Page 1

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

USER INSTRUCTIONS

Valtek MaxFlo 3

Control Valves

Installation

Operation

Maintenance

1

Page 2

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

SUMMARY

1 GENERAL INFORMATION

2 INSTALLATION

3 QUICK-CHECK

4 PREVENTATIVE MAINTENANCE

5 VALVE DISASSEMBLY

6 BODY REASSEMBLY

7 SEAT REPLACEMENT

8 ACTUATOR REMOUNTING

9 PRINCIPLES OF SHAFT ANTI-BLOWOUT SYSTEM

10 MOUNTING ORIENTATION– AIR-TO-OPEN CONFIGURATION

11 MOUNTING ORIENTATION – AIR-TO-CLOSE CONFIGURATION

12 TROUBLESHOOTING

2

Page 3

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

STOP!

STOP!

1 GENERAL INFORMATION

1.1 Use

The following instructions are designed to assist in

the unpacking, installation, and maintenance as required for Flowserve products. Product users and

maintenance personnel should thoroughly review this

manual prior to installing, operating, or performing

any maintenance.

In most cases, Flowserve accessories, actuators and

valves are designed for specific applications (e.g. with

regard to medium, pressure and temperature). For this

reason, they should not be used in other applications

without first contacting the manufacturer.

1.2 Terms related to safety

The terms DANGER, WARNING, CAUTION, NOTE are

used in this document to highlight particular dangers

and/or to provide additional information on points

which may not be clearly obvious.

DANGER: Indicates that death, severe personal injury

and/or substantial property damage will occur if proper precautions are not taken.

WARNING: Indicates that danger of death or severe

personal injury and/or property damage can occur if

proper precautions are not taken.

CAUTION: Indicates that minor personal injury and/or

serious damage to property can occur if the appropriate precautions are not taken.

NOTE: Indicates and provides additional technical in-

formation which may not be obvious, even to qualified

personnel.

Compliance with other notes, which may not be partic-

ularly emphasized, with regard to transport, assembly,

operation and maintenance and with regard to technical documentation (e.g. in the operating instructions,

product documentation, or on the product itself) is

essential, in order to avoid faults, which can directly

or indirectly cause severe personal injury or property

damage..

2 INSTALLATION

2.1 Before installing the valve, clean the pipeline of all con

tamination, carbon deposits, welding chips, and other

foreign material. Carefully clean gasket surfaces to ensure a tight seal. Pipelines must be correctly aligned to

ensure that the valve is not fitted under tension.

2.2 Check the direction of fluid flow to ensure that the valve

is correctly installed. Flow direction is indicated by the

arrow attached to the body. All installation orientations

for fitting the valve into the pipeline are defined at the

end of this manual.

DANGER: To avoid serious injury, keep hands, hair,

clothing, etc away from the plug and seat when the

valve is working.

2.3 Connect the air supply and instrument signal lines.

Throttling control valves are equipped with a valve

positioner. Connections are marked for the air supply

and the instrument signal. Check that the actuator and

positioner can withstand the maximum air supply from

the network. The required air supply is indicated on a

sticker located on the actuator. An air regulator will be

necessary in certain cases in order to limit the supply

pressure. A filter is recommended unless the air supplied is exceptionally clean and dry (air quality without

humidity, oil, or dust as per IEC 770 and ISA-7.0.01).

All connections must be completely tight.

