Page 1

USER INSTRUCTIONS

Limitorque ® WG Series

FCD LMENIM2101-02 – 1/15

Installation

Operation

Maintenance

Experience In Motion

Page 2

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 01/15

Contents

1 Introduction 4

1.1 Purpose 4

1.2 User Safety 4

2 Inspection, Installation and Mounting Procedures 5

2.1 Initial Inspection and Storage Instructions 6

2.2 Inspection and Recording 6

2.3 Storage Procedure 6

2.4 General Mounting Instructions 7

2.5 Assembly Positions 8

2.6 Setting Position Limit Stops - WG-00 Through 12 9

3 Lubrication 10

4 Disassembly and Reassembly Instructions 11

4.1 Safety Precautions 11

4.2 Safety Practices 12

4.3 WG-00 Through WG-35 12

4.4 WG-04 Through WG-12 16

4.5 Single Reduction Spur Gear Attachment (1S) 20

4.6 Double Reduction Spur Gear Attachment (1SD) 22

5 How to Order Parts 24

Figures

Figure 2.1 – Typical WG Exploded View 5

Figure 2.2 – Assembly Position A 8

Figure 2.3 – Assembly Position D 8

Figure 2.4 – Setting Position Limit Stops 9

Figure 4.1 – Splined Adapter Assembly 12

Figure 4.2 – WG-00 Through WG-35 Exploded View 13

Figure 4.3 – WG-00 Through WG-35 Assembly View 14

Figure 4.4 – WG-00 Through WG-35 Assembly View 14

Figure 4.5 – WG-00 Through WG-35 Assembly View 15

Figure 4.6 – WG-00 Through WG-35 Assembly View 15

Figure 4.7 – WG-04 Through WG-12 Splined Adapter Assembly 16

Figure 4.8 – WG-04 Through WG-12 Exploded View 17

Figure 4.9 – WG-04 Through WG-12 Assembly View 18

Figure 4.10 – WG-04 Through WG-12 Assembly View 18

Figure 4.11 – WG-04 Through WG-12 Assembly View 19

Figure 4.12 – WG-04 Through WG-12 Assembly View 19

Figure 4.13 – WG-00 Through WG-12 Spur Gear Attachment (1S) Exploded View 21

Figure 4.14 – WG-00 Through WG-12 Spur Gear Attachment (1SD) Exploded View 23

2

Page 3

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 1/15

Tables

Table 3.1 – Lubricants 10

Table 4.1 – WG-00 Through WG-35 Parts List 15

Table 4.2 – WG-04 Through WG-12 Parts List 19

Table 4.3 – WG-00 Through WG-12 Spur Gear Attachment (1S) Parts List 21

Table 4.4 – WG-00 Through WG-12 Spur Gear Attachment (1SD) Parts List 23

flowserve.com

3

Page 4

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 01/15

Introduction

1

1.1 Purpose

The installation and maintenance manual (IOM) explains how to install and maintain the Flowserve Limitorque WG

operator. Information on installation, disassembly, reassembly, lubrication and spare parts is provided.

1.2 User Safety

Safety notices in this manual detail precautions the user must take to reduce the risk of personal injury and damage

to the equipment. The user must read and be familiar with these instructions before attempting installation, operation

or maintenance. Failure to observe these precautions could result in serious bodily injury, damage to the equipment,

voiding of the warranty, or operational difficulty.

Safety notice is presented in this manual in three forms:

c WARNING: Refers to personal safety. Alerts the user to potential danger. Failure to follow warning notices

could result in personal injury or death.

a CAUTION: Directs the user’s attention to general precautions that, if not followed, could result in personal injury

and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of the operator’s installation and operation.

