Page 1

USER INSTRUCTIONS

MXa/QXM Linear Base

FCD LMENIM2315-00 – 6/14

Installation

Operation

Maintenance

Experience In Motion

Page 2

MXa/QXM Linear Base FCD LMENIM2315-00 – 6/14

Contents

1 Subassembly Instructions 3

1.1 LB Subassembly, QXM and MX Units 3

1.1.1 Optional LB Subassembly Removal From QXM and MX Units 3

1.1.2 Optional LB FA or EN (F) Base and Stop Nut Subassembly 4

1.1.3 Removal of Thrust Base Subassembly From LB Assembly 5

1.1.4 Disassembly of LB Subassembly 6

2 Reassembly Instructions 7

2.1 LB Reassembly 7

2.1.1 Reassembly of Optional LB Subassembly 7

2.1.2 Reassembly of Thrust Base to LB Subassembly 8

2.1.3 Reassembly of Optional FA/EN (F) Base to LB Subassembly 8

2.1.4 Assembly or Adjustment of Optional Stop Nut for LB Subassembly 10

2.1.5 LB Lubrication 11

2.1.6 Reassembly of QXM or MX Actuators to LB/Thrust Base Assembly 11

Figures

Figure 1.1 – LB Subassembly Removal From Actuator 3

Figure 1.2 – Optional LB FA/EN (F) Base and Stop Nut Subassembly 4

Figure 1.3 – Thrust Base with LB Assembly 5

Figure 1.4 – LB Assembly 6

Figure 2.1 – LB1 Subassembly Cross-Section 9

Figure 2.2 – LB2 Subassembly Cross-Section 9

Tables

Table 1.1 – Optional LB1 and LB2 Subassembly 4

2

Page 3

MXa/QXM Linear Base FCD LMENIM2315-00 – 6/14

1 Subassembly Instructions

1.1 LB Subassembly, QXM and MX Units

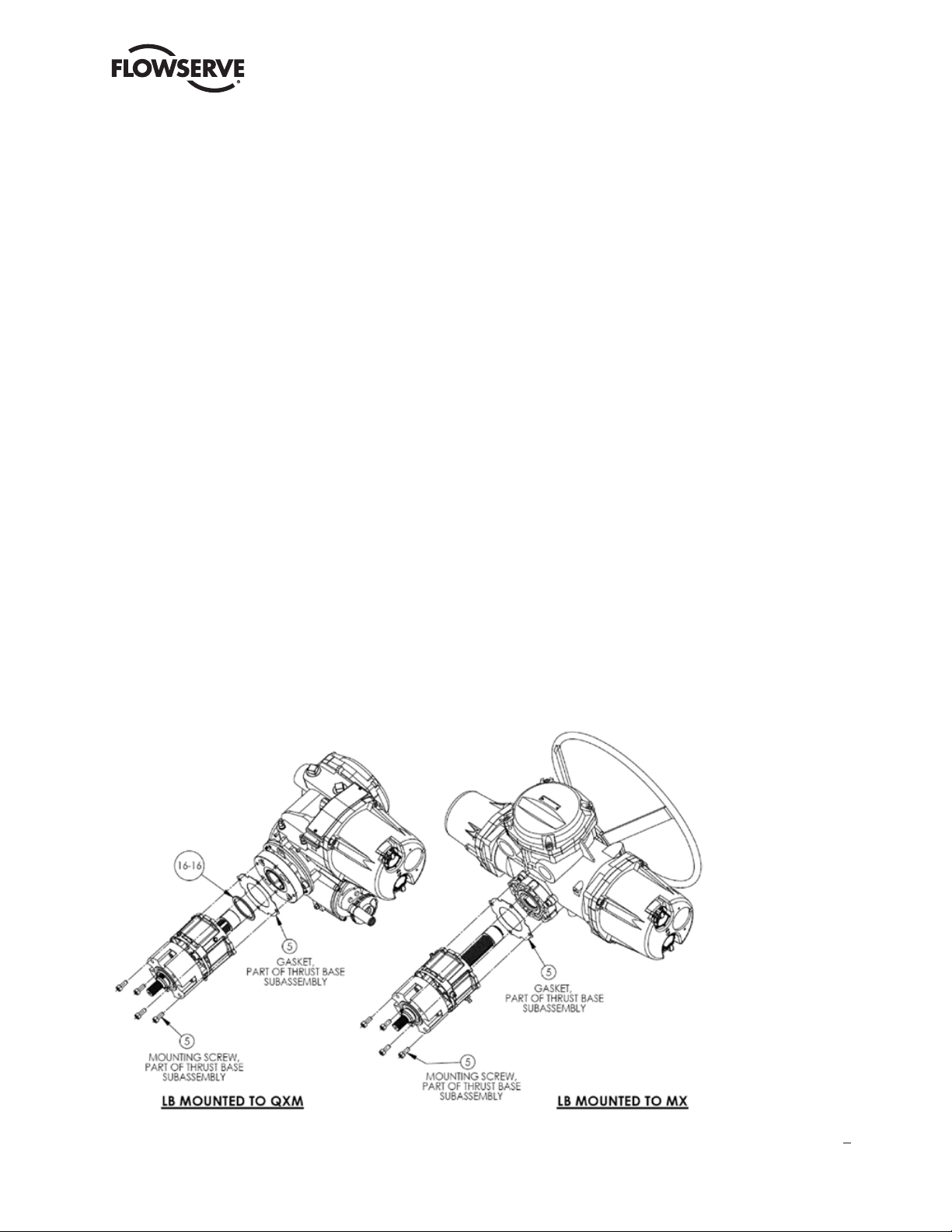

1.1.1 Optional LB Subassembly Removal From QXM and MX Units

