Page 1

8FG SUPER

14-CHANNEL RADIO CONTROL SYSTEM

FASST-2.4GHz Multi-ch/7-ch mode selectable

INSTRUCTION MANUAL

1M23N22218

Page 2

TABLE OF CONTENTS

INTRODUCTION............................................... 4

●Support and Service ......................................... 4

●Application, Export, and Modication ........... 5

●Denitions of Symbols ...................................... 6

●Safety Precautions (do not operate without

reading) ............................................................. 6

BEFORE USE ................................................... 10

●Features of 8FG SUPER ................................ 10

●Contents and technical specications ........... 11

●Accessories ....................................................... 12

●Transmitter controls ....................................... 13

Cautions on handling antenna ...................... 14

LED monitor ................................................... 14

Switch (SA-SH) ............................................... 14

Volume (LD, RD) ............................................ 15

Slide Lever (LS, RS) ....................................... 15

Digital trim (T1-T4) ....................................... 15

Touch sensor ................................................... 16

Stick adjustment ............................................. 17

SD card ............................................................ 18

Connector/Plug ............................................... 19

Installation and removal of the battery ........ 20

●Range testing your R/C system...................... 29

RACEIVER AND SERVO INSTALLATION 30

●Receiver and servos connection ..................... 30

●Servo connection by model type .................... 31

●Safety precautions when installing receiver and

servos ............................................................... 35

●Receiver's antenna installation ...................... 36

MODEL BASIC SETTING PROCEDURE ...37

●Airplane/glider basic setting procedure ........37

●Helicopter basic setting procedure ................ 39

FUNCTIONS OF SYSTEM MENU ................ 43

Trainer ............................................................. 44

Display ............................................................. 47

User Name ....................................................... 48

Sound ............................................................... 49

H/W Setting ..................................................... 50

Start SEL. ....................................................... 50

Auto Lock ....................................................... 55

Information .................................................... 56

●Receiver nomenclature ................................... 21

BASIC OPERATION ....................................... 22

●Battery Charging ............................................ 22

How to charge the Ni-MH Battery ............... 22

●How to turn ON/OFF the transmitter ..........23

When turning on ............................................ 23

When turning off ............................................ 23

Low battery alarm and auto shut-down ...... 23

Warning display at power on ........................ 23

●Registration of the user's name ..................... 23

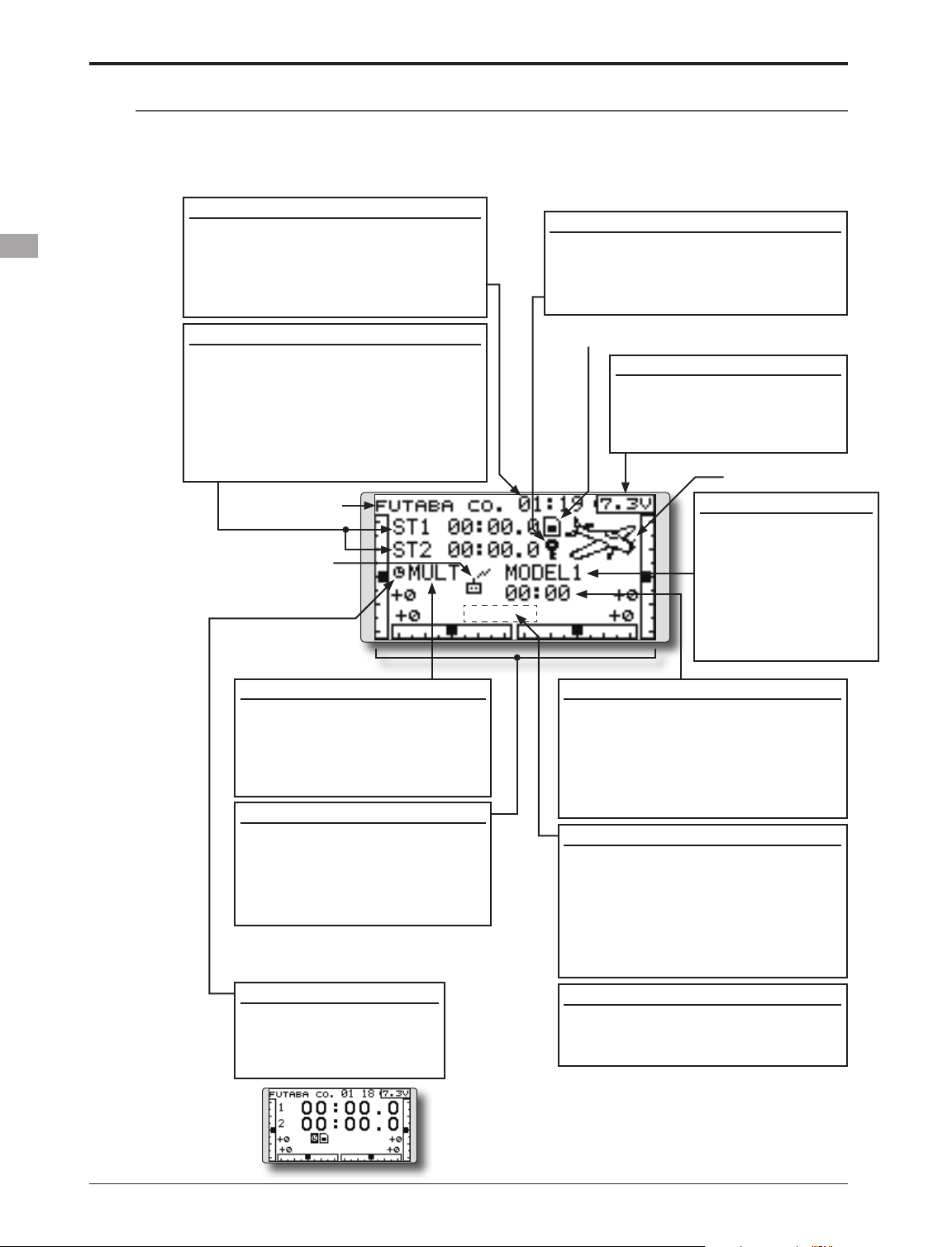

●Home screen .................................................... 24

User Menu ....................................................... 25

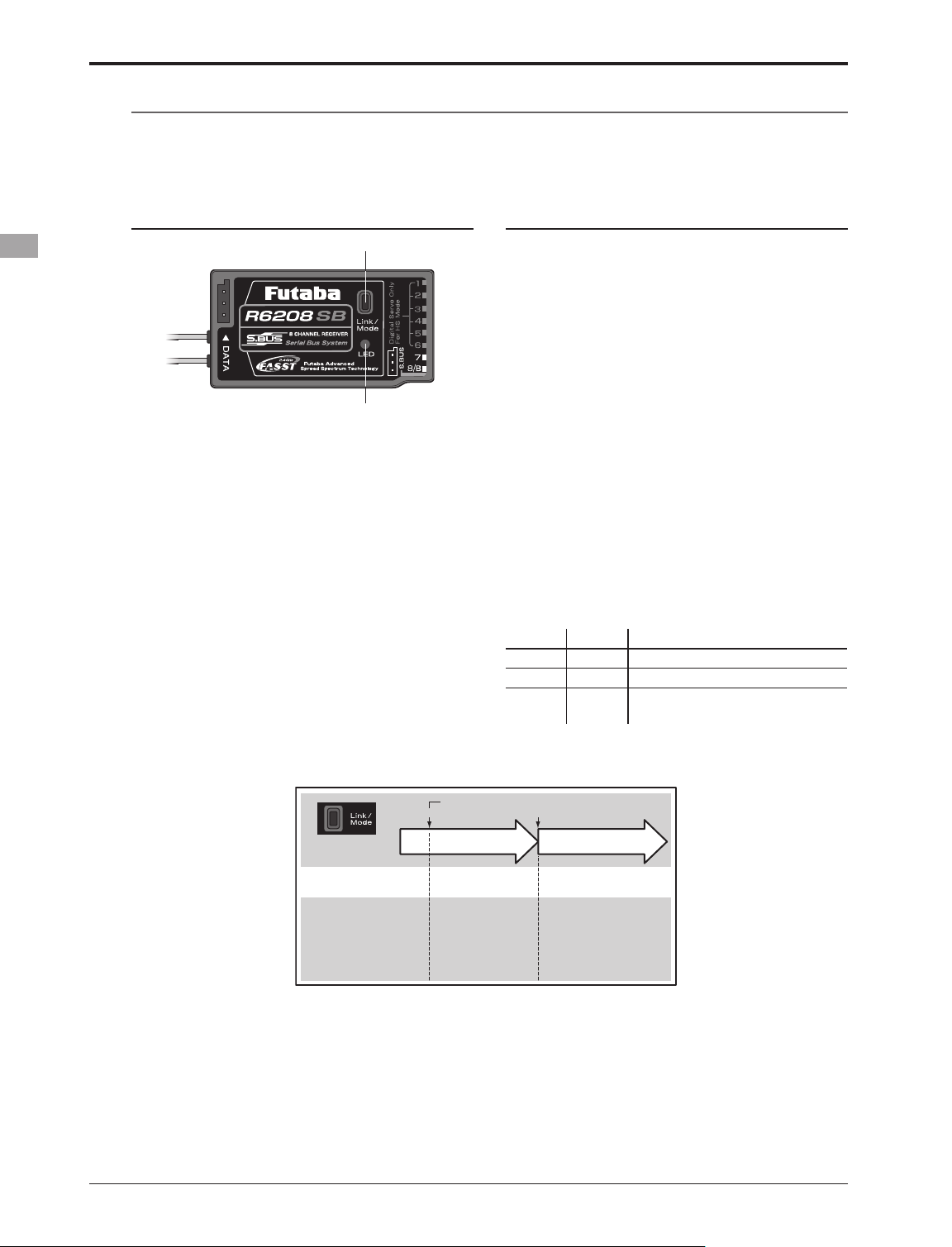

●Operation mode select (R6208SB) ................ 26

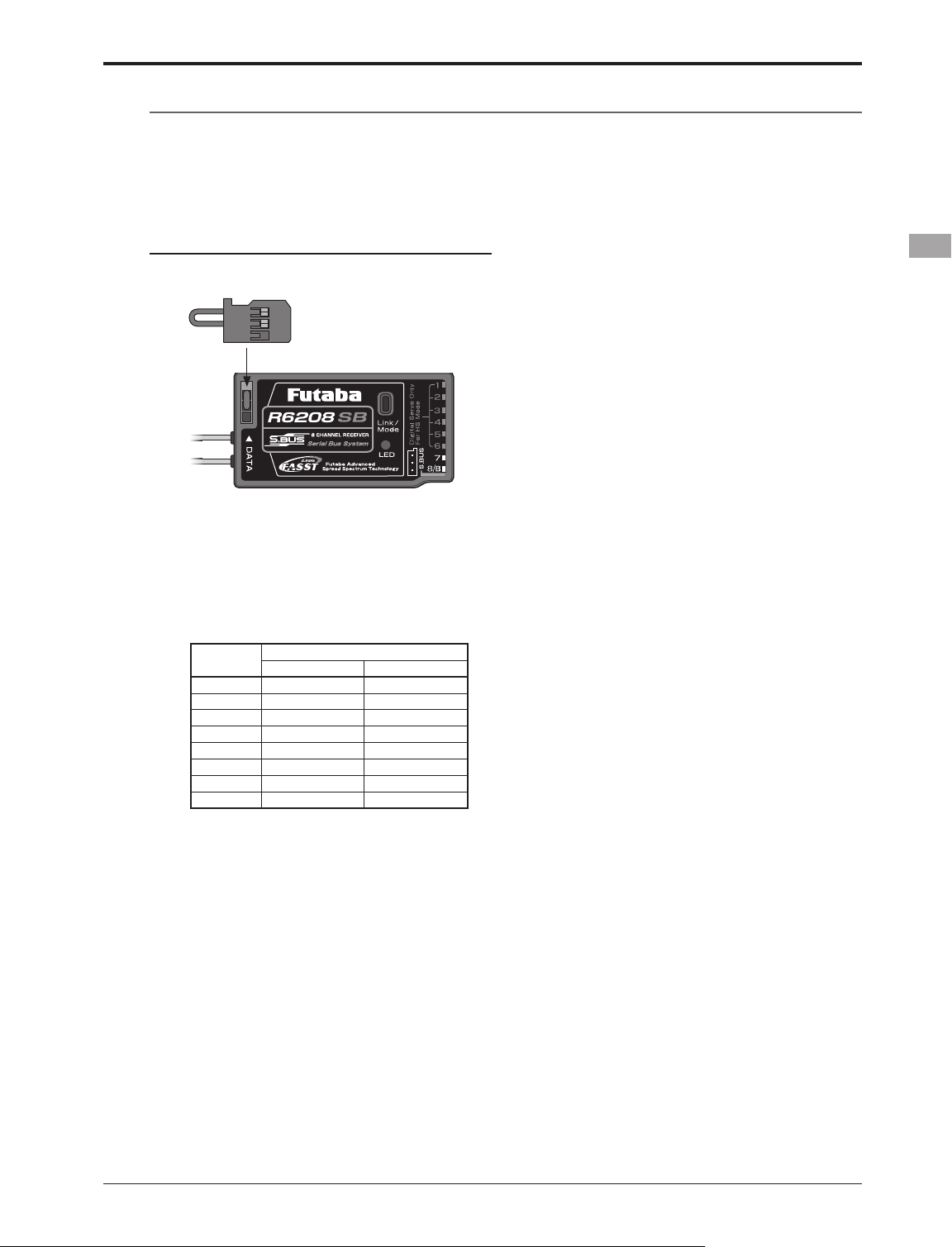

●S.BUS servo channel setting (R6208SB) ....... 27

●Link procedure (T8FGS/R6208SB) .............. 28

<Table of Contents>

2

FUNCTIONS OF LINKAGE MENU ............. 57

(Common Functions)

Linkage Menu functions table ...................... 57

Servo Monitor ................................................. 58

Model Select .................................................... 59

Model Type...................................................... 61

Frequency ........................................................ 63

Function .......................................................... 64

Sub-Trim ......................................................... 66

Servo Reverse ................................................. 67

Fail Safe ........................................................... 68

End Point ........................................................ 69

Throttle Cut (Air/Heli only) .......................... 70

Idle Down (Air only) ...................................... 71

Swash Ring (Heli only) .................................. 72

Swash (Heli only, except H-1) ........................73

T1-T4 Setting .................................................. 76

Page 3

Warning ...........................................................77

Data Reset ....................................................... 78

FUNCTIONS OF MODEL MENU ................. 79

●Common Functions ........................................ 79

Servo Monitor (Linkage Menu)

Condition Select (Glid/Heli only) .................. 80

Dual Rate ........................................................ 82

Program Mix ................................................... 84

Fuel Mix (Air/Heli only) ................................ 86

●Airplane/Glider Functions ............................. 88

Model Menu functions list ............................. 88

Pitch Curve (Air only) ................................... 90

Throttle Curve (Air only) .............................. 91

Throttle Delay (Air only) ............................... 92

AIL Differential (Except 1-AIL) ................... 93

Flap Setting (2-FLP and up) .......................... 94

AIL to Camber FLP (2-AIL+2-FLP and up)95

AIL to Brake FLP (Glid only, 4-FLP) .......... 96

AIL to RUD ..................................................... 97

RUD to AIL ..................................................... 98

Camber Mix (Except 1-AIL) ....................... 100

ELE to Camber (Except 1-AIL) .................. 102

Camber FLP to ELE (2-AIL+1-FLP and up) 103

Buttery (Glid only, normal wing 2-AIL and

up, ying wing 2-AIL+1FLP and up) ......104

Trim Mix (Glid only, 2-AIL and up) ........... 106

Airbrake (Air only, 2-AIL and up) ............. 108

Gyro (Air only, for GYA type gyro) ............ 110

V-tail .............................................................. 112

Ailevator ........................................................ 113

Winglet (Flying wing only) .......................... 114

Motor ............................................................. 115

RUD to ELE (Air only) ................................ 117

Snap Roll (Air only) ..................................... 118

Swash Mix ..................................................... 128

Throttle Mix .................................................. 129

PIT to RUD (Revolution mix) ..................... 130

Gyro (for GY type gyro) .............................. 131

Governor ....................................................... 133

APPENDIX ...................................................... 135

Timer ST1/ST2 ............................................. 136

Switch Setting Method ................................. 137

●Helicopter Functions .................................... 120

Model Menu functions list ........................... 120

PIT Curve/Pit trim ....................................... 121

THR Curve/Throttle hover trim/Throttle

limiter ......................................................... 124

Throttle Hold ................................................ 127

<Table of Contents>

3

Page 4

INTRODUCTION

®

Thank you for purchasing a Futaba

FASST-2.4GHz* 8FG SUPER series digital proportional R/C system. This

system is extremely versatile and may be used by beginners and pros alike. In order for you to make the best use

of your system and to y safely, please read this manual carefully. If you have any difculties while using your

system, please consult the manual, our online Frequently Asked Questions (on the web pages referenced below),

your hobby dealer, or the Futaba Service Center.