4

Page 5

2

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 1/15

Inspection,

Installation and

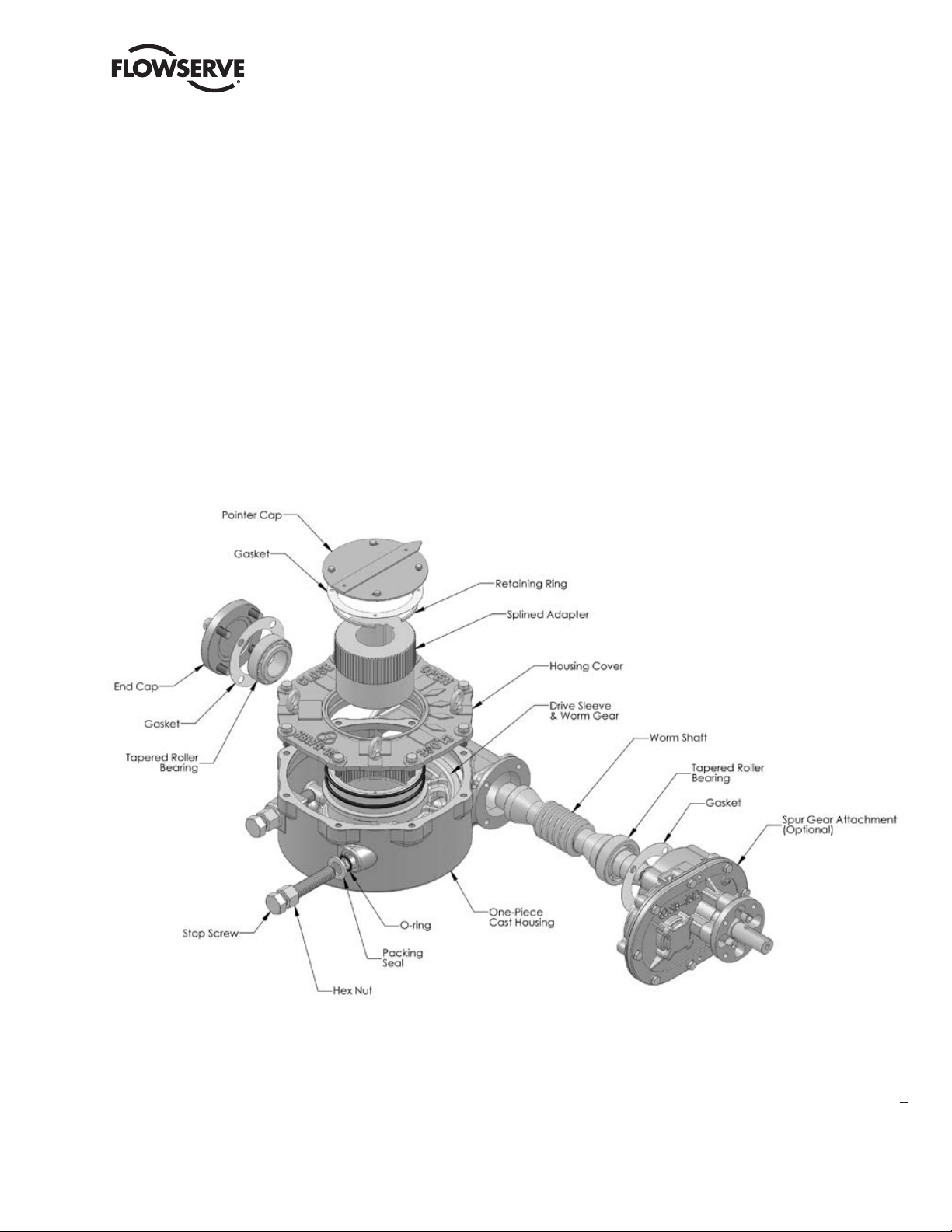

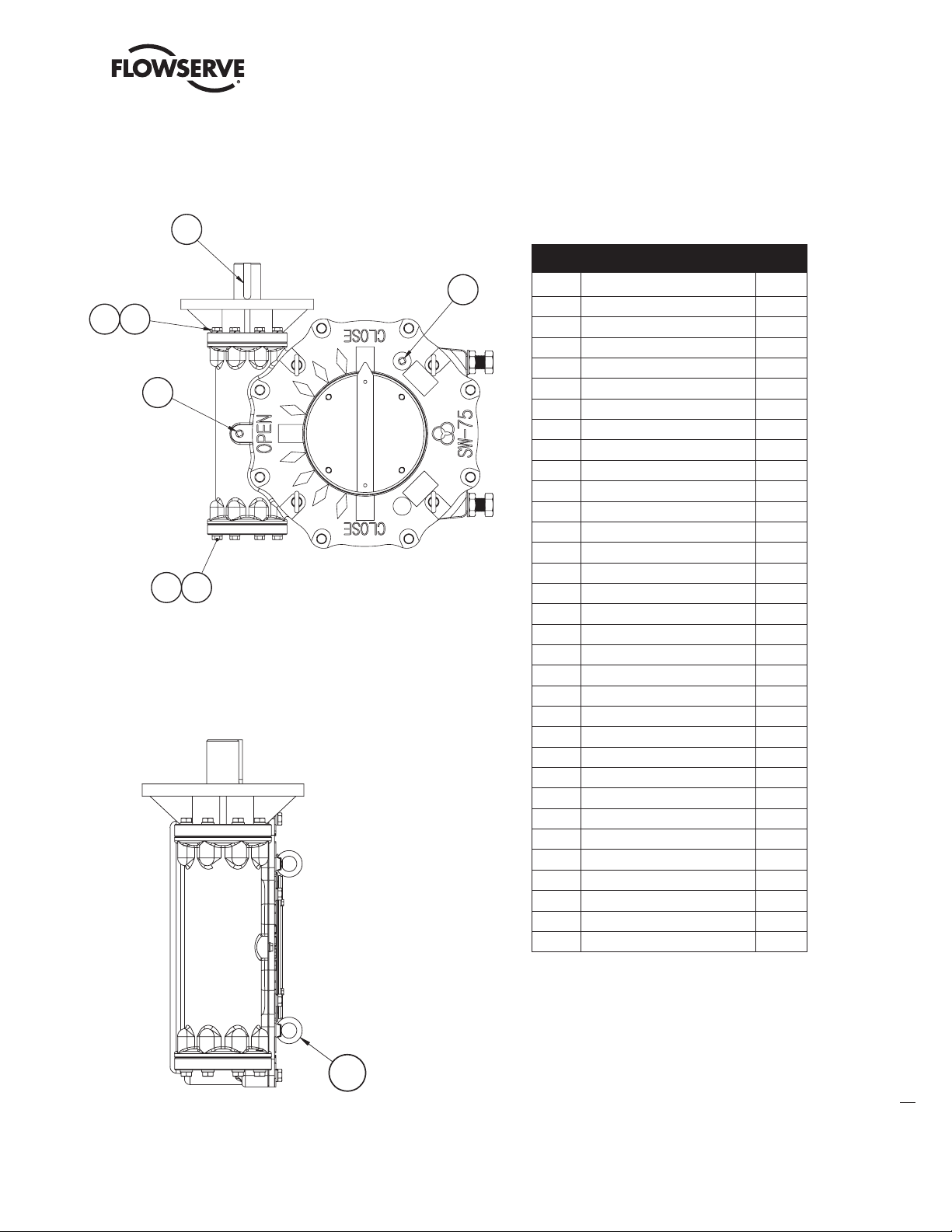

Figure 2.1 – Typical WG Exploded View

Mounting Procedures

c WARNING: Do not manually operate the WG operator with devices other than the installed handwheel or wrench

nut. Using additive force devices (cheater bars, wheel wrenches, pipe wrenches, or other devices of this nature)

on the operator handwheel, wrench or wrench nut may cause serious personal injury and/or damage to the

operator or valve.

