Page 1

INSTALLATION INSTRUCTIONS

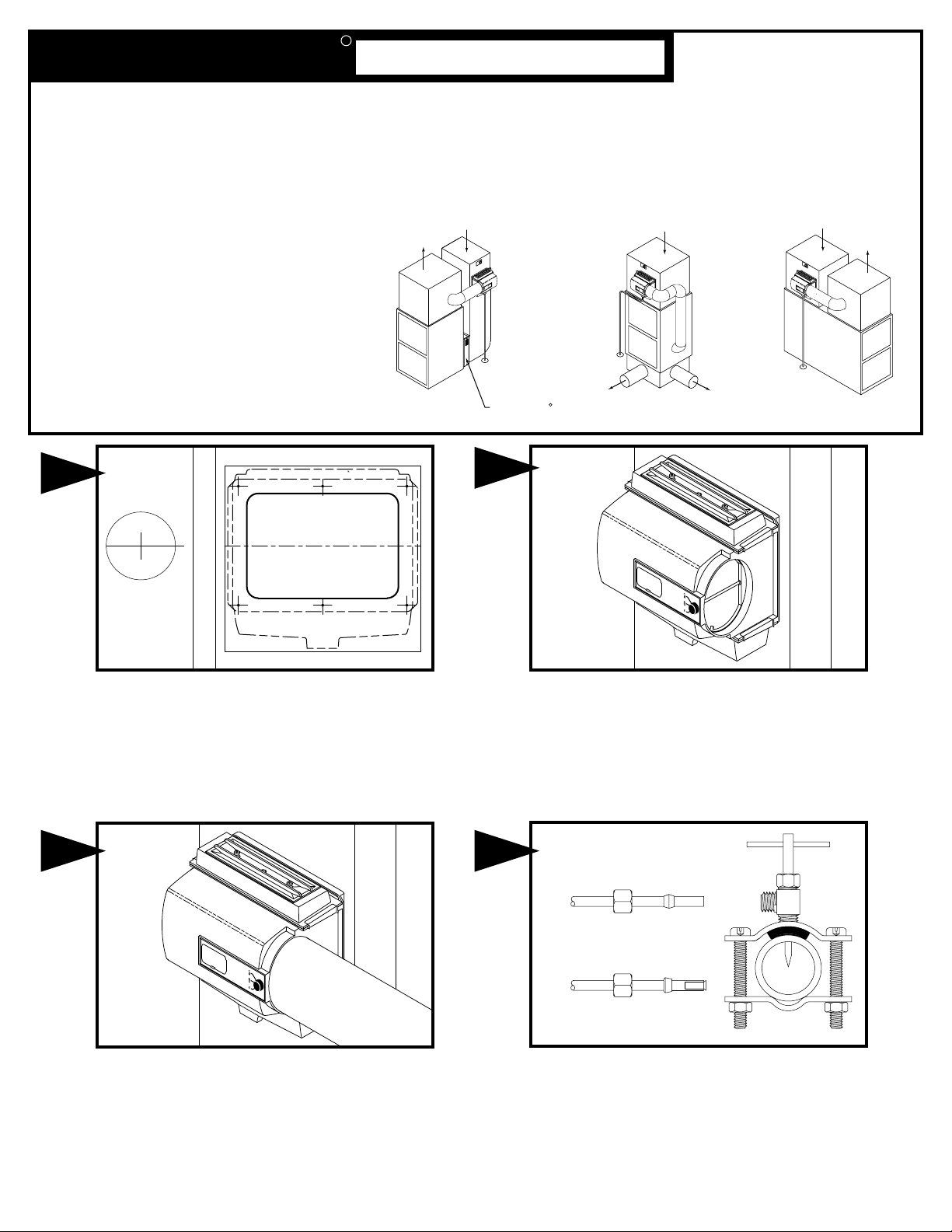

1

PRECAUTION: The installer should be an experienced service technician. Disconnect electrical power before

beginning installation. Do not install where temperatures fall below 32 degrees F or where plenum temperatures

exceed 200 degrees F. When wiring into a multi-speed blower circuit see Step 6C.

