GE ZDP304LP2SS, ZDP304LP3SS, ZDP304LP4SS, ZDP304LP5SS, ZDP304LP6SS Installation Guide

...

Installation

Instructions

30", 36" and 48"

Professional Ranges

Cuisini_res professionnelles

de 30" (76 cm), 36" (91 cm)

et de 48" (121 cm)

Instructions d'installation

La section fran_aise commence 6 la page 24

131-i0689-31

06-09JR

Cocinas profesionales

de 30", 36"y 48"

Instrucciones de instalaci6n

La secci6n en espa6ol empieza en la p6gina 46

Installation Instructions

BEFORE YOU BEGIN

Readthese instructions completely and carefully.

• IMPORTANT-Savethese instructionsfor local

inspector's use.

• IMPORTANT-Observeallgoverningcodesand

ordinances.

• Note to Installer- Besureto leavethese instructions

with the Consumer.

° Note to Consumer- Keepthese instructions

with your Owner's Manualfor future reference.

• Completion Time- i to 3 hours.

• Properinstallation isthe responsibility ofthe installer.

Productfailure due to improper installation isnot covered

under the warranty. SeeOwner's Manualfor warranty

information.

- WARNING:

Thisappliance must be properly grounded. See"Electric

Supply."

ForMonogram localservice in your area,1.800.444.1845.

ForMonogram Servicein Canada,call 1.800.561.3344.

ForMonogram Partsand Accessories,call 1.800.626.2002.

If you receiveda damaged range,you should contact your

dealer.

Inthe Commonwealth of Massachusetts:

• Thisproduct must be installed by a licensedplumber or gas

fitter.

• When usingballtype gas shut off valves,they shall be

T-handletype.

• A flexible gasconnector,when used,must not exceed

3feet.

-AWARNING:

All ranges can tip. Injury could result. Install the

supplied Anti-Tip Bracket provided. See instructions

in this manual or with the bracket.

Ifsoldoutside the U.S.and Canada:

Vent hood Combinations:

It isrecommended that these ranges be installed

in conjunction with a suitable overhead vent hood.

• Installahood with at least 1200CFMabove a 48"

wide range.

• Installahood with at least600 CFMabove a 30"

or 36" range.

Dueto the high heat capacity ofthis unit, particular attention

should be paid to the hood and ductwork installation to

assure it meets local building codes.

-AWARNING:

Clearancesto horizontal surfaces above the range,

measured to the cooking surface:

• Installationswithout a hood require 48"minimum

to combustibles.

• A custom hood installation with exposedhorizontal

combustiblessurfaces must have an Auto-On feature.

• Forother installationswith a hood,refer to hood installation

instructionsfor specifichood clearances.

- CAUTION:

Theserangesweigh up to 700 pounds. Somedisassembly

will reduce the weight considerably. Dueto the weight and

sizeof the range and to reducethe riskof personal injury

or damage to the product:

TWOPEOPLEAREREQUIREDFORPROPERINSTALLATION

OF36" AND 30" RANGES.

THREEPEOPLEAREREQUIREDFORPROPERINSTALLATION

OF48" RANGES.

Leaktesting of the appliance shallbe conducted according

to the manufacturer's instructions.

Installation must conform with localcodes. Inthe absence

of local codes,the range must comply with the National Fuel

GasCode,ANSIZ223.1/NFPA54,latest edition and National

ElectricalCode ANSI/NFPA70 latest addition. In Canada,

installation must conform with the current Natural Gas

Installation Code,CAN/CGA-B149.1or the current Propane

Installation Code,CAN/CGA-B149.2,and with local codes

where applicable.Thisrange hasbeen design-certified by

CSAInternational according to ANSIZ21.1,latest edition and

CanadianGas Associationaccording to CAN/CGA-I.1latest

edition.

-AWARNING:lfyouwishtousethis product with

Liquefied Petroleum (LP)gas containing greater than 10%

butane, you must purchase the butane conversion kit

#WB28K10589. Toorder, please call 1.888.664.8403

or 1.787.276.4051.

Design Information

CONTENTS

Design Information

Models Available ......................................................................3

Backsplash Accessories ......................................................3

Product Dimensions and Clearances ......................../4-7

Tools and Materials Required ..........................................8

Installation Preparation

Power Supplg Locations ..............................................9, 10

MODELS AVAILABLE

These Monogram ranges are factorg set for either

natural gas or LP gas. Order the model for gour

installation situation.

48" Natural Gas Models:

ZDP484NG - 4 gas burners, grill and griddle

ZDP486NR - 6 gas burners and grill

ZDP486ND - 6 gas burners and griddle

48" LP Gas Models:

ZDP484LG - 4 gas burners, grill and griddle

ZDP486LR - 6 gas burners and grill

ZDP486LD - 6 gas burners and griddle

Installation Instructions

Step 1, Remove Packaging ..............................................

Step 2, Move Range Indoors ..........................................

Step 3, Install Anti-Tip Device ........................................

Step 4, Connect Range to Gas........................................

Step 5, Connect Electrical ................................................

Step 6, Roll Range into Position ....................................

Step 7, Level the Range ....................................................

Step 8, Replace Oven Doors ............................................

Step 9, Check Burners ........................................................

Finalize Installation ..............................................................

Installation Checklist ..........................................................

Accessories ..............................................................................

1

2

3

.4

4

4

5

5

6

6

6

7

Accessorg Installation ................................................18J20

Gas Conversion ............................................................21-23

36" Natural Gas Models:

ZDP366N - 6 gas burners

ZDP364NR- 4 gas burners and grill

ZDP364ND - 4 gas burners and griddle

36" LP Gas Models:

ZDP366L - 6 gas burners

ZDP364LR - 4 gas burners and grill

ZDP364LD - 4 gas burners and griddle

30" Natural Gas Model: ZDP304N

30" LP Gas Model: ZDP304L

BACKSPLASH ACCESSORIES

All models require 12" minimum clearance to a

vertical combustible surface at the rear. If clearance

is less than 12L the entire surface of the back wall

above and the full width of the range must be

protected by a backsplash. The backsplash must be

constructed of non-combustible material, such as

metal, ceramic tile, brick, marble or other stone.

Two Backsplash Accessories Available:

• The 12" high stainless steel backsplash accessorg

is available. Use this backsplash in combination

with a custom, non-combustible backsplash built

begond the 12" height. The combined height of

the backsplash accessorg and the custom

backsplash must reach the bottom of a hood,

or when there is no hood, to 48" above the

cooking surface.

• An adjustable 30" to 36" high backsplash with

shelf is also available. This backsplash fills in the

space between the top of the range and the

bottom of the hood. The shelf is positioned so that

heat lamps from the bottom of a Monogram

professional hood are directed towards the shelf.

12"HighBacksplash

ZX12B48PSS,for48"wideranges

ZX12B36PSS,for36"wideranges

ZX12B30PSS,for30"wideranges

30"to36" AdjustableHeight

BacksplashWith Shelf

ZXADJB48PSS,for 48"wide ranges

ZXADJB36PSS,for 36"wide ranges

ZXADJB30PSS,for 30"wide ranges

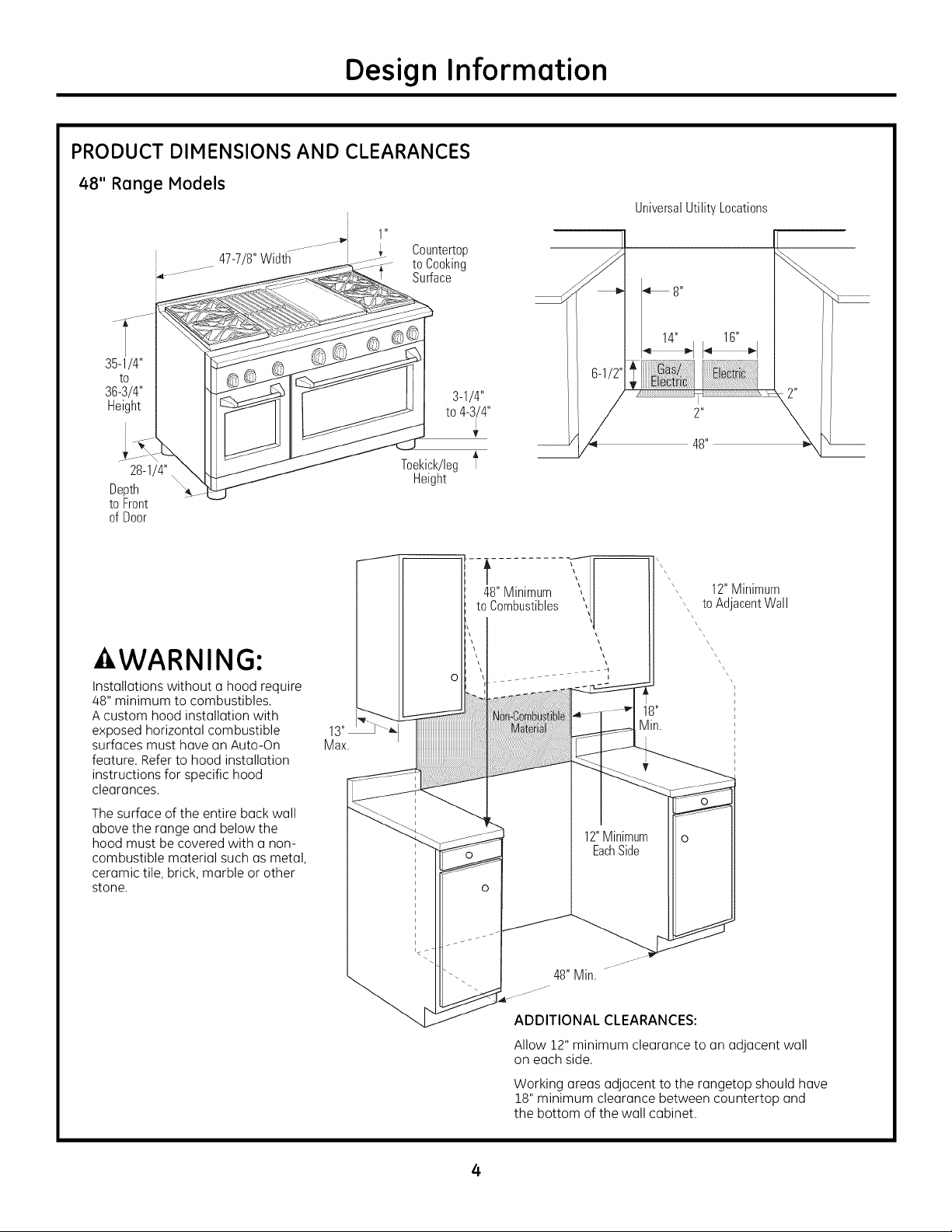

Design Information

PRODUCT DIMENSIONS AND CLEARANCES

48" Range Models

1 "

Countertop

_ .......47-7/8"Width to Cooking

.............. Surface

UniversalUtilityLocations

35-1/4"

to

36-3/4"

Height

28-1/4"

Depth

to Front

of Door

WARNING:

Installations without a hood require

48" minimum to combustibles.

Acustom hood installation with

exposed horizontal combustible

surfaces must have an Auto-On

feature. Refer to hood installation

instructions for specific hood

clearances.

The surface of the entire back wall

above the range and below the

hood must be covered with a non-

combustible material such as metal,

ceramic tile, brick, marble or other

stone.

Ii i

3-1/4"

to 4-3/4"

Toekick/leg _'

Height

12"Minimum

', toAdacentWall

Max.

ADDITIONAL CLEARANCES:

Allow 12" minimum clearance to an adjacent wall

on each side.

Working areas adjacent to the rangetop should have

18" minimum clearance between countertop and

the bottom of the wall cabinet.

4

Design Information

PRODUCT DIMENSIONS AND CLEARANCES

36" Range Models

1 "

35-7/8"Width

35-1/4"

to

36-3/4"

Height

Countertop

to Cooking

Surface

UniversalUtility Locations

28-1/4"

Depth

to Front

of Door

-AWARNING:

Instollotions without o hood require

48" minimum to combustibles.

A custom hood instollotion with

exposed horizontol combustible

surfoces must hove on Auto-On

feoture. Refer to hood instollotion

instructions for specific hood

cleoronces.

The surfoce of the entire bock woll

obove the ronge ond below the

hood must be covered with o non-

combustible moteriol such os metol,

ceromic tile, brick, morble or other

stone.

Toekick/leg

Height

12"Minimum

to Ac acentWall

48"Minimum

toCombustibles

Max.

