Page 1

®

Pump Division

Type: WDX

CENTRIFUGAL PUMPS

USER INSTRUCTIONS:

INSTALLATION, OPERATION, MAINTENANCE

PCN=71576322 06-05 (E)

These instructions must be read prior to installing,

operating, using and maintaining this equipment.

Page 2

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

CONTENTS

PAGE

1 INTRODUCTIONAND SAFETY..........................4

PAGE

6 MAINTENANCE................................................28

1.1 General.......................................................4

1.2 CE marking and approvals...........................4

1.3 Disclaimer...................................................4

1.4 Copyright....................................................4

1.5 Duty conditions............................................4

1.6 Safety.........................................................5

1.7 Safety labels summary.................................8

1.8 Specific machine performance......................8

1.9 Noiselevel..................................................9

2 TRANSPORT AND STORAGE..........................10

2.1 Consignment receipt and unpacking...........10

2.2 Handling...................................................10

2.3 Lifting........................................................11

2.4 Storage.....................................................12

2.5 Recycling and end of product life................12

3 PUMP DESCRIPTION.......................................12

3.1 Configurations...........................................12

3.2 Nomenclature............................................13

3.3 Design of major parts.................................13

3.4 Materials of construction............................14

3.5 Performance and operating limits................14

3.6 Coverage charts........................................15

4 INSTALLATION.................................................16

4.1 Location....................................................16

4.2 Cleaning priorto installation.......................16

4.3 Foundation................................................16

4.4 Grouting....................................................17

4.5 Initial alignment.........................................17

4.6 Piping.......................................................18

4.7 Final shaft alignment check........................21

4.8 Electrical connections................................21

4.9 Protection systems ....................................22

6.1 General.....................................................28

6.2 Maintenance schedule...............................28

6.3 Spare parts................................................31

6.4 Recommended spares and consumable..........

items..............................................................32

6.5Tools required............................................32

6.6 Fastener torques.......................................32

6.7 Renewal clearances..................................32

6.8 Disassembly..............................................32

6.9 Inspection of components...........................36

6.10 Assembly................................................37

7 FAULTS; CAUSES AND REMEDIES..................38

8 PARTS LISTS AND DRAWINGS........................40

8.1 Sectional drawings, WDXR grease lubricated

uncooled........................................................40

8.2 Sectional drawings, variants.......................41

8.3 Sectional drawings, otherdetails................42

8.4 Sectional drawingspart list.........................43

8.5 General arrangement drawing....................45

9 CERTIFICATION..............................................45

10 OTHER RELEVANT DOCUMENTATION AND

MANUALS....................................................45

10.1 Supplementary User Instructions..............45

10.2 Change notes..........................................45

10.3 Additional sources of information..............45

5 COMMISSIONING, START-UP, OPERATIONAND

SHUTDOWN................................................22

5.1 Pre-commissioning procedure....................22

5.2 Pump lubricants.........................................23

5.3 Direction of rotation....................................24

5.4 Guarding...................................................24

5.5 Priming and auxiliary supplies....................24

5.6 Starting the pump......................................25

5.7 Running the pump.....................................25

5.8 Stopping and shutdown..............................27

5.9 Hydraulic, mechanical and electrical duty....27

5.10 Pumpsfor Food Use or Potable Water......27

Page 2 of 46

Page 3

®

INDEX

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

PAGE

PAGE

Additional sources (10.3)......................................45

Alignment of shafting (see 4.3,4.5 and 4.7)

Assembly (6.10)...................................................37

ATEX marking (1.6.4.2)..........................................7

CE marking and approvals (1.2)..............................4

Certification (9)....................................................45

Change notes(10.2)............................................45

Clearances(see 6.7, Renewal clearances)............32

Commissioning, start-up, operation (5)..................22

Compliance, ATEX (1.6.4.1)...................................6

Configurations (3.1) .............................................12

Copyright (1.4).......................................................4

Coverage charts(3.6)..........................................15

Design ofmajorparts(3.3)...................................13

Direction of rotation (5.3)......................................24

Disassembly (6.8)................................................32

Disclaimer (1.3).....................................................4

Dismantling (see 6.8, Disassembly)......................32

Drawings (8)........................................................40

Duty conditions(1.5)..............................................4

Electrical connections(4.8)...................................21

End of product life (2.5)........................................12

Inspection of components (6.9).............................36

Fastener torques(6.6)..........................................32

Faults; causesand remedies (7)...........................38

Foundation (4.3)..................................................16

Forces and moments (4.6.3).................................20

General arrangement drawing (8.5).......................45

Grouting (4.4)......................................................17

Guarding (5.4).....................................................24

Handling (2.2)......................................................10

Hydraulic, mechanical and electrical duty (5.9)......27

Inspection (6.2.1 and 6.2.2)..................................29

Installation (4)......................................................16

Lifting (2.3)..........................................................11

Location (4.1)......................................................16

Lubrication (see 5.1.1, 5.2 and6.2.3)

Lubrication schedule (5.2.4)..................................24

Maintenance (6)...................................................28

Maintenance schedule (6.2)..................................28

Nomenclature (3.2)..............................................13

Nameplate (1.7.1)..................................................8

Operating limits(3.5.1).........................................14

Ordering spare parts (6.3.1)..................................31

Partslists (8.4)....................................................43

Performance (3.5)................................................14

Piping (4.6)..........................................................18

Pre-commissioning (5.1).......................................22

Protection systems(4.9).......................................22

Pumpmasses(2.2.2)...........................................11

Reassembly (see 6.10, Assembly)........................37

Receipt and unpacking (2.1).................................10

Recommended fill quantities(see 5.2.3)................23

Recommended grease lubricants (5.2.2)...............23

Recommended oil lubricants (5.2.1)......................23

Recommended spares (6.4).................................32

Recycling (2.5)....................................................12

Replacement parts (see 6.3 and 6.4).....................31

Running the pump (5.7)........................................25

Safety action (1.6.3)...............................................5

Safetymarkings(1.6.1)..........................................5

Safety,protection systems (see 1.6 and 4.9)

Sectional drawings (8.1).......................................40

Sound level (see 1.9, Noise level)...........................9

Sources, additional information (10.3)...................45

Spare parts (6.3)..................................................31

Specific machine performance (1.8)........................8

Starting the pump (5.6).........................................25

Stop/start frequency (5.7.6)..................................26

Stopping and shutdown (5.8)................................27

Storage, pump (2.4).............................................12

Storage, spareparts (6.3.2)..................................32

Supplementarymanualsor information sources.....45

Thermal expansion (4.5.1)....................................17

Toolsrequired (6.5)..............................................32

Torques for fasteners (6.6)...................................32

Transport (2).......................................................10

Trouble-shooting (see 7)......................................38

Vibration (5.7.5)...................................................26

Warninglabels (1.7.2)............................................8

Page 3 of 46

Page 4

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

1 INTRODUCTION AND SAFETY

1.1 General

These instructions must always be kept close

to the product's operating location or directly with

the product.

Flowserve productsare designed,developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit isproduced with greatcare

and commitment to continuous quality control, utilizing

sophisticated quality techniques, and safety

requirements.

Flowserve iscommitted to continuous quality

improvement and being atservice for any further

information about the product in its installation and

operation or aboutits support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructionsis importantto help ensure reliability in

service and avoid risks. The instructions maynot take

intoaccount local regulations; ensure such regulations

are observed byall, including those installing the

product.Always coordinate repair activity with

operations personnel, and followall plant safety

requirementsand applicable safetyand healthlaws

and regulations.

These instructions must be readprior to

installing, operating, using andmaintaining the

equipment in any region worldwide. The

equipment must not be put into service until all the

conditions relating to safety noted in the

instructions, have beenmet.

1.2 CEmarking and approvals

It isa legal requirement that machinery and equipment

put into service within certain regions of the world shall

conform with the applicable CE Marking Directives

covering Machinery and, whereapplicable, Low

Voltage Equipment, Electromagnetic Compatibility

(EMC), Pressure Equipment Directive (PED) and

Equipment for Potentially Explosive Atmospheres

(ATEX).

To confirm the Approvalsapplying andif the productis

CEmarked, check the serial numberplate markings and

the Certification.(See section9, Certification.)

1.3 Disclaimer

Information in these User Instructions is believed to

be reliable. In spite of all theefforts of Flowserve

Pump Divisionto provide sound andall necessary

information the content ofthis manual may appear

insufficientand is notguaranteed by Flowserve as to

its completeness or accuracy.

Flowservemanufacturesproductstoexacting

International QualityManagement System Standards as

certifiedandaudited byexternal Quality Assurance

organizations. Genuine parts andaccessorieshave been

designed, testedandincorporatedinto theproducts to

helpensuretheircontinuedproduct quality and

performancein use.AsFlowserve cannottest parts and

accessories sourced from other vendorstheincorrect

incorporation of such partsand accessoriesmay

adversely affect the performanceand safety features of

theproducts. The failure to properly select,install oruse

authorized Flowserve parts andaccessoriesis

considered to bemisuse. Damageor failure caused by

misuse is notcoveredby the Flowserve warranty. In

addition, any modification of Flowserveproducts or

removal of original components mayimpair the safetyof

these productsin theiruse.

1.4 Copyright

All rightsreserved. No part of these instructionsmay

be reproduced, stored in a retrieval system or

transmittedin any form or byany meanswithout prior

permission of Flowserve Pump Division.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditionshas been sent

separately to the Purchaser. Acopy should be kept

with these instructions.