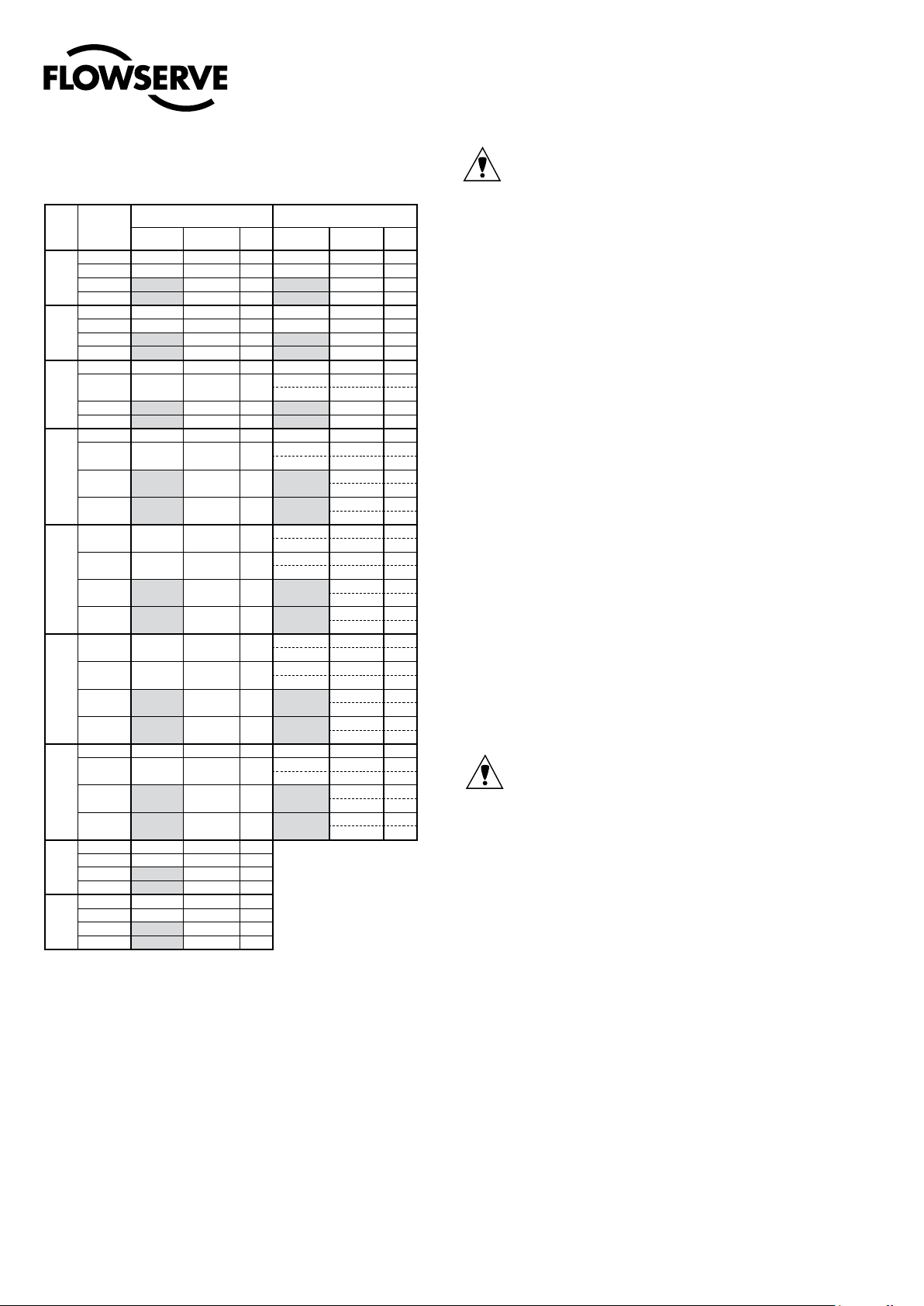

2.4 Use the bolts indicated in table I for installing the valve

in the pipeline, and then tighten alternately according

to good practice. The user must in all cases confirm

the capacity of the bolts to ensure a sufficiently tight

gasket seal for the expected service conditions.

-

1.3 Protective clothing

Flowserve products are often used in problematic ap-

plications (e.g. under extremely high pressures with

dangerous, toxic or corrosive mediums). When performng service, inspection, or repair operations, always ensure that the valve and the actuator are depressurized and that the valve has been cleaned, and

that it is free of harmful substances. In such cases, pay

particular attention to personal protection (e.g. protective clothing, gloves, glasses etc).

1.4 Qualified personnel

Qualified personnel are people who on account of their

education, experience, training, and knowledge of relevant standards, specifications, accident prevention,

and operating conditions have been authorized by

those responsible for the safety of the plant to perform

the necessary work, and recognize and avoid possible

dangers.

3

Page 4

®

Table I: Line Flange Bolting Specifications

Size

Nominal

vanne

Pressure /

Rating

ANSI 150 1/2 X 2.62 M12 X 65

ANSI 300 5/8 X 3.12 M16 X 80 8 5/8 X 6.88 M16 X 175 4

DN25

1"

PN 16

PN 40 M12 X 70 8 M12 X 175 4

ANSI 150 1/2 X 2.88 M12 X 70

ANSI 300 3/4 X 3.62 M20 X 95 8 3/4 X 8.38 M20 X 215 4

DN40

1½"

PN 16

PN 40 M16 X 80 8 M16 X 200 4

ANSI 150 5/8 X 3.25 M16 X 85

ANSI 300 5/8 X 3.5 M16 X 90 16

DN50

2"

PN 16

PN 40 M16 X 85 8 M16 X 215 4

ANSI 150 5/8 X 3.62 M16 X 95

ANSI 300 3/4 X 4.25 M20 X 110 16

DN80

3"

PN 16

PN 40 M16 X 95 16

ANSI 150 5/8 X 3.62 M16 X 95 16

ANSI 300 3/4 X 4.5 M20 X 115

DN100

4"