ADDITIONAL CLEARANCES:

Allow 12" minimum cleoronce to on odjocent woll

on each side.

Working oreos odjocent to the rongetop should hove

18" minimum cleoronce between countertop ond

the bottom of the woll cobinet.

5

Design Information

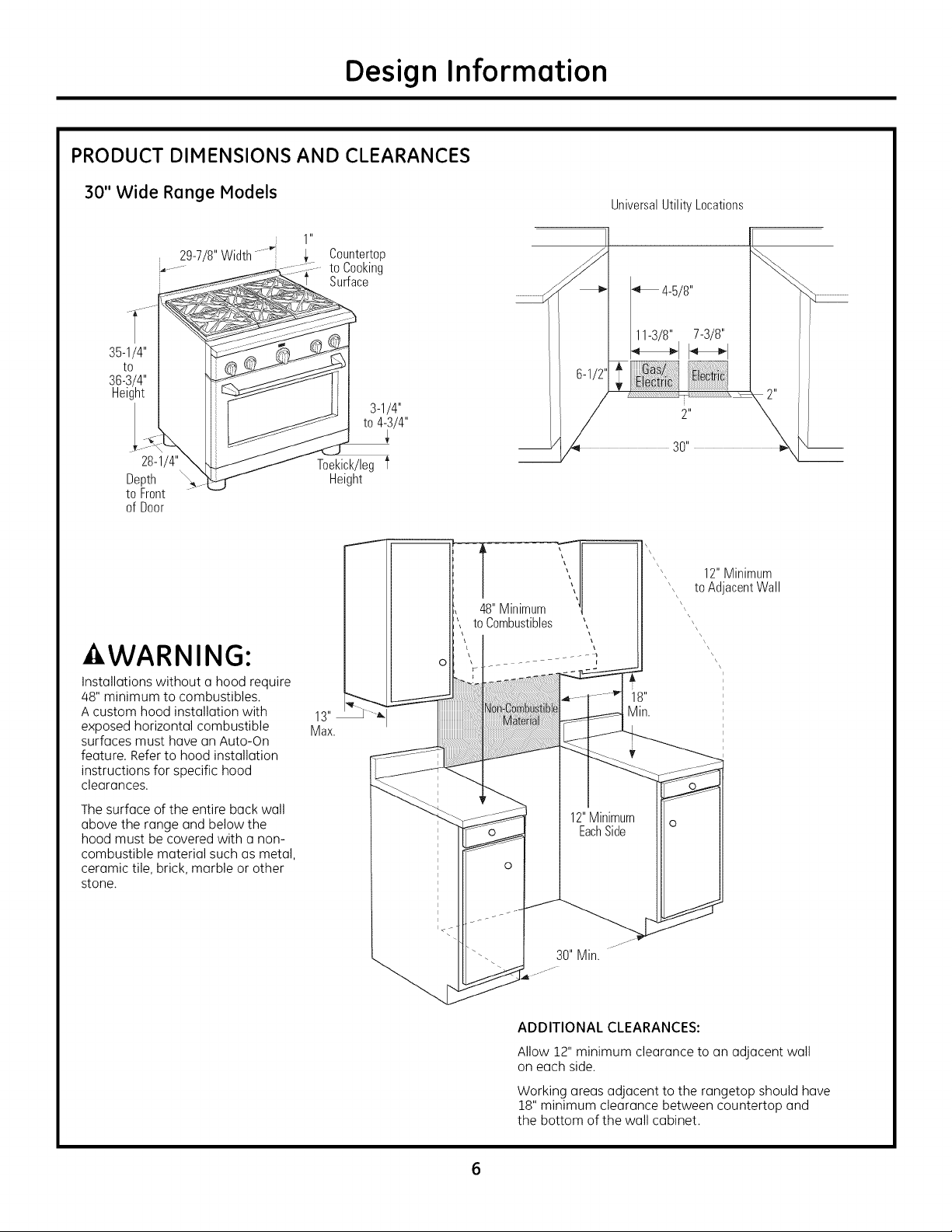

PRODUCT DIMENSIONS AND CLEARANCES

30" Wide Range Models

29-7/8"Width

35-1/4"

to

36-3/4"

Height

28-1/4"

Depth

to Front

of Door

1 "

Countertop

to Cooking

Surface

Toekick/leg f

Height

UniversalUtility Locations

12"Minimum

\\

\\

to Ac acentWall

WARNING:

Installations without a hood require

48" minimum to combustibles.

Acustom hood installation with

exposed horizontal combustible

surfaces must have an Auto-On

feature. Refer to hood installation

instructions for specific hood

clearances.

The surface of the entire back wall

above the range and below the

hood must be covered with a non-

combustible material such us metal,

ceramic tile, brick, marble or other

stone.

ADDITIONAL CLEARANCES:

Allow 12" minimum clearance to an adjacent wall

on each side.

Working areas adjacent to the rangetop should have

18" minimum clearance between countertop and

the bottom of the wall cabinet.

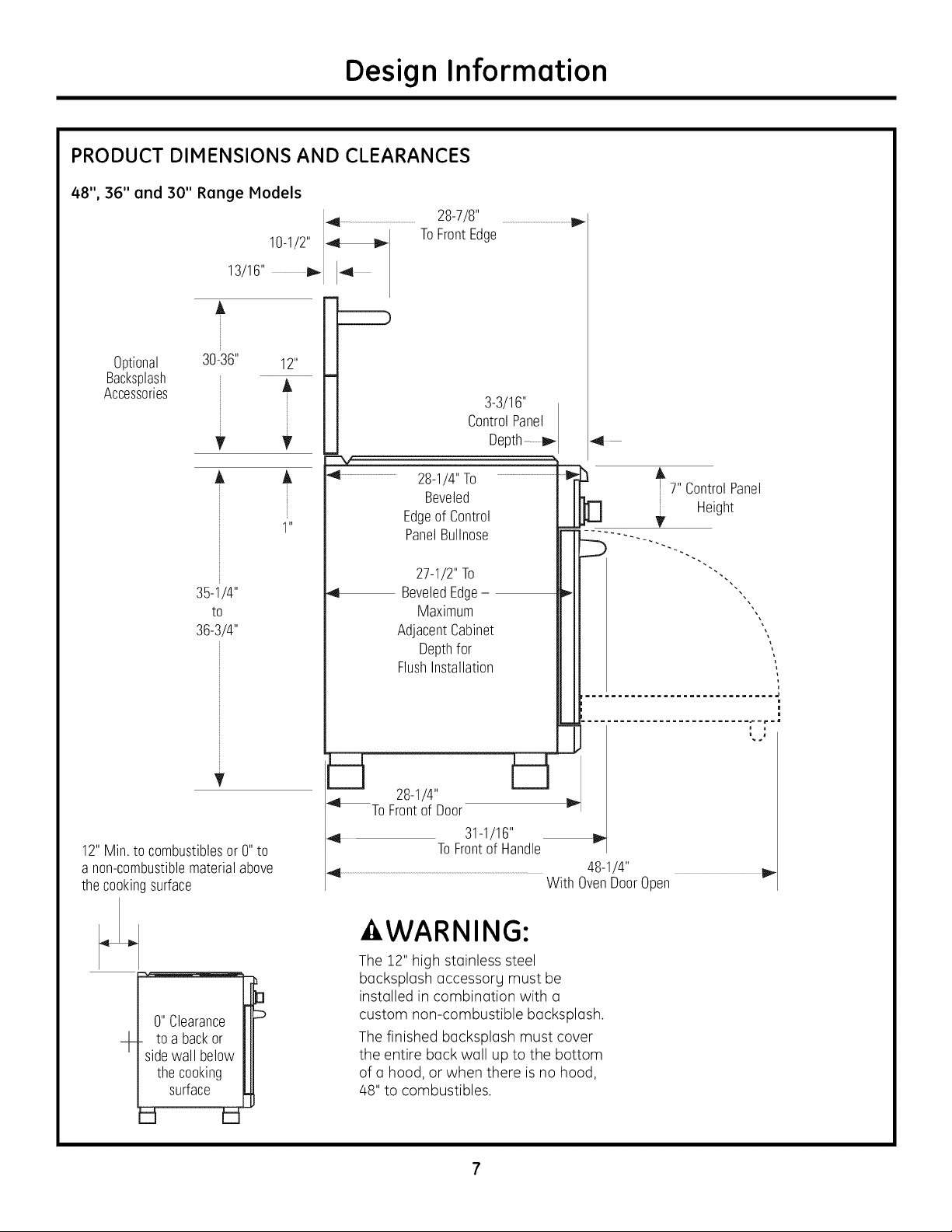

Design Information

PRODUCT DIMENSIONS AND CLEARANCES

48", 36" and 30" Range Models

28-7/8" ............................................................

10-1/2" _

13/16" I_ 4

A

ToFrontEdge

Optional

Backsplash

Accessories

30-36"

35-1/4"

to

36-3/4"

v

,,

A

--__

,,11 28-1/4"To

,1

,4t

bl b1

4 ToFrontof Door

3-3/16"

ControlPanel

Beveled

Edgeof Control

PanelBullnose

27-1/2"To

BeveledEdge

Maximum

AdjacentCabinet

Depthfor

FlushInstallation

28-1/4"

Depth

4

A

7" ControlPanel

Height

V

u

u

u

12"Min.to combustiblesor0"to

a non-combustiblematerialabove

thecookingsurface

0"Clearance

- toabackor

sidewall below

thecooking

surface

4 31-1/16"

ToFrontof Handle

48-1/4" 11_

With OvenDoorOpen

- WARNING:

The 12" high stoinless steel

bocksplosh occessorg must be

instolled in combinotion with o

custom non-combustible backsplash.

The finished backspl(]sh must cover

the entire back wall up to the bottom

of a hood, or when there is no hood,

48" to combustibles.

Installation Information

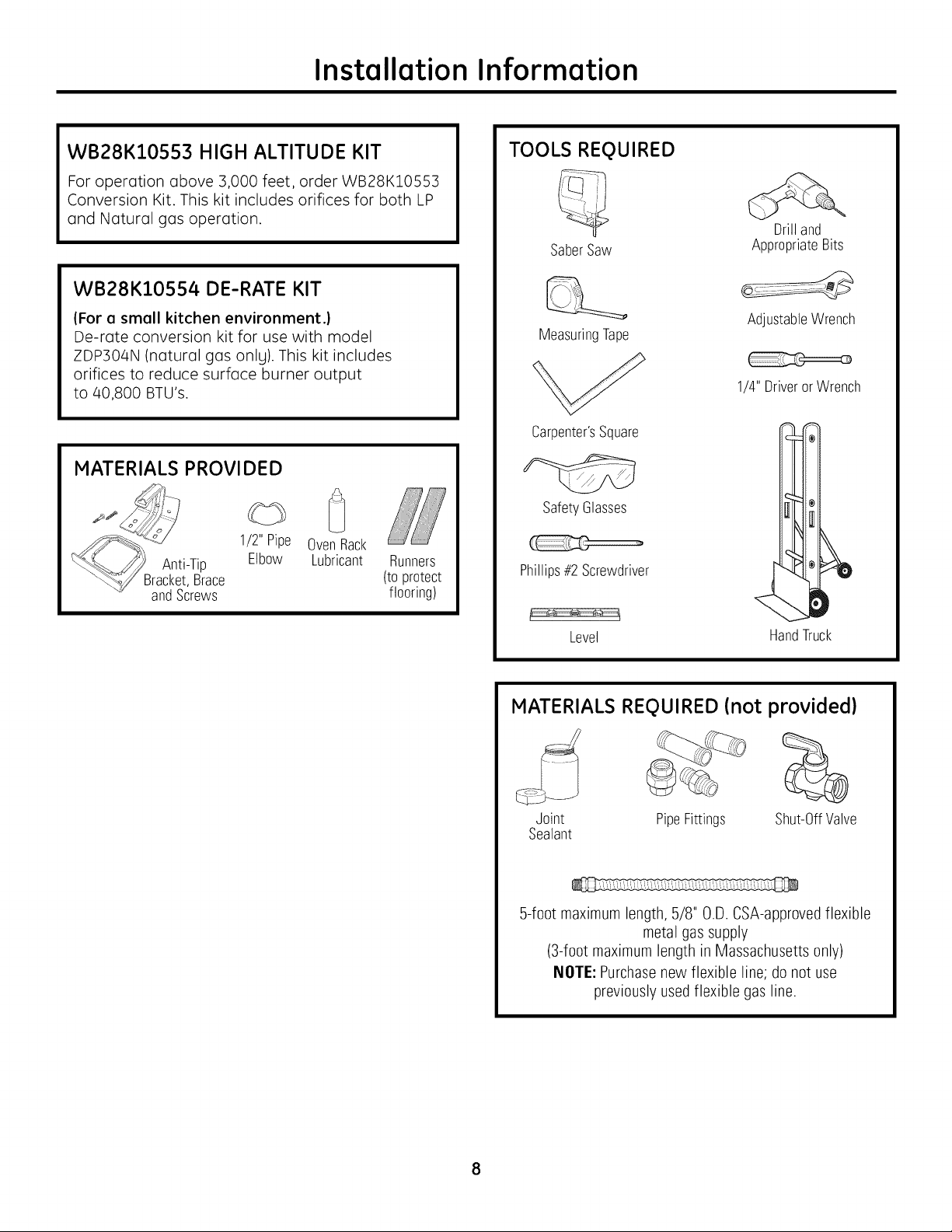

WB28K10553 HIGH ALTITUDE KIT

For operation above :3,000 feet, order WB28K10553

Conversion Kit. This kit includes orifices for both LP

and Natural gas operation.

