Page 1

GESTRA

GESTRA Steam Systems

UNA 14

UNA 16

UNA 16A (Stainless Steel)

UNA 14P

Installation Instructions 810877-01

Steam Traps UNA 14, UNA 16, UNA 16A

Air Trap for Compressed Air and Gases UNA 14P

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose ............................................................................................................. 8

Safety note ............................................................................................................................................ 8

Danger ................................................................................................................................................... 8

Classification pursuant to article 9 of the Pressure Equipment Directive (PED) ..................................... 9

Explanatory Notes

Scope of supply ..................................................................................................................................... 9

Description .......................................................................................................................................... 10

Function............................................................................................................................................... 10

Technical data ............................................................................................................................... 11, 12

Corrosion resistance ............................................................................................................................ 13

Sizing................................................................................................................................................... 13

Name plate/marking ........................................................................................................................... 13

Installation

UNA 14, UNA 16, UNA 16A, UNA 14P ...................................................................................................13

Flanged design .................................................................................................................................... 13

Screwed-socket design ...................................................................................................................... 14

Socket-weld design ............................................................................................................................ 14

Butt-weld design ................................................................................................................................14

Heat treatment of welds ...................................................................................................................... 15

Change direction of flow ...................................................................................................................... 15

Air balance pipe................................................................................................................................... 15

Hand vent valve (optional extra) .......................................................................................................... 16

Float-lifting lever (optional extra) ........................................................................................................ 16

Commissioning

UNA 14, UNA 16, UNA 16A, UNA 14P ................................................................................................... 16

Maintenance

Clean trap ............................................................................................................................................ 17

Clean/replace control unit.................................................................................................................... 17

Clean/replace control unit (only DUPLEX design) ................................................................................. 18

Torques ............................................................................................................................................... 18

Spare Parts

Spare parts list .................................................................................................................................... 19

2

Page 3

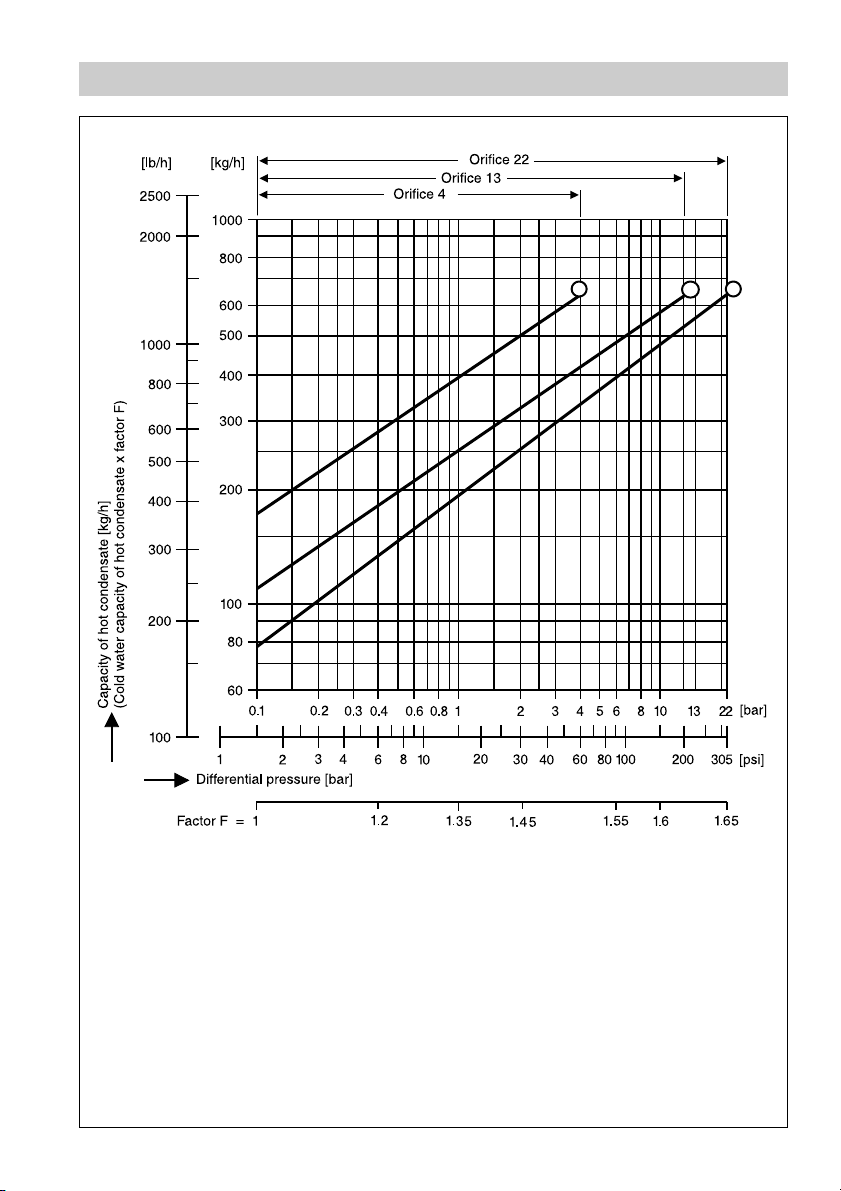

Capacity Charts UNA 14, UNA 16, UNA 16A

1 2 3

Fig. 1

Orifice 4, DN 15 - 25, ½" - 1"