*FASST: Futaba Advanced Spread Spectrum Technology

Due to unforeseen changes in production procedures, the information contained in this manual is subject to

change without notice.

Support and Service: It is recommended to have your Futaba equipment serviced annually during your hobby’s

“off season” to ensure safe operation.

IN NORTH AMERICA

Please feel free to contact the Futaba Service Center for assistance in operation, use and programming. Please

be sure to regularly visit the 8FG Frequently Asked Questions web site at www.futaba-rc.com/faq/. This page

includes extensive programming, use, set up and safety information on the 8FG SUPER radio system and is

updated regularly. Any technical updates and US manual corrections will be available on this web page. If

you do not nd the answers to your questions there, please see the end of our F.A.Q. area for information on

contacting us via email for the most rapid and convenient response.

Don’t have Internet access? Internet access is available at no charge at most public libraries, schools, and other

public resources. We nd internet support to be a fabulous reference for many modelers as items can be printed

and saved for future reference, and can be accessed at any hour of the day, night, weekend or holiday. If you do

not wish to access the internet for information, however, don’t worry. Our support teams are available Monday

through Friday 8-5 Central time to assist you.

FOR SERVICE ONLY:

Futaba Service Center

3002 N. Apollo Drive, Suite 1

Champaign, IL 61822

Phone: 217-398-0007

www.futaba-rc.com/service.html

(PROGRAMMING AND USER QUESTIONS)

Please start here for answers to most questions:

FOR SUPPORT :

www.futaba-rc.com/faq/

Fax: 217-398-7721

Phone: 217-398-8970 option 2

Email: service@futaba-rc.com

OUTSIDE NORTH AMERICA

Please contact your Futaba importer in your region of the world to assist you with any questions, problems or

service needs.

Please recognize that all information in this manual, and all support availability, is based upon the systems sold

in North America only. Products purchased elsewhere may vary. Always contact your region’s support center for

assistance.

<Introduction>

4

Page 5

Application, Export, and Modication

1. This product may be used for model airplane or surface (boat, car, robot) use. It is not intended for use in

any application other than the control of models for hobby and recreational purposes. The product is subject to

regulations of the Ministry of Radio/Telecommunications and is restricted under Japanese law to such purposes.

2. Exportation precautions:

(a) When this product is exported from the country of manufacture, its use is to be approved by the laws

governing the country of destination which govern devices that emit radio frequencies. If this product is then reexported to other countries, it may be subject to restrictions on such export. Prior approval of the appropriate

government authorities may be required. If you have purchased this product from an exporter outside your

country, and not the authorized Futaba distributor in your country, please contact the seller immediately to

determine if such export regulations have been met.

(b) Use of this product with other than models may be restricted by Export and Trade Control Regulations, and

an application for export approval must be submitted. This equipment must not be utilized to operate equipment

other than radio controlled models.

3. Modication, adjustment, and replacement of parts: Futaba is not responsible for unauthorized modication,

adjustment, and replacement of parts on this product. Any such changes may void the warranty.

Compliance Information Statement (for U.S.A.)

This device, trade name Futaba Corporation of America, model number R6208SB, complies with part 15 of the

FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired

operation.

The responsible party of this device compliance is:

Futaba Service Center

3002 N Apollo Drive Suite 1, Champaign, IL 61822 U.S.A.

TEL (217)398-8970 or E-mail: support@futaba-rc.com (Support)

TEL (217)398-0007 or E-mail: service@futaba-rc.com (Service)

The RBRC. SEAL on the nickel-cadmium battery contained in Futaba products indicates that

Futaba Corporation of America is voluntarily participating in an industry-wide program to collect

and recycle these batteries at the end of their useful lives, when taken out of service within the

United States. The RBRC. program provides a convenient alternative to placing used nickelcadmium batteries into the trash or municipal waste system, which is illegal in some areas.

(for USA)

You may contact your local recycling center for information on where to return the spent battery. Please

call 1-800-8BATTERY for information on Ni-Cd battery recycling in your area. Futaba Corporation of

America's involvement in this program is part of its commitment to protecting our environment and conserving

natural resources.

*RBRC is a trademark of the Rechargeable Battery Recycling Corporation.

<Introduction>

5

Page 6

Federal Communications Commission Interference Statement (for U.S.A.)

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in

a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following measures:

--Reorient or relocate the receiving antenna.

--Increase the separation between the equipment and receiver.

--Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

--Consult the dealer or an experienced radio/TV technician for help.

CAUTION:

To assure continued FCC compliance:

Any changes or modifications not expressly approved by the grantee of this device could void the user's

authority to operate the equipment.

Exposure to Radio Frequency Radiation

To comply with FCC RF exposure compliance requirements, a separation distance of at least 20cm must be

maintained between the antenna of this device and all persons.

This device must not be co-located or operating in conjunction with any other antenna or transmitter.

Meaning of Special Markings

Pay special attention to safety where indicated by the following marks:

DANGER - Procedures which may lead to dangerous conditions and cause death/serious injury if not

carried out properly.

WARNING - Procedures which may lead to a dangerous condition or cause death or serious injury to

the user if not carried out properly, or procedures where the probability of supercial injury or physical

damage is high.

CAUTION - Procedures where the possibility of serious injury to the user is small, but there is a danger of

injury, or physical damage, if not carried out properly.

= Prohibited = Mandatory

Warning: Always keep electrical components away from small children.

FLYING SAFETY

WARNING

To ensure the safety of yourself and others, please observe the following precautions:

Have regular maintenance performed. Although your 8FG SUPER protects the model memories with

non-volatile EEPROM memory (which does not require periodic replacement) and not a battery, the

transmitter still should have regular checkups for wear and tear. We recommend sending your system to

the Futaba Service Center annually during your non-ying-season for a complete checkup and service.

<Introduction>

6

Page 7

Ni-MH/Ni-Cd Battery

Charge the batteries! (See Charging the Ni-Cd batteries, for details.) Always recharge the transmitter and

receiver batteries before each ying session. A low battery will soon die potentially, causing loss of control

and a crash. When you begin your ying session, reset your T8FGS’s built-in timer, and during the session

pay attention to the duration of usage.

Stop ying long before your batteries become low on charge. Do not rely on your radio’s low battery

warning systems, intended only as a precaution, to tell you when to recharge. Always check your

transmitter and receiver batteries prior to each ight.

Where to Fly

We recommend that you y at a recognized model airplane ying eld. You can nd model clubs and elds

by asking your nearest hobby dealer, or in the US by contacting the Academy of Model Aeronautics.

You can also contact the national Academy of Model Aeronautics (AMA), which has more than 2,500

chartered clubs across the country. Through any one of them, instructor training programs and insured

newcomer training are available. Contact the AMA at the address or toll-free phone number below.

Academy of Model Aeronautics

5161 East Memorial Drive

Muncie, IN 47302

Tele. (800) 435-9262

Fax (765) 289-4248

or via the Internet at http:\\www.modelaircraft.org

Always pay particular attention to the flying field’s rules, as well as the presence and location of

spectators, the wind direction, and any obstacles on the eld. Be very careful ying in areas near power

lines, tall buildings, or communication facilities as there may be radio interference in their vicinity.

<Introduction>

7

Page 8

Ni-MH/Ni-Cd Battery Safety and Handling instructions

IMPORTANT!

Use only the Futaba special charger included with this set or other chargers approved by Futaba to

charge the Ni-MH batteries in the T8FGS transmitter included with this set.

It is important to understand the operating characteristics of Ni-MH/Ni-Cd batteries.Always read the

specications printed on the label of your Ni-MH/Ni-Cd battery and charger prior to use. Failure to follow the

proceeding precautions can quickly result in severe, permanent damage to the batteries and its surroundings and

possibly result in a FIRE!

IMPORTANT PRECAUTIONS

Do not attempt to disassemble Ni-MH/Ni-Cd packs or cells.

Do not allow Ni-MH/Ni-Cd cells to come in contact with moisture or water at any time.

Always provide adequate ventilation around Ni-MH/Ni-Cd batteries during charge, discharge, while in

use, and during storage.

Do not leave a Ni-MH/Ni-Cd battery unattended at any time while being charged or discharged.

Do not attempt to charge Ni-MH/Ni-Cd batteries with a charger that is NOT designed for Ni-MH/Ni-Cd

batteries, as permanent damage to the battery and charger could result.

Always charge Ni-MH/Ni-Cd batteries in a reproof location. Do not charge or discharge Ni-MH/Ni-Cd

batteries on carpet, a cluttered workbench, near paper, plastic, vinyl, leather or wood, or inside an R/C

model or full-sized automobile! Monitor the charge area with a smoke or re alarm.

Do not charge Ni-MH/Ni-Cd batteries at currents greater than the “1C” rating of the battery (“C” equals

the rated capacity of the battery).

Do not allow Ni-MH/Ni-Cd cells to overheat at any time! Cells which reach greater than 140 degrees

Fahrenheit (60°C) should be placed in a reproof location.

Ni-MH/Ni-Cd cells will not charge fully when too cold or show full charge.

It is normal for the batteries to become warm during charging, but if the charger or battery becomes

excessively hot disconnect the battery from the charger immediately!! Always inspect a battery which has

previously overheated for potential damage, and do not re-use if you suspect it has been damaged in any

way.

Do not use a Ni-MH/Ni-Cd battery if you suspect physical damage has occurred to the pack. Carefully

inspect the battery for even the smallest of dents, cracks, splits, punctures or damage to the wiring and

connectors. DO NOT allow the battery’s internal electrolyte to get into eyes or on skin—wash affected

areas immediately if they come in contact with the electrolyte. If in doubt, place the battery in a re-proof

location for at least 30 minutes.

Do not store batteries near an open ame or heater.

Do not discharge Ni-MH/Ni-Cd batteries at currents which exceed the discharge current rating of the

battery.

Always store Ni-MH/Ni-Cd cells/packs in a secure location away from children.

Secure Digital (SD) Memory Card Handling Instructions

(SD card is not included with this set)

Never remove the SD card or turn off power while

entering data.

Never store the SD card where it may be subject

to strong static electricity or magnetic elds.

Do not expose the SD card to direct sunlight,

excessive humidity or corrosive environments.

<Introduction>

8

Do not expose the SD card to dirt, moisture, water

or uids of any kind.

Always hold the SD card by the edges during

installation and removal.

Be certain to insert the SD card in the correct

direction.

Page 9

At the ying eld

To prevent possible damage to your radio gear, turn the power switches on and off in the proper sequence:

1. Pull throttle stick to idle position, or otherwise disarm your motor/engine.

2. Turn on the transmitter power and allow your transmitter to reach its home screen.

3. Conrm the proper model memory has been selected.

4. Turn on your receiver power.

5. Test all controls. If a servo operates abnormally, don’t attempt to y until you determine the cause of the

problem.

Test to ensure that the FailSafe settings are correct after adjusting them. Turn the transmitter off and

conrm the proper surface/throttle movements. Turn the transmitter back on.

6. Start your engine.

7. Complete a full range check.

8. After ying, bring your throttle stick to idle position, engage any kill switches or otherwise disarm your

motor/engine.

9. Turn off receiver power.

10. Turn off transmitter power.

If you do not turn on your system in this order, you may damage your servos or control surfaces, ood your

engine, or in the case of electric-powered or gasoline-powered models, the engine may unexpectedly turn on

and cause a severe injury.

While you are getting ready to y, if you place your transmitter on the ground, be sure that the wind

won't tip it over. If it is knocked over, the throttle stick may be accidentally moved, causing the engine to

speed up. Also, damage to your transmitter may occur.

In order to maintain complete control of your aircraft it is important that it remains visible at all times.

Flying behind large objects such as buildings, grain bins, etc. is not suggested. Doing so may result in the

reduction of the quality of the radio frequency link to the model.

Do not grasp the transmitter's antenna during ight. Doing so may degrade the quality of the radio

frequency transmission.

As with all radio frequency transmissions, the strongest area of signal transmission is from the sides of the

transmitter's antenna. As such, the antenna should not be pointed directly at the model. If your ying style

creates this situation, easily move the antenna to correct this situation.

Don’t y in the rain! Water or moisture may enter the transmitter through the antenna or stick openings

and cause erratic operation or loss of control. If you must y in wet weather during a contest, be sure to

cover your transmitter with a plastic bag or waterproof barrier. Never y if lightning is expected.

<Introduction>

9

Page 10

BEFORE USE

Features

FASST-2.4GHz system

The T8FGS transmitter is capable of transmitting in both FASST-2.4G 7-ch and Multi-ch modes. Select

the desired modulation mode in the Frequency Menu. For complete details on how to do so, please refer to

the Frequency Selection section located elsewhere in this manual. The compatibility is dependent upon the

receiver selected. The R6208SB receiver is capable of controlling models up to 8(eight) channels by using

the outputs for conventional system and up to 14(fourteen) channels including the 2(two) digital channels

by using the output for S.BUS system. R6208SB has two (2) operation mode as shown below.

Receiver: Normal mode/High Speed mode

The "Normal mode" accepts any type of servos or the peripherals as the frame rate of the output is 14ms.

The "High Speed mode" only accepts the digital servos for outputs from 1ch to 6ch. This includes the BLS

series, and most peripheral equipment such as gyros and brushless ESCs. The frame rate of the outputs is

7ms. The outputs for other channels indicated allow the use of any type of servos as the frame rate of these

outputs are still 14ms on the High Speed mode.

FASST-2.4GHz system features:

• 2.4GHz Spread Spectrum radio communication system.

• Exclusive ID code to avoid interference from other FASST systems.

