Page 1

GESTRA

GESTRA Steam Systems

LRG 16-40

LRG 17-40

Installation Instructions 818524-01

Conductivity Electrode LRG 16-40

Conductivity Electrode LRG 17-40

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose ..............................................................................................................4

Safety note .............................................................................................................................................4

Danger ...................................................................................................................................................4

PED (Pressure Equipment Directive) ........................................................................................................4

ATEX (Atmosphère Explosible) .................................................................................................................4

Explanatory Notes

Scope of supply ...................................................................................................................................... 5

Description .............................................................................................................................................5

Function .............................................................................................................................................5, 6

System components ...............................................................................................................................6

Design .................................................................................................................................................... 6

Technical Data

LRG 16-40, LRG 17-40 .....................................................................................................................

Corrosion resistance ............................................................................................................................... 9

Sizing .....................................................................................................................................................9

Name plate / marking ...........................................................................................................................10

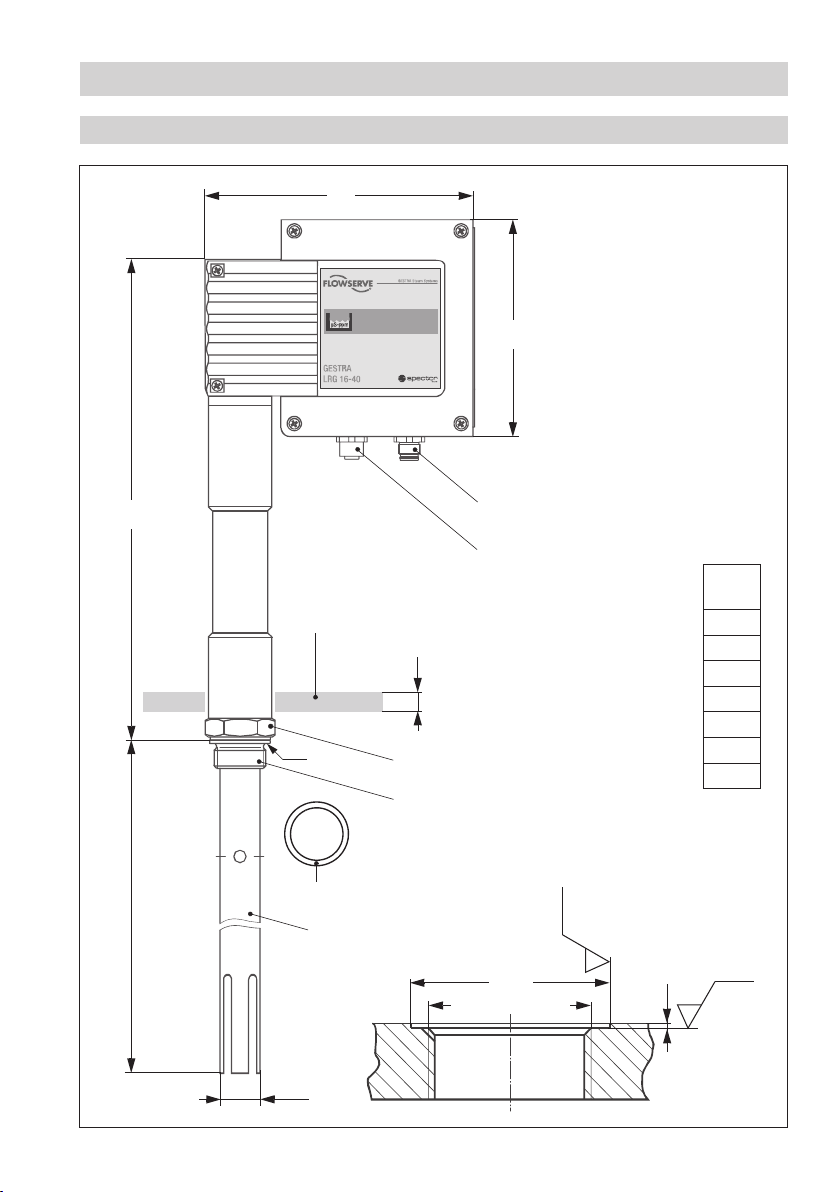

Dimensions LRG 16-40 ........................................................................................................................

Dimensions LRG 17-40 ........................................................................................................................

Key .......................................................................................................................................................14

Functional Elements

LRG 16-40 / LRG 17-40 ........................................................................................................................13

Key .......................................................................................................................................................14

Installation

Installation notes ..................................................................................................................................15

Mounting conductivity electrode ...........................................................................................................15

Terminal box .........................................................................................................................................16

Opening terminal box ............................................................................................................................16

Aligning terminal box ............................................................................................................................ 16

Removing terminal box .........................................................................................................................16

Mounting terminal box .......................................................................................................................... 17

Closing terminal box .............................................................................................................................17

Tools ....................................................................................................................................................17

Example of Installation

Conductivity metering ........................................................................................................................... 18

Conductivity metering and continuous boiler blowdown ..................................................................18, 19

Key .......................................................................................................................................................19

7 – 9

11

12

2

Page 3

Contents – continued –

Page

Wiring

Bus cable .............................................................................................................................................20

Note .....................................................................................................................................................20

Assigning the connector and jack .........................................................................................................20

Wiring diagram of conductivity electrode LRG 16-40, LRG 17-40 .................................................... 21, 22

Attention ...............................................................................................................................................22

Basic Settings

Factory settings .................................................................................................................................... 22

Commissioning

Check wiring ........................................................................................................................................23

Apply mains voltage..............................................................................................................................23

Setting parameters ...............................................................................................................................23

Operation

Start .....................................................................................................................................................23

System Malfunctions

Causes .................................................................................................................................................24

Note .....................................................................................................................................................24

Systematic malfunction analysis ........................................................................................................... 25

Malfunctions

Fault finding list for troubleshooting ................................................................................................ 26, 27

Cleaning measuring electrode .............................................................................................................. 27

Replacing electronic circuit board ......................................................................................................... 27

Note .....................................................................................................................................................27

Decommissioning

Replacing conductivity electrode ...........................................................................................................28

Danger / Attention ................................................................................................................................. 28

Disposal................................................................................................................................................28

Annex

CAN bus ...............................................................................................................................................29

Factory set node IDs .............................................................................................................................29

Node ID ................................................................................................................................................29

Establishing / changing node ID ............................................................................................................ 30

Attention ...............................................................................................................................................30

Table “Node ID” ....................................................................................................................................31

Declaration of conformity ......................................................................................................................32

3

Page 4

Important Notes

Usage for the intended purpose

Use conductivity electrodes LRG 16-40/LRG 17-40 only for measuring the electrical conductivity of

liquid fluids.

