Page 1

®

Pump Division

Model: VCT

VERTICAL CENTRIFUGAL PUMPS

USER INSTRUCTIONS:

INSTALLATION, OPERATION AND

MAINTENANCE for self lubricated pump

User Instructions No. MX0301 - 07/03 (E)

Page 2

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

CONTENTS

PAGE

1 INTRODUCTION AND

SAFETY

1.1 General………………………….. 3

1.2 CE marking and approvals……. 3

1.3 Disclaimer………………………. 3

1.4 Copyright………………………... 3

1.5 Duty conditions…………………. 3

1.6 Safety……………………………. 3

1.7 Nameplate and warning labels.. 5

1.8 Specific machine performance.. 5

1.9 Noise level……………………… 5

2 TRANSPORT AND STORAGE 5

2.1 Consignment and unpacking…. 6

2.2 Handling………………………… 6

2.3 Lifting……………………………. 6

2.4 Storage………………………….. 7

2.5 Recycling and end of product

life

3 PUMP DESCRIPTION 7

3.1 Configurations………………….. 7

3.2 Design of mayor parts…………. 7

3.3 Performance and operating

limits……………………………... 7

4 INSTALLATION 7

4.1 Location…………………………. 7

4.2 Part assemblies………………… 8

4.3 Foundation……………………… 8

4.4 Grouting………………………… 8

4.5 Alignment………………………. 8

4.6 Piping………………………….… 9

4.7 Final alignment check…………. 9

4.8 Electrical connections…………. 9

5 COMMISSIONING, START-UP,

OPERATION AND SHUTDOWN

5.1 Pre-commissioning procedure.. 9

5.2 Motor lubricants………………… 9

5.3 Direction of rotation……………. 9

5.4 Guarding………………………… 10

5.5 Rotor setting……………………. 10

5.6 Starting the pump……………… 10

5.7 Running the pump……………... 11

5.8 Stopping and shutdown……….. 11

5.9 Emergency shutdown…………. 11

3

7

9

6 MAINTENANCE 11

6.1 General………………………….. 11

6.2 Maintenance schedule………… 12

6.3 Spare parts…………………….. 13

6.4 Recommended spares and

13

consumable items………………

6.5 Tools required………………….. 13

6.6 Fastener torques………………. 13

6.7 Renewal clearances…………… 14

6.8 Disassembly……………………. 14

6.9 Examination of parts…………... 15

6.10 Assembly……………………….. 16

7 FAULTS; CAUSES AND REMEDIES 18

8 PARTS LIST AND DRAWINGS 19

8.1 Typical sectional drawings……. 19

8.2 Parts list………………………… 26

8.3 General arrangement drawing.. 26

9 CERTIFICATION 26

10

SUPPLEMENTARY INFORMATION

27

10.1 Long term storage………………….. 27

10.2 Coupling alignment…………….

30

Procedure

10.3 Gasket eliminator application… 31

1

11

OTHER RELEVANT DOCUMENTATION

AND MANUALS

31

11.1 Supplementary user instructions………. 31

11.2 Change notes…………………... 31

11.3 Additional sources of ………….

31

Information

11.4 Customer service information… 32

Page 2 of 32

Page 3

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

1 INTRODUCTION AND SAFETY

1.1 General

These instructions must always be kept

close to the product's operating location or

directly with the product.

Flowserve's products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great

care and commitment to continuous quality control,

utilising sophisticated quality techniques, and

safety requirements.

We are committed to continuous quality

improvement and being at your service for any

further information about the product in its

installation and operation or about its support

products, repair and diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted

use. Operating the product in compliance with

these instructions is important to help ensure

reliability in service and avoid risks. The

instructions may not take into account local

regulations; ensure such regulations are observed

by all, including those installing the product. Always

coordinate repair activity with operations personnel,

and follow all plant safety requirements and

applicable safety and health laws and regulations.

These instructions should be read entirely

prior to installing, operating, using and

maintaining the equipment in any region

worldwide. The equipment must not be put into

service until all the conditions relating to safety

noted in the instructions, have been met.

1.2 CE marking and approvals

It is a legal requirement that machinery and

equipment put into service within certain regions of

the world shall conform with the applicable CE

Marking Directives covering Machinery and, where

applicable, Low Voltage Equipment,

Electromagnetic Compatibility (EMC), Pressure

Equipment Directive (PED) and Equipment for

Potentially Explosive Atmospheres (ATEX),

American National Standards Institute (ANSI),

Institute of Electrical and Electronics Engineers

(IEEE), International Electrotechnical Commission

(IEC), National Electrical Manufacturers

Association (NEMA), National Fire Protection

Association (NFPA).

1.3 Disclaimer

Information in these User Instructions is

believed to be reliable. In spite of all the efforts

of Flowserve Corporation to provide sound and

all necessary information the content of this

manual may appear insufficient and is not

guaranteed by Flowserve as to its

completeness or accuracy.

Flowserve manufactures products to exacting

International Quality Management System

Standards as certified and audited by external

Quality Assurance organisations. Genuine parts

and accessories have been designed, tested and

incorporated into the products to help ensure their

continued product quality and performance in use.

As Flowserve cannot test parts and accessories

sourced from other vendors the incorrect

incorporation of such parts and accessories may

adversely affect the performance and safety

features of the products. The failure to properly

select, install or use authorised Flowserve parts

and accessories is considered to be misuse.

Damage or failure caused by misuse is not covered

by Flowserve's warranty. In addition, any

modification of Flowserve products or removal of

original components may impair the safety of these

products in their use.

1.4 Copyright

All rights reserved. No part of these instructions

may be reproduced, stored in a retrieval system or

transmitted in any form or by any means without

prior permission of Flowserve Pump Division.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been

sent separately to the Purchaser.

The product must not be operated beyond

the parameters specified for the application. If

there is any doubt as to the suitability of the

product for the application intended, contact

Flowserve for advice, quoting the serial

number.

If the conditions of service on your purchase order

are going to be changed (for example liquid

pumped, temperature or capacity) it is requested

that you/the user seek our written agreement

before start up.

1.6 Safety

1.6.1 Summary of safety markings

These user instructions contain specific safety

markings where non-observance of an instruction

would cause hazards. The specific safety markings

are:

Page 3 of 32

Page 4

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

This symbol indicates electrical

safety instructions where non-compliance would

affect personal safety.

This symbol indicates safety instructions

where non-compliance would affect personal

safety.

This symbol indicates safety instructions where

non-compliance would affect protection of a safe life

environment.

This symbol indicates safety

instructions where non-compliance would affect the

safe operation or protection of the pump unit.

This symbol indicates explosive atmosphere

zone marking according to ATEX. It is used in

safety instructions where non-compliance in the

hazardous area would cause the risk of an

explosion.

This sign is not a safety symbol but

indicates an important instruction in the assembly

process.

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the

personnel in question do not already possess the

necessary knowledge and skill, appropriate training

and instruction must be provided. If required the

operator may commission the

manufacturer/supplier to provide applicable

training.

Always coordinate repair activity with operations

and health and safety personnel, and follow all

plant safety requirements and applicable safety and

health laws and regulations.

1.6.3 Safety action

This is a summary of conditions and actions to

prevent injury to personnel and damage to

equipment.

LEVELED FUNDATION PLATE

Fundation plate or suction barrel flange must be

leveled within 0.050mm ( 0.002 in.) as maximum

variation which is indispensable for operation free

of trouble.

Use a rectified long bar in order to support

precision level across the foundation plate (side-toside) and levelling all directions every 45 degrees.

Foundation plate must be verified before and after

pour the grouting.

PREVENT EXCESSIVE

EXTERNAL PIPE LOAD

a) Do not use pump as a support for piping.

Piping must be independently supported

and must not be drawn into position with

flange bolting. Pipe strains on the pump can

be a definite source of trouble, resulting in

possible misalignment, excessive wear,

vibration and even broken shafts.

b) If expansion joint is used, employ tie rods

of adequate strength (i.e. size for 1-1/2

times shut off pressure).

c) Ensure pump and piping is flushed before

use .