The product must not be operated beyond

the parameters specified for theapplication. If

there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice, quoting the serial number.

Where applicablethe Directivesand any additional

Approvals coverimportant safety aspects relating to

machineryand equipment andthe satisfactoryprovision

of technical documentsand safetyinstructions. Where

applicablethisdocument incorporatesinformation

relevant to these Directivesand Approvals.

Page 4 of 46

If the conditions of service on your purchase order are

going to be changed (for example liquid pumped,

temperature or duty) itis requested that the user seeks

the written agreementof Flowserve before start up.

Page 5

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

1.6 Safety

1.6.1 Summary of safetymarkings

These User Instructionscontain specificsafetymarkings

where non-observance of aninstruction would cause

hazards.The specific safetymarkings are:

This symbol indicateselectrical safety

instructionswhere non-compliance will involve a high

risk to personal safety orthe lossof life.

This symbol indicatessafety instructions where

non-compliance would affect personal safety and could

result in lossof life.

This symbol indicates “hazardous substances and

toxic fluid” safety instructions where non-compliance

would affect personal safetyand could result in lossof

life.

This symbol indicatessafety instructions

where non-compliance will involve some riskto safe

operation and personal safetyand woulddamage the

equipment orproperty.

1.6.3 Safety action

This is a summary of conditionsand actions to

prevent injury to personnel and damage to the

environment and to equipment. For products used

in potentially explosive atmospheres section1.6.4

also applies.

NEVER DOMAINTENANCE WORK

WHEN THE UNIT IS CONNECTEDTO POWER

GUARDS MUST NOT BE REMOVED WHILE

THE PUMP IS OPERATIONAL

DRAIN THE PUMP AND ISOLATE PIPEWORK

BEFORE DISMANTLINGTHE PUMP

The appropriate safety precautions should be taken

where the pumped liquids are hazardous.

FLUORO-ELASTOMERS (When fitted.)

When a pump has experienced temperaturesover 250

ºC (482 ºF), partial decomposition offluoro-elastomers

(example: Viton) will occur. In this condition these are

extremely dangerousand skin contact must be

avoided.

This symbol indicatesexplosive atmosphere

zone marking according to ATEX. Itisused in safety

instructionswhere non-compliance in the hazardous

area would cause the riskof an explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaceswith a dry

cloth; ensure cloth is damp.It isused where non-

compliance in the hazardousarea would cause the risk

of an explosion.

This signis not a safety symbol butindicates

animportant instruction inthe assembly process.

1.6.2 Personnel qualification and training

All personnel involvedin the operation, installation,

inspection and maintenance ofthe unit must be

qualified to carry out the work involved. If the

personnel in questiondo not already possessthe

necessary knowledge and skill, appropriate training

and instruction must be provided. If required the

operatormay commission themanufacturer/supplier to

provide applicable training.

Always coordinate repair activity with operationsand

health and safety personnel,and follow all plant safety

requirementsand applicable safetyand healthlaws

and regulations.

HANDLING COMPONENTS

Many precision partshave sharp corners and the

wearing ofappropriate safetygloves and equipmentis

required when handling these components. To lift

heavy piecesabove 25 kg (55 lb) use a crane

appropriate for the massand in accordance with

current local regulations.

THERMAL SHOCK

Rapid changes in the temperature of theliquid within

the pump can cause thermal shock, which can result in

damageor breakage of componentsand should be

avoided.

NEVERAPPLY HEAT TO REMOVE IMPELLER

Trappedlubricant or vapourcould cause an explosion.

HOT (and cold) PARTS

If hot orfreezing componentsor auxiliary heating

supplies can present a danger to operatorsand

persons entering the immediate area actionmust be

taken to avoid accidental contact. If complete

protection is notpossible, the machine accessmust be

limited to maintenance staff only,with clear visual

warningsandindicatorsto those entering the

immediate area.Note: bearing housingsmust not be

insulated and drive motors and bearings maybe hot.

If the temperature is greater than 68 °C (175 °F) or

below 5 °C (20 °F) in a restricted zone, or exceeds

local regulations, action as above shall be taken.

Page 5 of 46

Page 6

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

HAZARDOUS LIQUIDS

Whenthe pump ishandling hazardousliquidscare must

be taken to avoid exposure to the liquid by appropriate

sitting ofthe pump,limiting personnel accessand by

operatortraining. If theliquid isflammable and/or

explosive, strict safety proceduresmust be applied.

Gland packing must not be used when pumping

hazardous liquids.

PREVENT EXCESSIVE EXTERNAL

PIPE LOAD

Do not use pump asa support for piping. Do not mount

expansion joints, unlessallowed by Flowservein

writing, so that their force, due tointernal pressure,

acts on the pump flange.

ENSURE CORRECT LUBRICATION

(See section 5, Commissioning, startup, operation and

shutdown.)

START THE PUMPWITHOUTLET

VALVE PART OPENED

(Unless otherwiseinstructed at a specific point in the

User Instructions.)

This is recommended to minimize the riskof

overloading and damaging the pump motor at full or

zero flow. Pumpsmay be started with the valve further

open only oninstallations where this situation cannot

occur. Pumpoutlet valve shall may need to be

adjusted to comply with the duty following the run-up

process. (See section 5, Commissioning start-up,

operation and shutdown.)

NEVER RUNTHE PUMP DRY

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

Avoid excess temperature.

Prevent build up of explosive mixtures.

Prevent thegeneration of sparks.

Preventleakages.

Maintain the pump to avoid hazard.

The following instructions forpumpsandpump units

wheninstalledinpotentially explosive atmospheres

must be followed tohelp ensure explosion protection.

Both electrical andnon-electrical equipment mustmeet

the requirementsofEuropean Directive 94/9/EC.

1.6.4.1 Scope of compliance

Use equipmentonlyin the zone for whichitis

appropriate. Always check thatthe driver, drivecoupling

assembly, seal andpump equipmentare suitably rated

and/or certifiedfor the classificationof the specific

atmospherein which theyare tobeinstalled.

Where Flowserve hassupplied only the bare shaft

pump, the Ex rating applies only to thepump. The party

responsibleforassembling the pump set shall selectthe

coupling,driverandany additional equipment, with the

necessary CE Declarationof Conformity establishing it

issuitable for the area in which itis to be installed.

The output from a variable frequency drive (VFD)can

cause additional heating affectsin themotorand so, for

pumpssetswith a VFD, the ATEX Certification for the

motormust statethatitis coversthe situation where

electrical supplyis from the VFD.This particular

requirement still applies evenif the VFDis in a safearea.

INLET VALVES TO BE FULLYOPEN

WHEN PUMP IS RUNNING

Running the pump at zero flow orbelow the

recommended minimum flow continuously will cause

damage to the seal.

DO NOT RUN THE PUMPAT

ABNORMALLY HIGH ORLOW FLOW RATES

Operating at a flow rate higher than normal or at a flow

rate with no backpressure on the pump may overload

the motor and cause cavitations. Low flow rates may

cause a reduction in pump/bearinglife, overheating of

the pump,instability and cavitations/vibration.

Page 6 of 46

Page 7

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

1.6.4.2 Marking

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

II 2 GD c IIC135 ºC (T4)

Equipment Group

I =Mining

II = Non-mining

Category

2 orM2 = Highlevel protection

3 = normallevel of protection

Gas and/or Dust

G = Gas; D= Dust

c = Constructional safety

(in accordance with prEn13463-5)

Gas Group (Equipment Category2 only)

IIA –Propane (typical)

IIB –Ethylene (typical)

IIC –Hydrogen (typical)

Maximum surface temperature (Temperature Class)

(see section 1.6.4.3)

1.6.4.3 Avoiding excessive surface temperatures

ENSURE THE EQUIPMENT TEMPERATURE

CLASS IS SUITABLE FORTHE HAZARD ZONE

Pumpshave a temperatureclassas stated in the

ATEX Exrating on the nameplate. These are based on

a maximum ambient of 40 °C (104 °F); refer to

Flowserve forhigher ambient temperatures.

The surface temperature on thepump is influenced by

the temperature of theliquid handled. The maximum

permissible liquid temperature depends on the

temperature classand must notexceed the values in

the table that follows.

The temperature rise at the seals, bearingsand due to

the minimum permitted flow rate is taken into account

in the temperatures stated.

Temperaturelimit of liquid

handled (* depending on

materialandconstruction

variant - check which is

lower)

Consult Flowserve

Consult Flowserve

115 °C (239°F) *

180 °C (356°F) *

275 °C (527°F) *

400 °C (752°F) *

Temperature

class to

prEN 13463-1

T6

T5

T4

T3

T2

T1

Maximum

surface

temperature

permitted

85°C (185°F)

100 °C (212°F)

135 °C (275°F)

200 °C (392°F)

300 °C (572°F)

450 °C (842°F)

The responsibility for compliance with the specified

maximum liquid temperature is with the plant

operator.

Temperature classification “Tx” is used when the liquid

temperature variesand the pump could be installed in

differenthazardous atmospheres. In thiscase the user

isresponsible for ensuring that the pump surface

temperature doesnot exceed that permitted in the

particular hazardous atmosphere.

If an explosive atmosphere exists during the

installation, do notattempt to check the direction of

rotation by starting the pump unfilled. Even a short run

time maygive a high temperature resulting from

contact between rotating and stationary components.

Where thereis any riskof thepump being run against a

closed valve generating high liquid and casing external

surface temperaturesit is recommended that users fit

an external surface temperature protectiondevice.