5

flowserve.com

Page 6

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 01/15

2.1 Initial Inspection and Storage Instructions

c WARNING: Read this installation and maintenance manual carefully and completely before attempting to

store the operator. If an electric actuator is attached to the WG manual operator, be aware of the electrical

hazards. Consult the electric actuator installation and maintenance manual for guidance.

2.2 Inspection and Recording

Upon receipt of the operator, inspect the condition of the equipment, and record nameplate information.

1. Carefully remove operator from shipping carton or skid. Thoroughly examine the equipment for any physical

damage that may have occurred during shipment. If damaged, immediately report the damage to the transport

company.

2. A nameplate is attached to each operator with the following information:

• Operator size

• Assembly position

• Order number

• Serial number

• Customer tagging

Record this information for future reference, e.g., ordering parts, or obtaining further information.

2.3 Storage Procedure

NOTE: The following is the recommended storage procedure to retain maximum product integrity during storage.

Failure to comply with recommended procedure will void the warranty.

Storage (less than one year)

Store operators on wooden skids to protect the machined mounting flange. Place the wooden skids containing the

operators in a clean, dry, protected warehouse. If the operators must be stored outside, they must be covered in

polyethylene protection with silica gel crystals to absorb moisture. If an electric actuator is attached to the WG, refer

to the storage procedures in its respective manual for appropriate storage procedures. Rotate input shafts every three

months to mix the lubricant.

6

Page 7

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 1/15

2.4 General Mounting Instructions

a CAUTION: To avoid the potential for disengaging the worm gear segment, ensure that the pointer cap pointer is

oriented to the mid-point of the 90º valve travel. Full stroke rotation of the quadrant should not move the pointer

past the corresponding Open or Close ID marks on the housing cover.

The mounting instructions for the WG series worm gearboxes are outlined below. The WG-00 through WG-35 gearboxes

are designed with a bottom entry splined adapter. The WG-04 through WG-12 gearboxes are designed with a top entry

splined adapter. A separate set of instructions for each design is provided. See Section 2.4.1 for the WG-00 through WG-35

and Section 2.4.2 for the WG-04 through WG-12.

2.4.1 WG-00 through WG-35

1. Place the valve disk in the full closed position.

Note: If the Splined Adapter is already installed in the operator, go to step 6.

2. Remove the Pointer Cap (see Section 4 for removal instructions).

3. Turn the gearbox upside down so that the bottom of the housing is accessible.

4. Remove the Retaining Ring, and install the Splined Adapter.

Note: The notch in the Worm Gear at the Closed position must be aligned with the

keyway in the Splined Adapter.

5. Reinstall the Retaining Ring.

6. Place the gearbox in the upright position so that the top of the gearbox is accessible.

7. Mount the operator on the valve and bolt securely.

8. Rotate the input shaft to align the keyway of the Splined Adapter with the keyway of the

Valve Shaft and install the key.

9. Confirm that the gearbox Stop Screws are properly set for valve disk travel in both the Open and Close

directions of travel. See Section 2.6.

10. Reinstall the Pointer Cap.

flowserve.com

7

Page 8

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 01/15

2.4.2 WG-04 through WG-12

1. Place the valve disk in the full closed position.

2. Remove the Pointer Cap (see Section 4 for removal instructions).

Note: If the Splined Adapter is already installed in the operator, go to step 6.

3. Remove the Retaining Ring and install the Splined Adapter.

Note: The notch in the Worm Gear at the Closed position must be aligned with the keyway in the Splined Adapter.

4. Reinstall the Retaining Ring.

5. Mount the operator on the valve and bolt securely.

6. Rotate the input shaft to align the keyway of the Splined Adapter with the keyway of the Valve Shaft and install the key.

7. Confirm that the gearbox Stop Screws are properly set for valve disk travel in both the Open and Close directions of travel.

See Section 2.6.

