Page 1

V altek Position Pac

GENERAL INFORMATION

The following instructions are designed to assist with

installing, calibrating and troubleshooting the Valtek

Position Pac™ valve position indicator. Product users

and maintenance personnel should thoroughly review

this bulletin in conjunction with the maintenance bulletin

for the appropriate valve body and actuator being used.

To avoid possible injury to personnel or damage

to valve parts, WARNING and CAUTION notes

must be strictly adhered to. Modifying this product, substituting non-factory or inferior parts, or

using maintenance procedures other than outlined could drastically affect performance, be

hazardous to personnel and equipment, and may

void existing warranties.

OPERATION

Position Pac is a ‘package’ unit containing a potentiometer and transmitter, two or four limit switches, or a

combination of a transmitter and two limit switches.

The position transmitter utilizes a potentiometer to

measure the valve’s position and a transmitter circuit

that sends a 4 to 20 mA electrical signal to a remote

monitoring device. Position Pac will continuously transmit the position of a control valve as it modulates

between the open and closed positions.

The limit switches in Position Pac can be independently

set to indicate open, closed or any intermediate valve

position.

Position Pac’s sealed construction provides protection

®

from the entry of water, dust and oil as defined by the

National Electrical Manufacturers Association (NEMA)

1, 3, 3R, 4, 12 and 13. Position Pac is also explosionproof, providing protection from flammable hydrocarbon

atmospheres, metal dust, coal dust, and grain dust. It i s

UL and CSA listed for Class I, Division 1, Groups B, C, D;

Class II, Division 1, Groups E, F, G (See Table I). All

electrical wiring should be installed per NEC articles

501-4 and 501-5.

WARNING: Keep hands, hair, clothing, etc. away

from moving parts when operating the valve. Failure to do so can cause serious injury.

INSTALLATION INSTRUCTIONS

The following instructions are designed to assist in the

field installation of Position Pac units.

Valtek Linear Actuators

To install Position Pac on Valtek linear actuators, refer

to Figures 1 and 2, and proceed as follows:

1. Remove the name plate from the yoke leg opposite

from the stroke indicator plate.

2. Using the two tapped holes, attach the Position Pac

mounting bracket to the yoke leg using two mounting

bolts. When facing this yoke leg, the bracket will jog

in towards the valve center and protrude to the left.

3. Remove the nut from the stem clamp bolting. Place

the tripper bracket on the bolt so the ‘S’ shape extends down. Replace the nut and tighten it firmly.