• Fail Safe (F/S) function (for throttle channel at 7-ch mode)-F/S, Battery F/S

• Dual antenna diversity (R6208SB)

• Normal mode or High Speed mode is selectable (R6208SB)

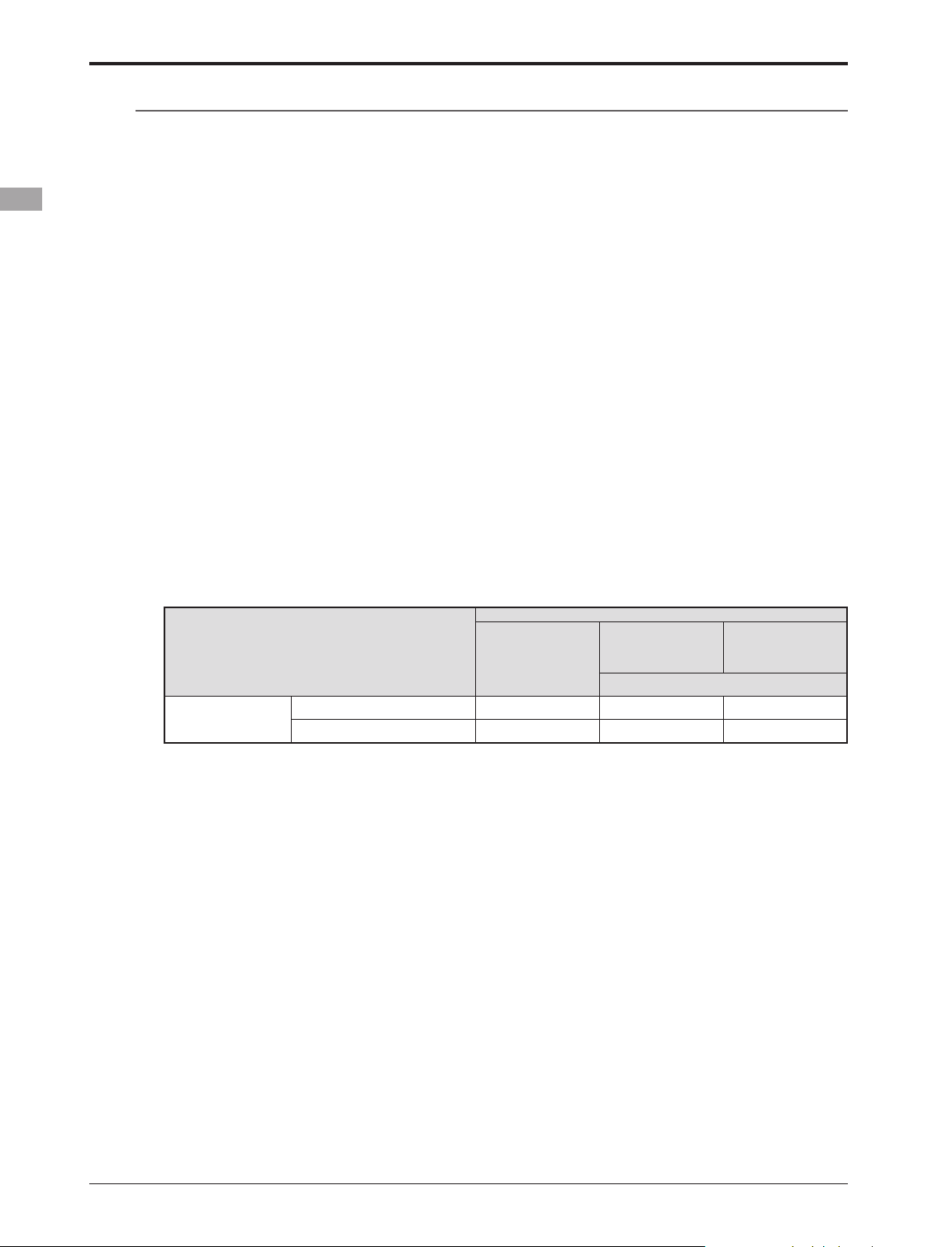

T8FGS-2.4GHz system and receiver compatibility

Receiver

T8FGS 2.4G System

R6004FF, R616FFM,

Transmitter

Multi-ch mode (MLT2/MULT) — — Okay

7-ch mode Okay Okay —

(*)Since these receivers have few ports, S.BUS is used for them when using many channels.

R606FS

R6106HF/HFC

R607FS, R617FS

R6203SB,R6203SBE,R6303SB,R6303SBE(

R608FS, R6208SB,

R6108SB

R6014FS/HS

)

*

Model types

Six swash types are available for helicopters. Six types of main wings and three types of tail wings are

available for airplanes and gliders. Functions and mixing functions necessary for each model type are set in

advance at the factory.

Data input

Large graphic LCD and new type Touch Sensor substantially improve ease of setup.

Stick

New stick design with improved feel, adjustable length and tension.

Ni-MH battery

T8FGS is operated by a 7.2 V/1,700 mAh Nickel-Metal Hydride battery.

SD card (Secure Digital memory card) (Not included)

Model data can be saved to an SD card (32MB-2GB). When T8FGS transmitter software files are

released, the software can be updated by using an SD card update.

<Before Use>

10

Page 11

Contents and Technical Specications

Your 8FG SUPER includes the following components:

(Specications and ratings are subject to change without notice.)

• T8FGS transmitter for airplanes or helicopters

• R6208SB Receiver

• HT6F1700B Ni-MH battery & Charger

• Switch harness

• Neck strap

*The set contents depend on the type of set.

Transmitter T8FGS

(2-stick, 14-channel, FASST-2.4G system)

Transmitting frequency: 2.4GHz band

Modulation: 2.4G 7-ch or 2.4G Multi-ch, switchable

Power supply: 7.2V HT6F1700B Ni-MH battery

Receiver R6208SB

(FASST-2.4G system, dual antenna diversity, S.BUS system)

Power requirement: 3.7V~7.4V battery or regulated

output from ESC, etc. (*1)

Size: 0.98 x 1.86 x 0.56 in. (24.9 x 47.3 x 14.3 mm)

Weight: 0.49 oz. (13.8g)

(*1) When using ESC's make sure that the regulated

output capacity meets your usage application.

Usage condition on "High Speed mode"

(R6208SB)

(Suggested Servo for use with your 8FG SUPER system)

Servo S9252 (Digital servo)

Control system: Pulse width control, 1.52 ms neutral

Power requirement: 4.8 V (from receiver)

Output torque: 91.7 oz.-in. (6.6 kg-cm) at 4.8V

Operating speed: 0.14 sec/60 at 4.8V

Size: 1.57 x 0.79 x 1.44 in. (40 x 20 x 36.6 mm)

Weight: 1.76 oz. (50 g)

Servo S9255 (Digital servo)

Control system: Pulse width control, 1.52 ms neutral

Power requirement: 4.8 V (from receiver)

Output torque: 125.0 oz.-in. (9.0 kg-cm) at 4.8V

Operating speed: 0.16 sec/60 at 4.8V

Size: 1.57 x 0.79 x 1.44 in. (40 x 20 x 36.6 mm)

Weight: 1.94 oz. (55 g)

Servo S3151 (Standard, Digital servo)

Control system: Pulse width control, 1.52 ms neutral

Power requirement: 4.8 V (from receiver)

Output torque: 43.1 oz.-in. (3.1 kg-cm) at 4.8V

Operating speed: 0.21 sec/60 at 4.8V

Size: 1.59 x 0.79 x 1.42 in. (40.5 x 20 x 36.1 mm)

Weight: 1.48 oz. (42 g)

CAUTION

When using the R6208SB in the high speed

(HS) mode, digital servos are required for

the rst six channels (1-6).

If an analog servo is connected to one of the first

six channels when in the high speed mode, the

servo will not function properly. Additionally,

while many peripheral devices will operate in either

the high speed or normal mode, some will not. If

there are any difficulties noted, please return the

reciever's operational mode to the "Normal" mode

to determine if this resolves the difculty.

If using the R6208SB in the high speed mode,

analog servos may be used for channels seven and

eight.

(For Operation Mode Selection, see p.26)

Servo S3001 (Standard, ball-bearing)

Control system: Pulse width control, 1.52 ms neutral

Power requirement: 4.8 - 6.0V (from receiver)

Output torque: 41.7 oz.-in. (3.0 kg-cm)

Operating speed: 0.22 sec/60

Size: 1.59 x 0.78 x 1.41 in. (40.4 x 19.8 x 36 mm)

Weight: 1.59 oz. (45.1g)

<Before Use>

11

Page 12

The following additional accessories are available from your dealer. Refer to a Futaba catalog for

more information:

• HT6F1700B Transmitter battery pack - the (1700mAh) transmitter Ni-MH battery pack may be easily

exchanged with a fresh one to provide enough capacity for extended ying sessions.

• Trainer cord - the optional training cord may be used to help a beginning pilot learn to fly easily by

placing the instructor on a separate transmitter. Note that the T8FGS transmitter may be connected to

another T8FGS system, as well as to any other models of Futaba transmitters. The T8FGS transmitter

uses one of the three cord plug types according to the transmitter connected. (Refer to the description at

the TRAINER function instructions). The part number of this cord is: FUTM4405.

• Neckstrap - a neckstrap may be connected to your T8FGS system to make it easier to handle and improve

your ying precision since your hands won’t need to support the transmitter’s weight.

• Y-harnesses, servo extensions, etc - Genuine Futaba extensions and Y-harnesses, including a heavy-duty

version with heavier wire, are available to aid in your larger model and other installations.

• Gyros - a variety of genuine Futaba gyros is available for your aircraft or helicopter needs.

• Governor (GY701) - for helicopter use. Automatically adjusts throttle servo position to maintain a

constant head speed regardless of blade pitch, load, weather, etc.

• Receivers - various models of Futaba receivers may be purchased for use in other models. (Receivers for

FASST-2.4GHz Multi-ch mode and 7-ch mode types are available.)

• Optional Charger - Futaba CR-2000 Ni-MH/Ni-Cd Transmitter/Receiver Battery Charger.

<Before Use>

12

Page 13

Transmitter controls

●Monitor LED

●Switch (SA,SB,SE,SF)

●Antenna

●Carring Handle

●Volume (LD,RD)

●Switch (SC,SD,SG,SH)

●Slide Lever (LS)

●Stick

(J3)

(J4)

●Digital Trim (T3,T4)

●Power Switch

●Neck Strap Attachment

●LCD Display

●Slide Lever (RS)

●Stick

(J2)

(J1)

●Digital Trim (T1,T2)

●SensorTouch

(SYS, LNK, MDL,

EXIT, RTN)

TM

<Before Use>

13

Page 14

Transmitter's Antenna:

As with all radio frequency transmissions, the

strongest area of signal transmission is from the

sides of the transmitter's antenna. As such, the

antenna should not be pointed directly at the model.

If your flying style creates this situation, easily

move the antenna to correct this situation.

CAUTION

Please do not grasp the transmitter's

antenna during ight.

Doing so may degrade the quality of the RF

transmission to the model.

Monitor LED display

The status of the transmitter is displayed by LED

at the bottom left and right sides of the "T8FG

SUPER" logo.

LED (Left)

Displays the "non-default condition" warning.

• Blinking

Power switch is turned on when any

condition switch is activated (in the ON

state).

LED (Right)

Displays the state of radio frequency

transmission.

• Off

Radio waves are in the OFF state.

• On

Radio waves are being transmitted.

Switch (SA-SH)

(Switch Type)

• SA : 3 positions; Alternate; Short lever

• SB : 3 positions; Alternate; Long lever

• SC : 3 positions; Alternate; Long lever

• SD : 3 positions; Alternate; Short lever

• SE : 3 positions; Alternate; Short lever

• SF : 2 positions; Alternate; Long lever

• SG : 3 positions; Alternate; Short lever

• SH : 2 positions; Momentary; Long lever

<Before Use>

14

*You can choose switch and set the ON/OFF-direction in the

setting screen of the mixing functions.

Page 15

Volume

Digital Trim

LD RD

Volume LD and RD:

The volume LD and RD knobs allow analog

input.

*The T8FGS transmitter beeps when the volume knob

reaches the center position.

*You can use each setting screen of the mixing functions to

select volumes and dene the direction of a movement.

Slide Lever

RSLS

LS (Left), RS (right):

The slide lever LS and RS offer analog input.

*The T8FGS transmitter beeps when the lever comes to the

center.

*You can select a slide lever and set the movement direction

on the setting screen of mixing functions.

T4

T2T3

T1

Digital Trim T1, T2, T3 and T4:

This transmitter is equipped with four (4) digital

trims. Each time you press a trim button, the trim

position moves one step. If you continue pressing it,

the trim position starts to move faster. In addition,

when the trim position returns to the center, the

tone will change. You can always monitor trim

positions by referencing the LCD screen.

*You can select the trim step amount and the display unit

on the home screen on the T1-T4 setting screen within the

linkage menu.

Note: The trim positions you have set will be stored in the

non-volatile memory and will remain there.

<Before Use>

15

Page 16

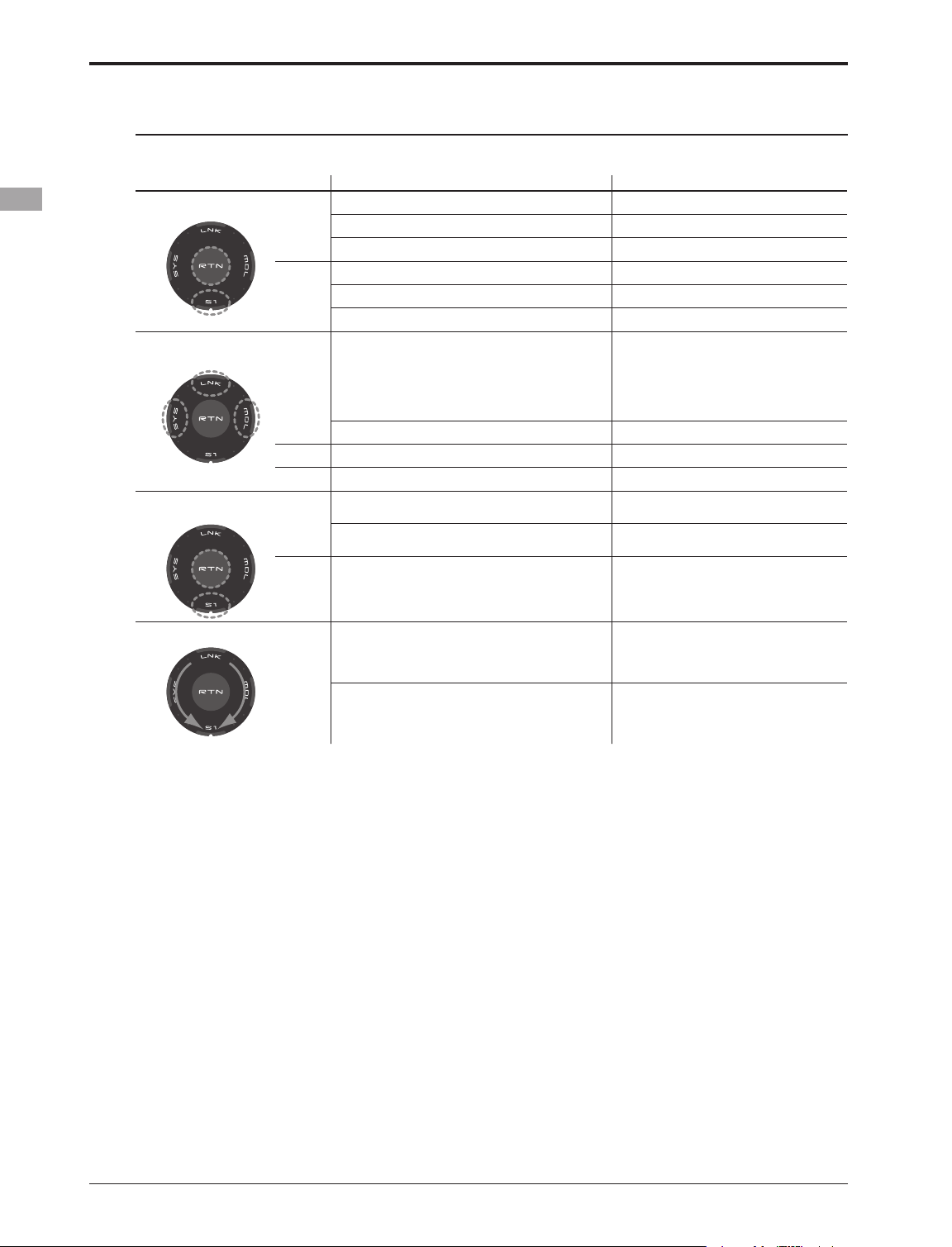

Touch sensor operation

Data input operation is performed using the touch sensor.

