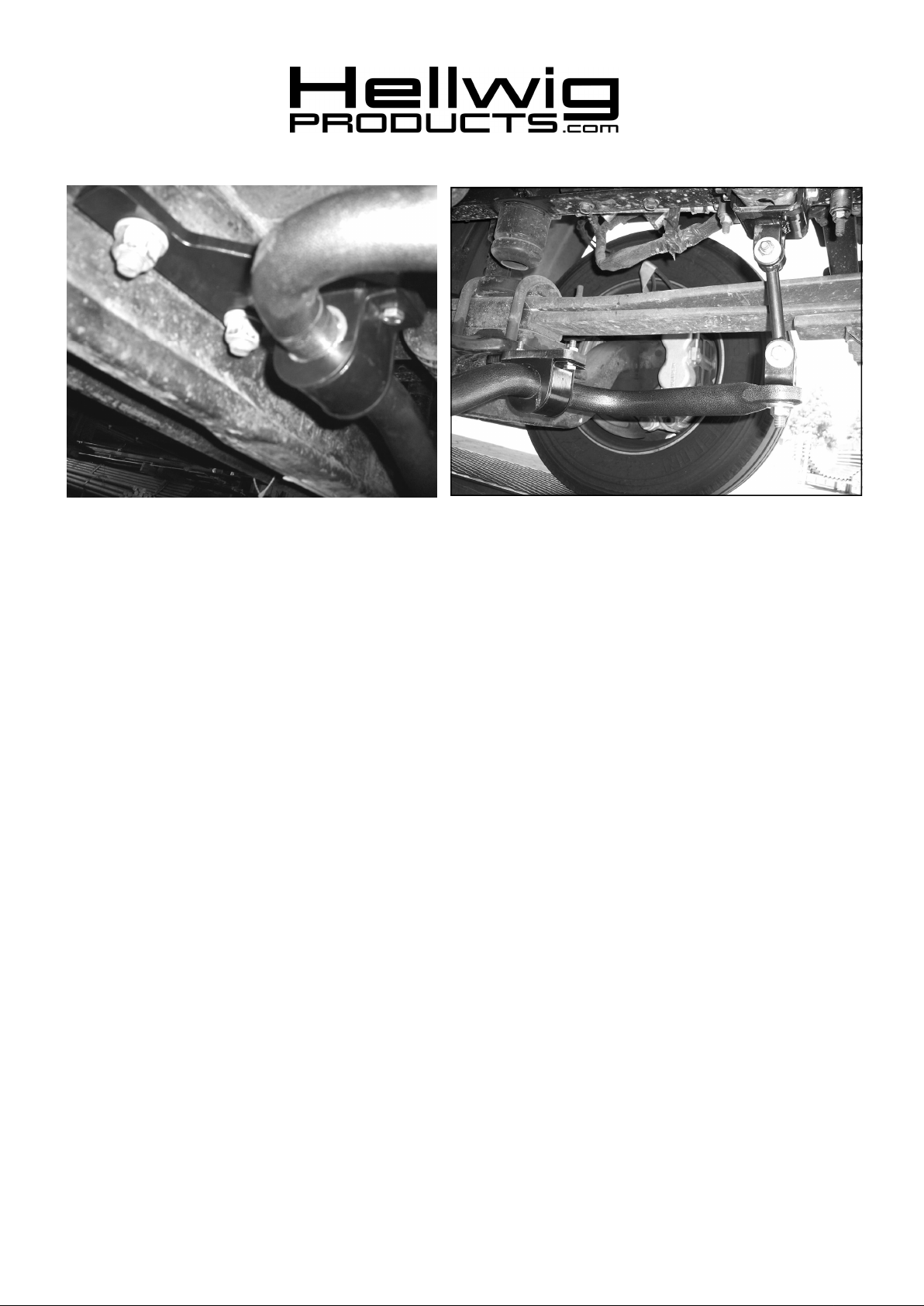

3. Install the axle plates on the axle as shown in photos by inserting legs of u-bolts through the holes

in the mounting plates. Install mounting plates with the bushing mounting surfaces inboard of the

leaf springs. Make sure the plates sit squarely against the axle mounting surface. Re-install nuts

and torque to factory specification.

4. Assemble end links by inserting hourglass bushing first and then inner sleeve into the each loop of

the end link. Fully lubricate bushings and sleeves before installation.

5. Attach end links to clevis of frame brackets using 7/16X2-3/4” bolts, washers, and locknuts as

shown in photos. Leave loose for adjustment later.

6. Lubricate the D-bushings and place on sway bar in approximate mounting location of the axle

brackets.

7. Raise sway bar upward to so that the bushings contact the mounting surface on the axle plates and

attach swaybar using the u-plates and the 3/8X1-1/4” bolts, washers, and locknuts. Install bolts

with threaded portion pointing upwards as shown in photo. Leave loose for adjustment later.

8. Attach clevis to sway bar end as shown in photo with 1/2-2” bolt, washer and locknut. Do not

place washer under bolt head. Align clevis so that it will mate to end link when installed. Torque

to 80 ft-lb.

9. Rotate sway bar and attach each clevis on end of sway bar to an end link using 7/16-2-3/4” bolts,

washers, and locknuts. Leave loose for adjustment later.

10. Align the sway bar under the vehicle to be as centered as possible and so that the end links are as

even from side to side as possible. The end links will allow a wide range of pivot and do not need

to be straight up and down front to rear.

11. When bar is centered, tighten the 3/8” bolts on axle plates to 30-35 ft-lb and tighten the 7/16” end

link bolts to 55-60 ft-lb.

12. Check for clearance on all undercarriage components etc. shocks, spare tire, fuel tank, exhaust,

brake and fuel lines. Test drive the vehicle and recheck your installation readjust in needed. After

one week of driving recheck your installation. Recheck on a monthly regular basis thereafter.

ATTENTION INSTALLER: BE SURE THAT THE CUSTOMER RECEIVES THIS INSTRUCTION SHEET,

ALL IMORTANT NOTE CARDS AND THE WARRANTY FORM

7243 ( R-7243) 10/08/2007

Loading...

Loading...