Page 1

USER INSTRUCTIONS

LPS Pneumatic Heavy-Duty Actuator Series

Single Acting & Double Acting

FCD LFENIM0001-02-AQ

Installation

Operation

Maintenance

Experience In Motion

Page 2

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Contents

1 Standard Information 4

Using Flowserve Valves, Actuators and Accessories Correctly 4

1.1 Terms Concerning Safety 4

1.2 General Usage 5

1.3 Protective Clothing 5

1.4 Qualified Personnel 5

1.5 Other Requirements for In-plant Installation 6

1.6 Spare Parts 6

1.7 Service/Repair 6

1.8 Actuator Lifting and Handling 6

1.9 Storage 9

1.10 Valve and Actuator Variations 10

1.11 Unpacking 10

2 Installation Instructions 11

2.1 Valve and Actuator Check 11

2.2 Connection With Valve and Mounting Kit 12

2.3 Travel-stop Bolts and Accessories 13

2.4 Grounding System 13

2.5 Initial Operation 14

2.6 Fail Open and Fail Close Configuration 15

3 Field Conversion 16

Field Conversion From Fail CW to Fail CCW or Vice Versa (for Spring Return Actuators) 16

3.1 Actuator Disassembled From the Valve 16

3.2 Actuator Connected to the Valve (and the valve can be stroked) 17

4 Maintenance Instructions 19

4.1 General Disassembly Instructions 20

4.2 Spring Container Maintenance 20

4.3 Pneumatic Cylinder Maintenance 22

4.4 Scotch Yoke Housing Maintenance 23

4.5 Spare Parts 24

5 Troubleshooting 25

