Page 1

GESTRA

GESTRA Steam Systems

UNA 38

UNA 39

Installation Instructions 818603-00

Steam Traps

UNA 38, UNA 39

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose ..............................................................................................................4

Safety note ............................................................................................................................................. 4

Danger ...................................................................................................................................................4

Attention .................................................................................................................................................4

PED (Pressure Equipment Directive) ........................................................................................................4

ATEX (Atmosphère Explosible) .................................................................................................................4

Explanatory Notes

Scope of supply ...................................................................................................................................... 5

Description ............................................................................................................................................. 5

Function ...........................................................................................................................................5 – 6

Technical Data

UNA 38, UNA 39 ......................................................................................................................................6

Pressure/temperature ratings .................................................................................................................6

Corrosion resistance ............................................................................................................................... 6

Sizing .....................................................................................................................................................6

Name plate/marking ...............................................................................................................................7

Design

UNA 38, UNA 39 ..............................................................................................................................8 – 10

Key .......................................................................................................................................................11

Installation

UNA 38, UNA 39 ....................................................................................................................................12

Design with flanges .............................................................................................................................. 12

Design with socket-weld ends .............................................................................................................. 12

Design with butt-weld ends .................................................................................................................. 12

Attention ...............................................................................................................................................12

Heat treatment of welds........................................................................................................................13

Hand vent valve (UNA 38)......................................................................................................................13

Float lifting lever (optional extra) ........................................................................................................... 13

Tools .....................................................................................................................................................13

Commissioning

Danger .................................................................................................................................................13

UNA 38, UNA 39 ...................................................................................................................................13

2

Page 3

Contents – continued –

Page

Operation

Danger .................................................................................................................................................14

Hand vent valve .................................................................................................................................... 14

Float lifting lever ................................................................................................................................... 14

Maintenance

Checking the steam trap .......................................................................................................................15

Cleaning /exchanging the control unit ....................................................................................................15

Changing the bimetallic air vent (UNA 38) ............................................................................................. 15

Torques ................................................................................................................................................ 16

Tools .....................................................................................................................................................16

Retrofitting

Cleaning /exchanging the control unit ....................................................................................................17

Torques ................................................................................................................................................ 17

Tools .....................................................................................................................................................17

Spare Parts

Spare parts list UNA 38, UNA 39 ........................................................................................................... 18

Annex

Declaration of conformity ......................................................................................................................19

3

Page 4

Important Notes

Usage for the intended purpose

UNA 38, UNA 39:

Use the steam traps only for the discharge of condensed steam and liquids. Use the equipment for

the discharge of condensed steam and other condensable gases in pipes only within the specified

pressure and temperature ratings, and check the corrosion resistance and chemical suitability for the

application in question.

Safety note

The equipment must only be installed and commissioned by qualified staff.

Maintenance and service work must only be performed by adequately trained persons who have

a recognized level of competence.

Danger

The steam trap is under pressure during operation.

When loosening flanged connections, sealing plugs or the control unit, it is possible

that hot water, steam, corrosive liquids or toxic gases may escape.

This presents the danger of severe burns and scalds to the whole body or severe cases

of poisoning by toxic gases.

Installation and maintenance work should only be carried out when the system is

depressurized.

Isolate the trap from both upstream and downstream pressure.

The steam trap becomes hot during operation.

This presents the risk of severe burns to the whole body.

Before performing maintenance work on the valve or flanged connections or undoing

the gland packing screws or sealing plugs, ensure that all the connected pipes are

pressureless (0 bar) and have cooled down to room temperature (20 °C).

Attention

The name plate indicates the technical specification of the equipment.

Do not commission or operate a steam trap without a name plate.

PED (Pressure Equipment Directive)

The equipment fulfils the requirements of the Pressure Equipment Directive PED 97/23/EC.

UNA 38 and UNA 39 are intended for applications with fluids of group 1 and 2.

With CE marking (apart from equipment according to section 3.3).

ATEX (Atmosphère Explosible)

The equipment does not have its own potential source of ignition and is therefore not subject to the

ATEX Directive 94/9/EC. The equipment can be used in potentially explosive areas 0, 1, 2, 20, 21, 22

(1999/92/EC).

