Page 1

NRS 1-41

Installation Instructions 810830-00

Level Switch NRS 1-41

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose .....................................................................................6

Safety note......................................................................................................................6

Danger ............................................................................................................................6

Explanatory Notes

Scope of supply ..............................................................................................................6

Description ...................................................................................................................... 7

Function ..........................................................................................................................7

Technical data ................................................................................................................. 8

Installation

NRS 1-41 ......................................................................................................................... 9

Example of installation .................................................................................................27

Wiring

Wiring diagram..................................................................................................... 3, 9 –11

Basic Adjustment

CAN bus........................................................................................................................11

Node ID .........................................................................................................................11

Factory setting ..............................................................................................................11

Commissioning

NRS 1-41 ....................................................................................................................... 12

Operation

NRS 1-41 ....................................................................................................................... 12

Test Cycle

NRS 1-41 ....................................................................................................................... 12

Alarm

High-level alarm............................................................................................................13

System Malfunctions

Fault analysis, system malfunctions 1 to 6........................................................... 14– 20

Operation Malfunctions

Fault finding list for troubleshooting..............................................................................21

Annex

Factory set default node IDs ........................................................................................ 22

Assigning/changing node ID...................................................................................23, 24

Declaration of conformity..............................................................................................26

2

Page 3

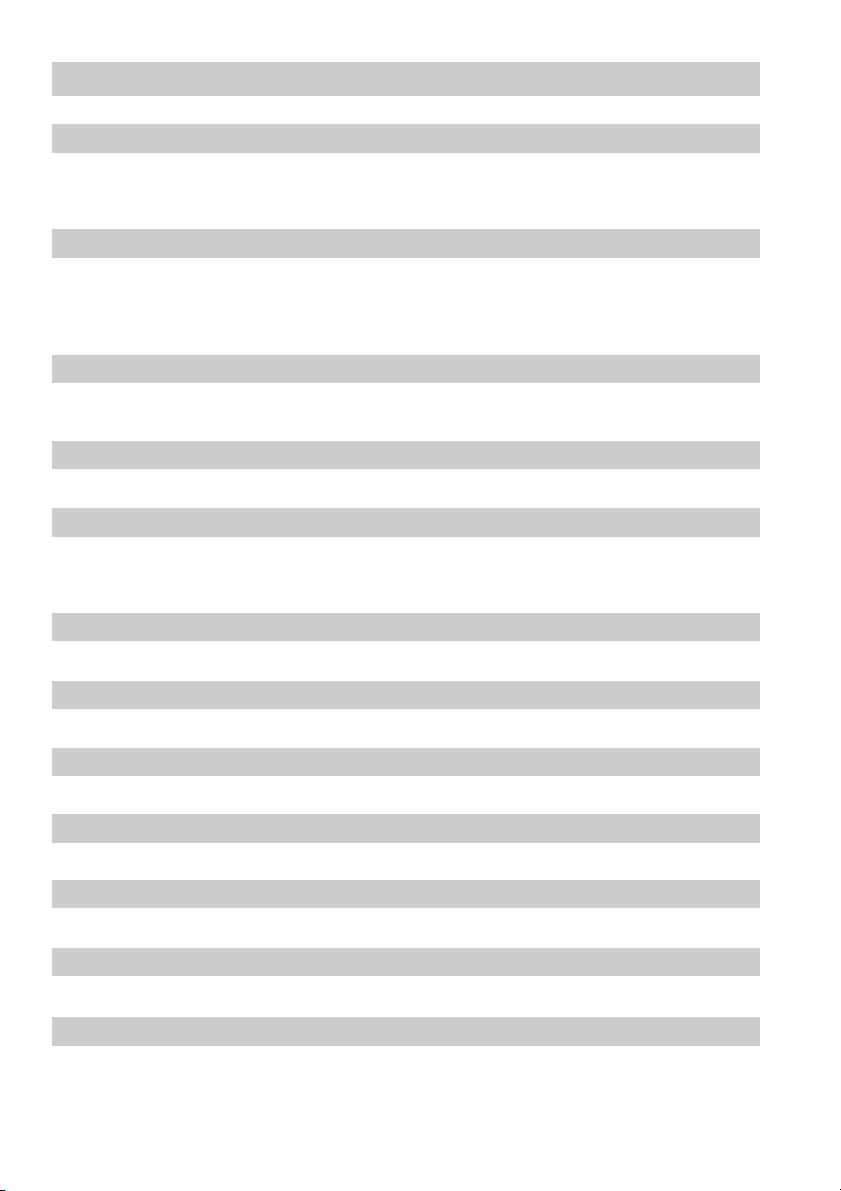

Wiring Diagram

Twisted pair cable

Twisted pair cable

Fig.1

Control circuit

make-up unit

– uninterrupted –

Further equipment in

control circuit

Note:

NRS 1-41 is the first

equipment in the

control circuit!

