Page 1

Futaba

DIGITAL PROPORTIONAL

RADIO CONTROL

PCM

SINGLE STICK

PULSE CODE MODULATION SYSTEM

Page 2

Thank you for purchasing a Futaba

digital proportional radio control set

Please read this manual carefully before using your set.

The names and functions of the transmitter controls can be easily understood

by

reading this section with the three-fold page at the end of this manual unfolded.

Page 3

TABLE OF CONTENTS INDEX FOR TRIMMER PANEL FUNCTIONS

1

GENERAL INFORMATION

Features

............................

Contents and Ratings

Glossary of Terms

Basic

Transmitter

Batteries and Charging

Tachometer/Timer Operation

Receiver

and

Controls

Instructions

Servos

.....................

...................

......................

..................6~9

.............

................

.2~3

10~11

.12~14

ADJUSTMENTS AND FLIGHT TECHNIQUES

Basic

Linkages and

Using ATV (Adjustable Travel

2ND

ATV

Servo

Reversing

Using Dual Rate (Aileron, Elevator, and Rudder) . . . .

Automatic

Using VT R (Variable Trace Ratio)

Suggestions

Using ATL (Adjustable

FS (Fail Safe) and HOLD Functions ............

BFS (Battery Fail

Servo

Test

Aircraft

with

Throttle

Position

Aircraft

with

Elevator/Flap

Flap/Elevator Mixing (Pro-Set Flaps and Etev. Trim). . . .30

Aircraft

with

Flap

Trim

Snap

Roll

Programmable

Mutual (Bi-directional) Mixing (FLPRON,

ELEVN,

V-TAIL,

FP-S130and

Transmitter

Splined Horns

Installation

(Conventional)

Switches

Dual Rate

on

ATV,

D/R,

Safe)

Functions

Function

Switch

.....................

Variable

Trimmer

Flaps

......................

Mixing

....................

Flaps and Spoilers

.....................

.......................

Mixing

DIFF)

FP-S130G

Controls

..........................40

...............

Volume)

..................

..................

on

Rudder

..............

.............

and VT R

Throttle

Limit)

and BFS

Memory

Pitch

Prop

.............

.................

(Airbrake)

and

Examples.

..................

Exploded Views

..................... .

..........

............

..........

........

........

...........

.........

.16

. 19

.

.23

.24

.25

.25

.26~27

.28

.29

.30)

.32

.32~33

.34~36

.4

.5~6

.15

.17~18

. 19

. 20

21

. 21

.22

.29

.31

.37

38 39

Switch or Description Ref. Page

Trimmer

Number

1 Aileron Dual Rate 1 Trimmer .............20

2

Aileron

Dual Rate 2 Trimmer

3

Aileron

Linear/VTR Safety

4

Throttle

Delay

5

Pitch

6

Throttle/Pitch

7

Throttle/Pitch

8

Throttle

9

Elevator Flap

10

Elevator Flap

11 & 12 Programmable Mixing Rate Trimmers ..... .32 33

Slave

13

14 Master Channel Mixing

15 Aileron Differential

16 ELEVN/V. Tail

17 FLPRON/DIFF

18 Flap

Switch

19 Airbrake Elevator

20

Airbrake Flap

21

Rudder Dual

22 Rudder Linear/VTR Safety

23 Elevator Dual Rate

24 Elevator Linear/VTR Safety

25-28 Snap Roll Timer Setting Trimmers (Optional) . • .32

29 Snap

30

Switch

31 Automatic Dual Rate Rudder Safety

32 Flap, Spoiler Elevator

33 Throttle Flap, Spoiler Elevator Mixing Switch . . . . .31

34-35

Aileron

36 37 Elevator

38-45 Servo

46-47 ATV/FS

48 Channel Select

49

Function Select Switch

Trimmer

Delay

Trimmer

Mixing

Mixing

Position

Trimmer

Mixing

Mixing

Channel

Mixing

Trimmer

Mixing

Mixing

........................

Trimmer

Trimmer

Rate

Trimmer

Trimmer

Roll

Safety Switch

16

Function

2ND

ATV Trimmers

2ND

ATV

Reversing

Switches

Buttons

Switch

..............

Switch

.................

...................

Trimmer

Safety

Trimmer

Safety

Board

Board

Switch

Switch

.................

..................

Select

Mixing

Trimmer

...................

.................. .18

.................

..........

.............

Switch

..........

...............

.............

Switch

..........

..............

............... 32 33

..............

.............

.............

...............

...............

Switch

..........

..............

Switch

..........

Switch

............

Switch

Switch

............

............

..............

......

.........

.20

.20

.26

.26

.26

.26

.26

.29

.29

.32

.34~36

.35~36

.34~36

.31

.30)

.30)

.20

.20

.20

.20

32

21

21

.30

.19

.19

.19

.17

.18

27

27

27

27

28

33

23~25

23~25

23~25

NOTE:

Please read and follow instructions for installation and usage in their entirety and

follow carefully. Failure to follow instructions could result in serious property

damage and/or personal injury. This system is intended for use by exp erie nced

R/C hobbyists. Beginners should seek expert advice and Assistance before operating this system.

Page 4

•FEATURES

The FP-8SSAP was specially developed to use PCM (pulse code modulation) for FAI

RC aerobatics F3A aircraft. It is an extremely noise and dead-point resistant digital

proportional RC set with a microprocessor in the transmitter and the receiver. Please

read this manual before using your set.

TRANSMITTER FP-T8SSAP

•Pitch

• RF module system. The frequency band can be

changed with one touch.

• DSC (Direct Servo Controller) allows operation

of the servos without turning on the transmitter.

Wire operation is possible by using the special

cord supplied (FSC.1).

•Servo reversing switch for all channels allows

reversing

• Dual rate or non-linear VTR (variable trace

ratio) aileron, elevator, and rudder. Two-stage

dual rate on aileron.

• Rudder auto dual rate. Rudder dual rate is

2

turned on and o ff automatically with operation

of the throttle lever.

• Newly designed rotatable open gimbal stick

provide maximum operation feel. Stick position

and spring tension c an be adjusted.

• New throttle -> pitch control mixing is perfect

for variable pitch propeller which maximizes

engine power and propeller efficiency.

• Mutual m ix ing function allows aileron + elevator, aileron + flaps, and aileron + rudder mixing

and aileron differential operation.

• Elevator -> flap mixing is especially advantageous

in circle aerobatics.

• Flap, spoiler -> elevator mixing allows control of

the aircraft attitude while using the air brake

(flap, spoiler).

• Throttle -> (flap, spoiler) -> elevator mixing

allows enhancement of the air braking effect by

throttle lever operation when div in g and landing.

• Programmable mixing function permits mixing

with the desired channel.

• Four-function snap roll switch (Timer is op-

tional).

• Idle-up lever, the engine idling speed can be

independently adjusted during throttle -> pitch

control mixing.

• New single-chip microprocessor allows one-touch

fail safe setting and introduction of an automatic

transmission system which eliminates the need

for fail safe setting at the beginning of each

flight and improves safety.

of the

servos

with

the

flip

of a switch.

•Trainer

control

pitch propeller can be adjusted during throttle

-> pitch control mixing.

• New ATV (Adjustable Travel Volume) on all

channels allows independent adjustment of servo

left, right, up, and down throw.

• Second A TV. Besides new pushbutton ATV on

aileron and elevator, conventional trimmer ATV

is also installed.

• Monitor lamp comes on when throttle -> flap,

spoiler -> elevator mixing or throttle -> pitch

control mixing and flap, spoiler -> elevator mixing and snap roll are set and goes out when they

are

in

use.

• Fail-safe switch (function OFF switch) is provided for each function so that only the desired

functions need be turned

•Throttle ATL (Adjustable Throttle Limiter)

makes throttle linkage simple and positive.

• Two servo test functions. A slow sweep to check

neutral characteristic, trackability cycle servo to

test servo operation.

•Tachometer/timer with built-in tachometer, up

timer, down timer, integrating timers, and battery alarm functions.

• Built-in power error back-up circuit. When the

internal Nicd battery approaches the fully dis-

charged state, an LED flashes to indicate that

the memories presetted (memory, ATV, FS,

etc.) are gone. Please charge battery and set all

memory functions again.

•

Highest quality anodized

sophisticated transmitter design gives easy comfortable feeling to your hands.

for beginners.

system

lever.

offers

HIGH

an

side

pitch

on.

aluminum

easy

training

of

variable

case

of

with

flight

Page 5

RECEIVER FP-R118GP

3

•The

receiver

ceiver in which the highest reliability has been

pursued. It is the first R/C receiver in the world

to incorporate the newest computer technology.

• Miniature PCM receiver with high speed single

microprocessor. Resistance to adjacent band and

spark noise interference has been increased by

one full order of magnitude.

• Microprocessor servo hold function eliminates

erroneous

is entered.

• Microprocessor provides fail safe and battery fail

safe functions for greater safety.

• Error lamp display allows checking of the receiver operating state.

of this

operation

set

is a miniature

when a "dead

PCM

point"

re-

area

SERVO FP-S130

•Small, double ball bearing, water-tight & dusttight servo. High output torque 55.6 oz-in (5kgcm), high-speed .24sec/60°.

• New indirect drive potentiometer improves

vibration and shock resistance and neutral

precision.

• Futaba low-power custom 1C provides high starting torque, narrow dead band, and excellent

trackability.

• Fiberglass reinforced PBT (polybutylene terephthalate) molded servo case is mechanically

strong and invulnerable to glow fuel.

• DC-DC converter in the power supply improves

low-voltage operation characteristics.

• High sensitivity design with RF amplifier.

• Ultra narrow-band ceramic filter and PCM system are invulnerable to adjacent band interference.

• Gold plated connector pins eliminate poor con-

tact. Polarized housing improves reliability

against shock and vibration.

• DSC circuit. Each servo can be controlled from

the transmitter without turning on the transmitter by connecting the transmitter directly to the

C terminal.

• Strong polyacetal resin ultra-precision servo gear

features smooth operation, positive neutral, and

very little backlash.

•

Fiberglass

thru-the-hole plating improves servo amp vi bra tion and shock resistance.

•Thick

contact and improve reliability against shock and

vibration. The connector housing is polarized to

prevent reverse insertion.

• Six special adjustable splined horns.

reinforced epoxy

gold plated connector pins ensure positive

resin

PC

board

with

SERVO FP-S130G

•Small

retractable landing

class 5-pole micromotor. High output torque

4.7kg-cm, high-speed 0.34sec/60°, waterproof

type.

•Since forward/reverse operation is controlled by

the pulse width of the signal generated by turning the transmitter snap switch on and off, the

motor stops at the end of its throw in either

direction.

• Unlike other proportional servos, motor drive

current does not flow when the servo is stopped

even if a load is applied. Thus current drain is

extremely low.

gear

servo

with

high

• Fiberglass reinforced PBT (polybutylene terephthalate) injection molded servo case is mechanically strong and invulnerable to glow fuel.

