Page 1

Valtek Logix 1200e/1210e

Digital Positioner

GENERAL INFORMATION

The following instructions are designed to assist in

unpacking, installing and pe rforming maintenanc e as

required on Valtek

Series 1000 is the term used for all the positioners

herein; however, specific numbers indicate features

specific to a model (i .e. Logix 1200 e indicat es th at the

positioner uses HART

maintenance per sonnel should thorou ghly review this

bulletin prior to inst allin g, operating, or per forming any

maintenance on the valve.

Separate Valtek Flow Control Products Installation,

Operation, Maintenance instructions cover the valve

(such as IOM 1 or IOM 27) and actuator (such as IOM

2 or IOM 31) por tio ns of the system and o ther accessories. Refer to the appropria te instruc tions when this

information is needed.

WARNING: To avoid possible injury to personnel or damage to valve parts, users must

strictly adhere to WARNING and CAUTION

notes. Modifying this product, substituting

non-factory or inferior parts, or using maintenance procedures other than outlined could

drastically affect performance and be hazardous to personnel and equipment, and may

void existing warranties.

®

Logix® 1200e digital positioners.

®

protocol). Product users and

WARNING: Standard industry safety practices

must be adhered to when working on this or any

process control product. Specifically, personal

protective and lifting devices must be used as warranted.

Valve and Instrumentation Storage Procedures

Storage

Control valve packages (a control valve and its instrumentation) can be safely stored in an enc losed building that affords environmental protection; heating is

not required. Contr ol valve packages must be stored

on suitable skids, not directl y o n th e fl oor. The storage

location must also be free from flooding, dust, dirt, etc.

Pre-installation Inspection

If a valve control package has been stored for more

than one year, inspect one actuator by disassembling

it per the appropriate

Maintenance In struct ions

tion. If O-rings are out-of-r ound, deter iorated, or both ,

they must be replaced and the actuator rebuilt. All

actuators must then be disassembled and inspected. If

the actuator O-rings are replaced, complete the following steps:

1. Replace the pressure-balanced plug O-rings.

2. Inspect the solenoi d and positioner so ft goods and

replace as necessary.

Installation, Operation, and

(IOM) pr ior to valve inst alla-

Valtek SKU 138430 44-1

Page 2

Table of Contents

General Information ...................................................1

Valve and Instrumentation Storage Procedures....1

Logix 1200e Positioner Overview...............................3

Specifications.............................................................3

Positioner Operation...................................................4

Detailed Sequence of Positioner Operations.........4

Logix 1000 Series Positioner Vented-design

Conversion.................................................................5

Tubing Positioner to Actuator ................................ 6

Wiring and Grounding Guidelines..........................6

Available Spare Part Kits for Logix 1200e digital

postioner.............................................................. 22

4 to 20 mA Analog Output Retrofit.......................24

General Information.............................................24

Calibration............................................................25

Troubleshooting........................................................30

Introduction..........................................................30

Theory of Operation.............................................30

Mounting and Installation.....................................31

Calibration............................................................33

Control and Tuning............................ ...... ....... ..... 34

HART Communication......................................... 35

Alarms..................................................................37

Alerts....................................................................38

Advanced Features.................................................. 40

Logix 1200e Digital Positioner

on Valtek Mark One Control Valve

44-2 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 3

Unpacking

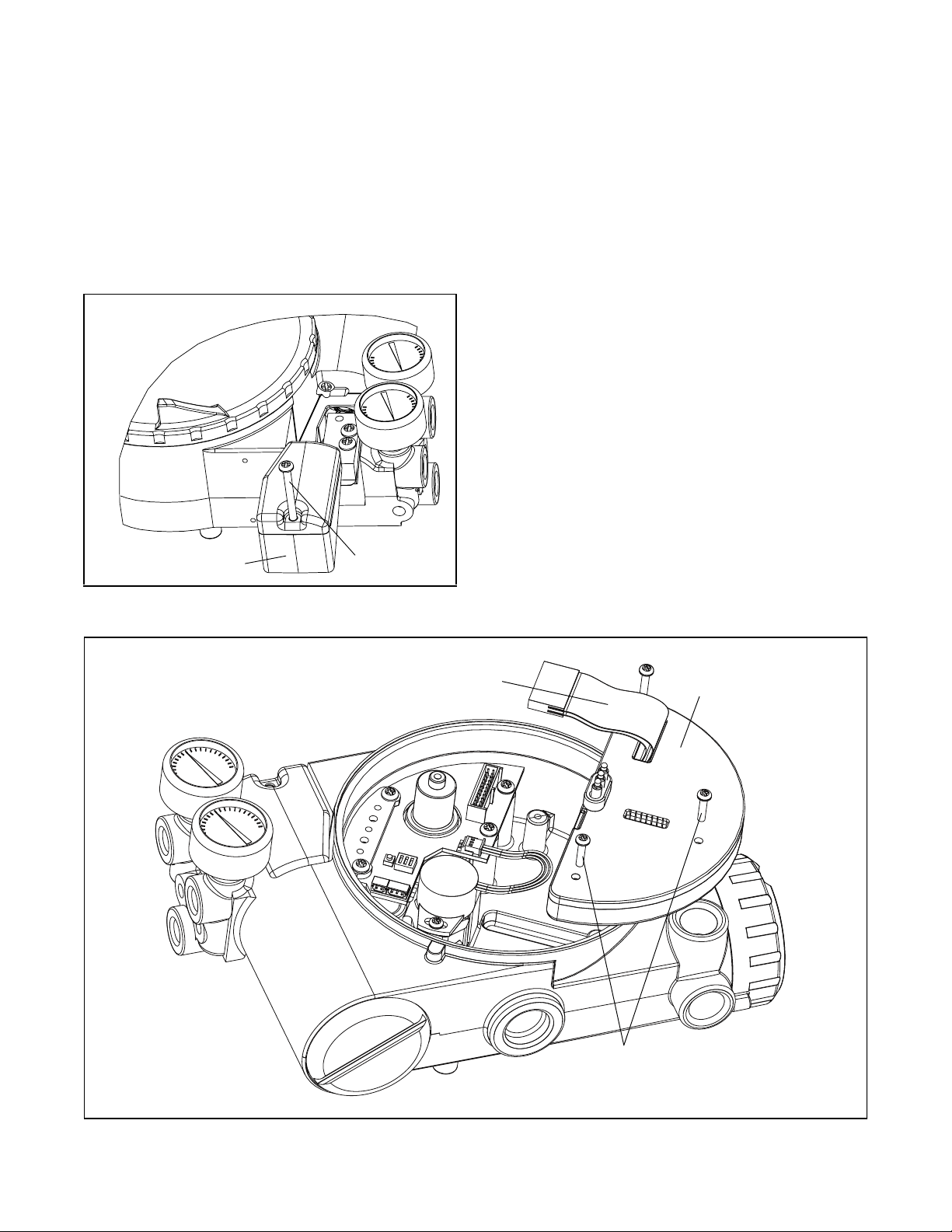

Logix 1200e Positioner Overview

1. While unpacking the Logix 1 200e p ositi oner, check

the packing list against the materials received. Lists

describing the system and accessories are

included in each shipping container.

2. When lifting the system from the shipping con-

tainer, position lifting straps to avoid damage to

mounted accessories. Systems with valves up to

six inches may be lifted by actuator lifting ring. On

larger systems, lift uni t using li fting straps or hooks

through the yoke legs and outer end of body.

WARNING: W hen lifting a v alve/actuator assembly with lifting straps, be aware the center of

gravity may be above the lifting point. Therefore, support must be given to prevent the

valve/actuator from rotating. Failure to do so

can cause serious injury to personnel or damage to nearby equipment.

3. In the event of shipping damage, contact the ship-

per immediately.

4. Should any problem arise, contact a Flowserve

Flow Control Division representative.

The Logix 1200e digital positioner is a two-wire,

4-20 mA input, digital valve positioner. The Logix

1200e positioner also utilizes the HART protocol to

allow two-way remote communications with the positioner. The Logix 1200e positioner can control both

double and single-acting actuators with linear and

rotary mountings. Start up current must be at least

3.5 mA but once started, the L ogix 120 0e digita l positioner operates with a signal as low as 2.8 mA . Below

2.8 mA, the operation and communication are suspended.

Since the positione r is insensitive to supply pr essure

changes and can handle suppl y pressures from 30 to

150 psig, a supply regulator is usually not required;

however, in applications where the supply pressure is

higher than the maximum actuator pressure rating a

supply regulator is required to lower the pressure to

the actuator’s maximum rating (not to be confused

with operating range). An air filter is required for all

applications due to the close clearances in the spool.

NOTE: The air su pply must conform to ISA Standard

ISA 7.0.01 (a dew point at least 18 degrees Fahrenheit

below ambient temperature, particle size below five

microns – one micr on re co mme nde d – and oil content

not to exceed one part per million).

Specifications

Table I: Electrical Specifications

Power supply Two-wire, 4-20 mA 12.0 VDC

Compliance voltage 12.0 VDC

Effective resistance 625 Ω @ 20 mA

Communications HART Protocol

Minimum required

start-up current

Minimum oper ati ng

current

Maximum voltage 40.0 VDC

Table II: SoftTools Suite Software Specifications

Minimum Pentium processor running Win-

Computer

HART Modem RS-232 Modem or PCMCIA card

HART Filter

HART MUX MTL 4840 system

dows 95 or NT, 16-MB total memory

(32-MB recommended), 20-MB available

hard disk space, one CD-ROM drive

May be required in conjunction with some

DCSs

3.5 mA

2.8 mA

Table III: Physical Specifications

Operating

Temperature Range

Housing

Weight

-40° F to +185° F

(-40° C to +85° C)

Cast, powder -painted aluminum,

stainless steel

8.3 pounds (3.9 kg) aluminum 20.5

pounds (9.3 kg) stainless steel

Table IV: Positioner Specifications

Dead band <0.1% full scale

Repeatability < 0.05% full scale

Linearity

Air Consumption at

< 0.5% (rotary), < 0.8%

(sliding stem) full scale

< 0.3 SCFM (0.5 Nm

(4 barg)

Table V: Hazardous Area Certifications

Explosion Proof

Non-incendive

Intrinsically Safe

FM/CSA Class 1, Div 1, Groups B, C, D

CENELEC EExd IIB+H2 T5, IP-66

FM/CSA Class 1, Div 2, Groups A, B, C,

D; CENELEC IIC Exn, T6,BS 6941,

IP-66, T

FM/CSA Class 1, Div 1, Groups A, B, C,

D; CENELEC EExib, T4 & T5, IP-66

3

/hr)@60 psig

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-3

Page 4

.

O

Digital Position

Algorithm

LED

Display

Air-to-open

Configuration

Flame Arrestors

Spool Valve

Exhaust

OUTPUT 1

Collector Board

Pressure Sensor

Air Supply

OUTPUT 2

Exhaust

Flame

Arrestor

Stem Position Sensor

Hall Effect Sensor

Electro magnetic Coil

Nozzle

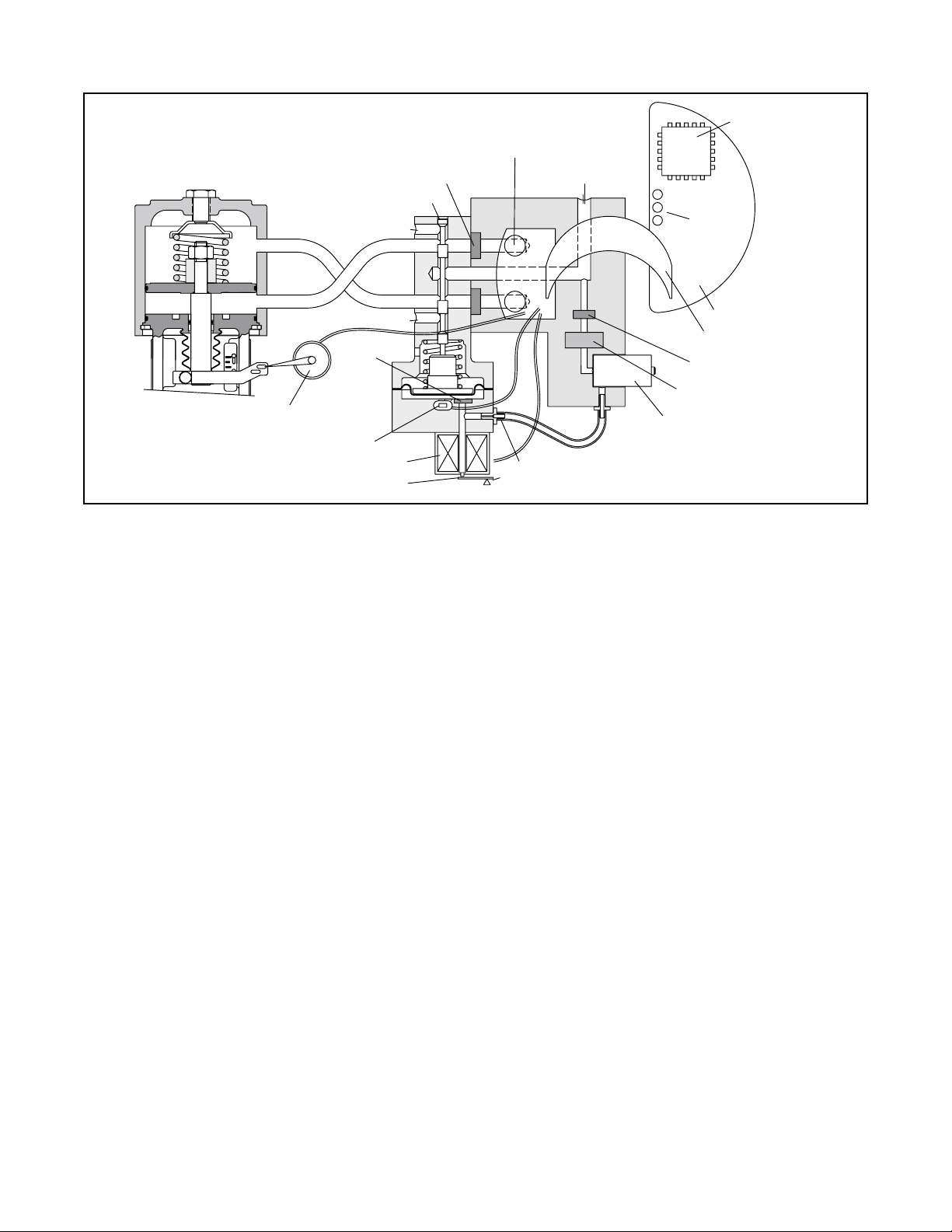

Figure 1: Logix 1200e Digital Positioner Schematic

Positioner Operation

The Logix 1200e positioner is an electric feedback

instrument. Fig ure 1 shows a Logi x 1200e positioner

installed on a double-acting actuator for air-to-open

action. Positioning is based on a bal ance of two signals: one proportional to the command input signal