ENSURE CORRECT

LUBRICATION

When external water source or oil is needed for

lubrication-see General Arrangement Drawing.

(See drawings attached)

See section 5.3, Direction of rotation

before connecting the motor to the electrical supply.

START THE PUMP WITH OUTLET

VALVE PART OPENED 30%.

(Unless otherwise instructed at a specific point in

the user instructions, see section 5,

Commissioning, start up, operation and shutdown.)

This is recommended to minimize the risk of

overloading and damaging pump motor at full or

zero flow. The pump outlet control valve may need

to be adjusted to comply with the duty following the

run-up process.

DO NOT RUN THE PUMP AT

ABNORMALLY HIGH OR LOW FLOW RATES

Operating at a flow rate higher or lower than normal

may overload the motor and cause cavitation,

instability and vibration.

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER

HAZARDOUS LIQUIDS

When the pump is handling hazardous liquids care

must be taken to avoid exposure to the liquid by

appropriate sitting of the pump, limiting personnel

access and by operator training. If the liquid is

flammable and/or explosive, strict safety

procedures must be applied.

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and

equipment is required when handling these

components. To lift heavy pieces above 25 kg (55

lb) use a crane appropriate for the mass and in

accordance with current local regulations.

Page 4 of 32

Page 5

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

party responsible for assembling the pump set shall

LIFTING DEVICES

Mounted on individual parts are intended for lifting

the individual part only. Lifting slings must not put

excessive side thrust on the lifting device.

GUARDS MUST NOT BE REMOVED WHILE

THE PUMP IS OPERATIONAL

LIFTING ROTOR

Lifting rotor must be setting before start up the

pump, according nameplate. See point 5.5

FLUORO-ELASTOMERS (When fitted.)

When a pump has experienced temperatures over

250 ºC (482 ºF), partial decomposition of fluoroelastomers (eg Viton) will occur. In this condition

these are extremely dangerous and skin contact

must be avoided.

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and

equipment is required when handling these

components. To lift heavy pieces above 25 kg (55

lb) use a crane appropriate for the mass and in

accordance with current local regulations.

1.6.4 Products used in potentially explosive

atmospheres

select the coupling, driver and any additional

equipment, with the necessary CE Certificate/

Declaration of Conformity establishing it is suitable

for the area in which it is to be installed.

1.6.4.6 Preventing leakage

The pump must only be used to handle

liquids for which it has been approved to have the

correct corrosion resistance.

1.7 Nameplate and warning labels

1.7.1 Nameplate

Every pump has a name plate made in stainless

steel with information regarding operating condition

as capacity, total dynamic head, rotational speed,

specific gravity, rotor setting, power consumption

and serial number.

1.7.2 Warning labels

A stainless steel plate is attached to discharge

head requesting removing coupling bolts before

checking motor rotation and avoid damage to the

equipment.

Measures are required to:

• Avoid excess temperature

• Prevent build up of explosive mixtures

• Prevent the generation of sparks

• Prevent leakages

• Maintain the pump to avoid hazard

The following instructions for pumps and pump

units when installed in potentially explosive

atmospheres must be followed to help ensure

explosion protection. Both electrical and nonelectrical equipment must meet the requirements of

European Directive 94/9/EC.

1.6.4.1 Scope of compliance

Use equipment only in the zone for which it is

appropriate. Always check that the driver, drive

coupling assembly, seal and pump equipment are

suitably rated and/or certified for the classification of

the specific atmosphere in which they are to be

installed.

Where Flowserve has supplied only the bare shaft

pump, the Ex rating applies only to the pump. The

2 TRANSPORT AND STORAGE

1.8 Specific machine performance

For performance parameters see data sheet and

performance curve in this User Instructions.

1.9 Noise level

When pump noise level exceeds 85 dBA attention

must be given to prevailing Health and Safety

Legislation, to limit the exposure of plant operating

personnel to the noise. The usual approach is to

control exposure time to the noise.

Pump noise level is dependent on a number of

factors - the type of motor fitted, the operating

capacity, pipework design and acoustic

characteristics of the building.

Page 5 of 32

Page 6

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

2.1 Consignment receipt and

unpacking

Immediately after receipt of the equipment it must

be checked against the delivery/shipping

documents for its completeness and that there has

been no damage in transportation. Any shortage

and/or damage must be reported immediately to

Flowserve Pump Division and must be received in

writing within one month of receipt of the

equipment. Later claims cannot be accepted.

Check any crate, boxes or wrappings for any

accessories or spare parts that may be packed

separately with the equipment or attached to side

walls of the box or equipment.

Each product has a unique serial number. Check

that this number corresponds with that advised and

always quote this number in correspondence as

well as when ordering spare parts or further

accessories. For Flowserve contact see point 11.4

For installing pump handle the pump as follow:

2.2 Handling

Boxes, crates, pallets or cartons may be unloaded

using fork-lift vehicles or slings dependent on their

size and construction.

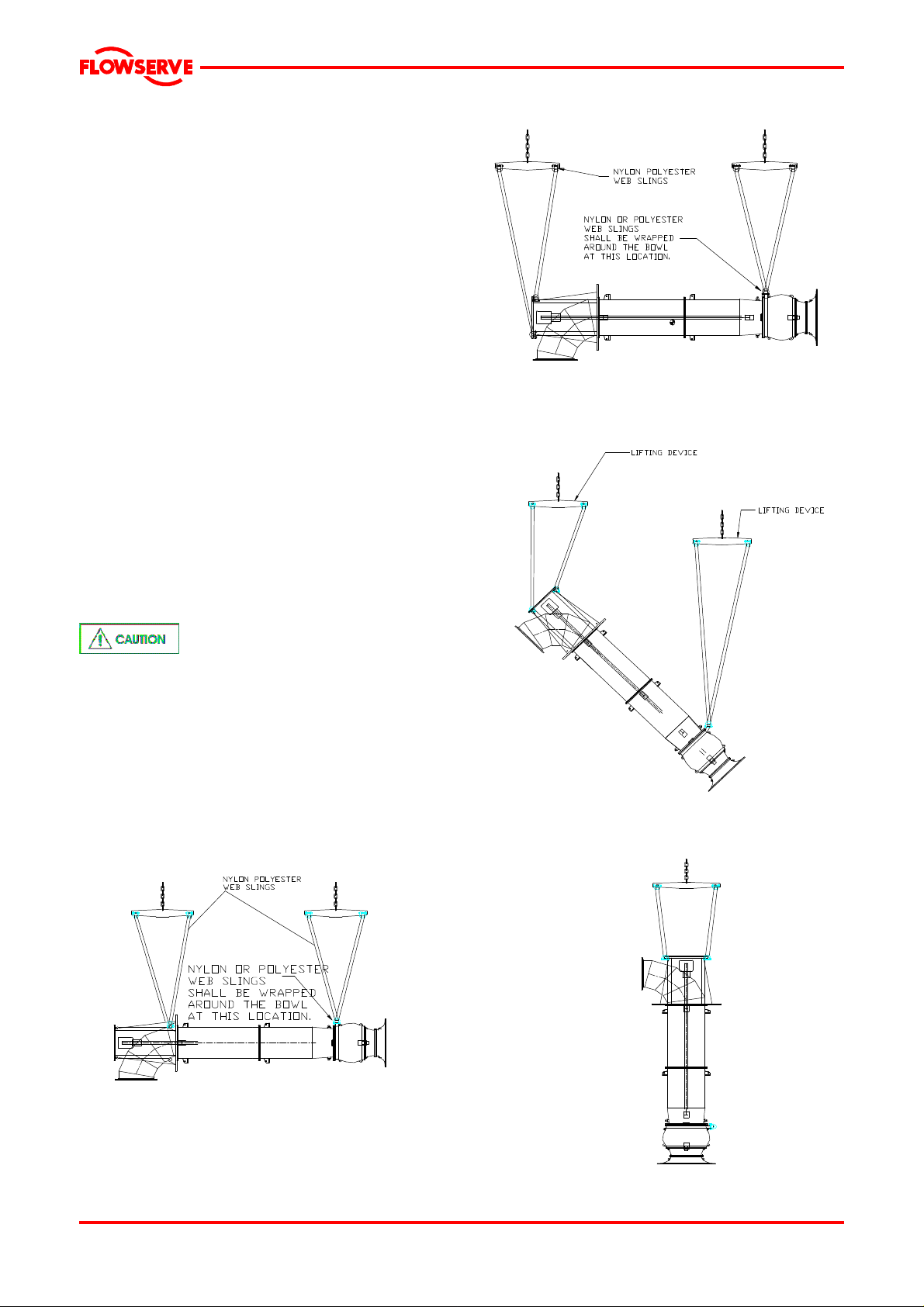

2.3 Lifting

To avoid distortion, the pump unit

should be lifted as shown. All lifting should be done

using the lifting points that have been provided.

