Page 1

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

®

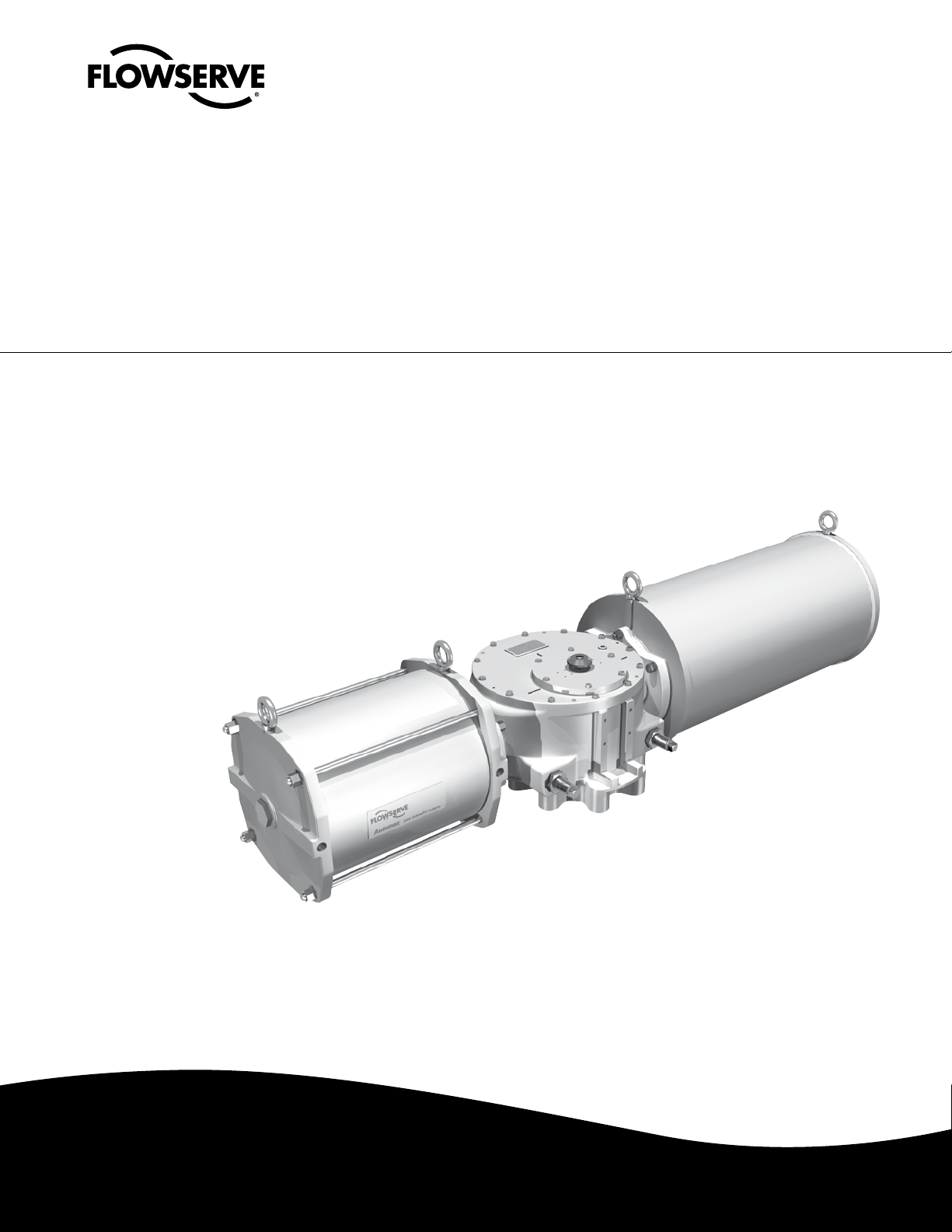

RG Series Standard Actuator

USER INSTRUCTIONS

FCD AXENIM0122-00 12/09

Installation

Operation

Maintenance

Experience In Motion

1

Page 2

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

STOP!

®

INDEX

1 Using Flowserve Valves, Actuators and Ac-

cessories Correctly

2 Installation

3 Travel Stop Adjustments

4 Maintenance Instructions

5 Field Conversion from Fail CW to Fail CCW

6 Torque Shaft

7 Long Term Storage

Compliance with other, not particularly emphasised

notes, with regard to transport, assembly, operation and

maintenance and with regard to technical documentation

(e.g. in the operating instruction, product documentation

or on the product itself) is essential, in order to avoid

faults, which in themselves might directly or indirectly

cause severe personal injury or property damage.

1.3 Protective clothing

FLOWSERVE products are often used in problematic

applications (e.g. extremely high pressures, dangerous,

toxic or corrosive mediums). In particular valves with

bellows seals point to such applications. When performing service, inspection or repair operations always

ensure, that the valve and actuator are depressurised and

that the valve has been cleaned and is free from harmful

substances. In such cases pay particular attention to

personal protection (protective clothing, gloves, glasses

etc.).

1 Using Flowserve Valves, Actuators and Acces-

sories Correctly

1.1 General usage

The following instructions are designed to assist in

unpacking, installing and performing maintenance

as required on FLOWSERVE products. Product users and maintenance personnel should thoroughly

review this bulletin prior to installing, operating or

performing any maintenance.

