Page 1

AXAIM032-00 (AUTO-97) 3/02 Page: 1 of 2

© 2002, Flowserve Corporation, Printed in USA

Flowserve Corporation 765 South 100 East 1978 Foreman Dr.

Flow Control Division Provo, Utah 84606 Cookville, TN 38501

www.flowserve.com Phone: 801 373 3078 Phone: 931 432 4021

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Mechanical Installation

Installation is best performed with our NAMUR mounting

kits. These kits allow direct mounting of the Resin Aviator

™

shaft to the actuator pinion without a coupler. NAMUR

mounting kits will work with any actuator conforming to the

NAMUR standard for accessory mounting hole locations

and pinion dimensions. Simply attach bracket to actuator

and Resin Aviator™to bracket with the included fasteners.

The Resin Aviator™shaft features an integral alignment pin

which engages the tapped pinion hole. Automax also offers

a full line of non-NAMUR kits.

Electrical Connections

The Resin Aviator™features one (1) 1/2" NPT conduit entry.

The switches and pilot solenoid are pre-wired to a terminal

strip to simplify customer wiring connections. A wiring

diagram is included under the lid. Simply make desired

connections to the pre-wired screw terminal block. Secure a

grounding wire under the green grounding screw. Make

sure the solenoid control voltage is the same as the

solenoid electrical rating. For hazardous locations, U.L. and

National Electric codes require an approved sealing fitting

within 18 inches of the switch enclosure. Sealing fittings are

not required for Division 2 non-incendive applications. Open

conduit entries must be closed after installation using a

close-up plug approved for hazardous locations. Conduit

and plugs must engage a full five (5) threads.