Valtek No. 62152

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

29-1

Page 2

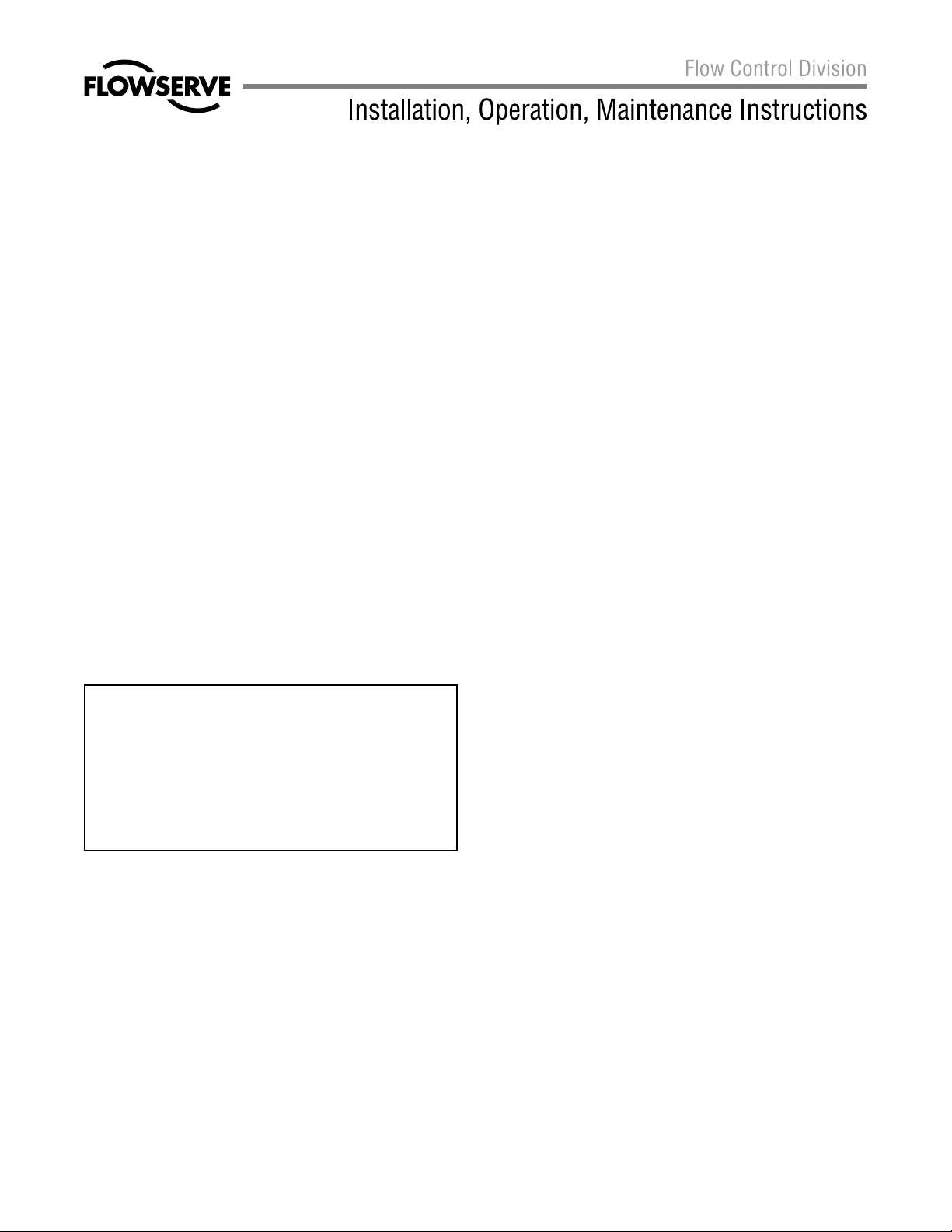

Figure 1: Linear Application – Front View

(cover removed)