In most cases FLOWSERVE valves, actuators and

accessories are designed for specific applications

with regard to medium, pressure and temperature.

For this reason they should not be used in other applications without first contacting the manufacturer.

1.2 Terms concerning safety

The safety terms DANGER, WARNING, CAUTION

and NOTE are used in these instructions to highlight

particular dangers and/or to provide additional information on aspects that may not be readily apparent.

DANGER: indicates that death, severe personal

injury and/or substantial property damage will occur

if proper precautions are not taken.

WARNING: indicates that death, severe personal

injury and/or substantial property damage can occur

if proper precautions are not taken.

CAUTION: indicates that minor personal injury and/

or property damage can occur if proper precautions

are not taken.

1.4 Qualified personnel

Qualified personnel are people who, on account of their

training, experience and instruction and their knowledge

of relevant standards, specifications, accident prevention

regulations and operating conditions, have been authorised by those responsible for the safety of the plant to

perform the necessary work and who can recognise and

avoid possible dangers.

1.5 Installation

DANGER: Before installation check the order-no.,

serial-no. and/or the tag-no. to ensure that the valve/

actuator is correct for the intended application.

Do not insulate extensions that are provided for hot or

cold services.

Pipelines must be correctly aligned to ensure that the

valve is not fitted under tension.

Fire protection must be provided by the user.

1.6 Spare parts

Use only FLOWSERVE original spare parts. FLOWSERVE

cannot accept responsibility for any damages that occur from using spare parts or fastening materials from

other manufactures. If FLOWSERVE products (especially

sealing materials) have been on store for longer periods

check these for corrosion or deterioration before using

these products. Fire protection for FLOWSERVE products

must be provided by the end user.

NOTE: indicates and provides additional technical

information, which may not be very obvious even

2

to qualified personnel.

Page 3

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

STOP!

®

1.7 Service / repair

To avoid possible injury to personnel or damage to

products, safety terms must be strictly adhered to.

Modifying this product, substituting nonfactory parts,

or using maintenance procedures other than outlined

in this instruction could drastically affect performance

and be hazardous to personnel and equipment, and may

void existing warranties. Between actuator and valve

there are moving parts. To avoid injury FLOWSERVE

provides pinch-point-protection in the form of cover

plates, especially where side-mounted positioners are

fitted. If these plates are removed for inspection, service

or repair special attention is required. After completing

work the cover plates must be refitted.

Apart from the operating instructions and the obligatory

accident prevention directives valid in the country of

use, all recognised regulations for safety and good

engineering practices must be followed.

WARNING: Before products are returned to FLOWSERVE

for repair or service FLOWSERVE must be provided

with a certificate which confirms that the product has

been decontaminated and is clean. FLOWSERVE will

not accept deliveries if a certificate has not been provided (a form can be obtained from FLOWSERVE).

1.10 Unpacking

Each delivery includes a packing slip. When

unpacking, check all delivered valves and accessories

using this packing slip.

Report transport damage to the carrier immediately.

In case of discrepancies, contact your nearest

FLOWSERVE location.

1.8 Storage

In most cases FLOWSERVE products are manufactured

from stainless steel. Products not manufactured from

stainless steel are provided with an epoxy resin coating.

This means that FLOWSERVE products are well protected

from corrosion. Nevertheless FLOWSERVE products

must be stored adequately in a clean, dry environment.

Plastic caps are fitted to protect the flange faces to

prevent the ingress of foreign materials. These caps

should not be removed until the valve is actually mounted

into the system.

1.9 Valve and actuator variations

These instructions cannot claim to cover all details of

all possible product variations, nor can they provide

information for every possible example of installation,

operation or maintenance. This means that the

instructions normally include only the directions to

be followed by qualified personal where the product

is being used for is defined purpose. If there are any

uncertainties in this respect particularly in the event of

missing product-related information, clarification must

be obtained via the appropriate FLOWSERVE sales office.

3

Page 4

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

®

Introduction

The RG Series is a fully modular design, scotch-yoke ac-

tuator; with torque range from 2000Nm to 250,000Nm

(2,800 in-Lbs to 2.2 M in-Lbs) in eight models, RG1

through RG8, with maximum actuator torque and

mounting base in compliance with ISO 5211.

The RG series Spring Return Actuators, in contrast with

R-series, use Pull-to-Compress the spring design.

2 Installation

2.1 All actuators are factory lubricated for life, but still

should be protected from the elements and stored indoors until ready for use. The ports of the actuator are

plugged as supplied from the factory. If actuators are

stored for a long period of time prior to installation, follow the Long Term Storage instructions.

2.2 Prior to assembly, manually open and close valve (if

possible), to ensure freeness of operation. Be sure,

valve and Automax actuator rotate in the same direction

and are in the same position (i.e., valve closed, actuator

closed).

2.3 Check the mounting surfaces, the stem adaptor and

the bracket to assure proper fit. Secure the valve in the

closed position with the stem vertical. Bolt the bracket

to the valve and place the stem adaptor on the valve

stem. Position the actuator over the valve and lower, to

engage the stem adaptor to the actuator’s bore. Continue to lower until the actuator seats on the bracket

mounting surface. In order to align the bolt holes, it

may be necessary to loosen the valve-to-bracket bolting

to allow more play in the bracket. The mounting bolts

should easily fit into the bolt holes without any binding.