GENERALAire

RESIDENTIAL AIR TREATMENT PRODUCTS

FOR INSTALLATION ON A VERTICAL

PLENUM SURFACE OF ANY

FORCED AIR FURNACE

INST ALL ER: PLEASE FI LL O UT A ND M AI L GUARANTEE C ARD AFTER INSTALLATION

IS COMPLETE. LEAVE INSTALLATION

INSTRUCTION S WITH HOME OWNER

2

FLOW THROUGH

BYPASS HUMIDIFIER

R

3

COPPER

TUBING

PLASTIC

TUBING

Mount the self tapping saddle valve on either a cold or a hot water pipe. A

side or top mount is best to avoid clogging from pipe sediment. Connect 1/4”

O.D. tubing to the saddle valve. Copper tubing requires a brass compression

nut and brass sleeve. Plastic tubing requires a brass insert inside the tubing,

a plastic sleeve on the outside with a brass compression nut.

NOTE: DO NOT USE PLASTIC TUBING ON HOT WATER OR IN

CONTACT WITH ANY HOT PLENUM SURFACE OR DUCT.

INSTALLATION OF THIS SADDLE VALVE MUST MEET OR EXCEED

LOCAL CODES AND ORDINANCES.

4

INSTALLATION: The humidifier may be mounted with the

7" outlet to the right or left by inverting the cabinet and

reversing the positions of the distributor trough and drain

pan. The humidifier may be mounted on the warm or

return air plenum with equal efficiency.

See Typical Installations.

ADDITIONAL MATERIALS THAT MAY BE NECESSARY:

1. 1/4" diameter plastic supply tubing or 1/4" copper

supply tubing for hot water applications

2. 7" diameter galvanized by-pass pipe

3. electrical wire and wire nuts

4. air pressure switch (G.F. Model #12500 suggested)

MODEL 1099

Install connecting collar and connect 7" elbow and by-pass pipe to

collar and humidifier cabinet. USE UNCRIMPED END IN

HUMIDIFIER CABINET. Using holes at top and bottom of humidifier

bypass opening drill 2---1/8" holes through bypass pipe and screw bypass pipe to humidifier cabinet.

Select location on vertical surface of warm or return air plenum for

mounting humidifier. Stick mounting template in place making sure the

template is level. Do not install humidifier or 7" bypass pipe where the

blanked off ends of a cooling coil will restrict air flow to the humidifier.

Extend horizontal centerline from template to the adjacent plenum. Scribe

7” circle 10” to 15” from side of humidifier, on cabinet centerline, using

connecting collar as guide.

Center punch and drill all six mounting holes as shown on template.

Cut out center section

of template and 7” hole

. Install all six cabinet

screws. Install drain pan, evaporator pad and distributor trough using

the four slide clips provided.

HIGH BOY COUNTER-FLOW LOW BOY

RETURN AIR

RETURN AIR

RETURN AIR

WARM AIR

WARM AIR

WARM AIR

WARM AIR

GENERALAire

AC SERIES

HIGH EFFICIENCY AIR CLEANER

R

DRAIN

DRAIN

DRAIN

Haut de la matrice

MATRICE POUR L'INSTALLATION

D'UN HUMIDIFICATEUR DE DÉRIVATION

COUPER SUR CETTE LIGNE

ALLOW 2 1/2 INCHES CLEARANCE ABOVE

THIS SURFACE FOR SERVICING

LAISSER 2 PO D'ESPACE LIBRE AU DESSUS

DE CETTE SURFACE POUR L'ENTRETIEN

SUIVRE LES INSTRUCTIONS DANS L'EMBALLAGE DE

L'HUMIDIFICATEUR

1. RETIRER LE PAPIER PROTECTEUR DU DOS DE LA

MATRICE ET COLLER À NIVEAU.

2.

3. DÉCOUPER LA PARTIE DU MILIEU DE LA MATRICE.

4. RETIRER LE RESTANT DE LA MATRICE.

ALLONGER CETTE LIGNE AFIN DE SITUER LE TROU SUR

LE PLÉNUMADJACENT

5.

6.

7.