6 Disposal of Decommissioned Actuators 27

7 Annex 28

2

Page 3

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Figures

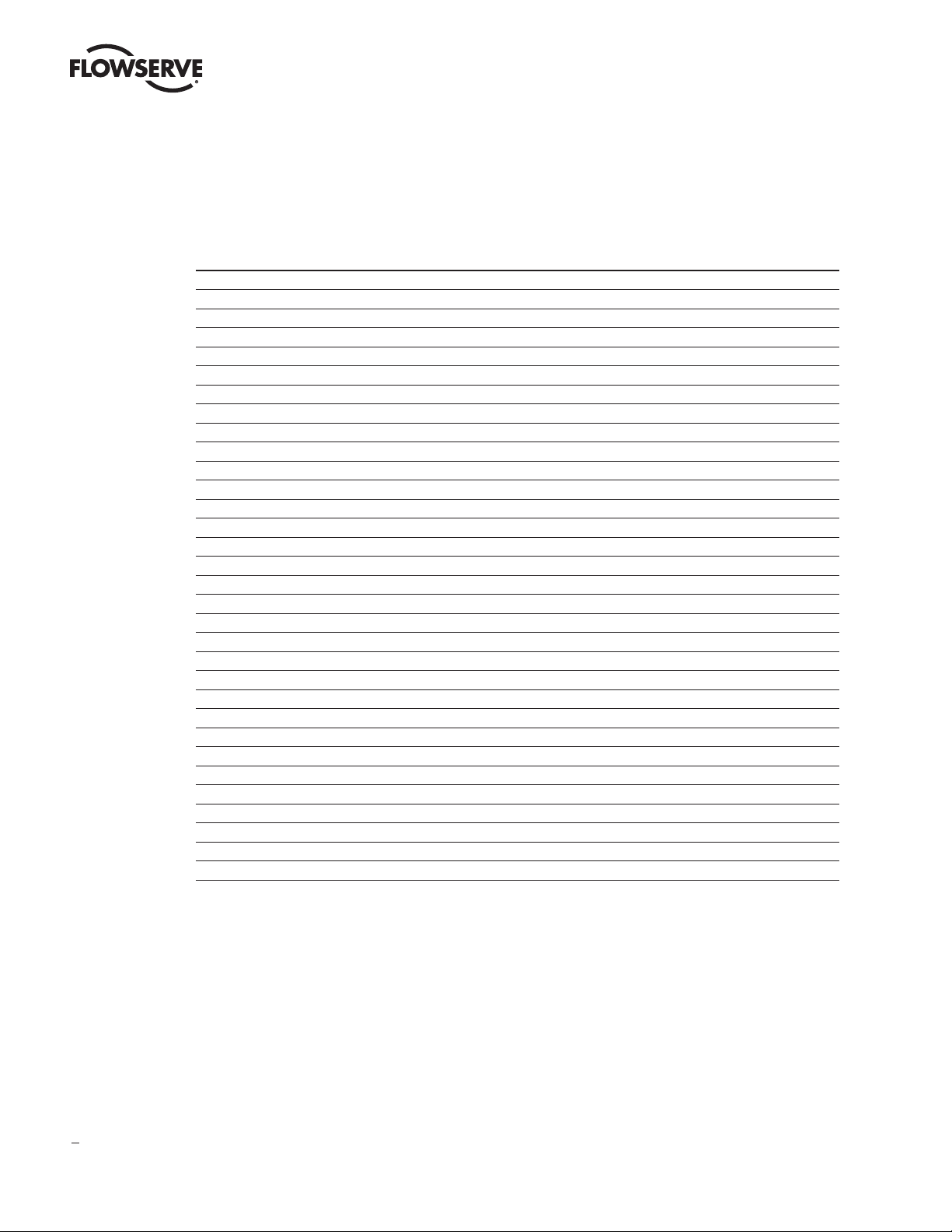

Figure 1: Lifting Lug for Spring Can Lifting Only 7

Figure 2: Correct Lifting of Pneumatic Single Acting Actuator 7

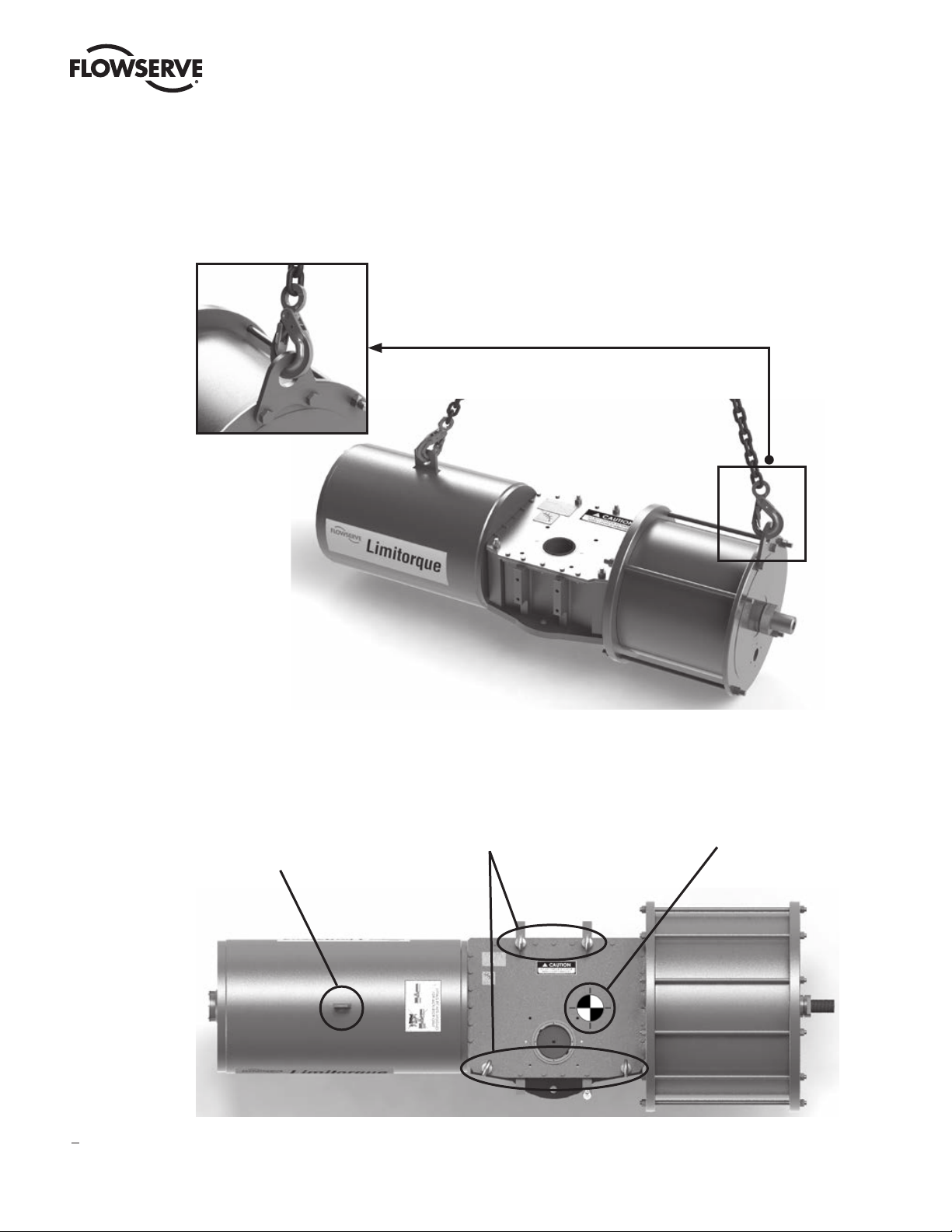

Figure 3: Use of Eyebolt for the Scotch Yoke Housing Cover 7

Figure 4: Vent Valve Correct Position 7

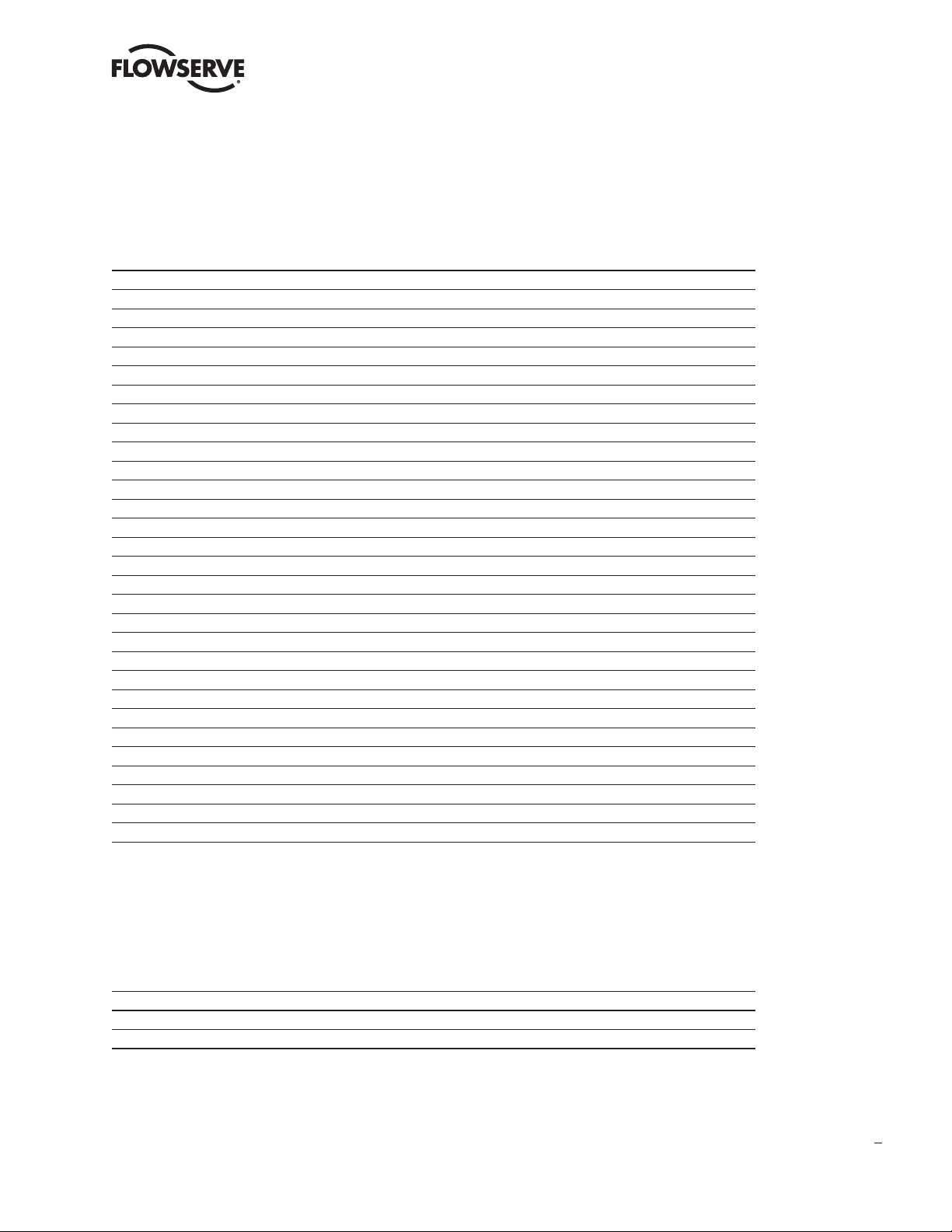

Figure 5: Lifting Lug on the Pneumatic Cylinder 8

Figure 6: Correct Lifting of LPS-15, LPS-20 and LPS-25 Pneumatic Single Acting Actuator Models 8

Figure 7: Single Acting Actuator Center of Gravity Position and Lifting Arrangement 8

Figure 8: Double Acting Actuator Center of Gravity Position and Lifting Arrangement 9

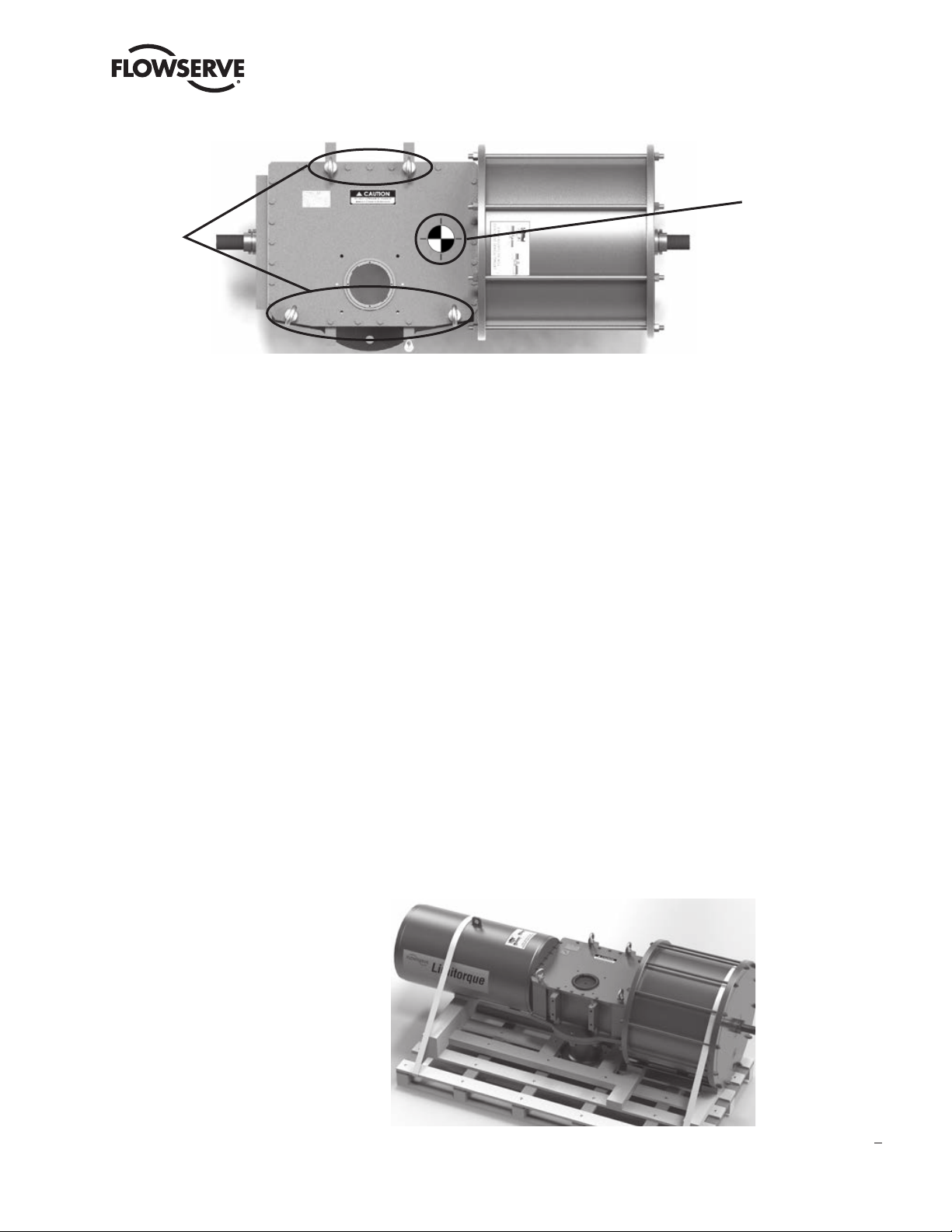

Figure 9: Actuator’s Safe Packed Position on Wooden Pallet 9

Figure 10: Fail CW Plate, According to EN 15714-3 Standard 11

Figure 11: Nameplate Sample 11

Figure 12: Standard Nameplate Position 11

Figure 13: Air Supply Plate 11

Figure 14: Grounding Kit Detail 13

Figure 15: Grounding Kit Assembled 13

Figure 16: Grounding Kit – Exploded Lettered View 14

Figure 17: Single Acting Actuator Configuration: Fail Close – Fail Clockwise 15

Figure 18: Single Acting Actuator Configuration: Fail Open – Fail Counter Clockwise 15