WB28K10554 DE-RATE KIT

(For e smell kitchen environment.)

De-rate conversion kit for use with model

ZDP304N (natural gas only). This kit includes

orifices to reduce surface burner output

to 40,800 BTU's.

MATERIALS PROVIDED

1/2" Pipe

Anti-Tip Elbow

3racket,Brace

andScrews

OvenRack

Lubricant

Runners

(toprotect

flooring)

TOOLS REQUIRED

SaberSaw

MeasuringTape

Carpenter'sSquare

SafetyGlasses

Phillips#2Screwdriver

Drilland

AppropriateBits

AdjustableWrench

1/4" DriverorWrench

Level

HandTruck

MATERIALS REQUIRED (not provided)

Joint PipeFittings Shut-OffValve

Sealant

5-foot maximum length, 5/8" 0.D. CSA-approvedflexible

metal gas supply

(3-foot maximum length in Massachusetts only)

NOTE: Purchasenew flexible line; do not use

previously used flexible gas line.

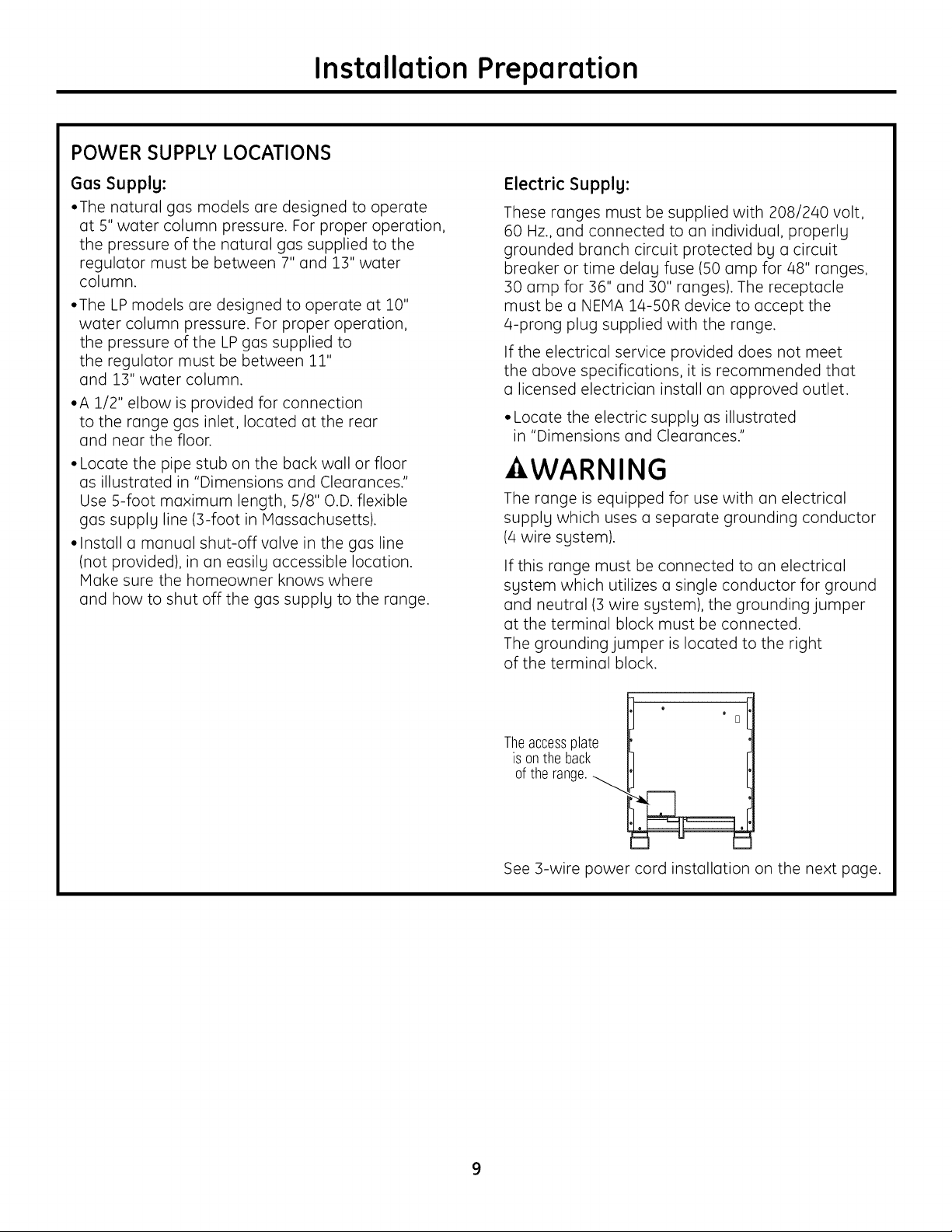

POWER SUPPLY LOCATIONS

Installation Preparation

Gas Supplg:

•The naturalgas models are designed tooperate

at 5"water column pressure.Forproper operation,

the pressureofthe naturalgas suppliedtothe

regulatormust be between 7"and 13"water

column.

• The LP models are designed to operate at 10"

water column pressure. For proper operation,

the pressure of the LP gas supplied to

the regulator must be between 11"

and 13" water column.

• A 1/2" elbow is provided for connection

to the range gas inlet, located at the rear

and near the floor.

• Locate the pipe stub on the back wall or floor

as illustrated in "Dimensions and Clearances."

Use S-foot maximum length, 5/8" O.D. flexible

gas supplg line (3-foot in Massachusetts).

• Install o manual shut-off valve in the gas line

(not provided), in on eosilg accessible location.

Make sure the homeowner knows where

and how to shut off the gas supplg to the range.

Electric Supplg:

These ranges must be supplied with 208/240 volt,

60 Hz., and connected to an individual, properlg

grounded branch circuit protected bg a circuit

breaker or time delog fuse (50 amp for 48" ranges,

30 amp for 36" and 30" ranges). The receptacle

must be o NEMA 14-50R device to accept the

4-prong plug supplied with the range.

If the electrical service provided does not meet

the above specifications, it is recommended that

a licensed electrician install an approved outlet.

• Locate the electric supply as illustrated

in "Dimensions and Clearances."

WARNING

The range is equipped for use with an electrical

supply which uses a separate grounding conductor

(4 wire system).

If this range must be connected to an electrical

system which utilizes a single conductor for ground

and neutral (3 wire system), the grounding jumper

at the terminal block must be connected.

The grounding jumper is located to the right

of the terminal block.

o

Theaccessplate

is onthe back

of the range.

See 3-wire power cord installation on the next page.

o

D

Installation Preparation

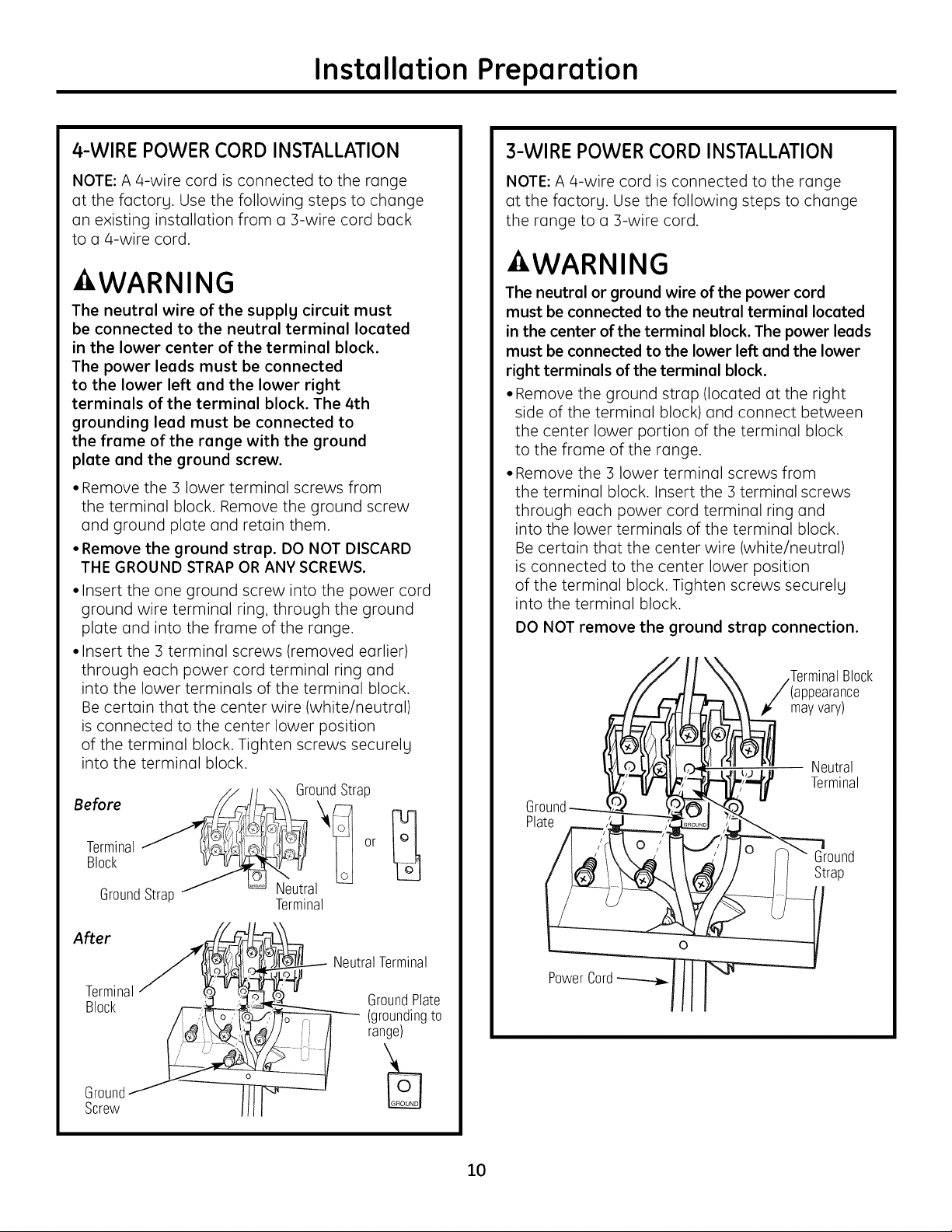

4-WIRE POWER CORD INSTALLATION

NOTE: A a-wire cord is connected to the range

at the factory. Use the following steps to change

an existing installation from a 3-wire cord back

to a a-wire cord.

-&WARNING

The neutral wire of the supplg circuit must

be connected to the neutral terminal located

in the lower center of the terminal block.

The power leeds must be connected

to the lower left end the lower right

terminals of the terminal block. The 4th

grounding lead must be connected to

the frame of the range with the ground

plate end the ground screw.

• Remove the 3 lower terminal screws from

the terminal block. Remove the ground screw

and ground plate and retain them.

• Remove the ground strap. DO NOT DISCARD

THE GROUND STRAP OR ANY SCREWS.

• Insert the one ground screw into the power cord

ground wire terminal ring, through the ground

plate and into the frame of the range.

• Insert the 3 terminal screws (removed earlier)

through each power cord terminal ring and

into the lower terminals of the terminal block.

Be certain that the center wire (white/neutral)

is connected to the center lower position

of the terminal block. Tighten screws securely

into the terminal block.