Terminals 26, 27, 28

and 30 must not be

connected!

Photo-MOS output

24 V – 230 V AC/DC, 100 mA

Instantaneous HW alarm,

clocked malfunction signal.

Terminating resistor

120 Ω

Control terminal

URB 1

Terminating resistor

120 Ω

Fig. 2

Level switch

NRS 1-40

CEP

Voltage supply

Controller

...

Level electrode

NRG16-40

CAN data line

Terminating resistor

120 Ω

Level sensor

NRG...

3

Page 4

Parts Drawings

Fig. 3

1

3 2567

4

A

9

8

A

B

Fig. 4

4

Page 5

Key

Indicator LED

1

LED 1 Electrode 1

LED 2 Electrode 1

LED “Bus status”

2

3

LED “Power”

4

Enter / Test mode

5

Decrease

6

Increase

7

Program key

8

Two-pole code switch Note: Do not change factory setting!

9

Ten-pole code switch

A

Terminal strip

B

Screws for terminal strip

Alarm Malfunction

High-level alarm Multifunction

High-level alarm Multifunction

5

Page 6

Important Notes

Usage for the intended purpose

Use level switch NRS 1-41 only in conjunction with GESTRA level electrode

NRG 16-41, NRG 17-41 or NRG 19-41 for signalling high water level

(max. alarm).

Safety Note

Installation must only be performed by qualified staff.

Qualified staff are those persons who – through adequate training in electrical

engineering, the use and application of safety equipment in accordance with

regulations concerning electrical safety systems, and first aid & accident

prevention – have achieved a recognised level of competence appropriate to the

installation and commissioning of this safety device.

Danger

The terminal strip of the NRS 1-41 is live during operation.

This presents the danger of electric shock.

Cut off power supply before mounting or removing the terminal strips and

housing lid.

Explanatory Notes

Scope of supply

NRS 1-41

1 Level switch NRS 1-41 (plug-in unit in plastic case with terminals)

1 Terminating resistor 120 Ω

1 Installation manual

6

Page 7

Explanatory Notes – continued –

Description

The switching controller type NRS 1-41 is a self-monitoring high-water level limiter

with periodic self-checking and monitoring feature of the output relay contacts

designed to be used in conjunction with one level electrode type NRG 16-41, 17-41

or 19-41. The switching controller has the following function:

■ High-water level alarm with one level electrode

The equipment detects the max. water level (high-level limiter) and complies with the

German regulations for use in steam and hot-water plants operating without constant

supervision according to TRD 604, sheets 1 and 2 (72 hrs operation).

This item of electrical equipment complies with the Technical Regulations on

Protection Circuits DIN VDE 0116 (prEN 50156).

The level data are transferred from the electrode NRG 1…-41 to the switching

controller via CAN bus using the CANopen protocol. Only one high-level limiting

system may be used per CAN-based network.

Function

At regular intervals the level electrode NRG 1…-41 sends a data telegram to the

switching controller NRS 1-41. The data transfer is effected by means of a CAN bus

according to ISO 11898. The transferred measuring data are constantly evaluated by

the controller. A periodic self-checking routine tests every 3 seconds the integrity of

the system and its safety functions, with a malfunction in the switching controller

resulting in immediate boiler shutdown. When the CAN bus line and, consequently,

the data transmitting cycle are interrupted, the controller sends a visual signal to

indicate a faulty condition and the relays are instantaneously de-energized (fail-safe

position).

The switching controller also facilitates user-friendly performance tests and

detection/evaluation of malfunctions.

To guarantee the correct and safe functioning of the high-level limiter a min. electrical

conductivity of 0.5 µS/cm at 25°C is required.

The relay de-energizing delay is normally set to 3 seconds at the factory but delays

of 15 to 25 seconds are available on request.

Apart from the burner protection circuit there is also a separate Photo-MOS make

contact output for remote indication.

The automatic self-testing routine of the switching controllers checks every 3

seconds their safety functions. The corresponding functions of the level electrodes

will be tested by the electrode’s self-checking routine every 10 sec.

The malfunction information is updated with every self-test. If no faults have occurred

the malfunction information will be deleted automatically. If faults persist the

malfunction information remains stored.

As part of the automatic self-testing routine of the switchting controller, the

switching-off of the output relays every 6 hrs is checked, too. If a fault is detected,

the information on this malfunction will be saved accordingly.