The equipment is not Ex marked.

4

Page 5

Explanatory Notes

Scope of supply

UNA 38 with DUPLEX control unit

loat trap UNA 38

1 F

1 Installation manual

UNA 39 with DUPLEX control unit

1 Foat trap UNA 39

1 Installation manual

Retrofit set for UNA 38, UNA 39

1 Control unit as per specification

1 Installation manual

Spare parts

1 Set according to spare parts list on page 18

Description

UNA 3... are high-pressure steam traps with ball float and needle closing mechanism. The steam traps

work independently of back pressure, thus ensuring universal application.

The steam trap UNA 3… features a body with bolted cover and a control unit. Various control units

are available.

Level-dependent SIMPLEX control is particularly suitable for cold condensate and superheated steam.

Temperature-dependent DUPLEX control offers automatic deaeration by means of a bimetallic air vent

for saturated and superheated steam systems.

The orifice type O 80 MAX (UNA 38) is a control unit for large flowrates and high pressures, and can

be supplied as a SIMPLEX or DUPLEX version.

The orifice type O 140 MAX (UNA 39) is a SIMPLEX control unit for large flowrates and high pressures.

UNA 38 with SIMPLEX control unit

1 Float trap UNA 38

1 Hand vent valve with gasket, installed

1 Float lifting lever with gasket, installed (optional)

1 Installation manual

UNA 39 with SIMPLEX control unit

1 Float trap UNA 39

1 Hand vent valve with gasket, installed

1 Float lifting lever with gasket, installed (optional)

1 Installation manual

.

Function

UNA 38, UNA 39:

The ball valve of the control unit is operated by the float as a function of the condensate level in the

trap. The cross-sectional area (CSA) of the orifice (O) dictates the maximum flowrate when the valve is

completely open. The maximum admissible differential pressure of the control unit is a function of the

CSA of the orifice, the density of the fluid to be discharged, and the pressure/temperature ratings of the

body. Different closing units (orifices) are available.

Float traps equipped with DUPLEX control units enable automatic temperature-dependent deaeration

of saturated steam systems during start-up and in continuous operation.

5

Page 6

Explanatory Notes – continued –

Function – continued –

UNA 38 control unit O 80 MAX and UNA 39 control unit O 140 MAX:

The float ball controls a pilot valve depending on the level of condensate in the trap body. If more

condensate flows through the pilot valve out of the control chamber than follows through a balance

opening, the pressure in the control chamber drops and the bellows of the control chamber is

compressed. The main valve then opens and the condensate is discharged.

The flowing condensate moves the float ball upwards and the pilot valve closes. By means of the vent

hole, the pressure between the control chamber and the interior of the steam trap is evened out, so

that the main valve closes.

The cross-sectional areas of the pilot and main valves are chosen so that only one orifice (O) is needed

for the entire range of differential pressures up to 80 bar (or 140 bar).

Technical Data

UNA 38, UNA 39

Orifices (O)

Type

O 50 50 X

O 64 64 X

O 80 80 X X

O 80 MAX 80 X

O 110 110

O 140 140

O 140 MAX 140

1

) Observe the pressure/temperature ratings!

2

) Inlet pressure minus outlet pressure.

∆PMX [bar] 1)2)

UNA 38 UNA 39

X

X

X

Pressure/temperature ratings

For the pressure and temperature ratings, see the designation on the body or the data given on the

name plate.

Corrosion resistance

When used for its intended purpose, the safe functioning of the steam trap will not be impaired by

corrosion.

Sizing

The trap body must not be subjected to sharp increases in pressure. The sizing and dimensional

allowances for corrosion reflect the latest state of technology.