GroundStrap

3-WIRE POWER CORD INSTALLATION

NOTE: A 4-wire cord is connected to the range

atthe factory. Use the following steps to change

the range to a 3-wire cord.

-AWARNING

The neutral or ground wire of the power cord

must be connected to the neutral terminal located

in the center of the terminal block. The power leeds

must be connected to the lower left end the lower

right terminals of the terminal block.

• Remove the ground strap (located at the right

side of the terminal block) and connect between

the center lower portion of the terminal block

to the frame of the range.

• Remove the 3 lower terminal screws from

the terminal block. Insert the 3 terminal screws

through each power cord terminal ring and

into the lower terminals of the terminal block.

Be certain that the center wire (white/neutral)

is connected to the center lower position

of the terminal block. Tighten screws securely

into the terminal block.

DO NOT remove the ground strap connection.

.TerminalBlock

3earance

mayvary)

Neutral

Terminal

Terminal or

Block

GroundStrap Neutral

After

Terminal

Block

Ground

Screw

Terminal

NeutralTerminal

Plate

Ground

Strap

PowerCord

GroundPlate

(groundingto

range)

10

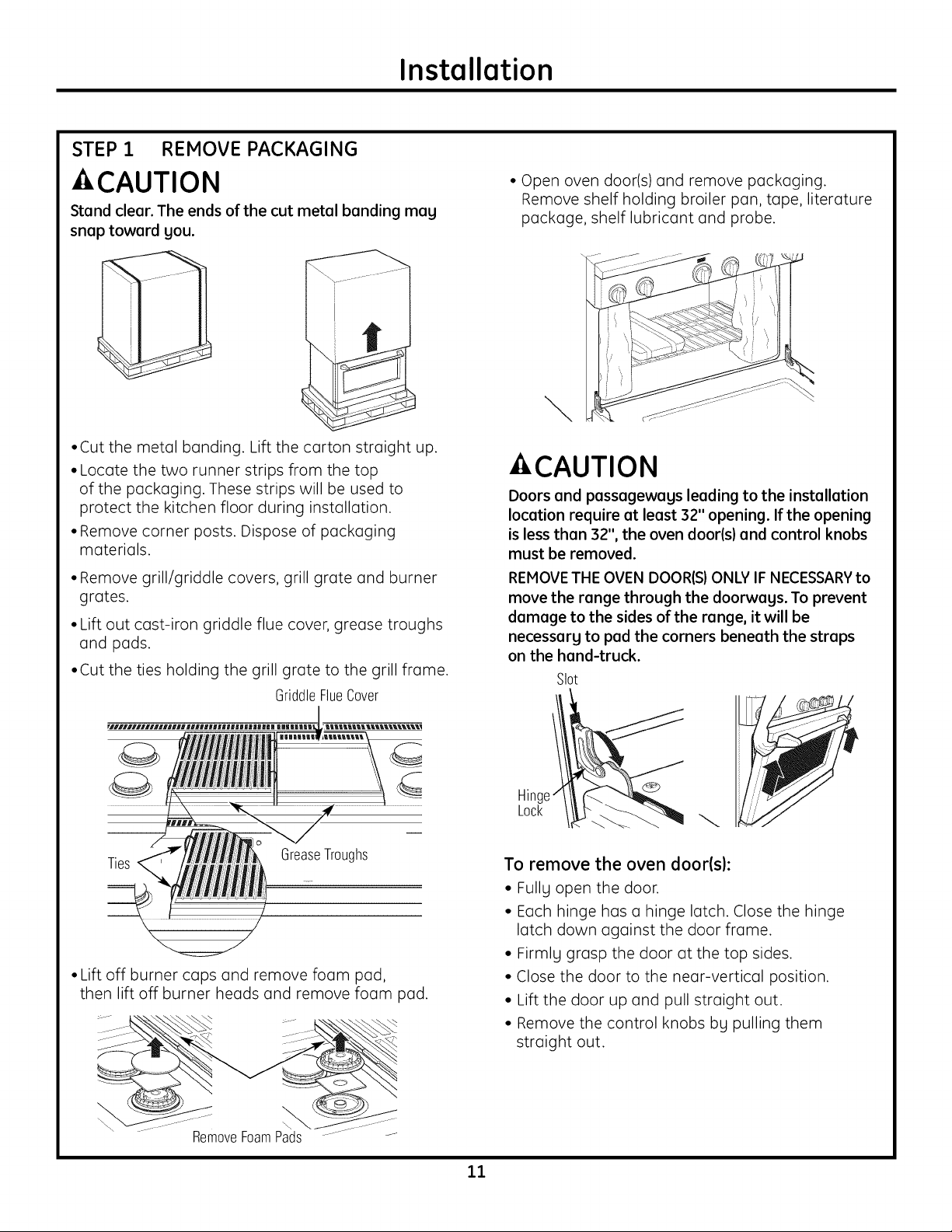

STEP 1 REMOVE PACKAGING

Installation

- CAUTION

Stand clear. The ends of the cut metal banding mag

snap toward gou.

•Cut the metal banding. Lift the carton straight up.

• Locate the two runner strips from the top

of the packaging. These strips will be used to

protect the kitchen floor during installation.

• Remove corner posts. Dispose of packaging

materials.

• Remove grill/griddle covers, grill grate and burner

grates.

• Lift out cast-iron griddle flue cover, grease troughs

and pads.

•Cut the ties holding the grill grate to the grill frame.

GriddleFlueCover

• Open oven door(s) and remove packaging.

Remove shelf holding broiler pan, tape, literature

package, shelf lubricant and probe.

\

CAUTION

Doors and passagewags leading to the installation

location require at least 32" opening. If the opening

is less than 32", the oven door(s) and control knobs

must be removed.

REMOVETHE OVEN DOOR(S)ONLY IF NECESSARYto

move the range through the doorwags. To prevent

damage to the sides of the range, it will be

necessarg to pad the corners beneath the straps

on the hand-truck.

G

Ties

• Lift off burner caps and remove foam pad,

then lift off burner heads and remove foam pad.

RemoveFoamPads

GreaseTroughs

Hinge

Lock

To remove the oven door(s):

• Fully open the door.

• Each hinge has a hinge latch. Close the hinge

latch down against the door frame.

• Firmlg grasp the door at the top sides.

• Close the door to the near-vertical position.

• Lift the door up and pull straight out.

• Remove the control knobs bg pulling them

straight out.

11

Installation Preparation

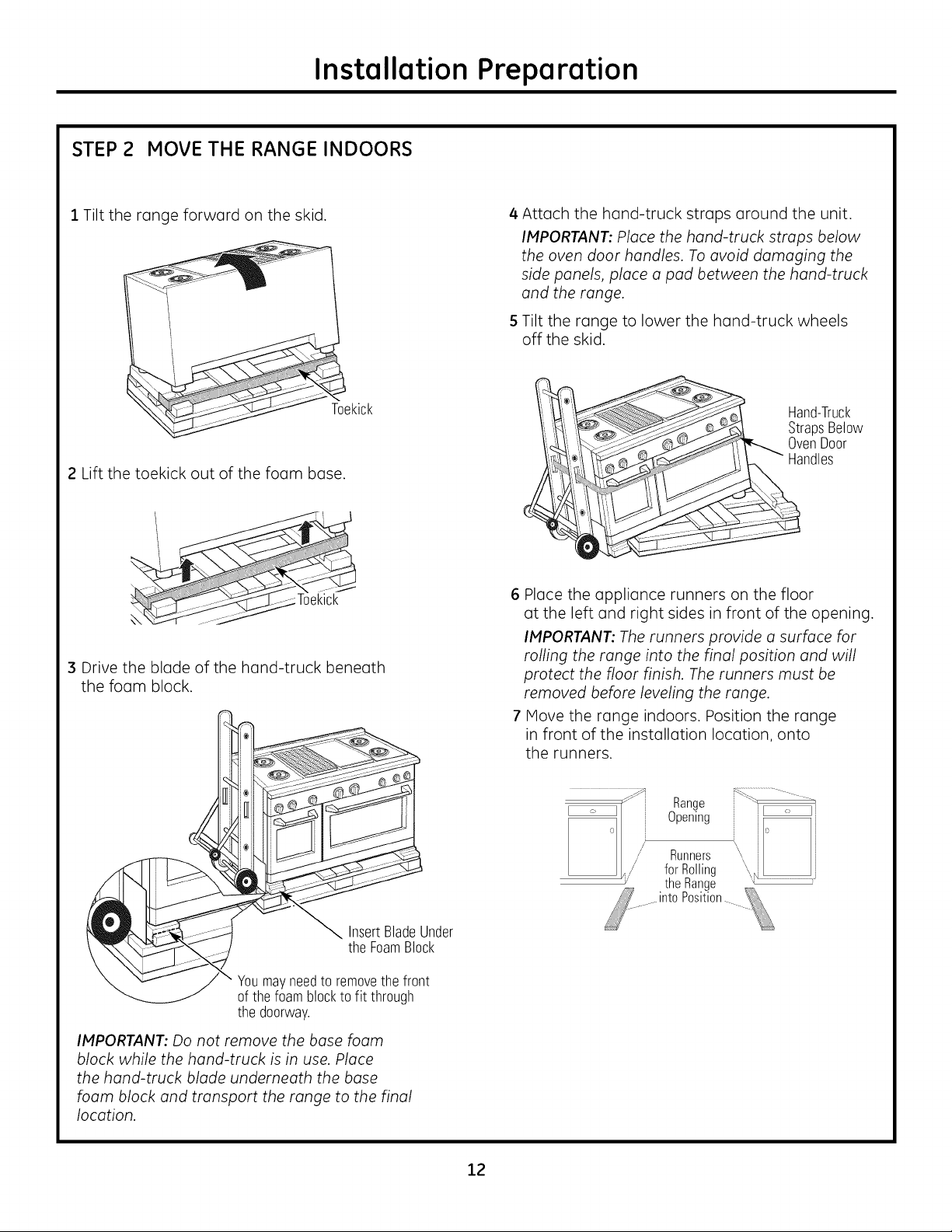

STEP 2 MOVE THE RANGE INDOORS

1 Tilt the range forward on the skid.

_Toekick

2 Lift the toekick out of the foam base.

, ,,J

,_,_" _i_I

3 Drive the blade of the hand-truck beneath

the foam block.

4 Attach the hand-truck straps around the unit.

IMPORTANT: Place the hand-truck strops below

the oven door handles. To ovoid damaging the

side ponds, place a pod between the hand-truck

and the range.

5 Tilt the range to lower the hand-truck wheels

off the skid.

Hand-Truck

StrapsBelow

OvenDoor

Handles

6 Place the appliance runners on the floor

at the left and right sides in front of the opening.

IMPORTANT: The runners provide a surface for

rolling the range into the final position and will

protect the floor finish. The runners must be

removed before leveling the range.

7 Hove the range indoors. Position the range

in front of the installation location, onto

the runners.

InsertBladeUnder

the FoamBlock

Youmayneedto removethefront

ofthe foamblockto fit through

the doorway.

IMPORTANT: Do not remove the base foam

block while the hand-truck is in use. Place

the hand-truck blade underneath the bose

foam block and transport the range to the final

location.

