Page 1

VZ 10

Installation Instructions 810748-00

Pneumatic Rail Hook VZ 10

1

Page 2

Contents

Page

Important Notes

Safety Note .....................................................................................................................7

Danger ............................................................................................................................ 7

Explanatory Notes

Description ......................................................................................................................8

Function .......................................................................................................................... 8

Danger ............................................................................................................................ 8

Design .............................................................................................................................8

Technical Data .................................................................................................................9

Wiring

Key ................................................................................................................................10

Wiring Diagram ............................................................................................................. 11

Operation

Danger ..........................................................................................................................12

Tools ..............................................................................................................................12

Annex

Spare Parts ...................................................................................................................13

2

Page 3

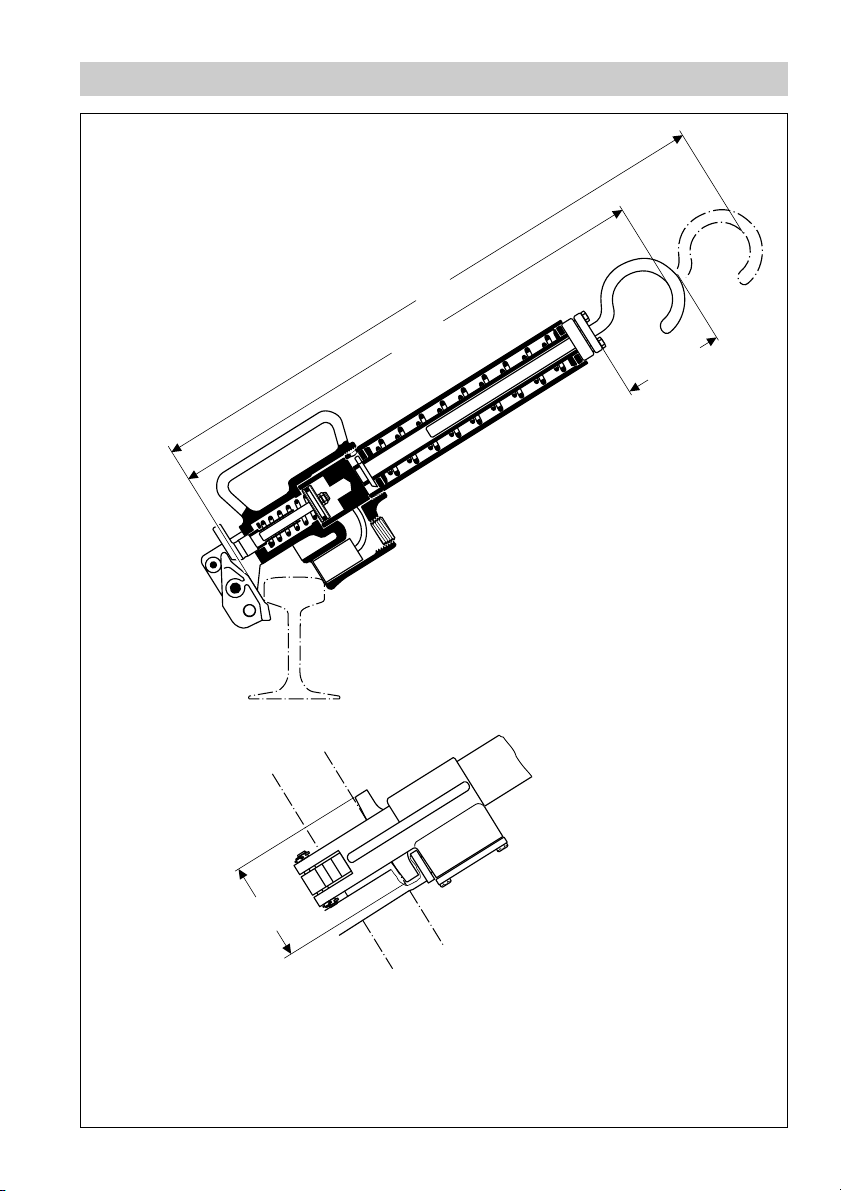

Dimensions

615

540 ± 5

135 ± 5

Fig. 1

100

3

Page 4

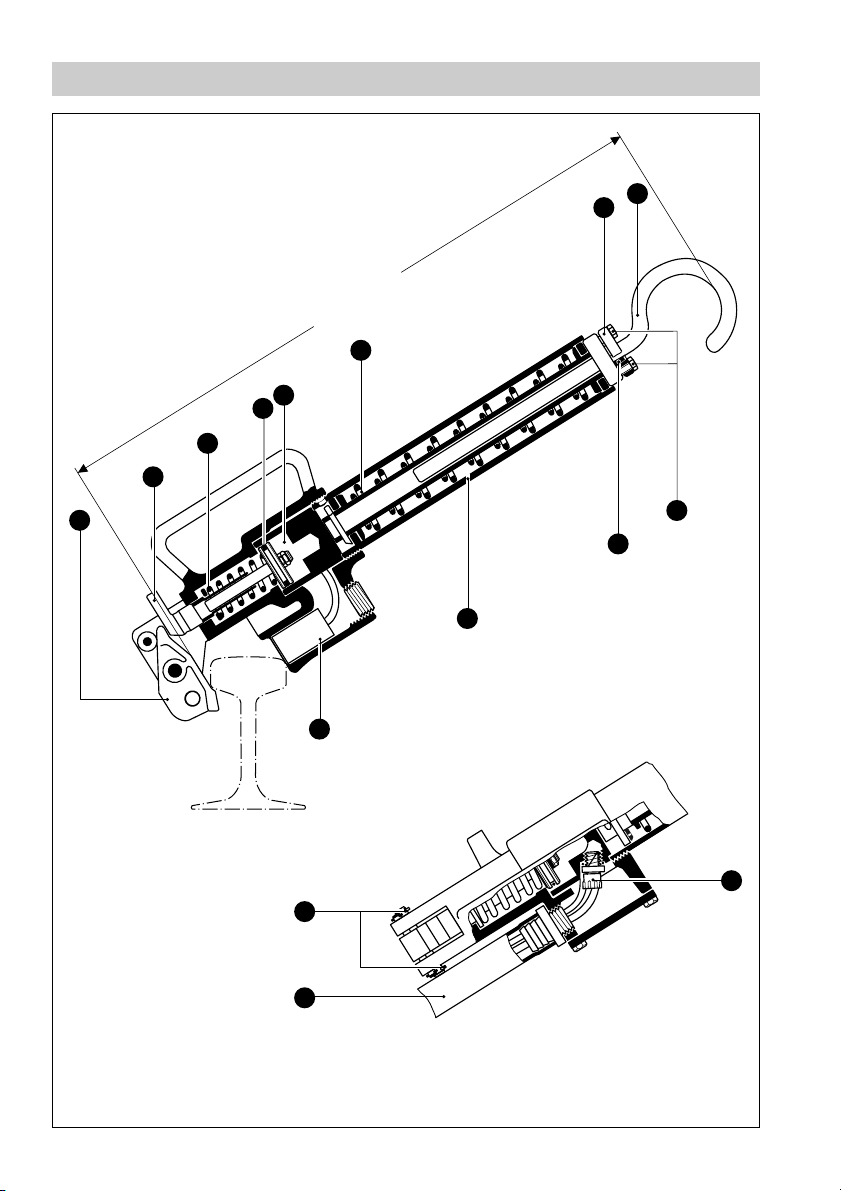

Functional Elements

E

D

C

B

A

540 – 650 mm

F

H

G

I

J

V

Fig. 2

4

K

N

M

L

Page 5

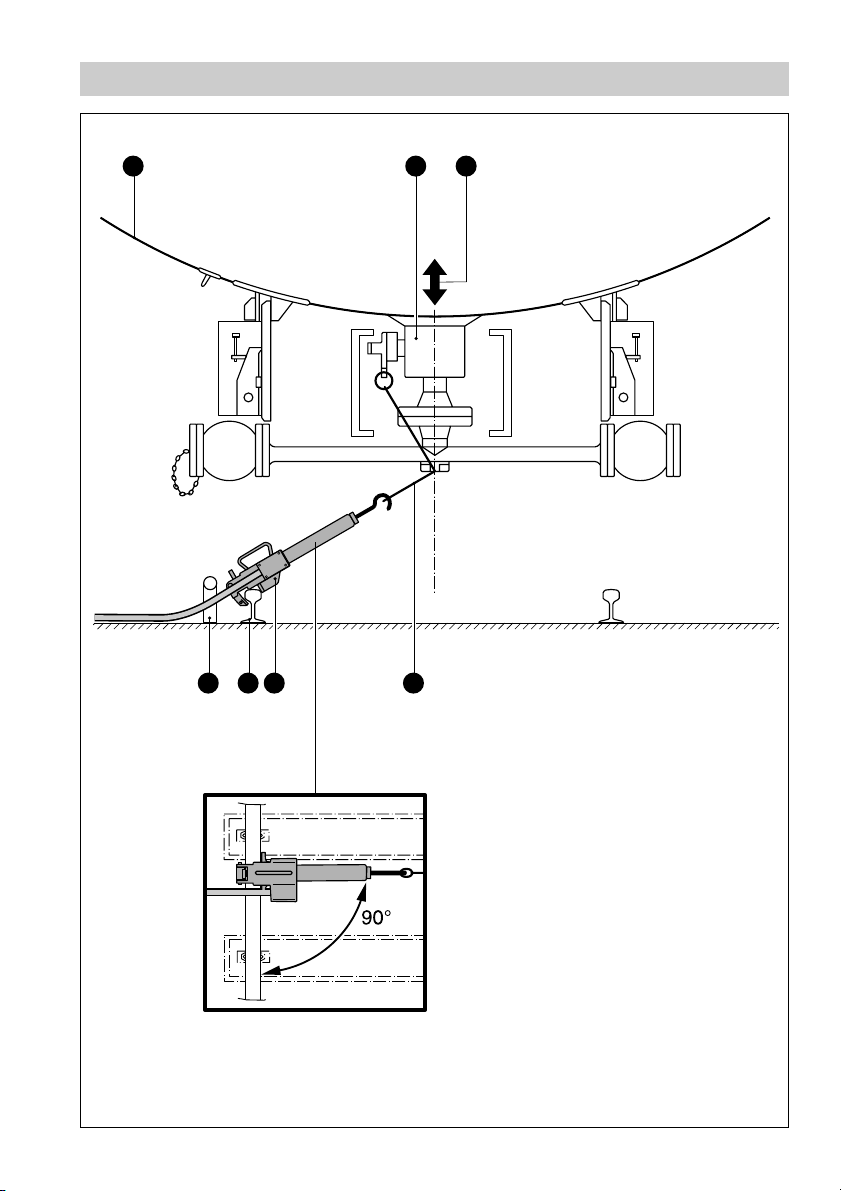

Function

O

P Q

RSTU

Fig. 3

5

Page 6

Key

A

Nose

B

Push rod

C

Compression spring

O-ring

D

Compressed air cylinder

E

Spring for compensating the height variation

F

G

Washer

H

Hook for attaching to the cable

Hexagon screws M 8 x 20

I

Ring

J

Proximity switch

K

Protective hose

L

Split pin

M

Compressed air hose with rapid-action threaded coupling

N

O

Tank of the tank car

P

Rapid-action bottom valve

Q

Height variation

R

Cable as per DIN 26 026

S

VZ 10

T

Rail

U

Auxiliary device (consisting of a tube, ∅ 63 mm)

V

Tube

6

Page 7

Important Notes

Safety Note

Do not use the pneumatic rail hook VZ 10 for any purpose other than keeping the

bottom valves of tank cars open. The device may only be installed by qualified staff.

“Qualified staff” are those persons who have achieved a recognised level of

competence appropriate to the installation and commissioning of this critical safety

device.

Danger

When the rail hook is released, there is a danger of injury to the legs and

feet.

7

Page 8

Explanatory Notes

Scope of Supply

VZ 10

1 Rail hook

1 Installation instructions

Description

According to TRB 851 Paragraph 4.2.5.3, loading plants for combustible gases in

the region of storage facilities with a capacity exceeding 30 t must be equipped with

an emergency shut-down system. In the emergency shut-down system and in other