Top Of Template

TEMPLATE FOR INSTALLING

BYPASS HUMIDIFIER

CUT ON THIS LINE

FOLLOW INSTRUCTIONS PACKED WITH HUMIDIFIER

1. REMOVE PROTECTIVE PAPER FROM BACK OF

TEMPLATEAND STICK IN LEVEL POSITION.

2. CENTER PUNCH AND DRILLTHETHREE TOP

MOUNTING HOLES WITH A 3/32" OR 1/8 " DIA. DRILL.

3. CUT OUT CENTER SECTION OF TEMPLATE.

4. REMOVE REMAINING TEMPLATE.

EXTENDTHIS LINE FOR LOCATING HOLE ON ADJACENT

PLENUM

5. INSTALL CABINET WITH THREETOP SCREWS.

6. LEVEL CABINETANDTIGHTEN SCREWS.

7. DRILLAND INSTALL BOTTOM SCREWS.

TEMPLATE NO. 1099-29

MATRICE NO. 1099-29

Page 2

SADDLE VALVE INSTALLATION INSTRUCTIONS

Copper Pipe

1. Retract piercing pin into valve body by turning handle

counterclockwise.

2. Screw valve body into upper bracket and tighten.

3. Place rubber gasket over piercing pin.

4. Assemble saddle valve over copper pipe using enclosed screws,

nuts and lower bracket.

5. Tighten screws evenly and firmly. Brackets should be parallel.

6. Complete compression connection to saddle valve outlet.

7. Turn handle clockwise to pierce tubing and close saddle valve.

8. Turn handle counterclockwise to

open saddle valve, leave open for

several seconds to flush dirt from pipe and tubing.

Steel, Brass or Hard Plastic Pipe

1. Shut off water supply and drain pipe.

2. Turn handle clockwise to expose piercing pin and close saddle

valve.

3. Place rubber gasket over piercing pin.

4. Drill 1/8" hole in pipe using a hand crank drill to avoid shock hazard.

5. Assemble saddle valve over steel, brass or hard plastic pipe using

enclosed screws, nuts and lower bracket.

6. Tighten screws evenly and firmly. Brackets should be parallel.

7. Complete compression connection to saddle valve outlet.

8. Turn handle counterclockwise to

open saddle valve, leave open for

several seconds to flush dirt from pipe and tubing.

Threaded Pipe Fittings

1. Turn handle clockwise to expose piercing pin and close saddle

valve.

2. Seal valve body threads using pipe tape or sealant.

3. Install valve into 1/8" NPT fitting.

4. Complete compression connection to saddle valve outlet.

5. Turn handle counterclockwise to

open saddle valve, leave open for

several seconds to flush dirt from pipe and tubing.

5

Attach solenoid valve to side of humidifier cabinet with flow arrow

pointing up, using thumb nuts provided. Do not reverse brass

fittings as valve will not function if flow is reversed. Inlet and outlet

ports on valve may be reversed by loosening hex nut on solenoid

coil and rotating valve 1/2 turn. Assemble distributor tube so that it

is directed into the center opening of the distributor trough cover.

Connect 1/4" water supply tube to brass filter at inlet of solenoid.

DO NOT USE PLASTIC TUBING IN CONTACT WITH ANY

HOT PLENUM SURFACE OR DUCT. IF USING PLASTIC

TUBING, USE TUBE SUPPORT PROVIDED.