1

Orifice 13, DN 15 - 25, ½" - 1"

2

Orifice 22, DN 15 - 25, ½" - 1" (only UNA 16)

3

3

Page 4

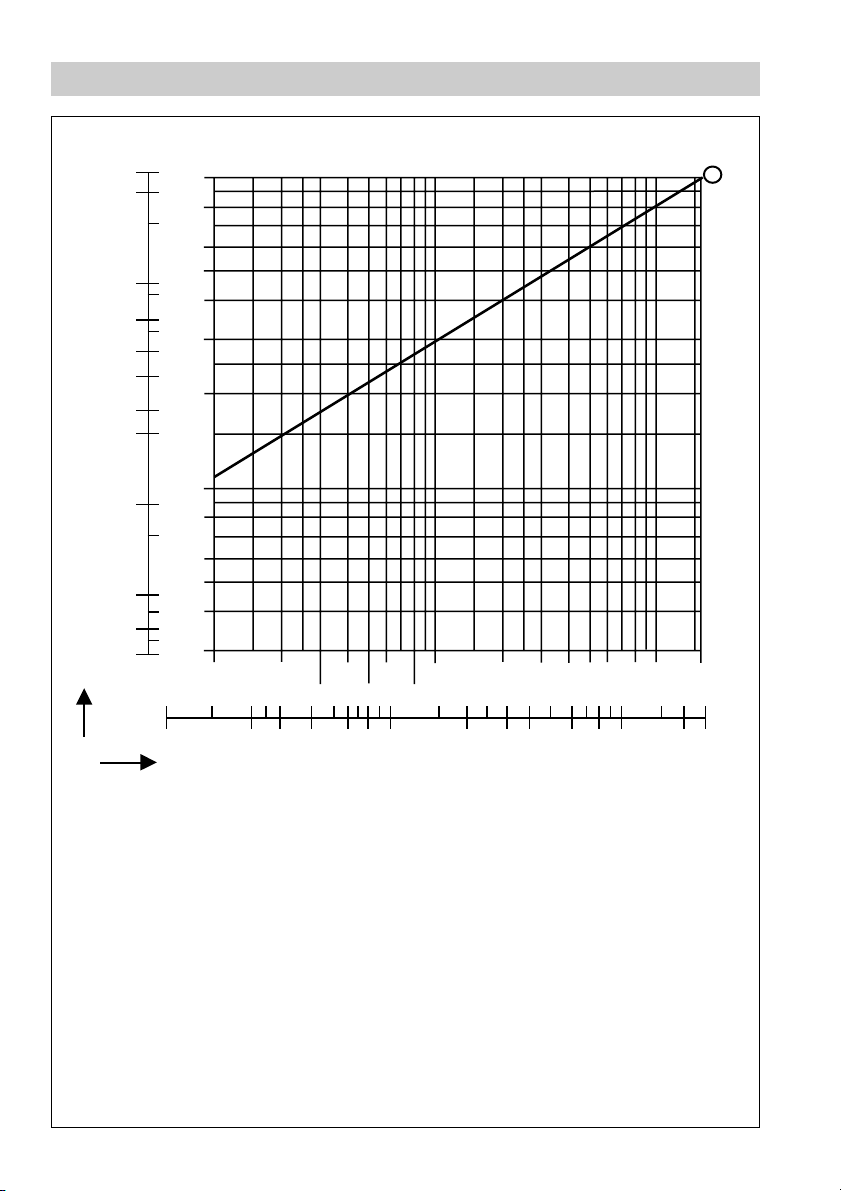

Capacity Chart UNA 14P

lb/h kg/h

2000

1000

800

600

500

400

300

200

100

Capacity of cold condensate [kg/h]

1000

800

600

500

400

300

200

100

80

60

50

80

60

40

30

0.1 0.2 0.4 0.6 1 2 3 4 5 6 8 10 16

4

bar

0.3 0.5 0.8

4

Fig. 2

1 2 3 4 6 8 10 20 30 40 60 80 100 200

Differential pressure (assuming discharge to atmospheric pressure)

Max. capacity of cold condensate

4

from liquids or gases.

