Page 1

USER INSTRUCTIONS

Limitorque

Electronic Controls Module

FCD LMENIM1205-03-AQ – 05/15

®

UEX

Installation

Operation

Maintenance

Experience In Motion

Page 2

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Contents

1. Introduction 4

1.1 Purpose 4

1.2 User Safety 4

1.3 Product Description 5

2. Safety 6

2.1 Safety Precautions 6

2.2 Safety Practices 7

3. Limit Switch and Torque Switch Setting Procedures 8

3.1 Initial Actuator Preparation 8

3.2 Torque Switch 8

3.2.1 Setting Torque Switch 8

3.2.2 Balancing Torque Switch 9

3.3 Geared Limit Switch 10

3.3.1 Setting Limit Switch 10

3.3.2 Setting Procedure (Refer to Figure 3.2) 11

3.3.3 Combination of Contacts (Refer to Figure 3.2) 12

4. Removal of UEC-3 Electronic Controller 13

5. UEX Electronic Controller Installation 18

6. Standard Control Features 22

6.1 Basic Specifications 22

6.2 Local Control 23

6.3 Remote Control Modes of Operation 23

6.4 Emergency Shutdown (ESD) 24

6.5 Remote External Interlocks/Inhibits 25

6.6 Absolute Position Encoder 25

7. Protection Features 26

7.1 Autophase Protection and Correction 26

7.2 Jammed Valve Protection 26

7.3 Instantaneous Reversal Protection 26

7.4 Motor Thermal Protection 26

8. Optional Control Features 27

8.1 Modutronic 27

8.2 Analog Position Transmitter (APT) 28

8.3 Two-Speed Timer 28

8.4 Control Station (CSE) 28

9. Network Communications 29

9.1 Modbus™ 29

9.2 Master Station III 30

9.3 Foundation Fieldbus Communication 30

9.4 PROFIBUS DP V1 Communication 31

9.5 PROFIBUS PA Communication 31

9.6 DeviceNet 32

10. Monitoring and Diagnostic Features 33

10.1 Local Features 33

10.2 Diagnostics 34

2

11. Remote Indication Features 36

11.1 Actuator Status Contacts (S1a, S1b, S2a, S2b) 36

11.2 Monitor Relay (RM) 37

11.3 Exact End Position Indication 37

12. Auxiliary Power Supply 38

Page 3

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

13. Isolated Commons 38

14. Actuator Configuration 39

14.1 Local Configuration 39

14.2 Default Configuration 39

15. UEX Wiring Diagrams 41

16. Network Protocol Connections 47

16.1 Network Wiring – Modbus 47

16.2 Network Wiring – Foundation Fieldbus H1 49

16.3 Network Wiring – Profibus DP and PA 51

16.4 Network Wiring – DeviceNet 52

17. How to Order Parts 54

18. Regulatory Information 55

Figures and Tables

Figure 1.1 – UEX Local Control Panel 5

Figure 3.1 – Microswitch-Style Torque Switch and 600 Volt Torque Switch 9

Figure 3.2 – Limit Switch 11

Figure 3.3 – Setting the Open and Closed Contacts 12

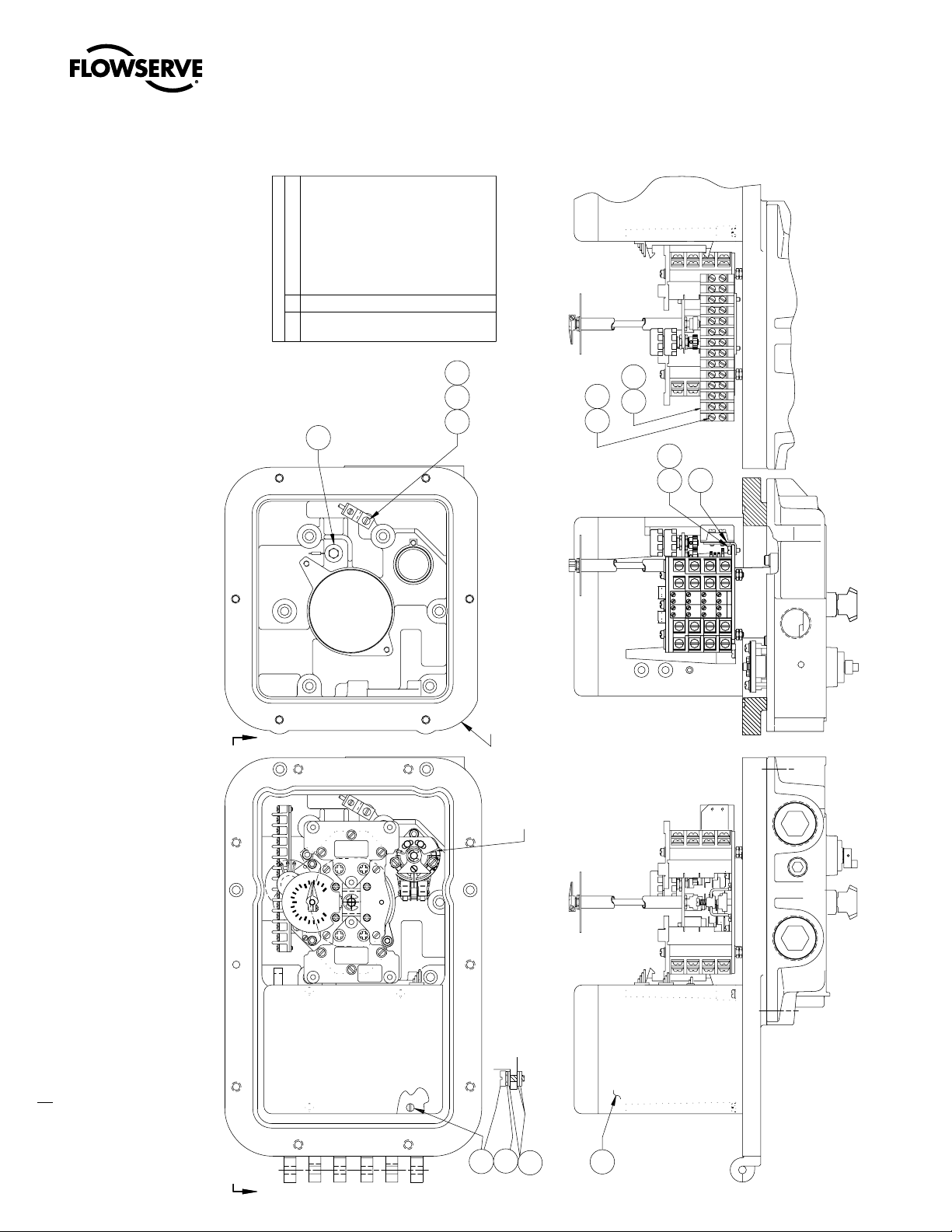

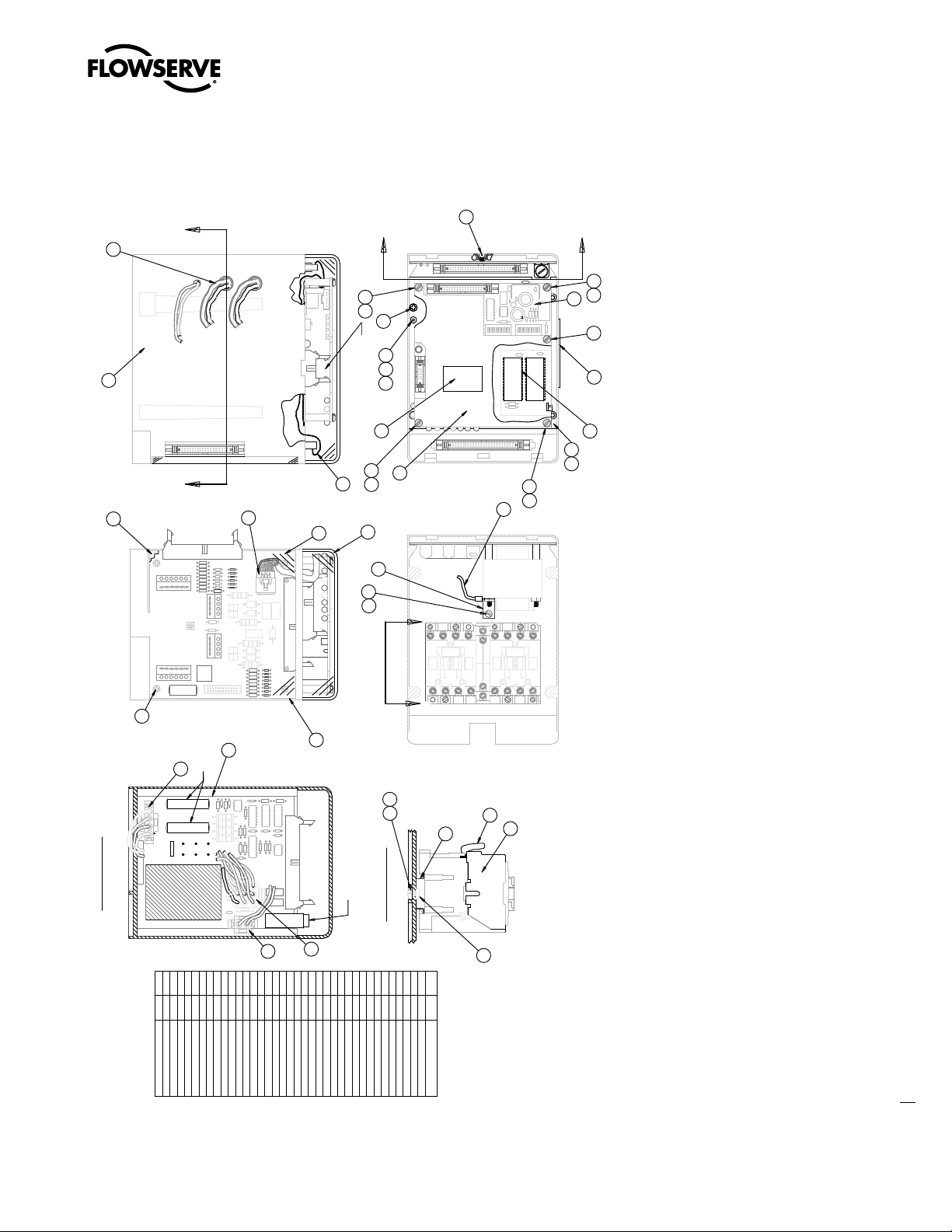

Figure 4.1 – Removal of the UEC-3 Electronic Controller 14

Figure 4.2 – UEC-3, MPC, DDC Assembly 17

Figure 5.1 – Encoder / MDPI / Transformer Installation 19

Figure 5.2 – Power / Interface Board Assembly 19

Figure 5.3 – Main Board Set Installation 20

Figure 5.4 – CSE Jumper Assembly 20

Figure 5.5 – CSE Control Station 20

Figure 5.6 – Controls Compartment Assembly 21

Figure 6.1 – UEX Local Control Panel 22

Figure 6.2 – Absolute Position Encoder 25

Figure 10.1 – Normal and Diagnostic Displays 35

Figure 14.1 – Default Configuration Guidelines 40

Figure 14.2 – Configuring the UEX Controller 40

Figure 15.1 – Standard Wiring Diagram for UEX Controllers 42

Figure 15.2 – DDC Wiring Diagram for UEX Controllers 43

Figure 15.3 – MOD APT Wiring Diagram for UEX Controllers 44

Figure 15.4 – Optional Features Wiring Diagrams 45

Figure 15.5 – Modbus, Foundation Fieldbus, Profibus DP V1, and Profibus PA, 46

and DeviceNet Network Wiring Diagrams

Figure 16.1 – Typical Modbus Network Wiring Diagrams – Single Loop 48

Figure 16.2 – Typical Foundation Fieldbus System with a DCS Host (Daisy Chain Shown) 50

Figure 16.3 – Typical Profibus System with a DCS Host (Daisy Chain Shown) 52

Table 1.1 – Standard Application Voltages with +/- 10% Nominal Range 5

Table 2.1 – Required Rating for External Wiring 7

Table 3.1 – Maximum Number of Drive Sleeve Turns for Standard Four-Gear 10

and Optional Five-Gear Limit Switches

Table 3.2 – Limit Switch Parts 11

Table 5.1 – UEX Parts List 21

Table 16.1 – Specifications for the Profibus Cable 51

Table 16.2 – Maximum Segment Length 51

Table 16.3 – Belden Cable Specifications 53

Table 16.4 – Total Cable Length Between Repeaters or Nodes 53

3

flowserve.com

Page 4

1

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Introduction

1.1 Purpose

This Installation and Maintenance Manual explains how to install, setup, and maintain the UEX controller

for the L120-10, L120-20, and L120-40 actuators. Information on installation, operation, control

features, and maintenance is provided.

