Page 1

Valtek StarPac Intelligent

Control Systems

GENERAL INFORMATION

The following instructions are designed to assist in

unpacking, installing and performing maintenance as

required on Valtek® StarPac® Intelligent Control Systems. Product users and maintenance personnel should

thoroughly review this bulletin prior to installing, operating, or performing any maintenance on the valve.

More detailed installation, maintenance and operation instructions are included in the StarPac manual;

refer to it when more information is needed.

Separate Flowserve Installation, Operation and Maintenance (IOM) manuals cover the valve (IOM 1 or IOM

27), actuator (IOM 2 or IOM 31) and positioner (IOM 45)

portions of the system and other accessories. Refer to

the appropriate instructions when this information is

needed.

To avoid possible injury to personnel or dam-

age to valve parts, WARNING and CAUTION

notes must be strictly adhered to. Modifying

this product, substituting non-factory parts, or

inferior parts, or using maintenance procedures

other than outlined could drastically affect performance and be hazardous to personnel and

equipment, and may void existing warranties.

WARNING: Standard industry safety practices

must be adhered to when working on this, or any

other, process control product. Specifically,

personal protective and lifting devices must be

used as warranted.

Unpacking

1. While unpacking the StarPac system, check the

packing list against the materials received. Lists

describing the system and accessories are included in each shipping container.

2. When lifting the system from the shipping container, position lifting straps to avoid damage to

tubing and mounted accessories. Valves up through

6-inches may be lifted by the actuator lifting ring.

On larger systems, lift unit using lifting straps or

hooks through the yoke legs and outer end of body.

WARNING: When lifting a valve/actuator assembly with lifting straps, be aware the center

of gravity may be above the lifting point. Therefore, support must be given to prevent the

valve/actuator from rotating. Failure to do so

can cause serious injury to personnel or damage to nearby equipment.

3. In the event of shipping damage, contact the shipper immediately.

4. Should any problem arise, contact a Flowserve

representative.

INSTALLATION

Valve Installation

The StarPac Intelligent Control System valve is installed in the same manner as a conventional control

valve and according to industry standards. Refer to the

appropriate valve installation, operation, maintenance

instructions for proper installation procedures.

If the StarPac system is being installed in an insulated

process line, do not place more than four inches of

insulation around the StarPac pressure or temperature

sensors; otherwise the sensors may not operate

properly. In addition, NEVER insulate the StarPac

electronics assembly or remote-mounted temperature/

pressure sensors (when used).

CAUTION: Do not insulate the StarPac electronics

housing or remote-mounted pressure or temperature sensors; otherwise excessive heat may build

up and affect operation.

41-1Valtek No. 125694

Page 2

Valtek StarPac

Valtek StarPac

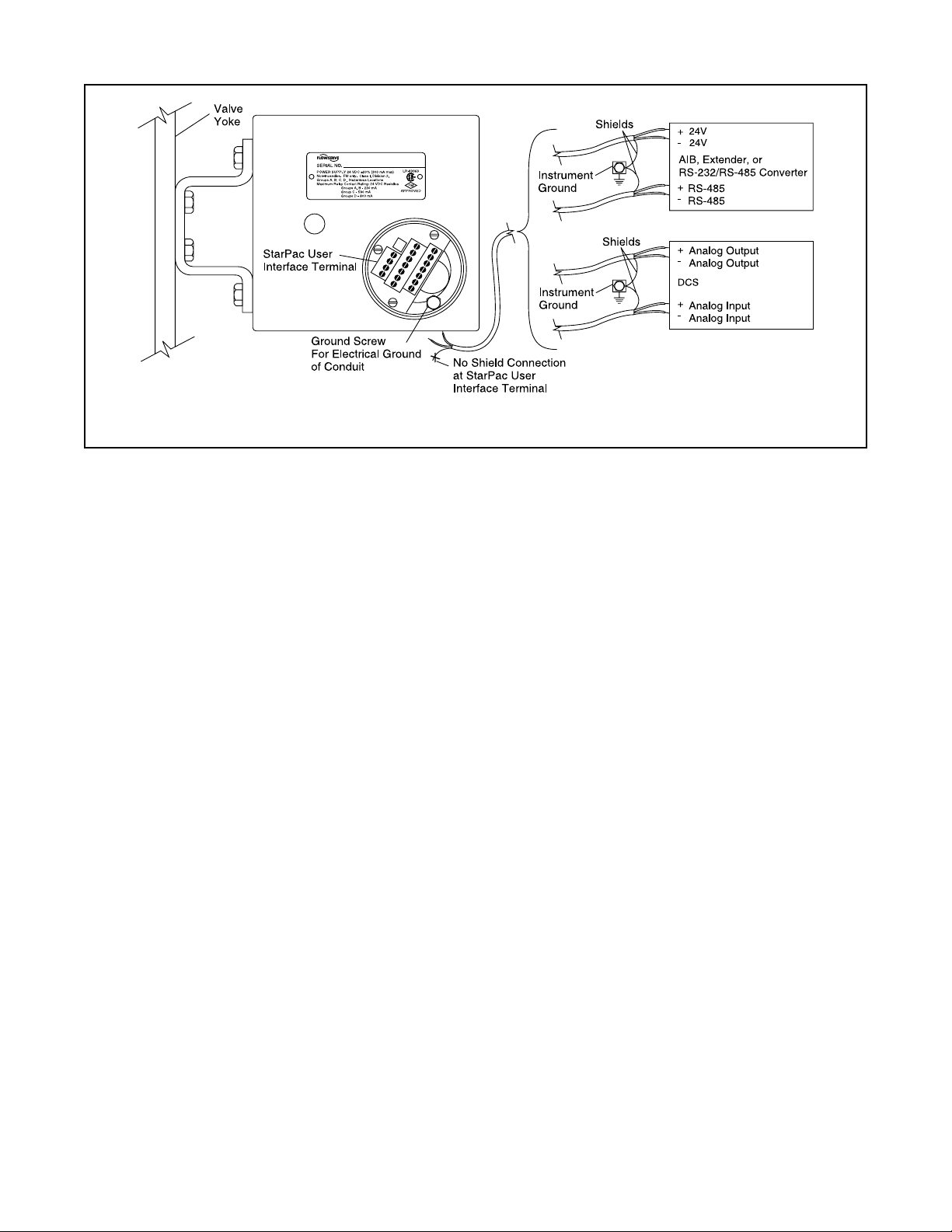

Figure 1: Shielded Wire Diagram

Wiring and Grounding Guidelines

This section will help achieve a maximum 'noise-free'

environment and performance with a StarPac unit.

Shielding Versus Grounding

All signals to the StarPac system should be in shielded

cables. Shields must be tied to a ground at only one end

of the cable to provide a place for environmental electrical noise to be removed from the cable. A ground wire

unlike a shield is attached at both ends to provide a

continuous path for electrical conductivity.

Grounding Screw

The green grounding screw by the user interface terminal block should be used to provide the unit with an

adequate and reliable earth ground reference. This

ground should be tied to the same ground as the

electrical conduit. Additionally, the electrical conduit

connecting to the StarPac unit should be earth grounded

at both ends of its run. The green grounding screw

must not be used to terminate signal shield wires.

24VDC Power

The 24VDC connection points will work best with

shielded twisted pair wire with the shield wire connected only at the source. The input power is isolated

within the StarPac system and may be referenced to

whatever level is necessary. The 24VDC power sup-

ply should not be connected to earth ground.

RS-485 Communication

RS-485 wiring requires the use of a shielded twisted

pair cable, which is grounded only at the source and not

in the StarPac unit. (For maximum performance, wire

should have a characteristic impedance of 120 ohms.)

These signals are referenced to the StarPac internal

system ground; hence this is the main fault path should

one of the isolation points fail. Therefore, care must be

taken to ensure the RS-485 cable is wired correctly.

The RS-485 allows only a 7 to 12V common mode

voltage differential between stations. Flowserve's

Valtek RS-232 to RS-485 converter is not a grounded

connection. PCs with internal RS-485 cards, on the

other hand, are often grounded. If another ground

communication device is on the network, a fault condition will almost certainly exist due to transient and

steady state differences in ground potential.

4 - 20 mA Command Input, Auxiliary Input, and

Feedback Output

These signals are isolated, but shielded twisted pair

wire should be used to reduce crosstalk from other

signals. The shield should be connected only at the

source.

4 - 20 mA I/P Output

This signal is not isolated from the StarPac internal

system ground and will provide a fault path if the I/P or

connecting wires become grounded. Shielded twisted

pair wire should be used with the shield connected in I/P.

Discrete Inputs and Outputs

These signals are isolated, but because they are frequently used to switch high voltage (120VAC), they

should be run in separate shielded wire paths away

from the other StarPac signals.

AIB and RS-232 to RS-485 Converter Connection

When connecting a StarPac system to a communication device, no shield or ground connections exist.

Hence, the 24VDC power and RS-485 communication

shield drain wires must be connected to a convenient

ground near the AIB or converter.