7

Page 8

Explanatory Notes – continued –

Technical Data

Type approval no.

TÜV · WB · 99-403

EG BAF-MUC 0202 103881 002

Input/Output

Interface for CAN bus to DIN ISO 11898 CANopen protocol

Output voltage supply for electrode

18 – 36, short-circuit protected

Output for control circuit

Power supply of level electrode: 24 V DC, short-circuit protected

Two volt-free relay contacts, locally connected in series.

Max. contact rating for switchting voltages 24 V AC/DC, 115 V AC and 230 V AC:

4 A resistive/inductive. Contact material: hard-gold plated

Interference suppression

Provide contactor with external RC combination (100 Ω / 47 nF)

Signal output

Photo-MOS output, instantaneous with high level, timed malfunction signal, max.

contact rating for switching voltages 24 V AC, 115 V AC and 230 V AC/DC:

100 mA resistive

Relay de-energizing delay

Output “High-level alarm”, set to 3 sec. (standard);

optional (for e. g. marine applications): 15 sec. or 25 sec.

Indicators and adjustors

4 pushbuttons “Parameterisation/TEST”

1 red LED for “High-level alarm electrode 1”

3 red LEDs “Multifunction”

1 red LED “Bus status”

1 green LED “Power”

1 ten-pole code switch, 7 poles for setting node ID, 3 poles for setting baud rate

1 two-pole code switch, without function. Do not change factory setting!

Internal self-checking routine

Every 3 seconds

Periodic testing of output relay contacts

Every 6 hours

Mains voltage

230 V +/– 10 %, 50/60 Hz, 115 V +/– 10 %, 50/60 Hz (optional)

Power consumption

10 VA

Sensitivity

≥ 0.5 µS/cm at 25°C

Protection

Enclosure: IP 40 to DIN EN 60529

Terminal strip: IP 2o to DIN EN 60529

Admissible ambient temperature

0 °C to 55 °C

Enclosure material

Front panel: polycarbonate, grey

Enclosure: polycarbonate, black

Weight

Approx. 0.8 kg

8

Page 9

Installation

NRS 1-41

Installation on mounting rail

1. Clip switching controller onto mounting rail 35 x 15 mm (DIN EN 50022).

2. Align switching controller, Fig. 9, Fig. 10

Note

■

If an external measuring pot is used, each level electrode type NRG

1…-41 requires one switching controller type NRS 1-41 and one

GESTRA monitoring unit SRL 6.

Tool

■

Screwdriver (5.5/100)

Wiring

Note that screened multi-core twisted-pair control cable is required, e. g.

UNITRONIC

®

BUS CAN 2 x 2 x … mm² or RE-2YCYV-fl 2 x 2 x … mm².

The baud rate (data transfer rate) dictates the cable length between the bus nodes

and the total power consumption dictates the conductor size.

