Page 1

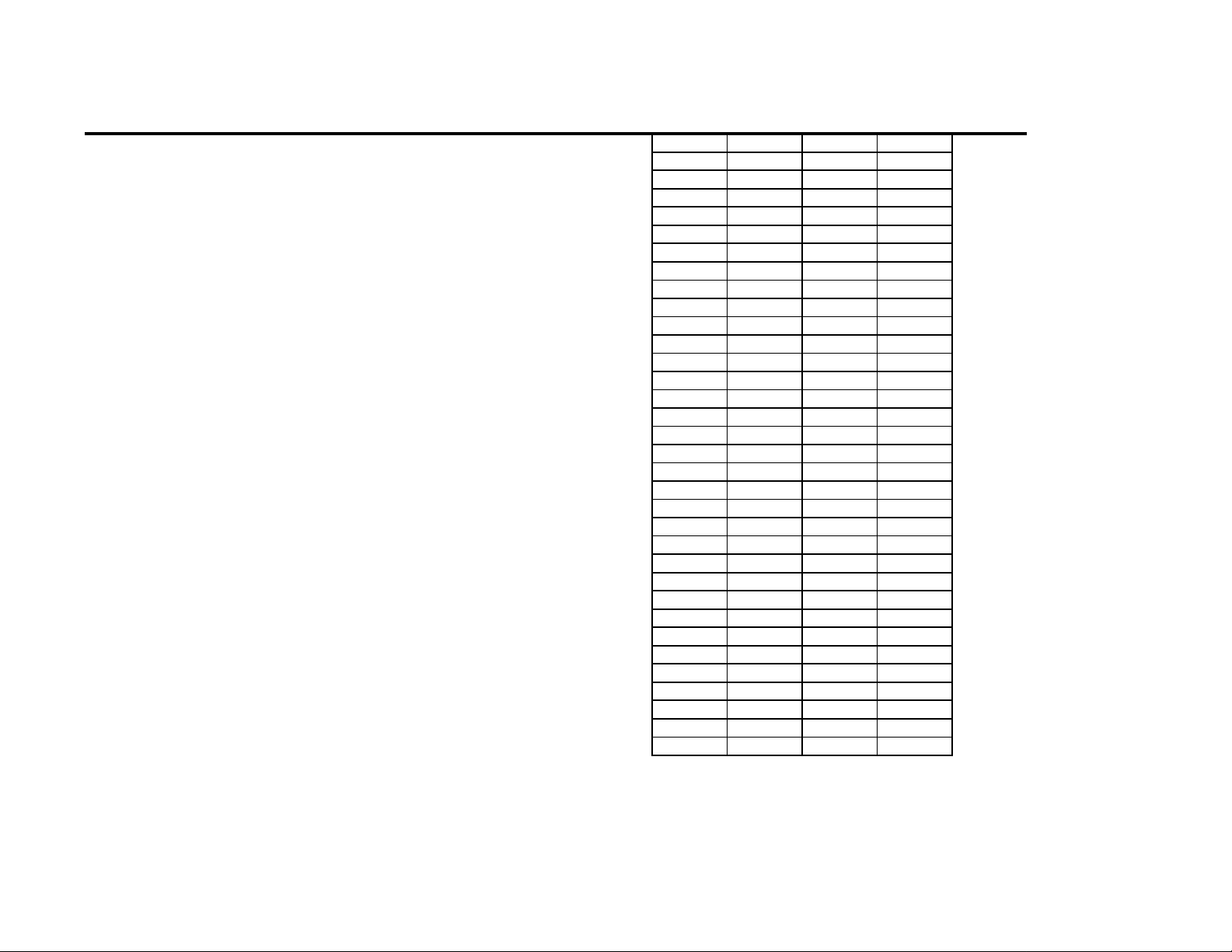

GETINGE HOROZONTAL DOOR SYSTEMS

1

ORDER TIMING BELT LENGTH EQUAL TO CHAMBER WIDTH PLUS 500MM, ROUND UP TO

DESCRIPTION PART # ITEM # NOTE

< 49X57 > 49 x 57 < 49X57 > 49 x 57

ASSMEMBLY DRAWING # 5607301 5607499 5625142 5625143

TIMING BELT BELT0001 877920103 X X X X 1

DOOR GUIDE ROLLER SOCKET DRSYS0004 560726501 X X X X 2

DOOR GUIDE ROLLER DRSYS0005 560560301 X X X X 2

AIR MOTOR ASSEMBLY & COG 560726670 X X

AIR MOTOR REPLACEMENT AIRMO0001 X X 1

AIR MOTOR COG REPLACEMENT AIRMO0003 MSD0463 X X 1

AIR MOTOR ASSEMBLY & COG AIRMO0004 561384670 X X 1

CATCH UNIT CYLINDER DRSYS0006 560563601 X X X X 1

CATCH UNIT CYLINDER AXLE DRSYS0011 560560001 X X X X 1

CATCH UNIT CYLINDER ROLLER DRSYS0007 560559902 X X X X 1

CATCH UNIT ROLLER BUSHING DRSYS0008 738187000 X X X X 2

CATCH UNIT CYL AXLE BUSHING DRSYS0009 738190100 X X X X 1

TIMING BELT BACKER ROLLER DRSYS0001 560678901 X X 2

TIMING BELT BACKER ROLLER DRSYS0012 561383001 X X 2

BACKING ROLLER BUSHING DRSYS0003 560725901 X X 2

BACKING ROLLER DUST CAP DRSYS0017 560678903 X X 2

BACKING ROLLER BALL BEARING DRSYS0002 738210102 X X 4

BACKING ROLLER BALL BEARING DRSYS0013 738220254 X X 2

DOOR RAIL LINEAR BALL BUSHING DRSYS0010 560730001 X X 2

DOOR RAIL LINEAR BALL BUSHING DRSYS0010 560730001 X X 4