41-2 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 3

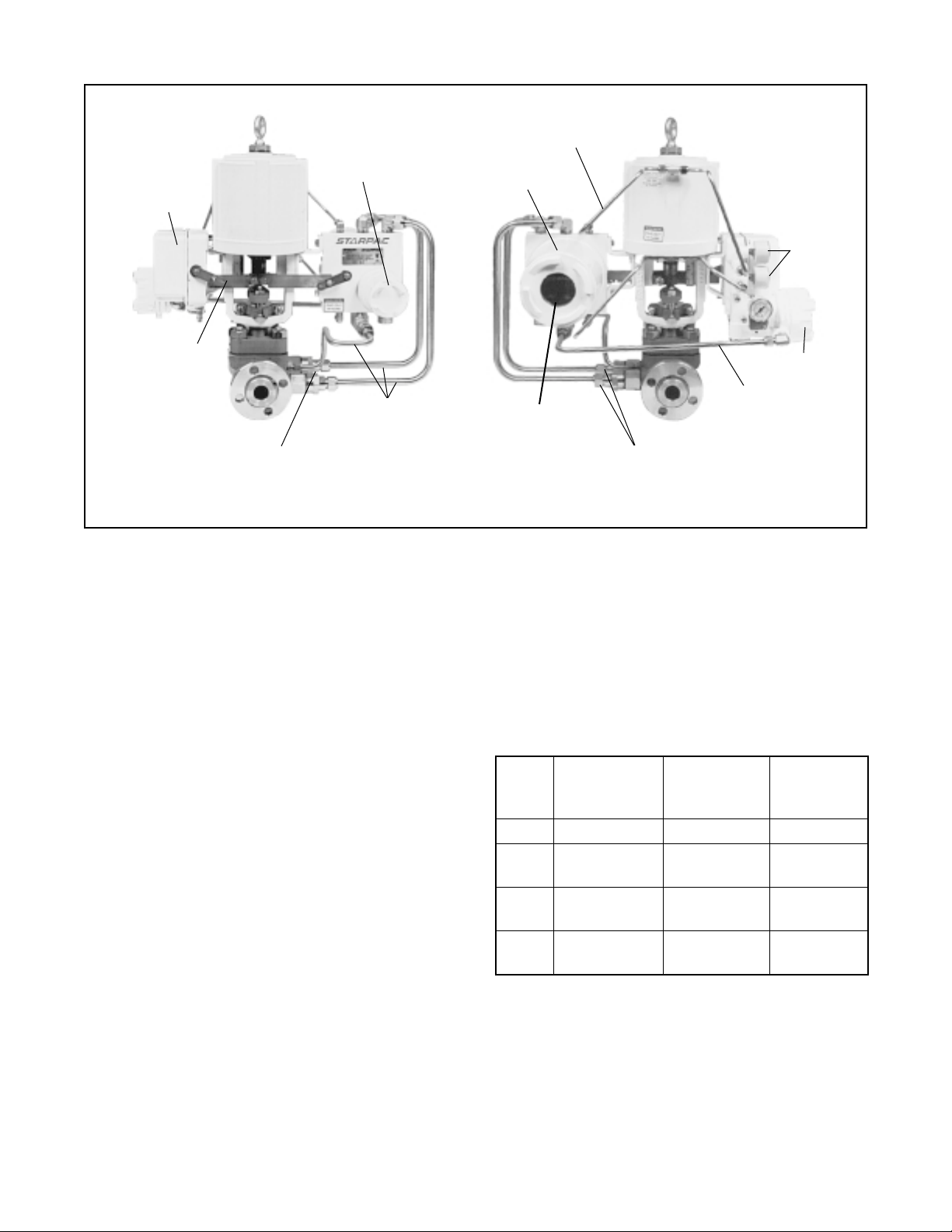

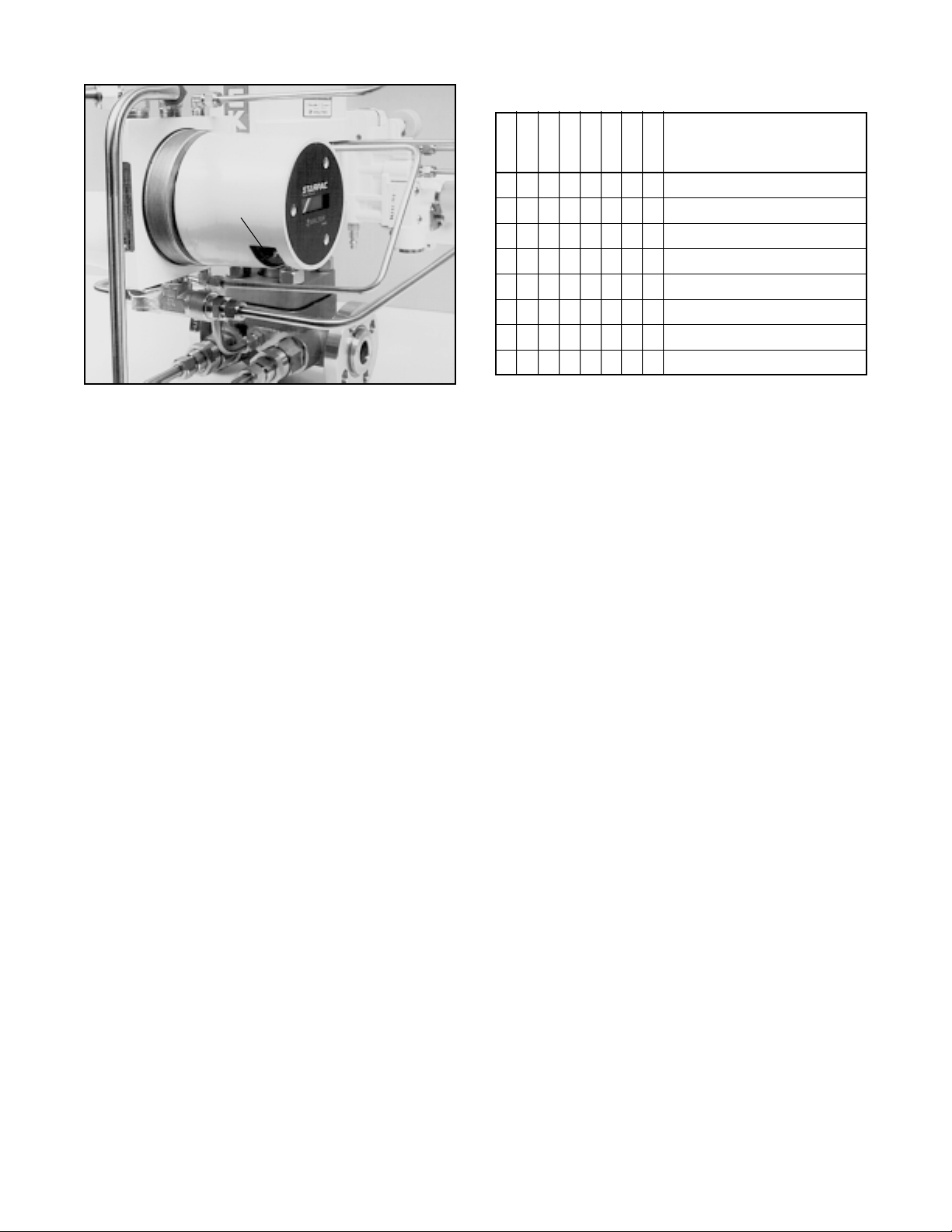

XL Positioner

Positioner

Sensor Arm

User Access

Terminal Cap

Actuator Pressure

Sense Tubing

Electronics

Housing

Actuator

Pressure

Gauges

I/P Module

Electrical

Conduits

Thermocouple

Figure 2: StarPac Intelligent Control System Components

Wiring The StarPac System

All electrical connections must be done according to

local and industry electrical codes. Flowserve recommends a shielded cable be used for the RS-485 command signal wire (i.e., Belden 9841 or equivalent).

When connecting multiple StarPac systems, a parallel

daisy-chain wiring pattern is used. Connect the StarPac

branch lines to the main line, keeping branch lines as

short as possible. The total length of wiring should not

exceed 4,000 feet (1,200 meters) without the use of

repeaters.

Avoid devices producing electrical 'noise' while installing

the cable.

CAUTION: The following procedure should be

performed on the bench or with the unit isolated so

that unexpected valve stroking will not adversely

affect the process.

WARNING: The following procedures may cause

the valve to stroke, causing pressures and

temperatures to vary from their norms. Notify

appropriate personnel that the valve may stroke

unexpectedly. Flowserve suggests that the

system be isolated from the process, if installed

in line.

Four StarPac system models are available: SP, SPJS

SPJD and NT. The electronics model for a system is

most easily identified by the face plate of the local

display. If the black cover of the face plate has printed

information with an 'ABC' table for the display parameters, the system contains SP electronics package.

4/20 mA Electrical

Local Display

Process Pressure Sensors

Conduit

If the black cover of the face plate shows only the

StarPac and Valtek logos, the system is an SPJS,

SPJD, or NT unit. The SPJS and SPJD models are

identical except that the SPJD version has two Modbus

ports. To tell the difference, remove the cover on the

user access terminal. If the user interface terminal block

has 18 connections, the unit is a SPJS electronics

package; if the terminal block has 20 connections, it is

the SPJD or NT package.

resU

ledoM yalpsiDlacoL

ecafretnI

kcolB

PS ylnOciremuN slanimreT81 klaTratS

SJPS ciremunahplA slanimreT81 rofklaTratS

DJPS ciremunahplA slanimreT02 rofklaTratS

TN ciremunahplA slanimreT02 rofklaTratS

NOTE: StarTalk and StarTalk for Windows® interface

software packages use different communication protocols and are not compatible. Contact a Flowserve representative for more information about upgrade options

To connect the wiring to the StarPac system, refer to

Figures 1, 2, 3 and Table I, and proceed as follows.

1. Remove the StarPac user interface housing cover

(small cap).

erawtfoS

swodniW

swodniW

swodniW

.

41-3Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 4

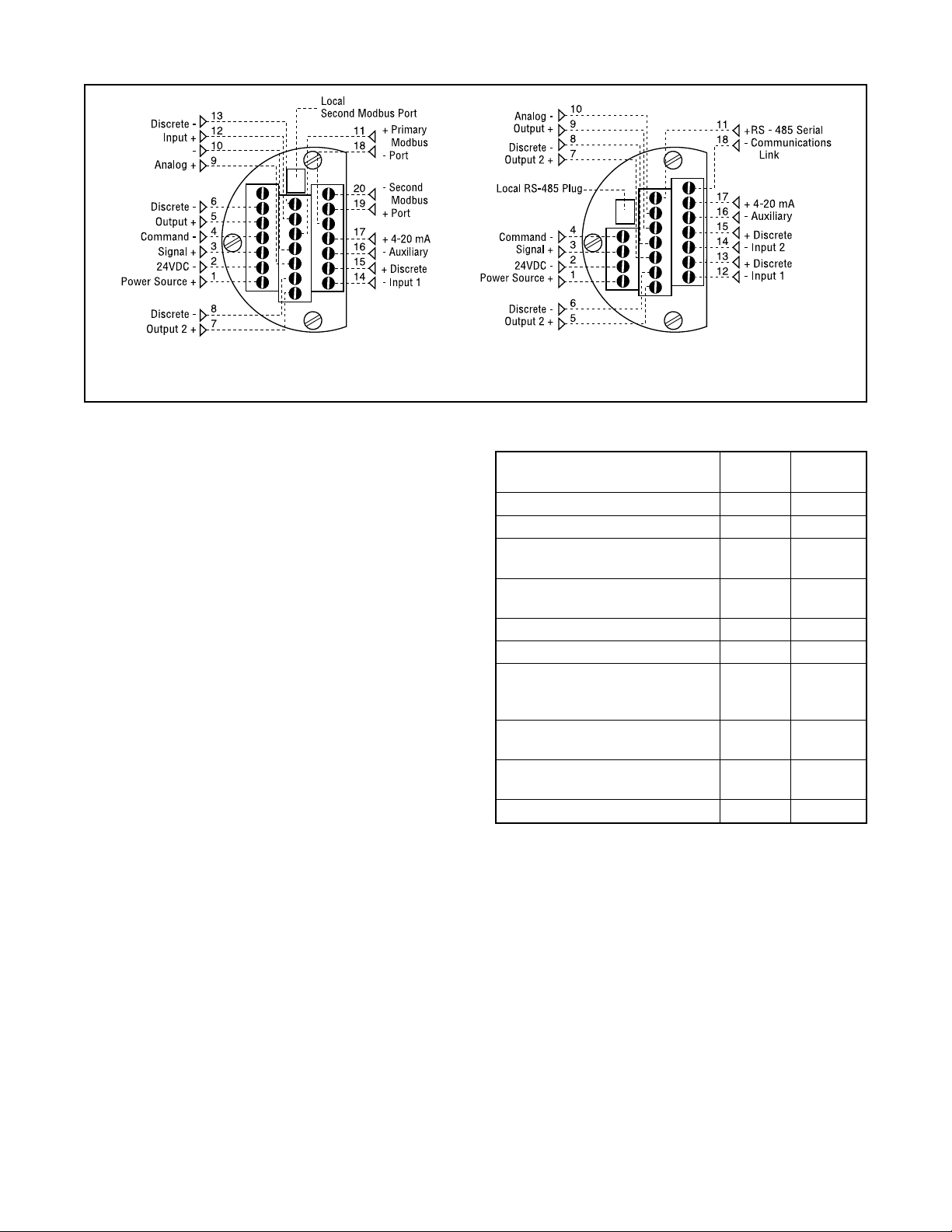

Model SPJD, NT Model SP, SPJS

Figure 3: User Interface Terminal Pinouts

WARNING: Do not remove the electronic

housing cover in flammable atmospheres;

otherwise possible injury to personnel or equipment may occur.