For conductivity limiting or continuous boiler blowdown the conductivity electrodes LRG 16-40/

LRG 17-40 must only be used in conjunction with TDS controller LRR 1-40 and an operating terminal &

display unit type URB or SPECTORcontrol.

To guarantee a trouble-free operation observe the requirements made on water quality as specified in

the pertinent TRD and EN regulations.

Safety note

The equipment must only be installed and commissioned by qualified staff.

Maintenance and service work must only be performed by adequately trained persons who have

a recognized level of competence.

Danger

When loosening the electrode steam or hot water might escape.

This presents the danger of severe scalding. It is therefore essential not to remove or

install the electrode unless the boiler pressure is verified to be zero.

The electrode is hot during operation. This presents the danger of severe burns to hands

and arms. Installation and maintenance work should only be carried out when the system

is cold.

PED (Pressure Equipment Directive)

The equipment fulfills the requirements of the Pressure Equipment Directive (PED) 97/23/EC.

Applicable in fluids of group 1 and 2. With CE marking (apart from equipment according to section 3.3).

ATEX (Atmosphère Explosible)

According to the European Directive 94/9/EC the equipment must not be used in explosion-risk areas.

4

Page 5

Explanatory Notes

Scope of supply

LRG 16-40

1 Level electrode type LRG 16-40

1 S. S. joint ring

1 Terminating resistor 120

1 Installation manual

LRG 17-40

1 Level electrode type LRG 17-40

1 S. S. joint ring

1 Terminating resistor 120

1 Installation manual

Description

The conductivity electrode LRG 1x-40 consists of a TDS (= Total Dissolved Solids) monitoring electrode

for conductivity measurement, a temperature sensor for detecting the fluid temperature and a conductivity transmitter that is fully integrated in the terminal box.

The equipment is of the two electrode type and works according to the conductometric measurement

principle, measuring the electrical conductivity of electrically conductive fluids.

Together with the TDS controller LRR 1-40 and an operating device type URB or SPECTOR

the conductivity electrode LRG 1x-40 can be used as conductivity limiter and continuous blowdown

controller in steam boilers and (pressurized) hot water plants.

The data exchange between the conductivity electrode LRG 1x-40, the control and operating equip

ment and other devices is effected by the CAN-Bus to ISO 11898, using the CANopen protocols.

∅ 33 x 39, form D, DIN 7603 (made of 1.4301), bright annealed

∅ 33 x 39, form D, DIN 7603 (made of 1.4301), bright annealed

Ω

Ω

control

-

Function

A measuring current of variable frequency flows through the fluid and creates a potential gradient

between the measuring electrode and the measuring tube. The potential gradient is evaluated as

measuring voltage UU.

The electrical conductivity is a function of temperature. To relate the measured values to a reference

temperature the resistance thermometer integrated in the electrode measures the fluid temperature.

The electrical conductivity is calculated from the measuring voltages UU and UI and – through

temperature compensation – is based on a reference temperature of 25 °C.

The electrical conductivity is a non-linear function of temperature. For the compensation of the

measured values one of the following three procedures can be applied:

n Temperature compensation Auto: The conductivity electrode records the specific conductivity/

temperature curve of the respective fluid and based on the data obtained, performs the compensation.

The auto-curve temperature compensation is suitable for boilers operating with variable pressure,

which means that the boiler does not have a fixed working pressure (e. g. low load 10 bar, full load

15 bar). The system detects in steps of 10°C all temperatures and conductivity values from 100 °C

to the service temperature. For this purpose the boiler must reach its working pressure (with variable

pressure operation: max. allowable working pressure). If the standard curve is not suitable for variable

pressure operation, use can be made of the recorded curve.

5

Page 6

Explanatory Notes – continued –

Function – continued –

n Temperature compensation NORM: The conductivity/temperature curves of 11 normally used

conditioning agents are stored in the electrode and can be selected.

The standard curve temperature compensation is suitable for boilers operating with variable pressure,

which means that the boiler does not have a fixed working pressure (e.g. low load 10 bar, full load

15 bar). The standard curves of feedwater conditioning agents with different basic conductivities com

pensate for the influence of the temperature on readings within the operating range.

n Temperature compensation LINEAR: A fixed temperature coefficient (Tk) is used to correct the

measured conductivity value linearly.

The gradient (default setting: 2.1 % / °C) is normally used for steam boilers operating with constant

pressure. The conductivity is ascertained at an ambient temperature of 25°C. The cell constant can

be modified in order to calibrate the value measured by the electrode. The gradient can be verified at

operating pressure with the aid of a calibrated conductivity meter.

At regular intervals the conductivity electrode LRG 1x-40 sends a data telegram via CAN-bus to the

controller with the following information:

n Measured conductivity value, referred to 25°C as actual value (X),

n Measuring range / adaptation of actual value output,

n Alarm: self-monitoring of electrode supply cables,

n Alarm: temperature sensor defective,

n Alarm: excessively high temperature in terminal box.

A short circuit in the cables leading to the measuring electrode, the measuring tube and the resistance

thermometer or the interruption of the data transmission via CAN bus will be indicated by a malfunction message.

A sensor monitors the temperature in the terminal box and indicates a malfunction if the limit value is

exceeded.

-

System components

LRR 1-40

Digital switching controller for conductivity electrode LRG 1x-40

Functions: Conductivity limiter, continuous blowdown controller

Data exchange via CAN bus to ISO 11898 using CANopen protocol

URB 1, URB 2

Operating & display unit

Functions: Parameterization, indication via LCD display

Data exchange via CAN bus to ISO 11898 using CANopen protocol

Design

LRG 1x-40

Screwed 1", ISO 228-1.