If needed, turn or stroke the actuator a few degrees and/

or adjust the actuator travel stops. Bolt the actuator to

the bracket.

tor several times to assure proper operation. The stem

adaptor should not bind during operation. If the actuator is equipped with an UltraSwitch or other accessories, adjust them at this time.

2.5 To prolong actuator life use only clean, dry plant air. Lubricated air is not required, however it is recommended

particularly for high cycle applications. Do not use lubricated air with positioners.

CAUTION! Lifting bolts holes on the actuator are for

lifting the actuator modules only with eye bolts, not a

complete valve and actuator assembly.

3 Travel Stop Adjustments

All actuated valves require accurate travel-stop adjust-

ments at both ends of the stroke to obtain optimum

performance and valve seat life. The accumulation of

tolerances in the adaption of actuators to valves is such

that there must be a range of adjustments for both ends

of the stroke to achieve optimum performance.

The RG actuators have travel stop adjustments in both

the clockwise and counter-clockwise directions. The

+/- 3 degree adjustment feature provides shaft rotation

from 84 to 96 degrees.

4 Maintenance Instructions

4.1 Disassembly Instructions

4.1.1 Disconnect all air and electrical supplies from actuator.

4.1.2 Remove all accessories from actuator and dismount actuator from valve.

4.1.3 Drawing References: Drg # 263188, Drg # 263189

2.4 Adjust the travel stop bolts of the actuator for the proper

open and closed valve positions, per valve manufacturer’s recommendations. Pneumatically stroke the actua-

Actuator Configuration

4 2

Fig.: 1 Spring Module

4

4.2 Spring Module (see Fig.: 1)

CAUTION! Personal Injury may result if Step 2 is at-

tempted before Step I is completed.

CW

CWW

4 2

Page 5

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

®

4.2.1 Apply air pressure to port 2 on FCW (port 4 on FCCW)

actuator, raising pressure slowly, enough to release

spring pressure from the Stop Bolt (17). Back off fully

both Stop Bolts on the Torque Module and release air

pressure. This will relieve the spring preload.

4.2.2 The Spring Module is welded into an integral component and cannot be disassembled. To remove from actuator, remove Spring Module end cover (60) and using an extended socket spanner /tube spanner, unscrew

and disconnect the Pull Rod (54) from the Torque Module.

CAUTION! Take extra care not to drop the socket/small

tools inside the spring can. Small objects dropped inside may fall through the spring guide and get stuck

in the spring coils.

NOTE: A retainer ring on the threaded side of the Pull

Rod stops it from being removed completely from the

Spring Module.

4.2.3 Sling the Spring Module using lifting bolts on the Module and remove the Adapter Nuts (19) and Lock washers (20).Spring Module can now be removed from the

Torque Module.

4.2.4 Before reassembling Spring Module to body, make sure

stud threads are clean of any dirt, shavings, or other

debris. Clean threads with rag and solvent if required,

and lubricate threads with an anti-seize compound.

NOTE: Support the Spring Module during removal so

as not to damage the Pull Rod and the studs’ threads.

4.3 Pressure Module

4.3.7 Remove the Retainer Ring (40) and take the Split

Collar (39) off the Piston Rod (35).Pull the Piston

Rod off the Piston.

4.4 Torque Module (Body Group)

NOTE: Spring Module and Pressure Module must

be removed before disassembling the Torque

Module

4.4.1 Remove the Indicator (29), if fitted.

4.4.2 Remove Top Cover Bolts (65) and the cover, O-ring

and the Namur Shaft Assembly (15).

4.4.3 Remove Body Cover Bolts, Lock Washers (26) and

Thread Plugs (31).

4.4.4 Using the removed Body Cover Bolts, jack open the

cover by threading in the bolts in the two tapped

holes until cover is separated enough to pry apart.

Take care to jack the bolts evenly, as the cover is

positioned by four dowel pins, and cross loading

may cause bending/ breakage of pins on small actuator sizes.

4.4.5 Gently tap with PU/Plastic hammer and pull off the

Guide Bar (2) from the body.

4.4.6 Lift Yoke Sub Assembly out of body bore.

4.4.7 Remove Delrin Plate (7) retaining screws. Pull out

the Yoke Pin (9), and Slider Block (10).

4.4.8 Slide out the Guide Block (11) out of the Yoke and

remove the bottom Slider Block.

4.3.1 Pressurize rod end of cylinder, enough to stroke to end.

Vent out the air from the cylinder.

4.3.2 Remove end cover plate/plug from pressure module

and unscrew the piston rod with a socket/tube spanner.

4.3.3 Sling the pressure module from the eye bolts, remove

the Adaptor Stud Nuts (19) and Lock washers (20) and

take the Pressure module off the Torque module.

4.3.4 Remove the Tie Rod Nuts (37), the End Plate (33) and

Tie Rods (36).

4.3.5 Slide the Cylinder (34) over and off the Piston (38), being careful not to scratch or dent the honed and chrome

plated surface of the cylinder.

4.3.6 Slide out the Piston- Piston Rod assembly off the

Adapter Plate (32).

4.4.9 Remove Yoke Seals (5) and Yoke Bushing (4) if

worn out/damaged.

