Page 1

USER INSTRUCTIONS

LPC Compact Actuator Series

Single Acting & Double Acting

FCD LFENIM0002-00-AQ – 07/14

Installation

Operation

Maintenance

Experience In Motion

Page 2

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

Contents

1 Standard Information 3

1.1 General Usage 3

1.2 Terms Concerning Safety 3

1.3 Protective Clothing 4

1.4 Qualified Personnel 4

1.5 Other General Requirements for In-Plant Installation 4

1.6 Spare Parts 4

1.7 Service/Repair 4

1.8 Storage 5

1.9 Valve and Actuator Variations 6

1.10 Unpacking 6

2 Installation Instructions 7

2.1 Valve and Actuator Check 7

2.2 Connection With Valve and Mounting Kit 8

2.3 Travel-stop Bolts and Accessories 8

2.4 Pneumatic Supply Fluids 8

2.5 Initial Operation 9

2.6 Fail Open and Fail Close Configuration 9

3 Field Conversion 11

4 Maintenance Instructions 12

4.1 General Disassembly Instructions 12

4.2 Spring Container and Pneumatic Cylinder Maintenance 12

4.3 Housing and Scotch Yoke Maintenance 14

5 Troubleshooting 15

6 Disposal of Decommissioned Actuators 17

7 Annex 18

Figures

Figure 1: Actuator’s Position on the Wooden Pallet 5

Figure 2: Position of the Output Shaft 5

Figure 3: Standard Data Plate Position 7

Figure 4: Nameplate Sample 7

Figure 5: Actuator Configuration: Fail Close – Fail Clockwise – Single Acting 9

Figure 6: Actuator Configuration: Fail Open – Fail Counter Clockwise – Single Acting 9

Figure 7: Double Acting Actuator Configuration – Close Position 10

Figure 8: Double Acting Actuator Configuration – Open Position 10

Figure 9: Fail Close Configuration With Valve 10

Figure 10: Fail Open Configuration With Valve 10

Figure 11: Model Selection Table 18

Figure 12: Seals Material 18

Figure 13: Weights and Dimensions Table – Single Acting – Symmetric and Canted 20

Figure 14: Weights and Dimensions Table – Double Acting – Symmetric and Canted 21

Figure 15: Exploded View 23

2

Page 3

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

Standard Information

1

1. Using Flowserve Valves, Actuators and Accessories Correctly

1.1 General Usage

The following instructions are designed to assist in unpacking, installing and performing maintenance as required on

Flowserve products. Product users and maintenance personnel should thoroughly review this bulletin prior to installing,

operating or performing any maintenance.

In most cases Flowserve actuators and accessories are designed for specific applications with regard to medium,

pressure and temperature. For this reason they should not be used in other applications without first contacting the

manufacturer.

1.2 Terms Concerning Safety

The safety terms DANGER, WARNING, CAUTION and NOTE are used in these instructions to highlight particular

dangers and/or to provide additional information on aspects that may not be readily apparent.

DANGER: indicates that death, severe personal injury and/or substantial property damage will occur if proper

c

precautions are not taken.

a WARNING: indicates that death, severe personal injury and/or substantial property damage can occur if proper

precautions are not taken.

a CAUTION: indicates that minor personal injury and/or property damage can occur if proper precautions are not

taken.

NOTE: indicates and provides additional technical information, which may not be very obvious, even to qualified

personnel.

Compliance with other, not particularly emphasized notes, with regard to transport, assembly, operation and maintenance and with regard to technical documentation (e.g. in the operating instruction, product documentation or on

the product itself) is essential, in order to avoid faults, which in themselves might directly or indirectly cause severe

personal injury or property damage.

flowserve.com

3

Page 4

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

1.3 Protective Clothing

Flowserve products are often used in problematic applications (e.g. extremely high pressures, dangerous, toxic or

corrosive media). When performing service, inspection or repair operations always ensure, that the valve and actuator

are depressurized and that the valve has been cleaned and is free from harmful substances. In such cases pay particular

attention to personal protection (protective clothing, gloves, glasses etc.).

1.4 Qualified Personnel

Qualified personnel are people who, on account of their training, experience and instruction and their knowledge of

relevant standards, specifications, accident prevention regulations and operating conditions, have been authorized by

those responsible for the safety of the plant to perform the necessary work and who can recognize and avoid possible

dangers.

1.5 Other General Requirements for In-Plant Installation

• Pipelines must be correctly aligned to ensure that the valve is not fitted under tension.

• Flowserve can provide a fire protection system. If not expressly agreed, fire protection must be provided by user.

1.6 Spare Parts

Use only Flowserve original spare parts. Flowserve cannot accept responsibility for any damages that occur from using

spare parts or fastening materials from other manufacturers. If Flowserve products (especially sealing materials) have

been on store for longer periods check these for corrosion or deterioration before using these products.

1.7 Service/Repair

To avoid possible injury to personnel or damage to products, safety terms must be strictly adhered to. Modifying

this product, substituting non-factory parts, or using maintenance procedures other than outlined in this instruction

could drastically affect performance and be hazardous to personnel and equipment, and may void existing warranties.

Between actuator and valve there are moving parts. To avoid injury Flowserve provides pinch-point-protection in the

form of cover plates, especially where side-mounted positioners are fitted. These protections are according to Machine

Directive 2006/42/EC recommendations. If these plates are removed for inspection, service or repair special attention

is required. After completing work the cover plates must be refitted. Apart from the operating instructions and the

obligatory accident prevention directives valid in the country of use, all recognized regulations for safety and good

engineering practices must be followed.

a WARNING: Before products are returned to Flowserve for repair or service, Flowserve must be provided

with a certificate which confirms that the product has been decontaminated and is clean. Flowserve will not

accept deliveries if a certificate has not been provided (a form can be obtained from Flowserve).