•Strong

•

• Thick gold plated connector pins ensure positive

polyacetal

features smooth operation, positive neutral, and

very little backlash.

Fiberglass

thru-the-hole plating improves servo amp vibration

contact and improve reliability against shock and

vibration. The connector housing is polarized to

prevent reverse insertion.

reinforced epoxy resinPCboard

and shock

resin

ultra-precision

resistance.

servo

gear

with

Page 6

•CONTENTS AND RATINGS

Ratings and specifications are subject to change without prior notice.

Model

Transmitter

Receiver

Servos

Switch

Nicd battery

Accessories

Transmitter FP-T8SSAP

Operating system

Transmitting

frequency

4

Modulation

Power requirement

Current drain

Battery charger, landing gear adaptor, DSC cord, CHG adaptor, DSC-CHG cord,

servo tray, frequency flag, spare horn, screws

Receiver FP-R118GP

Single-stick, 8 channels for

F3A pattern

50/53MHz BANDS

72/75MHz BANDS

53MHz ~ 72MHz

Frequency change to any of

above bands is possible by

merely changing RF module.

PCM,FM

9.6V 8/500mAH internal

Nicd battery

250mA

FP-8SSAP

FP-T8SSAP x 1 with module FP-TF-FM

FP-R118GPx 1

FP-S130x4

SWH-5x 1 (R4-SWJx1»

NR-4Jx1

Receiving frequency

Chosen

band

Intermediate

frequency

Power requirement

Current drain

Dimensions

Weight

Receiving range

50/53MHz BANDS [chosen

72/75MHz BANDS (band

455kHz

4.8V Nicd battery (shared

with servo)

42mA (4.8V reception)

2.23 x 1.65x0.94 in

(57 x 52 x 24mm)

1.85oz (53g)

500m on the ground

1000m in the air

When FP-T8SSAP used.

(At the best radio wave con-

dition of environment)

Servo FP-S130 Landing Gear Servo FP-S130G (Option)

Control system

Operating angle

Power requirement

Current drain

Output torque

Operating speed

Dimensions

Weight

+pulse width control,

uS.N

One side 45° or greater

including trim)

4.8V

(shared

5mA (at idle)

55.6oz.in (4kg-cm)

0.24 sec/60°

1.52

x

(38.5 x 19.5x34.5mm)

1.47oz(42g)

with receiver)

0.77 x 1.36 in

1520

in-

Control system

Operating angle

Power requirement

Current drain

Output torque

Operating speed

Dimensions

Weight

+pulse width control

Rotary approx 160°

4.8V

(shared

8mA (at idle)

65.3oz.in (4.7kg-cm)

0.34 sec/60°

1.52x0.77x 1.36 in

(38.5 x 19.5x34.5mm)

1.48oz (42g)

with

receiver)

Battery Charger FBC-8B(2) Receiver Servo Nicd Battery NR-4J

Input voltage

Output

: 120VAC,50/60Hz

: TX side 9.6V/45mA

:RX

side 4.8V/45mA

Voltage

Dimensions

Weight

: 4.8V, 4/500mAH

:

2.01 x 2.28 x 0.59

(51 x 58 x 15mm)

: 3.35oz (95g)

in

Page 7

GLOSSARY OF TERMS

NOTE: Please take the time to familiarize yourself with the terms and abbreviations

below. They will be used throughout the instructions and are important in understanding the operation and potential of your system.

PCM (Pulse Code Modulation) SERVO REVERSING

Pulse Code Modulation utilizes a precise digital

code to convey information from the transmitter

encoder to the receiver. This state of the art method makes many of the sophisticated functions of

the FP-8SSAP possible, as well as providing far

superior immunity to noise and interference than

is possible with conventional encoding methods.

ATV (Adjustable Travel Volume)

This feature allows independent adjustment of

servo travel in each direction. ATV is sometimes

referred to as "endpoint adjustment". Two dif-

ferent types of ATV are standard with this system,

(1) Pushbutton or Programmed (Memory) ATV

and (2) 2nd ATV (Conventional).

MEMORY ATV

This type is available on all eight channels. These

adjustments are stored in the transmitter memory

circuit and are retained when the power switch is

turned OFF. They are lost however, if the trans-

mitter Nicd batteries reach full discharge.

2ND

ATV

Available on Aileron (CH 1) and Elevator (CH 2).

This is the conventional type ATV which is set by

using trimmer pots on the transmitter back panel.

These settings are NOT affected if the transmitter

batteries are discharged.

DUAL RATE

Rate switches allow the pilot to select different

servo travel limits (for varying control sensitivity)

in flight. Servo travel is affected equally in both

directions from center.

SAFETY (ACT/INHIB)

These switches, located on the transmitter trimmer

panel allow mixing and certain other functions to

be deactivated when not desired. When the Safety

Switches are set to the INHIB position, the function will remain OFF even if the transmitter control switch is set to ON.

VTR (VARIABLE TRACE RATIO)

This is a special type of non-linear control response. When VT R is used, servo travel is normal

and linear up to about 80 percent of the transmit-

ter control stick movement where the servo travel

is abruptly increased to a higher rate (both rates

adjustable). This allows a normal feel f or most fly-

ing with extra movement available for emergencies

and certain acrobatic maneuvers. Another way to

think of this function is as "automatic Dual Rate".

SWITCHES

This function allows the modeler to reverse the

direction of servo movement (in relation to control stick movement) for various installation requirements. This can be done by conveniently

flipping a switch on the trimmer panel. Servo

travel and neutral position are not affected.

The

Safe)

throttle

to

set

elevens

Limit)

trim

lever

the proper idle

on

tailless

BFS (Battery Fail

This function provides a warning to the flyer when

airborne battery voltage reaches a critically low

level by moving the throttle se rvo to medium slow

or slow position.

ATL (Adjustable Throttle

This feature makes adjusting the throttle linkage

easier.

much

the LOW or IDLE position and not the HIGH

throttle servo position. Therefore, the linkage can

be set for proper opening at high throttle and the

trim

lever

used

out changing the maximum opening.

MIXING

In

general, mixing functions allow two or more

different channels to be operated by moving a

single transmitter control. Many useful and versatile functions are made possible in this manner.

Three types of mixing functions are provided.

(1) Unidirectional mixing — This function allows

one or more channels to be "slaved" to a "master"

channel. Movement of the master channel control

causes movement of both master and sl aved servos

simultaneously. Operation of the slave channel

control however, does not cause movement of the

master channel servo. An example is Aileron/Rudder mixing (see page 3 3) wh ere the Rudder is

slaved to Ailerons for coordinated turns.

(2) Mutual (Bi-Directional) Mixing - With this

type of mixing, two channels are mixed so that

operation of the control for either channel causes

movement of both servos. This is useful in providing sophisticated functions such as V-tail operation,

flaprons, and

(3) Switch-Activated Mixing — Two or more-

channels can be programmed so that the servos

involved move to a preset position when a trans-

mitter control switch is pulled or button pushed.

Snap roll switches, roll buttons, and pre-set

switches are examples of this type of mixing.

affects

speed

designs.

only

with-

5

flap

Page 8

PROGRAMMED MIXING FAIL SAFE

Unidirectional mixing of any two channels desired

is possible using the pin board and jumper connectors on the transmitter back panel. Either channel may be designated as "master" or "slave".

DSC

(Direct

Servo

Control)

Operation of the entire system with the transmitter switch in OFF position is possible using the

DSC cord. This is useful for checking and adjusting

control movements on the ground while someone

else is flying on your frequency.

The Fail Safe function moves servos to a pre-set

position if the transmitter signal is lost or interrupted by strong interferrence. The servos will be

held in the pre-set position until a proper signal is

again received at which time Fail Safe is released.

HOLD

The Hold function holds servos at the same position

as

immediately prior

Hol d is released when a proper signal is resumed.

•Trainer system offers an easy training of flight

for beginners.

to

signal

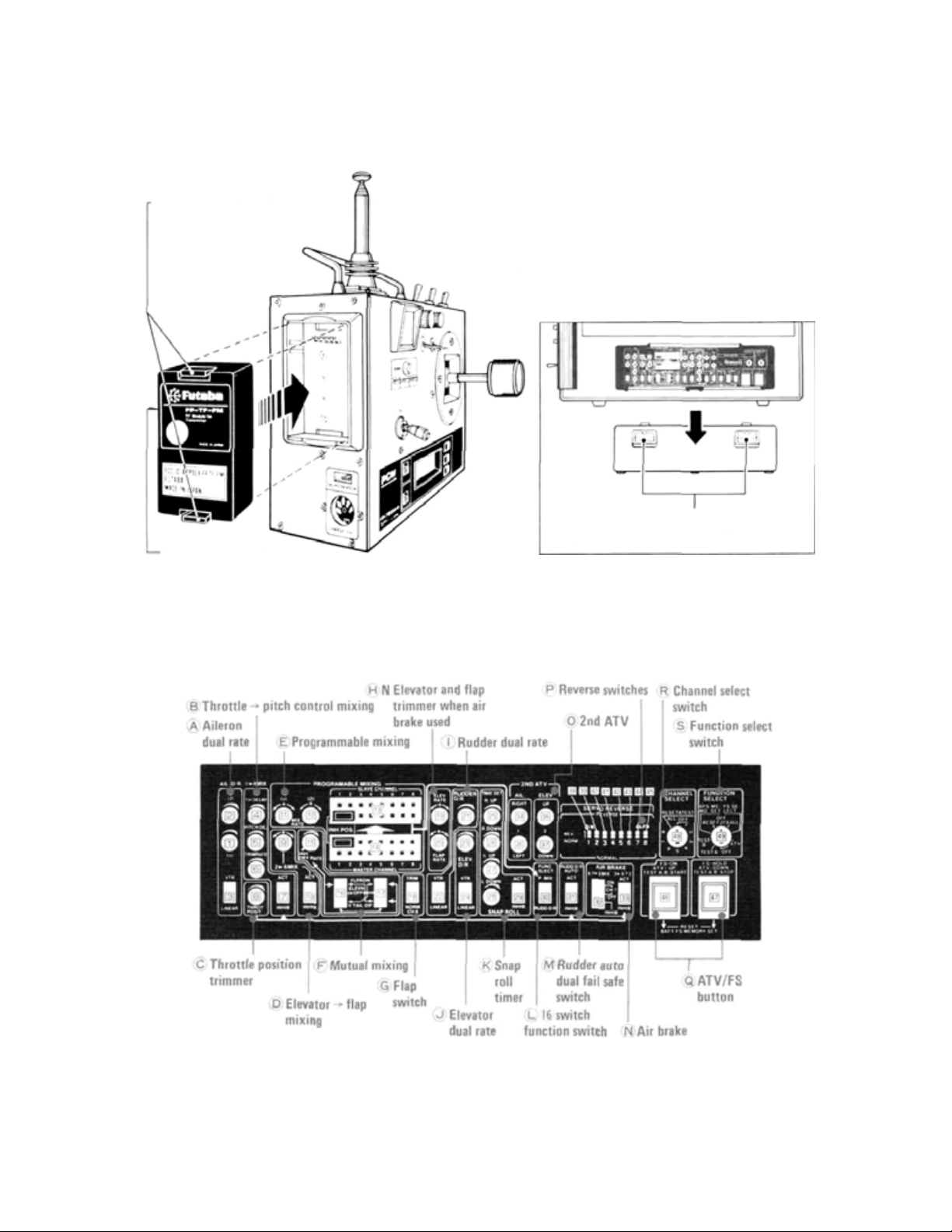

•BASIC TRANSMITTER CONTROLS

The servo reversing switches are assumed to be in the normal position in the descriptions in this section. When the reversing switches are in the reverse position, servo

operation is the opposite of that described here.

interruption.