SensorTouch™ operation Condition Working

• Short 'tap'

• Two short 'taps'

• Touch and hold for

one (1) second.

If the screen has more than one page. (Ex. P-MIX screen)

If the screen have only one (1) page. The cursor moves to the top of page.

S1

If the input data mode with blinking the setting data. The input data is canceled.

At the moving cursor mode. Change to the input data mode.

At the input data mode. Change to the moving cursor mode.

RTN

At the input data mode with blinking the setting data. The data is entered.

Home screen, System menu, Linkage Menu, Model

menu, Selecting ON/OFF Switch, USER NAME,

MODEL NAME, DISPLAY, INFO, MODEL SELECT,

MODEL TYPE, FREQUECY, DATA RESET, TIMER,

SYS

Selecting Control, Selecting Function, SERVO

MONITOR

At all screens except those noted above. Jump to Servo Monitor screen directly.

At all screens Jump to Linkage Menu screen directly.

LNK

At all screens Jump to Model Menu screen directly.

MDL

At the HOME screen Key lock On or Off

S1

Except the HOME screen Jump to Home Screen directly.

The cursor moves to the top of next page.

Jump to System Menu screen directly.

At the input data mode without blinking the setting

RTN

data.

• Scrolling

Lightly circling the outside edge of the RTN button. The cursor moves accordingly.

Outline

of

“RTN”

During the data input mode. Increases or decreases values accordingly.

Movement of cursor, value input or mode selection

:

Movement of the cursor on the menu screen and

movement of the cursor among items on a setup

screen can be controlled by scrolling your finger

to the left and right in the direction of the arrow in

the scrolling diagram above. You can also go to the

next page, if there is a next page.

This scrolling technique is also used for data

input, value input, mode selection, and similar

operations. Examples include: Value, ON, OFF,

INH, ACT, etc.

RTN button:

Touch the RTN button when you want to open

a setup screen or to switch between cursor move

mode (reverse display) and data input mode (box

display).

This button can also be used as the enter button

when a confirmation message is displayed on the

screen, etc.

Reset to the initialized value.

S1 button:

When there is a next page on a menu screen or

setup screen, you can go to that page by touching

the S1 button. In this case, the cursor moves to the

screen title item of the page.

Exiting setup screen:

To end the operation on a setup screen and return

to the menu screen, move the cursor to the screen

title item and touch the RTN button.

To return to home screen directly, touch the S1

button for 1 second.

Alternatively, move the cursor to the screen title

item and touch the RTN button to return to the

home screen from a menu screen.

<Before Use>

16

Page 17

Note:

*Scroll operation: Circle your nger on the outside edge of

the RTN button. The sensors may mis-read your touch as a

reverse rotation if the circle is smaller, or performed on the

inside edge of the RTN button.

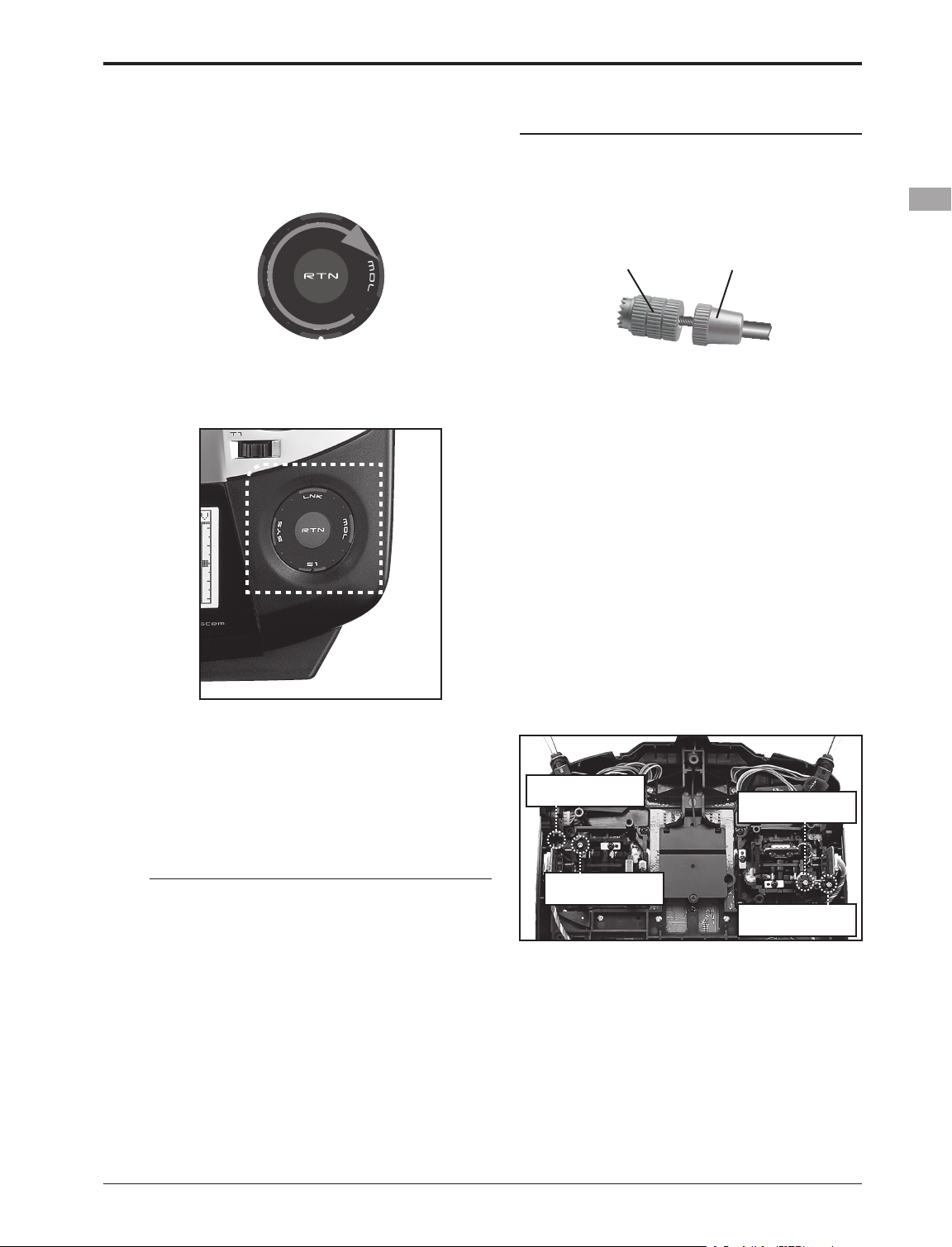

Stick Adjustment

Adjustment of the stick lever length

You can adjust the length of stick levers, as you

like. It is recommended to adjust the length of the

sticks in line with your hand size.

Lever Head

A

Lever Head

B

* The SensorTouch™ may not operate smoothly if your hand

is touching the surrounding case parts. As such, please

make sure that the tip of your nger is actually operating the

SensorTouch™.

*If the SensorTouch™ does not register your input, please

try again after lightly tapping your nger on the sensor once

again.

* Do not operate the SensorTouch™ with gloves worn. The

SensorTouch™ might not react.

1. Hold the lever head "B" and turn the lever

head "A" counter-clockwise. The lock will be

released.

2. Turn the lever-head "A" clockwise as you hold

the lever-head "B" after placing it as you like.

Adjustment of stick lever tension

The tension of the self-return type stick lever can

be adjusted.

1. First, Remove the battery cover on the

bottom of the transmitter. Next, unplug the

battery wire and remove the battery from

the transmitter.

2. Next, using a screwdriver, remove the five

screws that hold the transmitter's rear case

in position, and put them in a safe place.

Gently ease off the transmitter's rear case.

Now you'll see the view shown in the figure

below.

•Stick Tension (J2)

(Mode 2)

•Stick Tension (J4)

(Mode 1/2)

CAUTION

The touch sensor might not operate by

receiving the spark noise generated from

the gasoline engine etc. In this case, please

operate your transmitter from the noise

source apart.

•Stick Tension (J1)

(Mode 1/2)

2. Use a small Phillips screwdriver to adjust the

spring strength as you prefer by turning the

adjusting screw of the stick you want to

adjust.

*Turning the screw clockwise increases the tension.

CAUTION: If you loosen the screw too much,

the stick may not operate because it is

caught internally.

3) At the end of adjustment, re-install the rear

case.

•Stick Tension (J3)

(Mode 1)

<Before Use>

17

Page 18

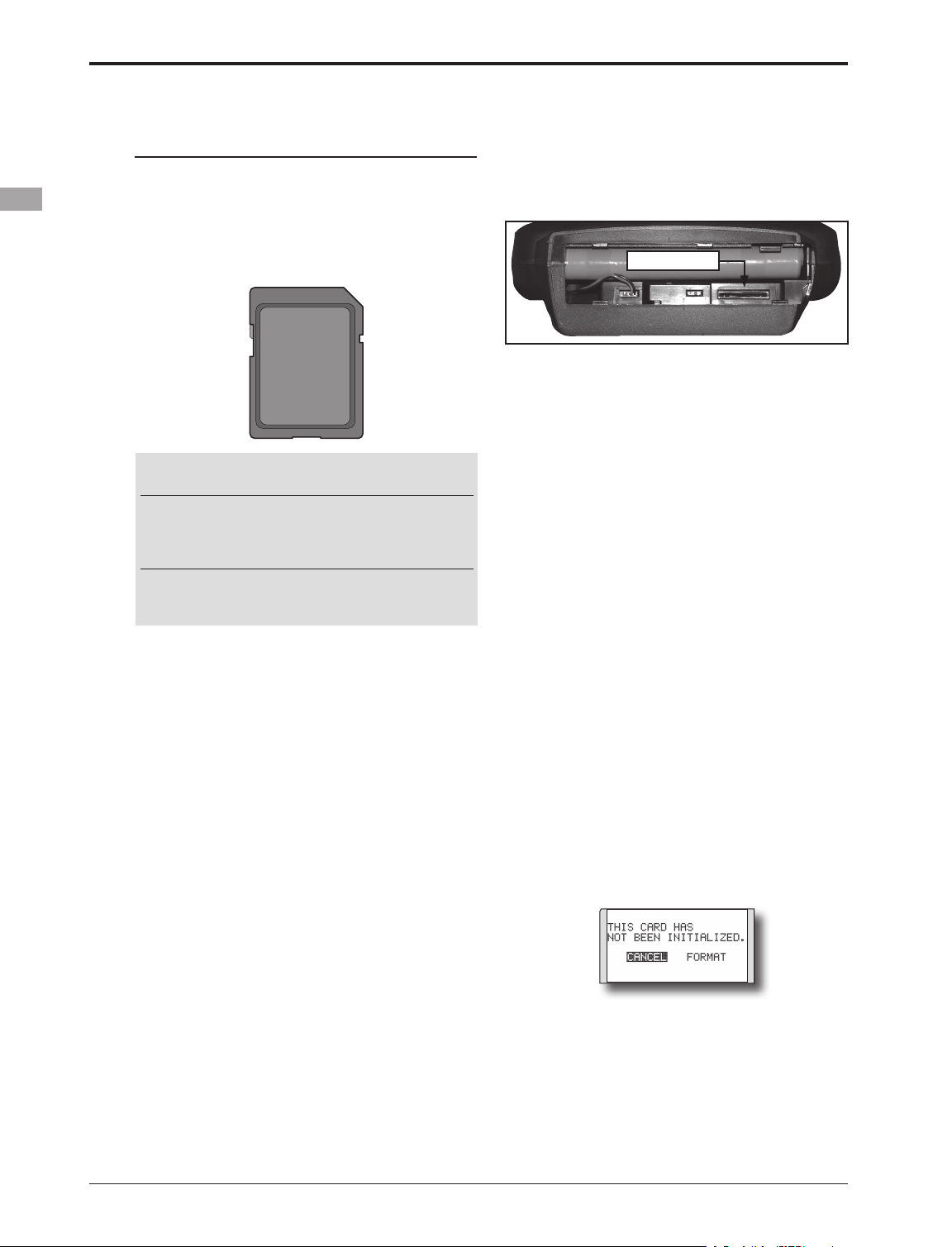

SD Card (Secure Digital memory card) (Not

included)

The T8FGS transmitter model data can be stored

by using any commonly found SD card. When

T8FGS transmitter update software is released, the

software is updated using an SD card. The T8FGS

is capable of using SD cards with a memory size

between 32MB and 2GB.

Caution

Be sure to turn off the power to the

transmitter before inserting or removing

the SD card.

As the SD card is a precision device, do not

use excessive force when inserting.

Restrictions when using an SD card

The following restrictions apply when using an

SD card:

*The SD card must first be initialized using the T8FGS

dedicated format. The SD card cannot be used as is without

formatting for the T8FGS.

*Initializing destroys all the data previously saved on the

card.

*An SD card formatted to the T8FGS cannot be written

directly from a PC by Windows Explorer, etc. The files

must be converted and written by the Futaba File System

software. Files are identified by number instead of name.

This special conversion software can be downloaded from

Futaba's web site at:

http://www.futaba-rc.com/sellsheets/downloads.html

Inserting/removing the SD card

1. Turn off the transmitter power and then

open the battery cover at the bottom of the

transmitter.

2.

SD Card Slot

[Inserting the card]

Turn the SD card so that the front of the card

faces the rear of the transmitter and slide the

card into the card slot.

*Push in the card until it is rmly seated in the card slot.

[Removing the card]

When the SD card is pressed in once again,

the card will be released from the card slot.

and can be removed.

3. Close the battery cover.

SD card initialization

To use an SD card with the T8FGS, the card

must first be formatted. Once formatted, the card

does not have to be reformatted. Formatting is

performed by the T8FGS.

[IMPORTANT] When an SD card is formatted

for the T8FGS, all pre-existing data is

destroyed. Do not format a card containing

important data.

[Formatting procedure]

1. Insert the SD card into the SD card slot of the

T8FGS.

2. Turn on the T8FGS power. When an

unformatted card is inserted into the T8FGS,

the screen shown below appears.