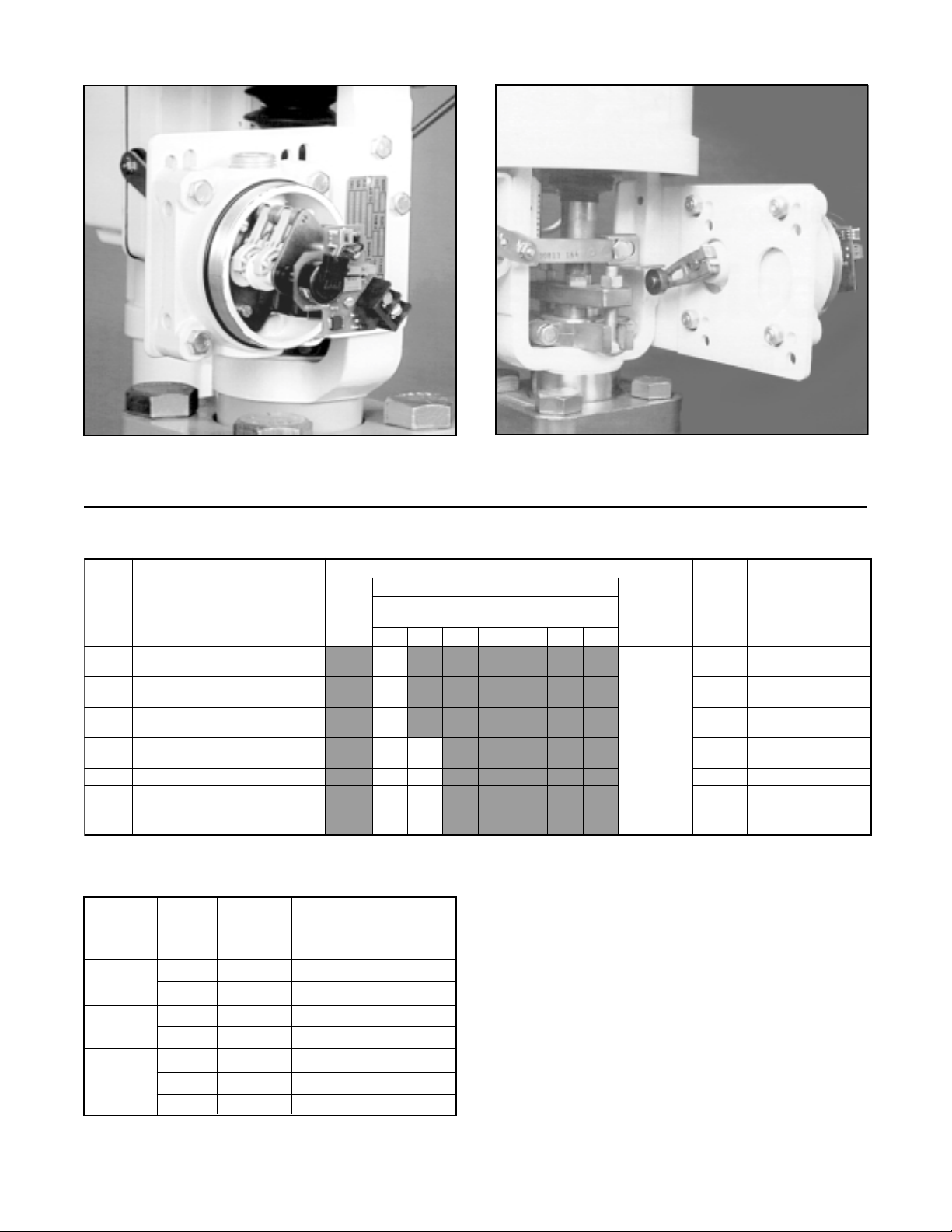

Table I: Model Configuration

ledoMnoitpircseD

2HT

ST2H

XT rettimsnartgolanA

2AT

2A sehctiwsTDPSowT

4A sehctiwsTDPSruoF

ST2A

sehctiwsTDPSdelaesyllacitem

TDPSdelaesyllacitemrehowT

hctiwslanimrethtiwsehctiws

owthtiwrettimsnartgolanA

sehctiwsTDPS

htiwsehctiwsTDPSowT

pirtslanimret

AMEN

4

-rehowthtiwrettimsnarTgolanA

2&1 )puorG(

ABCDEFG

Figure 2: Linear Application – Rear View

(cover removed)

aerAlacirtcelE

foorPnoisolpxE

noisiviDIssalC

2&1 )puorG(

noisiviDIIssalC

CELENEC

lavorppA

gnidneP

gnitaR

LUseYgnoL

LUseYgnoL

ASC/LUoNtrohS

LUoNgnoL

LUoNtrohS

LUoNgnoL

LUoNgnoL

delaeS

sehctiwS

gnisuoH

eziS

Table II: Linear Mounting Information

Actuator Valve Spud Kit Hole

Size Stroke Size No.* Set

(sq. in.) (inch) (inch) (Mounting)

25 0.5-1.0 2.00 37434 bottom of slot

1.5 2.00 37434 top of slot

50 0.5-2.5 2.62 37345 bottom holes

3.0 2.62 37345 top holes

100 1.0-3.5 2.62/2.88 37436 bottom holes

& larger 4.0 3.38 37630 top holes

4.0 4.75 71636 top holes

*Kit includes: bracket, arm, trip lever or stem clamp with trip lever

nuts and bolts.