Contact Flowserve Limitorque if assistance is needed or preferred for installation, upgrading, or training

in the operation of the UEX.

1.2 User Safety

Safety notices in this manual detail precautions the user must take to reduce the risk of personal injury

and damage to the equipment. The user must read and be familiar with these instructions before

attempting installation, operation, or maintenance. Work should be performed by a qualified tradesman

who is familiar with the operation and maintenance of electric actuators. Failure to observe these

precautions could result in serious bodily injury, damage to the equipment, voiding of the warranty, or

operational difficulty.

Safety notices are presented in this manual in three forms:

c WARNING: Refers to personal safety. Alerts the user to potential danger. Failure to follow warning

notices could result in personal injury or death.

a CAUTION: Directs the user’s attention to general precautions that, if not followed, could result in

personal injury and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of the actuator’s installation and

4

operation.

Page 5

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

1.3 Product Description

The UEX is designed for use with the three-phase L120 electric actuators for weatherproof, explosionproof, and submersible applications. The UEX is field-retrofittable to replace existing UEC-3 controllers.

With state-of-the-art controls based on MX control technology, the UEX offers an expanded feature set

compared to the UEC-3.

Please refer to LMENIM2306 for detailed menu configurations

Table 1.1 Standard Application Voltages with +/- 10% Nominal Range

Design Voltage Application Voltage

230 VAC, 60 Hz, 3 ph 208/220/230/240 VAC, 60 Hz, 3 ph

460 VAC, 60 Hz, 3 ph 380/400/415/440 VAC, 50 Hz, 3 ph

380/440/460/480 VAC, 60 Hz, 3 ph

525 VAC, 50 Hz, 3 ph 525 VAC, 50 Hz

575 VAC, 60 Hz, 3 ph 550/575/600 VAC, 60 Hz, 3 ph

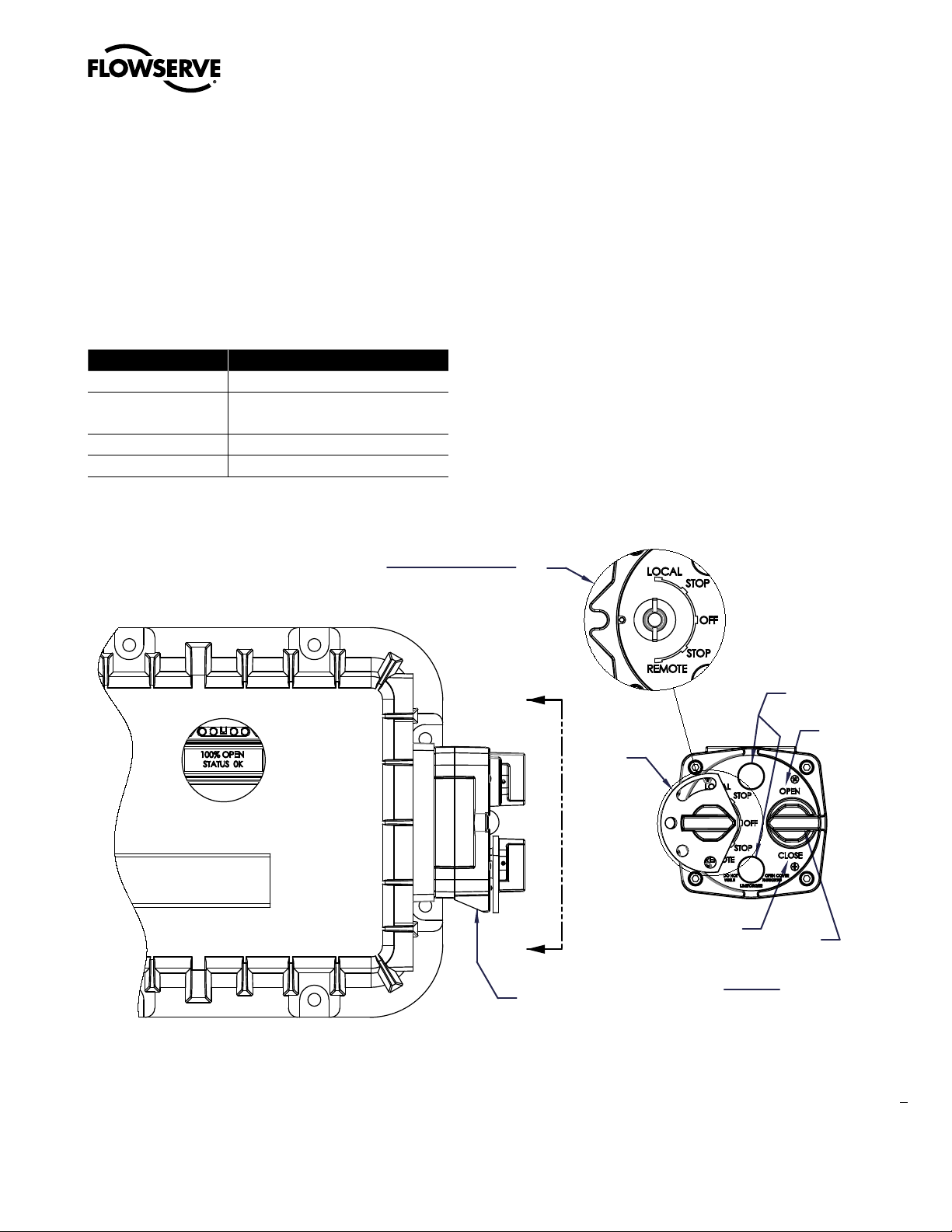

Figure 1.1 – UEX Local Control Panel

Selector Switch Detail

(Knob removed for clarity)

A

A

Blue

Knob

Close

(No)

Lights (2)

Open

(Yes)

Red

Knob

CSE Control

Station

VIEW A-A

5

flowserve.com

Page 6

2

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Safety

2.1 Safety Precautions

c WARNING: Read this Installation and Maintenance Manual carefully and completely before

attempting to install, operate, or troubleshoot the Limitorque L120 actuator.

c WARNING: Be aware of electrical hazards. Turn off incoming power before working on the actuator

and before opening the switch compartment.

c WARNING: Potential HIGH-PRESSURE vessel – Be aware of high-pressure hazards associated with

the attached valve or other actuated device when installing or performing maintenance on your

L120 actuator. Do not remove the actuator mounting bolts when the actuator is mounted on a rising

stem valve unless the valve is in the FULLY OPEN position and there is NO pressure in the line.

c WARNING: Do not manually operate the actuator with devices other than installed Handwheel and

Declutch Lever. Using force beyond the ratings of the unit and/or using additive force devices such

as cheater bars, wheel wrenches, pipe wrenches, or other devices on the actuator Handwheel or

Declutch Lever may cause serious personal injury and/or damage to the actuator or valve.

c WARNING: Do not work on the actuator while it is mounted on a torque-seated valve.

6

Page 7

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

2.2 Safety Practices

The following checks should be performed to maintain safe operation of the L120 actuator.

• Mount motors on a horizontal plane, if possible.

• Keep the switch compartment clean and dry.

• Keep the valve stem clean and lubricated.

• Set up periodic operating schedule for infrequently used valves.

• Use a protective stem cover. Check valve stem travel and clearance before mounting covers on rising

stem valves.

• Verify all actuator wiring is in accordance with the applicable wiring diagram, national and local codes,

and Table 2.1.

Table 2.1 – Required Rating for External Wiring

Up to: Use wire rated at least:

40°C 60°C

60°C 75°C

flowserve.com

7

Page 8

3

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Limit Switch & Torque Switch

Setting Procedures

3.1 Initial Actuator Preparation

Replace all molded plastic conduit and top protectors (installed for shipping purposes only) with pipe

plugs when installation wiring is complete.

3.2 Torque Switch

The torque switch is designed to protect the actuator in open and close directions.

a CAUTION: Disconnect all incoming power before opening limit switch compartment or working on

the torque switch.

• Do not use abrasive cloth to clean the contacts on the torque switch.

• Do not torque seat 90° operation valves nor run them against the stops. This may cause damage

to the valve.

NOTE: If the actuator has “torqued out,” release torque buildup by operating the actuator manually.

3.2.1 Setting Torque Switch

The torque switch was set at the factory according to customer-supplied information regarding necessary torque or thrust output that was provided at the time of the order. However, if the setting needs to

be adjusted, perform the following procedure:

a CAUTION: A torque switch limiter plate is provided on most actuators.

• Removal or modification of the torque switch limiter plate will void the actuator warranty.

8

• Do not exceed the setting indicated by this plate without contacting the Limitorque service

department.

Page 9

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

• Installing or adjusting the torque switch with the actuator in a loaded condition will result in a loss

of torque protection.

Item letters correspond to Figure 3.1.

1. Place the L120 actuator in manual mode.

2. Release the load on the wormshaft spring pack.

3. For open and close directions, loosen Screw (A) and move Pointer (B) to desired position. A higher

number indicates a high torque and/or thrust output.

4. Tighten Screw (A).

5. Operate the valve electrically to seat valve and to ensure tight shutoff.

6. Rebalance torque switch if required.

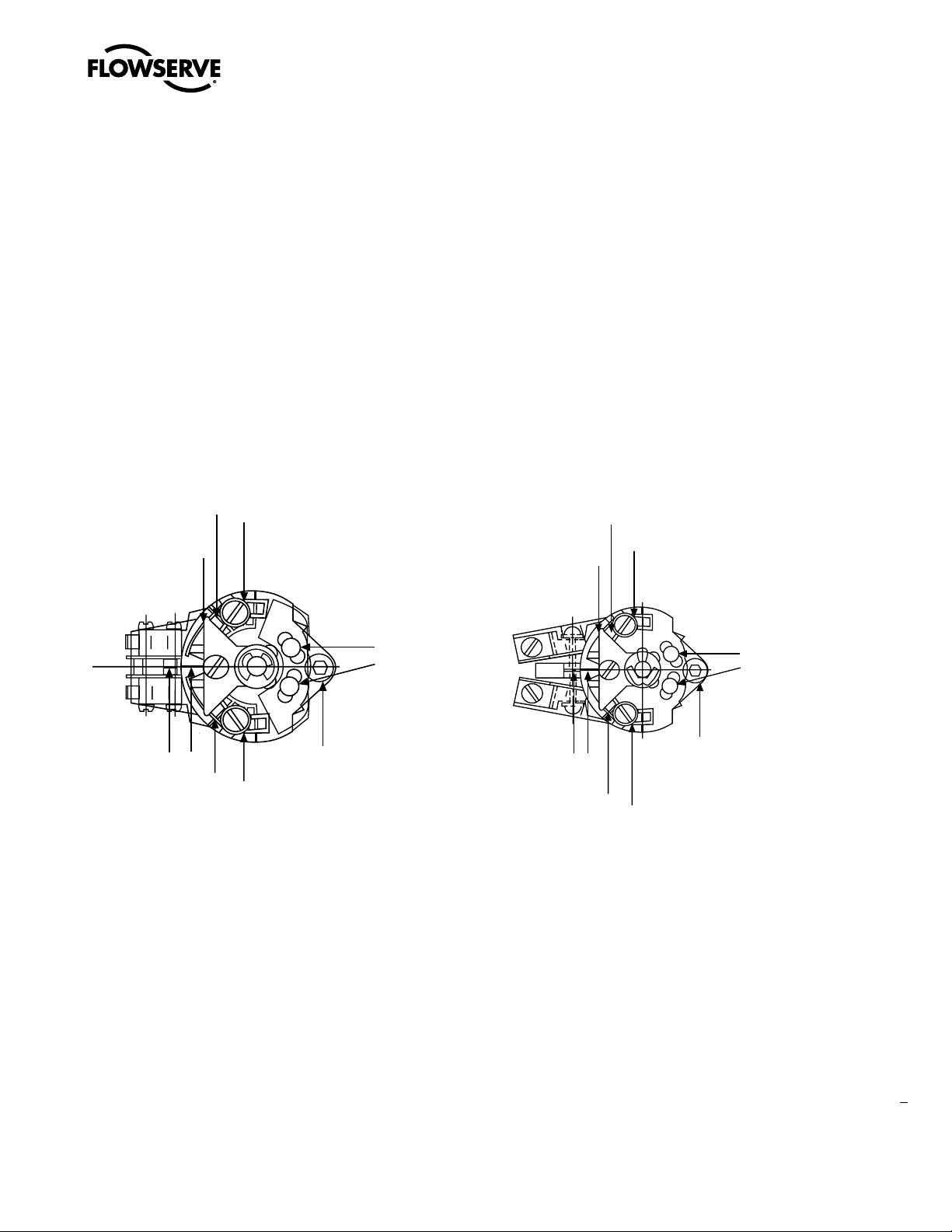

Figure 3.1 – Microswitch-Style Torque Switch and 600 Volt Torque Switch

B

Maximum Stop

Setting Plate

A

Maximum Stop

Setting Plate

B

A

OPEN

-10-20

Balancing

Screws

-10-20

CLOSE

Index Marks

B

A

Microswitch-Style Torque Switch

Mounting

Screw

Index Marks

600 Volt Torque Switch

3.2.2 Balancing Torque Switch

Item letters correspond to Figure 3.1.