psi

Page 5

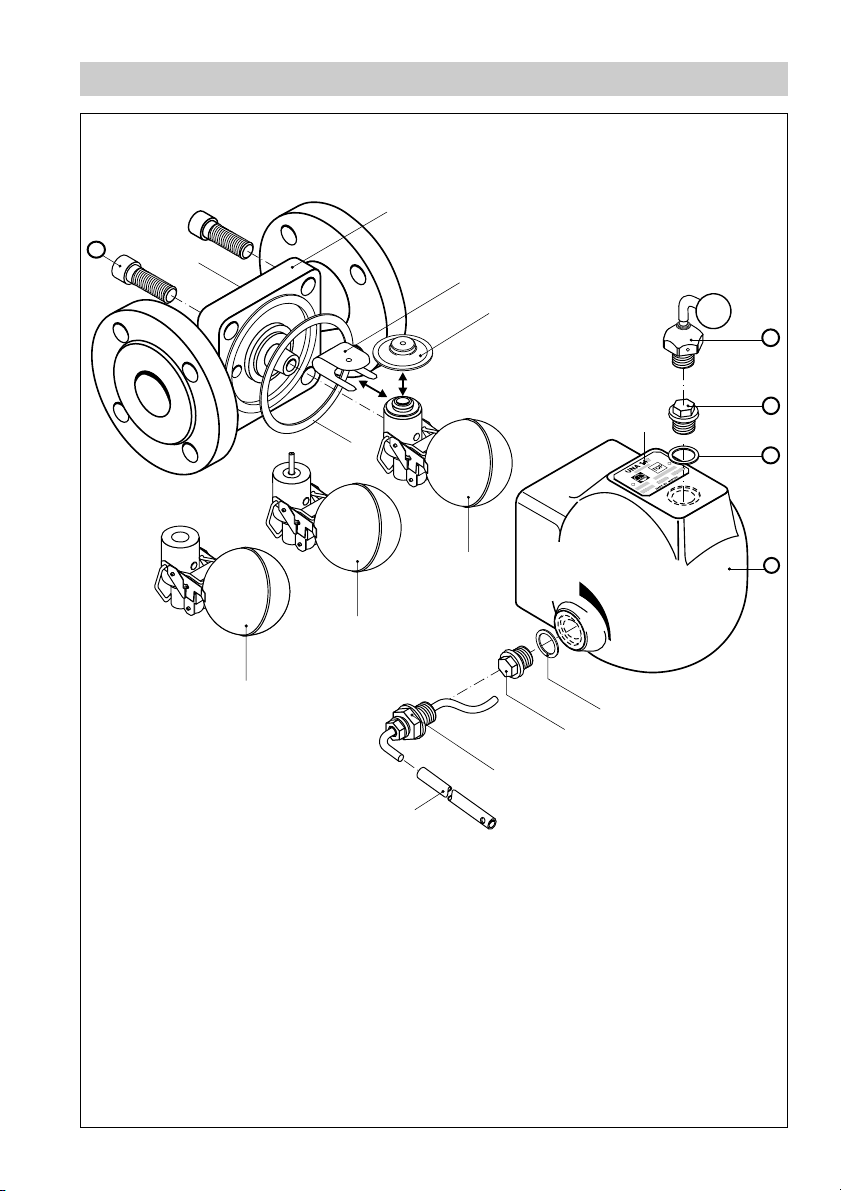

Design

B

P

A

Fig. 3

L

O

M

K

C

N

D

F

G

H

I

H

G

J

5

Page 6

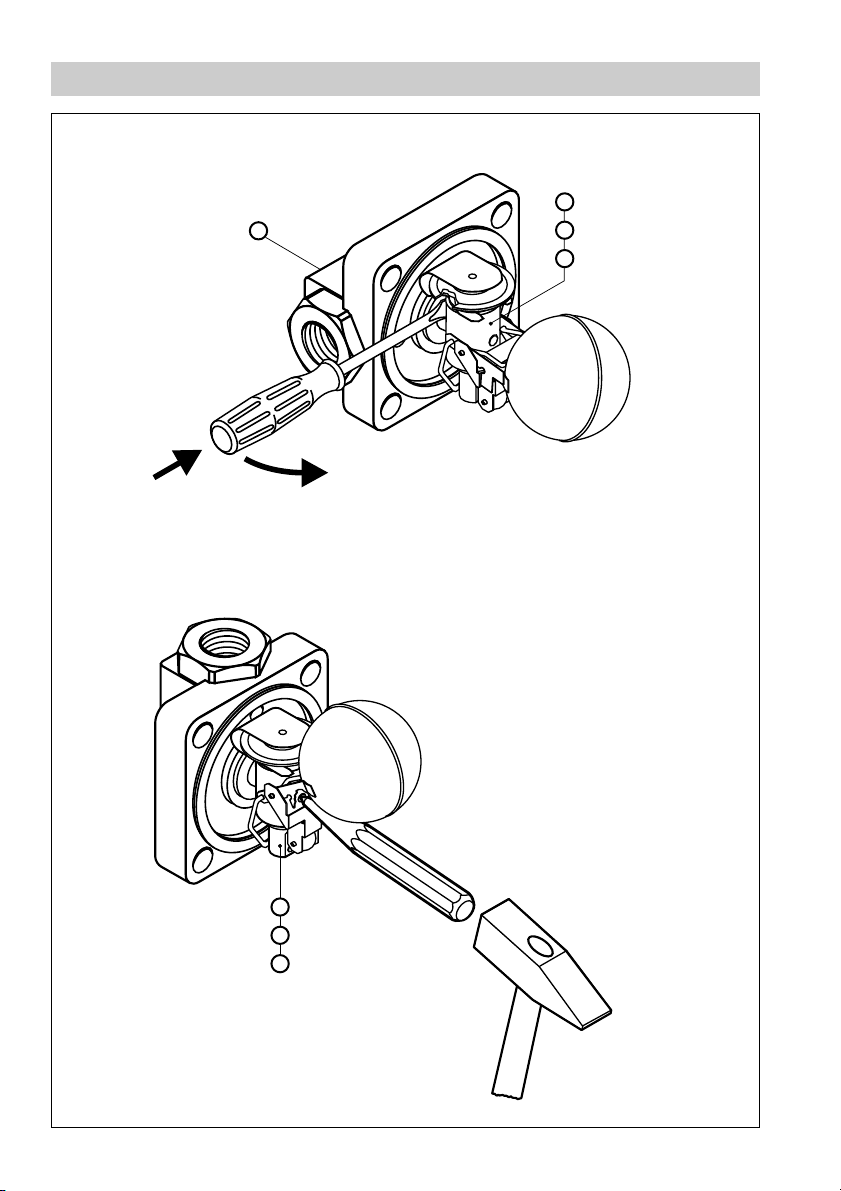

Maintenance

Fig. 4

A

L

M

N

L

M

N

Fig. 5

6

Page 7

Key

Flow direction arrow

A

Body

B

Retainer

C

Thermostatic capsule (5N2)

D

Name plate

E

Hand vent valve (optional extra)

F

Plug*) (optional extra)

G

Gasket*) C 17 x 23 (optional extra)

H

Cover (standard design without holes)

I

Manual float-lifting lever*) (optional extra)

J

Lever extension for float-lifting device*) (optional extra)

K

Control unit SIMPLEX or SIMPLEX P*) for UNA 14P with Perbunan® valve ball

L

Control unit SIMPLEX R

M

Control unit DUPLEX

N

Cover gasket 77 x 67 x1 (graphite/CrNi)

O

Socket-head cap screw

P

*) Standard version of air trap type UNA 14P

Perbunan® is a registered trademark of Bayer AG, Leverkusen

7

Page 8

Important Notes

Usage for the intended purpose

Use steam traps UNA 14, UNA 16, UNA 16A and air trap UNA 14P only for the discharge of condensate

and liquids.

UNA 14, UNA 16, UNA 16A:

Use the equipment only for the discharge of condensate from steam lines within the specified pressure

and temperature ratings and check the corrosion resistance and chemical suitability for the application

in question.

UNA 14P:

Use the equipment only for the discharge of condensate from compressed air lines or other gas lines

within the specified pressure and temperature ratings and check the corrosion resistance and chemical

suitability for the application in question.

Safety note

The equipment must only be installed by qualified staff.

Qualified staff are those persons who – through adequate training in engineering, the use and

application of equipment in accordance with regulations concerning steam systems, and first aid &

accident prevention – have achieved a recognised level of competence appropriate to the installation

and commissioning of this device.

Danger

The trap is under pressure during operation.

When loosening flanged connections, plugs or the control unit hot water, steam,