Avoid mechanical, hydraulic or electrical overload by

using motor overload trips, temperaturemonitor or a

powermonitor and make routine vibration monitoring

checks.

In dirty or dusty environments, regular checks must be

made and dirt removed from areas around close

clearances, bearing housingsand motors.

1.6.4.4 Preventing the build up of explosive

mixtures

ENSURE PUMP IS PROPERLY FILLED AND

VENTED AND DOES NOT RUN DRY.

Ensure pump and relevant suction and discharge

pipeline system istotally filled with liquid at all times

during the pump operation, so that an explosive

atmosphere is prevented. In addition itis essential to

make sure that seal chambers, auxiliary shaft seal

systems and any heating and cooling systems are

properly filled.

If the operation of the system cannot avoid this

condition the fitting of an appropriate dry run protection

device is recommended (eg liquid detection or power

monitor).

To avoid potential hazards from fugitive emissionsof

vapour or gasto atmospherethe surroundingarea

must be well ventilated.

Page 7 of 46

Page 8

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

1.6.4.5 Preventingsparks

To prevent a potential hazardfrom mechanical

contact, the coupling guard must be non-sparking.

To avoid the potential hazardfrom random induced

current generating a sparkthe ground contacton the

baseplatemust be used.

Avoid electrostatic charge: do not rub nonmetallic surfaceswith a dry cloth, ensure cloth is

damp.

The couplingmust be selected to comply with 94/9/EC

and correct alignment must be maintained.

Additional requirements for metallic pumps on

non-metallic baseplates

When metallic components are fitted on a non-metallic

baseplate they must be individually earthed.

1.6.4.6 Preventing leakage

The pump must only be used to handle liquids

for which it has been approved to have the correct

corrosion resistance.

Where there is a riskfrom such tools or materials;

maintenancemust be conducted in a safe area.It is

recommended that a maintenance plan and schedule

isadopted. (See section 6, Maintenance.)

1.7 Safety labels summary

1.7.1 Nameplate

For details of nameplate, see the Declaration of

Conformity, or separate documentation included with

these User Instructions.

1.7.2 Warning labels

Avoidentrapmentofliquid in the pumpand associated

piping dueto closing of suctionand discharge valves,

which couldcause dangerousexcessive pressuresto

occurif there isheatinput to the liquid.Thiscanoccurif

thepump is stationaryor running.

Bursting of liquid containing partsdue to freezing must

be avoided by draining or protecting the pump and

ancillary systems.

Where there is the potential hazard of alossof a seal

barrier fluid or external flush, the fluid must be

monitored.

If leakage ofliquid to atmosphere can resultin a

hazard, the installationof a liquid detection device is

recommended.

1.6.4.7 Maintenance to avoid the hazard

CORRECT MAINTENANCE IS REQUIREDTO

AVOID POTENTIAL HAZARDS WHICH GIVE A RISK

OF EXPLOSION

The responsibility forcompliance withmaintenance

instructions is with the plant operator.

Oil lubricated units only:

1.8 Specific machine performance

For performance parameterssee section 1.5, Duty

conditions. When the contract requirement specifies

these to beincorporated into User Instructions these

are included here. Where performance data hasbeen

supplied separately to the purchaser these should be

obtained and retained with these User Instructions if

required.

To avoid potential explosion hazards during

maintenance, the tools, cleaning and painting

materials used must not give rise to sparking or

adversely affect the ambient conditions.

Page 8 of 46

Page 9

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

1.9 Noise level

When pump noise level exceeds 85dBA attentionmust

be given to prevailing Health and Safety Legislation, to

limit the exposure of plantoperating personnel to the

noise. The usual approach is to control exposure time

to the noise or to enclose the machine to reduce

emitted sound. Youmay have already specified a

limitingnoise level when the equipment was ordered,

however if no noise requirements were defined then

machines above a certain power level will exceed 85

dB(A). In such situations consideration must be given

to the fitting of an acoustic enclosure to meetlocal

regulations.

Pumpnoise level isdependent on a numberof factors

- the type of motor fitted, theoperating capacity,

pipeworkdesign and acoustic characteristics of the

building. Typical sound pressure levelsmeasured in

dB and A-weighted are shown in the table below.

The figures are indicative only, theyare subject to a +3

dB tolerance, and cannot be guaranteed.

The values are based on the noisiest ungeared electric

motorswhich are likely to be encountered.Theyare

LpAsound pressure levels at 1m (3.3ft) from the

directly driven pump, for "free field over a reflecting

plane". For estimating LwAsound powerlevel (re 1 pW)

add 14 dB(A) to the sound pressure value.

If a pump only hasbeen purchased, for fitting with your

own driver, then the "pump only" noise levelsfrom the

table should be combined with thelevel forthe driver

obtained from the supplier. If the motor is driven by an

inverter, it may showan increase in noise level at

some speeds. Consult a Noise Specialist for this

calculation

For units driven by equipmentother than

electric motors or unitscontained within enclosures,

see the accompanying information sheetsand

manuals.

Typicalsoundpressure level, dBA,LpA at 1 m reference 20 μPa (LwAsound power1 pWwhere LpA>85 dBA)

and speed

kW (hp)

5.5 (7.5)

7.5 (10)

11 (15)

15(20)

18.5(25)

22(30)

30(40)

37(50)

45(60)

55(75)

75(100)

90(120)

110 (150)

150 (200)

200 (270) * * * * * 83 * 80

300 (400) - - - - * 84 * 81

500 (670) - - - - *

* Motors inthis rangeare generallyjobspecific and noiselevelsshould be calculated based onactual equipmentinstalled.

For 960 rpmreduce 1450rpm values by 5 dBA.

3550 r/min 2900 r/min 1750 r/min 1450 r/minMotor size

Pump and

motor

dBA

90(99)

90(99)

91(100)

92(101)

92(101)

92(101)

100 (109) 85(94) 93(102)

100 (109) 86(95) 93(102)

100 (109) 87(96) 93(102)

100 (109) 88(97) 95(104)

100 (109) 90(99) 95(104) 86(95) 88(97)

100 (109) 90(99) 95(104) 86(95) 90(99)

100 (109) 91(100) 95(104) 87(96) 91(100)

101 (110) 92(101) 96(105) 88(97) 91(100)

Pump

only

dBA

77 83 73 76 73 72 71

78 83 74 77 74 73 72

80 84 76 78 76 74 73

83

83

83

Pump and

motor

dBA

85(94)

85(94)

85(94)

Pump

only

dBA

79 80 79 76 75

79 80 79 76 75

79 81 79 77 75

81 84 80 80 76

82 84 80 80 76

83 84 80 80 76

84

Pump and

motor

dBA

86(95)

Pump

only

dBA

81 82 77

81 83 78

81

83

83

85(94)

Pump and

motor

dBA

85(94)

86(95)

86(95)

* 83

Pump

only

dBA

78

79

79

Page 9 of 46

Page 10

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

In areas where the staff hasto intervene, remember

that when the level of the sound pressure is:

Below 70dBA :It is not necessary to take

special precautions.

Above 70 dBA :People working continuously in

the machine room must be

supplied with protective devices

against noise.

Below 85dBA :No particular measuresneed to be

taken for casual visitorsstaying in

the room during a limitedperiod.

Above 85 dBA :The room must be considered as a

dangerousarea because of the

noiseand a warning sign must be

fixed at each entry warning the

people coming into the room, even

for a short period, that they must

wear hearing protection.

Above 105 dBA:Special hearing protection adapted

to this noise level and to the

spectral noise componentsmust

beinstalled and a warning sign to

this effect erected at each entry.

The staff in the room must wear

ear protection.

Each product has a unique serial number. Checkthat

this number corresponds with that advised and

always quote this numberin correspondence aswell

as when ordering spare parts or furtheraccessories.

2.2 Handling

2.2.1 General instructions concerning handling

Boxes, crates, pallets or cartons maybe unloaded

using fork-lift vehiclesor slings dependent on their

size and construction. See 2.3.1 for positioning of

slings.

To lift heavy piecesabove 55 lb (25 kg), use a crane

corresponding to the massand in accordance with

the current local regulations.

To lift machines or pieces with one or several lifting

rings, only use hooksand chainsin compliance with

the local regulations concerning safety. Never put

cables, chainsor ropesdirectly on orin the lifting

rings. Cables, chains orlifting ropes must never

present excessive bending.

Never bend thelifting hooks, lifting rings, chains,

etc...They are only made to endurestresses within

calculated limits. Remember that the capacity of a

lifting device decreases when the direction of the

lifting force direction makes an angle with the device

axis.

Make sure that the noise, which travels through the

wallsand windows, does notgenerate too high noise

levels in the machine room's surroundings.

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery and shipping documents

for its completenessand thatthere has been no

damagein transportation.

Any shortage and ordamage must be reported

immediately to Flowserve Pump Division and

received in writing within one month ofreceipt of the

equipment. Later claims cannot be accepted.

Check any crate, boxesand wrappingsfor any

accessories or spare parts thatmay be packed

separately with the equipmentor attached to side

wallsof the boxor equipment.

To increase the safety and efficiency of the lifting

device, all the lifting elementsmust be as

perpendicular as possible. If necessary a lifting beam

can be placed between the crane and theload.

When heavy piecesare lifted up, never stay or work

under theload or in the area which could be in the

path of the load if it were to swing or fall away. Never

leave a load hanging from a crane. The acceleration

or the deceleration of lifting equipment must stay in

the safetylimits for the staff.