6

The names and functions of the transmitter

controls can be easily understood by reading this section wit h th e three-fold page at

the end of this manual unfolded.

1

Aileron stick

2

Elevator stick

3

Throttle

4

Rudder knob

5 Landing gear switch Controls the landing gear.

6 Flap and flap trim control (CH6) knob

7 Spoiler (CH7) control knob

8 Pitch control (CH8) lever and pitch control

HIGH side trimmer

9 Idle-up lever

10 Flap, spoiler -> elevator (6, 7 -> 2) mixing

OFF switch

11 Throttle -> (flap. spoiler) -> elevator

2) mixing / Throttle -> pitch control mixing

ON-OFF switch

Elevator -> flap

12

13 Snap Roll ON-OFF switch (self

Controls the ailerons.

Controls the elevators.

lever

Controls the

Controls the rudder.

(2 -> 6) mixing ON-OFF switch

throttle.

(3 — 6. 7 ->

off)

ON-

1 4 Aileron dual rate switch (2-stage)

15 Elevator dual rate switch

16 Rudder dual rate/Programmable mixing ON-

OFF switch

17 Aileron trim lever

18 Elevator trim lever

19 Throttle trim lever with ATL

20 Rudder trim lever

21 Tachometer/timer

The tachometer/timer has the following functions:

1. TACHOMETER

• Measurement by external sensor

• Two blade propeller specifications

• LOW range 100 to 30,000 rpm

Error 100 rpm

•HIGH

2. UP

• 0 to 60 minutes with seconds display

3. DOWN TIMER

• 60 to 0 minutes with seconds display

4. INTEGRATING TIMER

• 0 to 60 hours with minutes displ a y

5. BATTERY ALARM

• Alarm sounds when the transmitter Nicd

range

100

TIMER

batteries approach the

to

Error 200 rpm

60,000

usage

rpm

limit.

Page 9

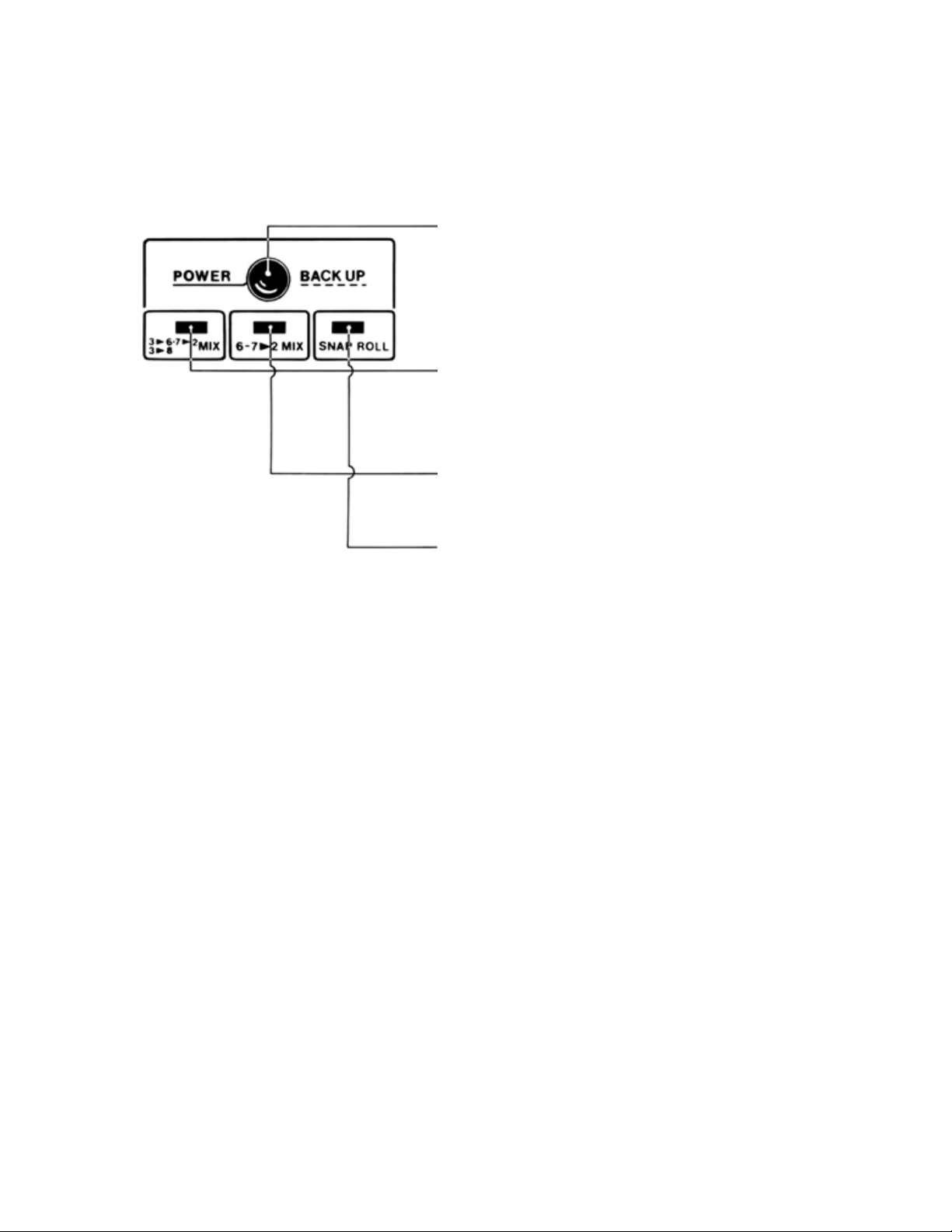

22 Monitor Lamps

7

IMPORTANT: In all instructions on control functions. Items designated by a number inside a circle

(For example 10 ) are transmitter controls normally accessable and operated in flight.

Items designated by a number within a box (For example 10 ) are adjustment functions not operated

while in flight.

Lamp A Power Monitor

• When the power switch

briefly and then goes out momentarily as the Fail Safe data is automatically matically transmitted to the receiver. Fail Safe data is

transmitted every 60 seconds at which time the lamp al so goes out

momentarily. If the transmitter Nicd battery nears full discharge,

this lamp starts blinking, indicating that the power error backup

function is activated. When this occurs, transmitter memory function settings are lost and must be reset.

23 is set to ON, this lamp flashes on

LampB3 -> 6. 7 -> 2 I 3 -> 8 Mix

This lamp comes on when Safety Switch 7 and/or [33] is set to

ACT position, indicating that throttle —-> flap, spoiler —-> elevator

mixing and/or throttle -> pitch control mixing functions are activated. This lamp will blink when transmitter control switch II is set

to ON (placing these functions in operation).

Lamp C 6, 7 -> 2 Mix

• This lamp comes on when Safety Switch [32] is set to ON (flap,

spoiler -> elevator mix) or CH7 OFF (flap -> elevator mix) position.

This lamp blinks when transmitter control switch 10 is set to ON.

Fig.1

When the power switch 23 is set to ON, lamp (A) will go out momentarily. This indicates automatic data

transmission on and is not a failure.

23 Power switch

• The transmitter power ON-OFF switch is provided with a locking feature to prevent accidental movement. To operate the switch, pull the

knob gently outwards and set to the desired

position (UP=ON. DOWN=OFF).

25 Level meter

• This meter indicates the transmitter battery

voltage and output power.

•W hen the antenna 26 is extended fully and

the power switch 23 is set to ON, the pointer

should move to the white zone.

•If the transmitter RF Module

32 is not

stalled, the meter pointer will not move.

• If the meter pointer moves to the red zone,

indicating that the Nicd battery voltage is low,

the

signal

range

will

become

shorter.

Tachometer/timer 2 1 power switch is ON, the

Lamp D Snap Roll

• When Safety Switch [29] is set to ACT (snap roll function activated), this lamp blinks. When the Snap Roll switch 13 is pulled,

this lamp continues blinking.

26 Antenna

Strong 1m 10cm telescoping antenna. Extend

the antenna to its full height when using the

transmitter. The antenna will lock in place with

a click when pulled up to its ful l height.

27 Carrying handle

28 Tachometer sensor connector

•When not using t his connector and the charging socket 29, cover them with the rubberbacked cover supplied to protect them against

dust.

in-

29 Charging socket and DSC (Direct Servo Con-

troller) connector

• This connector is used as both the charging

If

the

socket and DSC connector. See

charging instructions.

page 10 for

battery alarm function will operate after about

one more flight. When the meter pointer stops

at the boundary between the white and red

zones, recharge the battery.

Page 10

32 Transmitter RF module

• Change this module when switching frequency bands (50, 53, 72, and 75MHz).

While pushing this tab to the

inside, pull the RF module

forward.

Transmitter crystal

A temperature rise

at the R F module

section during use

is normal.

Fig.

34 Snap roll direction switch (R/L)

35 Snap roll direction switch (UP/DOWN)

•These switches control the direction of the

snap roll when the Snap roll switch 13 is used.

36 Fail safe set button

• This pushbutton is used when setting the Fail

Safe servo positions (FS instructions Page 24).

37 Back Cover

• Removal of this cover exposes

panel. Remove as shown in Fig. 3.

Remove the back cover by pulling

these stoppers in the arrow direction.

the trimmer

Fig.

3

2

8

38 Trimmer Panel

•This

panel contains switches,

transmitter functions. Use the small screwdriver supplied with the set for making adjustments.

Use the transmitter with fail-safe switches [7], [10], [29], [31], [32], and [33] in the INHIB (function off)

position until you become familiar with the set.

buttons,

and trimmers

for

setting and adjusting the many

versatile

Fig.