PN 16

PN 40 M20 X 100 16

ANSI 150

ANSI 300 3/4 X 4.88 M20 X 125 24

DN150

6"

PN 16

PN 40 M24 X 115 16

ANSI 150 3/4 X 4.25 M20 X 110 16 3/4 X 4.25 M20 X 360

ANSI 300 7/8 X 5.5 M22 X 140 24

DN200

8"

PN 16

PN 40 M27 X 135 24

ANSI 150 7/8 X 4.62 M22 X 120 24

ANSI 300 1 X 6.25 M24 X 155 32

DN250

10"

PN 16

PN 40 M30 X 150 24

ANSI 150

ANSI 300 1 1/8 X 6.75 M27 X 170 32

DN300

12"

PN 16

PN 40 M30 X 160 32

MaxFlo 3 flanged

Size x Length

Inches Metric

M12 X 70 8 M12 X 175 4

M16 X 80 8 M16 X 200 4

M16 X 85 8 M16 X 215 4

M16 X 85 16

M16 X 85 16

3/4 X 3.75 M20 X 105 16

M20 X 100 16

M20 X 100 24

M24 X 110 24

7/8 X 4.75 M22 X 120 24

M24 X 115 24

Qty /

vanne

8 1/2 X 6.75 M12 X 170 4

8 1/2 X 7.50 M12 X 190 4

8 5/8 X 8.38 M16 X 215 4

8 5/8 X 10.5 M16 X 265 4

16

MaxFlo3 flangeless

Size x Length

Inches Metric

5/8 X 3.50 M16 X 90 4

5/8 X 8.50 M16 X 220 6

3/4 X 4.25 M20 X 110

3/4 X 11.00 M20 X 280

M16 X 85 6

M16 X 255

M16 X 95 6

M16 X 265

5/8 X 3.62 M16 X 95

5/8 X 11.5 M16 X 295

3/4 X 4.5 M20 X 115 4

3/4 X 12.25 M20 X 315

M16 X 85 6

M16 X 285

M20 X 100 6

M20 X 300

3/4 X 3.75 M20 X 105 4

3/4 X 13.25 M20 X 340

3/4 X 4.88 M20 X 125 8

3/4 X 14.00 M20 X 360

M20 X 100 4

M20 X 335

M24 X 115 4

M24 X 350

7/8 X 5.5 M22 X 140 4

7/8 X 15.19 M22 X 390 10

M20 X 100 8

M20 X 350

M27 X 135 8

M27 X 385

Qty /

vanne

4

6

5

5

4

6

6

5

5

6

8

6

6

8

8

8

3 QUICK-CHECK

Before commissioning, check the control valve by fol

lowing these steps:

3.1 Check for full stroke by varying the instrument signal

settings appropriately. Observe the plug position indicator located on the actuator or the positioner. The

plug should change position with a smooth turning

movement.

3.2 Check all air connections for leaks. Tighten or replace

any leaking lines.

3.3 Check packing box bolting for proper tightness.

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

CAUTION: Do not overtighten packing. This can cause

excessive packing wear and high stem friction that

may impede shaft movement. After the valve has been

in service for a short period, recheck the packing-box

nuts. If the packing-box leaks, tighten the nuts just

enough to stop the leak.

3.4 Make sure the valve fails in the correct direction in case

of air failure. This is done by positioning the valve at

mid-stroke and turning off the air supply and observing the failure direction. If the action is incorrect, see

the section “Reversing the Air-action” in the instructions of the installation, operation and maintenance

manual of the appropriate actuator.

4 PREVENTATIVE MAINTENANCE

At least once every six months, check for proper oper-

ation by following the preventative maintenance steps

outlined below. These steps may be performed while

the valve is in-line and without interrupting service. If

an internal problem is suspected, refer to section “Disassembling the Valve”.

4.1 Look for signs of gasket leakage through the end

flanges and bonnet. If necessary, re-torque flange,

bonnet and post bolting.

4.2 Examine the valve for damage caused by corrosive

fumes or process drippings.

4.3 Clean the valve and repaint areas of severe oxidation.

4.4 Check the packing-box for proper tightness. If there is

a persistent leak, change the packing after referring to

section “Valve Disassembly and Body Reassembling”.

CAUTION: Do not overtighten packing. This can cause

excessive packing wear and high friction that may impede shaft movement.

4.5 If the valve is equipped with a lubricator, add lubricant

if necessary.

4.6 If possible, stroke the valve and check for smooth,

full-stroke operation. Unsteady shaft movement may

indicate an internal valve problem.

4.7 Check the calibration of the positioner. For further

preventative maintenance, see the instructions in the

installation, operation and maintenance manual for the

-

applicable positioner.