4

Page 5

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

1.8 Storage

In many cases Flowserve products are manufactured from stainless steel. Products not manufactured from stainless

steel are typically provided with an epoxy resin coating or with other painting systems agreed with the customer. This

means that Flowserve products are well protected from corrosion. Nevertheless, in order to maintain good working

conditions and a good finish until the actuator is installed on the plant, it is necessary to follow a few rules during the

storage period:

• Flowserve products must be stored adequately in a clean, dry environment.

• Ensure that plastic caps are fitted to protect the pneumatic connections and the cable entries, to prevent the ingress

of foreign materials. These caps should not be removed until the product is actually mounted into the system.

• If the storage is outdoor, or if long-term storage (more than four months) is necessary, the plastic protection plugs

have to be replaced by metal plugs, because the plastic plugs are not weatherproof function, whereas the metal ones

guarantee a weatherproof protection.

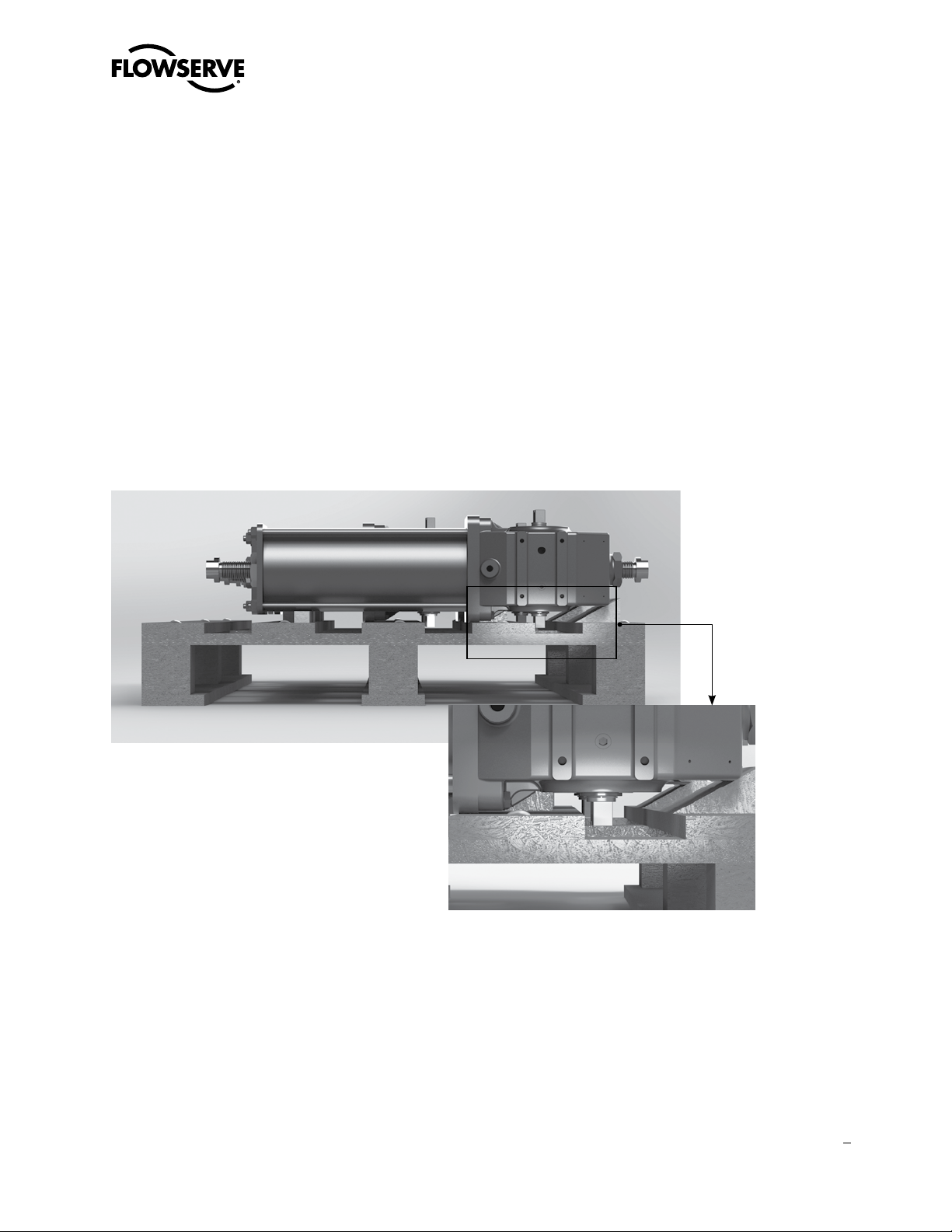

• The actuator must be placed on a wooden pallet, in order to not damage the coupling base and avoid that other

surfaces other surfaces rest on the ground.

Figure 1: Actuator’s Position on the Wooden Pallet

Figure 2: Position of the Output Shaft

In case of long-term storage (more than four months), additionally perform the following measures:

• Coat the coupling parts (spool piece base, flanges, bushings, joints) with protective oil or grease.

• If possible, blank off the spool piece base flange by a protection disk.

• Provide a tarpaulin cover or some other means of protection, especially if the storage is outdoor.

• It is important to periodically operate the actuator with filtered, dehydrated and lubricated air while in a storage.