2. Connect the required wires to the terminal interface

block and computer as described in Figure 3 and

Table I. (The system must have 24 VDC power and

signal cable for operation.)

NOTE: The StarPac system remembers the operating mode setting (automatic or manual) from the

last time the unit had power. When power to the

system is turned on again, the unit will resume

operation in the previous mode.

Normally the StarPac system arrives from the factory set in the manual operating mode. This means

a command signal will position the valve the same

as a conventional control valve, providing a plug

position proportional to the 4 - 20 mA signal.

To avoid upsetting the process because of improper operating mode selection:

• Ensure that the system arrived from the factory with

the proper operating mode setting in the shop prior

to installation by connecting the air supply and

command signal, then turning on the power and

looking at the mode value on the local display, or;

• Set the proper operating mode for the particular

application in the shop prior to installation by selecting the desired operating mode from the Tuning/

Tune screen in the StarTalk software, or;

• Ensure that the block valves in the process line

around the StarPac system are closed and the

process is diverted around the unit.

3. Turn on the 24 VDC power to the unit, and verify that

the StarPac system has been correctly wired by

checking the following:

• 24 VDC power is at least 300 mA and between

21.6 and 27.0 VDC

Table I: User Interface Terminal Connections

Signal Positive Negative

Term.No. Term. No.

24 VDC power 1 2

Valve command signal 3 4

Primary RS-485 11 18

communication link (Port A)

RS-485 communication 19 20

link (second / Port B)

Auxiliary input (4 - 20 mA) 17 16

Analog output (4 - 20 mA) 9 10

Discrete input 1 – switch/ 13 12

solenoid monitoring (discrete

mode source input)

Discrete input 2 – switch/ 15 14

solenoid monitoring

Discrete output 1 5 6

(malfunction alarm contact)

Discrete output 2 (special) 7 8

• Polarity is correct

• Local display is on; if not, check the power supply

or reset switch

The StarPac local display should now be on, indi-

cating the following:

• Valve stem position

• Setpoint signal

• Process flow value (gas or liquid)

• Temperature of process

• Upstream (P1) and downstream (P2) pressures

At this point the StarPac unit is installed and will

operate as a conventional control valve receiving a

4 - 20 mA command signal from a DCS, or other

device, and stroking the valve accordingly.

41-4 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 5

Before additional work can be done with the StarPac

system (configured, calibrated and operation mode

changed, etc.) a RS-485 communication cable must

be connected to the unit and RS-485 communication port on a computer with the StarTalk software.

See the StarPac manual for more information.

4. Replace the StarPac user interface housing cover.

System Default Configurations

StarPac systems are shipped from the factory ready for

installation and operation. Rarely do the units need to be

reconfigured prior to operation. Table II lists the factory

default communication/failure mode settings. If these

settings are not correct for the equipment being used,

proceed to the following sections.

Table II: Factory Default Mode Settings

Description Setting

Address 1

Parity odd

Baud Rate 19,200

Modbus Communication RT U

Mode

RS-485 Termination Installed

Resistor

Failure Mode Setting Pass through command

signal on loss of power

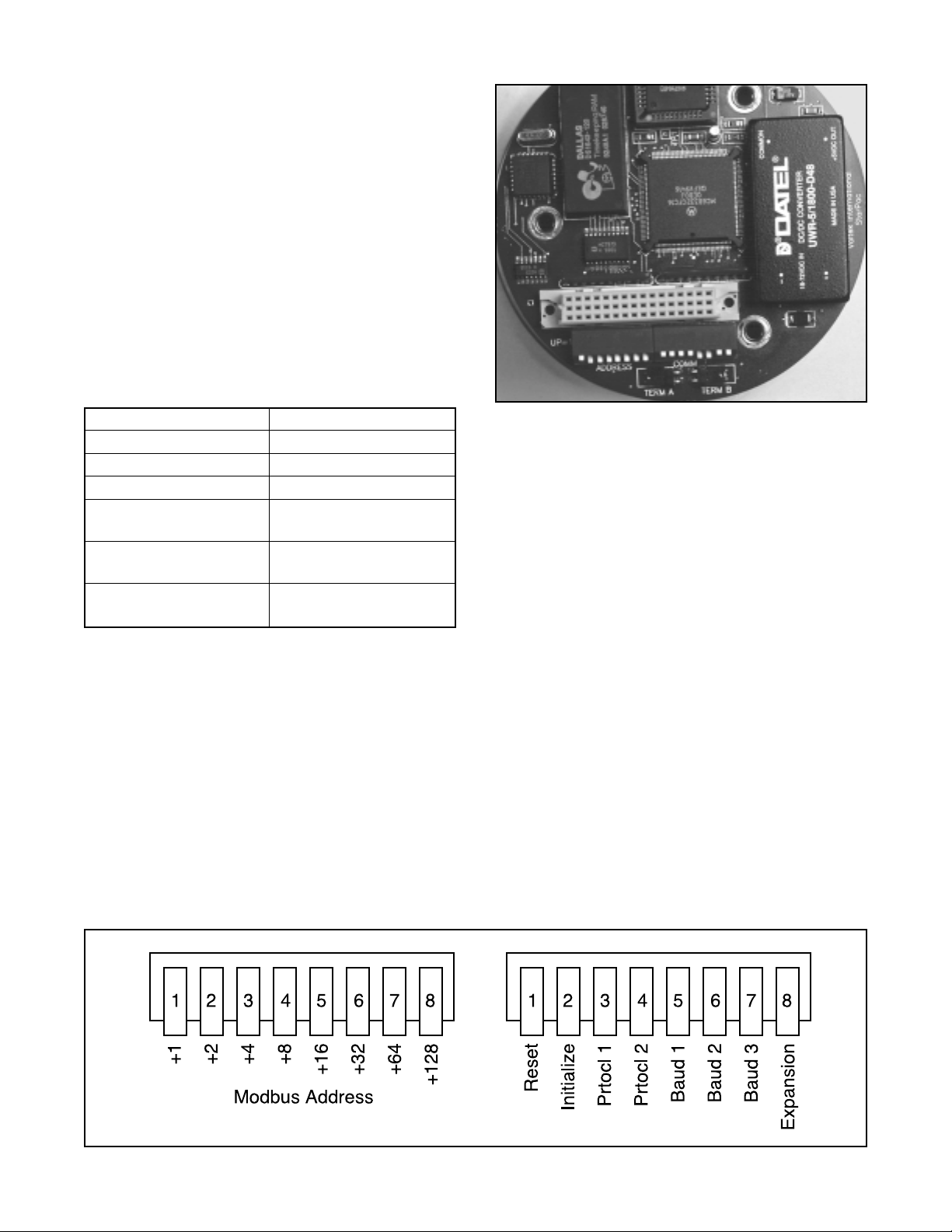

Figure 4: Dip Switch Blocks

Selecting Correct Baud Rate Setting

StarPac systems support baud rates of up 57,600 baud.

However, both the StarPac system and StarTalk software are shipped from the factory set to 19,200 baud.

If the default baud rate setting needs to be changed, refer

to Figures 4 and 5, Table IV and Changing Communication Settings section, and make the necessary change.

Selecting Correct Address Setting

If the StarPac system is the only unit on the communication network, the default address (1) is acceptable.

If multiple StarPac systems will be operating on the

same communication network, each unit must have a

unique address. Before changing the address, use the

StarTalk software to determine what other devices are

on the existing line. (Remember to include devices that

may be temporarily off line.)

If the default address setting needs to be changed, refer

to Figures 4 and 5, Table III and Changing Communication Settings section, and make the necessary change.

Selecting Correct Modbus

Transmission Mode

Two transmission modes exist in a Modbus system,

ASCII and RTU (default). Use the ASCII mode when

transmitting information through a device that uses

ASCII control codes; for example, a modem. Use the

RTU mode when connecting directly to both devices; for

example, an RS-485 interface card wired directly to a

StarPac system.

If the default Modbus transmission mode setting needs

to be changed, refer to Figures 4 and 5, Table IV and

Changing Communication Settings section, and make

the necessary change.

Figure 5: Dip Switches with Labels

41-5Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 6

Dipswitch

access slot

Table III: Address Dip Switch Settings

Switch no. on address block

12345678

1

1 Adds 2 to address value

1 Adds 4 to address value

1 Adds 8 to address value

1 Adds 16 to address value

1 Adds 32 to address value

1 = up = off

0 = down = on

Adds 1 to address value

1 Adds 64 to address value

1 Adds 128 to address value

Figure 6: Dip Switch Access

Selecting Proper RS-485 Termination

Resistor Setting

A termination resistor must be installed on the two most

remote devices on the network, counting the host computer as any other device.

(For example, a single StarPac system and the RS-485

driver in the host computer would each require the

termination resistor to be installed. If four StarPac

systems were on the network with a host computer,

decide which of the two devices have the most combined cable length between them. These two devices

should have the termination resistors installed. The

termination resistors should be disabled in the devices

not considered to be the most remote using the instructions in the next section. Using more than two termination resistors in a network can cause the RS-485 communications to operate erratically or fail.)

If the RS-485 termination resistor needs to be changed,

refer to Figure 5, Table IV and Changing Communication

Settings section, and make the necessary change.

Changing Communications Settings

If the StarPac system communication settings (address, parity, baud rate, Modbus transmission mode,

and RS-485 termination resistor) need to be changed;

refer to Figures 4 and 5 and Table IV and proceed as

follows.

WARNING: Never remove the StarPac electronics

housing cover in explosive atmospheres; otherwise,

nearby personnel and equipment could be injured.

CAUTION: Properly ground yourself before handling

the sensitive StarPac electronics; otherwise unseen

damage to components may occur.

1. If the StarPac system is installed in line, make sure

that taking it and the valve off line will not adversely

affect the process.

NOTE: Down means toward the circuit board; up means

away from the circuit board.

