Page 1

SERVICE

INSTRUCTIONS

Washer disinfector

Getinge 8666/8668

Mfg. no. SEV0320078-

5015108-00

Page 2

Page 3

Safety regulations

Technical data

Description

Software description and

settings

Preventive maintenance

Fault indications and

troubleshooting

Repair and adjustment

5015108-00 2004-03-01

We reserve the right to change without prior notice,

our design and material specifications

Service instruction

Getinge 8666/8668

Page 4

Page 5

Safety regulations

1

Service instructions

5015108-00Edition 0403

Safety regulations

CONTENTS

Safety regulations __________________________________________3

General safety regualtions __________________________________ 3

Product libaility __________________________________________ 3

Isolator switch ___________________________________________ 3

Attention symbols ________________________________________ 3

Page 6

Safety regulations

2

Service instructions

5015108-00 Edition 0403

Page 7

Safety regulations

3

Service instructions

5015108-00Edition 0403

Safety regulations

This machine is designed with a number of built-in safety devices. To avoid injury, it is highly

important not to bypass or disable these safety devices.

General safety regulations

• Take care when handling the chemical agent used in the machine. Read the details on the

container or contact the manufacturer:

- if agent comes into contact with the operator’s eyes or skin or if the vapours are breathed in, etc.

- about storing the agent and disposing of empty containers.

• The machine must be connected in accordance with the installation instructions.

• Only adults may operate the machine.

• Installation and service work must be done by personnel trained for this machine.

• Never bypass the door switch of the machine.

• Leakage in the system, due to a worn door seal for example, must be dealt with immediately.

• Before repair or service work is done, the personnel concerned must study the relevant

documentation and service manuals.

• Before welding begins on or close to the machine, all wiring connected by plugs and sockets

must be disconnected from all circuit boards in the machine.

• Do not hose down the machine with water.

• Take care when using corrosive detergent .

• Take care with hot water and steam.

• Run a process before starting servicing. If this is not possible, disinfect the machine with

disinfectant before starting servicing.

Product liability

Modifications to the equipment made without the approval of the manufacturer, or incorrect

use, invalidate the manufacturer’s product liability.

Isolating device

The machine must always be fitted with a separate isolating device in the power supply,

mounted in an easily accessible position on the wall.

Attention symbols

Some of the warnings, instructions and advice in this manual are so important that we used the

following special symbols to draw attention to them. The symbols and designs used are:

This symbol indicates a warning in the text of the manual. It warns of a hazard

that may lead to more or less severe injury and in certain cases mortal danger.

It also highlights warnings to avoid damage to equipment.

This symbol highlights a warning in the text of the manual dealing with the

handling of components sensitive to ESD. The hazard that is warns about may

result in damage to hardware and/or circuit boards.

Page 8

Page 9

Technical data

1

Service instructions

5015108-00Edition 0403

Technical data

Contents

Technical data______________________________________________3

Alternative connection arrangements ___________________________4

Page 10

Technical data

2

Service instructions

5015108-00 Edition 0403

Page 11

Technical data

3

Service instructions

5015108-00Edition 0403

Technical data

Weight incl. water

chamber depth 720 mm 385-525 kg

chamber depth 800 mm 385-525 kg

Width 1110 m m

Depth

chamber depth 720 mm 9 10 mm

chamber depth 800 mm 9 90 mm

Height 1870 m m

Environmental requirements:

Air humidity max 80% at 31 °C

Room temperature 5 - 40 ° C

Water consumption

chamber depth 720 mm ≥ 33 litres/phase

chamber depth 800 mm ≥ 40 litres/phase

Cold water

Connection 20 (3/4") mm

Pressure 100-800 kPa

Flow 30 l/min

Hot water

Temperature 45-60 °C

Connection 20 (3/4") mm

Pressure 100-800 kPa

Flow 30 l/min

Dist./de-ion. water

Connection 20 (3/4") mm

Pressure 100-800 kPa (if the pressure is below 50 kPa a

separate feed pump must be connected)

Flow 30 l/min

Condensate 15 (1/2") mm

Steam

Connection 15 (1/2") mm

Pressure 300-500 kPa

Consumption approx 1.0 kg/min at 300 kPa

Waste ø 50 (2") mm

Capacity 50 l/min

Evacuation air

Air quantity approx 350 m3/h

Electrical connection See Alternative connection

arrangements

Compressed air connection 4-8 bar

Max outside temperature 5 0 ° C

Sound level 60 dB (A)

Page 12

Technical data

4

Service instructions

5015108-00 Edition 0403

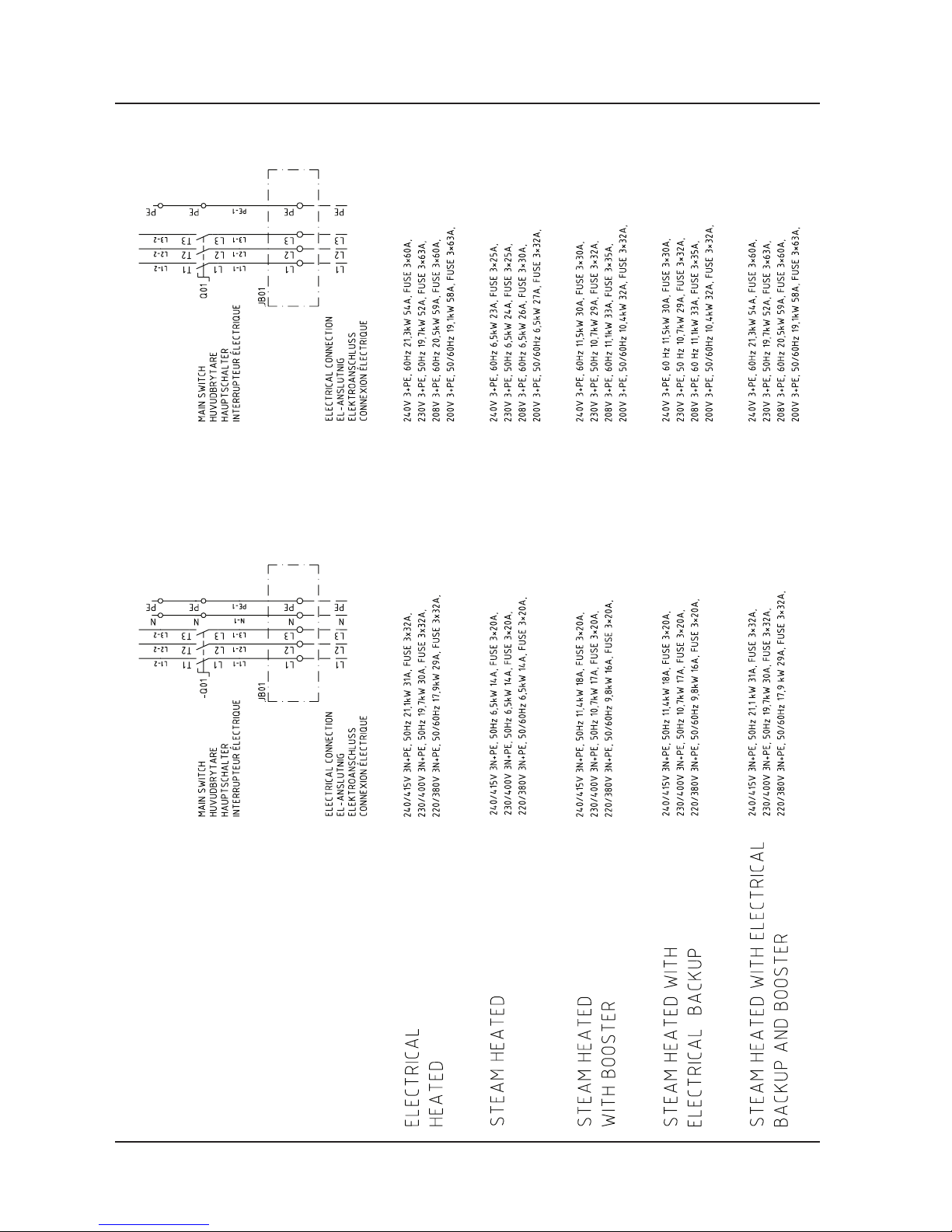

Alternative connection arrangements

Page 13

Description

1

Service instructions

5015108-00Edition 0403

Description

Contents

General ___________________________________________________ 3

Schematic diagram _________________________________________ 4

Electric heating ___________________________________________ 4

Steam heating ____________________________________________ 4

Steam and electric heating __________________________________ 5

Explanation of symbols _____________________________________5

Safe and simple ____________________________________________ 6

Simple service and installation ________________________________ 6

Door operation _____________________________________________ 6

Manually-operated door ____________________________________ 6

Automatically-operated door ________________________________ 7

Dosing system _____________________________________________ 7

Drying ___________________________________________________ 8

Programs _________________________________________________ 9

Abort at start of process ___________________________________ 10

Aborting an ongoing process ______________________________ 10

Fast-stepping a program ___________________________________ 11

Page 14

Page 15

Description

3

Service instructions

5015108-00Edition 0403

General

The machine is a fully-automatic washer disinfector for cleaning and disinfecting goods in

hospitals, laboratories and the pharmaceutical industry.

The machine has two washing vanes and two dockings and can be equipped with several

different accessories for different cleaning requirements. These accessories are presented in a

special accessories catalogue.

There are several possible ways of installing and equipping the machine depending on its field

of application:

• Heating by electricity or steam.

• Connection of distilled or de-ionised water.

• Electrically-heated or steam-heated booster tank for the last rinse water.

• Integral drying system.

• Single or double door.

• Extra dosing pump which allows chemical disinfection of heat-sensitive goods.

• Infeeder/outfeeder

• Automatic program selection (basket indication)

• Audible signal on process complete, fault code, etc.

The washer-disinfector has been tested and approved in accordance with SPRI and BGA

recommendations.