5

flowserve.com

Page 6

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

1.9 Valve and Actuator Variations

These instructions cannot claim to cover all details of all possible product variations, nor can they provide information

for every possible example of installation, operation or maintenance. This means that the instructions normally include

only the directions to be followed by qualified personnel where the product is being used for its defined purpose. If

there are any uncertainties in this respect particularly in the event of missing product-related information, clarification

must be obtained via the appropriate Flowserve sales office.

1.10 Unpacking

• Each delivery includes a packing slip. When unpacking, check all delivered actuators and accessories using this

packing slip.

• Report transport damage to the carrier immediately.

• In case of discrepancies, contact your nearest Flowserve location.

• If necessary, retouch minor damage to the paint coating which may have occurred during transport or storage.

NOTE: When the actuator has ATEX or SIL requirements, ensure that the “LPC Series Safety Manual”

(Functional Safety and SIL Certification) and “LPC Series Safety Extract and Instruction Manual” (Explosive

Atmosphere Equipment and ATEX Certification) accompany this manual and are refer to equipment for usage.

6

Page 7

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

Installation Instructions

2

The LPC range of Limitorque Pneumatic Actuators is a robust, lightweight modular scotch yoke design, available in

both spring return and double acting configurations, with a torque range up to 1600 Nm (1180 ft-lb); contact factory for

lager size. Available with valve interface in compliance with ISO 5211, or customized upon request.

a WARNING! Actuator operation/pressure limitations must be in accordance with Technical Bulletin (LFENTB0002-00)

2.1 Valve and Actuator Check

DANGER: Before installation check the order no., serial no., and/or the tag no. to ensure that the valve/actuator is

c

correct for the intended application.

Figure 3: Standard Data Plate Position

Figure 4: Nameplate Sample

Prior to assembly, manually open and close valve (if possible), to ensure freedom of operation. Be sure valve and

Limitorque actuator rotate in the same direction and are in the same position (i.e., valve closed, actuator closed). The

assembly position of the actuator, with reference to the valve, has to be in accordance with the plant requirements

(actuator axis parallel or perpendicular to the pipeline axis).

7

flowserve.com

Page 8

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

2.2 Connection With Valve and Mounting Kit

The LPC actuator is usually supplied with the spool piece already assembled. To assemble the actuator onto the valve,

perform the following steps:

1. Check the mounting surfaces, the stem adaptor and the spool piece to assure the proper fit. Clean the flange of the

valve and spool piece to remove oils and greases since the torque is transmitted by friction. Also remove any rust

that may have occurred during the storage.

2. Secure the valve in the closed/open position, if possible, with the stem vertical. Lubricate the valve stem in order to

ease the assembly. Place the stem adaptor on the valve stem.

3. Lift the actuator using a proper lifting system. Position the actuator over the valve and lower to engage the stem

adaptor to the actuator bore. Continue to lower until the spool piece sits on valve mounting surface. This coupling

has to take place without force and only with the weight of the actuator. The mounting bolts (or studs) of the valve

should easily fit into the bolt holes of the spool piece without any binding. If needed, turn or stroke the actuator a few

degrees and/or adjust the actuator travel-stops.

4. The mounting nuts (or bolts) connecting the base of the spool piece to the valve flange must be evenly tightened

according to specific tables, available upon request to Flowserve After Sales Department.

2.3 Travel-stop Bolts and Accessories

All actuated valves require accurate travel-stop adjustments at both ends of the stroke to obtain optimum performance

and valve seat life. Adjust the travel-stop bolts of the actuator for the proper open and close valve positions, per valve

manufacturer’s recommendations.

The LPC actuators have travel-stop adjustments in both the clockwise and counter-clockwise directions. The

+/- 5-degree adjustment feature provides shaft rotation from 80 to 100 degrees overall. The adjustment of the travelstops is performed in accordance with the following steps. Refer to Figure 15.

• Pneumatic cylinder stop (19): Loosen the hex nut (20) with a proper wrench. Screw or unscrew the stop (19), using

a proper Allen key, while keeping the hex nut stationary. Tighten the hex nut.

• Housing stop (19): Loosen the hex nut (20) with a proper wrench. Screw or unscrew the stop (19), using a proper

Allen key, while keeping the hex nut stationary. Tighten the hex nut.

Adjust the travel stop bolts of the actuator for the proper open and closed valve positions, per valve manufacturer’s

recommendations. Pneumatically stroke the actuator several times to assure proper operation. If the actuator is

equipped with a switch, positioner or other accessories, adjusts them at this time.

2.4 Pneumatic Supply Fluids

To prolong actuator life use only clean, dry pneumatic supply fluids. Lubricated fluids are not required; however, they

are recommended, particularly for high cycle applications. Do not use lubricated fluids with positioners, as they may

damage the positioner.

8

Page 9

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

2.5 Initial Operation

Before initial operation of the actuator, perform the following checks:

• Check that all electrical supply, control and signal lines are properly connected, by following the dedicated customer

procedures.

• Check that the pressure and quality of the supply fluids are as prescribed.

• Check the absence of leaks in the pneumatic connections. If necessary tighten the pipe fittings.

2.6 Fail Open and Fail Close Configuration

The actuator is designed for work in both configurations: fail open and fail close. For conversion from one configuration

to the other, refer to next paragraph.