A crane must be positioned in such a way that the

load will be raised perpendicularly. Where possible

necessary precautions must be taken to avoid the

swing of the load. For example use two winches

making approximately the same angle,lessthan 30°,

with the vertical.

Page 10 of 46

Page 11

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

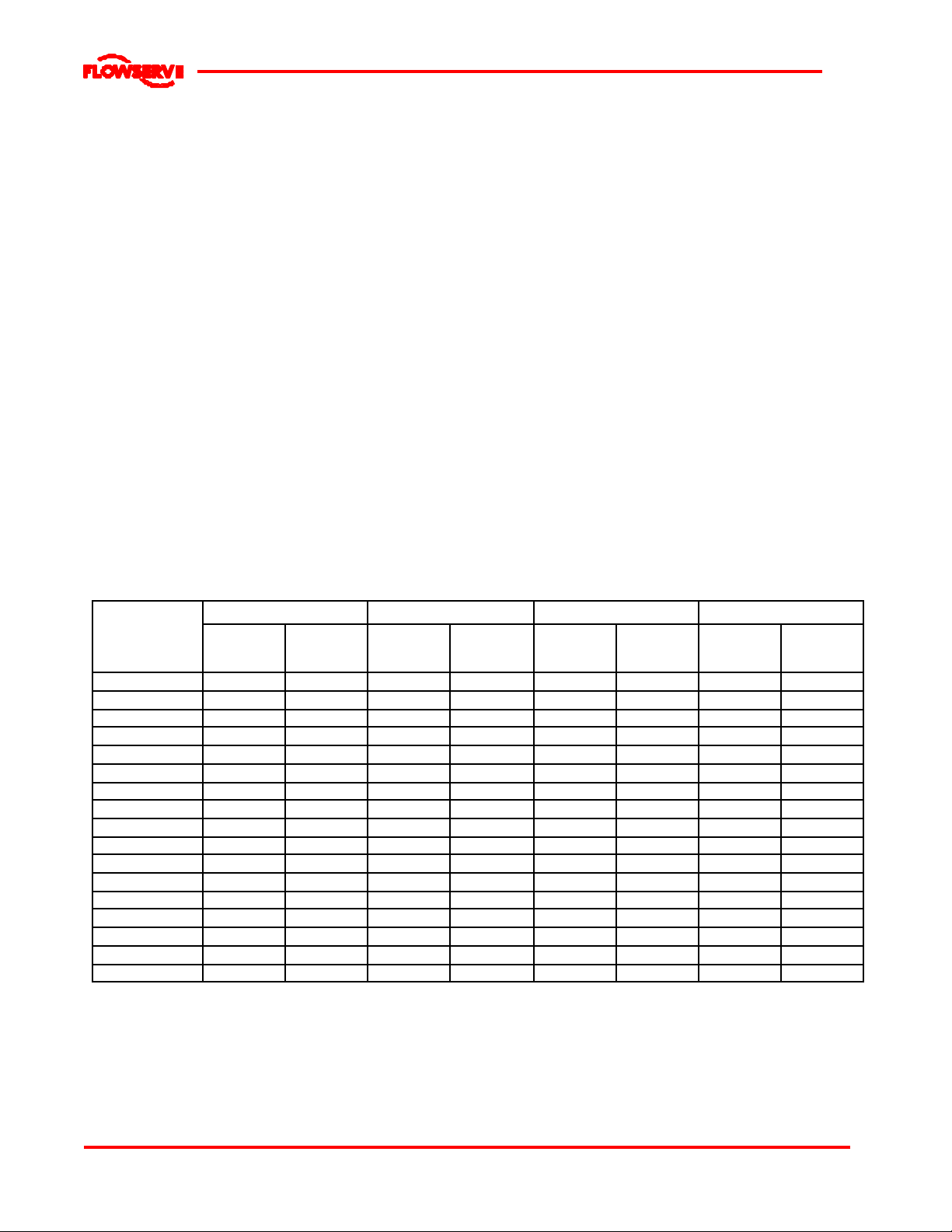

2.2.2 Pump masses

All masses, in the table below,are for 3 stages, in

construction M2.

PUMP

SIZE

1.5WDX

2WDX

3WDX

4WDX

MET PUMP MASS

WDXR/C WDXE WDXS

lb kg lb kg lb kg lb kg

Non

298 135 271 123 243 110 23

cooled

Cooled

309 140 295 134 267 121 23

Non

355 161 315 143 302 137 31

cooled

Cooled

386 175 342 155 328 149 31

Non

483 219 450 204 421 191 46 21

cooled

Cooled

516 234 478 217 450 204 46 21

Non

661 300 606 275 562 255 60 27

cooled

Cooled

694 315 628 285 606 275 60 27

MASS

PER

STAGE

All masses, in the table below,are for 3 stages, in

construction M3,M4, M5, M6, M7.

To avoid distortion, the pump unit

should belifted asshown.

Motor pump unit

10.5

10.5

14

14

PUMP

SIZE

MET PUMP MASS

WDXR/C WDXE WDXS

MASS

PER

STAGE

lb kg lb kg lb kg lb kg

Non

324 147 298 135 260 118 25

1.5WDX

cooled

Cooled

335 152 322 146 293 133 25

Non

375 170 335 152 322 146 34

cooled

2WDX

Cooled

406 184 362 164 348 158 34

Non

527 239 494 224 465 211 51 23

3WDX

4WDX

cooled

Cooled

560 254 522 237 494 224 51 23

Non

710 322 650 295 602 273 66 30

cooled

Cooled

743 317 672 305 694 315 66 30

2.3 Lifting

2.3.1 Slinging of motor pumps units

Use handlingmeans in accordance with motor

pump unit massmentionedon the CE plate.For the

massesof the pumps bare end of shaft see table §

2.2.2 and nameplate.

11.5

11.5

15.5

15.5

When handling always wear gloves, safety

shoes and an industrial safety helmet.

For massesabove 55 lb (25 kg), manual

handling is forbidden.

Page 11 of 46

Page 12

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

2.4 Storage

Store the pump in a clean, dry location

away from vibration. Leave piping connection covers

in place to keep dirtand other foreignmaterial out of

pump casing.Turn pump at intervalsto prevent

brinelling of the bearings and the seal faces, if fitted,

from sticking.

Do not store pumps starting on the fanguard.

The pump maybe stored asabove forup to 6

months. Consult Flowserve forpreservative actions

when a longer storage period is needed.

2.5 Recycling and end of product life

At the end of the service life of the product orits

parts, the relevant materials and partsshouldbe

recycled or disposed of using an environmentally

acceptable method and local regulations.

If the product contains substances which are harmful

to the environment,these should be removed and

disposed of in accordance with currentregulations.

This also includes the liquidsand or gases in the

"seal system" or otherutilities.

Make sure that hazardous substances or toxic

fluid are disposed of safely and that the correct

personal protective equipment isused. The safety

specifications must be in accordance with the current

regulations at all times.