<Before Use>

18

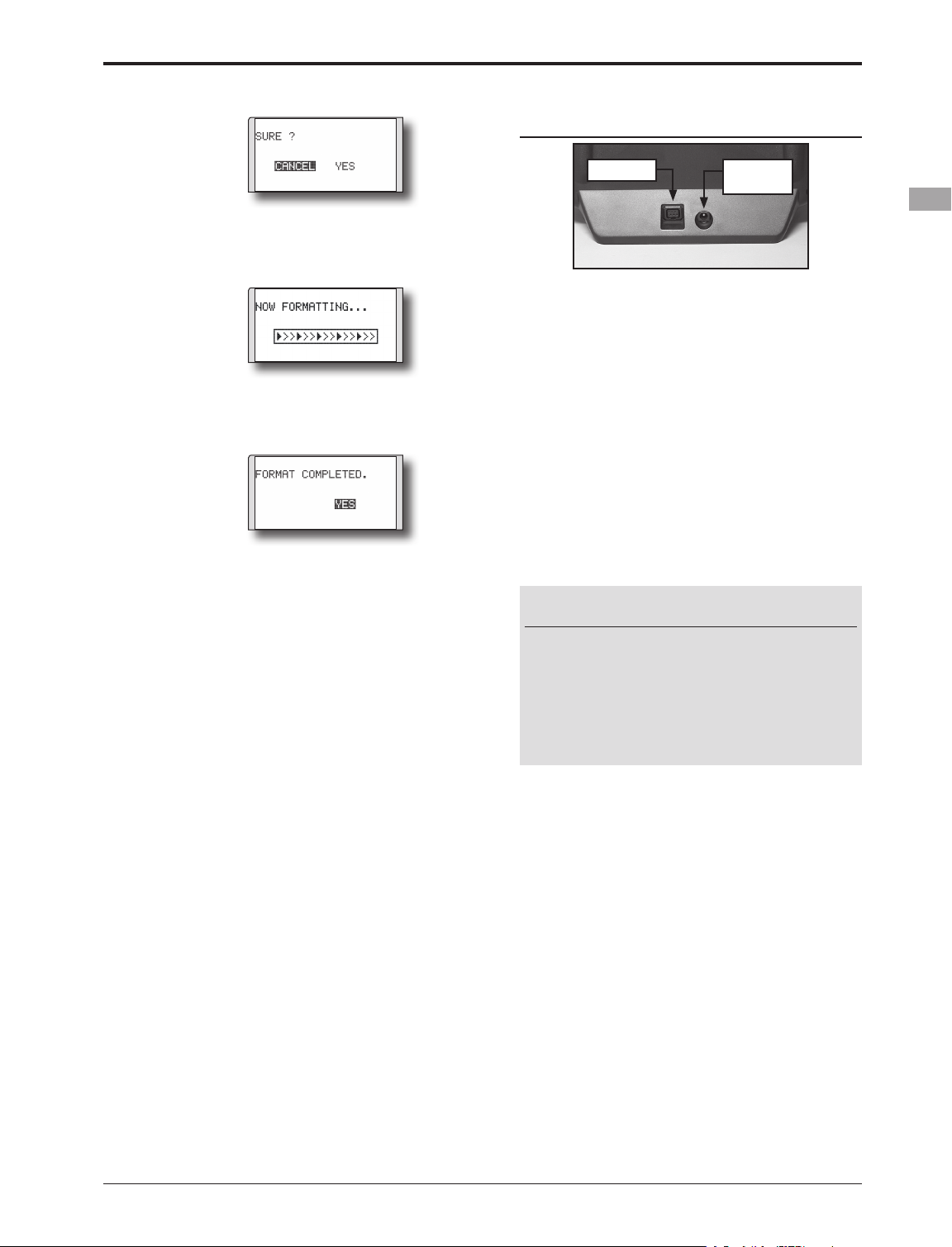

3. If the T8FGS is ready to format, move the

cursor to [FORMAT] and touch the RTN

button. (To cancel formatting, move the

cursor to [CANCEL] and touch the RTN

button.)

Page 19

Connector/Plug

4. Move the cursor to [YES] and touch the RTN

button.

* Formatting starts. During formatting, the [NOW

FORMATTING...] message is displayed.

*When formatting is completed, The [FORMAT

COMPLETED] message is displayed. Depending on the

card capacity and speed, formatting may take as long as

several minutes.

[IMPORTANT] Do not turn off the power

until the [FORMAT COMPLETED] message is

displayed.

5. End formatting by touching the RTN button.

SD card reader/writer

Saving model data and update files (released

from Futaba) into the SD card, you can then

transfer those files to your T8FGS transmitter.

Equipment for reading and writing SD cards is

available at most electronics stores.

•Trainer •Battery

charge

Connector for trainer function

When you use the trainer function, connect the

optional trainer cable between the transmitters for

teacher and student.

*You can set the trainer function on the Trainer Function

screen in the System menu.

Connector for battery charger

This is the connector for charging the Ni-

MH battery HT6F1700B that is installed in the

transmitter. Do not use any other chargers except

the attached special charger corresponding to Ni-

MH battery.

Warning

Do not connect any other chargers except

the special charger to this charging

connector.

*If you take out the Ni-MH battery HT6F1700B from

the transmitter, you can use the optional quick charger

CR-2000 corresponding to Ni-MH battery.

Stored data

If you have a problem saving or reading data

after a long period of use, we suggest obtaining a

new SD card to avoid further difculties.

*Futaba is not responsible for compensating any failure or

damage to the data stored in the memory card. As such, we

suggest that you maintain a backup of your important data

contained on your SD card.

<Before Use>

19

Page 20

Installation and Removal of the HT6F1700B

Transmitter Battery

Attachment of the battery

1. Slide the battery cover on the bottom of the

transmitter toward the right side and open it.

2. Install the battery in the holder.

3. Connect the battery connector.

•Battery

•Battery Connector

4. Close the battery cover completely.

Battery Removal

Note: If you remove the battery while the

power is on, the data you have set will not

be saved.

1. Open the battery cover.

2. Disconnect the battery connector.

3. Pull up the right side of the battery and

remove the battery.

4. Close the battery cover completely.

Warning

Be careful not to drop the battery.

Never disconnect the battery connector

from the T8FGS transmitter after turning

off the power until the screen is completely

blank and the transmitter has shut down

completely.

* Internal devices such as memories may be damaged.

* If there is any problem, the message "Backup Error" will

be shown the next time when you turn on the power of

the transmitter. Do not use the transmitter as it is. Send it

to the Futaba Service Center.

<Before Use>

20

Page 21

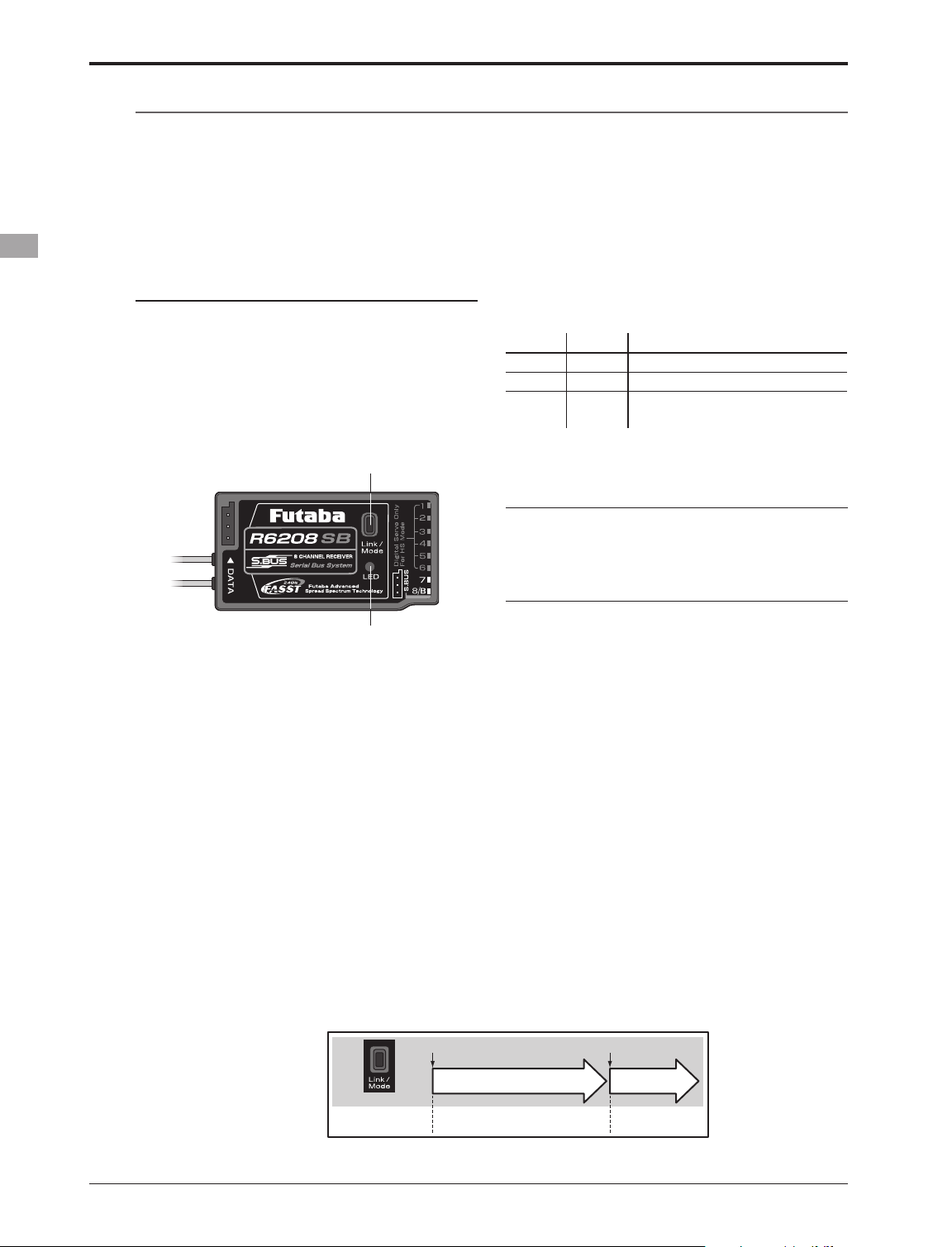

Receiver nomenclature

Before using the receiver, be sure to read the precautions listed in the following pages.

The R6208SB has an S.BUS system output port and a conventional system channel output. It can also be used

with conventional system servos, etc. in addition to S.BUS system compatible servos and gyros, etc.

In addition, the operating mode (high-speed mode/normal mode) can be selected.

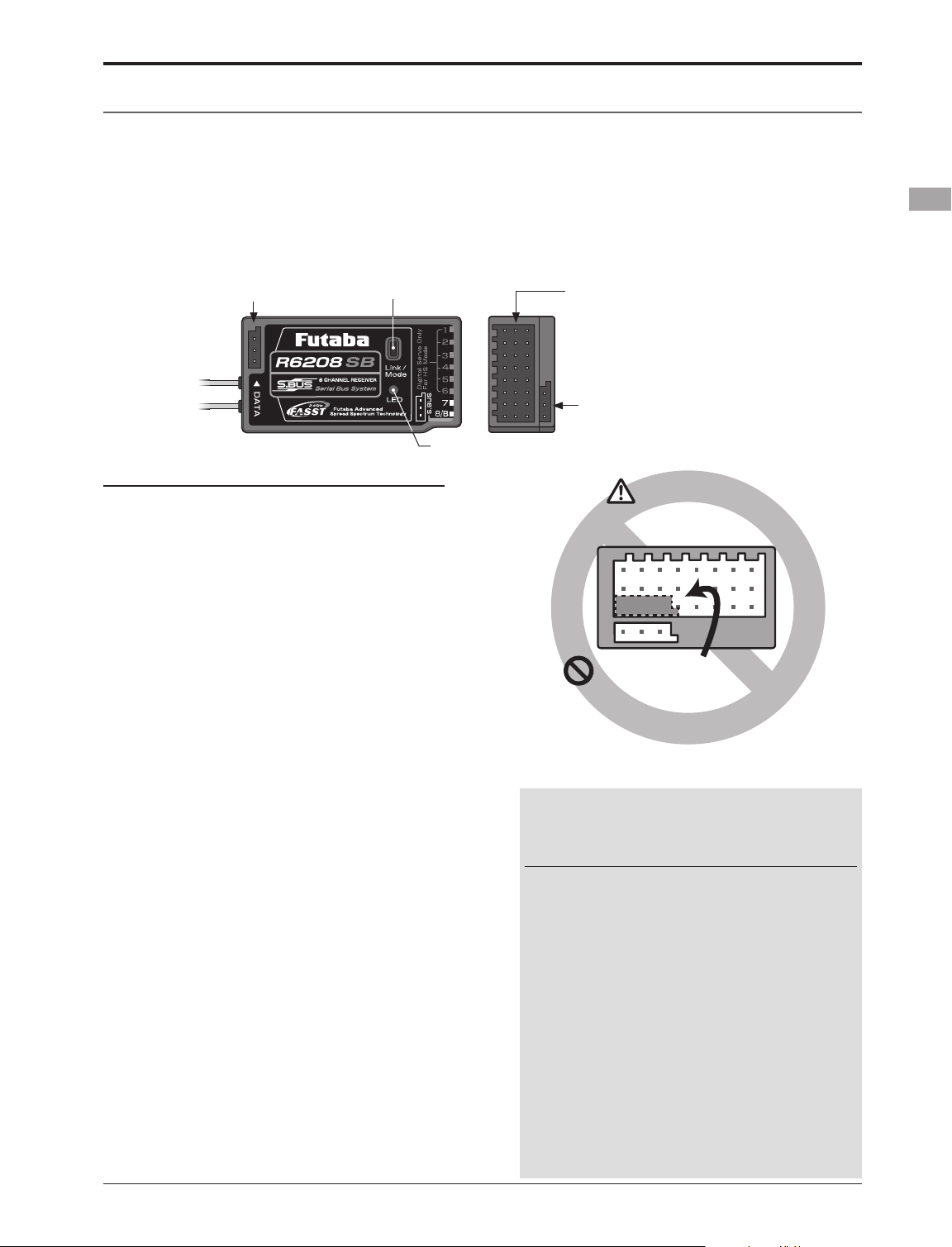

DATA p o r t

Link/Mode switch

LEDR6208SB

Connector

"1 through 6": outputs for the channels 1 through 6.

(Digital servo only in the High Speed mode.)

"7", "8": outputs for the channels 7 and 8.

(Analog or digital servos regardless of mode.)

"B": connector for the power.

"S.BUS": output for the S.BUS system.

The R6208SB has two(2) operation modes as

shown below.

Receiver Normal mode/High Speed mode

The "Normal mode" accepts any type of servos

or peripherals as the frame rate of the output is

14ms. The "High Speed mode" only accepts digital

servos for outputs from 1ch to 6ch. This includes

the BLS series, and most peripheral equipment

such as gyros and brushless ESCs. The frame rate

of the outputs is 7ms. The outputs from 7ch to 8ch

allow the use of any type of servos as the frame

rate of these outputs are still 14ms ever in the High

Speed mode.

• Channel outputs for conventional

system (1 to 8)

• Battery terminal (B)

• S.BUS Port (S.BUS)

Danger

Receiver

Don't connect neither a switch

nor a battery in this way.

* It will short-circuit, if it connects in this way.

A short circuit across the battery terminals may

cause abnormal heating, fire and burns.

Usage condition on "High Speed mode"

CAUTION

When using the R6208SB in the high speed

(HS) mode, digital servos are required for

the rst six channels (1-6).