4.5 Reassembly Instructions

4.5.1 Inspect all parts for wear and replace any worn

parts as needed. Normally, all O-rings and seals

should be replaced when reassembling an actuator.

Use seal lubricant, Dow Corning 55 for all lubrication in the pressure group.

Ensure the replacement seals are suitable for the

service temperature.

4.5.2 The Metal backed bronze-ptfe bearings may be inspected and assessed for replacement, referring to

guide (see Fig.: 2) on the useful residual life

To replace the bearings, the unit or the subassembly

5

Page 6

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

®

Fig.: 2 Residual Life Guide

needs to be brought in to workshop, with suitable

facilities to carefully remove the bearing without

damaging the housing and to press new bearing

with proper pressing tools per manufacturer’s instructions and a press.

Do not attempt to pry out any of the bearings in the

actuator with sharp tools, or hammer in a replacement bearing.

4.5.3 Clean thoroughly and grease all Torque Module

components with NLGI grade 2 multi-purpose

grease. Use Shell Alvania EP2 for Standard Actuators. For low temperature units, use Dow 55 grease

or equivalent.

4.5.4 Reverse the disassembly procedures to reassemble. Apply recommended torque, refer torque

chart, on the Tie Rod Locknuts, the Mounting Flange

Nuts, the Body Cover & Top Plate bolts, the Piston

Rod / Pull Rod (see tables on pafe 7.

The Tie Rod and Mounting Flange Stud threads

should be lubricated with Locktite Antiseize, 77164

or equivalent.

The Pull /Piston Rod threads and cover bolts to be

tightened with thread lock compound, Loctite 243

or equivalent.

4.5.5 Refer to parts and materials drawings for all required spare parts (see pages 9 + 10).

Test the actuator for smooth operation and air

leakage at service pressure before reinstalling into

service.

5 Field Conversion from Fail CW to Fail CCW

(For Spring Return Actuators)

The RG spring return actuator can be converted from

fail CW to fail CCW easily, without having to remove the

Torque Module, mounting bracket, stem adaptor and

the shaft driven accessories, mounted on the centre

body . Simply switch the positions of the Pressure and

Spring Modules.

Actuator Designation needs to be suitably changed on

the name plate.

Follow steps below, if operating the valve is permitted:

5.1 Apply enough air pressure to the actuator to relieve

spring load on the stopper bolt.

5.2 Back off both the stopper bolts on the Torque Module

and depressurize the actuator.

5.3 Remove Spring Module end cover, unscrew and disconnect the Spring Pull Rod.

5.4 Pressurize rod end of Pressure Module, to end of

stroke. Depressurize and remove the end cover/plug

on the Pressure Module. Use a tube/socket spanner,

loosen piston rod by one turn, fit back end cover/plug

and pressurize cap end, enough to stroke to end. Depressurize, remove end cover/plug and fully unscrew

and disconnect the piston rod from the Torque Module.

5.5

Remove the Pressure and Spring Modules off the Torque

Module by removing the mounting flange stud nuts.

6

Page 7

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

®

Bolt Torques

Fastner Model RG1 RG2 RG3 RG4 RG5 RG6 RG7 RG8

Thread Size M8 M10 M12 M12 M16 M16

Mounting Flange Nut

Body Cover Bolts

Top Plate Bolts

Stopper Bolt Locknuts

Piston Rod/Pull Rod

Tightning

torque

Thread Size M6 M6 M8 M8 M10 M10

Tightning

torque

Thread Size M6 M6 M8 M8 M10 M10

Tightning

torque

Thread Size M16 M20 M20 M30 M36 M48 M56 M64

Tightning

torque

Hex Size, A/F 18 18 24 30 36 46 65 85

Tightning

torque

ft Lb 10-12 18-22 30-35 30-35 80-90 80-90 140-160 280-320

kgm 1.4-1.7 2.5-3.0 4.2-4.8 4.2-4.8 11.0-12.5 11.0-12.5 19-22 38-44

ft Lb 3-5 3-5 10-14 10-14 18-22 18-22 26-30 26-30

kgm 0.5-0.7 0.5-0.7 1.4-2.0 1.4-2.0 2.5-3.0 2.5-3.0 3.5-4.0 3.5-4.0

ft Lb 3-5 3-5 10-14 10-14 18-22 18-22 22-26 22-26

kgm 0.5-0.7 0.5-0.7 1.4-2.0 1.4-2.0 2.5-3.0 2.5-3.0 3.0-3.5 3.0-3.5

ft Lb 75-85 90-100 90-100 100-110 120-130 140-150 175-200 200-240

kgm 10-12 12-14 12-14 14-15 16-18 19-21 25-28 28-33

ft Lb 30-35 35-45 50-60 60-75 75-85 100-140 175-200 200-240

kgm 4-5 4-5 7-8 8-10 10-12 13-19 24-28 28-33

Tie Rod Nut Torque

Cylinder Size (in.)

Tie Rod Nut Size

Tightening

Torque (ft Lb)

5.6 Switch the positions of the two modules, connect the

Pressure Module first and ensure the ports are on the

stopper bolts side of actuator. Thread in and torque the

piston rod to recommended value, fit back end cover

plate/plug. Pressurize cap end to stroke the actuator to

end.

