Page 1

Valtek VL-C Spring Cylinder

Linear Actuators

GENERAL INFORMATION

The following instructions are designed to assist in

installing, troubleshooting and servicing Valtek VL-C

spring cylinder linear actuators sizes 100, 150 and 200.

Separate installation, operation and maintenance

instructions cover 25 and 50 sizes as well as additional

features (such as handwheels, limit stops, fail-safe

systems or limit switches). Product users and maintenance personnel should thoroughly review this bulletin

prior to installing, operating or disassembling the

actuator.

This publication does not contain information on

Flowserve positioners. Refer to the appropriate installation operation and maintenance instructions for installing, maintaining, troubleshooting, calibrating and

operating Flowserve positioners.

To avoid possible injury to personnel or damage to valve parts, WARNING and CAUTION

notes must be strictly followed. Modifying this

product, substituting non-factory or inferior

parts or using maintenance procedures other

than outlined could drastically affect performance, void product warranties and be hazardous to personnel and equipment.

WARNING: Standard industry safety practices must

be followed when working on this or any process

control product. Specifically, personal protection

and lifting devices must be used as warranted.

Unpacking

While unpacking the actuator, check packing list against

materials received. Lists describing the actuator and

accessories are included in each shipping container.

1. Position the lifting straps and hoist to avoid damage

to the tubing and mounted accessories when lifting

the actuator from the shipping container.

WARNING: When lifting an actuator with lifting

straps through the yoke legs, be aware the

center of gravity may be above the lifting point.

Therefore, support must be given to prevent the

actuator from rotating or causing serious injury

to personnel or damage to nearby equipment.

2. Contact your shipper immediately in the event of

shipping damage.

3. Contact your Flowserve representative with any

problems.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Valtek No. 188485

54-1

Page 2

Installation

Prior to installation, make sure adequate overhead

clearance for the actuator is provided to allow for proper

removal from the valve body and for proper maintenance. Refer to Table I.

Table I:

Overhead Clearance for Maintenance

Actuator Size Minimum Clearance

100, 150, 200 9 inches

NOTE: If an actuator is attached to a valve body

assembly, see the appropriate installation, operation,

maintenance instructions.

1. Connect the air supply and instrument signal air

lines to the two marked connections on the

positioner. Since both the cylinder and positioner

are suitable for 150 psi (10.3 bar) air supply, an air

regulator should not be used unless the supply

exceeds 150 psi (10.3 bar).

NOTE: In some cases, air supply must be limited to

100 psi (6.9 bar) rather than 150 psi (10.3 bar); this

will be indicated by a sticker found near the upper

air port on the cylinder.

WARNING: To avoid personal injury or equipment damage, do not exceed recommended

supply pressure.

2. Installation of an air filter on the supply line is

recommended.

3. Use a soap solution to make sure all air connections

are leak-free.

MAINTENANCE

At least once every six months, check for proper operation by following the preventative maintenance steps

outlined below.

while the actuator is in service.

suspected with the actuator, refer to the

and Reassembly

WARNING: To avoid serious injury, the following

steps should only be performed with the air supply

or positioner input disconnected.

1. When disconnecting air supply, observe actuator

for correct fail-safe action.

2. Examine the actuator for damage caused by corrosive fumes and process drippings.

3. Clean the actuator and repaint any areas of severe

oxidation.

4. If possible, stroke the actuator and check for

smooth, full-stroke operation.

WARNING: To avoid serious injury, keep hands,

hair and clothing away from all moving parts

while operating the actuator.

These steps should not be performed

If an internal problem is

Disassembly

section.

5. Make sure positioner mounting bolts, linkage and

stem clamp are fastened securely.

6. Ensure all accessories, brackets and associated

bolting are fastened securely.

7. Check rubber bellows for wear.

8. Spray soap solution around the base and top of the

cylinder, the adjusting screw and the lower actuator

stem bushing to check for air leaks through the

O-rings and gasket.

9. Clean any dirt or foreign material from the actuator

stem.

10. If an air filter is supplied, isolate the air filter, then

check and replace cartridge as necessary.