and the other proportional to the valve stem position.

The supply pressure for the positioner pressure modulator is tapped off the main supply. Next it passes

through an inter n al pres su re regul ato r that regul ates it

to approximately 22 psig. The air the n pass es throug h

an orifice that restricts the flow and air consumption.

The pressure modulator further controls the air to

6-10 psig, when operatin g current is applied, using a

spring-diaphragm fl apper that is attracted by an electromagnet to a nozzle. A temperature compensated

hall effect sensor mounted on a circuit board senses

the spool valve position. The hall effect sensor and circuitry create an inner feedback loop, which determines

how much current to send to the ele ctromagnet for a

desired spool valve position. The electro-magnet in

the feedback loop varies the nozzle-flapper spacing,

which regulates the o utput p ressure to 6-10 psig, proportional to the digital position algorithm.

When the command and stem position signals are

equal, the system will be in equilibrium and the valve

stem will be in the posi tion ca lled for by the command

signal. If these opposing signals are not equal, the

spool valve will move up (or down) and, by means of

Main PCB Tray

Ribbon Cable

Flame Arrestor

Filter

Regulator

Orifice

Flapper

the pressure modulato r, change output pressures an d

flow rate. This will cause the actuator pi ston to move

until the signal of the position sensor equalizes with

the command signal.

Detailed Sequence of Positioner Operations

The detailed sequen ce of positioner operations is as

follows: An increase in the command signal causes

the modulator pressur e to incr ease, push ing the spool

assembly upward from its equilibrium position. This

opens the spool valve ports, su pplying air to Output 1

and exhausting air from Output 2. This causes the

actuator piston to move upward.

The upward motion of the piston is transmitted back to

the positioner through the s tem pos ition feedback linkage, changing propor tionally to the valve stem position. The piston continues to stroke upward until the

stem position signal of the sensor increases sufficiently to counter th e signal being sent to the control

algorithm. At this po int, the spool is at its equilibriu m

position as the pres sures in the cylinde r stabilize and

the air flow to the actu ator decreases. The positio ner

will then make small null adjustments to fine-tune the

desired position and compensate for changes in

dynamic loading.

A decrease in the command signal reverses the

described actions, causing a proportional downward

movement of the actuator piston and stem.

44-4 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 5

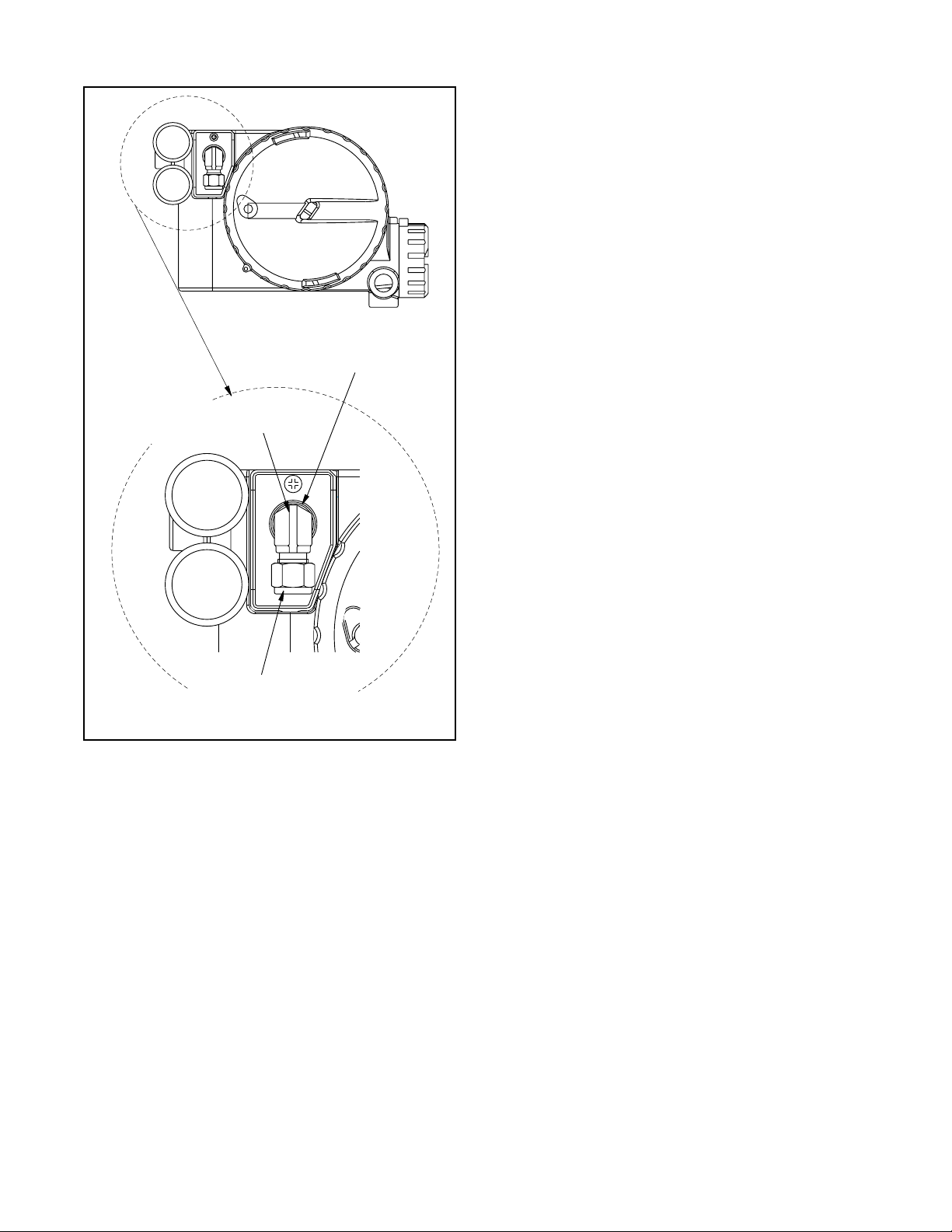

Logix 1000 Series Positioner Vented-d esign Conversion

A standard Logix 1000 series positioner is vented

directly to the atmosp here. When supply air is su bstituted with sweet natural gas, the following changes

and considerations must be met . Piping must be u sed

to route the exhausted natural g as to a safe environment. This piping system may cause som e positioner

back pressure in the main chamber (from mod ulator)

and spool chambers (fro m actuator). This increase i n

pressure is due to restrictions caused by piping losses

from the pipe and fittings

Maximum Allowable Housing

Back Pressure

1 psi (0.07 bar)

1

4

-inch NPT x 4-inch

Swagelok Tube Fitting

1

4

-inch FNTP x 8-inch

MNPT Reducer

1

Figure 3: Main Housing Vent

1

Two chambers must be vented on the Logix 1000

series positio ners: the main hou sing cham ber and the

spool valve chamber (Figures 1 and 2). The main

chamber vent is located on the backside of the positioner (see Figur e 1). Ther e is a small, silver-colored

cover (item 24, SKU 10097867), protecting the vent

which must be removed and can be discarded.

1

A fitting may now be threaded into th e

/8-inch NPT

hole and tubing/piping attached.

NOTE: On rotary prod ucts, the mounting bracket covers the main housing vent. An adequate size access

hole must be drilled in the bracket at the time of

assembly to allow access to the main housing vent.