corrosive fluids or toxic gases may escape.

This presents the risk of severe scalds and acid burns to the whole body.

Toxic gases may cause severe cases of poisoning.

Before carrying out installation and maintenance work make sure the system is

depressurized.

Isolate the trap from both upstream and downstream pressure.

The trap becomes hot during operation.

This presents the risk of severe burns to hands and arms.

Before carrying out installation and maintenance work make sure that the trap is cold.

Sharp edges on internals present a danger of cuts to hands. Always wear industrial

gloves when replacing the control unit.

8

Page 9

Classification pursuant to article 9 of the Pressure Equipment Directive (PED)

UNA 14, UNA 16, UNA 14P UNA 16A (Stainless steel)

Fluid group

Use no yes no yes yes yes yes yes

Category Exception pursuant to article 3.3 Exception pursuant to article 3.3

Nominal size DN 15 –25 15 –25

CE marking no no

Type all all

gas liquid gas liquid

12121212

Explanatory Notes

Scope of supply

UNA 14

1 Steam trap UNA 14

1 Installation manual

UNA 16

1 Steam trap UNA 16

1 Installation manual

UNA 16A (stainless steel)

1 Steam trap UNA 16 A (stainless steel)

1 Installation manual

UNA 14P

1 Air trap UNA 14P

1 Lever extension for manual float-lifting device

1 Installation manual

9

Page 10

Explanatory Notes – continued –

Description

UNA 14, UNA 16, UNA 16A, UNA 14P are steam/air traps with ball float and rolling ball valve. The

steam traps can be used for all operating conditions, as they are unaffected by back pressure. They

consist of a body with bolted cover and a control unit. The control unit is freely accessible after

removing the cover. It can be completely replaced without having to remove the valve body from the

line. A conversion of “h” design to “v” design or vice versa is possible without any problem by

repositioning body and control unit. The direction of flow is indicated by an arrow, the position of

installation by the word “Top” on the name plate.