2. Turn off the 24VDC power to the StarPac System.

3. Remove the large cover from the StarPac electronics housing. (See Figure 2.)

4. Make the required dip switch changes (address,

parity, baud rate, and Modbus transmission mode)

according to Tables III and IV. These switches are

visible through the window cut in the lower side of

the shroud. (See Figure 5.)

a. The first dip switch block (marked address)

defines the Modbus address of the StarPac

system using binary coded decimal numbers

(switch 1 = 1; 2 = 2; 3 = 4 ; 4 = 8; 5 = 16; 6 = 32;

7 = 64; 8 = 128). The switches that are up (off

condition) define the address, refer to Table III.

For example, set address 11 by putting switches

1, 2, and 4 (1 + 2 + 8 = 11) up (off condition) and

3, 5, 6, 7, and 8 down (on condition).

b. The second dip switch block sets the parity,

baud rate and Modbus transmission mode.

NOTE: This block also contains initialization and

reset switches described later. Parity changes are

also done by using the switches marked PRTOCL

1 and 2 as shown in Table IV.

c. Set the baud rate by using the switches marked

BAUD 1, 2, and 3 as shown in Table IV.

d. Set the Modbus transmission mode with the

switch marked EXPAN. When the switch is up

(off), the transmission mode is RTU. When the

switch is down (on), transmission mode is ASCII.

NOTE: If the StarPac unit has a dual communication

port (model SPJD or NT), the single set of DIP

switches configures both ports. All of the communication parameters are the same including the address

of two ports. The identical address settings should

not conflict because separate ports are isolated

and independent for use on different networks.

41-6 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 7

Table IV: Protocol Dip Switch Settings

Switch Label Description

Reset

Init

Protocol 1

Protocol 2

Baud 1

Baud 2

Baud 3

Expan

0 Reset (halt processor)

1 Normal Operation *

0 Initialize on Startup

1 Normal Startup

0 0 No Parity

1 0 Even Parity

0 1 No Parity

1 1 Odd Parity *

0 0 0 Invalid

1 0 0 1200 Baud Rate

0 1 0 2400 Baud Rate

1 1 0 9600 Baud Rate

0 0 1 19200 Baud Rate *

1 0 1 31250 Baud Rate

0 1 1 38400 Baud Rate

1 1 1 57600 Baud Rate

0 ASCII Trans. Mode

1 RTU Trans. Mode *

* default factory settings

5. The jumper for the termination resistor labeled

TERM (see Figure 4) is located at the end of the

protocol dip switch block. Place the jumper over

both pins if the termination resistor is needed, and

over one pin for storage if it is not.

NOTE: If the StarPac unit has a dual communication port (model SPJD or NT) the termination resistor jumper for the second port is located 90 degrees

clockwise from the jumper described above and

can only be accessed by removing the white protective plastic shroud from the electronics assembly. Note second port jumper only needs to be set

according to requirements of the second network.

6. When the required communication settings have

been made, replace the white shroud (if removed)

and the large StarPac electronic housing cover.

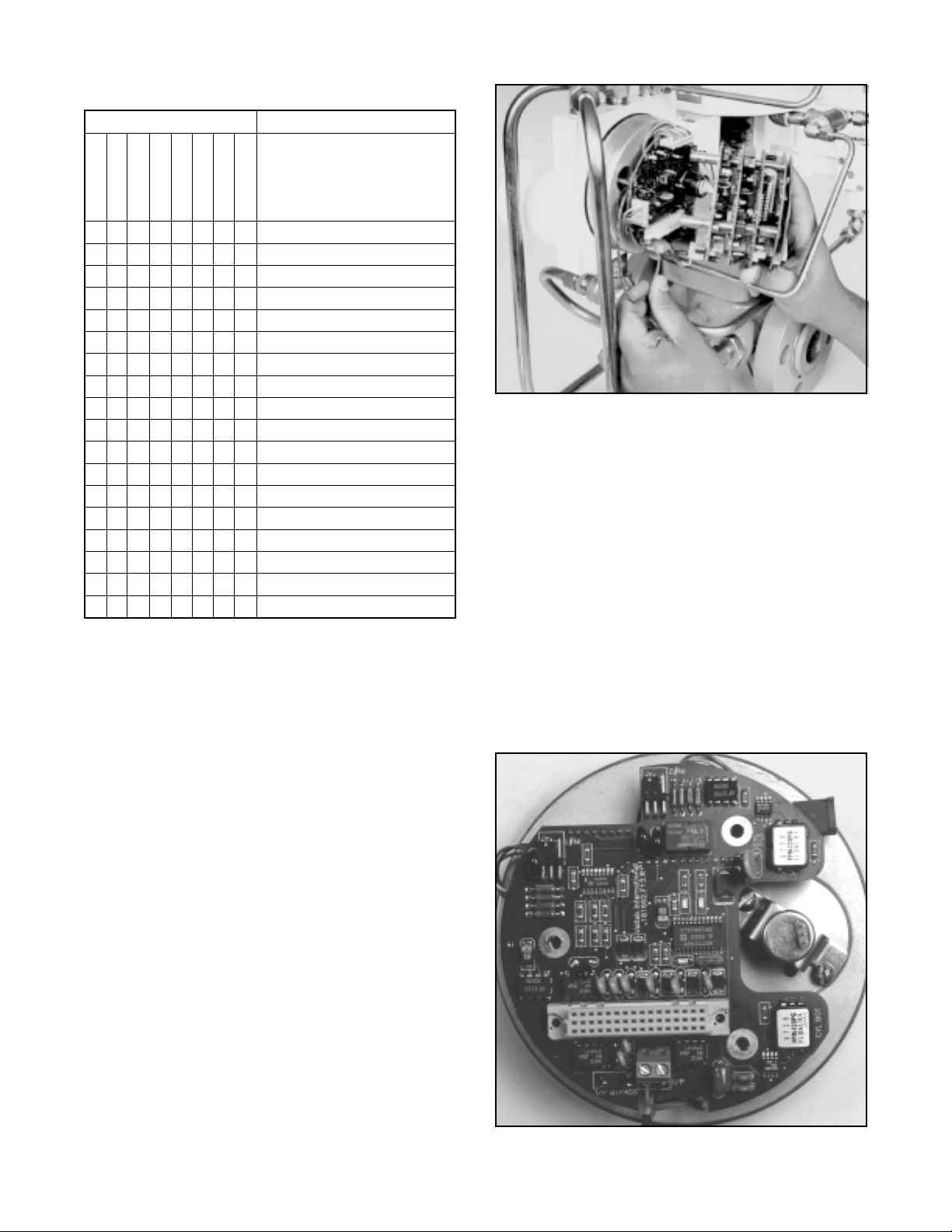

Figure 7: Removing Board Stack

the power failure setting as described below. (Refer to

Figures 2, 6, 7 and 8.)

WARNING: Never remove the StarPac cover in

explosive atmospheres; otherwise potential injury

may result to personnel and equipment.

CAUTION: Properly ground yourself before handling

the StarPac electronics; otherwise the sensitive

components may be damaged.

1. If the StarPac system is currently installed in-line,

make sure that the StarPac system (including valve)

can be taken off line in the current process.

2. Turn off the 24-volt power supply and disconnect

the supply air to the StarPac valve.

3. Remove the large electronic housing cover from

the StarPac unit.

Changing the Power Failure Setting

On loss of power, the StarPac is factory set to pass the

command signal to the I/P (unless ordered otherwise).

This configuration causes the system to assume a

traditional control valve mode and respond to an external

4 - 20 mA command signal. During loss of power and if

the application warrants, the StarPac system can be

configured to fail using the fail-safe spring(s) inside the

cylinder actuator. This is accomplished by changing

Figure 8: NT Failure Jumper Location

41-7Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 8

Figure 9:

Shroud Retaining Screws / Local Display

4. Remove the white plastic protective shroud from

the electronic assembly by removing the two screws

from the display end of the assembly. For NT units,

locate the jumper I/P Bypass at the edge of Analog

board number 1. (Refer to Figure 8 and proceed to

step 9.)

5. Next, for SP units only, remove the third screw that

holds the board stack in place.

6. Carefully grasp the computer boards and gently

pull them away from the housing.

7. Locate the jumper on the bottom board (shown in

Figure 8), labeled J105. Remove the jumper from

the two pins and reinsert it onto only one pin for

storage if wanting the valve to fail immediately per

the actuator fail-safe spring configuration. To reactivate the manual failure mode place the jumper

over the two pins labeled J105.

8. Carefully reinstall the top four computer boards

onto the assembly. Be certain the computer board

connector pins are lined up and securely attached

to the bottom board connector. Be certain the top

boards are in line with the bottom board.

9. Replace the protective shroud, install and tighten

the three computer board assembly retaining

screws.

10. Replace the StarPac electronics assembly cover.

Resetting or Initializing the StarPac

The 'Reset' and 'Initialize' switches are the first two dip

switches on the second switch block (see Figure 4). On

rare occasions it may be necessary to reset or initialize

the embedded software program on the StarPac system to stop abnormal operation or clear persistent

errors. This includes errors sometimes caused by brief

power interruptions, or resetting the software after

changing the EPROM.

The reset switch forces the StarPac system through the

startup and diagnostics sequence that the system normally goes through on system power up, and it initializes the program execution to the starting instruction.

The startup sequence also checks internal CPU registers and all of the volatile and nonvolatile RAM. While

initializing the system the local display shows the version number of the EPROM currently installed in the

system. The last thing done by a reset is to clear and

initialize the watchdog timer on the CPU.

A reset can be done by powering the unit down for five

seconds or more and reconnecting the power, or by

resetting the system by pushing the 'Reset' switch down

(on) for five seconds and then moving the switch back

up (off).

NOTE: If the reset switch is left down (on) the CPU will

be halted until the switch is moved up (off).

The 'Initialize' switch (no. 2 or labeled INIT on the PC

board) resets some of the internal work registers to

known values and resets the EPROM checksum. The

switch also sets the command or setpoint source to

receive a 4 - 20 mA analog signal. The 'Initialize' switch

is only accessed by the CPU during a reset.

An initialization is done by setting the INIT switch

down (on) and then resetting the CPU as described

above. After an initialization the system is left in the

calibration mode, which is an out of service mode,

meaning that the system will not respond to normal

commands. StarTalk software must be used to put

the system back into an operating mode. The command or setpoint source must also be reset to

digital if that is the normal operating source.

If the INIT switch is left down (on), the system will

startup in the calibration mode each time power is lost

to the unit or the Reset switch is put in the on position.

This feature can be beneficial if it is desired to manually

reset the system after a power outage to ensure safe

startup.

If the system must be reset using the dip switch as

described above or initialized, refer to Figure 4 and

proceed as follows:

1. Make sure that the StarPac system and valve can

be taken off line without disrupt the process.

2. Remove the large cover from the StarPac electronic housing.

WARNING: Never remove the StarPac cover in

explosive atmospheres; otherwise potential

injury may result to personnel and equipment.