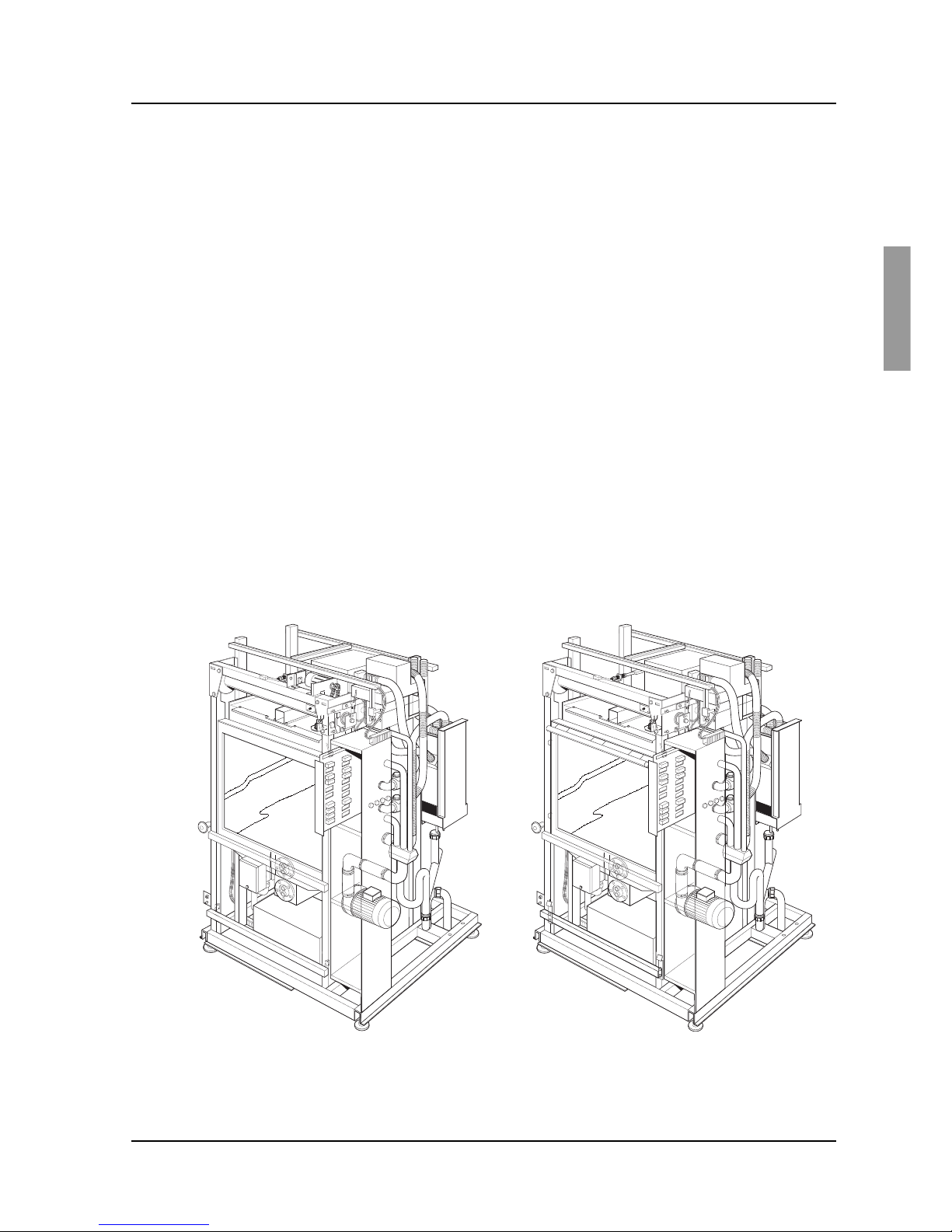

V1452

V1297

Washer-disinfector with manual doorWasher-disinfector with automatic door

Page 16

Description

4

Service instructions

5015108-00 Edition 0403

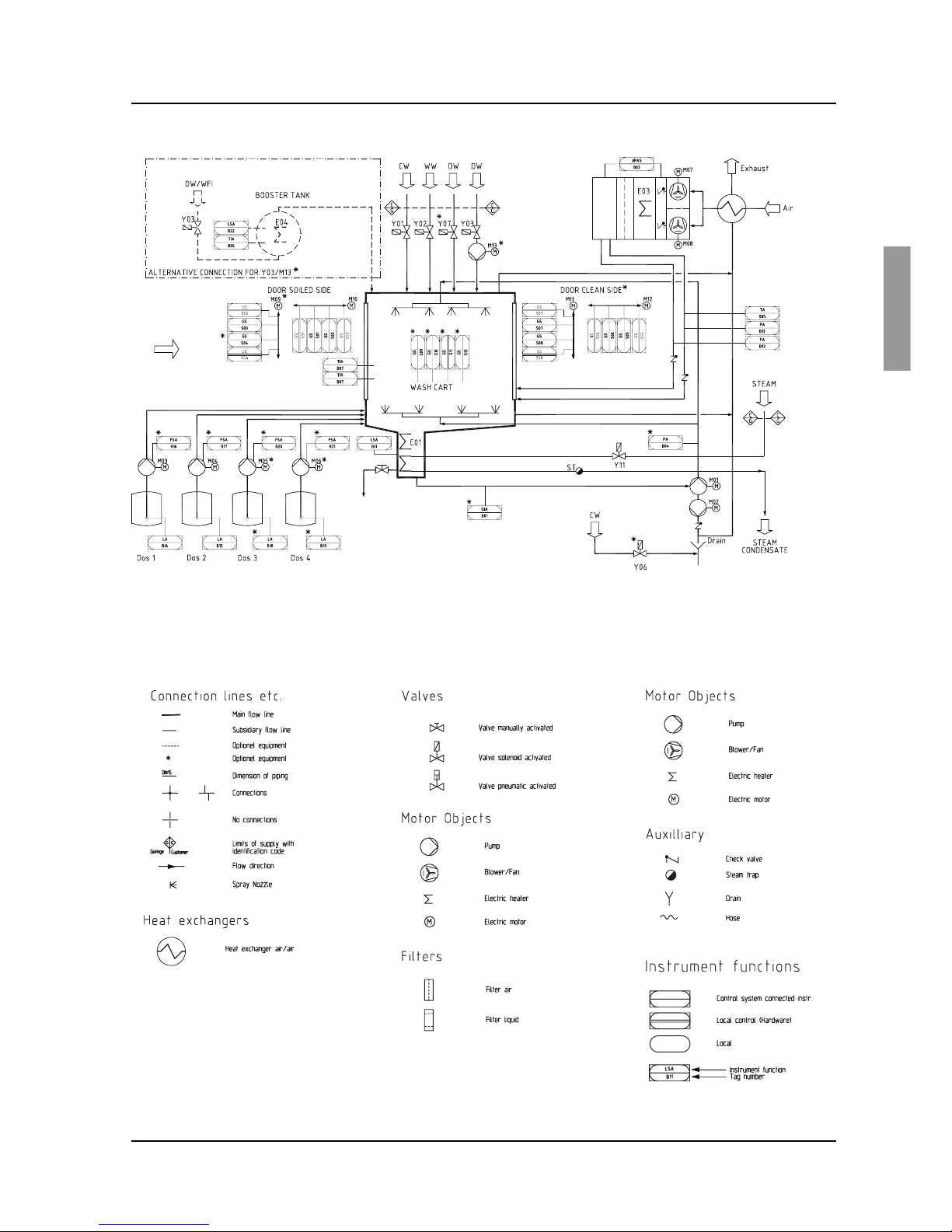

V1434

Schematic diagram

Electric heating

Steam heating

V1433

Page 17

Description

5

Service instructions

5015108-00Edition 0403

Steam and electric heating

Explanation of symbols

V1559

V1560

Page 18

Description

6

Service instructions

5015108-00 Edition 0403

Safe and simple

The disinfector is controlled by a microprocessor. This has several advantages:

• the built-in service program makes troubleshooting and servicing far easier

• safety and reliability can be kept high by continuous monitoring of the process

• the dosing of detergent, the temperature and the disinfection time can all be altered with

great precision to suit different conditions.

The programs can be adapted precisely to suit the needs of each user. Existing programs can be

re-programmed via a PC. As standard, the washer-disinfector has two to six programs.

The door and wash chamber are well insulated, so that the washer-desinfector is energyefficient and silent in operation.

Operation is simple and the control buttons and few and clearly marked.

Programming may only be done by authorised personnel.

Simple service and installation

Valves and electrical equipment are easily accessible from the front for inspection and service.

Door function

The washer-disinfector can be fitted with a single door or double doors. All doors are of the

vertical sliding type.

The doors can be motorised for automatic opening and closing. The doors have efficient anticrush protection.

Machines with double doors have a system of interlocks to ensure that only one door can be

opened at a time. This means that the clean-side door must be closed and locked by pressing

the W button before the dirty-side door can be opened.

When V is pressed, the door is locked and a yellow lamp flashes (process running) for about

10 seconds. If V is pressed again during this “cancel time”, the dirty-side door is unlocked and

the door can be opened manually or alternatively it opens automatically.

The doors can be locked an unlocked individually from the service program (authorisation required).

Manually-operated door

When the door is closed manually and V is pressed, the door is clocked automatically, the

yellow lamp flashes and the program starts.

When the program is complete, a green lamp lights up on both sides (if there are double doors)

and the clean-side door is unlocked. When the door has been opened manually, the green lamp

goes out. With double doors, the clean-side door must be closed manually and locked by

pressing the W button before the dirty-side door can be unlocked.

A manually-closed door can be opened by pressing the U button for about five seconds. Press

U to unlock the door.

Page 19

Description

7

Service instructions

5015108-00Edition 0403

Automatically-operated door

WhenVis pressed, the door is locked, the yellow lamp flashes and the program starts.

When the program is complete, a green lamp lights up on both sides (if there are double doors)

and the clean-side door opens automatically. When the door is fully open the green lamp goes

out on both sides. With double doors, the clean-side door must be closed and locked by

pressing the W button before the dirty-side door opens automatically.

An automatically-operated door can be closed on the dirty side without starting a process.

Press and hold U for about five seconds. The door is closed and locked automatically. Press U

to unlock the door.

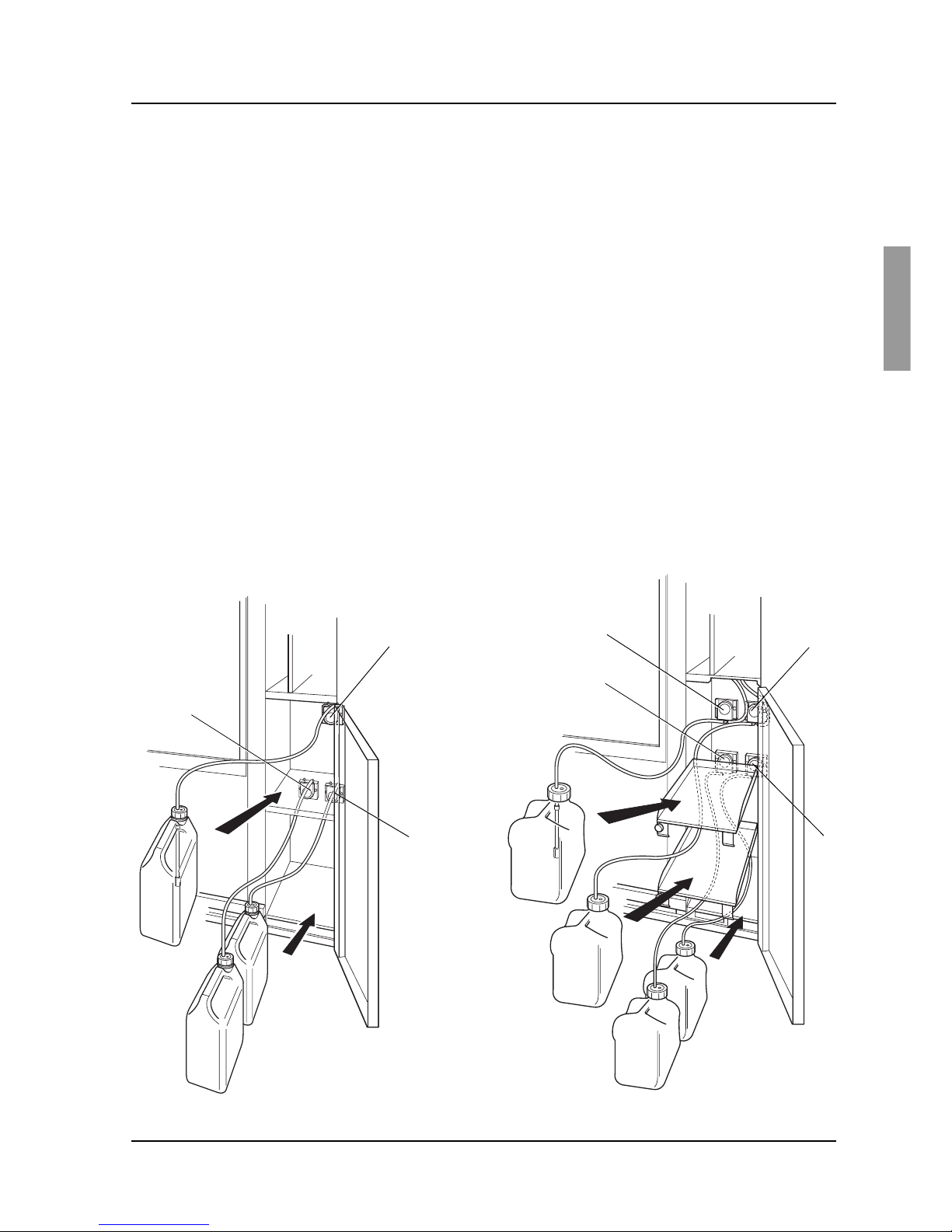

Dosing system

In standard form, the machine has two different dosing systems. One is for alkaline detergent and

one is for rinse-aid or acid detergent. The dosing amount can be set individually for each program.