5.7 Reinstall Spring Module, torque the pull rod to recommended value, fit end cover back. Pressurize rod end of

cylinder and adjust the stopper bolts.

5.8 Check actuator for proper operation, at the rated working pressure.

NOTE: If operation of valve is not permitted, during

changing of the Fail Safe direction, then the actuator

needs to be taken off the valve and reconfigured, as

explained above.

5 6 7 8 9 10 12 14 16 18 20 22 24 28 32 32T 36 36T 40

M10 M10 M10 M10 M12 M12 M16 M16 M20 M20 M24 M24 M30 M30 M30 M36 M30 M36 M30

8 11 14 19 28 34 64 88 143 181 268 325 485 330 431 1028 564 876 673

7

Page 8

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

®

Actuator Designation

How to Order

Body

Series

Size

1

2

3

4

5

RG

6

7

8

Model Code Example:

RG 5 22 SR 6 C N D GE TC

Cylinder Size Action

05 06 07 08 09 10 12

08 09 10 12 14 16

10 12 14 16 18 20

14 16 18 20 22 24

16 18 20 22 24 28

18 20 22 24 28 32 36

24 28 32 36 40

28 32 36 40

DA-

DD-

SR-

SO-

Double Acting Single Cylinder

Double Acting Dual Cylinder

Spring Return Fail CW

Spring Return Fail CCW

Spring

Torque Pattern

Module

(Yoke)

0 S-

Symmetrical N-Nitrile,

1 C-

Canted

2 H-

3 D-

4 L-

5

6

7

8

Sealing/Temp Manual Override Material/ Coatings Options

-20˚ F to 180˚ F

High Temp

(Viton),

0˚ F to 300˚ F

Low Temp,

(material)

-55˚ F to 180˚F

0-

None

G-

Sandwich Declutch Gbox

J-

Jackscrew

Bevel Gear Jackscrew

H-

Hydraulic

GE-

PO-

WE-

SP-

Grey Epoxy

Primer Only

White Epoxy

Specials

(std)

00-

TC-

TO-

TB-

S xxx-

None

Ext. Stopper -CW

Ext. Stopper -CCW

Ext. Stopper -Both Dir

Specials code

Body Size

1

2

3

4

5

6

7

8

DA DD SR/SO

9 8 12

12 10 16

16 14 20

20 16 24

22 20 28

28 24 36

36 32 40

40 40 40

Module Weights (approx.)

Torque

Model

Module

5 6 7 8 9 10 12 14 16 18 20 22 24 28 32 36 40 1 2 3 4 5 6 7 8

31

68

RG1

RG2

RG3

RG4

RG5

RG6

RG7

RG8

(14)35(16)47(22)53(24)66(30)94(43)

(31)

99

– – –

(45)

143

– – – – –

(65)

295

– – – – – – –

(134)

510

– – – – – – – –

(231)

933

– – – – – – – – –

(423)

1881

– – – – – – – – – – – – –

(853)

3718

– – – – – – – – – – – – –

(1686)

56

(25)69(32)99(45)

Max. Cylinder Size

139

– – – – – – – – – –

(63)

143

209

(65)

(95)

100

142

(64)

200

(91)

217

(99)

(45)

Pressure Module Spring Module

Module Weights, Lbs (kgs)

320

– – – – – – – –

(145)

318

406

561

(145)

339

(154)

356

(162)

(185)

427

(194)

455

(207)

493

(224)

– – – – – –

(255)

586

741

942

(266)

610

(277)

616

(280)

(337)

853

(388)

861

(391)

– – – –

(428)

994

1634

(452)

(743)

1051

1732

(478)

(787)

1824

(829)

2165

(984)

– – –

2321

3044

(1055)

(1384)

2411

3156

(1096)

(1435)

2819

3372

(1282)

(1533)

–

3913

(1779)

4159

(1891

88

(40)97(44)

128

(58)

226

(103)

402

(183)

639

(290)

1283

(583)

2283

(1038)

4627

(2103)

145

(66)

260

(118)

442

(201)

737

(335)

1738

(790)

2946

(1339)

5800

(2637)

101

(46)

154

(70)

267

(121)

462

(210)

770

(350)

1671

(760)

3043

(1383)

6113

(2779)

103

(47)

158

(72)

269

(122)

477

(217)

783

(356)

1730

(787)

3177

(1444)

6227

(2830)

106

(48)

158

(72)

276

(125)

510

(232)

901

(410)

2061

(937)

3630

(1650)

7111

(3232)

114

(52)

172

(78)

330

(150)

545

(248)

955

(434)

1995

(907)

3709

(1686)

7423

(3374)

119

(54)

180

(82)

321

(146)

565

(257)

– –

– –

– –

– –

119

(54)

186

(85)

–

581

(254)

8

Page 9

Drawing # 263188

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

®

SP

CHK

DATE

11/24/09

1

REVISIONS

2

DESCRIPTION

PULL ROD UPDATED

LTR

ZONE

1

REV

ECO NO

3

67

4

1

1

2

1

STEEL

PTFE BRONZE

ASTM A689 516 OH

ASTM A689 516 OH

BUSH

SPRING

SPRING

EYE BOLT

58

55

56

57

2

1

4

1

A

BGL

SITE

Flow Control Division

TM

HD ACTUATOR, RG SERIES

6/10/09

6/10/09

Ra

MACHINE FINISH

DESIGN FILE

SP

KNS

ENG BY

CHK BY

DRW BY

REF LAYOUT

NEXT ASSY

1/2

ANGLES

1

.75

.25

AND ARE AFTER PLATING.