Figure 5: Actuator Configuration: Fail Close – Fail Clockwise – Single Acting

Figure 6: Actuator Configuration: Fail Open – Fail Counter Clockwise – Single Acting

9

flowserve.com

Page 10

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

Figure 7: Double Acting Actuator Configuration – Close Position

10

Figure 8: Double Acting Actuator Configuration – Open Position

Figure 9: Fail Close Configuration With Valve Figure 10: Fail Open Configuration With Valve

Page 11

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

Field Conversion

3

For field conversion from fail open (CCW) to fail close (CW) and vice versa, follow the following steps.

NOTE:

• An additional adapter kit is not required for field conversion

• Disassemble the actuator from the valve before carrying out the conversion

THE ACTUATOR IS DISASSEMBLED FROM THE VALVE

a WARNING: Ensure that the pneumatic connection ports of the cylinder are disconnected. Also make sure that

all pneumatic supplies to the control unit and all power supplies are disconnected. Finally, make sure that the

actuator is in fail position.

3.0.1 Starting with the actuator in a fail open (CCW) execution,

remove the actuator from the valve, keeping the spool

adaptor installed onto the valve.

3.0.2 Rotate the actuator.

3.0.3 Reassemble in the new position the actuator onto

the spool piece and the valve. Now the actuator is in

a fail close (CW) execution. Similar steps will apply for

conversion from fail close (CW) to fail open (CCW).

flowserve.com

11

Page 12

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

Maintenance Instructions

4

LPC series compact actuators are designed to offer the greatest ease of operations of assembly, disassembly and maintenance. The maintenance and disassembly do not require special equipment or special or large wrenches. Furthermore

the joints among the moving parts of the actuator are made exclusively through pins and then not using bolts to be

tightened with specific torques.

LPC compact actuators do not need maintenance for a long period, even if they are working in severe condition. The

lifetime of these actuators is guaranteed for 25 years with a regular and programmed maintenance operation every five

years. However, if the actuator operation happens infrequently, it is recommended to periodically check the actuator by

performing the following steps:

• In the plants, where it is possible, carry out a few opening and closing operations, involving all the control unit

components, checking that the actuator operates correctly and within the required stroking times.

• Check that all the signals (pneumatic and electric) arriving at the actuator are correct and that the supply fluid pressure is within the required range. Check for the absence of leaks in the pneumatic connections. If necessary, tighten

the pipe fittings.

• Check the paint coating. If some areas are damaged due to accidental events, retouch them according to paint

procedure supplied along with the actuator documentation.

In case of scheduled preventive maintenance, or following accidental events, refer to the following maintenance

instructions regarding the main actuators components (pneumatic cylinder and housing).

4.1 General Disassembly Instructions

1. Disconnect all air and electrical supplies from actuator;

2. If removal of the actuator from valve is necessary, before dismounting the actuator, remove all accessories from

actuator.

3. The reference drawings for the instructions reported in the following paragraphs are exploded views of single acting

and double acting actuators, included as Figures 15.

4.2 Spring Container and Pneumatic Cylinder Maintenance

The pneumatic cylinder maintenance mainly consists in the replacement of all parts that may degrade in the course of

time, even in the absence of faults. These components are the o-rings and the sliding elements of the piston.

12

NOTE: In the LPC Compact Actuator Series, in single acting execution, the spring is located inside the

pneumatic cylinder, as shown in Figures 5 and 6.

a WARNING: Ensure that the pneumatic connection ports of the cylinder are disconnected. Also make sure that

all pneumatic supplies to the control unit and all power supplies are disconnected. Finally, make sure that

the actuator is in fail position, i.e. that it is not locked in a position with the spring compressed by means of

locking devices.

Page 13

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

Standard in-field maintenance

Perform the following steps with reference to Figure 15:

4.2.1 Unscrew and remove the travel stop of the pneumatic

cylinder (19). For removing the stop, refer to the indications

given in paragraph 2.3.

4.2.2 Remove four tie rods (16) positioned on the cylinder by

unscrewing the nuts (18) on the sides of the End Flange and

unscrewing the tie rods from the adaptor flange (26).

4.2.3 Remove carefully the end flange (23) from the can (17).

Remove the two o-ring (21 and 22) from the end flange.

4.2.4 Finally remove the can (17) without damaging or scratching

the inner surface.

4.2.5 Remove the o-ring (25) and finally the two guide-tapes (36)

from the piston (15). Clean all the surface of piston and flanges in

contact with these components with a clean rag and solvent

compatible with o-ring material (for information contact Flowserve).

Brush the o-rings grooves with a light oil film and install the

new o-rings. Spread a thin layer of oil on the bottom of the guide

tape grooves and install a new guide tapes. Clean the internal

surface of the tube and lubricate with a protective oil film.

4.2.6 Reassemble the parts of the cylinder with reverse procedure as

described in points 3.2.1 to 3.2.4. The tie rods should be tightened

using a torque wrench, applying a torque in accordance with

specific tables, available upon request to Flowserve After

Sales Department.

4.2.7 Readjust the travel stops as instructed in paragraph 2.3.

NOTE: After the standard maintenance steps, stroke the actuator a few times to check for normal operation.

13

flowserve.com

Page 14

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

4.3 Housing and Scotch Yoke Maintenance

Standard maintenance of the housing may take place in the field.

Standard in–field maintenance

A first standard maintenance is available unscrewing the housing stop bolt (11) and applies a film of grease (with an

applicator) directly on the yoke’s sliding surface.

NOTE: Take note of the length of the stop bolt before making the standard maintenance

and reassemble it at the same length.