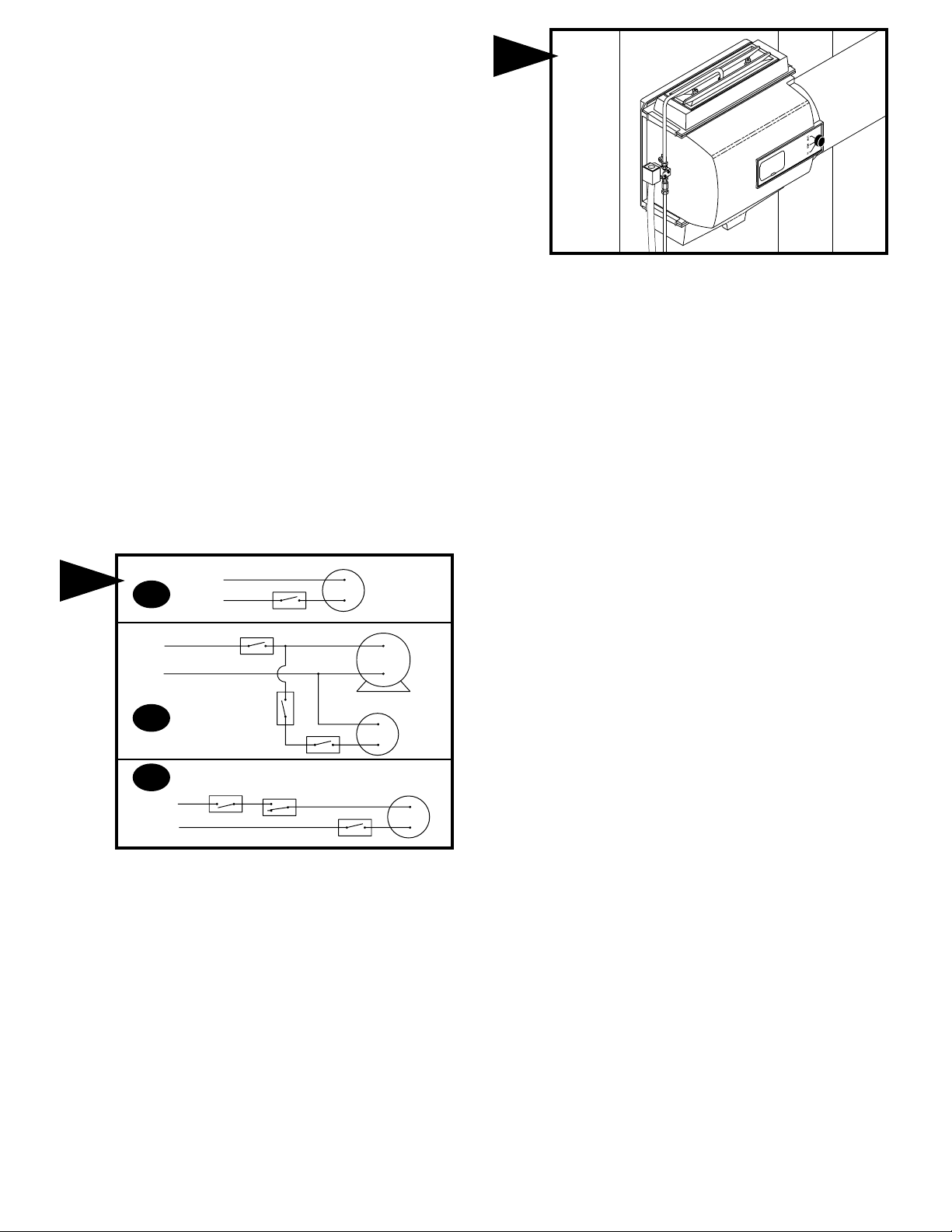

6

6 A

115v.

60CY.

6 B

6 C

115v.

60CY.

L1

(HOT)

L2

60CY.

L1

(HOT)

L2

115v.

ACC

EAC

(HOT)

C

FAN CONTROL

ON-OFF

SWITCH

ON-OFF

SWITCH

NO

HUMIDISTAT

12500 AIR

PRESSURE

SWITCH

HUMIDISTAT

HUMIDISTAT

C

HUMIDIFIER

115v. SOLENOID

VALVE

SINGLE

SPEED

BLOWER

MOTOR

HUMIDIFIER

115v.

SOLENOID

VALVE

HUMIDIFIER

115v. SOLENOID

VALVE

INSTRUCTIONS FOR WIRING

FIG. 6A WITH FURNACE CIRCUIT BOARD

On furnaces with output terminals ACC, or EAC check output voltage

to determine if terminals are 115V.

FIG. 6B WITH SINGLE SPEED BLOWER MOTOR

On furnaces with single speed blowers, wire the 115v. solenoid valve

in parallel with the blower circuit and install a manual on-off switch in

series with the 115v. solenoid valve.