6

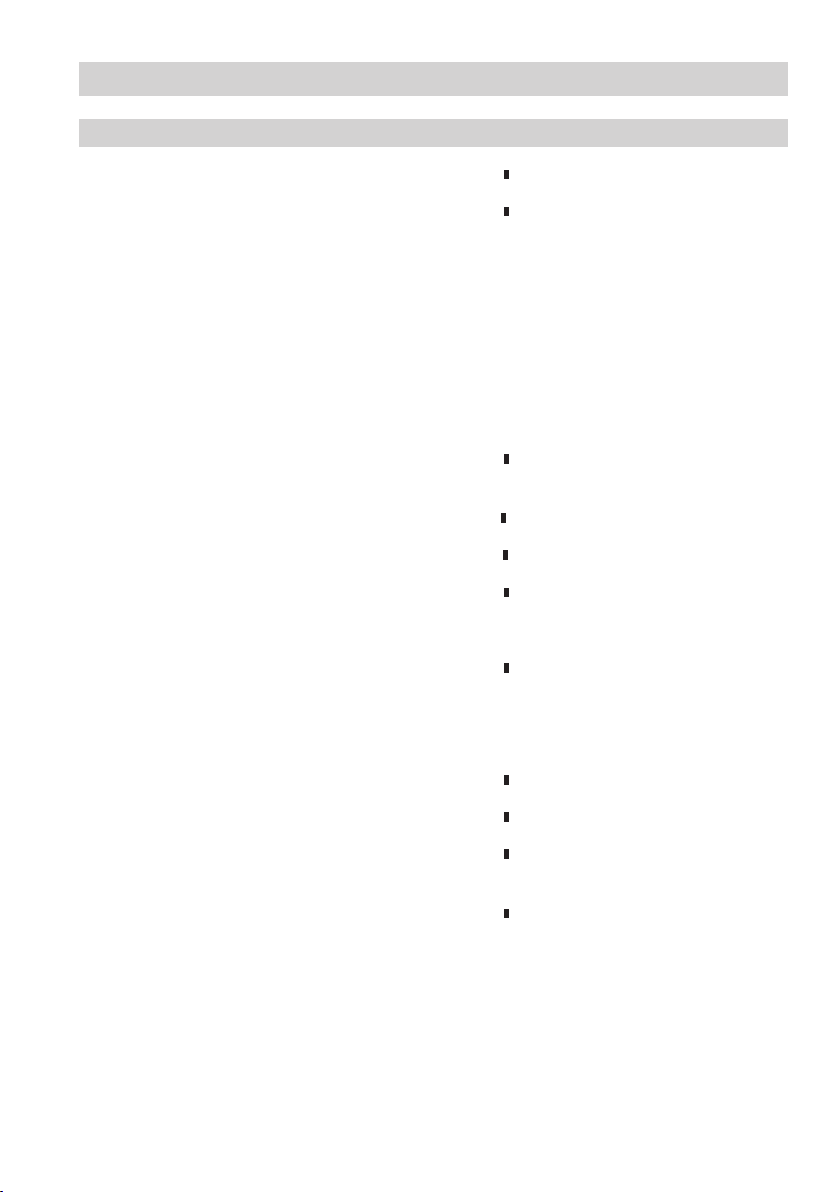

Page 7

Technical Data – continued –

Name plate / marking

For the pressure and temperature ratings, see the designation on the trap body or the data given on

the name plate. Further details are given in various GESTRA publications, such as datasheets and

technical information.

In accordance with EN 19, the following type and design data are indicated on the name plate or body:

n Manufacturer

n Type designation

n Pressure class PN or Class

n Material number

n Maximum temperature

n Maximum pressure

n Direction of flow

n Stamp on the body / name plate, e.g. specifies the manufacturing quarter and year

(in this case the 3rd quarter of 2005).

n Type designation UNA 38 h: design for horizontal lines

UNA 38 v: design for vertical lines

UNA 39: angle type

n SIMPLEX or DUPLEX: type of control unit (see Description)

n ∆PMX (∆p max): max. admissible differential pressure [bar],

corresponding to the ordered “O...” (orifice).

3

05

Maximum

admissible

differential

pressure

Fig. 1

Nominal size Nominal pressure

Maximum admissible pressure

Design/version

Maximum

admissible

temperature

Design

7

Page 8

Design

UNA 38

Fig. 2 UNA 38h

k

;

<

l

X

:

C

D

z

E

F

G

L

O

C

N

r

s

G

L

t

u

w

8

Page 9

Design – continued –

UNA 38 – continued –

Fig. 3 UNA 38v

9

Page 10

Design – continued –

UNA 39

r

2

2

u

2

t

Fig. 4 UNA 39

W

V

<

2

U

2

:

z

T

2

2

w

;