Range

Opening

Runners

forRolling

the Range

Position

12

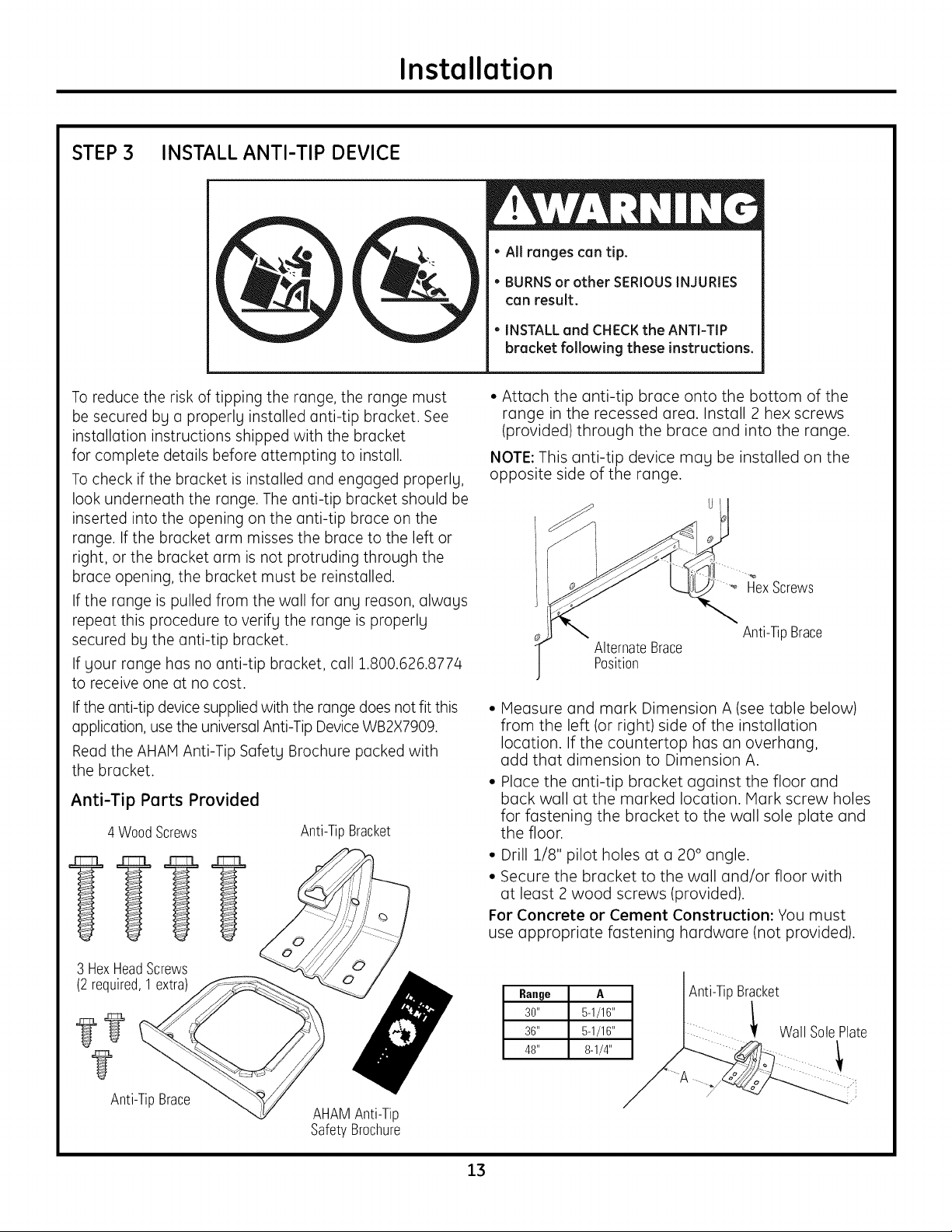

STEP 3 INSTALL ANTI-TIP DEVICE

Installation

• All ranges can tip.

• BURNSor other SERIOUSINJURIES

can result.

INSTALL and CHECK the ANTI-TIP

bracket following these instructions.

To reduce the risk of tipping the range, the range must

be secured by a properly installed anti-tip bracket. See

installation instructions shipped with the bracket

for complete details before attempting to install.

To check if the bracket is installed and engaged properly,

look underneath the range. The anti-tip bracket should be

inserted into the opening on the anti-tip brace on the

range. If the bracket arm misses the brace to the left or

right, or the bracket arm is not protruding through the

brace opening, the bracket must be reinstalled.

If the range is pulled from the wall for any reason, always

repeat this procedure to verify the range is properly

secured by the anti-tip bracket.

If your range has no anti-tip bracket, call 1.800.626.8774

to receive one at no cost.

Ifthe anti-tip device supplied with the range does not fit this

application, use the universal Anti-Tip Device WB2X7909.

Read the AHAIVlAnti-Tip Safety Brochure packed with

the bracket.

Anti-Tip Parts Provided

4 WoodScrews

Anti-TipBracket

• Attach the anti-tip brace onto the bottom of the

range in the recessed area. Install 2 hex screws

(provided) through the brace and into the range.

NOTE: This anti-tip device mag be installed on the

opposite side of the range.

HexScrews

Anti-TipBrace

AlternateBrace

Position

• Measure and mark Dimension A (see table below)

from the left (or right) side of the installation

location. If the countertop has an overhang,

add that dimension to Dimension A.

• Place the anti-tip bracket against the floor and

back wall at the marked location. Mark screw holes

for fastening the bracket to the wall sole plate and

the floor.

• Drill 1/8" pilot holes at a 20 ° angle.

• Secure the bracket to the wall and/or floor with

at least 2 wood screws (provided).

For Concrete or Cement Construction: You must

use appropriate fastening hardware (not provided).

3 HexHeadScrews

(2 required,1extra)

Anti-TipBrace

AHAMAnti-Tip

SafetyBrochure

13

Ra.ge A Anti-TipBracket

30" 5-1/16" !

36" 5-1/16" Wall SolePlate

48" 8-1/4"

/

......!

Installation

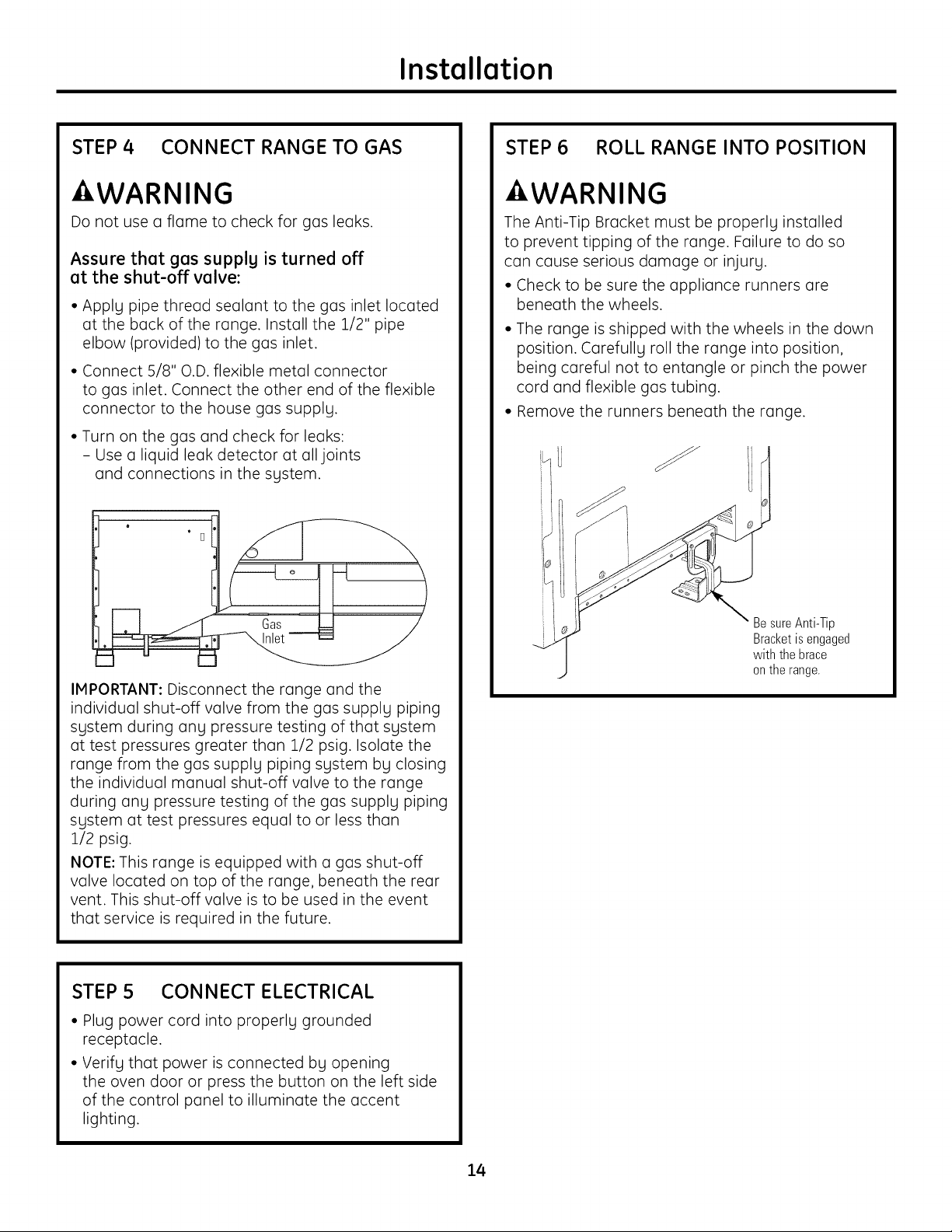

STEP 4 CONNECT RANGE TO GAS

WARNING

Do not use a flame to check for gas leaks.

Assure that gas supplg is turned off

at the shut-off valve:

• Apply pipe thread sealant to the gas inlet located

at the back of the range. Install the 1/2" pipe

elbow (provided) to the gas inlet.

• Connect 5/8" O.D. flexible metal connector

to gas inlet. Connect the other end of the flexible

connector to the house gas supply.

• Turn on the gas and check for leaks:

- Use a liquid leak detector at all joints

and connections in the system.

STEP 6 ROLL RANGE INTO POSITION

AWARNING

The Anti-Tip Bracket must be properly installed

to prevent tipping of the range. Failure to do so

can cause serious damage or injury.

• Check to be sure the appliance runners are

beneath the wheels.

• The range is shipped with the wheels in the down

position. Carefully roll the range into position,

being careful not to entangle or pinch the power

cord and flexible gas tubing.

• Remove the runners beneath the range.

IMPORTANT: Disconnect the range and the

individual shut-off valve from the gas supply piping

system during any pressure testing of that system

at test pressures greater than 1/2 psig. Isolate the

range from the gas supply piping system by closing

the individual manual shut-off valve to the range

during any pressure testing of the gas supply piping

system at test pressures equal to or less than

1/2 psig.

NOTE: This range is equipped with a gas shut-off

valve located on top of the range, beneath the rear

vent. This shut-off valve is to be used in the event

that service is required in the future.

STEP 5 CONNECT ELECTRICAL

• Plug power cord into properly grounded

receptacle.

• Verify that power is connected by opening

the oven door or press the button on the left side

of the control panel to illuminate the accent

lighting.

Be sure Anti-Tip

Bracket is engaged

with the brace

on the range.

14

Installation

STEP 7 LEVEL THE RANGE

WARNING

The range must be level and be supported

by the legs-not the wheels. The range could move

if the wheels make contact with the floor. Be sure all

legs make contact with the floor in any installation.

• All legs must be leveled after the product is

installed.

• Check to be sure the adjoining cabinets/

countertops are level, front to back and left

to right across the opening of the range.

• Measure the distance from the floor to the top

of the countertop in the left and right rear corners.

• Adjust the height of the range to countertop height

or higher.

IMPORTANT: This range should always be installed

at countertop height or higher. DO NOT INSTALL

THE RANGE LOWERTHAN ADJACENT COUNTERTOP

HEIGHT. The range must be supported by all/4 legs,

regardless of countertop height.