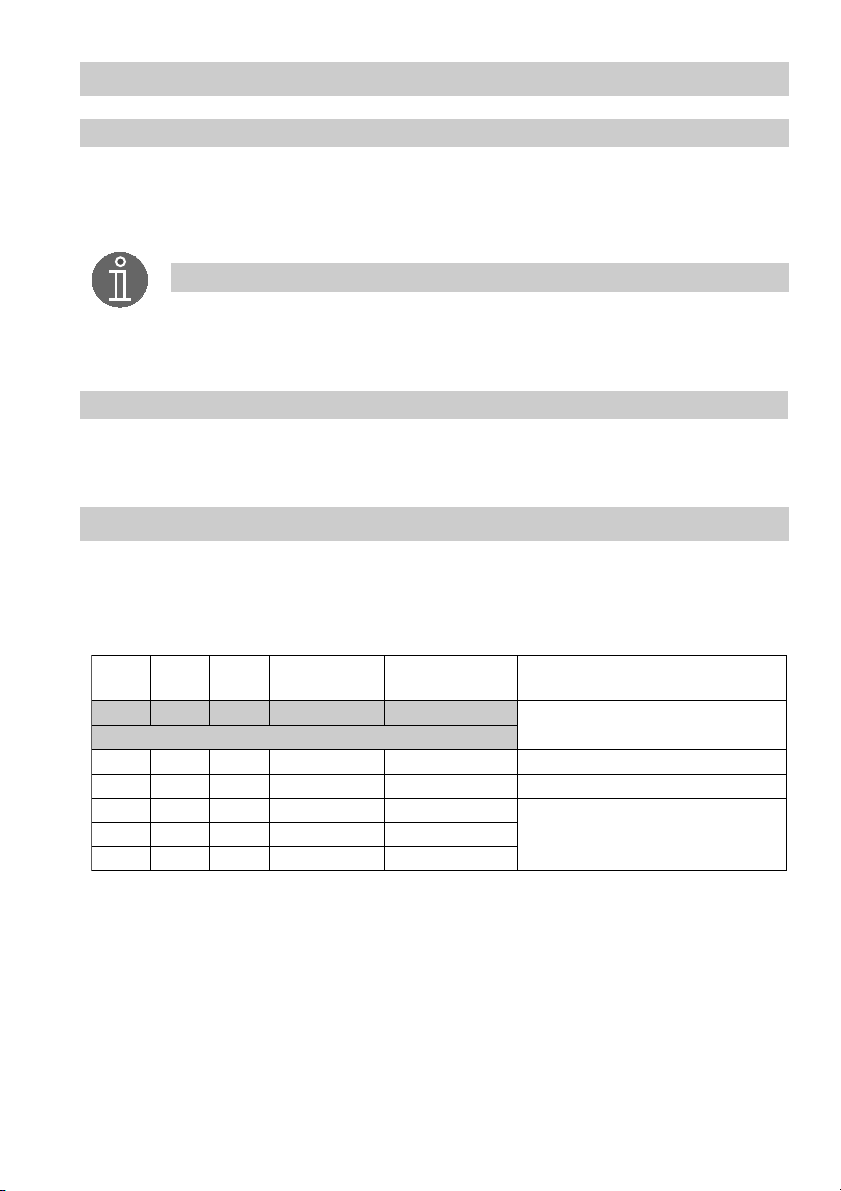

8S9S01SetarduaBhtgnelelbaC

FFO NO FFO s/tiBk052 m521

gnittesyrotcaF

NONOFFOs/tiBk521m0525.0x2x2

FFOFFONOs/tiBk001m53357.0x2x2

NOFFONOs/tiBk05m005

FFONONOs/tiBk02m0001

NONONOs/tiBk01m0001

sriapforebmuN

2

]

mm[ezisrotcudnocdna

43.0x2x2

notnedneped,tseuqerno

noitarugifnocsub

The baud rate is set via a code switch. Reduce baud rate if cable is longer than

specified in the table above. Make sure that all bus nodes feature the same settings.

To protect the switching contacts fuse circuit with 2.5 A (anti-surge fuse) or according

to TRD regulations (1.0 A for 72 hrs operation).

When a max. cable length of more than 125 m (up to 1000 m) is desired, make

sure to modify the baud rate accordingly. Refer to pages 23 and 24 for more

details.

UNITRONIC® is a registered trademark of LAPP Kabelwerke GmbH, Stuttgart

9

Page 10

Wiring – continued –

Wiring Diagram

Wiring diagram see page 3.

Attention

■

Wire equipment in series. Star-type wiring is not permitted.

■

Interlink screens of control cables such that electrical continuity is

ensured and connect them once to the central earthing point (CEP).

■

To protect the switching contacts fuse circuit with 2.5 A (slow blow

fuse) or according to TRD regulations (1.0 A for 72 hrs operation).

■

If more than one system component is connected to a CAN bus

network provide the first and last equipment with a terminating resistor

of 120 Ω, Fig. 2.

■

Use only one water-level limiting system per CAN bus network.

■

The CAN bus line must not be interrupted while operating with one or

more system components.

Any interruption will open the control circuit!

If the switching controller has to be replaced be sure to remove first the

terminal strips , Fig. 4

Note: Make sure that all system components connected are

operating

before removing the CAN bus line from the terminal strip!

A

not

10

Note

■

Connect screen only to terminal 3, ensuring electrical continuity and

connect equipment once to the central earthing point (CEP).

■

The loop resistance must be under 10 Ω.

■

The rated voltage is stated on the name plate.

■

When switching off inductive loads voltage spikes are produced that

may impair the operation of control and measuring systems. Inductive

loads should therefore be provided with commercial arc suppressor RC

combinations, e. g. 0.1 µF/100 Ω.

■

Despite correct wiring H. F. interference caused by the installation may

lead to system breakdowns and malfunction messages. If necessary

refer to the “Fault finding list for troubleshooting” on page 21.

■

In the event of a shut-down due to a malfunction the signal output

(terminals 7 and 8) is cyclically openend and closed in order to ensure

an optical distinction between “High level” (signal output closed) and

“Malfunction shut-down”. If necessary conncect terminals 7 and 8

externally to an indicator lamp, Fig. 1.

