Page 1

McCANNA Actuation Systems

17710-B

Ramcon Series 8/25 C/CR, 50/100 B/BR, 250/500 B/BR

Electric Actuators

Installation, Operation and Maintenance Instructions

Contents

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Repairs – Warranty Terms and Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Illustrations

Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

8C-25C Unidirectional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

8CR-25CR Reversible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

50BR-100BR Reversible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

250BR-500BR Reversible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Page 2

2 17710-B

Flow Control Division

McCANNA Actuation Systems

Storage

If the actuator is not to be installed as soon as received, heated

indoor electrical instrument storage conditions must be provided. The

actuator and any auxiliary equipment should be protected from

corrosive materials and atmosphere, flooding, and dirty conditions.

Conduit openings should be plugged and must not be subjected to

rain, snow or water hosing. Storage must be in a place where other

materials will not be placed or dropped on the actuator.

Installation

Installation of this actuator in applications where life-threatening

conditions can be expected must include adequate

monitoring/warning, interlock, and/or redundant control equipment.

Electrical

A. The wiring and conduits must be installed in accordance with all

local codes and consistent with good practice for electrical work.

B. In hazardous areas the conduit seals required must be locally

installed. No conduit seal is provided in the actuator.

C. If the actuator case is used as a splice box, the cover must be

kept in place except when actually wiring or making adjustments.

When replacing the cover all wires must be clear of pinch and

scrape points and, if gasketed, proper gasket positioning must be

observed.

D. Each actuator must have its own control switch. Do not operate in

parallel with another actuator or other equipment.

E. Required and optional electrical connections are shown on the

wiring schematic(s) supplied with the actuator (located either on

the motor O.D. close to terminal block or inside of the housing)

and also shown on page 3.

CAUTION: The typical wiring schematics shown may not show

all wiring for actuators with optional features and must not be

used as the basis for final wiring.

Single-phase AC actuator: (Verify that the nameplate voltage is the

same as the AC supply voltage.) Connect actuator leads to the AC line

as shown on the wiring schematic.

DC actuator: (Verify that the supply voltage matches the nameplate

voltage.) The actuator rotation depends upon polarity at the terminals

and it is essential that the polarity of connections be as shown on the

wiring schematic supplied with the actuator.

Mechanical

A. The valve or other load to be driven must be free of obstructions

and must turn freely throughout its entire operating range.

B. If mechanical stops are a part of the equipment, adjustment of

these stops is necessary to avoid contact during normal

operation. Limit switch must stop motor before mechanical stops

are contacted.

C. If the actuator is to be field-mounted be sure that it is positioned

so that the operating range is compatible with the load; i.e., if load

is at its extreme clockwise position the actuator output shaft must

also be at the same clockwise limit.

D. When positioning the actuator for a direct in-line connection to a

valve, the two shaft centerlines must coincide to assure proper

operation and to avoid excessive side loading of either shaft. A

coupling with cross slots will provide some compensation for

small misalignment. Position so that there is not axial loading of

either shaft at any point of travel.

E. If connection is other than direct coupling, the linkages used must

operate freely and must be clear of all obstructions throughout

the complete travel range.

F. Unless specifically required to make other adjustments, the

actuator shaft travel for standard units will be clockwise when

viewed from the motor and cam side, or counter-clockwise when

viewed from the mounting flange side of the actuator with the

yellow and red circuit energized. The same is true for DC

actuators with polarity connection as shown on the wiring

schematic. Reversible actuators (standard configurations) will

rotate counter-clockwise, motor and cam end, when the yellow

and black leads are energized.

G. If adjustments are required, cam settings can be changed. (See

figures 1, 2, 3, and 4)

Maintenance

Maintenance recommendations given are for the typical or average

installation conditions. In severe installation conditions including

items such as corrosives, extremes of heat and cold, humidity, etc.,

and where the potential for dangerous or life-threatening conditions in

case of malfunction exist, more frequent and thorough maintenance

procedures will be required. Local conditions and procedures must be

used to determine an appropriate inspection and/or maintenance

program.

The McCANNA Ramcon electric actuator is completely enclosed by a

rugged housing designed to resist the most frequently encountered

installation atmospheres, and contains a closed, grease-filled gear

train. All standard AC motors are brushless induction types with no

commutators or brushes to wear or get dirty. For many installations

no formal or only minimum maintenance procedures will be required.