Fig. 3, Fig. 4

6

Page 7

Technical Data

LRG 16-40, LRG 17-40

Type approval no.

TÜV.WÜL.02-007

EG BAF-MUC 02 05 103881 003

Service pressure

LRG 16-40: 32 bar at 238°C

LRG 17-40: 60 bar at 275°C

Connection

Screwed 1" BSP (to ISO 228-1)

Materials

Screw-in enclosure: 1.4571, X6CrNiMoTi17-12-2

Measuring electrode/reference tube/screw: 1.4571, X6CrNiMoTi17-12-2

Electrode insulation: PTFE

Terminal box: 3.2161 G AlSi8Cu3

Spacer disc: LRG 16-40: PEEK

Spacer disc: LRG 17-40: PEEK HT

Length of installation / measuring length

200, 300, 400, 500, 600, 800 and 1000 mm

Temperature sensor

Resistance thermometer PT 1000

Cell constant C

-1

0.2 cm

Conductivity measuring range

0.5 – 12000 μS/cm at 25°C

0.25 – 6000 ppm (parts per million)

Note

The electrical conductivity is measured in μS/cm. For ppm (parts per million) use the

following conversion: 1 μS/cm = 0.5 ppm.

7

Page 8

Technical Data – continued –

LRG 16-40, LRG 17-40 – continued –

Measuring cycle

1 sec.

Accuracy

5 %, referred to conductivity readings without temperature compensation

Temperature compensation

Type of temp. compensation can be adjusted with URB or SPECTORcontrol:

n Temperature compensation AUTO:

with conductivity/temperature curve characteristic of the installation.

n Temperature compensation NORM:

with standard conductivity/temperature curve.

n Temperature compensation LINEAR:

with set temperature coefficient (Tk).

Time constant T (measured as specified in DIN 3440)

Temperature: 9 sec.

Conductivity: 14 sec.

Input/Output

CAN bus interface with power supply 18 – 36 V DC, short circuit protected

Data exchange

CAN-bus to ISO 11898, CANopen protocol

Power consumption

3.8 W

Fuse

Electronic thermal fuse Tmax 85°C, hysteresis -2K.

Indicators and adjustors

Two LEDs for internal status messages.

One 10-pole code switch for node-ID and baud rate settings.

Electric connection

M 12 sensor connector, 5 poles, A coded

M 12 sensor jack, 5 poles, A coded

Protection

IP 65 to EN 60529

Ambient temperature

Max. 70°C

Weight

Approx. 2.5 kg

8

Page 9

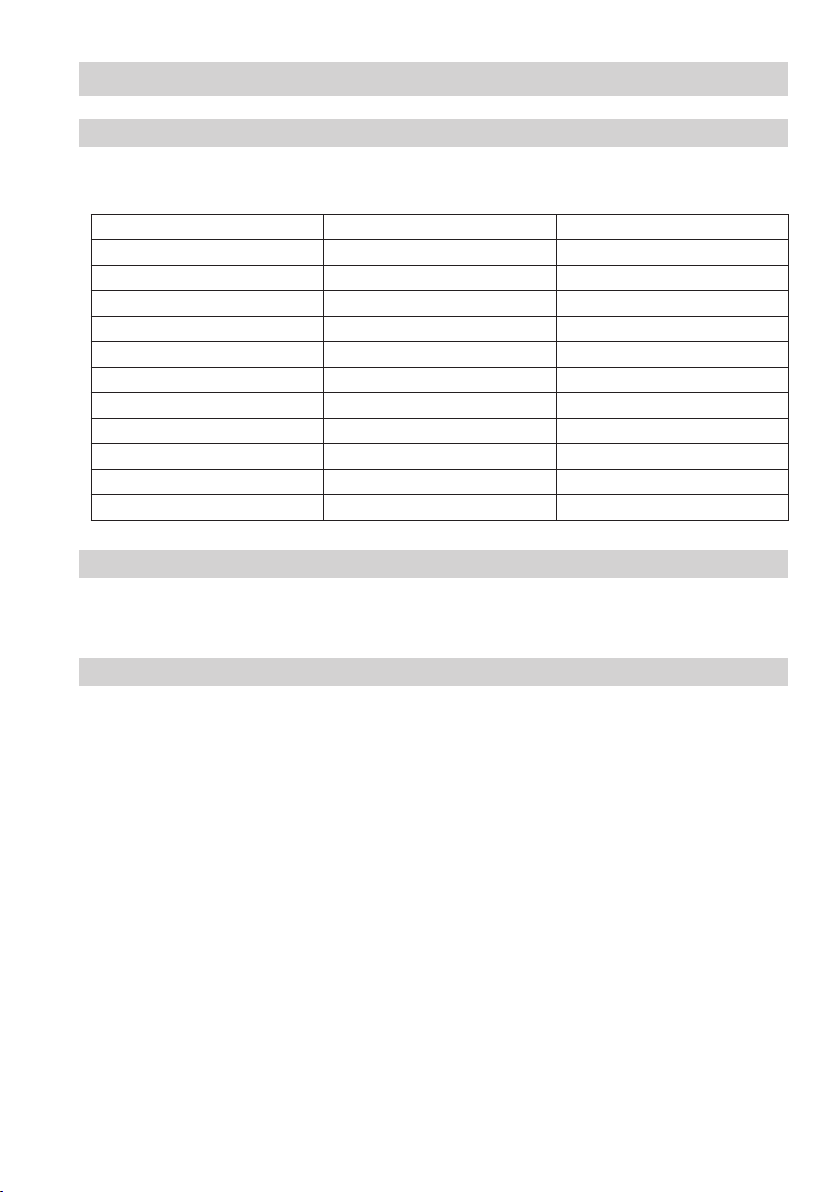

Technical Data – continued –

LRG 16-40, LRG 17-40 – continued –

The standard conductivity-/temperature curves can be adjusted using the operating & display devices

SPECTORcontrol and URB.