4.8 Ensure all accessories, brackets and bolting are securely fastened.

4.9 If possible, remove air supply and observe actuator for

correct fail-safe action.

4.10 Check the actuator and all air connections for leaks.

4.11 If an air filter is supplied, check and replace the cartridge if necessary.

4

Page 5

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

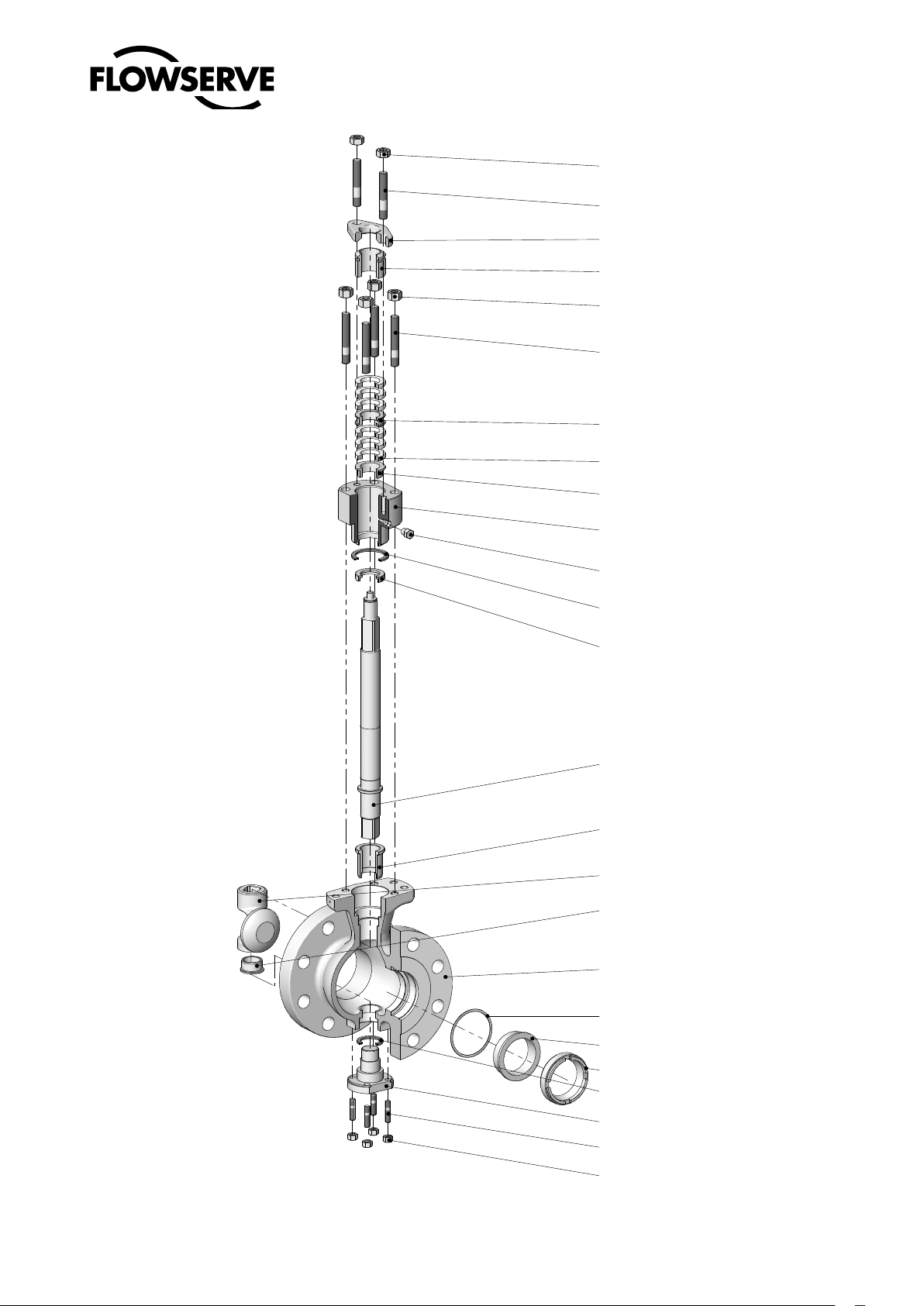

Item 117 Packing box nuts

Item 109 Packing box studs

Item 80 Gland flange

Item 87 Packing follower

Item 114 Bonnet nuts

Item 108 Bonnet studs

Item 93 Packing spacer

Item 88 Packing set

Item 99 Packing stop

Item 40 Bonnet

Item 42 Purge plug (optional)

Item 58 Bonnet gasket

Item 46 Thrust bearing

Figure 1: MaxFlo 3 valve body assembly

item numbers correspond directly to the valve’s bill of material. Refer

to it for specific part numbers.

Item 51 Shaft

Item 83 Shaft bearing

Item 50 Plug

Item 84 End post bearing

Item 1 Body

Item 23 Shims

Item 20 Seat

Item 30 Seat retainer

Item 61 End post gasket

Item 122 End post

Item 115 End post studs

Item 119 End post nuts

5

Page 6

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

STOP!

5 VALVE DISASSEMBLY

WARNING: To carry out this operation, it is essential to

disconnect the valve from the pipework. Depressurize

line to atmospheric pressure and drain all fluids before

working on the valve. Failure to do so can cause serious injury. Remove the valve from the pipeline.

Refer to figure 1 to find parts according to the item

numbers.

5.1 Remove the actuator from the body by separating the actuator at the yoke. Refer to the installation, operation and

maintenance manual for the corresponding actuator.

5.2 Remove the four bonnet nuts (item 114).

5.3 Remove the packing nuts and gland flange (item 80)

5.4 Carefully pull the shaft (item 51) out of the body. The

bonnet, thrust bearing, packing stop and packing will

all slide out of the body bore as an assembly.

5.5 Remove the end post nuts (item 119) and carefully remove the end post (item 122) from the body.

NOTE: At this point in the disassembly operation, the

plug is inside the valve body and is only supported by the

end post. When removing the end post, support the plug

so it does not drop into the bottom of the valve body.

5.6 Remove the plug from the body. See figure 2a.

5.7 Loosen the packing-box nuts (item 117) and remove the

shaft from the bonnet by sliding it out slowly. The thrust

bearing (item 46) and the shaft stop spacer (item 47, only

for sizes 10 to 12”) can now be removed from the shaft.

5.8 Remove the packing follower (item 87) as well as the

packing (item 88), spacers (item 93) and the packing

stop (item 99).

5.9 Remove the bonnet gasket (item 58) and end post

gasket (item 61). Clean all bearing and seal surfaces.

5.10 Remove the shaft bearing (item 83) from the valve

body. Use a suitable dowel to push the bearing out if

necessary. Be careful not to damage the bearing.

5.11 Unscrew the seat (item 30) using the appropriate tool

(see Table IV) and remove the seat (item 20) as well as

the adjustment shims (item 23).

6 BODY REASSEMBLY

NOTE: Lubricate all threads, bearings and the shaft

shoulder with a boron nitride paste (e.g. Molydal

NB1200) . Place the valve body in a vice and clamp

securely in a vertical position.

6.1 Always use new packing and gaskets when reassembling a valve.

6.2 Make sure that the shaft, bonnet bore and gasket surfaces in the body have been thoroughly cleaned (these

are sealing surfaces and it is important to remove any

contamination before reassembly).

6.3 Make sure that all bearing surfaces have been

cleaned.

6.4 Install all end post (item 115) and bonnet (item 108)

studs.

6.5 Insert the plug in the body as shown in figure 2b.

NOTE: The end post bearing (item 84) is pressed into

the plug.

6.6 Place the end post gasket (item 61) on the end post

(item 122). Insert the end post into the small flanged

port in the end of the body. As the end post is inserted,

locate the plug (item 50) so the end post will insert

into the end post bearing located in the plug.

NOTE: For valves 3’’ and larger, insert the end post

with the milled faces parallel to the flanges of the valve

body.

6.7 Tighten the end post nuts to finger tight.

6.8 Insert the shaft bearing (item 83) into the body until the

shoulder on the bearing contacts the step in the valve

body. The bearing will protrude slightly into the body gallery area.

6.9 Place the thrust bearing onto the shaft. Slide it up

to the thrust runner. The shaft thrust bearing will

surround the thrust runner.

NOTE: for sizes 10” and 12”, an end spacer (item 47)

is placed above the thrust bearing.

6.10 Place the bonnet gasket (item 58) on the gasket step

Table II: Nut tightening torques for bonnet and pivot post

Size A193-B8 cl2

M8 10 Nm 14 Nm

M12

M16

37 Nm 41 Nm

53 Nm 59 Nm

A453-Gr660

(Nace)

Figure 2a: Plug Removal

6

inside the body. Gently push the bonnet into the bonnet bore.

NOTE: When installing the bonnet, orient the milled

faces on the bonnet perpendicular to the flanges of the

valve body.

Figure 2b: Plug Installation

Page 7

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

6.11 Place the packing stop (item 99) into the bonnet,

then install the packing spacer (item 93) and packing

as shown in figure 3.

6.12 Install the packing follower (item 87) and gland flange

(item 80), then tighten the packing nuts to finger

tight.