Page 3

17710-B 3

Flow Control Division

McCANNA Actuation Systems

NOTE: Series 23 includes models 8C, 8CR, 25C and 25CR. Series 14

includes models 50B, 50BR, 100B and 100BR. Series 16 includes

models 250BR and 500BR

Page 4

4 17710-B

Flow Control Division

McCANNA Actuation Systems

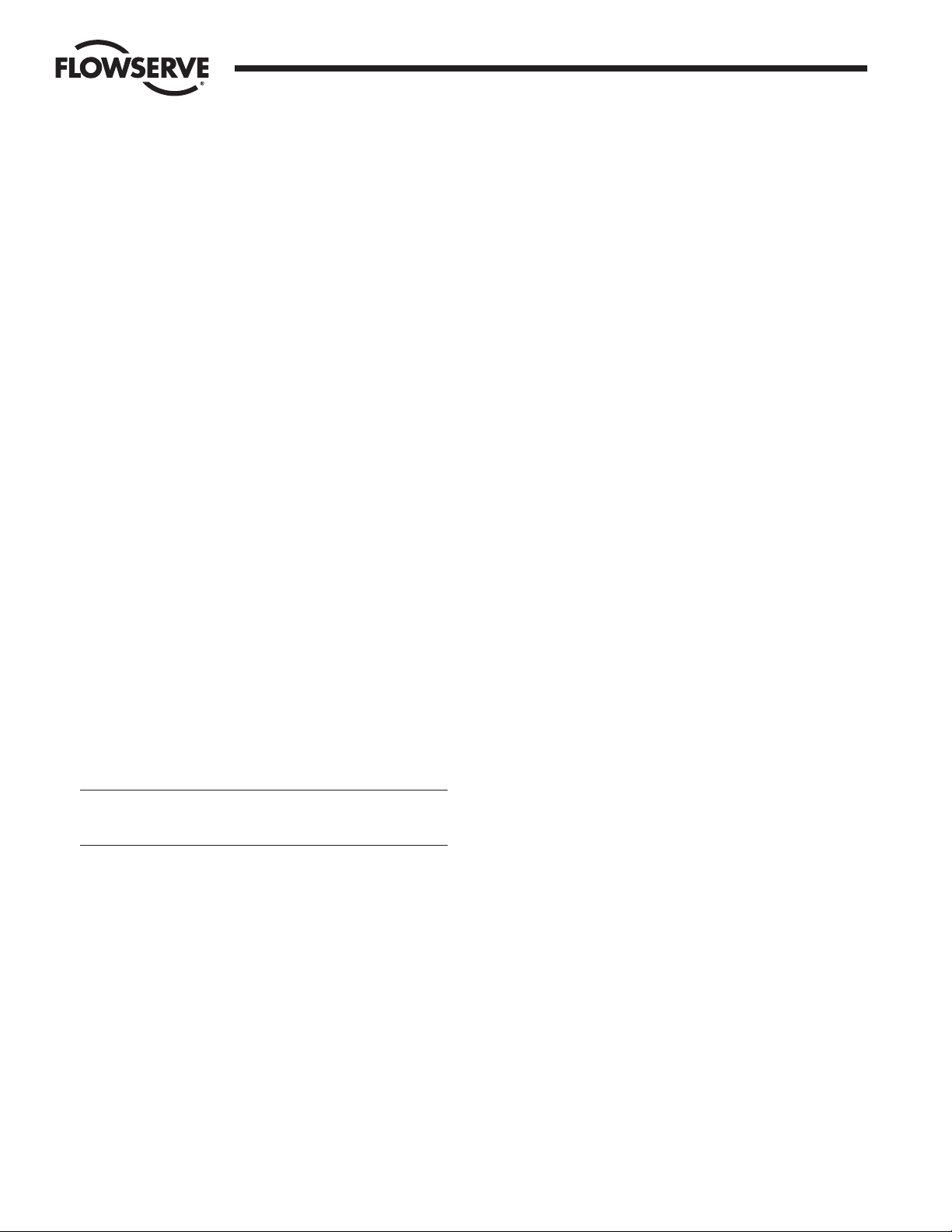

Figure 1: 8C-25C Unidirectional

Figure 2: 8C-25CR Reversible

Page 5

17710-B 5

Flow Control Division

McCANNA Actuation Systems

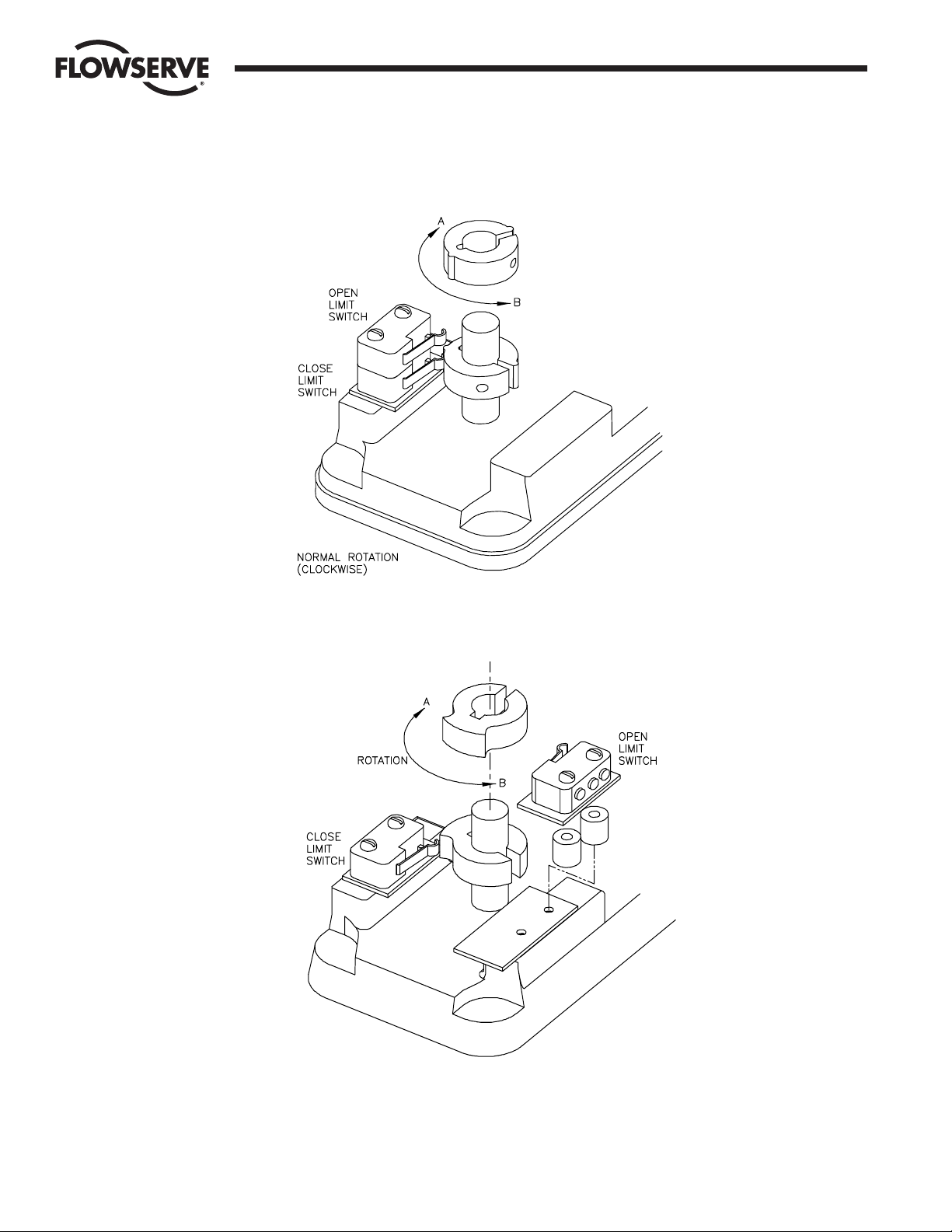

Figure 3: 50BR-100BR Reversible

Figure 4: 250BR-500BR Reversible

Page 6

6 17710-B

Flow Control Division

McCANNA Actuation Systems

A. Inspection

Inspect the actuator regularly to check:

• Any evidence of corrosion

•To make sure alignment is maintained relative to the load.

• That the actuator case has not been physically damaged.

• For excessive dirt and water entering actuator cases. (Clean

and correct as necessary).

• For evidence of loosening or shifting of parts due to vibration,

shock, wear or other conditions.

•Free action of brake and proper electrical release and holding

with no power.

• Any evidence of overheating.

• Any cracking or damage to wire joint and/or insulation.

• Any evidence of arcing or electrical shorts.

Under normal conditions, this inspection may be at intervals of

six months to a year. Where conditions are more severe, the

inspection should be at more frequent intervals as dictated by the

actual conditions. In all cases the consequences of a failure

should be a factor determining frequency of inspection or

servicing.

Always promptly check actuator in any case of malfunction or

erratic operation, and correct the cause.

B. Spare Parts

There has been no history of failure or weakness in any category

of parts which would dictate stocking of spares. Some users have

stocked items such as motors, capacitors, switches, gear trains,

complete actuators, or their combinations of parts and assemblies

depending upon their local conditions and requirements of

uninterrupted service.

When spare parts are required, include actuator model, and

description of part(s).

C. Repairs – Warranty Terms and Conditions

Before attempting repairs, modifications or addition of equipment

to the actuator by non-authorized personnel, the following

warranty terms and conditions should be reviewed.