The machine cannot be started until detergent has been dispensed. If the detergent holder is

empty “DOS 1-4 Low level” appears on the display.

A third and a fourth dosing system for heat-sensitive goods or instrument milk, for example, can

be installed.

Dosing pumps for:

1 Alkaline detergent

2 Rinse-aid or neutralisation

3 Instrument milk or enzyme agent (option)

4 Chemical disinfection (option)

V1313

1

2

4

3

1

2

3

V1576

Chamber depth 720 mm Chamber depth 800 mm

Page 20

Description

8

Service instructions

5015108-00 Edition 0403

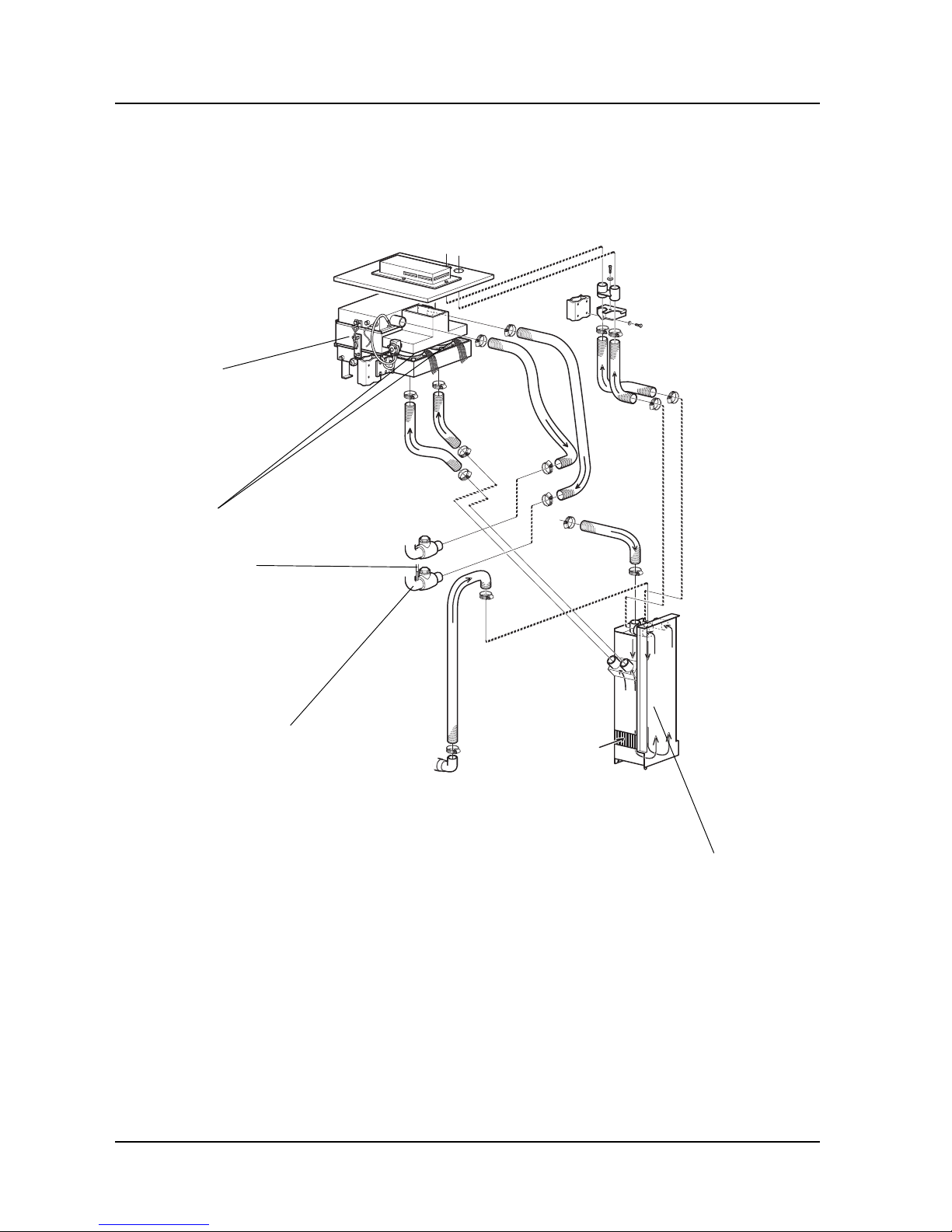

Drying

The machine is equipped with a drying system as standard.

V1293

Heat exchangers

Non-return valve

Filter(s)

Fans

Hose for

connection to

pressure switch

Page 21

Description

9

Service instructions

5015108-00Edition 0403

Program

The machine has an electronically programmable control system which can hold up to 10-15

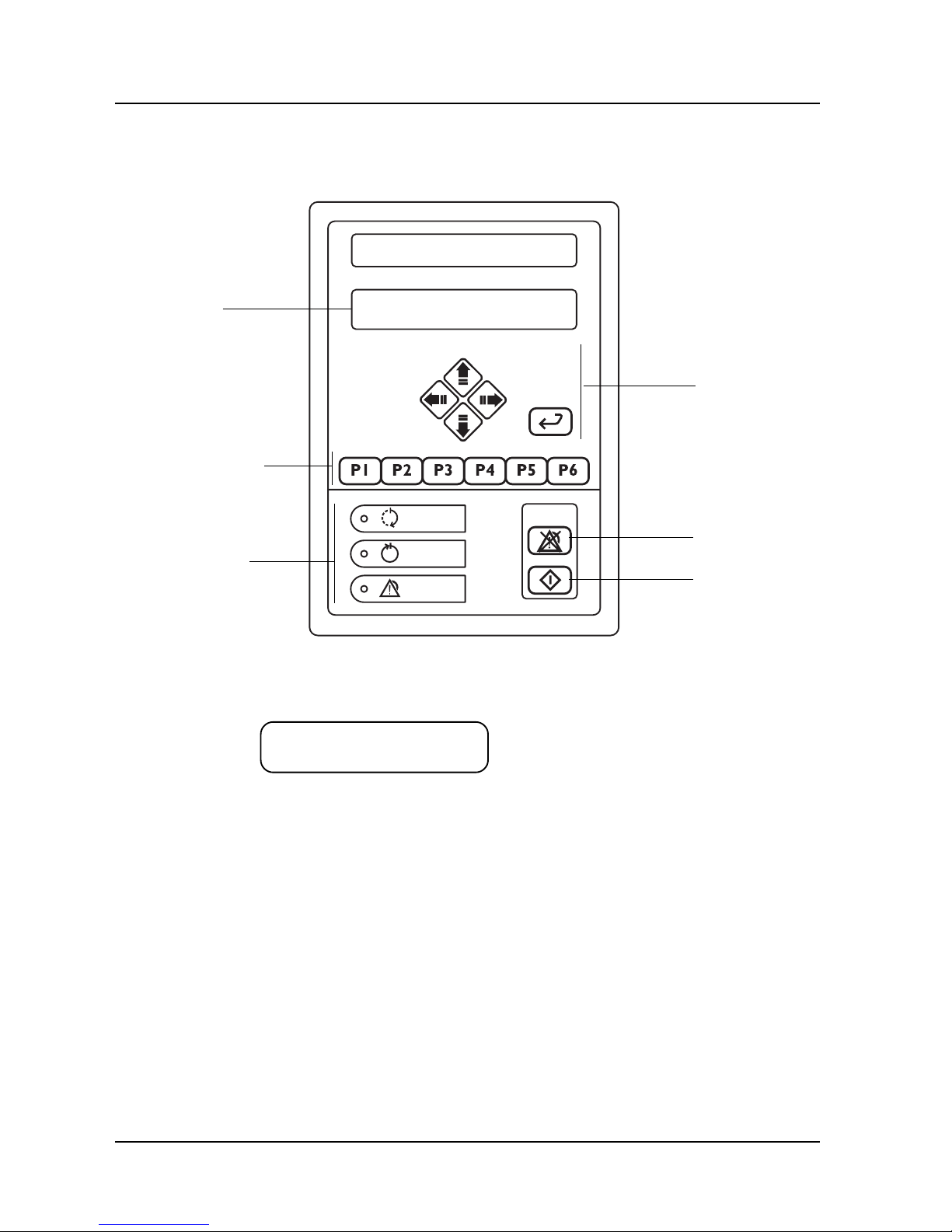

programs. Six of these programs can be started with the program selection buttons. With 1-6

you can choose up to six programs. If the control system has more programs, the subsequent

ones are chosen from a scrollable list. You can reach the list of available programs by pressing

S twice, then choosing a program with J or H. Confirm the chosen program with S .

The machine comes with a number of standard programs in the programmer (see the appendix

for Standard programs). Parameters in these programs can be modified to suit the needs of

individual users. Individual programs can be created with a PC. An entire standard program or

parts of one can be used as a starting point for programming.

P01 OP-D

60.0C 100

Programming buttons

(see Software description

and settings)

Start wash program

Program selection buttons

V1363

Resets alarm

Green: Process complete

Yellow: Process running

Red: Fault code

Programming may only be done by an authorised service technician.

Programs are chosen with the program selection buttons and the process is started with V (starting

of a process is indicated by the yellow lamp at M flashing for ten seconds and then going out).

When the process is complete, the green lamp at N lights up and the door can be opened

manually (on a machine with manual door). With an automatic door, the door opens

automatically when the process is complete.