8. Reinstall the Pointer Cap.

2.5 Assembly Positions

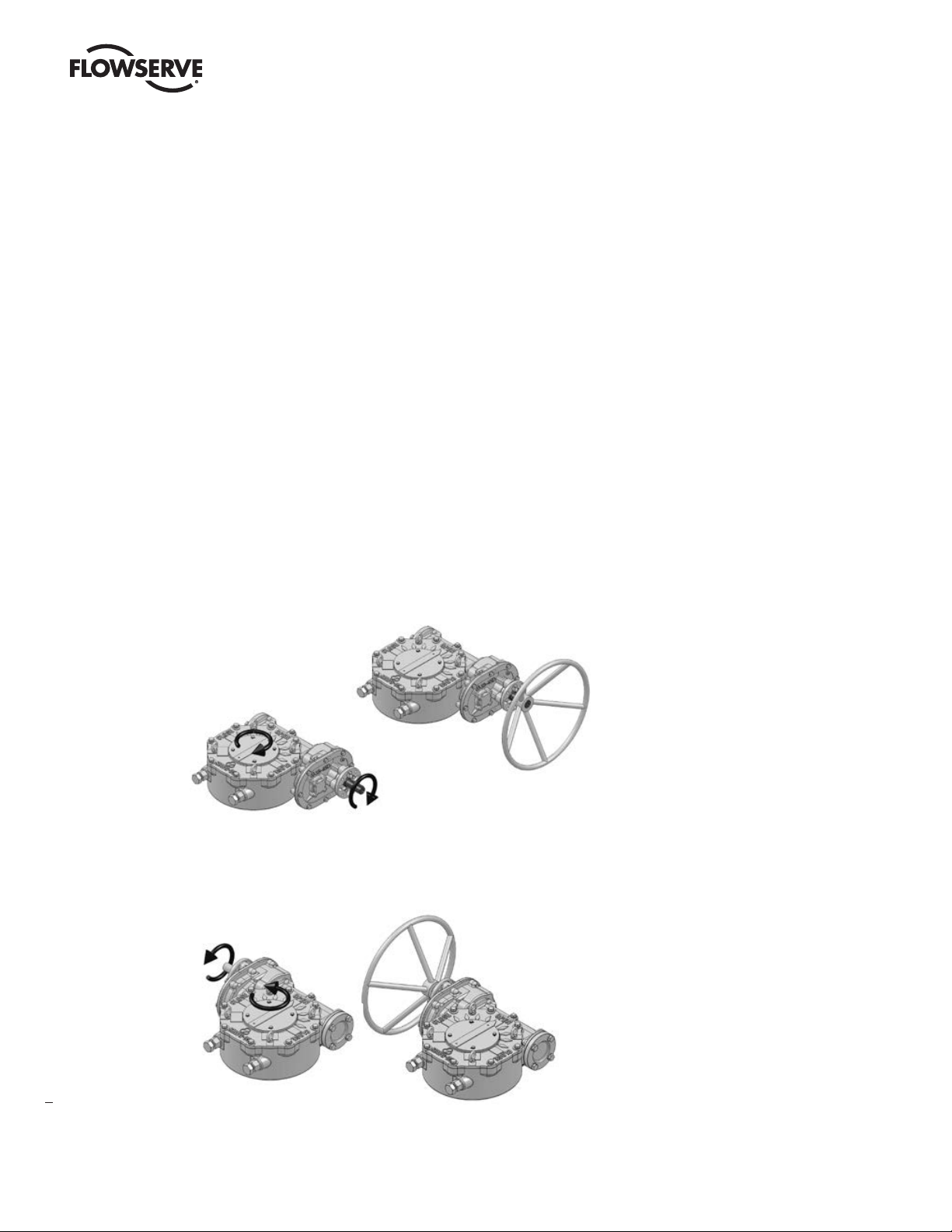

Figure 2.2 – Position A

STANDARD ASSEMBLY POSITION

Clockwise Input Rotation –

Clockwise Output Rotation

Figure 2.3 – Position D

OPTIONAL ASSEMBLY POSITION

Clockwise Input Rotation –

Counterclockwise Output Rotation

8

Page 9

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 1/15

21

2

20

8

17

17

10

9

31 18

14 29

12

9

30

2.6 Setting Position Limit Stops – WG-00 Through WG-12

Refer to Figure 2.4

1. Loosen the Hex Nut (pc# 16) and turn it several turns to allow for stop screw adjustment.

2. Adjust the Stop Screw by turning it counterclockwise to back the screw away from the Worm Gear/Drive Sleeve (pc# 5).

3. Place the valve disk in the full closed position.

4. Turn the Stop Screw (pc# 15) in the clockwise direction until the end of the screw contacts the Worm Gear/Drive Sleeve.

5. Tighten the Hex Nut to secure the closed set position.

6. Move the valve disk to the full open position.

7. Follow steps 1 through 5.

a CAUTION: If the valve is operated with an electric actuator/gear operator combination, and the valve is position-seated,

set the actuator limit switches to trip prior to engagement of the WG Worm Gear/Drive Sleeve with the Stop Screws.

Damage to the operator could result from the Worm Gear/Drive Sleeve contacting the Stop Screw under motorized

operation.

Note: The stops are adjustable to +/- 5º of total travel to allow for proper positioning

of the worm gear quadrant.

3

Figure 2.4 – Setting Position Limit Stops – WG-00 through WG-12

15

16

23

5

32

7

19

22

4

11

1

11

22

6

9

flowserve.com

Page 10

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 01/15

Lubrication

3

Flowserve Limitorque WG operators are shipped with the following lubricants:

Table 3.1 – Lubricants

Product Lubricant Soap Base Temperature Range

WG-00 through WG-10 Zenith LH 2 Calcium -40°C to 90°C (-40°F to 194°F)

NOTE: The lubricant should be checked every 18 months for manual operators.

a CAUTION: Do not add a different lubricant to a Flowserve Limitorque operator unless it is of the same soap base

as the existing lubricant, or you have received the approval of the lubricant manufacturer.

Quantity

Limitorque operators are built to operate on the partial immersion principle. The primary concern regarding the amount

of lubricant is whether the “worm” is totally immersed in grease. This can be verified by the use of one or more of the

“fill” and “drain” plugs provided on the operator housing in most sizes.

Quality

When removing a “fill” or “drain” plug to inspect the lubricant level, remove a small amount and ensure that it is clean

and free of any contaminant, including water. Should dirt, water or other foreign matter be found, the operators should

be flushed with a commercial degreaser/cleaner which is non-corrosive and does not affect seal materials such as

Buna-N or Viton. Repack operator with fresh lubricant.

Consistency

The main gear box lubricant should be slightly fluid, approximating a standard NLGI-2 grade consistency or less.

Alternate lubricants may be used in place of the standard lubricants supplied by Flowserve, provided they are of a

formulation similar to those listed above for the respective product.

10

Page 11

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 1/15

Disassembly and

4

Reassembly Instructions

4.1 Safety Precautions

c WARNING: Read this Installation, Operation and maintenance manual carefully and completely before attempting

to install, operate or troubleshoot the Limitorque operator.

c WARNING: Potential HIGH-PRESSURE vessel — be aware of high-pressure hazards associated with the attached

valve or other actuated device when installing or performing maintenance on the operator. Do not remove the

operator mounting bolts from the valve or actuated device unless the valve or device stem is secured or there is

no pressure in the line.

c WARNING: For maintenance and/or disassembly of the operator while installed on the valve, ensure that the

operator is not under thrust or torque load. If the valve must be left in service, the valve stem must be locked in

such a way as to prevent any movement of the valve stem.

c WARNING: Do not manually operate the operator with devices other than the installed handwheel. Using force

beyond the ratings of the operator and/or using additive force devices such as cheater bars, wheel wrenches, pipe

wrenches, or other devices on the operator handwheel may cause serious personal injury and/or damage to the

operator and valve.

c WARNING: Do not exceed any design limitations or make modifications to this equipment without first consulting

Limitorque.

c WARNING: Use of this product must be suspended any time it fails to operate properly.

a CAUTION: If a motor actuator is driving the manual operator, do not operate the valve under motor operation

without first checking and setting the limit switch and checking for correct motor rotation.

a CAUTION: Do not use replacement parts that are not genuine Flowserve Limitorque parts, as serious personal

injury and/or damage to the operator and valve may result.