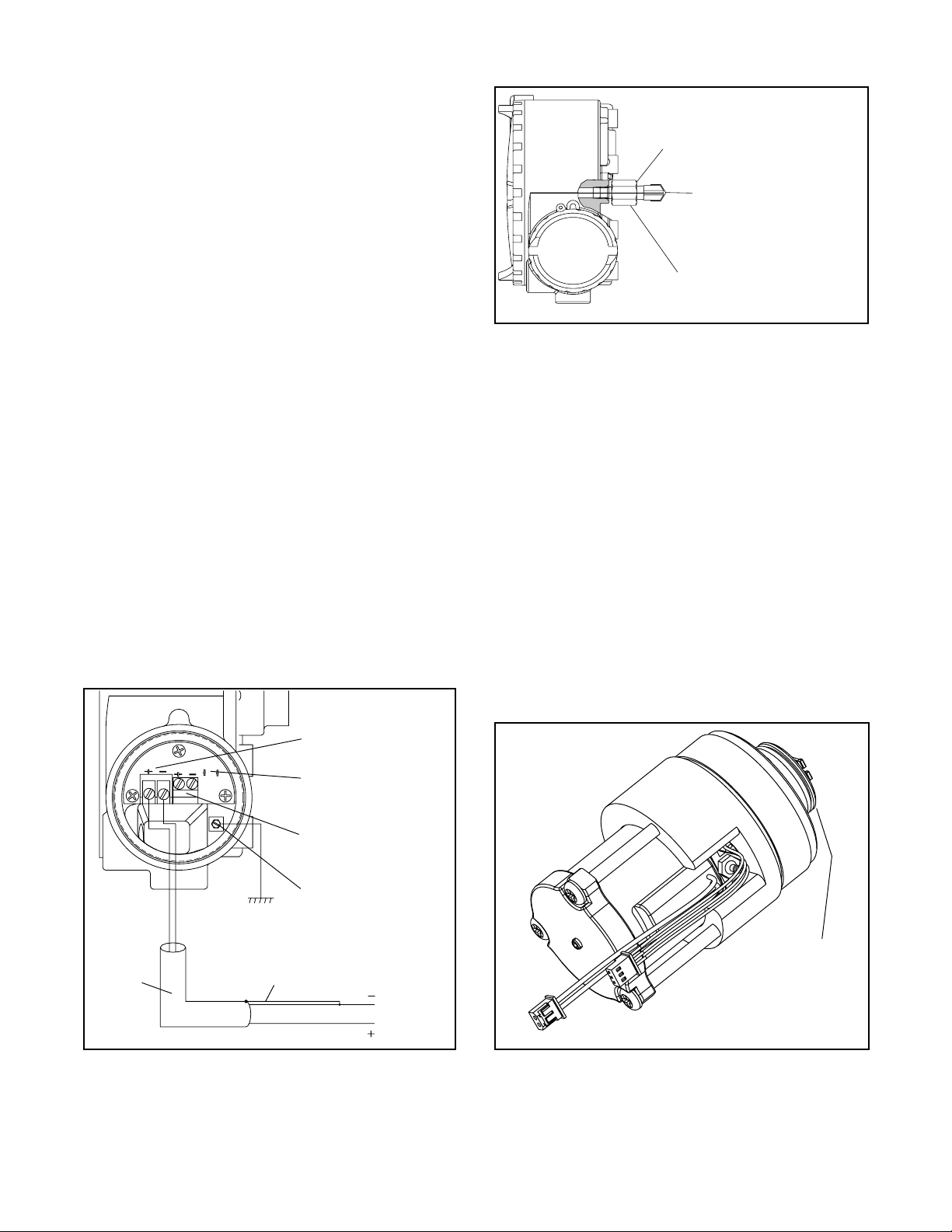

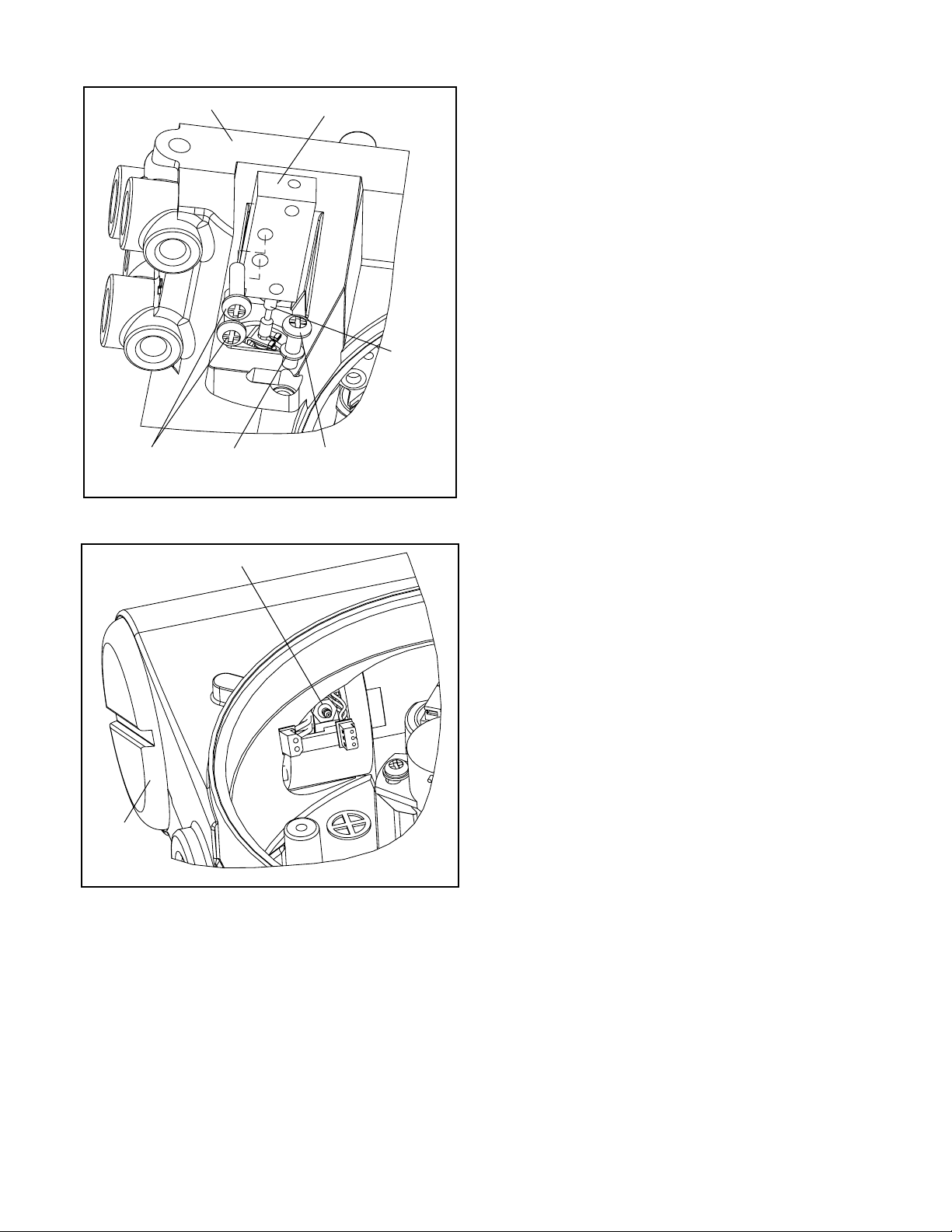

Field Terminations

HAR T Connection

Terminals

The maximum all owa ble back pressure fr om the collection device on the main housing vent is 1.0 psi

3

(0.07 bar). Vent flow rate is 244 standard in

/min.

WARNING: The back pressure must never rise

above 2.0 psi (0.14 bar).

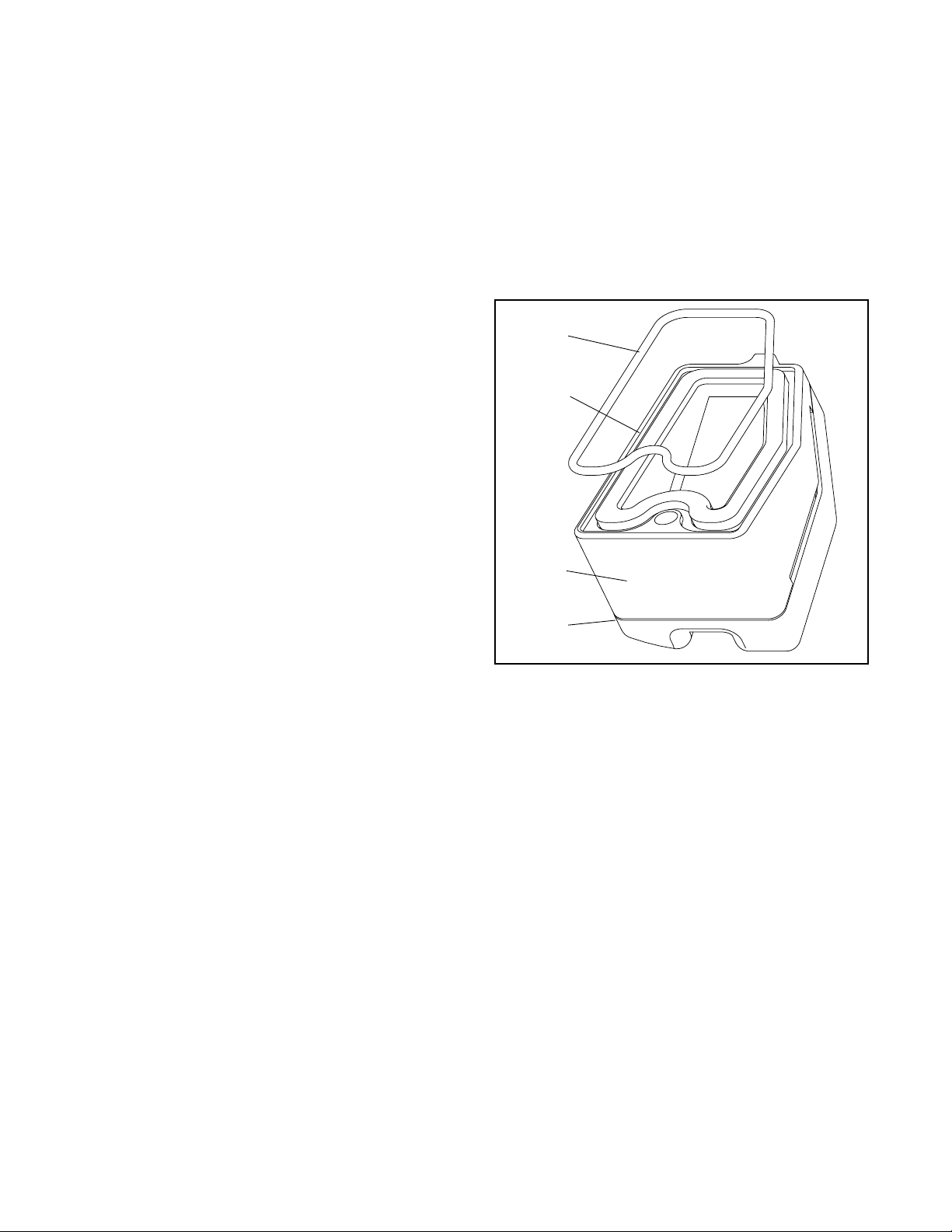

If this occurs the weather seal boot (SKU 130884),

found on the early versions of the Logix 1000 positioner, identified by the diagonal window in the main

cover, must be checked for proper sealing, as overpressure will move the seal out of place. (See

Figure 4). Damage will not oc cur to the s eal, only s eal

alignment will be affected. A typic al sign of boot lea kage is a dramatic deterioration of positioner performance. To correct the seal, remove the driver module

and simply re-ali gn back into its groove. If back pressure of 3.5 psi (0.24 bar) is reached, total valve control

will be lost.

4-20 mA Feedback

Terminals (optional)

Housing EARTH

Terminal

Seal Boot

Shielded

Connect Shield at Source Ground

Cable

4-20 mA Current Source

Figure 2: Field Termination

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-5

Figure 4: Seal on Modulator

Page 6

3

/8-inch NPT x 3/8-inch

Swagelok Tube Fitting

Maximum Allowable

spool Back Pressure

8 psi (0.55 bar)

will cause problems with overshoot but permanent

damage will not occur until pressures exceed 20 psi

(1.4 bar).

Tubing Positioner to Actuator

Proper tubing orientation is critical for the posit ion er to

function correctly and have the proper failure mode.

Refer to Figure 1 and note that for air-to-open valves,

the Output 1 port of the positioner mani fold is tubed to

the bottom side of the ac tuator. The Output 2 port of

the positioner manifold is tubed to the top side of the

actuator. For air-to-close valves the above configuration is reversed.

For single-acting actuators Output 1 port is always

tubed to the actuator regardless of air action. Output 2

port must be plugged.

WARNING: This product has electrical conduit

connections in either thread sizes 0.5- inch NPT or

M20 which appear identical but are not interchangeable. Forcing dissimilar threads together

will damage equipment, cause personal injury and

void hazardous location cer tifications. Conduit fittings must match equipment housing threads

before installation. If threads do not match, obtain

suitable adapters or contact a Flowserve office.

Customer Connection

3

/8-inch Tubing

Figure 5: Spool Cover Vent

The spool valve chamber has two parts: the spool

valve cover, (item 9, SKU 130811) and spool valve

shroud (item 10, SKU 1308 25). The spo ol valve cover

is replaced by SKU 101346 49 for early versions of the

Logix 1000 posi tioner or SKU 1016 0335 for later versions (identified by the 1200e or the round win dow in

the main cover). This new cover has a

hole where tubing/pipin g must be attach ed. The sp ool

valve shroud is discarded and not replaced with a nything. The maximum allowable back pressure while

stroking the valve is 8 psi (0.55 bar). Hi ghe r p re ssur es

3

/8-inch NPT

Wiring and Grounding Guidelines

Input Cable Shielding (Figure 2)

The input loop current signal to the Logix 1200e digital

positioner should be in shielded cable. Shields must

be tied to a ground at only one end of the cable to provide a place for environmental electrical noise to be

removed from the cable. In general, shield wire should

be connected at the source.

Grounding Screw

The green grounding scr ew, locate d inside the term ination cap, should be used to provide the unit with an

adequate and reliable earth ground reference. This

ground should be tied to the same ground as the electrical conduit. Additionally , the electrical conduit should

be earth grounded at both ends of its run.

The green grounding screw must not be used to

terminate signal shield wires

.

44-6 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 7

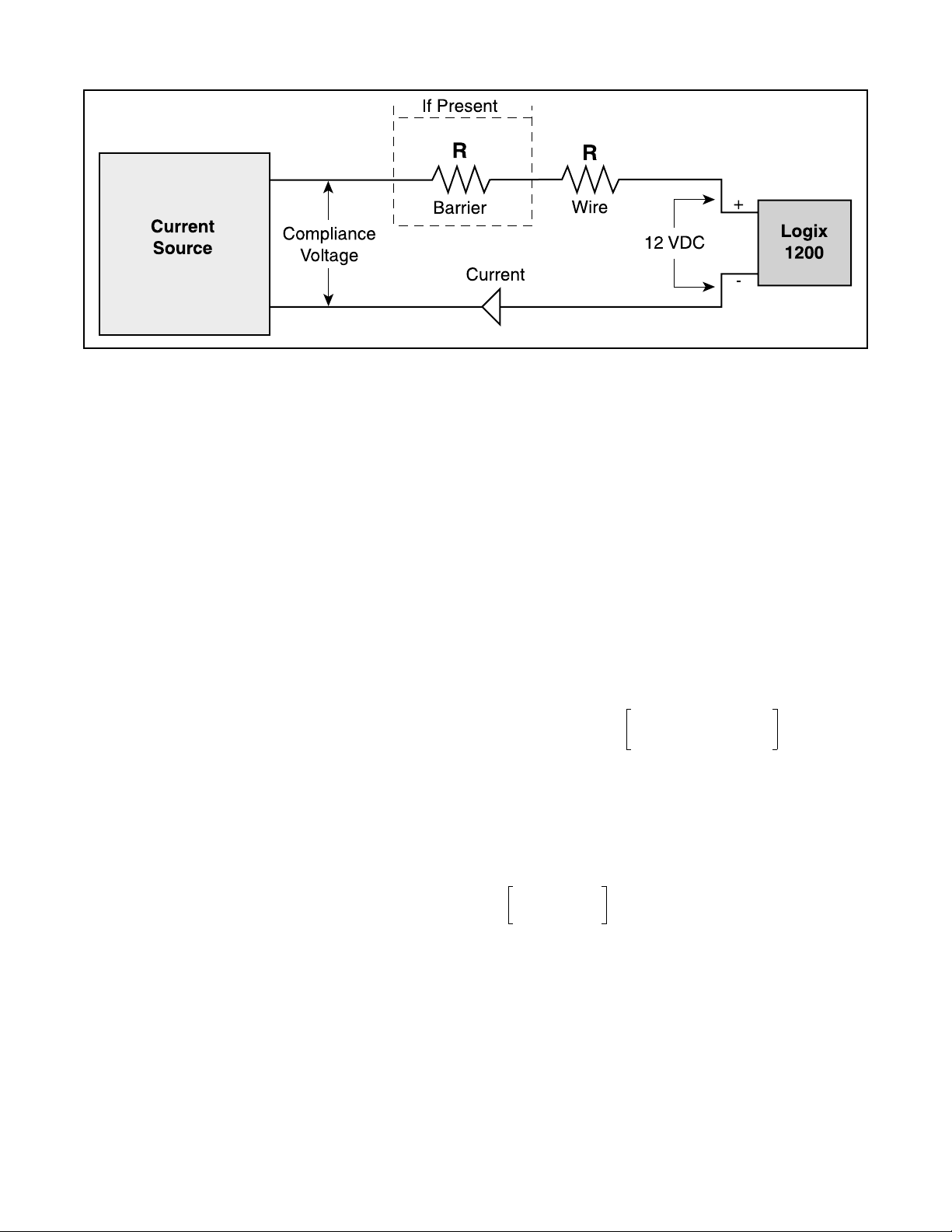

Figure 6: Co mpliance Voltage

Compliance Voltage (Figure 6)

Output compliance voltage refers to the voltage limit

that can be provided by the current source. A current

loop system consists of the current source, wiring

resistance, barrier resistance (if present), and the

Logix 1200e posi tioner impedance. The Logix 1200 e

digital positioner r equires that the current lo op system

allows for a 12.0 VDC drop across the positioner at

maximum loop current. The 12.0 VDC drop across the

Logix 1200e positi oner terminals is ge nerated by the

positioner from the 4-20 mA loop current input.