THIRD ANGLE PROJECTION

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN MILLIMETERS

X..X.XX

4

1

1

1

4

STEEL

BUNA - N

BUNA - N

STEEL A-36

STEEL Gr 8.8

COVER

O-RING

O-RING

WASHER

BOLT M16

62

63

61

59

60

1

1

2

1

2

REV

1

1 OF 1

SHEET

1

263188

1:10

DRAWING NO.

SIZE

D

SCALE

2

ALL RIGHTS RESERVED

MATERIAL

COPYRIGHT - FLOWSERVE CORPORATION

R

INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND IS THE

EXCLUSIVE PROPERTY OF FLOWSERVE CORPORATION, DELIVERY

SUCH INFORMATION TO UNAUTHORIZED PERSONS IS FORBIDDEN.

OF THIS DOCUMENT OR ANY COPY THEREOF OR DISCLOSURE OF

UNSPEC RADII

TOLERANCES

DO NOT SCALE

PER ANSI Y14.5M - 1982

ARE IDEAL DESIGN DIMENSIONS.

DIMENSIONS WITH

ALL DIMENSIONS AND TOLERANCES

3

6

1

2

1

24

BUNA - N

UHMWPE

UNS S31600

STEEL Gr 8.8

CARBON STEEL

4

PIN

BOLT

O-RING

BUTTON

RET RING

64

65

67

68

66

1

1

1

1

1

D

4

9

1

2

11

7

12

56

63

10

3

26

19

5

13

52

64

57 58

51

DETAIL B

C

24

27

66

28

41

59

61

54

29

49

60

B

SECTION G-G

141521

65

53

6

30

22

1

1

1

MATERIAL QTY.

SA-216-WCB

SA-216-WCB

STEEL AISI 4340

END CAP

PULL ROD

DESCRIPTION

SPRING GUIDE

53

54

52

NO.

ITEM

1

4

4

68

5

6

7

45

35

3940

8

3D12Q1S\SKALANIDHI (11/24/2009 7:02:06 PM)

D

47

42

DETAIL A

DETAIL C

STEEL

RUBBER

SAE-4140

MATERIAL QTY.

SA-193-B7

50

16

17

8

65

31

G

18

19

20

C

38 4443

34 36

48

62

46

26

65

C

G

23

32

37

33

B

STEEL Gr 8

STEEL AISI 4340

ASTM A-536 Gr 60-40-18

PISTON

TIE ROD

LOCKNUT

PISTON ROD

DESCRIPTION

35

36

37

38

NO.

ITEM

1

12

12

12

STEEL

BUNA - N

MATERIAL QTY.

STEEL Gr 8

STEEL Gr 8.8

NUT

STUD

O-RING

WASHER

DESCRIPTION

21

19

20

18

NO.

ITEM

1

1

1

2

MATERIAL QTY.

PTFE BRONZE

STEEL AISI 4340

ASTM A-536 Gr 60-40-18

ASTM A-536 Gr 60-40-18

BUSH

COVER

GUIDE ROD

DESCRIPTION

CENTER BODY

1

2

3

4

NO.

ITEM

SPLIT COLLAR

39

1

BUNA - N

O RING

22

2

BUNA - N

O-RING

5

RUBBER

PTFE BRONZE

CARBON FILLED PTFE

BUSH

EYE BOLT

QUAD SEAL

WEAR RING

42

43

44

41

1

1

4

18

STEEL

SA-193-B7

STEEL A-36

PTFE BRONZE

PIN

BUSH

COVER

WASHER

24

25

26

27

2

2

1

12

DELRIN

B-150-C62400

STEEL AISI 4340

PIN

SCREW STEEL Gr 8.8

RETAINER

SLIDER BLOCK

9

7

8

10

BUNA - N

O-RING

QUAD SEAL

45

46

1

1

1

PLASTIC

BUNA - N

SCREW STEEL Gr 8.8

O-RING

INDICATOR

28

29

30

1

2

PTFE BRONZE

STEEL A-148 Gr. 90-60

BUSH

GUIDE BLOCK

11

12

UNS S31600

RET RING

40

2

BUNA - N

O-RING

23

1

ASTM A-536 Gr 60-40-18

YOKE

6

A

BUNA - N

BUNA - N

STEEL A-36

SA -216-WCB

STEEL SA-53-B

PIPE

O-RING

O-RING

ADAPTOR

COVER PLATE

51

47

48

49

50

1

1

1

2

SA-106 -B

ASTM A-536 Gr 60-40-18

ASTM A-536 Gr 60-40-18

SCREW STEEL Gr 8.8

END CAP

CYLINDER

ADAPTOR

34

33

31

32

2

1

1

2

2

STEEL Gr 8

UNS S31600

UNS S31600

STEEL Gr 8.8

PTFE BRONZE

NUT

BUSH

PLATE

SHAFT

STOP BOLT

13

14

15

16

17

5

6

7

8

9

Page 10

Drawing # 263189

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

®

SP

CHK

DATE

11/24/09

1

REVISIONS

2

DESCRIPTION

PULL ROD UPDATED

D

LTR

ZONE

1 2

REV

ECO NO

3

4

5

6

7

53

65

1

1

24

MATERIAL QTY.