1. Place the actuator in manual mode.

2. Remove the load from the wormshaft spring pack.

3. Note the open and close torque switch settings prior to reinstalling the torque switch.

4. Loosen Screws (A) and position both Pointers (B) at the #1 setting, tighten Screw (A). In this

position the index marks should be aligned.

Balancing

Screws

Mounting

Screw

B

A

9

flowserve.com

Page 10

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

5. Loosen balancing screws and install the torque switch. The base of the torque switch should be

flush against the compartment and the hole for the mounting screw should be aligned.

6. Install the mounting screw.

7. Tighten the balancing screws.

a CAUTION: The balancing screws should not be touched except during the balancing procedure.

The switch is now balanced and ready for the pointers to be returned to their original settings.

3.3 Geared Limit Switch

a CAUTION: The geared limit switch is not preset at the factory and must be adjusted after the

actuator has been mounted on associated equipment.

• Disconnect all incoming power to the actuator prior to opening the limit switch compartment and

adjusting the switch.

• Consult the relevant wiring diagram for limit switch contact development. All L120 units are

supplied with 16-contact limit switches - four switches on each of the four rotors. Two rotors are

used for end of travel indication. The remaining two rotors may be adjusted for any intermediate

point of travel.

• Do not use abrasive cloth to clean the contacts on the limit switch.

• Do not attempt to repair gearing in the limit switch. Replace entire gear frame assembly if

necessary.

10

3.3.1 Setting Limit Switch

Set the limit switch as follows. All item letters and piece numbers refer to Figure 3.2.

NOTE: See chart below for maximum number of drive sleeve turns for each unit size. The Intermediate

Shaft (B), shown in Figure 3.2, may take a considerable number of turns before rotor trip occurs.

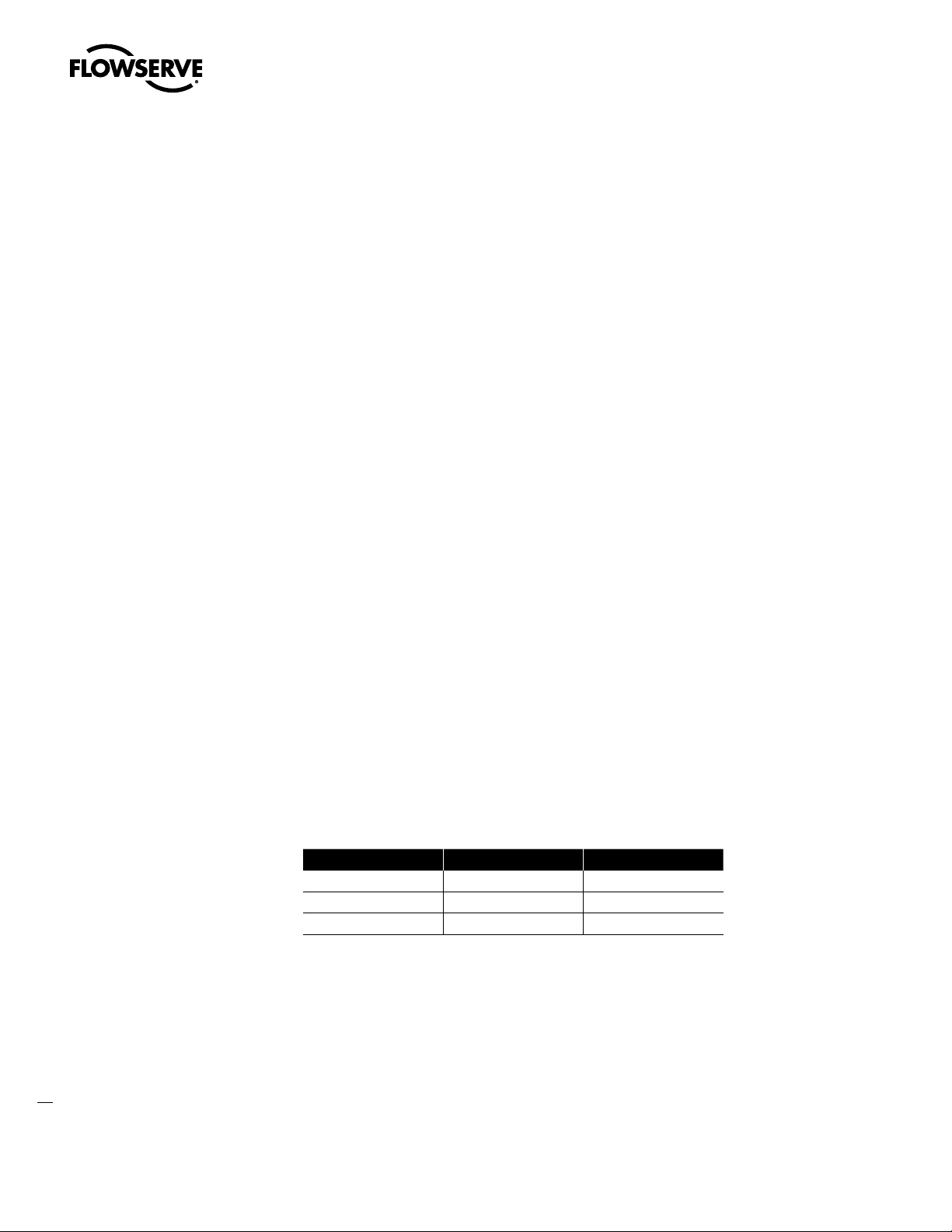

Table 3.1 – Maximum Number of Drive Sleeve Turns for Standard Four-Gear and Optional Five-Gear

Limit Switches

Actuator Size Four-Gear Five-Gear

L120-10 630 6300

L120-20 740 7400

L120-40 640 6400

c WARNING: Potential Explosion Hazard. Do not use a variable speed electric drill for setting the limit

switch in an explosive environment.

a CAUTION: When setting the limit switch rotor segments (cams) using a variable speed electric drill,

do not run drill at speeds higher than 200 RPM. Operating the drill at high speeds can damage the

gearing within the limit switch.

Page 11

Figure 3.2 – Limit Switch

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

7

8

6

5

B

A

4

9

3

2

1

Table 3.2 – Limit Switch Parts

Piece Quantity Description

11 Gear Frame Assembly

22 Eight-Switch Contact Block Assy.

312Rotor Segment (short)

44 Rotor Shaft

54 Machine Screw

64 Flat Washer

74 Lock Washer

88 Hex Nut

94 Rotor Segments (long)

3.3.2 Setting Procedure (Refer to Figure 3.2)

1. Open the Controls Compartment Cover (refer to Figure 5.5).

2. Put the actuator into manual operation. Use the handwheel to operate the valve in the “open” direction. While operating the valve, note the direction of the Intermediate Shaft (B) corresponding to the

rotor or rotors to be set.

3. When the valve is fully open, close it one turn of the handwheel to allow for coast of moving parts

or refer to the valve manufacturer setting requirements.

4. Push in the Setting Rod (A) and turn one-quarter turn. The rod will latch in this depressed position.

11

flowserve.com

Page 12

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

5. Refer to the applicable wiring diagram for contact development. The limit switch contact is closed

when the rotor is engaged with the plunger. If the rotor to be set has not turned 90 degrees to

operate the plunger, turn the intermediate shaft in the same direction as noted in Step 2 until the

rotor clearly trips the switches. This rotor is now set correctly.

6. Before moving the valve, depress and turn the Setting Rod (A) one-quarter turn to the spring

released position. Insert a screwdriver into the intermediate shafts to ensure that they will not move.

a CAUTION: Do not operate the valve when Setting Rod (A) is in a fully depressed position. Loss of

contact setting will occur and the setting rod will be damaged.

7. Operate the valve by handwheel to fully “close” position; reverse direction by one turn of the handwheel to allow for coast of moving parts or refer to the valve manufacturer setting requirements.

8. Set the other rotors by following Steps 4 through 6.

Figure 3.3 – Setting the Open and Closed Contacts

Closed

position

Open

position

3.3.3 Combination of Contacts (Refer to Figure 3.2)

The rotor segments can be separated and rotated through 90 degrees to give various combinations of

normally open or normally closed contacts to each rotor.

1. Remove Nuts (piece 8) and Fillister Head Machine Screws (piece 5, for a total of two fasteners on

each side of the switch).

2. Remove complete contact assembly from the back plate.

3. Rearrange cams on the camshaft to produce the required combination of contacts.

4. Replace contact assembly on back-plate (ensuring that the registers fit correctly) and secure with

the machine screw and nuts.

12

5. Set limits according to the procedure above.

NOTE: For mechanical operation and maintenance of the L120 actuators, please see section 5 and 6 of

LMENIM1201.

Page 13

4

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Removal of the UEC-3

Electronic Controller

NOTE: Confirm that the limit switches are set properly prior to disassembly and removal of the UEC-3

and related components. Confirming the settings will allow for installation of the UEX Electronic

Controller without requiring a reset of the limit switches.

1. Turn off the power to the actuator.

2. Open the Controls Compartment Cover.

3. Cut and remove all wire ties from wiring that is connected to the UEC-3 assembly (pc# C-201).

4. Disconnect the incoming power from the Interconnect Board.

5. Disconnect the Motor leads and Heater leads from the Interconnect Board.

6. Disconnect the Pushbutton Station ribbon cable from the Interconnect Board.

7. Disconnect the Analog-to-Digital Circuit Board (pc# C-223) ribbon cable from the Interconnect Board.

8. Disconnect the R/I circuit board (pc# C-210) ribbon cable

9. Uninstall the Potentiometer by removing the screws that fasten it to the MDPI assembly.

10. Uninstall the MDPI assembly by removing the screws that fasten it to the Geared Limit Switch

assembly.

11. Unplug the optional I/O Circuit Board (pc# C-223) from the SBC Board on the UEC-3 Assembly.

12. Label all customer wiring and disconnect from the Interconnect Boards.

13. Remove the four screws from the UEC-3 Assembly (pc# C-201) and carefully remove the Assembly

from the Controls Compartment.