4. Mount Position Pac to the bracket using the mounting holes as specified in Table II: Insert the lever

onto the switch shaft. On larger actuators (size 50

and larger) that use the adjustable lever arm, adjust

the length so that the center of the roller rests on the

center of the tripper bracket. To preload the Position

Pac’s restoring spring, be certain the control valve is

in its minimum signal position. Loosen the lever arm

clamp screw with a 0.14-inch ( 9/64) hex wrench,

allowing the arm to turn on the shaft. While holding

the arm in contact with the bottom of the tripper

bracket and using a slotted screwdriver to rotate the

switch shaft perform the following (all rotation direction instructions are as viewed from the lever arm

side of the Position Pac):

29-2 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 3

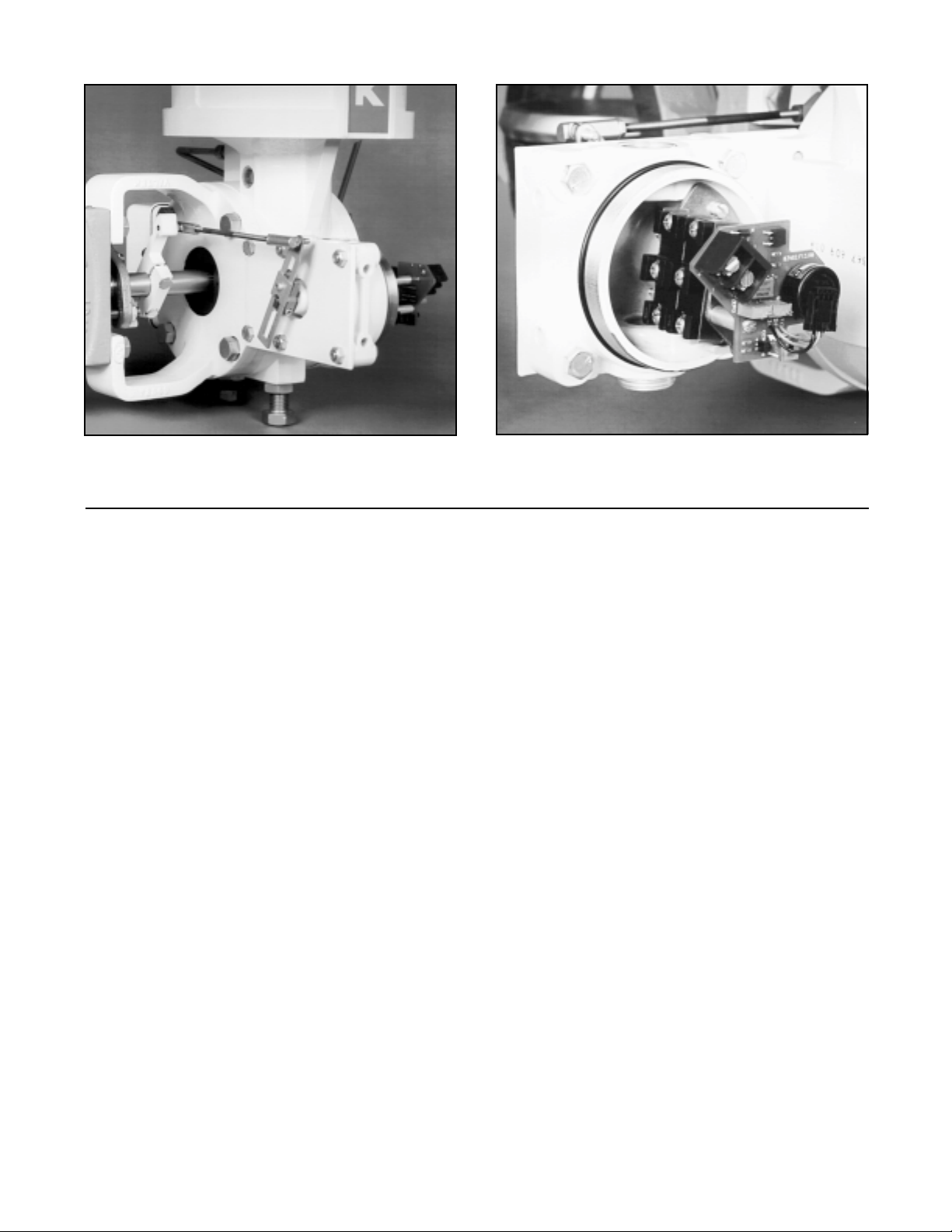

Figure 3: Rotary Application – Rear View

(cover removed; air-to-close valve)