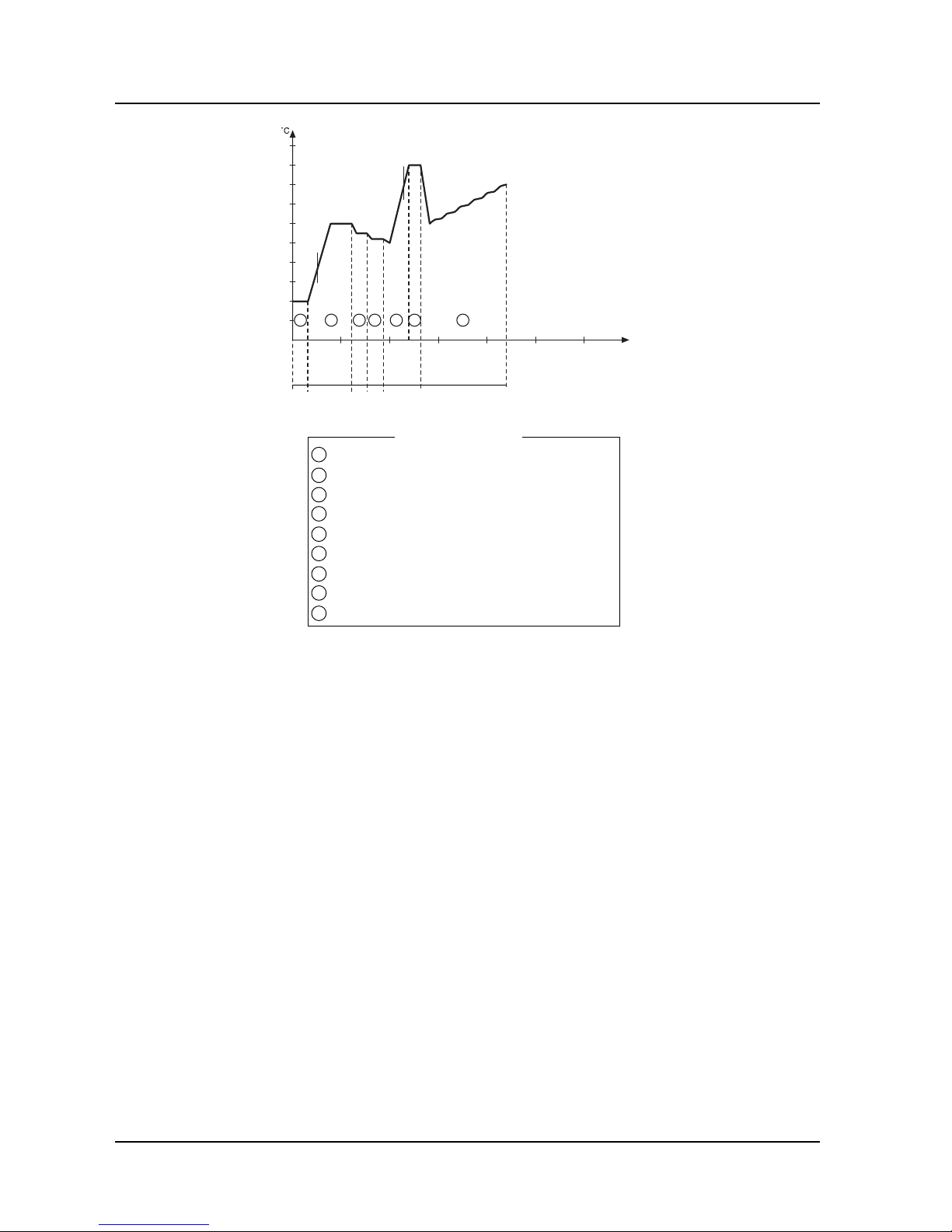

The illustration on the next page shows the program sequence in the OP-D program.

Page 22

Description

10

Service instructions

5015108-00 Edition 0403

V1513

1 Pre-rinse 1

2 Pre-rinse 2

3 Wash

4 Neutralize

5 Post-rinse 1

6 Post-rinse 2

7 Final rinse

8 Disinfection

9 Drying

Program phases

A Alkaline detergent

B Neutralisation

C Instrument milk (extra

equipment)

If instrument milk is

does, neutralisation is

not dosed.

Abort at start of process

A started program can be aborted within ten seconds of the door locking. To abort a started

process, press V. During the period when the program can be aborted, a yellow lamp flashes at

M. The door is unlocked and opened automatically and the machine can be restarted in the

usual way.

Aborting an ongoing process

During a process, the machine can be stopped with the main switch. If the power is switched on

within 60 seconds, the program continues until the end. If the power is switched on after more

than 60 seconds, error code F00 POWER FAIL is displayed. Press U to silence the alarm

signal. Pressing U again drains liquid from the machine and the dirty side door goes down.

90

80

70

60

50

40

30

20

10

100

10 20 30 40 50 60 min

5

CW HW HW

(DW

option)

A

B

9

3 861

HWCW+HW

7

(C)

Page 23

Description

11

Service instructions

5015108-00Edition 0403

Fast-stepping a program

All safety functions are disabled for fast stepping.

Fast stepping must only be used during servicing.

Never stop fast stepping in a heating phase. If you do, the machine may

be damaged.

An ongoing program can be fast-stepped phase by phase. Fast stepping can be chosen during

an ongoing process.

1. Fast stepping is chosen in the service program; see tab 5 Software description and setting,

under DIP switches display (1.4.2.4).

2. Set DS02 STEP in STATUS to 1 and press S . Exit the service program.

3. Fast-step with U.

4. Reset DS02 STEP STATUS to 0 and press S . Exit the service program.

Reset DS02 STEP STATUS to 0 after completion of fast stepping.

Page 24

Page 25

Software description and settings 1

Service instructions

5015108-00Edition 0403

Contents

Description ________________________________________________ 3

Control panel ______________________________________________ 4

Display _________________________________________________ 4

Program selection buttons __________________________________ 4

Menu tree navigation buttons _______________________________ 5

Scroll in menus and lists _____________________________________ 5

Field editing _______________________________________________ 5

Password _________________________________________________ 6

Operator ________________________________________________6

Parameter ________________________________________________ 6

Supervisor _______________________________________________ 6

Service _________________________________________________ 7

Programming _____________________________________________ 7

Software description and settings

Menu tree ___________________________________________ Appendix

Page 26

Page 27

Software description and settings 3

Service instructions

5015108-00Edition 0403

Description

This section describes the PACS 300 control and monitoring system. PACS 300 is an electronic

system that is used to control the various functions of the washer-disinfector. The letters

PACS stand for Programmable Autoclave Control System.

The purpose of the control system is to issue orders and send them to the executive

components of the washer-disinfector so that a number of process steps can be performed in

accordance with a predetermined template. The order signals are worked out by the computer

program of the control unit in conjunction with measurements of actual parameter values for the

current program. These are usually times, temperatures and pressures.

Several different pieces of equipment can be connected to the control unit for programming,

monitoring and documenting the disinfection processes.

The operator communicates with the control unit via a control panel or an ordinary PC.

All operator panels can be used to monitor the processes, since they display all the set

parameter values as well as actual values on request. All relevant data associated with a given

process, such as batch number, operator number, date, etc., can be entered by the operator.

Programs, system definitions and process data can be documented by connecting a printer to

the unit. A host computer can also be connected directly to the CPU of the control system.

When the need arises, a measuring and monitoring system entirely independent of the control

system, can be set up by connecting a PACS SUPERVISOR system, consisting of CPU,

operator panel and connections to the control unit CPU. The measurements of the

SUPERVISOR are made by its own separate temperature and pressure sensors.

The computer contains programs for automatic calibration of the temperature and pressure

sensors. Where alternative correction constants are known, they can be entered manually. The

testing functions include means of activating analog and digital outputs and for monitoring

analog and digital inputs.

Page 28

Software description and settings4

Service instructions

5015108-00 Edition 0403

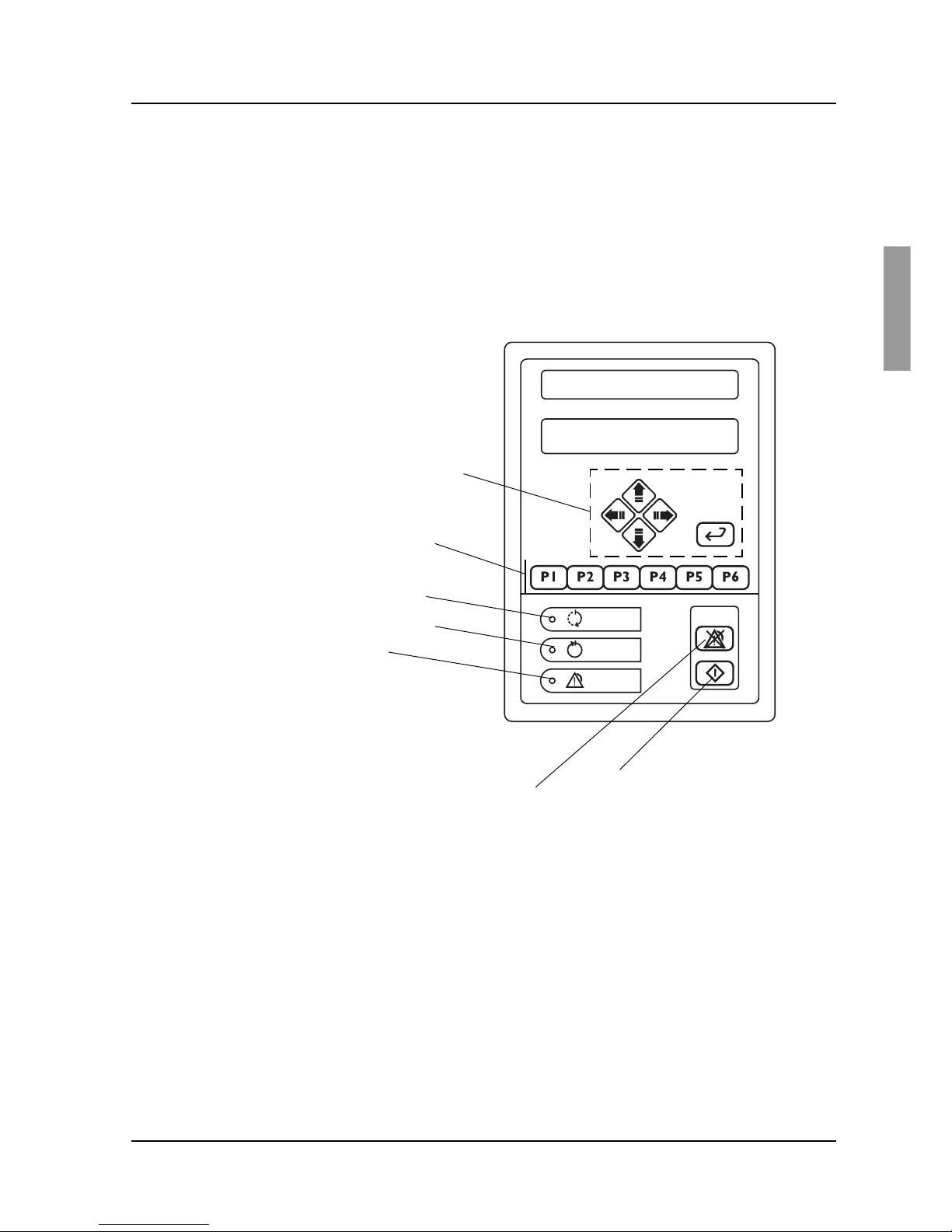

The control panel

The buttons on the control panel are used to choose programs, navigate the menu tree,

acknowledge error codes, etc.

Buttons for

menu tree

navigation

Program selection

buttons

V1363

Acknowledgement

of error

message

Start wash

program

Display

Display

The screen has two lines, each with a capacity 20 characters.

P01 OP-SHORT-D

47.0 °C

Information or error messages appear on the bottom line and replace the text that would

otherwise appear here.

Program selection buttons

With 1-6 you can choose up to six programs. If the control system has more programs, the

subsequent ones are chosen from a scrollable list. You can reach the list of available programs

(from standby mode), by pressing S twice and choosing a program with J or H. Confirm

the chosen program with S .