14. Remove the Pushbutton Station with ribbon cable from the L120 gear housing conduit entry.

13

flowserve.com

Page 14

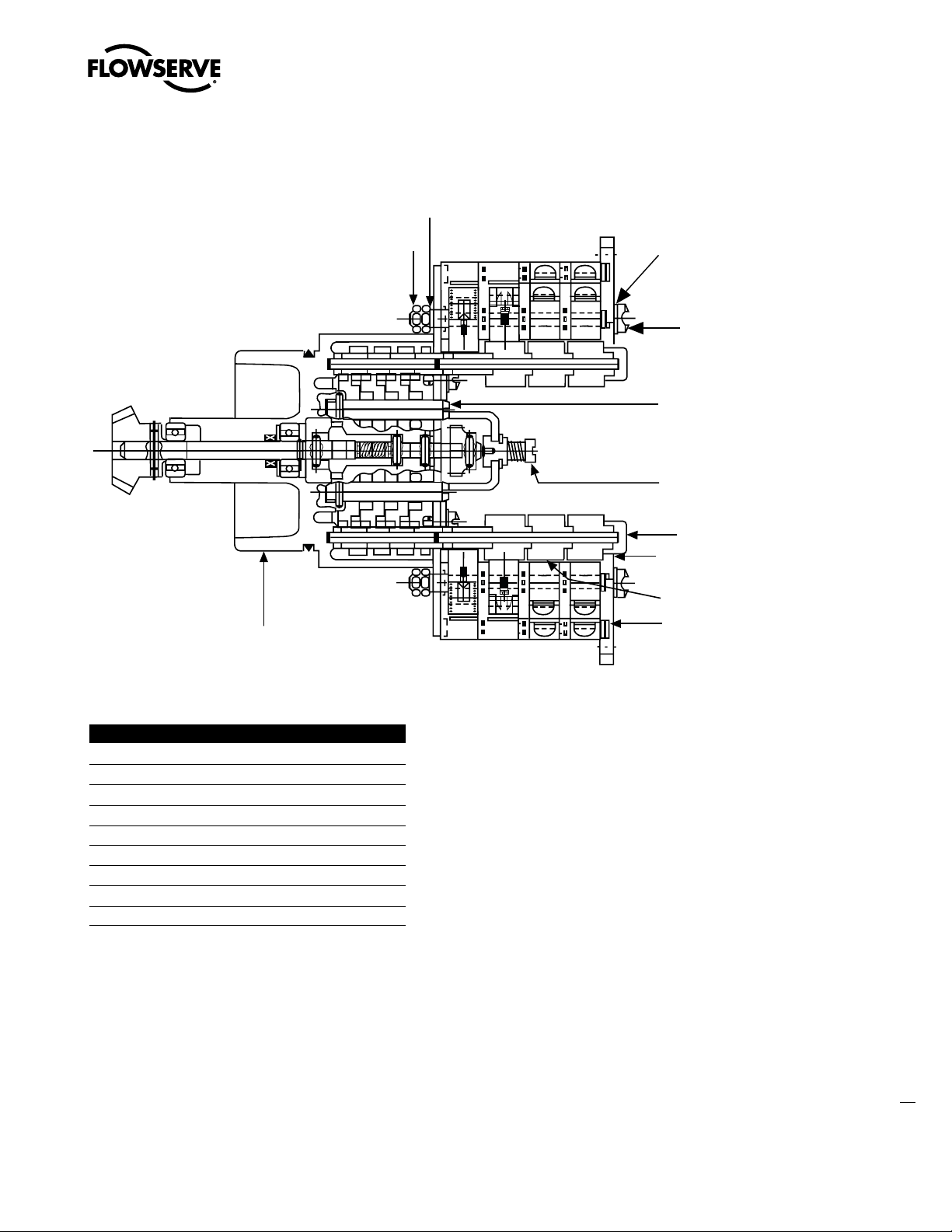

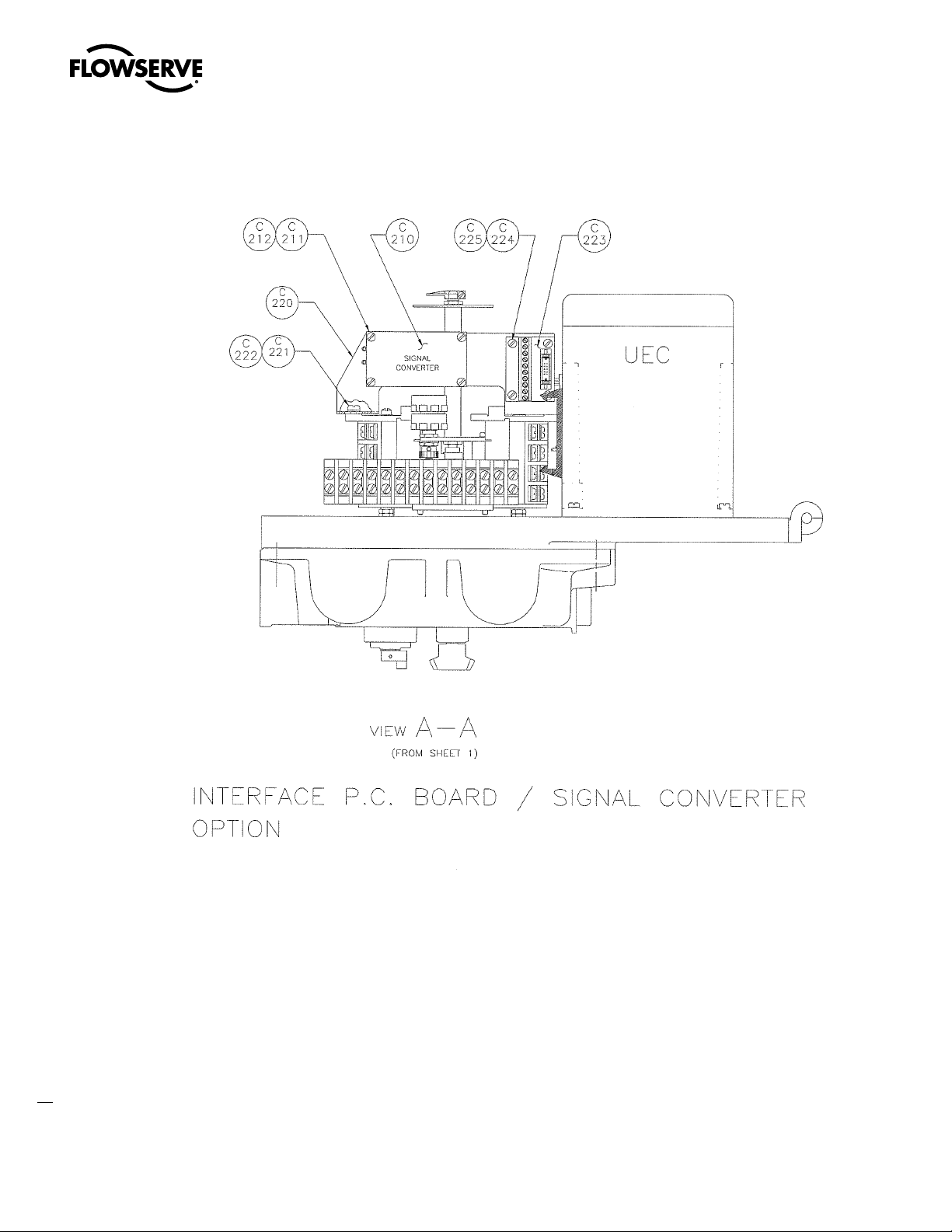

Figure 4.1 - Removal of the UEC-3 Electronic Controller

DESCRIPTION

TMI INTERGAL ITEMS

SCREW, PAN HD. MACH.

LOCKWASHER,EXT. TOOTH

GROUND LUG

UNIVERSAL ELECTRONICS CONTROLLER

1

C185 1C186

1

C201

SCREW,PAN HD.MACH.

4

C202

LOCKWASHER

4

C203

FLAT WASHER

12

C203-1

TERMINAL STRIP (12 POINT)

TERMINAL STRIP INSULATOR

1 4 4

1

C204

C204-1

SCREW,PAN HD.MACH.

C205

HEATER ASSY

QTY.

1

1

PC.

NO.

C184

C23

LOCKWASHER,EXT.TOOTH

C206

SIGNAL CONVERTER

SCREW,PAN HD.MACH.

1 4 4

C210

C211

SCREW, PAN HD. MACH.

BRACKET, TERMINAL STRIP

LOCKWASHER,EXT.TOOTH

2

1

C217

C216

C212

LOCKWASHER,EXT. TOOTH

2

C218

BRACKET

1 2 2

C220

SCREW,PAN HD.MACH.

C221

LOCKWASHER,EXT.TOOTH

C222

INTERFACE P.C. BOARD

1 2 2

C223

SCREW, PAN HD. MACH.

C224

LOCKWASHER,EXT. TOOTH

C225

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

UEC

PIFF ASSY

1

311

C

186

C

185

(HEATER)

C

23

(GROUND LUG)

C

184

C

-1

204

C

C

206

204

C

205

C

218

C

C

216

217

12C1111C1010C99C

12C1111C1010C99C

INT.1

INT.1

12

12

INT.2

INT.2

16

16

16C1515C1414C1313C

16C1515C1414C1313C

(GEAR LIMIT SWITCH AND OTHER ITEMS REMOVED FOR CLARITY)

AA

(TORQUE SWITCH)

E

S

O

L

-10-20

INT 1

INT 2

C

14

75

100

50

OPEN

PERCENT

0

25

OPEN

CLOSE

4 GEAR

L120-10

UEC UEC

UNIVERSAL

ELECTRONICS

CONTROLLER

(UEC)

X3

C

T 2

C

A

A

202

203

C

203-1

C

201

Page 15

Figure 4.1 – Removal of the UEC-3 Electronic Controller (continued)

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

flowserve.com

15

Page 16

Figure 4.1 – Removal of the UEC-3 Electronic Controller (continued)

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

16

Page 17

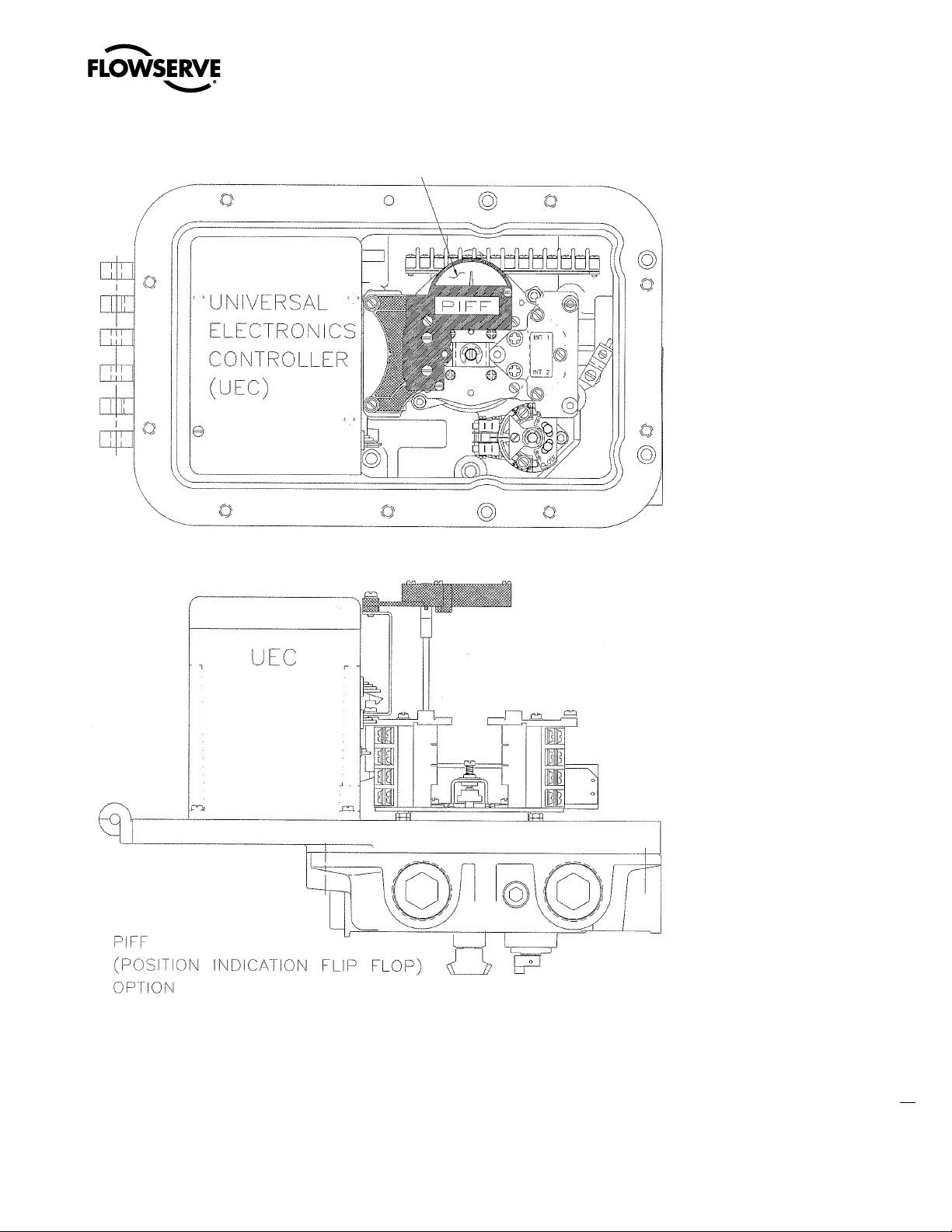

Figure 4.2 – UEC-3, MPC, DDC Assembly

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

11

23

17

INSULATOR BEHIND PCB

B-E ELEC

34

25

31

4

ON BOM 4805-455

PLASTIC COVER

7

A

31

25

35

RIBBON FOR SW93

30

25

26

ON CLEAR

20

31

9

25

22

8

37

29

c

B

SUPPLY

MOTOR

HEATER

B

3

21

A

FUSE

FUSE

25

28

13

32

15

36

1918

35

2

FUSES

6

12

SECTION A-A

c

24

27

10

14

1

VIEW C-C

FUSE

16

37

1

SCREW, PAN HD

5

15

16

31

1348351362

1

SCREW, PT FLAT

SCREW, PT OVAL HD

BITBUS/MODBUS PROM

SCREW, PAN HD

SCREW, PAN HD

SCREW, PAN HD

SCREW, PAN HD

1DDC/4 UEC

LOCKWASHER (INT TOOTH)

SCREW, PAN HD

2271291303

5DDC/4 UEC

1261

LOCKWASHER (INT TOOTH)

HEX NUT 25HEX NUT

24

1

1

2

LOCKWASHER (EXT TOOTH)

TERMINAL COVER, UEC

CONTROL BOX, UEC

FRONT COVER, UEC

21

22

23

28

33

32

14

1

1

1

1

SBC W/ CIRCUIT TRACE

RAIL, DIN

STICKER, UEC-3 ALL

HARNESS, CONTACTOR

10

12

11

13

1

1

1

INTERCONNECT BD (DDC SHOWN)

HARNESS, STARTER

MOV SNUBBER, 12A/25A

7

8

9

1

1

1

HARNESS, RIBBON 50PIN

BRACKET, TRANSFORMER

DAUGHTER BOARD (DDC ONLY)

17

18

19

20

1

1

1

1

INSULATOR, SBC

SCREEN PLATE

LABEL, FRONT COVER

INSULATOR, ICB

3

5

6

1

141

1

GROUND WIRE, POWER

HARNESS, POWER

HARNESS, HEATER

HARNESS, ICB TO D. BOARD

ITEM

1

2

QT Y.