dangerous situations, the rail hook VZ 10 serves as the safety link between the

loading plant and the tank car. To ensure reliable functioning, there are two necessary

prerequisites:

■ The hydraulic or mechanical equipment of the tank car’s bottom valve must be

equipped with a cable as per DIN 26026 or UIC 573.

■ The rail on which the tank car is standing must have a cross-section corresponding

to DIN 5902 type S-49. If this is not the case, the rail hook can be attached to the

auxiliary device .

Function

During the loading and unloading process, the rail hook VZ 10 is stretched between

the cable and the rail (see Fig. 3) and keeps the bottom valves open. The compressed

air supply is not used to open the bottom valves – it only serves the purpose of

applying a compressive force to the compression spring . The spring for

compensating height variations prevents the rail hook from being torn off the rail

during emptying of the tank car. The proximity switch triggers the emergency shutdown system if the rail hook comes off the rail because of unintentional movement of

the tank car.

U

C

K

F

Danger

Only dry instrument air may be used.

There is a danger of ice formation in the compressed air cylinder.

Design

VZ 10

■ Rail hook with pneumatic control and proximity switch.

8

Page 9

Explanatory Notes – continued –

Technical Data

Control air

Pressure min. 3 bar

Pressure max. 10 bar

Length of compressed air hose and sensor cable

6 m

Response temperature of fire protection system

150 °C

Holding force of rail hook

350 N

Release of rail hook

Tank car movement distance

Materials of the casing

External parts bronze/brass (spark-proof).