Figure 19: Double Acting Actuator Configuration – Close Position 15

Figure 20: Double Acting Actuator Configuration – Open Position 15

Figure 21: Single Acting LPS With Valve 15

Figure 22: Double Acting LPS With Valve 15

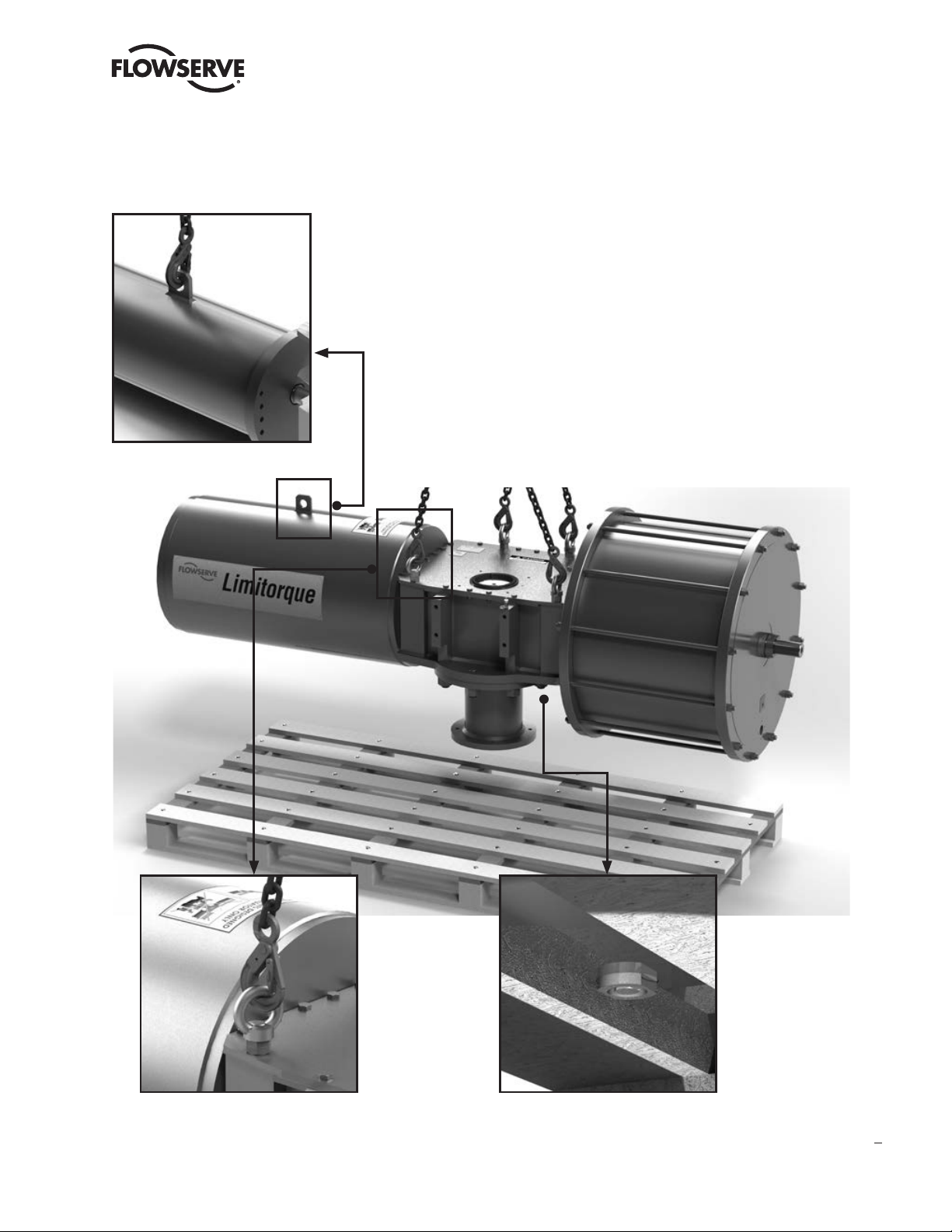

Figure 23: Single Acting Actuator 20

Figure 24: Spring Can Exploded View 21

Figure 25: Exploded View of Pneumatic Cylinder 22

Figure 26: Exploded View of Housing 23

Figure 27: Exploded View of Assembling Kit 23

Figure 28: LPS Model Selection Table 28

Figure 29: Weight Selection Table – Single Acting and Double Acting Versions 28

Figure 30: Mounting Interface Dimensions 30

Figure 31: Actuator Orientation/Installation 31

Tables

Table 1: Spare Parts List for Standard ON/OFF Applications 24

Table 2: Tightening Torques for Screws Without Lubricant (Tie Rods Excluded) 29

Table 3: Tightening Torque Table for Standard Cylinder (Without Ped Certification) 29

Table 4: Tightening Torque Table for PED Certified Cylinder Tie Rods Without Lubricant 29

3

flowserve.com

Page 4

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Standard Information

1

Using Flowserve Valves, Actuators and Accessories Correctly

The following instructions are designed to assist in unpacking, installing and performing maintenance as required on

the LPS Actuator Series. Product users and maintenance personnel should thoroughly review this bulletin prior to

installing, operating or performing any maintenance.

In most cases Flowserve actuators and accessories are designed for specific applications with regard to medium,

pressure and temperature. For this reason they should not be used in other applications without first contacting the

manufacturer.

1.1 Terms Concerning Safety

The safety terms DANGER, WARNING, CAUTION and NOTE are used in these instructions to highlight particular

dangers and/or to provide additional information on aspects that may not be readily apparent.

DANGER: indicates that death, severe personal injury and/or substantial property damage will occur if proper

c

precautions are not taken.

a WARNING: indicates that death, severe personal injury and/or substantial property damage can occur if proper

precautions are not taken.

a CAUTION: indicates that minor personal injury and/or property damage can occur if proper precautions are not

taken.

NOTE: indicates and provides additional technical information, which may not be very obvious, even to qualified

personnel.

Compliance with other, not particularly emphasized notes, with regard to transport, assembly, operation and

maintenance and with regard to technical documentation (e.g., in the operating instruction, product documentation

or on the product itself) is essential, in order to avoid faults, which in themselves might directly or indirectly cause

severe personal injury or property damage.

4

Page 5

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

1.2 General Usage

To prolong actuator life, use only clean, dry pneumatic supply fluids. Lubricated fluids are not required for LPS

actuators. Pay attention to follow positioner and other control prescriptions, regarding supply fluid instrument air.

The LPS actuator standard ambient temperature range is: -29°C to 100°C (-20°F to 212°F). Low temperature -60°C

(-76°F) and High temperature 160°C (320°F) ranges (polar, cold, arid and tropical temperature requirements in

accordance with IEC 60721) are available with different materials of construction. In any case, please refer to the

temperature range located in the actuator nameplate.

NOTE: For PED certified applications the standard operating temperature range is -20°C to 100°C (-4°F to 212°F). For

lower temperature applications the range can be extended to -40°C to +100°C (-40°F to 212°F) or -50°C to +100°C

(-58°F to 212°F) with different materials of construction. In any case, please refer to the temperature range located in

the actuator nameplate.

It is the end user’s responsibility to guarantee that the ambient temperature is in according with the actuator nameplate

indications.

a WARNING: It is recommended not to exceed the minimum and maximum allowable temperatures indicated

on the actuator nameplate. More factors like the valve and pipe temperatures, sun direct exposure and other

environmental conditions shall be considered, not to exceed the temperature range.

a WARNING: It is recommended not to exceed the allowable pressure range of the supply fluids, as stated in the

actuator nameplate. It is very important to make the standard maintenance at all safety components. In case

of PED certified cylinders the value of design pressure of the cylinder is indicated on, specific and separate

nameplate: it is necessary to verify that the supply line to the actuator does not exceed the design pressure stated

in the cylinder nameplate.

NOTE: The standard supply fluids are instrument air and nitrogen. Different types of fluids may be used only after

Flowserve verification. In case of PED certified cylinders the type of fluid is indicated on the specific nameplate on

the cylinder.

a WARNING: Only use the recommended type of fluid that is indicated on the nameplate (PED cylinders) and/or in

the contract.

NOTE: The supply fluid must be properly filtered. In case of positioner and/or other components installed on the

control panel, take care that the cleanliness, the filtration and the hydration of the supply fluid are in accordance

with the requirements of these accessories indicated on their own maintenance and user manuals.

1.3 Protective Clothing

Flowserve products are often used in dangerous applications (e.g., extremely high pressures, flammable, combustible,

toxic or corrosive media). When performing service, inspection or repair operations, always ensure that the valve and

actuator are depressurized and that the valve has been cleaned and is free from harmful substances. In such cases pay

particular attention to personal protection equipment (protective clothing, gloves, glasses, etc.).

1.4 Qualified Personnel

Only qualified personnel should perform installation, operation or maintenance activities. Qualified personnel are people

who, on account of their training, experience, instruction and their knowledge of relevant standards, specifications,

accident prevention regulations and operating conditions, have been authorized by those responsible for the safety of

the plant to perform the necessary work and who can recognize and avoid possible dangers.

5

flowserve.com

Page 6

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

1.5 Other Requirements for In-plant Installation

• Pipelines must be correctly aligned to ensure that the valve is not fitted under tension.

• If not expressly agreed, fire protection is not supplied along with the acuator and it must be provided by the user.

1.6 Spare Parts

Use only Flowserve brand original spare parts. Flowserve cannot accept responsibility for any damages that occur from

using spare parts or fastening materials from other manufacturers. If Flowserve products (especially sealing materials)

have been in storage for long periods, check these for corrosion or deterioration before using these products. A table

with the list of the main spare parts for standard ON/OFF applications with the interval times can be found in Paragraph

4.5 at Table 1.

1.7 Service/Repair

To avoid injury to personnel or damage to products, safety terms must be strictly adhered to. Modifying this product,

substituting non-factory parts, or using maintenance procedures other than as outlined in this instruction could

drastically affect performance and be hazardous to personnel and equipment, and may void existing warranties.

Between actuator and valve there are moving parts. To avoid injury, Flowserve provides pinch-point-protection in the

form of cover plates, especially where side-mounted positioners are fitted. These protections are according to Machine

Directive 2006/42/EC recommendations. If these plates are removed for inspection, service or repair special attention is

required. After completing work the cover plates must be refitted.

In addition to the operating instructions and the obligatory accident prevention directives valid in the country of use, all

recognized regulations for safety and good engineering practices must be followed.

a WARNING: Before products are returned to Flowserve for repair or service, Flowserve must be provided with

a certificate which confirms that the product has been decontaminated and is clean. Flowserve will not accept

deliveries if a certificate has not been provided (a form can be obtained from Flowserve).

1.8 Actuator Lifting and Handling

Only Allen wrenches and hexagonal wrenches of the few sizes are required for the overall operations. The lifting

equipment consists on commercial chains and slings of adequate dimensions.

In order to prevent damage to actuator accessories, before starting the lifting operations, ensure that the lifting tools,

like chain and clevis hook, are in the correct position and don’t interfere with the control panel and related tubing.

a CAUTION: Lifting and handling of the actuator should be done by qualified personnel and in compliance with the

laws and regulations in force.

a WARNING: The lifting lugs or eyebolts are appropriate for actuator lifting only. They are not designed to support

the combined weight of the valve and actuator assembly together. During the lifting operations do not stand under

the actuator. The actuator should be handled with appropriate lifting equipment. The weight of the actuator is

reported on the packing slip and on the overall-dimensions drawing furnished with the documents accompanying

the actuator.

For actuator weight, please, refer to Figure 29 in the Annex section. For the general actuator dimensions please refer to

LPS technical bulletin LFENTB0001, available on www.flowserve.com.