1

1

REVERSING CONTACTOR

POWER SUPPLY BOARD

33

DESCRIPTION

17

flowserve.com

Page 18

5

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

UEX Electronic

Controller Installation

c WARNING: Turn off all incoming power before installing or working on the UEX Electronic Controller.

1. Install the MDPI Gearing Assembly (pc# 2-1) to the Geared Limit Switch Mounting Plate using the

two Socket Head Cap Screws (pc# 2-1-12, 2-1-13). (See Figure 5.1)

2. Install the Transformer/Bracket Assembly (pc# 2-2, 2-9) to the Geared Limit Switch using the six

10-32 Pan Head Screws (pc# 2-11). (See Figure 5.1)

3. Connect the Primary leads (L1 & L2) and the Secondary leads (H1 & H2) to the matching terminals

on the Terminal Strip (pc# 3-5). (See Figure 5.2)

4. Install the Power/Interface Board Assembly using the five Socket Head Cap Screws (pc# 3-6).

(See Figure 5.2)

5. Connect the Power Board leads L1, L2, and L3 to the mating terminals on the Terminal Strip.

(See Figure 5.6)

6. Connect the Power Board Motor leads T1 to T3 on the Terminal Strip. Connect T2 to T2 on the

Terminal Strip and connect T3 to T1 on the Terminal Strip. (See Figure 5.6)

a CAUTION: Ensure that wire connections are as described in Step 6 to prevent incorrect rotation.

7. Install the Encoder/Bracket Assembly onto the Transformer Bracket using the three Panel Fasteners.

(See Figure 5.1)

8. Remove the Sight Glass Retention Plate from the Controls Compartment Cover. This part will not

be reused.

18

NOTE: Retain the sight glass and hardware for use in the following step.

9. Install the Main Board Assembly Bracket (pc# 1-1) into the Controls Cover using the four screws

(pc# 204-4) previously used to mount the Sight Glass Retention Plate. (See Figure 5.3)

10. Connect the Main Board Interconnect Harness to the Main Board Assembly (pc# 1-2) and then to

the Interface Board (pc# 3-3). (See Figures 5.2 & 5.3)

Page 19

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

11. Connect the Encoder Board Harness (pc# 2-4) to the Main Board J-1 (pc#1-2). (See Figures 5.1 & 5.3)

12. Install the Main Board Assembly (pc# 1-2), with option boards (pc# 1-3) if supplied, using four Pan Head Screws

(pc# 1-4). (See Figure 5.3)

13. Connect the existing UEC-3 Harness to the Interface Board (pc# 3-3). (See Figure 5.2)

14. Install the O-Ring onto CSE Control Station (pc# 3-7) and slide the CSE into the Controls Compartment Cover.

15. Connect the CSE Ribbon Cable to the Interface Board (pc# 3-3). (See Figure 5.2)

16. Connect the 120V cable from the Main Board Interconnect Harness to the Terminal Strip. (See Figure 5.6)

17. Attach one UEX identification label (pc# 3-8) in between the feet of the interface board bracket (See Figure 5.2).

Attach one UEX identification label to the left of the existing unit nameplate on the gearbox.

Figure 5.1 - Encoder / MDPI / Transformer Installation

Figure 5.2 - Power / Interface Board Assembly

19

flowserve.com

Page 20

Figure 5.3 - Main Board Set Installation

201

-1

204

-3

204

-1

204

-6

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

204

-4

1-2

Figure 5.4 - CSE Jumper Assembly

1-1

1-3

ASSEMBLY VIEW

1-4

20

Figure 5.5 - CSE Control Station

Controls

Compartment

Display

Window

3-7

3-7

-4

3-7

-25

3-7

-24

ASSEMBLY VIEW

Page 21

Figure 5.6 - Controls Compartment Assembly

Option Boards

MDPI Gearing

Control

Station

Display

Window

Main LCS Board

Encoder

Assembly

Power / Interface

Board Assembly

Compartment

Cover

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Table 5.1 – UEX Parts List

ITEM NO. QTY. DESCRIPTION

1-1 1 MOUNTING BRACKET, MAIN BOARD SET

1-2 1 MAIN LCS BOARD

1-3 3 (max) OPTIONAL BOARDS

1-4 4 MACHINE SCREW

2-1 1 MDPI GEARING ASSEMBLY

2-1-12 2 SOCKET HEAD CAP SCREW

2-1-13 2 LOCKWASHER

2-2 1 TRANSFORMER BRACKET

2-3 1 ENCODER MTG BRACKET

2-4 1 ENCODER ASSEMBLY

2-9 1 TRANSFORMER ASSEMBLY

2-10 (6) HEX NUT

2-11 6 PAN HEAD MACHINE SCREW

2-12 1 GEARED LIMIT SWITCH ASSEMBLY

2-13 1 HEATER ASSEMBLY

3-1 1 POWER BOARD ASSEMBLY

ITEM NO. QTY. DESCRIPTION

3-2 1 POWER / INTERFACE BOARD CHASSIS

3-3 1 INTERFACE BOARD ASSEMBLY

3-5 1 TERMINAL STRIP ASSEMBLY

3-6 5 SOCKET HEAD CAP SCREW

3-7 1 CONTROL STATION

3-7-4 1 O-RING

3-7-24 4 SOCKET HEAD CAP SCREW

3-7-25 4 LOCKWASHER

3-8 1 LABEL

201-1 1 COMPARTMENT COVER

202 1 ELECTRICAL COMPARTMENT MTG PLATE

204-1 1 DISPLAY WINDOW

204-3 1 O-RING

204-4 4 HEX HEAD SELF-TAPPING SCREW

204-6 1 GASKET

Note: Items in parentheses are not shown

21

flowserve.com

Page 22

6

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Standard Control Features

6.1 Basic Specifications

The standard UEX controller wiring diagrams are shown in Section 15. Optional wiring diagrams are on

subsequent pages. The most current wiring diagram is provided with the product.

The following control features are included in the basic UEX controller.

For Optional Features, please refer to Section 8-Optional Control Features.

Figure 6.1 – UEX Local Control Panel

Selector Switch Detail

(Knob removed for clarity)

A

Blue

Knob

Lights (2)

Open

(Yes)

22

A

CSE Control Station

Close

(No)

VIEW A-A

Red

Knob

Page 23

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

6.2 Local Control

The Control Panel includes a red Local/Stop/Remote selector switch (padlockable in all three positions;

a ¼" (6 mm) hasp is recommended) and a black Open/Close rotary switch (spring-return to center). The

Open and Close switches may be configured to allow either push-to-run (inching) control or maintained

control.

Local Indication

The Control Panel includes the following:

• 32-character graphical LCD

Displays valve position as “PERCENT OPEN” and the current actuator status.

• Red/Green LED Indicators – the color assignment for the red and green LEDs is reversible as

standard.

Red ON = Valve fully open

Red “BLINKING” = Valve opening

Green “BLINKING” = Valve closing

Green ON = Valve fully closed

• Yellow LED

Yellow ON = Actuator available for remote operation,

= Valve stopped in Intermediate position.

Yellow “BLINKING” = Monitor Relay de-energized, actuator not available for remote operation.

6.3 Remote Control Modes of Operation

The actuator may be controlled remotely by two, three or four wires.

• Four-Wire Control – Three momentary contacts. Valve can be opened, closed or stopped.

• Two-Wire Control – Single open or closed contact. Valve can be opened or closed, but not stopped in

mid-travel.

• Three-Wire Maintained – Two momentary contacts for self-maintained control. Valve can be opened

or closed but not stopped in mid-travel.

• Three-Wire Inching – Two “push-to-run” contacts. Valve can be opened, closed and stopped in

mid-travel.

Refer to Figure 15.4 for remote wiring connections.

flowserve.com

23

Page 24

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Remote Control Type

The actuator may be placed in digital only, modulation only, network only, or multi-command types.

• Digital (Discrete) Only Control Type – Only digital input commands are recognized and acted upon.

All other types of remote control commands are ignored.

• Analog (Modutronic) Only Control Type – Only Modutronic 4-20 mA commands are recognized and

acted upon. All other types of remote control commands are ignored.

• Network Only Control Type – Only network (DDC, Fieldbus, Profibus, Device Net) commands are

recognized and acted upon. All other types of remote control commands are ignored.

• Multi-control Mode Operation - there are three modes of remote control when remote mode is

configured for multi control: digital control, analog control, and network control. Digital and network

control operation is based on the last command received. Analog operation is initiated by either

toggling user input 2 (configure for CSE input) or breaking and reapplying the analog control.

Remote Control Signal Power

Power for remote control signals may be derived internally from the actuator or provided externally by

the user. Signals can range from 24 to 125 VAC or VDC.

External Power Supply

An external power supply in the range of 12 to 24 VDC may be provided by the user with the optional

UPS board.

Standard Internal Power Supply

The standard internal signal supply is 24 VDC. The 24 VDC supply offers a maximum loading of 5 W.

The 24 VDC supply, in conjunction with the opto-isolated digital inputs, allows control from remote voltfree contacts over long distances and simplifies the user’s control scheme. Standard control employs a

negative earth. Positive earth (negative switching) is available by wiring to the (+) positive common as

shown on the wiring diagrams.

6.4 Emergency Shutdown (ESD)

Up to three independent ESD signals may be applied, prioritized and configured for different actions

for the ESD event associated with each. Either of these ESD signals may be applied to the actuator

to override any existing command signal and send the valve to its preselected shutdown position,

providing the actuator is in Remote mode (default configuration for ESD is “Ignore, take no action”).

Any new command signal will be ignored until the ESD signal is removed. During setup, the actuator

may be configured to close, open, stop, take no action, or “move to a previously configured position” on

receipt of the ESD signal. The ESD action may also be configured to override any inhibit signal, the local

selector switch, the local stop switch, an overtorque condition, lost phase, or jammed valve protection.

Motor thermal protection may be bypassed for critical ESD applications in non-hazardous or special

service locations. Disabling the motor thermostat voids all third-party certifications, including Factory

Mutual and CSA.

24

Page 25

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

6.5 Remote External Interlocks/Inhibits

Three user-defined inputs are provided for the connection of remote contacts that will prevent motorized operation of the actuator. These are effective in both Remote and Local modes and may only be

overridden by a maintained ESD signal, if so configured (refer to Figure 15.1 for wiring connections).

For ESD connections, the user may select either a single common or isolated commons.

6.6 Absolute Position Encoder

An absolute position encoder, incorporated into the L120 actuators, is the same as the encoder used in the

MXa. It includes 18 phototransistors that are switched on and off by a gear/wheel mechanism.Valve position

is sensed by an 18-bit, optical, absolute position encoder with redundant position sensing circuits designed

for Built-In Self-Test (BIST).