Standard curve Conditioning agent Basic conductivity at 25°C

1 NaOH (caustic soda) 260 μS/cm

2 NaOH (caustic soda) 1080 μS/cm

3 NaOH (caustic soda) 5400 μS/cm

4 NaOH (caustic soda) 11000 μS/cm

5 Na3PO4 (trisodiumphosphate) 190 μS/cm

6 Na3PO4 (trisodiumphosphate) 1100 μS/cm

7 Na3PO4 (trisodiumphosphate) 5900 μS/cm

8 Na3PO4 (trisodiumphosphate) 11200 μS/cm

9 Na2SO3 (sodium sulfite) 980 μS/cm

10 Dipolique 444 200 μS/cm

11 Levoxin 195 μS/cm

Corrosion resistance

If the conductivity electrode LRG 1x-40 is used for its intended purpose, its safety is not impaired by

corrosion.

Sizing

The electrode body must not be subjected to sharp increases/decreases in pressure. The dimensional

allowances for corrosion reflect the latest state of technology.

9

Page 10

Technical Data – continued –

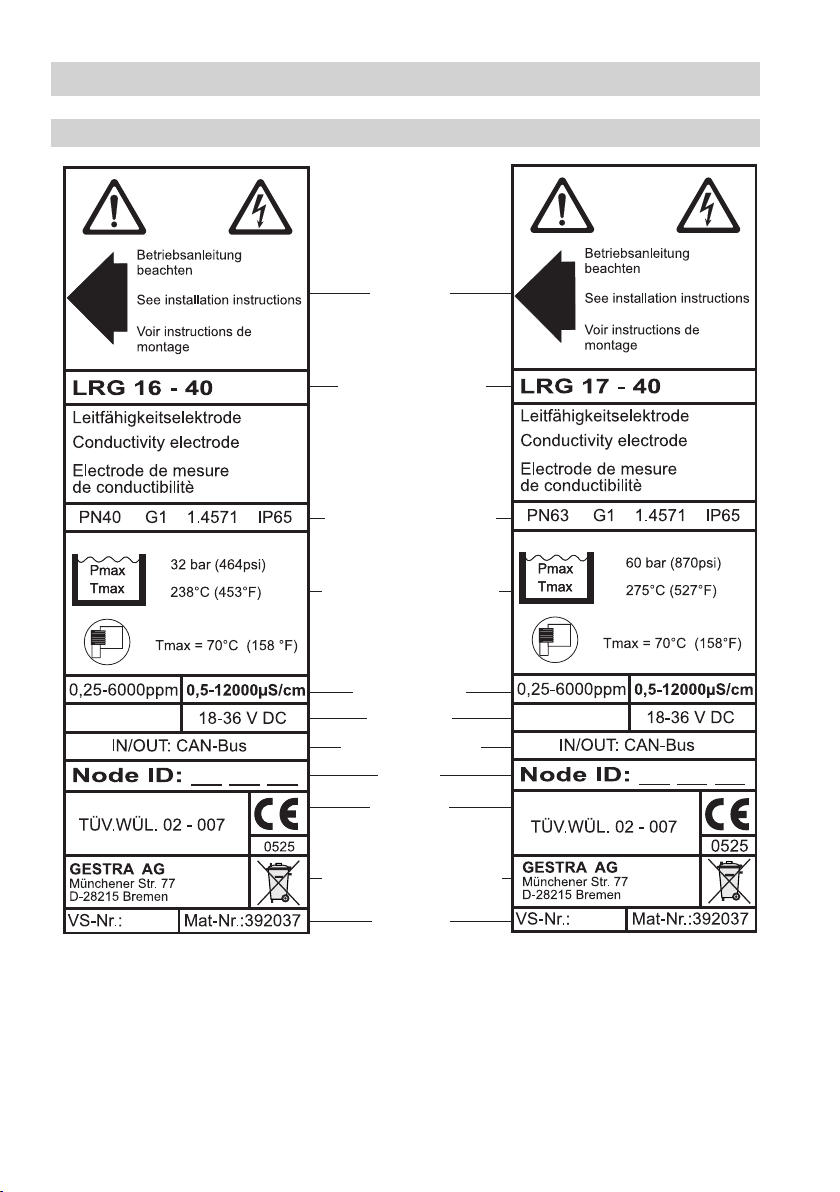

Name plate / Marking

Safety note

Equipment designation

Pressure rating, thread type,

material number, protection

Pressure/temperature rating

Fig. 1

10

Measuring range

Power rating

Output characteristics

Node ID

CE marking

Manufacturer / Disposal note

Spare part

specification

Fig. 2

Page 11

Technical Data – continued –

Dimensions LRG 16-40

173

140

b = 68

G

Fig. 3

336

∅ 28

C

D

E

F

A

B

20

A. F. 41

1" BSP (ISO 228-1)

∅ 40

1" BSP (ISO 228-1)

G

[mm]

200

300

400

500

600

800

1000

Ra 12.5

Ra 3.2

0.5

11

Page 12

Technical Data – continued –

Dimensions LRG 17-40

173

140

b = 68

G

Fig. 4

336

∅ 28

C

D

E

F

A

B

20

A. F. 41

1" BSP (ISO 228-1)

1" BSP (ISO 228-1)

∅ 40

G

[mm]

200

300

400

500

600

800

1000

Ra 12.5

Ra 3.2

0.5

12

Page 13

1

2

3

4

5

6

PT1000

Schaltwippe weiß

IP 65

MAX 70°C

MAX 95%

Functional Elements

LRG 16-40 / LRG 17-40

Fig. 5

Fig. 6

O

N

M

H

I

L

1

32

Code switch, white

J

K

13

Page 14

Technical Data / Functional Elements – continued –

Key

1 LED 1 (green)

2 LED 2 (red)

3 Code switch

A M 12 sensor connector, 5 poles, A coded

B M 12 sensor jack, 5 poles, A coded

C Thermal insulation

D Seating surface

E Joint ring ∅ 33 x 39, form D, DIN 7603, material: 1.4301, bright-annealed

F Measuring tube

G Length of installation and measuring length

H Cover screws (cross recess head screws M4)

I Cover

J Terminal strip

K Fixing screws for electronic circuit board

L Connection for functional earth

M Joint ring

N Fixing nut for terminal box

O Terminal lugs for electrode wires, functional earth

14

Page 15

Installation

Installation notes

Attention

n The seating surfaces and threads on the vessel and mounting flange must be

accurately machined.

n Use only the supplied ring joint ∅ 33 x 39, form D, to DIN 7603,

material: 1.4301, bright-annealed!

n Do not insulate the threads with hemp or PTFE tape!

n Do not lag the electrode body.

n Install electrode horizontally or with a vertical inclination. The measuring surface must

be permanently submerged.

n Provide a spacing of approx. 30 mm between the lower end of the measuring tube

and the boiler wall, the smoke tubes and any other metallic fittings as well as the low

water level.

n The specified torques must be strictly observed.