2

L

l

2

t

2

2

s

2

k

N

L

O

Fig. 5 UNA 39

10

Page 11

Design – continued –

Key to components

k UNA 38 hexagon nut M20

l UNA 38 sleeve

C UNA 38 bimetallic air vent

D Gasket, shape A 16 x 20

E UNA 38 control unit DUPLEX,

Orifice 50, O 64 or O 80

F Plug

G Gasket, shape D 17 x 21

r UNA 38 control unit DUPLEX,

Orifice 80 MAX

s UNA 38 hand vent valve

t UNA 38 handle for float lifting lever

u UNA 38 float lifting lever

L Gasket, shape D 21 x 26

w UNA 38 cover

N Name plate

O Plug

2

k UNA 39 hexagon nut M24

2

l UNA 39 sleeve

2

r UNA 39 control unit,

Orifice 140 MAX

2

s UNA 39 hand vent valve

2

t UNA 39 handle for float lifting lever

2

u UNA 39 float lifting lever

2

w UNA 39 cover

z UNA 38 expansion bolt

: UNA 38 body gasket 129 x 141 x 1

; UNA 38 control unit SIMPLEX,

Orifice 50, O 64 or O 80

< UNA 38 body

T Hexagon-socket screw

U Gasket 30 x 40 x 1

V UNA 39 split pin for float lifting lever

W UNA 39 distance sleeve for float lifting lever

X UNA 38 union nut

2

z UNA 39 expansion bolt

2

: UNA 39 body gasket 182 x 112 x 1

2

; UNA 39 control unit SIMPLEX,

Orifice 80, O 110 or O 140

2

< UNA 39 body

11

Page 12

Installation

UNA 38

Depending on its body design, the float trap UNA 38 can be installed in horizontal or vertical pipes with

downward flow.

UNA 39

The float trap UNA 39 can be installed in vertical pipes with downward flow.

Design with flanges

1. Ensure correct position of installation. The name plate

2. Observe direction of flow. The arrow indicating the flow direction is on the trap body.

3. Consider space required for opening trap. When the trap is installed, a minimum space of at least

150 mm (UNA 39) or 310 mm (UNA 38) is required for removing the cover M.

4. Remove plastic plugs. They are

5. Clean the seating surfaces of both flanges.

6. Install the steam trap.

Design with socket-weld ends

1. Ensure correct position of installation. The name plate N must always be on top (UNA 38).

2. Observe direction of flow. The arrow indicating the flow direction is on the trap body.

3. Consider space required for opening trap. When the trap is installed, a minimum space of at least

150 mm (UNA 39) or 310 mm (UNA 38) is required for removing the cover M.

4. Remove plastic plugs. They are

5. Clean the socket-weld ends.

6. Arc-weld the trap

Design with butt-weld ends

1. Ensure correct position of installation. The name plate

2. Observe direction of flow. The arrow indicating the flow direction is on the trap body.

3. Consider space required for opening trap. When the trap is installed, a minimum space of at least

150 mm (UNA 39) or 310 mm (UNA 38) is required for removing the cover M.

4. Remove plastic plugs. They are

5. Clean the butt-weld ends.

6. Arc-weld the trap manually (welding process 111 and 141 in accordance with ISO 4063) or use

gas-welding (welding process 3 in accordance with ISO 4063).

only manually (welding process 111 and 141 in accordance with ISO 4063).

only used as transit protection.

only used as transit protection.

only used as transit protection.

N must always be on top (UNA 38).

N must always be on top (UNA 38).

12

Attention

n

Only qualified welders certified e.g. according to EN 287-1 may weld the steam trap

into pressurized lines.

Page 13

Installation – continued –

Heat treatment of welds

After welding the steam trap, it may be necessary to apply heat treatment to the welds (stress-relief

annealing as per DIN EN 100529).

The heat treatment is limited to the area immediately around the weld.

It is not necessary to remove the internals of the steam trap to perform the heat treatment.

Hand vent valve (UNA 38)

Remove plug F.

1.

Insert the gasket G and fit the hand vent valve I in place.

2.

For the torque, see the table “Torques”.

Close the hand vent valve.

3.

Float lifting lever (optional extra)

For the UNA 38 and UNA 39, the float lifting lever is installed in the factory.