Each of the position sensing circuits is redundant, facilitating BIST. The BIST feature discerns which

failures will signal a warning only and require a warning plus safe shutdown of the actuator. Open and

closed positions are stored in permanent, nonvolatile memory. The encoder measures valve position at

all times, including both motor and handwheel operation, with or without power present, and without the

use of a battery. The absolute encoder is capable of resolving ±7° of output shaft position and over 10,000

output drive rotations, however, in the L120, the encoder is limited to the maximum geared limit switch

travel. Refer to Table 3.1.

This design permits continuous monitoring of valve position during motor and handwheel operation. The

encoder is 100% repeatable and requires no backup power source for operation. The output is used to

control the open and closed valve position and measure and report valve position, as well as provide local

and remote position feedback.

The positioning accuracy is better than 99% for valves requiring 50 or more turns. For the maximum

actuator turns and resolution, see Table 3.1.

Figure 6.2 – Absolute Position Encoder

18-bit optical, redundant position

encoder provides continuous valve

position monitoring without battery

backup with Built-In Self-Test (BIST)

capabilities.

flowserve.com

25

Page 26

7

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Protection Features

7.1 Autophase Protection and Correction

The phase rotation of the incoming three-phase supply is continuously monitored. In the event that field

wiring is reversed, UEX controls automatically correct to ensure the valve operates in the commanded

direction. In addition, the detector circuit monitors the presence of all three phases. If a phase is lost,

valve starting will be prevented and the user alerted via an LCD error message and Monitor Relay Alarm.

7.2 Jammed Valve Protection

If the actuator cannot overcome the required valve starting torque, a jammed valve condition occurs.

Jammed valve protection senses the lack of valve movement and initiates a brief reverse/forward cycle

to free the valve. If this is unsuccessful, further electrical operation is prevented and the monitor relay is

signaled.

7.3 Instantaneous Reversal Protection

The control logic incorporates a brief time delay (from 0.5 to 1.0 seconds) between motor reversals.

This reduces motor current surges and prolongs the life of the contactor. Note: It is not necessary to

switch to STOP before reversing the actuator.

7.4 Motor Thermal Protection

The motor is protected against overheating by a thermal OL in the motor enclosure. Thermal cutout

threshold is set for 120˚C (Class B). Options are available for other classifications.

26

a CAUTION: Confirm that motor thermals are rated no higher than 120°C for Explosionproof service.

Page 27

8

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Optional Control Features

8.1 Modutronic

The Modutronic controller will alter valve position in proportion to an analog command signal. It

includes an automatic pulsing mode to reduce overshoot at the set point.

The following parameters may be easily set during the configuration of the unit:

• Proportional Band range from 2% to 100% (15% = default)

• Dead Band range from ± 1% to 50% (2% = default)

• Polarity 20 mA = OPEN (default) or 20 mA = CLOSE

• Action on loss of command signal OPEN, CLOSE, STOP (CLOSE = default), or Move-to a previously

configured position

• Delay after stop 0–60 seconds (0 = default)

• Command Signal

• 4–20 mA

• Input impedance - 150 ohms

Repeatability – The Modutronic is repeatable to within ±1 % for 60 seconds stroke time or longer,

and 2% for 30 to 60 seconds.. Repeatability is defined as encoder feedback position versus position

command. Overall valve and actuator system accuracy depends on many factors, including actuator

gearing backlash and valve/actuator coupling tolerance, and therefore cannot be defined by this

document.

Extrema Mode – If the command signal represents a position of 0–2% OPEN (nominal 4.00–4.32 mA)

or 98–100% OPEN (nominal 19.68–20.00 mA), then the UEX/L120 will move the valve directly to that

position, without pulsing.

Positioning Frequency – The standard frequency is suitable for a rate of 600 starts/hour for short

periods, typical of process start-up. Typical process control of ≤ 100 starts/hour.

27

flowserve.com

Page 28

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

8.2 Analog Position Transmitter (APT)

The APT is an internally powered, non-contacting valve position transmitter. The isolated output signal

is proportional to the position of the valve and is available as 4–20 mA and/or 0-20 mA, 0-10 VDC, 2-10

VDC, 0-5 VDC, or 1-5 VDC.

The user may select the minimum signal to represent either the fully OPEN or the fully CLOSE position

of the valve during the setup procedure.

• Accuracy = 99% of full scale value (for Drive Sleeve Turns > 50)

• Non-Linearity = ± 1% of full scale value

• Impedance = 0–600 ohms (4–20 mA signal)

• Minimum external load = 1000 ohms (0–10 VDC signal)

8.3 Two-Speed Timer

A two-speed pulsing timer can be enabled to extend the operating time in the close and/or the open

directions. Pulsing may be applied from 0.5 (if precision is set to xxx.x%) to 99% of full valve travel or

to a small portion. The ON pulsing cycle is configurable from 0.5 to 20 seconds in 0.5 second increments, and the OFF pulsing cycle is configurable from 1.0 to 200 seconds in 1 second increments. The

two-speed timer is especially effective where concerns of hydraulic shock exist.

28

8.4 Control Station (CSE)

The CSE is a separate control station designed for the operation of inaccessible actuators. It is available

with LEDs, Remote/Local and Open/Close selector switches. The CSE may be powered by the actuator

internal supply, provided wire resistance and other external loads do not limit the available signal power

presented to the UEX.

Page 29

9

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Network Communications

The UEX provides a comprehensive network option portfolio to the user. Network solutions are improved

for the user that has an L120 with UEC, with the addition of DeviceNet to complement Modbus,

Fieldbus H1, Profibus DP_V1 and Profibus PA. UEX provides the user with predictable, reliable, and safe

operation for years to come, in applications which are subject to the most rigorous requirements and

environmental extremes.

With each of the provided network protocols a user may configure the unit to move to a predefined

fail-safe position on loss of communication. Action on loss of command signal OPEN, CLOSE, STOP, or

MOVE-TO preconfigured position. The user may also configure the length of time communication must be

lost before the unit indicates communication loss and performs the communication loss action.

9.1 Modbus

Modbus™ provides the ability to control and monitor up to 250 actuators over a single twisted-pair

cable. The communication network employs Modbus

dant. Redundancy assures that any single break or short in the communication cable will not disable

any actuators. Each actuator has included an addressable field unit that communicates over the twisted

pair network and executes open, close, stop, ESD, and GO TO position commands. The field unit

also communicates all actuator status and alarm diagnostic messages over the same communication

network.

Modbus Network

• Single-ended loop (as standard – See Figure 16.1)

• Modbus protocol

• High speed – up to 19.2K baud

™

™

protocol on an RS-485 network and is redun-

Foundation

flowserve.com

29

Page 30

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

9.2 Master Station III

L120 actuators equipped with Modbus can be controlled via Flowserve Limitorque’s Master Station II or III.

The next-generation master station is designed specifically for use with Limitorque’s line of DDC

(Modbus) electric actuators. The Master Station III acts as a single-source controller for up to 250

actuators.

The Master Station III is a plug-and-play solution that provides complete control and diagnostics for

Limitorque field units through a simple touch-panel operator interface. The key features of the Master

Station III include:

• A network time protocol to allow for time synchronization of alarms/diagnostic data to Host device

• Multilingual support includes English, Spanish, German, French, Italian

• Asset management and diagnostic via Bluetooth V2.0+ Enhanced Data Rate (EDR) Class 100m

• Configuration of slave register polling schedule

• Industry standard Modbus RTU, ASCI, UDPor TCP/IP protocols

• Three levels of user password protection

• 5.6” TFT touch-screen display

• E-mail notification of configurable alarm conditions

• Data/event logging

• Network control of up to 250 devices

• Front access to peripheral ports: Ethernet, USB x 2, VGA, printer/debug

• Modular hot-swappable redundant design

• Built-in secure Web server for control, monitoring and asset management capabilities

30

9.3 Foundation Fieldbus Communication

L120 actuators can be fitted with Foundation Fieldbus protocol that complies with the IEC 61158-2

Fieldbus H1 standard. The field unit device is able to support several topologies, such as, point-to-point,

bus with spurs, daisy chain, tree, or a combination of these. The FF device has network features that

include:

• Link Active Scheduler that controls the system

• High-speed communications at to 31.25 kbits/sec

• Publisher - subscriber communication

• One analog input block, one analog output block, two discrete output function blocks, Transducer

block, Resource block, and four discrete input function blocks

• PID (proportional integral derivative) loop control

• Device descriptions

• Configurable by user

Link Active Scheduler communication: Fieldbus segments have one active Link Active Scheduler (LAS)

at a given time, which is the bus arbiter, and does the following:

Page 31

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

• Recognizes and adds new devices to the link

• Removes non-responsive devices from the link

• Schedules control activity in, and communication activity between, devices

• Regularly polls devices for process data

• Distributes a priority-driven token to devices for unscheduled transmissions

9.4 PROFIBUS DP V1 Communication

L120 actuators can be fitted with Profibus DP_V1 protocol field units that comply with EN50170

Fieldbus Standard for RS-485 communications. The device supports several topologies, such as,

point-to-point, bus with spurs, daisy chain, tree, or a combination of these. The PB device has network

features that include:

• High-speed communications up to 1.5 m/bits/s

• Master-to-slave communication

• One analog input block, one analog output block, two discrete output function blocks, Transducer

block, Physical block, and four discrete input function blocks

• Device descriptions configurable by user

High-Speed Data Exchange – Startup Sequence

• Power ON / Reset – Power On / Reset of master or slave

• Parameterization – download of parameters into field device (selected during configuration by the

user)

• I/O Configuration – download of I/O configuration into the field device (selected during configuration

by the user)

• Data Exchange – cyclic data exchange (I/O Data) and field device reports diagnostics

• Also supports Profibus_DP redundancy

9.5 PROFIBUS PA Communication

A Profibus PA protocol is available and complies with EN50170 Fieldbus Standard and Fieldbus physical

layer per IEC 61158-2 for communications. The device supports several topologies, such as point-topoint, bus with spurs, daisy chain, tree, or a combination of these. The PB device has network features

that include:

• High-speed communications at to 31.25 kbits/s with Manchester coding

• Master-to-slave communication

• Bus powered for 9-32 VDC and 15 mA per actuator

• Stand-by communication channel

• One analog in and one analog out, four digital input and up to eight digital output function blocks

• Device descriptions configurable by user

31

flowserve.com

Page 32

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

9.6 DeviceNet

DeviceNet complies with CAN based protocol and provides the following features:

• DeviceNet Group 2 Server implementation.

• Bus Powered Network Interface allows power alarm information to be communicated when actuator

loses main power. The actuator does NOT drop off the network when 3-phase power is lost.

• Standard Polled I/O Connection

• Standard Bit Strobed I/O Connection

• Standard Change of State / Cyclic I/O Connection

• Standard explicit connections defined as:

• Various Assembly Objects and sizes that allow the network user to determine how much data to

transfer to accommodate network installation data throughput requirements.

• Automatic BAUD rate detection.

• Node Address configurable via local setup menu, or via the remote network user.

• Broadcast or group network originated ESD support.

The following commands and information may be transmitted over the DeviceNet network:

• “OPEN,” “STOP,” and “CLOSE” commands

• “ESD” and “MOVE–TO” position commands

• Actuator status and alarm messages

• Four digital inputs, two digital outputs, one analog input and one analog output for user configuration

• A surge-protected and isolated communication channels

• UEX control panel configuration

Please see Section 16 for network connection topologies and cabling recommendations.

32

Page 33

10

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Monitoring and

Diagnostic Features

10.1 Local Features

LCD Displays – The LCD displays an array of data concerning the status of actuator components

in clear, graphical or textual language. The UEX is available with eleven languages:

English, Spanish, German, French, Italian, Portuguese, Mandarin, Russian, Bahasa

Indonesia, Turkish and Katakana.

Normal Display – The normal display illustrates current valve position and status.

Alarm Functions – Alarm functions (active alarms will be toggled every four seconds)

that may be displayed include:

• Valve Jammed - Valve cannot start moving

• Lost Phase - One of three phases lost

• Motor Overtemp – Thermal overload exceeded

• Overtorque - Torque exceeded in mid-travel

• Hardware Failure - Indication

• Modbus, Profibus,

• ESD Active - ESD signal active

• Inhibit Active - Inhibit signal present

• No analog signal - 4–20 mA signal absent (Modutronic enabled, red selector switch in

“REMOTE”)

• DDC, PB, FF, DNet comm. Loss – Enabled, signal absent

• Analog Output Loss - Enabled, but output current loop open

Foundation Fieldbus, DeviceNet off - Enabled, but “OFF”

33

flowserve.com

Page 34

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

10.2 Diagnostics

Standard Diagnostic Screens – Diagnostic screens may be accessed quickly through the Setup

dialogue or the UEX Dashboard Software solutions package. These screens provide detailed data of

actuator status. Included are:

• Hardware – status of electronic components such as thermistor, encoder, power board, DDC/FF/

PB/DeviceNet network board, analog board, DIGIN and ANIN (digital in and analog in)

• Motor – Phase rotation

• Power Supply – Maximum and minimum voltage, frequency

• Identification – Tag number, serial number, order number, software revision

• View Network Status – Checks for Standby, Recoverable Fault, Nonrecoverable Fault, and View

Network Status

• Operation Log – Actuator turns, contactor operations, motor run-time, stroke time, manual

operations

• View Control Compartment Temperature (View Power Supply Menus)

34

Page 35

Figure 10.1 – Normal and Diagnostic Displays

Normal Display - STATUS OK conrms that the actuator

is suitable for remote operation.