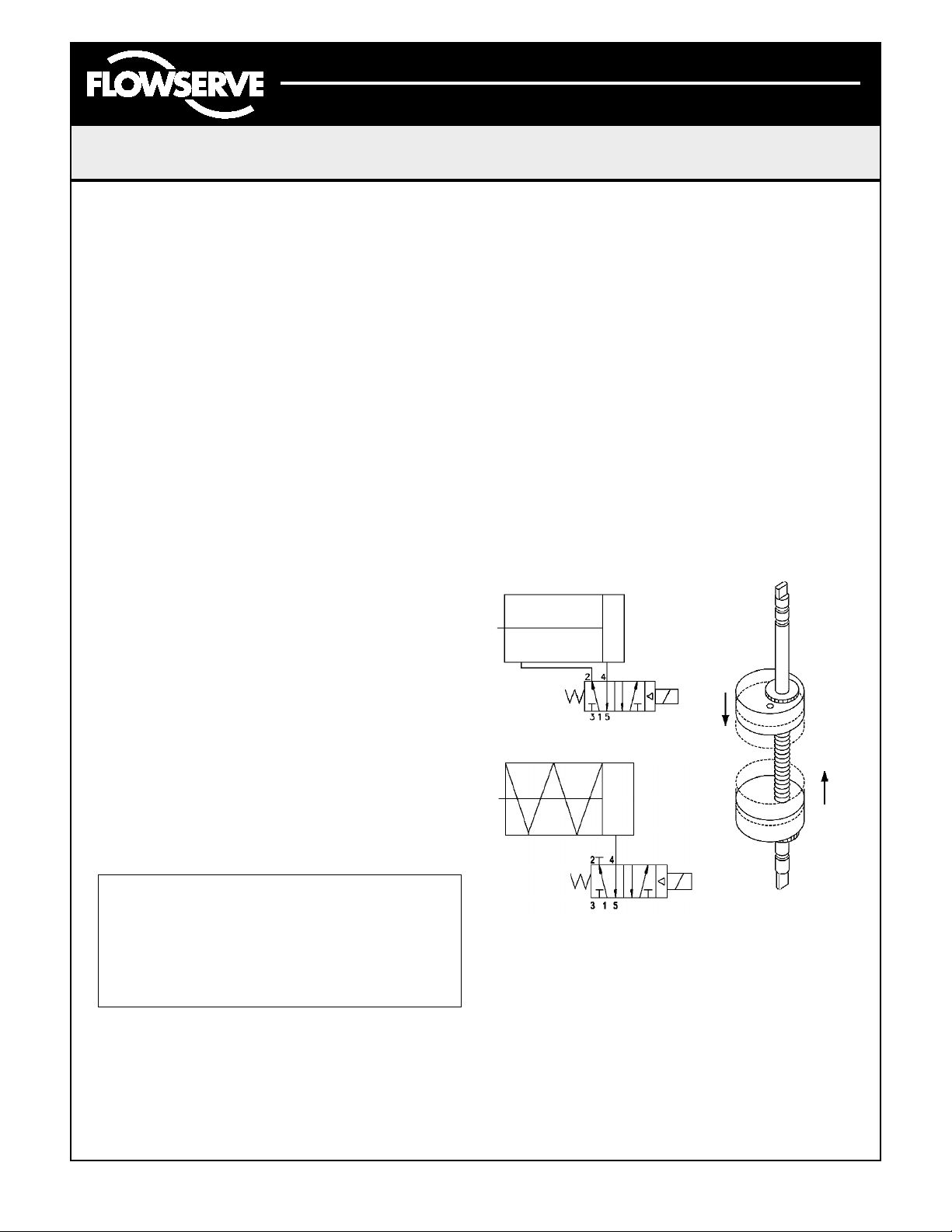

Spool and Tubing Configuration

1. For spring return actuators, a 4-way spool valve is

provided with port #2 plugged. For double acting

actuators, the same valve is provided with no plugs.

Make sure the correct spool is selected before

installing tubing. (Note: the APS2 module can be

supplied on spring return actuators to purge the spring

chamber with supply air.)

2. Make sure all air pressure is removed before

installing tubing.

3. Attach tubing according to Figures 1 or 2 below,

depending upon application. Attach supply tubing to

Port 1 and use Ports 3 and 5 for exhaust.

4. To prolong actuator life use only clean, dry plant air.

Lubricated air is not required, although it is

recommended particularly for high cycle applications.

Caution:

To prevent ignition of hazardous

atmospheres, keep all cover bolts tight

WHILE CIRCUITS are live. Disconnect

supply circuit before opening.

Figure 1

Figure 2

Figure 3

Resin Aviator

™

Switch Setting

1. Rotate actuator to desired position.

2. Loosen five captive cover screws and remove lid,

turning slightly while lifting.

3. To adjust the limits, lift or depress cam against spring

to disengage splines and turn cam until switch

activates/deactivates as desired (Figure 3).

4. Release cam, assuring that the splines are engaged.

5. Clean base and lid flanges and replace lid on base.

Make sure wires are NOT caught between flanges, and

tighten captive screws.

Page 2

AXAIM032-00 (AUTO-97) 3/02 Page: 2 of 2

© 2002, Flowserve Corporation, Printed in USA

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East 1978 Foreman Dr.

Flow Control Division Provo, Utah 84606 Cookville, TN 38501

www.flowserve.com Phone: 801 373 3078 Phone: 931 432 4021

Lubrication

All Resin Aviator™spool valves are pre-lubricated and will

operate dry (with no additional lubrication). The use of

lubricated air will not interfere with the Aviator’s

functioning. If air lubrication is used, the oils listed below

are popular, easily obtainable fluids that are recommended

for use with the Resin Aviator™Spool valve:

Gulf Harmony 47, Mobil DTE Medium, Shell Tellus 29,

Texaco Rondo B, Sohivis 47 and Sunnis 921. Many other

lubricants are acceptable providing they do not contain

detergents that will attack Buna N or Viton Seals.