PTFE BRONZE

BOLT

BUSH

PULL ROD ALLOY STEEL

SHORTDESC

#

52

53

54

NO.

4

1

4

STEEL

MATERIAL QTY.

PLATED STEEL

DUCTILE IRON

PISTON

LOCKNUT

SHORTDESC

SPLIT COLLAR

35

36

37

NO.

1

1

12

STEEL

BUNA - N

BUNA - N

MATERIAL QTY.

STUD

O RING

O-RING

SHORTDESC

18

20*

19*

NO.

1

1

1

A

BGL

SITE

Flow Control Division

TM

EXPLODED VIEW, HD ACTUATOR,

RG SERIES

Ra

03/30/09

03/30/09

MACHINE FINISH

MATERIAL

DESIGN FILE

SP

KNS

DRW BY

UNLESS OTHERWISE SPECIFIED

1

ALLOY STEEL

SPRING

55

1

STEEL

RING

RET

38

2

BUNA - N

O-RING

21*

2

R

ENG BY

CHK BY

REF LAYOUT

UNSPEC RADII

NEXT ASSY

1/2

ANGLES

1

.75

.25

AND ARE AFTER PLATING.

THIRD ANGLE PROJECTION

DIMENSIONS ARE IN MILLIMETERS

X..X.XX

1

4

1

4

1

1

6

2

STEEL

STEEL

PLASTIC

BUNA - N

BUNA - N

BUNA - N

ALLOY STEEL

CARBON STEEL

BOLT

COVER

SPRING

O-RING

O-RING

O-RING

BUTTON

WASHER

*

*

*

56

57

58

59

62

60

61

63

2

1

1

2

1

2

1

1

PTFE

STEEL

RUBBER

RUBBER

BUNA - N

BUNA - N

PTFE BRONZE

C FILLED

CARBON STEEL

BOLT

BUSH

O-RING

O-RING

QUADSEAL

QUAD SEAL

WEAR RING

COVER PLATE

39

46

41*

42*

43*

44*

45*

40#

1

4

1

1

1

1

2

12

STEEL

PLASTIC

BUNA - N

ALLOY STEEL

ALLOY STEEL

PTFE BRONZE

PLATED STEEL

CARBON STEEL

PIN

BUSH

SCREW

SCREW

COVER

O-RING

WASHER

WORCESTER

23

24

25

26

27

29

28*

22#

2

1

2

1

2

1

2

12

REV

1

1 OF 1

SHEET

1

263189

1:20

DRAWING NO.

SIZE

D

SCALE

2

ALL RIGHTS RESERVED

COPYRIGHT - FLOWSERVE CORPORATION

INFORMATION IN THIS DOCUMENT IS CONFIDENTIAL AND IS THE

EXCLUSIVE PROPERTY OF FLOWSERVE CORPORATION, DELIVERY

SUCH INFORMATION TO UNAUTHORIZED PERSONS IS FORBIDDEN.

OF THIS DOCUMENT OR ANY COPY THEREOF OR DISCLOSURE OF

TOLERANCES

DO NOT SCALE

PER ANSI Y14.5M - 1982

ARE IDEAL DESIGN DIMENSIONS.

DIMENSIONS WITH

ALL DIMENSIONS AND TOLERANCES

3

1

2

1

12

18

4

STEEL

STEEL

STEEL

STEEL

STAINLESS STEEL

NUT

PIN

BOLT

RET RING

WASHER

64

68

65

66

67

5

1

1

1

1

1

BUNA - N

DUCTILE IRON

CARBON STEEL

CARBON STEEL

CARBON STEEL

PIPE

O-RING

END CAP

ADAPTOR

SPRING GUIDE

6

48

49

50

51

47*

1

1

1

1

4

STEEL

ALLOY STEEL

ALLOY STEEL

DUCTILE IRON

DUCTILE IRON

CARBON

TIE ROD

7

END CAP

ADAPTOR

CYLINDER

PISTON ROD

30

31

32

33

34

2

1

1

2

2

D

52

50

67

51

62

48

*

61

*

63

64

24

#

54

18

*

63

32

47*

46

44*

35

39

C

57

59

58

*

60

61

49

5*

4#

1

67

9

30

39

34

37

45*

31

36

2

6

10

7

8

20*

23

3

68

29

43*

33

37

B

62

MARKED PARTS

#

MARKED PARTS

*

SERVICE KITS CONTAINS

SEAL KITS CONTAIN

2.

1.

NOTE:

12#

16

13#

11

10

53

65

26

15

28*

40#

17

21*

4#

5*

14

25

53

27

ITEM

24

19*

ITEM

ITEM

AL BRONZE

ALLOY STEEL

PTFE BRONZE

DUCTILE IRON

PIN

BUSH

SLIDER BLK

GUIDE BLOCK

9

10

11

12#

STEEL

STEEL

PTFE BRONZE

STAINLESS STEEL

STAINLESS STEEL

NUT

BUSH

PLATE

SHAFT

STOP BOLT

14

15

16

17

13#

8

STEEL

PLASTIC

BUNA - N

MATERIAL QTY.