41-8 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 9

3. Perform the desired actions as described above to

reset or initialize the system.

CAUTION: Properly ground yourself before

handling the StarPac electronics; otherwise the

sensitive components may be damaged.

4. Replace the StarPac electronic housing cover.

Reading Local Display

The local display on StarPac models SPJS, SPJD or NT

displays two lines of information about the system and

the process. The top line of the display has two functions: the left side is a description of the variable

displayed on the second line. The right side of the top

line has information on the current mode of operation

MAN = manual, AUT= automatic, and CAL = calibrate

(or out of service), OVR = over range, TRP = tripped.

Figure 10: Local RS-485 Connector

The second line of the local display shows process or

valve information as configured using the StarTalk II

software.

An 'A' flashing on the right side of the display indicates

there currently is an alarm condition. An 'E' flashing

indicates an error condition. Generally at this point,

these problems are caused by one or more of the

following three conditions:

1. Air supply is not turned on to system

2. The 4 - 20 mA signal is not turned on, or is not being

received by system.

3. The system has just been initialized or is operating

in the calibration mode. The alarm signal will cease

when the system is reconfigured or set to the proper

mode.

For more information, refer to StarPac manual section

on alarms and errors.

Adjusting Display View

The StarPac alphanumeric local display has an adjustment to allow some changes to the display for optimum

visibility.

WARNING: Never remove the StarPac cover in

explosive atmospheres; otherwise potential injury

may result to personnel and equipment.

CAUTION: Properly ground yourself before

handling the StarPac electronics; otherwise the

sensitive components may be damaged.

This adjustment is made by removing the plastic shroud

and adjusting the blue trim potentiometer until the

display is visible. Replace the plastic shroud, secure in

place and replace the large StarPac electronic housing

when done.

Table V: Hardware Specifications

Power Supply 24 VDC ±10%, 300 mA

maximum

RS-485 length Up to 4000 feet (22-26 AWG)

4–20 mA input 232 ohms, 500 V isolation

4–20 mA up to 750 ohm load, 500 V

output drive isolation

Output contact 1 amp at 110 VAC (for Division

rating II areas the ratings are reduced

to 24VDC resistive load: Groups

A & B- 230 mA; Group C- 590

mA; Group D- 800 mA)

Discrete inputs 26.6 kohm, 75 V DC or AC

(peak-peak) rising, 22 V DC or

AC (peak-peak) falling with

180 V maximum.

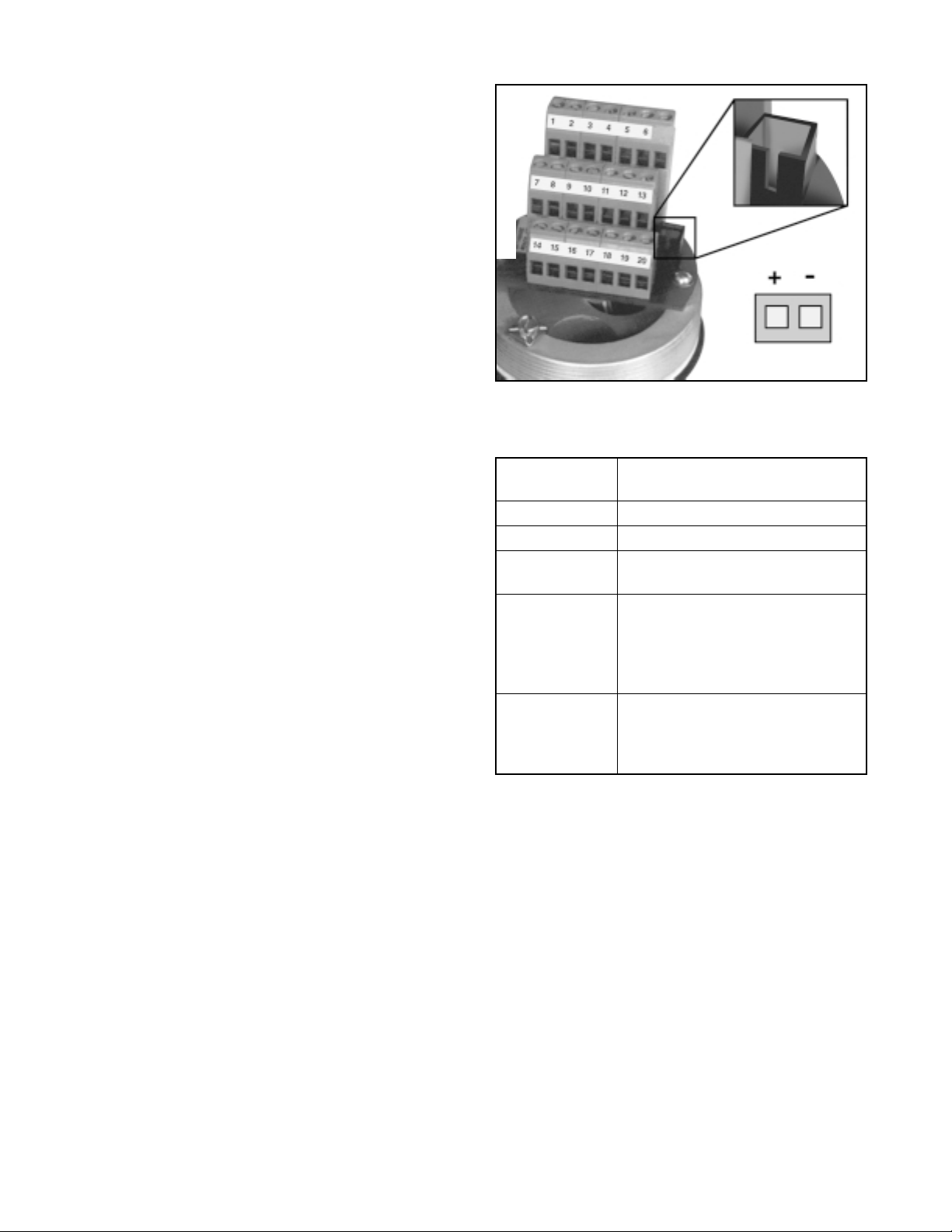

Local RS-485 Connector

A local RS-485 connector is located on the user terminal block (Figure 9) to allow ease of direct field interfacing to the StarPac system. This connection is a parallel

connection to the RS-485 port terminals (11, 18) on the

user interface terminal block. On StarPac models

SPJD and NT, this is connected only to Port B.

NOTE: The StarPac can only communicate to one

master device on a communication port. When using

the local interface, one of the RS-485 screw interface

wires may need to be disconnected to prevent a conflict

in communications.

A plug connector is available from the factory that will

allow an interface cable to be established. (Request

Part No. 83213.FOT from Flowserve Advanced Product Development Group.) The connector’s crimp terminals are made for 22-26 AWG wire. Note the correct

polarity of the terminals as shown in Figure 9.

41-9Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 10

Procedure for Upgrading to StarPac NT

Prior to making this upgrade, make sure that a current

copy of the system's .CCT file is saved and available.

Refer to the StarTalk software manual for details about

saving configuration tables if unfamiliar with this procedure. Those converting from older SP DataStream

models will first need to save a .TBL file for the system

and then use the Flowserve Advanced Product Development Configuration File Conversion Utility program

for Windows to convert the old parameter table to a

compatible Modbus file. Follow the prompted procedure to make this conversion.

NOTE: This file must be created by a StarTalk 2.0x

version. (Please contact a Flowserve representative

with any questions.)

The upgrade kit consists of the following parts: StarPac

NT boardstack w/EPROM, NT User Interface Assembly, Hallpot Mounting Bracket and new StarTalk software. (If upgrading from an SP DataStream Model, a

plastic shroud should also be included.)

Upgrade Instruction

1. Disconnect all power sources and air supply to the

unit.

2. Disconnect all wiring to the user terminal block of

the StarPac. (Mark each wire pair for ease of reinstallation into new terminal block.)

3. Remove the large electronics cap (turn counter

clockwise) and take off the plastic shroud by removing the three assembly screws from the electronics

module.

4. Remove the old electronics module by first unplugging the top three circuit boards. Remove the next

board by carefully disconnecting the eight-wire

pressure sensor connector from the bottom of the

board and the three-wire hallpot connector from the

top of the hallpot. Unplug the board from the remaining bottom board. Remove the last board by

disconnecting all of the interface connectors and

thermocouple wires. Next, use a 11/16-inch allen

wrench to loosen the hallpot shaft connector set

screw. Rock the board slightly while pulling straight

out from the board to disengage the actuator pressure sensors from their standoffs and the hallpot

shaft.

5. Remove the three screws attaching the use interface terminal block to the base. Pull the old interface wiring back through the base. (Twist the two

white plastic connectors against the wires and push

them into the hole in the base while pulling from the

terminal block side.)

6. All of the old StarPac electronics and user terminal

have now been removed. The pressure cables,

thermocouple wires, and the black and red two-wire

I/P cable should be left on electronic side of the

base.

7. Cut off the small white two-pin connector from the

I/P cable, leaving between 11/2 to 13/4-inch of the

cable extending from the base. Strip the wire ends

approximately 1/4-inch.

8. Remove the hallpot position sensor from the old

StarPac board by removing the 1/2-inch nut and

locking washer. Discard the fiber washer. Attach

the hallpot into the new mounting bracket by aligning the three connector pins on the top of the hallpot

with the notched leg of the new mounting bracket.

The shaft of the hallpot extends into the 'U' of the

bracket.

CAUTION: Over tightening the mounting nut

will put excessive strain on the metal case of the

hallpot and may cause damage.

9. Begin installing the new NT components by first

replacing the new user terminal block. This is done

by gently twisting the two brown connectors back

against the attached wires and pushing these connectors through the hole in the base from the small

cover side to the large electronics side. Replace

the three small mounting screws to secure the user

terminal block to the base.

10. Attach the new hallpot mounting bracket by first

removing the screw that is nearest to the center of

the base. The un-notched end of the hallpot bracket

uses this screw hole. Loosen the opposite screw

three full turns to allow the notched end of the

bracket to swing into place under the screwhead.

Insert the hallpot shaft into the coupling. Rotate the

bracket into place and reinsert the removed screw.

Check that the coupling is centered in the base

hole and does not touch the sides of the hole

before tightening the screws.

Do not tighten the

hallpot shaft set screw at this time.

The coupling cover is spring loaded to provide a

positive force on the feedback arm and this method

allows installation of the bracket without affecting

the spring load.

11. Unplug the new NT bottom board from the rest of

the stack. Plug the two interface connectors from

the user interface into their appropriate connectors

on the bottom of this board. Twisting the connector

once, prior to plugging it into the board, will keep the

wires bundled together and out of the way. Also,

folding the wires flat against the base will keep them

from pushing the board away from the base.

12. Carefully align the two actuator pressure transducer nipples into their pressure standoffs and

press firmly on the top of the two transducers to seat

41-10 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 11

them into the standoffs and hold the board in place.