4

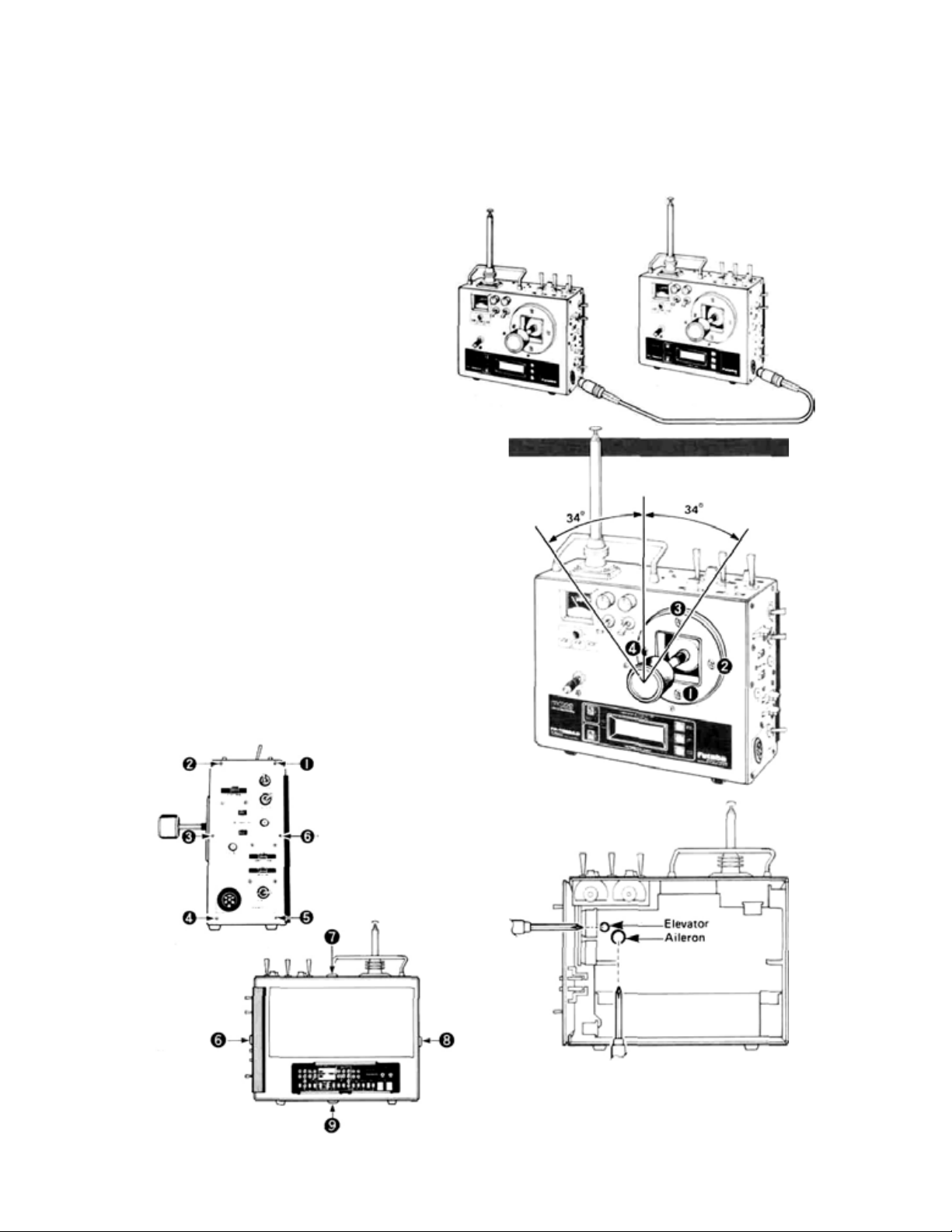

39 Trainer cord socket

Page 11

40 Trainer switch

9

Pull on/self-off switch. The transmitter connected by the trainer cord (M-TC) operates and when

it is OFF, your-own transmitter only operates.

• Trainer

Connect the transmitters with the trainer cord

(M-TC-FM, purchased separately) as shown in

Fig.5. When the switch is in the ON (pull) position,

the

student's

when the switch is in the OFF position, the

instructor's transmitter operates. The transmitter at which the trainer switch is operated onoff becomes the instructor's.

transmitter

operates

and

Fig.

5

(Power switch ON and transmitter operating)

Instructor transmitter

• Rotative open gimbal stick

• Rotative open gimbal stick allows setting of the

operating direction of the stick within a range of

±34 degrees by losening screws I to 4 in the

figure 1/2 turn and turning the stick grille.

• Set the stick in the direction in which operation

is easiest.

• After setting, retighten the screws.

• The new gimbal is open. This one has been used

only for the most expensive radio controls. It

also has the built-in tension adjustment mech-

anism on open gimbal for the first time. You can

adjust tension of spring for your best stick

feeling.

• Remove the rear panel and right side panel and

adjust the spring tension.

Right side panel mounting screw

Remove these

screws, and

remove the longer

back cover.

Common screw

Student transmitter

(Power switch always OFF)

Fig.

Fig.

6

8

Rear panel Mounting screw

Common

screw

Fig. 7

Turn with a Phillips screwdriver.

The spring tension can be adjusted as desired

by removing the transmitter longer back cover

and turning the adjusting screw of each stick.

Adjust the spring tension for the best stick feel.

Page 12

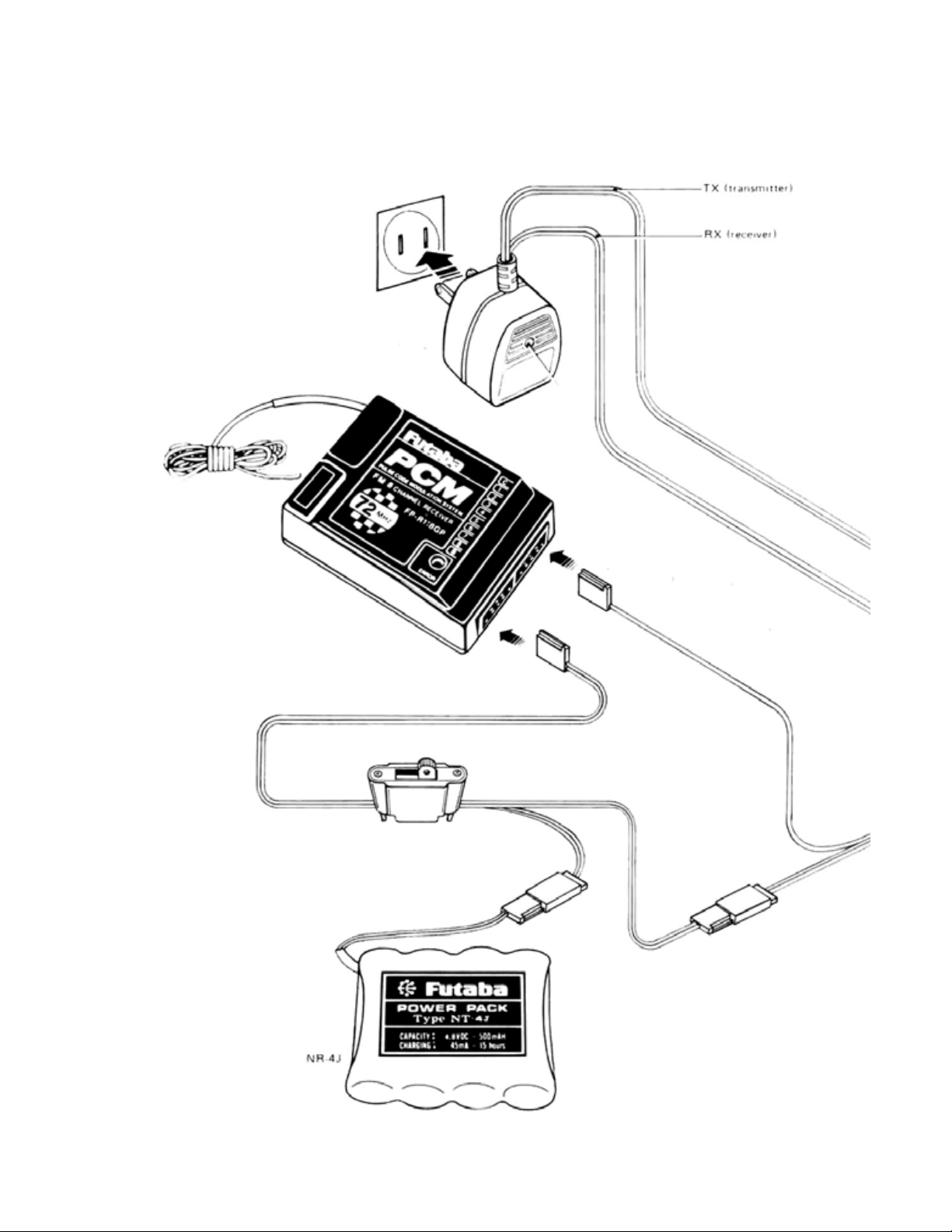

•BATTERIES AND CHARGING INSTRUCTIONS

AC-120V

Battery charger

FBC-8B (2)

LED

Antenna

10

Receiver

R4-SWJ

Female

Female

Male

Female

Install the accessory

DSC.CHG cord

(connector with tab)

to the side of the

aircraft fuselage to

use the charging/DSC

socket.

DSC.CHG

cord

Female

Male

Fig.