Flowserve warrants its products against defects in materials and

workmanship for a period of one year from date of shipment from

its factory provided the equipment is properly installed and

operated. Liability is limited to repair, return of purchase price, or

replacement of any parts shown to be defective, and does not

extend to damage caused by accident, misuse, abuse, neglect,

tampering, or deterioration by corrosion. Products or parts not

manufactured by Flowserve are warranted only for the extent of

the original manufacturer’s warranty. There are no implied

warranties of fitness for a particular purpose. In no event shall

Flowserve be liable for loss of profits, loss by plant shutdown,

increased expense of operation, or other special or consequential

damages.

Should repair be necessary due to damage, wear, or malfunction,

identify any parts which may be required and contact your

McCANNA Ramcon Distributor or the factory. If it is necessary to

disassemble the actuator, observe proper orientation of all parts

and proper routing of all wires. Contact the factory for major

repair and RMA (Return Material Authorization) number.

Adjustments

NOTE: See Figures 1-4.

Unidirectional

TO ADJUST OPEN

1. Loosen set screw on second level cam

2. Rotate cam in direction “A” to reduce overtravel, “B” to reduce

undertravel

3. Tighten set screw

4. Run actuator to verify proper settings

TO ADJUST CLOSE

1. Loosen set screw on bottom cam

2. Rotate cam in direction “A” to reduce overtravel, “B” to reduce

undertravel

3. Tighten set screw.

4. Run actuator to verify proper settings

Reversible

TO ADJUST OPEN

1. Loosen set screw on second level cam

2. Rotate cam in direction “A” to reduce undertravel, “B” to reduce

overtravel

3. Tighten set screw

4. Run actuator to verify proper settings

TO ADJUST CLOSE

1. Loosen set screw on bottom cam

2. Rotate cam in direction “A” to reduce overtravel, “B” to reduce

undertravel

3. Tighten set screw.

4. Run actuator to verify proper settings

Page 7

17710-B 7

Flow Control Division

McCANNA Actuation Systems

Troubleshooting

Power interruption due to power

failure or from loose or broken

wires, tripped circuit breakers, etc.

High voltage causing burnout.

Shorted switches or other electric

components due to foreign material

or wiring not properly routed.

Correct position of declutch lever

(250BR, 500BR).

Damaged or corroded switch

contacts.

Low Voltage.

Capacitor function.

Gear Train free.

Motor alignment.

Brake not releasing.

Stops operating

Cam may be loose on the shaft.

Cam may be worn and miss the limit

switch.

Switch mounting may be loose.

Switch may be stuck on its closed

position.

Cam shaft may be bent away from

the switch.

Continuous turning

in one direction on

reversible actuator

Continuous turning

during one of the

travel segments on

unidirectional actuator

Reduced torque output

Hot areas, either line or ambient.

Excessive duty cycle.

Stalling due to incorrect cam setting.

(See Paragraph B under Mechanical

on page 2).

Obstruction preventing cam travel to

switching point.

Forward and reverse windings

powered at the same time.

Overheating

Power not getting to the motor.

Limit switch open.

Switch contact resistance.

Capacitor function on AC actuators.

Brush/commutator continuity on DC

actuators.

Optional brake not being released (not

wired, coil problems or relay

problems).

Actuator will not run

Brake not releasing.

Excessive torque in valve.

Both limit switches being powered

(control circuit or wiring).

Both motor windings being powered

(within actuator).

Actuator runs slower

than rating

Gear train may be worn, broken, or

incorrectly assembled in the field.

Correct position of declutch lever

(250BR, 500BR)

Motor turning but

output shaft stationary

Problem

Check for ...

Problem

Check for ...

NOTICE

McCANNA actuators are designed and manufactured using good workmanship and materials, and they meet all applicable industry standards.

Flowserve is anxious to avoid injuries and property damage which would result from misapplication of the product. Proper selection is

imperative. Examples of misapplication or misuse include use in a service in which the pressure/temperature rating is excessed or in a chemical

service incompatible with the materials of construction; use of undersized actuators; use of extremely fast actuation and/or continuous cycling on

standard product; making modifications of the product of any kind; failure to use caution on operating in high-temperature, high-pressure, or

highly hazardous services; failure to maintain product as recommended.

Page 8

Flow Control Division

McCANNA Actuation Systems

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, contact www.flowserve.com or call USA 1-800-225-6989.

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

McCANNA Actuation Systems

5114 Woodall Road,

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone (434) 528-4400

Fax (434) 845-9736

© 2003 Flowserve Corporation, Irving, Texas, USA. Flowserve and McCANNA are registered trademarks of Flowserve Corporation. 17710-B 8/03 Printed in USA

Loading...

Loading...