INSTALLATION

INSTRUCTIONS

Washer disinfector

46-2,46-4,46-5

Mfg. no.. SEV0632001-

5018606-00 Rev.C

2

Contents

Contents

Safety regulations _________________________________________________ 3

The machine must be assembled and installed by ___________________ 3

When the work is complete, check that _____________________________ 3

Product liability __________________________________________________ 3

Isolator switch ___________________________________________________ 3

Attention symbols _______________________________________________ 3

Installation ________________________________________________________ 4

Wall-mounted model _____________________________________________ 5

Free-standing model _____________________________________________ 6

Connecting electric power ________________________________________ 7

Connecting water, steam, waste and dryer __________________________ 8

Function check _________________________________________________ 10

Technical data ____________________________________________________ 12

Alternative connection arrangements ______________________________ 15

5018606-00 Rev.C Edition 0704

Installation instructions

Safety regulations

Safety regulations

This machine has been designed with a number of built-in safety devices. To avoid

injury, it is very important that these safety devices are not bypassed and thus

disabled.

The machine must be assembled and installed by

• qualified personnel.

• in accordance with current local regulations and rules.

When the work is complete, check that

• all parts have been installed in accordance with the installation instructions

• all screws have been properly tightened

• there are no sharp edges on any parts that may come into contact with people

• all hoses, pipes and connections are intact and free from defects

• all the functions of the machine are working properly. Adjust if necessary.

3

Product liability

Any modification or incorrect use of the equipment without the approval of Getinge

Disinfection AB invalidates Getinge Disinfection AB’s product liability.

Isolating device

The machine should be fitted with a separate isolating device in the electric power

supply. The isolating device must be easily accessible on a wall close to the

machine.

Attention symbols

Some of the warnings, instructions and advice in this manual are so important that

we use special symbols to draw attention to them. The symbols used are as follows:

This symbol indicates a warning in the text of the manual. The nature of the

hazard that the warning relates to is such that it may result in more or less

severe injury and in certain cases mortal danger.

It also highlights warnings to avoid damage to equipment.