LEVELING FOOT FOOT0006 560598606 X X X X 1

PNEUMATIC LIMIT SWITCH SWITL0008 560507601 X X X X 1

PNEUMATIC SAFETY VALVE DRSYS0018 561383302 X X 1

INTERLOCK SAFETY SWITCH KEY SWISA0002 XCKY09 X X 1

DOOR STOP BUMPER STOPS0002 470825502 X X 1

DOOR STOP BUMPER STOPS0001 470825501 X X 1

AIR MOTOR LIMIT PLUNGER DRSYS0019 561383501 X X 1

AIR MOTOR LIMIT PLUNGER FOOT DRSYS0020 561383201 X X 1

AIR MOTOR PLUNGER GUIDE DRSYS0014 561259804 X X 1

AIR MOTOR PLUNGER BUSHING DRSYS0015 561259803 X X 1

AIR MOTOR PIVOT SHAFT DRSYS0021 561383101 X X 1

AIR MOTOR PIVOT SHAFT BUSHING DRSYS0008 738187000 X X 2

AIR MOTOR STUB SHAFT DRSYS0022 561383102 X X 1

DOOR TRAVEL LIMIT SWITCH DRSYS0023 460212903 X X 1

-92 92a

THE NEAREST METER.

2 SPECIFY LEFT OR RIGHT HAND DOOR OPERATION

3 CHAMBERS WITH AN ASME NB # ABOVE 2443 WILL USE 92A COMPONENTS

4 REFER TO OPERATING MANUAL FOR INFORMATION

5 ALWAYS REFERENCE PROJECT NUMBER WHEN ORDERING

Page 2

Page 3

DRSYS0007

DRSYS0008

Page 4

Page 5

EXIT MANUAL

INSTALLATION INSTRUCTIONS

Horizontally opening motor-operated door

Door system 92A

These instructions replace all instructions of this number with an earlier

issue date.

NOTE: Only users registered with the publisher will automatically

receive updated versio ns of these instructions.