11

flowserve.com

Page 12

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 01/15

4

28 13

2

21

20

9

5

9

6

22

11

24

1

3

32

23

16

15

27

1328

11

22

19

7

17

17

10

(VARIES)

PC-7 IS REPLACED BY

OPTIONAL SPUR GEAR

ATTACHMENT, IF SUPPLIED

4.2 Safety Practices

The following checkpoints should be performed to maintain safe operation of the WG gear operator:

• Set up a periodic operating schedule on infrequently used valves.

• Ensure that the limit and/or torque switches on any electric actuator fitted to the WG worm gear operator are

correctly and appropriately adjusted.

4.3 WG-00 Through WG-35

Refer to Figures 4.1 through 4.6.

Disassembly Instructions:

1. Place the operator upside down to access the mounting base.

2. Remove Retaining Ring (pc# 10) and Splined Adapter (pc# 4).

3. Return the operator to the upright position (mounting base down) and remove the Hex Head

Cap Screws (pc# 14), Pointer Cap (pc# 8) and O-rings (pc# 18 & 31).

12

4. Remove the Hex Head Cap Screws (pc# 12), Housing Cover (pc# 2) and Cover Gasket (pc# 21).

5. Remove the Input Flange (pc# 7), with Oil Seal (pc# 19) and Gasket (pc# 22), or remove the Spur Gear

Attachment (See Section 4.5 or 4.6).

6. Remove Worm Shaft (pc# 3) with Tapered Roller Bearing (pc# 11) from the Housing (pc# 1).

7. Remove the Tapered Roller Bearing (pc# 11) from the Worm Shaft (pc# 3), if required.

8. Remove the End Cap (pc# 6) and Gasket (pc# 22).

9. Remove the Tapered Roller Bearing (pc# 11).

10. Remove the Worm Gear/Drive Sleeve (pc# 5), O-Rings (pc# 17), and Thrust Washers (pc# 9).

11. Remove the Stop Screws (pc# 15) with Hex Nuts (pc# 16), Packing Seals (pc# 23) and O-rings (pc# 32).

Reassembly Instructions:

1. Install the Stop Screws (pc#15), including the O-Rings (pc# 32),

Packing Seals (pc# 23) and Hex Nuts (pc# 16).

2. Place the lower Thrust Washer (pc# 9) in the Housing (pc# 1).

3. Replace the lower O-Rings (pc# 17) in the base of the

Housing (pc# 1).

Note: Lubricate all O-Rings before installation.

4. Install the Worm Gear/Drive Sleeve (pc# 5).

5. Install the Tapered Roller Bearing (pc# 11) into the

Housing bore on the End Cap side.

Figure 4.1 – Splined Adapter Assembly

Page 13

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 1/15

4

29

14

30 12

28 13

8

31

18

2

21

20

9

5

9

6

22

11

24

1

3

32

23

16

15

27

1328

11

22

19

7

17

17

10

(VARIES)

PC-7 IS REPLACED BY

OPTIONAL SPUR GEAR

ATTACHMENT, IF SUPPLIED

6. Install the End Cap (pc# 6) and Gasket (pc# 22).

7. Insert the Worm Shaft (pc# 3) into the Housing bore.

8. Install the Tapered Roller Bearing (pc# 11) onto the Worm Shaft in the Housing bore.

9. Replace the Oil Seal (pc# 19) in the Input Flange (pc# 7), if required.

10. Install the Input Flange (pc# 7) with Gasket (pc# 22) or install the Spur Gear Attachment (See Section 4.5 or 4.6).

Note: Lubricate the worm gear mesh to replace lubricant lost during disassembly (see Lubrication, Section 3).

11. Place the upper Thrust Washer (pc# 9) on the Worm Gear/Drive Sleeve (pc# 5).

12. Replace the upper O-Ring (pc# 20) in the Housing Cover (pc# 2).

Note: Lubricate all O-Rings before installation.

13. Install the Housing Cover (pc# 2) with Cover Gasket (pc# 21).

14. Replace the upper O-Ring (pc# 18) in the Housing Cover (pc# 2).

15. Replace the Pointer Cap O-ring (pc# 31) in the top of the Worm Gear/Drive Sleeve (pc# 5).

Note: Lubricate all O-Rings before installation.

16. Install the Pointer Cap (pc# 8).

17. Turn the operator upside

down and insert the Splined

Adapter (pc# 4).

18. Install the Splined Adapter

Retaining Ring (pc# 10).

Figure 4.2 –

WG-00 through WG-35 Exploded View

13

flowserve.com

Page 14

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 01/15

21

2

20

8

17

17

10

9

25

31 18

14 29

12

9

30

Figure 4.3 – WG-00 through WG-35 Assembly View

15

23

16

32

5

4

3

7

19

22

11

1

11

22

6

14

Figure 4.4 – WG-00 through WG-35 Assembly View

20

8

2

21

17

17

14 29

31 18

10

12930

9

Page 15

27

24

28 13

Figure 4.5 – WG-00 through WG-35 Assembly View

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 1/15

27

28 13

24

28 13

Figure 4.6 – WG-00 through WG-35 Assembly View

Table 4.1 – WG-00 through WG-35 Parts List

Parts List

Item Description Qty.