Figure 4: Rotary Application – Front View

(cover removed; air-to-close valve)

For direct-acting, air-to-open actuators, rotate the

shaft counter clockwise as far as it will go, then back

off approximately 5 to 10 degrees. For direct-acting,

air-to- close actuators, rotate the shaft counter clockwise approximately 5 to 10 degrees.

For reverse-acting, air-to-open actuators, rotate the

shaft counter clockwise approximately 5 to 10 degrees. For reverse-acting, air-to-close actuators,

rotate the shaft counter clockwise as far as possible,

then back off approximately 5 to 10 degrees. With the

slot in this position, tighten lever arm clamp screw

tightly (until the teller tab will not move). With this procedure completed, stroke valve to ensure spring is

preloaded throughout the entire valve travel.

5. To make electrical connections, remove the housing

cover.

WARNING: On explosion-proof installations,

disconnect electrical power or be certain the

area is safe from combustible atmospheres before removing the housing cover.

(Refer to the specifications in Table IV for component

electrical ratings.) Attach transmitter signal wiring to

the transmitter terminal block, using caution to attach

the positive and negative wires to the appropriate

terminal.

CAUTION: Do not apply a voltage greater than 40

volts to the transmitter terminals or the circuit

will be damaged.

Attach limit switch wiring to the ‘COMM’ (common)

and either ‘NC’ (normally closed) or ‘NO’ (normally

open) terminals according to the needed signal.

6. To adjust the limit switches and/or position transmitter, remove the housing cover and refer to the

bration

WARNING: On explosion-proof installations,

disconnect electrical power or be certain the

area is safe from combustible atmospheres before removing the housing cover.

7. Replace the housing cover.

8. Reinstall the name plate to the mounting bracket.

section in this document.

Cali-

NOTE: Name plate reinstallation is important for

valve identification/servicing purposes.

Valtek Rotary Actuators

To install Position Pac on Valtek rotary actuators, refer

to Figures 3 and 4, and proceed as follows:

1. Mount the bracket to the mounting pad on the backside of the actuator using two 0.31-inch (5/16) mounting bolts.

2. Mount the Position Pac to the bracket using four

0.31-inch (5/16) mounting bolts and nuts.

3. Loosely mount the trip lever to the valve shaft within

the yoke.

4. Attach the switch lever to the Position Pac shaft.

5. Connect the linkage assembly to both levers as

shown in Figure 3.

6. Measure the approximate radius of the trip lever from

the center of the valve shaft to the linkage assembly

connection (not the end of the lever). Next, adjust

the switch lever to approximately the same radius

and tighten.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

29-3

Page 4

Table III: Rotary Mounting Kits

Actuator Valve Shaft

Size Diameter Kit No.*

(sq. in.) (inches)

25 0.62 97556

25 0.75 97557

25 0.88 97558

50 0.62 97559

50 0.75 97560

50 0.88 97561

50 1.12 97562

100 0.88 97563

100 1.12 97564

100 1.50 97565

100 1.75 97566

*Kit includes: bracket, trip lever, switch lever, linkage assembly,

nuts and bolts.

7. With the actuator at its minimum signal position,

slide the trip lever along the shaft until the linkage

assembly is parallel to the mounting bracket. At the

same time, rotate the trip lever until it is at a 45degree angle to the mounting bracket and pointing

toward the top yoke bolt closest to the Position Pac.

Tighten the trip lever on the shaft in this position.