9

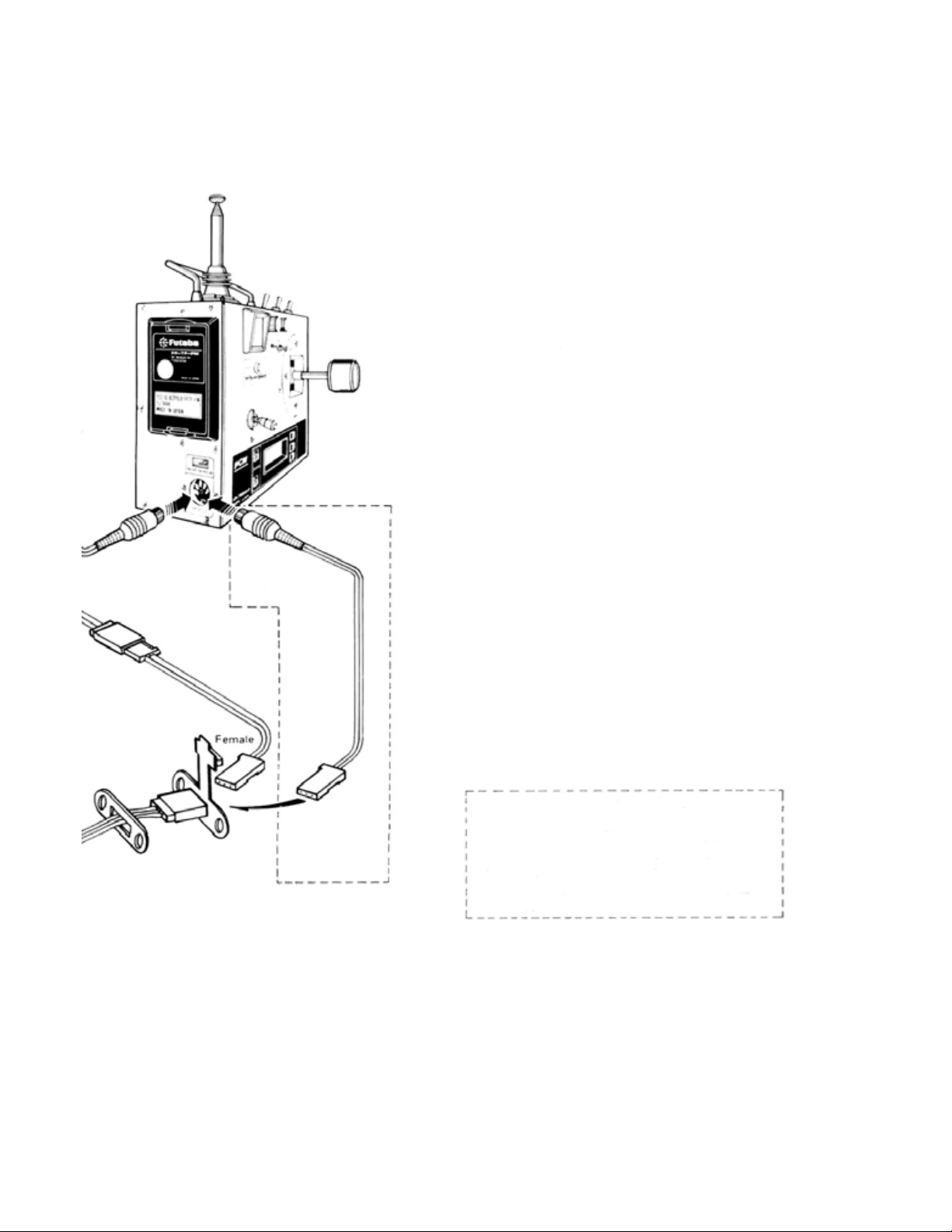

Page 13

DSC cord

29

Charging socket

and DCS connector

Male

Female

CHG

Adaptor

Female

Male

Notes:

(1) F irst,

(2) Then, connect to RX Nicd after connecting

(3) In case of separate charging, L.E.D,

connect to TX N icd and red lamp goes

on.

L.E.D, changes color from red to greenish

red (orange) which indicates that both T X

and RX Nicds are being charged.

will be:

RX Nicd-Green TX Nicd - Red

Make.this

connection when

using the DSC.

color

•The

Direct

Servo

Controller

system

connects

the signals from the transmitter directly to

terminal C of the receiver through a wire and

controls the

without

radiating

radio-

servos

waves. It is extremely convenient when flying

on the sam e band or during meets, etc.

• Make the connections shown in Fig. 9. Connecting the

receiver terminal C and installing it to the

special

DSC.CHG cord

with

tab

to

side

of the aircraft fuselage is very convenient.

•When the DIN connector of the DSC cord is

connected to the DSC connector 29, the

power to the encoder inside the transmitter is

turned on. The transmitter power switch is

OFF.

• When not using the DSC, disconnect the DIN

connector.

• To operate the servos, turn on the receiver

and servo switch.

Before using your

as follows:

teries

system, recharge the Nicd bat-

•Connect the DIN connector of the FBC-8B (2)

battery charger to the transmitter charging

socket 29. Also connect the 3P connector to

the airborne NR-4J Nicd battery and plug the

battery charger into a 120VAC outlet as shown

in Fig. 9. The airborne batteries can also be

charged through the DSC/CHG harness by connecting the CHG adaptor to the charger as

shown in Fig. 9. In this manner, the airborne

batteries can be charged without removing them

fr om the model.

•Normally recharge the battery for about 15

hours. If it has not been used for some time,

discharge and recharge it two or three times and

then charge it a full 15 hours.

• The amount of time remaining before the batteries must be recharged can be estimated

using the Integrating Timer function of the

Tachometer/Timer

21. It

is recommended

that thi s function be used to monitor remaining flying time. (See Page 12 for detailed

instructions.)

•The

transmitter

and

receiver

Nicd batteries

can

be charged together or independently.

•A fully-charged transmitter battery can be used

for about 10 flights of 10 minutes each. The

airborne NR-4J Nicd battery can be used for

about 6 flights when 6 servos are used and about

4 flights when 10 servos are used.

• If the system is not to be used fo r some time, it

should be fully charged before storage and

recharged monthly to avoid full discharge and

loss of memory settings (ATV, FS, BFS memory,

etc.).

Page 14

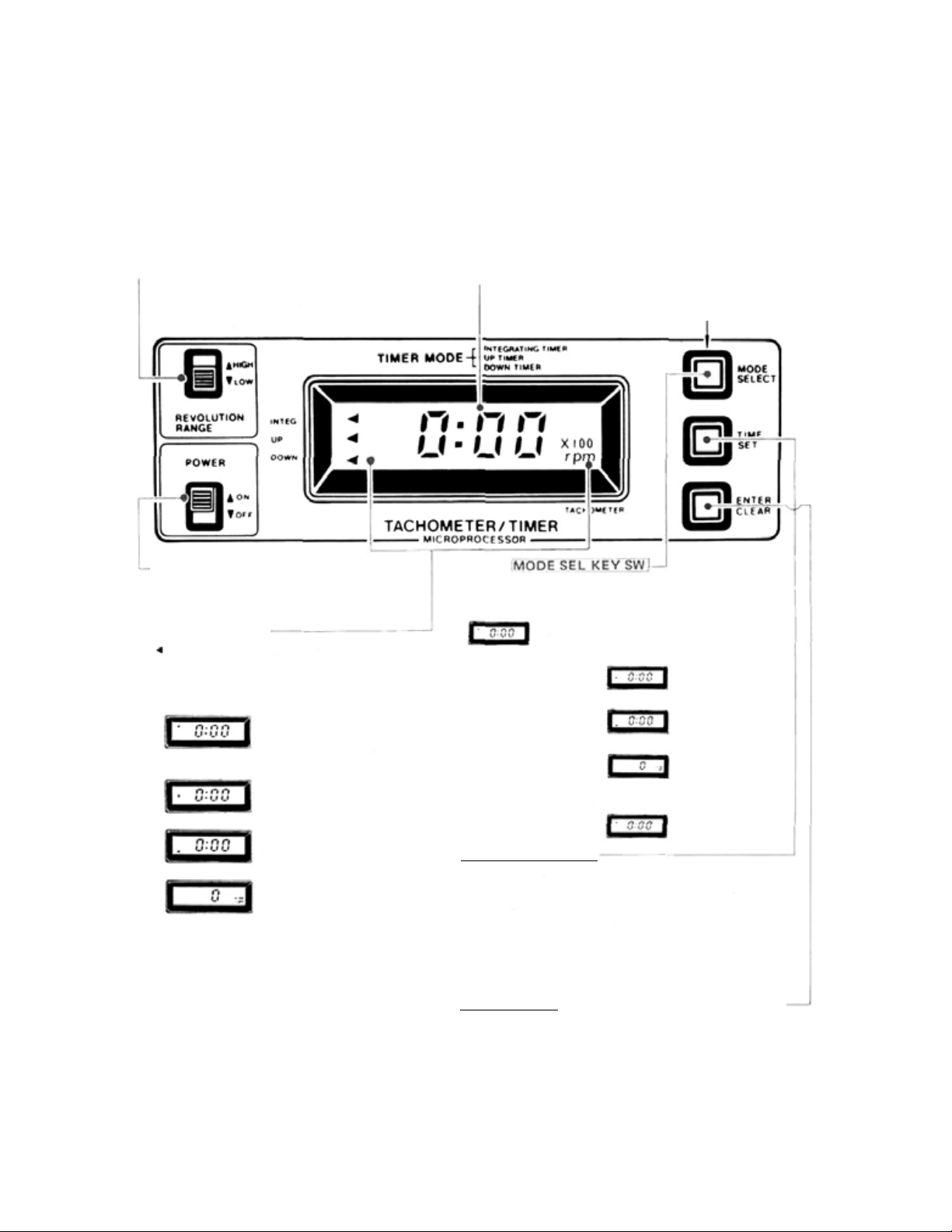

•TACHOMETER/TIMER OPERATION

NOMENCLATURE AND FUNCTIONS

REV. RANGE SW

Switches the range when used as a

tachometer. LOW -100 t o 30,000 rpm.

HIGH -100 to 60,000 rpm

LIQUID CRYSTAL DISPLAY

Fig.

10

Do not press the keys too quickly.

Press them at a speed of about once

per second. |

12

POWERSW

Tachometer/timer power switch.

MODE DISPLAY

< is displayed at the mode selected at

the MODE SEL key switch.

INTEGRATING TIMER

Blinks during counting

and stops blinking when

counting stops.

UP TIMER

DOWN TIMER

TACHOMETER

Selects the tachometer/timer mode.

The INTEGRATING TIMER mode is selected and

is displayed when t h e power is turned on.

The first time this switch is pressed, the UP TIMER

mode is selected and

The

second time it is pressed, the DOWN

mode is selected and

The

third

time

it

is

pressed,

mode is selected and

The fourth time this switch is pressed, the

tachometer/timer returns to the INTEGRATING

TIMER mode and

TIME SET KEY SW

This switch sets the alarm time in the UP TIMER

and DOWN TIMER modes. One minute is set each

time this key is pressed. If it is pressed and held for

two seconds or longer, the time is set in 5 minute

steps.

A beeping signal begins 10 seconds before the dot

time. A beep is produced every minute to indicate

the lapse of time.

ENTER

This switch is used for memorization, starting,

stopping, and clearing in the UP TIMER and

DOWN TIMER modes. In the INTEGRATING

TIMER mode, this switch acts a s the reset switch.

KEYSW————————————————————

is displayed.

TIMER

is displayed.

the TACHOMETER

is displayed.

is displayed.

Do not expose the display to direct sunlight

for a long time.

Page 15

OPERATING INSTRUCTIONS

1.Tachometer

Set the tachometer/times POWER switch to ON.

appears on the display. Next, press the

MODE SEL key switch at the upper-right corner

three times. The display changes to

the tachometer mode is selected. Hold t he sensor

about 20 to 30 cm from the rotating propeller

(two blade). The propeller speed is displayed on

the

LCD.

Sensor

indicates that the propeller is rotating at

12,300 rpm. For propeller speeds up to 30,000

rpm, set the REVOLUTION RANGE switch at the

upper left-hand corner to LOW and for propeller

speeds above 30,000 rpm, set the REVOLUTION

RANGE switch to HIGH.

The speed of a three blade propeller is displayed

value divided by 3 x 2.

The speed of a four blade propeller is 1/2 the dis-

played value.

——Measure the speed of the

\ rotating propeller at this

point

and

Connect the accessory tachometer

sensor to the sensor connector

as shown above.

Fig. 11

Make all speed measurements outdoors under

natural lighting. Accurate speed measurements

cannot be made indoors under artificial lighting

because of the affect of the 50 or 60 Hz power.

Fig.