Note

n For the approval of the boiler standpipe the relevant local and national regulations must

be observed.

n Three examples of installation are shown on pages 18 and 19.

Mounting conductivity electrode

1. Check seating surfaces of threads or mounting flange provided on vessel or boiler standpipe

(see Fig. 3 and Fig. 4). If necessary rework the surfaces according to the specifications indicated in

the drawing.

2. Place joint ring

E onto the seating surface D of the conductivity electrode.

3. Apply a light smear of silicone grease to the electrode thread.

4. Screw conductivity electrode into thread or flange provided on vessel or boiler standpipe

(see page 11) and tighten with an open-end spanner A. F. 41 mm. The torque required when cold is

150 Nm.

15

Page 16

Installation – continued –

Terminal box

Note

When the terminal box is open it can be aligned, removed and mounted, the terminal

strips can be wired, and – if necessary – the baud rate and node-ID settings can be

changed all in a single operation.

Opening terminal box

1. Undo cover screws

the cover to be removed.

Aligning terminal box

Terminal box open:

1. Use open-end spanner A. F. 19 to loosen the fixing nut

direction (cable gland!).

2. Re-tighten the fixing nut

If necessary you can take off the terminal box in order to align the electrode part. The terminal box

must be re-installed after alignment.

Removing terminal box

Terminal box open:

1. Unplug the electrode wires from terminal lugs for electronic circuit board

2. Use open-end spanner A. F. 19 to unscrew the fixing nut

N.

3. Remove terminal box. Run all electrode wires through the hole for the fixing screw (see

4. Remove the joint ring

H and remove terminal cover I. The arrow on the name plate points towards

N and turn the terminal box in the desired

N with a torque of 25 Nm.

O, functional earth L.

N. Pull electrode wires through fixing nut

Fig. 6).

M between the electrode and the terminal box.

16

Page 17

Installation – continued –

Mounting terminal box

1. Put joint ring M onto the electrode.

2. Run all electrode wires through the hole for the fixing screw (see

3. Place the terminal box onto the electrode part and turn it into the desired direction (cable gland).

Make sure that the joint ring is properly placed between the electrode and the terminal box.

4. Pull all electrode wires through the fixing nut

hexagon nut to the fixing screw, applying a torque of 25 Nm.

5. Connect the electrode wires according to the wiring diagram (see page 21) to the terminal lugs

(electronic circuit board O, functional earth L).

Closing terminal box

When the work is finished:

1. Install the terminal cover

ring.

Tools

n Open-end spanner A. F. 19 mm

n Open-end spanner A. F. 41 mm

n Screwdriver for cross recess head screws, size 1 and 2

I and tighten the cover screws H, ensuring correct position of the joint

N. Use an open-end spanner A. F. 19 to fasten the

Fig. 6) in the terminal box.

17

Page 18

Example of Installation

Conductivity metering, direct installation of electrode LRG 16-40 via lateral flanged connection

NW

LW

NB

NB

R 30

400

4

336

~250

1" BSP (ISO 228-1)

LRG 16-40

E

Fig. 7

Conductivity metering and continuous boiler blowdown, direct installation of electrode LRG 16-40 via

measuring pot and connection of continuous blowdown valve

NW

LW

NB

NB

600

~250

197

DN 50

336

1" BSP

(ISO 228-1)

Fig. 8

18

R 30

4

5 6 7 E

LRG 16-40

DN

[mm]A [mm]

15 182

20 184

25 184

40 189

Page 19

M

R

T

SEG

A

t

sySmaetS

mes

R

T

SEG

A

t

sySmaetS

mes

R

T

S

E

G

A

1

-6

1

TG

R

L

R

T

S

E

G

A

1

-6

1

TG

R

L

mp

p-Sµ

Example of Installation – continued –

Conductivity metering and continuous boiler blowdown, installation of electrode LRG 16-40 in top

blowdown line via separate measuring pot

Outlet

6

5

Inlet

DN 15-40

Fig. 9

Key

E Joint ring ∅ 33 x 39, form D, DIN 7603, material: 1.4301, bright-annealed

4 Boiler drum

5 Shut-off valve GAV

6 Continuous blowdown valve BAE 36

DN 15-40

1" BSP (ISO 228-1)

LRG 16-40

7 Measuring pot

19

Page 20

Wiring

Bus cable

Use screened multi-core twisted-pair control cable – e.g. UNITRONIC® BUS CAN 2 x 2 x...mm2 or

RE-2YCYV-fl 2 x 2 x...mm

2

as bus cable or the preassembled control cable that is available as

accessory.

The baud rate (data transfer rate) dictates the cable length between the bus nodes, and the total power

consumption of the sensor dictates the conductor size.

S 8 S 9 S 10 Baud rate Cable length

OFF ON OFF 250 kBit/s 125 m

Factory setting

ON ON OFF 125 kBit/s 250 m 2 x 2 x 0.5

OFF OFF ON 100 kBit/s 335 m 2 x 2 x 0.75

ON OFF ON 50 kBit/s 500 m

OFF ON ON 20 kBit/s 1000 m

ON ON ON 10 kBit/s 1000 m

Number of pairs and

conductor size [mm2]

2 x 2 x 0.34

available on demand

(depends on bus configuration)

The baud rate is set via code switches 3 (S8 to S10), Fig. 6. Default factory setting of conductivity

electrode LRG 1x- 40: baud rate 250 kbit/s (cable length 125 m).

