Page 1

NRS 2-5

Installation Instructions 810455-00

Level Switch Type NRS 2-5

1

Page 2

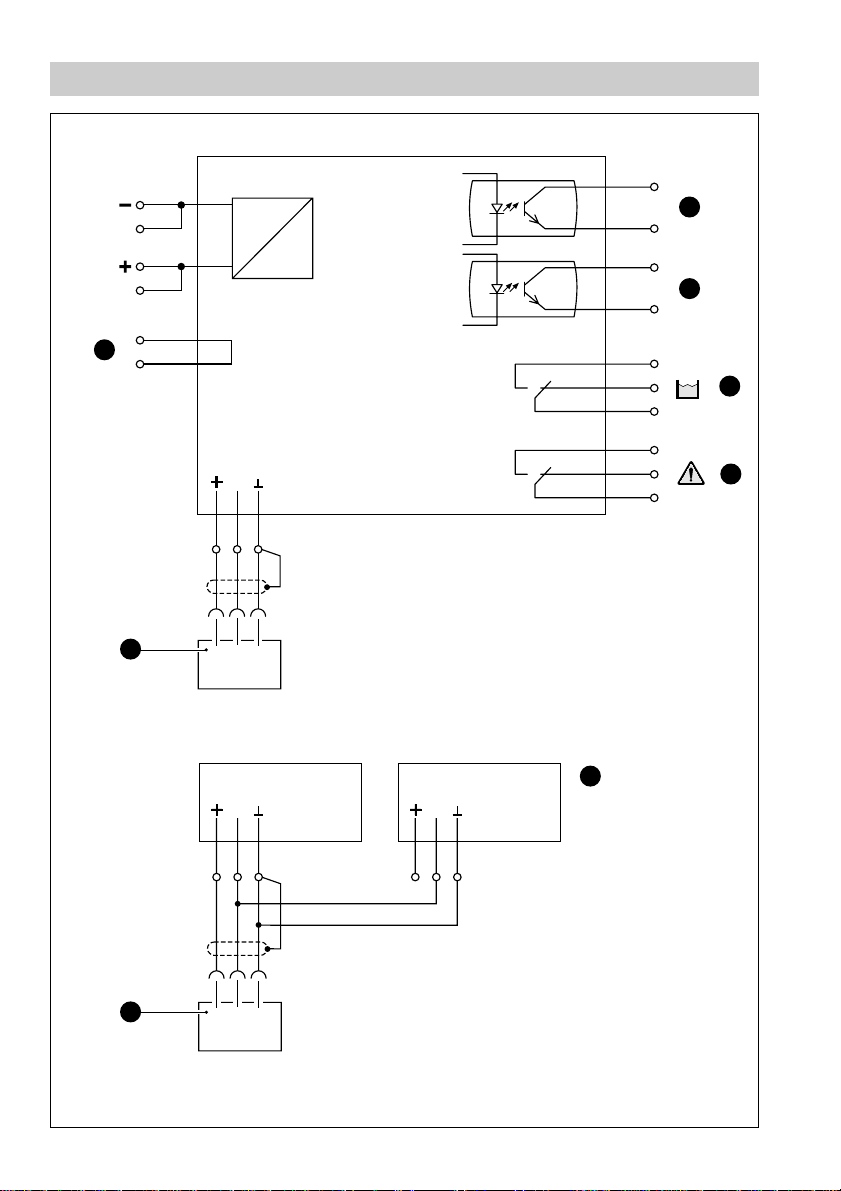

Wiring Diagram

24V DC

11

Fig. 1

C28

A28

A30

C30

A24

C24

10

DC

12V DC

M

C16

C18

1

NRG 211

DC

NRS 2-5

Illustrated relay position:

Alarm, malfunction

A18

32

A22

C22

A20

C20

C 8

A 10

C 12

A 2

C 4

A 6

5

6

MIN

7

8

2

Fig. 2

12V DC 12V DC

NRS 2-5 NRS 2-5

MM

C16

C18

A18

10

1

NRG 211

32

C16

C18

A18

9

Page 3

Dimensions

Fig. 3

A

B

NRS2-5

128.5

MIN

B

C

30.01

(6 TE)