If an analog servo is connected to one of the first

six channels when in the high speed mode, the

servo will not function properly. Additionally,

while many peripheral devices will operate in either

the high speed or normal mode, some will not. If

there are any difficulties noted, please return the

reciever's operational mode to the "Normal" mode

to determine if this resolves the difculty.

If using the R6208SB in the high speed mode,

analog servos may be used for channels seven and

eight.

(For Operation Mode Selection, see p.26)

<Before Use>

21

Page 22

BASIC OPERATION

Battery Charging

Before charging batteries, read the "Cautions for handling battery and battery charger" in the section "Ni-

MH/Ni-Cd Battery Safety and Handling Instructions".

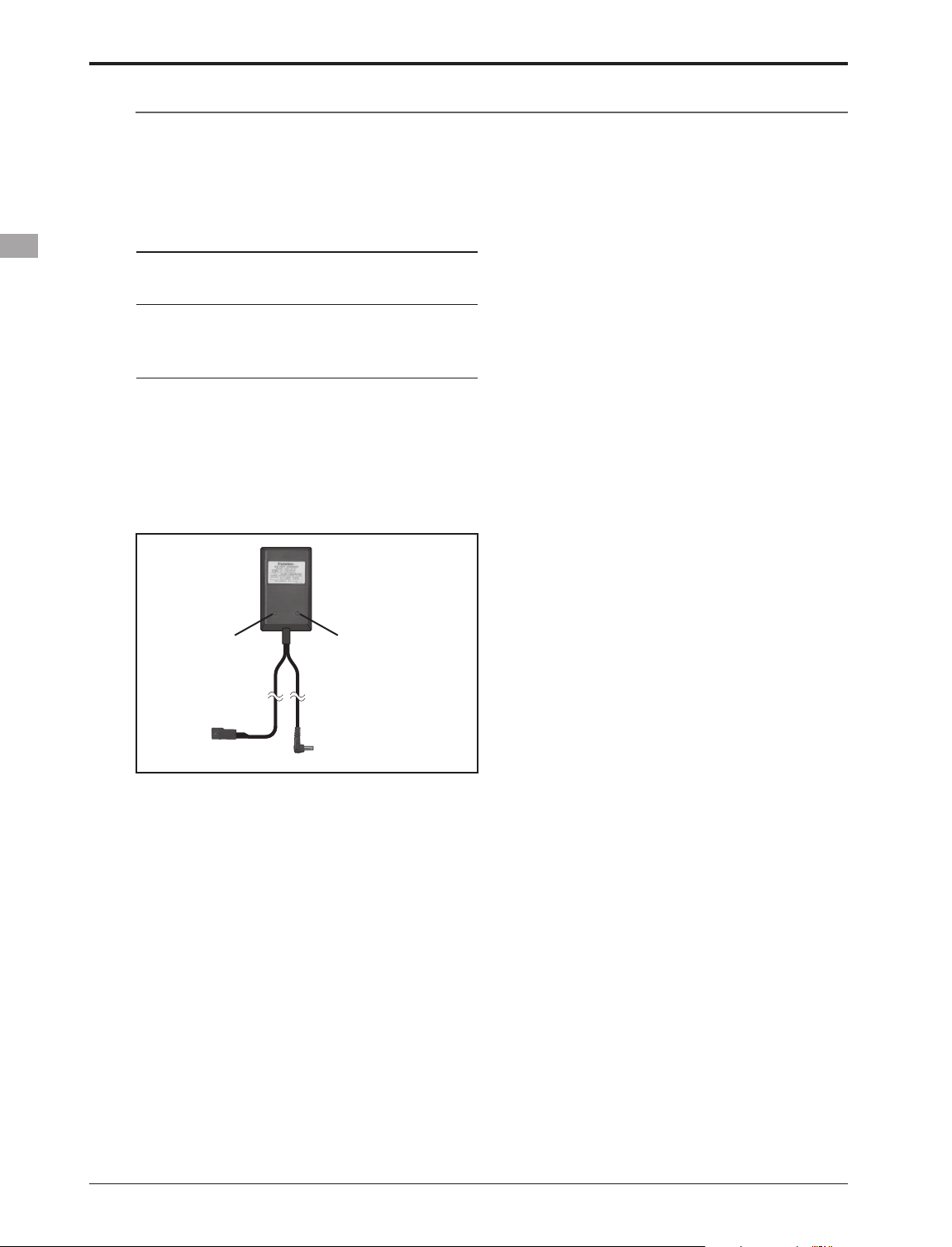

How to charge the Ni-MH battery HT6F1700B

for the transmitter

Danger

The Ni-MH battery HT6F1700B is only for

your T8FGS, T8FG and T12FG. Do not use

this battery for other equipment.

Be sure to use the attached special charger to

charge the battery.

*If you take out the Ni-MH battery HT6F1700B from the

transmitter, you can use the optional quick charger CR-2000

corresponding to Ni-MH battery.

[Method of charging battery]

●Special charger

*Connect to AC outlet

specified.

Receiver Batt.

Charging display

Transmitter Batt.

Charging display

*Battery charging will not automatically stop. Remove the

battery and transmitter from the charger and remove the

charger from the wall socket.

*It is recommended to reactivate the battery by cycling

several times if the battery has not been used for a long

period.

*In the case of Ni-MH/Ni-Cd batteries, you may find poor

performance of the battery if you have used the battery

only for a short period or if you repeat charging while the

battery is not fully discharged. It is suggested to discharge

the battery to the recommended level after use. It is also

recommended to charge the battery just before use.

To T8FGS charge

connector

1. Connect the special charger to the wall

socket (AC outlet).

2. Connect the connectors to the T8FGS

charging connector.

*Conrm that the charging indicator, LED lamp, is on.

*Turn off the transmitter while charging the battery.

3. Remove the battery after 15 hours.

<Basic Operation>

22

Page 23

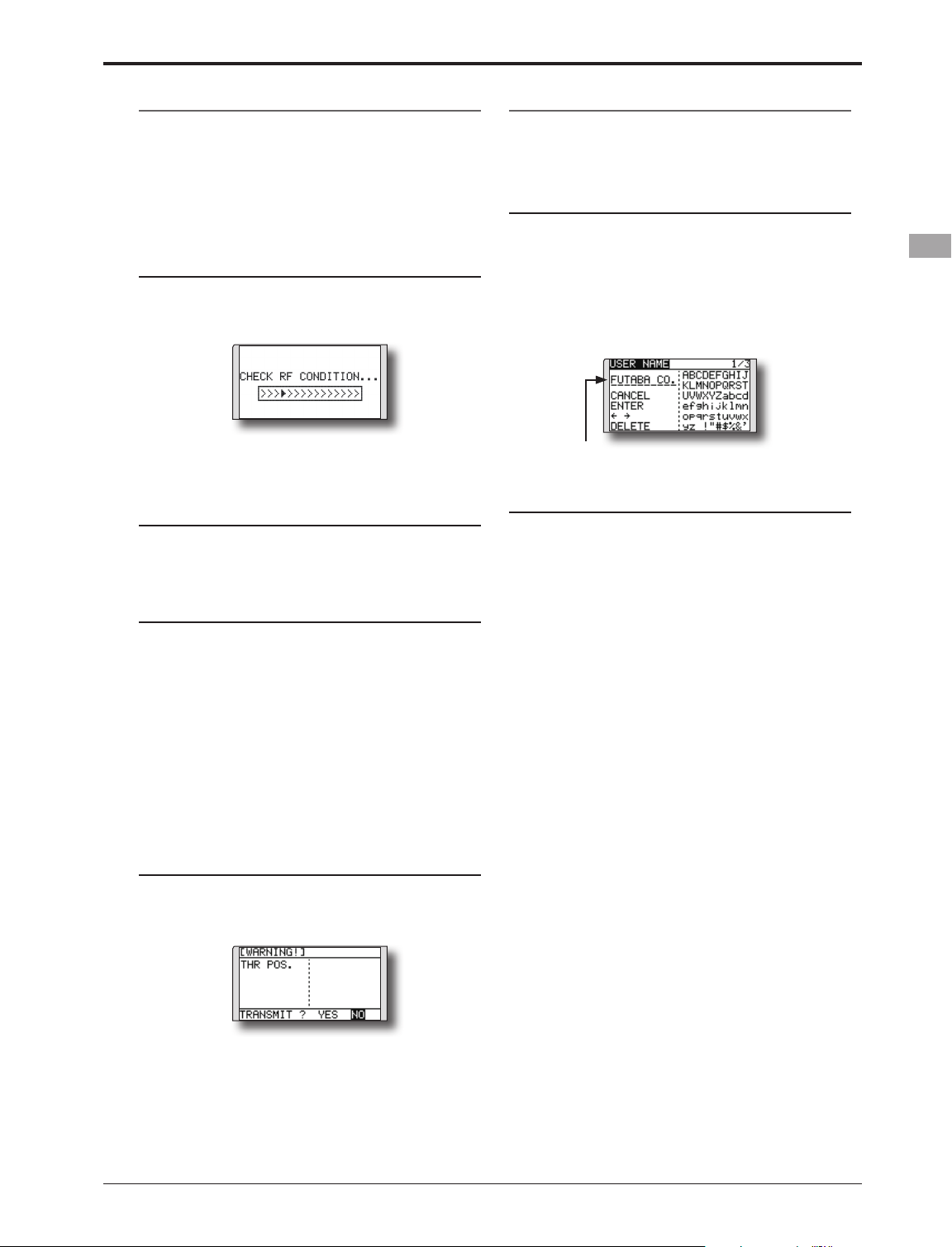

How to turn transmitter power ON/OFF

When turning on the power, the T8FGS

transmitter will begin emmiting RF automatically

after it conrms the surrounding RF conditions.

The T8FGS transmitter also offers the ability to

auto shut-down.

When turning on the power of the transmitter

1. Turn on the power switch of the transmitter.

*The message "CHECK RF CONDITION" is displayed for a

moment. At the same time the left LED monitor blinks.

Registration of the user's name

If so desired, the T8FGS transmitter can

indicate the owner's name.

User's name setup screen

1. Turn on the power of the transmitter.

*The home screen appears.

2. Lightly touch the SYS button twice rapidly

and the System menu appears.

2. Select [USER NAME] in the System menu and

touch the RTN button.

*The user name set up screen appears.

2. Then, you will see the home screen and the

transmitter begins to emit radio waves.

*The left and right LED monitors will change to solid red.

How to stop the transmitter

1. Turn off the power switch of the transmitter.

*The transmitter shuts down at once.

Low battery alarm and auto shut-down

When the battery voltage reaches 6.8V, an

audible alarm will sound. Land your aircraft

immediately.

When the battery voltage reaches 5.5V, the

transmitter will be turned off automatically.

*If you do not operate the transmitter (or move a stick,

knob, switch or digital trim) for 30 minutes, the message

"PLEASE TURN OFF POWER SWITCH" is displayed and

an audible alarm will sound.

Warning display at power ON (Airplane/

Helicopter)

When the throttle stick at power ON is at the

high side (1/3 or more the same as throttle cut

operation), a warning is displayed.

Input Box

*Current user name is displayed.

Changing the user name

1. Change the user name as described below:

[Moving cursor in input box]

Select [←] or [→], and touch the RTN button.

[Deleting a character]

When [DELETE] is selected and the RTN button

is touched, the character immediately after

the cursor is deleted.

[Adding a character]

When a character is selected from the

character list and the RTN button is touched,

that character is added at the position

immediately after the cursor.

*A name of up to 10 characters long can be entered as the

user name. (A space is also counted as one character.)

2. At the end of input, select [ENTER] and tuoch

the RTN button. (To terminate input and

return to the original state, select [CANCEL]

and touch the RTN button.)

* When the throttle stick is returned to SLOW, the warning

display goes off.

<Basic Operation>

23

Page 24

Home screen

Use the touch sensor to select the following display area to call each setting screen, and touch the RTN

button. The setting screen appears.

System timer

• This shows the accumulated time since

the latest reset. (Hour):(Minute)

• Use the cursor to highlight this, then

touch the RTN button for one second

to reset the system timer.

Up/Down timer (ST1, ST2)

• Timer is displayed here.

Touch the RTN button at the [xx]:[xx.x]

item to start/stop the timer.

• Use the cursor to highlight this, then

touch the RTN button at the ST1 or ST2

item to call the timer set-up screen.

*See the description at the back of this manual.

User's name

RF indicator

Key lock

• Touch the S1 button for one second

to lock/unlock the key operation.

In the key lock mode the key icon is

displayed here.

SD card indicator

Battery Indicator

• When the battery voltage

reaches 6.8V, the alarm will

beep. Land your aircraft

immediately.

Model type

Model Name

• The model name that

is currently used is

displayed here.

• Use the cursor to

highlight this, then

touch the RTN button

to call the model

select set-up screen.

FASST mode

• FASST mode is displayed here.

• Use the cursor to highlight this,

then touch the RTN button

to call the frequency set-up

screen.

Digital trim (T1 to T4)

• Trim position is displayed here.

• You can select the display unit

on the home screen on the

T1-T4 setting screen within the

linkage menu.

2nd Home screen

• Touch the RTN button at

the clock icon to call the

nd

2

home screen (large

size timer).

Model timer

• This shows the accumulated time

since the latest reset. (each model)

(Hour):(Minute)

• Use the cursor to highlight this,

then touch the RTN button for one

second to reset the model timer.

Condition name (Heli/Glider)

• In the normal condition, move the

cursor to the condition name and

touch the RTN button. The condition

name is changed and blinked.

It is possible to operate the

digital trim other than the normal

condition.