Issued by: Anders Carlsson

Assembly

As the force available for openi ng or closin g the door is very low, it is

important that the door is correctly hung so that it can move freely, with

no other friction than that of the ball bearing track.

It is therefore important that the sterilizer is correctly installed, levelled

and plumbed in accordance with its installation instructions before starting to fit the door.

1. Lift the door and use the pins to support it in the appropriate lugs.

Fit transportation spacers (1) in two lugs on each side of the door.

This hangs the door at approximately the right height.

2. Attach the beam holder (2) and the beam (3) and adjust to horizontal

using the adjusting bolts (4). Adjust the beam roughly to its correct

fore-and-aft position using the setti ngs in the table below.

Door

Door

weight, kg

0 - 600 100 40 35 ~ 84

600 - 1600 150 65 40 ~ 119

thick-

ness,

mm

150 65 35 ~ 112

Dimensions, mm

ABC

Datafil:C:\FILES\MAKERDOC\AM-HBOK\HAND-

BOK\5625194e.r04

Ugåva nummer 4

562 51 94

Click here to

Click here to

EXIT Manual

EXIT Manual

1/8

Page 6

EXIT MANUAL

INSTALLATION INSTRUCTIONS

Horizontally opening motor-operated door, Door system 92A

Issued by: Anders Carlsson

TYPE A

ALUMINIUM DOOR HANGER

A

3. Fit the ball bushing (5) with the door hanger (30) and any pole, if

used.

4. Fit the bush connector (10) on the door hanger without ti ghtening

the bolts. Do not tighten the bolts (11) until the ball bushings are

carrying the weight of the door.

5. Fit the buffers to the beam (3).

B

Datafil:C:\FILES\MAKERDOC\AM-HBOK\HAND-

BOK\5625194e.r04

Ugåva nummer 4

562 51 94

The buffers must be fitted bef ore the door is hung on

to the ball bushing in order to prevent it acc identally

rolling off.

6. Fit the door holders (12) to the door.

7. In sert the suppor t bolt (13 ) with the washer (33) under the bolt head

and nut (18) in the slit in the door hanger and screw it into the door

holder without lifting the door. Fit the pin (32) and circlips (31).

8. Screw in the support bolts (13) until the door is hanging freely.

9. Remove the transportation spacers(1) from the bolt holes and then

tighten the bolts (11) on the bush connector.

2/8

Page 7

EXIT MANUAL

INSTALLATION INSTRUCTIONS

Horizontally opening motor-operated door, Door system 92A

Issued by: Anders Carlsson

TYPE B

STAINLESS STEEL DOOR HANGER

A

3. Fit the ball bushing and bearing housing (5, 6) and support brackets

(7) with bolts and nuts and any pole (8), if used.

4. Fi t the bush co nnector (10 ) to the bea ring housi ngs withou t tightening the bolts. Do not tighten the bolts (11) until the ball bushings

are carrying the weight of the door.

5. Fit the buffers to the beam (3).

B

Datafil:C:\FILES\MAKERDOC\AM-HBOK\HAND-

BOK\5625194e.r04

Ugåva nummer 4

562 51 94

The buffers must be fitted bef ore the door is hung on

to the ball bushing in order to prevent it acc identally

rolling off.

6. Fit the door holders (12) to the door and screw in the support bolts

(13) into the door holders until the door is hanging freely.

7. Remove the transportation spacers(1) from the lugs and then tighten

the bolts (11).

HEIGHT ADJUSTMENT

Adjust the height of th e door by the two support bo lt s (13). The height

is correct when the adjusting bolts (14) touch the pins (15) on their centre line. In this position, the top of the door plate (16) and the top of the

heating channel (17) should be at the same level.

Check that at least 15 mm length of thread of the support bolts (13) are

engaged, and tighten the locknuts (18) against the doo r holders (12).