8. Adjust the linkage assembly until the switch lever is

approximately the same angle as the trip lever and

the linkage assembly is horizontal. To preload the

Position Pac's restoring spring (used to remove

backlash in the linkage), be certain the actuator is in

its minimum signal position and perform the following using a slotted screw driver to rotate the switch

shaft (all rotation direction instructions are as viewed

from the lever arm side of the Position Pac):

For direct-acting, air-to-open actuators, rotate the

shaft counter clockwise as far as it will go, then back

off approximately 5 to 10 degrees. For direct-acting,

air-to-close actuators, rotate the shaft clockwise

approximately 5 degrees.

For reverse-acting, air-to-open actuators, rotate the

shaft clockwise approximately 5 degrees. For reverse-acting, air-to-close actuators, rotate the shaft

counter clockwise as far as possible, then back off

approximately 5 to 10 degrees.

With the slot in this position, tighten the lever arm

clamp screw tightly (until the teller tab will not move).

9. If possible, stroke the valve; the linkage assembly

should travel back and forth remaining horizontal.

10.To make electrical connections, remove the housing cover. (Refer to the specifications in Table IV for

the component electrical ratings.) Attach the transmitter signal wiring to the transmitter terminal block,

using caution to attach the positive and negative

wires to the appropriate terminal. Attach the limit

switch signal wiring to ‘COMM’ (common) and either

‘NC’ (normally closed) or ‘NO’ (normally open) terminals according to the needed signal.

WARNING: On explosion-proof installations,

disconnect electrical power or be certain the

area is safe from combustible atmospheres before removing the housing cover.

11.To adjust the limit switches and/or the position transmitter, remove the housing cover and refer to the

Calibration

12.Replace the housing cover.

section in this document.

CALIBRATION

When a Position Pac is installed in the field or a factory

installed unit needs to have output signal adjustments

made, refer to Figure 5 and proceed as follows:

Limit Switch

Position Pac limit switches are adjusted at the factory

before shipment and should not require on-site adjustment. However, if the mechanical lever has shifted

position, the unit may need readjustment. To readjust

the limit switch, proceed as follows:

CAUTION: If the valve cannot be stroked without

disturbing the process fluid, bypassing or removing the valve from the line may be necessary before

calibrating the Position Pac.

WARNING: Prior to removing the valve from the line,

depressurize the line to atmospheric pressure, drain

all process fluid and, if caustic or hazardous material are present, decontaminate the valve. Failure to

do so can cause serious injury.

1. Stroke the valve to the closed position.

WARNING: Keep hands, hair, clothing, etc. away

from moving parts when operating the valve.

Failure to do so can cause serious injury.

2. Remove the housing cover from the Position Pac.

WARNING: On explosion-proof installations,

disconnect electrical power or be certain the

area is safe from combustible atmospheres before removing the housing cover.

3. Lift the appropriate cam follower lever. Move the

cam wheel axially to disengage the teeth on the

wheel from the teeth on the shaft disc.

4. Turn the cam wheel to the desired position. Each

notch on the cam wheel represents an operating

point change of 70 20'.

5. When the cam wheel has been rotated to the desired

location, slide the cam wheel to engage with the

mating shaft disc. (For finer adjustment, use the

setscrew in the cam follower.)

6. Release the cam follower lever.

7. Cycle the valve and check for proper adjustment.

Readjust if necessary.

8. Replace the housing cover.

29-4 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 5

Transmitter

terms

block

Limit switch

wiring terminal

Limit switch

adjustment cams

(not shown)

Transmitter span

adjusting screw

(pot)

Transmitter zero

Adjusting Screw

(pot)

Figure 5: Calibration Points

Position Transmitter

1. Remove the housing cover from the Position Pac.

WARNING: On explosion-proof installations,

disconnect electrical power or be certain the

area is safe from combustible atmospheres before removing the housing cover.

2. Wire the Position Pac transmitter in series with a

12.5-40 VDC power supply and a milliamp meter.

NOTE: Instructions within parenthesis ( ) refer to

older Position Pac models characterized by a white

label.

CAUTION: Do not apply a voltage greater than 40

volts to transmitter terminals or the circuit will be

damaged.