1 Housing 1

2 Housing Cover 1

3 Worm Shaft 1

4 Splined Adapter 1

5 Worm Gear/Drive Sleeve 1

6 End Cap 1

7 Input Flange VARIES

8 Pointer Cap 1

9 Thrust Washer 2

10 Splined Adapter Retaining Ring 1

11 Tapered Roller Bearing 2

12 Hex Head Cap Screw 8

13 Hex Head Cap Screw 4

14 Hex Head Cap Screw 4

15 Stop Screw 2

16 Hex Nut 2

17 Drive Sleeve O-Ring VARIES

18 Drive Sleeve O-Ring 1

19 Oil Seal 1

20 Drive Sleeve O-Ring 1

21 Cover Gasket 1

22 Gasket 2

23 Packing Seal 2

24 Pipe Plug/Grease Fitting 1

25 Eye Bolt 4

26

27 Key 1

28 Lock Washer 4

29 Lock Washer 4

30 Lock Washer 8

31 Pointer Cap O-Ring 1

32 Stop Screw O-Ring 2

N/A

15

25

flowserve.com

Page 16

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 01/15

14 29

1328

6

22

11

26

24

1

3

26

11

22

19

7

4

17

17

9

5

9

20

18

21

8

31

10

(QTY VARIES)

(VARIES)

(VARIES)

(VARIES)

1

PC-7 IS REPLACED BY

OPTIONAL SPUR GEAR

ATTACHMENT, IF SUPPLIED

4.4 WG-04 Through WG-12

Refer to Figures 4.7 through 4.12

Disassembly Instructions:

1. Remove the Hex Head Cap Screws (pc# 14), Pointer Cap (pc# 8), Gasket (pc# 31) and O-ring1 (pc# 18).

2. Remove Retaining Ring (pc# 10) and Splined Adapter (pc# 4).

3. Remove the Hex Head Cap Screws (pc# 12), Housing Cover (pc# 2), Cover Gasket (pc# 21), and O-Ring (pc# 20).

Note: Remove O-Ring (pc# 18) if applicable1.

4. Remove the Input Flange (pc# 7) and Gasket (pc# 22), or remove the Spur Gear Attachment (See Section 4.5 or 4.6).

5. Remove Worm Shaft (pc# 3) with Tapered Roller Bearing (pc# 11) and Ball Bearing2 (pc# 26) from the Housing (pc# 1).

6. Remove the Tapered Roller Bearing (pc# 11) and Ball Bearing2 (pc# 26) from the Worm Shaft (pc# 3), if required.

7. Remove the End Cap (pc# 6) and Gasket (pc# 22).

8. Remove the Tapered Roller Bearing (pc# 11) and Ball Bearing2 (pc# 26).

9. Remove the Worm Gear/Drive Sleeve (pc# 5), O-Rings (pc# 17), and Thrust Washers (pc# 9).

10. Remove the Stop Screws (pc# 15) with Hex Nuts (pc# 16), Packing Seals (pc# 23) and O-rings (pc# 32), if applicable.

Reassembly Instructions:

1. Install the Stop Screws (pc# 15), including the Hex Nuts (pc# 16),

Packing Seals (pc# 23) and O-rings (pc# 32), if applicable.

2. Place the lower Thrust Washer (pc# 9) in the Housing (pc# 1).

3. Replace the lower O-Rings (pc# 17) in the base of the Housing (pc# 1).

Note: Lubricate all O-Rings before installation.

4. Install the Worm Gear/Drive Sleeve (pc# 5).

5. Install the Ball Bearing2 (pc# 26) and the Tapered

Roller Bearing (pc# 11) into the Housing bore

on the End Cap side.

6. Install the End Cap (pc# 6) and Gasket (pc# 22).

7. Insert the Worm Shaft (pc# 3) into the Housing bore.

8. Install the Ball Bearing2 (pc# 26) and the Tapered

Roller Bearing (pc# 11) onto the Worm Shaft in the

Housing bore.

9. Replace the Oil Seal (pc# 19) in the Input Flange (pc# 7), if required.

10. Install the Input Flange (pc# 7) with Gasket (pc# 22) or

install the Spur Gear Attachment (See Section 4.5 or 4.6).

Figure 4.7 –

WG-04 through WG-12

Splined Adapter Assembly

16

Note: Lubricate the worm gear mesh to replace lubricant lost during

disassembly (See Lubrication, Section 3).

Page 17

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 1/15

14 29

1328

6

22

11

26

24

1

23

16

15

3

27

26

11

22

19

7

13 28

4

17

17

9

5

9

20

18

21

2

1230

25

24

8

31

10

(QTY VARIES)

(QTY VARIES)

(VARIES)

(VARIES)

(VARIES)

1

PC-7 IS REPLACED BY

OPTIONAL SPUR GEAR

ATTACHMENT, IF SUPPLIED

11. Place the upper Thrust Washer (pc# 9) on the Worm Gear/Drive Sleeve (pc# 5).

12. Replace the O-Rings (pc# 20) in the Housing Cover (pc# 2).

Note: Lubricate the O-Rings before installation.

13. Install the Housing Cover (pc# 2) with the Cover Gasket (pc# 21).

14. Insert the Splined Adapter (pc# 4) into the Worm Gear/Drive Sleeve (pc# 5).

15. Install the Splined Adapter Retaining Ring (pc# 10).

16. Install the Pointer Cap (pc# 8), Gasket (pc# 31) and Drive Sleeve O-Ring1 (pc# 18).

Figure 4.8 – WG-04 through WG-12 Exploded View

1

O-Ring (pc# 18) applies to WG-04 through -07 only. (Pc# 20), quantity of 2, applies to WG-75 through WG-12.