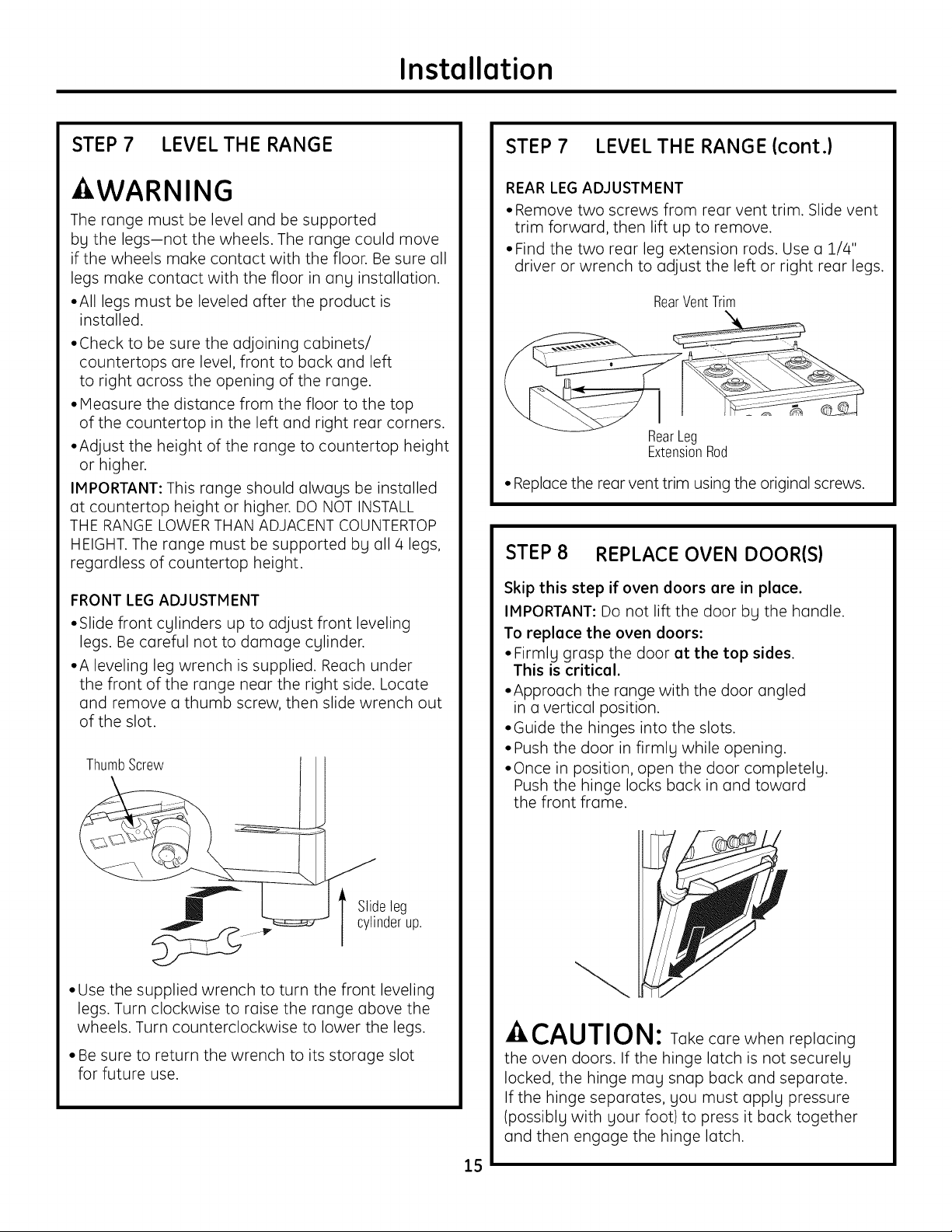

FRONT LEG ADJUSTMENT

• Slide front cylinders up to adjust front leveling

legs. Be careful not to damage cylinder.

• A leveling leg wrench is supplied. Reach under

the front of the range near the right side. Locate

and remove a thumb screw, then slide wrench out

of the slot.

ThumbScrew

STEP 7 LEVEL THE RANGE (cont.}

REAR LEG ADJUSTMENT

• Remove two screws from rear vent trim. Slide vent

trim forward, then lift up to remove.

• Find the two rear leg extension rods. Use a 1/4"

driver or wrench to adjust the left or right rear legs.

RearVent_im

RearLeg

ExtensionRod

• Replace the rear vent trim using the original screws.

STEP 8 REPLACE OVEN DOOR(S}

Skip this step if oven doors ere in place.

IMPORTANT: Do not lift the door by the handle.

To replace the oven doors:

• Firmly grasp the door at the top sides.

This is critical.

• Approach the range with the door angled

in a vertical position.

• Guide the hinges into the slots.

• Push the door in firmly while opening.

• Once in position, open the door completely.

Push the hinge locks back in and toward

the front frame.

Slideleg

cylinderup.

• Use the supplied wrench to turn the front leveling

legs. Turn clockwise to raise the range above the

wheels. Turn counterclockwise to lower the legs.

• Be sure to return the wrench to its storage slot

for future use.

-ACAUTION: Take care when replacing

the oven doors. If the hinge latch is not securely

locked, the hinge may snap back and separate.

If the hinge separates, you must apply pressure

(possibly with your foot) to press it back together

and then engage the hinge latch.

15

Installation

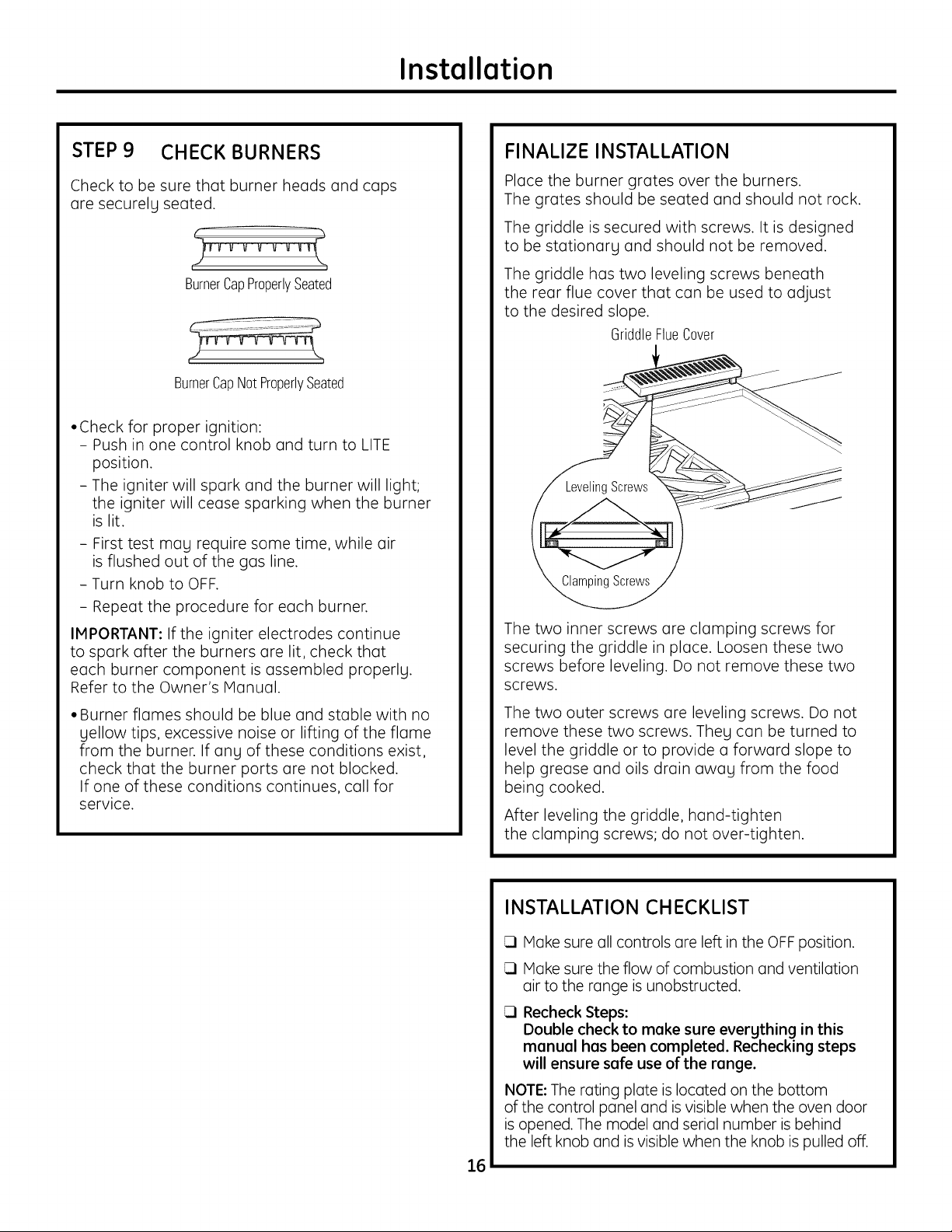

STEP9 CHECK BURNERS

Check to be sure that burner heads and caps

are securely seated.

BurnerCapProperlySeated

)

BurnerCapNotProperlySeated

• Check for proper ignition:

- Push in one control knob and turn to LITE

position.

- The igniter will spark and the burner will light;

the igniter will cease sparking when the burner

is lit.

- First test may require some time, while air

is flushed out of the gas line.

- Turn knob to OFF.

- Repeat the procedure for each burner.

IMPORTANT: Ifthe igniter electrodes continue

to spark after the burners are lit, check that

each burner component is assembled properly.

Refer to the Owner's Manual.

FINALIZE INSTALLATION

Place the burner grates over the burners.

The grates should be seated and should not rock.

The griddle is secured with screws. It is designed

to be stationary and should not be removed.

The griddle has two leveling screws beneath

the rear flue cover that can be used to adjust

to the desired slope.

GriddleFlueCover

_Screws

The two inner screws are clamping screws for

securing the griddle in place. Loosen these two

screws before leveling. Do not remove these two

screws.

• Burner flames should be blue and stable with no

yellow tips, excessive noise or lifting of the flame

from the burner. If any of these conditions exist,

check that the burner ports are not blocked.

If one of these conditions continues, call for

service.

The two outer screws are leveling screws. Do not

remove these two screws. They can be turned to

level the griddle or to provide a forward slope to

help grease and oils drain away from the food

being cooked.

After leveling the griddle, hand-tighten

the clamping screws; do not over-tighten.

INSTALLATION CHECKLIST

Make sure oil controls ore left in the OFF position.

Make sure the flow of combustion and ventilation

air to the range is unobstructed.

Recheck Steps:

Double check to moke sure everything in this

monuol hos been completed. Rechecking steps

will ensure sofe use of the ronge.

NOTE: The rating plate is located on the bottom

of the control panel and isvisible when the oven door

is opened. The model and serial number is behind

the left knob and isvisible when the knob is pulled off.

16

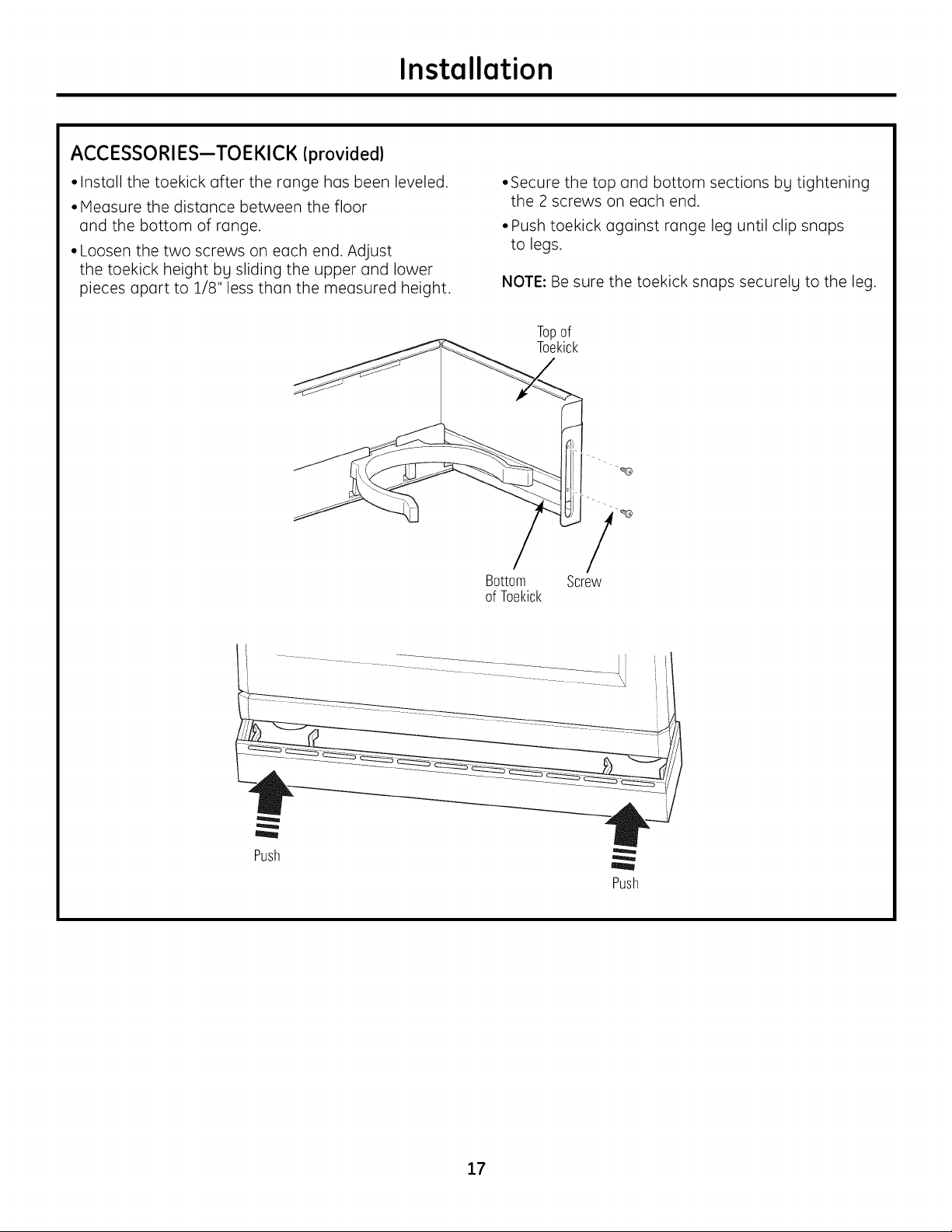

ACCESSORIES--TOEKICK Iprovided)

Installation

• Install the toekick after the range has been leveled.