5018606-00 Rev.C

Installation instructions

Edition 0704

4

Installation

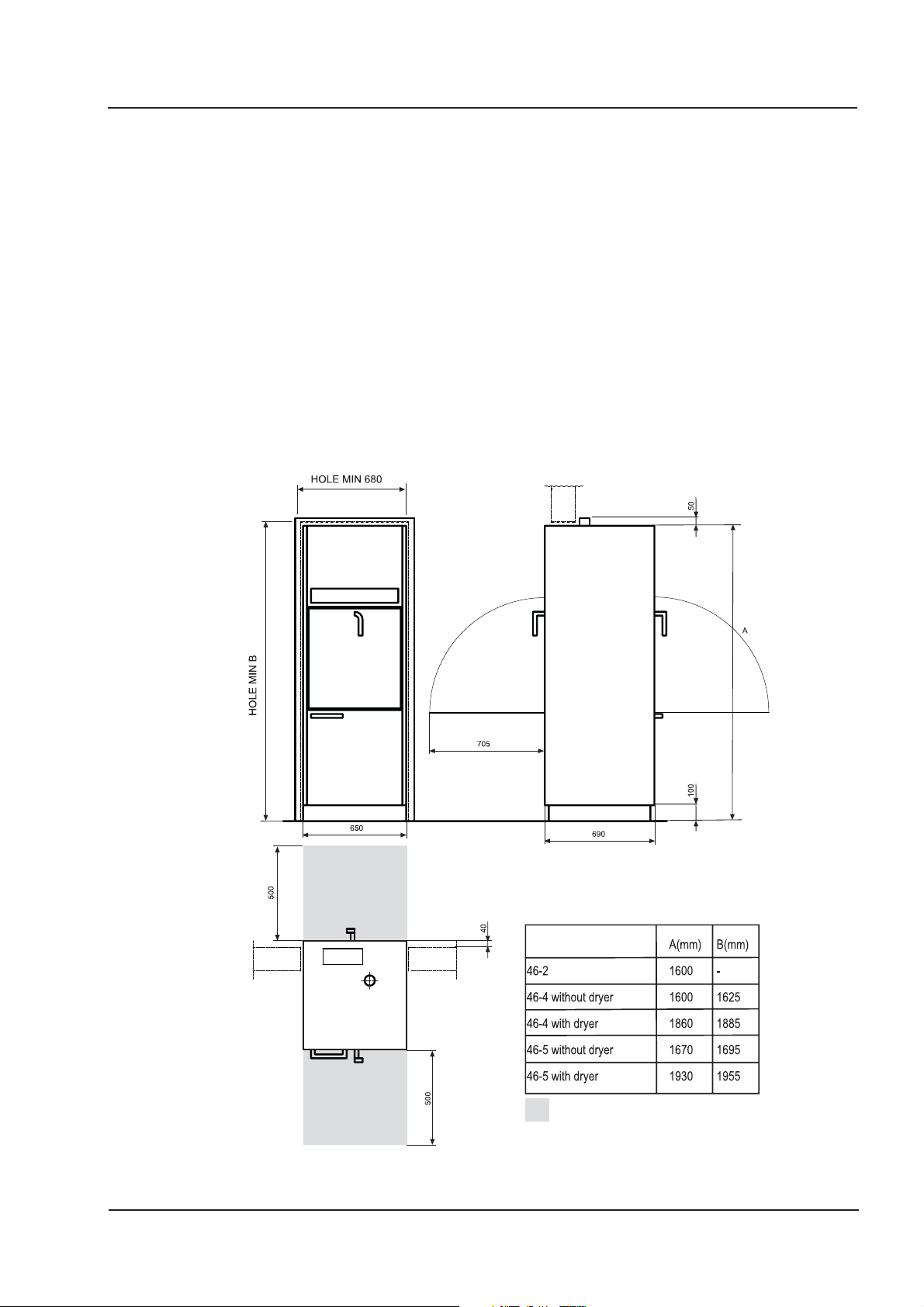

• The floor where the machine is to stand must be flat and level within ±5 mm.

• Pull the machine (on a transport pallet) to the location where it will be installed.

• Lift the machine off the pallet.

• Position the machine at the chosen location and adjust the feet so that the

machine is stable. The adjusting feet must be screwed out not more than

110 mm from the underside of the machine (the 100 mm dimension on Figure 3

can be ±10 mm). There must be clear space for loading/unloading the machine

1700 mm in front of the door(s) of the machine.

• Place a foot plate under each adjusting screw. Foot plates are supplied in a

plastic bags in the chamber of the machine.

Level the machine

with a spirit level.

Installation

V1634

Figure 1. Adjustment

• Using a spirit level, check as shown in Figure 1 that the machine is level within ±2 mm,

• Free-standing model: prepare a water supply and a waste connection by breaking

out suitable prepared openings in the rear cover plate panel of the machine.

• If the machine is to be moved with a pallet truck, the forks of the pallet truck

must be positioned as shown in Figure 2 to avoid damage to the machine.

Bottom frame

Adjusting screws

Foot plate

V318

Figure 2. Positioning the pallet truck forks.

5018606-00 Rev.C Edition 0704

Installation instructions

Installation

Wall-mounted model

• If the machine has double doors and is to be mounted in a wall, the distance

between machine and wall must be 15 mm.

• If more than one machine is to be installed next to each other they must be

adjusted to the same height on installation.

• Where a plinth plate is used, the height from the floor to the underside of the

machine must be at least.

• Set the machine horizontal with a spirit level on the side of the machine and

adjust with the feet. The adjusting feet must be unscrewed not more than 110

mm from the underside of the machine.

• For the loading trolley to work in all the machines, the floor in front of them must

be flat and level.

5

5018606-00 Rev.C

Service area

Figure 3. Mounting in a wall

Installation instructions

Edition 0704

6

Free-standing model

• Secure the tipover protection to the machine with the screws, then secure the

backplate.

• Fix the tipover protection to the wall with screws.

Installation

Tipover protection

V1640

Figure 4. Tipover protection

• Check that the door and the two side plates are parallel.

If not:

• Open the lower door and adjust the machine.

• To adjust the machine to the left, turn the nuts to the left; to adjust the machine

to the right, turn the nuts to the right.

The door and the

two side plates

must be parallel.

V1639

Fig 5. Diagonal adjustment

5018606-00 Rev.C Edition 0704

Installation instructions

Installation

Connecting electric power

Installation may only be done by authorized personnel.

Connect electric power to the machine as follows:

• Install the machine in accordance with installation category CAT II.

• Connect the power supply to the electrical connections of the machine; see the

diagram with alternative connection arrangements.

For easier servicing and maintenance, the supply to the machine must be fitted

with an isolator switch with a 3 mm isolating gap. The device must be located in

an easily accessible position close to the machine.

• Open the lower hatch.

• Remove the inner safety plate to access the electrical box.

It is important that the connection has the correct overcurrent protection. The

correct fuse rating is stated on the type plate.

7

Isolating device

Electrical box

V1638

Figure 6 Electrical connection (see electrical diagram in the service instructions)

Terminal block

5018606-00 Rev.C

Figure 7. Electrical box

Installation instructions

Edition 0704

8

Connecting water, steam, waste and dryer

Installation may only be done by authorized personnel.