(See the outline drawing for location, size

configuration and for total equipment weight.)

Arrange any slings, chains or cables so that the

weight is distributed uniformly. Use spread bars

when necessary to avoid undue pressure on light

sheet metal parts.

If lifting lugs are provided on discharge head

baseplate lift it as shown.

If lifting lugs are provided in the top of discharge

head , lift it as follow.

Page 6 of 32

Page 7

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

The typical nomenclature above is the general

Fully trained personnel must carry out lifting,

in accordance with local regulations. The driver

and pump weights are recorded on their respective

General Arrangement Drawing.

2.4 Storage

Store the pump in a clean, dry

location away from vibration. Equipment stored in

horizontal position must be placed upon enough

skids or wood blocks to prevent contact with

ground and surface contaminants. Leave piping

connection covers in place to keep dirt and other

foreign material out of pump casing.

Renew the preservative coating in areas where it

has been rubbed off or scraped including internal

areas and replace covers on openings.

Touch up the areas has been chipped or scraped.

Twice a month 180° rotation of pump is needed in

order to decrease shaft distortion due to horizontal

storage.

Longer storage periods (more than 5 months), it is

required to create and store the pump fully

disassembled when it has rubber bearings in order

to prevent rubber bearings deformation. Contact

Flowserve´s representative when longer than 5

months storage will be done ( See section 10 )

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and in accordance with local

regulations. If the product contains substances that

are harmful to the environment, these should be

removed and disposed of in accordance with

current local regulations.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the

current local regulations at all times.

3 PUMP DESCRIPTION

3.1 Name nomenclature

The pump size will be engraved on the nameplate

as exemplar below:

65 APM

Where:

Nominal size: 65

Pump type: APM

guide. Identify the actual pump size and serial

number from the pump nameplate. Check that this

agrees with the applicable certification provided.

3.2 Design of major parts

3.2.1 Bowl.

The pump has its main part in the bowl which

conducts liquid from impeller to column pipe and

converts to pressure the velocity added by the

impeller.

3.2.2 Impeller

The impeller is semi-open type and it is dynamically

balanced

3.2.3 Shaft

The large diameter stiff shaft, supported by

bearings is accurately machined.

3.2.4 Bearings and lubrication

Bearings are fitted as standard and are lubricated

by pumped liquid.

3.2.5 Suction bell

This piece approaches liquid to impeller eye in

optimum way.

3.2.6 Stuffing box housing

The stuffing box contains packing which controls

leakage thru pump shaft passage.

3.2.7 Driver

The driver is normally an electric motor. Different

drive configurations may be fitted such as internal

combustion engines, turbines, hydraulic motors etc.

driving via couplings, belts, gearboxes, drive shafts

etc.

3.2.8 Accessories

Accessories may be fitted when specified by the

customer on data sheet or purchase order.

3.3 Performance and operating limits

This pump has been selected to meet the

specifications of your purchase order for more

details see attachment in this User Instructions.

4 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations.

4.1 Location

The pump should be located to allow room for

access, ventilation, maintenance and inspection

Page 7 of 32

Page 8

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

with ample headroom for lifting it. Refer to the

general arrangement drawing for the pump set.

4.2 Part assemblies

Motor is typically supplied loose. It is the

responsibility of the installer to ensure that the

motor is assembled to the pump and lined up as

detailed in section 4.5.2 and 5.5

4.3 Foundation

The foundation should be

sufficiently substantial to absorb vibration and to

form a permanent, rigid support for the pump. The

mass of the foundation it is considered that

foundation has an infinite mass since there will not

be resonance between pump mass and foundation

mass.

The combined resonant frequency of the pump,

motor, foundation and discharge piping has been

calculated to be sufficiently removed from the

rotational speed so that no vibration amplification

will occur. This analytical model has been based

upon the following:

A). A rigid foundation support system that has

a stiffness of at least 2.5 x 105 lb/ft. It has been

assumed that the pump foundation provides no

lateral deflection to the combined assembly.

B). An assumed discharge piping stiffness has

been used to simulate the effect of the discharge

piping.

Non-compliance with the provision of correct

foundation and installation may lead to failure of the

pump and, as such, would be outside the terms of

the warranty.

4.4 Grouting

After levelling foundation plate, soleplate or suction

barrel flange at 0.050mm (0.002 in.) maximum,

using a straight bar which cross the sole plate sideto-side and a precision level device. Pour the

grouting in order to fill the cavity below the

foundation plate. It is important that a non-shrink

type of grout be used. Ordinary cement, sand and

water mixtures tend to shrink as the water

evaporates, often leaving the underside of the

foundation plate insufficiently supported. It is

recommended that grouting be performed by a

qualified grouting contractor. If in any doubt, see

attachment in this user instructions or please

contact your nearest service centre.

Grouting provides solid contact between the pump

unit and foundation, prevents lateral movement of

running equipment and dampens resonant

vibrations.

Foundation bolts should only be fully tightened

when the grout has cured.

4.5 Alignment

4.5.1 Thermal expansion

The pump and motor will normally

have to be aligned at ambient temperature and

thermal expansion occurs after running at operating

temperature. After eight hours of operation shut

down and check the alignment immediately.

4.5.2 Alignment method

Ensure pump and driver are isolated

electrically and the half couplings are disconnected.

The alignment MUST be checked to

ensure successful operation using dial indicators as

follow:

a) Before mounting the motor check rotation

(see point 5.3 ).

b) Support driver vertically, shaft facing down

and thoroughly clean the shaft and

mounting faces.

c) Install motor half coupling with its key and

split ring on motor shaft, pull it down to

seat firmly against the split ring.

d) Install pump half coupling and adjusting

nut.

e) Using a dial indicator mounted to the driver

half coupling, rotate driver shaft to take

readings from the pump shaft, and move

the driver as necessary to align driver and

pump shaft within 0.002” ( 0.03 mm) total

indicator run out and tighten driver

mounting fasteners.(see Rotor setting

point 5.3)

f) Refer to driver manufacturer’s manual for

driver operating instructions and

lubrication. ( See point 10.2 )

Page 8 of 32

Page 9

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

4.6 Piping

Protective covers are fitted to the

discharge flange, pipe connections and suction

head, to prevent foreign bodies entering during

transportation and installation. Ensure that these

covers and shipping brace are removed from the

pump before connecting any pipes.

Never use the pump as a support

for piping.

Maximum forces and moments allowed on the

pump flanges vary with the pump size and type

(see general arrangement drawing for specific

values). To minimize these forces and moments

that may, if excessive, cause misalignment,

vibration and the possible failure of the pump , the

following points should be strictly followed:

• Prevent excessive external pipe load, design

piping system to minimize pump nozzle loads.

• Permit no excessive strain on the pump

discharge flange

• Never draw piping into place by applying force

to pump flange connections

• Provide expansion joints with tie rods of

suitable strength ( sized for 1 ½ times shut off

pressure).

• Discharge valve should be located at least one

pipe diameter from face of pump discharge

flange.

• Special considerations and provisions must be

made to avoid the chance of water-hammer

during pump operation and start up pump.

Ensure piping is flushed before use.