2

Ball Bearing (pc# 26) applies to WG-55 thru -12 only.

17

flowserve.com

Page 18

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 01/15

31

21

17

17

4

9

3

7

19

22

25

11

1

26

11

22

6

11

26

32

16

23

5

15

4

23

2

20

20 31

8

14 29

10

9

12 30

18

20

ALTERNATE CONSTRUCTION:

DRIVE SEAL O-RING & GASKET

WG-04 THRU WG-07

ALTERNATE CONSTRUCTION:

STOP SLEEVE & O-RINGS

WG-04 THRU WG-07

ALTERNATE CONSTRUCTION:

SINGLE WORM SHAFT BEARING

WG-04 THRU WG-05

31

21

17

17

4

9

3

2

20

20 31

8

14 29

10

9

12 30

18

20

27

ALTERNATE CONSTRUCTION:

DRIVE SEAL O-RING & GASKET

WG-04 THRU WG-07

Figure 4.9 – WG-04 through WG-12 Assembly View

18

Figure 4.10 – WG-04 through WG-12 Assembly View

Page 19

Figure 4.11 – WG-04 through WG-12 Assembly View

27

24

1328

1328

24

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 1/15

27

1328

24

1328

Figure 4.12 – WG-04 through WG-12 Assembly View

24

Table 4.2 – WG-04 through WG-12 Parts List

Parts List

Item Description Qty.

1 Housing 1

2 Housing Cover 1

3 Worm Shaft 1

4 Splined Adapter 1

5 Worm Gear/Drive Sleeve 1

6 End Cap 1

7 Input Flange 1

8 Pointer Cap 1

9 Thrust Washer 2

10 Splined Adapter Retaining Ring 1

11 Tapered Roller Bearing 2

12 Hex Head Cap Screw 8

13 Hex Head Cap Screw VARIES

14 Hex Head Cap Screw 4

15 Stop Screw 2

16 Hex Nut 2

17 Drive Sleeve O-Ring 2

18 Drive Sleeve O-Ring VARIES

19 Oil Seal 1

20 Drive Sleeve O-Ring VARIES

21 Cover Gasket 1

22 Gasket 2

23 Packing Seal 2

24 Pipe Plug/Grease Fitting 2

25 Eye Bolt 4

26 Ball Bearing VARIES

27 Key 1

28 Lock Washer VARIES

29 Lock Washer 4

30 Lock Washer 8

31 Pointer Cap Gasket 1

32 Stop Screw O-Ring VARIES

25

19

flowserve.com

Page 20

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 01/15

4.5 Single Reduction Spur Gear Attachment (1S)

Refer to Figure 4.13

Disassembly Instructions:

1. Remove the Socket Head Cap Screws and Input Flange (not shown) from the Cover (pc# 4).

2. Remove the Hex Head Cap Screws (pc# 12) and Cover (pc# 4).

3. Remove all traces of the Cover Gasket (pc# 9).

4. Remove the Input Shaft/Pinion (pc# 3) and Ball Bearings (pc# 6) from the Cover (pc# 4).

5. Remove the Ball Bearing (pc# 10) and Retaining Ring (pc# 5) from the Worm Shaft.

6. Remove Gear (pc# 2) and Key (pc# 8) from the Worm Shaft.

7. Remove the Socket Head Cap Screws (not shown) which mount the Spur Gear Attachment to the

WG Gearbox and remove the Spur Gear Housing (pc# 1)

8. If disassembly of the WG Gearbox is required, see Sections 4.3 or 4.4.

Reassembly Instructions:

1. Install the Spur Gear Housing (pc# 1) on the WG Gearbox, ensuring proper gasket is installed between

Gearbox and Spur Gear Housing (see Section 4.3 or 4.5).

2. Install Gear (pc# 2) onto the WG Gearbox Worm Shaft with Key (pc# 8). Fasten with Retaining Ring (pc# 5).

3. Install Ball Bearing (pc# 10) onto the Worm Shaft.

4. Install Ball Bearing (pc# 6) into the Spur Gear Housing (pc# 1).

5. Install the Input Shaft/Pinion (pc# 3).

6. Install Ball Bearing (pc# 6) onto the Input Shaft/Pinion (pc# 3).

7. Replace the Cover Gasket (pc# 9).

8. Replace the Oil Seal (pc# 11) in the Cover (pc# 4).

Note: Lubricate the Spur Gearing. See Section 3.

9. Install the Cover (pc# 4), mounting with Hex Head Cap Screws (pc# 12).

10. Install the Input Flange (not shown) onto the Cover (pc# 4) using Socket Head Cap Screws (not shown).

Note: Replace any worn or damaged O-Rings or Gaskets to ensure proper sealing and operation.

20

Page 21

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 1/15

Figure 4.13 – WG-00 through WG-12 Spur Gear Attachment (1S) Exploded View

1

WORM SHAFT

2

8

6

3

6

Table 4.3 – WG-00 through WG-12 Spur Gear

Attachment (1S) Parts List

Parts List

Item Description Qty.