• Provide separate shutoff valves on the water and (if used) steam lines. Flush out

the water and steam pipes that are to be connected to the machine, to prevent

clogging of filters and valves.

• Connect the disinfector to cold and hot water and to steam and condensate

connections, if used. The connections must meet the following requirements:

Connection Pressure Consumption Flow rate

Cold water 1/2" (15 mm) female 100-800 kPa approx 15 liters/phase min 20 l/min

Hot water 1/2" (15 mm) female 100-800 kPa approx 15 liters/phase min 20 l/min

Dist. water/ 3/4" (20 mm) male 50-900 kPa* approx 15 liters/phase min 20 l/min

De-ion. water

Steam 1/2" (15 mm) female 300-500kPa 0.5 kg/min

Installation

(300 kPa)

V1632

Condensate 1/2" (15 mm) female

* Where the pressure is lower than 50 kPa a separate feeder pump must be used. Where a separate

feeder pump is used, the pressure must not exceed 60 kPa (risk of serious damage to the pump).

• PTFE tape is recommended for sealing the connections.

NOTE:

Distilled or de-ionised water must have a conductivity of less than 40 μS/cm.

1. Distilled/de-ionized water 160 mm above

the floor*.

2. Hot water, 245 above the floor, flexible

hose, L= 1500 mm supplied*.

3. Cold water, 305 mm above the floor,

flexible hose, L= 1500 mm supplied*.

4. Electrical connection , 500 mm above floor.

5. Waste, adjustable within this range

(C/L of outlet pipe)

6. Steam connection, 200 mm above floor.

7. Condensate connection, 200 mm above

floor.

8. Dryer, exhaust air, at roof, 46-4, 46-5

9. Dryer, exhaust air, at roof, 46-2

10. Distilled/de-ionized water without

pressure, 200 mm above the floor.

* A flexible hose can be connected from

above directly to the valve 1400 mm above

the floor. A hole for the hose in the ceiling or

cover plate must be made on site.

Figure 8. Connecting water, steam, waste and dryer

5018606-00 Rev.C Edition 0704

Installation instructions

Installation

9

Leave this air

hole open

avlopp_46

Figure 9. Connecting waste and draft traps

• Connect the disinfector to a waste outlet with a capacity of at least 50 litres/min.

The trap can be connected towards the rear or downwards, as shown in

Figure 8. Waste diameter: 50 mm.

• Connect air exhaust from dryer (if the machine has a dryer). Air quantity approx

3

125 m

/h.

5018606-00 Rev.C

Installation instructions

Edition 0704

10

Function check

• Check that the machine is connected to the correct voltage and the waste,

water, steam and condensate connections are correctly connected. Open the

valves for water and steam.

• Fill the detergent and rinse aid containers and place alarm sensors in the

containers.

Machines with double doors have a system of interlocks to ensure that only one

door can be opened at a time.

If the soiled-side door cannot be opened, check that the clean-side door is

closed. The clean-side door can only be opened if the completed process has

been approved and the door on the soiled side is closed and locked.

• Place a wash rack in the wash chamber and close the door.

• Choose a program where dosing is done from all detergent and rinse-aid

containers and start the machine (see Instructions for use).

• Check that the machine draws water.

Note: If the machine has a distilled water pump, make sure that the pump has been filled

with water so that it can deliver enough pressure to open the distilled water valve.

Installation

NOTE:

On starting, there must be water in the circulation pump. If there is no water in the pump,

the shaft seal may suffer damage.

• Check that the circulation pump is rotating the right direction as indicated by the

arrow on the pump motor. If not, isolate the power, change the phase sequence

at the electrical connections and restart the machine.

V1426

Figure 10. Circulation pump

• Check that the dosing pumps work at the right time in accordance with the

program description in the instructions for use and that detergent is drawn off.

• While the program is running, check that the door(s) cannot be opened.

5018606-00 Rev.C Edition 0704

Installation instructions

Installation

11

• On a machine with manual double doors, check the door locking function when

the program is complete as follows:

- Check that the soiled-side door side cannot be opened.

- Open and close the clean side door.

- Open the soiled-side door.

- Check that the clean side door cannot be opened.

• Check that there are no water or steam leaks. If necessary, retighten water,

steam and waste connections.