Step 1

c WARNING: Hazardous voltage! Turn off all power sources to actuator before removing actuator from LB assembly.

Power sources may include main power or control power. If necessary, disconnect incoming power leads L1, L2,

L3 and control wiring from terminal block.

Step 2

Remove the four bolts (#5) that secure the LB assembly to the actuator base plate and slide down the LB subassembly

until the LB shaft clears the unit actuator.

Step 3

Remove gasket (#5) and slide gasket off thrust base assembly or remove from actuator baseplate.

Step 4 (QXM actuators only)

Remove pilot spacer (#16-16) by sliding over LB shaft.

NOTE: Pilot spacer (#16-16) is used to pilot an ISO thrust base assembly to the QXM adapter plate. If an MSS thrust

base assembly is used on a QXM actuator, the pilot spacer is not required. The MX units do not require this pilot spacer

in this location on any assemblies as long as the MX base plate and thrust base are of the same type, i.e., ISO/ISO or

MSS/MSS.

Figure 1.1 – LB Subassembly Removal From Actuator

NOTE: The thrust base assembly is considered part of the LB subassembly. For this procedure the thrust base parts

are called out as item number (#5) in the figures. Other item numbers may be used in other manuals. For disassembly

and reassembly of the thrust base assembly (#5), refer to the QXM or MX manuals, (QXM) LMENIM3314 section 3

and (MX) LMENIM2306 section 3.