Indicator lamps

Page 29

Software description and settings 5

Service instructions

5015108-00Edition 0403

>PRINT LAST CYCLE

SYSTEM V

>SYSTEM ^

ABOUT

SYSTEM ^

>ABOUT

The angle bracket “>” to the left of the top line shows which object will be chosen if you press

S. Bottom right there is a “v” indicating that there are more objects in the list which are

displayed if you press J.

This is what you see if you are in a list. The “arrows” to the right show that there are objects

both above and below the displayed line.

When you reach the end of the object list, only one up-arrow appears at the right edge of the

displayed. Menus and lists are “endless”; you can reach the top of the list by pressing J at

the end of the list.

Buttons for menu tree navigation

The are five buttons for navigating the panel. These fixed buttons are four arrow buttons that

control the cursor (I, K, J and H) and S.

I Used to go back one step (up one level) in menus. If the button is held down for a little

longer, you are returned to the main menu.

K Not used in menus and lists.

J Shows the next object in the list.

H Shows the previous object in the list.

S Goes to the chosen object in the list or opens a field for editing if there is an editable field.

Scroll in menus and lists

You can use I, K, J and H to scroll through menus and lists. You can scroll either line

by line or two lines at a time, depending on what is displayed. The top line of the list may look

like the example below.

Field editing

S opens the chosen field for editing. The content of the field is changed with H or J.

These arrow keys scroll in an endless list containing numbers. When a field is opened for

editing, the first character is highlighted. To move the cursor use I or K.

Entered values are saved when you press S. On saving, the system checks that the value is in

the permitted range.

Page 30

Software description and settings6

Service instructions

5015108-00 Edition 0403

Passwords

There are five passwords with different levels of authorisation in the system program. The

operator password has the lowest authority; the programming password has full authority.

The following password levels are as follows:

• Operator – code 558387.

• Parameter – contact service for code.

• Supervisor – contact service for code.

• Service – contact service for code.

• Programming – contact service for code.

NOTE: In the menu tree where the password must be entered there is a letter

code (between PW: A-K) which refers to the function for which the relevant

password is authorised.

When a password is entered, the top line shows “ENTER PASSWORD”. Press S to open the

entry field for editing . Each number can be changed with J and H. I and K toggle

between the numbers. Press S to confirm the entered password.

If the wrong password is entered, “WRONG PASSWORD” appears on the first line. Press S to

return to the display showing “ENTER PASSWORD”

NOTE: The password cannot be changed.

Operator

Code in Authority to change

menu tree

A Parameters of type A and to see parameters of type I.

Parameters

Code in Authority to change

menu tree

A Parameters of type A and to see parameters of type I.

H Process-critical configurations, parameters of type P.

Supervisor

Code in Authority to change

menu tree

A Parameters:

B Calendar (time and date)

H Process-critical configurations, parameters of type P.

J Password configuration

K Documentation

Page 31

Software description and settings 7

Service instructions

5015108-00Edition 0403

Service

Code in Authority to change

menu tree

A Parameters:

B Calendar (time and date)

C Sensor calibration

E Service messages

F DIP switches

G Non-critical system configurations.

H Process-critical configurations, parameters of type P.

J Password configuration

K Documentation

Programming

Code in Authority to change

menu tree

A Parameters:

B Calendar (time and date)

C Sensor calibration

E Service messages

F DIP switches

G Non-critical system configurations.

H Process-critical configurations, parameters of type P.

I Programming (phases and programs)

J Password configuration

K Documentation

Page 32

Preventive maintenance

1

Service instructions

5015108-00Edition 0403

Preventive maintenance

Contents

General ___________________________________________________ 3

Periodic maintenance _______________________________________ 3

Function check _____________________________________________ 4

Instructions, cable, switch __________________________________ 4

Filter and valves __________________________________________ 4

Controls ________________________________________________ 4

Insert for goods __________________________________________ 4

Door ___________________________________________________ 5

Detergent dosing _________________________________________ 5

Washing system __________________________________________ 5

Temperature control _______________________________________ 5

Dryer ___________________________________________________ 5

Printer (extra equipment) ____________________________________ 5

Page 33

Page 34

Preventive maintenance

3

Service instructions

5015108-00Edition 0403

General

The required maintenance interval will depend largely on the quality of the incoming water and

how often the machine is used. The maintenance will have to be determined in each individual

case. We recommend that the stated maintenance operations are done at the specified intervals.

We also recommend that a function check is done once or twice a year.

For repairs or adjustments, see under Repair and adjustment.

Periodic maintenance

This may only be done by authorised personnel.

The machine is connected to the electricity supply and some components are live.

Component Interval

Check Replace if Replace

Replace every

Replace

yearly necessary every year other year 1000 hours

Door seal ••

Hoses between •l

dosing pump and

detergent container

Hose between dosing ••

pump and machine

Filter in incoming ••

media

Overheat protection ••

Hose in hose pump ••

Spray arm wings ••

Sterile filter in dryer ••

Hoses to dryer ••

Non-return valve in dryer ••

Check valve in waste outlet ••

Fan to dryer ••

Ink ribbon for printer ••

Manual door: Spring •

on door closing

Automatic door: Crush •

protection on door closing

Page 35

Preventive maintenance

4

Service instructions

5015108-00 Edition 0403

Function check

This must only be done by authorised personnel.

The machine is connected to the electricity supply and some components are live.

Instructions, cable, switch

• Check that a goods placing sign has been put up on the wall behind the disinfector.

• Check that the isolator switch on the wall is working and that the connecting cable is

undamaged and free from defects.

Filter and valves

• Check that level switches and manual shutoff valves are working properly.

• Check the filters in the supply line (see under Cleaning the filters in the supply line). Clean

when necessary.

• Check all pipe couplings. Tighten and seal if necessary.

Controls

• The machine is operated with the buttons on the control panel.

• Check that the control buttons are working. If the buttons are working, a beep will be heard.

• While a program is running check that the yellow lamp at M is lit. When the program is

complete, the green lamp at N should light up.

Insert for goods

• Check that the inserts for the machine dock properly with the water outlets.

• Check that washing arms (if fitted) rotate and are not clogged.

• Check that the goods to be cleaned are retained in the insert.

V190

Container alarm

Page 36

Preventive maintenance

5

Service instructions

5015108-00Edition 0403

Door

Check that the door seal closes tight and is undamaged and that there is no leakage while a

program is running. Clean or replace the seal if necessary.

Detergent dosing

Check that the suction hose and pump are full of detergent or rinse-aid before running a

program. When the pre-programmed amount of detergent is changed, the consumption must be

checked with a measuring glass.

Washing system

All supply lines must be closed when working on the pipe system.

• Check that the washing arms can rotate freely.

• Check that the holes in the washing arms are not blocked. Clean when necessary.

• Check that the coarse strainer in the bottom of the washing chamber is correctly installed.

Clean when necessary.

• Check that all couplings connecting the washing system to the pump and chamber are

leaktight. Tighten and seal if necessary.

Temperature check

• Check the temperature during a program run. Compare time and temperature with the program

sheet. Time and temperature are especially important in the disinfection phase.

The measuring equipment must be capable of registering temperature and time continuously.

High-performance equipment is essential for reliable measuring results, because of the

relatively rapid temperature changes.

Only one measuring point in the centre of the machine is need for the function check.

Note:

Washer-disinfectors that have been shown not to meet the requirements in terms

of temperature, sequence, washing system and safety must not be used until the

faults have been corrected.

Dryer

• Check seals and hoses for leaks once a year.

• Replace the sterile filter if necessary or in the event of an alarm.

Printer (extra equipment)

• Check ink ribbon cartridge

• Check the printout quality.

Page 37

Page 38

Fault indications and troubleshooting

1

Service instructions

5015108-00Edition 0403

Fault indications and troubleshooting

Contents

Fault indications ___________________________________________ 3

A red lamp lights up _______________________________________ 3

Messages _______________________________________________ 3

Fault codes ______________________________________________ 4

Acknowledging a fault code _________________________________ 4

Troubleshooting ____________________________________________ 5

Page 39

Page 40

Fault indications and troubleshooting

3

Service instructions

5015108-00Edition 0403

Fault indications

Messages appear in plain text on the display. The machine cannot be started until the fault has

been put right. The following messages can be displayed:

Dose 1 low level Empty container alarm 1: if detergent 1 is finished, an operation code is

generated. The alarm is reset automatically when the container is refilled.

Dose 2 low level Empty container alarm 2: if detergent 2 is finished, an operation code is

generated. The alarm is reset automatically when the container is refilled.

Dose 3 low level Empty container alarm 3. If detergent 3 is finished, an operation

code is generated. The alarm is reset automatically when detergent is added.

Dose 4 low level Empty container alarm 4. If detergent 4 is finished, an operation code is generated.

code is generated. The alarm is reset automatically when detergent is added.

Note:

The last process had access to detergent. A message is displayed for future processes.

Red lamp: Disinfection

not achieved

Fault message or

fault code

V1363

P02 OP-D

DOSE 1 LOW LEVEL

P01

Add detergent 1

A red lamp lights up

If the red lamp at O lights up, the process has been aborted because of a fault. Call service

personnel.

Messages

Page 41

Fault indications and troubleshooting

4

Service instructions

5015108-00 Edition 0403

P02 OP-D

F00 POWER FAIL

Error codes

Fault codes indicate that a serious fault has occurred in the washing process. The fault must be

put right by an authorised service technician.

Acknowledging a fault code

Reset the fault code by:

1. pressing U. The alarm signal is silenced.

2. correcting the fault.

3. The machine is still locked but the current process has been aborted. Pressing U again

drains liquid from the machine and the dirty side door goes down.

Note:

If the draining pump is faulty, the water is not drained from the machine.

NOTE:

The goods in the machine are not clean. Start a new process.

Page 42

Fault indications and troubleshooting

5

Service instructions

5015108-00Edition 0403

Troubleshooting

The table below describes the fault codes that may be generated and a possible action for each

fault code.

This may only be done by authorised personnel.

The machine is connected to the electricity supply and some components are live.

Fault code Fault Comment

F00 Power failure If the power failure lasts for more than 59 seconds, the process is aborted. The

fault code is generated when the power returns.

F01 The motor cutout has tripped. The motor cutout (–F01) for the circulation pump has tripped.

Possible action:

a. Check that there is power on all phases from the circulation pump.

b. Check that the motor cutout is correctly set (see electrical diagram).

c. Check that the pump impeller rotates easily.

d. Check the direction of rotation (see installation instructions).

F02 Water filling too slow. The water level sensor (-B11) is not activated within ten minutes of filling starting.

Possible action:

a. Check that the shutoff valves are open and that water is reaching the machine.

b. Check that the solenoid valves open and that their filters are not clogged.

F03 Emptying time too long Emptying takes longer than five minutes or the water level sensor (-B11) is still

activated when the emptying phase is complete.

Possible action:

a. Check that the waste pump pumps out water.

b. Check that the pressure switch changes over.

c. Check that the solenoid valve closes (water does not leak in).

F04 Water leakage in the dryer Switch to water level sensors (-B12, -B13) open.

Possible action:

a. Check that the check valves to the dryin connection close.

F05 Fault door, dirty side Door does not lock (-S02) within 10 seconds or opens while a program is running.