4.7 Final shaft alignment check

After connecting piping to the pump, rotate the

shaft several times by hand to ensure there is no

binding and all parts are free.

Recheck the coupling alignment, as previously

described, to ensure no pipe strain. If pipe strain

exists, correct piping, see point 4.5.2

4.8 Electrical connections

4.8.1 Electrical connections must be

made by a qualified Electrician in accordance with

relevant local national and international regulations.

4.8.2 It is important to be aware of the

potentially explosive areas where compliance is an

additional requirement for making electrical

connections.

4.8.3 The motor must be wired up in

accordance with the motor manufacturer's

instructions in this user instructions including any

temperature, earth leakage, current and other

protective devices as appropriate. The

identification nameplate should be checked to

ensure the power supply is appropriate.

4.8.4 A device to provide emergency

stopping must be fitted.

4.8.5 The controller/starter electrical details will

also be supplied within the controller/starter when

applied.

4.8.6 See section 5.3, Direction of

rotation before connecting the motor to the

electrical supply.

5 COMMISSIONING, START-UP,

OPERATION AND SHUTDOWN

These operations must be carried

out by fully qualified personnel.

5.1 Pre-commissioning procedure

5.1.1 Lubrication

Determine the mode of lubrication of the pumpmotor set and supply it.

5.2 Motor lubricants

See Motor’s manual and motor outline in

attachment in these User Instructions for motor

lubrication details before any start up or test.

5.3 Direction of rotation

Ensure the pump motor is given the

same rotation as the pump direction arrow marked

on the pump nameplate and Outline Drawing.

Some vertical motors are required to have non

reverse couplings (non reverse device), to avoid

pump-motor back spinning do to water column flow

back during shutdown.

However the device is designed to support the

forces developed by the pump, when the water is

flowing back, which is increase gradually, the

device is not expected to support the motor torque,

which is suddenly applied as a shock a would

damage the pins or ratchet plate teeth; Base on

this, the motor must never be started against the

ratchet pins, to avoid pins or ratchet plate damage

Page 9 of 32

Page 10

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

and as in consequence, catastrophic failure to the

top parts of the motor.

If the phase sequence of the incoming motor power

cables is not positively known and the motor is to

be “bumped” for rotation check, the ratchet pins

must be removed from the pin carrier, to avoid the

expected damage to the non reverse device.

The pins removal is under customer or motor

installer responsibility.

Whenever the dismantling of couplings is

necessary, the use of witness marks will assure a

balanced condition when assembly is complete.

If maintenance work has been

carried out to the site's electricity supply, the

direction of rotation should be re-checked as above

in case the supply phasing has been altered.

It is recommended that records be kept pf the

steady state uncoupled vibration and bearing

temperatures to use for comparison with coupled

and loaded conditions, and to provide a data base

for judging the motor’s performance in the future.

These records should be permanently retained for

reference.

5.4 Guarding

f) Turn motor half coupling so bolt holes will

line up with the bolt holes in the pump half

coupling

g) Insert two of the coupling bolts and tighten

progressively until secure, thereby closing

the gap above the adjusting nut and raising

rotor to running position.

h) Insert the remaining bolts and tighten them

securely.

i) Check for free rotation of driver and pump

shaft. (See coupling detail in section 8)

j) If mechanical seal is supplied, the set

screws of drive collar must be tighten in

this moment.

Guarding is supplied fitted to the pump set. If

this has been removed or disturbed ensure that all

the protective guards around the pump coupling and

exposed parts of the shaft are securely fixed.

5.5 Rotor Setting

Before pump start up, it is required

adjust the impeller setting and avoid rubbing

between impeller and impeller liner which can

damage severely the pump, Rotor setting is

specified on pump nameplate and pump outline

drawing.

Follow next procedure in order to adjust the rotor

setting:

a) Fit motor half coupling on motor shaft.

b) Fit split ring on motor shaft and move

motor half coupling until it covers the split

ring.

c) Fit pump half coupling on the pump top

shaft.

d) Fit adjusting nut on the pump top shaft.

e) Adjust separation between adjusting nut

and motor half coupling at rotor setting

specified on nameplate; Use feeler gages.

5.6 Starting the pump

a) CLOSE the outlet valve, two –speed motor

operator with valve opening and slow closing.

Generally 15/45 second timing works

satisfactorily for most pump systems. 15

second to open , 45 second to close totally the

valve. A single speed valve motor, most

economical, at 60 second should be

satisfactory.

b) PRE-OPEN pump valve to 30 degrees with

motor interlocked to start and stop position.

The system can be primed or unprimed. If

unprimed, system downstream should be fully

opened and vented while hold valve to 30

degrees until system is stabilized, motor

reaches rated speed and / or discharge piping

is completely full.

c) On Fully Prime System using a 15/45 second

valve operator. Start pump and valve

simultaneously.

Page 10 of 32

Page 11

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

5.7.2 Pumps fitted with mechanical seal

d) Check outlet pressure.

e) Check outlet capacity.

f) Check vibration at rated capacity. Note that

vibration at different capacity than rated

capacity could be bigger.

g) Check motor current.

5.7 Running the pump

5.7.1 Pumps fitted with packed gland

Mechanical seals will be adjusted to pump shaft

tighten collar set screws and moving set pieces

after rotor setting was done according point 5.5;

Any slight initial leakage will stop when the seal is

run in.

Before pumping dirty liquids it is advisable, if

possible, to run in the pump mechanical seal using

clean liquid to safeguard the seal face.

External flush or quench should be

started before the pump is run and allowed to flow

for a period after the pump has stopped.

Never run a mechanical seal dry,

even for a short time.(See mech. seal IOM manual)

5.7.3 Normal vibration levels, alarm and trip

If the pump has a packed gland there must be

some leakage from the gland. Gland nuts should

initially be finger-tight only. Leakage should take

place soon after the stuffing box is pressurised.

The gland must be adjusted evenly to give

visible leakage and concentric alignment of the

gland to avoid excess temperature. If no leakage

takes place the packing will begin to overheat. If

overheating takes place the pump should be

stopped and allowed to cool before being restarted. When the pump is re-started, check to

ensure leakage is taking place at the packed gland.

The pump should be run for 30 minutes with steady

leakage and the gland nuts tightened by 10

degrees at a time until leakage is reduced to an

acceptable level, normally a minimum of 120 drops

per minute is required. Bedding in of the packing

may take another 30 minutes.

Care must be taken when adjusting the gland

on an operating pump. Safety gloves are essential.

Loose clothing must not be worn to avoid being

caught up by the pump shaft. Shaft guards must

be replaced after the gland adjustment is complete.

Never run gland packing dry or too

tighten, even for a short time.

Alarm and trip values are given in

attachment in these User Instructions. Measuring

vibration at regular intervals will then show any

deterioration in pump or system operating

conditions.

5.8 Stopping and shutdown

a) Close the outlet valve until 30

degrees.

b) Stop the pump motor.

c) Continue closing the outlet valve.

5.9 Emergency shutdown

In the event of power failure, water from system will

flow in reverse through the pump while the pump

discharge valve must be slowly closing. The pump

and motor are designed so that no damage will

occur from turning at speeds until 140% of rated

speed which will be generated by the operating

head in the pipe discharge system.

6 MAINTENANCE

6.1 General

It is the plant operator's responsibility to

ensure that all maintenance, inspection and

assembly work is carried out by authorized and

qualified personnel who have adequately

familiarized themselves with the subject matter by

studying this manual in detail. (See also section

1.6.2.)

Any work on the machine must be performed when

it is at a standstill. It is imperative that the

Page 11 of 32

Page 12

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

procedure for shutting down the machine is

followed, as described in section 5.8.

On completion of work all guards and safety

devices must be re-installed and made operative

again.

Before restarting the machine, the relevant

instructions listed in section 5, Commissioning,

start up, operation and shut down must be

observed.

Oil and grease leaks may make the ground

slippery. Machine maintenance must always

begin and finish by cleaning the ground and the

exterior of the machine.