3/8

Page 8

EXIT MANUAL

INSTALLATION INSTRUCTIONS

Horizontally opening motor-operated door, Door system 92A

Issued by: Anders Carlsson

TOTAL DOOR CLEARANCE

Close the door and insert a piece of metal sheet at each corner between

the door plate and th e sealing groove. The thickness of these spa cers

should be 3 mm for doors with 100 mm frames and 6 mm for doors with

150 mm frames.

Carefully tighten all adjusting bolts so that the spacers are just retained.

Lock the adjusting bolts and remove the spacers.

VERTICAL ADJUSTMENT

If the distances above and below the door are not the same, the position

of the centre of gravity must be adjusted.

Slacken the door holder bolts and adjust their positions in their oval

holes until the door is hanging vertically. Retighten the bolts. The front

of the door must be fitted while this is being done.

FORE-AND-AFT ADJUSTMENT

Slacken the beam holder bolts and move the holders in their oval holes

until the door is hangin g equidistant in the total door gap, i.e. the distance between the chamber and the door must be the same as the distance between the pin and its adjustment bolt. Retighten the beam

holder bolts. Do not touch the beam holder adjustment bolts, but check

that the horizontal setting of the beam is maintained.

GUIDE ROLLERS

Adjust and tighten the gu ide r oller s at th e lower edge o f the d oor. The

correct distance between the rollers and the door is about 1 mm.

TOOTHED DRIVE BELT

Fit the belt somewhat slack so that the motor can overcome its static

friction without having to move the door. The guide rollers prevent the

belt from slipping when it is slack.

Bend the belt dou ble to pr ovide an ea sy bend rad ius and to reduce the

risk of wear.

STOP WITH PNEUMATIC LIMIT SWITCH VALVE

Using the threaded end of the piston rod, adjust the position of the stop

so that the roller lifts 2-3 mm above the door plate when the cylinder is

pressurised. When not pressurised, the stop must prevent the door from

opening. The clearance between side of the door plate and the roller

must be 1-2 mm. Check that the pneumatic limit switch valve shuts off

Datafil:C:\FILES\MAKERDOC\AM-HBOK\HAND-

BOK\5625194e.r04

Ugåva nummer 4

562 51 94

4/8

Page 9

EXIT MANUAL

INSTALLATION INSTRUCTIONS

Horizontally opening motor-operated door, Door system 92A

Issued by: Anders Carlsson

the air flow before the roller has been lifted through a height of half its

diameter above the top of the doo r plate.

POSITIVE BREAK ELECTRIC SAFETY LIMIT SWITCH

•

Door closed.

bearing bush connector (10) so that the gap between it and the roller

on the switch is 2-3 mm when the switch is changi ng over. While

slowly closing the door, check that is less than 5 mm from the fully

closed position when the limit switch operates.

•

Door open. Bend the tongue on the bearing conn ector so that the

switch operates when the door pins have reached 8-10 mm past the

inner edge of the sterilizer chamber.

PNEUMATIC MOTOR

Fully close the door and then adjust the length of the

Datafil:C:\FILES\MAKERDOC\AM-HBOK\HAND-

BOK\5625194e.r04

Ugåva nummer 4

562 51 94

IEC 1010-2-41 spe cifies that the closing force of the door motor must

not exceed 150 N. Getinge's do or system complies with this requirement when the equipment is supplied.

Adjust the tension of the spring supporting the motor by bolt (21) so that

the valve interrupts the air supply to the motor if door travel is

obstructed.

NOTE: Too low a spring tension will cau se the door to stop un necessarily.

5/8

Page 10

EXIT MANUAL

INSTALLATION INSTRUCTIONS

Horizontally opening motor-operated door, Door system 92A

Issued by: Anders Carlsson

Dismantling

There are two alternatives:

I. When A < B on the assembled sterilizer.

II. When A > B and when only the chamber

is supplied.

ALTERNATIVE 1

Transportation locking device only

(Door beam not removed)

•

With the door cl osed, l ift i t wi thou t usi ng the supp ort bolt s (in orde r

not to upset the height adjustment), and insert transportation spacers

in two lugs on each side of the door.