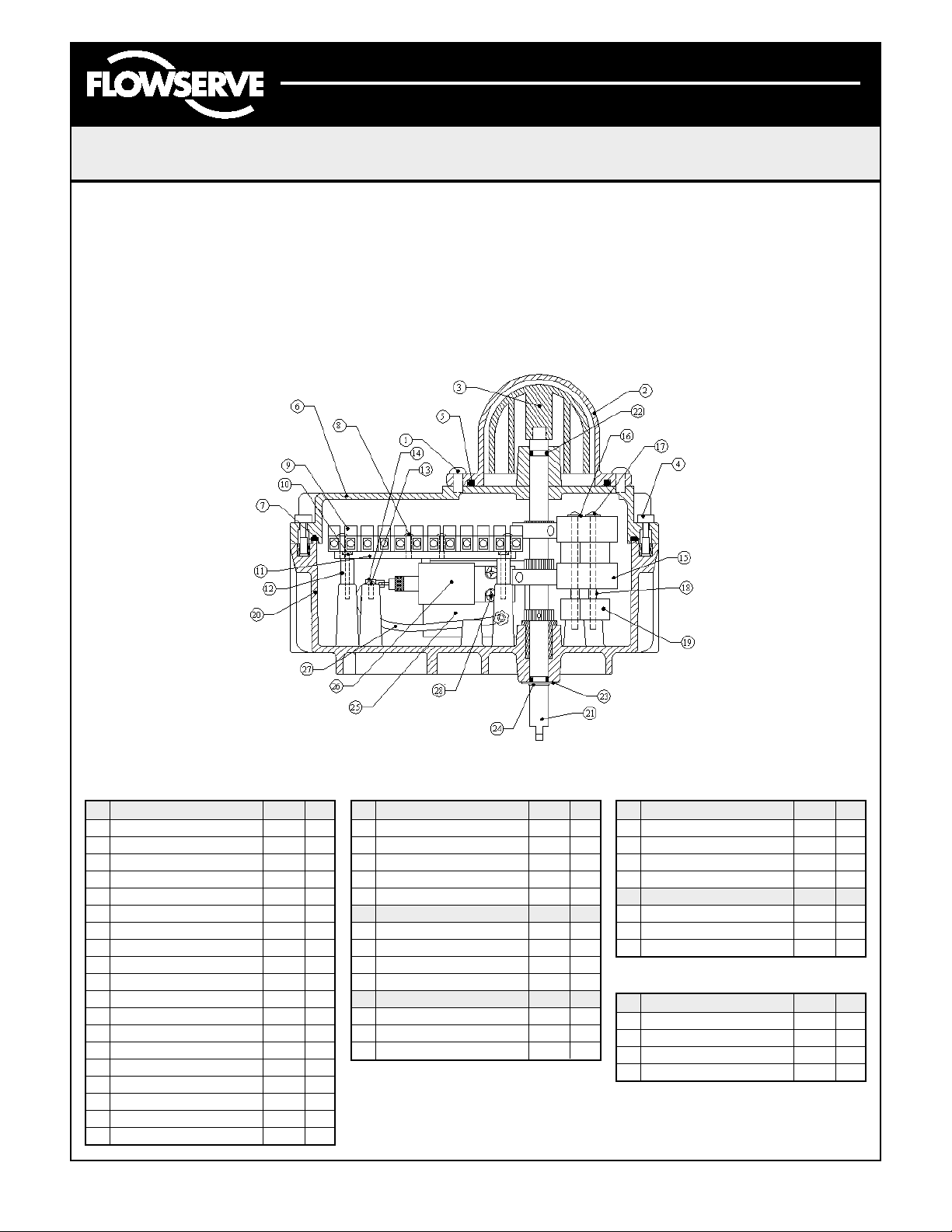

Part Numbers

How to Specify

NO. ITEM P/N QTY

1 10-24 x 1/2 Phillips Head Screw X00676 4

2 Ultra Dome X00662 1

3 Rotor X00663 1

4 10-24 Capture Screw X00360 6

5 O-ring X00677 1

6 Cover XM0310 1

7 Gasket X00981 1

8 4-40 x 1/2 Phillips Head Screw X00318 4

9 Terminal Block, 12 Position 103683 1

10 4-40 x 1/2 Phillips Head Screw 100518 2

11 Bracket, Terminal Block XM0063 1

12 Spacer, 0.68" High 104158 2

13 4-40 x 3/16 Ground Screw 104147 1

14 8-32 Ground Cup Washer 105626 1

20 Base XM0311 1

21 Shaft Assembly Varies 1

22 O-ring 103603 1

23 Washer X00361 1

24 Snap Ring 101810 1

Switch Options

NO. ITEM P/N QTY

15 Proximity Switch Varies 2

16 4-40 Washer X00425 2

17 4-40 x 2.25 Phillips Head Screw 106130 2

18 Spacer, 0.2" High 105679 2

19 Spacer X00691 2

SPDT Mechanical Switch Varies 2

4-40 x 1.125 Phillips Head Screw 100159 2

Insulator 103675 2

Spacer, 0.2" High 105679 2

DPDT Mechanical Switch 103628 2

4-40 x 1.125 Phillips Head Screw 100159 2

Insulator 103675 2

Solenoid Options

NO. ITEM P/N QTY

25 Manifold, 2 Watt Coil Varies 1

26 2 Watt Coil Varies 1

27 1/8 Tubing X00837 1

28 4-40 x 1 Phillips Head Screw 100158 2

Manifold, 0.67 Watt Coil Varies 1

0.67 Watt Coil Varies 1

1/8 Tubing X00837 1

Spool Valve Options (Not Shown)

NO. ITEM P/N QTY

Spool Valve Varies 1

O-ring X01039 Varies

10-32 x 1.5 Socket Head Screw X00784 3

Muffler Varies 2

Loading...

Loading...