Horizontal

WDXR

Radial suction

Driveend on dischargeside- CW

Thrustbearing ondriveside

Radial bearing onsuction side

2shaftseals

WDXC

Horizontal

Radial suction

Driveend on suction side- CCW

Thrustbearing onsuctionsi de

Radial bearing ondischargeside

2shaftseals

3 PUMP DESCRIPTION

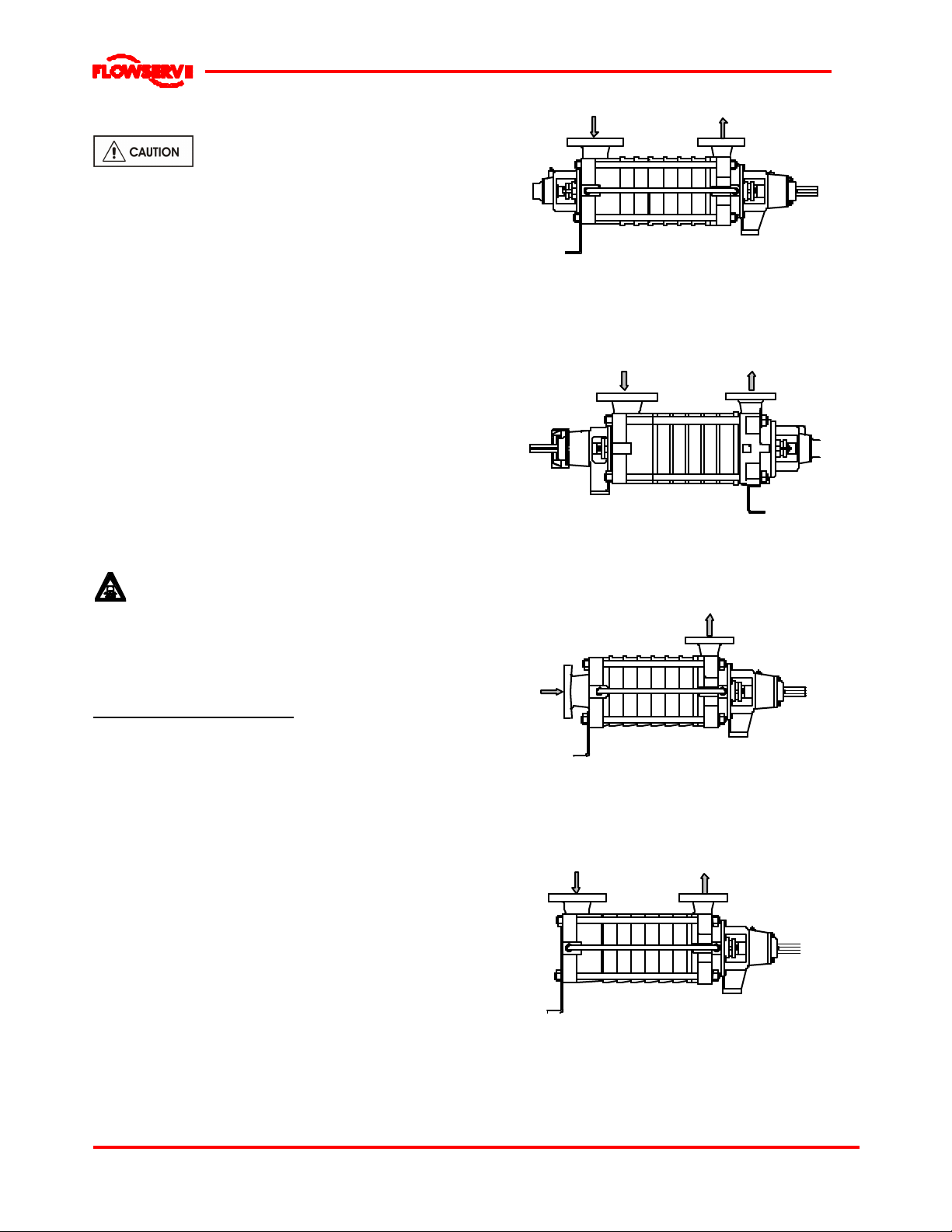

3.1 Configurations

The WDX type pump isa horizontal,multistage,

radial split case, vaned diffuser type centrifugal pump

equipped with a special suctionimpeller for low

NPSH. It can be used with motor, steam turbine and

gasoline ordiesel engine drives.

The WDX pumpsare of modular construction with

identical stages being stacked axially to achieve the

desired pressure output. Four high strength external

tie rods connecting the two end casingshold them

together. A variety of optimal features and materials

allow it to fit a wide range of applications such as

boiler feed or reverse osmosis.

Various orientationsfor the radial suction and

discharge nozzles are allowed every 90°except

towardsthe bottom.

The WDX can have the following configurations:

Horizontal

WDXE

End suction

Driveend on dischargeside- CW

Thrustbearing ondriveside

Sleeve bearing on suctionside

1shaftseal

WDXS

Horizontal

Radial suction

Driveend on dischargeside- CW

Thrustbearing ondriveside

Sleeve bearing on suctionside

1shaftseal

Page 12 of 46

Page 13

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

Year of construction +

Maximumadmi

ssible

Maximum/ minimum

3.2 Nomenclature

Characteristics shown on the nameplate fixed on the pump are as shown below:

Each pump issupplied with the following nameplate:

Speed ofrotation

Pump type

Flowrate

Head

Radial/thrust bearing

Manufacturenumber

Each pump unitis supplied with the following nameplate:

Mass

Pressure at 20°C

temperature

Mass of the set

The pump size will be engraved on the nameplate

typicallyas below:

4 WDX E 6 D

Nominal discharge branch size.

Seriesname

Configuration (see 3.1 above)

Number of stages

Hydraulic type

The typical nomenclatureabove is the general guide

to the WDX configuration description. Identify the

actual pump size and serial numberfrom the pump

nameplate. Checkthat this agrees with the applicable

certification provided.

3.3 Design of major parts

3.3.1 Pump casing

The pump casings(suction, discharge and stage) are

sealed with o’rings and designed to contain the

pressures generated by the pump at the various

possible design pressures and temperatures.

3.3.2 Impeller

Theimpeller is fully shrouded and may be fitted with

optional wear rings.

The suction impelleris specifically designed to have a

low NPSH requirement.

3.3.3 Diffuser

The diffusersare fully machined to optimise

performance.

3.3.4 Shaft

The shaft mounted on bearings with a keyed drive

end.

Page 13 of 46

Page 14

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

3.3.5 Pump bearings andlubrication

WDX pumpsare designed so the antifriction bearings

may be either oil orgrease lubricated.

WDXE and WDXS have product lubricated line

bearingswith sleeve andbushing made of silicon

carbide.

Bearingisolators or stationarylabyrinths maybe fitted

as an optionin the bearing coversto protect the

bearings.

3.3.6 Bearing housing

Grease nipplesenable grease lubricated bearings to

be replenished between major service intervals. For

oil-lubricated bearings, a constant level oilerisfitted.

3.3.7 Stuffing box housing

The stuffing box housing hasa spigot (rabbet) fit

between the pump casing and bearing housing for

optimum concentricity. The design enablesa number

of sealing optionsto be fitted.

3.3.8 Shaft seal

Themechanical seal(s) attached to the pump shaft

sealsthe pumped liquid fromthe environment.

Stuffing boxeshave been designed for component or

cartridge seals. Glandpackingmay be fitted as an

option.

3.3.9 Driver

The driver isnormallyan electricmotor.Differentdrive

configurationsmaybe fitted such asinternal combustion

engines, turbines, hydraulicmotorsetcdriving via

couplings,belts,gearboxes,drive shaftsetc.

3.3.10 Accessories

Accessories may be fitted when specified by the

customer.

3.4 Materials of construction

Material

column

M2 Castiron Cast iron Chrome steel

M3 Carbonsteel Castiron Chrome steel

M4 Carbonsteel

M5 Chrome steel

M6

M7 Stainless steel

Casing Impeller Shaft

Duplex

stainless steel

Stainless

steel

Stainless

steel

Stainless

steel

Stainless

steel

Chrome steel

Chrome steel

stainless steel

stainless steel

Duplex

Duplex

3.5 Performance and operating limits

This product has been selected to meet the

specifications of your purchase order.See the

nameplate and section 1.5.

Themaximumallowable speed forcast iron

impellersis3600RPMand for steel impellersis4000

RPM.

3.5.1Minimal flow

20 % of BEP up to 280° F (140 °C)

25 % of BEP between 280 °F (140 °C) and 410 °F

(210 °C)

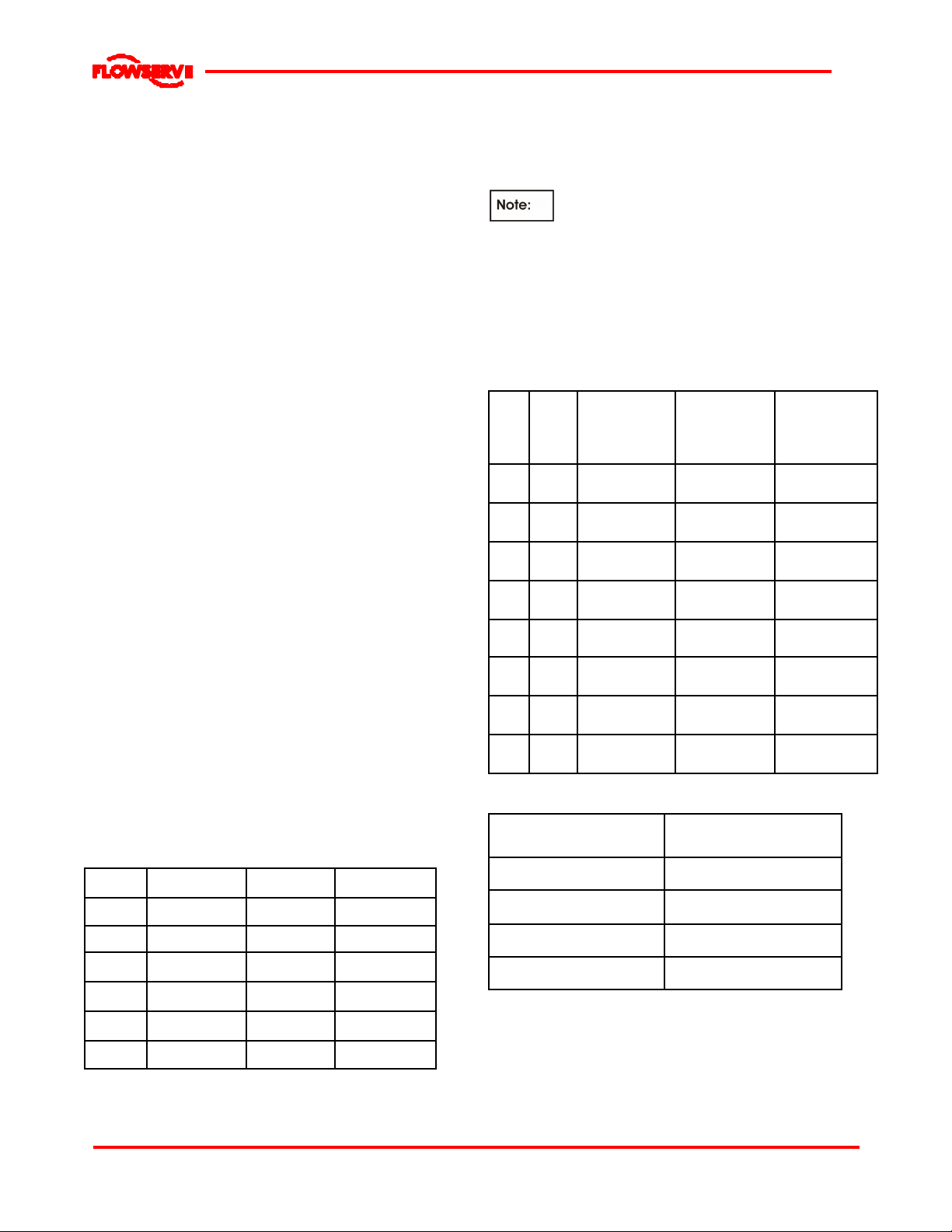

3.5.2 Clearance data

Nominal

Interstage

clearance

min/max

mm(inch)