DISASSEMBLY AND REASSEMBLY

Disassembling the Actuator

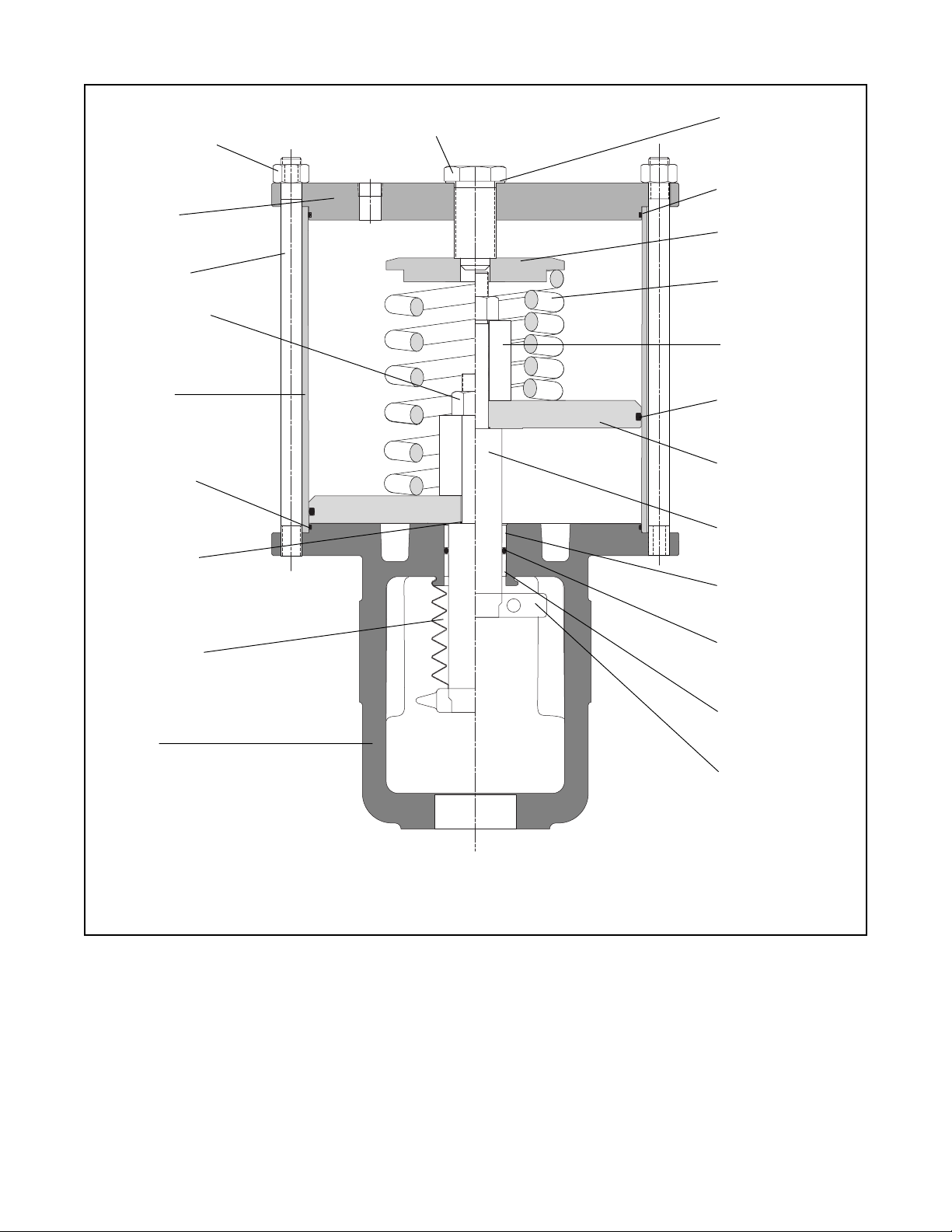

Refer to Figures 1 through 4 to disassemble the cylinder

actuator.

1. Shut off air supply. If actuator is installed on a

Flowserve valve, remove the valve per the appropriate installation operation, maintenance instructions.

WARNING: To avoid serious injury, depressurize the line to atmospheric pressure and drain

all fluids before working on the actuator.

2. Disconnect all tubing. Remove stem clamp and

stem bellows from the actuator stem.