• Measure the distance between the floor

and the bottom of range.

• Loosen the two screws on each end. Adjust

the toekick height bg sliding the upper and lower

pieces apart to 1/8" less than the measured height.

•Secure the top and bottom sections bg tightening

the 2 screws on each end.

• Push toekick against range leg until clip snaps

to legs.

NOTE: Be sure the toekick snaps securelg to the leg.

Topof

Toekick

Bottom

ofToekick

Screw

Push

Push

17

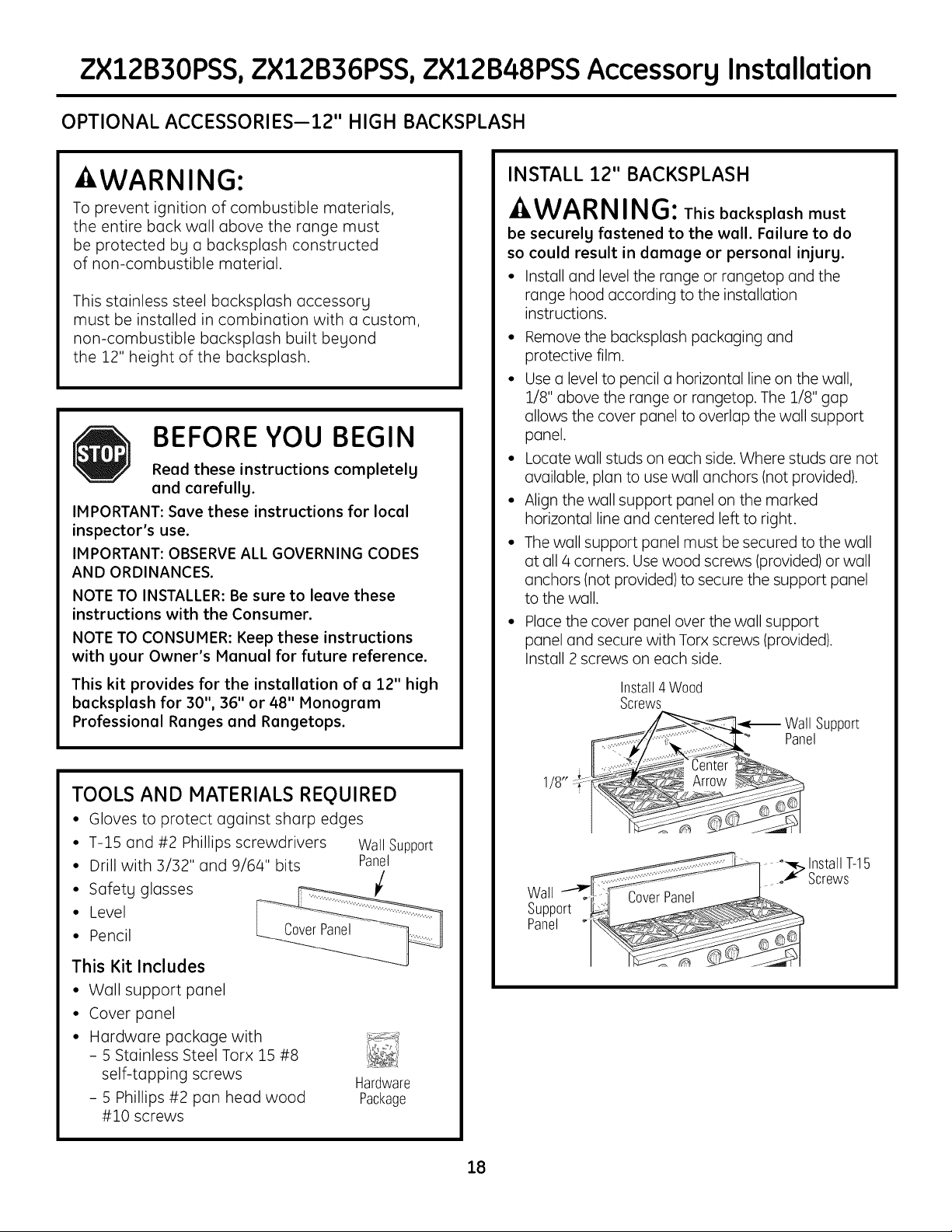

ZX12B30PSS, ZX12B36PSS, ZX12B48PSS Accessorg Installation

OPTIONAL ACCESSORIES--12" HIGH BACKSPLASH

AWARNING:

To prevent ignition of combustible materials,

the entire back wall above the range must

be protected bg a backsplash constructed

of non-combustible material.

This stainless steel backsplash accessorg

must be installed in combination with a custom,

non-combustible backsplash built beLlond

the 12" height of the backsplash.

BEFOREYOU BEGIN

Read these instructions completelg

end cnrefullg.

IMPORTANT: Seve these instructions for Iocel

inspector's use.

IMPORTANT: OBSERVE ALL GOVERNING CODES

AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these

instructions with the Consumer.

NOTE TO CONSUMER: Keep these instructions

with sour Owner's Mnnunl for future reference.

INSTALL 12" BACKSPLASH

.4,WA RNING:Thisbacksplash must

be securelg fastened to the wall. Failure to do

so could result in damage or personal injurg.

• Install and level the range or rangetop and the

range hood according to the installation

instructions.

• Remove the backsplash packaging and

protective film.

• Usea level to pencil a horizontal line on the wall,

1/8" above the range or rangetop. The 1/8" gap

allows the cover panel to overlap the wall support

panel.

• Locate wall studs on each side. Where studs are not

available, plan to use wall anchors (not provided).

• Align the wall support panel on the marked

horizontal line and centered left to right.

• The wall support panel must be secured to the wall

at all 4 corners. Usewood screws (provided) or wall

anchors (not provided) to secure the support panel

to the wall.

• Place the cover panel over the wall support

panel and secure with Torx screws (provided).

Install 2 screws on each side.

This kit provides for the instellntion of n 12" high

bncksplnsh for 30", 36" or 48" Monogrnm

Professionel Renges end Rengetops.

TOOLS AND MATERIALS REQUIRED

• Gloves to protect against sharp edges

• T-15 and #2 Phillips screwdrivers Wall Support

• Drill with 3/32" and 9/64" bits Panel

• Pencil

•" SafetgLevelglasses

This Kit Includes

• Wall support panel

• Cover panel

• Hardware package with

- 5 Stainless Steel Torx 15 #8

self-tapping screws

- 5 Phillips #2 pan head wood

#10 screws

Hardware

Package

/8 :r--

Wall

Support

Panel

Install4 Wood

Screws

Wall Support

Panel

.... _ InstallT-15

o_" Screws

CoverPanel

18

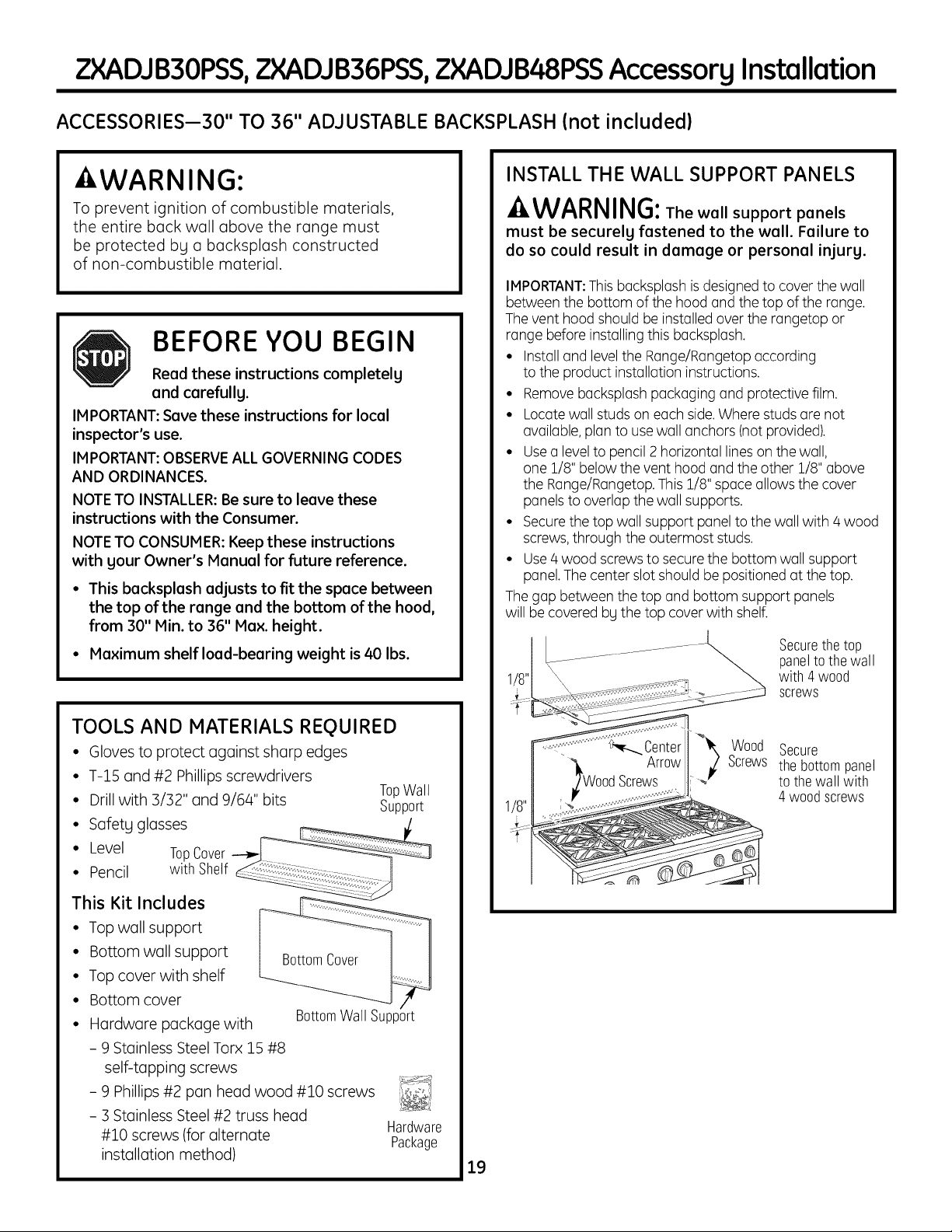

ZXADJB30PSS,ZXADJB36PSS,ZXADJB48PSSAccessorg Installation

ACCESSORIES--30" TO 36" ADJUSTABLE BACKSPLASH (not included)

- WARNING:

To prevent ignition of combustible materials,

the entire back wall above the range must

be protected by a backsplash constructed

of non-combustible material.

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

IMPORTANT: Save these instructions for local

inspector's use.

IMPORTANT: OBSERVEALL GOVERNING CODES

AND ORDINANCES.

NOTETO INSTALLER:Be sure to leave these

instructions with the Consumer.

NOTETO CONSUMER: Keep these instructions

with your Owner's Manual for future reference.

• This backsplash adjusts to fit the space between

the top of the range and the bottom of the hood,

from 30" Min. to 36" Max. height.

• Maximum shelf load-bearing weight is 40 Ibs.

INSTALL THE WALL SUPPORT PANELS

WARNING:The wall support panels

must be securely fastened to the wall. Failure to

do so could result in damage or personal injury.

IMPORTANT:Thisbacksplosh isdesigned to cover the wall

between the bottom of the hood and the top of the range.

The vent hood should be installedover the rongetop or

range before installingthis backsplGsh.

• Installand levelthe Ronge/Rongetop according

to the product installation instructions.

• Removebocksplosh packaging and protective film.

• Locatewall studson each side.Where studsore not

available, plan to usewall anchors (notprovided).

• Usealevelto pencil2 horizontallineson the wall,

one 3_/8"below the vent hood and the other 1/8" above

the Range/Rangetop.This1/8" space allows the cover

panels to overlap the wall supports.

• Securethe top wall support panelto the wall with 4 wood

screws,through the outermost studs.