•

Lower the door so that it rests on the spacers, and check that the door

support system no longer carries its weight. Bolt the transport bar to

the side of the door.

•

Remove the toothed belt at the motor end and remove the motor unit

(19) by removing bolts (20).

•

Refit the toothed belt and the securing bolts ( 20).

•

Pack the motor unit with desiccant in a sealed plastic bag.

A

B

Datafil:C:\FILES\MAKERDOC\AM-HBOK\HAND-

BOK\5625194e.r04

Ugåva nummer 4

562 51 94

ALTERNATIVE II

With the door beam removed

•

Secure the door for transport as described in Alternative I above.

•

Remove any support pole if fitted.

TYPE A

Aluminium door hangers

•

Remove a circlip (31) and extract the locking pin (32).

•

Remove the bolts that hold the beam.

6/8

Page 11

EXIT MANUAL

INSTALLATION INSTRUCTIONS

Horizontally opening motor-operated door, Door system 92A

Issued by: Anders Carlsson

•

Lift away the beam and bar, the door hangers, the ball bushings and

the bearing connector with drive belt as one unit, and pack them as a

unit.

Do not alter the settings of the support bolts.

•

Refit the locking pins, circlips and bolts in position.

TYPE B

Stainless steel door hangers

•

Remove the bolts between the hangers and the bearing housing and

between the beam and its supports.

REFITTING

•

Lift away the beam and bar, the bearing housing with ball bushings

and the bearing connector with drive belt as one unit, and pack them

as a unit.

Do not alter the settings of the support bolts.

•

Strap the hangers to a board or pallet and refit the bolts in position.

ALTERNATIVE I

With transport braces only

(Door beam not fitted)

•

Remove the transport brace on the side of the door.

•

Lift the door, without using the support bolts (in order not to upset

the height adjustment), and remove the transportation spacers.

•

Lower the door.

Datafil:C:\FILES\MAKERDOC\AM-HBOK\HAND-

BOK\5625194e.r04

Ugåva nummer 4

562 51 94

•

Check the height setting of the door. If it is correct, the ad justment

bolts should meet the pins on their centre lines.

•

Remove the toothed drive belt at the motor end and fit the motor unit

by means of bolts (20). See the drawing on page 3 for positioning.

•

Fit the toothed drive belt with some slackness, so that the motor can

overcome its starting friction before it has to move the door.

7/8

Page 12

EXIT MANUAL

INSTALLATION INSTRUCTIONS

Horizontally opening motor-operated door, Door system 92A

Issued by: Anders Carlsson

ALTERNATIVE II

With the door beam removed

TYPE A

Aluminium door hangers

•

Lift the beam unit (3 ) on to t he beam su pports (2 ) and mak e sure th at

the support bolts with the washer (33) under the bolt head locate in

the slits in the hangers.

•

Secure the beam and fit the locking pins (32) with the circlips in the

hangers.

•

Refit the support pole under the door beam, if used.

•

Carry out the operations described above under ALTERNATIVE I.

•

Check the fore-and-aft position of the door: see 'FORE-AND-AFT

ADJUSTMENT' on page 4

TYPE B

Stainless steel door hangers

•

Lift the beam unit (3) on to the beam supports (2) and bolt it fast.

Bolt the door ha ngers (7) to th e bearing hou sings (6). Make su re that

the upper mount of the door hangers is properly positioned against

the machined surface of the up per side of the bearing housing.

•

Refit the support pole under the door beam, if used.

•

Carry out the operations described above under ALTERNATIVE I.

•

Check the fore-and-aft position of the door: see 'FORE-AND-AFT

ADJUSTMENT' on page 4

Datafil:C:\FILES\MAKERDOC\AM-HBOK\HAND-

BOK\5625194e.r04

Ugåva nummer 4

562 51 94

8/8

Loading...

Loading...