The board is properly seated when the pressure

standoffs are almost flush against the bottom of the

board.

CAUTION: Do not twist or bend the board once

the nipples are plugged in or they may break.

Using one of the assembly screws to hold the

board in alignment while attaching the other

wires and boards will help prevent this.

13. Attach the I/P cable wires to the two-screw terminal

block marked 'I/P,' (red wire to the positive terminal

and black wire to the negative terminal). Notice that

this is a plug-in terminal block and may be unplugged without removing the wires.

14. Detach the second NT board from the new stack.

Attach the three-wire hallpot harness from the new

stack into the hallpot connector. The small 'ears' on

the outer edges of the new brown plug should point

to the outside edge of the hallpot.

15. Plug the process sensor connector into the J4

connector on the bottom of this board. On older

StarPac models this connector is a single soldered

eight-pin connector. The more recent models have

two sensor cables which are terminated separately

with crimped on pins and a brown housing. For the

separated cable arrangement, be sure to plug the

correct sensor into the correct half of the board

connector (P1 to P1 and P2 to P2 section).

16. Plug the board into the bottom board mounted on

the base while making sure all pins are aligned.

Use an assembly screw to temporarily hold the

board in place.

17. Attach the thermocouple wires to the two-screw

terminal block on this board, noting the correct

polarity. Red wire to 'R' and yellow wire to 'Y.' If

additional wire length is needed, gently pull more

wire from the base. Also, bend the wires close to

the terminal block (excessive looping is not needed

due to the notches cut in the boards).

18. Plug in the remaining boards. (Be sure to check the

alignment of the pins.) Secure the board stack

together by placing the one spacered assembly

screw in the upper right hand corner.

19. Set the dip switches on the digital board to match

the settings on the old board stack.

NOTE: This step does not apply when upgrading

from the DataStream model.

20. Reaffirm that all connections are properly aligned

and secure.

21. Reattach field wiring to the user interface terminals.

22. Apply 24 VDC power. The liquid crystal display

should display the version number and then the

default display mode.

23. Establish communications and use the StarTalk

software to upload the saved .CCT file for this

system into the new NT module. (If updating from

an older StarPac DataStream model, use the file

conversion utility to convert the old .TBL file into a

compatible Modbus file.)

24. With the air supply shut off, the valve should be

either fully closed or fully opened, depending on the

failure spring action ordered. Use the configuration

menu to set the LCD to display the position continuously. Rotate the hallpot shaft until the displayed

value for position is within a few percentages of

either zero percent (if the valve is closed) or 100

percent (if the valve is open). Tighten the hallpot

connector set screw. (

to the set screw is difficult due to the alignment of

the takeoff arm, connect the air supply and stroke

the valve 50 or 100 percent open as indicated on

the valve stroke plate. Adjust the hallpot shaft to an

indicated position reading of 50 or 100 percent,

then tighten the set screw. Care must be taken if

this method is used to ensure that the ADC values

of the position feedback do not go out of range at

either end of stroke.) Once this has been adjusted

correctly, if the boardstack needs to be replaced,

redoing the setting is not needed unless the hallpot

itself is damaged.

Alternate method

: If access

NOTE: If the position values displayed decrease

rather than increase when the valve strokes open,

the three-wire hallpot connector is reversed and

needs to be unplugged and rotated 180°.

25. Replace the plastic shroud and the remaining two

assembly screws. Make sure all wiring is beneath

the shroud and that no wires are trapped between

the bottom board and the vibration isolators in

which the assembly screws attach.

26. Turn the air supply back on to the actuator.

27. After verifying that stroking the valve is safe, use

the calibration menu to first recalibrate the actuator

pressure sensor, and then perform a valve stroke

calibration. During this calibration, watch the position ADC values to ensure that the hallpot adjustment is not at its limit on either end of stroke. (If

needed, readjust the hallpot shaft setting to keep

the shaft rotation within the operating range of the

hallpot, then recalibrate.)

28. Secure both the large electronics and the smaller

interface covers.

29. Use the StarTalk software to calibrate the process

sensors and verify the other operational parameters of the system.

Do not forget to reconfigure the

LCD to display the desired variables.

30. Return the system to operation.

41-11Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 12

SYSTEM MAINTENANCE

Flowserve recommends that the StarPac system calibration and maintenance work be done once every six

months. If after checking the calibration of the StarPac,

a component is determined to be defective the following

section will help with the component replacement.

The following items may be needed to install, start up

and calibrate the StarPac system electronics.

• Power supply: 24 VDC regulated ±2.4 VDC, 300 mA

• StarTalk software (proper version for the electron-

ics being used)

• Computer with internal or external RS-485 communication adapter

• RS-485 connection cable

• Digital volt meter with 4 - 20 mA range

• Air supply: 50 psig (3.4 bar) minimum, 80 - 100 psig

(6.3 - 7.8 bar) preferred; coalescing air filter required

• Gauges or the ability to accurately determine process pressures and valve air supply pressures

• 4 - 20 mA command source

• Thermocouple calibrator or simulator with 0 - 932°

Fahrenheit (0 to 500° Celsius) range

Mechanical Subsystem Maintenance

Refer to the appropriate Flowserve Installation, Operation & Maintenance (IOM) instructions for details on the

repair and maintenance of the control valve positioner

and actuator components. Please refer to the manufacturers’ manuals for maintenance and operation instructions for non-pneumatic actuators, e.g., electric or

electro-hydraulic actuators.

At first glance the additional tubing and connections of

the StarPac system may appear to make standard

valve maintenance more difficult and complex. The

following instructions will show a maintenance method

that will make this task much easier. Please note that

most of the additional tubing attached to the StarPac

system is electrical conduit and does not contain process fluid.

WARNING: The process line must be depressurized and drained of process fluid, and decontaminated prior to working on the internal valve components. Failure to do so may cause serious injury to

personnel.

1. Depressurize the line, decontaminate the valve (if

needed) and shut off the air supply to the valve

positioner.

2. Disconnect the four actuator air tubes from the

positioner and StarPac system.

3. Disconnect the four mounting bolts that attach the

StarPac system bracket and positioner bracket.

4. Disconnect the follower arms from the StarPac

base and positioner. This is done by removing the

follower arm nut and washer and pulling the arm off

the shaft. Notice that this shaft connection is keyed

and that the shafts are slightly spring loaded.

5. The actuator subassembly is now isolated and is

removed by loosening the bonnet bolts and lifting

the actuator away from the body.

The StarPac system tubing holds the StarPac base

and positioner in place, eliminating the need to

disconnect wiring or air connections.

6. Standard valve maintenance may now be done on

the actuator or valve body components. Refer to

the Flowserve IOM instructions for details on such

things as trim or packing replacement. If the trim

needs to be replaced, use the same trim number

and characteristic as the original trim, or the flow

calculations could be affected. If a trim size change

is needed, contact a Flowserve representative to

find out about flow calibration options.

7. Reassemble the system by reversing the above

steps. Be sure to follow the procedures outlined in

the Flowserve IOM instructions for valve reassembly. Make sure when reconnecting the follower

arms that the arms fit correctly on the keyed shafts

and have a positive spring action.

8. Turn on the air supply to the valve and check for

leaks in the reattached actuator tubing lines. Check

the calibration of the positioner for proper operation. Refer to Flowserve IOM 24 instructions for

details on calibrating the Beta positioner.

9. Turn on power to the StarPac system. Use the

StarTalk software to check the system calibration

and do a valve stroke calibration to reset the

StarPac’s position feedback. Refer to the Calibration section of the StarPac manual.

Position Feedback System

The position feedback linkage of the StarPac system is

a critical part of the flow metering ability of the system.

This linkage is used to calculate the valve’s CV for a

given stroke. This linkage should be lubricated and

checked periodically for tight, smooth operation. The

follower arm should operate smoothly with no binding

and have a positive spring loading on the arm. Inspect

the follower arm pin for excess wear and replace if

needed. The takeoff arm attached to the stem clamp

must be firmly secured to the stem clamp and perpendicular to the actuator stem. If this takeoff arm is canted

or misaligned, problems may occur with positioner

calibration and the position reading on the StarPac may

go out of range.

On rotary actuators, make sure the adjustment linkage

locknut is tight and has no excessive play in the ball

joints. The rotary shaft clamp must be tight and should

not freely rotate on the shaft.

41-12 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 13

Figure 12: Board Removal

Figure 11: Disconnecting Lemo Connector

Pressure Sensor Replacement

Standard StarPac pressure sensors are installed

directly into the control valve body. Before they can be

removed, the process line must be depressurized and

drained of all fluids and the valve decontaminated.

To replace a pressure sensor, refer to Figure 10 and

proceed as follows.

WARNING: The process line must be depressurized

and drained of process fluid, and decontaminated

prior to working on the internal valve components.

Failure to do so may cause serious injury to

personnel.

WARNING: If optional pressure sensor extensions

are included, the sensor will be located in a sensor

housing located in the tubing line and not in the

sensor housing located on the valve body. This

section of the tubing contains process fluid and

must be drained and decontaminated before the

sensor is removed. The procedure for sensor

removal and replacement will be similar to that

outlined below.

(Refer to alternate sensor information when this type of

sensor is included with system.)

1. Depressurize and decontaminate the line and valve.

Loosen the tubing nuts on the conduit leading to the

pressure sensor, if applicable.

2. Loosen the sensor nut.

3. Gently pull the conduit and sensor nut approximately 1/2 to 3/4-inch from the sensor. Release the

locking sleeve of the Lemo™ connector by moving

the collar away from the sensor (use needle nose

pliers). Remove the connector from the sensor and

swing the sensor conduit out of the way.

4. Unscrew the sensor from the sensor boss.

5. Remove the sensor O-ring or gasket and replace

with a new one. Make sure the environmental

O-ring seal is in good condition and in place on the

new sensor.

6. Install the new sensor into the sensor port making

sure the O-ring or gasket remains properly in place

while tightening the sensor. Tighten the sensor

until it seats metal-to-metal at the gasket section of

the sensor port, assuring the proper compression

of the process O-ring or gasket seal.

7. Align the red dots on the sensor and connector, and

reconnect the Lemo connector. Fully seat the

connector until the locking sleeve latches. Replace

the sensor nut and tighten.

8. Pressurize the valve body to make sure the sensors are properly seated before attaching the sensor conduit and tightening.

9. Reattach the conduit lines and securely tighten the

fittings.

Temperature Sensor Replacement

(Model NT)

The StarPac temperature sensor (middle sensor on the

valve body) does not penetrate the wall of the control

valve; therefore, replacement does not require that the

process line be drained.

To replace a StarPac temperature sensor, refer to Figure

14 and proceed as follows:

1. Disconnect the power and air supply to the unit.

2. Remove the large StarPac electronics assembly

cover.

WARNING: Never remove the StarPac's electronics assembly covers if explosive atmospheres are present.

3. Remove the plastic shroud by unscrewing the two

assembly screws.