VPP condition # (Air)

• When VPP function is assigned to a

channel, the current VPP condition

# is displayed here.

<Basic Operation>

24

Page 25

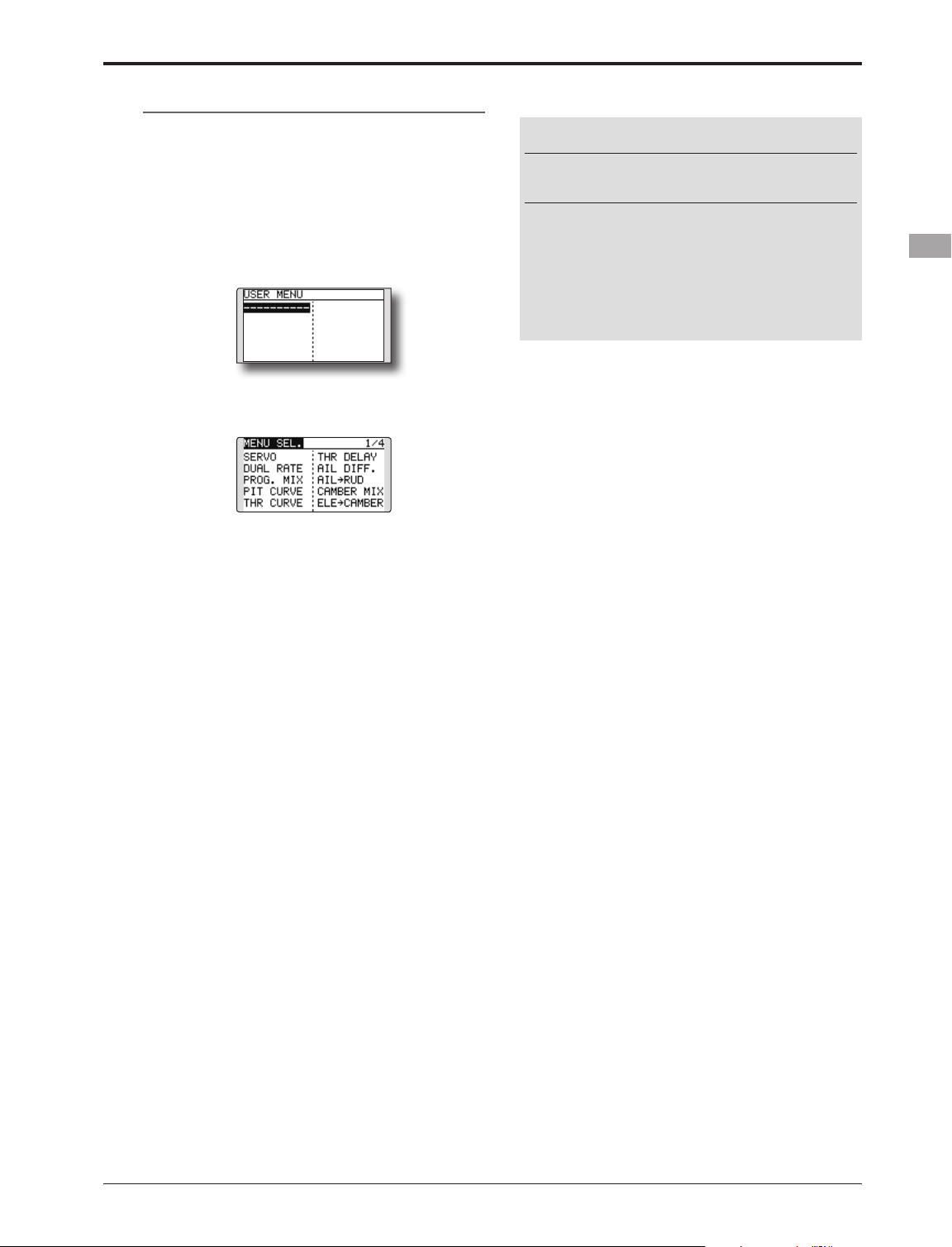

User Menu

A user menu which allows the user to customize

and display frequently used functions has been

added.

1. When the S1 button on the home screen is

touched, the user menu appears.

* Return to the home screen by touching the S1 button while

the user menu is being displayed.

2. When the cursor is moved to the "---------" button and the RTN button is touched ,the

menu selection screen appears.

3. When the cursor is moved to the setting

screen you want to register at the user menu

and the RTN button is touched, that setting

screen is registered at the user menu.

4. The registered setting screen can be called

by moving the cursor to it and touching the

RTN button.

Warning

Be sure to confirm the model name before

ying your aircraft.

Check the battery voltage as often as possible

and try to charge the battery earlier. If the

battery alarm makes a sound, land your

aircraft immediately.

*You can adjust the LCD contrast by the display setting in

the System menu.

*When you want to delete a registered screen from the user

menu, press the RTN button for one second.

<Basic Operation>

25

Page 26

Operation Mode Select (R6208SB)

The receiver operation mode is on "Normal mode" from factory shipping. To change the mode, please

adhere to the following steps:

Changing the operation mode

Link/Mode Button

LED

1. Turn off the receiver.

2. Press and hold the Link/Mode button and

turn on the receiver. Continue holding the

button for more than one(1) second. The LED

begins ashing to indicate the current status.

3. Release the button.

4. Turn off the receiver.

By doing so, the receiver will change modes.

Conrming the operation mode

Please check the operation mode by observing

the LED when turning on the receiver.

If possible ensure that there's no FASST

transmitter in operation near the receiver.

1. When the receiver is turned on:

Red when on "Normal mode"

Initially flashes green and Red (making

Orange) when in "High Speed mode". After

two(2) seconds, change to Red.

If there are additional FASST transmitters turned

on near the receiver, the LED may show the above

status for a brief moment before changing to the

status indication as shown in the "LED indication"

table below.

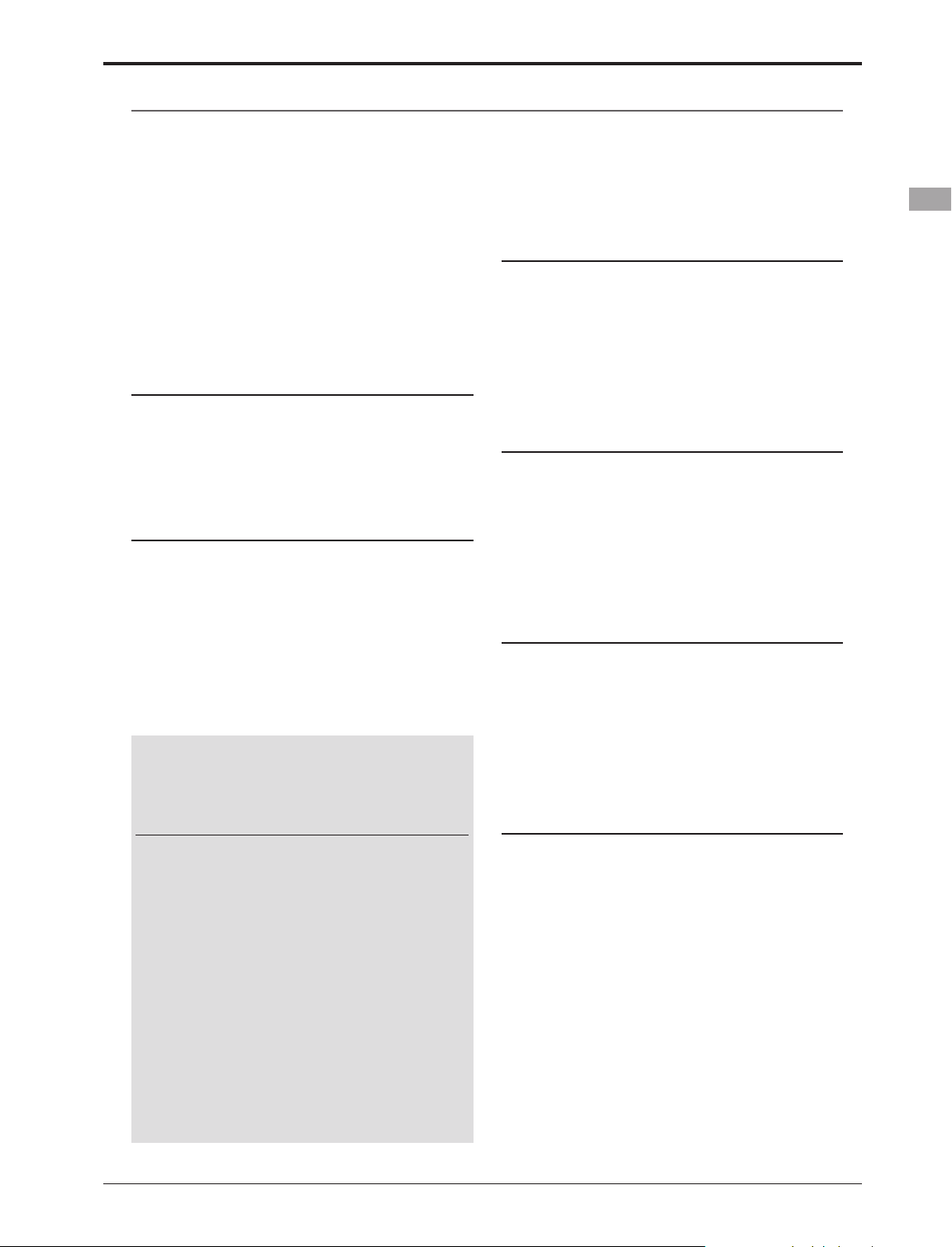

LED Indication (R6208SB)

Green Red Status

Off Solid No signal reception

Solid Off Receiving signals

Blink Off

Receiving signals but ID is

unmatched

<Basic Operation>

26

Press and Hold time

(Function)

Status)

(LED

(Operation Mode Select)

Turn on the receiver.

0 sec. 1 sec.

0 to 1 sec. More than 1 sec.

No function

Showing the CURRENT

mode with blink.

Red Blink = Normal

Green/Red Blink =

High Speed

To change the mode between

Normal and High Speed

Solid as the mode changed.

Red Solid = Normal

Green/Red Solid = High

Speed

(Become Red after one (1)

second)

Page 27

S.BUS Servo Channel Setting (R6208SB)

S.BUS servo channel setting can be performed by using an S.BUS compatible receiver, an SBC-1

channel changer or CIU-2 USB serial interface. To set the channel by using your R6208SB, please adhere

to the following steps:

Channel setting

1. Connect the accessory short-plug to the

DATA port of the receiver.

Short-plug

(accessory)

* Connect the short-plug to the DATA port only when an

S.BUS servo channel is set. Normally do not connect the

plug.

2. Connect an S.BUS servo to the conventional

system output connector(1 to 8)

corresponding to the channel you want to

set.

Output

connector

1 1 9

2 2 10

3 3 11

4 4 12

5 5 13

6 6 14

7 7 15

8 8 16

* Channel setting mode A (ch1 to 8 setting mode) or channel

setting mode B (ch9 to 16 setting mode) can be set.

3. Turn on the receiver.

* At once when turning on the receiver, the channel setting is

completed in mode A.

(To switch to mode B, press the Link/Mode

button until the red and green LED starts to

blink simultaneously. The channel setting is

completed in mode B.)

* The LED corresponding to the setting mode blinks.

Mode A: Red blinks 3 times

Mode B: Green blinks 3 times

4. Turn off the receiver.

Channel setting

Mode A Mode B

<Basic Operation>

27

Page 28

Easy Link (T8FGS/R6208SB)

Each transmitter has an individually assigned, unique ID code. In order to start operation, the receiver

must be linked with the ID code of the transmitter with which it is being paired. Once the link is made,

the ID code is stored in the receiver and no further linking is necessary unless the receiver is to be used

with another transmitter. When you purchase additional R6208SB receivers, this procedure is necessary;

otherwise the receiver will not work.

Link procedure

1. Place the transmitter and the receiver close

to each other within one (1) meter.

2. Turn on the transmitter.

3. Check the LED that is placed on the front

side of the transmitter to see if the RF signal is

active. When the right LED is ON solid, the RF

signal is being sent.

4. Turn on the receiver.

Link/Mode Button

LED Indication (R6208SB)

Green Red Status

Off Solid No signal reception

Solid Off Receiving signals

Blink Off

Receiving signals but ID is

unmatched

Warning

After the linking is done, please cycle receiver

power and check if the receiver to be linked is

really under the control by the transmitter to be

linked.

LED

5. Press down the Link/Mode button for more

than two seconds, and release the switch.

The receiver begins the linking operation.

6. When the linking is complete, the LED in the

receiver will change to solid green. Please

conrm that the servos are now operational

from your transmitter. Please refer to the

table below for the LED status of the

receiver's condition.

* If there are many FASST systems turned on around your

receiver, it might not link to your transmitter. In this case,

even if the receiver's LED stays solid green, unfortunately

the receiver might have established a link to one of other

transmitters. This is very dangerous if you do not notice

this situation. In order to avoid the problem, we strongly

recommend you to doublecheck whether your receiver is

really under control by your transmitter by giving the stick

input and then checking the servo response.

(Easy Link Operation)

0 sec. 2 sec.

Press and Hold

Do not perform the linking procedure with

motor's main wire connected or with the engine

operating as it may result in serious injury.

0 to 2 sec.

No function Re-link(ID set)

More than 2 sec.

<Basic Operation>

28

Page 29

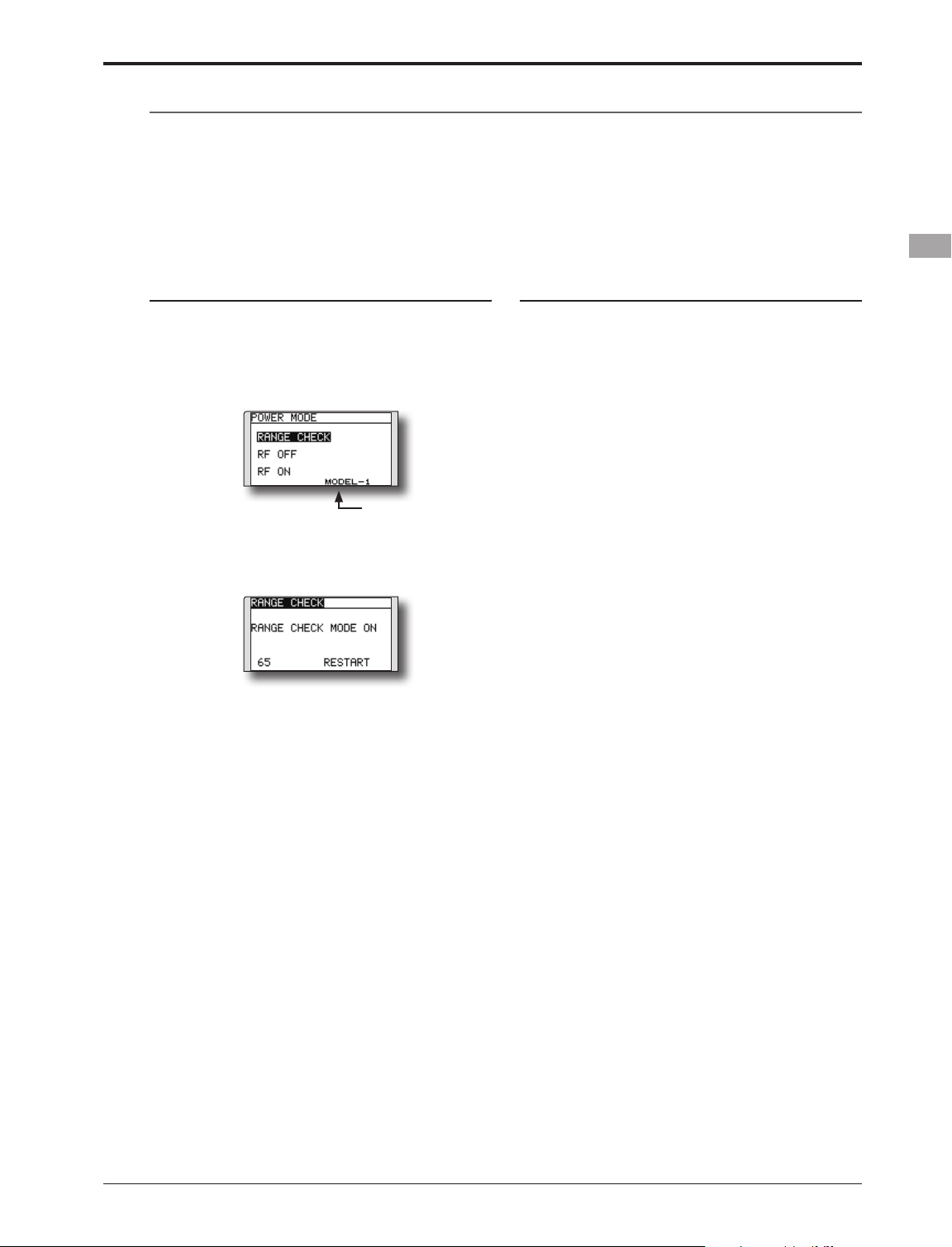

Range Testing Your R/C System

It is extremely important to range check your models prior to each ying session. This enables you to

ensure that everything is functioning as it should and to obtain maximum enjoyment from your time ying.

The T8FGS transmitter incorporates a system that reduces its power output and allows you to perform such

a range check.