3

flowserve.com

Page 4

MXa/QXM Linear Base FCD LMENIM2315-00 – 6/14

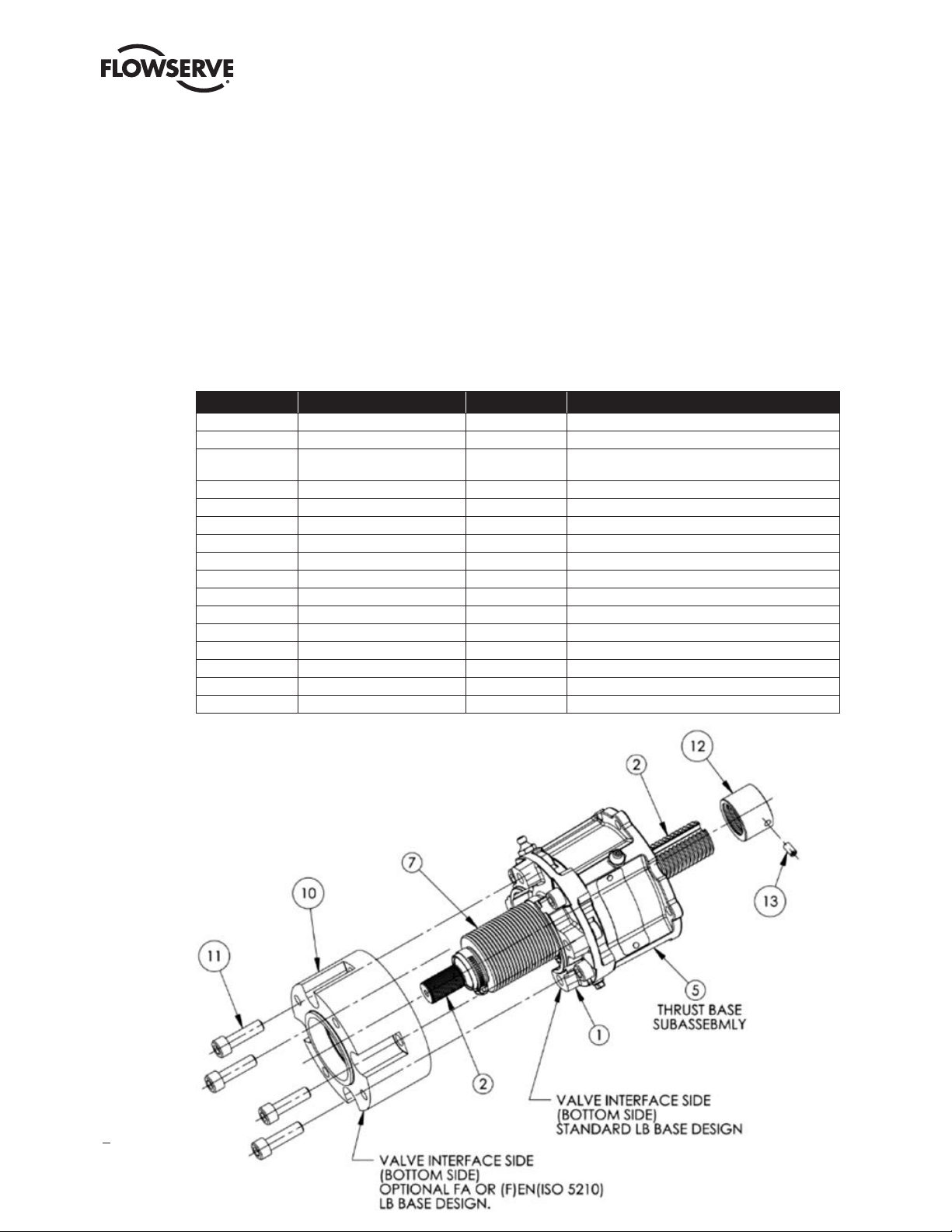

1.1.2 Optional LB FA or EN (F) Base and Stop Nut Subassembly

NOTE: The EN (F) base meets standard DS/EN 15714-2 but has the same mounting as an ‘F’ ISO style base.

Step 1

(Optional Stop Nut if supplied) Remove set screw (#13) and spin nut (#12) off shaft.

NOTE: Optional nut may only be used when LB is mounted to a QXM, MX-10 or MX-40 actuator.

Step 2

(Optional FA/EN (F) base) Remove the four bolts (#11) that secure the optional base to the anti-rotation base (#1) and

slide the base off over shaft (#2) and bellows (#7).

Table 1.1 – Optional LB1 and LB2 Subassembly

ITEM NUMBER DESCRIPTION QTY. NOTES

1 ANTI-ROTATION BASE 1

2 SHAFT 1

3 THRUST NUT 1

4 SOCKET HEAD CAP SCREWS 4

5 THRUST BASE ASSEMBLY 1

6 GASKET 1

7 BELLOWS AND TWO CLAMPS 1

8 GREASE FITTING 1

9 PIPE PLUG 1

10 OPTIONAL FA OR EN (F) BASE 1

11 SOCKET HEAD CAP SCREWS 4

12 OPTIONAL STOP, HW CLOSED 1 QXM, MX-10 AND MX-40 ONLY

13 SET SCREW, OPTIONAL STOP 1 QXM, MX-10 AND MX-40 ONLY

14 ANTI-ROTATION NUT 1 LB2 ONLY

15 O-RING 1 LB2 ONLY

16-16 SPACER, PILOT 1 SEE NOTES FOR USAGE

PART OF THRUST BASE ASSEMBLY, BUT MACHINED

TO MATE WITH LB ASSEMBLY

Figure 1.2 – Optional LB FA/EN (F) Base and Stop Nut Subassembly

LB1 assembly shown in this figure.