Possible action:

a. Check whether the microswitch (-S02) for the “door locked” limit position has

been activated within 10 seconds on door locking.

b. Check that the motor (-M10) and the switch (-S52) for door locking are working.

Page 43

Fault indications and troubleshooting

6

Service instructions

5015108-00 Edition 0403

Fault code Fault Comment

F06 Fault door, dirty side The door does not unlock (-S01) within 10 seconds.

Possible action:

a. Check whether the microswitch (-S01) for the “door open” limit position has

been activated within 10 seconds on door unlocking.

b. Check that the motor (-M10) and the switch (-S51) for door unlocking are working.

F07 Fault door, dirty side Door does not lock (-S03) within 20 seconds or opens while a program is

running. (Machine with automatic door only.)

Possible action:

a. Check that nothing is trapped in the door.

b. Check whether the microswitch (-S03) for closed door limit position has been

activated for 20 seconds.

c. Check that the motor (-M09) and the switch (-S53) for door locking are working.

d. Check the chain.

F08 Fault door, dirty side The door does not open (-S04) within 20 seconds. (Machine with automatic door only.)

Possible action:

a. Check that nothing is trapped in the door.

b. Check whether the microswitch (-S04) for closed door limit position has been

activated for 20 seconds.

c. Check that the motor (-M09) and the switch (-S54) for door opening are working.

d. Check the chain.

F09 Faulty door, clean side Door does not lock (-S05) within 10 seconds or opens while a program is running.

Possible action:

a. Check whether the microswitch (-S05) for the “door locked” limit position has

been activated within 10 seconds on door locking.

b. Check that the motor (-M12) and the switch (-S55) for door locking are working.

F10 Faulty door, clean side The door does not unlock (-S06) within 10 seconds.

Possible action:

a. Check whether the microswitch (-S06) for the “door open” limit position has

been activated within 10 seconds on door unlocking.

b. Check that the motor (-M12) and the switch (-S56) for door unlocking are working.

F11 Faulty door, clean side Door does not lock (-S07) within 20 seconds or opens while a program is

running. (Machine with automatic door only.)

Possible action:

a. Check that nothing is trapped in the door.

b. Check whether the microswitch (-S07) for closed door limit position has been

activated for 20 seconds.

c. Check that the motor (-M11) and the switch (-S57) for door locking are working.

d. Check the chain.

Page 44

Fault indications and troubleshooting

7

Service instructions

5015108-00Edition 0403

Fault code Fault Comment

F12 Faulty door, clean side The door does not open (-S08) within 20 seconds. (Machine with automatic door only.)

Possible action:

a. Check that nothing is trapped in the door.

b. Check whether the microswitch (-S08) for closed door limit position has been

activated for 20 seconds.

c. Check that the motor (-M11) and the switch (-S58) for door opening are working.

d. Check the chain.

F15 Flowmeter, dosing 1 Not enough detergent 1 dosed (-B16).

Possible action:

a. Check operation of the dosing pump.

b. Check that there is detergent in the container.

c. Check whether an empty container alarm has occurred.

d. Check that there is no air in the flowmeter and that it is rotating.

e. Check that the hoses are not blocked.

F16 Flowmeter, dosing 2 Not enough detergent 2 dosed (-B17)

Possible action:

a. Check operation of the dosing pump.

b. Check that there is detergent in the container.

c. Check whether an empty container alarm has occurred.

d. Check that there is no air in the flowmeter and that it is rotating.

e. Check that the hoses are not blocked.

F19 Flowmeter, dosing 3 Not enough detergent 3 dosed (-B20)

Possible action:

a. Check operation of the dosing pump.

b. Check that there is detergent in the container.

c. Check whether an empty container alarm has occurred.

d. Check that there is no air in the flowmeter and that it is rotating.

e. Check that the hoses are not blocked.

F20 Flowmeter, dosing 4 Not enough detergent 4 dosed (-B21)

Possible action:

a. Check operation of the dosing pump.

b. Check that there is detergent in the container.

c. Check whether an empty container alarm has occurred.

d. Check that there is no air in the flowmeter and that it is rotating.

e. Check that the hoses are not blocked.

Page 45

Fault indications and troubleshooting

8

Service instructions

5015108-00 Edition 0403

Fault code Fault Comment

F21 Booster tank slow to fill If filling (-B11) takes longer than 10 minutes, a fault code is generated.

Possible action:

a. Check that the shutoff valves are open and that water is reaching the machine.

b. Check that the solenoid valves open and that their filters are not clogged.

F23 High conductivity The conductivity (-U01) is higher than the set value after the third repeat rinse.

Possible action:

a. Check that the correct type of water is connected.

F24 Low pressure in dryer The differential pressure (-B03) is <150 Pa .

Possible action:

a. Check whether the fan, hoses or filter(s) are faulty.

b. When changing a filter, check that the new filter is correctly installed.

F25 High pressure in dryer The differential pressure (-B03) is > 750 Pa .

Possible action:

a. Check whether the filter is clogged.

F26 Low pressure from circulation pump The pressure (-B04) is <30 kPa.

Possible action:

a. Check the docking between machine and wash rack.

b. Check that the pump impeller rotates easily.

c. Check the direction of rotation (see installation instructions).

d. Check that the detergent is not foaming.

F27 High pressure from circulation pump The pressure (-B04) is > 130 kPa.

Possible action:

a. Check that no nozzles in the washing arms are blocked.

F28 Low temperature in dryer The temperature (-B05) has not risen to 20 degrees C below the set value after

two minutes.

Possible action:

a. Check that there is power on all phases up to the element.

F29 Faulty temperature sensor in booster tank. The temperature (-B06) is <0 °C or >130 °C.

Possible action:

a. Check the temperature sensor (for open-circuit or short-circuit)

F30 Faulty temperature sensor in washing chamber The temperature (-B07) is <0 °C or >130 °C.

Possible action:

a. Check the temperature sensor (for open-circuit or short-circuit)

Page 46

Fault indications and troubleshooting

9

Service instructions

5015108-00Edition 0403

Fault code Fault Comment

F31 Faulty temperature sensor in washing chamber Independent. The temperature (-B07) is <0 °C or >130 °C.

Possible action:

a. Check the temperature sensor (for open-circuit or short-circuit)

F32 Faulty temperature sensor in dryer The temperature (-B05) is <0 °C or >130 °C.

Possible action:

a. Check the temperature sensor (for open-circuit or short-circuit)

F33 Incorrect temperature in washing chamber Wash temperature (-B07) has not risen by at least 10 degrees C after eight

minutes’ washing.

Possible action for electrically heated machine:

a. Check that there is power on all phases up to the elements.

b. Check the overheat protection of the elements.

Possible action for steam heated machine:

a. Check the steam valve.

b. Check that the ball valve is open and that the filter in the incoming steam is clean.

c. Check steam pressure (see installation instructions).

d. Check condensate drain.

e. Check that there is no back pressure in the condensate drain.

F34 Faulty temperature sensor in washing chamber Wash temperature (-B07) dependent and independent differs by more than ±3

degrees C.

Possible action:

a. Check the calibration of the temperature sensor (see Calibration under

Repair and adjustment)

b. Check the temperature sensor.

Page 47

Page 48

Repair and adjustment

1

Service instructions

5015108-00Edition 0403

Repair and adjustment

Contents

Connecting a PC____________________________________________ 3

Connecting a barcode scanner _________________________________ 4

Handscanner ____________________________________________ 4

Barcode scanner _________________________________________ 5

Loading a program to flash memory_____________________________ 6

Loading system programs __________________________________6

Load language files _______________________________________ 8

Cold start ________________________________________________11

Calibration _______________________________________________12

Conductivity meter ______________________________________ 12

Check the output signal from conductivity meter ____________ 1 2

Set the cell constant___________________________________ 12

Calibration __________________________________________ 13

Pressure sensor for circulation pump ________________________ 16

Temperature sensor – with resistor __________________________ 18

Temperature sensors – with ice bath and oil bath _______________ 20

Differential pressure gauge for dryer _________________________ 22

Replacing a temperature sensor ______________________________25

In wash chamber and dryer ________________________________ 25

In booster tank _________________________________________ 25

Door ____________________________________________________26

Position and operation, door switches _______________________ 26

Adjusting door switches __________________________________ 28

Adjusting DOOR UP safety switch __________________________ 29

Replacing the door seal ___________________________________ 30

Removing the door ______________________________________ 31

Adjusting the door closing force____________________________ 32

Adjusting manual door ___________________________________ 33

Overheat protection ________________________________________34

Cleaning the filters in the solenoid valves _______________________35

Dryer____________________________________________________36

Conductivity measurement (extra equipment) ____________________37

Function in washing process_______________________________ 37

Measuring range ________________________________________ 37

Calibration _____________________________________________ 37

Removing a measuring cell ________________________________ 37

Setting detergent and rinse-aid quantities_______________________ 38

Printer (extra equipment)____________________________________39

Replacing the paper roll ___________________________________ 3 9

Ribbon cartridge replacement ______________________________ 4 0

Jumpering an expansion card ________________________________40

Replacing a hose to a hose pump ______________________________42

Booster tank ______________________________________________43

Booster tank with drain tap ________________________________ 43

List of components _________________________________________45

Page 49

Repair and adjustment

2

Service instructions

5015108-00 Edition 0403

Page 50

Repair and adjustment

3

Service instructions

5015108-00Edition 0403

V1561

Connecting a PC

An RS-232 cable is needed to connect a PC to the washer-disinfector.

Proceed as follows:

1 . Connect a cable between the PC and port X24 or X25 as shown below.

- X24 is mainly used for a PC and (for example) a scanner.

- X25 is used mainly for T-doc (RS485) and printer (RS232 or RS485).

2 . Set type of communication. The communication settings are done in the service program; see

under tab 5 Software description and settings. Proceed as follows if the PC is:

connected to port X24

- Go into Communication setup COM 0 (1.4.2.3.5.1); see tab 5 Software description and settings.

- Choose COMLI PROTOCOL and press S. Exit the service program.

connected to port X25

- Go into Communication setup COM 1 (1.4.2.3.5.2); see tab 5 Software description and settings.

- Choose COMLI PROTOCOL and press S.

- Go into Communication setup COM 1 (1.4.2.3.5.3); see tab 5 Software description and settings.

- Depending on the distance between the computer and the washer-disinfector, choose

communication speed RS232 (<5 m) or RS485 (>5 m) and press S. Exit the service program.

Page 51

Repair and adjustment

4

Service instructions

5015108-00 Edition 0403

reset factory defaults

configuration enable (*)

predefined terminal selections - RS-232 - special RS-232 configurations - slave mode (9600, 7, E, 2)

Code 128 / EAN 128 - active

\46\42\46\50\41\4A\01\29\41\5A\60

Code 128 / EAN 128 - EAN 128 identifier - remove ]C1 identifier

Code 93 - active

Code 39 - active (*)

\47\5A\00\41\5E\41\4C\60

RS-232 - preamble / postamble - STX / ETX

RS-232 - hardware/software protocols timeout - compose (ms): 2500

\45\53\3E\02\45\54\3E\03\51\27\04\60

RS-232 - ENQ - not used (*)

temporary configuration mode - update current configuration

\47\3E\00\46\41\02\60

Connecting a barcode scanner

Handscanner

To connect a barcode scanner, proceed as follows.