6

Page 7

a WARNING: ONLY for LPS-30 model and larger sizes

Figure 1: Lifting Lug for

Spring Can Lifting Only

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

DANGER: For lifting and handling, use the eyebolts on

c

the housing. The eyebolt on the spring can is only for the

mounting/dismounting steps or eventually for balancing

the actuator.

Figure 2: Correct Lifting of Pneumatic Single Acting Actuator

Figure 3: Use of Eyebolt for the Scotch Yoke

Housing Cover

Figure 4: Vent Valve Correct Position

7

flowserve.com

Page 8

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

a WARNING: ONLY for LPS-15, LPS-20 and LPS-25 model sizes

DANGER: For lifting and handling, use the appropriate lifting lug located

c

on the pneumatic cylinder and the lifting lug on the spring can.

Figure 5: Lifting Lug on the

Pneumatic Cylinder

Figure 6: Correct Lifting of LPS-15, LPS-20 and LPS-25 Pneumatic Single Acting Actuator Models

Eyebolts for Actuator LiftingLifting Lug for Spring Can

and Actuator Balancing

8

Figure 7: Single Acting Actuator Center of Gravity Position and Lifting Arrangement

Center of Mass

Page 9

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Eyebolts for

Actuator Lifting

Figure 8: Double Acting Actuator Center of Gravity Position and Lifting Arrangement

a WARNING: For lifting and handling use the appropriate lifting arrangement, as shown in Figure 2 and Figure 6.

Do not lift the actuator with the valve assembled.

a WARNING: After transportation, inspect the components to look for any damage.

Center of Mass

1.9 Storage

In many cases Flowserve products are manufactured from stainless steel. Products not manufactured from stainless steel

are typically provided with an epoxy resin coating or with other painting systems as agreed with the customer. This means

that Flowserve products are well protected from corrosion. Nevertheless, in order to maintain good working conditions and

a good finish, until the actuator is installed in the plant, it is necessary to follow a few rules during the storage period:

1.9.1 Flowserve products must be stored adequately in a clean, dry environment.

1.9.2 Ensure that plastic caps are fitted to protect the pneumatic connections and the cable entries, to prevent the

ingress of foreign materials. These caps should not be removed until the product is actually mounted into the

system.

1.9.3 If the storage is outdoors, or if long-term storage is necessary (more than four months), the plastic protection

plugs must be replaced with metal plugs, because the plastic plugs are not weatherproof, whereas the metal

ones guarantee weatherproof protection.

1.9.4 The actuator must be placed on a wooden pallet, in order to not damage the coupling base and avoid the

other surfaces resting on the ground.

In case of long-term storage (more than four months), additionally perform the following measures:

a. Coat the coupling parts (spool piece base,

flanges, bushings, joints) with protective oil

or grease.

b. If possible, blank off the spool piece base

flange with a protection disk.

c. Provide a tarpaulin cover or some other

means of protection, especially if the storage

is outdoors.

d. It is important to periodically operate the

actuator with filtered, dehydrated and

lubricated air while in storage.

Figure 9: Actuator’s Safe Packed Position on Wooden Pallet

9

flowserve.com

Page 10

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

1.10 Valve and Actuator Variations

These instructions cannot claim to cover all details of all possible product variations, nor can they provide information for every possible example of installation, operation or maintenance. If there are any uncertainties in this respect

particularly in the event of missing product-related information, clarification must be obtained via the appropriate

Flowserve sales office.

1.11 Unpacking

1.11.1 Each delivery includes a packing slip. When unpacking, check all delivered actuators and accessories using

this packing slip.

1.11.2 Report transportation damage to the carrier immediately.

1.11.3 In case of discrepancies, contact your nearest Flowserve location.

1.11.4 If necessary, retouch minor damage to the paint coating which may have occurred during transport or

storage.

NOTE: Ensure that the addendum “ATEX/PED/Machinery Directive Manual” accompanies this manual, when the

actuator is under one (or more) of the following European Directives:

• 2006/42/EC - Machinery Directive

• 94/9/EC - ATEX Directive

• 97/23/EC - PED Directive

If “ATEX/PED/Machinery Directive Manual” is not in your hands, contact Flowserve.

NOTE: When the actuator has SIL requirements according to IEC 61508, ensure that the “LPS Series Functional

Safety Manual” accompanies this manual and is referred to for equipment usage.

10

Page 11

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Installation Instructions

2

The LPS Series is a fully modular design, Scotch yoke actuator; with torque range up to 250 000 Nm (up to 184 000 ft-lbs),

with a mounting base in compliance with ISO 5211 and Figure 30 “Mounting Interface Dimensions”. It may also be

customized, if required.

The LPS pneumatic Scotch yoke spring LPS Series spring return actuators adopt a push-to-compress spring design.

a WARNING: Actuator operation/pressure limitations must be in accordance with Technical Bulletin (LFENTB0001);

contact Flowserve to get the last version.

2.1 Valve and Actuator Check

DANGER: Before installation check the order-no., serial-no. and/or the tag-no. to ensure that the valve/actuator is

c

correct for the intended application.

Figure 10:

Fail CW Plate, According to

EN 15714-3 Standard

Figure 11:

Nameplate Sample

Figure 12: Standard

Nameplate Position

The Flowserve nameplate is normally situated on the

cover of the Scotch yoke housing; if it’s not possible,

it could be situated in the front zone or in the rear

zone of the Scotch yoke housing.

Figure 13:

Air Supply Plate

11

flowserve.com

Page 12

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

NOTE: The air supply port and discharge are indicated by dedicated plates positioned close to the ports, as shown in Figure

13. In case of a double acting actuator, the ports for the air supply are identified by a number, according to ISO 5599-2.

NOTE: The direction of rotation is identified by a dedicated plate, as shown in Figure 10, in accordance with EN 15714-3.

Before mounting the actuator to the valve, manually open and close valve (if possible), to ensure it is not stuck. Be

sure valve and Limitorque actuator rotate in the same direction and are in the same position (i.e., valve closed, actuator

closed). The assembly position of the actuator, with reference to the valve, has to be in accordance with the plant

requirements (actuator axis parallel or perpendicular to the pipeline axis).

2.2 Connection With Valve and Mounting Kit

The LPS actuator is usually supplied with the spool piece already assembled. To assemble the actuator onto the valve,

perform the following steps:

2.2.1 Check the mounting surfaces, the stem adaptor and the spool piece

to assure proper fit. Clean the flanges of the valve and spool piece to

remove oils and greases since the torque is transmitted by friction. Also,

remove any rust that may have occurred during storage.

2.2.2 Secure the valve (possibly with the stem vertical) in the Close position

in case of Single Acting Fail Close actuator and in Open position in

case of Single Acting Fail Open actuator; in case of Double Acting Fail

Last actuator, secure the valve in the same Close/Open position as the

actuator that will be installed onto the valve.

2.2.3 Lift the actuator by the specific lift points (eyebolts), using a proper

lifting system. Position the actuator over the valve and lower to engage

the stem adaptor to the actuator bore. Continue to lower until the spool

piece sits on valve mounting surface. This coupling has to take place

without force and only with the weight of the actuator. The mounting

bolts (or studs) of the valve should easily fit into the bolt holes of the

spool piece without any binding. If needed, turn or stroke the actuator a

few degrees and/or adjust the actuator travel-stops.

2.2.4 The mounting nuts (or bolts) connecting the base of the spool piece to

the valve flange must be evenly tightened according to tightening torque

table without lubricant (Table 2 in Annex section).

12

NOTE: In some cases, the coupling between valve and actuator can be

direct, without the need of a spool piece. In these cases, Flowserve can

provide an intermediate adaptor flange (fitted under the actuator base)

and a special bushing to be inserted into the yoke bore.

Page 13

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

a WARNING: In case of spool piece (or adapter flange) installation by the client, it is mandatory to refer to Figure 30

“Mounting Interface Dimensions”, or to follow more specific instructions included in the job documentation

supplied along with the actuator. These assembling instructions include details of prescribed stud bolts and their

maximum allowable threaded length, in addition to the Loctite type to be used for a perfect sealing of Scotch yoke

housing.

a CAUTION: The actuator lifting and handling should be made by qualified personnel and in compliance with the

laws and provisions in force.

a WARNING: The lifting lugs or eyebolts are appropriate for actuator lifting only. They are not designed to support

the combined weight of the valve and actuator assembly together. During the lifting operations do not stand under

the actuator. The actuator should be handled with appropriate lifting means. The weight of the actuator is reported

on the packing slip and on the overall-dimensions drawing furnished with the documents accompanying the

actuator.

2.3 Travel-stop Bolts and Accessories

All actuated valves require accurate travel-stop adjustments at both ends of the stroke to obtain optimum performance

and valve seat life. Adjust the travel-stop bolts of the actuator for the proper open and close valve positions, per valve

manufacturer’s recommendations.

The LPS actuators have travel-stop adjustments in both the clockwise and counter-clockwise directions. The

+/- 5-degree adjustment feature provides shaft rotation from 80 to 100 degrees overall.

The adjustment of the travel-stops is performed in accordance with the following steps. Refer to Figures 23, 24, 25 and 26.

Pneumatic cylinder stop (28): Loosen the seal nut (62) with a proper wrench. Pneumatic cylinder stop (25): Loosen the

seal nut (if present) with a proper wrench. Screw or un-screw the stop (25), using a proper Allen key, while keeping the

seal nut stationary. Tighten the seal nut.

Spring container stop (7): Remove the spring container end flange (11) after unscrewing the hex screws (10). Screw

or unscrew the end stop (7) to the desired position, using a proper Allen key. Replace the end flange and tighten the

hex screws.

Pneumatically stroke the actuator several times to assure proper operation. The stem adaptor should not bind during

operation. If the actuator is equipped with a switch, positioner or other accessories, adjust them at this time.