Tools

n Combination spanner A.F. 22 mm to DIN 3113, form B

n Torque spanner 20 – 120 Nm to DIN ISO 6789

Commissioning

Danger

Burn hazard! The steam trap becomes hot during operation. Touching the hand vent valve

or the float lifting lever presents the risk of severe burns to hands and arms.

Always wear insulated, heat-resistant safety gloves when handling the valve.

UNA 38, UNA 39

Make sure that all flanged connections, the hand vent valve and the float lifting lever are firmly fixed to

the UNA 38 or UNA 39, ensuring a tight, leakproof joint.

If the steam trap is to be used in a new installation which has not been flushed yet, it is advisable to

check – and if required – clean the trap.

13

Page 14

Operation

Danger

Burn hazard! The steam trap becomes hot during operation. Touching the hand vent valve

or the float lifting lever presents the risk of severe burns to hands and arms.

Always wear insulated, heat-resistant safety gloves when handling the valve.

Hand vent valve

1. Open the hand vent valve if necessary.

2. Close the hand vent valve after completing the venting process.

Float lifting lever

1. Attach the handle J to the float lifting lever K. (See Fig. 2 and Fig. 4)

2. Turn the float lifting lever

3. Turn the float lifting lever in the opposite direction to the arrow (to close the valve),

and then remove the handle.

K in the direction of the arrow on the cover M.

14

Page 15

Maintenance

GESTRA steam traps of the type UNA do not require any special maintenance.

However, if the steam trap is to be used in a new installation which has not been flushed yet,

it is advisable to check and – if required – clean the trap.

Checking the steam trap

The UNA steam traps can be checked for steam loss during operation by using the GESTRA ultrasonic

measuring unit VAPOPHONE® or TRAPtest®.

In case of steam loss, clean the valve and/or replace the control unit or orifice.

Cleaning/exchanging the control unit

1. Take heed of the “Danger” note on page 4.

2. Undo the hexagon nuts

the cover M.

3. Undo the union nut

alternatively, undo and remove the hexagon socket-head screws T, and take out the control unit

2 2

r or ; (UNA 39).

Replace the control unit in case of visible signs of wear or damage.

4.

Clean the body, internals and all gasket surfaces.

5.

Apply heat-resistant lubricant to all threads and the seating surfaces of the control unit and cover

6.

(use e.g. WINIX® 2150).

Attach the control unit E, r or ; (UNA 38) with the union nut and align it within the body so that the

7.

float ball can move vertically. Tighten the union nut. Insert a new gasket U for control unit r or ;

(UNA 39), put on the control unit and tighten the hexagon socket-head screws T evenly crosswise.

For the torques, see the table “Torques” on page 16.

Insert a new body gasket Q.

8.

Put the cover onto the body and push the sleeves B onto the expansion bolts P. Tighten the

9.

hexagon nuts A evenly crosswise in several stages to the values specified in the “Torques” table.

A, remove the sleeves B from the expansion bolts P, and take off

X and take it out of the body together with the control unit E, r or ; (UNA 38);

2 2

Changing the bimetallic air vent (UNA 38)

1. Take heed of the “Danger” note on page 4.

2. Undo the hexagon nuts

k, remove the sleeves l from the expansion bolts z, and take off

the cover w.

Unscrew and remove the bimetallic air vent C; take out the gasket D.

3.

Install a new bimetallic air vent C together with a new gasket. For the torque, see the table “Torques”

4.

on page 16.

Insert a new body gasket :.

5.

Put the cover onto the body and push the sleeves l onto the expansion bolts z. Tighten the hexagon

6.

nuts k evenly crosswise in several stages to the values specified in the “Torques” table.