For longer cable lengths reduce baud rate accordingly. Make sure that all bus nodes feature the same

settings.

Note

The max. baud rates and cable lengths indicated above are based on empirical values

obtained by GESTRA. In certain cases it may be necessary to reduce the baud rate in

order to ensure operational safety.

The design and preparation of the data cable is an important factor for the electromagnetic compatibility (EMC) of the equipment. Wiring should therefore be carried out

with special care.

Assigning the connector and jack

If you do not use the preassembled control cable, connect the connector and the jack for the CAN bus

lines according to the wiring diagram.

UNITRONIC® is a registered trademark of LAPP Kabelwerke GmbH, Stuttgart.

20

Page 21

Wiring – continued –

Wiring diagram of conductivity electrode LRG 16-40, LRG 17-40

Terminal lug

Measuring electrode

Temperature sensor

Ground

Connecting for

functional earth

Terminating resistor 120 Ω

3 144512 253

6

Code switch, white

Code switch for

setting the node ID

and baud rate

e. g. UNITRONIC®

BUS CAN 2 x 2 x...2

twisted pair cable

Key

1 Screen

2 Voltage supply 24 V DC+

3 Voltage supply 24 V DC–

4 CAN Data line C

5 CAN Data line C

H

L

6 Terminating resistor 120 Ω

CEP

Central

Operating device

URB 2

Coupler with terminating resistor 120 Ω

earthing

point

Controller

NRS ...

LRR ...

TRS ...

Fig. 10

UNITRONIC® is a registered trademark of LAPP Kabelwerke GmbH, Stuttgart.

Level electrode

Conductivity electrode

NRG ...

LRG ...

Connector with terminating resistor 120

Temperature

transmitter

TRV ...

Ω

21

Page 22

Wiring – continued –

Wiring diagram of conductivity electrode LRG 16-40, LRG 17-40 – continued –

Attention

n Wire equipment in series. Star-type wiring is not permitted!

n Link screens of bus cables such that electrical continuity is ensured and connect them

once to the central earthing point (CEP).

n In the CAN bus network the first and the last equipment of the data line must be

provided with a terminating resistor of 120 ohm (terminal C

n The CAN bus data line must not be interrupted during operation.

L/CH

In the event of an interruption an alarm message will be generated.

Basic Settings

Factory settings

The conductivity electrode features the following factory set default values:

n Baud rate: 250 kbit/s (125 m bus cable length)

n Node ID: 051

Enter the assigned node ID on the name plate.

).

22

Page 23

Commissioning

Check wiring

Before commissioning the equipment please check:

n Is the wiring of all CAN bus devices in accordance with the wiring diagrams?

n Is the polarity of the bus line always correct?

n Are the bus lines of the first and last devices provided with 120 Ω terminating resistors?

Apply mains voltage

n Apply mains voltage to control unit LRR 1-40 or apply bus supply voltage.

n The green LED 1 lights up and goes out approx. every 5s. The data exchange is continuous.

Setting parameters

Use operating device URB or SPECTORcontrol to configure, parameterize, operate and show the control

parameters of the conductivity electrode.

Operation

Start

1. Apply mains voltage.

2. LED

1 is illuminated.

3. LED

1 briefly goes out after 5 sec.

4. Data exchange takes place.

5. LED

1 is illuminated.

If no switching-over takes place between the break and the data exchange, refer to “Malfunctions”.

23

Page 24

System Malfunctions

Causes

Faulty installation and/or configuration of CAN bus components, excessive temperatures in the devices,

defective electronic component parts or electromagnetic interferences of the supply system can result

in system malfunctions.

Other malfunctions are:

n Incorrect communication in the CAN bus system

n Overloading of the 24 V power supply unit that is integrated in the control unit

Note

Before carrying out the systematic malfunction analysis please check:

Wiring:

Is the wiring in accordance with the wiring diagrams?

Is the polarity of the bus lines always correct?

Are the bus lines of the first and last devices provided with 120 Ω terminating resistors?

Node ID:

Are all node ID settings correct?

Note that no node ID setting must be used twice!

Baud rate:

Does the baud rate setting correspond with the cable length?

Is the baud rate setting of all devices identical?

24

Page 25

System Malfunctions – continued –

Systematic malfunction analysis

The sources of malfunctions occurring in CAN bus systems operating with several bus-based stations

must be analysed systematically since faulty components or incorrect settings can give rise to

negative interactions with intact bus devices in the CAN bus system. These unwanted interactions

can cause error messages in fully functional bus devices, which will make fault detection even more

difficult.

We recommend the following systematic fault finding procedure:

Step 1 (Start)

Detach terminal strips

in all sensing units of

bus devices.

Level electrode

Conductivity electrode

Pressure sensor

Temperature sensor

etc.

Check

Use fault-finding

list to correct

fault(s)!

Final test:

Have all faults

been eliminated?

System

Malfunction

Use fault-finding

list to identify

the fault(s)!

Cut off power supply

to the equipment!

Step 2

Plug in terminal strips

of the sensing unit

of one system

e. g. NRS ...

and

NRG ... (electrodes)

Step 3

Apply mains voltage

to bus devices

of the system

e. g. NRS ...

and

NRG ...

Check next system

System O.K.

Detach terminal strips

between bus devices

of the system

e. g. NRS ...

and

NRG ...

25

Page 26

Malfunctions

Fault finding list for troubleshooting

Equipment does not work

Fault: No voltage supply, no function.

Remedy: Check voltage supply and wiring.

Fault: The electronic circuit board is defective.

Remedy: Replace electronic circuit board.

Only the red LED 2 is flashing

Fault: Conductivity electrode defective (internal connecting wires are short circuited or

Remedy: Replace conductivitiy electrode.

Fault: Measuring surface of conductivity electrode is exposed.

Remedy: Check installation and make sure that the measuring surface is submerged.

Fault: The measuring surface is contaminated and therefore an incorrect actual value is indicated

Remedy: Remove conductivity electrode and clean measuring surface.