Range check mode

We have installed a special "Range check

mode" for doing a ground range check. To access

the "Range check mode" touch and hold the RTN

button while turning on the transmitter. Doing so

will bring up POWER MODE menu.

The present model

To activate the "Range check mode" touch the

RTN button and the range check mode screen will

appear.

During this mode, the RF power output is

reduced so the range test can be performed. In

addition, when this mode is activated the right

LED on the front of the transmitter starts blinking

and the transmitter gives users a warning with a

beeping sound every 3 seconds.

The "Range check mode" continues for 90

seconds and after that the power will return

to the normal level. To exit the "Range check

mode" before the 90 seconds, select the "RANGE

CHECK" at the top of the screen and touch the

RTN button again. This mode is available one

time only so if you need to re-use this function the

transmitter power must be cycled. NEVER start

ying when the "Range check mode" is active.

Should you require additional time to perform

a range check, highlight Restart before your time

expires and press the RTN button one time.

Range check procedure

1. With the "Range check mode" on, walk

away from the model while simultaneously

operating the controls. Have an assistant

stand by the model to confirm that all

controls are completely and correctly

operational. You should be able to walk

approximately 30-50 paces from the model

without losing control.

2. If everything operates correctly, return to

the model. Set the transmitter in a safe, yet

accessible, location so it will be within reach

after starting the engine or motor. Be certain

the throttle stick is in the low throttle position,

then start the engine or motor. Perform

another range check with your assistant

holding the aircraft with the engine running

at various speeds. If the servos jitter or move

inadvertently, there may be a problem. We

would strongly suggest you do not y until the

source of the difculty has been determined.

Look for loose servo connections or binding

pushrods. Also, be certain that the battery

has been fully charged.

<Basic Operation>

29

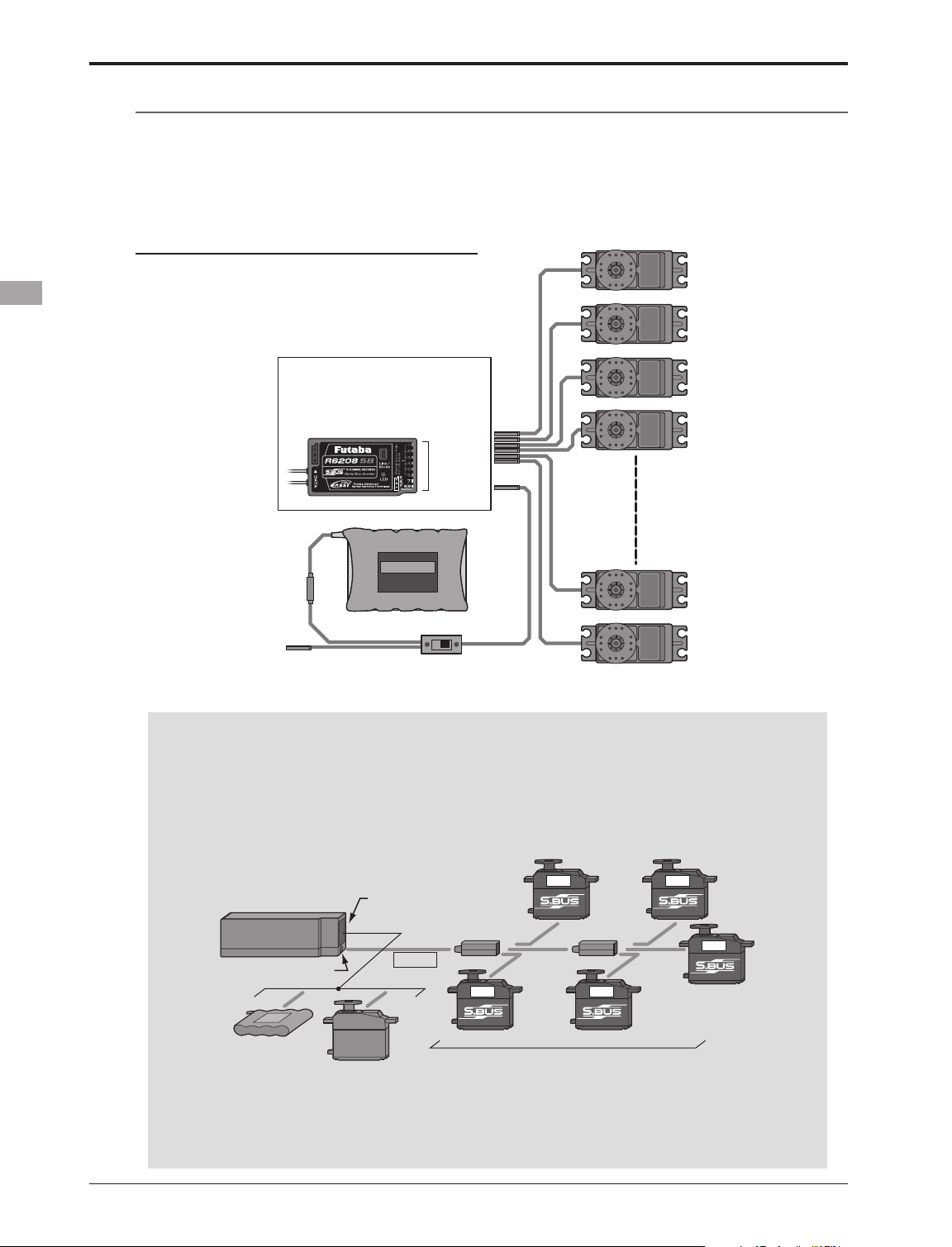

Page 30

RECEIVER AND SERVO INSTALLATION

Receiver and servos connection

Connect the receiver and servos in accordance with the connection diagram shown below. Always read

[Precautions when mounting the receiver and servos] or [Before using]. When mounting the receiver and

servos to the fuselage, connect the necessary points in accordance with the model's instruction manual.

Receiver and servos connection diagram

Always connect the necessary number of servos.

The receiver channel assignment depends on the

model type. See the Servo connection by model

type tables.

R6208SB (output connector section)

•B: Power supply

•CH1~8: Output connectors 1~8

•S.BUS: Output for S.BUS system

•DATA port: (factory use only)

CH1~8,

S.BUS,

B

Receiver battery

Charging port

Receiver switch

Servos

• S.BUS system

Different from conventional radio control systems the S.BUS system uses data communication to

transmit control signals from a receiver to a servo, gyro, or other S.BUS compatible device. This data

includes commands such as “move the channel 3 servo to 15 degrees, move the channel 5 servo to

30 degrees” to multiple devices. The S.BUS devices execute only those commands for their own set

channel. For this reason, it can be used by connecting multiple servos to the same signal line.

[Connection by S.BUS system]

3ch 5ch

R6208SB

S.BUS output

Battery

Conventional

* Can also be used together with conventional servos.

* When using servos with a remote battery pack, use S.BUS Hub with Cable (2-way/remote battery pack use). Please refer

to the instruction manual of S.BUS Hub with Cable (2-way/remote battery pack use) for the connection method.

Ch output/

Battery terminal

servo

S.BUS hub S.BUS hub

S.BUS

2ch 4ch

6ch

S.BUS servo

<Receiver and Servo Installation>

30

Page 31

Servo connection by model type

The T8FGS transmitter channels are automatically assigned for optimal combination according to the

type selected with the Model Type function of the Linkage Menu. The channel assignment (initial setting)

for each model type is shown below. Connect the receiver and servos to match the type used.

*The set channels can be checked at the Function screen of the Linkage Menu. The channel assignments can also be changed. For

more information, read the description of the Function menu.

Airplane/glider

Normal wing and V-tail

(*1)

RX

CH

1 Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron

2 Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator

3 Throttle Motor Throttle Motor Throttle Motor Throttle Motor Rudder Rudder Rudder Rudder

4 Rudder Rudder Rudder Rudder Rudder Rudder Rudder Rudder Aileron2 Aileron2 Aileron2 Aileron2

5 Gear AUX7 Gear AUX7 Gear AUX6 Gear AUX5 Flap Flap Aileron3 Aileron3

6 VPP AUX6 Aileron2 Aileron2 Flap Flap Aileron2 Aileron2 Flap2 Flap2 Aileron4 Aileron4

7 AUX5 AUX5 VPP AUX6 Aileron2 Aileron2 Flap Flap Flap3 Flap3 Flap Flap

8 AUX4 AUX4 AUX5 AUX5 VPP AUX5 Flap2 Flap2 Flap4 Flap4 Flap2 Flap2

9/VC1 AUX1 AUX1 Camber Camber Camber Camber Camber Camber Camber Camber Camber Camber

1AIL

Airplane Glider Airplane Glider Airplane Glider Airplane Glider Airplane Glider Airplane Glider

2AIL

(*1)

2AIL+1FLAP

(*1)

2AIL+2FLAP

(*2)

2AIL+4FLAP

(*3)

4AIL+2FLAP

(*3)

10/VC2 AUX1 AUX1 AUX1 Buttery AUX1 Buttery VPP Buttery Gear Buttery Gear Buttery

11/VC3 AUX1 AUX1 AUX1 AUX1 AUX1 AUX1 AUX1 AUX1 Throttle Motor Throttle Motor

12/VC4 AUX1 AUX1 AUX1 AUX1 AUX1 AUX1 AUX1 AUX1 VPP AUX1 VPP AUX1

● The above table shows the channel allocation at the FASST MLT2 mode.

● The wing types which can be selected depend on the FASST MLT2/MULT or 7-ch, selected.

(*1)

These wing types are available on the MLT2, MULT and 7-ch mode. However, the ch8 doesn't work on the 7-ch mode.

(*2)

This wing type is available on the MLT2, MULT and 7-ch mode. However, since the ch8 doesn't work on the 7-ch mode, please

assign the ap2 to another channnel which isn't used.

(*3)

These wing types are available on the MLT2 and MULT mode only. (Except the airplane types on the MULT mode.)

<Receiver and Servo Installation>

31

Page 32

Ailvator (Dual Elevator)

(*1)

RX

CH

1 Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron

2 Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator

3 Throttle Motor Throttle Motor Throttle Motor Throttle Motor Rudder Rudder Rudder Rudder

4 Rudder Rudder Rudder Rudder Rudder Rudder Rudder Rudder Aileron2 Aileron2 Aileron2 Aileron2

5 Gear AUX7 Gear AUX7 Gear AUX6 Elevator2 Elevator2 Flap Flap Aileron3 Aileron3

6 VPP AUX6 Aileron2 Aileron2 Flap Flap Aileron2 Aileron2 Flap2 Flap2 Aileron4 Aileron4

7 Elevator2 Elevator2 Elevator2 Elevator2 Aileron2 Aileron2 Flap Flap Flap3 Flap3 Flap Flap

8 AUX4 AUX4 VPP AUX5 Elevator2 Elevator2 Flap2 Flap2 Flap4 Flap4 Flap2 Flap2

9/VC1 AUX1 AUX1 Camber Camber Camber Camber Camber Camber Camber Camber Camber Camber

10/VC2 AUX1 AUX1 AUX1 Buttery VPP Buttery Gear Buttery Gear Buttery Gear Buttery

11/VC3 AUX1 AUX1 AUX1 AUX1 AUX1 AUX1 VPP AUX1 Throttle Motor Throttle Motor

12/VC4 AUX1 AUX1 AUX1 AUX1 AUX1 AUX1 AUX1 AUX1 Elevator2 Elevator2 Elevator2 Elevator2

1AIL

Airplane Glider Airplane Glider Airplane Glider Airplane Glider Airplane Glider Airplane Glider

2AIL

(*1)

2AIL+1FLAP

(*2)

2AIL+2FLAP

(*3)

2AIL+4FLAP

(*4)

4AIL+2FLAP

● The above table shows the channel allocation at the FASST MLT2 mode.

● The wing types which can be selected depend on the FASST MLT2/MULT or 7-ch, selected.

(*1)

These wing types are available on the MLT2, MULT and 7-ch mode. However, the ch8 doesn't work on the 7-ch mode.

(*2)

This wing type is available on the MLT2, MULT and 7-ch mode. However, since the ch8 doesn't work on the 7-ch mode, please

assign the ap2 to another channnel which isn't used.

(*3)

These wing types are available on the MLT2 and MULT mode only. However, the glider type is available on the 7-ch mode,

please assign the ap2 to another channnel which isn't used.

(*4)

These wing types are available on the MLT2 mode only.

(*4)

<Receiver and Servo Installation>

32

Page 33

Flying wing, Delta wing (Winglet)

(*1)

RX

CH

1 Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron Aileron

2 Rudder2 Rudder2 Rudder2 Rudder2 Rudder2 Rudder2 Aileron2 Aileron2 Aileron2 Aileron2

3 Throttle Motor Throttle Motor Throttle Motor Rudder Rudder Aileron3 Aileron3

4 Rudder Rudder Rudder Rudder Rudder Rudder Rudder2 Rudder2 Aileron4 Aileron4

5 Gear AUX7 Gear AUX6 Gear AUX6 Flap Flap Rudder Rudder

6 Aileron2 Aileron2 Flap Flap Flap Flap Flap2 Flap2 Rudder2 Rudder2

7 VPP AUX6 Aileron2 Aileron2 Aileron2 Aileron2 Flap3 Flap3 Flap Flap

8 AUX5 AUX5 VPP AUX5 Flap2 Flap2 Flap4 Flap4 Flap2 Flap2

9/VC1 Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator Elevator

10/VC2 Camber Camber Camber Camber Camber Camber Camber Camber Camber Camber

11/VC3 AUX1 AUX1 AUX1 Buttery VPP Buttery Gear Buttery Gear Buttery

12/VC4 AUX1 AUX1 AUX1 AUX1 AUX1 AUX1 Throttle Motor Throttle Motor

2AIL

Airplane Glider Airplane Glider Airplane Glider Airplane Glider Airplane Glider

2AIL+1FLAP

(*1)

2AIL+2FLAP

(*2)

2AIL+4FLAP

(*3)

4AIL+2FLAP

(*3)

● The above table shows the channel allocation at the FASST MLT2 mode.

● The wing types which can be selected depend on the FASST MLT2/MULT or 7-ch, selected.

(*1)

These wing types are available on the MLT2, MULT and 7-ch mode. However, the ch8 doesn't work on the 7-ch mode.

(*2)

This wing type is available on the MLT2, MULT and 7-ch mode. However, since the ch8 doesn't work on the 7-ch mode, please

assign the ap2 to another channnel which isn't used.

(*3)

These wing types are available on the MLT2 and MULT mode only. (Except the airplane types on the MULT mode.)

<Receiver and Servo Installation>

33

Page 34

Helicopter

RX CH H-4, H4X Swash All Other

1 Aileron Aileron

2 Elevator Elevator

3 Throttle Throttle

4 Rudder Rudder

5 Gyro Gyro

6 Pitch Pitch

7 Governor Governor

8 Elevator2 Needle

9/VC1 Gyro2 Gyro2

10/VC2 Gyro3 Gyro3

11/VC3 AUX1 AUX1

12/VC4 AUX1 AUX1

● Since the ch8 doesn't work on the 7-ch mode, please

assign the elevator2 (H-4, H4X) or the needle (all

other) to 7 channnel if the governor is not used.

<Receiver and Servo Installation>

34

Page 35

Precautions when mounting the receiver and servos

Follow these guidelines to properly mount the servos, receiver and battery.

• Make certain the alignment tab on the battery,