2.4 Grounding System

For the actuator earthing, use the grounding kit, shown in Figures 14, 15 and 16:

Figure 15: Grounding Kit AssembledFigure 14: Grounding Kit Detail

13

flowserve.com

Page 14

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

A

Letter Description

B

C

A High Nut

B Ground Nameplate

C High Nut

D Grub Screw

E Lock Washer

F High Locking Nut With Nylon Insert

D

E

F

Figure 16: Grounding Kit – Exploded Lettered View

2.5 Initial Operation

Before initial operation of the actuator, perform the following checks:

2.5.1 Check that all electrical supply, control and signal lines are properly connected, by following the dedicated

customer procedures.

2.5.2 Check that the pressure and quality of the supply fluids are as prescribed.

2.5.3 Check the absence of leaks in the pneumatic connections. If necessary, tighten the pipe fittings.

2.5.4 Check that the environmental conditions are compatible with the design conditions. For information,

contact Flowserve.

14

Page 15

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

2.6 Fail Open and Fail Close Configuration

The actuator is designed for work in both configurations: fail open and fail close. For conversion from one configuration

to the other, refer to next paragraph.

Figure 17: Single Acting Actuator Configuration: Fail Close – Fail Clockwise

Figure 18: Single Acting Actuator Configuration: Fail Open – Fail Counter Clockwise

Figure 19: Double Acting Actuator Configuration – Close Position Figure 20: Double Acting Actuator Configuration – Open Position

15

Figure 21: Single Acting LPS With Valve Figure 22: Double Acting LPS With Valve

flowserve.com

Page 16

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Field Conversion

3

Field Conversion From Fail Clockwise to Fail Counter Clockwise or

Vice Versa (for Spring Return Actuators)

NOTE:

• The clockwise/counter clockwise designation needs to be changed on the nameplate.

• Additional adapters are required for field conversion from Fail CW to CCW and vice versa.

There are two different situations, requiring different sequences of instructions:

• The actuator is already disassembled from the valve.

• The actuator is assembled on the valve.

The reference drawings are Figures 24, 25, 26 and 27.

3.1 Actuator Disassembled From the Valve

a WARNING: Ensure that the pneumatic connection ports of the cylinder are disconnected. Also make sure that all

pneumatic supplies to the control unit and all power supplies are disconnected. Finally, make sure that the actuator

is in fail position, i.e., that it is not locked in a position with the spring

compressed by means of locking devices.

3.1.1 Unscrew and remove the end stop (25) from the pneumatic cylinder.

For removing the stop, refer to paragraph 2.3. If necessary, feed the

pneumatic cylinder from the port on the head flange (19) at minimum

necessary pressure to facilitate the movement of the Scotch yoke

and assure the total retraction of the piston rod (20). Remove the

pressure. In this way the spring is fully extended.

3.1.2 Remove the cover (46) from the housing by unscrewing all of the

locking components: hex screws (45), hex head shoulder bolts (44)

and eyebolts (42) plus upper nuts (43). Leave the studs (41) screwed

into the housing (51).

16

Page 17

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

3.1.3 Remove the spring can, carefully following the instructions given

in paragraph 4.2. Manually rotate the yoke (36) counterclockwise

(or clockwise, depending on the original fail configuration) up to a

position of approximately 45°. Locate the studs (57) that connect the

housing to the pneumatic cylinder. With the Scotch yoke rotated of

45°, it is possible to easily access these studs. Carefully unscrew the

nuts (56) and the studs (57). Pull out the whole pneumatic cylinder

(the stem is fully retracted).

NOTE: Take care during removal, so as not to damage the piston rod

or the stud threads.

3.1.4 Change the adapter kit. Replace the adapters (54 and 55) designed for

fail close (open) action, with the new ones designed for the opposite

action.

NOTE: Take care to choose the adapter kit suitable for the Scotch yoke

type in use (symmetric or canted).

Reassemble the pneumatic cylinder with adapter, using the reverse

procedure as described in point 4.3.

NOTE: You can identify the cylinder adapter to the spring can adapter

through the three grub screws (53).

3.1.5 Manually rotate the Scotch yoke (36) until the guide block (48) is in

contact with the piston rod adapter (54), in correspondence of the

relevant slot.

Reassemble the spring can, as instructed in paragraph 4.2.

Reposition the cover, taking care to replace the cover gasket (47)

and tighten the screws in according with the torque table 2 and

table 3. Readjust the stops, as instructed in paragraph 2.3.

Periodically operate the actuator to check the functioning in the

new fail configuration.

3.2 Actuator Connected to the Valve (and the valve can be stroked)

NOTE: If the valve cannot be stroked, due to the requirements of the plant, the actuator must be removed from the valve

and the procedure described in paragraph 3.1 shall be followed. Then the actuator should be reinstalled in the same

position of the valve, following the instructions given in paragraph 2.2.

a WARNING: Ensure that the pneumatic connection ports of the cylinder are disconnected. Also make sure that all

pneumatic supplies to the control unit and all power supplies are disconnected. Finally, make sure that the actuator

is in fail position, i.e., that it is not locked in a position with the spring compressed by means of locking devices.

3.2.1 Apply the minimum necessary pressure to the cylinder pneumatic port on the end flange and move the

actuator to approximately 45°. If the actuator is provided with a manual override, you can use it to perform

this operation.

17

flowserve.com

Page 18

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

3.2.2 Measure the position of the spring can end stop (7) before removing it, and then lock the spring in the

compressed position by means of a specifically designed locking tool (provided by Flowserve upon request)

for this maintenance. This tool shall be installed in the opening of the spring can end flange (11) where the

spring-end travel-stop (7) has been removed. Screw the special tool to the spring shaft and follow other

detailed instructions provided with the special tool. Then remove pressure from the pneumatic cylinder.

a WARNING: At this point the spring is compressed and the spring module contains a large quantity of stored

energy. Failure to properly engage the specifically designed locking tool or failure to handle the spring carefully

could result in release of the spring with potential damage to equipment or injury to personnel.

3.2.3 Unscrew and remove the travel-stop of the pneumatic cylinder (25). For removing the stop, refer to

paragraph 2.3. Feed the pneumatic cylinder from the port on the head flange (19) at minimum necessary

pressure up to totally retract the piston rod (20).

3.2.4 Remove the cover (46) from the Scotch yoke housing by unscrewing all of the locking components: hex screw

(45), hex head shoulder bolts (44) and eyebolts (42) plus upper nuts (43). Leave the studs (41) screwed into

the Scotch yoke housing (51).

3.2.5 Remove the spring can, carefully following the instructions given in paragraph 4.2.

3.2.6 Locate the studs (57) that connect the Scotch yoke housing to the cylinder. With the Scotch yoke (36)

rotated 45°, it is possible to easily access these studs. Carefully unscrew the nuts (56). Pull out the whole

pneumatic cylinder. The stem has to be is fully retracted.

NOTE: Take care during removal, so as not to damage the piston rod or the stud threads.

3.2.7 Change the adapter kit. Replace the adapters (54 and 55) designed for fail close (open) action, with the new

ones designed for the opposite action. Take care to choose the adapter kit suitable for the Scotch yoke type

in use (symmetric or canted). The guide

block (48) of the symmetric Scotch yoke is

marked with the “S” letter on the top face,

while the guide block of the canted Scotch

yoke is marked with a “C” letter on the top

face, as shown in the pictures at right.

NOTE: The spring can adapter (55) and cylinder adapter (54) can be inserted in the guide block in one way

only, pending on the Fail Close (CW) or Fail Open (CCW) configuration. Component numbers are referred to

in Figures 26 and 27.

3.2.8 Reassemble the spring can, as instructed in paragraph 4.2.

3.2.9 Reassemble the pneumatic cylinder with adapter, following the reverse procedure as described in point 4.3.

3.2.10 Apply the minimum pressure necessary to the pneumatic cylinder from the port on the end flange (27) until

the piston rod moves the guide block (48) and partially compresses the spring. In this condition it will be

possible to remove the special tool from the spring can.

3.2.11 Remove the pressure, checking that the actuator goes in the correct new fail safe position.

18

3.2.12 Reposition the cover, taking care to replace the cover gasket (47).

3.2.13 Readjust the travel-stops, as instructed in paragraph 2.3.

Page 19

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Maintenance Instructions

4

LPS Series actuators are designed to offer the greatest ease of operation during assembly, disassembly and

maintenance. The maintenance and disassembly do not require special equipment or special or large wrenches.

Furthermore the joints among the moving parts of the actuator are made exclusively through pins and not using bolts

to be tightened with specific torques.

LPS actuators do not need maintenance for long periods, even if they are working in severe conditions. The LPS

actuator features a 25-year design life depending on service conditions, proper installation, operating and maintenance.

In order to achieve this industry-leading design life, in-field maintenance is prescribed to be performed every six years

of operations.

However, if the actuator operation happens infrequently, it is recommended to periodically check the actuator,

performing the following steps:

• In the plants where it is possible, carry out a few opening and closing operations, involving all the control unit

components, checking that the actuator operates correctly and within the required stroking times.

• Check that all the signals (pneumatic and electric) arriving at the actuator are correct and that the supply fluid

pressure is within the required range. Check for the absence of leaks in the pneumatic connections. If necessary,

tighten the pipe fittings.

• Check the paint coating. If some areas are damaged due to accidental events, retouch them according to the painting

specifications.

In case of scheduled preventive maintenance, or following accidental events, refer to the following maintenance

instructions regarding the main actuator components (pneumatic cylinder and housing).

The actuator is furnished with lubricant sufficient for all its life cycle. In case of scheduled or extraordinary maintenance,

it is possible to lubricate the parts of the housing with the following greases:

For standard temperature conditions

(-29 to +100°C)

Grease Characteristics* Grease Characteristics*

Worked Penetration [dmm] 280 Worked Penetration [dmm] 296

Dropping Point ASTM [°C] 190 Dropping Point ASTM [°C] 260+

2

Base Oil Viscosity at 40°C [mm

* Grease suggested: AGIP MUP2 or equivalent * Grease suggested: AEROSHELL 7 or equivalent

/s] 100 Base Oil Viscosity at -40°C [mm2/s] 3.1

For low temperature conditions

(lower limit -60°C)

For different conditions, contact your local Flowserve representative.