Page 11

Wiring – continued –

Tool

■

Screwdriver of slotted screws, size 2.5, completely insulated according to

VDE 0680

Basic Adjustments

CAN Bus

All level and conductivity controllers and associated electrodes are interconnected

by means of a CAN bus using the CANopen protocol. Every item of equipment

features an electronic address (node ID). The four-core bus cable serves as power

supply and data highway for high-speed data exchange.

The CAN address (node ID) can be set between 1 and 123.

The NRS 1-41 is configured at our works and ready for service with other GESTRA

system components without having to set the node ID.

If several systems of the same kind are to communicate in one CAN bus

network, be sure to assign one node ID for each individual system component

(e. g. controller). Refer to pages 22 and 23 for more details.

Node ID

Factory setting

The switching controller features the following factory set default values:

■ Baud rate: 250 kb/s

■ Sensitivity: 0,5 µS/cm

■ Node ID: 006

■ Relay de-energizing delay: 3 s

11

Page 12

Commissioning

NRS 1-41

Apply power to the unit.

The four indicator LEDs flash rapidly.

The LED “Power” lights up.

The test cycle takes about 3 sec.

Note

■ To analyse and eliminate malfunctions that may occur during the com-

missioning procedure refer to section “System Malfunctions” on page 14.

Operation

NRS 1-41

Normal operation, electrode submerged.

The four indicator LEDs are not

illuminated.

The LED “Power” lights up.

Indicator LEDs flash rapidly

LED “Power” illuminated

Indicator LEDs extinguished

Test Cycle

NRS 1-41

Press button briefly.

The test mode is activated for about 10 sec.

Be sure to press button or within

these 10 sec.

Note: The control circuit of the make up

unit will be interrupted during the test cycle.

Press button for 3 sec.

LED 1 flashes rapidly and remains

permanently illuminated after 3 sec.

A high-level alarm is simulated for the

level electrode.

12

LED “Power” illuminated

Indicator LED 1 changes after 3 sec.

from rapid flashing to lighting

3 sec.

Page 13

Alarm

There is one alarm condition:

■ High-level alarm

(one level electrode)

High-water level alarm

LED 1 flashes rapidly.

LED 1 remains permanently illuminated after

the de-energizing delay.

Note

■ The switching controller does not have its own lock-out circuit.

Lock-out and manual reset facilites are to be provided externally.

■ The signal output (terminal 7 and 8) is instantaneously energized

(no delay of response) in the event of an alarm.

13

Page 14

System Malfunctions

Faulty installation and/or configuration of CAN bus components, excessive

temperatures in the devices, defective electronic component parts or electromagnetic

interferences of the supply system can result in system malfunctions.

There are four system malfunctions that might occur in the level electrode and the

switching controller:

■ Max. admissible temperature in electrode terminal box exceeded

■ No or faulty communication between controller and electrode

■ Fault in CAN bus

■ Failure of 24 V power supply unit built in switching controller NRS 1-41

The malfunction information is updated with every self-test (switching controller:

every 3 sec., level electrode: every 10 sec.) If no faults have occurred the malfunction

information will be deleted automatically. If faults persist the malfunction information

remains stored.

As part of the automatic self-testing routine of the switching controller, the switching

off of the output relays every 6 hrs is checked, too. If a fault is detected the signal

output (terminals 7 and 8) will be opened and closed as a function of time.

Danger

The terminal strip of the NRS 1-41 is live during operation.

This presents the danger of electric shock.

Cut off power supply before mounting or removing the equipment.

14

Page 15

System Malfunctions – continued –

Systematic Malfunction Analysis

The sources of malfunctions occurring in CAN bus systems operating with several

bus-based stations must be analysed systematically since faulty components or

incorrect settings can give rise to negative interactions with intact bus devices in the

CAN bus system. These unwanted interactions can cause error messages in fully

functional bus devices, which will make fault detection even more difficult.

We recommend the following systematic fault finding procedure:

Step 1 (Start)

Detach terminal strips

in all sensing units of

bus devices.

Level electrode

Conductivity electrode

Pressure sensor

Temperature sensor

Check

Use fault-finding

list to correct

fault(s).

Final test:

have all faults

been eliminated?

System

Malfunction

Use fault-finding list

to identify the

fault(s).

Cut off power supply

to the equipment.

Step 2

Plug in terminal strips

of the sensing unit

of one system, e. g.

NRS ...

and

NRG ...

Step 3

Apply mains voltage

to bus devices

of the system, e. g.

NRS ...

and

NRG ...

Check next system

System O.K.

Detach terminal

strips between

bus devices

of the sytem e. g.

NRS ...

and

NRG ...