6.13 Install bonnet nuts and tighten to finger tight.

6.14 Tighten the bonnet and end post nuts evenly. Torque

nuts to the values listed in table II.

6.15 Install the shims (item 23) and seat ring (item 20) as

described in the Seat Replacement section.

6.16 Install the actuator and yoke as described in the installation manual for the corresponding actuator.

6.17 Install the valve into the process line as described in

the installation section.

Standard V-ring Twin V-ring Twin V-ring Vacuum Seal Standard graphite Twin graphite

“Live Loading” system:

- optional for SureGuard / XT

- standard for SafeGuard

“Live Loading” system:

- optional for SureGuard / XT

- standard for SafeGuard

Standard SureGuard

Standard SureGuard XT

Standard SafeGuard

Twin SureGuard

Twin SureGuard XT

Twin SafeGuard

Figure 3: Packing Configurations

Standard SureGuard Firesafe

Standard SureGuard XT Firesafe

Standard SafeGuard Firesafe

Twin SureGuard Firesafe

Twin SureGuard XT Firesafe

Twin SafeGuard Firesafe

7

Page 8

®

7 SEAT REPLACEMENT

STOP!

WARNING: The actuator must be removed from the

valve body prior to replacing the seat ring.

7.1 To replace the seat, see figures 5a and 5b, and proceed

as follows:

7.2 Loosen the packing box nuts.

7.3 Using the appropriate retainer tool (see Table III), remove the seat retainer. (Retainer tools are available

from the factory).

7.4 Remove the seat and any shims that may be installed

under the seat.

7.5 Check both seat and plug surfaces for wear and galling. Replace these parts if necessary.

7.6 Clean seat ring, seat retainer and body threads of old

sealant residue. Clean parts thoroughly.

7.7 To reinstall the seat, place the seat (without shims)

into the valve body. Rotate the plug to 90 degrees

open. Measure dimension “A” as shown in figure 4a.

7.8 Close the plug into the seat and then measure dimension “B” as shown in figure 4b.

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

NOTE: For optimum sealing do not over-rotate the plug

into the seat. A very slight under-rotation is recommended. (See figure 5)

7.9 The difference between dimension “A” and “B” represents the total thickness of the adjustment shims to be

added between the seat and the valve body. See table

III to select the necessary shim(s). Regardless of the

valve size, at least one shim must be present.

7.10 Remove the seat and add the appropriate number of

shims. (Flowserve recommends a sealant with a temperature range of –70 to 200°C, type Dow Corning

RTV 736, or a sealant with a graphite base for higher

temperatures or for steam processes.)

7.11 Apply lubricant to the threads of the seat retainer. Replace the seat retainer and tighten manually until it

makes contact with the seat, then loosen it by 1/8 of

a turn. Open and close the valve several times while

tightening the seat retainer manually to position the

seat correctly. Finally, close the valve and tighten the

seat retainer according to the values in table IV.

Parts supplied with the toolkit

for removing the seat retainer

Upon contact with the seat, the horizontal axis of the plug must never be rotated

past the horizontal axis of the valve body.

The plug should rotate into the seat as

close to the horizontal axis as possible.

To increase this lag, reduce the thickness

of the shims, and vice-versa.

Figure 4a: definition of dimension “A” with plug open

A

Figure 4b: definition of dimension “B” with plug closed

B

Figure 4: shimming the seat

8

Page 9

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

Recommended plug rotation.

Plug slightly under-rotated.

Maximum limit for plug rotation. The plug

should not be rotated further.

Recommended plug rotation

exceeded. Setting should be

avoided.

Figure 5: positioning of plug

Table III: Shim Selection

Thickness of shims available

Valve Size Rounding rule Example Chosen thickness 0.1 mm 0.15 mm 0.2 mm 0.3 mm 0.5 mm

1"

DN25

1.5" to 8"

DN40 – DN200

10" – 12"

DN250 – DN300

to 0.05 mm

to 0.1 mm

A - B - 0.3

rounded to 0.5mm

A – B = 0.27 mm

rounded to 0.25 mm

A – B = 0.27 mm

rounded to 0.2 mm

A – B = 0.9 mm

A – B – 0.3 mm = 0.6 mm

0.1 mm

0.15 mm

X X X X

0.2 mm X X X X

0.5 mm X X X

Table IV: Seat Retainer Removal Tools and Required Torque Values

Face-to-Face

Valve size

1"

DN 25

1.5"

DN 40

2"

DN 50

3"

DN 80

4"

DN 100

6"

DN 150

8"

DN 200

10"

DN 250

12"