19

flowserve.com

Page 20

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

4.1 General Disassembly Instructions

The LPS Series actuator is available in two different configurations, single acting and double acting, composed by the

main parts shown in Figure 23.

4.1.1 Disconnect all air and electrical supplies from actuator;

4.1.2 Before dismounting the actuator remove all accessories from actuator;

4.1.3 The reference drawings for the instructions reported in the following paragraphs are the exploded views of

single acting and double acting actuators, included as Figures 24, 25, 26 and 27.

Pneumatic Cylinder

Stop Bolt

Spring Can

Housing

Figure 23: Single Acting Actuator

4.2 Spring Container Maintenance

The spring container does not require maintenance. Lubrication of internal parts is carried out during assembly and is

not necessary during the normal life of the actuator. The substitution of the spring container is not expected over the

entire actuator life. However, accidental events may result in damage to this component. In these cases, proceed as

described in the following steps.

The spring container is a single welded module. In case of damage, the whole container must be disassembled from the

actuator and replaced with a new one equal to the original.

The removal of the spring container from the actuator has to be performed through the following steps. The reference

drawing is Figure 24.

a WARNING: Ensure that the pneumatic connection ports of the cylinder are disconnected. Also make sure that all

pneumatic supplies to the control unit and all power supplies are disconnected. Finally, make sure that the actuator

is in the fail safe position.

20

Page 21

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Figure 24: Spring Can Exploded View

Num Description Qty Spare Parts* Num Description Qty Spare Parts*

1 Split Ring 1 10 Hex Screw 1

2 Bushing 1 11 Spring Can End Flange 1

3 Spring Rod 1 12 Bar Pin 8

4 Bushing 1 13 Spring 1

5 Spring Rod End Nut 1 14 Spring Can 1

6 Spring Guide 1 15 Bar Pin 4

7 Spring Stop Bolt 1 16 Spring Plate 1

8 O-Ring 1 17 Bar Pin 8

9 Stop Bolt Cap 1 18 Spring Can Head Flange 1

* Standard maintenance spare parts for on/off applications

4.2.1 Unscrew and remove the travel-stop of the pneumatic cylinder (25). For removing the stop, refer to

paragraph 2.3. If necessary, feed the pneumatic cylinder from the port on the head flange (27) at minimum

necessary pressure to facilitate the movement of the Scotch yoke and assure the total retraction of the piston

rod (20). Remove the pressure. This way the spring is fully extended.

4.2.2 Remove the cover (46) from the housing by unscrewing all of the locking components: hex screw (45),

hex head shoulder bolts (44) and eyebolts (42) plus upper nuts (43). Leave the studs (41) screwed into the

Scotch yoke housing (51).

4.2.3 Hook and hold in tension the spring container using the specific lifting lug located on the top of the spring

can (shown in the above picture). Care should be taken to choose lifting equipment. Locate the studs (57)

that connect the Scotch yoke housing with the spring container. Carefully un-screw the nuts (56) and the

studs (57). Pull out the whole spring container.

NOTE: Take care to horizontally support the spring module during removal, so as not to damage the spring

rod or the stud threads.

4.2.4 Before reassembling the new spring module to body, make sure stud threads are free of any dirt, shavings,

or other debris. Clean threads with rag and solvent if required, and lubricate threads with an anti-seize

compound. Assemble the new spring can, following the reverse procedure as described in points 4.2.3 to

4.2.5. Readjust the travel stop (25) of the pneumatic cylinder, as instructed in paragraph 2.3.

21

flowserve.com

Page 22

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

4.3 Pneumatic Cylinder Maintenance

The standard pneumatic cylinder maintenance mainly consists in the replacement of those parts that may degrade over

time, even in the absence of faults. These components are the o-rings and the sliding elements of the piston.

The substitution of cylinder components (or of the whole cylinder) is not expected over the entire actuator life. However,

accidental events may result in damage to these components. In these cases, proceed as described in the following steps.

There are two possible types of maintenance: standard maintenance which can be performed in the field without the

need to remove the pneumatic cylinder from the actuator, and a more thorough maintenance, following unexpected

events, which can be performed only after removing the cylinder from the actuator.

DANGER: Do not attempt this maintenance operation with cylinder under pressure.

c

Standard In-field maintenance

22

Figure 25: Exploded View of Pneumatic Cylinder

Num Description Qty Spare Parts* Num Description Qty Spare Parts*

19 Cylinder Head Flange 1 28 O-Ring 2

20 Piston rod 1 29 O-Ring 2

21 Bushing 2 30 Tube 1

22 Piston 1 31 Tie Rod 12

23 Tape Guide 2 X • 32

24 Split Ring 2 33 O-Ring 1

25 Stop Bolt Assembly 1 34 Spacer (if necessary) 1

26 Hex Nut (High) 12

27 Cylinder End Flange 1

* Standard maintenance spare parts for on/off applications

X Spare parts that can be replaced

• Spare parts that can be replaced without removing the actuator from the valve

Spiral Retaining Shaft

Ring

2

X •

X •

X •

a WARNING: Before performing any maintenance operation on the cylinder it’s mandatory to remove the pressure

inside the cylinder itself. Make sure that the pneumatic connection ports of the cylinder are disconnected and open

to the ambient. Also make sure that all pneumatic supplies to the control unit and all power supplies are disconnected. Make sure that the actuator is in the fail position, i.e., that it is not locked in a position with the spring

compressed by means of the locking tool (as described at paragraph 3.2.2).

a WARNING: Use the pneumatic cylinder only for the intended function it has been designed for.

NOTE: During the maintenance operation inside the cylinder it’s suggested to have a visual check of the internal

parts of the cylinder in order to guarantee their integrity.

Page 23

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Perform the following steps:

4.3.1 If necessary, feed the pneumatic cylinder from the port on the head flange (19) at minimum necessary

pressure to facilitate the movement of the Scotch yoke and assure the total retraction of the piston rod (20).

In this way the spring is fully extended. Unscrew and remove the travel stop of the pneumatic cylinder. For

removing the stop, refer to the indications given in paragraph 2.3.

4.3.2 Remove at least two of the tie rods (31) positioned on the upper part of the cylinder by unscrewing the nuts

on the sides of the end flange and of the head flange (or unscrewing the tie rods from the head flange if

threaded into the flange.) This operation provides two free holes to be used for lifting the end flange (27).

Screw two male eyebolts in these two holes and connect the end flange to a lifting system. Care should be

taken to choose a lifting system suitable for the weight of the cylinder. Refer to the weight table shown in

Figure 29. Remove all other tie rods (31), following the same procedure described herein. Then remove the

end flange (27) from the tube (30).

4.3.3 Finally, remove the tube (22). Take care not to scratch or dent the honed and plated inner surface of the tube.

Remove the O-rings (28) from the flange; remove the O-ring of the piston (33) and finally the guide tapes

(23) from the piston. Clean all surfaces of piston and flanges in contact with these components with rag

and solvent. Brush the O-ring grooves with a light oil film and install the new O-rings. Spread a thin layer

of grease on the bottom of the guide tape grooves and install the new guide tapes (23). Clean the internal

surface of the tube (30) and lubricate with a protective oil film.

4.3.4 Reassemble the parts of the cylinder with the reverse procedure as described from points 4.3.2 to 4.3.5. The

tie rods should be tightened using a torque wrench, alternating between opposite holes, applying a torque

according to Table 3 or Table 4 included in Chapter 7. Readjust the stops as instructed in paragraph 2.3.

4.4 Scotch Yoke Housing Maintenance

Standard maintenance of the Scotch yoke housing may take place in the field, without the need to disassemble the

spring container or the pneumatic cylinder. Perform the following steps. The reference drawings are Figures 26 and 27.

a WARNING: Ensure that the pneumatic connection ports of the cylinder are disconnected. Also make sure that all

pneumatic supplies to the control unit and all power supplies are disconnected. Finally, make sure that the actuator

is in fail position.

Figure 26: Exploded View of Housing Figure 27: Exploded View of Assembling Kit

23

flowserve.com

Page 24

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Num Description Qty Spare Parts* Num Description Qty Spare Parts*

35 Bushing 2 48 Guide Block 1

36 Scotch Yoke 1 49 Bushing 2

37 Slider Block 2 50 Guide Bar 1

38 O-Ring 2 X • 51 Scotch Yoke Housing 1

39 O-Ring 2 X • 52 Center Ring 2

40 Guide Pin 1 53 Grub Screw 3

41 Stud 4 54 Cylinder Adapter 1

42 Eyebolt 4 55 Spring Adapter 1

43 Hex Nut (High) 4 56 Hex Nut (High) 8

44 Hex Head Shoulder Bolt 11 57 Studs 8

45 Hex Head Screw 2 581Guide Adaptor Pin 1

46 Cover 1 591Hex Head Screw 1

47 Cover Gasket 1 X •

* Standard maintenance spare parts for on/off applications

X Spare parts that can be replaced

• Spare parts that can be replaced without removing the actuator from the valve

1 Only in double acting actuators

4.4.1 Remove the position indicators or other accessories, if fitted.

Remove the cover (46) from the Scotch yoke by unscrewing

all the locking components: hex screw (45), hex head shoulder

bolts (44) and eyebolts (42) plus upper nuts (43). Leave the

studs (41) screwed into the Scotch yoke housing (51). Remove

the worn internal O-ring (39) of the bushing (35) inserted in the

cover (46). Clean the O-ring groove and the sliding area of the

CW/CCW Conversion Kit Sample

Num Description Qty

49 Bushing 2

54 Cylinder Adapter 1

55 Spring Adapter 1

56 Hex Nut (High) 8

57 Studs 8

Spare

Parts*

bushing and after having brushed these surfaces with a light oil

film, install the new internal O-ring (39).