12

13

Sensor

Make all

measurements

under natural

lighting.

20 30cm

Holding the sensor too close

to a spinning propeller is

dangerous.

To measure the speed of the main rotor of a

model helicopter, measure the speed of the tail

rotor as shown in Fig.13. and ca l cu l a t e the e x ac t

speed from the equation.

Main rotor speed =

Tail rotor speed

Main rotor and tail rotor gear ratio

Draw two lines

on the flywheel

with magic ink.

Helicopter tail rotor

The speed of model boat

and car engines can also be

measured in this fashion.

Warning: Use extreme caution. There is danger of

serious injury or death.

Sensor

Fig.

13

Page 16

Note do not expose the liquid crystal display to

direct sunlight for a long time.

Switches the range when

used as a tachometer.

Tachometer/timer power switch.

is displayed at the

mode selected at the

MODE SE L KEYSW.

2.UP TIMER

Set the tachometer/timer POWER switch to ON.

key switch at the upper right-hand corner one time.

The display changes to , and the UP

TIMER mode is selected. When the ENTER key

switch at the bottom right-hand corner is pressed, a

beep is head and the timer starts and the second

digit of the display changes every second. A beep is

is displayed. Next, press the MODE.SEL

ALARM SETTING

The alarm can be set with the TIME SET key. Clear

the display, by pressing the ENTER key, then press

the TIME SET key twice.

14

two minutes was set. Next, press the ENTER key

once to memorize this two minutes. The display

changes to and is memorized. Start the

timer by pressing the ENTER key. The display

changes

a second, to indicate that two minutes have

elapsed. Thereafter the timer continues to count

up to 60 minutes. If the TIME SET key is pressed

and held for two seconds or longer when memorizing the alarm time, the time is set in five minute

steps and the set alarm times are memorized until

appears on the display indicating that

every second. When the display reaches

, the timer keeps ten times, every once

Selects the tachometer/

timer mode.

This switch sets the

alarm time.

Memorize, start, stop,

and clear switch.

Fig.

14

produced every minute to indicate the passage of

time. To stop counting, press the ENTER key

switch again. The usage time is displayed on the display. For example, means that 12 minutes

:05

seconds had elapsed. The UP TIMER mode can

be

used as a second stop watch. To clear

play,

press the ENTER key switch again.

the power is turned off or reset. If the timer is

started without setting the time after the display

has been cleared, the previously set alarm time

remains effective. An

59

minutes can be

arbitrary alarm time up to

set.

the dis-

3 DOWN TIMER

Set the tachometer/timer POWER switch to ON

and press the MODE SE L key twice.

appears on the display to

the DOWN TIMER mode was selected. Next,

press the ENTER key. The timer keeps.

appears on the display, and the display begins to

count down every second. The timer keeps every

second from 10 seconds before the end of the

count-down, the same as the UP TIMER.

indicate that

TIME AND ALARM SETTING

Set the time and alarm with the TIME SET key,

the same as the UP TIMER. To set the alarm to

at

the display, clear the display by

pressing the ENTER key, then press the TIME

SET key three times. Next, memorize this time

by pressing the ENTER key again. The display

begins to count down in seconds. When the display begins to count down in seconds. Wh en the

display reaches , the timer begins to

keep every second to indicate that three minutes

have elapsed. If the TIME SET key is pressed

and held for two or more seconds, the time is set

in five minute steps, the same as the UP COUNTER, and the alarm can be set to any desired

time up to 33 minutes.

4 INTEGRATING TIMER

Set the tachometer/timer POWER switch and the

transmitter power switch to ON. The blinks,

counting begins, and the elapsed time is displayed

in minutes. For example indicates that

three minutes have elapsed. If the transmitter

power switch is set to OFF, counting stops. When

the transmitter power switch is turned back on,

counting continues. The integrating timer function can be started and stopped as long as the

tachometer/timer POWER switch is on even if

another mode is selected with the MODE.SEL

key. This can be used to monitor the transmitter

operating time. If the ENTER key is pressed in

the INTEGRATING TIMER mode, the old integrating time is cleared and a new count begins.

This can be used to forecast the remaining Nicd

battery capacity and other applications.

Page 17

•RECEIVER AND SERVOS

5

Receiver, Servo Switch, and

Battery Connections

Extension cord

AEC-3

Antenna wire

8SSAP 4 Servos

Aileron servo

Elevator servo

Throttle servo

Rudder servo

Landing gear servo

Landing gear servo

PCM receiver

FP-R118GP

Fig. 15

PCM RECEIVER FP-R118GP

Antenna

wire

crystal

Fig.

17

Power switch

SWH-5 (R4 -SWJ)

Charging plug

NR-4J

Landing gear adaptor

AEC-A

Error lamp

•This LED comes on when the

receiver operated erroneously.

• When the receiver and servo side

Nicd is connected and this LED

is on, radiowaves are not being

received from the transmitter,

check to be sure the frequency

is correct. Checking is possible

by the lamp being on.

•When strong noise has

received, or the radiowaves from

the transmitter are intermittently interrupted, this lamp will blink.

This is usually not a problem.

been

Pay careful attention to the polarity

of the connector.

Remove the receiver

crystal by pulling it in

this direction.

Receiver crystal

Flap servo

Spoiler

servo

Pitch

control

servo

Fig. 18

1

Page 18

ADJUSTMENTS AND FLIGHT TECHNIQUES

•BASIC LINKAGES AND INSTALLATION

The FP-8SSAP has a servo reversing switch and ATV (Adjustable Travel Volume) for

each channel. Mount the servos without regard to their direction. Select and link servo

horns somewhat larger than those specified by the model manufacturer.

• Install the servos securely. Tighten the mounting

screws until the rubber grommets are slightly

compressed.

the vibration dampening effect of the grommets

will be lost.

• Use extension cords as needed.

• It is suggested that a separate servo be used on

each aileron as this will allow use of the versatile

mixing and differential functions built in to the

transmitter. Retractable landing gear can be

operated

with

two

age as desired.

•Connect the pushrod to each servo horn, then

check to see if the direction of travel in relation

to stick movement is correct. If the direction of

travel is reversed, use the servo reversing switches

to correct.

• When installing the switch harness, cut a retangu-.

lar hole slightly larger that the full stroke of the

ON/OFF switch and install the switch so that it

operates smoothly. It is best to install the switch

16

inside the fuselage and attach a piece of wire to

the switch so that it can be operated from outside

the

not be exposed to engine oil, dust, etc.

•Wrap the receiver in soft foam rubber. Waterand dustproof the receiver by placing it in a

Note:

If

the

screws

with a single

servos

aircraft. Locate the switch where

to

simplify

servo

the

to

are

too

save

weight

mechanical

tight,

or

link-

it

will

plastic bag and tying the mouth of the bag w ith

a rubber band. Do the same with the airborne

battery pack. Caution: The foam rubber should

be loosely wrapped and not compressed. This

will provide maximum protection from vibration.

• Use the rubber bands wrapped around the receiver to hold the servo and switch leads.

• Even though th e receiver antenna may appear to

be too long, do not sh ort en it or fold it back.

• Be alert for possible electrical noise.

This system has nois e rejection circuits, however

noiseless parts are recommended.

•Operate each servo to its full throw and check

for slop or binding in the linkage. Unreasonable

force applied to the servo horns can damage the

servo or horns and will greatly shorten battery

life. Adjust linkages and servo horns so that the

servos move smoothly even when the tri m l ever

and stick are operated simultaneously in the

same direction.

• After installation is complete, recheck each part,

then perform a range check by collapsing the

transmitter antenna and extending the receiver

antenna to its full length. Operate the transmitter at a distance of 60 to 90 feet from the receiver. The servos should operate normally at this

distance.

Normal 8 channel use (mixing and other functions not used).

Set the switches on the trimmer panel at the back

of the transmitter as shown below. The switches

are set as shown in Fig. 19. Connect the aileron

servo

to

CH1,

elevator

Set the DIFF

trimmer 1 5

to the INHB

(counterclock

wise).

DIFF

trimmer set to INHB Counterclockwise.

Note: Monitor Lamps (B), (C), and (D) do not

come on at this time. Check if the direction of

operation of each servo is correct under this state.

If the direction of operation of a servo is incorrect,

reverse

the

position

reversing switch [38] to [45]. Next, set the 2ND

servo

to

CH2,

of

the corresponding

throttle

servo

servo

to CH3, rudder servo to CH4, landing gear servo to

CH5, flap servo to CH6, spoiler servo to CH7, and

the pitch control servo to CH8.

ATV trimmers on aileron and elevator to the

desired deflection angles on the aircraft. The

deflection angle decreases when the 2ND ATV

trimmer is turned co unterclockwise. Throttle control can be adjusted with the ATL trim lever 19 .

This completes the settings for basic 8 channel

use.

Fig.

19

Page 19

ADJUSTMENTS AND FLIGHT TECHNIQUES

7

•USING

GENERAL - ATV (Adjustable Travel Volume)

allows independent adjustment of servo maximum

throw in each direction (without affecting the

neutral position). This is also sometimes referred

to as "separate endpoint adjustment". ATV is very

convenient when for example: a model requires

more DOWN elevator deflection than UP fo r equal

inside and outside loops (with equal control stick

MEMORY (PUSHBUTTON) ATV

This type of ATV is available on all eight channels.

Servo travel is adjusted as outlined in the example

below.

NOTE: Memory ATV settings are retained in the

transmitter memory circuit even when the power

switch is turned OFF. They are lost however, if

the transmitter

is removed for servicing.

ATV SETTING

Switch switches S [

Press button [46] or [47] while holding the aileron

stick in the full position.

ATV

Nicd

49] and R [48]

(ADJUSTABLE

battery

nears

full

discharge

Fig.

or

20

TRAVEL

deflection). Other aircraft may require slightly

different RIGHT or LEFT aileron or rudder

deflection to give equal response in each direction

(due to engine torque, precision of the model,

etc.). Two different ATV functions are possible

with this system. Memory (Pushbutton) ATV and

2ND

ATV.

MEMORY (PUSHBUTTON) ATV - (Aileron CH1

used as example)

1. First, set Function Select Switch [49]toATV

position.

2. Set Channel Select Switch [48]

3.Set

the transmitter and

ON and check for proper servo operation.

4.Move the Aileron stick to full RIGHT aileron,

hold it in that position, and set servo movement

to the desired Right aileron deflection angle by

pressing Button 46 or 47].

5.Repeat Step 4 fo r LEFT aileron.

6. For other

switch 48 and adjust ATV as desired.

7. Wh en all adjustments are completed, set the

Function Select and Channel Select switches

([48]

and

8. T o cle a r the ATV settings on all channels, set

the Function Select switch [49] to RESET and

Channel Select switch [48] to POSITION 2 (Pos.

2 = ATV when [49] is on RESET) and press

Buttons 46 and [47] simultaneously. ATV is

cleared

on

move to 100% of their maximum throw.