Extensive maintenance

If it is necessary to carry out an extra-maintenance inside the housing, perform the following steps:

a WARNING: Ensure that the pneumatic connection ports of the cylinder are disconnected. Also make

sure that all pneumatic supplies to the control unit and all power supplies are disconnected. Finally,

make sure that the actuator is in fail position, i.e. that it is not locked in a

position with the spring compressed by means of locking devices.

4.3.1 Remove the actuator from the valve.

4.3.2 Remove the pneumatic cylinder unscrewing the six screws (29)

and unbolting the piston rod (11) to the guide block (13).

4.3.3 Unscrew the screw locates on the left of the housing stop bolt (33),

remove the flat washer (32) and remove the guide bar (10).

Remove the o-ring (9).

4.3.4 Remove the retaining rings (5), the bushes (4) and the o-rings (31),

unscrew the caps (2) and finally unscrew the two bolts (1). Now, pull

out the output shaft (28) from the housing (30).

4.3.5 Remove the scotch yoke (3) from the housing, unscrew

upper and lower screws (6) and pull out the two washers (7)

and roller bearings (8).

14

4.3.6 Apply a grease film on the slider surface of the yoke wings (3) and

the roller bearings (8) (For the grease characteristics refer to Grease

Characteristics Table, available upon request to Flowserve After

Sales Department). Replace the o-ring (9).

4.3.7 Reassemble the parts of the housing using a reverse

procedure as previously described.

Page 15

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

Troubleshooting

5

To prevent the actuator from not proper functioning or low performance, first ensure that the installation and the adjustment operations are carried out completely in accordance with this manual.

a WARNING: During the activities of identifying faults, it is very important to observe all the regulations and

instructions about safety. Read all the paragraphs of this manual concerning maintenance before opening for

inspection or starting to repair any actuator components. If in doubt, choose SAFETY FIRST.

You can identify the causes of possible malfunctions with the help of the following table (“troubleshooting table”). If a

malfunction cannot be identified and eliminated using the table, Flowserve Service Department should be contacted.

Troubleshooting Table

Problem Possible cause Solution

Check that all the pneumatic connections and

that all the pneumatic components have been

installed correctly, and are in accordance with the

Actuator has not been properly installed.

Supply pressure problems.

Problems in the control panel (if present).

The actuator does not move.

The valve is blocked.

Exhaust port(s) obstructed.

Problems with lubricants.

actuator operating mode.

Check that the actuator is properly connected to

the valve and that there aren’t problems in the

mounting kit.

Check that the actuator is properly connected to

the valve and that there aren’t problems in the

mounting kit.

Check the correct functioning of the control

panel. In particular, check all the pneumatic and

electric connections.

Check the correct level of supply voltage for

solenoid valves and other electrical/electronic

components.

Check that valve is free to rotate. If necessary

disassemble the actuator from the valve.

Screw cap(s) must be disengaged. Ensure vent

ports are free. If not, clean them of any obstructions and clean the dust excluders, if present.

Ensure that the actuator is properly lubricated,

and that there is no solidified grease among

sliding parts or rotating parts. If actuator

lubrication is inadequate or improper, apply a

uniform lubricant layer. Follow the instructions

for cylinder maintenance (par. 4.2). Consult

Flowserve for proper oil and grease to be used.

flowserve.com

15

Page 16

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

Troubleshooting Table

Problem Possible cause Solution

Check if any moving part is blocked. If so,

A moving part is seized up.

Leakage of the pneumatic cylinder.

The actuator model is not the correct one,

The actuator does not move.

The valve does not fully perform

the stroke, during opening or

closing.

During the stroke the actuator

exhibits excessive amounts of

backlash.

In case of other problems not listed in this table, you should contact Flowserve Service Department.

or is not suitable for the plant conditions.

Spring problems (if actuator is a single

acting model).

A lockout device has been inserted and

forgotten in that position.

The actuator is not correctly adjusted.

Exhaust port(s) obstructed.

Actuator torque lower than required.

Some components are excessively worn.

follow the maintenance instructions given in the

relevant paragraphs of this manual or in special

maintenance operating instructions.

A significant air leak may prevent the actuator

from operating. Ensure that there aren’t any leaks

in the pneumatic cylinder toward the outside. If

possible, detect them using a leak finder spray.

Check also that there are not leaks across the

piston. If leaks are present, follow the cylinder

maintenance instructions given in paragraph 3.2.

Check the actuator nameplate and the plant

requirements. If there are mismatches, contact

Flowserve Service Department.

Check the proper functioning of the spring can.

If problems are found, contact Flowserve Service

Department.

Perform the following test: disassemble the

actuator from the valve and measure the

minimum pressure values necessary to move

and compress the spring. Compare the measured

values with the ones reported on the Testing

Certificate. If there are significant differences you

should contact Flowserve Service Department.

Disconnect the lockout module.

As above, check the position of the stoppers

in opening and closing direction. If necessary

adjust them. Follow the instructions given in

paragraph 2.3.

Screw cap(s) must be disengaged. Ensure vent

port are free. If not, clean them of any obstruction and clean the dust excluders, if present.

In order to do a check it is necessary to perform

the following test: disassemble the actuator from

the valve and measure the minimum pressure

values necessary to move and compress the

spring (if the actuator is a single acting model)

or the minimum values necessary to move the

actuator yoke and perform a stroke (for double

acting models). Compare the measured values

with the ones reported on the Testing Certificate.

If there are significant differences you should

contact Flowserve Service Department.

Identify and replace these components,

according to the procedure described in the

relevant paragrahs of this manual, or in special

maintenance operating instructions.