FIG. 6C WITH TWO SPEED BLOWER MOTOR OR OUTSIDE

FURNACE CIRCUIT

On furnaces with a two speed blower motor or when wiring within the

furnace is not practical, the humidifier and a Model 12500 Air

Pressure Switch may be wired from a continuous 115 volt power

source. Install the on/off switch and Air Pressure Switch in series with

the 115v. solenoid valve on the hot or black wire. The Air Pressure

Switch will detect furnace operation and supply power to the

humidifier accordingly.

NOTE: ALL WIRING SHOULD COMPLY WITH LOCAL

ELECTRICAL CODES.

Page 3

FORM NO. 1099-30 REV. B (FILE 12428)

PARTS LIST FOR HUMIDIFIER

Turn on water supply and check operation of humidifier. Set

humidistat to a demand setting. With the furnace off, the

solenoid valve should be closed. Start the furnace, the

solenoid valve should open when the blower or burner circuit

is energized. Check flow of water through distributor trough

and evaporator pad. The standard 990-16-75 orifice will

supply approximately 4.8 GPH of water at a line water

pressure of 60 psi. For low water pressures (20-40 psi) a

larger orifice 990-16-74 is available to provide the same

flow.

Connect drain hose to 5/8" spout on humidifier cabinet using

hose clamp provided. Run 5/8" hose to suitable drain such

as floor drain, sewer or laundry sink. Be sure hose has

continuous slope and is not kinked at any point.

7

8

Litho in U.S.A.

FILL OUT AND MAIL THIS

WARRANTY CARD AND

LITERATURE REQUEST FORM

AIRC

LEANERS AND AIRPURIFIERS

H

UMIDIFIERS

D

IGITALHUMIDITYGAGE

AIRF

ILTERGAGE

F

UELOILFILTERS AND

A

CCESSORIES

1099-9 THUMB NUT

1099-8 TROUGH COVER

1099-2 DISTRIBUTOR TROUGH

1099-12 DISTRIBUTOR TUBE

1099-20 EVAPORATOR PAD

CABINET ASSEMBLY

1099-24 (115 V.)

P-103 COMPRESSION NUT

P-104 COMPRESSION SLEEVE

P-111 CONNECTOR

SOLENOID VALVE ASSEMBLY

1099-41 (115 V.)

990-37-75 ORIFICE & STRAINER

ASSEMBLY

990-16-75 ORIFICE FITTING

990-17 STRAINER SCREEN

990-18 STRAINER BODY

1099-7 SLIDE CLIP

1099-3 DRAIN PAN

P-163 HOSE CLAMP

1099-16 DRAIN TUBE

Page 4

LIMITED WARRANTY

This humidifier, if properly registered by the return of the warranty registration card to the manufacturer, is warranted to the consumer against defects in

materials and workmanship for a period of one year from the date of installation. Evaporator pads, sleeves or plates are not covered by this limited

warranty or any other warranties. Any other defective parts will be repaired without charge except for removal, reinstallation and transportation costs. To

obtain repair service under this limited warranty, the consumer must send the defective part or the complete humidifier to the manufacturer.

THERE ARE NO EXPRESS WARRANTIES COVERING THIS HUMIDIFIER OTHER THAN AS SET FORTH ABOVE, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED IN DURATION TO ONE YEAR. THE MANUFACTURER

ASSUMES NO LIABILITY IN CONNECTION WITH THE INSTALLATION OR USE OF THIS PRODUCT, EXCEPT AS STATED IN THIS LIMITED

WARRANTY. THE MANUFACTURER WILL IN NO EVENT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

This limited warranty gives you specific legal rights, and you may also have other rights which vary from state to state. Some states do not allow either

limitations on implied warranties, or exclusions from incidental or consequential damages, so the above exclusion and limitation may not apply to you.

Any questions pertaining to this limited warranty should be addressed to the manufacturer. (U.S.A.: The manufacturer has elected not to make available

the informal dispute settlement mechanism which is specified in the Magnuson-Moss Warranty Act.)