0.170/0.259

(0.0067/0.0102)

0.170/0.259

(0.0067/0.0102)

0.170/0.259

(0.0067/0.0102)

0.170/0.259

(0.0067/0.0102)

0.200/0.303

(0.0079/0.0119)

0.200/0.303

(0.0079/0.0119)

0.200/0.303

(0.0079/0.0119)

0.200/0.303

(0.0079/0.0119)

Size

Mat

M2M30.170/0.259

1.5

M4 toM70.320/0.409

1.5

M2M30.170/0.259

2

M4 toM70.330/0.419

2

M2M30.200/0.303

3

M4 toM70.360/0.463

3

M2M30.200/0.303

4

M4 toM70.410/0.513

4

Nominalwear

ringclearance

min/max

mm(inch)

(0.0067/0.0102)

(0.0126/0.0161)

(0.0067/0.0102)

(0.0130/0.0165)

(0.0079/0.0119)

(0.0142/0.0182)

(0.0079/0.0119)

(0.0161/0.0202)

3.5.3 Sleeve bearing clearance (WDXE/S)

Pump size

1.5 WDX

2WDX

3WDX

4WDX

Diametral clearance

min/max

mm(inch)

0.007 - 0.041

(0.0003- 0.0016)

0.007 - 0.041

(0.0003- 0.0016)

0.007 - 0.041

(0.0003- 0.0016)

0.007 - 0.041

(0.0003- 0.0016)

3.5.4 Bearing bushings

Interstage bearing bushings can bemounted on the

pump. Their numberand location depend on the

material chosen and the number of stagesof the

pump. For furtherinformation, see general

arrangement drawing ofthepump.

Nominal

Balancedrum

clearance

min/max

mm(inch)

0.150/0.226

(0.0059/0.0089)

0.300/0.376

(0.0118/0.0148)

0.170/0.259

(0.0067/0.0102)

0.470/0.559

(0.0185/0.0220)

0.170/0.259

(0.0067/0.0102)

0.480/0.569

(0.0189/0.0224)

0.180/0.269

(0.0071/0.0106)

0.500/0.603

(0.0197/0.0237)

Page 14 of 46

Page 15

3.6 Coverage charts

3.3.1 2970 min-1(50 Hz): coverage charts (Q, H)

3.3.2 3550 min-1(60 Hz): coverage charts (Q, H)

Page 16

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

4 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations. See section 1.6.4, Products usedin

potentially explosive atmospheres.

All equipment must be grounded.

4.1 Location

The pump should be located to allow room for

access, ventilation, maintenance and inspection with

ample headroom forlifting and should beasclose as

practicable to the supplyof liquid to bepumped.

The pump should be located above the floodlevel.

The pipework should be such that thereis an

adequate NPSH at the pump centreline.The

foundation should provide enough support so that the

pump is not supported by the pipework.

Refer to the general arrangementdrawing for the

pump set.

4.2 Cleaning prior to installation

Remove glue and dirt from suction and discharge

flanges. Check motors to make sure no foreign

objects haveentered through fan and cooling

openings. Remove any compounds on exposed

areasof pump shaft. Cleanpump and motor

nameplate.

A unit mounted on steel workor structural members

should bemounted over oradjacent to girdersor

wallsso that no misalignment will occur from yielding

or sagging of the structure.

Anchor boltsmust be in accordance with the foot bolt

holes. Use anchor bolts of accepted standards and

sufficient to ensure seave fitting in the foundation.

Particularly, thisapplies to individual plateswhere the

anchor boltshave to withstand the driving torque.

Provide sufficient space in the foundation to

accommodate the anchorbolts. Ifnecessary, provide

concrete risers.

4.3.2 Positioning on foundation

Pumpsare generallyshipped mounted, andit is

usuallyunnecessary with unitsof moderate size to

remove the pump or driver from its baseplate when

levelling.

Ensure the following are met:

a) Clean the foundation thoroughly.

b) The baseplate should be mounted onto a firm

foundation, either an appropriate thicknessof

quality concrete or sturdy steel framework

capable of absorbing all normal vibrations. (It

should NOT be distorted or pulled down onto the

surface of the foundation, butshould be

supported to maintain the original alignment).

c) Install the baseplate onto packing pieces evenly

spaced and adjacent to foundation bolts.

4.3 Foundation

Therearemanymethodsof installing

pump units to their foundations. The correct method

dependson the size of the pump unit, itslocation and

noise vibrationlimitations. Non-compliance with the

provision of correct foundation and installationmay

lead to failure of the pump and, assuch, would be

outside the terms of the warranty.

4.3.1 General recommendations

Foundation bolts should belocated or embedded in

the concrete by lay-out ortemplate in relation to the

suction and discharge piping. Foundation bolts of the

specified size maybe enclosed in a pipe sleeve two

or three diameterslarger than the boltsto

compensate forminor variationin alignment.

Standard accessory steel baseplates furnished with

these pumps and motors10 HP (7.5 kW) and under

may be bolted to machine or equipment structures,

either rigidly or,if flexible piping is used, with properly

designed vibration isolators.

d) Level with shims, about 25 mm (1”), between

baseplate and packing pieces.

e) Checkthe horizontal position by meansof a

precision level placed upon an adequate

reference (discharge flange, machined surfaces

of casings etc...).Tolerances within 0.5 mm per

m (0.006in per ft).

f) The pumpanddriver havebeenaligned before

dispatchhowever thealignmentofpump and motor

half couplingmustbe checked. Ifthisisincorrect,it

indicates that the baseplate hasbecome twisted

and should be corrected by re-shimming.

Page 16 of 46

Page 17

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

barriers

g) If anchorboltshave been embeddedin the

foundation, slightly tighten the anchor bolts.

Otherwise let them hang in the foundation holes.

h) If not supplied, guarding shall be fitted as necessary

to meet the requirementsofEN292and EN953 and

orany applicable local safety regulations.

4.4 Grouting

Where applicable, groutin the foundation bolts.

Grouting provides solid contact between the pump

unit and foundation prevents lateral movement of

running equipment and dampens resonant vibrations.

Prepare the site forgrouting.Beforegrouting clean

the foundation surface thoroughly. Provide external

barriers asshown:

4.5.1 Thermal expansion

The pump and motor will normally

have to be aligned at ambient temperatureand

should be corrected to allow for thermal expansion at

operating temperature. In pump installationsinvolving

high liquid temperatures, the unit should be run atthe

actual operating temperature, shut down and the

alignment checked immediately.

4.5.2 Alignment methods

Ensure pump and driver areisolated

electrically and the half couplings are disconnected.

Ensure that the pump pipework, suction and

discharge,is disconnected.

The alignment MUST be checked.

Although the pump will havebeen aligned at the

factoryit is most likely that this alignment will have

been disturbed during transportation or handling. If

necessary, align themotor to the pump, not the pump

to the motor.

Prepare grouting product (concrete, resin) in

accordance withmanufacturers' instructions.

(Use anti-shrink products)

To grout up to the required level. Polish surfaces.

Take necessary precautions to avoid air bubbles.

Lay-down the barrier, break external angles and

polish the different surfaces.

Foundation bolts should only be fully tightened when

the grout hascured.

4.5 Initial alignment

Pump-Driver unit supplied assembled on their

baseplate:

Themachines have originally been aligned in the

work-shop.

Pump and Driver supplied on separate baseplates:

Themachines have originally been mounted on their

respective baseplate in the workshop. The pumpis to

be installed first and should be considered as the

fixedpoint.The alignment is then performedon the

driveralone.

Before aligning verify that the pump is horizontal by

using a flange surface or otherhorizontal surface.

Adjust if necessary by adjusting the height of the

wobble foot. Tighten any nuts that have been

loosened.

Alignmentisachieved by adding or removing shims

under themotor feet and also moving the motor

horizontally as required. In some cases where the

alignment cannot be achieved it will be necessary to

move the pump before recommencing the above

procedure.

Before connecting the couplings verify

the motor rotation direction.

For couplings with narrow flangesuse a dial indicator

as shown below to check both parallel and angular

alignment.

Page 17 of 46

Page 18

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

Parallel

Angular

Maximum permissible misalignment at working

temperature:

Parallel 0.2 mm (0.008 in.)TIR

Angular 0.1 mm (0.004 in.) TIR

When checking parallel alignment, the total indicator

read-out (TIR) shown is twice the value of the actual

shaft displacement.

Alignin thevertical plane first, then horizontally by

movingmotor.When performing final alignment,check

for soft-foot under the driver. A TIR indicatorplacedon

the coupling, readingin the vertical direction, should not

indicate more than 0.05mm (0.002 in.)movement when

anydriverfoot fastenerisloosened.

Whilethe pumpiscapable of operating with the

maximum misalignment shownabove, maximum pump

reliabilityis obtained by nearperfect alignment of 0.05

to 0.10 mm (0.002 to0.004in.)TIRparallel and

0.05mm (0.002in.)per100mm (4in.) of coupling

flange diameter asTIR angular misalignment.This

coversthefull series of couplings available.