4

Page 5

MXa/QXM Linear Base FCD LMENIM2315-00 – 6/14

1.1.3 Removal of Thrust Base Subassembly From LB Assembly

Step 1

Remove the four bolts (#4) that secure the thrust base subassembly (#5) to the LB anti-rotation base (#1).

Step 2

Remove thrust base subassembly (#5) by rotating the thrust base up and around the LB shaft threads (#2) until the

thrust base is disengaged from the LB shaft.

NOTE: If the thrust base is still attached to the actuator, the LB assembly may be removed from the thrust base by

rotating the LB assembly down until the LB shaft is disengaged from the thrust base subassembly.

Step 3

Remove gasket (#6), and slide off LB assembly or remove from thrust base.

Step 4

If supplied, remove pilot spacer (#16-16) by sliding over LB shaft.

NOTE: Pilot spacer (#16-16) is used to pilot an MSS thrust base assembly (#5) to the LB anti-rotation base (#1). If an

ISO thrust base assembly is used, the pilot spacer is not required in this location.

This note applies to all LB assemblies mounted to both QXM and MX actuators.

Figure 1.3 – Thrust Base With LB Assembly

LB1 assembly shown in this figure.

flowserve.com

5

Page 6

MXa/QXM Linear Base FCD LMENIM2315-00 – 6/14

1.1.4 Disassembly of LB Subassembly

Step 1

Loosen the two clamps (#7) that secure the bellows boot in place on the anti-rotation base (#1) and shaft (#2). Slide

both clamps over the bellows boot and remove.

Step 2

Remove the bellows boot (#7) by turning and pulling off of the anti-rotation base (#1).

Step 3

Remove shaft (#2) by pulling shaft out through the bottom of the anti-rotation base (#1), as shown in Figure 1.4.

NOTE: Steps 4 and 5 are for the LB2 assembly only. The LB2 anti-rotation base consists of three parts: the base (#1),

the nut (#14) and the O-ring (#15).

Step 4

LB2 assembly only.

Remove the anti-rotation nut (#14) by pushing the nut from the bottom side of the anti-rotation base then removing

from the top side.

Step 5

LB2 assembly only.

Remove O-ring (#15) from anti-rotation nut (#14).

Figure 1.4 – LB Assembly

LB2 assembly shown in this figure.

6

Page 7

MXa/QXM Linear Base FCD LMENIM2315-00 – 6/14

2 Reassembly Instructions

2.1 LB Reassembly

2.1.1 Reassembly of Optional LB Subassembly

See Figure 1.4 for the following steps.

NOTE: Steps 1 and 2 are for the LB2 assembly only. The LB2 anti-rotation base consists of three parts: the base (#1),

the nut (#14) and the O-ring (#15). The LB1 requires only one part for the anti-rotation base (#1).

Step 1

LB2 assembly only.

Lightly lubricate O-ring (#15) and carefully slide O-ring over anti-rotation nut (#14) and into the O-ring groove.

Step 2

LB2 assembly only.

Align anti-rotation nut (#14) lugs with key slots in the anti-rotation base (#1), and slide nut into the base until seated in

base.

Step 3

Generously lubricate shaft (#2) threads and slots and anti-rotation base (#1) or nut (#14) internal lugs with Mobil SHC

220 Mobilith grease. Align the shaft key slots with the anti-rotation base (#1) lugs or (#14) nut lugs, and slide the shaft

into the anti-rotation base (#1) from the bottom side.

NOTE: Before mounting the bellows boot per the following steps, 4 thru 6, the thrust base assembly may be mounted

per section 2.1.2. Mounting of the thrust base will hold the shaft in place for assembling of the bellows boot.

Step 4

Slide the big end of the bellows boot (#7) over the bottom of the shaft (valve side), and push boot onto the anti-rotation

base boss, making sure that the boot is completely pushed onto the base or nut boss.

NOTE: The mating boss for the boot is part of the base (#1) on LB1 and is part of the nut (#14) on the LB2 assembly.

Step 5

Slide the big clamp (#7) over the boot and up to the mating bellows and base boss. Rotate clamp screw for access thru

one of the two slots in the bottom of the anti-rotation base. Secure boot to the base with clamp by tightening the clamp

to 8–10 inch-pounds.

Step 6

Gently push the bellows boot (#7) onto the smaller OD on the shaft (#2). Slide the small clamp over the shaft and boot.