GENERAL FILTERS, INC. 43800 GRAND RIVER AVE. NOVI, MICHIGAN 48375-1115 WWW.GENERALAIRE.COM

CANADIAN GENERAL FILTERS, LTD. 39 CROCKFORD BLVD. SCARBOROUGH, ONTARIO M1R3B7 WWW.CGFPRODUCTS.COM

CARE AND MAINTENANCE

Your Humidifier is engineered to give helpful and trouble-free humidification. For maximum efficiency the following cleaning procedures should be carried

out at the end of each heating season:

1. Turn off water supply and electrical power to humidifier.

2. Remove water distributor tube, distributor trough, evaporator pad and drain pan. The evaporator pad may be

removed from either the top or bottom of the humidifier. Clean excessive mineral deposits from the distributor trough,

cover, drain pan and humidifier cabinet. A solution of 1/2 vinegar & 1/2 water will help loosen mineral deposits.

3. If the evaporator pad has excessive mineral deposits, replace with a new “990-13” evaporator pad. Install trough

and drain pan. Replace cover and the distributor tube to proper position over the distributor trough.

4. In heavy mineral areas or if the solenoid valve fails to function disconnect the 1/4” water supply line from the

solenoid valve. Remove the brass strainer body (P.N. 990-18) from the solenoid valve. Carefully pull the strainer

screen (P.N. 990-17) from the orifice fitting (P.N. 990-16). Clean the mineral deposits from all parts. If the orifice is

clogged, it may be opened by inserting a small needle. Reinsert the filter into the orifice fitting and screw the brass

strainer body into the solenoid valve.

5. Reconnect the 1/4” water line to the solenoid valve if necessary. Turn on the water supply and check all points for

leakage. The operation of the unit may be checked by starting the furnace. The humidifier operates only when the

furnace blower is running or the burner circuit is energized. The humidifier is now ready for operation.

6. During the summer, turn off water supply and electrical power to humidifier. Close air damper.

AT

OUTSIDE

TEMPERATURE

-20 F -29 Cϒ 15%

-10 F -23 Cϒ 20%

0 F -18 Cϒ 25%

+10 F -29 C

ϒ 30%

+20 F - 7 C

ϒ 35%

+30 F - 1 Cϒ 40%

RECOMMENDED

ϒ

ϒ

ϒ

ϒ

ϒ

ϒ

SETTING

OWNER FILL IN

REGISTRATIO

AND MAIL TO

D

C

ATE OF

ITY

:

I

NSTALLATION:

D

S

TREET

C

EALER'S

ITY

:

A

DDRESS

N

AME

:

:

S

TATE

:

S

ERIAL

N

UMBER:

P

OSTAL

C

ODE

S

TATE

:

P

OSTAL

C

ODE

O

S

TREET

WNER'S NAME

A

DDRESS

:

:

MODEL 1099 Flow Through Bypass Humidifier

WARRANTY REGISTRATION

:

N

GENERAL FILTERS, INC.

43800 GRAND RIVER AVE

NOVI, MI 48375-1115

economical means of evaporating water to the air. The humidifier uses only

six watts of electrical power during operation, less than the smallest

household light bulb. The heat necessary for evaporating water is produced

by the furnace.

The water supply to the humidifier is controlled by the electric solenoid

valve.

HUMIDITY TOO HIGH DURING COLD WEATHER. EXCESSIVE

HUMIDITY MAY CAUSE CONDENSATION ON WINDOWS OR IN WALLS.

Water flows through a strainer, is metered through an orifice to provide the

proper amount of water, and is supplied to the evaporator pad by the

distributor trough. Approximately 200 CFM of air is by-passed from the

warm air plenum through the humidifier and returned to the cold air plenum.

Moisture is evaporated to the air passing through the evaporator pad.

Minerals are not blown into the air stream as occurs in atomizing

humidifiers; they are left on the evaporator pad where a high percentage is

carried off with the waste water.

necessary other than setting the control knob on the humidifier to the

desired level of humidification.

To turn the humidifier off, close water supply valve, switch electrical power

off and turn humidistat off. If furnace is used for summer cooling or

ventilating set air damper on "LOW" or "SUMMER".

HOW THE HUMIDIFIER WORKS

The operating principle of the humidifier is based on the most efficient and

ELECTRICAL RATING: 115 VAC / 60 Hz. DO NOT SET RELATIVE

When the humidifier is installed and operating, no adjustments are

:

:

Loading...

Loading...