■ suitable for large condensate flowrates

■ “h”-design for horizontal lines

■ “v”-design for vertical lines

(To convert “h” to “v” design or vice versa turn cover and control unit respectively)

UNA 14, UNA 16, UNA 16A

Three different control units are available: Control unit “SIMPLEX”: level-dependent float control

particularly suitable for cold condensate. Control unit “SIMPLEX R”: level-dependent float control

with internal vent pipe for continuous air-venting. Control unit “DUPLEX”: float control with

temperature-dependent automatic air-venting of saturated steam systems.

UNA 14P

The air trap is suitable for draining compressed air and gas systems. Two different control units are

available: Control unit “SIMPLEX” with steel valve ball or control unit “SIMPLEX P” with Perbunan

valve ball. The air traps feature as standard a manual purging device (float-lifting lever) and a 3/8"

BSP connection (with plug) for subsequent fitting of an air-balance pipe.

Function

®

As the condensate flows into the steam trap it operates the float, which in turn opens the rolling ball

valve of the control unit, and in doing so uncovers the discharge passage. The cross-sectional area

of the orifice dictates the max. flowrate when the discharge passage is completely open. The max.

allowable differential pressure of the control unit used depends on the cross-sectional area of the

orifice and the density of the fluid to be discharged.

Three different orifices are available (retrofitting possible).

Float-operated steam traps equipped with control units DUPLEX enable automatic temperaturedependent deaeration of saturated steam systems at start-up and during continuous operation.

The air trap UNA 14P features an orifice as standard which is rated for a max. differential pressure of

up to 16 bar and a liquid density of

ρ = 1000 kg/m

3

. Note that lower densities reduce the max.

service range accordingly.

The flowrates are indicated in the capacity charts. Air traps for other pressure ratings are available

on request.

Perbunan® is a registered trademark of Bayer AG, Leverkusen

10

Page 11

Technical Data

Max. admissible

Orifices (O) UNA 14 UNA 16 UNA 16A UNA 14P

differential pressure

∆∆

∆PMX [bar]

∆∆

1)2

)

Orifice 4 4 X X X

Orifice 13 13

3

)XXXX

Orifice 22 22 X X

1

) Observe pressure/temperature specifications!

2

) Inlet pressure minus outlet pressure.

3

) Max. admissible differential pressure 16 bar with a liquid density of ρ = 1000 kg/m

AMPerusserpelbawolla.xaM]rab[524.918.7151

AMTerutarepmetelbawolla.xaM]C°[02002052053

( telni sunimerusserp teltuo )erusserp

erusserplaitnereffidmumixaM ∆ XMP

]rab[)*4ro31

AMPerusserpelbawolla.xaM]rab[042.038.521.32

AMTerutarepmetelbawolla.xaM]C°[02002003004

( telni sunimerusserp teltuo )erusserp

erusserplaitnereffidmumixaM ∆ XMP

]rab[)*4ro31,22

AMPerusserpelbawolla.xaM]rab[3.718.312.015.6

AMTerutarepmetelbawolla.xaM]C°[02002003004

( telni sunimerusserp teltuo )erusserp

erusserplaitnereffidmumixaM ∆ XMP

]rab[)*4ro31

3

52NP,)0E3(nori)elitcud(.G.S41ANU)1-2901NID(gnitaRerutarepmeT/erusserP

04NP,)0E3(leetsnobrac61ANU)1-2901NID(gnitaRerutarepmeT/erusserP

051SSALC,leetsnobrac61ANUgnitaRerutarepmeT/erusserP

AMPerusserpelbawolla.xaM]rab[046.533.928.52

AMTerutarepmetelbawolla.xaM]C°[02001002003

)NPlitnu(erutarepmetwol.xaM]C°[691–

erusserplaitnereffidmumixaM ∆ XMP

( telni sunimerusserp teltuo )erusserp

Pressure/temperature ratings according to type of connection!

*) Depending on orifice (O)

04NP,)0E31(leetssselniatsA61ANU)1-2901NID(gnitaRerutarepmeT/erusserP

]rab[)*4ro31,22

11

Page 12

Technical Data – continued –

051SSALC,)leetssselniats(A61ANUgnitaRerutarepmeT/erusserP

AMPerusserpelbawolla.xaM]rab[3.910.710.412.01

AMTerutarepmetelbawolla.xaM]C°[02001002003

( telni sunimerusserp teltuo )erusserp

erusserplaitnereffidmumixaM ∆ XMP

Pressure/temperature ratings according to type of connection!