4. Unplug the temperature wires from the computer

board and undo the thermocouple wire.

41-13Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 14

5. Loosen the conduit nuts containing the temperature sensor wire. Remove the conduit, pulling the

sensor wires out of the tubing.

6. Remove the temperature sensor by unscrewing it

from the body.

7. Screw the new sensor into the body. Tighten firmly.

8. Reinstall the stainless steel fitting and conduit,

feeding the sensor wire through to the StarPac

computer board.

9. Cut the temperature wire about 31/2-inches from

the StarPac housing. Strip the wire about 1/4-inch

from the end.

10.Reconnect the temperature wires to computer board.

11. Replace the StarPac electronics assembly shroud

and secure the two-board assembly screws. Assure that no wires are trapped between the bottom

circuit board and the rubber vibration isolators.

12. Turn on the power supply to the unit again.

Warning: Do not turn on (energize) the StarPac

unit in explosive atmospheres with the assembly cover removed. Injury to personnel could

result.

13. Communicate to the system using the StarTalk

software and verify the data for that particular valve.

14. Replace the large StarPac cover and restore the air

supply to the unit.

15. Check the sensor calibration.

Temperature Sensor Replacement

(Model SPxx)

The StarPac temperature sensor (middle sensor on the

valve body) does not penetrate the wall of the control

valve; therefore, replacement does not require that the

process line be drained.

To replace a StarPac system temperature sensor, refer

to Figures 2, 12, 13, and 14 and proceed as follows.

1. Disconnect the power and air supply to the unit.

2. Remove the large StarPac electronics assembly

cover.

WARNING: Never remove the StarPac electronics assembly cover if explosive atmospheres

are present; otherwise, injury to personnel can

occur.

3. Separate the top four boards from the bottom

computer board, by first removing the three computer board assembly screws and sliding off the

plastic shroud. Carefully grasp the top four computer boards and pull them away from the bottom

board while holding it in place. Disconnect the

three-wire hallpot and eight-wire pressure sensor

harness connectors and set the four boards aside.

4. Disconnect the temperature sensor wires from the

terminal block 'J102' on the bottom computer board.

5. Loosen set screw on the hallpot base connector.

6. Disconnect the three remaining wire harness connections and carefully remove the bottom computer

board from the StarPac system housing base.

Some resistance will be felt as the air-pressure

connections disengage.

7. Loosen the conduit nuts containing the temperature sensor wire. Remove the conduit, pulling the

sensor wires out of the tubing.

8. Remove the temperature sensor by unscrewing it

from the body.

9. Screw the new sensor into the body. Tighten firmly.

10. Reinstall the stainless steel fitting and conduit,

feeding the sensor wire through to the StarPac

computer board.

11. Install the bottom computer board on StarPac system housing base, being careful to connect the two

air-pressure connections and hallpot arm to their

appropriate places. Do not tighten the set screw

now. Reconnect the three wire harness connections. Cut new temperature sensor wire to length

and attach it to terminal block, noting polarity.

12. Reattach the remaining top four computer boards,

being certain to reconnect the two wire harness

connections and the interface connections.

13. Replace at least one of the three computer board

assembly screws and tighten to hold stack in place.

14. Turn on the power supply to the unit again.

WARNING: Do not turn on (energize) the StarPac

unit in explosive atmospheres with assembly

cover removed. Injury to personnel may result.

15. Communicate to the system using StarTalk software and verify the data for that particular valve.

16. Use the

set the local display to show

hallpot shaft (arrow in Figure 13) within five percent

of the valve's actual position. (Since the valve's air

supply is shut off, this will be either 100 percent

open or closed.) Tighten the hallpot set screw.

17. Replace the StarPac electronics assembly shroud

and secure the three board assembly screws.

Assure that no wires are trapped between the

bottom circuit board and the rubber vibration

isolators.

18. Replace the StarPac electronic housing cover and

restore the air supply to the unit.

19. Check the sensor calibration, following the procedure outlined in the Calibration section of the StarPac

manual, if needed. A stroke calibration will need to

be done to finish calibrating position feedback; refer

to the StarPac manual.

Configuration

menu of StarTalk software to

Position

. Adjust the

41-14 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 15

Three-wire position

sensor cable

Eight-wire pressure

sensor cable

Set

screw

Figure 13: Removing Top Four Boards

Board Stack Replacement (Model NT)

Inside the electronic housing cover and under the white

plastic shroud of a StarPac unit are five printed circuit

boards, together referred as the board stack. This design

allows each board to have a single purpose, which

simplifies troubleshooting and diagnostic procedures.

(Refer to Figure 7 on page 7.)

If, after consulting with the local Flowserve or factory

representative, the StarPac system's computer board

stack is found defective and needs replacement, proceed as follows. (Prior to proceeding, make sure a copy

of the configuration .CCT file is saved and available.)

1. Disconnect the power and air supply to the unit.

2. Remove the StarPac electronics assembly cover.

WARNING: Never remove the StarPac electronics assembly cover if explosive atmospheres

are present; otherwise, injury to personnel can

occur.

Figure 14: Position Sensor Alignment

(Model SPxx)

the user interface into their appropriate connectors

on the bottom of this board. Twisting the connector

once prior to plugging it into the board will keep the

wires bundled together and out of the way. Also,

folding the wires flat against the base will keep them

from pushing the board away from the base.

7. Carefully align the two actuator pressure transducer nipples into their pressure standoffs and

press firmly on the top of the two transducers to seat

them into the standoffs and hold the board in place.

The board is properly seated when the pressure

standoffs are almost flush against the bottom of the

board.

CAUTION: To avoid damaging the nipples, do

not twist or bend the board once the nipples are

plugged in.

to hold the board in alignment while attaching

the other wires and boards will help prevent

this.)

(Using one of the assembly screws

3. Remove the plastic shroud by unscrewing the three

board assembly screws. Carefully grasp the top

four computer boards and pull them away from the

bottom board holding it in place. Disconnect the

three-wire hallpot and eight-wire process harness

connectors and set the four computer boards aside.

4. Unplug the temperature sensor wires from the

terminal block marked 'T /C ' on the second computer board.

5. Disconnect the three remaining wire harness connections and carefully remove the bottom computer

board from the StarPac housing base. Some resistance will be felt as the air pressure connections

disengage.

6. Unplug the new NT bottom board from the rest of

the stack. Plug the two interface connectors from

Figure 15: Thermocouple Installation

41-15Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 16

8. Attach the I/P cable wires to the two-screw terminal

block marked 'I/P.' (Red wire to the positive terminal and black wire to the negative terminal.)

9. Detach the second NT board from the new stack.

Attach the three-wire hallpot harness from the new

stack into the hallpot connector. The small 'ears' on

the outer edges of the new brown plug should point

to the outside edge of the hallpot.

10. Plug the board into the bottom board, mounted on

the base, making sure all pins are aligned. Use an

assembly screw to temporarily hold the board in

place.

11. Plug the thermocouple wires into the two-screw

terminal block on this board, noting the correct

polarity. Red wire to 'R' and yellow wire to 'Y.' If

additional wire length is needed, gently pull more

wire from the base. Also, bend the wires close to

the terminal block (excessive looping is not needed

due to the notches cut in the boards).

12. Plug the process sensor connector into the J4

connector on the bottom of this board. On older

StarPac models this connector is a single soldered

eight-pin connector. On more recent models have

two sensor cables which are terminated separately

with crimped on pins and a brown housing. If the

cable arrangement has been separated, be sure to

plug the correct sensor into the correct half of the

board connector (P1 to P1 and P2 to P2 section).

13. Plug in the remaining boards. (Be sure to check the

alignment of the pins.) Secure the board stack

together by placing the one spacered assembly

screw in the upper right hand corner.

14. Set the dip switches on the digital board to match

the settings on the old board stack.

15. Reaffirm that all connections are properly aligned

and secure.

16. Apply 24 VDC power. The liquid crystal display

should display the version number and then the

default display mode.

17. Establish communications and use the StarTalk

software to upload the saved .CCT file for this

system into the new NT module.

18. Replace the plastic shroud and the remaining two

assembly screws. Make sure all wiring is beneath

the shroud and that no wires are trapped between

the bottom board and the vibration isolators in

which the assembly screws attach.

19. Turn the air supply back on to the actuator.

20. After verifying that stroking the valve is safe, use

the calibration menu to first recalibrate the actuator

pressure sensor, and then perform a valve stroke

calibration. During this calibration, watch the posi-

tion ADC values to ensure that the hallpot adjustment is not at its limit on either end of stroke. (If

needed, readjust the hallpot shaft setting to keep

the shaft rotation within the operating range of the

hallpot, then recalibrate.)

21. Secure both the large electronics and the smaller

interface covers.

22. Use the StarTalk software to calibrate the process

sensors and verify the other operational parameters of the system.

23. Return the system to operation.

Board Stack Replacement (Models SPxx)

Inside the electronic housing cover and under the white

plastic shroud of a StarPac unit are five printed circuit

boards, together referred to as the board stack. This

design allows each board to have a single purpose,

which simplifies troubleshooting and diagnostic

procedures.

If, after consulting with the local Flowserve or factory

representative, the StarPac system’s computer board

stack is found defective and needs replacement, refer

to Figures 2, 7, 13 and 14 then proceed as follows.

NOTE: Make sure a current copy of the configuration

file exists.

1. Download or find a backup copy of .CCT File.

2. Disconnect the power and air supply to the unit.

3. Remove the StarPac electronics assembly cover.

WARNING: Never remove the StarPac electronics assembly cover if explosive atmospheres

are present; otherwise, injury to personnel can

occur.

4. Remove the plastic shroud by unscrewing the three

board assembly screws. Carefully grasp the top

four computer boards and pull them away from the

bottom board holding it in place. Disconnect the

three-wire hallpot and eight-wire process harness

connectors and set the four computer boards aside.

5. Disconnect the temperature sensor wires from the

terminal block marked 'J102' on the bottom computer board.

6. Loosen the set screw on the hallpot base connector. Refer to Figure 13.

7. Disconnect the three remaining wire harness connections and carefully remove the bottom computer

board from the StarPac housing base. Some resistance will be felt as the air pressure connections

disengage.

8. From the new computer board stack, install the

bottom computer board on the StarPac device

41-16 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 17

housing base, being careful to connect the two airpressure connections and hallpot arm to their appropriate places. Do not tighten the set screw

now. Reconnect the three wire harness connections. Attach the temperature sensor wires to the

terminal block, noting polarity.

9. Reattach the remaining top four computer boards,

being certain to reconnect the two wire harness

connections. Properly line up and fully seat the

interface connections.

10. Replace at least one of the three computer board

assembly screws and tighten to hold the stack in

place.

11. Turn on the power supply to the unit again.

WARNING: Do not turn on (energize) the StarPac

unit in explosive atmospheres with the assembly cover removed. Injury to personnel may

result.

12. Use the StarTalk software to apply a stored configuration table for the StarPac unit. Refer to the

Technician Support section of the StarPac manual

for details.