4.4.2 Apply a generous layer of grease on the sliding surfaces of the accessible moving parts inside the housing.

In particular, grease the guide bar (50) and the surfaces of the slots of the wings of the Scotch yoke (36), in

which the slider blocks (37) run. Reposition the cover, taking care to replace the cover gasket (47).

The LPS actuator is designed for easy on-site maintenance and increased actuator life cycle. For this reason, specific

instructions and equipment were created to allow the replacement of all parts of the Scotch yoke without removing the

actuator from the valve. For these instructions, contact Flowserve.

NOTE: The spring can and pneumatic cylinder must be removed before disassembling the Scotch yoke housing.

4.5 Spare Parts

The main spare parts and the interval time for standard ON/OFF applications are listed in the table below. Maintenance

for standard ON/OFF applications is required after 1800 cycles and/or after six years of usage, whichever occurs first.

To obtain spare parts lists specific for each job/order, please contact your Flowserve Limitorque representative.

Part numbers are referred to in Figures 26 and 27.

24

Number Description Qty Maintenance Interval Times

23 Tape Guide 2

28 O-Ring 2

29 O-Ring 2

33 O-Ring 1

38 O-Ring 2

39 O-Ring 2

47 Cover Gasket 1

6 years 1800 Cycles

Table 1: Spare Parts List for Standard ON/OFF Applications

a WARNING: It is recommended to follow the regular maintenance interval times suggested in the previous table.

Page 25

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Troubleshooting

5

To prevent the actuator from not functioning properly or a reduction in performance, first ensure that the installation

and the adjustment operations are carried out completely in accordance with this manual.

a WARNING: When attempting to identify faults, it is very important to observe all the regulations and instructions

about safety. Read all the paragraphs of this manual concerning maintenance before opening for inspection or

starting to repair any actuator components. If in doubt, choose SAFETY FIRST.

The following table lists potential problems along with corresponding causes and possible solutions. If a malfunction

cannot be identified and eliminated using the table, please contact a Flowserve representative.

Troubleshooting Table

Problem Possible Cause Solution

Check that all the pneumatic connections and

that all the pneumatic components have been

installed correctly, and are in accordance with

Actuator has not been properly installed.

Supply pressure problems.

Problems in the control panel (if present).

The actuator does not move.

The valve is blocked.

Exhaust port(s) obstructed.

Problems with lubricants.

the actuator operating mode.

Check that the actuator is properly connected to

the valve and that there aren’t problems in the

mounting kit.

Check that sufficient supply pressure is available

at actuator inlet port. If possible, place a gage in

line and monitor the pressure level, in order to

discover unexpected pressure drops.

Check the correct functioning of the control

panel. In particular, check all the pneumatic and

electric connections.

Check the correct level of supply voltage for

solenoid valves and other electrical/electronic

components.

Check that valve is free to rotate. If necessary,

disassemble the actuator from the valve.

Screw cap(s) must be disengaged. Ensure vent

ports are free. If not, clean them of any obstructions and clean the dust excluders, if present.

Ensure that the actuator is properly lubricated,

and that there is no solidified grease among

sliding parts or rotating parts. If actuator

lubrication is inadequate or improper, apply a

uniform lubricant layer. Follow the instructions

for Scotch yoke and cylinder maintenance

(par. 4.3). Consult Flowserve for proper oil and

grease to be used.

25

flowserve.com

Page 26

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Troubleshooting Table

Problem Possible Cause Solution

Check if any moving part is blocked. If so, follow

the maintenance instructions given in paragraphs

4.2, 4.3 and 4.4.

A significant air leak may prevent the actuator

from operating. Ensure that there aren’t any

external leaks of the pneumatic cylinder. If

possible, detect them using a leak finder spray.

Check also that there are not leaks across the

piston. If leaks are present, follow the cylinder

maintenance instructions given in paragraph 4.3.

Check the actuator nameplate and the plant

requirements. If there are mismatches, contact

Flowserve Service Department.

Check the proper functioning of the spring can.

If problems are found, contact the Flowserve

Service Department.

Perform the following test: disassemble the

actuator from the valve and measure the

minimum pressure values necessary to move

and compress the spring. Compare the measured

values with the ones reported on the Testing

Certificate. If there are significant differences you

should contact Flowserve Service Department.

Disconnect the lockout module.

Adjust the end stops of the pneumatic cylinder

and of the spring can until the valve is leak-tight

across the seat. Follow the instructions given in

the paragraph about Travel-stop bolts (2.3).

As above, check the position of the end stop

in opening and closing direction. If necessary,

adjust them. Follow the instructions given in

paragraph 2.3.

Screw cap(s) must be disengaged. Ensure vent

ports are free. If not, clean them of any obstructions and clean the dust excluders, if present.

In order to do a check it is necessary to perform

the following test: disassemble the actuator from

the valve and measure the minimum pressure

values necessary to move and compress the

spring (if the actuator is a single acting model)

or the minimum values necessary to move the

actuator yoke and perform a stroke (for double

acting models). Compare the measured values

with the ones reported on the Testing Certificate.

If there are significant differences you should

contact Flowserve Service Department.

The actuator does not move.

The valve does not shut off

properly and there are leaks.

The valve does not fully perform

the stroke, during opening or

closing.

A moving part is seized up.

Leakages of the pneumatic cylinder.

The actuator model is not the correct one,

or is not suitable for the plant conditions.

Spring problems (if actuator is a single

acting model).

A lockout device has been inserted and

forgotten in that position.

The actuator is not correctly adjusted.

The actuator is not correctly adjusted.

Exhaust port(s) obstructed.

Actuator torque lower than required.

26

During the stroke the actuator

exhibits excessive amounts of

backlash.

In case of other problems not listed in this table, you should contact the Flowserve Service Department.

Some components are excessively worn.

Identify and replace these components,

according to the procedure described in

paragraphs 4.2, 4.3 and 4.4.

Page 27

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Disposal of

Decommissioned

6

Actuators

Actuators that are to be decommissioned permanently must have the stored energy in the spring neutralized. This can

be done in several ways:

6.1 Decommissioning by filling with cement – following proper removal of the actuator from any hazardous areas,

the spring module may be neutralized by cutting a small opening in the end or side of the spring can and filling

the spring can with liquid cement and allowing the concrete to dry. This will eliminate any possibility of spring

decompression if it were to be removed from the actuator without following proper procedures.

6.2 Decommissioning by cutting the spring – following proper removal of the actuator from any hazardous areas,

the spring module may be neutralized by cutting a small opening in the side of the spring can and accessing the

spring coils. The spring coils are then cut using a torch to relieve all compression and stored energy. Care should

be taken that the opening in the spring can is sufficiently small to prevent any pieces of the spring from escaping

when the spring is cut.

a WARNING: Failure to neutralize the spring in the actuator or to follow these instructions could lead to injury to

personnel or property damage.

Either method is acceptable to Flowserve, although the method outlined in the first point is preferred, as the stored

energy in the spring is not suddenly released when the spring is cut. Hence, this is the safest method.

No actions need be taken on any other portions of the actuator to decommission it.

flowserve.com

27

Page 28

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Annex

LPS 15X 155Y example model n°FC 1-1

7

15

20

25

30

35

CENTER BODY SIZE

40

Figure 28: LPS Model Selection Table

A

B

C

YOKE TYPE

155

175

200

235

255

285

300

PNEUMATIC CYLINDER SIZE

335

360

385

435

485

535

585

635

685

735

785

835

885

935

985

1050

1150

1200

SEAL MATERIAL

B–Buna

V–Viton

S–Silicon

Z–Special

---

®

SINGLE

FC–Fail Close

FO–Fail Open

ACTING

D1–1 Cylinder D.A.

D2–2 Cylinder D.A.

DOUBLE

ACTING

DD–2 Cylinders Tandem

1-1

1-2

1-3

1-4

1-5

2-1

SPRING CAN SIZE

2-2

2-3

2-4

2-5

3-1

3-2

3-3

3-4

3-5

4-1

4-2

4-3

4-4

4-5

28

LPS 15X

Assembling Kit

Assembling Kit

SINGLE ACTING

7,5 (16,5)

13 (28,7)

26 (57,3)

Notes:

selected.

configurations.

1,5 (3,3)

2,5 (5,5)

3,5 (7,7)

DOUBLE ACTING

9 (19,8)

12 (26,5)

25,5 (56,2)

41 (90,4)

93,2 (205,6)

150,1 (330,8)

Kg (Lb)weights in

50 (110)

15

90 (198)

20

140 (309)

25

295 (650)

30

561 (1237)

HOUSING SIZE

35

879 (1938)

40

-Cylinder End Stop Kit is inclusive of the end stop

assembly that is installed on the pneumatic cylinder side.

The weight of this assembly is related to the cylinder size

and independent from the Scotch yoke housing size

-The Assembling Kit is different in case of Single Acting

and Double Acting versions, and its weight changes

upon different housing sizes.

Assembling Kit for Single Acting:

Adaptor Kit for Fail Close (CW) or Fail Open (CCW)

-Screws and Nuts

Assembling Kit for Double Acting:

-Adaptor kit for Double Acting configuration

-Side flange to be installed on the housing side instead

of the Spring Can

-End Stop installed on the Side Flange

-Screws and Nuts

Weights may be subject to changes over time. For the accurate

measurement, please contact Flowserve.