1. Connect power to the scanner.

2. Calibrate the scanner by scanning in the barcodes below.

Scan in the top barcode. Wait for a beep, then scan in the

next code. Continue until all codes have been scanned in.

3. Connect a communication cable between the scanner and

port X24.

4 . Set type of communication. The communication settings are done in the service program; see

under tab 5 Software description and settings.

- Go into Communication setup COM 0 (1.4.2.3.5.1); see tab 5 Software description and settings.

- Choose Scanner and press S. Exit the service program.

Page 52

Repair and adjustment

5

Service instructions

5015108-00Edition 0403

Barcode scanner

To connect a barcode scanner, proceed as follows.

1. Connect power to the scanner.

2 . Connect a communication cable between the scanner

and port X24.

3 . Set type of communication. The communication

settings are done in the service program; see under

tab 5 Software description and settings.

- Go into Communication setup COM 0 (1.4.2.3.5.1);

see tab 5 Software description and settings.

- Choose Scanner and press S. Exit the service

program.

Barcode

scanner

Page 53

Repair and adjustment

6

Service instructions

5015108-00 Edition 0403

Loading a program to flash memory

The flash memory can be loaded with new wash programs or new system programs. Loading

new wash programs requires the CS-1000 program, which can be purchased from Getinge.

Instructions are supplied with CS-1000. System programs and language versions are loaded

with Flashloader.

Loading system programs

Note:

Always make a backup copy before starting work on updating system programs.

1 . Connect a PC to the machine; see under Connecting a PC.

2 . Check that the machine is in STANDBY mode.

3 . Make a backup copy by starting CS 1000 and choosing Tools/PACS RAM/Upload To File...

4 . Save the *.prm file in your chosen location.

The program will report an error during conversion. Disregard this. To check that conversion

was successful, check the size of the *.prm file. The size of the file should be 84416 bytes.

5 . Switch off the power to the machine with the main switch.

6 . Change the jumper (X29) on the board for the PACS 300 control system from Normal to Test.

Flash

Prom

X28

X29

TEST

Norma

X30

ON OFF

V1544

V1577

Page 54

Repair and adjustment

7

Service instructions

5015108-00Edition 0403

7 . Switch on the power to the machine with the main switch. The display should now show:

GETINGE

Ram OK

or

GETINGE PACS 300

Version X.XX (XXXX)

8 . Start Flashloader from PC.

9. Set up as shown.

File name Choose the right program file (*.a37).

Com port The port to which you connected the data cable to your PC.

Baud rate Choose 57600

All Sectors and Verbose must be checked (=selected).

10. Start loading by pressing Program !. The following image appears.

V1578

V1579

Page 55

Repair and adjustment

8

Service instructions

5015108-00 Edition 0403

11. When loading is complete, the following image appears. Press OK.

12. Now the display shows:

SW Update 0x2497

Updating CRC....

A beep is heard and the display shows:

SW Update 0x2497

CRC OK

13. Check that the battery jumper (X30) is set to ON.

14. Switch off the power to the machine with the main switch.

15 . Change the jumper (X29) to Normal.

16. Switch on the power to the machine with the main switch. The display should now show:

P00

17 . Close Flashloader.

18 . Start CS-1000 and load wash programs; see instructions for CS-1000.

Load language files

Note:

Always make a backup copy before starting work on updating system programs.

1 . Connect a PC to the machine; see under Connecting a PC.

2 . Check that the machine is in STANDBY mode.

3 . Make a backup copy by starting CS 1000 and choosing Tools/PACS RAM/Upload To File...

4 . Save the *.prm file in your chosen location.

The program will report an error during conversion. Disregard this. To check that

conversion was successful, check the size of the *.prm file. The size of the file should be

84416 bytes.

5 . Switch off the power to the machine with the main switch.

V1580

V1577

Page 56

Repair and adjustment

9

Service instructions

5015108-00Edition 0403

6 . Change the jumper (X29) on the board for the PACS 300 control system from Normal to Test.

Flash

Prom

X28

X29

TEST

Norma

X30

ON OFF

V1544

7. Set up as shown.

File name Choose the right program file (*.a37).

Com Port The port to which you connected the data cable to your PC.

Baudrate Choose 57600

All Sectors and Verbose must be checked (=selected).

V1578

Page 57

Repair and adjustment

10

Service instructions

5015108-00 Edition 0403

8. Choose the Language tab.

9 . Choose the relevant files:

- Language support file,

- Language file for PACS database.

10. Set Flash Sector for Language to 8 and 10 (as shown).

11 . Check (select) Transfer.

11 . Click Transfer->. The language files are now transferred to PACS 300.

12 . Close Flashloader.

V1581

Page 58

Repair and adjustment

11

Service instructions

5015108-00Edition 0403

Flash

Prom

X28

X29

TEST

Norma

X30

ON OFF

V1544

Cold start

Do a cold start when the machine has hung and you cannot proceed with the program.

1 Switch off the power to the machine.

2 Move the battery jumper (X30) to Off.

3 Move the programming jumper (X29) from Normal to Cold.

4 Switch on the power.

5 Wait until CRC OK appears on the display.

6 Move the battery jumper (X30 back to On. Note: The power is still on.

7 Switch off the power.

8 Move the programming jumper (X29) from Cold to Normal.

9 Switch on the power.

10 Set the doors to the home position using the service program (tab 5 Software description

and settings, Test digital output display (1.4.2.5.3.4)) or CS1000.

Home position for the doors:

Dirty side = door unlocked and open

Clean side = door closed and locked

Page 59

Repair and adjustment

12

Service instructions

5015108-00 Edition 0403

Calibration

Conductivity meter

Check the output signal from conductivity meter

To check the output signal, proceed as follows.

1. Press [ on the conductivity meter.

2 . Enter code 22 with Y and Z.

3. Press [. Setup 1 appears.

4 . Choose with Y and Z Output.

5. Press [. Sel. Type appears.

6. Choose LIN with Y and Z.

7. Press [.

8 . Choose 4-20 mA with Y and Z.

9. Press [ .

10 .Set with Y and Z so that 4 mA =0.000 µS/cm.

11 .Press [.

12 .Set with Y and Z so that 20 mA = 200 µS/cm.

13 .Press [.

14.Press Y and Z at the same time to log out.

Set the cell constant

To set the cell constant, proceed as follows:

1. Press [ .

2 . Enter code 22 with Y and Z.

3. Press [. Setup 1 appears.

4. Press [ until the display shows Cellconst.

5. With Y and Z, set the relevant cell constant; see the calibration certificate.

6. Press [ .

7. Press Y and Z at the same time to log out.

Page 60

Repair and adjustment

13

Service instructions

5015108-00Edition 0403

Calibration

To calibrate the conductivity meter, proceed as follows.

1 . Connect a PC with the CS 1000 program installed to the disinfector.

2. Press [ on the conductivity meter.

3 . Enter code 22 with Y and Z.

4. Press [. Setup 1 appears.

5 . Choose Output with Y and Z .

6. Press [. Sel. Type appears.

7 . Choose SIM with Y and Z.

8. Press [.

9 . Choose to 0 …22 mA with Y och Z.

10 . Set 4 mA.

11 . Press [.

12. Start CS 1000 and choose Settings/Calibration/Analog Input Automatic...

V1563

Page 61

Repair and adjustment

14

Service instructions

5015108-00 Edition 0403

13 .Click Conductivity (A) and then Calibrate (B).

A

B

A

14 .Enter the value 0 (A) and click Set Low.

V1564

V1565

Page 62

Repair and adjustment

15

Service instructions

5015108-00Edition 0403

15. Set 20 mA on the conductivity meter with Y and Z.

16 . Enter 200 (A) in CS 1000 and click Set High.

17. Check that the value (B) rises to 200.

18 . Log off CS 1000.

19 . Choose Output with Y and Z.

20. Press [. Sel. Type appears.

21 . Choose LIN with Y and Z.

22 . Press [.

23. Press Y and Z together several times until you are logged out of the conductivity meter.

A

B

V1566

Page 63

Repair and adjustment

16

Service instructions

5015108-00 Edition 0403

A

B

Pressure sensor for circulation pump

To calibrate the pressure sensor for the circulation pump, proceed as follows.

1. Connect a PC with the CS 1000 program installed to the disinfector.

2 . Connect a process simulator to A01-X2;

+ to 2

- to 5.

3 . Set the process simulator to 4 mA.

4 . Start CS 1000 and choose Settings/Calibration/Analog Input Automatic...

5 . Click Pump pressure (A) and then Calibrate (B).

V1563

V1567

Page 64

Repair and adjustment

17

Service instructions

5015108-00Edition 0403

6 . Enter the value 0 (A) and click Set Low.

7 . Set the process simulator to 20 mA.

8 . Enter 160 (A) in CS 1000 and click Set High.

9 . Check that the value (B) rises to 160.

10. Log off CS 1000.

A

A

B

V1569

V1568

Page 65

Repair and adjustment

18

Service instructions

5015108-00 Edition 0403

Temperature sensor – with resistor

Proceed as follows to calibrate the temperature sensors with the aid of resistors:

1. Connect a PC with the CS 1000 program installed to the disinfector.

2. Insert resistors for 20 ºC at the following places:

A01-X7 Chamber temperature (two sensors)

A01-X6 Booster tank

A01-X5 Dryer

3 . Start CS 1000 and choose Settings/Calibration/Analog Input Automatic...

4 . Click Temp booster, Temp chamber and Temp chamb indep(A), then click Calibrate (B).

A

B

V1571

V1563

Page 66

Repair and adjustment

19

Service instructions

5015108-00Edition 0403

5 Enter the value 20 (A) and click Set Low.

6 Check that the value (B) rises to 20.

7 Replace resistors for 20 ºC with resistors for 90 ºC.

8 Enter 90 (A) in CS 1000 and click Set High.

9 . Check that the value (B) rises to 90.

10. Log off CS 1000.

11. Remove the resistors and reinstate the temperature sensors.

A

A

B

B

V1572

V1571

Page 67

Repair and adjustment

20

Service instructions

5015108-00 Edition 0403

Temperature sensors – with ice bath and oil bath

Proceed as follows to calibrate the temperature sensors with the aid of resistors:

1. Connect a PC with the CS 1000 program installed to the disinfector.

2 . Prepare an ice bath and an oil bath.

The ice bath must consist of crushed ice in a bowl of cold water. The bath must stand for at

least 20 minutes so that the temperature can stabilise.

The oil bath must be switched on for at least 45 minutes at the set temperature (100 ºC) to

stabilise the temperature.

3. Remove the temperature sensors from the disinfector. Tape the sensors together.

4 . Lower the temperature sensors into the ice bath together with an external thermometer.

5 . Start CS 1000 and choose Settings/Calibration/Analog Input Automatic...

6 . Click Temp booster, Temp chamber and Temp chamb indep(A), then click Calibrate (B).

A

B

V1563

V1570

Page 68

Repair and adjustment

21

Service instructions

5015108-00Edition 0403

7 Check that the reading of the external thermometer stabilises. Enter the reading of the external

thermometer (A) and click Set Low.

8 Check that the value (B) rises to the set value.

9 Move the temperature sensors and the external thermometer to the oil bath. Check that the

reading of the external thermometer stabilises. Enter the reading of the external thermometer

(A) and click Set High.

10.Check that the value (B) rises to the set value.

11 .Log off CS 1000.