Fault: Dirt deposits on the measuring surface cause MAX or MIN alarms although the actual value

Remedy: Remove conductivity electrode and clean measuring surface.

Fault: The earth connection to the vessel is interrupted. No function.

Remedy: Clean seating surfaces and screw in the equipment together with the supplied joint ring

Green LED 1 and red LED 2 are flashing alternately

Fault: The thermal fuse has been triggered.

Remedy: Check installation. The ambient temperature must not exceed 70°C. As soon as the tem-

interrupted, insulating seal defective).

(ascertained by reference measurement).

is between these limits (reference measurement).

∅ 33 x 39, form D, DIN 7603 (material: 1.4301, bright-annealed). Do not insulate the

electrode with hemp or PTFE tape!

perature falls below the max. admissible limit, the equipment switches back to operating

mode.

Fault: The fluid temperature sensor is either short circuited or interrupted.

Remedy: Replace conductivitiy electrode.

26

Page 27

Malfunctions – continued –

Fault finding list for troubleshooting – continued –

Green LED 1 and red LED 2 are not illuminated

Fault: The electrode and the control unit cannot communicate.

Remedy: Check 24 V bus supply, wiring, node ID, baud rate and terminating resistors.

If modifications have to be made, switch off the mains voltage and switch it on again after

about. 5 sec.

Cleaning measuring electrode

The equipment must only be installed and removed by qualified and competent staff.

Take chapter “Installation” into account.

Before cleaning the measuring electrode, decommission and remove the conductivity electrode.

Then undo the safety grub screw and unscrew manually the measuring tube.

Cleaning electrode rod and measuring surface:

n Wipe off non-adhesive deposits with a grease-free cloth.

n To remove adhesive deposits use emery cloth (medium grain).

Replacing electronic circuit board

1. Undo cover screws

2. Pull the electrode wires out of the terminal lugs

Remove terminal strip J.

3. Undo earth connection

4. Unscrew the fixing screws

circuit board is available as spare part type LRV 1-41.

5. Install the new electronic circuit board in reverse order.

H and remove terminal cover I.

O on the circuit board.

L.

K of the electronic circuit board and take out the circuit board. The

Note

When ordering spare parts please state the serial number indicated on the name plate.

After replacing the electronic circuit board carry out reference measurements in order

to check the conductivity readings indicated by the operating device URB or

SPECTORcontrol.

If deviations occur correct the cell constant of the electrode. Observe the installation

instructions of URB or SPECTORcontrol.

27

Page 28

Decommissioning

Replacing conductivity electrode

1. Switch off power supply for all control units of the CAN bus system.

2. Undo cover screws

3. Unplug terminal strip

4. Remove conductivity electrode.

5. Install and connect new conductivity electrode.

6. Apply supply voltage to all control units.

Attention

The CAN-bus data line must not be interrupted during operation. Before removing bus

cables from the terminal strip make sure that all connected devices are out of service.

If data lines of equipment sending data are interrupted a malfunction message will be

generated.

Disposal

H and remove terminal cover I.

J.

Danger

Risk of severe burns and scalds to the whole body!

Before removing the electrode make sure that the vessel and the measuring pot are

depressurised (O bar) and cooled down to room temperature (20 °C).

Remove the conductivity electrode and separate the waste materials in accordance with the material

specification.

Electronic components (boards) must be disposed of separately.

For the disposal of the conductivity electrode observe the pertinent legal regulations concerning waste

disposal.

28

Page 29

Annex

CAN bus

All devices (level, conductivity) are interconnected via CAN bus. The CANopen protocol is used for the

data exchange between the equipment groups. All devices have an electronic address – the node ID.

The four-core bus cable serves as power supply and data highway for high-speed data exchange.

The CAN address (node ID) can be set between 1 and 123.

The conductivity electrode LRG 1x-40 has already been configured at our works for operation with

other GESTRA components and can be used straight away without having to set the node ID.

Factory set node IDs

Control Units Sensors

NRS1-40 ID:001

NRS 1-41 ID:006

NRS 1-42 ID:020

NRS 2-40 ID:039

NRR 2-40 ID:040

LRR 1-40 ID:050

NRG 16-40 ID:002

NRG 16-40 ID:003

NRG 16-41 ID:007

NRG 16-42 ID:021

NRG 26-40 ID:041

LRG 16-40 ID:051

Individual node IDs must be set manually in the respective equipment.

Please observe the pertinent installation instructions.

Node ID

Should it be necessary to establish other node IDs please take the interdependence of the equipment

into consideration and assign the node IDs for the individual group components according to the

following table:

Controller

URZ 40a

Intermittent

blowdown valve

BAE 3x-40

X – 1 X X + 1 X + 2

49 50 51 52

Control unit

LRR 1-40

Reserved area

Conductivity

electrode

LRG 1x-40

Reserved

Factory setting

29

Page 30

Annex – continued –

Establishing / changing node ID

In order to enable communication within the CAN bus system, each item of equipment (e.g. controller)

must have a unique node ID.

Terminal box open:

1. Use a thin blade screwdriver to set the node ID via code switches

reference.

2. Replace terminal cover

3. Enter the adjusted node ID on the name plate.

4. If necessary (refer to installation instructions) change the node ID of the control equipment

LRR 1-40.

Attention

A node ID must not be used for more than one item of equipment in the CAN bus system.

The node ID 0 is not permissible.

I and fasten cover screws H tightly.