Secure boot to the shaft with clamp by tightening the clamp to 8–10 inch-pounds, ensuring boot and clamp are on the

smaller OD of shaft.

flowserve.com

7

Page 8

MXa/QXM Linear Base FCD LMENIM2315-00 – 6/14

2.1.2 Reassembly of Thrust Base to LB Subassembly

See Figure 1.3 for the following steps.

Step 1

If required, place the pilot spacer (#16-16) into the top of the anti-rotation base (#1) pilot ID.

NOTE: The pilot spacer in this location is only required if using an MSS thrust base assembly. When using an ISO thrust

base assembly, the pilot spacer is not required.

Step 2

Place gasket (#6) over the shaft and place onto the top of the anti-rotation base. Place the thrust base assembly over

top of the threads of the shaft, and turn the thrust base on by threading the thrust nut to the shaft until seated on the

anti-rotation base and gasket, making sure the gasket and thrust base are centered on the anti-rotation base.

Step 3

Insert the four mounting screws (#4) thru the anti-rotation base into the thrust base and tighten.

QXM, MX-05 and MX-10, M10 or 3/8-16 screw tighten to 18–20 Ft-LBS/24–27 Nm.

MX-20 and MX-40, M16 or 5/8-11 screw tighten to 95–100 Ft-LBS/129–135 Nm.

2.1.3 Reassembly of Optional FA/EN (F) Base to LB Subassembly

See Figures 1.2, 2.1 and 2.2 for the following steps.

Step 1

Slide the optional FA/EN (F) base (#10) over the shaft and bellows boot aligning to anti-rotation base, and insert the four

mounting screws (#11) thru the optional base holes and tighten to the anti-rotation base (#1).

QXM, MX-05 and MX-10, M10 screws tighten to 18–20 Ft-LBS/24–27 Nm.

MX-20 and MX-40, M16 screws tighten to 95–100 Ft-LBS/129–135 Nm.

8

Page 9

Figure 2.1 – LB1 Subassembly Cross-Section

MXa/QXM Linear Base FCD LMENIM2315-00 – 6/14

Figure 2.2 – LB2 Subassembly Cross-Section

flowserve.com

9

Page 10

MXa/QXM Linear Base FCD LMENIM2315-00 – 6/14

2.1.4 Assembly or Adjustment of Optional Stop Nut for LB Subassembly

QXM, MX-10 and MX-40 only.

NOTE: This LB stop nut must not be used for electric motorized operation stops. The stop nut is for use of the manual

override operated closed position only.

IF LB UNIT STOP NUT IS USED FOR ACTUATOR ELECTRIC MOTORIZED CLOSED POSITION, ACTUATOR PREMATURE

FAILURE WILL OCCUR.

To assemble or adjust the stop nut, the LB subassembly must be mounted to the valve with the actuator removed.

Customer must decide on the manual override closed position of the LB unit for placement of the stop nut allowing for

coast when unit is in electric motorized operation. See steps 2 and 3 for recommended stop nut position.

Step 1

Mount the LB with thrust base assembly to valve. Using the thrust base nut lugs, rotate the LB unit to the planned

electric motorized operation closed position (Closed position is where the LB shaft on the bellows side is extended away

from the LB base).

NOTE: LB assembly with QXM/MX actuator may be mounted to valve and electric motorized to the closed position.

Once in the closed position, remove the QXM/MX actuator and proceed with stop assembly.

Step 2

Place stop nut (#12) over the top of the LB shaft (#2) and thread the stop nut down until it bottoms out on the thrust

base thrust nut (#3).

Recommended stop nut position:

Once stop nut has been threaded down to the thrust base nut back-stop off of thrust nut 1 millimeter. For a 3 mm pitch

shaft, 1 mm = 1⁄3 turn; 4 mm pitch shaft = ¼ turn; 8 mm pitch shaft = 1⁄8 turn; and a 10 mm pitch shaft = 1⁄10 turn.

Step 3

Once stop nut has been positioned, stop nut must be drilled and tap to secure stop in place and shaft must be spot

faced for the set screw. The LB1 requires an M6 set screw and the LB2 requires an M8 set screw.

NOTES:

1. The supplied set screw length is intended to be positioned where the tap drill is within one of the two slots on the

shaft. In this orientation and with small shaft spot face, the supplied set screw length will not protrude past the OD

of the stop nut and disturb the shaft threads. See Figures 2.1 or 2.2.