CAUTION: Never connect a voltage source directly

across the positioner terminals. This co uld cause

permanent circuit board damage.

Determine if the loop will support the Logix 1200e digital positioner by performing the following calculation.

Voltage = Compliance Voltage (

- Current

MAX

*(R

barrier+Rwire

)

@

Current

MAX

)

The calculated voltage must be greater than 12 VDC

in order to support the Logix 1200e digital positioner.

Example: DCS Compliance Voltage = 19 V

Cable Requirements

The Logix 1200e digital positioner utilizes the HART

Communication protocol. This communication signal

is superimposed on the DC 4-20 mA current signal.

The two frequencies used by the HART protocol are

1200e Hz and 220 0 Hz. In order to prevent distortio n

of the HART communication, cable capacitance and

cable length restrictions must be calculated. The cable

length must be limited if the capacitance is too high.

Selecting a cable with lower capacitance/foot rating

will allow longer cable runs. In addition to the cable

capacitance, the network resistance also affects the

allowable cable length.

In order to calculate the maximum network capacitance, use the following formu la.

C

network

Example: R

= 50

R

wire

Ω

µF()

barrier

C

cable

≤

--------------------------------------------------------------

R

()

barrierRwire

= 300

Ω

22ρF

--------------

65

++

foot

390

0.000022µF

--------------------------------==

foot

0.0032

–

R

= 300

barrier

= 25

R

wire

Ω

CURRENT

Ω

= 20 mA

MAX

65

---------------------------------------

30050390

++

Max Cable Length

0.0032–0.08µFC

==

C

-----------------------------------=

network

C

network

network

µF()

Max

µF()

()

Voltage = 19 V - 0.020 A*(300 Ω + 25 Ω)

= 12.5 V

Max Cable Length

0.08µF

-----------------------------------------------=

0.000022µF foot

⁄

The voltage 12.5 V is greater than the required 12.0 V;

therefore, this system will support the Logix 1200e digital positioner. The Logix 1200e positioner has an

input resistance equivalent to 625 Ω at a 20 mA input

current.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-7

To control cable resistance, No. 24 AWG cable should

be used for runs less than 5000 feet. For cable runs

longer than 5000 feet, No. 20 AWG cable should be

used.

Page 8

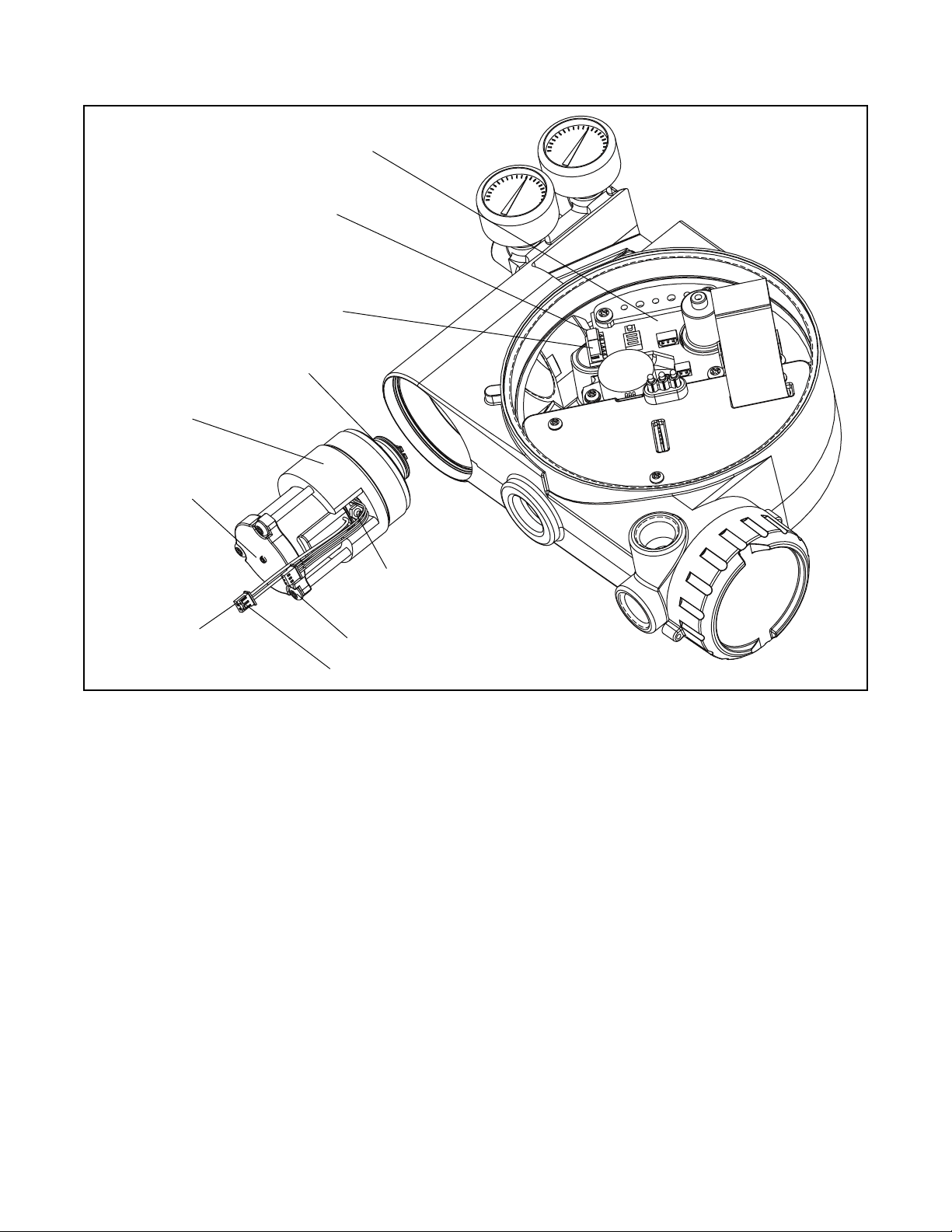

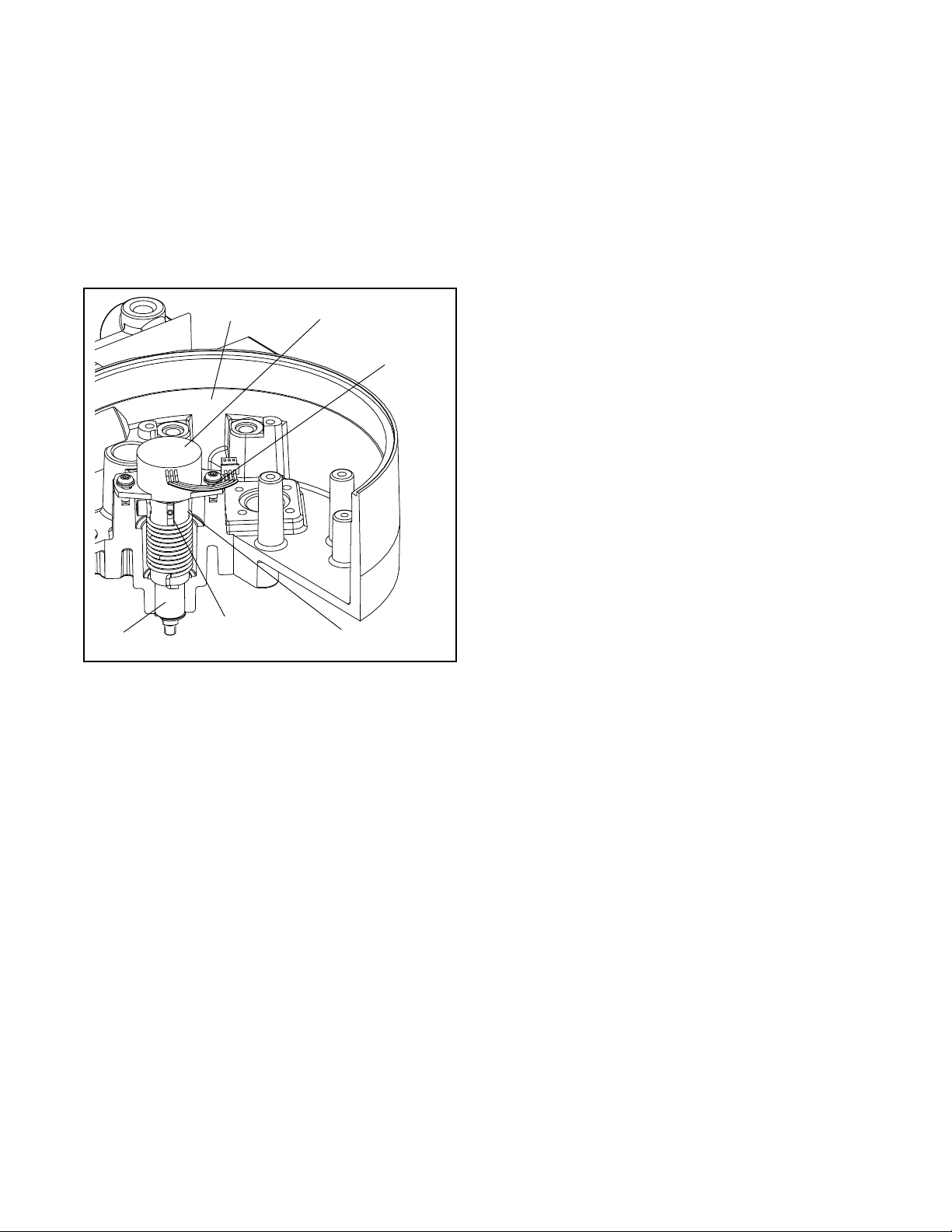

Driver Module Assembly

Minimum Pressure

Set Screw (factory

calibrated)

Collector Board

Pressure

Modulator

Connection

Hall Sensor

Connection

O-ring

Install orifice before driver

module is in housing

Position wires to

the rear of Modulator

Hall Sensor Connector

Pressure Modulator Connector

Figure 7: Driver Module Assembly

Driver Module Assembly

The driver module assembly moves the spool valve by

means of differential pressures on its diaphragm. Air is

routed to the module from the regulator through a

hose that connects to the assembly through a hose

barb with an integral orifice. Wires from the module

connect the hall effect sensor an d the pr es su re modulator coil to the collector board.

Driver Module Assembly Replacement

To replace the driver module assembly, refer to

Figure 7, 8, 9, 11, 20 and procee d as outlined below.

The following tools are required:

Flat plate/bar about

Phillips screwdriver

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the driver module cover (Figure 9), using

flat bar/plate in slot.

1

/8-inch thick

4. Remove the spool valve cover by removing the

screw and sliding the cover assembly backwards

until the tab is clear of the slot. Removing the sheet

metal cap, hydrophobic filter, or O-ring from this

assembly is not necessary (Figure 11).

5. Being careful not to l ose the nylon washer, remove

the Phillips-head screw that attaches the driver

module to the main housing (Figure 8).

6. Remove the spool valve block by removing the two

Phillips-head scr ews and carefully slidin g the block

off the spool (Figure 8).

CAUTION: The spool (extending from the driver

assembly) is easily damaged. Use extreme caution when handling the spool and spool valve

block.