15

Page 16

System Malfunctions – continued –

Danger

The terminal strip of the NRS 1-41 is live during operation. This presents

the danger of electric shock. Cut off power supply before mounting and

removing the equipment.

System Malfunction 1

LED 1 flashes slowly.

A system malfunction in the level

electrode was detected.

Hold down button .

LED 1 flashes slowly.

Fault:

The max. admissible temperature in the terminal box of the electrode

NRG 1…-41 has been exceeded.

Remedy:

Insulate electrode flange against heat radiation.

Hold down button .

LED 2 flashes slowly.

LED 1 flashes slowly

LED 1 flashes slowly

LED 2 flashes slowly

Fault:

The electronic circuit board of the level electrode NRG 1…-41 is

defective.

Remedy:

Replace electronic circuit board of the level electrode.

The system will continue to work once

the causes of the system malfunction

are completely eliminated.

16

Page 17

System Malfunctions – continued –

System Malfunction 2

LED 3 flashes slowly.

A communication malfunction in the

bus line was detected.

Hold down button .

LED 1 flashes slowly.

A communication malfunction in the bus

line between level switch and level

electrode was detected.

Fault:

Remedy:

The data transfer between level switch and electrode is interrupted.

Make sure that the bus lines are all wired in accordance with the wiring

diagram (observe polarity). All end-of-line devices must be provided

with a terminating resistor of 120 Ω (see wiring diagram).

Cut off power supply and restart system after 5 sec.

Fault:

Remedy:

The baud rate of one or more bus devices is not set correctly.

Check baud rate settings of all bus devices. The baud rate settings must

be identical. Please refer to section “Annex”.

Cut off power supply and restart system after 5 sec.

LED 3 flashes slowly

LED 1 flashes slowly

Fault:

Remedy:

Fault:

Remedy:

The overall length of the bus line does not correspond to the baud rate

setting.

Change baud rate settings of all bus based equipment as described

under “Annex”.

Cut off power supply and restart system after 5 sec.

In spite of correct wiring and commissioning of the equipment an

interference signal is indicated.

The interference signal is caused by H. F. interferences coming from the

installation. For interference suppression of the voltage supply we supply

ferrite rings, stock code 147253. The 230 V supply lines should be

looped through the ferrite ring five to ten times. If several controllers are

used in the system, they can be fed from the interference suppressed

supply lines. For the interference suppression of the bus line we supply

hinged-shell ferrite rings, stock code 147254. The hinged-shell ferrite

rings are clamped onto the bus line close to the terminal strip of the

controller.

Restart the system after installation.

17

Page 18

System Malfunctions – continued –

System Malfunction 3

LED 4 flashes slowly.

A malfunction in the level switch

has been detected.

Fault:

The electronic circuit board of the level switch is defective

(e. g. output relay).

Remedy:

Fault:

Remedy:

Replace level switch. Restart system.

No voltage across terminal 25, self-checking routine unsuccessful.

Wire NRS 1-41 as first device in the safety chain. Wire NRS 1-41

according to wiring diagram (ensure constant voltage supply across

terminal 25). Restart system.

Fault:

Remedy:

Voltage across terminal 26 and/or 30.

Do not connect these terminals.

System Malfunction 4

LEDs 1 to 4 flash rapidly.

A general communication

malfunction has been detected.

LED 4 flashes slowly

LEDs flash rapidly

Fault:

Remedy:

18

No communication between bus devices possible.

Check wiring, node ID, baud rate setting and bus cable.

Cut off power supply and restart system after 5 sec.

Page 19

System Malfunctions – continued –

System Malfunction 5

LED “Bus status” flashes slowly.

LED flashes slowly

Fault:

Remedy:

Fault:

Remedy:

Fault:

Remedy:

Data transfer in CAN bus interrupted.

The bus cables have to be correctly connected according to the wiring

diagram (observe polarity!). Make sure that all end-of-line nodes are

provided with 120 Ω terminating resistors.

Cut off power supply and restart system after 5 sec.

The baud rate of one or more nodes is not set correctly.

Check baud rate settings of all bus nodes. The baud rates must be

identical. Refer to section “Annex” for more details.

Cut off power supply and restart system after 5 sec.

The overall length of the bus cable does not correspond to the selected

baud rate.

Change baud rate settings of all nodes according to “Annex”.

Cut off power supply and restart system after 5 sec.

19

Page 20

System Malfunctions – continued –

System Malfunction 6

LED “Power” flashes slowly

LED flashes slowly

Fault:

Remedy:

Fault:

Remedy:

The power supply unit (PSU) is overloaded. The PSU may be misused for

other components.