3. Relieve spring compression by completely removing the adjusting screw. Remove adjusting screw

gasket from adjusting screw.

WARNING: To avoid serious personal injury,

relieve the spring compression before further

disassembly. The cylinder end cap may fly off

the yoke when removing the cylinder tie-rod

nuts.

4. Remove the four self-locking tie rod nuts by unscrewing in an alternating pattern. Remove the

cylinder end cap.

5. Lift the cylinder off the yoke and piston. If excessive

O-ring resistance is felt, use a rubber mallet to

gently tap around the cylinder perimeter.

WARNING: To avoid serious personal injury, do

not use air pressure to remove the cylinder. The

cylinder may fly off the yoke.

CAUTION: When removing the actuator stem

lock nut, do not hold the actuator stem with a

pipe wrench as the sealing surface may be

damaged; instead, use a wrench on the flats of

the actuator stem.

6. For air-to-retract configurations, remove the

spring(s) and spring button for cleaning and inspection (see Figures 1, 3 and 4). Remove the actuator

54-2

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 3

Tie Rod Nut (4)

(Item No. 205)

End Cap

(Item No. 207)

Tie Rod (4)

(Item No. 206)

Actuator Stem

Lock Nut

(Item No. 348)

Adjusting Screw

(Item No. 210)

Adjusting Screw

Gasket

(Item No. 248)

End Cap O-ring

(Item No. 227)

Spring Button

(Item No. 227)

Spring

(Item No. 229)

Stem Spacer

(Item No. 228)

Cylinder

(Item No. 202)

Yoke O-ring

(Item No. 271)

Piston Stem

O-ring

(Item No. 272)

Stem Bellows

(Item No. 247)

Yoke

(Item No. 201)

Quad-seal

(Item No. 271)

Piston

(Item No. 225)

Actuator Stem

(Item No. 211)

Bushing

(Item No. 253)

Actuator Stem

O-ring

(Item No. 275)

Bushing

(Item No. 253)

Stem Clamp

No. 26906

(Valtek Positioner)

Figure 1: Air-to-retract Cylinder Actuator

NOTE: Item numbers correspond directly to actuator's bill of material. Refer to it for specific part numbers.

stem locknut by holding the flats on the actuator

stem and slide the piston and stem spacer off the

actuator stem. The spring guide should be removed

when using dual or heavy-duty spring designs.

NOTE: The dual spring configuration (Figure 3) has

two springs, one inside the other. Remove both

springs during this step.

7. For air-to-extend configurations, slowly loosen and

remove the actuator stem locknut and piston.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

(Remove the piston and stem locknut together,

making sure the piston does not bind on the actuator stem.) Next, remove the spring button, spring

and stem spacer.

WARNING: To avoid personal injury, be certain

the spring force is completely relieved before

removing actuator stem locknut.

8. Remove the piston quad-seal, piston stem O-ring

and yoke O-ring.

54-3

Page 4

Spring Button

(Item No. 227)

Spring

(Item No. 229)

Stem Spacer

(Item No. 228)

Figure 2: Air-to-extend Cylinder Actuator

NOTE: Item numbers correspond directly to actuator's bill of material. Refer to it for specific part numbers.

Parts listed change location upon reversing air action. No new parts are required.

9. Remove the actuator stem O-ring.

NOTE: The stem bushing is pressed into the yoke.

The actuator stem O-ring can be replaced without

removing the bushing.

10. Use an appropriately sized press to push a worn or

damaged bushing out of the yoke.

Reassembling the Actuator

To reassemble the cylinder actuator, refer to Figures 1

through 4:

54-4

1. All O-rings and the quad-seal should be replaced

and lubricated with a calcium complex grease

(DuBois MPG-2 or equivalent). Silicone O-rings

must be lubricated with Magnalube-G lubricant or

equivalent.

2. Thoroughly clean all internal parts before beginning

assembly. Check the cylinder bore for scratches,

pitting or worn areas. Lubricate cylinder wall and all

internal surfaces with the appropriate lubricant.