3. Be certain the CW/CCW Switch located next to the

potentiometer (Direct/Reverse Switch located next

to the wire terminal block) is set to provide the desired output signal action. In the CW (DIR) position,

a clockwise rotation of the Position Pac shaft will

cause the output signal to increase. In the CCW

(REV) position, a counterclockwise stem rotation

causes the signal to increase.

4. Stroke the valve to the closed position.

WARNING: Keep hands, hair, clothing, etc. away

from moving parts when operating the valve.

Failure to do so can cause serious injury.

Clockwise/counterclockwise switch

5. Referring to Figure 5, adjust the ZERO adjusting

screw with a small, straight end screw driver, until the

meter reads 4 mA DC.

6. Stroke the valve to the open position.

7. Adjust the SPAN adjusting screw until the meter

reads 20 mA DC.

8. Stroke valve to the closed position and recheck the

meter for 4 mA DC. Some readjusting of the calibration may be required. Repeat steps 4-8 until satisfied.

9. If calibration is unsuccessful after following this procedure, one of two problems may exist: (a) The orientation of the Position Pac stem may need to be

adjusted. (b) The ZERO and SPAN potentiometers

may be adjusted out of range.

NOTE: The electrical travel of the potentiometer is

340 (150) degrees. To operate properly, the poten-

tiometer wiper must stay within the center 185 degrees of its 340 degree electrical range during the full

stroke of the valve.

9a.To adjust, stroke the valve to its middle position.

Loosen the potentiometer collar nut. While measuring the voltage between pins 1 and 2 on the back of

the potentiometer, rotate the potentiometer until the

voltage is between 0.55 and 0.65 volts. Retighten

the potentiometer being careful to keep the potentiometer oriented in the same position.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

29-5

Page 6

9b.Set the ZERO and SPAN potentiometers to their

approximate middle position. This is accomplished

by first turning each potentiometer clockwise 25

turns or until a ‘click’ is either felt or heard. Then turn

each potentiometer counterclockwise approximately 12 complete turns. Repeat steps 2 through 8

to complete calibration.

10.Replace the housing cover.

REVERSING POSITION TRANSMITTER

SIGNAL

The following instructions should be used when the signal being transmitted from the position transmitter is

either incorrect or needs to be reversed. Refer to

Figure 5.

Figure 6: Wiring Diagram

1500

L

Max. Load Resistance, R (Ω)

R = V - 12.5V

1250

1000

750

500

250

L max PS

20 mA

Operating

Region

0

0 10 20 30 40 50 60

Power Supply Voltage, V (volts)

PS

Figure 7: Power Supply Requirements

NOTE: Instructions within parenthesis ( ) refer to older

Position Pac models characterized by a white label.

1. Remove the housing cover.

WARNING: On explosion-proof installations,

disconnect electrical power or be certain the

area is safe from combustible atmospheres before removing the housing cover.

2. Locate the switch next to the position transmitter’s

wiring terminal. Move switch to the opposite position, CCW or CW (DIR or REV). Repeat steps 3-9 in

the

Calibration

section for the position transmitter.

NOTE: The SPAN potentiometer will generally not

need readjustment.

3. Replace the housing cover.

Table IV: Specifications

Analog Output

Power Supply Range 12.5 to 40 VDC (24V DC typical)

Maximum Load Maximum Resistance (ohms) =

Resistance Supply Voltage - 12.5

(see Figure 3)

Current Signal Output 4-20 mA

Span Adjustable from 5° to 100° of angular

Null 4 mA position may be set at any angular

Linearity ±1.0% full-scale*

Repeatability ±0.25% full-scale

Hysteresis ±1.0% full-scale

Operating -40O to 185O F (-40O to 85O C)

Temperature Range

Ambient Temperature For a 100O F (38O C) change in ambient

Range temperature, maximum zero shift is

Power Supply Output signal changes less than

rotation

position

±0.4% full scale, maximum span

shift is ±0.7% full scale

0.05% when supply voltage is varied

between 12.5 and 40 volts dc

Limit Switches

(SPDT) 20 amps, 125, 250, 480 VAC, ind. and

UL/CSA Rating (L23) res. 1 Hp. 125 VAC; 2 Hp, 250 VAC, 0.5

amp. 125 VDC; 0.25 amp, 250 VDC res.