Check load of PSU. Be sure to use the PSU only for the voltage supply of

bus-based network components.

Cut off power supply and restart system after 5 sec.

Power supply unit defective.

Replace power supply unit.

20

Page 21

Operation Malfunctions

Danger

The terminal strip of the NRS 1-41 is live during operation.

This presents the danger of electric shock.

Cut off power supply before mounting and removing the equipment.

Fault finding list for troubleshooting

Equipment does not work – Malfunction message

Fault:

Remedy:

High-water level switchpoint exceeded – No function

In spite of correct wiring and commissioning of the equipment an

interference signal is indicated.

The interference signal is caused by H. F. interferences coming from the

installation. For interference suppression of the voltage supply we supply

ferrite rings, stock code 147253. The 230 V supply lines should be

looped through the ferrite ring five to ten times. If several controllers are

used in the system, they can be fed from the interference suppressed

supply lines. For the interference suppression of the bus line we supply

hinged-shell ferrite rings, stock code 147254. The hinged-shell ferrite

rings are clamped onto the bus line close to the terminal strip of the

controller.

Restart the system after installation.

Fault:

Remedy:

High-water level switchpoint not reached – High level alarm

Fault:

Remedy:

Fault:

Remedy:

Fault:

Remedy:

Fault:

Remedy:

If faults occur that are not listed above or cannot be corrected, please contact our

service centre or authorized agency in your country.

LED “Power” does not light up.

Apply power. Connect the equipment properly according to wiring

diagram.

High-level alarm is given although the electrode is exposed.

The electrode rod is too long! Cut electrode rod according to switchpoint.

The electrode body does not have earth connection to the vessel.

Clean seating surfaces and insert metal joint ring (of stainless steel

1.4301) D 27x32 to DIN 7603.

Do not insulate the level electrode with hemp or PTFE tape!

The vent hole in the protection tube does not exist, is obstructed or

flooded.

Check protection tube and, if necessary, provide vent hole.

The isolating valves of the external measuring pot (optional item) are

closed.

Open isolating valves.

21

Page 22

Annex

Danger

The terminal strip of the NRS 1-41 is live during operation.

This presents the danger of electric shock.

Cut off power supply before mounting and removing the equipment.

Factory set default node IDs

Switching

controller

The individual node IDs must be manually adjusted on the equipment.

Please observe the installation instructions of the device in question.

Level

electrode

22

Page 23

Annex – continued –

Assigning/changing node ID

If several systems of the same kind are to communicate in one CAN bus network, be

sure to assign one node ID for each individual system component (e. g. controller).

Detach terminal strips in order to change the code switch setting .

Attention

A 9

■ Do not assign the same node ID twice within the CAN bus network.

■ Do not change the settings of the code switch .

8

98

Fig. 5

23

Page 24

Annex – continued –

99

Node ID

OFF

S1

ON

S2

ON

S3

OFFS4

OFFS5

OFFS6

OFFS7

Fig. 6 (Factory setting) Fig. 7 (Example)

S8

OFF

ON

OFF

ON

OFF

ON

Fig. 8 (Factory setting 250 kBit/s)

S9

ON

ON

OFF

OFF

ON

ON

1

2

4

8

16

32

64

S0

OFF

OFF

ON

ON

ON

ON

6

Baud rate

250 kBit/s

125 kBit/s

100 kBit/s

50 kBit/s

20 kBit/s

50 kBit/s

OFF

S1

OFFS2

S3

S4

OFFS5

OFFS6

OFFS7

Cable length

Node ID

ON

ON

125 m

250 m

335 m

500 m

1000 m

1000 m

12

1

2

4

8

16

32

64

24

Page 25

For your notes

25

Page 26

Annex – continued –

Declaration of conformity

We hereby declare that the equipment NRS 1-41 conforms to the following

European guidelines:

■ LV guideline 73/23/eec version 93/68eec

■ EMC guideline 89/336/eec version 93/68/eec

which are based on the following harmonised standards:

■ LV standard DIN EN 50178

■ EMC standard DIN EN 50 081-2, DIN EN 61000-6-2

This declaration is no longer valid if modifications are made to the equipment

without consultation with us.

Bremen, 27th October 2000

GESTRA GmbH

Head of the Design Dept.