ALLOY STEEL

PTFE BRONZE

DUCTILE IRON

DUCTILE IRON

DUCTILE IRON

8

D

37

38

C

42*

41*

B

SHORTDESC

CENTER BODY

1

NO.

ITEM

BUSH

COVER

O-RING

GUIDE ROD

2

3

5*

4#

YOKE

RETAINER

6

7

A

SCREW

8

10

Page 11

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

®

6 Torque Shaft

The output shaft is recommended to have two key en-

gagements. Shaft material shall be alloy steel with minimum yield strength of 85,000psi. The recommended

hardness of keys is 25-28HRc.

Recommended engagement length of the keys is as be-

low (see Fig.: 3).

Model Lk (mm) Lo (mm)

RG1

RG2

RG3

RG4

RG5

RG6

RG7

RG8

165 180

195 210

200 215

255 270

300 315

350 375

500 515

585 610

L

k

L

o

Fig.: 3 Key Length

7 Long Term Storage

It is recommended to take precautions and certain

measures when storing the actuators for extended

periods of time, more than 4 months to two years.

Potential problems and recommended protections

are as below:

Potential Problem Protection

Water entry into pneumatic cylinder, degrades the cylinder, particularly in saline or corrosive environment.

Temperature swings cause condensation inside cylinders

Seal compression set Cycle actuator 5-6 times with clean dry instrument air or nitro-

Degradation of seals in excessively corrosive or hot environments

Physical damage to actuator or accessories. Store actuator assembly on skid, off the floor, out of pathways.

• Store actuator in clean, dry and protected warehouse, or under ventilated dust cover.

• Plug all ports after purging with dry instrument air or nitrogen.

• Store vertical, to avoid seal set.

gen, every 3 months.

• Do not store in locations subjecting the actuator to temperatures in excess of seal rating. Std seals are Nitrile, max

temp 180deg F.

• Do not store in environments harmful to resilient seals.

Inspect the protections every 3 months and record inspection results.

11

Page 12

Contact:

User Instructions RG Series Standard Actuator - AXENIM0122-00 12/09

®

All data subject to change without notice

© ©12.2009 Flowserve Corporation. Flowserve and Kämmer are trademarks of Flowserve Corporation

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected this Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser

or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot

provide specific data and warnings for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/

user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate they are supplied for informative purposes only and should not be considered certified or as a guarantee of satisfactory results by reliance thereon.

Nothing contained herein is to be construed as a warranty or guarantee, expressed or implied, regarding any matter with respect to this product. Because Flowserve is continually improving and upgrading its product design, the specifications,

dimensions and information contained herein are subject to change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

Flowserve Corporation

Flow Control Division

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone: +931 432 4021

Fax: +931 432 5518

www.flowserve.com

Flowserve Corporation

Flow Control Division

1350 North Mountain Springs Parkway

Springville, Utah 84663-0913 USA

Phone: +801 373 3028

Fax: +801 489 2228

Flowserve Pte Ltd

No. 12 Tuas Avenue 20

Singapore 638824

Phone: +65 6879 8900

Fax: +65 6862 4940

Flowserve Flow Control (UK) Ltd.

Burrell Road

Haywards Heath

West Sussex United Kingdom

RH16 1TL

Phone:

+44 1444 314400

Fax:

+44 1444 314401

Automax

Im groß Rohr 2

Limburg, Hessen 65549

Germany

Phone: +49 (0)6431 96610

Fax: +49 (0)6431 966130

Flowserve Ahaus GmbH

von-Braun-Str. 19a

48683 Ahaus

Phone: +49 2561 686-119

Fax: +49 2561 686-109

Flowserve Flow Control GmbH

Actuators and Auto mation Center

Germany

Rudolf Plank Str. 2

D-76275 Ettlingen

Germany

Phone +49 (0)7243 103 0

Fax +49 (0)7243 103 222

Flowserve Flow Control Benelux BV

Rechtzaad 17

4703 RC Roosendaal NB

Netherlands

Phone: +31 165 598 800

Fax: +31 165 555 670

Flowserve Australia Pty Ltd

Flow Control Division

14 Dalmore Drive

Scoresby, Victoria 3179

Austrialia

Phone: +61 3 9759 3300

Fax: +61 3 9759 3301

Flowserve S.R.L

Via Prealpi 30

Cormano MI Italy I - 20032

Phone:

+39 02 663251

Fax:

+39 02 6151863

Flowserve do Brasil Ltda

Rua Tocantins, 128 - Bairro Nova Gerti

São Caetano do Sul,

São Paulo 09580-130 Brazil

Phone: +5511 4231 6300

Fax: +5511 4231 6329 - 423

Unit 01\02\06\07 9F

China Fortune Tower

No. 1568, Century Avenue, Pudong

Shanghai China 200122

Phone: +86 21 38654800

Fax: +86 21 50811781

Flowserve Corporation

No. 35, Baiyu Road

Suzhou Industrial Park

Suzhou 215021, Jiangsu Province,

PRC

Phone: +86-512-6288-1688

Fax: +86-512-6288-8737

12

Loading...

Loading...