If platforms, stairs and guard rails are required for

maintenance, they must be placed for easy access

to areas where maintenance and inspection are to

be carried out. The positioning of these

accessories must not limit access or hinder the

lifting of the part to be serviced.

When air or compressed inert gas is used in the

maintenance process, the operator and anyone in

the vicinity must be careful and have the

appropriate protection.

Do not spray air or compressed inert gas on skin.

Do not direct an air or gas jet towards other people.

Never use air or compressed inert gas to clean

clothes.

Before working on the pump, take measures to

prevent an uncontrolled start. Put a warning board

on the starting device with the words: "Machine

under repair: do not start".

With electric drive equipment, lock the main switch

open and withdraw any fuses. Put a warning board

on the fuse box or main switch with the words:

"Machine under repair: do not connect".

Never clean equipment with inflammable solvents

or carbon tetrachloride. Protect yourself against

toxic fumes when using cleaning agents.

6.2 Maintenance schedule

of the gland follower to prevent excessive

temperature of the packing or follower.

c) Check for any leaks from gaskets and

packings. The correct functioning of the shaft

seal must be checked regularly.

d) Check that the duty condition (capacity, head,

voltaje, current, etc. ) is in the design operating

range for the pump and record them.

e) Check vibration to confirm satisfactory

operation.

f) Check dirt and dust is removed from areas

around pump and motor.

g) Check coupling alignment and re-align if

necessary.

Our specialist service personnel can help with

preventative maintenance records and provide

condition monitoring for vibration to identify the

onset of potential problems.

If any problem are found the following sequence of

actions should take place:

a) Refer to section 7, Faults; causes and

remedies, for fault diagnosis.

b) Ensure equipment complies with the

recommendations in this manual.

c) Contact Flowserve if the problem persists.

6.2.1 Routine inspection (daily/weekly)

The following checks should be

made and the appropriate action taken to remedy

any deviations:

a) Check operating behaviour. Ensure vibration is

normal.

b) Check that there are no abnormal fluid or

lubricant leaks (static and dynamic gasket or

packing ) and that any sealant systems (if

fitted) are full and operating normally.

c) Check that shaft seal leaks are within

acceptable limits.

d) Check the level and condition of motor

lubricant. Check running hours since last

recharge or complete lubricant change.

e) Check any auxiliary supplies (if fitted) are

functioning correctly.

Refer to the manuals of any associated

equipment for routine checks needed.

6.2.2 Periodic inspection (six monthly)

It is recommended that a maintenance plan

and schedule is adopted, in line with these User

Instructions, to include the following:

a) Any auxiliary systems installed must be

monitored, if necessary, to ensure they function

correctly.

b) Gland packings must be adjusted correctly to

give visible leakage and concentric alignment

Page 12 of 32

a) Check foundation bolts for

security of attachment and corrosion.

b) Check pump running records for hourly usage

to determine if there is some operating change.

c) The coupling should be checked for correct

alignment (If necessary ).

Page 13

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

(optional:

Refer to the manuals of any associated

equipment for periodic checks needed.

6.2 3 Re-lubrication

Refer to the motor manual and any

associated equipment for periodic checks needed.

6.3 Spare parts

6.3.1 Ordering of spares

Flowserve keep records of all pumps that have

been supplied. When ordering spares the following

information should be quoted:

1) Pump serial number

2) Pump size

3) Part name – taken from sectional drawing

in attachment.

4) Part number – taken from sectional

drawing in attachment.

5) Number of parts required

The pump size and serial number are shown on the

pump nameplate.

If over size or under size parts are required (liked to

wear rings) a sketch is required with indication of

diameter dimension required.

To ensure continued satisfactory operation,

replacement parts to the original design

specification should be obtained from Flowserve.

Any change to the original design specification

(modification or use of a non-standard part) will

invalidate the pump’s safety certification. For

Flowserve contact see section 10 at the end of

these user instructions.

6.3.2 Storage of spares

Spares should be stored in a clean dry area away

from vibration. Inspection and re-treatment of

metallic surfaces (if necessary) with preservative is

recommended at 6 monthly intervals.

1 - impeller wear rings)

For 4 years operation:

1 - set of bearings

1 - sets of gland packing

1 - shaft sleeves

1 - set of gaskets

1 - set of casing wear rings

1 - impeller

(optional:

1 - impeller wear rings)

6.5 Tools required

Any special tool is required to maintain these

pumps.

6.6 Fastener torques

6.6.1 Flange mating

Surfaces shall be thoroughly cleaned. Assemble

joint and hand tighten all fasteners to insure

uniform metal-to-metal contact of the mating

surfaces.

6.6.2 Using the proper size torque wrench

( Work in ¼ to ¾ of wrench scale ) Pretorque

fasteners with an even steady pull to approximately

1/3 of the torque value in the sequence specified

below. Repeat sequence increasing torque to

approximately 2/3 of the specified value.

Finally repeat sequence for the specified torque.

6.6.3 start with any bolt

Identify as (1) and location designated as 0°, bolt

(2) will be at 180°, bolt (3) at 270° , and bolt (4 ) at

90°, Using counterclockwise rotation, tighten bolt

(5), (see figure below , where number of bolts are

only as example) and continue rotation until all

bolts have been tightened.

6.4 Recommended spares and

consumable items

For start up purposes:

1 - complete set of packing

1 - set of gaskets and o rings

For 2 years operation:

1 - set of bearings

1 - set of packing

1 - shaft sleeve

1 - set of gaskets

1 – set of casing wear rings

Page 13 of 32

Page 14

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

Bolt size Torque Nm (lbft)

M 16 (⅝ in.) 84 (62)

M 20 (¾ in.) 165 (120)

M 24 (⅞ in.) 285 (210)

M 27 (1 in.) 375 (275)

M 30 (1⅛ in.) 540 (400)

M 36 (1⅜ in.) 900 (660)

M 42 (1⅝ in.) 1 410 (1 040)

M 48 (1⅞ in.) 2 060 (1 500)

6.7 Renewal clearances

As wear takes place between the impeller and

casing ring the overall efficiency of the pump set

will decrease. To maintain optimum efficiency it is

recommended that rings are replaced and the

impeller renovated when the radial clearance

detailed in attachment in this User Instructions is

1.5 bigger than new clearance.

6.8 Disassembly

f) Remove pump half coupling (7210) with key

from upper shaft (2130).

g) Remove bolting holding split gland (4120) to

stuffing box (4110) and remove split gland.

Remove stuffing box packing (4120).

6.8.1.2 Removing the pump

This pump is best removed from the system to

carry out complete strip down, next procedure is for

short pumps which can be removed completely

assembled. Longer pumps should be removed from

the pit removing sections at time.

Refer to section 1.6, Safety, before

dismantling the pump; All numbers in parenthesis( )

correspond to the part numbers on the Sectional

drawing.

a) Using the overhead hoist, lift the complete

pump from the pit until the suction head (1130)

is about two feet above the pit opening. With

the pumping element suspended in a vertical

position ring a sling (provided by customer)

around the casing (1170) as showed in figure

Before dismantling the pump for

overhaul, ensure genuine Flowserve replacement

parts are available.

Refer to sectional drawing in attachment for part

numbers and identification.

6.8.1 Maintenance

6.8.1.1 Dismantling procedure

WARNING.- Do not attempt any maintenance,

inspection, repair or cleaning in the vicinity of

rotating equipment. Such action could result in

personal injury to operating personnel.

a) Break and tag motor circuit breaker.

Disconnect the motor leads.

b) Remove coupling guards from “windows” in

discharge head (1371) and motor support.

c) If mechanical seal is supplied, loose set screws

from the drive collar ( in this way, the shaft and

seal sleeve will have free movement).

d) Disconnect coupling halves (7210-7220) taking

precautions not to allow the pump rotor to fall

as the coupling bolts are removed, turn

opposed bolts alternately.

e) Remove the motor bolting. Lift off the motor

from the discharge head (1371) and place it on

blocking on the floor.

of point 2.3, Using both overhead hoist,

maneuver the pump into a horizontal position.

b) Using both overhead hoist, lower the pump

onto wood blocking on the floor

NOTE

At not time should the whole pump be lifted or

supported by the casing or column lugs. At not time

should the pump rotated or supported on the

suction head.

c) Install slings (provided by customer) around

discharge head at the upper/lower flanges and

ring to and overhead hoist. Remove bolting

holding discharge head to outer column (6579).