5018606-00 Rev.C

Installation instructions

Edition 0704

12

Technical data

Dimensions

Outside dimensions

Weight Total Loading per machine foot

Machine 46-2 without dryer 150 kg 50 kg

Machine 46-2 with dryer 150 kg 50 kg

Machine 46-4 without dryer 150 kg 55 kg

Machine 46-4 with dryer 180 kg 65 kg

Machine 46-5 without dryer 155 kg 60 kg

Machine 46-5 with dryer 185 kg 70 kg

Width 650 mm

Depth 690 mm

Height

Machine 46-2 without dryer 1600 mm

Machine 46-2 with dryer 1600 mm

Machine 46-4 without dryer 1600 mm

Machine 46-4 with dryer 1860 mm

Machine 46-5 without dryer 1670 mm

Machine 46-5 with dryer 1930 mm

Technical data

incl. water and load

Chamber size

Machine 46-2, 46-4 Chamber depth =590 mm

Machine 46-5 Chamber height =660 mm

Chamber width =550 mm

Chamber depth =620 mm

Operational volume 201 liters

Total volume 280 liters

Chamber width = 550 mm

Chamber depth = 620 mm

Operational volume 225 liters

Total volume 305 liters

5018606-00 Rev.C Edition 0704

Installation instructions

Technical data

Connections

Water consumption

about 15-19 liters/phase

Cold water

Water quality Driinking water with max 5 °dH

Connection 15 (1/2") mm

Pressure 100-800 kPa

Flow rate, min 20 l/min

Hot water

Water quality Preheated drinking water with max 5 °dH

Temperature 45-60 °C (113 - 140 °F)

Connection 15 (1/2") mm

Pressure 100-800 kPa

Flow rate, min. 20 liters/min

13

Dist./De-ion. water

Temperature, max 90 °C (194 °F)

Connection 20 (3/4") mm

Pressure 50-800 kPa. Where the pressure is lower than 100 kPa, a separate

Flow rate, min 20 liters/min

The maximum conductivity is determined by the desired washing result.

Steam

Temperature, max 160 °C (320 °F)

Connection 15 (1/2") mm

Pressure 300-500 kPa

Consumption 0.5 kg/min at 300 kPa

Waste, water

ø 50 mm (2")

Capacity 50 liters/min

pressure booster pump must be connected. This is available as an

option. Where a separate feeder pump is used, the pressure must

not exceed 60 kPa (risk of serious damage to the pump).

Waste, air

5018606-00 Rev.C

ø 63 mm

Capacity 125-150m3/h, 35 °C (95 °F)

Humidity 100% 40 sec< 40% after 2 min.

Installation instructions

Edition 0704

14

Other points

Max outside temperature

50 °C (122 °F)

Sound level

Table 1

Calculated sound power level Lw for the test object, db ref 1 pW.

Octave band frequency (Hz) 12 5 250 50 0 1000 2000 4000 8000 LwA LwAFmax

Correction terms (Kok) 63 67 62 59 58 57 54 66 83

The calculated sound power level implies different sound levels LpA in different types of space. With a larger

room volume, the sound level decreases slightly and with a smaller room level it increases slightly. Table 2 below

shows three example of what to expect in practice.

Table 2

Calculated sound level LpA for the test object in a 70m3 room, db ref 20 μPa.

Type of room Description Operator position* 3 meters f rom

the machine

Hard to sound All surfaces of tile, plaster, concrete or similar, ie no

sound absorbing surfaces and no furniture 65 65

Normally-damped Some sound absorption in the form of furniture and textiles. 61 60

Damped Full-cover ceiling absorbent and some furnishing with

tables, chairs and textiles. 58 56

* Operator position means 1 meter from the machine and 1.5 meters above the floor. All values are for one

machine.

Electrical connections

See Alternative connection arrangements

Overcurrent protection as per Curve C

Heat dissipation to the room

Max 2000W (hot air during drying).

Heat radiation to the room

Max 1100W (during disinfection at 90 °C (194 °F))

Circulation system

Design pressure 0.2 MPa

Working pressure max 0.1 MPa

Design temperature 100 °C (212 °F)

Working temperature max 93 °C (200 °F)

Environmental requirements:

Air humidity max 80% at 31°C (87 °F)

Room temperature 5 - 40 °C (41 - 104 °F)

Degree of protection

IP21

5018606-00 Rev.C Edition 0704

Installation instructions

Alternative connection arrangements

Alternative connection arrangements

46-5

Electric heater

46-4

Electric heater

15

46-2

Electric heater

46-5

Steam heater

with dryer

46-4

Steam heater

with dryer

46-5

Steam heater

without dryer

46-4

Steam heater

without dryer

5018606-00 Rev.C

Installation instructions

Edition 0704

This product is manufactured by:

GETINGE DISINFECTION AB, Ljungadalsgatan 11, Box 1505, 351 15 Växjö, Sweden

Loading...

Loading...