Mechanical

Input motion ±105O from the center; spring

* Linearity is ±1.0% for 90O rotary shaft input. When mounted to

linear travel valves, linearity is dependent on linkage design and

stroke length. Typical linearity is ±1.5% full-scale on Valtek Mark

One control valves.

loaded to return to the center

0.02

29-6 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 7

Rotary

Short Housing Long Housing

4.00

102

1.26 dia. max.

32

0.72

18

3.15

80

2.00

51

0.33 dia. thru (4)

8

1.57

40

0.25

Front Mounting

0.49

12

0.75

19

0.88

22

0.37

9

2.38 typ

60

0.80

20

1.00

25

4.09 max.

104

3.78 max.

96

3.86 dia.

98

0.75 - 14 NPT

(5 full threads min.) (2)

Eight side mounting holes

can be tapped 5/16 - 18-inch

Lever Actuators

6

4.04

103

0.74

19

0.83

21

0.39

10

1.50

38

0.88

22

0.37

9

Adjust

1.50 - 3.70

38 - 94

0.72

18

0.29 dia.

7

0.80

20

1.00

5.71 max.

145

3.78 max.

133

3.82 dia.

97

0.75 - 14 NPT

1.00

25

0.57

0.50

14

13

25

0.27

7

0.16

4

0.09

(5 full threads min.) (2)

0.16

4

0.31

8

2

Figure 8: Dimensions

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

29-7

Page 8

Troubleshooting

Failure Probable Cause Corrective Action

Operation erratic 1. Loose bracket bolting 1. Tighten bolting bracket to yoke leg or transfer

and inconsistent case: readjust position transmitter and switches

2. Loose Position Pac mounting 2. Tighten mounting screws, readjust position

screws transmitter and switches

3. Loose tripper bracket 3. Tighten tripper bracket or extended spline

(linear actuator) or extended connector

spline connector (rotary

actuator)

4. Internal or electrical 4a. Ensure that terminal block connections are

malfunction tight

4b. Check for foreign material in contact with printed

circuit board or components

4c. Check for components or wires broken loose

from printed circuit board

4d. Check that the switch is fully set in desired

position

Indicating 1. Incorrect adjustment 1. Refer to

incorrect position

2. Internal or electrical 2a. Ensure that terminal block connections are

tight

2b. Check for foreign material in contact with printed

circuit board or components

2c. Check for components or wires broken loose

from printed circuit board

2d. Check that the switch is fully set in desired

position

Calibration

section, step 9

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its

intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications

under a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible

applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation and maintenance of Flowserve products.

The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe

use of Flowserve products in connection with the specific application.

While the information and specifications presented in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or

as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect

to this product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change

without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any of its worldwide operations or offices.

For more information, contact:

Flowserve and Valtek are registered trademarks of Flowserve Corporation.

29-8 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

FCD VLAIM029-04 © 2000 Flowserve Corporation. Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

For more information about Flowserve, contact www.flowserve.com or call USA 972 443 6500

Regional Headquarters

1350 N. Mt. Springs Prkwy.

Springville, UT 84663

Phone 801 489 8611

Facsimile 801 489 3719

12 Tuas Avenue 20

Republic of Signapore 638824

Phone (65) 862 3332

Facsimile (65) 862 4940

12, av. du Québec, B.P. 645

91965, Courtaboeuf Cedex,

France

Phone (33 1) 60 92 32 51

Facsimile (33 1) 60 92 32 99

Quick Response Centers

5114 Railroad Street

Deer Park, TX 77536 USA

Phone 281 479 9500

Facsimile 281 479 8511

104 Chelsea Parkway

Boothwyn, PA 19061 USA

Phone 610 497 8600

Facsimile 610 497 6680

1300 Parkway View Drive

Pittsburgh, PA 15205 USA

Phone 412 787 8803

Facsimile 412 787 1944

Loading...

Loading...