3

Page 4

Parts Drawings

1

2

MAX 70°C

NRS2-5

%

MAX 95%

IP 10

3

4

Fig. 4

MIN

4

Page 5

Key

A

32 way screw-type connector

B

Fixing screw

C

19" Slide-in unit to DIN 41495

LED MALFUNCTION IN ELECTRODE

1

LED MALFUNCTION IN SUPPLY CABLE

2

3

LED LOW LEVEL ALARM

4

LED OPERATION

5

Switching contact ALARM (optocoupler)

6

Switching contact

7

Switching contact

8

Switching contact

9

Example of two low-level switches (redundancy)

10

Level electrode NRG 211

11

Test loop

MALFUNCTION (optocoupler)

ALARM (relay)

MALFUNCTION (relay)

5

Page 6

Contents

Page

Important Notes

Safety note ...................................................................................................................... 7

Warning ........................................................................................................................... 7

Explanatory Notes

Scope of supply ..............................................................................................................7

System description ......................................................................................................... 8

Function .......................................................................................................................... 8

Design ............................................................................................................................. 8

Technical Data ................................................................................................................9

Installation

NRS 2-5 c/d ....................................................................................................................9

Wiring

NRS 2-5 c/d ..................................................................................................................10

Commissioning

Check wiring .................................................................................................................11

Apply mains voltage...................................................................................................... 11

Functional test .............................................................................................................. 11

Table 1........................................................................................................................... 11

Annex

Warning .........................................................................................................................12

Fault finding list .............................................................................................................12

Declaration of conformity ..............................................................................................13

6

Page 7

Important Notes

Safety Note

Low level switches are essential safety devices that are required according to the

approvals for the equipment to which they are fitted.

Use low level switch NRS 2-5 only for indicating min. water level.

The equipment must only be installed by qualified staff.

Qualified staff are those persons who – through adequate training in electrical

engineering, the use and application of safety equipment in accordance with

regulations concerning electrical safety systems, and first aid & accident

prevention – have achieved a recognised level of competence appropriate

to the installation and commissioning of this critical safety device.

Warning

The terminal strip of the NRS 2-5 is live during operation. This presents

the danger of electric shock. Cut off power supply before mounting or

removing the case lid.

Explanatory Notes

Scope of supply

NRS 2-5c

1 Level switch, 19" slide-in unit, front panel to DIN 41494, part 5, 6 TE

(TE = division units; 1 TE = 5.08 mm)

2 Guide rails

1 Screw-type connector

1 Installation instructions

NRS 2-5d

1 Level switch, 19" slide-in unit, front panel to DIN 41494, par t 5, 6 TE

1 Installation instructions

7

Page 8

Explanatory Notes – continued –

System description

The level switch NRS 2-5 is an analogue electronic amplifier for the capacitance

electrode NRG 211.

In combination with this level electrode it can detect low water level. In addition, the

level switch evaluates possible malfunction signals coming from the electrode and

monitors the electrode supply cable.

The level switch in combination with the level electrode can be used as par t of a

low-water level limiting system in steam boilers (separate approval).

Function

The NRS 2-5 has one channel and is provided with a power supply unit and a

voltage decoder. The supply voltage (12VDC) going to the electrode is converted

into a measuring voltage as a function of the operating mode. The signal decoder

assigns the measuring voltage to an operating mode which is indicated by LEDs at

the front panel of the NRS 2-5.

The level switch is designed for four operating modes:

■

Normal operation

■

Low-level alarm

■

Malfunction in level electrode

■

Malfunction in connecting cable

In the case of a low-level alarm or malfunctions the corresponding output relay will

be de-energized. Optocouplers are connected in parallel and assigned to the

output relays as additional switching elements.