WINIX® 2150 is a registered trademark of WINIX GmbH, Norderstedt

15

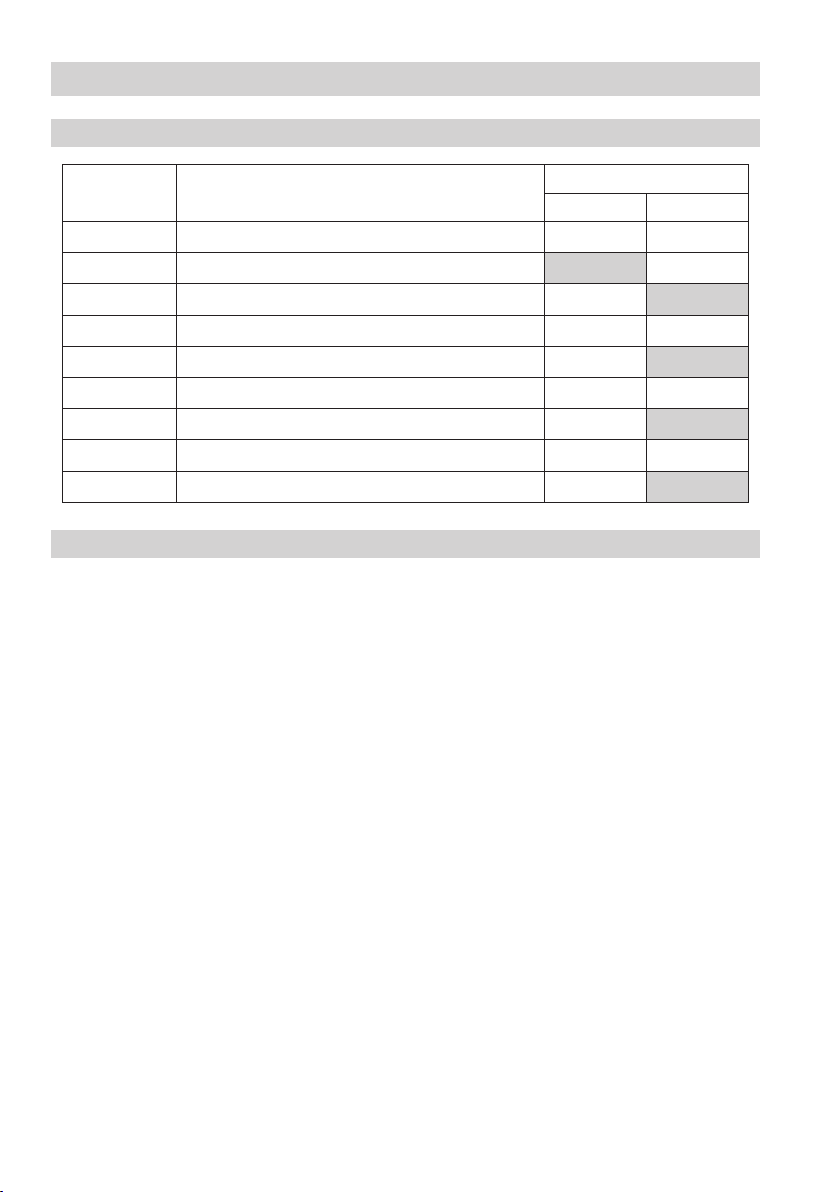

Page 16

Maintenance – Continued –

Torques

Item Designation

A

T

X

P

C

I

K

O

F

Hexagon-socket screw (UNA 39)

Hexagon nut

Union nut (UNA 38)

Expansion bolts

Bimetallic air vent

Hand vent valve

Float lifting lever

Plug

Plug

Tools

n Combination spanner A.F. 17, 19, 22, 24, 30, 46 mm to DIN 3113, form B

n Allen key A.F. 5, 8 mm to ISO 2936

n Torque spanner 10–60 Nm, 60–120 Nm, 120–300 Nm to DIN ISO 6789

Torque [Nm]

UNA 38 UNA 39

270 340

40

120

20 20

90

70 170

110

70 170

110

16

Page 17

Retrofitting

GESTRA steam traps can be retrofitted with different control units.

Cleaning /exchanging the control unit

1. Take heed of the “Danger” note on page 4.

2. Undo the hexagon nuts

the cover M.

3. Undo the union nut

alternatively, undo and remove the hexagon socket-head screws T, and take out the control unit

2 2

r or ; (UNA 39).

Replace the control unit in case of visible signs of wear or damage.

4.

Clean the body, internals and all gasket surfaces.

5.

Apply heat-resistant lubricant to all threads and the seating surfaces of the control unit and cover

6.

(use e.g. WINIX® 2150).