Remove discharge head off over coupling end

of upper shaft (2130) and place on blocking on

the floor. Remove “gasket eliminator” (See

point 10.3 ) material from mating surfaces or

discharge head and outer column.

d) Rig outer column (1350) to an overhead hoist.

Remove the bolting (6579) from between outer

column and casing (1170). Remove outer

column off over coupling end of upper shaft

(2130) and place on blocking on the floor.

Remove “gasket eliminator” material from

mating surfaces of outer column and casing.

Page 14 of 32

Page 15

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

NOTE

As outer column (1350) is being removed from

upper shaft (2130), the blocking under exposed

portion of upper shaft will have to be removed and

reinstalled under exposed portion of upper shaft.

e) Install sling along upper shaft (2130) and rig to

an overhead hoist. Remove the bolting

between the gib key and shaft coupling (7238).

Remove split ring (7415) from groove in pump

end shaft (2110). Slide shaft coupling up on

upper shaft until the shaft coupling key in upper

shaft is exposed. Remove both gib key and

shaft coupling key in upper/pump end shaft

(2110). Using the overhead hoist, lift and place

upper shaft on horses and block to prevent

rolling and dropping. Remove shaft coupling

(7238) from lower end of upper shaft.

f) Install a sling in exposed upper flange of casing

(1170) and rig to overhead hoist. Install a sling

around suction head (1130) and rig to auxiliary

hoist. Using both hoists, lift the pump assembly

from blocking and carefully maneuver into a

vertical position until assembly is suspended

vertically from the rigging attached to the

eyebolts in casing (1170) upper flange. At not

time should the pump rotated or supported on

the suction head.

g) Remove the casing to suction head bolting

(6579). Using the rigging attached to casing

(1170) upper flange. Lift and remove casing off

over upper end of pump end shaft. Remove

“gasket eliminator” (See point 10.3) from

mating surfaces of casing and suction head

(1130).

NOTE

Take care when removing the casing (1170) so as

not to damage bearings (3312)

h) Install eyebolts and slings (not provided) into

upper end of the pump end shaft (2110) and rig

to overhead hoist, Remove pump end shaft

and impeller (2262) as a unit from the suction

head (1130).

i) Remove the four socket head caps crews (6579 )

with lockwasher from the split lock collar (2531).

Block up the impeller (2262). Place a block of wood

over the top of the pump shaft (2110) and tap until

lock collar is completely clear of the impeller.

Remove the lock collar (2110) and withdraw the

pump shaft , with key (6710) from the impeller,

Place pump shaft on horses and block to prevent

rolling.

6.8.1 Multistage pumps

Described procedure is applicable for pumps with

two or more stages which will be disassembly and

assembly at same way, see figure 8.1.3 page 22

6.9 Examination of parts

Used parts must be inspected

before assembly to ensure the pump will

subsequently run properly. It is recommended

replace all gaskets, “O” rings, bearings and wear

rings during overhaul.

In particular, fault diagnosis is essential to enhance

pump and plant reliability.

1. Wire brush and clean all pump parts. Inspect

parts for wearing, corrosion, and erosion. Inspect

the impeller (2262) and casing (1170) for cracks.

2. Indicate each section of shaft on rollers or Vblocks for runout.

A. Indicate each section of shaft on “V” blocks or

rollers for total indicated runout (TIR). The shaft

shall be supported by two “V” blocks (rollers) near

the ends of the shaft at the bearing and/or coupling

areas of approximately the same diameter. The TIR

of the rollers (“V blocks) shall not exceed .0005

E

inches per foot, with a maximum variation of

0.005”. The shaft journals or journals sleeves must

be round to within .001 inch at the support areas on

the “V” blocks or rollers.

B. Total indicator readings should be taken at every

bearing and coupling area and/or every 12 inches

between long bearing spans. Record distances

from end of shaft to each TIR measurement. TIR

measurements are to be taken every 90 degrees

around the shaft.

C. Maximum allowable TIR is .001 inch X total

length of shaft in feet. Shaft that exceed the limit

can be straightened by either cold straightening or

heat straightening. Refer to Flowserve Engineered

Pump Division for heat straightening procedure.

Page 15 of 32

Page 16

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

3. Journal sleeves (3420).

Inspect journal sleeves. If journal sleeves are worn,

they can be removed and sliding sleeves from

shafts. Install new journal sleeve onto shaft and

locate sleeve on its key.

4. Bearings (3320)

A. Removal

Remove setscrews from bearings. Bearing can be

removed by pressing the old bearing out of its

respective fit in the stuffing box extension (4110)

and casing (1170). If this is not practical, bearing

must be machined until disappear it

B. Assembly

Chill rubber bearing and fit into place or press

bronze bearing into its fit.

If graphite bearings are supplied, they can be

installed using a constant hydraulic press in dry,

but, it is recommended that bushings should be

dipped in water solvent or kerosene for easier

installation.

Chill carbon bearing using nitrogen or refrigerator is

a good option too.

CAUTION

WHEN INSTALLING THE “CUTLESS RUBBER

BEARING” (3300- 3320) DO NOT CHILL TO

LESS THAT 0°F. AS THE RUBBER PORTION OF

THE BEARING WILL DETACH FROM ITS

RESPECTIVE METAL BACKING.

Install new setscrews in bearings and apply “loctite”

(screw lock grade) to the threads.

NOTE

If used holes for bearing setscrews cannot be

located when installing the bearings, then new

holes will have to be drilling to spot the bearings to

ensure securing to the bearing in their proper

location with setscrew.

5.-Renew “O” rings (4610) and packing (4120)

during reassembly procedure.

6.10 Assembly

To assemble the pump consult the sectional

drawings, see section 8, Parts list and drawings.

Ensure threads, gasket and O-ring mating faces

are clean. Apply thread sealant to thread fittings.

Threaded fittings torque should be periodically

checked to assure that it is at the recommended

value and be sure fittings are not loose.

6.10.1 Wear rings

a) Impeller rings (when fitted) should be slipped

onto the impeller and pressed down to the

shoulder. (Do NOT use a steel hammer to

knock them into position).

b) Drill and tap 3 holes approximately 120° apart

into the diametral mating faces of the ring and

impeller and insert set screws. (The existing

tapped holes from the removed impeller ring

cannot be re-used).

c) Case wear rings must be fitted onto casing (Do

NOT use a steel hammer to knock them into

position) and locate set screws approximately

120° apart (The existing tapped holes from the

removed set screws cannot be re-used).

d) Check the running clearance between impeller

and casing ring against value indicated in

attachment in these User Instructions.

6.10.2 Reassembly

a) Place pump shaft (2110) on horses and block to

prevent rolling. Install impeller key (6710) in

machined groove of pump shaft (2110). Install

impeller (2262) on shaft.

b) Install split lock collar (2531), plus four cap

screw / tabwashers. Tighten the cap screws to

a final torque and bend the tab of the washer.

c) Install the eyebolt (not provided) into coupling

end pump shaft (2110) and rig to an overhead

hoist. Raise pump shaft with impeller intact, to

a vertical position.

d) Be sure suction head (1130) assembly is

properly supported, in a vertical position,

blocking on the floor. Carefully place pump

shaft with impeller, into suction head (1130)

until impeller vanes are resting against inner

wall of suction head.

Page 16 of 32

Page 17

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

e) Using eyebolts with washer/nuts (not provided),

rig casing (1170) upper flange to overhead

hoist. Raise casing to a vertical position

directly over pump shaft. Apply a layer of

“gasket eliminator” (See point 10.3) to upper

flange of suction head (1130). Carefully lower

casing over end of pump shaft until casing is

resting in position on suction head. Install

casing to suction head bolting (6579) and

torque. Do not unhook rigging attached to

eyebolts in casing upper flange.