Pumpswith thick flanged non-spacer couplings can

be alignedby using a straight-edge across the

outsidediametersof the coupling hubsand

measuring the gap between the machined faces

using feeler gauges, measuring wedge or calipers.

When the electric motor has sleeve bearings it is

necessary to ensure that themotor isaligned to run

on its magnetic centreline.

Refer to themotor manual for details.

A button (screwed into one of the shaft ends)is

normally fitted between the motorand pump shaft

ends to fix the axial position.

If the motor does not run in its

magneticcentre the resultantadditional axial force

may overload the pump thrust bearing.

Complete piping asbelow and see sections4.7,

Final shaft alignment check up to and including

section 5, Commissioning, startup, operation and

shutdown before connecting driver and checking

actual rotation.

4.6 Piping

The user must verify that the equipment is

isolated from any external sources of vibration.

Protective coversare fitted to the pipe

connectionsto prevent foreign bodies entering during

transportation andinstallation. Ensure that these

coversare removed from the pump before connecting

anypipes.

4.6.1 Suction and discharge pipework

In order to minimize friction losses and hydraulic

noise in the pipeworkit is good practice to choose

pipeworkthatisone or two sizes larger than the

pump suction and discharge.Typicallymain pipework

velocitiesshould not exceed 2 m/s (6 ft/sec) suction

and 3 m/s (9 ft/sec) on the discharge.

Takeinto account the available NPSH must be higher

than the required NPSH of the pump. When

determining the NPSH available the vapour pressure

at the operating temperature must be taken into

account.

Never use the pump as a support for

piping.

Maximum forces and moments allowed on the pump

flangesvary with the pump size and type.To

minimize these forcesandmoments thatmay,if

excessive, cause misalignment, hot bearings, worn

couplings, vibration and the possible failure of the

pump casing, the following points should be strictly

followed:

Prevent excessive external pipe load

Never drawpiping into place by applying forceto

pump flange connections.

Do not mount expansionjoints so that their force,

due to internal pressure, acts on the pump flange.

It isrecommended that expansion jointsuse

threaded rod to limit any forcesof thistype.

Thermal expansions must be compensatedin

such a way that no additional forces act on the

pump flanges.

Make sure that piping flanges are square and

concentric to the pump flanges.

Page 18 of 46

Page 19

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

The table in 4.6.3 summarizes the maximum forces

and moments allowed on WDX pump casings. Refer

to Flowserve forother configurations.

Ensure piping and fittings are flushed

before use.

Ensure piping for hazardous liquids is arranged

to allow pump flushing before removal ofthe pump.

Excessive external strains(forces, moments)

may causemisalignment, general vibrations, hot

bearingsor excessive wear on couplingsand seals.

In extreme cases, leakage may result with potential

lossof life with hot or corrosive liquids.

4.6.2 Suction piping

Refer to the diagrams below for typical designs of

suction piping for both flooded suction and suction lift.

a) Theinlet pipe should be one or two sizes larger

than the pump inlet boreand pipe bends should

be as large a radius aspossible.

b) Pipeworkreducers should be conical and have a

maximum total angle of divergenceof 15 degrees.

c) Pipeworkshould be arranged to avoidair pockets.

d) If high pointscannot beavoided on the suctionline

equip them with air relief cocks.

e) On suction lift the piping should be inclined up

towardsthe pumpinlet with eccentric reducers

incorporated to prevent air locks.

f) On positive suction, the inlet piping must have a

constant fall towards the pump.

g) Flow should enterthe pump suction with uniform

flow, to minimize noise and wear. Thisis

particularly important on large or high-speed

pumpswhich should have a minimum of five

diameters of straight pipe on the pump suction

between the elbow and inlet flange. See section

10.3, Reference 1, for more detail.

h) Inlet strainers, when used, should have a net `free

area' of at least three times the inlet pipe area.

i) Do notinstall elbowsat an angle other than

perpendicular to the shaft axis. Elbowsparallel to

the shaft axis will cause uneven flow.

j) Except in unusual circumstancesstrainersare

not recommended in inlet piping. If considerable

foreign matter is expected a screen installed at

the entrance to the wet well is preferable.

k) Fitting anisolation valve will allow easier

maintenance.

l) If an inlet valve is necessary, choose a model

with full bore so as to limitlosses. Valve stem

should bein a vertical position. There should be

a minimum of five pipe diametersbetween the

pump and the valve.

m) Never throttle pump on suction side and never

place a valve directly on the pump inlet nozzle.

n) Do not tighten flanges before the final check.

Typical design –flooded suction

Note:

Ideallyreducers should be limited toone pipediameter change,

ie 150 mm (6 in.) to 200 mm (8 in.). Must have a maximumtotal

angleof divergence of15 degrees.

Typical design –suction lift

Notes:

1. S = Minimum submergence >3E.

2. Ideallyreducers to be limitedto one pipediameter change,

ie 150 mm (6 in.) to 200 mm (8 in.). Must have a maximumtotal

angleof divergence of 15 degrees.

Page 19 of 46

Page 20

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

4.6.3Maximum forces and momentsallowed on WDX pump flanges

Direction of forces

Fx = horizontal parallel to pump axis

Fy = horizontal perpendicular to pump axis

Fz = vertical perpendicular to pump axis

Direction of moments

Mx = around a horizontal axis parallel to pump axis

My = around a horizontal axis nozzle axis

Mz = around a horizontal axis perpendicular to pump axis

PIPE

CONFIGURATION

Vertical pipework 50 mm

perpendicular 3in

totheshaft 80 mm

Horizontal pipework 3 in

perpendicular 80 mm

totheshaft 4 in

Horizontal 4in

within the pump axis 100 mm

FLANGE FORCES MOMENTS

Diameter Fy Fz Fx F My Mz Mx M

1.5 in

40 mm

2in

4in

100 mm

6in

150 mm

1.5 in

40 mm

2in

50 mm

100 mm

6in

150 mm

3in

80 mm

6in

150 mm

130 lbf 200 lbf 160 lbf 290 lbf 170 ft-lbf 260 ft-lbf 340 ft-lbf 460 ft-lbf

58 daN 89 daN 71 daN 128 daN 23 daN.m 35 daN.m 46 daN.m 62 daN.m

130 lbf 200 lbf 160 lbf 290 lbf 170 ft-lbf 260 ft-lbf 340 ft-lbf 460 ft-lbf

58 daN 89 daN 71 daN 128 daN 23 daN.m 35 daN.m 46 daN.m 62 daN.m

200 lbf 300 lbf 240 lbf 430 lbf 350 ft-lbf 530 ft-lbf 700 ft-lbf 950 ft-lbf

89 daN 133 daN 107 daN 193 daN 47 daN.m 72 daN.m 95 daN.m 128 daN.m

260 lbf 400 lbf 320 lbf 570 lbf 500 ft-lbf 740 ft-lbf 980 ft-lbf 1330ft-lbf

116 daN 178 daN 142 daN 256 daN 68 daN.m 100 daN.m 133 daN.m 180 daN.m

460 lbf 700 lbf 560 lbf 1010 lbf 870 ft-lbf 1300 ft-lbf 1700ft-lbf 2310ft-lbf

205 daN 311 daN 249 daN 448 daN 118 daN.m 176 daN 230 daN.m 313 daN.m

130 lbf 200 lbf 160 lbf 290 lbf 170 ft-lbf 260 ft-lbf 340 ft-lbf 460 ft-lbf

58 daN 89 daN 71 daN 128 daN 23 daN.m 35 daN.m 46 daN.m 62 daN.m

130 lbf 200 lbf 160 lbf 290 lbf 170 ft-lbf 260 ft-lbf 340 ft-lbf 460 ft-lbf

58 daN 89 daN 71 daN 128 daN 23 daN.m 35 daN.m 46 daN.m 62 daN.m

200 lbf 300 lbf 240 lbf 430 lbf 350 ft-lbf 530 ft-lbf 700 ft-lbf 950 ft-lbf

89 daN 133 daN 107 daN 193 daN 47 daN.m 72 daN.m 95 daN.m 128 daN.m

260 lbf 400 lbf 320 lbf 570 lbf 500 ft-lbf 740 ft-lbf 980 ft-lbf 1330ft-lbf

116 daN 178 daN 142 daN 256 daN 68 daN.m 100 daN.m 133 daN.m 180 daN.m

460 lbf 700 lbf 560 lbf 1010lbf 870 ft-lbf 1300 ft-lbf 1700 ft-lbf 2310 ft-lbf

205 daN 311 daN 249 daN 448 daN 118 daN.m 176 daN 230 daN.m 313 daN.m

240 lbf 200 lbf 300 lbf 430 lbf 350 ft-lbf 530 ft-lbf 700 ft-lbf 950 ft-lbf

107 daN 89 daN 133 daN 193 daN 47 daN.m 72 daN.m 95 daN.m 128 daN.m

320 lbf 260 lbf 400 lbf 570 lbf 500 ft-lbf 740 ft-lbf 980 ft-lbf 1330ft-lbf

142 daN 116 daN 178 daN 256 daN 68 daN.m 100 daN.m 133 daN.m 180 daN.m

560 lbf 460 lbf 700 lbf 1010lbf 870 ft-lbf 1300 ft-lbf 1700 ft-lbf 2310 ft-lbf

249 daN 205 daN 311 daN 448 daN 118 daN.m 176 daN.m 230 daN.m 313 daN.m

Notes:

1) F = External force (tension or compression).

M = External moment, clockwise or counter-clockwise.

2) Forces and moments may be appliedsimultaneously inany

direction.