3 S1 – S7. Use the table as

30

Page 31

Annex – continued –

ON

1

23546

7 8

9 0

ON

1

23546

7 8

9 0

ON

1

23546

7 8

9 0

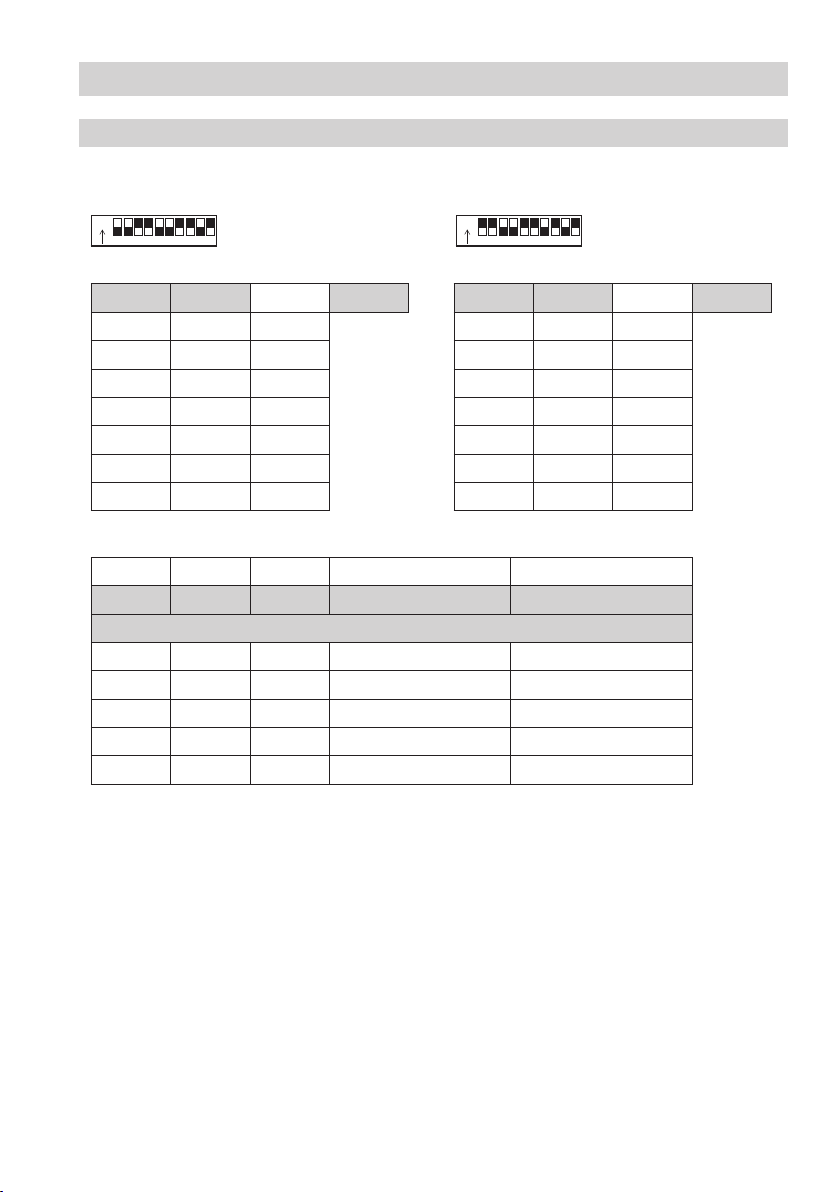

Table “Node ID”

In a CAN bus system a maximum of 123 nodes (devices) can be administered. Each node has its own

address (node ID). This address can be set via a 10-pole code switch

3.

3 3

Code switch, white Code switch, white

Node ID 51

S1

S2

ON 1

ON 2

S3 OFF 4

S4 OFF 8

S5 ON 16

S6 ON 32

S7 OFF 64

(Factory setting)

S1

S2

S3 ON 4

S4 ON 8

S5 OFF 16

S6 OFF 32

S7 ON 64

(Example)

OFF 1

OFF 2

S 8 S 9 S 10 Baud rate Cable length

OFF ON OFF 250 kBit/s 125 m

Factory setting

ON ON OFF 125 kBit/s 250 m

OFF OFF ON 100 kBit/s 335 m

ON OFF ON 50 kBit/s 500 m

OFF ON ON 20 kBit/s 1000 m

ON ON ON 10 kBit/s 1000 m

Node ID 76

31

Page 32

Annex – continued –

Declaration of Conformity

We hereby declare that the equipment LRG 16-40, LRG 17-40 conform to the following European

guidelines:

n LV guideline 73/23/eec version 93/68/eec

n Pressure Equipment Directive (PED) 97/23/EC of 29 May 1997

Applied conformity assessment procedure: Annex III, Module B and D,

verified by notified body 0525

This declaration is no longer valid if modifications are made to the equipment without consultation with

us.

Bremen, 1st December 2005

GESTRA AG

Dipl.-Ing. Uwe Bledschun

(Academically qualified engineer)

Head of Design Dept.

Dipl.-Ing. Lars Bohl

(Academically qualified engineer)

Quality Assurance Representative

32

Page 33

For your notes

33

Page 34

For your notes

34

Page 35

For your notes

35

Page 36

Agencies all over the world:

www.gestra.de

GESTRA

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 34 91 / 5 15 20 32

Fax 00 34 91 / 4 13 67 47; 5 15 20 36

E-mail: aromero@flowserve.com

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: gestraukinfo@flowserve.com

Italia

Flowserve S.p.A.

Flow Control Division

Via Prealpi, 30

l-20032 Cormano (MI)

Tel. 00 39 02 / 66 32 51

Fax 00 39 02 / 66 32 55 60

E-mail: infoitaly@flowserve.com

Polska

GESTRA POLONIA Spolka z.o.o.

Ul. Schuberta 104

PL - 80-172 Gdansk

Tel. 00 48 58 / 3 06 10 -02 od 10

Fax 00 48 58 / 3 06 33 00

E-mail: gestra@gestra.pl

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0 03 51 22 / 6 19 87 70

Fax 0 03 51 22 / 6 10 75 75

E-mail: jtavares@flowserve.com

USA

Flowserve GESTRA U.S.

2341 Ampere Drive

Louisville, KY 40299

Tel.: 00 15 02 / 502 267 2205

Fax: 00 15 02 / 502 266 5397

E-mail: dgoodwin@flowserve.com

GESTRA AG

P. O. Box 10 54 60, D-28054 Bremen

Münchener Str. 77, D-28215 Bremen

Telephone +49 (0) 421 35 03 - 0

Fax +49 (0) 421 35 03 -393

E-Mail gestra.ag@flowserve.com

Internet www.gestra.de

818524-01/806cm · 2005 GESTRA AG · Bremen · Printed in Germany

36

Loading...

Loading...