16

Page 17

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

Disposal of

Decommissioned

6

Actuators

Actuators that are to be decommissioned permanently due to a plant closure or for another reason must have the

stored energy in the spring neutralized. This can be done in several ways:

• Decommissioning by filling with concrete – following proper removal of the actuator from any hazardous areas,

the spring module may be neutralized by cutting a small opening in the end or side of the spring can and filling

the spring can with liquid concrete and allowing the concrete to dry. This will eliminate any possibility of spring

decompression if it were to be removed from the actuator without following proper procedures.

• Decommissioning by cutting the spring – following proper removal of the actuator from any hazardous areas, the

spring module may be neutralized by cutting a small opening in the side of the spring can and accessing the spring

coils. The spring coils are then cut using a torch to relieve all compression and stored energy. Care should be taken

that the opening in the spring can is sufficiently small to prevent any pieces of the spring from escaping when the

spring is cut.

a WARNING: Failure to neutralize the spring in the actuator or to follow these instructions could lead to injury to

personnel or property damage.

Either method is acceptable to Flowserve although the method outlined in the first point is preferred, as the stored

energy in the spring is not suddenly released when the spring is cut. Hence, this is the safest method.

No actions need be taken on any other portions of the actuator to decommission it.

flowserve.com

17

Page 18

7

CENTERBODY

DOUBLE

ACTING

SEALMATERIAL

SINGLE

ACTING

LPCACTUATORS:NOMENCLATURE

LPC10X

SR01

160Y

SPRINGCANSIZE

YOKETYPE

PNEUMATICCYLINDERSIZE

example model n°

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

Annex

SELECTIONTABLE

examplemodeln°

05

10

SIZE

Figure 11: Model Selection Table

Code Material Temperature Range Climate Classification According to IEC60721

B Buna Std Temp: -29°C to +100°C (-20°F to 212°F)

V Viton Hi Temp: up to +160°C (320°F)

S Silicon Low Temp: down to -40°C (-40°F) Temperate

Z Other Special Applications - Consult Factory Cold & Polar

Figure 12: Seals Material

A

B

080 BBUNA

100

120

140

160

180

200

220

VVITON

SSILICON

ZSPECIAL

SRSPRINGRETURN

DADOUBLEACTING

Tropical & Arid

01

02

03

04

05

06

18

Page 19

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

TOLERANCE ±10% TO BE CONSIDERED ON DIMENSIONS

Dimensions mm (in) - Kg (lbs)

Model A B D E K H L Q Z 'N' NPT PORT Weight

LPC-05X-080Y-SR01

LPC-05X-080Y-SR02

LPC-05X-100Y-SR01

LPC-05X-100Y-SR02

LPC-05X-100Y-SR03

LPC-05X-120Y-SR01

LPC-05X-120Y-SR02

LPC-05X-120Y-SR03

LPC-05X-120Y-SR04

LPC-05X-120Y-SR05

LPC-05X-140Y-SR01

LPC-05X-140Y-SR02

LPC-05X-140Y-SR03

LPC-05X-140Y-SR04

LPC-05X-140Y-SR05

LPC-05X-140Y-SR06

LPC-05X-160Y-SR01

LPC-05X-160Y-SR02

LPC-05X-160Y-SR03

LPC-05X-160Y-SR04

LPC-05X-160Y-SR05

LPC-05X-160Y-SR06

716 178 100 438 38 175 69 120 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 4.72 5.51 82

716 178 100 438 38 175 69 120 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 4.72 5.51 83

716 178 100 438 38 175 69 140 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 5.51 5.51 94

716 178 100 438 38 175 69 140 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 5.51 5.51 95

716 178 100 438 38 175 69 140 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 5.51 5.51 96

716 178 100 438 38 175 69 150 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 5.91 5.51 97

716 178 100 438 38 175 69 150 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 5.91 5.51 98

716 178 100 438 38 175 69 150 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 5.91 5.51 99

716 178 100 438 38 175 69 150 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 5.91 5.51 100

716 178 100 438 38 175 69 150 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 5.91 5.51 102

716 178 100 438 38 175 69 165 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 6.50 5.51 104

716 178 100 438 38 175 69 165 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 6.50 5.51 106

716 178 100 438 38 175 69 165 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 6.50 5.51 107

716 178 100 438 38 175 69 165 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 6.50 5.51 108

716 178 100 438 38 175 69 165 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 6.50 5.51 110

716 178 100 438 38 175 69 165 140

28.19 7.01 3.94 17.24 1.50 6.89 2.72 6.50 5.51 119

716 178 100 438 38 185 69 185 140

28.19 7.01 3.94 17.24 1.50 7.28 2.72 7.28 5.51 117

716 178 100 438 38 185 69 185 140

28.19

28.19 7.01 3.94 17.24 1.50 7.28 2.72 7.28 5.51 119

28.19 7.01 3.94 17.24 1.50 7.28 2.72 7.28 5.51 120

28.19 7.01 3.94 17.24 1.50 7.28 2.72 7.28 5.51 122

28.19 7.01 3.94 17.24 1.50 7.28 2.72 7.28 5.51 126

7.01 3.94 17.24 1.50 7.28 2.72 7.28 5.51 118

716 178 100 438 38 185 69 185 140

716 178 100 438 38 185 69 185 140

716 178 100 438 38 185 69 185 140

716 178 100 438 38 185 69 185 140

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

37

38

43

43

44

44

44

45

45

46

47

48

48

49

50

54

53

54

54

55

56

57

19

flowserve.com

Page 20

20

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

TOLERANCE ±10% TO BE CONSIDERED ON DIMENSIONS

Dimensions mm (in) - Kg (lbs)