3) Values apply to all materials.

4) Higher loads maybe applicable, if direction and magnitude of

individual loads are known, but these need written approval

fromFlowserve PumpDivision.

5) Pumps must be onrigidfoundations andbaseplates must be

fullygrouted.

6) Pump/baseplate should not be used as pipe anchor. Suction

and dischargepiping should beanchored asclose as possible

tothe pump flanges toreduce vibration and prevent strainon

the pump casing. Expansion joints are recommended. They

must be properlytied andlocated on thesideof the pipe anchor

awayfromthe pump

7) The pump mounting bolt torquesspecifiedmust be usedto

prevent relative movement betweenthe pump casing and

baseplate.(Seesection 6.6, Fastener torques.). The bolt

materialmust havea minimum yieldstrength of 600N/mm

(87000lb/in.2).

2

Page 20 of 46

Page 21

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

4.6.4 Discharge piping

See section 4.6.2 for typical pipeworkdesign.

A non-return valve should belocated in the discharge

pipeworkto protect the pump from excessive back

pressure and hence reverse rotation when the unit is

stopped.

Pipeworkreducers should have a maximum total

angle of divergence of 9 degrees.

Fitting anisolation valve will alloweasiermaintenance.

It should be installed downstream of thenon-return

valve.

If needed a control pressure gaugemay be installed

on the pipework.

Do not tighten the pipe flanges before the final check.

4.6.5 Auxiliary piping

4.6.5.1 Drains

Pipe pump casing drains and glandleakage to a

convenient disposal point.

4.6.5.2 Pumps fitted with mechanical seals

Single seals requiring re-circulation will normally be

provided with the auxiliarypiping from pump casing

already fitted.

If the seal requires an auxiliary quench then a

connectionmust be made to a suitable source of

liquid flow,lowpressure steam or static pressure from

a header tank. Recommended pressure is0.35 bar (5

psi) or less. Check General arrangement drawing.

Special seals may requiredifferent auxiliary piping to

that described above. Consult separate User

Instructionsand or Flowserve if unsure of correct

method orarrangement.

For pumping hot liquids, to avoid seal damage,it is

recommended that any external flush/cooling supply

be continued after stopping the pump.

4.6.6 Final checks

Check the tightnessof all bolts in the suction and

discharge pipework. Tightenif necessary. Check also

the tightnessof all foundation bolts. Tighten if

necessary. Checkthe tightness of all auxiliary piping.

Tightenif necessary.

4.7 Final shaft alignment check

After connecting piping to the pump, rotate the shaft

several times by hand to ensure there is no binding

and all partsare free.

Recheck the coupling alignment, aspreviously

described, to ensure no pipe strain. If pipe strain

exists, correct piping.

Alignment can only be considered definitive after

pipeworkhas been connected.

4.8 Electrical connections

4.8.1 Safety conditions about electrical

connections

Electrical connectionsmust be made

by a qualified Electrician in accordance with relevant

local national and international regulations.This

includes any grounding.

It is important to be aware of the EUROPEAN

DIRECTIVE on potentially explosive areaswhere

compliance with IEC60079-14 is an additional

requirement for making electrical connections.

Avoid mechanical, hydraulic or electrical

overload byusing motor overload tripsor a power

monitor and make routine vibration monitoring.

Itis important tobe aware of the EUROPEAN

DIRECTIVEon electromagneticcompatibility when

wiringup andinstalling equipment on site.Attention

must be paid toensure that the techniquesused during

wiring/installationdonotincrease electromagnetic

emissionsor decrease the electromagneticimmunityof

theequipment, wiring oranyconnected devices. Ifin

anydoubt, contact Flowserve foradvice.

The motormust be wired upin

accordance with the motor manufacturer's

instructions(normally supplied within the terminal

box)including anytemperature, earth leakage,

current and otherprotective devices asappropriate.

Theidentification nameplate should be checked to

ensure the power supply is appropriate.

A device toprovide emergency stopping must

be fitted.

If not supplied pre-wired to the pump unit, the

controller/starterelectrical detailswill also be supplied

within the controller/starter.

For electrical detailson pump sets with controllers

see the separate wiring diagram.

See section 5.3, Direction of rotation

before connecting the motor to the electrical supply.

Page 21 of 46

Page 22

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

4.9 Protectionsystems

The following protection systemsare

recommended particularly if the pump is installed in a

potentially explosive area or is handling a hazardous

liquid. Ifin doubt consult Flowserve.

If there is any possibilityof the system allowing the

pump to run against a closed valve or below

minimum continuoussafe flowa protection device

should beinstalled to ensure the temperatureof the

liquid does not rise to an unsafe level.

If there are any circumstancesin which the system

can allow the pump to run dry, or start up empty, a

powermonitor should be fitted to stop the pump or

preventit from being started.This is particularly

relevant if the pump ishandling a flammable liquid.

If leakage of product from the pump or its associated

sealing system can cause a hazard it is

recommended that an appropriate leakage detection

system isinstalled.

To prevent excessive surface temperatures at

bearingsit is recommended that temperature or

vibration monitoring are carried out. See sections

5.7.4 and 5.7.5.

If a defect of cooling can lead to temperature higher

than those acceptable a system of cooling

surveillance must be installed.

In the case of product lubricated

bearingsthe sourceof product supply should be

checked against the order.There maybe

requirementsfor an external clean supply, particular

supply pressure or the commencement of lubrication

supply before pump start-up.

5.1.2 Oil Lubrication

The bearingsare lubricated by pins. A constant level

oiler automatically maintainsthe correct oil level.

The oiler suppliesthe necessary quantity of oil. It

operates on theliquid seal principal and feedswith oil

only when the quantity of oil becomes toolow in the

bearing. It will stop to feed once a sufficient quantity

of oil is in the bearing.

The reserve contained in the reservoir refills

automatically the natural losses of the bearing. As

soon as the oil level approaches the minimum level of

the reservoir, refill the reservoir.

Regarding the qualityand the quantity of the oil to be

used, refer to the lubrication table and information

below.

Foroil lubricated pumps,fill the bearing

housing with correctgrade of oil to thecorrectlevel,ie

sightglassor constant level oilerbottle.

Except when explicitly required bythe customerin

the specifications, when a possibility of reverse

rotation existsthe customermust install a reverse

rotation protection device.

The customer must install all equipment required to

avoid water hammer.

5 COMMISSIONING, START-UP,

OPERATION AND SHUTDOWN

These operations must be carried out by

fully qualified personnel.

5.1 Pre-commissioning procedure

5.1.1 Lubrication

Determine the mode of lubrication of the pump set,

eg grease, oil, product lubrication etc.

Grease lubricated pumpsand electric motors are

supplied pre-greased.

Otherdriversand gearboxes, if appropriate, should

be lubricatedin accordance with their manuals.

See below for the correct side on which constant

level oilersshould be installed.

Oiler

Direction of rotation of

thepump

Driveendside

Oiler

When fitted with a constant level oiler, the bearing

housing should be filled onlybyunscrewing or

hinging backthe transparent bottle and filling the

bottle with oil.Do notfill the bearing housing through

the breather hole.

Page 22 of 46

Page 23

WDX USER INSTRUCTIONS ENGLISH 71576322 06-05

®

Oil levels are as indicated below. The distance

indicated is distance below the shaft centreline.

The oil filled bottle should then be refitted so as to

returnit to the upright position. Filling should be

repeated until oil remainsvisible within the bottle.

Pump size

Oil Level mm (inch)

Drive end Non Drive end

1.5 WDX 41 (1.61) 41 (1.61)

2 WDX 46 (1.81) 46 (1.81)

3 WDX 56 (2.20) 46 (1.81)

4 WDX 66 (2.60) 46 (1.81)

5.2 Pump lubricants

5.2.1 Recommended oil lubricants

Viscosity grade ISO 46

Ambient temperature

Bearings temperature 80 °C maximum

MANUFACTURER TYPE

CHARACTERISTICS

BP

ENERGOL

HLP 46

ELF

TURBELF

SA 46

Density at 15 C 0.885 0.881 0.868 0.878 0.87 0.872 0.877

Viscosity at 40 °C.cst 45 48.6 43 43 46 46 46

Viscosity at 50 °C.cst 30 31.5 29.4 28 30 29.5 30

Viscosity at 100 °C.cst 6.9 7.1 6.7 7 6.9 6.9 6.8

Pour-point °C - 30 - 27 - 12 - 15 - 30 - 12 - 21

Flash-point °C 210 220 220 220 214 230 230

Fire-point °C 240 252 280 240 245

Aniline point °C 99 102 110 102 109 101 101

Viscosityindex 105 106 109 105 113 100 100

Acid value 0.2 0.6 0.2 0.13 0.7 0.1 0.7 to 1.2

Colour 1 ½ 2 1 2 2 1 ½ 1

TABLE OF EQUIVALENCEAND CHARACTERISTICS

OF RECOMMENDED OILS

ESSO

TERESSO

46

MOBIL

DTE

Medium

SHELL

TELLUS

T 37

TOTAL

PRESLIA

46

TOTAL

AZOLLA

ZS 46

Anti erosion additives yes yes yes yes yes

Foaminhibitors yes yes yes yes yes yes yes

Anticorrosion additives yes yes yes yes yes yes yes

Antioxidant yes yes yes yes yes yes yes

Conradson carbon residue 0.01 0.2

Limits on temperature °C - 12

to

120 °C

110 °C

Saponification < 0.5 1.2

5.2.2 Recommended grease lubricants