Design

NRS 2-5c:

19" Slide-in unit with guide rails and 32 pole screw-type connector for installation in

19" magazines to DIN 41494 part 5. Front panel to DIN 41494, part 5, 6 TE

NRS 2-5d:

Spare 19" slide-in unit, front panel to DIN 41494, part 5, 6 TE

8

Page 9

Technical Data

Input – measuring voltage

1–10 V DC (measuring voltage coming from level electrode)

Output – measuring voltage

12VDC (supply voltage going to level electrode)

Output

2 volt-free relay contacts

Max. contact rating with switching voltages of 24/115 /230V AC: 4 A resistive, 0.75A

inductive at cos ϕ 0.5.

Max. contact rating with switching voltage 24 V DC: 4A

Contact material: silver, hard-gold plated

2 optocouplers (npn), short-circuit protected due to inherent current limiting

characteristics, max. ratings: 70 V, 10 mA

Indicators and adjustors

1 green LED

ALARM, 2 LEDs MALFUNCTION, 1 LED OPERATION

Mains voltage

24 VDC

Power consumption

2VA

Case materials

NRS 2-5c

Front panel: aluminium, Fig. 7

NRS 2-5d

Front panel: aluminium, Fig. 7

Weight

NRS 2-5 c/d: approx. 0.6 kg

Installation

NRS 2-5c

1. Install plastic guide rails into 19" magazine.

2. Install screw-type connector.

3. Insert level switch into the 19" magazine and fasten with screws .

B

NRS 2-5d

1. Insert level switch into the 19" magazine and fasten with screws .

B

Tools

■

Screwdriver (5.5/100)

9

Page 10

Wiring

NRS 2-5

Use screened four-core cable, conductor size 0.8 mm², max. cable length 500 m for

the supply of the electrode.

Wire screw-type connector according to wiring diagram, Fig. 1

Wiring diagram

See wiring diagram page 2.

Attention

■

To protect the relay contacts fuse the control circuit with T 2.5A or

according to TRD regulations (1.0 A for 72 h operation).

■

The screen must not make any other electrical contact.

Important Note

■

Connect screen only to terminal A18 of the level switch.

■

The monitoring of the level electrode and the monitoring of the

connecting cable can be integrated in the safety circuit. For this

purpose connect the safety circuit to the relay output

■

The rated voltage is indicated on the name plate.

■

When switching off inductive loads, voltage spikes are produced that

may impair the operation of control and measuring systems.

Inductive loads should be provided with commercial arc

suppressor RC combinations, e. g. 0.1 µF/100Ω.

MALFUNCTION.

Tools

■

Screwdriver for slotted screws, size 2.5, completely insulated acc. to VDE 0680

10

Page 11

Commissioning

Check wiring

Check whether the NRS 2-5 and the associated system component NRG 211 are

wired according to the wiring diagram. Fig.1, Fig. 2

Apply mains voltage

Switch on mains supply. The green LED is illuminated. Fig. 4

4

Functional test

NRS 2-5 c/d

1. After switching on the mains voltage the green LED must be permanently

4

illuminated. Fig. 4

2. Lower the water level until it falls below the low-level mark.

The red LED at the level switch must light up.

3

3. Raise the water level until it exceeds the low-level mark. The red LED must

extinguish.

4. After removing the terminal box from the level electrode the yellow LED must

2

light up (malfunction in connecting wire).

5. Bridge terminals C16 and C18. The yellow LED must light up (malfunction in

1

electrode).

The measuring voltages of the different operating modes are represented in table 1.

Table 1

Measuring voltage U

≤1V

Decoded

M

Malfunction in electrode supply cable

(short circuit, interruption)

1V–4V Electrode exposed, low level

4V–7V Electrode submerged

≥ 9V

Malfunction in electrode (defective insulating seal,

leaking stuffing box)

11

Page 12

Annex

Warning

The terminal strip of the NRS 2-5 is live during operation. This presents the

danger of electric shock.

Cut off power supply before inserting or removing the 19" slide-in unit and

before undertaking any installation or maintenance work.

Fault finding list

Fault: The level switch raises an alarm during normal operation.

Remedy: Check whether the green LED is illuminated. If not, check whether the

4

mains voltage is applied.

Fault: The yellow LED is illuminated.