7. Carefully remove spool by slid ing end of spool ou t

of connecting clip. Excessive force may bend spool.

8. Remove main cover.

44-8 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 9

Spool Valve

Screws

Spool Valve BlockHousing

Ny lon

Gaskets

Driver to

Housing Screws

Figure 8: Spool and Block

Spool

opening. This will al low the dri ver module to threa d

out without tangling or cutting the wires.

12.Grasp the driver module pressure modulator cap to

rotate the entire driver module. Turn it counter

clockwise to remove. After it is threaded ou t, carefully retract the driver module from the housing.

13.Take new driver module, and verify that the O-ring

is in place. Lay the wires back and along modulator

as shown in Figure 7, and hold in place by hand.

14.Gently direct the driver module into the housing

bore. Turn the dr iver module clockwise to thread it

into the housing. Continue rotating the module until

it bottoms out.

15.Once the threads are fully engaged, rotate the

driver module counter clockwise until the flat on the

driver module and the flat on the housing are

aligned. This wi ll align the sc rew holes for the next

step.

16.Verify that nylon gasket is in the counter bore in the

driver module retaining screw hole as shown in

Figure 8.

Orifice

Driver

Modul e

Cover

Figure 9: Driver Module Orifice

9. Remove the tubing from the orifice in the driver

module assembly (Figure 9) .

10.Remove the two wiring connections that link the

driver module assembly to the collector board.

17.Insert a driver-to-housing screw into the driver

housing through the counter-bored hole in positioner main housing. T ighten with a phillips screwdriver.

18.Feed the driver module wires in to the main chamber of the housing , an d c onn ec t th em to th e c olle ctor board.

19.Verify that the three O-rings are in the counterbores on the machined platform where the spool

valve block is to be placed (Figure 20).

20.Carefully slide the spool in to the connec ting clip of

the driver module assembly.

21.Carefully slide the block over the spool, using the

machined surface of the housing base as a register

(Figure 8). Slide the block toward the driver module

until the two retaining holes line up with the

threaded holes in the base.

22.Install two spo ol-valve screws and ti ghten se curely

with a Phillips screwdriver.

23.Slide the spool valve cover assembly over the spool

valve until the tang engages into housing slot.

Install spool valve cover screw and tighten securely .

11.Feed the wires back through the housing so they

extend backward, out toward the driver module

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-9

24.Thread main cover and driver module cover into

the main housing.

Page 10

Spool Valve

To replace the spoo l valve, refe r to Figure 8, 10 & 1 1

and proceed as outlined below.

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the spool valve cover by removing the

screw and sliding the cover assembly backwards

until the tab is clear of the slot. It is not neces sary

to remove the sheet metal cap, hydrophobic filter,

or O-ring from this assembly (Figure 11).

5. Grasp the bottom of the regulator and unscrew it

from the interface plate.

6. Ver ify that the O-ri ngs are in place on the base of

the new regulator and thread it into the hole in

interface plate.

7. Install four screws to fasten the collector boar d into

the housing. Replace the four wire connections.

8. Attach the flexible tubing to the orifice.

9. Re-install all covers.

4. Remove the spool valve block by removing the two

phillips-head s crews and car efully sl iding the block

off the spool (Figure 8).

CAUTION: Spool (extending from driver assembly) is easily damaged. Use extreme caution

when handling spool and spool valve block.

5. Carefully remove spool by sliding en d of spool out

of connecting clip. Excessive force may bend the

spool.

6. Verify that the three O-rings are in the counterbores on the machined platform where the new

spool valve block is to be placed (Figure 20).

7. Careful slide the spool into the connecting clip of

the driver module assembly.

8. Carefully slide the block over the spool, using the

machined surface of the housing base as a register

(Figure 8). Slide the block toward the driver module

until the two retaining holes line up with the

threaded holes in the base.

9. Install two spool-valve screws and tighten securely

with a phillips screwdriver.

10.Slide the spool valve cover assembly over the spool

valve until the tang engages into housing slot.

Install the spool valve cover screw and tighten

securely.

O-ring

Hyd rophobic

Filter

Spool Valve Cover

Spool

Valve Shroud

Figure 10: Spool Valve Cover Assembly

Spool Valve Cover

The spool valve cover incorporates a coalescing filter

element in a t wo-piece cover. This protects t he spool

valve chamber from moisture and provides a low back

pressure vent for exhaust air from the spool valve.

Replacing Filter in Spool Valve Cover

1. Make sure valve is bypassed or in a safe condition.

Regulator

The regulator reduces the pressure of the incoming

supply air to a level that the driver module can use.

Replacing Regulator

2. Disconnect the power and air supply to the unit.

3. Remove the spool cover by removing the screw

and sliding the cover assembly backwards until the

tab is clear of the slot. The sheet metal cover may

be removed and cleaned with a brush or by blowing

out with compressed air (Figure 11).

1. Make sure valve is bypassed or in a safe condition.

4. Remove the O-ring from around hydrophob ic filter

2. Disconnect the power and air supply to the unit.

3. Remove the main cover.

4. Remove the four wire connections from the c ollector board. Next remove the four screws that fasten

the collector board to the housing.

44-10 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

element and set aside (Figure 10).

5. Remove the molded filter element by pulling

straight out of chamber cover vent piece.

6. Install O-ring into base of chamber cover vent piece

as shown in Figure 10.

Page 11

7. Place new molded filter element into the chamb er

cover vent piece. This element provides part of the

track to secure the O-ring installed in the last step.

8. Place spool valve shroud onto spool valve cover.

9. Place the spool valve cover assembly in place by

setting it on the ramp and sliding it until the tab seats

in the slot (Figure 11) and secure with No. 8-32

screw.

Spool Valve Cover

Screw

Main PCB Assembly

The main PCB assembly contains the circuit board

and processor that perform control functions of the

positioner. The board is encapsulat ed in a tray with a

protective silicon coating. This module can be easily

replaced if necess ar y. None of the compo nents insid e

the tray are serviceable. This module is to be replaced

as a unit.

Replacing Main PCB Assembly (Figure 12)

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the main cover and disconnect the ribbon

cable from the collector board.

CAUTION: To avoid damaging any components,

exercise caution by gently raising the locking

tab to release the ribbon cable.

4. Remove the PCB assembly by removing the three

No. 6-32 screws and lifting the tray out of housing.

5. Place the new PCB assembly on th e bo ss es i nsid e

the positioner housing.

6. Insert three No. 6-32 screws through the tray into

the threaded bosses and tighten evenly, using a

phillips screwdriver. Do not overtighten.

Figure 11: Spool Valve Cover Assembly

Ribbon Cable

7. Reconnect the ribbon ca ble to the collect or board

Main PCB

Assembly

Screws (3)

Figure 12: Main PCB Assembly

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-11

Page 12

Collector Board

The collector board assem bly provides a central routing for all electronic connec tio ns in the pos it ion er, linking the pressure modulato r coil, hall effect sensor and

field in put s to the mai n el ect ro nics. The collector b oar d

assembly also provides for mount ing of the pressure

sensors used in the advanced model.

Removing Collector Board (Figure 20)

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remov e th e main co v er an d discon nect t he wi ring to

the collector board. Each cable has its own unique

connector to prevent mistakes in reconnecting.

4. Remove the four No. 8-32 screws holding the

collector board to the housing.

5. Remove the collector board.

NOTE: Th e two screws through the stiffener plate

are longer.

5. Tighten all four screws.

6. Connect the main ribbon from the electronics tray.

7. Reconnect wiring to the collector board.

Field Terminations

The customer interface board provides a connection

point inside the explosion proo f housing for all hookups to positioner. While the board is not li kely to experience a failure, it can easily be replaced.

Replacing Customer Interface Board

(Figure 2 & 20)

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

3. Remove the main cover and disconnect the customer interface cable from collector board.

Replacing Collector Board

NOTE: A Logix 120X (standard model) cannot be

upgraded to a Logix 1210e (advanced model) by

changing out the co llect or bo ard. T he Logi x 12 0X an d

Logix 1210e use different positioner housings.

1. Advanced collector board only – Verify that pressures sensors are in place on back of collector

board, and that the two O-rings are in place.

2. Set collector board assembly in place.

3. Advanced collector boards req uire a stiffener plate

above the pressure sensors (Figure 2 0) .

4. Insert four No. 8-32 screws through the collector

board into the threaded holes of the housing.

4. Remove the customer interface cover and the three

No. 8-32 screws.

5. Remove customer interface board, c aref ully p ullin g

wiring through bore.

6. Verify that the O-ring is in pl ac e in the co unte r bore

in the positioner housing.

7. Feed wiring through p assageway into main chamber of housing.

8. Set the circuit board in pl ac e a nd s ecur e wit h th re e

No. 8-32 screws.

9. Connect customer interface cable to collector

board.

10.Replace covers.

44-12 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 13

Stem Position Sensor

The position feedback assembly transmits valve position information to the proces so r. This is accom p li sh ed

by means of a rotar y position sensor that con nects to

the valve stem through a feedback linkage. To provid e

for accurate tracking of the pin in the slot, the follower

arm is biased against one side of the slot with a rotary

spring. This spring also automatically moves the position feedback assembly to its limit in the unlikely event

of failure of any component in the linkage.

8. Route wires alon g the position sensor and reconnect to collector board.

Mounting to Linear Mark One Valves

(See Figure 14)

The tools required for the following procedure are:

9

/16-inch open-end wrench

7

/16-inch box wrench

3

/8-inch open-end wrench

Bearing

Housing

Stem Position

Sensor Dot

Stem Position

Sensor

Sensor

Cable

Feedback Shaft

Figure 13: Stem Position Sensor

Orientation

Stem Position Sensor Replacement

(Figure 13, 20)

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the power and air supply to the unit.

1. Remove washer and nut first from follower pin

assembly. Insert pin into the appropriate hole in follower arm, based on stroke length. The stroke

lengths are stamped next to their corresponding

holes in the follower arms. Make sure the

unthreaded end of the pin is on the stamped side of

the arm. Reinsert lock washer and tighten nut to

complete follower arm assembly.

2. Slide the double-D slot i n the follower arm assembly over the flats on the position feedback shaft in

the back of the positioner. Make sure the arm is

pointing toward the customer interface side of the

positioner. Slide lock washer over the threads on

the shaft and tighten down the nut.

3. Align the bracket with the three outer mounting

holes on the positioner. Fasten with

1

/4-inch bolts.

4. Screw mounting bolt into the hole on the yoke

mounting pad nearest the cy linder. Stop when the

bolt is approximately

/

from being flush with

3

16-inch

mounting pad.

5. Slip the large end of teardrop shaped mounting

hole in the back of the position er/bracket assembly

over mounting bolt. Slide the small end of teardrop

under mounting bo lt and align the lower mountin g

holes.

3. Remove the main cover and disconnect rotary

6. Insert lower mounting bolt and tighten bolting.

position sensor wires from collector board.

7. Slide appropriate pin slot on the take-off arm, based

4. Remove the two screws from rotary position sensor

and remove the sensor from the housing.

5. Turn position sensor shaft until the dot on the slot is

oriented with the wires on the pot (Figure 13).

on stroke length, over follower arm pin. The appropriate stroke lengths are stamped by each pin slot.

8. Position the take-off arm mounting slot aga inst the

stem clamp mounting pad. Apply Loctite 222 to

take off arm bolting and insert through washers into

6. Insert the position sensor into the shaft with wires

stem clamp. Torque to 120 in-lbs.

pointing toward the main PCB assembly. Tur n the

position sensor clockwise until bolting slots align

with the housing screw holes an d the wires on th e

sensor protrude over the main PCB assembly tray.

7. Carefully center positi on sensor on the s haft bore,

insert and tighten the screws.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-13

Do not over tigh ten.

9. Center the take-off ar m on the rolling sleeve of the

follower pin.

10.Align take-off ar m wit h top pl ane of th e s tem cl am p

and tighten bolting.