Uwe Bledschun

(Academically qualified engineer)

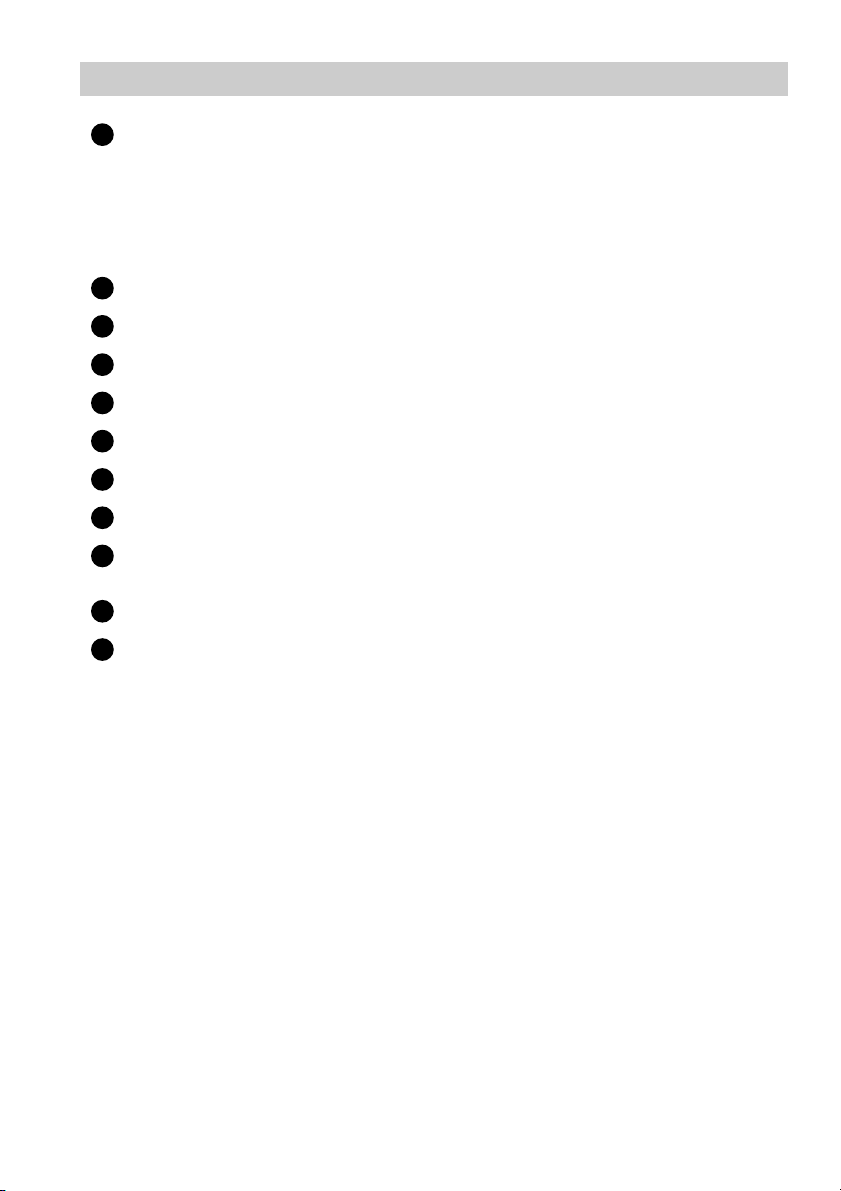

Key

Terminal strips

A

Mounting rail 35 x 15 to DIN EN 50022

C

Quality Assurance Manager

(Academically qualified engineer)

Lars Bohl

26

Page 27

Example of Installation

A

A

Fig. 9

100

C

73

MAX 55°C

118

MAX 95%

Fig. 10

20 20

27

Page 28

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 40

E-mail: sales@flowserve.com

France

Flowserve Flow Control S.A.S.

10 Avenue du Centaure, BP 8263

F-95801 CERGY PONTOISE CEDEX

Tél. 0 03 31 / 34 43 26 60

Fax 00331/34432687

E-mail: gnation@flowserve.com

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 003491/5152032

Fax003491/4136747; 5152036

E-mail: gestra@gestra.es

Italia

Flowserve S.p. A

Divisione Italgestra

Via Prealpi, 30 – 20032 Cormano (MI)

Tel. 003902/663251

Fax 00 39 02 / 66 32 55 60

E-mail: info@italgestra.it

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0035122/6198770

Fax 003 51 22 / 6 107575

E-mail: gestra@gestra.pt

®

GESTRA GmbH

P. O. Box 10 54 60, D-28054 Bremen, Münchener Str. 77, D-28215 Bremen

Telephone +49 (0) 421 35 03 - 0, Fax +49 (0) 421 35 03 - 393

E-Mail gestra.gmbh@flowserve.com, Internet www.gestra.de

A Unit of Flowserve Corporation

810830-00/903c · © 2003 GESTRA GmbH · Bremen · Printed in Germany

28

Loading...

Loading...