Weight

Approx. 5.3 kg

Proximity switch

Type (Pepperl & Fuchs) NJ 10-30 GK-N NJ 10-30 GK-SN

Rated voltage 8 V 8 V

Current consumption

Active surface exposed ≤ 3 mA ≤ 3 mA

Active surface covered ≤ 1 mA ≤ 1 mA

Permissible ambient temperature –25 °C to +100 °C –40 °C to +100°C

Protection IP 68 to DIN 40050 IP 68 to DIN 40050

≤ 500 mm

9

Page 10

Wiring

VZ 10

Install the proximity switch in accordance with the wiring diagram.

Key

1

Power input

2

On

3

Off

Control

4

Ready for operation

5

Wire break

6

Air on

7

Pump on

8

Wire break monitoring

9

Limit-switch signal

10

Air valve

11

K

10

Page 11

Wiring – continued –

Wiring Diagram

11

10

9

3

3

2

8

7

6

5

2

8

7

4

Fig. 4

1

11

Page 12

Operation

1. If rail type is not S-49: Install an auxiliary device consisting of a tube, ∅ 63 mm

U

. Fig. 3

2. Push back the push rod and position the nose so that it is at right angles to

the longitudinal axis of the rail hook.

3. Via the compressed air hose , apply compressed air to the cylinder at a

pressure in the range 3 bar to 10 bar.

Insert the hook in the eye of the cable, and pull the rail hook towards yourself.

H

Before the rail hook is attached to the rail, the distance between the washer and

the tube should be approximately 40 to 50 mm.

V

4. If the distance is greater than 50 mm, the hook must be adjusted so that the

distance described is achieved.

5. To adjust the hook , undo the hexagon screws M 8 and either pull the hook

out or push it in.

6. Tighten the hexagon screws , and use the rail hook as described in 3.

7. After the end of the loading process, remove the rail hook from the rail by hand.

The bottom valves close at the same time.

Danger

Switching off the compressed air after the end of the loading process

produces a very high risk of injury due to the rail hook flying off the rail.

Similarly, during this operating step there is a risk of breakage of the rail

hook.

B A

N

H

H I H

I

E

G

Tools

■

Open-end spanner, 13 mm A.F.

12

Page 13

Annex

Spare Parts

Part

A

B

C

D

G

H

J

K

L

M

N

Part No. Name Stock code

3 Nose, 2.0975.01 048417

2 Push rod, complete, 2.0401 079739

6 Compression spring, 1.4310 079756

7.3 O-ring 34, 52 x 3, 53, Busak + Luyken, NBR 079759

9.80 Washer, 2.0401 079745

9.10 Hook, 2.0401 079752

9.7 Ring, split, PA 043420

10 Proximity switch NJ10-30GK-SN 079757

or

proximity switch NJ10-30GK-N 079851

Pepperl & Fuchs

11.6 Compressed air hose DN 19, DIN 73411, 079763

rubber with fabric insert

4.4 Split pin 4 x 20 DIN 94, brass 013993

11.3 Rapid-action threaded coupling CK-1/4-PK-6-Festo, AL 079761

13

Page 14

141516

Page 15

Page 16

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 0034 91/ 5152032

Fax 003491/4136747; 5152036

E-mail: gestra@gestra.es

Polska

GESTRA POLONIA Spolka zo. o.

Ul. Schuberta 104, P. O. Box 71

PL-80-172 Gdansk

Tel. 00 48 58/ 306 1002 oder 306 1010

Fax 00 48 58/ 306 1003 oder 306 33 00

E-mail: gestra@gestra.pl

France Portugal

Flowserve Flow Control S.A. S.

10 Avenue du Centaure, BP 8263

F-95801 CERGY PONTOISE CEDEX

Tél. 0 03 31/ 344326 60

Fax 00331/34432687

E-mail: gnation@flowserve.com

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0035122/6198770

Fax 003 51 22/ 61075 75

E-mail: gestra@gestra.pt

Italia

Italgestra S.r.l.

Via Carducci 125

l-20099 Sesto San Giovanni (MI)

Tel. 0039 02 / 2410 12.1

Fax 00 39 02/ 2410 12.460

E-mail: info@italgestra.it

®

GESTRA GmbH

Postfach 1054 60

D-28054 Bremen

Münchener Str. 77

D-28215 Bremen

Tel. + 49 (0) 421 35 03-0

Fax + 49 (0) 421 35 03-393

E-mail

gestra.gmbh@flowserve.com

Internet www.gestra.de

A Unit of Flowserve Corporation

810748-00/1102c · © 1997 GESTRA GmbH · Bremen · Printed in Germany

Loading...

Loading...