Page 14

Logix 1200 Positioner

Locknut

Washer

Follower

Arm

Take-off Arm

Nut

Lock Washer

Nut

Follower Pin

Bracket Bolts

Bracket

Positioner

Bolts

Nut

Stem Clamp

Bolts

Figure 14: Linear Mark One Control Valve Mounting

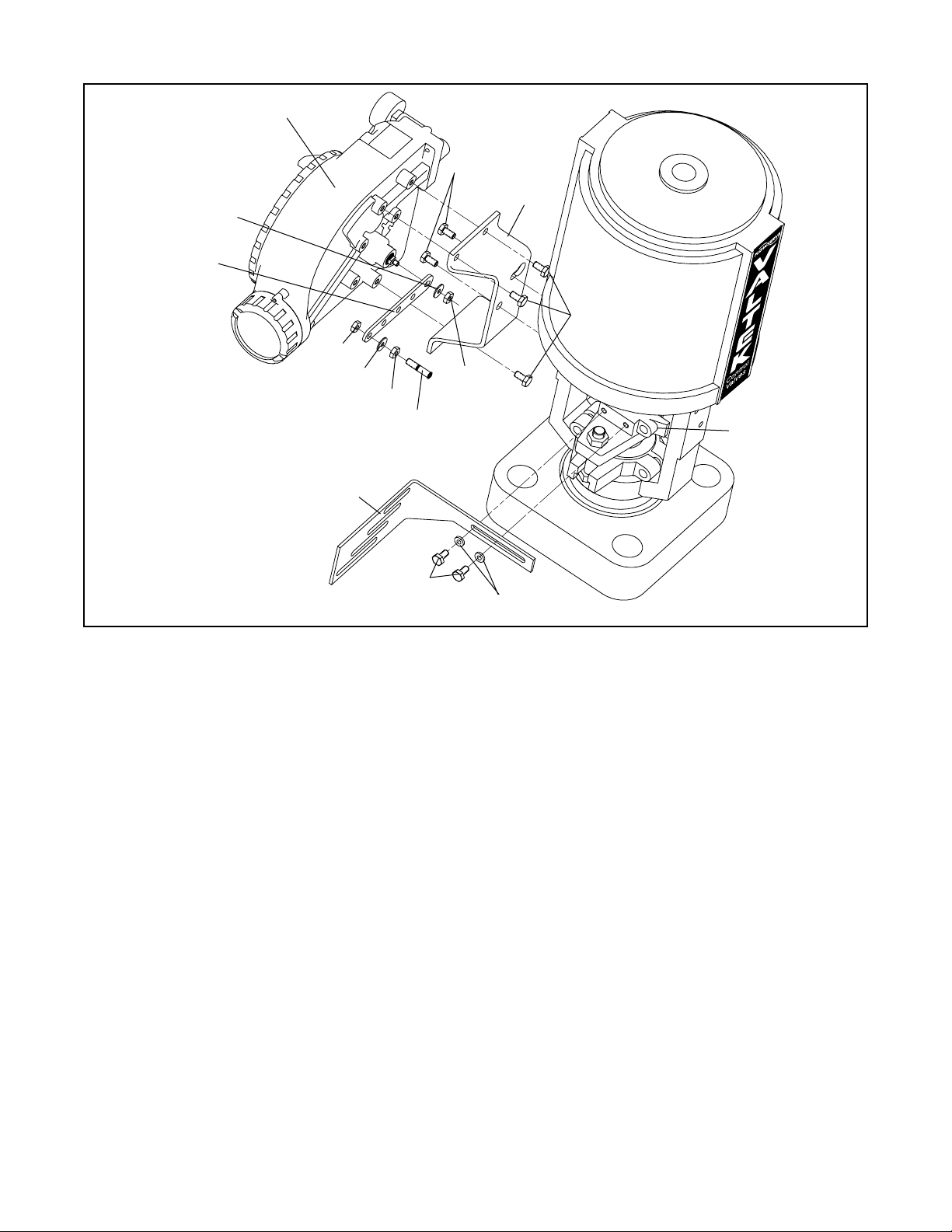

Standard Rotary Mounting Procedure

(See Figure 15)

The standard rotar y mounting applies to valve/actuator assemblies that do not have mounted volume tanks

or handwheels. The standard mounting uses a linkage

directly coupled to the valve shaft. This linkage has

been designed to allow for minimal misalignment

between the positioner and the actuator. The tools

required for the following procedure are:

5

/32 allen wrench

1

/2-inch end wrench

7

/16-inch end wrench

3

/8-inch socket with extension

3

/16 nutdriver

1. Fasten spline lever adapter to splined lever using

two No. 6 x 0.50-inch self tapping screws.

2. Slide take-off arm assembly onto spline lever

adapter shaft. Insert screw with star washer

through take-off arm and add second star washer

and nut. Tighten nut with socket so arm is lightly

snug on shaft but still able to rotate. This will be

tightened after linkage is correctly oriented.

Metal

Washers

3. Attach follower arm to positioner feedback shaft

using the star washer and No. 10-32 nut.

NOTE: Arm will poi nt up when feedback shaft is in

the free position.

1. Using four 0.25-20 x 0.50 L. bolts, fasten positioner

to universal bracket using appropr iate hole patter n

(stamped on bracket).

2. Using a

1

/2-inch end wrench and two 0.3125-18 x

0.50 L. bolts, attach bracket to actuator transfer

case pad. Leave these bolts slightly loose until final

adjustments are made.

3. Rotate take-off arm so the follower pin will slide into

its slot. Adjust bracket position not ing the engagement of the follower pin and the take-off ar m slot.

1

The pin should extend approximately

16-inch

/

past

take-off arm. When properly adjusted, securely

tighten the bracketing bolts.

Orienting the Take-off Arm for Final Lock Down

Tube positioner to valve in the following manner:

1. OUTPUT 1 por t of the m anifold to the bottom side

of the Actuator.

44-14 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 15

n

Logix 1200

Digital Positioner

Positioner Bolts 1/4-20 (4)*

5

Bracket Bolts

/16-18 (2) (not shown)

Take off Arm, Rotary

Lock Washer (2)

Bolt No.10-32

Nut No.10-32

Self Tapping Screws (2)

Spline Lever Adapter

Nut No.10-32

Lock Washer

Figure 15: Standard Rotary Mounting

2. OUTPUT 2 port of the manifold to the topside of

the actuator.

3.

With supply pressure off

the same direction the shaft would rotate upon a

loss of supply pressure. When the mechanical stop

of the follower arm (positioner) is reached, rotate

back approximately 15 degrees.

4. Hold the take-off arm in pl ace; tighten th e screw of

the take-off arm.

NOTE: The take-off arm should be snug enough to

hold the follower arm in place but allow movement

when pushed.

5. Connect regulated air suppl y to appropriate por t in

manifold.

, rotate the follower arm in

Follower Arm

* Located in appropriate

hole pattern as indicated o

bracket. (25, 50, 100/200)

8. Press the Quick-Cal button for 5 to 10 seconds or

until positioner b egins to move. The positioner will

now perform a stroke calibration.

9. If the calibration was successful the green LED will

blink and the valve will be in control mode. Continue with step 10. If calibration failed the A/D feedback values were exceeded and the arm must be

adjusted away from the positioners limits. Return to

step 3 and back off approximately 10 degrees.

NOTE: Remember to remove the air supply before

re-adjusting take-off-arm.

10.Tighten the nut on the take-off arm. The socket

head screw of the take-off arm must be tight, about

40 in-lbs.

NOTE: If the take-off arm slips, the positioner must

be re-calibrated.

6. Remove main cover and locate DIP switches and

Quick-Cal button

7. Refer to sticker on main board tray and set DIP

switches accordingly

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-15

WARNING: Failur e to follow this proce dure will

result in positioner and/or linkage damage.

Check air-action and stroke carefully before

lockdown of take-off arm to spline lever

adapter.

Page 16

Tripper

Tripper Clamp

Tie Rod must be cut to desired length

Figure 16: Optional Rotary Mounting

Bo lts (2)

Locknuts (2)

*Tie Rod

Nut No. 10-32

Lock Washer

5

Bracket Bo lts

/16-18 (2)

Ball oint Ends

Follower Arm

Rotate Positioner 90°

Mounting Bo lts

1

/4-20 (4)

Optional Rotary Mounting Procedure

The optional rotar y mounti ng applie s to valve/actuator

assemblies that are equipped with mounted volume

tanks or handwheels. The optional mounting uses a

four-bar linkage coupled to the valve shaft. The following tools are required:

3

8-inch

/

box wrench

7

16-inch

/

1

/

2-inch

box wrench

box wrench

90 degrees from normal so gauges are facing

upward.

3. Attach follower arm to positioner feedback shaft,

using the star washer and No. 10-32 nut.

4. Attach tripper and tr ipper clamp to shaft, u sing two

-

0.25

20 L. bolts and two 0.25-20 locknuts. Leave

tripper loose on shaft until final adjustment.

5. Thread ball joint link age end to tripper and tighten

(Thread locking compoun d such as Loctite is rec-

1

1. Using a

x 0.50 L. bolts, attach bracket to actuator t ransfer

case pads. Leave bracket loose to allow for

adjustment.

2. Using four 0.25

box wrench, fasten positioner to universal b racket,

2-inch

/

box end wrench and two 0.3125-18

-

20 x 0.50 L. bolts and a 7/

16-inch

ommended to prevent back threading). Adjust

length of tie rod so follower arm and tripper rotate

parallel to each other ( the rod must be cut to the

desired length). Connect other ball joint end to follower arm using a star washer and a No. 10-32 nut.

6. Tighten bracket and tripper bolting.

using the four-hole pattern that locates the positioner the farth est from the valve. Rotate position er

44-16 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

7. Check for pr op er o per a tio n, no te d irect ion of ro tat io n.

Page 17

WARNING: If rotating in wrong direction, serious damage will occur to the positioner and/or

linkage. Check air action and stroke direction

carefully.

LED Indicators

The Logix 1200e has three LED indicators that are visible through a window in the main cover . Only one LED

will blink at any given time. Each LED ha s a different

color to convey basic information abou t the positioner

status. Green indicates th at th e positioner is operatin g

normally. Yellow indicates that a ‘customer defined

limit’ or ‘alert’ has been reached. Red indicates that an

error condition exists. The HART hand held com municator, ValTalk or SoftTools P C software must be u sed

to determine the specific reason for a yellow or red

LED status.

During stroke and actuator calibration, no LED will

blink. After calibration is complete, the green LED indicates that the calibration was completed successfully.

If the yellow or red LED blinks after a calibration process, a warning or err or was detected and the HART

communication to the device must be used to identify

the specific calibration error.

NOTE: If the LED indicator changes from green to yellow after a calibration process, the user may have set

a warning limit (position alert, cycle counter alert,

etc.). Use HART communications to monitor status.

Stroke Calibration using the Quick-Cal Button

For cases when the HART hand held communicator,

Va lTalk or SoftTools PC software is no t avail able, the

Logix 1200e has a Quick-Cal feature that performs a

stroke calibration and allows basic operation of the

positioner. The Quick-Cal routine applies full supply

pressure to the uppe r and lower mechanical limits t o

determine the valve stroke. Valve systems without

mechanical stops must use the ValTalk or SoftTools

software to manually calibrate the valve.

WA RNING: The calibration routines are only to be

used on systems which have mechanical stops.

The calibration routines apply full supply pressure

to determine stroke length and may cause damage

to the valve, actuator or positioner.

NOTE: The Quick-Cal operation retains all previously

configured information except for the three DIP switch

settings and stroke parameters. The settings of

ATO/ATC, Linear/Rotary, Linear/Custom and stroke

parameters are overridden and res t to the DIP switch

settings when the Quick-Cal button is used. If the

device is being installed for the first time, factory

default parameters are used.

The Quick-Cal button and DIP switch settings are

located on the collec tor board inside the main housing

chamber as shown in Figure 17.

Quick-Cal DIP Switch

Quick-Cal Button

Figure 17: Quick-Cal Button

WARNING: Accessing this function requires

removal of the main cover. The user must take all

precautions if this operation is performed in e xplosion-proof areas.

Make the approp r i ate configurat io n s e tt ings, using the

DIP switches on the collector board.

air-to-open or air-to-close (this is determined by the

mechanical tubing of the actuator). The

LIN_VALV/ROT_VALV

linear or rotary feedback linkage. The LIN_VALV

switch enables the feedback potentiometer to utilize

the entire resolution through a maximum of 60

degrees rotation (45 degrees is typical). The

ROT_VALV switch increases the rotation of the potentiometer up to 105 degrees (90 degrees is typical).

Thus a long stroke sliding stem valve may require this

dip switch to be set on ROT_VALV if the stroke rotates

the feedback potentiometer more than 60 degrees.

The

LIN/CUSTOM

custom control characterization. If

selected, the positioner activates custom characterization. If the device is being installed for the first time,

the default custo m characterization i s equal percent.

However, if a custom curve has been previously

loaded, the previous curve will be used. The DIP

switch settings ar e only read afte r the Quick-Cal button is pressed for 5 seconds; otherwise, the settings

do not have any effect. The DIP switch settings will

override any previous configuration done using HART

communication s. Press th e Qui c k-Cal b u tton f or fiv e to

ten seconds. I f the butto n is re leased before five seconds have elapsed, no action will be taken. After

approximately five seconds, the positioner will begin a

ATO/ATC

button allows the user to select

option allows selection of linear or

selects

Custom

is

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-17

Page 18

stroke calibration. Release the Quick-Cal button once

calibration has star ted. The positioner will automatically stroke the valve. The stroke sequence will be to

the extremes (open to close), to the mid stroke, then

to the signal position. No LED will blink during this

process.

NOTE: If Quick-Cal is interrupted during calibration

the mode of the positioner may stay in digital, requiring

HART communications to place it back into analog.