9. If only one channel is to be cleared or changed,

simply repeat Steps I through 5 with Channel Select Switch [48] set to the appropriate

channel.

VOLUME)

channels,

[49)

to

OFF.

ALL

CHANNELS and

receiver

select

to 1 (Ail.).

power switches

the channel

servos

with

will

1

ATV/FS BUTTON

•These two pushbutton switches are used for servo deflection angle setting of ATV. FS or HOLD function, servo test start & stop; reset; battery FS memory set, etc.

——————————————————————[46]

Fig.

21

This

pushbutton

1 Making the ATV servo deflection angle larger.

2 Turning the FS function on.

3 Starting

[47] This pushbutton switch is used when:

1 Making the ATV servo deflection angle smaller.

2 Turning the HOLD function on.

3 Stopping th e servo test.

When button [46] and [47] are pressed at the same

time, reset or battery FS memory setting is possible. At this time, lamp A of memory lamps 22

goes out momentarily so that setting can be moni-

tored.

the

switch

servo

is

test.

used

when:

Page 20

ADJUSTMENTS AND FLIGHT TECHNIQUES

18

CHANNEL SELECT SWITCH

• This switch 48 selects the channel when setting

FS and HOLD functions. It also acts as the chan-

nel select switch for SERVO TEST function.

When switch 49 is set to RESET, the Channel

Select switch is used to designate the function

(ATV, FS, BFS memory, or ALL) to be cleared

by Buttons [46] and [ 47]. Note that the positions

on switch 48 have a different meaning when

the Function Select Switch is set on RESET.

This is summarized in the table below:

[48] Channel select switch

FUNCTION SELECT SWITCH

• This switch selects the function to be set (ATV,

FS, BFS memory) or test (A or B) to be per-

formed. It is also used in the R ESET position to

clear ATV, FS, and BFS memory (in conjunction

with [46], [47], and 48). Note: In RESET position, the Channel Select Switch 48 is used to

designate the function(s) to be cleared.

[49] Function select switch

Fig.

23

(48] Rel ati onship among channel select switch

number, servo and reset.

At switch [49] FS SELECT,

No.

ATV. TESTA.B

Aileron

1.

Elevator

2.

3.

Throttle

4.

Rudder

Channel 5 switch (landing

5.

gear)

Flaps

6.

7.

Channel 7 knob (spoiler)

Channel 8 lever (variable

8.

pitch)

RESET &

TEST ALL

OFF

• Normally set it to OF F.

1.FS

Switch

for

TO

2.FS SELECT

This position allows setting of fail safe and

hold as described in the "HOW TO USE

FS" section.

3.ATV

This position allows setting ATV as described in the "HOW TO USE ATV" section.

4.TEST A

This position allows servo test

in the "SERVO TEST" section.

5.TEST B

This position allows servo test

in the "SE R VO TEST" section.

6.BFS MEMO

Switch to this position when setting the

release point as described in the "BATTERY

FS

7.OFF

Normally set to this position.

All the servos are

operated at servo

test.

Usually set to this OFF position.

ALL

to

this position when se tting fail

all channels, FS is described in the "HOW

USE FS" section.

SET

MEMORY SETTING" section.

At switch [49]

RESET

FS (fail safe)

ATV

BFS memory

FS,

ATV, and

memory are reset

simultaneously.

A as described

B as described

BFS

safe

BFS

Page 21

S

•2ND

9

ADJUSTMENTS AND FLIGHT TECHNIQUE

ATV

(CONVENTIONAL)

2ND ATV is available on the aileron and elevator

channels. This is the conventional type ATV and is

set using trimmers

transmitter back panel.

Servo movement can be adjusted from 0 to 100%.

These adjustments are retained even if the trans-

mitter

battery

ory ATV settings are not.).

[34], [35), [36],

reaches a full

[34]Aileron right-

[35]Aileron left-

and [37] on the

discharge state (Mem-

SERVO REVERSING SWITCHES

When the ATV trimmer is turned clockwise, the

steering angle increases. When the ATV trimmer is

turned counterclockwise, the steering angle decreases.

The

to

100%.

steering angle can be

Fig.

24

[36] Elevator u p

[37] Elevator down

adjusted

from

0

1

These switches reverse the direction of rotation of

the servos. They are convenient when connecting

the linkage.

NORM: For ward

REV: Reverse

[40]

Throttle

[38]Aileron

[39]Elevator-

Fig.

[42]CH5 switch channel

[44]

Spoiler

[45]Pitch control

[41]Rudder

25

Page 22

ADJUSTMENTS AN D FLIGHT TECHNIQUES

20

•USING

DUAL

RATE

(AILERON, ELEVATOR, AND RUDDER)

Dual rate functions allow the flyer to alter the

maximum servo travel (and therefore control sensitivity) during flight by using the appropriate rate

switch. At D/R OFF , servo deflection is maximum

in both directions (unless limited by ATV set-

AILERON DUAL RATE

• The aileron rate switch 14 has two D/R ON positions. Thus three different servo travel rates are available

on aileron. Rates can be adjusted to suit varying aircraft and maneuver requirements.

1 Aileron dual rate trimmer (I)

This trimmer sets the aileron travel when the aileron dual rate switch 14 is set

to the dual ON I position.

2 Aileron dual rate trimmer 2

This trimmer sets the aileron travel

when the aileron dual rate switch

14 is set to the dual ON 2 position.

Trimmers [1] and [2] can adjust the

aileron travel from 40% to 80% of

the total travel.

When the dua l rate switch is set to

ON, the servo throw can be set to

an arbitary angle smaller than

when the dual rate switch is OFF

(normal) as shown in Fig. 2 7. Use

the throw matched to the aircraft

and the maneuvers to be performed.

tings). At D/R ON, servo deflection is reduced by

a percentage set with the D/R trimmers. Dual rate

adjustments always effect both directions of servo

travel.

Dual rate switch OFF

(Switch in LINEAR Position)

Servo

throw

N

Stick deflection

When the dual rate switch

is ON, th e servo throw can be

adjusted within this range wit h

the dual rate trimmers.

3 LINEAR ->VTR selector

This switch linearly switches the

Fig.

26

ELEVATOR DUAL RATE RUDDER DUAL RATE

Fig.

28

aileron servo when the aileron dual

rate switch 14 is in the OFF position.

23 Elevator dual rate trimmer

This trimmer sets the elevator

deflection angle when the elevator dual rate switch 15 is

in the ON position. It has the

same functions as (A) aileron

dual rate I .

24 L INEAR ->VTR selector

This switch changes the elevator servo operation linearity

when the selector dual rate

switch 15 is in the OFF position. It has the same functions

as

(A) aileron dual

rate(I),

Fig.

2 1 Rudder dual ra te trimmer

22 LINEAR -> VTR selector

switch 16 is in the OFF po-

29

sition. It has the same functions

Fig.

27

This trimmer sets the rudder

deflection angle when the

rudder dual rate switch 16 is

in the ON position. It has the

same functions as (A) aileron

dual rate I .

This switch changes the rudder servo operating linearity

when the rudder dual rate

as

(A) aileron dual

rate(I).

Page 23

ADJUSTMENTS AN D FLIGHT TECHNIQUES

•AUTOMATIC DUAL RATE ON RUDDER

• This function automatically switches rudder D/R to ON as the throttle lever is moved fr om LOW to HIGH

position. This allows a smaller rudder throw for precise inputs during rolling maneuvers (at HIGH throttle) and i ncreased throw (at LOW throttle) during stall turns, taxing,

etc.

1 Safety Switch [31] is set to

2 Adjust desired Rudder travel in D/R ON using Trimmer [21] .

3 Throttle Position Trimmer 8 can be used to set the throttle lever

ON and OFF. Medium slow is recommended.

SWITCH ID FUNCTION SELECTOR

Fig.

30

RUDDER AUTO DUAL RATE SAFETY SWITCH

Fig.

31

ACT.

30 •Transmitter control switch

can be used as a Rudder D/R switch

or for turning the programmable

mixing function ON and OFF.

Usage is determined by the Function Select switch [30] on the transmitter back panel.

•When switch [30] is set to the P

MIX position the programmed

mixing function can be turned ON

30 • When the Rudder Auto D/R

Safety Switch 31 is set to ACT,

rudder auto D/R is ON. If Function

Select Switch 30 is also set to

RUDD D/R, the rudder D/R can

be turned ON and OFF with control switch 16 but the rudder auto

D/R function will still remain activated regardless of Switch 16.

16

position at which D/R is turned

or OFF with switch 16 . The Rudder D/R function will not operate

unless

Rudder

is used.

• When switch [30] is set to the

RUDD D/R position, the rudder

D/R can be turned ON or OFF with

Switch 16 . In this mode, the programmed mixing function will remain on regardless of Switch 16 .

•When switch [31] is set to INHIB,

the rudder auto D/R function is

inoperative. If Function Select

switch [30] is in the RUDD D/R

position, the rudder D/R function

can be turned ON or OFF with con-

trol switch 16 . Trimmer [21] sets

the rudder D/R and Auto D/R

deflection angles.

Auto

D/R function

21

•USING

•VTR

(Variable

non-linear control response. It is similar to Exponential Control, but is easier to use. Aileron

will b e used as an example.

•When the Aileron LINEAR/VTR Switch [3] is

in the LINEAR position, servo travel is linear

and directly proportional to the deflection of

the transmitter control stick as shown in Fig. 32.

In the VTR position (Ail. D/R Switch 14 must

also be in D/R OFF pos.), servo maximum throw

is unchanged. However servo tracking is the same

as when the rate switch is in the D/R 1, ON

position up to about 80% of the transmitter

stick deflection. Servo throw then abruptly increases to the same deflection as when D/R

Switch 14 is in D/R OFF position. Fig. 32

shows the servo movement curve when VT R is

used. Another way to think of VT R is as "auto-

matic dual rate" that is switched off automatically as the control stick is moved past the 80%

deflection point.

VTR

Trace

Ratio)

(VARIABLE TRACE RATIO)

is a new type

of

• Note: Maximum servo travel is the same in both

LINEAR and V TR modes and i s determined by

ATV settings or maximum travel of the servo

itself if no ATV is set.

• If rate swit ches are set to D/R ON while in the

VT R mode, servo tracking will revert to LINEAR

and travel is set by the D/R trimmer.

Fig.

32

Servo tracking

can be

set

within this

range with [1]

dual

trimmer.

N

Stick deflection

•When the dual

rate switch is

ON, operation

is the same as

when the

LINEAR-VTR

swi t c h is set to

the LINEAR

position.

Page 24

ADJUSTMENTS AND FLIGHT TECHNIQUES

•SUGGESTIONS ON ATV, D/R, AND VTR

POINTS TO REMEMBER (ATV, D/R. VTR)

• Servo maximum deflection is always determined

by ATV. If no ATV is set, maximum travel is

governed by the servo itself and is approximately

45 degrees i n each d i rection from neutral.