NOTE

Be sure case bearing (3312) was fitted previously

into case and during assembly bearings do not

“Hang –up” when passing over shafts.

f) Using rigging attached to eyebolts in casing

(1170) upper flange. Lift pump assembly

slightly and install sling (provided by customer)

around lower portion of the casing. Rig sling to

an auxiliary hoist. Using both hoist lift pump

assembly from blocking and maneuver into a

horizontal position on blocking on the floor.

NOTE

At no time should the pump assembly be rotated on

the suction head (1130) or strikes the floor or other

object.

g) Be sure casing and pump shaft are properly

positioned on blocking on the floor (horizontally

leveled).

h) Install sling along upper shaft (2130) and rig to

an overhead hoist. Install shaft coupling (7238)

over lower end of upper shaft. Slide shaft

coupling beyond keyway for shaft coupling key.

Lift upper shaft in a horizontal position taking

care that shaft coupling (7238) does not drop

off upper shaft. Place upper shaft into position

as close as possible to pump shaft (2110)

without hitting them together. Install split ring

halves (7415) which locks the upper shaft to

pump end shaft. Install shaft coupling keys into

keyways of both shafts. Slide shaft coupling

down over keys and split ring until the shaft

coupling comes in contact with gib key. Install

the socket screw bolting between shaft

coupling and key. Tighten and torque.

NOTE

Upper shaft (2130) must be supported on blocking

before removing rigging from overhead hoist (do

not hung it).

i) Using the overhead hoist, lift the outer column

(1350) from blocking on the floor in a horizontal

position. Apply layer of “gasket eliminator” to

upper flange of casing (1170). Install outer

column over coupling end of upper shaft and

into position against upper flange of casing.

Install bolting between outer column and

casing and torque them.

NOTE

Blocking under upper shaft (2130) will have to be

removed and reinstalled as outer column (1350) is

being installed.

j) Install slings (provided by customer) through

“windows” of the discharge head (1371) and rig

to an overhead hoist. Lift the discharge head

from blocking on the floor in a horizontal

position. Apply a layer of “gasket eliminator”

on upper flange of outer column (1350). Install

discharge head over coupling end of upper

shaft and into position on outer column. Install

bolting between discharge head and outer

column and torque them.

k) Install “O” ring (4610) and stuffing box

extension journal sleeve (4610) over upper end

of upper shaft (2130) and position on key

(6733) and retaining ring at the sleeve end.

l) Rig and install stuffing box extension (4110) on

discharge head. Install stuffing box extension

to discharge head bolting and torque them.

m) Install chains or slings (provided by customer)

through big lifting lugs in discharge head

(1371) and around casing (1170) and rig to an

overhead hoist. Using both hoists, carefully

raise the unit to a vertical position over the pit,

taking care not to rotate or support the

assembly on suction head (1130). Remove

sling around casing. Lower unit into pit unit until

the discharge head flange rests on the

soleplate (6140) and bolting.

n) Check pump / motor direction of rotation as

described on point 5.3

o) If mechanical seal is supplied, install seal box

and seal cartridge – without tight set screws of

drive collar

p) Install pump half coupling, adjusting nut and

motor with its half coupling and make

alignment according point 4.5.2

q) Adjust rotor setting according point 5.5

r) Install back ring (4132), packing (4120) and

packing gland, see point 5.7.1 (if mechanical

seal is supplied, tight set screws of drive collar)

s) Install auxiliary piping and wiring. Install air

release valve (if used). Install coupling guards

on “windows” in the pump discharge head.

Page 17 of 32

Page 18

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

7 FAULTS; CAUSES AND REMEDIES

Trouble Cause Remedy

Insufficient Capacity Speed to low Check power supply to motor for

correct voltage.

Wrong rotation Reconnect motor leads

Foreign material in impeller,

casing, diffusion vanes, and/or

discharge head nozzle

Mechanical defects:

Impeller damaged.

Share impeller key.

Insufficient supply of water to be

pumped

Pump vibrates Loose mounting or coupling

bolts.

Broken or worn pieces

Coupling misalignment Check alignment and correct

Cavitation Determine proper level of water in

Foreign material in impeller

causing unbalance.

Mechanical defects:

Shaft bent.

Bearing worn.

Pump overloads driver Speed to high Check power supply for correct

Pump bearing Seize or rotating

element binds

Pump stops abruptly Pump binding at running fits Dismantle pump and correct

Stuffing box overheats Stuffing box packed too tight Repack stuffing box with new

Insufficient Leakage in packing Loosen gland nuts and retighten

Excessive Gland

Packing not seated Gland not tighten evenly loosen

Leakage

Worn Packing Replace packing

Pump is noisy Cavitation Determine proper level of water in

Loose parts Tighten or replace defective parts

Noise in driver Check driver IOM manual

Refer to driver manufacturer´s instruction manual for trouble shooting of driver

Dismantle pump and remove any

foreign material

Dismantle pump and check

Determine proper level of water in

sump and proper pump

submergence.

Tighten bolts

Inspect and replace same

sump and proper pump

submergence

Dismantle pump and remove

foreign material.

Dismantle pump and replace part

or parts causing vibration

frequency

Check rotor setting. Dismantle

pump and replace parts causing

rubbing, seizures or binding.

packing per “Stuffing Box

Packing” instructions.

finger tight or until proper leakage

is obtained

nuts and tighten evenly. (see

“Stuffing Box Packing”

instructions)

sump and proper pump

submergence

Page 18 of 32

Page 19

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

8 PARTS LIST AND DRAWINGS

8.1 Typical sectional drawing

Page 19 of 32

Page 20

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

8.1.1 Stuffing box typical sectional drawing

Page 20 of 32

Page 21

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

8.1.2 Coupling assembly drawing

Page 21 of 32

Page 22

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

8.1.3 Coupling assembly with spacer drawing

Page 22 of 32

Page 23

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

8.1.4 Discharge typical sectional drawing

Page 23 of 32

Page 24

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

8.1.5 Typical cross sectional drawing of multistage pump

Page 24 of 32

Page 25

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

8.1.6 Suction bell with bearing

When suction bell bearing is provided, it is

permanently lubricated with water resistant

grease (Shell retinax AM, Alvania EP-2 or

Mobil grease special) which does not

require change during operation.

Page 25 of 32

When pump would be removed for

overhall maintenance and suction bell

bearing would be inspected and reinstalled then the cavity into the suction

bell must be filled with clean and new

grease.

Page 26

8.2 Parts list

8.3 General arrangement drawing

The typical general arrangement drawing

and any specific drawings required by the

contract will be sent to the Purchaser

separately and a copy will be included in this

User Instructions.

9 CERTIFICATION

Certificates, determined from the contract

requirements will be provided separately.

Page 27

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

10 SUPPLEMENTARY INFORMATION

10.1 Long term storage

During extended periods of storage prior to installation and from the time of installation until commercial

operation, precautions must be taken to protect the pump from deterioration. The various parts of the pump are

protected prior to shipment by applying varying grades of preservative and paint. However, during shipment and

handling, the preservatives are subjected to conditions that can cause their removal. Also during extended

periods of time, the preservatives may deteriorate. The following procedures should be followed to prevent

deterioration of the pump during the extended storage period. These procedures may also be supplemented by

the experience of the person(s) performing the tasks.

Vertical pumps are shipped assembled when weight, length and bearing material permit. When the

pump length exceeds approximately 30 feet and/or when carbon bearings are furnished, the pump is shipped in

subassemblies. The motor driver and auxiliary accessories are packed separately.

Upon arrival at the storage site, each unit and accompanying crating should be visually inspected for shipping

damage, any of which should be reported to Flowserve.

All material shall be placed in a location protected against weather, floods and traffic damage while in storage.

All items should be stored in an accessible area, where air can circulate around them fully and completely.

Indoor storage facilities should be provided by the contractor or user, with accessories prepared in accordance

with this procedure.