If calibration was successful, upon completion the

green LED will blink and the valve will be in control

mode. If the yellow LED blinks immediately after a

stroke calibration, this usually indic ates that the valve

did not stroke. Check the air supply and cable connections. If a calibration e rror occurred, the red LED will

blink. The cause of a red LED is generally a stem position linkage/feedback sensor alignment problem. For

linear linkage, the active electrical feedback angle is

65 degrees. For rotary linkage, the active electrical

feedback angle is 95 degrees. The red LED indicates

that the mechanical travel is not centered within the

electrical sensor travel. If a red LED is blinking after a

stroke calibration, loosen the feedback sensor mounting screws as shown in F ig ure 18. Turn the stem position sensor slowly while watching the LED indicators.

Try small movements, both clockwise and counterclockwise. If the yellow LED begins to blink, the feedback sensor has been correctly moved into range.

Tighten the feedback sensor mounting screws and

repeat the Quick-Cal procedure. If the LED remains

red even after moving the full length of the sensor slot,

verify the following items are correctly set:

LIN_VALV/ROT_VALV

DIP switch setting, stem cl amp

and take-off arm height.

NOTE: If the stroke calibration stops in the closed

position, the error occurred when the position

sensor/linkage was at closed position. If the stroke

calibration stops in the open position, the error

occurred when position sensor/linkage was at the

open position. No ca libration parameters are saved if

an error occurs. If the power to the positioner is

removed, the unit will power-up with the previous

configuration parameters. A successfu l calibration wi ll

save parameters.

If the valve does not stroke after pressing the QuickCal button, this may be an indication that the inter nal

regulator pressure and/o r the driver module minimum

pressure is low. Refer to the following instruct ions to

check and set the internal regulator and minimum

pressure settings.

NOTE: Ensure that all linkages are tight an d correctly

mounted before attempting to calibrate. Loose or

incorrectly moun ted linkage will cause c alibration failure and difficulty in troubleshooting.

Rotate Stem Position Sensor slol

Stem Position

Sensor Mounting Screws (2)

Figure 18: Stem Position Sensor

Adjustment

Checking or Setting Internal Regulator Pressure

The tools and equipm ent used in the next procedure

are from indicated vendors.

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect the air supply from the positioner.

3. Remove the main cover and the

tubing from the driver module orifice.

4. Obtain a barbed tee (Pneumadyne part No. SBF16T or equivalent) and two p ieces o f

ble tubing, a few inches in length each.

5. Connect the

1

/16 inch flexible tubing, found in the

positioner, to the barbed tee. Using one of the new

flexible tubing pieces connect the barb ed te e to th e

orifice. Connect the remaining tee port to a 0 to 30

psi pressure gauge.

6. Reconnect the air supply to the positioner and read

the internal regulator pressure on the 0 to 30

gauge. The inter nal pressur e sho uld b e set to 21. 5

±0.5 psi. If adjustment in needed, scrape off the silicon compound covering the screw. Then adjust the

regulator pressure by turning the setscrew on top

of the regulator with a small screwdriver.

7. Once the regulator pressure is set, remove the air

supply to the positioner, remove the barbed tee,

and reconnect the posi tioner 's flexible tubing to the

orifice.

8. Reconnect air supply to positioner.

1

16

/

inch flexible

1

16

/

inch flexi-

44-18 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 19

No. 10-32 Extension

(Clippard Part No. 15010)

5. Remove the No. 10-32 x 0.016 orifice and gasket

1

(Figure 9) from the driver module using a

2-inch

/

nut driver. Take care to not misplace the gasket.

Minimum Pressure

Test Port

1

No.10-32 x

/16

Barb

No.10-32 x .016

Orifice

Pressure from Internal

Regulator to be tubed to

No.10-32 x Swivel

TEE (Pneumadyne

Part No. SFL-10)

this orifice

Figure 19: Driver Module Minimum

Pressure Check

Checking or Setting the Driver Module Minimum Pressure

Refer to Figure 19, proceed as follows:

1. Make sure valve is bypassed or in a safe condition.

2. Disconnect power from the positioner.

3. Remove the main cover and remove the

ble tubing from the orifice.

4. Obtain a No. 10-32 x swivel elbow (Pneumadyne

part No. SFL-10 or equivalent) and a No. 10-32

extension (Clippard part No. 15010 or equivalent).

1

/16 flexi-

6. Screw in the 10-32 extension followed by the 10-32

x swivel elbow.

7. Direct the swivel elbow so the minimum pressure

test port is accessible.

8. Screw a No. 10-32 x

1

/16-inch barb fitting into the

test por t, and screw the No. 10-32 x 0.016 or ifice

into the end of the elbow as shown.

9. Connect the tubing from the inter nal regulator output port to the orifice.

10.Using some

1

/16-inch flexible tubing, connect a 0 to

30 psi gauge to the minimum pressure set port.

11.Once the gauge is connected, reapply the positioner air supply. The minimum pressure should

now be registering on the gauge and must be 3.8 to

4.2 psi. If the minimum pressure is not correct, take

9

a

/64 allen wrench and tur n the minimum pressure

set screw located at th e bottom of the dri ver module (Figure 7) until the pressure is in the range indicated. Cycle the posi tioner air sup ply several times

and recheck the minimum pressure and re-adjust, if

necessar y, to ensure that the pressure has settle d

within the range specified.

12.When the pressure is set, remove the air supply.

13.Remove the No. 10-32 x

1

/16 barb and orifice f rom

the swivel elbow and then remove swivel elbow and

extension.

14.Replace the orifice and gasket as shown in

Figure 9 and reco nnect t he

1

/16 inch flexible tubing

from the internal regulator output port to the orifice.

Reconnect the positioner air supply and power. The

positioner should now be ready to calibrate.

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-19

Page 20

LOGIX 1200 Model Numbers

PROTOCOL

Selection Code

HART *2

DIAGNOSTICS

Selection Code

Standard *0

Advanced 1

MATERIAL

Selection Code

Aluminum, Valtek (White Paint) *0

Stainless Steel, Valtek (No Paint) 1

Aluminum, Automax (Black Paint) 2

Aluminum, Automax (Food Grade White Paint) 3

Aluminum, Accord (Black Paint) 4

Aluminum, Automax (Food Grade White Paint) 5

CERTIFICATIONS

Selection Code

Explosion proof EEx d IIB + H

Nonincendive Class I, Div. 2, (Factory Mutual), Class I, Div. 2 (CSA) 08

Explosion proof Class I, Div. 1, Groups B,C,D Intrinsically Safe Class I, 10

Div. 1, Groups A thru G (FM, CSA) FM Nonincendive. CSA Class I,

Div. 2 Class I, Zone 1, Group IIB + H

Group IIC (CSA ONLY)

Intrinsically Safe EEx ib, Nonincendive EEx n (CENELEC SCS) 13

General Purpose 14

Selection Code

DD Shaft *Blank

NAMUR N

Selection Code

1/2” NPT *Blank

M20 M

Selection Code

4 way *Blank

3 way 3

4 way Vented V

3 way Vented W

Selection Code

No Specials *Blank

4-20 mA Position Feedback F

(CENELEC SCS) 07

2

and Exia Class 1, Zone 0,

2

SHAFT

CONDUIT CONNECTIONS

ACTION

SPECIAL OPTIONS

Diagnostics

Protocol

Material

1

Design Version

Shaft

Certifications

e

Action

Conduit Connections

Special Options

Note: *Product Default Value 1 = Logix Product Line

44-20 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 21

Item

No. Part

1. Housing Logix 1200 Positioner

2. Main Housing Cover

3. O-ring, Main Housing Cover

4. LED Display Window

5. O-ring, Window

6. Washer, Seal ring

7. Retaining Ring

8. Screw, Anti-Rotation

9. Spool Valve Cover

10. Spool Valve Shroud

11. Hyd rophobic Filter,

Spool Valve Chamber

12. O-ring, Spool Valve Cover

13. Screw, Spool Valve Cover

14. Driver Module Cover

15. O-ring, Driver Module

Cover

16. Regu lator, 5 to 30 psi

(I ncludes O-ring)

17. Internal Filter

18. O-ring, interface plate to

housing se al

19. Screw, interface plate to

housing (4)

20. Interface Plate

21. Orifice, Barbed Fitting

22. Flexi ble Tubing

23. Hex Barbed Fitting

W/Captive O-ring

24. Main vent cover

25. Screw, Main vent Cover

26. Customer Interface Cover

27. O-ring, Customer Interface

Cover

29

48

49

51

28. Screw, Anti-Rotation

29. Pressure Gauge , 0-160 psi (2)

30 . Customer Interface Board

2

8

13

10

9

4

11

44

43

41

42

47

3

12

39

40

44

38

5

37

31. Screw, Customer Interface Bboard (3)

32. O-ring, Customer Interface Board

33 . Grounding Screw (2)

34. Main PCB Assembly

35. Screw, Main PCB Assembly (3)

36. Collector Board Assembly

(Standard / Advanced Model)

37. O-ring, Sensor to Housing (2)

38. Collector Board Stiffener (Advanced only)

39. Screw, Pressure Sencors to Housing

(2 Advanced only)

6

7

16

19

21

36

20

18

17

35

34

50

52

Aluminum or Stainless Steel

26

46

32

1

53

54

33

55

56

22

45

15

14

23

25

40. Screw, Collector Board to Housing

24

(4 Standard - 2 Advanced)

41. Spool Valve Block

42. Spool Valve

43. Screw, Spool Valve to Housing (2)

44. O-ring, Spool Valve (3)

45. Driver Module Assembly

46. Nyl on Washer (1)

47. Screw, Driver to Housing (1)

48. Stem Position Sensor

49. Screw, Potentiometer to Housing (2)

50. Metal washers (2)

51. Screw, Spring to Feedback Shaft

52. Feedback Shaft

53. O-ring, Feedback Shaft

54. Bearing

55 . Torsion Spring

56. E-ring

31

30

27

28

Figure 20: Exploded View

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-21

Page 22

Available Spare Part Kits for Logix 1200e digital postioner

Kit 1 – Driver Module Assembly

SKU 10130943

Item No. Description Quantity

45 Driver module 1

47 Screw, driver to housing 1

46 Nylon washer 1

23 Orifice barbed fitting and gasket 1

16 Regulator and captive O-ring(s) 1

Kit 2 – Spool V alve Kit

SKU 10130950

Item No. Description Quantity

41 Spool valve Block 1

42 Spool valve 1

43 Screw, spool valve to housing 2

44 O-ring, sp ool valve 3

Kit 3 – Soft Goods Kit

SKU 10130944

Item No. Description Quantity

3 O-ring, main housing cover 1

15 O-ring, driver module cover 1

27 O-ring, customer interface cover 1

32 O-ring, customer interface board 1

37 O-ring, pressure sensor to housing 2

44 O-ring, sp ool valve 3

53 O-ring, feedback shaft 1

5 O-ring, main cover window 1

18 O-ring, interface plate 1

12 O-ring, sp ool valve cover 1

17 Internal filter 1

Kit 4 – Standard Collector Board Assembly

SKU 10130945

Item No. Description Quantity

36 Collector board 1

40 Screw, collector board 4

Kit 5 – Advanced Collector Board Assembly

SKU 10130946

Item No. Description Quantity

36 Collector board 1

37 O-ring, se nsor to housi ng 2

38 Collector board stiffener 1

39 Screw, pressure sensors to housing 2

40 Screw, collector board to standoffs 2

Kit 6 – Customer Interface Assembly

SKU 10130947

Item No. Description Quantity

30 Customer i nterface board 1

31 Screw, customer interface board 3

32 O-ring, customer interface board 1

33 Grounding screw 1

Kit 7 – Main PCB Assembly

SKU 10130948

Item No. Description Quantity

34 Main PCB assembly 1

35 Screw, main PCB assembly 3

Kit 8 – Regulator

SKU 10070875

Item No. Description Quantity

6 Regulator and captive O-ring(s) 1

Kit 9 – Stem Position Sensor

SKU 10061643

Item No. Description Quantity

48 Stem position sens or 1

HART Filter

SKU 10079944

4-20 mA Position Feedback Kit

SKU 10125599

Table VI: Valtek Linear Mounting Kits

25 Square-inch

Spud Standard Handwheel Standard Handwheel Standard Handwheel

2.00 10067289 10067368 10091897 10067368

2.62 10067316 10067384

2.88 10067329 10067386

3.38 10067351 10067389

4.75 10067351 10067389

* A 50 square-inch, 2.00 spud with live loading requires kit number 10067301.

† Live loading is not available on a 100 square-inch, 2.62 spud.