•When Dual Rate is ON, servo travel in each

direction is reduced by the same percentage

(adjustable using D/R trimmers). For example,

in Fig. 33 one direction has been limited using

ATV. Both sides are reduced 20% when D/R is

ON. In other words, the ratio of UP to Down

will be maintained when D/R is ON or OFF.

• VTR operates only when D/R is set to OFF position (LINEAR/VTR switch must also be se t to

VTR position).

•Servo tracking is always LINEAR when Dual

Rate is ON (regardless of LINEAR/VTR switch).

Fig.

33

22

SUGGESTIONS

• VTR is useful when different throw rates are

desired for different portions of the same ma-

neuver or when there may be insufficient time

between maneuvers for changing rate switches

manually such as in the FAI F3A or "Turn-

around" Pattern event.

•When preparing to test fly a new model, if you

are unsure as to the amount of Aileron deflec-

tio n needed, s e t up as follows.

1 LINEAR/VTR switch [3] on LINEAR

2 Aileron D/R I at best estimate of desired

throw for normal flying or deflection speci-

fied on aircraft plans.

3 Aileron D/R 2 less movement than D/R (1)

4 D/R OFF set to provide somewhat more

throw than specified.

5 Set Ail. D/R Switch 14 to (1) position for

takeoff.

6 If aileron response is not comfortable, it can

easily be increased or decreased while airborne.

Try this set-up for AMA Pattern:

1 Aileron LINEAR/VTR Switch [U set to

LINEAR.

2 Adjust D/R (1) to give 3 rolls in approxi-

mately 5 seconds.

3 Use ATV to adjust for a fast roll rate when

D/R Switch 14 is OFF.

4 Adjust D/R 2 for slow roll (1 roll in 5

seconds).

OR

Same as above except Aileron LINEAR/

VT R Switch [3] set to VTR position.

Page 25

ADJUSTMENTS AN D FLIGHT TECHNIQUES

3

•USING ATL (ADJUSTABLE THROTTLE LIMIT)

The Throttle Trim Lever 19 affects the servo position only when the thr ottle control lever is in the

HIGH

Fig.

34

FS FUNCTION/HOLD FUNCTION

Fail Safe (FS) is a function which moves the servo

of each channel to a position preset (at the transmitter) when an erroneous signal or continuous

strong noise is received for about 1 second or

longer. When the proper signal is lost or strong

interference received, the airborne system will

operate in the HOLD mode for about 1 second

before switching to the FS mode. When a normal

signal is received again for about 1 second, FS is

released and normal control resumes.

The HOLD functionstops all servos selected (by

button [47] at the position just before noise or

interference was received. When a normal signal is

resumed, HOLD is released.

SLOW

LOW (IDLE) position. HIGH throttle position

remains

linkage is there fore very convenient.

A combination of FS and HOLD functions can be

selected on each channel at the modeler's discretion.

ated using three switches on the trimmer panel.

unchanged. Adjustment

1 Use a servo horn that allows slightly more

throw than needed.

2 Set the maximum opening at HIGH throttle

using Memory ATV (Page 17).

3 Use Memory ATV to set the extreme LOW

position to prevent servo binding when the

throttle barrel closes against the idle stop

screw.

4 With the engine running, use ATL Throttle

Trim Lever 19 to set the optimum idle

speed.

FS, HOLD, and SERVO TEST functions are oper-

A. ATV/FS Buttons [4 6]

B. Channel Select Switch [48]

C. Function Select Switch [49]

48 Channel select switch

Fig.

36

of

the

throttle

and

2

[47]

Fig.

35

Fig.

49 Function select switch

37

Page 26

ADJUSTMENTS AND FLIGHT TECHNIQUES

•FS (FAIL SAFE) AND HOLD FUNCTIONS

HOW TO USE FS (FAIL SAFE) (THROTTLE CHANNEL AS AN EXAMPLE.)

1 Set Function Select Switch 49 to FS SELECT.

2 Set

transmitter

ON and check servo movements.

3 While switching the Channel Select Switch [48]

from 1 to 8 in order, set the channel(s) to be

used with FAIL SAFE by pressing Button 46

and those to be used with HOLD by pressing

Button 47 . (In this example, set CH3 to FS

with Button 46.)

4 Move

5 CH3 is now set to LOW throttle for the FS

6 Test

• Function status can be confirmed by means of Monitor Lamp (A).

•When Switch 49 is set to FS ALL, Lamp (A) is

•When Switch 4 9 is set to ATV and Button 46or47 is pressed. Lamp (A) blinks.

the

tion, and press the FS Set Button 36 on the

transmitter back.

function. After setting FS, turn the Channel

Select Switch 48 and Function Select Switch

49

to OFF.

FS

switch to OFF. (In this example, all servos

should move to neutral except the throttle

servo which should move to the LOW position

that was just set.)

FS/HOLD CAN BE CONFIRMED BY MONITOR LAMP.

When Function Select Switch 49 is at FS SELECT: Lamp A ON = HOLD

and

throttle

by turning

lever

receiver

to

maximum

the

transmitter

power

switches

slow

power

to

posi-

7 Fail Safe for all channels selected can be set

with one touch by moving the sticks and

switches of all the channels to the desired positions and pressing the FS Set Button 36 once.

(Switch 49 previously set to FS ALL.)

8 FS settings are retained in the transmitter

memory circuit and transmitted automatically

every 60 seconds (Monitor Lamp A goes out

momentarily during data transmission.) Therefore, resetting before each flight is unnecessary

even though the receiver switch has been turned

OFF.

9 After

1 0 To clear all FS settings, set Switch [48] to Posi-

Lamp (A) OFF= FS

OFF.

FS

settings

Function Select Switch [49] to OFF to prevent

erroneous settings.

tio n 1, then press buttons [46| and [47] si mu ltaneously.

have

been

made,

always

set

Page 27

ADJUSTMENTS AND FLIGHT TECHNIQUES

•BFS

•BFS

which moves only the throttle servo to the same

position as set fo r FS when there is only a small

amount of power left in the receiver Nicd batteries. (If no FS position is set, the throttle servo

is moved to medium slow.)

•When BFS occurs, the throttle servo can be released and throttle control regained for 36

seconds by lowering the throttle lever to IDLE.

• The throttle lever position at which thr ottle control is regained is programmable. This is known

as BFS Memory and is set as follows:

(BATTERY FAIL SAFE) AND BFS MEMORY

(Battery

Fail

Safe)

is a warning

function

•SERVO TEST FUNCTIONS

•The

operation of the

setting the transmitter and receiver power

switches to

•When switch 49 is switched to TEST-A, the

servos move half-side first and then, come back

to neutral and repeat the other-half from channel 1 to channel 8. (Channel select switch (R)

48 to TEST-ALL position at this time.) The

servos set by the channel select switch do not

operate. (If set to 5, the landing gear servo does

not operate.)

•When switch 49 is switch to TEST-B, all the

servos operate linearly over their full travel.

(Channel select switch (R) 48 in TEST-ALL

position at this time.) Only the servos set at the

channel select switch are operated.

ON.

servos

can

be

checked

by

1 Se t Function Select Switch 49 to BFS MEMO

SET and set Channel Select Switch 48 to Pos.

3 (Throttle).

2 Set

the Throttle

point (between Slow and Medium Slow recommended) and press Buttons 46 and 47 simultaneously. BFS Memory is now set.

3 Set

Switches

4 Whenever BFS occurs in flight, lower the throt-

tle lever to regain control and immediately land

the aircraft.

•The

servo

test

and is stopped by pressing button .47].

48

and

is

started

lever

49

to

the

to

OFF.

by

pressing

desired

Fig.

38

release

button

46

25

Page 28

ADJUSTMENTS AND FLIGHT TECHNIQUES

•AIRCRAFT WITH VARIABLE PITCH PROP

ADVANTAGES OF VA R IABLE PITCH PROPELLEJB

The variable pitch propeller offers such advantages as:

1. The desired speed and pull can be adjusted.

2. Speed matched to the engine is obtained.

3. Low noise.

4. Air braking effect by

5. Idling is unnecessary.

Pitch control

servo

High pitch— —Low pitch

Matching of the variable pitch propeller to the di gital proportional RC set is essential. Improper use is extremely dangerous. Therefore, read t his section carefully.

Connect the pitch control servo to channel 8. A variable pitch propeller can be adequately controlled by a

common servo. Handle the servo the same as any other servo.

Install the servo and linkage as specified by the manufacturer. (Note) This section explains how to use a

MK variable pitch propeller.

zero

pitch.

Set switch [7] to the ACT

position.

and

wise.

Since trimmer'6 ] is adjusted

after making a test flight,

it to about the center.

Switch II is the mixing ONOFF switch. When it is set to

the OFF position, monitor

lamp 22 (B) comes on. When

it is set to the ON position,

the lamp goes out. Set the

switch to the ON position

and check the pitch control

(channel 8) servo stroke and

direction. Set the servo so

the propeller is pitched when

the throttle stick is set to

HIGH and is zero pitch when

the throttle stick is set to

Fig.

40

Next, adjust the servo stroke. First set the transmitter pitch control lever 8 to the HIGH posi-

tion.

Then adjust

with the ATV tri mmers 48 and 49 so a load is not

applied to the linkage. Set the mixing throttle position is 1 stop from the SLOW position (Fig. 41)

with the THROT POSIT trimmer

if:

LOW. If the servo turns in

the wrong direction, reverse

the setting of servo reversing

switch [57] .

the

pitch control

Turn trimmers [4]

[5] fully counterclock-

set

servo

stroke

[8].

and check

* The pitch is zero (minimum) when the throttle

lever is set to minimum slow.

* The pitch becomes 11 (maximum) when the

throttle lever is raised one stop.

Next, adjust the transmitter upper side pitch control

HIGH

side

trim

lever

8 throw.

tle lever to the HIGH side before making this

adjustment.

pitch 11 (maximum) the propeller pitch when this

lever is set to the lowest position must be checked.

A variable pitch propeller is difficult to measure

with a pitch gauge. Therefore, adjust trimmer [6]

for a pitch somewhat lower than the maximum

pitch 11 ] .

Since

lever

8 should

Set

be

the

linked

throt-

with

Page 29

ADJUSTMENTS AN D F LIGHT TECHNIQUES

7

Pitch zero does not have an air braking affect. If

Pitch 8-9

NOTE:

When lowering lever 8 , be careful that the pitch

does not go negative. This is adjusted during flight.

For example, flight is affected by the temperature,

air pressure, wind, and other conditions. Use this

lever adjusting the speed, pull, etc. to your liking.

Also select the engine tone quality by adjusting

the propeller pitch. Make quiet flights by fine adjusting the propeller pitch.

Next, adjust the throttle. First, set switch II to

the OFF position. Adjust the engine idling speed

to 2,200~2,500 rpm with the throttle trim lever

9 . Then set switch II to the ON position and

set the throttle lever to the maximum slow (zero