1

Remedy: The level electrode is defective. Replace the equipment.

Fault: The yellow LED is illuminated.

2

Remedy: Check whether the connecting line to the electrode is interrupted.

If faults occur that are not listed above, please contact our subsidiary or agency in

your country.

12

Page 13

Annex – continued –

Declaration of conformity

We hereby declare that the equipment NRS 2-5 c/d conforms to the following

European guidelines:

■

LV guideline 73/23/EWG version 93/68/EWG

■

EMC guideline 89/336/EWG version 93/68/EWG

which are based on the following harmonised standards:

■

LV standard EN 60947-5-1: 1991

■

EMC standard EN 50081-2, EN 50082-2

This declaration is no longer valid if modifications are made to the equipment without

consultation with us.

Bremen, 28th April 1997

GESTRA GmbH

Dr. Anno Krautwald

Dr. Christian Politt

13

Page 14

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

Italia

España

España

GESTRA ESPAÑOLA S.A.

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

Luis Cabrera, 86-88

E-28002 Madrid

E-28002 Madrid

Tel. 003491/5152032

Tel. (091) 5 152 032

Fax 003491/413 6747 ; 51520 36

Fax (091) 4 136 747; (091) 5 152 036

E-mail: gestra@gestra.es

France

France Portugal

GESTRA S.A.R.L.

10 Avenue du Centaure, BP 8263

Flowserve Flow Control S.A.S.

F-95801 CERGY PONTOISE

10 Avenue du Centaure, BP 8263

Tél. (01) 34.43.26.60

F-95801 CERGY PONTOISE CEDEX

Fax (01) 34.43.26.87

Tél. 00331/34432660

Fax 00331/34432687

Great Britain

E-mail: gnation@flowserve.com

GESTRA (U.K.) LTD.

9-11 Bancroft Court

Italia

Hitchin, Hertfordshire, SG5 1PH

Tel. (0 14 62) 4316 81

Italgestra S.r.l.

Fax (0 14 62) 4203 96

Via Carducci 125

l-20099 Sesto San Giovanni (MI)

Tel. 003902/241012.1

Fax 003902/241012.460

E-mail: info@italgestra.it

Polska

GESTRA POLONIA Spolka zo.o.

ITALGESTRA S.r.l.

Ul. Schuberta 104, P.O. Box 71

Via Carducci 125

PL-80-172 Gdansk

l-20099 S.S. Giovanni (MI)

Tel. 004858/3061002 oder 3061010

Tel. (02) 2 6297-0

Fax 004858/3061003 oder 3063300

Fax (02) 26 2974 60

E-mail: gestra@gestra.pl

Polska

GESTRA POLONIA Spolka z o.o.

Ul. Schuberta 104

GESTRA PORTUGUESA VALVULAS LDA.

PL-80-172 Gdansk

Av. Dr. Antunes Guimarães, 1159

Tel. (058) 306 10 02

Porto 4100-082

Fax (058) 306 10 03

Tel. 0035122/ 6198770

Fax 0035122/6107575

Portugal

E-mail: gestra@gestra.pt

GESTRA PORTUGUESA VALVULAS LDA.

Av. Dr. Antunes Guimarães, 1159

P-4100 Porto

Tel. (02) 6 107551

Fax (02) 6 10 75 75

®

®

GESTRA GmbH

GESTRA GmbH

Postfach 10 54 60

Postfach 10 54 60

D-28054 Bremen

D-28054 Bremen

Hemmstraße 130

Münchener Str. 77

D-28215 Bremen

D-28215 Bremen

Tel. +49 (0) 421 35 03- 0

Tel. +49 (0) 421 35 03-0

Fax +49 (0) 421 35 03-393

Fax+49 (0) 421 3503-393

Internet www.gestra.de

E-mail

gestra.gmbh@gestra.de

E-mail

gestra.gmbh@gestra.de

Internet www.gestra.de

A Unit of Flowserve Corporation

An Invensys company

810455-00/999c · ©1999 GESTRA GmbH · Bremen · Printed in Germany

14

Loading...

Loading...