44-22 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

50 Square-inch

*

10067329

100-200 Square-inch

†

10067384

Page 23

Table VII: Valtork Rotary Mounting Kits

25 Square-inch 50 Square-inch 100-200 Square-inch

Shaft Diameter Sta nda rd

0.44 10067418 10067527 1006790 10067502

0.63 10067418 10067565 1006790 10067573 10067502

0.75 10067418 10067569 10067490 10067574 10067502

0.88 10067418 10067572 10067490 10067575 10067502 10067615

1.12 10067418 10067490 10067580 10067502 10067616

1.50 10067418 10067490 10067502 10067617

1.75 10067418 10067490 10067502 10067618

* Standard: All Rotary Valves with Standard Accessories (End of Shaft Mount)

Optional: All Rotary Valves with Handwheels or Volume Tanks (Linkage Design)

Optiona

l

Standard

Optiona

*

l

Standard

Optiona

l

Table VIII: Logix Mounting Kits

Model Size Mounting Kit

Fisher

30

1010078034

40

50

657 & 667

60

70 10124086

80 10124087

225

1250

675

1052 33 10124203 Rotary

657-8 40 10126736

RC 10124060

RD 10131247

Slid-Std 10126255

Linear 10131247

Trooper 10119289 0.75 – 1.5-in. Std

Automax R314 10094495 HD

SNA115 10406329

NAMUR Mounting Kits

Prefix

NK – NAMUR Accessory Mounting Kit

Bracket Option

28 – 20mm Pinion x 80mm Bolt Spacing

38 – 38mm Pinion x 80mm Bolt Spacing

313 – 30mm Pinion x 80mm Bolt Spacing

513 – 50mm Pinion x 130mm Bolt Spacing

10124070 0.5 – 1.5-in. stroke

10124085 2-in. stroke

10124070 0.5 – 1.5-in. stroke

10124085 2-in. stroke

4-in. stroke

10125818450

Neles

Foxboro

Valtek

Automax

Table VIII: Logix Mounting Kits (Continued)

Model Size Moun ting Kit

Bolt Option

A – 10-24 UNC Bolting

B – 10-32 UNF Bolting

L – M5-.8 Metric Bolting

Notes

Example: NK313A

Kits designed for the following O.E.M.'s

Air-torque AT Series AT0 — AT6

SNA

Automax

Bettis

EL-O-Matic

Hytork XL Series XL45 — XL4580

Unitorq M Series M20 — M2958

Worcester 39 Series 2539 — 4239

VST-VA3R 17-in. dia. 10126736

VSL-VA1D 12-in. dia. 10126736

37

38

Series

N Series N250 . 300

R Series R2 — R5

RPC

Series

G Series G2009-M11 — G3020-M11

E Series E25 — E350

P Series P35 — P4000

Masoneilan (Linear Actuators)

9

11

13 10124593

18 10125747

24 10126826

11 10125402

13 10125401

15 10140783

18

24 10126826

SNA3 — SNA2000

RP — TPC11000

Honeywell

10124594

10125747

*

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-23

Page 24

Table VIII: Logix Mounting Kits (Continued)

Model Size Mounting Kit

Masoneilan (Linear Actuators, cont.)

25 10125644

71 Domotor

88

47 B 10125702

48 B 10125702

“D” Domotor 200 10127467

71-2057AB-D 10129359

71-40413BD 10129461

33 B 10125542

35

70 10 10125542

37/64 10127426

* Adjustable Mounting kit 10126736 may be needed if

handwheels are used.

50 10125645

100 10125646

6 10124595

16 10126752

Masoneilan (Rotary Actuators)

4

101255426

7

Va nguard

vided between the supplies powering the Logix

unit and the analog output board.

Available for explosion-proof and safe applications

•

(CSA, FM).

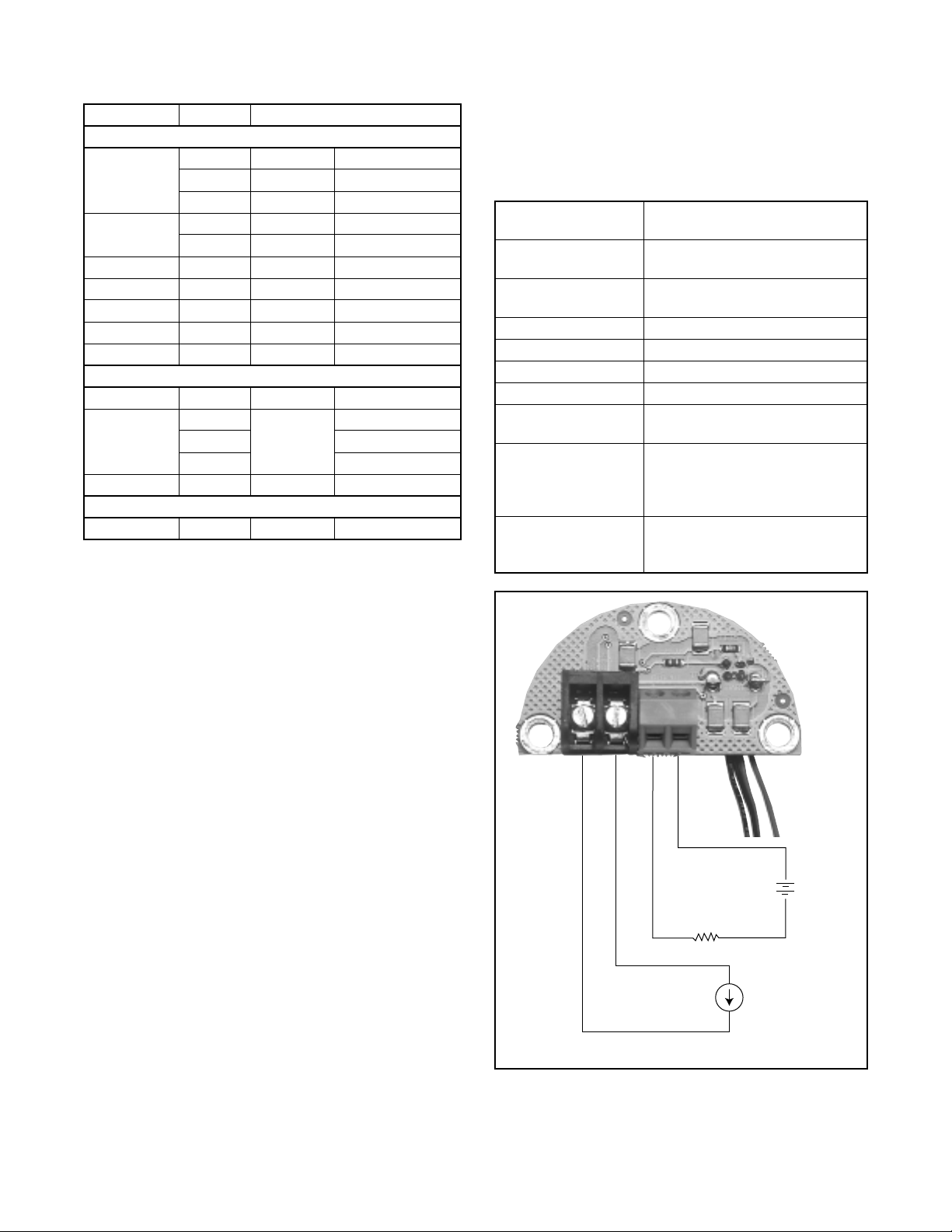

Specifications

Potentiometer Range

of Rotation

Po wer Supply Range

Maximum Load

Resistance (ohms)

Current Signal Output 4-20 mA

Linearity 1.0% F.S.

Repeatability 0.25% F.S.

Hysteresis 1.0% FS

Operating

Temperature

Ambient

Temperature

Po wer Supply

Effects

40° to 95°

12.5 to 40 VDC

(24V DC typical)

(Supply Voltage - 12.5) / 0.02

-40° to 185° F

(-40° to 85° C)

For a 100° F (38° C) change in

ambient temperature, maximum

zero shift is 0.4% FS, maximum

span shift is 0.7% FS

Out put signal change is less than

0.05% FS when supply voltage is

varied between 12.5 and 40 VDC

4 to 20 mA Analog Output Retrofit

General Information

The Logix 1200e digital positioner/controller can be

retrofitted to provide an anal og feedback signal of the

stem position. This position feedback option has the

following features and specifications:

Does not in terfere with positioner operation.

•

Zero and span adjustments of the feedback signal

•

are independent of the positioner and can be

adjusted manually.

Output follows actual position of valve, including all

•

failure modes of positioner except loss of power. An

output of 3.15 mA is transm itted with loss of power

to the analog output board.

Immune to RFI/EMI disturbances.

•

Can be retrofitted in the field.

•

CAUTION: Because the analog output board

shares common signals with the Logix internal

circuitry, the two units cannot be powered by

the same external power supply or by power

supplies that share a common reference.Galvanic isolation of at least 50 VDC must be pro-

+

Positioner Command

Current Loop

(Logix Input)

CAUTION: Isolated power sources required.

+

––

Position Feedback

Current Loop

(Logix Output)

R

Load

–

12.5 to

40 VDC

Power

Supply

+

–

4 to 20 mA

Current Source

+

Figure 21: Analog Output Board Power

44-24 Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611

Page 25

Terminal Board

Connection

Span Adjustment

Zero Adjustment

DIR/REV Switch

Potentiometer

Connections

Control Board

Connection

Figure 22: 4-20 mA Analog Output Board

Calibration

To calibrate the Logix 1200e or 1200e digital positioner equipped with analog output, follow the procedure outlined below:

1. Wire the position transmitter in series with a 12.5 to

40 VDC power supply and a milliamp meter.

CAUTION: Do not apply a voltage greater than

40 volts to transmitter terminals or the circuit

will be damaged.

2. Be certain the direct/reverse switch is set to provide

the desired output signal action. In the DIR position, a counterclockwise rotation of the potentiometer shaft (when looking at the label side of the

potentiometer) will cause the output signal to

increase. In the REV position, a clockwise stem

rotation causes the signal to increase. Perform a

stroke calibration whenever the direct/reverse

switch is changed.

WARNING: Keep hands, hair, clothing, etc.

away from moving parts when operating the

valve. Failure to do so can cause serious injury.

3. Stroke the valve to the close position.

4. Referring to Figure 22, adjust the zero adjusting

screw with a small, flathead screwdriver until the

meter reads 4 mA DC.

5. Stroke the valve to the open position.

6. Adjust the span adjusting screw until the meter

reads 20 mA DC.

7. Stroke the valve to the closed position and recheck

the meter for 4 mA DC. Some fine tuning of the calibration may be required. Repeat steps 3 through 7

until satisfied.

Retrofitting to a Logix 1200e Digital Positioner (with Circular Window in the Main Cover)

As shown in Figure 23, th e newer model of the Logix

digital positioner has a circular window in the main

cover (as opposed to a diagonal, oblong window in the

earlier model ). To retrofit Logix digi tal positioner to 420 mA analog output, use the following procedure:

1. Remove the main cover (Figure 29).

2. Remove the lower and middle screws holding the

control board in place; disc ard thes e screws.

3. Place the analog output board on the lower por tio n

of the control boa rd an d s ec ure wit h th e t wo lon ger

screws (6 x 32 1.25-in.) provided (Figure 33).

4. Unplug the orange/red/brown or brown/red/orang e

three-wire-set from the collector board.

5. Plug the orange/red/brown or brown/red/orange

three-wire-set into th e correct receiver in the analog output board (Figure 26).

6. Plug the three-wire set from the analog output

board into the rec eiver on the collector bo ard (that

previously had held the orange/red/brown or

brown/red/orange wire-set).

Flowserve Corporation, Valtek Control Products, Tel. USA 801 489 8611 44-25

Page 26

7. Connect the blue/yellow two-wire-set from the user

interface board to the remaining receiver on the

analog output board (Figure 27).

NOTE: On some boards both set of wires are

red/black but have different connectors - only one

set will be able to be plugged into the analog output

board.

8. Replace the main cover.

Retrofitting to a Logix Digital Positioner (with Diagonal Window in the Main Co ver)

As shown in Figure 28, th e earlier model of th e Logix

digital position er has an oblong, diagonal win dow (as

opposed to a circul ar window in t he newer model). To

retrofit an existing Logix dig ital positioner to 4-20 mA

analog output, use the following procedure:

1. Remove the main cover and the user interface

cover from the Logix unit (Figure 29).

2. Disconnect the ribbon cable that conn ects th e control board from the collector board.

3. Remove the three screws holding the control board

in place. Discard two of the screws .

4. Remove the control board from the Logix unit

(Figure 30).

5. Disconnect the cable that goes from the user interface board to the collector board.

6. Remove the three screws holding the user interface

board in place. Save these scr ews as well as the

O-ring that goes between the user interface board

and the housing (Figure 31).

7. Install the new user interface board with its two

connectors in serted into the cavity of the housing.

Make sure the O-ring is between the u ser inte rface

board and the housing (Figure 32).

9. Feed the user interface two-wire-sets in the housing, placing the wires in the trough at the bottom of

the housing. Connect the r ed/black two-wire-set to

the collector board where the old user interface

wire-set was connected. Pull the new blue/yellow

feedback two-wire-set so that it is next to the

red/black two-wire-set on the collector board.

NOTE: With some boards both sets of wires are

red/black but have different connector s

. The feedback wire-set will be co nnected later t o the analog

output board.

10.Carefully replace the control board, ensuring that

the clear pressure hose found inside the Log ix unit

is not pinched.

11.Place the analog outp ut board on the lower portion

of the control board and secure wit h the two longer

screws provided. Secure the top of the control

board with the original shorter screw (Figure 33).

12.Connect the contro l board ribbon cable to the collector board.

13.Unplug the orange/red /brown or brown/red/orange

wire set from the collector board.