Model A B D E K H L Q Z 'N' NPT PORT Weight

LPC-10X-100Y-SR01

LPC-10X-120Y-SR01

LPC-10X-120Y-SR02

LPC-10X-140Y-SR01

LPC-10X-140Y-SR02

LPC-10X-140Y-SR03

LPC-10X-160Y-SR01

LPC-10X-160Y-SR02

LPC-10X-160Y-SR03

LPC-10X-160Y-SR04

LPC-10X-160Y-SR05

LPC-10X-180Y-SR01

LPC-10X-180Y-SR02

LPC-10X-180Y-SR03

LPC-10X-180Y-SR04

LPC-10X-180Y-SR05

LPC-10X-180Y-SR06

LPC-10X-200Y-SR01

LPC-10X-200Y-SR02

LPC-10X-200Y-SR03

LPC-10X-200Y-SR04

LPC-10X-200Y-SR05

LPC-10X-200Y-SR06

LPC-10X-220Y-SR01

LPC-10X-220Y-SR02

LPC-10X-220Y-SR03

LPC-10X-220Y-SR04

LPC-10X-220Y-SR05

LPC-10X-220Y-SR06

844 240 132 472 50 245 105 140 172

33.23 9.45 5.20 18.58 1.97 9.65 4.13 5.51 6.77 149

844 240 132 472 50 245 105 165 172

33.23 9.45 5.20 18.58 1.97 9.65 4.13 6.50 6.77 159

844 240 132 472 50 245 105 165 172

33.23 9.45 5.20 18.58 1.97 9.65 4.13 6.50 6.77 163

844 240 132 472 50 245 105 165 172

33.23 9.45 5.20 18.58 1.97 9.65 4.13 6.50 6.77 169

844 240 132 472 50 245 105 165 172

33.23 9.45 5.20 18.58 1.97 9.65 4.13 6.50 6.77 174

887 240 132 515 50 245 105 165 172

34.92 9.45 5.20 20.28 1.97 9.65 4.13 6.50 6.77 179

844 240 132 472 50 245 105 185 172

33.23 9.45 5.20 18.58 1.97 9.65 4.13 7.28 6.77 175

844 240 132 472 50 245 105 185 172

33.23 9.45 5.20 18.58 1.97 9.65 4.13 7.28 6.77 178

887 240 132 515 50 245 105 185 172

34.92 9.45 5.20 20.28 1.97 9.65 4.13 7.28 6.77 183

887 240 132 515 50 245 105 185 172

34.92 9.45 5.20 20.28 1.97 9.65 4.13 7.28 6.77 188

923 240 132 551 50 245 105 185 172

36.34 9.45 5.20 21.69 1.97 9.65 4.13 7.28 6.77 192

844 240 132 472 50 245 105 230 172

33.23 9.45 5.20 18.58 1.97 9.65 4.13 9.06 6.77 199

844 240 132 472 50 245 105 230 172

33.23 9.45 5.20 18.58 1.97 9.65 4.13 9.06 6.77 202

887 240 132 515 50 245 105 230 172

34.92 9.45 5.20 20.28 1.97 9.65 4.13 9.06 6.77 206

887 240 132 515 50 245 105 230 172

34.92 9.45 5.20 20.28 1.97 9.65 4.13 9.06 6.77 211

923 240 132 551 50 245 105 230 172

36.34 9.45 5.20 21.69 1.97 9.65 4.13 9.06 6.77 215

923 240 132 551 50 245 105 230 172

36.34 9.45 5.20 21.69 1.97 9.65 4.13 9.06 6.77 219

844 240 132 472 50 245 105 245 172

33.23

33.23 9.45 5.20 18.58 1.97 9.65 4.13 9.65 6.77 221

34.92 9.45 5.20 20.28 1.97 9.65 4.13 9.65 6.77 226

34.92 9.45 5.20 20.28 1.97 9.65 4.13 9.65 6.77 231

36.34 9.45 5.20 21.69 1.97 9.65 4.13 9.65 6.77 234

36.34 9.45 5.20 21.69 1.97 9.65 4.13 9.65 6.77 241

33.23 9.45 5.20 18.58 1.97 9.65 4.13 9.65 6.77 254

33.23 9.45 5.20 18.58 1.97 9.65 4.13 9.65 6.77 257

34.92 9.45 5.20 20.28 1.97 9.65 4.13 9.65 6.77 261

34.92 9.45 5.20 20.28 1.97 9.65 4.13 9.65 6.77 266

36.34 9.45 5.20 21.69 1.97 9.65 4.13 9.65 6.77 269

36.34 9.45 5.20 21.69 1.97 9.65 4.13 9.65 6.77 273

9.45 5.20 18.58 1.97 9.65 4.13 9.65 6.77 218

844 240 132 472 50 245 105 245 172

887 240 132 515 50 245 105 245 172

887 240 132 515 50 245 105 245 172

923 240 132 551 50 245 105 245 172

923 240 132 551 50 245 105 245 172

844 240 132 472 50 245 105 245 172

844 240 132 472 50 245 105 245 172

887 240 132 515 50 245 105 245 172

887 240 132 515 50 245 105 245 172

923 240 132 551 50 245 105 245 172

923 240 132 551 50 245 105 245 172

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

1/4"