*) Depending on orifice (O)

AMPerusserpelbawolla.xaM]rab[52

AMTerutarepmetelbawolla.xaM

llabevlavleetshtiw

®

nanubrePhtiw

llabevlav

erusserplaitnereffid.xaM ∆ XMP

llabevlavleetshtiw

®

nanubrePhtiw

llabevlav

( telni sunimerusserp teltuo )erusserp

slairetaM NENIDNIDMTSA

ydoB

61,P41,41ANU

41ANUrevoC

61ANUrevoC)9160.1(HG042PG)9160.1(52C-SGBCW612A

,A61ANUydoB

leetssselniats

,A61ANUrevoC

leetssselniats

swercsgnixiF

61,P41,41ANU

,A61ANUswercsgnixiF

leetssselniats

taolfllaB

taeS)5034.1(9-81SiNrC8X)5034.1(981SiNrC01X303ISIA

llabevlaV)1034.1(01-81iNrC5X)1034.1(0181iNrC5X403F281A

teksagrevoCiNrC-etihparG

eluspaccitatsomrehT

2N5

slanretnirehtOleetssselniatS

1

) Physical and chemical properties comply with DIN grade. ASTM nearest equivalent grade is stated for guidance only.

2

) Perbunan valve ball available as optional extra. (UNA 14P)

]rab[)*4ro31,22

]C°[

]C°[

]rab[

]rab[

)0640.1(HG052P)0640.1(8.22C501A

TL-81-004-SJG-NE

)9401-SJ-NE(

3.04GGG

)3407.0(

2-21-71oMiNrC2X

)4044.1(

)8034.1(01-91iNrC5X-G)8034.1(981iNrC6X-G8FC153A

)5227.1(4oMrC24

2-51-52BVoMiTrCiN6X

)0894.1(

2-21-71iToMiNrC6X

)1754.1(

5162iTrCiN5X

)0894.1(

22171iToMiNrC6X

)1754.1(

leetssselniats/yolletsaH

52NP,)0E3(nori)elitcud(.G.SP41ANU)1-2901NID(gnitaRerutarepmeT/erusserP

021

04

61

61

)4044.1(23171oMiNrC2XL613F281A

1

)

81-04-06635A

1

)

7B391A

1

613F281A

)

1

)

1

)

Perbunan® is a registered trademark of Bayer AG, Leverkusen

12

Page 13

Corrosion resistance

If the unit is used for the intended purpose, its safety is not impaired by corrosion.

Sizing

The trap body must not be subjected to sharp increases in pressure.

The dimensional allowances for corrosion reflect the latest state of technology.

Name plate / Marking

Ratings and design as specified in EN 19 and EN ISO 26652 on name plate which is firmly attached

to the trap body/cover.

■ Type designation UNA 1 ...h: horizontal design

UNA 1 ...v: vertical design

■ SIMPLEX or DUPLEX: type of control unit (see “Description”)

additional “P”: with Perbunan

®

valve ball (max. 40°C)

additional “R”: provided with internal venting pipe

■ O...(orifice): installed orifice

■ Stamp on name plate, e. g. indicates term and year of production

(Example: 4

th

quarter 2003)

4

03

Design

Control unit

Name plate

must be on top

TMA

PN / Class

Orifice

DN

Design

Control unit

Name plate

must be on top

TMA

PN / Class

Orifice

DN

Installation

UNA 14, UNA 16, UNA 16A, UNA 14P

Float-operated steam traps can – depending on the design of the trap body – be installed in

horizontal or vertical lines with downward flow. Conversion to obtain a different flow direction

is possible:

Flanged design

1. Observe position of installation. The name plate E must always be on top.

2. Observe the direction of flow. The arrow indicating the flow direction A is on the trap body.

Change direction of flow of UNA 14, UNA 16, UNA 16A or UNA 14P if necessary.

3. Consider space required for opening trap. When the trap is installed a minimum space of at least

120 mm is required for removing the cover I!

4. Remove plastic plugs. They are only used as transit protection.

5. Clean seating surfaces of both flange faces.

6. Install trap.

Perbunan® is a registered trademark of Bayer AG, Leverkusen

13

Page 14

Installation – continued –

Screwed-socket design

1. Observe position of installation. The name plate E must always be on top.

2. Observe the direction of flow. The arrow indicating the flow direction A is on the trap body.

Change direction of flow of UNA 14, UNA 16, UNA 16A or

UNA 14P if necessary.

3. Consider space required for opening trap. When the trap is installed a minimum space of at least

120 mm is required for removing the cover I!