1 Housing 1

2 Gear 1

3

4 Cover 11

5

6

7

8

9

10

11

12

13

Input Shaft/Pinion

Retaining Ring

Ball Bearing

Key

Key

Gasket

Ball Bearing

Oil Seal

Hex Head Cap Screw

Lockwasher

5

9

10

4

12 13

11

1

1

2

1

1

1

1

1

8

8

21

flowserve.com

Page 22

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 01/15

4.6 Double Reduction Spur Gear Attachment (1SD)

Refer to Figure 4.14

Disassembly Instructions:

1. Remove the Socket Head Cap Screws (pc# 19) and Input Flange (pc# 18) from the Cover (pc# 12).

2. Remove the Hex Head Cap Screws (pc# 14) and Cover (pc# 12).

3. Remove the Helical Gear/2nd Set Pinion Subassembly.

4. Remove all traces of the Cover Gasket (pc# 13).

5. Remove the Input Shaft/Pinion Subassembly from the Cover (pc #12) by removing the Retaining Ring (pc# 16).

6. Remove the Retaining Ring (pc# 4) and Ball Bearings (pc# 11) from the Input Shaft/Pinion (pc #9).

7. Remove the Ball Bearing (pc# 8) from the 2nd Set Pinion (pc# 5).

8. Remove the Retaining Ring (pc# 4) and the Helical Gear (pc# 2) from the 2nd Set Pinion (pc# 5).

9. Remove the Retaining Ring (pc# 4) and the Helical Gear (pc# 2) from the Worm Shaft.

10. Remove the Socket Head Cap Screws (pc# 20) from the Spur Gear Housing (pc# 1) and remove the

Spur Gear Housing (pc# 1) from the WG Gearbox.

11. If disassembly of the WG Gearbox is required, see Sections 4.3 or 4.4.

Reassembly Instructions:

1. Install the Spur Gear Housing (pc# 1) on the WG Gearbox, ensuring proper gasket is installed between Gearbox

and Spur Gear Housing (See Section 4.3 or 4.4).

2. Install the Helical Gear (pc# 2) on the WG Gearbox Worm Shaft with two Keys (pc# 3). Fasten with Retaining

Ring (pc# 4).

3. Insert the Bushing (pc# 10) into the end of the Input Shaft/Pinion (pc# 9).

4. Install the Ball Bearings (pc# 11) and Retaining Ring onto the Input Shaft/Pinion (pc# 9)

5. Install the Input Shaft/Pinion with Ball Bearings (pc# 11) into the Cover (pc# 12) using Retaining Ring (pc# 16).

6. Install the Ball Bearing (pc# 6) in the Spur Gear Housing (pc# 1).

7. Assemble the Helical Gear (pc# 2) on the 2nd Set Pinion (pc# 5) with two Keys (pc# 7). Fasten with Retaining

Ring (pc# 4).

8. Install the Ball Bearing (pc# 8) on the 2nd Set Pinion (pc# 5).

9. Install the Helical Gear/2nd Set Pinion Subassembly in

the Ball Bearing (pc# 6).

22

Note: Lubricate the Spur Gearing. See Section 3.

10. Replace the Gasket Cover (pc# 13).

11. Install the Cover (pc# 12) with Input Shaft/Pinion Subassembly onto the Spur Gear Housing, ensuring proper mesh of

gear teeth on Input Shaft/Pinion (pc# 9) and Helical Gear (pc# 2), and alignment of Ball Bearing (pc# 8) with Cover (pc# 12).

Page 23

Limitorque WG Series Worm Gear Operator FCD LMENIM2101-02 – 1/15

WORM

SHAFT

INPUT SHAFT/PINION

SUBASSEMBLY

HELICAL GEAR/2ND

SET PINION

SUBASSEMBLY

B

A

3

1

6

4

12

2

5

8

1

1

6

5

7

7

2

4

8

2

4

4

11

9

11

13

12

14

17

15

18

19

10

16

21

20

A

B

12. Replace the Oil Seal (pc# 15).

13. Install the Input Flange (pc# 18).

Note: Replace any worn or damaged O-Rings or Gaskets to

ensure proper sealing and operation.

Figure 4.14 – WG-00 through WG-12 Spur Gear

Attachment (1SD) Exploded View

Table 4.4 – WG-00 through WG-12 Spur Gear Attachment (1SD) Parts List

Item Description Qty. Item Description Qty.

1 Spur Gear Housing 1 11 Ball Bearing 2

2 Helical Gear 2 12 Cover 1

3 Key 2 13 Gasket - Cover 1

4 Retaining Ring 3 14 Hex Head Cap Screw 8

5 2nd Set Pinion 1 15 Oil Seal 1

6 Ball Bearing 1 16 Retaining Ring 1

7 Key 2 17 Lockwasher 8

8 Ball Bearing 1 18 Input Flange 1

9 Input Shaft / Pinion 1 19 Socket Head Cap Screw 4

10

Bushing

Parts List

1 20 Socket Head Cap Screw VARIES

23

flowserve.com

Page 24

Flowserve Corporation

Flow Control

United States

Flowserve Limitorque

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone: 434-528-4400

Fax: 434-845-9736

England

Flowserve Limitorque

Euro House

Abex Road

Newbury

Berkshire, RG14 5EY

United Kingdom

Phone: 44-1-635-46999

Fax: 44-1-635-36034

Singapore

Limitorque Asia, Pte., Ltd.

12, Tuas Avenue 20

Singapore 638824

Phone: 65-6868-4628

Fax: 65-6862-4940

FCD LMENIM2101-02-AQ Printed in USA. January 2015

To find your local Flowserve representative,

visit www.flowserve.com, www.limitorque.com

or call USA 1 800 225 6989.

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended

function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a

wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications.

The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation and maintenance of Flowserve products. The purchaser/

user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve

products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as

a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this

product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice.

Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2015 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

China

Limitorque Beijing, Pte., Ltd.

RM A1/A2

22/F, East Area, Hanwei Plaza

No. 7 Guanghua Road, Chaoyang

District

Beijing 100004, Peoples Republic of

China

Phone: 86-10-5921-0606

Fax: 86-10-6561-2702

India

Flowserve Limitorque

Plot No. #4, 1 A, Road No. 8, EPIP

Whitefield, Bangalore – 560066

Karnataka

India

Phone: 91-80-40146200

Fax: 91-80-28410286

Italy

Flowserve Limitorque

Fluid Power Systems

Via Rio Vallone 17

20883 Mezzago MB

Italy

Phone: 39-039-620601

Fax: 39-039-62060 213

flowserve.com

Loading...

Loading...