NOTE: Applying a light coating of lubricant to the

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 5

Adjusting Screw

(Item No. 210)

Outer Spring

(Item No. 229)

Inner Spring

(Item No. 230)

Spring Button

(Item No. 227)

Spring Guide

(Item No. 326)

Actuator Stem

(Item No. 211)

Figure 3: Dual-spring Cylinder Actuator

NOTE: Item numbers correspond directly to actuator's bill of material. Refer to it for specific part numbers.

Parts listed indicate differences from the single-spring model.

entire cylinder bore, end cap and both sides of the

piston enables smooth operation and can help

reduce corrosion.

3. Lubricate the outside of the replacement bushing if

the stem bushing has been removed. Press a new

lower stem bushing into the actuator stem bore in

the yoke until it bottoms out. Press the upper stem

bushing into the bore until it is flush with the top of

the yoke (refer to Figures 1 or 2).

4. Replace the actuator stem O-ring and yoke O-ring.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

NOTE: When installing the actuator stem, align the

actuator stem flats with the yoke legs. This allows

the stem clamp to work properly and helps prevent

plug assembly rotation.

CAUTION: When installing the actuator stem

lock nut, do not hold the actuator stem with a

pipe wrench as the sealing surface may be

damaged; instead, use a wrench on the flats of

the actuator stem.

5. Reassemble the piston, piston stem O-ring and

54-5

Page 6

stem spacer on the actuator stem according to the

proper air-action (see either Figure 1 or 2). Replace

the piston quad-seal. Air-to-extend configurations

require the spring button to be stored under actuator stem locknut. Tighten the locknut firmly by

holding the flats on the actuator stem.

NOTE: When reassembling dual or heavy-duty

spring actuators, the spring guide must be first

inserted under the actuator stem locknut (see Figures 3 and 4).

6. For air-to-extend configurations, place the spring

under the piston and insert the actuator stem

through the yoke, being careful not to pinch the

actuator stem O-ring or gall the stem and stem

bushing. For air-to-retract configurations, insert the

actuator stem through the yoke and place the

spring(s) and spring button above the piston.

7. Install the tie rods into the yoke using Loctite

No. 242 NSF61 or equivalent.

Table II: Tie Rod Nut Torque Values

Actuator Size Torque Value (ft.-lbs.)

100 207 – 229

150, 200 336 – 371

12. Reinstall the stem bellows and stem clamp.

NOTE: To ensure maximum clamping strength

when installing the stem clamp, make sure the stem

clamp bolting is perpendicular to one of the slots

machined into the actuator stem.

13. Apply air over the piston. Tighten the stem clamp

bolting with the stem clamp adjusted to point at the

closed position of the stroke indicator plate.

NOTE: If the actuator is installed on a Flowserve

valve, refer to the appropriate installation, operation, maintenance instructions for correct plug stem

thread engagement.

14. Reconnect tubing, supply and signal lines.

8. Install the cylinder, making sure the cylinder is

completely seated on the yoke. Care should be

taken not to scar or cut the piston and yoke O-rings.

9. Replace the cylinder end cap and secure to the tie

rods using new self-locking nuts. Refer to Table II

for the appropriate torque values.

WARNING: To avoid personal injury, the cylinder end cap must be solidly in place. The cylinder end cap may fly off when pressurized.

10. Reinstall the adjusting screw fitted with a new

adjusting screw gasket.

NOTE: Be certain the hole in the spring button is

directly centered under the adjusting screw hole in

the cylinder on air-to-retract configurations.

11. Tighten the adjusting screw enough to provide an

air seal with the gasket. Do not overtighten.

Reversing the Air-action

To change the air action from air-to-retract to air-to

extend, or vice versa, refer to Figures 1, 2 or 4:

NOTE: Dual spring actuators are not reversible.

1. Disassemble the actuator according to the

sembling the Actuator

2. For air-to-retract action, reassemble the actuator

with stem spacer and spring button over the piston.

3. For air-to-extend action, reassemble with spring

and stem spacer below the piston and with the

spring button stored above the piston.

4. Reassemble the actuator according to the

sembling the Actuator

5. The positioner must also be reversed. See the

appropriate positioner maintenance instructions.

section.

section.