Attach the control unit E, r or ; (UNA 38) with the union nut and align it within the body so that the

7.

float ball can move vertically. Tighten the union nut. Insert a new gasket U for control unit r or ;

(UNA 39), put on the control unit and tighten the hexagon socket-head screws T evenly crosswise.

For the torques, see the table “Torques” on page 16.

Insert a new body gasket Q.

8.

Put the cover onto the body and push the sleeves B onto the expansion bolts P. Tighten the

9.

hexagon nuts A evenly crosswise in several stages to the values specified in the “Torques” table.

Torques

A, remove the sleeves B from the expansion bolts P, and take off

X and take it out of the body together with the control unit E, r or ; (UNA 38);

2 2

Item Designation

A

T

X

P

C

I

K

O

F

Hexagon-socket screw (UNA 39)

Hexagon nut

Union nut (UNA 38)

Expansion bolts

Bimetallic air vent

Hand vent valve

Float lifting lever

Plug

Plug

Tools

n Combination spanner A.F. 17, 19, 22, 24, 30, 46 mm to DIN 3113, form B

n Allen key A.F. 5, 8 mm to ISO 2936

n Torque spanner 10–60 Nm, 60–120 Nm, 120–300 Nm to DIN ISO 6789

WINIX® 2150 is a registered trademark of WINIX GmbH, Norderstedt

Torque [Nm]

UNA 38 UNA 39

270 340

40

120

20 20

90

70 170

110

70 170

110

17

Page 18

Spare Parts

Spare parts list UNA 38

Designation

Item

Body gasket (graphite/CrNi) 524532

:

Control unit DUPLEX

E

with body gasket

r

Control unit SIMPLEX

;

with body gasket

Hand vent valve with gasket 560559

s

Float lifting lever with gasket 560560

u

Bimetallic air vent EBK 39 (only for Duplex control units) with gasket 560558

C

O = Orifice

Spare parts list UNA 39

Designation

Item

2

Body gasket (graphite/CrNi) 523031

:

2

Control unit, complete

r

2

with body gasket

;

2

Hand vent valve with gasket 560178

u

O = Orifice

Order no.

DN 15-50

O 50 560550

0 64 560551

O 80 560552

O 80 MAX 560553

O 50 560554

O 64 560555

O 80 560556

O 80 MAX 560557

Order no.

DN 15-50

O 80 560172

O 110 560171

O 140 560170

O 140 MAX 560179

18

Page 19

Annex

CE Declaration of Conformity

We hereby declare that the items of pressure equipment UNA 38 and UNA 39 conform to the following

European Directive:

n EC Pressure Equipment Directive (PED) 97/23/EC dated 29 May 1997, apart from the equipment

according to section 3.3.

n Applied conformity assessment procedure according to Annex III, module H, verified by Notified

Body 0525.

This declaration is no longer valid if modifications are made to the equipment without prior

consultation with us.

Bremen, 11 October 2005

GESTRA AG

Dipl.-Ing. Uwe Bledschun

Head of Design Dept.

Dipl.-Ing. Lars Bohl

Quality Assurance Representative

19

Page 20

Agencies all over the world:

www.gestra.de

GESTRA

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 34 91 / 5 15 20 32

Fax 00 34 91 / 4 13 67 47; 5 15 20 36

E-mail: aromero@flowserve.com

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 00 39 02 / 66 32 51

Fax 00 39 02 / 66 32 55 60

E-mail: infoitaly@flowserve.com

Polska

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 / 3 06 10 -02 od 10

Fax 00 48 58 / 3 06 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0 03 51 22 / 6 19 87 70

Fax 0 03 51 22 / 6 10 75 75

E-mail: jtavares@flowserve.com

USA

Flowserve DALCO Steam Products

2601 Grassland Drive

Louisville, KY 40299

Tel.: 00 15 02 / 4 95 01 54, 4 95 17 88

Fax: 00 15 02 / 4 95 16 08

E-mail: dgoodwin@flowserve.com

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telephone +49 (0) 421 35 03- 0

Fax +49 (0) 421 35 03 - 393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

818603-00/1205cm · © 2005 GESTRA AG · Bremen · Printed in Germany

20

Loading...

Loading...