Figure 29: Weight Selection Table – Single Acting and Double Acting Versions

155

175

200

235

255

285

300

335

360

385

435

485

535

585

635

PNEUMATIC CYLINDER SIZE

685

735

785

835

885

935

985

1050

1150

1200

29,4 (64,7)

31 (68,3)

36,3 (80)

47,1 (103,7)

52,8 (116,4)

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

54 (119)

–

–

59,7 (131,7)

90,6 (199,7)

79 (174,2)71,2 (156,9)

104,3 (230)

91 (200,6)81,8 (180,3)

110,6 (243,9)101,3 (223,4) 143,8 (317)119,7 (263,8)

128,2 (282,5)118,3 (260,8) 158,5 (349,5)137,7 (303,6)

143 (315,3)132,5 (292,1) 175,6 (387)153,1 (337,5)

204,6 (451)192,9 (425,2) 295,3 (651)230,1 (507,2)

267,4 (589,5)254 (560) 344,2 (758,7)287 (632,7)

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

339 (747,3)316,6 (698) 451,4 (995,2)403,8 (890,2)

422,3 (931)407,8 (899,1) 530,1 (1168,6)470,1 (1036,4)

521,4 (1149,6) 631,2 (1391,5)587 (1294,1)

645,4 (1422,8)

–

–

–

–

–

–

–

–

–

–

–

–

–

155Y

403530252015

–

–

–

–

–

–

–

–

–

–

–

–

761,8 (1679,5)700,5 (1544,4)

870,5 (1919,2)790,7 (1743,2)

1058 (2332,4)975,4 (2150,4)

1217,7 (2684,6)1132,7 (2497,3)

1427,3 (3146,7)1339,7 (2953,6)

1625,9 (3584,5)1536 (3386,3)

1817 (4005,8)

2147,5 (4734,3)

2789,4 (6149,6)

3163 (6973,2)

Cylinder End

Stop Kit

2,8 (6,2)

2,8 (6,2)

2,8 (6,2)

2,8 (6,2)

2,8 (6,2)

2,8 (6,2)

2,8 (6,2)

2,8 (6,2)

2,8 (6,2)

2,8 (6,2)

2,8 (6,2)

2,8 (6,2)

5 (11)

5 (11)

5 (11)

5 (11)

5 (11)

5 (11)

5 (11)

9 (19,8)

9 (19,8)

9 (19,8)

9 (19,8)

9 (19,8)

9 (19,8)

---

1-1

1-2

1-3

1-4

1-5

2-1

2-2

2-3

2-4

3-1

3-2

SPRING CAN SIZE

3-3

3-4

4-1

4-2

4-3

4-4

4-5

FC 1-1

–

49 (108)

48 (105,8) 611,7 (1348,5)

–

–

–

–

76 (167,6)

84 (185,2) 821,2 (1810,5)208,7 (460)153,2 (337,8) 1048 (2310,4)114 (251,3)

82 (180,8) 856,6 (1888,4)

–

69 (152,1) 1073,8 (2367,3)213,3 (470,2)181,9 (400,9) 1297 (2859,3)161,9 (356,8)

76 (167,6) 1197,8 (2640,7)230,8 (508,8)143,1 (315,4) 1412,1 (3113,2)178,5 (393,6)

74 (163,1) 1205,2 (2657,1)

–

–

–

–

–

–

153,4 (338,2) 1418,8 (3127,9)168,9 (372,3)

–

153,6 (338,5) 1410,1 (3108,8)

–

169,6 (373,9) 959,5 (2115,3)

–

–

–

––

example model n°

403530252015

–

397,8 (877)179,3 (395,4)147 (324,1)

449,1 (990)137,2 (302,5)

461,6 (1017,7)

776,1 (1711,1)193,6 (426,9)136,6 (301,2)

–

–

–

–

563,2 (1241,6)

607,6 (1339,6)402,7 (887,7)178,3 (393,2)132 (291)

–

–

1008,7 (2223,9)111,6 (246)

––––

––

166 (366)101 (222,7)53,3 (117,5)47,4 (104,4)

–

–––

211,3 (465,9)143,3 (315,8) 1078,6 (2377,9)130,4 (287,4)

207,2 (456,8)121 (266,8)

234,8 (517,5)

– –

271,6 (598,7)

291,9 (643,6)183,6 (404,7) 983,9 (2169,1)

294,1 (648,3)186,8 (411,7) 1270,7 (2801,5)

297,1 (655,1)183,8 (405,2) 1371,3 (3023,2)

293,8 (647,8)

Page 29

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

Screw Diameter Torque [Nm]

M3 1,1

M4 2,5

M5 5,0

M6 8,6

M8 21,0

M10 42,0

M12 72,0

M14 116,0

M16 180,0

M18 250,0

M20 354,0

M22 487,0

M24 609,0

Screw Diameter Torque [Nm]

M27 901,0

M30 1222,0

M33 1660,0

M36 2131,0

M39 2766,0

M42 3414,0

M45 4273,0

M48 5161,0

M52 6646,0

M56 8277,0

M60 10283,0

M64 12373,0

Table 2: Tightening Torques for Screws Without Lubricant (Tie Rods Excluded) – Applicable Also to Mounting Kit

Cylinder

Ø155 4 M10 30

Ø175 4 M10 30

Ø200 4 M10 30

Ø235 4 M12 65

Ø255 4 M12 65

Ø285 4 M12 65

Ø300 4 M12 65

Ø335 8 M12 65

Ø360 8 M12 65

Ø385 8 M12 65

Ø435 8 M16 170

Ø485 8 M16 170

Ø535 8 M16 170

Ø585 8 M16 170

Ø635 12 M16 170

Ø685 12 M16 170

Ø735 12 M20 340

Ø785 12 M20 340

Ø835 12 M20 340

Ø885 12 M24 500

Ø935 12 M24 500

Ø985 12 M24 500

Ø1050 12 M27 780

Ø1150 12 M27 780

Ø1200 12 M30 950

Number of

Tie Rods

Table 3: Tightening Torque Table for Standard Cylinder

(Without Ped Certification) Tie Rods Without Lubricant

Tie Rods

Diameter

Torque

[Nm]

Cylinder

Ø155 4 M10 30

Ø175 4 M10 30

Ø200 4 M10 30

Ø235 4 M12 50

Ø255 4 M12 50

Ø285 4 M12 50

Ø300 4 M12 50

Ø335 8 M12 50

Ø360 8 M12 50

Ø385 8 M12 50

Ø435 8 M16 125

Ø485 8 M16 125

Ø535 8 M16 125

Ø585 8 M16 125

Ø635 12 M16 125

Ø685 12 M16 125

Ø735 12 M20 250

Ø785 12 M20 250

Ø835 12 M20 250

Ø885 12 M24 425

Ø935 12 M24 425

Ø985 12 M24 425

Ø1050 12 M27 610

Ø1150 12 M27 610

Ø1200 12 M30 740

Number of

Tie Rods

Tie Rods

Diameter

Table 4: Tightening Torque Table for PED Certified

Cylinder Tie Rods Without Lubricant

Torque

[Nm]

29

flowserve.com

Page 30

Figure 30: Mounting Interface Dimensions

Model

ISO 5211 Flange

Interface (reference)

ØA

B

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

LPS/LHS Series Coupling Dimensions

Number of holes nHole Diameter

C

ØD

P.C.D.

[mm(inch)] EF

ØG

ØH

I

P

L

LPS/LHS 15

LPS/LHS 20

LPS/LHS 25

LPS/LHS 30

LPS/LHS 35

LPS/LHS 40

IMPORTANT: Position of the

keyways with actuator at 0°

degree (closed position).

F16

F25

F30

F35

F40

F48

B D10

D

n x

G 3/4

ØA D8

+

C

FLOW LINE

65 10

86 12

100 18

130 28

150 36

185 45

45°

0,20

0,10

+

70.6

91.6

108.8

138.6

166.8

205.8

Bottom View

(from "U")

8 Holes Flange

4

8

8

8

8

12

P ±0,05

M20

M16

M20

M30

M36

M36

1

ATTENTION: The angular positions

of the holes are rotated with respect

to indications of ISO 5211.

The holes are on centerlines.

IMPORTANT: threaded through

holes. During studs assembly use

Loctite 542 (or equivalent) in order to

obtain a perfect seal.

165 (6,50)

254 (10) 16 130 112 178

298 (11,73)

356 (14,02)

406 (15,98)

483 (19,02)

Notes:

- Holes in-line wit axis of actuator (NOt off-center)

- Flange torque different from ISO 5211 specification

18 86 78 161 8

18 150 133 201 6

28 168 152 261 10

33 199 185 323 9

38 244 230 338 10

90°

4 Holes Flange

DETAIL W

ØH e8

ØG H7

155

205

4.5

230

305

405

450

30°

12 Holes Flange

L

30

I

(max keyway length)

H e8

G H7

+-0,1

E

0,1

W

F

IMPORTANT: threaded through

holes. During studs assembly

use Loctite 542 (or equivalent)

in order to obtain a perfect

seal.

Stud threaded length must not

excede "F" + 3 mm.

"U"

Page 31

Figure 31: Actuator Orientation/Installation

LPS Series Heavy-Duty Actuators FCD LFENIM0001-02-AQ – 5/15

flowserve.com

31

Page 32

Flowserve Limitorque

Fluid Power Systems

Product Sales

Via Rio Vallone 17

20883 Mezzago (MB), Italy

Phone: +39 039 62060 1

Fax: +39 039 62060 213

Email: lfpsinfo@flowserve.com

Flowserve Limitorque

Fluid Power Systems

Manufacturing and Operations

Via Rio Vallone 17

20883 Mezzago (MB), Italy

Phone: +39 039 62060 1

Fax: +39 039 62060 213

Email: lfpsinfo@flowserve.com

Flowserve Limitorque

Fluid Power Systems

Research and Development

Viale dell’Artigianato 24

29122 Piacenza (PC), Italy

Email: lfpsinfo@flowserve.com

LFENIM0001-02-AQ 5/15 © 2015 Flowserve Corporation.

To find your local Flowserve representative,

visit www.flowserve.com or call:

USA +1 800 225 6989

International +1 972 910 0774

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform

its intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous

applications under a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings

for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of

Flowserve products. The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees

and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered

certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any

matter with respect to this product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein

are subject to change without notice. Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide

operations or offices.

© 2015 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

flowserve.com

Loading...

Loading...