4. Remove plastic plugs. They are only used as transit protection.

5. Clean female threads.

6. Install trap.

Socket-weld design

1. Observe position of installation. The name plate E must always be on top.

2. Observe the direction of flow. The arrow indicating the flow direction A is on the trap body.

Change direction of flow of UNA 16, UNA 16A if necessary.

3. Consider space required for opening trap. When the trap is installed a minimum space of at least

120 mm is required for removing the cover I!

4. Remove plastic plugs. They are only used as transit protection.

5. Clean socket-weld ends.

6. Arc-weld trap only manually (welding processes 111 and 141 in accordance with DIN EN 24063).

Butt-weld design

1. Observe position of installation. The name plate E must always be on top.

2. Observe the direction of flow. The arrow indicating the flow direction A is on the trap body.

Change direction of flow of UNA 16 if necessary.

3. Consider space required for opening trap. When the trap is installed a minimum space of at least

120 mm is required for removing the cover I!

4. Remove plastic plugs. They are only used as transit protection.

5. Clean butt-weld ends.

6. Arc-weld trap only manually (welding processes 111 and 141 in accordance with DIN EN 24063)

or use gas welding process (welding process 3 in accordance with DIN EN 24063).

Attention

■ Only qualified welders certified e. g. according to DIN EN 287 may weld the steam

trap into pressurized lines.

14

Page 15

Heat treatment of welds

A subsequent heat treatment of the welds is not required.

Change direction of flow

1. Remove cover I from body B, fig. 3

2. Lever control unit LMN off its support using a screwdriver, fig. 4

3. Turn body so that the arrow A points in the desired flow direction.

4. Position control unit on support and fix it by sharp blows, fig. 5

5. Clean seating surfaces of body and cover.

6. Apply heat-resistant lubricant to seating surface or cover and threads of fixing screws

(use for instance WINIX

®

2150).

7. Insert a new gasket O and put cover onto trap body. Tighten body screws P in diagonally

opposite pairs to a torque of 35 Nm. Retighten screws after the commissioning procedure.

Tools

■ Hexagon-type offset screwdriver (Allen key), size 8 to DIN 911L

■ Screwdriver (5.5/125), DIN 5265

■ Punch (120/10), DIN 7250

■ Hammer (500 /10), DIN 1041

Air balance pipe

For GESTRA air traps UNA 14P we recommend the installation of an air balance pipe K in order to

equilize the pressure. The air balance pipe ensures a continuous condensate flow from the fluid line

to the trap and effectively prevents the formation of water pockets.

Unfavourable piping geometries and certain positions of installation may also require the installation

of an air balance pipe for steam traps. The air balance pipe effectively prevents the formation of

water pockets.

WINIX® 2150 is a registered trademark of WINIX GmbH, Norderstedt

K

15

Page 16

Installation – continued –

Hand vent valve UNA 14, UNA 16, UNA 16A, UNA 14P (optional extra)

1. Remove plug G or, if installed, hand vent valve J.

2. Insert gasket H and mount hand vent valve F. Use a torque of 75 Nm.

3. Close hand vent valve.

Note

Standard covers are not provided with holes. Retroffiting is therefore not possible.

Tools

■ Spanner A. F. 17, DIN 3113, Form B

■ Torque spanner 20-120 Nm, DIN ISO 6789

Manual float-lifting lever UNA 14, UNA 16, UNA 16A (optional extra), UNA 14P

1. Remove plug G.

2. Insert gasket H and mount floating lifting lever J. In doing so insert the lever extension and

keep it upright. Use a torque of 75 Nm.

Note

Standard covers are not provided with holes. Retrofitting is therefore not possible.

Standard equipment for UNA 14P

Tools

■ Spanner A. F. 17, DIN 3113, Form B

■ Torque spanner 20-120 Nm, DIN ISO 6789

Commissioning

Make sure that the hand vent valve and the float-lifting lever are firmly attached to the UNA 14, UNA

16, UNA 16A and UNA 14P and tight.

16

Page 17

Maintenance

GESTRA steam traps UNA 14, UNA 16, UNA 16A do not require any special maintenance. However,

if used in new installations which have not been rinsed it may be necessary to check and clean the

trap.

The GESTRA air trap UNA 14P does not require any special maintenance. If, however, the trap is

used with very oily condensate we recommend to clean the trap at regular intervals or to install an

oil separator upstream of the trap.

Clean trap

1. Remove cover I from body B, fig. 3

2. Lever control unit LMNoff its support using a screwdriver, fig. 4

3. Remove old cover gasket O.

4. Clean body and internals.

5. Clean seating surfaces of body and cover. Insert new gasket O.

6. Position control unit on support and fix it by sharp blows, fig. 5

7. Apply heat-resistant lubricant to seating surfaces of cover and threads of fixing screws (use for

instance WINIX

8. Insert a new gasket and put cover onto trap body. Tighten body screws P in diagonally opposite

pairs to a torque of 35 Nm. Retighten screws after the commissioning procedure.

Clean/replace control unit

1. Remove cover I from body B, fig. 3

2. Lever control unit LMNoff its support using a screwdriver, fig.4

3. Remove old cover gasket O.

4. Clean seating surfaces of body and cover. Insert new gasket O.

5. Position new or cleaned control unit LMNon support and fix it by sharp blows, fig. 5

6. Apply heat-resistant lubricant to seating surfaces of cover and threads of fixing screws (use for

instance WINIX

7. Insert a new gasket and put cover onto trap body. Tighten body screws in diagonally opposite pairs

to a torque of 35 Nm. Retighten screws after the commissioning procedure.

®

2150).

®

2150).

WINIX® 2150 is a registered trademark of WINIX GmbH, Norderstedt

17

Page 18

Maintenance – continued –

Clean /replace thermostatic capsule (only DUPLEX design)

1. Remove cover I from body B, fig. 3

2. Lever control unit N off its support using a screwdriver, fig. 4

3. Remove old cover gasket O.

4. Clean seating surfaces of body and cover. Insert new gasket O.

5. Remove retainer C from control unit N and take out thermostatic capsule D.

6. Insert new or cleaned thermostatic capsule and push retainer C over the thermostatic

capsule. fig. 3

7. Clean seating surfaces of body and cover. Insert new gasket O.

8. Position control unit N on support and fix it by sharp blows, fig. 5

9. Apply heat-resistant lubricant to seating surfaces of cover and threads of fixing screws (use for

instance WINIX

10. Insert a new gasket and put cover onto trap body. Tighten body screws in diagonally opposite

pairs to a torque of 35 Nm. Retighten screws after the commissioning procedure.

Tools

■ Hexagon-type offset screwdriver (size 8), DIN 911L

■ Screwdriver (5.5/125), DIN 5265

■ Punch (120/10), DIN 7250

■ Hammer (500 g), DIN 1041

Torques

®

2150).

Item

FGJ

UNA 14, UNA 16, UNA 16A, UNA 14P

P

P

All torques indicated in the table are based at a room temperature of 20°C.

WINIX® 2150 is a registered trademark of WINIX GmbH, Norderstedt

Steam trap

UNA 14, UNA 16, UNA 14P

UNA 16A

18

Torque [Nm]

75

35

35

Page 19

Spare Parts

Spare parts list

Item

H

O

DO

NO

MO

LO

Designation

Gasket2) A17x 23

Body gasket1)

(graphite/CrNi) 67x 77x 1

Thermostatic capsule 5N2,

body gasket

Control

unit

Duplex,

complete

Control

unit

Simplex R,

complete

Control

unit

Simplex,

complete

Orifice 4

Orifice 13

Orifice 22

Orifice 4

Orifice 13

Orifice 22

Orifice 4

Orifice 13 560415560415

Orifice 13P3) 560418

Stock code

UNA 14

560486

560493

560494

560410

560409

560413

560412

560416

Stock code

UNA 16

UNA 16A S.S.

560486

560514

560493

560494

560410

560409

560408

560413

560412

560411

560416

Stock code

UNA 14P

560486

560493

560415

Orifice 22

FH

JH

1

) Purchasing quantity 20 pcs. For smaller quantities please contact your local dealer.

2

) Purchasing quantity 10 pcs. For smaller quantities please contact your local dealer.

3

) Control unit Simplex P with Perbunan® valve ball up to 40°C for UNA 14P.

Hand-vent valve

Float-lifting lever

560058

560434

Note

The cover I does not feature holes as standard, the subsequent fitting of F and J is

therefore not possible. Fig. 3

The cover I of the UNA 14P features holes as standard, the subsequent fitting of F and

J is therefore possible. Fig. 3

Perbunan® is a registered trademark of Bayer AG, Leverkusen

560414

560058

560125

560434

on request

560058

560434

19

Page 20

Agencies all over the world

www.gestra.de

GESTRA

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 0034 91/ 51 52 032

Fax 00 3491 / 41 36 747; 51 52 036

E-mail: aromero@flowserve.com

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 0039 02/ 66 32 51

Fax 00 39 02 /66 32 55 60

E-mail: infoitaly@flowserve.com

Polska

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 /306 10 -02 od 10

Fax 00 48 58 /306 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 003 5122 / 619 87 70

Fax 0035122/6107575

E-mail: jtavares@flowserve.com

USA

Flowserve DALCO Steam Products

2601 Grassland Drive

Louisville, KY 40299

Tel.: 00 15 02 / 4 95 01 54, 4 95 17 88

Fax: 00 15 02 / 4 95 16 08

E-Mail: dgoodwin@flowserve.com

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telephone +49 (0) 421 35 03 -0

Fax +49 (0) 421 35 03- 393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

810877-01/604c · © 2003 GESTRA AG · Bremen · Printed in Germany

20

Loading...

Loading...