12.Re-instate the temperature sensors.

A

A

B

B

V1572

V1571

Page 69

Repair and adjustment

22

Service instructions

5015108-00 Edition 0403

Differential pressure gauge for dryer

To calibrate the differential pressure gauge for the dryer, proceed as follows.

1 . Connect a PC with the CS 1000 program installed to the disinfector.

2 . Close the machine doors.

3 . Connect an external differential pressure gauge in parallel with the existing gauge on the

machine. Zero the external differential pressure gauge.

4 . Start CS 1000 and choose Settings/Calibration/Analog Input Automatic...

5 . Click Dryer pressure (A) and then Calibrate (B).

A

B

V1573

V1563

Page 70

Repair and adjustment

23

Service instructions

5015108-00Edition 0403

6 . Enter the value 0 (A) and click Set Low.

7 . Start the machine fan manually as follows:

Scroll to SETUP with J. Press S.

Scroll to SYSTEM with J. Press S.

Enter password. Press S.

Scroll to SERVICE with J. Press S.

Scroll to DIAGNOSTICS with J. Press S.

Scroll to TEST ANALOG OUT with J. Press S.

>SETUP

>SYSTEM

ABOUT

>ENTER PASSWORD

>SERVICE

SAVE TO RAM FLASH

SERVICE MESSAGES

>DIAGNOSTICS

>TEST ANALOG OUT

TEST DIGITAL IN

A

V1574

Page 71

Repair and adjustment

24

Service instructions

5015108-00 Edition 0403

Scroll to 01 FAN SPEED with J. Press S.

Change AUT to MAN with K. Set fan speed to 75 %.

8 . Check that the reading of the external differential pressure gauge stabilises. Enter the reading

of gauge (A) in CS 1000 and click Set High.

The reading should be between 200 and 300 Pa.

If it is too high, the filter may be clogged; if it is too low, there may be a hole in the filter.

9 . Check that the value (B) rises to the reading of the external differential pressure gauge.

10. Log off CS 1000.

11. Reinstate the fan.

Set fan speed to 0 %. Change MAN to AUT with K. Press S.

12. Log out.

13. Reinstate the differential pressure gauge.

>01 FAN SPEED

AUT 100%

>01 FAN SPEED

MAN 75%

A

B

>01 FAN SPEED

MAN 0%

V1574

Page 72

Repair and adjustment

25

Service instructions

5015108-00Edition 0403

Replacing a temperature sensor

This must only be done by authorised personnel.

The machine is connected to the electricity supply and some components are live.

In wash chamber and dryer

• Remove the old temperature sensor by pulling it out of the seal.

• Push the new sensor in through the seal.

In booster tank

• Remove the old temperature sensor by unscrewing the gland pulling the sensor out.

• Push in the new sensor and tighten the gland.

Temperature

sensors in dryer

Temperature sensors

in wash chamber

Temperature sensors

in booster tank

V1562

The booster tank contains hot water. This may cause scalding injuries if proper

procedures are not followed.

When servicing the booster tank and/or its associated components, there is a risk of contact

with hot water. The booster tank must therefore be drained before servicing.

To do this, clamp the hose above the solenoid valve. Disconnect the hose at the solenoid valve

and allow the hot water to run off into a drain.

Page 73

Repair and adjustment

26

Service instructions

5015108-00 Edition 0403

V1452

Door switch

DOOR

UNLOCKED

Door switch

DOOR LOCKED

Door switch

DOOR

CLOSED

Door

Position and operation, door switches

Manual door:

When the door is at its top position, the DOOR CLOSED and DOOR UNLOCKED switches are

activated. When the motor has pulled the door into its inner position, the DOOR LOCKED

switch is activated.

The illustration show which door switches are fitted to the machine with manual or automatic door.

Before starting work, make sure that the machine is isolated from the electric

power supply.

This must only be done by authorised personnel.

Page 74

Repair and adjustment

27

Service instructions

5015108-00Edition 0403

Door switch

DOOR OPEN

Door switch

DOOR UNLOCKED

Door switch

DOOR LOCKED

Safety switch

DOOR DOWN

Safety switch

DOOR UP

Door switch

DOOR CLOSED

V1297

Automatic door:

When the door is at its bottom position, the DOOR OPEN switch is activated and when the door

is in the top position the DOOR CLOSED and DOOR UNLOCKED switches are activated. When

the motor has pulled the door into its inner position, the DOOR LOCKED switch is activated.

If the door is obstructed on its way up and the force on the door is greater than 150 N, the

DOOR UP safety switch stops the door. When the door is stopped, the motor drive unit turns

around its fixing point and activates the safety switch. For adjustment, see under “Adjusting

safety switches, DOOR UP”.

If the door is obstructed on its way down, the DOOR DOWN safety switch stops the door. The

door is suspended on two wires. If the door is obstructed, the wires continue to be paid out, and

a spring force activates the DOOR DOWN safety switch, stopping the door.

Page 75

Repair and adjustment

28

Service instructions

5015108-00 Edition 0403

Adjusting door switches

This must only be done by authorised personnel.

Before starting work, make sure that the machine is isolated from the

electric power supply.

Check that the respective microswitches are activated. Adjust if necessary.

V1297

V444

Door switch

DOOR LOCKED

Safety switch

DOOR UP

Door switch

DOOR UNLOCKED

Door switch

DOOR CLOSED

Door switch

DOOR OPEN

Page 76

Repair and adjustment

29

Service instructions

5015108-00Edition 0403

Adjusting DOOR UP safety switch

This may only be done by authorised personnel.

The DOOR UP safety switch is fitted only to machines with automatic door.

To prevent damage, the spring must be adjusted so that the door stops when a

force of 150 N is applied to the door when the door is moving up. The illustration

below shows how to adjust the spring.

V1435

Safety switch

DOOR DOWN

Page 77

Repair and adjustment

30

Service instructions

5015108-00 Edition 0403

Replacing the door seal

This must only be done by authorised personnel.

• Automatic door: Remove door switches and bolts. (If a loading/unloading unit is installed,

there are door switches on the left-hand side only). This is so that the door can be pushed

down far enough to release the seal.

• Manual door: Remove bolts and leaf springs so that the door can be pushed down far

enough to release the seal.

• Push the door down to its lower position.

• Pull off the old seal.

• Fit the new seal and press it firmly into place.

• Automatic door: Install door switches and bolts.

• Manual door: Install bolts and leaf springs.

Door switch

Bolt

V1297

V679

Leaf springs

V1452

Machine with manual door:

Machine with

automatic door:

Page 78

Repair and adjustment

31

Service instructions

5015108-00Edition 0403

Removing the door

• Remove the front panels.

• Automatic door: Remove door switches and the door switches of the loader/unloader (if

there is one). Remove bolts.

• Remove leaf springs, bolts and spacers in the lower part of the frame.

• Remove the drain hose.

• Automatic door: Access the service program; Test the operation of the door.

• Move the door to the half-open position.

• Separate the door frame and the door closing mechanism.

• Free the door frame at the top edge. NOTE: Secure the frame so that it cannot fall forwards.

• Free the bottom edge of the door frame. NOTE: Secure the frame so that it cannot fall down

and suffer damage.

• The frame and door assembly can now be lifted out and placed on the floor or on a table.

• Release the wire from the door and hoist mechanism.

This must only be done by authorised personnel.

V679

V1297

Drain hose

Door switch

Bolt

Machine with

automatic door:

V1457

Page 79

Repair and adjustment

32

Service instructions

5015108-00 Edition 0403

V1583

Closed position

Adjusting the door closing force

This must only be done by authorised personnel.

When door is in its top position, the motor pulls the door in from the outer to the inner position.

The force with which it does this is adjusted with a spring as shown below.

Note:

The spring must never fully compressed.

22.5 + 1 mm

Page 80

Repair and adjustment

33

Service instructions

5015108-00Edition 0403

V1452

V693

Bolt A

Screw B

Spindle

Adjusting manual door

This must only be done by authorised personnel.

The door is held in its bottom position by two leaf springs. When the door is pushed up, it

must stop about 10 cm from its top position. The door must always be moved up manually for

the last part of its travel. The inertia of the door is adjusted with a spring as follows:

• Secure bolt A with a socket wrench and retain the grip.

• Remove screw B and insert a rod (4.5 mm diameter) in the hole.

• Adjust the spring by tightening bolt A about one-sixth of a turn with the socket wrench,

removing the rod at the same time.

Note:

Bolt A or the rod must be held securely or the spring will escape.

• When adjustment is complete, insert and tighten screw B.

Page 81

Repair and adjustment

34

Service instructions

5015108-00 Edition 0403

A

V767

V1297

Overheat protection

If the element overheats, the overheat protection trips. Reset the overheat protection with

button A.

Page 82

Repair and adjustment

35

Service instructions

5015108-00Edition 0403

Cleaning the filters in the solenoid valves

This must only be done by authorised personnel.

The machine is connected to the electricity supply and some components are live.

The filters in the solenoid valves should be regularly checked and cleaned if necessary.

V1584

Page 83

Repair and adjustment

36

Service instructions

5015108-00 Edition 0403

1

V1297

Temperature sensor

located inside the tube

V1292

Dryer

This must only be done by authorised personnel.

The machine is connected to the electricity supply and some components are live.

• Check seals and hoses for leaks once a year.

• Replace the sterile filter (1) if necessary or in the event of an alarm.

• Make sure that the filter seals tight when reinstalled, otherwise there is a risk of alarm.

Page 84

Repair and adjustment

37

Service instructions

5015108-00Edition 0403

V1453

Electrical

cabinet

Measuring cell

Conductivity instrument

V1312

Conductivity measurement (extra equipment)

Conductivity is measured with equipment from Endress+Hauser.

This must only be done by authorised personnel.

Function in washing process

The conductivity meter monitors the quality of the water in the final rinse, independently of the

process control.

If the conductivity at the end of the final rinse is higher than the preset value, the machine is

drained with the Emptying 2 phase, ie the machine is drained while at the same time being

supplied with DW/WFI water and the final rinse is repeated automatically.

If, after three repetitions, the conductivity is still above the preset value, the process is stopped

and fault code 11 appears on the display.

Measuring range

The normal measuring range is 0-20 µ S/ cm

Calibration

See under Calibration

Removing a measuring cell

For easy access to the measuring cell, slacken the two screws that keep the electrical cabinet in

place. Remove the right-hand screw. Move the electrical cabinet to the left and rotate it forward.

Unscrew the measuring cell. The cables are long enough to allow the measuring cell to be

immersed in a vessel of calibration liquid.

Page 85

Repair and adjustment

38

Service instructions

5015108-00 Edition 0403

Setting detergent and rinse-aid quantities

This must only be done by authorised personnel.

The machine is connected to the electricity supply and some components are live.

• Dispense 100 ml of the relevant substance into a measuring beaker. Check that the suction

hose and pump are full before the check.

• Push the suction hose down into the beaker and measure the consumption during an entire

cleaning program. Lift up the hose when reading the volume. Adjust if necessary, and repeat

the measurement until the amount of detergent conforms to the manufacturer’s

recommendations.

• If necessary, adjust the dosing time in the service program.

Page 86

Repair and adjustment

39

Service instructions

5015108-00Edition 0403

V335

Ink ribbon cassette

Paper roll

Printer (extra equipment)

Replacing the paper roll

• Open the front.

• Remove any paper residue.