13. Use the Configuration menu of StarTalk software to

set the local display to show Position. Adjust the

hallpot shaft (arrow in Figure 14 within five percent

of the valve’s actual position (since the valve’s air

supply is shut off, this will be either 100 percent

open or closed). Tighten the hallpot set screw.

14. Replace the StarPac electronics assembly shroud.

Tighten the three shroud retainer screws. Restore

the air supply to the unit.

15. Replace the StarPac electronics housing cover.

16. After the new computer boards have been replaced, the unit will need to be recalibrated following the procedures listed in the Calibration section

of the StarPac manual. Use Stroke Calibration

Section to finish calibrating the position feedback.

17. Reset the operational parameters to bring the system back into service.

EPROM Replacement

Occasionally the need may arise to replace the EPROM

of the StarPac. The EPROM contains the operating

program code for the StarPac system. (If the StarPac

system has a special feature or custom program

EPROM, ensure that the new electronics board stack

has the proper EPROM.) The EPROM from the old

board can be traded with the EPROM on the new board

if needed. If the digital board of the faulty system is

suspected to be damaged, a replacement EPROM can

be ordered from a Flowserve representative. The bill of

material for the system will contain the unique part

number for the special EPROM.

If the EPROM needs to be replaced, refer to Figures 4

and 5 then proceed as follows.

CAUTION: This procedure should only be done by

personnel trained in the proper handling of sensitive electronic components.

1. Make sure the valve is either by-passed or in a safe

condition.

2. Turn off the 24 VDC power to the StarPac and air

supply to the actuator.

3. Remove the StarPac electronics housing cover.

WARNING: Never remove the StarPac electronics assembly cover if explosive atmospheres

are present; otherwise, injury to personnel can

occur.

4. Remove three circuit board assembly screws and

lift the protective shroud off the board assembly.

5. Carefully unplug the local display board (top) from

the rest of the board assembly. This exposes the

digital board with the EPROM. The EPROM is

located in a square holder at the edge of the board.

6. Remove the old EPROM by using a PLCC extraction tool. Notice that two opposite corners of the

EPROM socket are slotted. The fingers of the tool

slide all the way into these slots. The fingers of the

tool should catch under the corners of the EPROM.

Squeeze the tool to extract the EPROM and pull it

out from the socket.

7. Carefully remove the new EPROM from its protective carrier. Handle the EPROM carefully by the

corners and use whatever anti-static precautions

are available. A typical method is to keep one hand

on a grounded metal item and handle the device

with the other hand. The static sensitive device is

protected once it is in its socket. Notice that the

EPROM has one corner trimmed, one top edge

beveled, and a dot cast into the top. Align the

EPROM in the socket so that the dot and beveled

edge face the small square silk-screened on the

edge of the PC board. The trimmed corner should

be on the left as shown by the silk-screen outline.

CAUTION: The StarPac contains sensitive electronic components. Use proper antistatic

(grounding) precautions when handling the

EPROM and insert properly or the EPROM may

be damaged.

8. Firmly press the EPROM into the socket. It should

be slightly below the edges of the socket to be fully

seated.

9. On the dip switch, located next to the bus connector, set switch 2 INIT on by toggling the switch down.

10. Carefully plug the top display board back on the

stack making sure all pins are aligned in the bus

socket.

41-17Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 18

11. Replace the protective shroud over the board assembly, aligning the window in the shroud over the

display. Make sure none of the interconnection

wiring at the base of the board assembly protrudes

outside the shroud. Replace the three circuit board

assembly screws and tighten snugly.

12. Turn the power on to the StarPac system. Toggle

the 2 INIT switch back to its up position. (This can

be reached from the side of the board and does not

require removing the display board again.) The

local display should display zeroes on SP models

or the word 'CAL' on SPJ and NT models.

13. Replace the StarPac electronic housing cover.

14. Restore power to the StarPac and the air supply to

the actuator.

15. The StarPac system can now be connected with the

StarTalk software to make whatever configuration

changes are needed.

The system has been reset to its initialization defaults. The StarPac will remain in a startup test

mode, signified by zeroes on the local display or

CAL, until the system is connected to the StarTalk

software for the first time. The non-volatile RAM

containing the system’s parameter table is not

affected by changing EPROMs so recalibration

should not be needed. Because of the internal

initialization that takes place in the StarPac unit

when this procedure is done, an error can be

detected during the reset. This will be cleared and

may be ignored if it is not ongoing (signified by a

continuously flashing error display).

16. The system now can be returned to service.

Table VI: StarPac Accessories

noitpircseD rebmuN

,584SR/232SR,retrevnoC

CAV022,011

ecafretnIgolanAcaPratS

CDV42,)lennahC8(

NID,ylppuSrewoP

otCAV011,detnuom-liar

CDV42

36955001

70296001

91597001

Table VII: Linear Actuator Follower Arms

eziSrotautcA

)sehcni(

52

52

52

52

05

05

05 3 26.2 41673001

001

001

001 8-5 57.4-83.3 61673001

ekortS

)sehcni(

1

/4 00.2 97834001

3

/8 00.2 97834001

1

/2 00.2 31673001

3

/4 1-1/2 00.2 31673001

1

/2 1-1/2 00.2 31673001

1

/2 2-1/2 26.2 11144001

3

/4 3- 88.2-26.2 41673001

3

/4 4- 57.4-83.3 51673001

dupS

)sehcni(

tiKmrArewolloF

41-18 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 19

27

28

23

22

18

26

25

24

20

21

19

13

17

16

15

14

12

11

10

8

6

9

7

29

3

1

5

Item Description

1. Large cap

2. Glass cap

3. Retaining ring

4. Large O-ring

5. Electronic stack screws

6. Bushing

7. Shroud

8. StarPac Electronics

9. Hallpot feedback sensor

10. Hallpot bracket

11. Hallpot screw

12. Spring bracket

13. Spring

4

14. Set Screw

15. Helical Coupling

16. Feedback shaft

17. Vibration isolator

18. Feedback shaft O-ring

19. Pressure Connector

20. Flame Arrestor

21. Groove pin

22. Mounting bracket

23. Mounting bolt

24. Valve yoke

25. Housing

26. Retaining ring

Figure 16: Exploded View

2

27. Follower arm

28. Follower pin

29. Lock washer

30. Follower pin nut

31. User interface terminal

32. User interface screws

33. Small cap O-ring

34. Small cap

41-19Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 20

StarPac Spare Parts Kits

See StarPac exploded view (Figure 16) for item numbers.

Kit 1 - StarPac Housing Replacement

Part No. 10055770

.oNmetI noitpircseD ytitnauQ

1 pacegraL 1

2 pacssalG 1

3 gnirgniniateR 1

4 gnir-OpacegraL 1

11 swercskcatscinortcelE 2

21 tekcarbgnirpS 1

31 gnirpS 1

41 wercsteS 1

51 gnilpuoclacileH 1

61 tfahskcabdeeF 1

71 rotalosinoitarbiV 3

81 gnir-O 1

91 rotcennocerusserP 2

02 rotserraemalF 2

12 nipevoorG 2

52 gnisuoH 1

62 gnirgniniateR 1

33 gnir-OpacllamS 1

43 pacllamS 1

Kit 5 - NT Shroud Replacement Kit

Part No. 10070583

.oNmetI noitpircseD ytitnauQ

5 swercskcatscinortcelE 3

6 gnihsuB 1

7 duorhS 1

Kit 6 - NT Electronics Upgrade Kit

Part No. 10202761

.oNmetI noitpircseD ytitnauQ

5 swercskcatscinortcelE 3

6 gnihsuB 1

7 duorhS 1

8 kcatsscinortceleTN

MORPE/w

01 tekcarbtopllaH 1

11 swercstopllaH 2

13 lanimretecafretniresU 1

23 swercsecafretniresU 3

1

NOTE: If hallpot is required, order hallpot replacement

kit (Kit 4).

Kit 2 - NT Electronics Replacement Kit

Part No. 10059202

.oNmetI noitpircseD ytitnauQ

5 swercskcatscinortcelE 3

6 gnihsuB 1

8 kcatsscinortceleTN

MORPE/w

Kit 3 - NT User Interface Replacement Kit

Part No. 10059203

.oNmetI noitpircseD ytitnauQ

13 lanimretecafretniresU 1

23 swercsecafretniresU 3

Kit 4 - Hallpot Replacement Kit

Part No. 10059205

.oNmetI noitpircseD ytitnauQ

9 rosneskcabdeeftopllaH 2

01 tekcarbtopllaH 1

11 swercstopllaH 1

Kit 7 - Replacement Helical Coupling

Part No. 10052650

.oNmetI noitpircseD ytitnauQ

51 gnilpuoClacileH 1

1

Kit 8 - Follower Pin Assembly for Linear

Actuators

Part No. 10036685

.oNmetI noitpircseD ytitnauQ

82 raenilrofniprewolloF

srotautca

92 rehsawkcoL 1

03 tunniprewolloF 1

Kit 9 - I/P Wire Replacement Kit

Part No. 10055394

noitpircseD ytitnauQ

eriwP/I 1

1

41-20 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 21

Pressure and Temperature Sensor Spare Part Kits

See Body-mount Sensor Configurations (Figure 17) and

Remote-mount Sensor Configuration (Figure 18) for item numbers.

Pressure Sensor Gasket Kits

NOTE: Kits 1 thru 4 will service two body or two remote-

mount pressure sensors from any one of the pressure

sensor configuration drawing numbers listed below each

table.

Kit 1 - Viton O-ring Replacement Kit

Part No. 10061027

Item No. Description Quantity

6 Environmental O-ring, Viton 2

8 Environmental O-ring, Viton 4

10 O-ring seal, Viton 2

20 Environmental O-ring, Viton 2

21 O-ring seal, Viton 2

Configuration Drawing Numbers: 83883, 83891,

83904, 83884, 83892, 101565, 83887 83900,

127586, 83888, 83901

Kit 2 - Spiral Wound Gasket Replacement Kit

Part No. 10061028

Item No. Description Quantity

6 Environmental O-ring, Viton 2

8 Environmental O-ring, Viton 4

10 O-ring seal, Viton 2

20 Environmental O-ring, Viton 2

21 Spiral wound gasket seal 2

Configuration Drawing Numbers: 83938, 83890,

122670, 83886, 83903, 127563, 83899, 127632

Kit 3 - PTFE Gasket Replacement Kit

Part No. 10061029

Item No. Description Quantity

6 Environmental O-ring, Viton 2

8 Environmental O-ring, Viton 4

10 PTFE gasket seal 2

20 Environmental O-ring, Viton 2

21 PTFE gasket seal 2

Configuration Drawing Numbers: 122513, 127565

Kit 4 - Kalrez O-ring Replacement Kit

Part No. 10061113

Item No. Description Quantity

6 Environmental O-ring, Viton 2

8 Environmental O-ring, Viton 4

10 O-ring seal, Kalrez