DN 300

ANSI/ISA-75.08.02, EN 558.1/2 series 36,

IEC 60534-3-2, DIN 3202 F1,

EN 558-1/2 series 1

Part number: 183224.999.000

Torque: 41 ft-lbs / 55 Nm

Part number: 183225.999.000

Torque: 103 ft-lbs / 140 Nm

Part number: 183226.999.000

Torque: 155 ft-lbs / 210 Nm

Part number: 183227.999.000

Torque: 406 ft-lbs / 550 Nm

Part number: 183228.999.000

Torque: 428 ft-lbs / 580 Nm

Part number: 183229.999.000

Torque: 959 ft-lbs / 1300 Nm

Part number: 183230.999.000

Torque: 701 ft-lbs / 950 Nm

Part number: 183231.999.000

Torque: 553 ft-lbs / 750 Nm

Part number: 183232.999.000

Torque: 752 ft-lbs / 1020 Nm

ANSI/ISA-75.08.0,

EN 558-1/2 series 37-38,

IEC 60534-3-1

Part number: 183229.999.000

Torque: 959 ft-lbs / 1300 Nm

Part number: 183230.999.000

Torque: 701 ft-lbs / 950 Nm

Part number: 183231.999.000

Torque: 553 ft-lbs / 750 Nm

9

Page 10

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

8 ACTUATOR REMOUNTING

NOTE: The MaxFlo 3 valve opens in a clockwise direc-

tion when looking down the valve shaft.

8.1 When remounting the actuator to the valve, refer to the

appropriate actuator manual.

9. PRINCIPLES OF SHAFT ANTI-BLOWOUT SYSTEM

NOTE: The actuator stroke stops must be adjusted

correctly to avoid any over-rotation of the plug stroke.

Poor adjustment can cause damage to the valve. Pay

special attention to the adjustment of the closing stop

when the valve has a soft seat.

8.2 Install the valve in the pipeline as indicated in the “Installation” section according to the orientation recommendations given at the end of the manual.

Figure 6a: old design

NOTE: The MaxFlo 3 valve has been significantly im-

proved, with even greater safety for the anti-blowout

system (see figure 6).

The diameter of the shaft shoulder exceeds the di-

ameter of the bonnet bore. Even if the thrust bearing

(item 46) is not installed during reassembly, the shaft

cannot pass through the bonnet.

10

Figure 6b: new design

It is possible to upgrade from the old design (prior to

mid-2006) by changing the bonnet (40) and the packing stop (99).

To order the correct replacement parts, contact your

Flowserve representative with the serial numbers

of the valves requiring the upgrade.