2. Once stop nut is assembled and actuator has been mounted to the LB unit per section 2.1.6, electrically run unit

to open and then back to the closed position. Declutch actuator and using the handwheel, manually open valve.

If valve is hard to unset in manual mode, the stop nut may be jammed and will need to be moved away from the

closed position. If stop needs readjusting, a new tap in the stop nut and shaft spot face will be required.

10

Page 11

MXa/QXM Linear Base FCD LMENIM2315-00 – 6/14

2.1.5 LB Lubrication

Step 1

Thrust base assembly (#5) lubrication.

Using only Mobil SHC 220 Mobilith grease, fill thrust base thru the grease fitting (#10-11) until grease is forced out of

the relief fitting.

Step 2

Anti-rotation base assembly lubrication.

Remove pipe plug (#9). Using only Mobil SHC 220 Mobilith grease fill anti-rotation base assembly thru the grease

fitting (#8) until grease is forced out of the pipe plug hole. Replace pipe plug.

NOTES:

1. Do not over-fill. It is best to fill the anti-rotation base assembly in the open position (stem retracted). If over-filled,

grease will be forced out when operating unit.

2. Grease at intervals of 2000 open-closed cycles and adjust depending on load profile.

2.1.6 Reassembly of QXM or MX Actuators to LB/Thrust Base Assembly

See Figure 1.1 for the following steps.

Step 1

Slide gasket (#5) or over shaft and place on top of LB thrust base. If required (QXM units with MSS base only), place

spacer pilot (#16-16) into LB thrust base pilot ID.

Step 2

Place unit actuator on top of LB subassembly and align actuator lugs, pilot and with LB thrust base lugs and pilot.

Check to make sure gasket is also aligned. Rotate actuator and gasket to align mounting holes.

Step 3

Insert mounting bolts (#5) thru thrust base and tighten to actuator.

MX-05, M10 or 3/8-16 screws, tighten to 10–12 Ft-LBS/13–16 Nm.

QXM and MX-10 M8 screws, tighten to 8–10 Ft-LBS/11–13 Nm.

MX-20 and MX-40 M12 screws, tighten to 17–20 Ft-LBS/23–27 Nm.

flowserve.com

11

Page 12

Flowserve Corporation

Flow Control

United States

Flowserve Limitorque

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone: 434-528-4400

Fax: 434-845-9736

England

Flowserve Limitorque

Euro House

Abex Road

Newbury

Berkshire, RG14 5EY

United Kingdom

Phone: 44-1-635-46999

Fax: 44-1-635-36034

Japan

Limitorque – Nippon Gear Co., Ltd.

Asahi-Seimei Bldg. 4th Floor

1-11-11 Kita-Saiwai, Nishi-Ku

Yokohama-Shi, (220-0004)

Japan

Phone: 81-45-326-2065

Fax: 81-45-320-5962

To find your local Flowserve representative,

visit www.flowserve.com, www.limitorque.com

or call USA 1 800 225 6989.

FCD LMENIM2315-00 (E) 6/14 © 2014 Flowserve Corporation.

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve

product is designed to perform its intended function safely during its useful life. However, the purchaser or user of Flowserve products should be aware

that Flowserve products might be used in numerous applications under a wide variety of industrial service conditions. Although Flowserve can (and

often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/

user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and

contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and

should not be considered certified or as a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a

warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve is continually improving and upgrading

its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise

concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2014 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

Canada

Flowserve Limitorque

120 Vinyl Court

Woodbridge, Ontario L4L 4A3

Canada

Phone: 905-856-4565

Fax: 905-856-7905

Singapore

Limitorque Asia, Pte., Ltd.

12, Tuas Avenue 20

Singapore 638824

Phone: 65-6868-4628

Fax: 65-6862-4940

China

Limitorque Beijing, Pte., Ltd.

RM A1/A2

22/F, East Area, Hanwei Plaza

No. 7 Guanghua Road, Chaoyang District

Beijing 100004, Peoples Republic of China

Phone: 86-10-5921-0606

Fax: 86-10-6561-2702

India

Flowserve Limitorque

No. 10-12, THE OVAL, Third floor

Venkatnarayana Road

T. Nagar, Chennai 600 017

Phone: 91-44-2432-8755

and 91-44-2432-4801

Fax: 91-44-2432-8754

flowserve.com

Loading...

Loading...