Disas-

Reas-

54-6

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 7

AIR-TO-

RETRACT

Spring Button

(Item No. 227)

Adjusting Screw

(Item No. 210)

Adjusting Screw Gasket

(Item No. 248)

Tie Rod Nut (4)

(Item No. 205)

Tie Rod (4)

(Item No. 206)

End Cap

(Item No. 207)

End Cap O-ring

(Item No. 208)

Actuator Stem Nut

(Item No. 348)

AIR-TO-

EXTEND

Spring

(Item No. 229)

Actuator Stem Nut

(Item No. 348)

Stem Spacer

(Item No. 228)

Quad-seal

(Item No. 271)

Piston

(Item No. 225)

Piston Stem O-ring

(Item No. 272)

Actuator Stem

(Item No. 211)

Actuator Stem O-ring

(Item No. 275)

Cylinder

(Item No. 202)

Upper Stem

Bushing

(Item No. 253)

Lower Stem Bushing

(Item No. 253)

Spring Button

(Item No. 227)

Quad-seal

(Item No. 271)

Piston

(Item No. 225)

Piston Stem O-ring

(Item No. 272)

Stem Spacer

(Item No. 228)

Actuator Stem

(Item No. 211)

Spring

(Item No. 229)

Stroke Plate

(Item No. 213)

Figure 4: Exploded View, Spring Cylinder Actuator

NOTE: Item numbers correspond directly to actuator's bill of material. Refer to it for specific part numbers.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Yoke O-ring

(Item No. 274)

Yoke

(Item No. 201)

Stem Bellows

(Item No. 247)

54-7

Page 8

Troubleshooting

Problem Probable Cause Corrective Action

High air consumption or 1. Leaks in the air supply or instru- 1. Tighten connections and replace any

leakage ment signal system leaking lines

2. Malfunctioning positioner 2. Refer to appropriate positioner

maintenance bulletin

3. Leaks through O-rings or adjusting 3. Replace O-rings or gasket

screw gasket

Actuator does not move to 1. Air pressure in cylinder not venting 1. Refer to appropriate positioner

fail position upon loss because of faulty positioner maintenance bulletin

of air supply pressure 2. Spring failure 2. Replace spring

3. Internal valve problem 3. Refer to valve’s maintenance bulletin

Jerky or sticking 1. Insufficient air supply pressure 1. Check air supply and any filters or

stem travel regulators; check for leaking O-rings

2. Unlubricated cylinder wall 2. Lubricate cylinder wall with silicone

lubricant

3. Worn or damaged stem bushings 3. Check actuator stem for damage;

replace actuator stem, O-ring, and

stem bushings, if necessary

4. Improperly assembled spring 4. Disassemble actuator and check

cylinder and piston for damage;

reassemble actuator correctly

5. Internal valve problem 5. Refer to valve’s maintenance

instructions

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this

Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve products

should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service conditions. Although

Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The

purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation and maintenance

of Flowserve products. The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with

the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications presented in this literature are believed to be accurate, they are supplied for informative purposes only

and should not be considered certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed

as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve is continually improving

and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should

any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any of its worldwide operations

or offices.

For more information, contact:

Flowserve and Valtek are registered trademarks of Flowserve Corporation.

For more information about Flowserve and its products,

contact www.flowserve.com or call USA 972 443 6500

Regional Headquarters

1350 N. Mt. Springs Prkwy.

Springville, UT 84663

Phone 801 489 8611

Facsimile 801 489 3719

12 Tuas Avenue 20

Republic of Signapore 638824

Phone (65) 862 3332

Facsimile (65) 862 4940

12, av. du Québec, B.P. 645

91965, Courtaboeuf Cedex, France

Phone (33 1) 60 92 32 51

Facsimile (33 1) 60 92 32 99

Quick Response Centers

5114 Railroad Street

Deer Park, TX 77536 USA

Phone 281 479 9500

Facsimile 281 479 8511

104 Chelsea Parkway

Boothwyn, PA 19061 USA

Phone 610 497 8600

Facsimile 610 497 6680

1300 Parkway View Drive

Pittsburgh, PA 15205 USA

Phone 412 787 8803

Facsimile 412 787 1944

54-8

FCD VLAIM054-00 © 2001 Flowserve Corporation. Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Loading...

Loading...