All of the components should remain in their original shipping crates (if applicable). All handling should be done

with slings only and with extreme care. The customer should inspect all units every 30 days.

Recommendations given herein are made with the strict understanding that Flowserve will incur no cost

resulting from Long Term Storage Procedures. Flowserve also relinquishes any responsibility for any damage or

malfunction incurred to the unit at the time of installation due to inadequate preservation by the Customer.

It should be noted that unless otherwise agreed to, full responsibility and costs associated with the

storage and inspection of this equipment rests with the customer.

WARNING !!!

Failure to follow this procedure will jeopardize the integrity of equipment, and may

contribute to poor performance, abnormalities and associated problems when

equipment is installed and operated.

Also, failure to follow this procedure will invalidate any warranty on equipment.

CAUTION

AT NO TIME DURING STORAGE OR HANDLING IS THE PUMP TO BE ROTATED ON OR SUPPORTED BY

THE SUCTION HEAD (Suction Bell)

NOTE

If pump is equipped with a mechanical seal and is stored or has not been run for 1 year or more, the seal must

be removed before start-up and faces re-lapped to guard against the possibility of seal leakage. When

reinstalling the seal, new “O” rings and gaskets must be used.

CAUTION

AT NO TIME DURING STORAGE OR HANDLING IS THE PUMP TO BE ROTATED ON OR SUPPORTED BY

THE SUCTION HEAD (Suction Bell)

NOTE

If pump is equipped with a mechanical seal and is stored or has not been run for 1 year or more, the seal must

be removed before start-up and faces re-lapped to guard against the possibility of seal leakage. When

reinstalling the seal, new “O” rings and gaskets must be used.

Page 27 of 32

Page 28

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

INSPECTION UPON ARRIVAL

When the pump is received, it should be inspected for damage, other signs of rough handling and

double check for missing pieces. Any damage or suspicion of missing pieces should be reported immediately to

the carrier, Flowserve’s Sales Representative and Factory’s Customer Service department (or Flowserve’s

Project Management department from the factory that shipped equipment).

Inspect the preservative coating on the various parts. If necessary, renew the preservative in areas

where it has been rubbed off or scraped.

Inspect all painted surfaces. If necessary, touch up the areas where paint has been chipped or scraped.

In some cases (and on some type of pumps), the rotor is shipped in a blocked position. Do not remove

blocking until unit is to be installed. This will minimize bearing loads and rotor distortion.

Inspect all covers over pump openings and piping connections. If covers are damaged or loose, they

are to be removed, and a visual inspection made of the accessible interior areas for accumulation of foreign

materials or water. If necessary, clean and recoat the interior parts with preservative to restore the parts to the “

as shipped” condition. Install or replace covers and fasten securely.

When selecting storage area, the following should be taken into consideration:

1. The deterioration of the equipment will be proportionate to the class/type of storage provided.

2. The expense involved in restoring the equipment at time of operation will be proportionate to the

class/type of storage provided.

STORAGE PREFERRED (DRY)

GENERAL

If at all possible, the pump and its parts should be stored indoors in either the horizontal or vertical

position where they will be protected from the elements. If it is not possible to store the pump and its

components indoor precautions must be taken to protect them from the elements. When stored outdoors, the

pump and its components should be protected from dirt, dust, rain, snow, or other suitable coverings.

All equipment stored in the horizontal position must be placed upon skids or blocks to prevent contact

with the ground and surface contaminants. Equipment must be adequately supported to prevent distortion and

bending. Also, periodic (twice a week) 180° rotation of pump’s rotor is needed in order to decrease shaft

distortion due to horizontal storage. When equipment is subjected to longer storage periods (more than 5

months), it is required to crate and store the pump’s rotor fully disassembled, in order to prevent rubber bearing

deformation (if applicable), shaft distortions, shaft couplings problems, and others. Please contact Flowserve’s

representative when longer than 5 months storage will be done.

Rubber parts such as spare o-rings have a shelf life of up to 3 years if stored in original heat sealed packing and

adequately protected from air, light, ozone, radiation, excessive temperature (120 degrees F), contamination

and physical damage.

If pump is stored vertically, rotor is to be lifted and blocked to dimension shown on rotor plate.

INSPECTION AND MAINTENANCE

1. Customer Inspection And Maintenance

The stored equipment is to be placed on a periodic inspection schedule by the customer.

NOTE:

The responsibility for setting up an inspection schedule rests with the customer and will be dependent upon the

class/type of storage provided. It would be expected that, initially, inspection would occur weekly, then

Page 28 of 32

Page 29

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

depending upon the inspection reports being favorable or unfavorable, inspection would continue weekly,

monthly, or quarterly, as may be determined. Inspection reports should be kept on file.

Each inspection should consist of a

general surface inspection to assure

that:

a) Pump supports and rotor blocking are firmly in place.

b) Pump covers over openings are firmly in place.

c) Pump covering, plastic or tarps, are firmly in place. Any holes or tears must be repaired

to prevent entrance of dirt or water.

d) Pump covers are periodically removed from openings and interior accessible areas

inspected. If surface rusting has occurred, clean and repaint or recoat with preservative.

e) If rusting occurs on exterior surfaces, clean and repaint or recoat with preservative.

f) Check individually wrapped parts for signs of deterioration. If necessary, renew

preservative and wrapping.

2. Six Months Prior to Installation

Six months prior to the scheduled installation date, a Flowserve representative is to be employed

to conduct an inspection. All costs involved during inspection, dismantling, restoration,

replacement of parts and reassembly will be responsibility of the customer. The customer should

supply all necessary labor, tools, and cranes. This inspection will include (not necessarily in its

entirety) but not be limited to the following:

a) An inspection of all periodic inspection records as kept on file by the customer, and all

the inspection reports that have been compiled during the storage period.

b) An inspection of the storage area to determine the “ as stored” condition of the

equipment prior to any protective covers being removed.

c) An inspection of the equipment with protective covers and flange covers removed.

d) Depending upon the length of time the equipment was stored, the class/type of storage

provided (indoor, heated, unheated ground floor, concrete floor, out-of-doors, under roof,

no roof, waterproof covering, on concrete, on ground) and as a result of the inspection of

a, b, and c above, Flowserve representative may require a partial or complete

dismantling of the equipment.

e) Dismantling may necessitate restoration by painting preserved surfaces, and/or

replacement of gaskets, “O” rings, packing or mechanical seal bearings.

Upon completion of the inspection, the Flowserve representative shall submit a report to the

customer, and to the Manager of Customer Service, stating in detail the results of the

inspection.

3. One Month Prior To Installation.

One month prior to installation of the equipment, a Flowserve representative is to be employed to

conduct a final inspection. This final inspection will be made to assure that the requirements of

the six-month inspection report were satisfactorily completed and that equipment is ready for

installation.

Upon completion of this inspection, the Flowserve representative shall submit a final report to the

customer, and to the Manager of Customer Service advising the results of the final inspection.

STORAGE NON-PREFERRED (WET)

GENERAL

It is not recommended that the pumping element be subjected to extended periods of

submergence or wetting prior to start-up. However, it is recognized that, in some cases, a long

period may lapse from installation until commercial operation.

Page 29 of 32

Page 30

USER INSTRUCTIONS APM, APMA and APH MX0301 - 07/03

®

If pump must be stored in a wet pit, the following inspection and maintenance procedures should

be performed:

1. Rotor is to be lifted and blocked to dimension shown on rotor plate.

2. Provide circulation of water in sump (high pressure water nozzles, air hoses,

etc.) and inject air into pump bell to agitate water. Take precautions that sump does not

freeze.

3. Flush bearings with 18.93 to 37.85 L/Min. (5 to 10 GPM) of clean water for 30

minutes every 3 days. See general arrangement drawing for location of bearing injection

pipe taps. Take precautions that pipes do not freeze.

4. Install sample metal strips (comparable to material in pump) in sump, and

inspect weekly for marine growth, corrosion, etc. Take necessary action to alleviate

problems.

5. Check sump for silt build-up, plugging of inlet screens and trash racks within one

week of start-up.