Page 11

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

LEFT

RIGHT

AIR OPENS

TOP

FLUID

LEFT

RIGHT

AIR OPENS

TOP

FLUID

LEFT

RIGHT

AIR OPENS

TOP

FLUID

LEFT

RIGHT

AIR OPENS

TOP

FLUID

LEFT

RIGHT

AIR OPENS

TOP

FLUID

RIGHT

LEFT

AIR OPENS

TOP

FLUID

LEFT

RIGHT

TOP

AIR OPENS

FLUID

LEFT

RIGHT

FLUID

AIR OPENS

TOP

10. PIPELINE MOUNTING ORIENTATIONS – AIR-TO-OPEN CONFIGURATION

Shaft downstream – Flow to open

VIEW

VIEW

Shaft upstream – Flow to close

VIEW

VIEW

-

ing

Horizontal Flow –

Left Hand Pipe Mount

Mounting

Right Hand Pipe

Horizontal Flow–

VIEW

VIEW

VIEW

VIEW

PIPE MOUNTING ORIENTATION CODES

3 - Air Action 4 - Configuration 5 - Actuator Mounting 6 - Shaft Direction

O Air-to-Open - ATO L Left Hand Mounting L Left U Shaft upstream

C Air-to-Close - ATC R Right Hand Mount-

ing

D Flow Down T Top

U Flow UP

R Right D Shaft downstream

recommended

Flow Down

Vertical Flow –

Flow Up

Vertical Flow –

11

Page 12

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

LEFT

RIGHT

TOP

AIR CLOSES

FLUID

LEFT

RIGHT

AIR CLOSES

TOP

FLUID

LEFT

RIGHT

TOP

AIR CLOSES

FLUID

LEFT

RIGHT

FLUID

AIR CLOSES

TOP

LEFT

RIGHT

FLUID

AIR CLOSES

TOP

LEFT

RIGHT

FLUID

AIR CLOSES

TOP

LEFT

RIGHT

AIR CLOSES

TOP

FLUID

LEFT

RIGHT

FLUID

AIR CLOSES

TOP

11. PIPELINE MOUNTING ORIENTATIONS – AIR-TO-CLOSE CONFIGURATION

Shaft downstream – Flow-to-open

VIEW

VIEW

Shaft upstream – Flow-to-close

VIEW

VIEW

Horizontal Flow –

Left Hand Pipe Mounting

ing

Horizontal Flow –

Right Hand Pipe Mount-

VIEW

VIEW

PIPE MOUNTING ORIENTATION CODES

3 - Air Action 4 - Configuration 5 - Actuator Mounting 6 - Action of fluid

O Air-to-Open - ATO L Left Hand Mounting L Left U Shaft upstream

C Air-to-Close - ATC R Right Hand Mount-

D Flow down T Top

ing

R Right D Shaft downstream

recommended

U Flow up

Flow down

Vertical Flow –

VIEW

Flow up

Vertical Flow –

VIEW

12

Page 13

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

12. TROUBLESHOOTING

Failure Probable Cause Corrective Action

Valve moves to failure position, exces

sive air bleeding from transfer case

Jerky shaft rotation 1. Overtightened packing 1. Retighten packing box nuts to slightly over finger-

Excessive leakage 1. Improper adjustment of external

Leakage through line flanges 1. Dirty line gasket surfaces 1. Clean gasket surfaces and reinstall valve

Leakage through packing box 1. Loose packing box nuts 1. Tighten packing box nuts to slightly over finger-tight

Valve slams, wont open, or causes se

vere water hammer

Shaft rotates, plug remains open or

closed

Actuator operates, shaft does not rotate 1. Broken internal actuator parts 1. Refer to appropriate actuator maintenance instruc

Leakage through bonnet joint; leakage

from end post

-

1. Failure of cylinder actuator O-ring 1. Replace actuator O-ring

2. Failure of sliding seal assembly in cyl-

2. Repair or replace sliding seal assembly

inder actuator

tight for V-ring packing, 14 ft-lbs/19 Nm for braided

packing.

2. Improper adjustment of lever arm on

shaft causing arm to contact transfer

2. Redjust lever arm (see step 1 in Actuator Remounting)

case

3. Cylinder wall of actuator not lubri

-

3. Lubricate cylinder wall with silicone lubricant

cated

4. Worn piston O-ring allowing piston to

gall on cylinder wall

5. Worn actuator stem O-ring causing

4. Replace O-ring; if galling has occurred replace all

damaged parts

5. Replace O-ring; if actuator stem is galled replace it

actuator stem to gall on stem collar

6. Worn (or damaged) thrust bearings,

shaft bearing or packing followers

6. Disassemble and inspect parts; replace any worn or

damaged parts

1. See Actuator Remounting

stroke stops

2. Improper seat adjustment 2. See Seat Replacement

3. Worn or damaged seat 3. Replace seat

4. Damaged plug seating surface 4. Replace plug

5. Improper handwheel adjustment act

-

5. Adjust handwheel until plug seats properly

ing as limit stop

2. Improper sealing of line flanges 2. Tighten line flanges evenly and completely (see Table

1 for proper torque)

3. Flange or pipe misalignment 3. Reinstall valve in line; check piping system

for V-ring packing, 14 ft-lbs/19 Nm for braided pack

ing.

2. Worn or damaged packing 2. Replace packing

3. Dirty or corroded packing 3. Clean body bore and stem, replace packing

-

1. Improper valve installation 1. See step 2 in Installation and correct flow direction

1. Broken shaft 1. Replace shaft, make sure plug does not overstroke

and contact plug stop

tions

1. Loose bolting or damaged gasket 1. Tighten bolting as recommended in Table II

2. Dirty gasket surfaces 2. Clean gasket surfaces, replace gaskets and retighten

bolting per Table II

-

-

13

Page 14

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

14

Page 15

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

15

Page 16

®

User Instructions - MaxFlo 3 - VLEEIM7001-03 07.07

Flowserve Essen GmbH

Flowserve Flow Control

Kämmer Ventile

Manderscheidtsrasse 19

45141 Essen

Germany

Phone: +49 (0) 201 89 19 0

Fax: +49 (0) 201 89 19 662

Flowserve (Austria) GmbH

Control Valves - Villach Operation

Kasernengasse 6

9500 Villach

Austria

Phone: +43 (0) 4242 41181-0

Fax: +43 (0) 4242 4118150

To find your local Flowserve representative:

For more information about Flowserve Corporation, visit

www.flowserve.com

All data subject to change without notice

©02.2007 Flowser ve Corporation. Flowserve is a trademark of the Flowser ve Corporation

Flowserve S.A.S.

12, avenue du Quebec

B.P. 645

91965 Courtaboeuf Cedex

France

Phone: 33 (0) 1 60 92 32 51

Fax: 33 (0) 1 60 92 32 99

16

Loading...

Loading...