50% OPEN

STATUS OK

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Normal Display/Alarm Condition - If the actuator is not suitable

for remote operation, the appropriate alarm will be shown.

50% OPEN

MOTOR OVERTEMP

Diagnostic Display informs user of failed hardware.

ENCODER

(FAULT) NEXT?

Typical Display

flowserve.com

35

Page 36

Remote Indication Features

11

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

11.1 Actuator Status Contacts

(S1a, S1b, S2a, S2b)

Four latched contacts provide remote feedback of actuator status. Two (S1a, S2a) contacts may be

individually configured for normally open, normally closed, or blinker (continuous opening and closing

of the valve) operation and provide feedback of one of the functions listed below. Two other relays are

complementary.

• Closed • Motor overtemp

• Closing • Overtorque

• Mid-travel • Open torque switch

• Opening • Close torque switch

• Open • ESD signal

• Stopped • Open inhibit

• Valve moving • Close inhibit

• Local selected • Lost phase

• Local STOP/OFF • No analog signal

• Manual operation • Hardware failure

• Valve jammed • Network controlled

• Remote selected • CSE controlled

36

Page 37

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Recommended settings are:

• S1a – Normally closed contact at valve fully CLOSE

• S1b – Normally closed contact at valve fully OPEN – Default position. See wiring diagram.

• S2a – Normally open contact at valve fully CLOSE

• S2b – Normally open contact at valve fully OPEN – Default position. See wiring diagram.

The standard contacts are rated for 2.0 A at 30 VDC and 0.5 A at 125 VAC.

11.2 Monitor Relay (RM)

The monitor relay provides immediate indication of problems that prevent remote valve operation. It has

a normally open contact and a normally closed contact (1 x SPDT contact) and is energized when the

three-phase supply is present and the actuator is in a normal/healthy state.

The relay will de-energize if any of the following events occur:

• Loss of one or more phases of the three-phase power supply

• Loss of internal control supply

• Jammed valve detected

• Motor overtemp is active (unless thermostat is configured to OFF)

During configuration, the following parameters may be added to the monitor relay function:

• Selector switch is in “Local” mode

• Selector switch is in “Stop” position

• Overtorque

• Inhibit signal active

• ESD signal active (The user can enable or disable “local” mode and “stop” position. Default is

enabled.)

The monitor relay resets when the faulty state is rectified. The standard contacts are rated for 5.0 A at

250 VAC, 30 VDC. The monitor relay can be disabled if the user chooses.

11.3 Exact End Position Indication

On torque-seated valves, the end-of-travel indication switch trips when the required torque is achieved

at the end of travel. This ensures that remote, self-latched signals will not be disconnected prematurely,

and that the valve will be tightly seated.

flowserve.com

37

Page 38

12

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Auxiliary Power Supply Uninterruptible Power Supply

(UPS) Connection

Isolated Commons

13

If the main three-phase power supply is not available during the configuration of the actuator, an optional

module contains provisions for connecting a 24 VDC, 1 A power source to the auxiliary input terminals

shown in the wiring diagram on the following pages. Power supply will draw up to 0.5 A.

The UEX is provided with isolated commons for control functions. Please refer to wiring diagram in

Section 15 for locations.

38

Page 39

Actuator Configuration

14

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

14.1 Local Configuration

UEX controllers may be configured through the CSE control station switches, with settings visible on the

LCD display. Settings that can be initiated or changed include:

• Direction of rotation

• Action on ESD

• External inhibits

• Remote control operating mode

• Motor thermostat action

• Stop valve on torque or position

• All optional features (Modutronic, Modbus, FF H1, PB-DPV1, PB-PA, DeviceNet, Timers, APT, etc.)

14.2 Default Configuration

Unless otherwise specified, UEX controllers will be shipped with the following configuration, which

becomes effective after the L120 limit switches are properly set.

• Open stop by limit

• Close stop by limit

• Maintained local controls

• Clockwise to close

• ESD is “off” and set to “IGNORE.”

• Inhibits enabled, turned “OFF”

• Remote control – three-wire maintained and Multi-mode

• Password – 100

• Modutronic Option (if installed)

39

flowserve.com

Page 40

Figure 14.1 – Default Configuration Guidelines

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Modutronic Option

Proportional band – 15%

Deadband – 2%

Polarity – 20 mA = Open

Action on loss of signal = Close

FF Option, DeviceNet and PB

Option

Analog scale = 0-100

Proportional band – 15%

Deadband – 2%

Figure 14.2 – Configuring the UEX Controller

Modbus RTU protocol

9600 baud

Analog scale = 0-100

Proportional band – 15%

Deadband – 2%

Offset – 0 mA

1 Place selector switch in "STOP." The LCD

display will read "% OPEN" and "STATUS OK."

Operate the selector switch to the (YES) (NO)

0% OPEN

STATUS OK

(YES) positions. The message "SETUP?" will

be displayed for 10 seconds. Answer "YES" to

enter setup routine.

OPEN

(YES)

CLOSE

(NO)

40

2 All parameters may be congured by

KNOB IN

OPEN (YES)

POSITION

50% OPEN

TORQUE VALUE

answering "YES"/"NO" questions. For

example, entering a "NO" response to the

displayed screen will change the displayed

torque value. Select "YES" when the desired

value is displayed.

Configuration screens are displayed in English. Languages such as Spanish, French, German, Italian,

Portuguese, Mandarin, Russian, Bahasa Indonesia, Turkish and Katakana are also available and can be

configured via the actuator control panel.

A three-digit numeric password is included as part of the initial setup procedure to prevent unauthorized

changing of the configured parameters. If the password is entered incorrectly, settings may be viewed,

but not changed. The default value for the password is 100.

Page 41

UEX Wiring Diagrams

15

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

flowserve.com

41

Page 42

Figure 15.1 – Standard Wiring Diagram for UEX Controllers

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

42

Page 43

Figure 15.2 – DDC Wiring Diagram for UEX Controllers

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

flowserve.com

43

Page 44

Figure 15.3 - MOD APT Wiring Diagram for UEX Controllers

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

44

Page 45

Figure 15.4 – Optional Features Wiring Diagrams

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

MODUTRONIC

+ve ANALOG INPUT

-ve ANALOG INPUT

STANDARD SIGNAL 4-20mA

ANALOG POSITION

4-20mA OUTPUT

APT

0-10VDC OUTPUT

or

AT T

COMMON -Ve

TRANSMITTER

21

20

47

48

49

Optional voltages or currents; 0-20 mA, 4-20

mA, 0-10 VDC, 2-10 VDC, 0-5 VDC, 1-5 VDC

EXTERNAL LOAD – APT & ATT

4-20 mA SIGNAL - 470 ohms MAXIMUM for 99.9% accuracy/750 ohms

MAXIMUM for 99% accuracy

0-10 VDC SIGNAL - 2700 ohms MINIMUM for 99% accuracy and 1000

ohms for 99.9% accuracy.

MODUTRONIC

COMMAND SIGNAL = 4-20 mA

INPUT IMPEDANCE = 150 ohms

INPUT CAPACITANCE = 0.1 µF ±30%

NOTE:

ACTUATORS SUPPLIED WITH “R” DEVICES ARE SHIPPED WITH

DEFAULT SETTINGS AS SHOWN ON THE DIAGRAM, UNLESS

OTHERWISE SPECIFIED.

EXACT END POSITION INDICATION

ON TORQUE-SEATED VALVES, THE LCD AND “S” CONTACTS

CONFIGURED AS END-OF-TRAVEL LIMITS AUTOMATICALLY PROVIDE

EXACT END POSITION INDICATION.

ANALOG INPUT

STANDARD SIGNAL 4-20 mA

INPUT IMPEDANCE = 350 ohms

INPUT CAPACITANCE = 0.1 µF ±30%

99% ACCURACY

CONFIGURABLE SCALING

INT ROTORS

LIMIT SWITCHES 9-16 MUST BE WIRED DIRECTLY TO THE LIMIT

SWITCH ASSEMBLY.

CONNECTIONS

CONNECTION LANDED ON INTERFACE BOARD.

flowserve.com

45

Page 46

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

RECOMMENDED DEVICENET CABLE IS BELDEN 3084A OR EQUAL.

120 OHM, 1/4W TERMINATION RESISTORS MUST BE CONNECTED AT EACH SEGMENT END.

PREFERRED NETWORK WIRING IS TO CONNECT SHIELD TO TERMINAL 3 FOR EVERY UNIT ON SEGMENT.

SHIELD SHOULD BE CONNECTED TO POWER SUPPLY GROUND AT THE CLOSEST POINT IN THE CENTER

OF THE NETWORK.

DeviceNet

DEVICENET BOARD

EGND

RED

WHT

BLK

BLU

NETWORK 0V

NETWORK +24V

NETWORK DATA (–)

NETWORK DATA (+)

SHIELDJ8.5

J8.1

J8.3

J8.4

J8.2

VIA STANDOFF

BLU

WHT

BLK

RED

N/C

F

OUNDATION

FIELDBUS

TERMINALS 29 AND 41 ARE REDUNDANT AND MAY BE USED FOR DAISY CHAIN

CONFIGURATION.

NOTES:

LOSS OF COMMUNICATION ON A1 => REGISTER 9 CHANNEL A

(BIT 0x0400) SET TO 1

LOSS OF COMMUNICATION ON A2 => REGISTER 9 CHANNEL B

(BIT 0x0800) SET TO 1

PREFERRED NETWORK WIRING IS TO CONNECT ONLY ONE SHIELD TO

EARTH/GROUND. REFER TO DDC INSTALLATION DOCUMENTATION.

33

34

28

35

36

NETWORK DATA-A2

NETWORK DATA-A2*

NETWORK DATA-A1

NETWORK DATA-A1*

Modbus BOARD

Modbus

EARTH/GROUND

SURGE PROTECTION

A

REG 9.0x0400

REG 9.0x0800

B

CUSTOMER IS REQUIRED TO CONNECT WIRE BETWEEN

TERMINAL 3 AND CHASIS GROUND FOR SURGE PROTECTION.

PREFERRED NETWORK WIRING IS TO CONNECT SHIELD TO

EARTH/GROUND AT BOTH ENDS OF THE SEGMENT. ATTACH

SHIELD TO TERMINAL 3 ONLY IF DEVICE IS LOCATED AT THE

ENDS OF THE SEGMENT. CUSTOMER MUST CONNECT REMAINING

INDIVIDUAL NETWORK CABLE SHIELDS TOGETHER TO ENSURE

PROPER SHIELDING OF THE ENTIRE NETWORK.

PBDP1 (+)

PBDP1 (–)

PROFIBUS

DPV1

IEC 61158–2

Profibus DP_V1

SURGE

CUSTOMER IS REQUIRED TO CONNECT WIRE BETWEEN TERMINAL 3

AND CHASIS GROUND FOR SURGE PROTECTION. PREFERRED NETWORK

WIRING IS TO CONNECT SEGMENT SHIELD TO EARTH/GROUND AT ONE

POINT ONLY. ATTACH SHIELD TO TERMINAL 3 ONLY IF SEGMENT IS NOT

GROUNDED. ELSEWHERE, CUSTOMER MUST CONNECT INDIVIDUAL

NETWORK CABLE SHIELDS TOGETHER TO ENSURE PROPER SHIELDING

OF THE ENTIRE NETWORK.

FF1 (+)

FF1 (–)

FF1 (+)

FF1 (–)

F

OUNDATION

FIELDBUS

IEC 61158–2

F

OUNDATION

Fieldbus_H1

SURGE

CUSTOMER IS REQUIRED TO CONNECT WIRE BETWEEN TERMINAL 3

AND CHASIS GROUND FOR SURGE PROTECTION. PREFERRED NETWORK

WIRING IS TO CONNECT SEGMENT SHIELD TO EARTH/GROUND AT ONE

POINT ONLY. ATTACH SHIELD TO TERMINAL 3 ONY IF SEGMENT IS NOT

GROUNDED. ELSEWHERE, CUSTOMER MUST CONNECT INDIVIDUAL

NETWORK CABLE SHIELDS TOGETHER TO ENSURE PROPER SHIELDING

OF THE ENTIRE NETWORK.