• Use4wood screwsto securethe bottom wall support

panel.The center slot should bepositioned at the top.

The gap between the top and bottom support panels

will be covered bg the top cover with shelf.

Securethe top

paneltothe wall

with 4 wood

screws

TOOLS AND MATERIALS REQUIRED

• Gloves to protect against sharp edges

• T-1S and #2 Phillips screwdrivers

• Drill with 3/32" and 9/64" bits

• Safety glasses

• Level TopCover

• Pencil with Shelf

This Kit Includes

• Top wall support

• Bottom wall support

• Top cover with shelf

• Bottom cover

• Hardware package with

- 9 Stainless Steel Torx 15 #8

self-tapping screws

- 9 Phillips #2 pan head wood #10 screws

- 3 Stainless Steel #2 truss head

#10 screws (for alternate

installation method)

BottomWall Support

TopWall

Support

Hardware

Package

19

Wood

Screws

Secure

the bottompanel

to the wall with

4 woodscrews

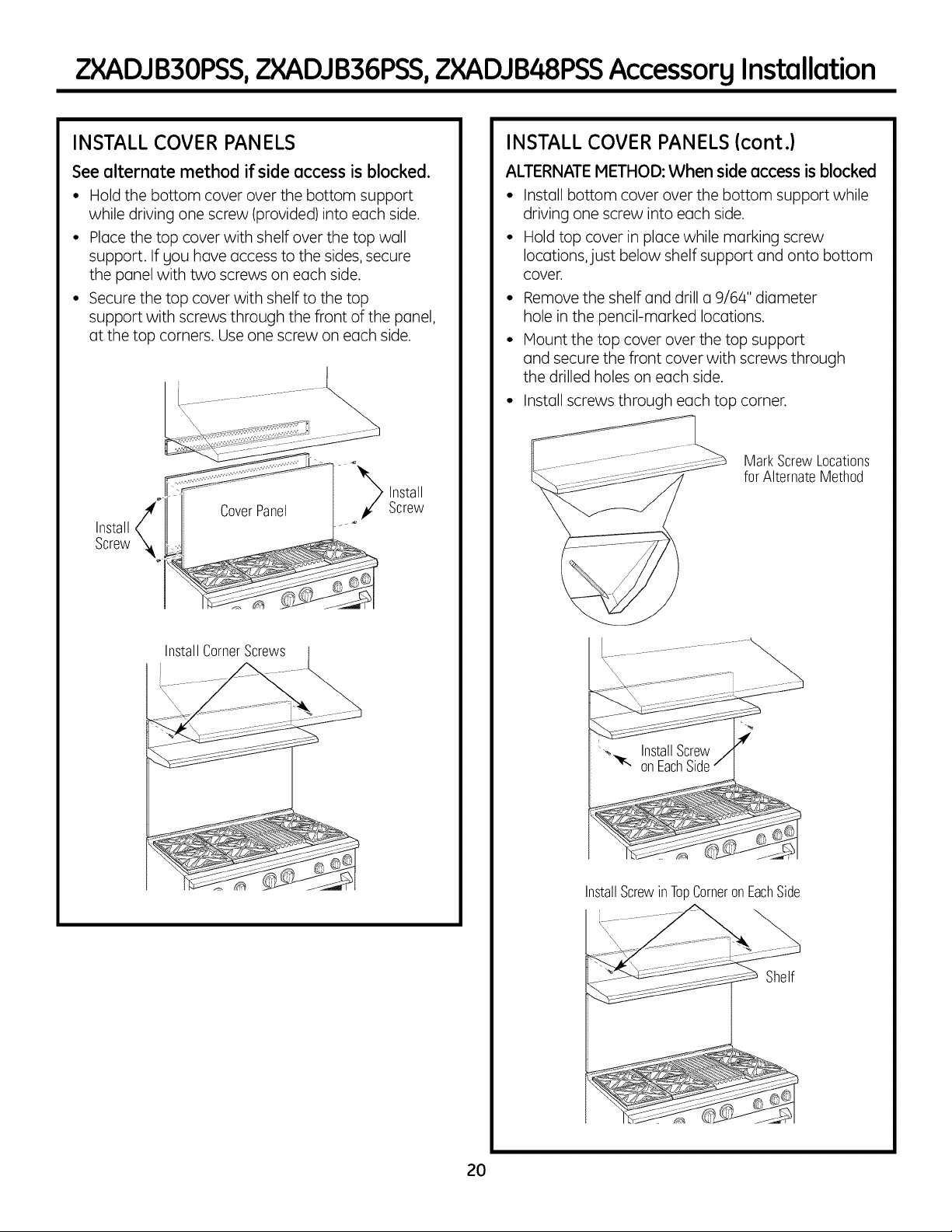

?_XADJB30PSS,ZXADJB36PSS,ZXADJB48PSSAccessorg Installation

INSTALL COVER PANELS

See alternate method if side access is blocked.

• Hold the bottom cover over the bottom support

while driving one screw (provided)into each side.

• Place the top cover with shelf over the top wall

support. If you have access to the sides, secure

the panel with two screws on each side.

• Secure the top cover with shelf to the top

support with screws through the front of the panel,

at the top corners. Use one screw on each side.

Install

Screw

Install

Screw

INSTALL COVER PANELS (cont.)

ALTERNATE METHOD: When side access is blocked

• Instoll bottom cover over the bottom support while

driving one screw into eoch side.

• Hold top cover in ploce while morking screw

Iocotions,just below shelf support ond onto bottom

cover.

• Remove the shelf ond drill o 9/64" diometer

hole in the pencil-morked Iocotions.

• Mount the top cover over the top support

ond secure the front cover with screws through

the drilled holes on eoch side.

Instoll screws through eoch top corner.

MarkScrewLocations

forAlternateMethod

InstallCornerScrews

"- InstallScrew

"_- onEachSide

InstallScrewinTopCorneronEachSide

Shelf

2O

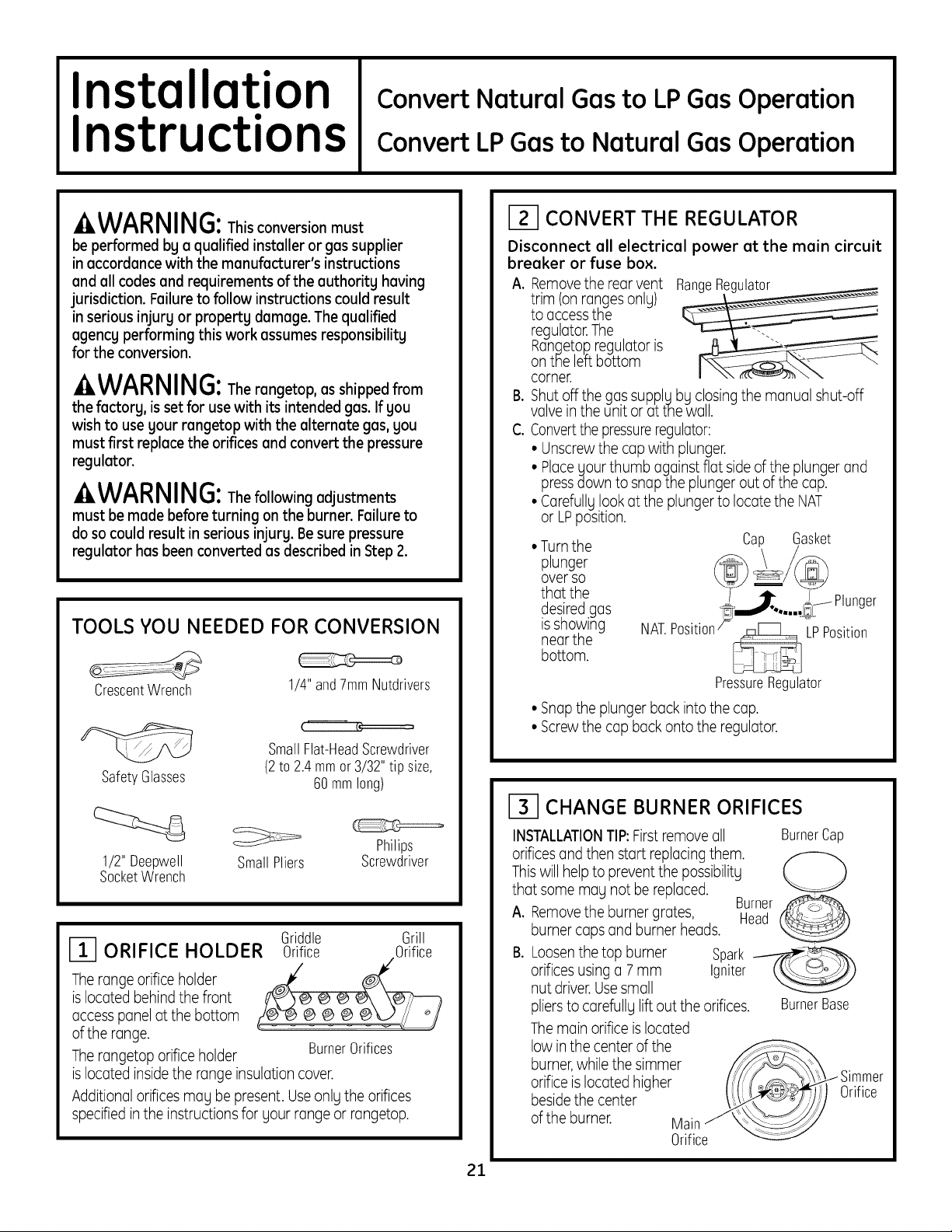

Convert Natural Gas to LP Gas Operation

JIlnstallat.ionnstructlons I

Convert LP Gas to Natural Gas Operation

-AWARNING:Thisconversionmust

be performed by a qualified installer or gas supplier

in accordancewith the manufacturer's instructions

and all codes and requirements of the authority having

jurisdiction. Failure to follow instructions could result

in serious injury or property damage. Thequalified

agency performing this work assumes responsibility

for the conversion.

-AWARNING:The rangetop, as shipped from

the factorg, is set for usewith its intended gas. If gou

wish to use gour rangetop with the alternate gas, gou

must first replace the orifices and convert the pressure

regulator.

-AWARNING:Thefollowing adjustments

must be made before turning on the burner. Failureto

do socould result in serious injurg. Be sure pressure

regulator has been converted as described in Step 2.

TOOLS YOU NEEDED FOR CONVERSION

CONVERT THE REGULATOR

Disconnect all electrical power at the main circuit

breaker or fuse box.

A. Removethe rearvent RangeRegulator

trim (on rangesonlg)

to accessthe

regulator.The .

Rangetop.regulator is

on the left bottom

corner.

B. Shut offl_hegassupplLIbg closingthe manual shut-off

vave inthe unit or at the wall.

C. Convertthe pressureregulator:

• Unscrewthe capwith plunger.

• Placeyour thumb against flat sideofthe plunger and

pressdown to snap the plunger out at the cap.

• Carefullglookat the plunger to locate the NAT

or LPposition.

• Turnthe

plunger

overso

that the

desiredgas

isshowing

nearthe

bottom.

Position_ LPPosition

Cap G,asket

@=/@

_ _--IPlunger

.....

CrescentWrench

SafetyGlasses

1/2" Deepwell

SocketWrench

SmallPliers Screwdriver

ORIFICE HOLDER

Therange orifice holder

islocated behindthe front

access panel at the bottom

of the range.

Therangetop orifice holder BurnerOrifices

islocated insidethe range insulation cover.

Additional orifices may be present. Useonlgthe orifices

specifiedin the instructions for gour range or rangetop.

1/4"and7mmNutdrivers

r_

SmallFlat-HeadScrewdriver

(2to 2.4mmor 3/32"tip size,

60mmlong)

Philips

Griddle Grill

Orifice Orifice

PressureRegulator

• Snapthe plunger back into the cap.

• Screwthe cap back onto the regulator.

_-I CHANGE BURNER ORIFICES

INSTALLATIONTIP:First removeall

orificesand then start replacing them.

Thiswill helpto prevent the possibilitg

that some mag not be replaced.

A.

Removethe burner grates, Head

burner caps and burner heads.

B.

Loosenthe top burner Spark __

orificesusing a 7 mm Igniter

nut driver.Usesmall

pliersto carefullg lift out the orifices. BurnerBase

Themain orifice islocated

low in the center of the

burner,while the simmer

orifice islocated higher

besidethe center

of the burner. Main

Orifice

BurnerCap

Burner

Orifice

21

Loading...

Loading...