68

72

74

77

79

81

79

81

83

85

87

90

92

93

96

97

99

99

100

102

105

106

109

115

117

119

121

122

124

Figure 13: Weights and Dimensions Table – Single Acting – Symmetric and Canted

Page 21

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

TOLERANCE ±10% TO BE CONSIDERED ON DIMENSIONS

Dimensions mm (in) - Kg (lbs)

Model A B D E K H L Q Z

LPC-05X-080Y-DA

LPC-05X-100Y-DA

LPC-05X-120Y-DA

LPC-05X-140Y-DA

LPC-05X-160Y-DA

LPC-10X-100Y-DA

LPC-10X-120Y-DA

LPC-10X-140Y-DA

LPC-10X-160Y-DA

LPC-10X-180Y-DA

LPC-10X-200Y-DA

LPC-10X-220Y-DA

568 178 100 290 38 175 69 120 140

22.36 7.01 3.94 11.42 1.50 6.89 2.72 4.72 5.51 72

568 178 100 290 38 175 69 140 140

22.36 7.01 3.94 11.42 1.50 6.89 2.72 5.51 5.51 87

568 178 100 290 38 175 69 150 140

22.36 7.01 3.94 11.42 1.50 6.89 2.72 5.91 5.51 88

568 178 100 290 38 175 69 165 140

22.36 7.01 3.94 11.42 1.50 6.89 2.72 6.50 5.51 94

568 178 100 290 38 185 69 185 140

22.36 7.01 3.94 11.42 1.50 7.28 2.72 7.28 5.51 103

713 250 130 333 50 245 105 140 172

28.07 9.84 5.12 13.11 1.97 9.65 4.13 5.51 6.77 123

713 250 130 333 50 245 105 165 172

28.07 9.84 5.12 13.11 1.97 9.65 4.13 6.50 6.77 132

713 250 130 333 50 245 105 165 172

28.07 9.84 5.12 13.11 1.97 9.65 4.13 6.50 6.77 138

713 250 130 333 50 245 105 185 172

28.07 9.84 5.12 13.11 1.97 9.65 4.13 7.28 6.77 147

713 250 130 333 50 245 105 230 172

28.07 9.84 5.12 13.11 1.97 9.65 4.13 9.06 6.77 162

713 250 130 333 50 245 105 245 172

28.07 9.84 5.12 13.11 1.97 9.65 4.13 9.65 6.77 165

713 250 130 333 50 245 105 245 172

28.07 9.84 5.12 13.11 1.97 9.65 4.13 9.65 6.77 179

'N' NPT

PORT

1/4" 1/4"

1/4" 1/4"

1/4" 1/4"

1/4" 1/4"

1/4" 1/4"

1/4" 1/4"

1/4" 1/4"

1/4" 1/4"

1/4" 1/4"

1/4" 1/4"

1/4" 1/4"

1/4" 1/4"

'P' NPT

PORT

Weight

33

39

40

43

47

56

60

63

67

73

75

81

21

Figure 14: Weights and Dimensions Table – Double Acting – Symmetric and Canted

flowserve.com

Page 22

19

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

4

31

Single Acting

38

33

30

32

28

29

26

9

6

34

8

7

35

2

27

22

Number Description Qt y.

1 Bolt 2

2 Cap 2

3 Scotch Yoke 1

4 Bush 2

5 Retaining Ring 2

6 Screw 2

7 Washer 2

1

13

3

Number Description Qt y.

8 Roller Bearing 2

9 O-Ring 1

10 Guide Bar 1

11 Piston Rod 1

12 Pin 2

13 Guide Block 1

14 Bushing 2

11

14

22

12

10

Number Description Qt y.

15 Piston 1

16 Tie Rod 4

17 Spring Can 2

18 Hex Nut 4

19 Stop Bolt 2

20 Hex Nut 2

21 O-Ring 2

Page 23

LPC Compact Actuator Series FCD LFENIM0002-00-AQ 07/14

25

24

25

22

26

Double Acting

16

17

11

24

15

36

23

21

20

18

19

37

36

16

15

Number Description Qt y.

22 O-Ring 1

23 End Flange 1

24 O-Ring 1

25 O-Ring 1

26 Adaptor Flange 1

27 Yoke Pin 1

28 Output Shaft 1

17

23

22

Number Description Qt y.

29 Screw 6

30 Housing 1

31 O-Ring 2

32 Flat Washer 1

33 Screw 1

34 Bushing 1

35 Spring 1

21

19

20

18

Figure 15: Exploded View

Number Description Qt y.

36 Guide Ring 2

37 Bar Pin 8

38 Bushing 1

23

flowserve.com

Page 24

FCD LFENIM0002-00-AQ 07/14 © 2014 Flowserve Corporation.

To find your local Flowserve representative

or for more information about Flowserve Corporation, visit

www.flowserve.com.

Flowserve Limitorque

Fluid Power Systems

Product Sales

Via Rio Vallone 17

20883 Mezzago (MB), Italy

Phone: +39 039 62060 1

Fax: +39 039 62060 213

Email: lfpsinfo@flowserve.com

Flowserve Limitorque

Fluid Power Systems

Manufacturing and Operations

Via Rio Vallone 17

20883 Mezzago (MB), Italy

Phone: +39 039 62060 1

Fax: +39 039 62060 213

Email: lfpsinfo@flowserve.com

Flowserve Limitorque

Fluid Power Systems

Research and Development

Viale dell’Artigianato 24

29122 Piacenza (PC), Italy

Email: lfpsinfo@flowserve.com

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended

function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide

variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should

read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in

connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as

a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this

product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice.

Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2014 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

flowserve.com

Loading...

Loading...