PBPA1 (+)

PBPA1 (–)

PBPA1 (+)

PBPA1 (–)

PROFIBUS

PA

IEC 61158–2

Profibus_PA

SURGE

PBDP1 (+)

PBDP1 (–)

DDC-100:

JP1 AND JP2 MUST BE IN POSITION “A”. THE 6-[IN CONNECTOR WITH

BLUE WIRES SHOULD BE CONNECTED TO J2 OF THE DDC-100 BOARD.

33

34

28

35

36

33

34

28

35

36

33

34

28

35

36

33

34

28

35

36

Figure 15.5 – Modbus, Foundation Fieldbus, Profibus DP V1, and Profibus PA, and DeviceNet Network Wiring Diagrams

NOTE: CONNECTIONS LANDED TO INTERFACE BOARD.

46

TERMINALS 13 &14 FOR FOUNDATION FIELDBUS, PROFIBUS PA, PROFIBUS DP_V1

ARE USED FOR CHANNEL B ON OPTIONAL REDUNDANT NETWORK BOARD.

Page 47

Network Protocol Connections

16

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

16.1 Network Wiring – Modbus

Please consult LMENIM2329 for detailed installation instructions.

• Belden 3105A Specifications

Total cable length between repeaters or nodes with repeaters:

• @ 9.6 kbps: 11500 ft. (3.5 km)

• @ 19.2 kbps: 5750 ft. (1.7 km)

Key Specifications

• Resistance/1000 ft = 22 AWG (7 x 30) 14.7 ohms each conductor (29.4 ohms for the pair)

• Capacitance/ft. = 11.0 pF (conductor-to-conductor)

• Capacitance/ft. = 20.0 pF (conductor-to-shield)

• Belden 3074F specifications

Total cable length between repeaters or nodes with repeaters:

• @ 9.6 kbps: 15000 ft. (4.5 km)

• @ 19.2 kbps: 7500 ft. (2.2 km)

Key Specifications

• Resistance/1000 ft = 18 AWG (7x26) 6.92 ohms each conductor (13.84 ohms for the pair)

• Capacitance/ft. = 14 pF (conductor-to-conductor)

• Capacitance/ft. = 14 pF (conductor-to-shield)

• Belden 9841 specifications

47

flowserve.com

Page 48

Total cable length between repeaters or nodes with repeaters:

• @ 9.6 kbps: 6560 ft (2 km)

• @ 19.2 kbps: 3300 ft. (1 km)

Key Specifications

• Resistance/1000 ft = 24 AWG (7 x 32)

24 ohms each conductor (48 ohms for the pair)

• Capacitance/ft. = 12.8 pF (conductor-to-conductor)

• Capacitance/ft. = 23 pF (conductor-to-shield)

Figure 16.1 – Typical Modbus Network Wiring Diagrams – Single Loop

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

MOV-2

A2

16

A1

41

A2*

15

Shield

•

•

•

A1*

29

30

N/C

MOV-1

A2

A2*

Shield

16

A1

41

15

A1*

29

30

N/C

MOV-250

A2

16

A1

41

A2*

15

Shield

A1*

29

30

N/C

48

Legend:

MOV - Motor Operated Valve

A1 -Data Channel 1

A1*-Data Channel 1*

A2 -Data Channel 2

A2*-Data Channel 2*

N/C-No Connection

Notes:

• Correct polarity for field unit and master station

connections is necessary for proper operation.

• The connections shown are typical. The number of

MOVs will vary up to a maximum of 250.

• The ground connection should be a ground rod or

ground grid.

Page 49

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

16.2 Network Wiring – Foundation Fieldbus H1

Please refer to LMENIM2330 for detailed installation instructions.

Limitorque’s F

for use on the H1 highway and uses a twisted-pair cable for connection to the highway.

The UEX FF field unit fits in the actuator in the sealed electrical housing. All adjustments to the UEX FF

settings may be made over the F

The UEX FF unit may command its actuator to open, stop, close, move to a set position, or perform an

emergency shutdown operation. Commands to the unit come over the network from the host system,

which may be a PC, Distributed Control System (DCS), Programmable Logic Controller (PLC), or some

other microprocessor-based device. Commands may also be generated in another network actuator or

device and transmitted over fieldbus using peer-to-peer, publisher/subscriber communication.

A fieldbus device is an intelligent device within the actuator that can send multiple variables to the

control system over a high-resolution and distortion-free digital communication network. The device

provides control and self-test capabilities, which allow abnormal conditions to be easily and immediately

identified before an unplanned shutdown.

Additional features and benefits are:

• Reduces cost of wiring and installation – existing wiring and multi-drop connections can be used.

• Interoperable devices – devices from different suppliers can communicate with one another on the

same network.

A typical UEX FF system is shown in Figure 16.2.

oundation Fieldbus field unit conforms to open Fieldbus standard IEC 61158. It is suitable

oundation Fieldbus data highway using a network configuration tool.

flowserve.com

49

Page 50

Figure 16.2 – Typical Foundation Fieldbus System with a DCS Host (Daisy Chain Shown)

Distributed Control

System (Host )

Control Highway

Fieldbus

Inte rf ace

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Fieldbus

Power

Supply

9-32 V

T erminator

UEX

Actuator

UEX

Actuator

UEX

Actuator

T erminator Fieldbus Network

UEX

Actuator

For fieldbus technology and cabling information, refer to the following documents:

• F

oundation Fieldbus Wiring and Installation 31.25 kbits/s, Voltage Mode, Wire Medium AG-140

• F

oundation Fieldbus Technical Overview, FD-043

• Relcom Inc. Fieldbus Wiring Design and Installation Guide

• ANSI/ISA-S50.02, Part 2-1992, Fieldbus Standard for Use in Industrial Control Systems Part 2:

Physical Layer Specification and Service Definition

• F

oundation Fieldbus FF-890 and FF-891, Foundation Specification, Function Block Application Process,

Part 1 and 2.

Reference can be made to the following books:

• Fieldbuses for Process Control: Engineering, Operation, and Maintenance. ISBN 1-55617-760-7.

Network Wiring – F

oundation Fieldbus

• Belden 3076F Specifications

Key Specifications – 18 AWG

• Nominal Capacitance 80 pF/m

• Nominal DC Resistance 24 ohm/km max

50

• Characteristic Impedance 100 ohms

• Nominal Impedance – 100.0

Page 51

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

16.3 Network Wiring – Profibus DP and PA

Please refer to LMENIM2336 for detailed installation instructions.

Profibus is based on RS 485 communication. The standard EN 50170 specifies the cable for use with

Profibus DP and PA. Table 16.1 shows specifications that need to be fulfilled by the Profibus cable.

Table 16.1 – Specifications for the Profibus Cable

Parameter Type – Profibus DP

Impedance 135 to 165 ohm/3 to 20 MHz

Capacity < 30 pF/m

Resistance < 110 ohm/km

Wire gauge > 0.64 mm

Conductor area > 0.34 mm

The Profibus DP cable is a shielded twisted pair cable.

In general, there are two different types of cables available. The most commonly used cable has

solid wire for the Profibus line.

2

When there is a need for more flexiblity (bending) and higher environmental resistance, a cable with

stranded wire for the Profibus line and special jackets shall be used.

Limitorque recommends the use of:

• Belden 3079A Specifications, 22 AWG, shielded, solid two conductor

Key Specifications

• Capacitance/ft = 8.5 pF

• Nominal Impedance (ohms) – 150.0

Network Wiring – Profibus PA – Belden 3076F

Please refer to IEC 61158 and ANSI/ISA S.50.02 Part 2-1992 for network wiring guidelines.

Maximum number of devices on a segment = 32 (including repeaters)

Table 16.2 – Maximum Segment Length

Data transfer

rate in kbit/s

Maximum

segment

length in m

9.6 19.2 45.45 93.75 187.5 500 1500 3000 6000 12000

1200 1200 1200 1200 1000 400 200 100 100 100

flowserve.com

51

Page 52

Figure 16.3 – Typical Profibus System with a DCS Host (Daisy Chain Shown)

Distributed Control

PA

System (Host)

Control Highway

Profibus DP

Interface

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Segment coupler

(PA only network)

Segment coupler

Power supply

Terminator

PB

Actuator

PB

Actuator

PB

Actuator

Te rminatorProfibus DP or PA Network

PB

Actuator

16.4 Network Wiring – DeviceNet

Please refer to LMENIM2328 for detailed installation instructions.

DeviceNet is a CAN - based protocol that uses 5 wires including a shield. Two of the conductors are

used for 24V DC power & up to 8 amps (4 amps for NEC Class 2) may be passed along the hi-way from

a suitable power source. Two conductors are used for the CAN bus signals, CAN_H and CAN_L, which

are usually smaller in diameter. Limitorque recommends Belden cable for connecting to a DeviceNet

network. The specifications for thick and thin cable (per site requirements) are as follows:

52

Page 53

Table 16.3 – Belden Cable Specifications

Belden

Part No.

3082A

3084A

AWG

(Stranding)

dia. Inches

Nom. DCR

2 – 15 AWG

(19 x 28)

3.6 ohm/1000 ft

11.8 ohm/km

2 – 18 AWG

(19 x 30)

6.9 ohm/1000 ft

22.7 ohm/km

2 – 22 AWG

(19 x 34)

17.5 ohm/1000

ft

57.4 ohm/km

2 – 18 AWG

(19 x 36)

28.0 ohm/1000

ft

91.9 ohm/km

Insulation

material

(color code)

Power pair

(Black/Red)

Data pair

(Blue/White)

Power pair

(Black/Red)

Data pair

(Blue/White)

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

Nominal

O.D.

12.2 mm 120 12.0 pF/ft

7.2 mm 120 12.0 pF/ft

Nom

Impedance

(ohms)

Nominal

Capacitance

Test

Frequency

(MHz)

0.125

0.5

1

0.125

0.5

1

Maximum

Attenuation

dB/100ft

0.13

0.25

1.36

0.29

0.50

1.70

Table 16.4 – Total Cable Length Between Repeaters or Nodes:

Network Size 125 KBPS 250 KBPS 500 KBPS

Thick Trunk Length 500 m (1,640 ft) 250 m (1,640 ft) 100 m (1,640 ft)

Thin Trunk Length 100 m (328 ft) 100 m (328 ft) 100 m (328 ft)

Flat Trunk Length 380 m (1,250 ft) 200 m (656 ft) 75 m (246 ft)

Maximum Drop Length 6 m (20 ft) 6 m (20 ft) 6 m (20 ft)

Cumulative Drop Length 156 m (512 ft) 78 m (256 ft) 39 m (128 ft)

Note: Each actuator includes 0.60 meters of internal drop length.

flowserve.com

53

Page 54

How to Order Parts

17

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

To order parts or obtain further information about your Limitorque L120 valve actuators, contact your

local Limitorque distributor sales office, or:

Flowserve Limitorque

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Telephone (434) 528-4400

Fax (434) 845-9736

All inquiries or orders must be accompanied by the following information:

1. Actuator Size

2. Limitorque Order Number

3. Limitorque Serial Number

54

Page 55

Regulatory Information

18

Limitorque UEX FCD LMENIM1205-03-AQ – 05/15

flowserve.com

55

Page 56

FCD LMENIM1205-03-AQ Printed in USA. May 2015

To find your local Flowserve Limitorque representative

visit www.limitorque.com or call 1 434 528 4400

Flowserve Corporation

United States

Flowserve Limitorque

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone: 434-528-4400

Fax: 434-845-9736

England

Flowserve Limitorque

Euro House

Abex Road

Newbury

Berkshire, RG14 5EY

United Kingdom

Phone: 44-1-635-46999

Fax: 44-1-635-36034

Singapore

Limitorque Asia, Pte., Ltd.

12, Tuas Avenue 20

Singapore 638824

Phone: 65-6868-4628

Fax: 65-6862-4940

China

Limitorque Beijing, Pte., Ltd.

RM A1/A2

22/F, East Area, Hanwei Plaza

No. 7 Guanghua Road, Chaoyang

District

Beijing 100004, Peoples Republic

of

China

Phone: 86-10-5921-0606

Fax: 86-10-6561-2702

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended